04/2018

WORKMASTER 1000

(SKU: GPDUAL & GP220)

ORTHO SANDER

Operator Manual

Manufactured by

Operator Manual - GRIND PRO DUAL

Landis International - 2

INTRODUCTION

BEFORE USING THE LANDIS MACHINES, READ OPERATING INSTRUCTIONS MANUAL:

1. KEEP GUARDS IN PLACE and in working order.

2. Always DISCONNECT ELECTRICAL SOURCE before

adjustments or servicing the machine.

3. REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it

on.

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

5. DON'T USE IN DANGEROUS ENVIRONMENT. Don't

use power tools in damp or wet locations or expose

them to rain. Keep work area well lighted.

6. KEEP CHILDREN AWAY. All visitors should be kept

safe distance from work area.

7. MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

8. DON'T FORCE TOOL. It will do the job better and

safer at the rate for which it was designed.

9. USE RIGHT TOOL. Don't force tool or attachment to

do a job for which it was not designed.

10. DO NOT USE EXTENSION CORD.

11. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewellery which may get caught in moving parts.

Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

12. ALWAYS USE SAFETY GLASSES. Also use face or dust

mask if cutting operation is dusty. Everyday

eyeglasses only have impact resistant lenses, they

are NOT safety glasses.

13. SECURE WORK. Use clamps or a vise to hold work when

practical. It's safer than using your hand and it frees

both hands to operate tool.

14. Make sure machine is PROPERLY GROUNDED.

15. DON'T OVERREACH. Keep proper footing and balance

at all times.

16. MAINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

17. DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and the like.

18. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure switch is in off position before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the

owner's manual for recommended accessories. The use

of improper accessories may cause risk of injury to

persons.

20. NEVER STAND ON TOOL. Serious injury could occur if the

tool is tipped or if the cutting tool is unintentionally

contacted.

21. CHECK DAMAGED PARTS. Before further use of the tool,

a guard or other part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function -- check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions

that may affect its operation. A guard or other part

that is damaged should be properly repaired or

replaced.

22. DIRECTION OF FEED. Feed work into a blade or cutter

against the direction of rotation of the blade or cutter

only.

23. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don't leave tool until it comes to a

complete stop.

24. Dust generated is FLAMMABLE – DO NOT SMOKE when

using Landis Machine.

25. Keep generators and covers IN PLACE and in proper

working order.

26. OBSERVE all SAFETY WARNINGS on the machine and in

this manual.

The Landis Grind Pro Dual Sander is a compact, durable machine designed for fast, complete finishing work.

It will deliver efficient, dependable service when used correctly and with care. As with any piece of

specialized equipment, for best performance the manufacturer’s instructions must be followed.

Operator Manual - GRIND PRO DUAL

Landis International - 3

RISK OF INJURY

• DISCONNECT TOOLS BEFORE SERVICING AND LOCK THE SWITCHES.

• EYE PROTECTION SHOULD ALWAYS BE WORN BY THE OPERATOR AND OTHERS IN THE

WORK AREA WHEN THE SANDER IS IN USE.

• EYE PROTECTION IS REQUIRED FOR PROTECTION FROM FLYING DEBRIS AND DUST, WHICH

COULD CAUSE EYE INJURY.

INSTALLATION

The Landis Sander should be located on a flat, firm surface, in an area free

of obstructions that could interfere with the safe operation of the

equipment. The Sander should be positioned and leveled with the 4 white

plastic legs to obtain quiet operation with a minimum of vibration.

• ALL ELECTRICAL WORK MUST BE PERFORMED BY A QUALIFIED ELECTRICIAN AND MUST

CONFORM TO ALL STATE AND LOCAL ORDINANCES.

• DO NOT, UNDER ANY CIRCUMSTANCE, TAMPER WITH, MODIFY, OR ADAPT THE

ELECTRICAL PLUG AND CORD PROVIDED WITH THIS MACHINE.

