Page 1

Volumetric Post-Mix Valve

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

This Manual supersedes Installation and Service Manual, 28-0301/02, dated 03/04/99

DATE: 06/01/04

P.N. 28-0301/03

• FAX ENGINEERING: • 210-310-7096 •

• "Lancer" is the registered trademark of Lancer •

• Copyright — 2004 by Lancer, all rights reserved •

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

FAX SALES

• NORTH AMERICA – 210-310-7245 • INTERNATIONAL SALES – 210-310-7242 • CUSTOMER SERVICE – 210-310-7242 •

• LATIN AMERICA – 210-310-7245 • EUROPE – 32-2-755-2399 • PACIFIC – 61-8-8268-1978 •

MAINTENANCE MANUAL

PUSH

Portion Control

Push Button

Standard Lever

Self-Serve Lever

Page 2

i

CONTENTS

CONTENTS.........................................................................................................................................................i

LISTING OF ILLUSTRATIONS...........................................................................................................................i

DESCRIPTION ...................................................................................................................................................1

SPECIFICATIONS..............................................................................................................................................1

MAINTENANCE TOOLS....................................................................................................................................1

1. PRINCIPLE OF OPERATION......................................................................................................................2

2. VOLUMETRIC VALVE CLEANING AND SANITIZING PROCEDURES ....................................................3

3. VALVE SET-UP............................................................................................................................................4

4. SYRUP RESTRICTOR SETTING................................................................................................................4

5. SYRUP PURGE PLUG................................................................................................................................4

6. PROGRAMMER OPERATING PROCEDURES..........................................................................................5

7. PORTION CONTROL PROGRAMMING PROCEDURES ..........................................................................7

8. COVER AND ID PANEL..............................................................................................................................8

9. VALVE .........................................................................................................................................................9

10. LEVER ARM ................................................................................................................................................9

11. NOZZLE/DIFFUSER ..................................................................................................................................10

12. CIRCUIT BOARD ......................................................................................................................................10

13. FLOWMETER ............................................................................................................................................10

14. FLOW WASHER ASSEMBLY ...................................................................................................................11

15. SYRUP REGULATOR PLUG ....................................................................................................................13

16. WATER SOLENOID ACCESS...................................................................................................................14

17. WATER SOLENOID ASSEMBLY..............................................................................................................14

18. SYRUP BODY ACCESS ...........................................................................................................................15

19. SYRUP SOLENOID ACCESS ...................................................................................................................16

20. SYRUP SOLENOID ASSEMBLY ..............................................................................................................17

21. TROUBLESHOOTING...............................................................................................................................18

VOLUMETRIC VALVE PARTS LIST ...............................................................................................................22

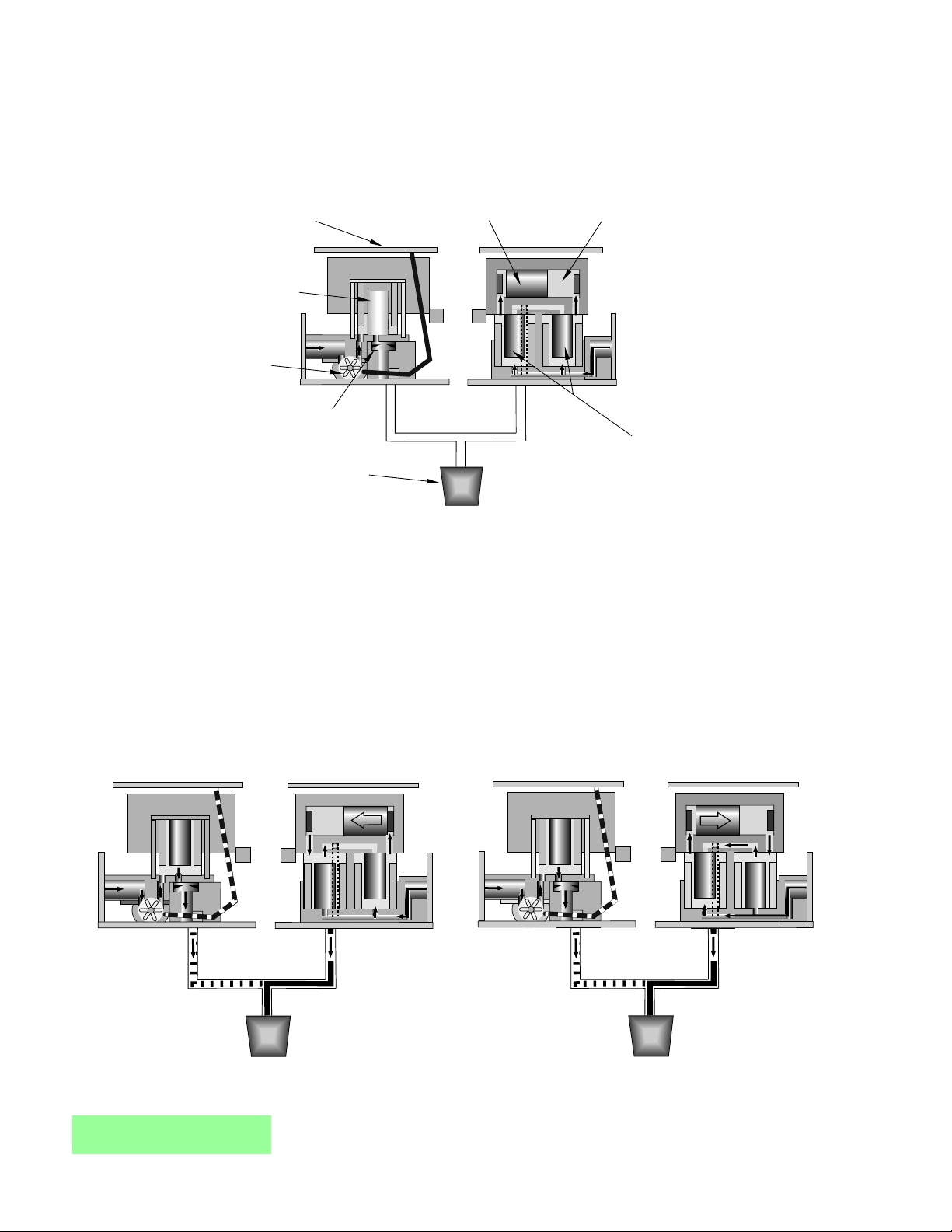

LISTING OF ILLUSTRA

TIONS

1. MAIN COMPONENTS .................................................................................................................................2

2. OPERATION DIAGRAM - VALVE ON ........................................................................................................2

3. OPERATION DIAGRAM - VALVE ON ........................................................................................................2

4. OPERATION DIAGRAM - VALVE OFF.......................................................................................................3

5. NOZZLE/DIFFUSER....................................................................................................................................3

6. VALVE CONTROLS ....................................................................................................................................4

7. SYRUP PURGE PLUG................................................................................................................................5

8, HAND HELD PROGRAMMER, PN 52-1420/01..........................................................................................5

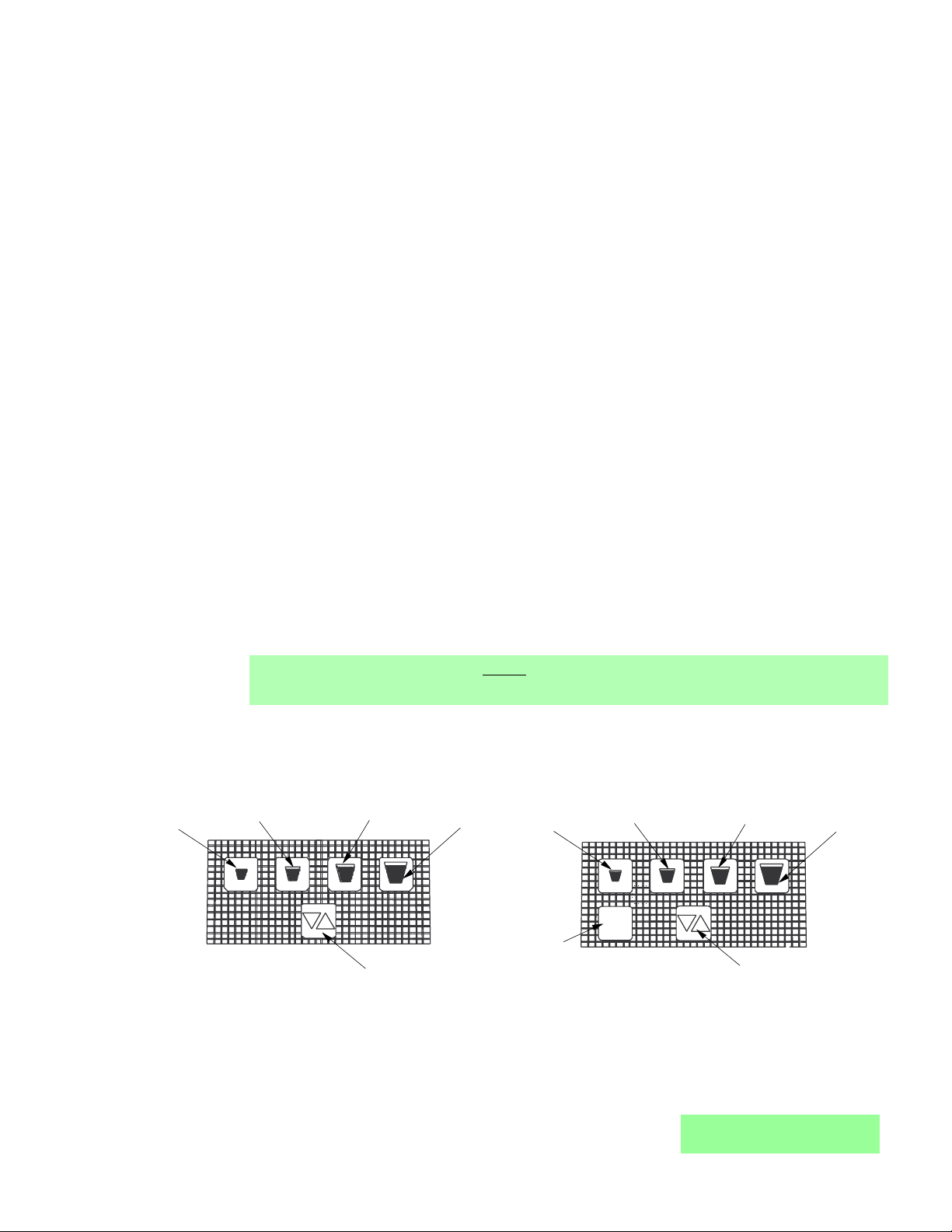

9. PORTION CONTROL, CUP BUTTONS, OVERLAY...................................................................................7

10. PORTION CONTROL, CUP BUTTONS, OVERLAY, WITH WATER ..........................................................7

11. RAISED TAB CONFIGURATION ................................................................................................................8

12. REMOVING THE HOUSING .......................................................................................................................8

13. ID PANEL INSTALLATION..........................................................................................................................9

14. LEVER ARM REPLACEMENT....................................................................................................................9

15. NOZZLE/DIFFUSER ..................................................................................................................................10

16. CIRCUIT BOARD CONNECTIONS...........................................................................................................10

17. CIRCUIT BOARD MOUNTING ..................................................................................................................11

18. FLOW METER ACCESS ...........................................................................................................................12

19. FLOW WASHER/SYRUP PLUG ACCESS ...............................................................................................12

20. WATER SOLENOID ACCESS...................................................................................................................13

21. WATER SOLENOID ASSEMBLY..............................................................................................................14

22. SYRUP BODY ACCESS ...........................................................................................................................15

23. SYRUP SOLENOID ACCESS ...................................................................................................................16

24. SYRUP SOLENOID ASSEMBLY ..............................................................................................................17

25. EXPLODED VIEW, VOLUMETRIC VALVE ASSEMBLY ..........................................................................23

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Page 3

DESCRIPTION

The Volumetric Valve dispenses post-mix beverages accurately over a broad range of pressures and syrup

viscosities. Configurations, from a cup lever to a portion control panel interface, allow the Volumetric Valve

to fit many different applications. The Volumetric Valve mounts to a standard LEV

® back block and utilizes

the same cover as the LEV®.

