Page 1

UNDER THE COUNTER BEER DISPENSER

Operation Manual

PN: 28-0915/01

Technical Support/Warranty: 800-729-1550

“Lancer” is the registered trademark of Lancer © 2014 by Lancer, all rights reserved.

Lancer Corp.

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

custserv@lancercorp.com

lancercorp.com

Manual PN: 28-0915/01

JUNE 2013

FOR QUALIFIED INSTALLER ONLY

Page 2

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product and should be handed over to the operator after the

installation and preserved for any further consultation that may be necessary. Please read carefully the guidelines and

warnings contained herein as they are intended to provide the user with essential information for the continued safe

use and maintenance of the product. In addition, it provides GUIDANCE ONLY to the user on the correct services and

site location of the unit.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with up-to-date

safety and hygiene knowledge and practical experience, in accordance with current regulations.

TABLE OF CONTENTS

SPECIFICATIONS................................................................................................................................4

PRE-INTALLATION CHECKLIST........................................................................................................5

WARNINGS/CAUTIONS...................................................................................................................6-8

1. INSTALLATION.............................................................................................................................8

1.1 UNPACKING......................................................................................................................8-9

1.2 SELECTING A LOCATION....................................................................................................9

1.3 ASSEMBLING THE UNIT.....................................................................................................9

1.4 CONNECTING TO ELECTRICAL POWER........................................................................10

1.5 CONNECTING THE DRAIN...............................................................................................10

1.6 EQUIPMENT SETUP..........................................................................................................10

2. GETTING STARTED...................................................................................................................10

2.1 SETTING AND ADJUSTING THE AIR PRESSURE REGULATOR...............................10-11

2.2 CONNECTING THE KEGS............................................................................................11-12

2.3 DISCONNECTING THE KEGS..........................................................................................13

2.4 CONNECTING A NEW KEG...............................................................................................13

2.5 KEG USE AND STORAGE CAUTION................................................................................14

3. BEER DISPENSE........................................................................................................................14

3.1 POURING RITUAL - STELLA ARTOIS...............................................................................14

3.2 POURING OTHER BEERS................................................................................................15

4. CLEANING AND SANITIZING.....................................................................................................15

4.1 GENERAL INFORMATION.................................................................................................15

4.2 CLEANING AND SANITIZING SOLUTIONS.................................................................15-16

4.3 DAILY CLEANING..............................................................................................................16

4.4 MONTHLY MAINTENANCE AND CLEANING...............................................................16-17

4.5 SIX WEEKS PREVENTATIVE MAINTENANCE.................................................................17

5. TROUBLESHOOTING GUIDE FOR END USER..................................................................17-19

5.1 TOO MUCH FOAM WHEN BEER DISPENSED.................................................................17

5.2 FIRST GLASS HAS A LOT OF FOAM................................................................................18

5.3 NOT ENOUGH FOAM........................................................................................................18

5.4 PRODUCT JETS OUT FROM THE SPOUT.......................................................................18

5.5 CANNOT LOCK THE FRONT DOOR OF THE CABINET..................................................18

5.6 BEER LEAKS.....................................................................................................................18

5.7 WARM BEER......................................................................................................................19

5.8 VERY LOW OR NO BEER FLOW......................................................................................19

5.9 UNIT MAKES BUZZING NOISE.........................................................................................19

5.10 UNIT DOES NOT MOVE EASILY.......................................................................................19

2

Page 3

6. TROUBLESHOOTING GUIDE FOR TECHNICIANS............................................................20-22

6.1 AIR COMPRESSOR DOES NOT START...........................................................................20

6.2 AIR COMPRESSOR IS NOT PROVIDING ENOUGH AIR FLOW......................................20

6.3 AIR COMPRESSOR TANK DOES NOT REACH A PRESSURE OF 101 PSI....................20

6.4 MISCELLANEOUS LEAKAGE OF COMPRESSED AIR....................................................20

6.5 REFRIGERATION COMPRESSOR DOES NOT TURN ON, OR STOPS RUNNING........21

6.6 CONDENSER FAN DOES NOT TURN ON, OR STOPS RUNNING..................................21

6.7 EXCESSIVE ICE BUILD UP AROUND EVAPORATOR AREA..........................................21

6.8 REFRIGERATION COMPRESSOR DOES NOT STOP.....................................................21

6.9 COMPRESSOR CYCLES ON AND OFF............................................................................21

6.10 CIRCUIT BREAKER TRIPPING.........................................................................................22

6.11 EXCESSIVE CONDENSATION APPEARS AROUND THE DOOR....................................22

6.12 DEFROST CYCLE SEEMS TO BE TOO LONG FOR THE 115V MACHINE.....................22

6.13 CONDENSER FAN DOES NOT SHUT OFF.......................................................................22

6.14 PRESSURE REGULATOR IS MALFUNCTIONING............................................................22

6.15 UNIT IS IN STANDBY MODE.............................................................................................22

7. PROGRAMMING THE COOLING PARAMETERS - 115 VOLT MODEL...................................22

7.1 ADJUSTING THE TEMPERATURE SET POINT................................................................22

7.2 ADJUSTING THE REFRIGERATION COMPRESSOR RELAY

TRIPPING DIFFERENTIAL................................................................................................23

7.3 ADJUSTING THE DEFROST ENDURANCE TIME............................................................23

7.4 ADJUSTING THE TIME INTERVAL BETWEEN DEFROSTING CYCLES.........................23

7.5 CHANGING THE CONTROLLER FROM FAHRENHEIT TO CELCIUS.............................23

8. PROGRAMMING THE COOLING PARAMETERS - 230 VOLT MODEL...................................24

8.1 ADJUSTING THE TEMPERATURE POINT........................................................................24

8.2 ADJUSTING THE REFRIGERATION COMPRESSOR RELAY

TRIPPING DIFFERENTIAL.................................................................................................24

9. DISPENSER DISPOSAL.............................................................................................................24

10. ILLUSTRATIONS, PART LISTINGS, AND WIRING DIAGRAMS...............................................25

10.1 WIRING DIAGRAM.............................................................................................................25

10.2 EXPLODED VIEW.........................................................................................................26-27