ELECTRICAL CONNECTIONS

Electrical connection may be made by

either plugging the provided electrical

cord into an appropriately wired

electrical socket, or by wiring the

machine directly into an electrical

disconnect box. The customer must

ensure that the voltage is 230 V.

• IF THE ELECTRICAL CORD, PLUG OR WIRING SHOULD BECOME FRAYED OR DAMAGED,

REPLACE IT AT ONCE. DO NOT ATTEMPT TO OPERATE THE MACHINE WITH FAULTY WIRING

AS IT COULD RESULT IN SEVERE INJURY OR DEATH.

NOTE: REFER TO THE MACHINERY IDENTIFICATION PLATE TO DETERMINE THE ELECTRICAL

SPECIFICATIONS OF THIS MACHINE IN RESPECT TO VOLTAGE, PHASE AND AMPERAGE

REQUIREMENTS.

Operator Manual - GRIND PRO DUAL

Landis International - 4

LOCKOUT PROCEDURES

PREPARATION

1. Notify all affected workers that a lockout is required

and the reason for the lockout of the machine.

MACHINE OR EQUIPMENT SHUTDOWN AND ISOLATION

1. If the equipment is operating, shut it down by

the normal stopping procedure (turn off the

switch). We recommend to install a padlock to

the Electrical control panel.

2. Disconnect the electrical plug from the

electrical source.

APPLICATION OF LOCKOUT / TAGOUT

1. Lock out and tag the switch with an assigned,

individual lock. A worker will not be protected

unless he/she uses his/her own padlock.

2. If more than one worker is working on the same

piece of equipment at the same time, each one

should lock out the equipment, by placing a

personal lock and tag on the group lockout

device when he/she begins work and should

remove those devices when he/she stops

working on the machine or equipment.

3. Locks and tags should clearly show the name of

the person who applied the device, the date,

and the reason for the lockout. This identifies

who is servicing the machinery or equipment. In

a multiple lockout/tagout situation, it will also

identify any worker(s) who may not have

finished working.

4. Locks and tags must be durable enough to

withstand the environment in which they are to

Operator Manual - GRIND PRO DUAL

Landis International - 5

be used. Information on the locks and tags

should remain legible.

5. Locks must be substantial enough to prevent

removal without the use of excessive force.

Tags must be substantial enough to prevent

accidental or inadvertent removal.

6. Both locks and tags are to be standardized by

color, shape, or size. Tags should be easily

recognized and provide appropriate

information about the lockout.

RELEASE FROM LOCKOUT / TAGOUT

1. Before locks and tags are removed and

electricity is restored to the machine, inspect

the work area to ensure that non-essential

items have been removed and that machine

components are operationally intact.

2. Ensure workers are a safe distance from any

potential hazard.

3. The lock and tag should be removed from

each energy-isolating device by the worker

who applied the lock and tag.

4. Notify affected workers that locks and tags

have been removed.

Operator Manual - GRIND PRO DUAL

Landis International - 6

START-UP

• EYE PROTECTION SHOULD ALWAYS BE WORN BY THE OPERATOR AND OTHERS IN THE

WORK AREA WHEN SETTING UP THE MACHINE. EYE PROTECTION IS REQUIRED FOR

PROTECTION FROM FLYING DEBRIS AND DUST, WHICH COULD CAUSE EYE INJURY.

Before shipment, your Landis Sander was checked at the factory for proper

adjustment and operation. However, due to the possibility of jarring or

damage during handling and shipping, it is necessary to check that the

machine is in proper working order before use.

• BEFORE INITIAL START-UP, TURN SANDING SHAFT BY HAND TO ENSURE THAT ALL

PARTS ARE FREE.

BEFORE CONNECTION TO AN ELECTRICAL POWER SUPPLY:

1. Check that the main switch is off.

2. Rotate the sanding shaft to see that all parts are free and not binding.

You can tell that one complete revolution has been made when the

joint of the sanding belt has gone by the sanding wheels twice.