SPECIFICATIONS

FINISHED DRINK FLOW RATES:

• 3.0 ounces per sec (88.7 ml/sec), Standard

• 2.25 ounces per sec (66.5 ml/sec)

• 1.50 ounces per sec (44.4 ml/sec)

PRESSURE REQUIREMENTS:

Flowing pressure (at the valve)

Minimum Maximum

Water 40 psig 110 psig

(2.8 Kg/cm2) (7.7 Kg/cm2)

Syrup (Sugar) 20 psig 70 psig

(1.4 Kg/cm2) (4.9 Kg/cm2)

Syrup (Diet) 10 psig 70 psig

(0.7 Kg/cm2) (4.9 Kg/cm2)

ELECTRICAL REQUIREMENT:

24 VAC, 50/60 Hz

MOUNTING

Mounts on the same hole pattern with the same mounting screws as the following valves:

Lancer LEV

® Cornelius SF-1 Dole SEV McCann Turbo Flo Jr. Dole FFV

MAINTENANCE TOOLS

When troubleshooting and accessing the Volumetric Valve, the following tools will be needed:

Standard

• #2 Phillips Head Screw Driver

• Flat End Screw Driver

• Dow Corning® 111 Valve Lubricant & Sealant

• Volumetric Valve Hand Held Programmer (Lancer PN 52-1420/02; CCPN 532179)

Optional

• 3/16 inch Hex Socket Driver

• Ohmmeter

1

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Page 4

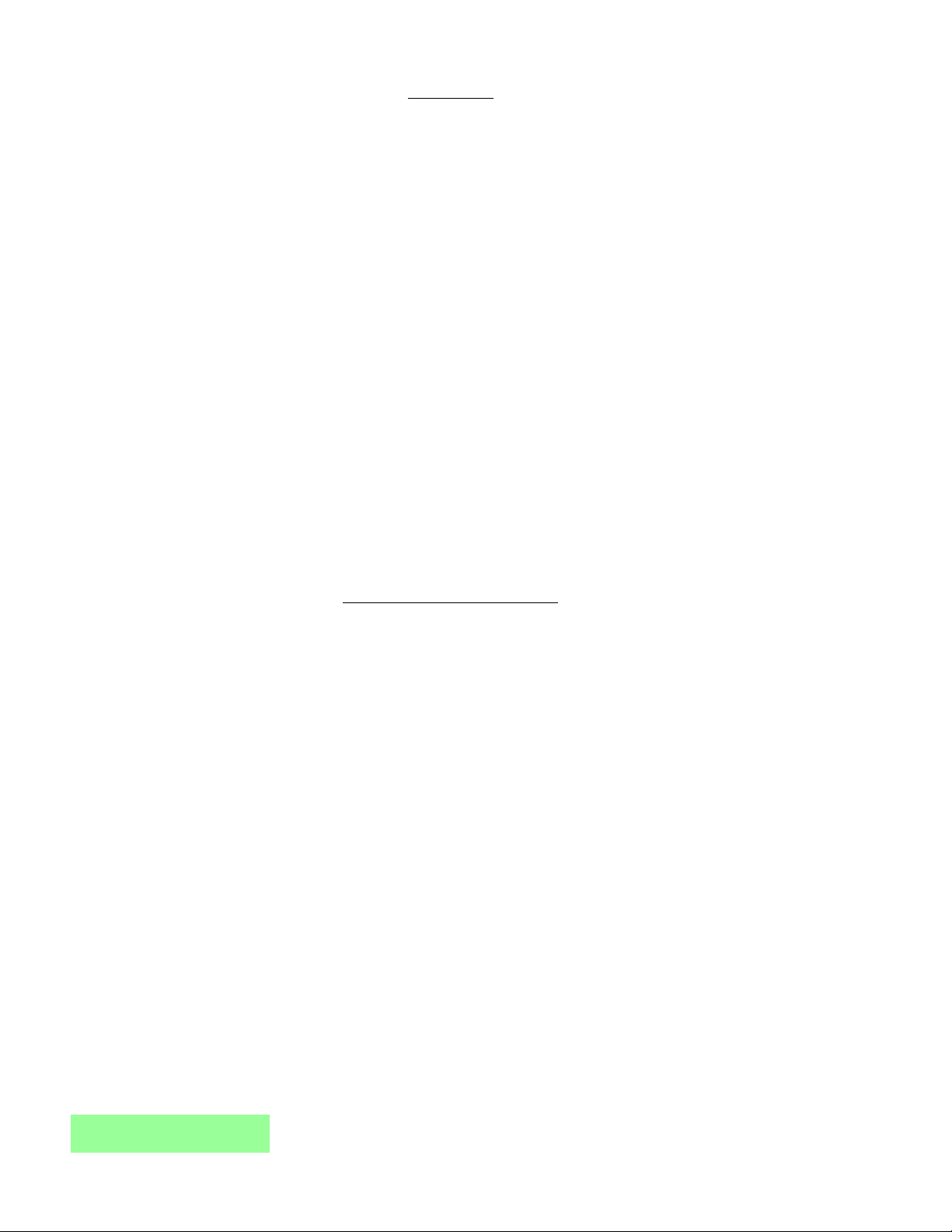

1. PRINCIPLE OF OPERATION

1.1 HOW THE SYSTEM WORKS

2

Main Components

Figure 1

A. Three systems in the Volumetric Valve work together to maintain an accurate syrup to water

ratio:

• The circuit board with its computer.

• The water measuring system.

• The syrup injecting system.

B. Set the ratio by using the hand held programmer (Lancer PN 52-1420/02; CCPN 532179).

C. When a customer activates the valve, the water starts flowing to the nozzle. The flow washer

ensures that the water does not flow too fast.

D. The paddle wheel in the flowmeter begins to spin, sending signals to the circuit board (see

Figure 2).

Operation Diagram - Valve ON

Figure 2

Operation Diagram - Valve ON

Figure 3

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Components:

Circuit Board

Water Syrup

Measuring

System

Water

Solenoid

Flowmeter

Flow Washer

Nozzle

W1

W1

Piston

S1

S1

Syrup Chamber

S2

S2

Injecting

System

Syrup Solenoids

S1

S1

S2

S2

Page 5

E. The computer on the circuit board

monitors the signals and determines

when to precisely inject syrup into the

water stream. The circuit board

energizes one syrup solenoid and then

the other. This alternating action injects a

metered amount of syrup into the water.

This happens seven to eight (7-8) times

a second (see Figures 2 and 3).

F. The circuit board indicates which

solenoid is activated with the LEDs

mounted on the front of the board. The

green LED corresponds to the water

solenoid and the red LEDs correspond to

the syrup solenoids.

3

Operation Diagram - Valve OFF

Figure 4

2. VOLUMETRIC VALVE CLEANING AND SANITIZING PROCEDURES

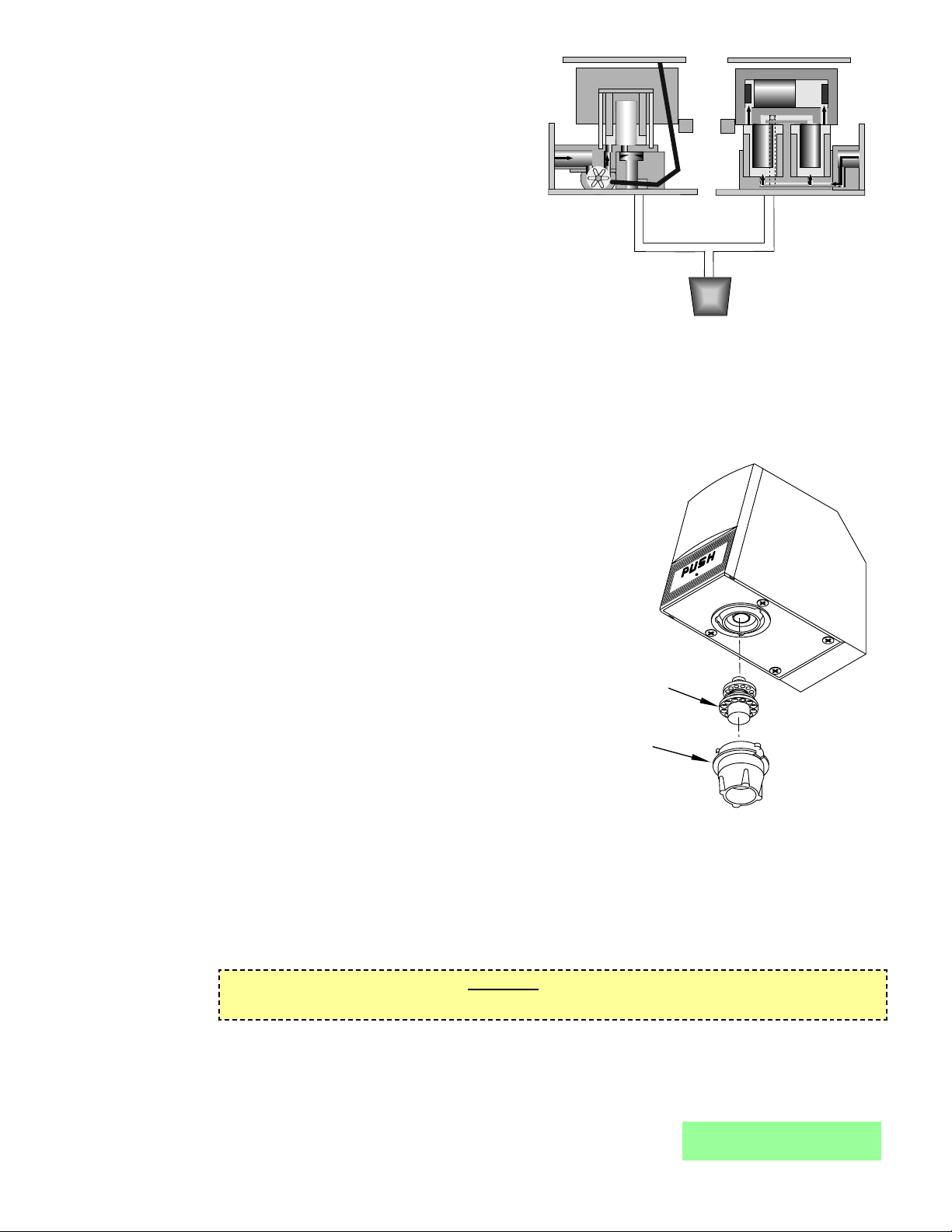

2.1 DAILY NOZZLE/DIFFUSER CLEANING (SEE FIGURE 5)

Use the following procedures to clean the nozzle, and the diffuser assembly, each day:

A. Remove nozzle by twisting it counter-clockwise and

pulling it down.

B. Pull the diffuser assembly down to remove it from the

valve.

C. Wash the nozzle and diffuser with warm water.

D. If needed, apply 111 lubricant to the o-ring on the

diffuser assembly. Then, carefully press it into the

diffuser mounting area on the underside of the valve.