3

Page 4

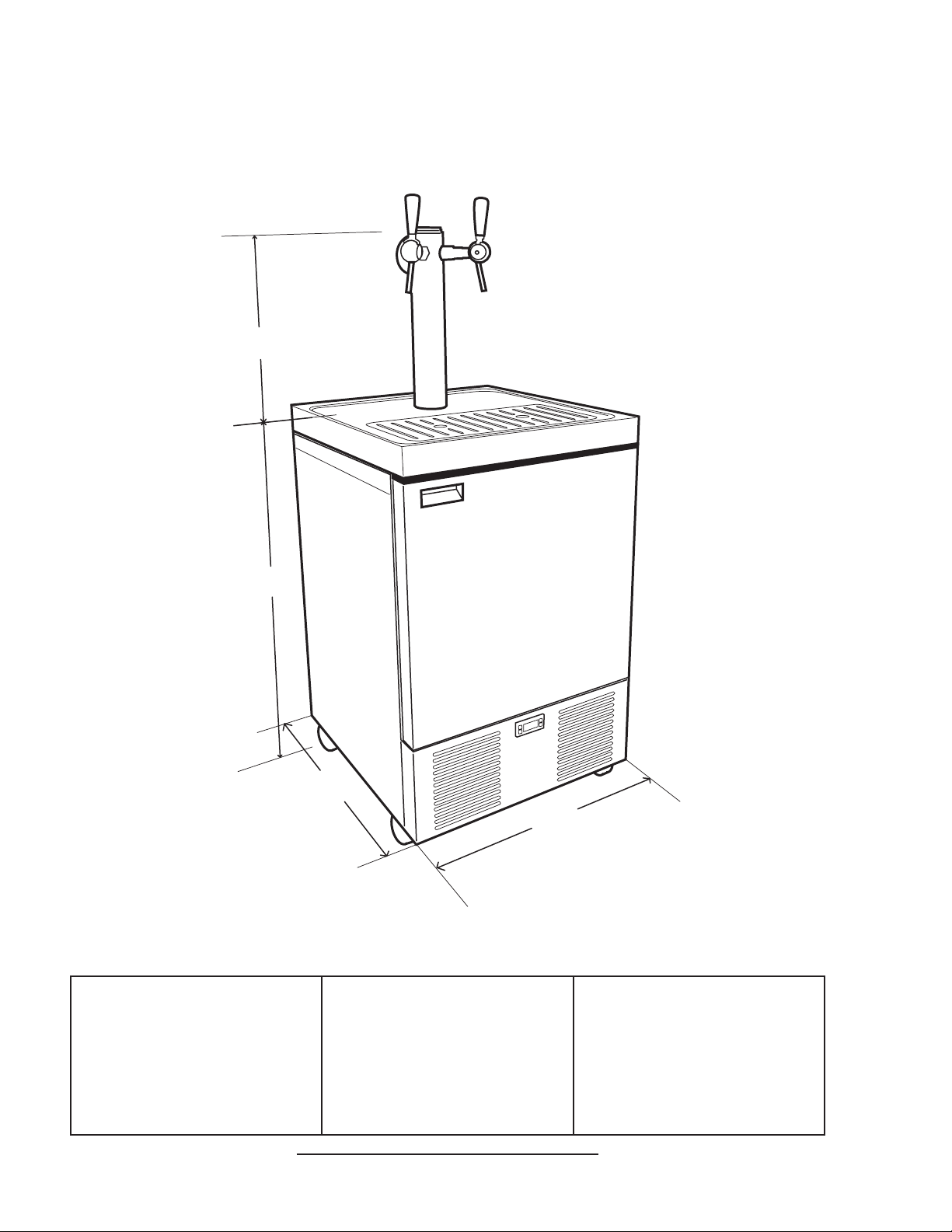

UTC BEER DISPENSER SPECIFICATIONS

39.88

(1,013)

23.60

(599.44)

25.70

(652.80)

17.25

(438.2)

32°F

DIMENSIONS

Width: 23.6 inches (599.4 mm)

Depth: 25.7 inches (652.8 mm)

Height: 57.13 inches (1451.5 mm)

Tower Height: 17.25 inches

(438.2 mm)

SPACE REQUIRED

Left Side: 1 inch (25.4 mm)

Right side: 1 inch (25.4 mm)

Back: 1 inch (25.4 mm)

Casters: 4 inches (101.6 mm)

ELECTRICAL

115 VAC/ 60 Hz / 9 Amps

230 VAC/ 50 Hz / 4.5 Amps

WEIGHT

Shipping: 227 lbs (103 kg)

Installed: 197 lbs (89.36 kg)

This unit emits a sound pressure level below 70 dB

4

Page 5

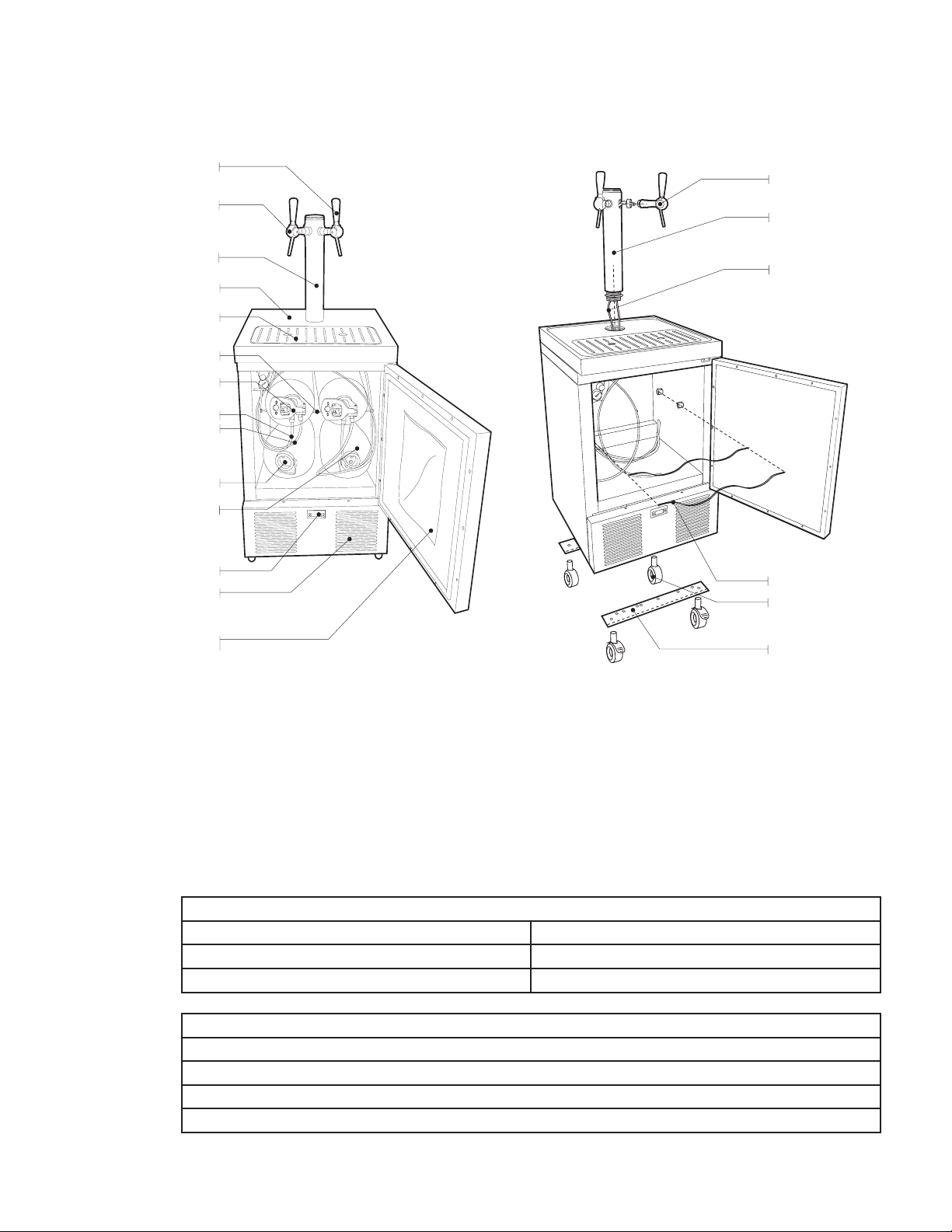

ABOUT THIS DISPENSER

AIR FILTER

TEMPERATURE CONTROL

KEG

KEG CLOSURE

AIR LINE

BEER TUBING

KEG CONNECTOR

RACK

CUP REST

STAGE

TOWER

TAP

TAP HANDLE

CABINET DOOR WITH

USAGE INSTRUCTIONS

BEER TUBING

KEG RACKS

CASTERS

SUPPORT

TOWER

TAP

The dispenser has its own cooling and air compression system and can house up to 4 kegs

of product. Only the top two kegs can be connected to the tower, and up to two taps can be

used on this dispensing unit (two taps mounted on 1 tower).