3. Rotate the Naumkeag by hand to see that the sanding pad is not

damaged and the shaft not bent. (optional accessory)

• AS WITH ANY PIECE OF ELECTRICAL EQUIPMENT, THERE IS AN EVER PRESENT HAZARD

OF ELECTRICAL SHOCK WHEN OPERATING OR TOUCHING THE SANDER. ENSURE THE

MACHINE IS PROPERLY GROUNDED AT ALL TIMES.

• DO NOT FORCE THE EQUIPMENT. IT WILL DO THE JOB BETTER AND SAFER AT THE

RATE FOR WHICH IT WAS DESIGNED.

Main Switch

OFF

Emergency

Button

Start/Stop

Switch

Main Switch

ON

To activate:

Push the button to stop the

machine immediately.

To desactivate:

Turn the knob in the direction

of the arrows indicated.

Operator Manual - GRIND PRO DUAL

Landis International - 7

SANDPAPER REPLACEMENT

• EYE PROTECTION SHOULD ALWAYS BE WORN BY THE OPERATOR AND OTHERS IN THE

WORK AREA WHEN CHANGING SANDPAPER. EYE PROTECTION IS REQUIRED FOR

PROTECTION FROM FLYING DEBRIS AND DUST, WHICH COULD CAUSE EYE INJURY.

• NEVER LEAVE MACHINE RUNNING WHILE UNATTENDED. TURN IT OFF.