E. Install the nozzle by inserting it into the bottom plate

and twisting it clockwise to lock it in place.

2.2 MONTHLY NOZZLE/DIFFUSER SANITIZING

Use the following procedures to sanitize the nozzle, and

the diffuser assembly, once a month.

A. Cleaning Solution

Prepare a caustic-based (low sudsing, non-perfumed,

and easily rinsed) detergent solution and clean,

potable water at a temperature of 90° to 110°F. The

cleaning solution should be 2% sodium hydroxide.

B. Sanitizing Solution

Nozzle / Diffuser

Figure 5

potable water at a temperature of 90° to 110°F. Any sanitizing solution may be used as long as it is

prepared in accordance with the manufacturer’s written recommendations and safety guidelines, and

provides 50 PPM available chlorine.

C. Cleaning Procedure

CAUTION

BE CAREFUL NOT TO GET SANITIZING SOLUTION ON THE CIRCUIT BOARD.

1. Disconnect power, so the valve will not be inadvertently activated while cleaning.

2. Remove nozzle by twisting it counter-clockwise and pulling it down.

3. Pull the diffuser assembly down to remove it from the valve.

4. Wash the nozzle and diffuser with the cleaning solution.

5. Immerse the nozzle and diffuser in a bath of the sanitizing solution for 15 minutes.

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Prepare a chlorine solution (less than pH 7.0)

containing 50 PPM available chlorine with clean,

W1

W1

Diffuser Assembly

54-0176/02

(24245)

Nozzle

05-2053

(24246)

NOTE: Part Number in ( ) is a Coca-Cola PN

S1

S1

S2

S2

Page 6

6. While the parts are in the sanitizing

solution, visually inspect around the

nozzle mounting area on the valve

for syrup residue. Using a cloth or

nozzle brush and warm water,

clean this area.

7. Wipe off the dispensing lever and

any other areas that may have

been splashed by syrup.

8. Wearing sanitary gloves, remove,

drain, and air dry the nozzle and

diffuser.

9. Wearing sanitary gloves, carefully

press the diffuser into the mounting

area on the underside of the valve.

10. Wearing sanitary gloves, install the

nozzle by inserting it into the

bottom plate and twisting it

clockwise to lock it in place.

4

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Valve Controls

Figure 6

11. Connect power and replace cover. Valve is ready for operation.

12. Draw drinks to flush residual sanitizing solution. Taste the beverage to verify that there is

no off taste. If an off taste is found, additional flushing may be required.

2.3 VALVE AND SYSTEM SANITIZING

A. The complete valve and dispenser system must be sanitized during initial installation. Follow

the manufacturer’s instructions when scheduling and conducting dispenser sanitizing. The

valve must be sanitized once every two weeks. The valve may remain on the dispensing tower

during the sanitizing process.

B. For syrup side line priming, and cleaning and sanitization procedures, refer to the Syrup Purge

Plug (Lancer PN 52-1912) in the Valve Set-Up Section.

3. VALVE SET-UP

3.1 The following steps provide an overview of the valve set-up procedures:

A. Mount valve on back block (see Section 9).

B. Verify that power supply is 24 VAC, 50/60 Hz, then connect to valve.

C. Connect water (soda) and syrup supplies. Flowing pressures must meet valve specifications

(see Specifications, Page i).

D. Set ratio and select carbonation. See Section 6 for hand held programmer procedures.

E. Set the syrup restrictor for either diet or sugar syrup (see Section 4).

F. Purge syrup lines using the hand held programmer (see Section 6).

G. Install valve cover, and if necessary, connect ID panel (see Section 8).

H. Activate valve to test dispensing.

4. SYRUP RESTRICTOR SETTING

4.1 SUGAR SYRUP AND DIET SYRUP FROM FIGALS

Restrictor out and down. Syrup restrictor is not in use.

4.2 DIET SYRUP FROM BAG-IN-BOX

Restrictor in and up. Syrup restrictor is in use.

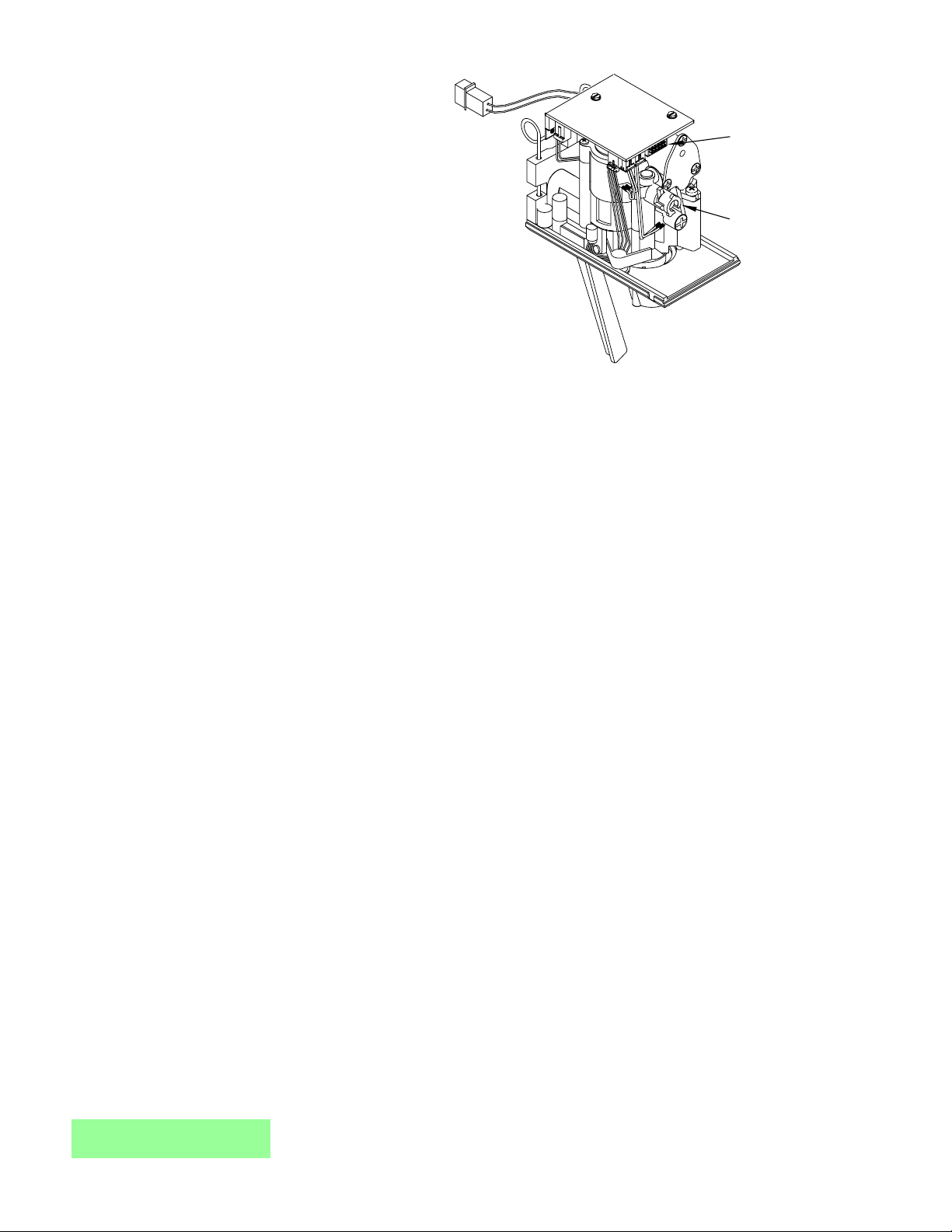

5. SYRUP PURGE PLUG

5.1 The Syrup Purge Plug (PN 52-1912), places the valve in continuous syrup side operation.

5.2 The targeted uses for the purge plug consist of priming the syrup line on an initial Volumetric Valve

install, and for cleaning and sanitization of the syrup side of the dispensing unit.

Plug (Programmer,

Portion Control,

Pushbutton, Syrup

Purge Plug)

Syrup Restrictor

Page 7

5.3 Operation of the syrup purge plug is as follows:

CAUTION

THE VALVE CONSUMES 12VA IN A CONTINUOUS SYRUP SIDE OPERATION. WITH A

STANDARD 75VA TRANSFORMER, UP TO SIX (6) VOLUMETRIC VALVES CAN BE OPERATED

IN SYRUP PURGE MODE SIMULTANEOUSLY.

A. Turn off electrical power to all valves.

B. Install syrup purge plugs into the valve or valves to be primed or sanitized. The syrup purge

5

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

plug installs in the ten-pin connector of the Volumetric

Valve circuit board.

C. Turn on electrical power to the valves. At this time, the

syrup side of the valves will begin continuous operation.

D. When through with the priming or sanitization operation,

syrup purge operation can be stopped either of two

ways:

1. Method 1: Turn off electrical power to all valves,

remove syrup purge plugs from the valves. Turn on

electrical power to all valves. Tap valve lever or

push button to ensure proper operation of all valves.

Syrup Purge Plug

Figure 7

2. Method 2: Remove syrup purge plug from the valves while they are in purge operation. In

this case, the valve may continue in the purge mode for up to six (6) seconds after removal

of the plug (this is normal). Tap valve lever or push button to ensure proper operation of all

valves.

5.4 With a standard 75 VA transformer, up to six (6) Volumetric Valves can be operated in syrup purge

mode simultaneously.