PRE-INSTALLATION CHECKLIST

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly inspected before

shipment. At the time of shipment, the carrier accepts responsibility for the unit. Upon

receiving the unit, carefully inspect the carton for visible damage. If damage exists, have

the carrier note the damage on the freight bill and le a claim with carrier. Responsibility for

damage to the dispenser lies with the carrier.

Beer Keg Racks (2) Keg Containers (2)

Tower Taps (2)

Tap handles (2) Casters (2 with brakes, 2 without brakes)

Drain

Grounded electrical outlet.

Heating and air conditioning ducts

Enough space to install the dispenser. A minimum of 1 inch on all sides is required.

ACCESSORIES

CONSIDER LOCATION OF THE FOLLOWING PRIOR TO INSTALL

5

Page 6

! !

WARNING/ADVERTENCIA/AVERTISSEMENT

! Respect the basic safety instructions given by the manufacturer. Take care of your personal safety. Dispenser is designed for

cooling and dispensing beer. The supplier shall not be liable for damages caused by improper use. This unit is not designed to

dispense dairy products. This appliance is intended to be used in commercial applications such as restaurants or similar. The

dispenser is only to be used in combination with the provided kegs. Do not use any other commercially available beer kegs. This

dispenser is for indoor use only. This unit is not a toy. Children should be supervised to not play with the appliance. It should not be

used by children or inrm persons without supervision. This dispenser is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the dispenser by a person responsible for their safety. Cleaning and user maintenance shall not be

performed by children without supervision. This unit is not suitable for installation in an area where a waterjet could be used. The

min/max ambient operating temperature for the dispenser is 40°F (4.4°C) to 86°F (30°C). Do not place unit on its side even during

transportation. Do not leave the cabinet door open longer than necessary while the dispenser is connected. Do not block the air inlet

of the dispenser (bottom panels). Keep enough free space around the dispenser according to the specications in this manual. Do

not tamper with the temperature control. Do not operate this dispenser when parts are missing or broken. Make sure all parts of the

dispenser are properly assembled before usage. Always use original parts the manufacturer or supplier does not take any

responsibility for parts which are not original or recommended by the manufacturer. The bottom panels (front and rear) of the

dispenser should only be opened by trained personnel. If not trained, opening the panels will be at the user’s own risk. To avoid

personal injury or damage, do not attempt to lift a unit without helpfor heavier units, use of a mechanical lift may be appropriate.

Always wear protective shoewear during installation.

! Respete las instrucciones básicas de seguridad indicadas por el fabricante. Cuide su seguridad personal. El dispensador está

diseñado para el enfriamiento y la dispensación de cerveza. El proveedor no será responsable por los daños causados por uso

inadecuado. Esta unidad no ha sido diseñada para suministrar productos lácteos. Esta unidad está diseñada para su uso en

aplicaciones comerciales tales como restaurantes, tienda o similares. El dispensador sólo debe ser utilizado en combinación con

los barriles suministrados. No utilice ningún otro barril de cerveza disponible comercialmente. El dispensador sólo debe usarse en

interiores. Esta unidad no es un juguete. Los niños deben ser supervisados para no jugar con aparato. No la deben usar niños ni

personas discapacitadas sin supervisión. Esta unidad no está destinada al uso por parte de personas (incluso niños) con capacidad

física, sensorial o mental reducida, o sin experiencia y conocimientos sucientes, a menos que una persona responsable de su

seguridad les haya dado supervisión o capacitación en el uso de la unidad. Limpieza y mantenimiento de usuario no deberá ser

realizada por los niños sin supervisión. Esta unidad no es adecuada para su instalación en un área donde podría utilizarse un

chorro de agua. La temperatura ambiente operativa mínima / máxima para el dispensador es de 40°F a 86°F (4.4°C a 30°C). No

coloque la unidad de lado incluso durante el transporte. No deje la puerta del armario abierta más tiempo del necesario mientras el

dispensador. Está conectado no obstruya la entrada de aire del dispensador (paneles de fondo). Mantenga suciente espacio libre

alrededor del distribuidor según las especicaciones de este manual. No manipule el control de temperatura. No opere este

dispensador cuando falten partes o haya partes rotas. Asegúrese de que todas las partes del dispensador estén montadas

correctamente antes de su uso. Siempre utilice piezas originales: el fabricante o el proveedor no asumen ninguna responsabilidad

por partes que no sean originales o recomendadas por el fabricante. Los paneles inferiores (delanteros y traseros) del dispensador

sólo deben ser abiertos por personal capacitado. Si no está entrenado, abrir los paneles será al riesgo del usuario. Evite las

lesiones personales, no trate de levantar el dispensador sin ayuda. Para los dispensadores màs pesados use un elevador

mecánico. Siempre use calzado protector durante la instalación.

! Respectez les consignes de securite de base fournies par le fabricant. Prenez soin de votre sécurité personnelle. Le distributeur

est conçu pour le refroidissement et la distribution de bière. Le fournisseur ne pourra pas être tenu responsable des dommages

causés par une mauvaise utilisation. Cet appareil n’est pas conçu pour distribuer des produits laitiers. Cet appareil est conçu pour

une utilisation dans des applications commerciales telles que les restaurants, les dépanneurs ou similaires. Le distributeur ne doit

être utilisé qu’en combinaison avec les fûts fournis. Ne pas utiliser d’autres fûts de bière disponibles sur le marché. Cet appareil

n’est pas un jouet. Les enfants doivent être surveillés an de ne pas jouer avec l’appareil. Il ne devrait pas être utilisé par des

enfants ou des personnes inrmes sans surveillance. Cet appareil n’est pas destiné à un usage par des personnes (y compris les

Enfants) ayant des capacités physiques, sensorielles ou mentales réduites, ou manquant d’expérience et de Connaissances, à

moins qu’elles obtiennent de la surveillance ou des instructions au sujet de l’utilisation de l’appareil de la part d’une personne

chargée de leur sécurité. Nettoyage et entretien de l’utilisateur ne doivent pas être effectués par des enfants sans surveillance. Cet

appareil n’est pas approprié pour une installation dans une zone où un jet d’eau pourrait être utilisé. La température de service

ambiante minimum/maximum pour le distributeur est de 40°F à 86°F (4.4°C à 30°C). Ne pas placer l’unité sur le coté, même durant

le transport. Ne laissez pas la porte du meuble ouverte plus longtemps que nécessaire lorsque le distributeur est relié. Ne bloquez

pas l’entrée d’air du distributeur (panneaux du bas). Gardez assez d’espace libre autour du distributeur en accord avec les

spécications dans ce manuel. Ne pas jouer avec le controle de la température. Ne pas utiliser ce distributeur lorsque des pièces

sont manquantes ou endommagées. Assurez-vous que toutes les pièces du distributeur sont assemblées correctement avant

l’utilisation. Utilisez toujours des pièces d’origine le manufacturier ou le fournisseur ne prend aucune responsabilité pour les

pièces qui ne sont pas d’origine ou recommandées par le manufacturier. Les panneaux du bas (avant et arrière) du distributeur ne

devraient être ouverts que par du personnel qualié. Si non qualié, l’ouverture des panneaux se fait aux risques de l’utilisateur.

