Land Pride 330-114A RC,RCM5020 User Manual

Baffle and Shredder Kits

For RC(M)5020 Rotary Cutters

Before You Start

When you see this symbol, the subsequent

instructions and warnings are serious - follow

!

without exception. Your life and the lives of

others depend on it!

IMPORTANT: Before you begin, read these

instructions and check to be sure all parts and tools

are accounted for. Please retain these installation

instructions for future reference and parts ordering

information.

The Baffle Kit and Shredder Kit are exclusively designed

for your 20’ Land Pride Rotary Cutter. Please read these

installation instructions and your Rotary Cutter

Operator’s Manual thoroughly before beginning.

Especially read information relating to safety concerns.

Also included in the Operator’s Manual is important

information on operation, adjustment, troubleshooting,

and maintenance for this attachment (some manual

sections do not apply to all accessories).

A separate Rotary Cutter Parts Manual is available free

of charge at www.landpride.com or can be purchased

from your nearest Land Pride dealer. Have the model

andserialnumbersofyourcutterhandywhenplacingan

order.

Manual Part Numbers:

• Operator’sManual . . . . . . . . . . . . . . . . . 318-474M

• Parts Manual . . . . . . . . . . . . . . . . . . . . . 318-474P

Manual No. 330-148M

Further Assistance

Your dealer wants you to be satisfied with your new

Baffle and Shredder Kits. If for any reason you do not

understand any part of this manual or are not satisfied

with the service received, the following actions are

suggested:

1. Discuss the matter with your dealership ser vice

manager making sure he is aware of any problems

youmay haveand that he has had the opportunity to

assist you.

2. If you are still not satisfied, seek out the owner or

general manager of the dealership, explain the

problem and request assistance.

3. For further assistance write to:

Land Pride Service Department

1525 East North Street

P.O. Box 5060

Salina, Ks. 67402-5060

E-mail address

lpservicedept@landpride.com

Safety Information

!

Always disconnect main driveline from tractor PTO before

servicing cutter deck. Cutter can be engaged if tractor is

started resulting in cutter damage, bodily injury and/or death.

DANGER

General Information

These assembly instructions apply to the Baffle and

Shredder Kits listed below:

330-309A SHREDDER/FIXED BLADE/BAFFLE

330-114A BAFFLES, FRONT

330-308A SHREDDER/FIXED BLADE

330-585A BAFFLES, REAR

Tools required:

•

Safety Glasses

• Work Gloves

• Two 3/4" wrenches . . . . . . . . . . . . . . . . .Baffle Kit Only

• Two 1 1/2" wrenches . . . . . . . . . . . . Shredder Kit Only

• One 55mm wrench . . . . . . . . . . . . . . Shredder Kit Only

© Copyright 2010 Printed

3/11/10

!

Never work under equipment supported by hydraulics.

Hydraulics can drop equipment if controls are actuated or if

hydraulic lines burst. Either situation can drop the cutter

instantly even when power to the hydraulics is shut off.

WARNING

Assembly Instructions

A detailed listing of parts for the Baffle and Shredder Kits

is provided on pages 10 & 11. Use the list as a checklist

to inventory parts received. Please contact your local

Land Pride dealer for any missing hardware.

IMPORTANT: Read all "Safety Information" above

before working on and around the cutter decks.

1. Cutters with Serial No. 536742 and lower:

Lower cutter and wings to the lowest position.

Cutters with Serial No. 536743 and above:

Raise wings fully up and lock into position with

transport locks.