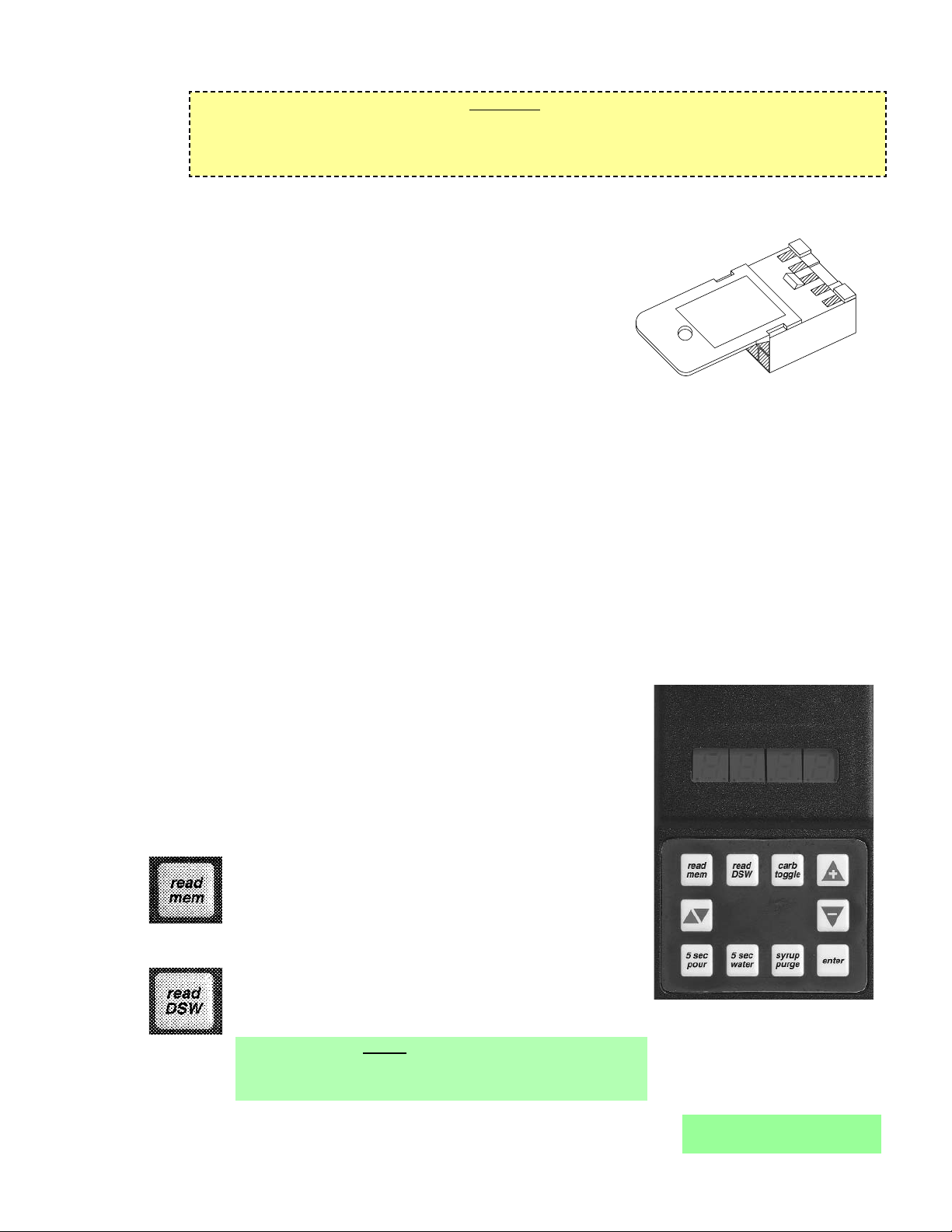

6. PROGRAMMER OPERATING PROCEDURES

6.1 CONNECTING

A. Remove the ID panel from the front of the valve.

B. Insert the programmer's 10-pin connector into the ID Panel plug on the front of the circuit board.

Hand Held Programmer,

Lancer PN 52-1420/02

CCPN 532179

Figure 8

C. When properly connected, the programmer will run a self

diagnostic test. The display will show all "8"s with the

decimal points lighted. After three (3) seconds, the display

indicates the setting of the dip switches.

D. If the programmer does not run its diagnostic test properly,

disconnect it and try plugging it in again. If the programmer

still fails, replace the programmer.

6.2 FUNCTIONS

Read Memory:

Press this button to read and display the current settings

programmed into the valve memory (i.e., S/W revision,

ratio, and carb/non carb settings).

Read Dip Switches:

Press this button to read the dip switch settings.

NOTE

Dip switches were used on some field test valves (see

28-0301, 12/20/95).

SYRUP PURGE

52-1912

Page 8

Write Memory:

Press this button to write the programmer’s displayed ratio and carbonation settings into the

valve’s memory.

Timed 5 Second Water:

Press this button to pour water for five (5) seconds. The programmer will display the ratio, the

counts from the flowmeter, the flow rate in oz/sec, and the flow rate in ml/sec.

Timed 5 Second Pour:

Press this button to dispense a five (5) second pour of water and syrup for ratio testing. When

complete, the programmer displays the ratio, carbonation settings, and total Flowmeter

counts.

Syrup Purge:

Press and release to dispense a six (6) second syrup purge. Continue holding to purge syrup

from system.

Ratio + (Plus):

Pressing this button will increase the ratio number on the display.

Ratio - (Minus):

Pressing this button will decrease the ratio number on the display.

Carb Toggle:

Pressing this button will toggle the carbonation setting from carbonated “C” to plain water “n”

(non-carbonated).

Pour/Stop:

Press this button to manually pour a mixed drink. This button will also stop a timed pour.

6.3 SETTING THE RATIO/CARBONATION

A. Connect the programmer to the Valve.

B. Press the “Read Mem” button.

C. Press the “Ratio +” or the “Ratio -” key until the desired ratio is displayed.

D. Verify drink type. Press “Carb Toggle”to select “C” for carbonated or “n” for non-carbonated.

E. Press the “Enter” button to program the valve with the setting on the display

F. Verify Ratio by pressing “Read Mem”.

G. Disconnect the programmer.

6

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Page 9

7. PORTION CONTROL PROGRAMMING PROCEDURES

The following procedures describe the operation and programming of portion control ID panels for the

Volumetric Valve.

7.1 OPERATION

A. Cup buttons are Small, Medium, Large, Extra-Large.

B. Press and release the desired cup size. Valve will fill cup as programmed (See below).

C. Pour/Cancel Button

1. Push and release to cancel or stop valve dispensing.

2. Push and hold for continuous pour.

D. Water Button

1. Push and hold for continuous water pour.

2. Valve will dispense carbonated or non-carbonated water, depending on its location on the

dispenser.

7.2 TEACH AND LEARN PORTION CONTROL PROGRAMMING

In this mode, the valve “learns” the steps to fill each cup size, including the top off delay time. When

activated, the valve dispenses the appropriate drink volume. Then, if a top off has been entered, it

will pause for the programmed length of time. Finally, the valve will dispense the correct top off

amount.

A. Initial Install Procedure

1. Simultaneously, press and hold the small cup button and the extra-large cup button

switches on the portion control until the LED light in center of module starts blinking, then

release switches. The blinking LED indicates that the set mode is active.

2. Put desired amount of ice in cup, place cup under valve and push selected size button

(small, medium, large, or extra-large). Hold button in until cup fills to desired portion, then

release button.

3. Top off: If a top off is not needed, go to Step 4. Wait for foam to settle, then actuate button

again to top off.

NOTE

Only one (1) top off is allowed.

4. Repeat steps 2 and 3 for other drink sizes. Go to Step 5 to exit program mode.

5. Press and release pour/stop button to return the portion control to the operational mode.

Blinking LED light will go out.

6. Repeat steps 1 through 5 for remaining valves.

7

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Portion Control, Cup Buttons, Overlay

Figure 9

Portion Control, Cup Buttons, Overlay, with Water

Figure 10

7.3 TO CHANGE DISPENSE SIZE

Use procedures in the Initial Install Procedure discussed above; it is not necessary to reprogram

every size.

Small

Cup Button

Medium

Cup Button

Large

Cup Button

Extra-Large

Cup Button

Small

Cup Button

Medium

Cup Button

Large

Cup Button

Extra-Large

Cup Button

water

Water

Pour/Stop

Cup Button

Button

Pour/Stop

Cup Button

Page 10

7.4 CALIBRATED CUP PORTION CONTROL PROGRAMMING

In this mode, the valve adds the volume from each programming step to the total drink size. When

activated, the valve dispenses the total drink, without pauses.

A. Simultaneously, press and hold the small and large buttons (see Figures 9 and 10) on the

portion control until the LED light in the center starts blinking, then release switches.

B. Place volume cup under nozzle of valve to be calibrated.

C. Press appropriate size switch and fill volume cup to a point just short of the calibration mark on

the volume cup. The LED will stay lighted constantly while programming an individual cup size.

D. Let foam settle, jog size switch until liquid reaches the calibration mark on the volume cup.

E. Press pour/stop button to end programming for selected cup size. LED will start blinking.

F. To program another cup size, repeat steps B through E, this section (above).

G. To exit the calibrated cup programming mode, press the pour/stop button when the LED is

blinking. If the LED is lighted constantly, press the pour/stop button once to end the cup size

program (LED starts blinking) and again to exit the program mode (LED off).

8. COVER AND ID PANEL

8.1 REMOVAL

8

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

A. ID panel: Slide ID panel up until it detaches from cover.

CAUTION

PULL CAREFULLY, IF WIRES FOR A PUSHBUTTON OR

PORTION CONTROL ARE ATTACHED.

B. ID panel connector (If applicable): The circuit board

connector on the Volumetric Valve has an interlock feature

that acts to keep an ID panel plug or Hand Held

Programmer (HHP) plug properly connected. The interlock

feature consists of a recess in the circuit board connector housing and a raised tab on the

housing plug. See Figure 11, for the raised tab configuration.

When removing the connector, it is important to

hold the housing and not the wires. The housing

easily slides out of the circuit board connector

by placing a very slight downward pressure

onto the housing as it is removed (see

Figure 12).

NOTE

Pulling straight out while holding onto the wires

is not recommended and will likely cause

damage to the valve, ID panel and/or HHP

cable.

C. Cover: Loosen, but do not remove, cover screw.

Pull cover straight up, until it is clear of the valve

body.

NOTE

Push Button ID panel or lever must be connected to run "Syrup Pour" test from dip switches.

Push Button ID panel or lever must be disconnected to use the hand held programmer.

8.2 INSTALLATION

A. Plug the ID panel connector (if applicable) into the front of the circuit board.

B. Slide cover over valve, making certain that wires do not get pinched.

NOTE

If solenoids were replaced or moved, ensure terminal blocks do not interfere with cover. Check

for proper orientation.

Removing the Housing

Figure 12

Raised Tab Configuration

Figure 11

Raised Tab,

Housing Plug

Slight downward pressure here,

while pulling housing straight out

PUSH

Page 11

the pivot axle can be positioned over the slot formed by the valve body and bottom plate.

Release the valve to allow the pivot axle to be seated in the slot.

C. Mount valve in back block.

D. Install ID panel and cover.

9

C. Tighten cover screw.

CAUTION

DO NOT PINCH OR DAMAGE ID PANEL WIRES DURING

INSTALLATION.

D. Align the bottom of the ID panel with the guide slots on

the front of the cover. Slide the ID panel down into place.

NOTE

Attach the ID panel connector before installing cover to

keep wires out of the way.

9. VALVE

9.1 REMOVAL FROM BACK BLOCK

A. Remove cover and ID panel (see Section 8).

B. Turn back block shut-offs to the closed position.

C. Activate the valve (press lever arm or pushbutton) to

relieve pressure.

D. Unplug 24 Volt supply.

E. Raise valve retainer.

NOTE

The retainer cannot be pulled up until the back block

shut-offs are properly closed.

F. Pull the valve off of the back block.

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

PUSH

2

1

PUSH

ID Panel Installation

Figure 13

9.2 MOUNTING ON BACK BLOCK

A. Check o-rings on back block. Replace o-rings, if necessary.

B. Apply 111 Lubricant to o-rings, if necessary.

C. Press valve into the back block.

D. Lower the valve retainer to lock the valve in place.

E. Turn the back block shut-offs to the open position.

F. Connect the 24 Volt supply to the plug on the circuit board.

G. Install cover and ID panel.

10. LEVER ARM

10.1 REMOVAL

A. Remove cover and ID panel (see Section 8).

B. Remove valve from back block (see Section 9).

C. Insert lever arm into bottom plate and

snap pivot axle into back of valve as

shown in Figure 14.

10.2 INSTALLATION

A. With the valve detached

from the back block, insert

the magnet end of the lever

arm into the hole on the

bottom, backside of the

valve.

Lever Arm Replacement

Figure 14

B. Pull the lever arm back while

pushing it into the valve, so

I.D. Panel, Large Pushbutton

Valve with

Cover in Place

Lever Arm

54-0125/01 Shown

(24234 Shown)

NOTE: Part Number in ( ) is a Coca-Cola PN

Page 12

11. NOZZLE/DIFFUSER

11.1 REMOVAL

A. Remove nozzle, by twisting it counter-clockwise and pulling

it in a downward direction (see Figure 15).

B. Remove the diffuser assembly, by pulling it in a downward

direction.

11.2 ASSEMBLY

A. Slide o-ring into the groove on the end of the diffuser

assembly, if necessary.

B. Apply 111 Lubricant to o-ring, as required.

C. Insert diffuser assembly carefully into the underside of the

valve.

D. Install nozzle by inserting it into the bottom plate and

twisting it in a clockwise direction to lock it into place.