Pour éviter des blessures ou des dommages, n’essayez pas de soulever une unité sans aide. Pour les unités plus lourdes,

l’utilisation d’un ascenseur mécanique peut être appropriée. Portez toujours des chaussures de protection pendant l’installation.

6

Page 7

PRESSURE WARNING/ ADVERTENCIA DE PRESIÓN/

! !

AVERTISSEMENT DE PRESSION

! This dispenser contains pressurized components. Only use these components according to the instructions in this

manual. Failure to follow the instructions can result in Serious injury and equipment damage. The allowable pressure

ranges between 18 psi (0.124 Mpa) and 24 psi (0.165 Mpa). It is recommended to set the pressure within the

allowable range to obtain proper beer dispensing. Do not tamper with the pressure regulator control. Do not use any

other external pressure source. Do not connect provided keg to any other external pressure source. The bottom

panels (front and rear) of the dispenser should only be opened by trained personnel. If not trained, opening the

panels will be at the user’s own risk. Do not store explosive substances such as aerosol cans with aammable

propellant in the dispenser.

! Este dispensador contiene componentes presurizados. Sólo utilice estos componentes según las instrucciones en

este manual. No seguir las instrucciones puede causar lesiones graves y daño al equipo. Las gamas de presión

permitidas son entre 18 PSI (0.124 MPA) y 24 PSI (0.165 MPA). Se recomienda ajustar la presión dentro del rango

permitido para obtener la dispensación correcta de la cerveza. No manipule el control del regulador de presión. No

utilice ninguna otra fuente de presión externa. No conecte el barril proporcionado a cualquier otra fuente de presión

externa. Los paneles inferiores (delanteros y traseros) del dispensador sólo deben ser abiertos por personal

capacitado. Si no está entrenado, abrir los paneles será al riesgo del usuario. No almacene sustancias explosivas

como latas de aerosol con un propulsor inamable en el dispensador.

! Ce distributeur contient des composantes pressurisées. N’utilisez ces composantes qu’en accord avec les

instructions dans ce manuel. Le non-respect des instructions peut résulter dans de graves blessures et des

dommages à l’équipement. La pression admissible est comprise entre 18 PSI (0.124 MPA) et 24 PSI (0.165 MPA).

Il est recommandé de régler la pression à l’intérieur de la plage admissible pour obtenir une distribution de bière

adéquate. Ne pas jouer avec le contrôle de régulation de pression. N’utilisez pas aucune autre source de pression

externe. Ne reliez pas le fût fournis à aucune autre source de pression externe. Les panneaux du bas (avant et

arrière) du distributeur ne devraient être ouverts que par du personnel qualié. Si non qualié, l’ouverture des

panneaux se fait aux risques de l’utilisateur. N’entreposez pas de substances explosives telles que des bonbonnes

d’aérosols avec des agents propulseurs inammables dans le distributeur

7

Page 8

ELECTRICAL WARNING/ADVERTENCIA ELÉCTRICA/

F F

AVERTISSEMENT ÉLECTRIQUE

! Check the dispenser serial number plate for correct electrical requirements. Do not plug into a wall electrical outlet

unless the current shown on the serial number plate agrees with local current. Follow all local electrical codes when

making connections. Make sure that all lines and tubing are tight and units are dry before making any electrical

connections. Keep the dispenser plugged in at all times, unless stated otherwise in the instructions. Each dispenser

must have a separate electrical circuit. Do not connect multiple. Electrical devices on the same outlet. Do not use

extension cords with this unit. The dispenser must be properly electrically grounded to avoid serious injury or fatal

electrical shock. The power cord has a three-prong grounded plug. If a three-hole grounded electrical outlet is not

available, use an approved method to ground the unit. Follow all local electrical codes when making connections. If

the supply cord is damaged, it must be replaced by the manufacturer, an authorized service agent or similarly

qualied person to avoid hazard or injury. Never touch electrical components with wet or damp hands. Always

disconnect electrical power to the unit to prevent personal injury before attempting any internal maintenance. Only

trained personnel should service internal components.

! Verique la placa con el número de serie del dispensador, donde encontrará los requisitos eléctricos correctos

de la unidad. No enchufe la unidad en un tomacorriente de pared a menos que la corriente indicada en la placa con

el número de serie concuerde con la corriente local disponible. Al hacer las conexiones, respete todos los códigos

eléctricos locales. Asegúrese de que todas las líneas de agua estén ajustadas y las unidades estén secas antes de

hacer conexiones eléctricas. Mantenga el dispensador conectado en todo momento a menos que las instrucciones

indiquen lo contrario. Cada dispensador debe tener un circuito eléctrico independiente. No use extensiones con esta

unidad. Es necesario poner a tierra eléctricamente el dispensador para evitar lesiones graves e incluso

electrochoques fatales. El cable de alimentación tiene un enchufe puesto a tierra de 3 clavijas. Si no se dispone

de un toma eléctrico conectado a tierra de tres agujeros, use un método aprobado para poner a tierra la unidad. Al

hacer las conexiones, respete todos los códigos eléctricos locales. Si el cable de alimentación está dañado, debe ser

reemplazado por el fabricante, un agente de servicio autorizado o una persona cualicada para evitar peligros o

lesiones. Nunca toque los componentes eléctricos con las manos mojadas o húmedas. Siempre desconecte la

alimentación eléctrica a la unidad para evitar lesiones personales antes de tratar de realizar tareas de

mantenimiento. El servicio de los componentes internos de la caja de control eléctrico debe conarse exclusivamente

a personal calicado.