1

Assembly Instructions

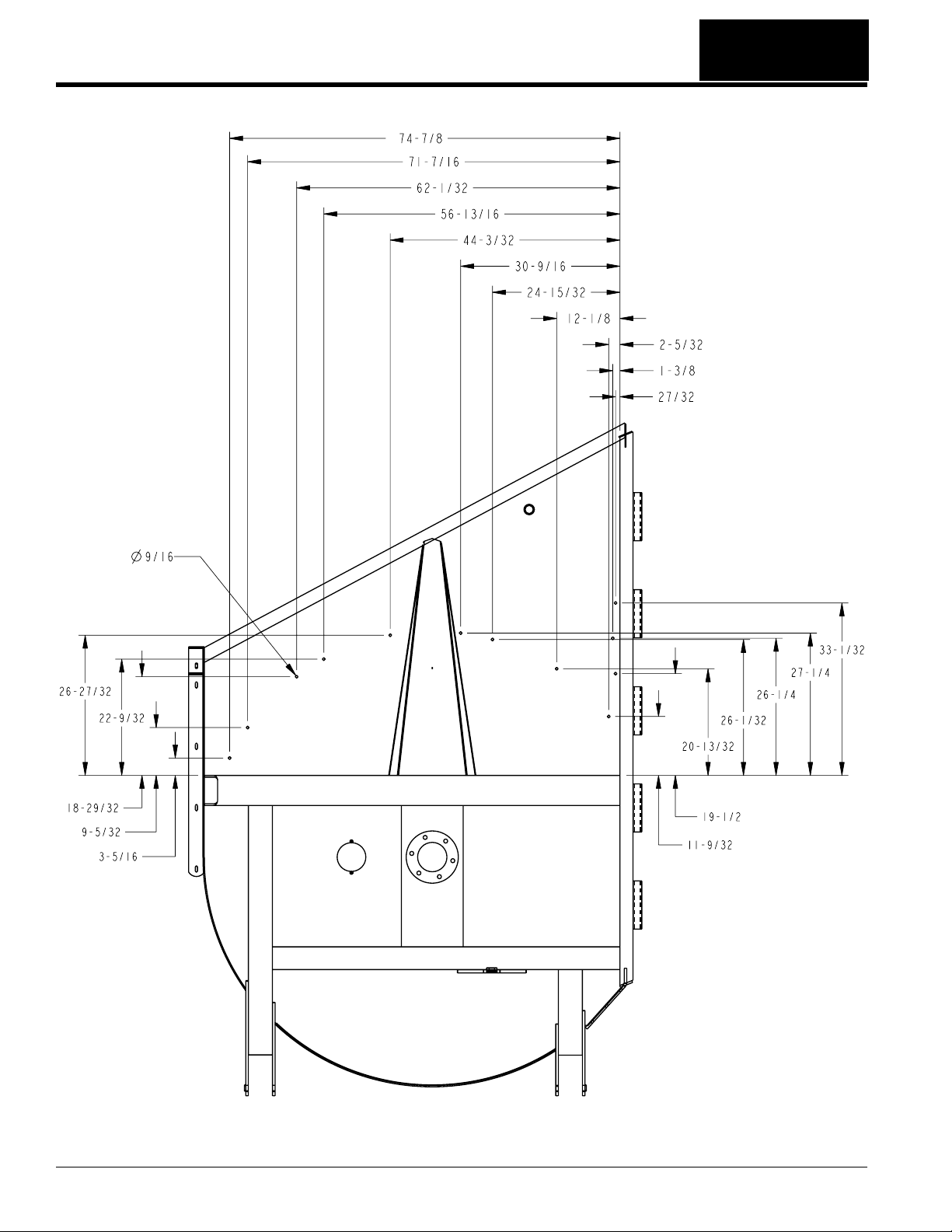

Bolt Hole Pattern (Left Wing Shown)

Figure 1

Manual No. 330-148M 3/11/10

2

Assembly Instructions

2. Place tractorgear selector in par k and/or set brakes,

shut engine off and remove ignition key.

3. Disconnect main driveline from tractor PTO.

Shredder/Fixed Blade/Baffle Kit

Kit No. 330-309A

This Kit consist of Kits 330-114A and 330-308A.

Therefore, see Kit No. 330-114A below for assembly

instructions of the front baffles and Kit No. 330-308A on

page 4 for assembly instructions of the shredder blades

and fixed blades.

Front Baffle Kit

Kit No. 330-114A

Adetailed listingof parts forthis accessory kitis provided

on page 10. Use the list as a checklist to inventory parts

received.Please contact your local Land Pridedealer for

any missing hardware.

NOTE: Drilling holes is not necessary on models

manufactured after Serial No. 536742. Skip to

step 2 below if cutter Serial No. is 536743 or higher.

Refer to Figure 1 on page 2:

1. Locate and drill twelve 9/16" dia. holes on each wing

deckas shownin Figure 1.If holes alreadyexist, skip

to step 2 below.