12. CIRCUIT BOARD

10

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Nozzle / Diffuser

Figure 15

12.1 REMOVAL

A. Unplug 24 Volt supply.

B. Use a flat end screw driver to remove each of the screws holding the circuit board in place.

C. Disconnect the solenoids and flowmeter from the circuit board, by pressing each connectors

locking tab and pulling it down out of its socket.

D. Lift the circuit board off of the valve.

D

S

Circuit Board Connections

Figure 16

12.2 INSTALLATION

A. Plug the connector from the rear syrup solenoid

into the receptacle on the underside of the circuit

board near the rear of the valve.

B. Plug the connector from the soda solenoid into

the receptacle located at the front, left corner of

the circuit board.

NOTE

Each solenoid plugs into the nearest circuit

board socket.

C. Plug the connector from the front syrup solenoid

into the receptacle between the soda solenoid

connector and the 10-pin connector on the front

of the circuit board.

D. Plug the 4-pin connector from the flowmeter in

the 4-pin receptacle near the front corner of the

circuit board.

E. Position circuit board on the mounting posts on

top of the syrup body 10-pin connector to the

front.

F. Secure circuit board with two (2) screws.

G. Connect 24 Volt supply.

13. FLOWMETER

13.1 REMOVAL

A. Remove cover and ID panel (see Cover and ID Panel, Section 8).

B. Remove valve from back block (see Valve, Section 9).

C. Remove nozzle/diffuser (see Nozzle/ Diffuser, Section 11).

Diffuser Assembly

54-0176/02

(24245)

Nozzle

05-2053

(24246)

NOTE: Part Number in ( ) is a Coca-Cola PN

Programmer Plug, ID Panel

Front Syrup Solenoid

Plug, Rear Syrup Solenoid

Plug, Flowmeter

Plug, Water Solenoid

Page 13

D. Remove lever arm, if applicable (see Lever

Arm, Section 10).

E. Remove four (4) screws holding the bottom

plate in place.

F. Pull bottom plate off.

CAUTION

CAREFULLY POSITION THE FLOWMETER

SENSOR WIRES, SO THAT THEY ARE NOT

DAMAGED WHILE YOU REMOVE THE

SCREWS.

G. Remove four (4) screws holding the flowmeter

body in place.

H. Carefully pull the flowmeter body and o-ring

off of the valve. Use caution to not pull the

rotor and bearings out of the flowmeter body

as they are snapped into place.

13.2 INSTALLATION

A. Place the o-ring in the groove in the flowmeter

body.

CAUTION

DO NOT PINCH THE FLOWMETER O-RING

DURING INSTALLATION. IT MUST STAY IN THE

GROOVE ON THE FLOWMETER BODY.

11

Screw

Circuit Board

D

S

NOTE: Part Number in ( ) is a Coca-Cola PN

04-0640

(24208)

52-2345/05

(24155)

Circuit Board Mounting

Figure 17

B. Carefully apply a small amount of 111 Lubricant to o-ring, if necessary.

NOTE

Do not get lubricant in the flowmeter.

C. With the wires exiting toward the front of the valve, carefully press the flowmeter sub-assembly

into place on the underside of the valve body. The flat surface of the flowmeter must be flush

against the mounting surface of the valve body.

D. Install four (4) screws to hold the flowmeter in place. Gently position the sensor wires so they

are not pinched or scraped when the screws are installed.

NOTE

The flowmeter screws are 5/8" long, and are longer than the bottom plate screws.

E. Thread the connector attached to the flowmeter sensor wires through hole on the valve body

that is in front of flow washer mounting port (see Figure 18).

F. Place the flowmeter sensor wires around the outside of the flow washer mounting port, so that

they will not interfere with the bottom plate installation.

CAUTION

DO NOT PINCH ANY WIRES WITH THE BOTTOM PLATE.

G. Line up holes on the bottom plate with the screw holes on the underside of the valve body. The

raised sections around the screw holes should fit completely in the counterbores on the bottom

plate.

H. Secure bottom plate in place with four (4) screws.

I. Replace nozzle/diffuser and lever arm (if applicable).

J. Install ID panel and cover.

14. FLOW WASHER ASSEMBLY

14.1 REMOVAL

A. Remove cover and ID panel (see Cover and ID Panel, Section 8).

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Page 14

B. Remove valve from back block (see Valve, Section 9).

C. Remove nozzle/diffuser (see Nozzle/ Diffuser, Section 11).

D. Remove lever arm, if applicable (see Lever Arm, Section 10).

E. Remove four (4) screws holding the bottom plate in place.

F. Pull bottom plate off.

G. Pull the flow washer assembly out of its port, next to the nozzle mount on the underside of the

valve. The flow washer assembly will be one of the following:

1. Gray, 3.0 ounce/sec product flow.

2. White, 2.25 ounce/sec product flow.

3. Red, 1.5 ounce/sec product flow.

12

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

S

D

Thread

Flow Meter Access

Figure 18

Flow Washer/Syrup Plug Access

Figure 19

D

S

Flowmeter

wires though

Valve Body

at this point

Thread Flowmeter wires though

Valve Body at this point.

Flowmeter

O-Ring

02-0354

Flowmeter

Body

54-0126

Screw

04-0549

(24242)

Bottom Plate

05-0960/01

(24244)

Screw

04-0633

(24209)

Diffuser Assembly

54-0176/02

(24245)

Nozzle

05-2053

(24246)

O-Ring

02-0005

(10050)

NOTE: Part Number in ( ) is a Coca-Cola PN

O-Ring

02-0003

(10049)

Regulator Plug

05-0779/01

(24236)

Flow Washer Assy

54-0192 (Red)

(24237)

Flow Washer Assy

54-0193 (White)

(24238)

Flow Washer Assy

54-0194 (Gray)

(24239)

Bottom Plate

05-0960/01

(24244)

Screw

04-0633

(24209)

O-Ring

02-0005

(10050)

Diffuser Assembly

54-0176/02

(24245)

Nozzle

05-2053

(24246)

NOTE: Part Number in ( ) is a Coca-Cola PN

Page 15

F. Secure bottom plate in place with four (4) screws.

G. Mount valve on back block.

H. Replace nozzle/diffuser and lever arm (if applicable).

I. Install ID panel and cover.

raised sections around the screw holes should fit

completely in the counterbores on the bottom plate.

CAUTION

DO NOT PINCH ANY WIRES DURING INSTALLATION.

F. Secure bottom plate in place with four (4) screws.

G. Mount valve in back block.

H. Replace nozzle/diffuser and lever arm (if

applicable).

I. Install ID panel and cover.

15. SYRUP REGULATOR PLUG

15.1 REMOVAL

A. If the syrup regulator plug or its o-rings need to be

replaced, remove the valve from the back block and

take off the bottom plate.

B. Pull the regulator plug from the regulator port near

the back of the underside of the valve body.

NOTE

There is nothing mounted inside the regulator port.

15.2 INSTALLATION

A. Install o-rings in groove on regulator plug.

B. Apply 111 Lubricant to the o-ring.

C. Insert regulator plug into keyed hole on the

underside of the valve body.

D. Place the flowmeter wires around the outside of the

flow washer assembly, so that they will not interfere

with the bottom plate installation.

CAUTION

DO NOT PINCH ANY WIRES DURING INSTALLATION.

E. Line up holes on the bottom plate with the screw

holes on the underside of the valve body.

13

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Water Solenoid Access

Figure 20

D

S

Screw

Solenoid

Circuit Board

Screw

Water

Soda Seat

O-Ring

NOTE: Part Number in ( ) is a Coca-Cola PN

02-0005

(10050)

05-0706

(24233)

Assembly

05-0707

(24222)

Retainer

Solenoid

04-0637

(24221)

52-2345/05

04-0640

(24208)

(24155)

14.2 INSTALLATION

A. Install o-rings, if necessary.

B. Apply 111 Lubricant to the o-rings, if necessary.

C. Install the appropriate flow washer assembly into the keyed port on the underside of the valve

body.

NOTE

The flow washer has a flat side and a concave side. The flow washer must be installed with the

concave side facing the small diameter hole in the flow washer retainer.

D. Place the flowmeter wires around the outside of the flow washer mounting port, so that they will

not interfere with the bottom plate installation.

E. Line up holes on the bottom plate with the screw holes on the underside of the valve body. The

CAUTION

THE BOTTOM PLATE HOLDS THE REGULATOR

PLUG AND THE FLOW WASHER RETAINER IN

PLACE. DO NOT PRESSURIZE UNTIL BOTTOM

PLATE IS FIRMLY ATTACHED.

Page 16

16. WATER SOLENOID ACCESS

16.1 REMOVAL

A. Disconnect valve from back block (see Valve, Section 9).

B. Remove circuit board (see Circuit Board, Section 12).

14

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

CAUTION

DO NOT LET THE SOLENOID AND ITS COMPONENTS FALL

WHEN THE RETAINER IS REMOVED. THEY CAN BE

DAMAGED, IF DROPPED.

C. Remove three (3) screws holding the water solenoid

retainer in place. Remove the retainer.

D. Take the water solenoid assembly out of the valve.

16.2 INSTALLATION

If a water seat is already installed, skip to Step H.

A. Put o-ring in groove on water seat.

B. Apply 111 Lubricant to outside edges of o-ring.

CAUTION

USE CARE TO NOT DAMAGE SEATING AREA WHILE

INSERTING WATER SEAT INTO VALVE BODY.

C. Carefully press water seat into the hole at the base of the

water solenoid mounting area in the valve body. Make

certain that the water seat remains completely inserted into

the hole. If it does not, apply more 111 Lubricant to the

o-ring.

D. If necessary, install flow washer (See Flow Washer

Assembly, Section 14).

CAUTION

DO NOT PINCH ANY WIRES DURING INSTALLATION.

Water Solenoid Assembly

Figure 21

F. Secure bottom plate in place with four (4) Screws.

CAUTION

DO NOT GET LUBRICANT ON THE SPRING OR CORE IN THE SOLENOID.

G. Apply 111 Lubricant to the outside edge of o-ring on the water solenoid sub-assembly.

H. Turn valve body over and insert water solenoid sub-assembly into the hole where the water seat

is mounted. Carefully twist the solenoid while pressing it into place, so that the o-ring does not

get pinched. The terminal block on the side of the solenoid must be on the outside edge of the

valve body, turned so that it touches the single solenoid retainer post towards the front of the

valve. Hold the solenoid in place until the retainer is firmly mounted.

I. Place the water solenoid retainer on top of the solenoid and install three (3) screws. The water

solenoid sub-assembly must remain firmly seated during installation to avoid damaging the

o-ring. Tighten each screw a little at a time, so that the retainer stays perpendicular to the water

solenoid.

J. Install the circuit board.

K. Reconnect the valve.

17. WATER SOLENOID ASSEMBLY

17.1 DISASSEMBLY

A. Remove the core/spring assembly from the solenoid.

B. Slide the o-ring off the end of the solenoid.

E. Place the flowmeter wires around the outside of the flow

washer assembly, so that they will not interfere with the

bottom plate installation.

Plug Nut

10-0877/03

O-Ring

02-0538

(10061)

Bonnet,

Solenoid

81-0289

(24224)

Coil

12-0132/02-01

(24225)

Washer,

Solenoid

04-0600

(24226)

O-Ring

02-0109

(17428)

Core/Spring

Assembly

82-1624

(24229)

NOTE: Part Number in ( ) is a Coca-Cola PN

Page 17

J. Pull the syrup down tube restrictor assembly out of the port on the side of the syrup body.

18.2 INSTALLATION

A. If necessary, install an o-ring on either end of the syrup down tube restrictor assembly.

B. Apply 111 Lubricant around each end of the syrup down tube restrictor, if necessary.

C. Insert syrup down tube restrictor assembly into port on the side of the syrup body

sub-assembly.