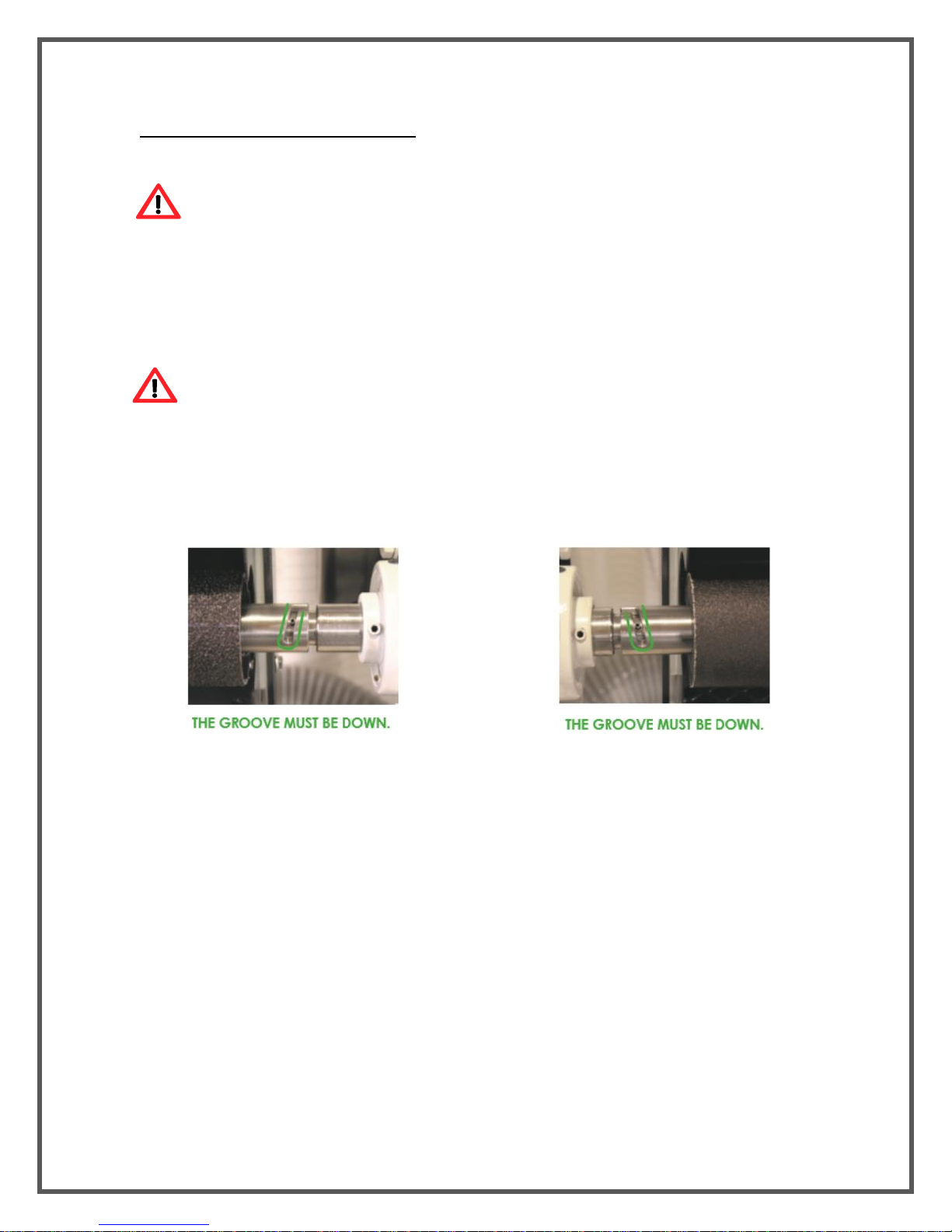

FOR YOUR SAFETY, NEVER INTERCHANGE THE BAYONETS.

• FAILURE TO PROPERLY MOUNT THE ADAPTOR WILL RESULT IN FLYING APART AND POSSIBLE

INJURY TO THE OPERATOR AND OTHERS IN THE WORK AREA.

• THESE QUICK CHANGE ACCESSORIES SHOULD BE PROPERLY ENGAGED ON THE SHAFT TO

ENSURE SAFE OPERATION. MAKE SURE PIN ON SHAFT ENGAGES THE ADAPTOR CORRECTLY.

LEFT BAYONET

CORRECTLY INSTALLED

RIGHT BAYONET

CORRECTLY INSTALLED

Operator Manual - GRIND PRO DUAL

Landis International - 8

FOR WORKMASTER 1000 (SKU: GPDUAL):

• It is not necessay to remove the bayonet to slide the new sand paper

on the rubber wheel.

• Slide and turn down the sandpaper to remove it. It is easier to put a

new sandpaper on the rubber wheel if you remove it from de bayonet.

Slide the new sandpaper on the rubber wheel and replace it on the

bayonet.

Sandpaper can be obtained in various grit to suit your needs and are

easily changed.

• Sandpaper, 24 grit, SKU: 27877824

• Sandpaper, 40 grit, SKU: 27877840

• Sandpaper, 60 grit, SKU: 27877860

• Sandpaper, 80 grit, SKU: 27877880

• Sandpaper, 100 grit, SKU: 278778100

Operator Manual - GRIND PRO DUAL

Landis International - 9

FOR WORKMASTER 1000 (SKU: GP220):

• SOME SANDPAPER ARE CONSTRUCTED TO ROTATE IN ONE DIRECTION ONLY. CHECK

ARROW INSIDE SANDPAPER FOR ROTATION. INCORRECT INSTALLATION CAN CAUSE

SUDDEN BELT FAILURE RESULTING IN SERIOUS INJURY TO OPERATOR AND OTHERS IN THE

WORK AREA. (GP220 ONLY)

1. For replace the sandpaper, make sure the grooves are at the

same side of the pictures above. It is not necessay to remove the

bayonet to slide the new sand paper on the expanding wheel.

2. For help the installation of the new sandpaper, slide and turn it at

the same direction of the grooves.

The sand paper can be obtained in various grit to suit your needs

and are easily changed.

NAUMKEAG (in option)

It is possible to adjust the blasting angle using the handle on the right of

the motor.

SAND PAPER REPLACEMENT

The sand paper can be obtained in various grit to suit your needs and are

easily changed.