F Examinez la plaque de numéro de série du distributeur pour connaître les bonnes exigences en matière

d’électricité pour l’appareil. Ne le branchez pas à une prise électrique murale à moins que le courant indiqué sur la

plaque de numéro de série corresponde au courant local disponible. Respectez tous les codes électriques locaux

lorsque vous faites des connexions. Assurez-vous que toutes les conduites d’eau sont étanches et que les

appareils sont secs avant de faire des connexions électriques. Gardez le distributeur branché en tout temps, sauf si

mentionné autrement dans les instructions. Chaque distributrice doit avoir un circuit électrique séparé. N’utilisez

pas de cordons prolongateurs avec cet appareil. La distributrice doit être mise à la terre électriquement correctement

pour éviter des blessures graves ou une décharge électrique mortelle. Le cordon d’alimentation a une che à trois

branches mise à la terre. Si aucune prise de courant électrique à trois trous n’est disponible, utilisez une méthode

approuvée pour mettre l’unité à la terre. Respectez tous les codes électriques locaux lorsque vous faites des

connexions. Si le cordon d’alimentation est endommagé, il doit être remplacé par le manufacturier, ou par un agent

de service autorisé ou autre personne similairement qualiée pour éviter tout risque ou blessure. Ne jamais toucher

à des composantes électriques avec des mains mouillées ou humides. Débranchez toujours le courant électrique à

l’appareil, an de prévenir des blessures, avant de faire un entretien interne quelconque. Seul le personnel qualié

devrait faire l’entretien/la réparation des composants internes dans le logement des commandes électriques.

Page 9

KEG WARNING/ ADVERTENCIA DEL BARRIL/

! !

AVERTISSEMENT FÛT

! Always read and follow the instructions and safety warnings on the keg before connecting to the dispenser. Never

store a keg in the freezer! Freezing may cause serious damage to the keg. Do not store the lled kegs at

temperatures higher than 86°F (30°C). Maximum working pressure: 24 PSI (0.165 MPA). Do not overpressurize the

keg. This may cause injury. Do not use pressurized co2 on the kegs. Always handle kegs with care. Do not shake the

keg. Do not drop the keg. Be careful with condensation droplets that will make the keg slippery in your hands. For

the integrity of the dispenser, do not place damaged kegs in it. Do not pierce a connected keg. Do not burn a keg,

even when empty. For storage purposes outside the dispenser: make sure the kegs are stacked in a safe way. Store

a connected keg using the racks in the dispenser. Make sure the dispenser is switched on at all times, unless stated

otherwise in the instructions. If dispenser is switched off due to non use for a long period (e.G. A holiday), always

remove the connected keg from the dispenser and dispose of it. Once a keg has been connected, the beer stays

fresh for 30 days.

! Siempre lea y siga las instrucciones y advertencias de seguridad sobre el barril antes de conectar el dispensador.

Nunca guarde un barril de cerveza en el congelador. La congelación puede causal graves daños al barril. No

almacene los barriles llenos a temperaturas superiores a 86° F (30° C). Presión máxima de trabajo: 24 PSI (0.165

MPA). No ponga presión superior en el barril. Esto puede causar lesiones. No use co2 presurizado en los barriles.

Siempre maneje los barriles con cuidado. No agite el barril. No deje caer el barril. Tenga cuidado con las gotas de

condensación que causarán que el barril sea resbaladizo en sus manos. Para la integridad del dispensador, no

coloque barriles dañados en él. No perfore un barril conectado. No queme un barril, incluso cuando esté vacío. Para

nes de almacenamiento fuera del dispensador: asegúrese de que los barriles se apilen en una manera segura.

Guarde un barril conectado usando las parrillas en el dispensador. Asegúrese de que el dispensador está encendido

en todo momento, a menos que se indique lo contrario en las instrucciones. Si el dispensador está desactivado

debido a la falta de uso durante un período prolongado (por ejemplo un día feriado), siempre retire el barril conectado

del dispensador y deséchelo. Una vez que se haya conectado un barril, la cerveza se mantiene fresca por 30 días.

! Lisez et suivez toujours les instructions et les avertissements de sécurité sur le fût avant de le relier au

distributeur. N’entreposez jamais un fût dans le congélateur! Le gel peut causer de sérieux dommages au fût.

N’entrepoesz pas les fûts remplis à des températures plus hautes que 86°F (30°C). Pression maximale de

fonctionnement : 24 PSI (0.165 MPA). N’utilisez pas de pression excessive avec le fût. Ceci pourrait causer des

blessures. Ne pas utiliser de c02 pressurisé sur les fûts. Manipulez toujours les fûts avec soin. Ne pas secouer le fût.

Ne pas laisser tomber le fût. Faites attention avec les goutelettes de condensation qui rendront le fût glissant dans

vos mains. Pour l’intégrité du distributeur, ne placez pas de fûts endommagés à l’intérieur. Ne percez pas un fût relié.

Ne brulez pas un fût, même lorsque vide. Lors de l’entreposage à l’extérieur du distributeur : assurez-vous que les

fûts sont empilés d’une manière sécuritaire. Entreposez les fûts en utilisant les supports fournis dans le distributeur

assurez-vous que le distributeur est allumé en tout temps, sauf si mentionné autrement dans les instructions. Si le

distributeur est éteint à cause d’une non-utilisation pendant une longue période (par exemple un congé), reitrez

toujours le fût reliédu distributeur et disposez-en. Une fois qu’un fût est relié, la bière reste fraîche pour 30 jours.

SANITIZING WARNING/ ADVERTENCIA DE

! !

DESINFECCIÓN/ AVERTISSEMENT DÉSINFECTION

! Before maintenance, always disconnect the dispenser from the electricity supply. Ensure sanitizing solution is

removed from the dispenser as instructed. Avoid getting sanitizing solution on circuit boards. Do not use strong

bleaches or detergents; these can discolor and corrode various materials. Do not use metal scrapers, sharp objects,

steel wool, scouring pads, abrasives, or solvents on the dispenser. Do not use hot water above 140°F (60°C). This

can damage the dispenser.

! Asegúrese de haber eliminado la solución de esterilización del dispensador de acuerdo con las instrucciones. Los

residuos de la solución de esterilización representan un peligro para la salud. Evite que la solución de esterilización

llegue a las placas de circuitos. No use lavandinas ni detergentes que podrían quitar el color y corroer distintos

materiales. No use raspadores metálicos, objetos losos, lana de acero, estropajos, abrasivos ni solventes en el

dispensador. No use agua caliente a más de 140 ºF (60 ºC). Podría dañar el dispensador.

! L’eau chaude permettra un meilleur procès de dissolution. Suivant les instructions jointes, il est impératif que la

solution septique soit entièrement enlevée. Evitez de mettre la solution en contact avec les circuits. N’utilisez pas de

javellisants ou dedétergents forts; ceux-ci peuvent décolorer et corroder divers matériaux. N’utilisez pas de

racleurs en métal, d’objets pointus, de laine d’acier, de tampons à récurer, d’abrasifs ou de solvants sur le

distributeur. N’utilisez pas de l’eau chaude de plus de 140 degrés F (60 degrés C). Ceci peut endommager le

distributeur.

Page 10

GOVERNMENT WARNING/ ADVERTENCIA

!

! According to the surgeon general, women should not drink alcoholic beverages during pregnancy because of the

risk of birth defects. Consumption of alcoholic beverages impairs your ability to drive a car or operate machinery, and

may cause health problems

! Según el cirujano general, las mujeres no deben beber bebidas alcohólicas durante el embarazo debido al riesgo

de defectos de nacimiento. El consumo de bebidas alcohólicas deteriora su capacidad para conducir o manejar

maquinaria y puede causar problemas de salud.