D. Apply 111 Lubricant to the outside edge of o-ring on the syrup solenoids.

CAUTION

DO NOT GET LUBRICANT ON THE SPRING OR CORE IN THE SOLENOID.

D

S

Screw

C. Lift the solenoid washer off the end of the solenoid.

CAUTION

THE PLUG NUT MAY PULL OUT OF THE COIL, WHEN YOU ARE TRYING TO LOOSEN IT. THE

COIL CAN BE DAMAGED IF IT IS DROPPED.

D. Carefully hold the wire terminal block on the side of the coil while pulling the solenoid bonnet to

loosen the water plug nut. When the water plug nut has been pulled out of the coil enough,

remove it and the bonnet by hand.

17.2 ASSEMBLY

A. Slide o-ring into the groove on the water plug nut.

15

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

B. Slide bonnet over coil.

C. Apply 111 Lubricant to o-ring in plug nut.

D. Press plug nut into top of coil/bonnet assembly.

E. Place solenoid washer on bottom end of the

coil/bonnet assembly.

F. Place o-ring over end of coil extending through the

solenoid washer.

G. Insert the core/spring assembly into the end of the

solenoid assembly.

NOTE

Water and syrup solenoid coils are interchangeable.

18. SYRUP BODY ACCESS

18.1 REMOVAL

A. Remove valve from back block (see Valve, Section 9).

B. Remove circuit board (see Circuit Board, Section 12).

C. Remove nozzle/diffuser (see Nozzle/Diffuser,

Section 11).

D. Remove lever arm, if applicable (see Lever Arm, Section

10).

E. Remove four (4) screws holding the bottom plate in

place.

F. Pull bottom plate off.

G. Remove two (2) screws located at front and rear of

syrup body.

H. Turn valve assembly over and remove the two (2)

screws on the underside of the main body, holding the

syrup body in place.

CAUTION

PARTS OF THE SYRUP SOLENOIDS MAY FALL OUT

WHEN THE SYRUP BODY IS REMOVED.

I. Lift the syrup body subassembly off of the syrup

solenoids.

Syrup Body Access

Figure 22

Circuit Board

52-2345/05

(24155)

Syrup Body

Subassembly

82-1117/01

(24217)

Down Tube

Restrictor

Assembly

54-0190

(24220)

04-0640

(24208)

Screw

04-0549

(24242)

Bottom Plate

05-0960/01

(24244)

Screw

04-0633

(24209)

O-Ring

02-0005

(10050)

Diffuser

Assembly

54-0176/02

(24245)

Nozzle

05-2053

(24246)

NOTE: Part Number in ( ) is a Coca-Cola PN

Screw

04-0637

(24221)

Page 18

E. Rotate the front syrup solenoid until its terminal block rests in groove, towards the syrup down

tube port.

F. Rotate the back syrup solenoid, so that its terminal block rests against the water solenoid

retainer mount.

CAUTION

SYRUP SOLENOIDS MUST BE SEATED AGAINST MAIN BODY. IF SOLENOIDS BECOME

UNSEATED, SEE SYRUP SOLENOID ACCESS, INSTALLATION, SECTION 19.

G. Carefully press the syrup body sub-assembly into place on top of the syrup solenoids. If the

syrup body will not smoothly press into place, then apply more 111 Lubricant to the solenoid

o-rings, so that they will not be pinched.

1. Make certain the syrup down tube restrictor assembly goes into the down tube port on the

valve body.

16

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

D

S

Syrup Solenoid Access

Figure 23

2 Hold the syrup body firmly in place until the

mounting screws are completely installed.

CAUTION

MOUNTING SCREWS MUST BE TIGHT. LOOSE

SCREWS WILL CAUSE LEAKS AND WILL CHANGE

VALVE PERFORMANCE.

H. Install screw at front and rear of syrup body.

I. Install two (2) screws on the underside of the main

body, to secure syrup body.

J. Install circuit board (see Circuit Board, Section 12) and

secure with two (2) screws.

K. Place the flowmeter wires around the outside of the

flow washer assembly, so that they will not interfere

with the bottom plate installation. Connect to circuit

board.

CAUTION

DO NOT PINCH ANY WIRES DURING INSTALLATION.

L. Line up holes on the bottom plate with the screw holes

on the underside of the valve body.

M. Secure bottom plate with four (4) screws.

N. Install nozzle/diffuser

O. Install lever arm, if applicable.

19. SYRUP SOLENOID ACCESS

19.1 REMOVAL

H. Turn valve assembly over and remove the two (2) screws, on the underside of the main body,

holding the syrup body in place.

CAUTION

PARTS OF THE SYRUP SOLENOIDS MAY FALL OUT WHEN THE SYRUP BODY IS REMOVED.

A. Remove valve from back block (see Valve, Section 9).

B. Remove circuit board (see Circuit Board, Section 12).

C. Remove nozzle/diffuser (see Nozzle/ Diffuser, Section

11).

D. Remove lever arm, if applicable (see Lever Arm,

Section 10).

E. Remove four (4) screws holding the bottom plate in

place.

F. Pull bottom plate off.

G. Remove the two (2) screws that hold the syrup body in

place.

Screw

04-0640

(24208)

Screw

04-0459

(24242)

Syrup Body

Subassembly

82-1117/02

(24217)

Syrup Down Tube

Restrictor Assembly

54-0190

(24220)

Bottom Plate

05-0960/01

(24244)

Screw

04-0633

(24209)

O-Ring

02-0005

(10050)

Nozzle

05-2053

(24246)

NOTE: Part Number in ( ) is a Coca-Cola PN

Circuit Board

54-2345/05

(24155)

Syrup

Solenoid

Subassembly

O-Ring

02-0005

(10050)

Screw

04-0637

(24221)

Diffuser

Assembly

54-0176/02

(24245)

Page 19

I. Lift the syrup body off of the syrup solenoids.

J. Lift each syrup solenoid out of the valve.

NOTE

The o-ring mounted underneath the solenoid, may stick to the solenoid when it is removed.

19.2 INSTALLATION

A. Install an o-ring over the port in the bottom of each syrup solenoid mounting area on the main

body. Ensure that o-ring seats to bottom of mounting port.

B. Apply 111 Lubricant to the outside edges of the o-rings.

C. Insert syrup solenoid sub-assembly into the rear mounting area on the main body. Twist the

solenoid while pushing it into place to avoid pinching the o-ring at the bottom of the mounting

area. Turn the solenoid, so that the terminal block rests against the water solenoid retainer post.

D. Insert syrup solenoid sub-assembly into the front mounting area on the main body. Twist the

solenoid while pushing it into place to avoid pinching the o-ring at the bottom of the mounting

area. Turn the solenoid so that the terminal block rests in groove towards, but not over, the

syrup down tube port.

E. Apply 111 Lubricant around each of the o-rings on the syrup down tube.

F. Insert syrup down tube into port on the side of the syrup body sub-assembly.

CAUTION

DO NOT GET LUBRICANT ON THE SPRING OR CORE IN THE SOLENOID.

G. Apply 111 Lubricant to the outside edge of o-ring on the syrup solenoids.

H. Carefully press the syrup body sub-assembly into place on top of the syrup solenoids. If the

syrup body will not smoothly press into place, then apply more 111 Lubricant to the solenoid

17

o-rings, so that they will not be pinched. Make certain the

syrup down tube goes into the down tube port on the valve

body. If the solenoid assembly becomes unseated, remove

solenoid assembly and repeat Steps A through D above. Hold

the syrup body firmly in place until the mounting screws are

completely installed.

I. Install two (2) upper screws located at front and rear of syrup

body.

J. Install two (2) screws on the underside of main body, to

secure the syrup body.

K. Place the flowmeter wires around the outside of the flow

washer assembly, so that they will not interfere with the

bottom plate installation.

CAUTION

DO NOT PINCH ANY WIRES DURING INSTALLATION.

L. Line up holes on the bottom plate with the screw holes on the

underside of the main body.

M. Secure bottom plate in place with four (4) screws.

N. Install nozzle/diffuser

O. Install lever arm, if applicable.

P. Install circuit board (see Circuit Board, Section 12).

20. SYRUP SOLENOID ASSEMBLY

20.1 DISASSEMBLY

A. Remove the core/spring assembly from the solenoid.

B. Slide the o-ring off the end of the solenoid.

C. Lift the solenoid washer off the end of the solenoid.

D. If the o-ring remains in the end of the syrup plug nut or on the

post inside the syrup solenoid mounting area on the main

body, remove it.

Syrup Solenoid Assembly

Figure 24

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

O-Ring

02-0109

(17428)

Coil

12-0132/02-01

(24225)

O-Ring

02-0538

(10061)

Core/Spring

Assembly

82-1624

(24229)

Solenoid

Washer

04-0600

(24226)

Solenoid

Bonnet

81-0289

(24224)

Plug Nut

10-0280/02

(24230)

O-Ring

02-0005

(10050)

NOTE: Part Number in ( ) is a Coca-Cola PN

Page 20

21.1 Drink Ratio A. Syrup restrictor A. Check location of restrictor. A. Position restrictor

Incorrect incorrectly set. Restrictor must be in and up for correctly.

(Weak or diet bag-in-box (BIB) applications,

Strong); directly above the the letter “D” in

Programmer the syrup down tube assembly.

available Restrictor must be down and out

for non-diet drinks, directly below

the letter “S” in the syrup down

tube assembly.

B. Flow washer bad B. Water flow over 2.7 oz/sec on a B. Replace flow washer

(if installed). timed pour. Flow washer installed assembly, or install

correctly. one if needed.

C. Insufficient syrup C. Run syrup purge test on hand held C. Increase dispensing

pressure. programmer. Output syrup should system syrup

be approximately 3 ounces. pressure.

D. Syrup obstructed. D. Incorrect ratio measurement after D. Disassemble syrup side

circuit board replaced. and remove obstruction.

E. Incorrect ratio E. 1. Plug in programmer and press E. 1. Reprogram valve’s

setting in memory. “Read Memory”, and ratio memory by using “+/-

and/or carbonation setting keys, Carb Toggle

incorrect. and Write Memory”.

2. Reprogramming of ratio and/or 2. Replace circuit

carbonation setting does not board.

work.

F. Flowmeter F. All other items above F. Replace flowmeter

malfunctioning. checked. assembly.

21.2 Drink Ratio A. Syrup restrictor A. Check location of restrictor. A. Position restrictor

Incorrect incorrectly set. Restrictor must be in and up for correctly.

(Weak or diet bag-in-box (BIB) applications,

Strong); directly above the the letter “D” in

Programmer the syrup down tube assembly.

unavailable Restrictor must be down and out

for non-diet drinks, directly below

the letter “S” in the syrup down

tube assembly.

(Section 21.2 continued on next page)

CAUTION

THE PLUG NUT MAY PULL OUT OF THE COIL, WHEN YOU ARE TRYING TO LOOSEN IT. THE

COIL CAN BE DAMAGED IF IT IS DROPPED.

E. Carefully hold the wire terminal block on the side of the coil while pulling the solenoid bonnet to

loosen the syrup plug nut. When the syrup plug nut has been pulled out of the coil enough,

remove it and the bonnet by hand.

