Landauer ZPA-500, ZPA-710, ZPA-700 User manual

InLight™ Systems Readers

Service Manual

For Models:

Manual Reader ZPA-500

Automatic Reader 200 Unit ZPA-710

Automatic Reader 500 Unit ZPA-700

Version 3 September 2006

© Landauer, Inc. 2006

Contents

1. Introduction

2. Measuring

2.1 Structure of InLight Dosimeter

2.2 Structure of Measuring Block

2.3 Magazine Changer

3. Reader Electrical Diagram (Block Diagram)

4. Operation of Slide Carrier and Element Position

5. Pulse Motor Drive and Response of Each Sensor

5.1 Measuring Block

5.2 Magazine Changer

6. Error Message Handling

6.1 Measuring Unit Error While Initializing Reader

6.2 Measuring Unit Error While Measuring

6.3 Dosimeter Push Up Unit Error While Initializing Reader

6.4 Dosimeter Push Up Unit Error While Measuring

6.5 Unload Error – Manual Reader

6.6 Magazine Loading Unit Error

6.7 Changer Unit Error with Magazine Shelf Failure

6.8 Changer Unit Error with Magazine Not Pushed into Reader

6.9 Cover Open

7. Periodic Inspection Items

8. Adjust Instruments

8.1 Adjust LED Intensity and Calibration

8.2 Setting of 2D Code Reader Controller

InLight™ Systems Reader Service Manual

2

InLight™ Systems Reader Service Manual

1. Introduction

InLight Systems Readers provide readout for InLight Systems dosimeters, and each system includes a reader,

an external PC, and dosimetry software. The InLight software resides on the external PC and provides control

over the setup, analysis, and data recording enabling dosimeter read out and reader quality control. This

service manual covers the InLight Systems manual reader, the 200 capacity automatic reader, and the 500

capacity automatic reader.

InLight Systems are automated dosimetry systems using Landauer’s optically stimulated luminescence (OSL)

technology. Dosimeters measure radiation exposure with aluminum oxide detectors (Al

technology. The reader stimulates the detector with a light emitting diode (LED) array causing it to luminesce

in proportion to the amount of radiation exposure and the intensity of stimulation light. The luminescence is

detected and measured by the reader’s photomultiplier tube using a high sensitivity photon counting system. A

dose calculation algorithm is then applied to the measurement to determine exposure results.

:C) and OSL

2O3

2. Measuring

2.1 Structure of InLight Dosimeter

InLight dosimeters are built on an assembly of a case component with metal and plastic filters along with a

four-positioned aluminum oxide detector slide component. Both the case and slide are uniquely bar coded with

serial numbers for chain of custody and sensitivity identification.

The InLight dosimeter and the InLight calibration dosimeter are shown below. A maximum of four elements are

located in the slide, and the slide is inserted in the case to shield from exposure by light. The case and slide

bar codes are automatically read in the InLight reader.