! En accord avec le médecin-chef, les femmes ne devraient pas boire de boissons alcoolisées pendant la

grossesse à cause des risques de malformations à la naissance. La consommation de boissons alcoolisés peut nuire

à votre capacité de conduire une voiture ou d’utiliser de la machinerie, et peut causer des problèmes de santé.

! Units equipped with moving fanblades, which can activate unexpectedly. Do not place hands or foreign objects in

or near the recirculation fan or condensor fan unplug the machine before removing the rear panel.

! Unidades equipadas con aspas de ventilador móviles que pueden activarse inesperadamente. No coloque las

manos u objetos extraños en o cerca del ventilador de recirculación o el ventilador del condensador desenchufe la

máquina antes de quitar el panel trasero

! Les unités sont équipées de pales de ventilateurs, qui peuvent s’activer de manière inattendue. Ne placez pas vos

mains ou des objects quelconques dans ou près du ventilateur de recirculation ou du ventilateur de condensation.

Débranchez la machine avant de retirer le panneau arrière

GUBERNAMENTAL/ AVERTISSEMENT GOUVERNEMENTAL

MOVING PARTS WARNING/ ADVERTENCIA DE

PIEZAS MÓVILES/ AVERTISSEMENT PIÈCES MOBILES

!

SHARP EDGES WARNING/ ADVERTENCIA DE BORDES

!

! Cautious handling is required during moving of the unit, maintenance and operation. Always handle unit with care

to avoid pinching hazard (e.G., During connection of a keg, closing of the cabinet door at door hinges. Use caution

as the unit has sharp edges at the different subparts of the dispenser, including the cup rest, bottom edges, vent slats

and corners.

! La unidad debe manejarse cuidadosamente al moverla, llevar a cabo mantenimiento y operación. Siempre

maneje la unidad con cuidado para evitar peligro de pellizcos (durante la conexión de un barril, cerrando la puerta del

armario (bisagras). Tenga cuidado ya que la unidad tiene bordes alados en las diferentes subpartes del

dispensador, incluyendo el posavasos, bordes inferiores, listones de ventilación y las esquinas

! Une manipulation prudente est requise lors du déplacement de l’unité, de l’entretien et de l’utilisation. Manipulez

toujours l’unité avec soin pour éviter tout risque de pincement (durant la connection d’un fût, fermeture de la porte du

meuble aux charnières de la porte.) Faites attention car l’unité a des rebords coupants à différentes sous-parties du

distributeur, incluant la coupe de repos, les rebords inférieurs, les lattes de ventilation et les coins.

1. INSTALLATION

BEFORE GETTING STARTED

The unit should always be stored and shipped upright. Do not place the unit on its side. If for some

reasonthe unit is placed on its side, allow the refrigerated cabinet to stand in upright position for a

minimum of 8 hours before connecting the power to allow the refrigerant to stabilize before unit activation.

WARNING TO AVOID PERSONAL INJURY OR DAMAGE, DO NOT ATTEMPT TO LIFT A UNIT WITHOUT ASSISTANCE

FOR HEAVIER UNITS, USE OF A MECHANICAL LIFT MAY BE APPROPRIATE. ALWAYS WEAR PROTECTIVE

SHOEWEAR DURING INSTALLATION.

FILOSOS/ AVERTISSEMENT REBORDS COUPANTS

!

!

ADVERTENCIA EVITE LAS LESIONES PERSONALES, NO TRATE DE LEVANTAR EL DISPENSADOR SIN AYUDA.

PARA LOS DISPENSADORES MÀS PESADOS USE UN ELEVADOR MECÁNICO. SIEMPRE USE CALZADO

PROTECTOR DURANTE LA INSTALACIÓN.

AVERTISSEMENT POUR ÉVITER DES BLESSURES OU DES DOMMAGES, N’ESSAYEZ PAS DE SOULEVER UNE

UNITÉ SANS AIDE. POUR LES UNITÉS PLUS LOURDES, L’UTILISATION D’UN ASCENSEUR MÉCANIQUE PEUT

ÊTRE APPROPRIÉE. PORTEZ TOUJOURS DES CHAUSSURES DE PROTECTION PENDANT L’INSTALLATION.

8

Page 11

1.1 UNPACKING

A. Cut banding and remove.

B. Remove top portion of carton by lifting up.

C. Remove accessory kit and loose parts from inside of the cabinet.

D. Remove side inserts

E. Lift unit up by plywood shipping base and remove lower portion of carton.

F. Inspect unit for concealed damage and if evident notify delivering carrier and le a claim.

G. Remove plywood shipping base from unit by moving unit to allow access to screws on the

bottom of the plywood shipping base.

H. Remove and replace the screws with the casters. Install the casters with brakes on the front of

the unit.

NOTE: Leave the unit secured to the plywood base when transporting.

I. When installing the casters on the dispenser, tilt the dispenser. DO NOT PLACE UNIT ON

SIDE OR BACK.

1.2 SELECTING A LOCATION

A. The dispenser is intended for indoor use. Do not store the dispenser outside

B. Select a location close to a properly grounded electrical outlet and to a drain or bucket that

meets the requirements on pages 4 and 5.

C. The selected location must allow the unit to be leveled on all sides.

D. The dispenser may be susceptible to EMC electrical interference. If this occurs, relocate the

dispenser to an alternative location. If interference is still present, contact Lancer Technical

Support.

1.3 ASSEMBLING THE UNIT

A. To assemble the tower, mount the 2 taps on the column.

B. Unscrew the nut from the shank.

C. Insert the shank, with the beer tubing, through the cabinet.

D. Check that the shank is the correct length. If not, tighten (screw) the shank until it is the correct

length. Verify there is enough space for the nut.

E. Tighten the nut over the shank from the inside of the cabinet. Make sure the connection is tight.

If the connection is not tight enough, tighten the nut until the tower does not rotate.

F. Verify the tap handles are in the closed upright position.

NOTE: Unlock the casters to roll the dispenser into its location. Use caution when rolling the

dispenser over rough surface.

A

D

B

E

C

F

9

Page 12

1.4 CONNECTING TO ELECTRICAL POWER

WARNING CHECK THE DISPENSER SERIAL NUMBER PLATE FOR CORRECT ELECTRICAL REQUIREMENTS. DO

NOT PLUG INTO A WALL ELECTRICAL OUTLET UNLESS THE SERIAL NUMBER PLATE VOLTAGE SHOWN AGREES

WITH LOCAL CURRENT. KEEP THE DISPENSER PLUGGED IN AT ALL TIMES, UNLESS STATED OTHERWISE IN

THE INSTRUCTIONS.

ADVERTENCIA VERIFIQUE LA PLACA DE NÚMERO DE SERIE DEL DISPENSADOR PARA OBTENER LOS

REQUISITOS ELÉCTRICOS CORRECTOS. NO ENCHUFE A UN TOMACORRIENTE A MENOS QUE EL VOLTAJE DE

LA PLACA DE NÚMERO DE SERIE QUE SE MUESTRA ACEPTE LA CORRIENTE LOCAL. MANTENGA EL

F

Route the power supply cord to a grounded electrical outlet of the proper voltage and amperage

rating, and plug in the unit. This will turn on the refrigeration system and allow it to start cooling

DISPENSADOR CONECTADO EN TODO MOMENTO, A MENOS QUE LAS INSTRUCCIONES INDIQUEN LO

CONTRARIO.