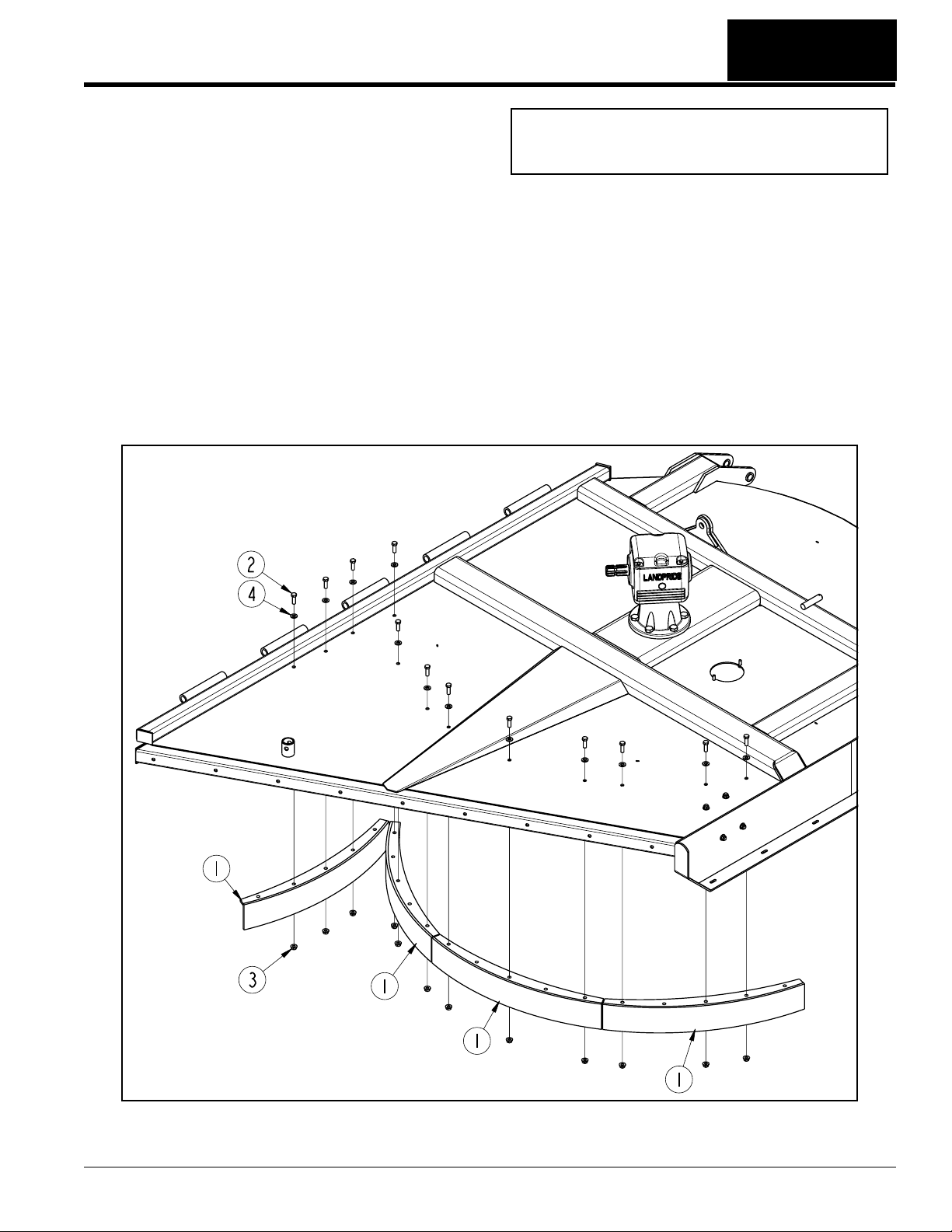

Refer to Figure 2:

2. The wings should be raised and locked into position

for the remainder of the assembly.

3. Attach four front baffles (#1) to the left-hand wing

deck with 1/2"-13 x 1 1/2" GR5 hex head bolts (#2),

1/2" flat washers (#4) and 1/2" hex whiz nut (#3).

4. Tighten nuts to 76 ft-lbs of torque.

5. Repeat steps 3 & 4 for the right-hand wing deck.

3/11/10

Baffle Installation (Left Wing Shown)

Figure 2

Manual No. 330-148M

3

Assembly Instructions

Shredder/Fixed Blade Kit

Kit No. 330-308A

Adetailed listingof parts forthis accessory kitis provided

on page 11. Use the list as a checklist to inventory parts

received.Please contact your local Land Pridedealer for

any missing hardware.

IMPORTANT: Read “Safety Information” on page 1

before installing shredder blades.