• Sandpaper 80 grit, SKU: PN80

• Sandpaper 100 grit, SKU: P100

• Sandpaper 120 grit, SKU: PN120

Result: 6’’ x 4’’left expanding wheel on bayonet

Operator Manual - GRIND PRO DUAL

Landis International - 10

TO REPLACE THE SAND PAPER

1. Unscrew the nut.

2. Move up the washer and change de

sand paper.

3. If necessary, it is possible to change the

pad according to its wear. Repeat the

procedure for changing paper.

DUST BAG

Dust composed of leather, rubber and plastic is

combustible and can readily be set on fire by a

lighted cigarette or sparks. This can occur

whether the dust is in the dust bag or the

machine duck work leading to the dust bag. Do

not sand or grind metal with the sander.

The cleaner you keep the dust bag, the less

likely you are to burn a hole in it. Failure to shake

the dust bag daily will not only increase this

likelihood, but will also cause a significant loss of

dust extraction from the sanding areas.

✓ Maintenance is important,

see our recommendations page 12.

Operator Manual - GRIND PRO DUAL

Landis International - 11

ACCESSORIES

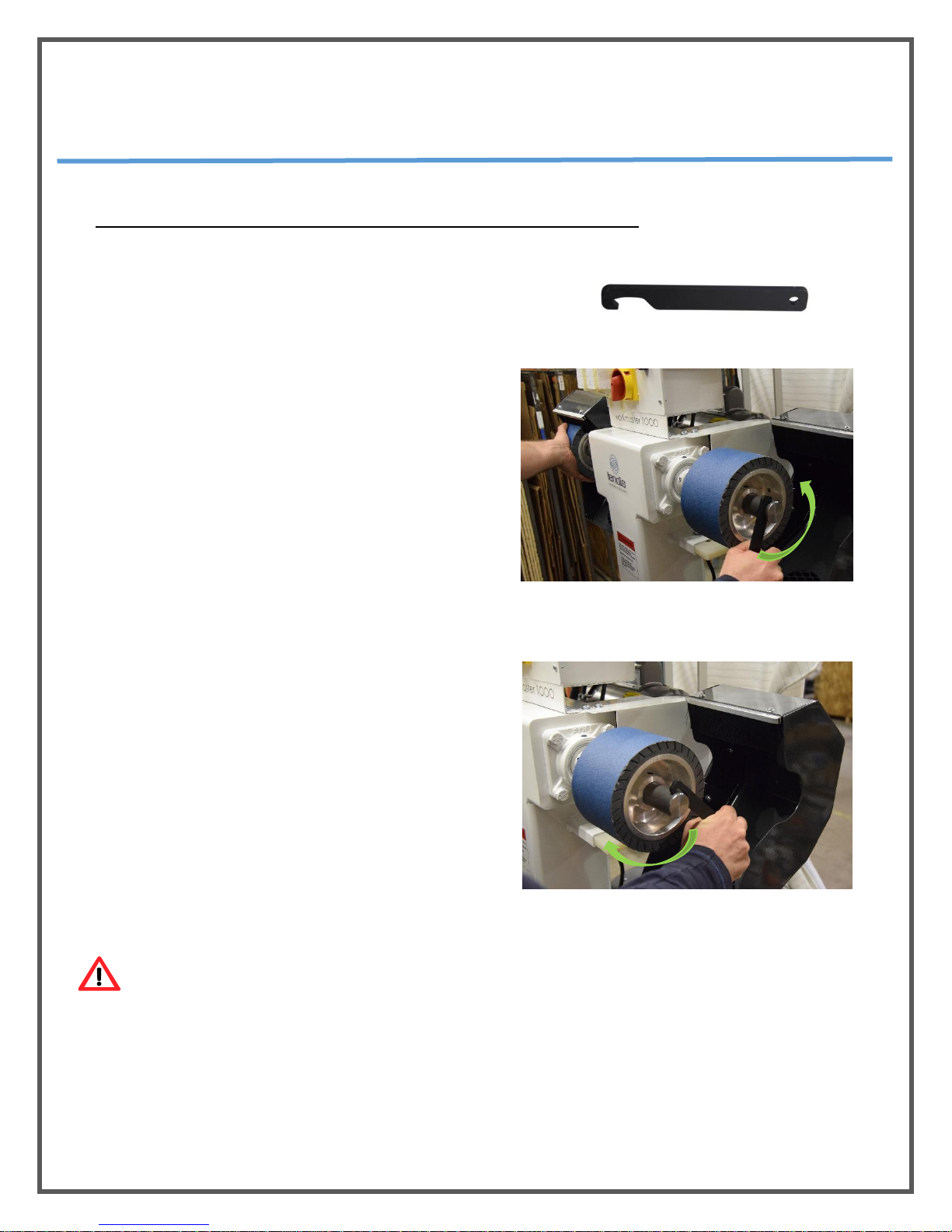

ACCESSORIES ON QUICK CHANGE BAYONET FITTING

Both ends of the sanding shaft are machined

to accommodate bayonet fitting (quick

change). Extra tools and sanding wheels are

available on request. (see accessories page

25-26)

When removing the quick change fittings, use

the special black spanner wrench (SKU: CCL)

supplied with the machine. Check that the

main switch is off. To remove, engage the

spanner in the hole near the end of the

bayonet fitting and apply a sharp rap

downward.

Before putting on a fitting be sure the opening

ends are cleaned. Hand tightening is

sufficient to hold the fitting in proper position.

N.B. When properly mounted, the bayonet fitting will

tighten itself by rotating it in the socket in the opposite