AVERTISSEMENT VÉRIFIEZ LE PANNEAU DU NUMÉRO DE SÉRIE DU DISTRIBITEUR POUR LES EXIGENCES

ÉLECTRIQUES ADÉQUATES. NE BRANCHEZ PAS DANS UNE PRISE DU MUR À MOINS QUE LE PANNEAU DU

NUMÉRO DE SÉRIE CONCORDE AVEC LE COURANT LOCAL. GARDEZ LE DISTRIBUTEUR BRANCHÉ EN TOUT

TEMPS, SAUF SI SPÉCIFIÉ AUTREMENT DANS LES INSTRUCTIONS.

while completing the rest of the installation.

1.5 CONNECTING THE DRAIN

The drain tube is shipped attached to the stage tray and drain tting. Locate the drain tube at the

rear of the unit and route the drain tube to a suitable drain or bucket.

1.6 EQUIPMENT SETUP

A. Insert the (white) air line into the side of the keg connector.

B. Insert the (transparent) beer tubing into the side of the keg connector.

A

B

10

Page 13

2. GETTING STARTED

2.1 SETTING AND ADJUSTING THE AIR PRESSURE REGULATOR

NOTE: The pressure regulator is located inside the cabinet. Target pressure is 21 PSI (0.145 MPA).

The allowable pressure range is 18- 24 PSI (0.124 MPA - 0.165 MPA).

WARNING IT IS RECOMMENDED TO SET THE PRESSURE WITHIN THE ALLOWABLE RANGE TO OBTAIN PROPER

BEER DISPENSING. DO NOT TAMPER WITH THE PRESSURE REGULATOR CONTROL.

ADVERTENCIA SE RECOMIENDA AJUSTAR LA PRESIÓN DENTRO DEL RANGO PERMITIDO PARA OBTENER

DISENSIÓN DE CERVEZA CORRECTA. NO MANIPULE EL CONTROL DEL REGULADOR DE PRESIÓN.

!

A. The pressure regulator is located inside the fridge.

B. Pull knob towards you until it clicks.

C. Rotate knob; clockwise to increase the pressure, counterclockwise to reduce the pressure.

D. Set pressure to the indicated recommended value.

E. Push knob back into place (until it clicks).

AVERTISSEMENT IL EST RECOMMANDÉ DE RÉGLER LA PRESSION À L’INTÉRIEUR DE LA PLAGE ADMISSIBLE

POUR OBTENIR UNE DISTRIBUTION DE BIÈRE ADÉQUATE.NE PAS JOUER AVEC LE CONTRÔLE DE

RÉGULATION DE PRESSION.

A

B

C

D

2.2 CONNECTING THE KEGS

Cool each keg at least 12 hours in advance prior to dispensing.

NOTE: Place connected kegs at the top only. Never place connected kegs at the bottom, as this will

prevent the door from closing properly. This might result in damage to the cabinet door, keg

connector and/or the connected keg.

E

11

Page 14

2.2 CONNECTING THE KEGS (CONTINUED)

WARNING CAUTIOUS HANDLING IS REQUIRED DURING MOVING OF THE UNIT, MAINTENANCE AND

OPERATION. ALWAYS HANDLE UNIT WITH CARE TO AVOID PINCHING HAZARD (DURING CONNECTION OF A

KEG, CLOSING OF THE CABINET DOOR AT DOOR HINGES. USE CAUTION AS THE UNIT HAS SHARP EDGES AT

THE DIFFERENT SUBPARTS OF THE DISPENSER, INCLUDING THE CUP REST, BOTTOM EDGES, VENT SLATS

AND CORNERS.

ADVERTENCIA LA UNIDAD DEBE MANEJARSE CUIDADOSAMENTE AL MOVERLA, LLEVAR A CABO

MANTENIMIENTO Y OPERACIÓN. SIEMPRE MANEJE LA UNIDAD CON CUIDADO PARA EVITAR PELIGRO DE

PELLIZCOS (DURANTE LA CONEXIÓN DE UN BARRIL, CERRANDO LA PUERTA DEL ARMARIO (BISAGRAS).

TENGA CUIDADO YA QUE LA UNIDAD TIENE BORDES AFILADOS EN LAS DIFERENTES SUBPARTES DEL

!

A. Place the keg vertically in front of the unit.

B. Check that the 3 valves are closed.

C. Check that beer needle is centered in the keg connector. Notice position of air needle.

D. Align air and beer needles in the keg connector with the air and beer holes in closure.

E. Place keg connector on keg.

F. Check that both clamps sit under edge of keg.

G. Push handle down until it clicks and locks into position.

H. If you feel an obstruction, do not push hard and verify alignment of air and beer needles.

I. Open the air valve.

DISPENSADOR, INCLUYENDO EL POSAVASOS, BORDES INFERIORES, LISTONES DE VENTILACIÓN Y LAS

ESQUINAS.

AVERTISSEMENT UNE MANIPULATION PRUDENTE EST REQUISE LORS DU DÉPLACEMENT DE L’UNITÉ, DE

L’ENTRETIEN ET L’UTILISATION. MANIPULEZ TOUJOURS L’UNITÉ AVEC SOIN POUR ÉVITER TOUT RISQUE DE

PINCEMENT (DURANT LA CONNECTION D’UN FÛT, FERMETURE DE LA PORTE DU MEUBLE AUX CHARNIÈRES

DE LA PORTE.) FAITES ATTENTION CAR L’UNITÉ A DES REBORDS COUPANTS À DIFFÉRENTES SOUS-PARTIES

DU DISTRIBUTEUR, INCLUANT LA COUPE DE REPOS, LES REBORDS INFÉRIEURS, LES LATTES DE

VENTILATION ET LES COINS.

A

D

B

E

C

F

G H I

12

Page 15

2.2 CONNECTING THE KEGS (CONTINUED)

J. Open the beer valve.

K. Place connected keg on the top rack of the fridge.

L. Start to dispense.

NOTE: First glass might contain more foam.

J

2.3 DISCONNECTING THE KEGS

NOTE: A keg should only be replaced when completely empty. Replacing a keg that is not yet

empty could result in some beer leakage and spillage in and around the dispenser.

A. Place the keg vertically in front of the unit.

B. Close the air valve.

C. Open the release valve - air will be released!

D. Release for at least 30 seconds.

E. Close the beer valve.

F. Pull release slide (1) and lift up handle (2).

G. Close the release valve.

H. Check that the 3 valves are closed.

A

K L

B

C

D

E

G H

F

NOTE: Before disconnecting

the keg connector, make

sure the air has been

released completely through

the release valve. If air is

still present in the keg, beer

can be spilled.

13

Page 16

2.4 CONNECTING A NEW KEG

To connect a new cooled keg, refer to Section 2.2 Connecting the Kegs.

2.5 KEG USE AND STORAGE CAUTION

A. Store a connected keg using the racks in the dispenser.

B. Make sure the dispenser is switched on at all times, unless stated otherwise in the instructions.

C. If dispenser is switched off due to non use for a long period (e.g. holiday), always remove the

connected keg from the dispenser and dispose of it.