20.2 ASSEMBLY

A. Slide o-ring into the groove on the syrup plug nut.

B. Slide bonnet over coil.

C. Apply 111 Lubricant to o-ring in plug nut, then press plug nut into top of coil/bonnet assembly.

D. Place solenoid washer on bottom end of coil/bonnet assembly.

E. Place o-ring over end of coil extending through solenoid washer.

F. Insert the core/spring assembly into the end of the solenoid assembly.

NOTE

Water and syrup solenoid coils are interchangeable.

21. TROUBLESHOOTING

Symptom Possible Cause Verification Solution

18

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Page 21

(Section 21.2 continued from previous page)

B. Flow washer bad B. Water flow over 2.7oz/sec on a B. Replace flow washer

(if installed). timed pour. Flow washer installed assembly, or install

correctly. one if needed.

C. Insufficient syrup C. Run syrup purge test on hand held C. Increase dispensing

pressure. programmer. Output syrup should system syrup pressure.

be approximately three (3) ounces.

D. Syrup obstructed. D. Incorrect ratio measurement after D. Disassemble syrup

circuit board replaced. side and remove

obstruction.

E. Flowmeter E. All other items above checked. E. Replace flowmeter

malfunctioning. assembly.

21.3 Nothing A. 24 Volt supply not A. 1. Check plug to 24 Volt supply. A. 1. Plug in 24 Volt

Dispensed plugged in. Supply.

When Valve 2. Neither green nor red LEDs 2. Key ON/OFF on

Activated light up. dispenser.

B. Mounting Block B. Programmer lights up when B. Open mounting block

shut-offs closed. plugged in. Green LED lights up. shut-offs.

C. Push Button or C. Programmer can activate valve, C. Replace ID panel.

Portion control but not Panel Buttons.

malfunctioning.

D. Circuit Board D. Programmer does not light up and D. Check fuse, or

malfunctioning. 24 Volt supply connected. replace circuit board.

E. Soda and front E. “5 sec water” button on E. Connect soda and

syrup solenoid programmer dispenses small front syrup to correct

wires plugged into amount of syrup. Green and red connectors.

wrong connector. LEDs light up.

F. Water solenoid F. Programmer lights up, but does F. Replace water

malfunctioning. not dispense water with solenoid.

“5 sec water”. Shut-offs open.

Green LED lights up.

G. Water Solenoid G. Rubber poppet in core is swollen G. Replace core.

Core defective. or deformed. Green LED lights up.

H. Circuit board H. A new ratio cannot be entered by H. Replace circuit board.

malfunctioning. programmer.

I. Circuit board I. Circuit board not screwed all the I. Ensure board is

misaligned. Lever way down. Board misaligned with aligned and screw

not making holes and mounting posts. board down all the way.

contact with circuit

board sensor.

21.4 Valve A. Syrup shut-off on A. Coils click when activated by A. Open syrup shut-off

Dispenses back block closed. programmer “syrup purge”. on mounting block.

Water Only Green and red LEDs light up.

B. Out of syrup. B. “Syrup purge” draws no syrup and B. Replace BIB or figal.

shut-off is open.

C. Syrup solenoid C. No clicking sound when “syrup C. Plug in syrup solenoid.

unplugged. purge” activated. Green and red

LEDs light up.

D. Flowmeter D. Flow rate zero (0) after programmer D. Plug in flowmeter

unplugged. “5 sec water” pour. Green LED connector.

lights up.

(Section 21.4 continued on next page)

19

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Symptom Possible Cause Verification Solution

Page 22

(Section 21.4 continued from previous page)

E. Flowmeter E. Flow rate zero (0) after E. Unplug. Dry connector.

connector wet. programmer “5 sec water” pour. Shake water out of

Circuit board wet. No LEDs plug.

light up.

F. Circuit board F. Programmer does not light up F. Replace circuit board.

malfunctioning. when plugged in.

G. Flowmeter rotor G. Flow rate zero (0) after G. Remove obstruction

obstructed, does programmer “5 sec water” pour. or replace flowmeter.

not turn freely. Green LED lights up.

H. Flowmeter H. Flow rate zero (0) after H. Replace flowmeter

sensor bad. programmer “5 sec water” pour. assembly.

Green LED lights up.

I. Syrup solenoid I. No clicking sound when “syrup I. Replace syrup

bad. purge” activated and coils properly solenoid.

connected. Green and red LEDs

light up.

J. Syrup solenoid J. Rubber poppet in core is swollen J. Replace core.

core is defective. or deformed. Green and red LEDs

light up.

K. Syrup side of K. Coils click when “syrup purge” K. Disassemble syrup

valve obstructed. activated, shut-off is open, and side and remove

syrup supply is full. Green and obstruction.

red LEDs light up.

21.5 Valve Pours A. Lever arm or A. Top end of lever arm does not A. Replace lever arm

On Its Own lever spring return to back of valve. and/or lever spring.

damaged.

B. Push Button/ B. Valve stops, when panel B. Replace panel.

Portion Control unplugged from circuit board.

malfunctioning.

C. Circuit board C. Valve pours with lever arm C. Replace circuit board.

malfunctioning. retracted, or pushbutton or

portion control unplugged.

D. Moisture in plug D. Circuit board covered with water D. Unplug. Dry out

(Push Button, or syrup. connector. Shake

programmer) on water out of plug.

front of circuit

card.

21.6 Valve Pours A. Connectors loose. A. Solenoid, flowmeter, and/or A. Insert connectors until

Erratically pushbutton connectors not locking tabs engage.

plugged into circuit board

completely.

B. Pushbutton B. Valve pours erratically when B. Replace pushbutton.

malfunctioning. pushed.

C. Connectors wet. C. Circuit board covered with water C. Unplug all connectors.

or syrup. Dry out and blow dry.

Shake water out of

plug.

D. Circuit board D. Valve pours erratically after D. Replace circuit board.

malfunctioning. pushbutton replaced and

connections cleaned.

E. Air in lines. E. Hissing sound heard out of E. Continue to pour until

valve. lines are purged of air.

Symptom Possible Cause Verification Solution

20

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Page 23

21.7 Water Leak A. Screw(s) loose. A. Water solenoid or flowmeter A. Tighten screw(s).

screws turn easily.

B. O-ring seal is B. Water leaks past o-ring, after B. Replace o-ring.

bad. screws have been tightened.

C. Flowmeter body C. Crack visible in flowmeter body. C. Replace flowmeter

is broken. assembly.

D. Debris in water D. Water leaks through nozzle. D. Remove debris from

solenoid. water solenoid.

E. Valve body E. Water continues to leak, after E. Replace valve.

broken. items (above) have been checked.

21.8 Syrup Leak A. Screw(s) loose. A. Syrup body or syrup retainer A. Tighten screw(s) to 9

screws turn easily. inch-pounds.

B. O-ring seal is B. Syrup leaks past o-ring, after B. Replace o-ring.

bad. screws have been tightened.

C. Syrup body is C. Crack visible in syrup body. C. Replace syrup body

cracked. Assembly.

D. Debris in syrup D. Syrup leaks through nozzle. D. Remove debris from

solenoid. Syrup Solenoid.

E. Valve body E. Syrup continues to leak, after E. Replace valve.

broken. items (above) have been

checked.

21.9 Excessive A. Diet restrictor A. Restrictor must be set up and in A. Set correctly.

Foam setting incorrect. for diet bag-in-box (BIB) drinks.

For all other drinks, restrictor

must be set out and sideways.

B. Air in system. B. Hissing sound heard from valve. B. Continue to pour until

air is purged from lines.

C. High flow rate. C. Water flow greater than C. Replace flow washer

2.7oz/sec. assembly, or install flow

washer assembly (if not

previously installed).

NOTES

21

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Symptom Possible Cause Verification Solution

Page 24

D

S

S

D

22. VOLUMETRIC VALVE ASSEMBLY

22

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Exploded View, Volumetric Valve

Figure 25

2

48

47

44

37

13

16

16

3

4

5

6

11

15

14

7

37

8

9

8

10

19

20

21

22

23

24

25

26

42

62

26

24

25

23

22

21

11

1

63

66

61

6

5

3

51

12

52

20

16

27

WATER

53

54

SODA

55

PUSH

46

45

49

50

28

17

18

30

31a

43

31b

34a

34b

34c

3

65

64

32

33

36

35

3

16

40

41

16

29

37

39

38

17

56

PUSH

WATER

58

WATER

57

PUSH

SODA

59

60

SODA

Page 25

Volumetric Valve Parts List

Lancer CCUSA

Part Part

Item Number

Description

Number

R 1 52-2345/05 PCB Assy 24155

(formerly 52-1561)

2 04-0640 Screw, 4 - 20 24208

R 3 04-0633/01 Screw, 6 - 19 x 0.437 24209

4 03-0188 Spring, Lever 24210

5 03-0187 Retainer, Syrup 24211

6 02-0221 O-Ring 22363

7 54-0115/01 Body Assy, Meter 24212

Assy, Syrup

8 02-0264 O-Ring 24213

R 9 81-0298 Sleeve, Syrup 1070147

10 81-0347 Piston 24215

R 11 05-0940/02 Retainer, Piston 24216

12 04-0302 Screw 21691

13 54-0175 Tube, Down, Syrup,

Restrictor

R 14 05-1094 Restrictor, Syrup 24219

15 02-0085 O-Ring 10060

16 02-0005 O-Ring 10050

17 04-0637 Screw 24221

18 05-0707 Retainer, Soda, 24222

Solenoid

R 19 10-0877/03 Plug Nut, Soda, 1071045

Solenoid

R 20 02-0538 O-Ring 10061

R 21 81-0289 Bonnet, Sub-assy, 24214

Solenoid

R 22 12-0132/01-01 Coil 24225

23 04-0600 Washer, Solenoid 24226

24 02-0109 O-Ring 17428

R 25 23-1071 Core Assy 1071046

26 03-0180 Spring, Core 24228

R 27 10-0280/02 Plug Nut, Syrup 24230

28 03-0233 Retainer, Valve 24231

R 29 54-0178 Main Body Assy 24232

30 05-0706 Seat, Soda 24233

R 31a 54-0125/01 Lever Arm 24234

R 31b 54-0195 Self-Serve Lever 24235

32 05-0779/01 Plug, Regulator 24236

33 02-0003 O-Ring 10049

34a 54-0192 Flow Washer Assy, 24237

Red, 1.50 Ounces

34b 54-0193 Flow Washer Assy, 24238

White, 2.25 Ounces

34c 54-0194 Flow Washer Assy, 24239

Gray, 3.00 Ounces

R 35 54-0126 Meter Assy

(Includes #36)

R 36 02-0354 O-Ring

37 04-0549 Screw, 6 - 19 X 0.625 24242

R 38* 05-1102 Filler, Plate, Bottom 24243

R 39 05-0960/01 Plate, Bottom 24244

R 40 54-0176/01 Diffuser, Body Assy 24245

R 41 05-2053 Nozzle 24246

R 42 54-0190 Down Tube, 24220

Restrictor Assy

R 43 82-0274 Mounting Block 19810

R 44 05-0266/01 Valve Stem, 12270

Mounting Block

R 45 05-0267 Washer 12286

R 46 02-0047 O-Ring 15175

R 47 04-0269 Screw 19894

R 48 03-0087 Retainer, Valve, 12263

Mounting Block

R 49 05-0265/01 Mounting Block 12189

R 50 02-0126 O-Ring 10706

R 51 54-0029/02 Cover Sub-assy 23984

R 52 05-0287/02 ID Panel 21432

R 53 52-1571 ID Panel, 24251

Water Button

R 54 52-1572 ID Panel, 24252

Soda Button

R 55 52-1399 ID Panel, 24253

Push Button

R 56 52-1573 ID Panel, 24254

Push Button, Water

R 57 52-1574 ID Panel, 24255

Push Button, Soda

R 58 52-1575/02 ID Panel, 24256

Portion Control,

R 59 52-1576/02 ID Panel, 24257

Portion Control,

Water

R 60 52-1577/02 ID Panel, 24258

Portion Control,

Soda

R 61 82-1117/02 Meter Assy, Syrup 24217

R 62 82-1624 Core/Spring Assy 24229

(Includes Items 25

and 26)