Slide

2-D code

Open Window

Window Type With Filters

2D Barcode

Case

Calibration dosimeter

3

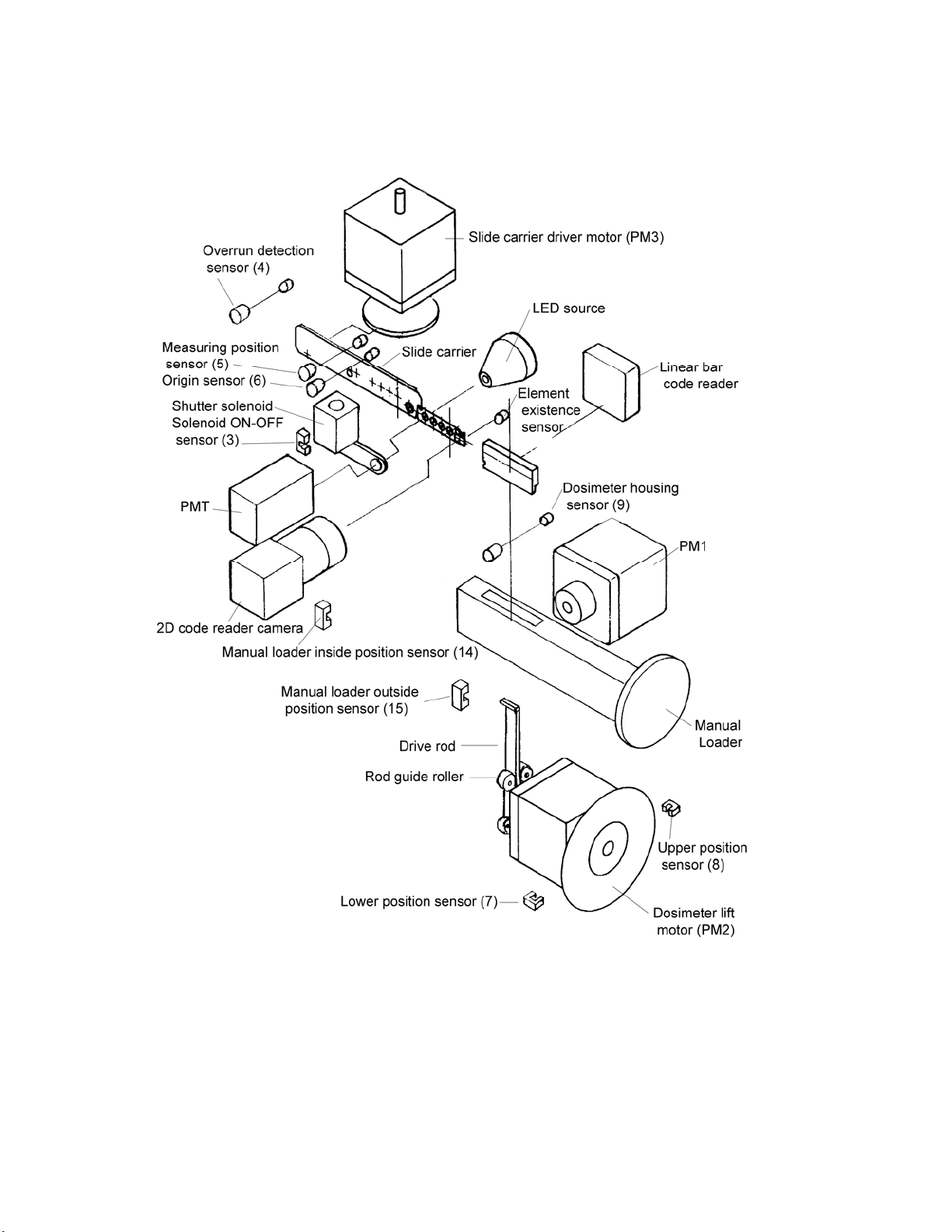

2.2 Structure of Measuring Block

Automatic Readers

InLight™ Systems Reader Service Manual

4

Manual Reader

InLight™ Systems Reader Service Manual

5

InLight™ Systems Reader Service Manual

Measuring Block Sensor Descriptions

Sensor

RSR

No.

1 1 116 2DCR_RDY 2D code reader is ready. OFF

2 2 115 2DCR_ERR 2D code reader error. OFF

3 3 114 Shutter solenoid on/off When solenoid is energized, LED is off. ON

4 4 113 Overrun position of carrier When slide carrier overruns, this is off. OFF

5 5 112 Measurement position of carrier

6 6 111 Origin position of carrier

7 7 110 Lower position of dosimeter

8 8 19 Upper position of dosimeter

9 9 18 Existence of dosimeter

10 10 17

11 11 16

12 12 15

13 13 14

14 14

15 15

16 16 11 Magazine head

LED

No.

Signal Name

PC No.

13

13

12

12 Automatic Reader: magazine end

Manual Reader: inside position of

manual loader

Automatic Reader: magazine slot

position

Manual Reader: outside position

of manual loader

Function Description

When measuring E1, E2, E3 or E4, this is

on.

When slide carrier stops at the origin

position, this is on.

When the dosimeter stops at the lower

position, this is on.

When the dosimeter stops at the upper

position, this is on.

When checking for dosimeter, this is off if

the dosimeter exists.

When the manual loader is pushed in, this

is off.

When the dosimeter is in measuring

position, this is on.

When the manual loader is pushed out,

this is off.

When the sensor detects end of

magazine, this is on.

When the sensor detects head of the

magazine, this is off.

LED

Active

State

ON

ON

ON

ON

OFF

OFF

ON

OFF

ON

OFF

LED1-16: on PCB (UDP516003A)

LEDs

6

Loading...

Loading...