direction of the sanding belt rotation.

• FAILURE TO PROPERLY MOUNT THE ADAPTOR WILL RESULT IN FLYING APART AND POSSIBLE INJURY TO THE

OPERATOR AND OTHERS IN THE WORK AREA.

• THESE QUICK CHANGE ACCESSORIES SHOULD BE PROPERLY ENGAGED ON THE SHAFT TO ENSURE SAFE

OPERATION. MAKE SURE PIN ON SHAFT ENGAGES THE ADAPTOR CORRECTLY.

To remove the quick change fitting. Help you

and hold the other bayonet with your hand.

To fix the quick change fitting.

Operator Manual - GRIND PRO DUAL

Landis International - 12

MAINTENANCE

A properly maintained machine will give you years of satisfactory service,

whereas an abused machine will not. We strongly recommend that you

observe the following procedures for your own benefit and safety.

• EYE PROTECTION SHOULD ALWAYS BE WORN BY THE OPERATOR AND OTHERS IN THE

WORK AREA WHEN SERVICING THE MACHINE EYE PROTECTION IS REQUIRED FOR

PROTECTION FROM FLYING DEBRIS AND DUST, WHICH COULD CAUSE EYE INJURY.

DAILY AND WEEKLY MAINTENANCE

1. Clean your Landis Sander daily.

2. Shake dust bag daily. Empty it weekly. (Optional dust collector

system)

3. After cleaning the machine, turn dust extraction motor off. While the

motor is coasting to a stop, shake bag vigorously.

The cleaner you keep the dust bag, the less likely you are to burn a

hole in it.

• DUST FROM SANDER IS COMBUSTIBLE. DO NOT SMOKE WHILE CLEANING THE

MACHINE AND DUST COLLECTOR.

• DAMAGED DUST BAG WILL ALLOW THE ESCAPE OF COMBUSTIBLE MATERIALS

CAUSING A FIRE HAZARD AROUND THE MACHINE.

• CHECK DAMAGED PARTS. BEFORE FURTHER USE OF A TOOL, GUARD OR OTHER PART

THAT IS DAMAGED, CHECK CAREFULLY TO DETERMINE THAT IT WILL OPERATE

PROPERLY AND PERFORM ITS INTENDED FUNCTION. CHECK FOR MOUNTING OR ANY

OTHER CONDITION THAT MAY AFFECT ITS OPERATION. A TOOL, GUARD OR OTHER

PART THAT IS HARMFULLY DAMAGED SHOULD BE PROPERLY REPAIRED OR

REPLACED.