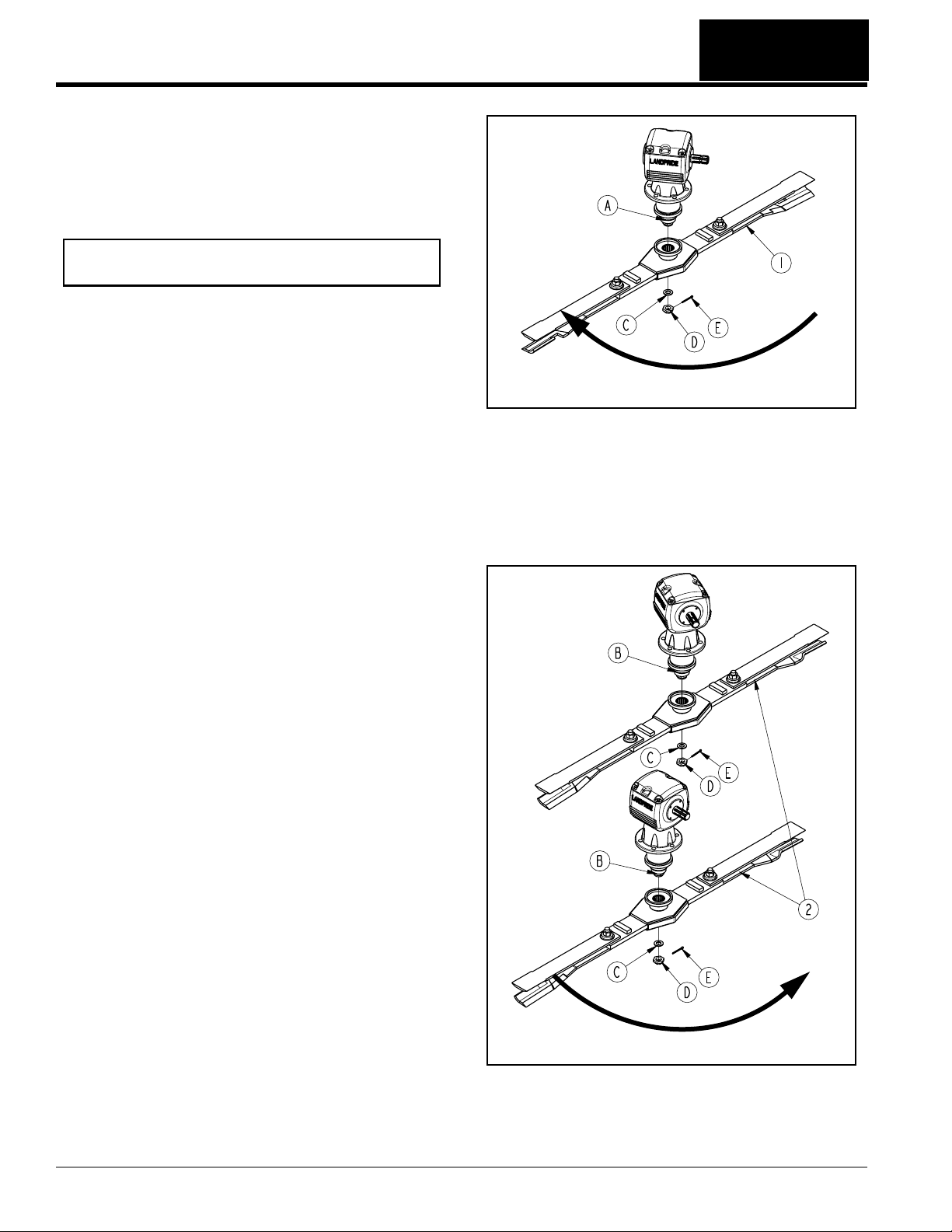

Refer to Figure 3 & Figure 4:

1. Remove all three existing blade carr ier assemblies

(not shown) from the gearbox output shafts (A & B).

Keepflatwashers (C), slottedhex nuts(D) and cotter

pins (E) for reuse.

Right Wing Shredder Assembly

(Part No. 330-228S)

Refer to Figure 3:

1. Attach right wing shredder assembly (#1) to gearbox

output shaft (A) with existing washer (C) and slotted

hex nut (D). Torqueslotted nut to 550 ft./lbs.

2. Install cotter pin (E) in the slotted nut and through

output shaft (A). Secure cotter pin (E) by bending its

legs around the nut.

Clockwise Rotation

Right Wing Shredder Assembly (P/N 330-228S)

Figure 3

25601

Center Deck & Left Wing Shredder Assembly

(Part No’s. 330-302S)

Refer to Figure 4:

1. Attach center deck and left wing shredder

assemblies (#2) to gearbox output shafts (B) with

existing washer (C) and slotted hex nut (D). Torque

slotted nut to 550 ft./lbs.

2. Install cotter pin (E) in the slotted nut and through

output shaft (B). Secure cotter pin (E) by bending its

legs around the nut.

Counterclockwise Rotation

25601

Center Deck Shredder Assembly (P/N 330-302S)

And Left Wing Shredder Assembly (P/N 330-302S)

Figure 4

Manual No. 330-148M 3/11/10

4

Loading...

Loading...