R 63 05-1187 Cover, 1071044

Programmer Plug

R 64 52-2491 Harness Assy,

Syrup Purge

R 65 05-1958 Holder. Purge Switch,

Volumetric Valve

R 66 12-0348 Fuse, 5 Amp, 5X15, 1070729

Fast Acting

R-- 52-1420/02 Hand Held 532179

Programmer Assy

* Model 150P - Pushbutton only

R in margin indicates change or revision

22. VOLUMETRIC VALVE ASSEMBLY (CONTINUED)

23

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Lancer CCUSA

Part Part

Item Number Description Number

Page 26

NOTES

24

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

Page 27

25

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Directory of USA - Canada Offices,

International Offices, and Authorized Distributors

(Continued)

(Continued from previous page)

Pell SudAmerica - Ecuador

Lancer Sales Company

Contact: Luciano Lopez

Sector Las Acacias

Luis De Beethoven #958

Y Capitan Rafael Ramos

Quito, Ecuador

Phone: 593-22-401-598, 400-937, 406-418

FAX: 593-22-400-535

e-mail: Llopez@ecnet.ec

Lancer Authorized Distributors

Eximport & Barter Co. - Caribbean

2101 S.W. 56th Terrace

Hollywood, FL 33023 USA

Phone: (954) 967-9999

FAX: (954) 967-9900

e-mail: edbrandao@aol.com

PromoVen, S.A. - Argentina

Contact: Rafael Mendoza

Juncal 858 - Piso 3 Depto. “L”

(1062) Buenos Aires

Argentina

Phone: (54.11)4394.7654

FAX: (54.11)4394.1193

e-mail: promoven@customw.com.ar

Bras Sulamericana LTDA. - Brasil

Contact: Fabio Queiroz

Rua. Dr. Ladislau Retti, 1400

Parque Alexandre

Cotia Sao Paulo - Brasil

CEP: 06714-150

Phone: 55-11-4612-1122

FAX: 55-11-4612-2219

e-mail: fabio.queiroz@bras.com.br

Lancer Chile Ltda. - Chile

Contact: Heriberto Concha

Vicuna Mackenna 3019, San Joaquin

Santiago, Chile

Phone: 56-2-552-1657

FAX: 56-2-552-1961

e-mail: chocha@lancer.tie.cl

Lancer Pacific

International Sales

6655 Lancer Blvd.

San Antonio, TX 78219

Phone: (210) 310-7000

FAX: (210) 310-7242

1-800-729-1500

e-mail: asia@lancercorp.com

Australia

Lancer Pacific Pty Ltd

5 Toogood Avenue

Beverley 5009

South Australia

Phone: 61-8-8268-1388

FAX: 61-8-8268-1978

e-mail: ian-lunniss@lancer-pacific.com.au

(General Manager, Lancer Pacific)

steve-sotiriou@lancer-pacific.com.au

(for Fountain)

fiore-alvaro@lancer-pacific.com.au

(for Beer)

Lancer Pacific Pty Ltd

7 Slough Avenue

Silverwater 2128

New South Wales

Australia

Phone: 61-2-9648-6840

FAX: 61-2-9648-6850

e-mail: neild-mcintosh@lancer-pacific.com.au

(Managing Director)

john-frize@lancer-pacific.com.au

(NSW State Manager)

Lancer Pacific Pty Ltd

55 Keele Street

Collingwood 3066

Victoria

Australia

Phone: 61-3-8415-1920

FAX: 61-3-8415-1929

e-mail: glenn-blakiston@lancer-pacific.com.au

Lancer Pacific Pty Ltd

Unit 31, 284 Musgrave Drive

Coopers Plains 4108

Queensland

Australia

Phone: 61-7-3274-5700

FAX: 61-7-3875-1805

e-mail: brett-thomson@lancer-pacific.com.au

New Zealand

Lancer Pacific Ltd

9 O’Rorke Street

Onehunga, Auckland

New Zealand

Phone: 64-9-634-3612

Mobile Phone: 64-21-745-389

FAX: 64-9-634-1472

e-mail: mike-peffers@lancer-pacific.com.au

andrew-nixon@lancer-pacific.com.au

Lancer Asia

Hong Kong

1001 Technology Plaza

651 King’s Road

North Point

Hong Kong

Patrick Co - Area Manager - Asia

Phone: 852-2214-9195

Rob Burdock - Senior Director - Asia

Phone: 852-2214-9196

FAX: 852-2214-9448

e-mail: rob-burdock@lancer-asia.com

patrickco@lancer-asia.com

Lancer Authorized Distributors

Shanghai Freser International Co Ltd. China

1856, Hu Tai Road

Shanghai, 200436, China

Phone: 86-21-5650-3555

FAX: 86-21-5650-2666

e-mail: daniel@freser.com.cn

Freser (HK) Company Ltd - Hong Kong

Flat A, 24/F., Houston Industrial Bldg.

32-40 Wang Lung Street

Tsuen Wan, N. T., Hong Kong

Phone: 852-2408-2595

FAX: 852-2408-2605

e-mail: freserhk@netvigator.com

P.T. Dikarunia Sejahtera - Indonesia

JI. Gelong Baru Tengah #1A, Tomang

Jakarta, Barat 11440, Indonesia

Phone: 62-21-5694-3242

62-21-5437-2534

FAX: 62-21-5694-3242

e-mail: dikarunia@cbn.net.id

Hayakawa Sanki - Japan

Hayakawa Sanki, Inc.

1-13-13, Kayaba-cho

Nihonbashi, Chuo-ku

Tokyo, 103-0025

Japan

Phone: 03-5651-1481

FAX: 03-5651-1445

e-mail: SANKI10217@aol.com

Tahoe Corporation - Korea

Tahoe Corporation

2FL, 835-66 Yocksam-dong

Kangnam-Ku

Seoul, Korea

Phone: 82-2-557-5612, -5614

FAX: 82-2-557-5615

e-mail: tahoepark@empal.com

Freser (MALAYSIA) SDN. BHD. - Malaysia

No. 31, Jalan TPP 5/13, Taman

Perindustrian Puchong, Seksyen 5,

47100 Puchong, Selangor, Malaysia

Phone: 60-3-8061-6666

FAX: 60-3-8062-1007

e-mail: freser@tm.net.my

R.B.P. Industrial Sales Inc - Philippines

Unit 20, Facilities Centre Bldg.

548 Shaw Blvd

Mandaluyong City, Philippines

Phone: 632-531-1215/1221/1289

FAX: 632-531-1271

e-mail: rbpsales@info.com.ph

Freser (S) Pte Ltd - Singapore

Blk 998 Toa Payoh North

#04-12/14

Singapore 318993

Phone: 65-6352-0943

FAX: 65-6352-8594

e-mail: fresersin@pacific.net.sg

Freser International Corporation - Taiwan

No. 76, Gui-Sui Street

Taipei 103, Taiwan R.O.C.

Phone: 886-2-2553-1555

FAX: 886-2-2553-2742

e-mail: herman@intl.freser.com.tw

Freser Makasan International Co., Ltd Thailand

Freser Makasan International Co., LTD.

Navanakorn Industrial Estate Zone 4

95/3 Moo 13, Klongnung, Klongluang

Patumthani 12120, Thailand

Phone: 662 520-3457 (Automatic, 7 lines)

FAX: 662 529-3840

e-mail: komsan@makasan.co.th

Lancer - Indian Sub-Continent

India

Shabbir Shafiqui - Area Manager

India and Sub-Continent

B-7, Pannalal Silk Mill Compounds

78, LBS Marg, Bhandup (W)

Mumbai 400-078, India

Phone: 91-22-2561-6665

Cel No.: 91-98-2029-5252

FAX: 91-22-5637-4018

e-mail: shafiquis@vsnl.com

Lancer Authorized Distributors

Western Refrigeration Ltd - India

B-7, Pannalal Silk Mill Compounds

78 L.B.S. Marg, Bhandup (W)

Mumbai 400-078, India

Phone: 91-22-2561-6665

FAX: 91-22-2562-2257

e-mail: western@bom5.vsnl.net.in

Bengal Marketing Company - Bangladesh

Skylark Point (6th Floor)

Room #G-2

24/A Bijoy Nagar,

Dhaka-1000, Bangladesh

Phone: 880-2-934-2987

FAX: 880-2-935-0127

e-mail: bmc@dhaka.agni.com

Dynamic Equipment - Pakistan

Dynamic Equipment and Controls (Pvt.) Ltd.

F-1/23, Canal Cottages, Block-D.

New Muslim Town.

Lahore. Pakistan.

Phone: 0092-42-583-6737

0092-42-583-6787

FAX: 0092-42-586-7924

e-mail: info@dynamic-eqpt.com.pk

m.ateeq@dynamic-eqpt.com.pk

Page 28

26

MAINTENANCE MANUAL

Volumetric Post-Mix Valve

Directory of USA - Canada Offices,

International Offices, and Authorized Distributors

Corporate Office

6655 Lancer Blvd. • San Antonio, Texas 78219 • 210-310-7000 • 1-800-729-1500 • FAX 210-310-7250

Lancer USA

Manufacturing LocationsFoster Road

Foster Road Facilities

6655 Lancer Blvd

San Antonio, TX 78219

Phone: (210) 310-7000

MFG FAX: (210) 310-7088

ENG FAX: (210) 310-7096

ACCT FAX: (210) 310-7091

PURCH FAX: (210) 310-7094

Lancer FBD

5620 Business Park

San Antonio, TX 78218

Phone: (210) 666-0544

FAX: (210) 666-2044

Lancer Ice Link

6655 Lancer Blvd

San Antonio, TX 78219

Phone: (210) 310-7174

FAX: (210) 310-7245

Remanufacturing

6655 Lancer Blvd

San Antonio, TX 78219

Phone: (210) 310-7256

FAX: (210) 310-7261

1-800-729-1550

Lancer North America

USA - Canada Sales

6655 Lancer Blvd.

San Antonio, TX 78219

Phone: (210) 310-7000

SALES FAX: (210) 310-7245

CUSTOMER SERVICE FAX: (210) 310-7250

1-800-729-1500

Georgia Office

1125 Northmeadow Parkway, Suite 116

Roswell, GA 30076

Phone: (770) 343-8828

FAX: (770) 475-8646

1-800-729-1750

Lancer Authorized Distributors

Advanced Beverage Solutions (ABS)

100 N. Gary Avenue, Suite C

Roselle, IL 60172

Phone: (847) 524-1707

(877) 814-2271

FAX: (847) 524-1710

www.absone.com

Bevco

6900 Camille Avenue

Oklahoma City, OK 73149

Phone: (405) 672-7770

FAX: (405) 672-7443

e-mail: info@bevcoinc.com

Joe Kirwan Company

119 White Oak Lane

Old Bridge, NJ 08857

Phone: (732) 679-1900

FAX: (732) 679-9236

e-mail: sales@jkirwan.com

L & M Beverage Equipment Co. Inc.

12510 Santa Fe Trail Drive

Lenexa, KS 66215

Phone: (913) 888-8988

FAX: (913) 888-9137

e-mail: L7mco@aol.com