• IF THE ELECTRICAL CORD, PLUG OR WIRING SHOULD BECOME FRAYED OR DAMAGED,

REPLACE IT AT ONCE.

• DO NOT OPERATE MACHINE WITHOUT HOODS PROPERLY INSTALLED.

• AFTER MAKING ADJUSTMENTS, REMOVE ALL WRENCHES AND OTHER TOOLS BEFORE

OPERATING THE SANDER.

• USE EXTRA CAUTION WHEN STARTING THE SANDER FOR THE FIRST TIME AFTER

INSTALLING A NEW TOOL OR PART.

Operator Manual - GRIND PRO DUAL

Landis International - 13

MONTHLY MAINTENANCE

1. V-Belt – Check tension and adjust if necessary.

V-BELT ADJUSTMENT AND REMOVAL

The V-Belt on the Landis Sander should be checked monthly for proper

tension and general condition. Loose V-Belt will decrease the power

available to the various tools and lower the efficiency of your Sander.

If you discover a worn or frayed belt, replace it now so it won’t break at an

inconvenient time.

• DISCONNECT ELECTRICAL POWER SUPPLY BEFORE WORKING ON THE MACHINE.

TO CHECK V-BELT TENSION

1. Disconnect the electrical power

supply.

2. Remove the 2 bolts of the white

guard box beside the motor. You

will access to the V-Belt.

3. Check the tension of the V-belt

running to the motor; it should

depress approximately 12 mm

(½”) when pressed in the middle

with moderate force.

4. Rotate the V-belt by hand, visually inspecting the belt for damage.

5. If tensions or conditions are bad, adjust tension or replace V-belt.

6. After making adjustments, remove all wrenches and other tools

before operating the Sander.

• DO NOT OVER TIGHTEN V-BELT, AS TO DO SO WILL CAUSE RAPID BELT WEAR AND

PREMATURE BEARING FAILURE.

• AFTER MAKING ADJUSTMENTS, REMOVE ALL WRENCHES AND OTHER TOOLS BEFORE

OPERATING THE SANDER.

Operator Manual - GRIND PRO DUAL

Landis International - 14

LUBRICATION

Your Landis Sander is equipped with sealed bearings throughout, which

should be replaced if they ever wear out.

Other parts should not require any lubrication, only cleaning the parts is

required.

Lubrication will only attract dust and would be more harmful than helpful.

MOTOR REPLACEMENT

• MOTOR REPLACEMENT REQUIRES WORKING WITH ELECTRICAL WIRING AND CAN BE

HAZARDOUS. IF YOU ARE NOT FAMILIAR WITH ELECTRICAL PROCEDURES, PLEASE

CALL A QUALIFIED ELECTRICIAN.

If you believe that the motor presents an anomaly, please contact

Landis customer service at 1 800 634-0806.

Operator Manual - GRIND PRO DUAL

Landis International - 15

TROUBLE SHOOTING

MOTOR STOPS WITH SWITCH ON

CAUTION! TURN SWITCH OFF IMMEDIATELY

1. Too much equipment operated on same circuit on which Landis

machine is connected. Check circuit breaker or fuse box.

2. Refer to the lockout procedures before the next step (page 4).

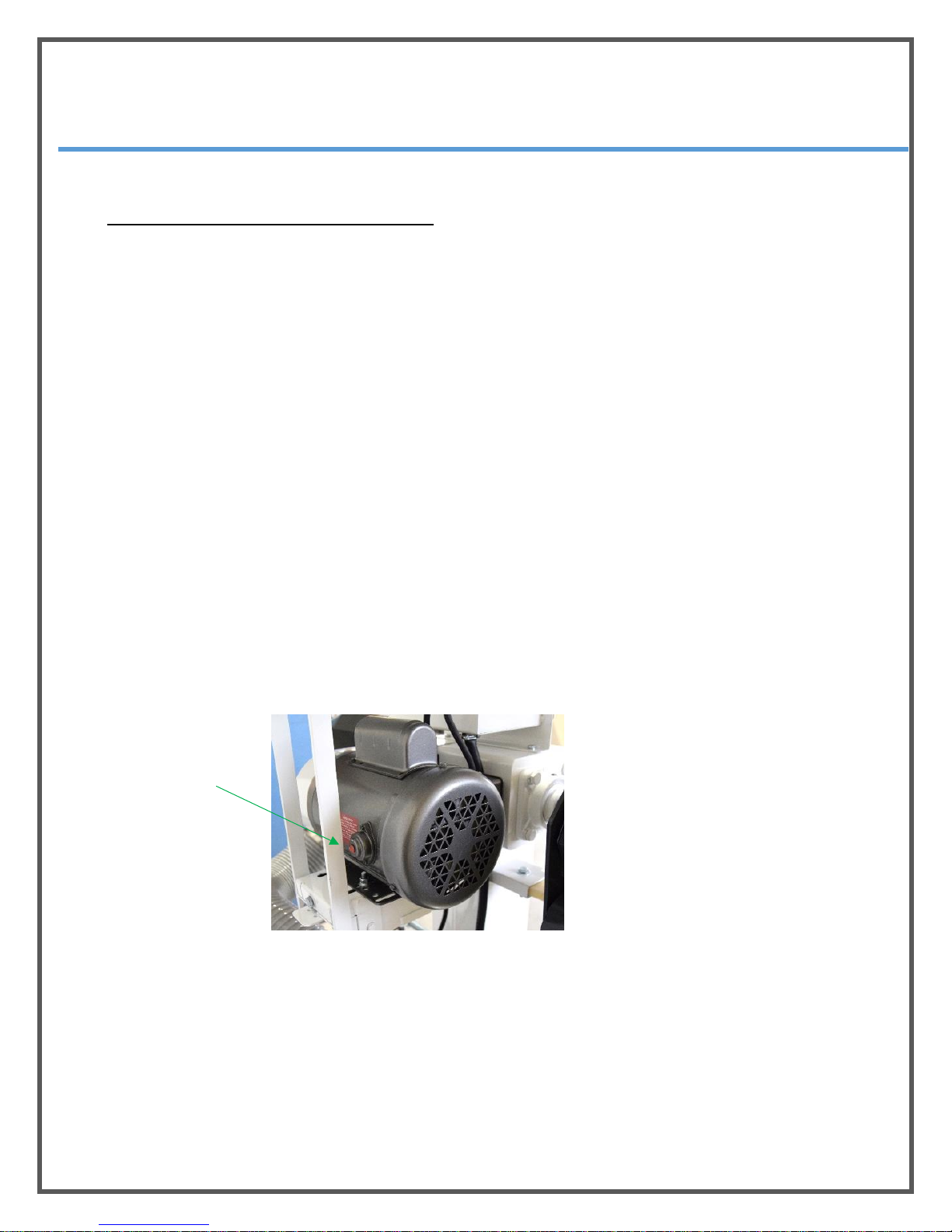

3. An overload may have caused the thermal overload protector in

motor to shut off current. Be sure sander is off, then find and

eliminate cause for overload.

Some motors are equipped with manual Re-Set thermal overload

protector wait at least 30 minutes, then firmly press Re-Set button

on motor with eraser end of pencil or a small blunt dowel. After

approximately 30 minutes you should be able to hear or feel

overload protector click in when pushed to reset. After Re-Set

clicks in, turn the main switch ON and start (Stop/Start switch) the

machine.

After this procedure, the motor should run normally. If the motor

has no Re-Set button, wait 30 minutes that the engine would shrink.

After this time, the engine should reset itself.

If you believe that the motor presents an anomaly, please contact

Landis customer service at 1 800 634-0806.

Sanding Motor

Re-Set button

in front of the

motor

Loading...

Loading...