D. Once a keg has been connected, the beer stays fresh for 30 days.

E. Make sure the air lines and beer tubing are free and not entangled nor pinched.

F. Never place a connected keg on the bottom row. The door will not close properly. This might

result in damage to the cabinet door, keg connector and/or the connected keg.

G. A keg should only be replaced when completely empty. If beer is still present after 30 days,

empty the keg, then disconnect and replace it.

H. Make sure the dispenser is well cleaned before loading a new keg.

I. Do not reconnect a keg that has been used before. Once a keg is connected, use the keg until

empty. If the keg is disconnected and reconnected later, the beer quality is not

guaranteed anymore.

3. BEER DISPENSE

3.1 POURING RITUAL - STELLA ARTOIS

A. THE PURIFICATION

The trademark Stella Artois chalice is designed to release the beer’s avor and aroma.

Your bartender will always use one, preferably cleaned with a non-fat-based detergent.

It’s then rinsed with cold water, allowing the glass to reach the same temperature as the beer.

B. THE SACRIFICE

Your bartender opens the tap in one swift motion to let the rst burst of foam ow away.

It must never enter the chalice glass, thus ensuring that every drop of Stella Artois is fresh.

C. THE LIQUID ALCHEMY BEGINS

The chalice glass is held at a 45-degree angle. When the beer hits the chalice and begins to

circulate, it creates the ideal proportion of foam relative to liquid.

D. THE HEAD, ALTHOUGH “CROWN” WOULD BE MORE APPROPRIATE

The natural creation of the foam head occurs by straightening and lowering the glass.

This initial foam is important as it prevents the beer from coming into contact with the air and

losing any avor.

E. THE REMOVAL

Your bartender then closes the tap in one quick action and moves the glass away from the font,

to prevent any drops from falling into the glass. These drops come into contact with the air, and

oxidize, making them unworthy of your glass of Stella Artois.

F. THE BEHEADING

While the head is owing over the edge of the glass, your bartender cuts it gently with a knife

on a 45-degree angle. This eliminates the larger bubbles, which burst easily and accelerate

the dissipation of the head.

G. THE JUDGEMENT

The right amount of foam is about two ngers (3cm) thick. The nal head creates a protective

“cap” that keeps your Stella Artois from going stale.

H. THE CLEANSING

Your bartender then rinses the bottom and sides of the glass. This step keeps the outside of the

chalice clean and comfortable to hold.

I. THE BESTOWAL

Finally, your Stella Artois is served to you on a coaster, accompanied by the drip catcher at the

base. Behold the perfect glass of Stella Artois. Cheers to you, and for your patience, a

refreshing reward.

14

Page 17

3.2 POURING OTHER BEERS

A. Use a chilled glass (preferred) or rinse a clean glass in cold, fresh water prior to tapping. This

will help reduce the amount of foam.

B. Hold the glass at a 45-degree angle under the spout. Keep the spout as close as possible to

the inside of the glass. The spout should not touch the glass.

C. Pull the tap handle all the way down in a quick movement.

D. Let the beer ow against the wall of the glass about one (1) inch below the rim of the glass.

E. Gradually straighten and lower the glass when the foam/beer reaches the rim of the glass.

F. When the glass is full, close the tap handle in one quick movement.

4. CLEANING AND SANITIZING

4.1 GENERAL INFORMATION

A. The cleaning and sanitizing procedures provided pertain to the Lancer equipment identied by

this manual. If other equipment is being cleaned, follow the guidelines established by the

manufacturer for that equipment.

B. Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized in

accordance with NSF* guidelines. The equipment must be cleaned and sanitized after

installation is complete. (Sanitization to be completed by the installer/technician). The operator

of the equipment must provide continuous maintenance as required by this manual, state and

local health department guidelines to ensure proper operation and sanitation requirements

are maintained. *NSF refers to the international food safety standards group

C. Cleaning and sanitizing should be accomplished only by trained personnel. Sanitary gloves are

to be used during cleaning and sanitizing operations. Applicable safety precautions must be

observed. Instruction warnings on the product being used must be followed.

D. Other Required Supplies: 1) Clean cloth towels, 2) bucket, and 3) sanitary gloves.

!

WARNING IF A POWDER SANITIZER IS USED, DISSOLVE IT THOROUGHLY WITH HOT WATER PRIOR TO

ADDING TO THE SYRUP SYSTEM. ENSURE SANITIZING SOLUTION IS REMOVED FROM THE DISPENSER AS

INSTRUCTED. AVOID GETTING SANITIZING SOLUTION ON CIRCUIT BOARDS. DO NOT USE STRONG BLEACHES

OR DETERGENTS; THESE CAN DISCOLORAND CORRODE VARIOUS MATERIALS. DO NOT USE METAL

SCRAPERS, SHARP OBJECTS, STEEL WOOL, SCOURING PADS, ABRASIVES, OR SOLVENTS ON THE

DISPENSER. DO NOT USE HOT WATER ABOVE 140° F (60° C). THIS CAN DAMAGE THE DISPENSER.

ADVERTENCIA SI SE USA UN HIGIENIZADOR EN POLVO, DISUÉLVALO BIEN EN AGUA ANTES DE AGREGARLO

AL SISTEMA DE CONCENTRADO. EL USO DE AGUA CALIENTE CONTRIBUYE A DISOLVER LOS HIGIENIZADORES

EN POLVO. ASEGÚRESE DE HABER ELIMINADO LA SOLUCIÓN DE ESTERILIZACIÓN DEL DISPENSADOR DE

ACUERDO CON LAS INSTRUCCIONES. LOS RESIDUOS DE LA SOLUCIÓN DE ESTERILIZACIÓN REPRESENTAN

UN PELIGRO PARA LA SALUD. EVITE QUE LA SOLUCIÓN DE ESTERILIZACIÓN LLEGUE A LAS PLACAS DE

CIRCUITOS. NO USE LAVANDINAS NI DETERGENTES QUE PODRÍAN QUITAR EL COLOR Y CORROER DISTINTOS

MATERIALES. NO USE RASPADORES METÁLICOS, OBJETOS FILOSOS, LANA DE ACERO, ESTROPAJOS,

ABRASIVOS NI SOLVENTES EN EL DISPENSADOR. NO USE AGUA CALIENTE A MÁS DE 140 ºF (60 ºC). PODRÍA

DAÑAR EL DISPENSADOR.

AVERTISSEMENT AVANT L’INJECTION DANS LE SYSTÈME, IL FAUDRA QUE LA POUDRE SEPTIQUE SOIT

DISSOLUE ENTIÈREMENT DANS CHAUDE. L’EAU CHAUDE PERMETTRA UN MEILLEUR PROCÈS DE

DISSOLUTION. SUIVANT LES INSTRUCTIONS JOINTES, IL EST IMPÉRATIF QUE LA SOLUTION SEPTIQUE SOIT

ENTIÈREMENT ENLEVÉE. EVITEZ DE METTRE LA SOLUTION EN CONTACT AVEC LES CIRCUITS. N’UTILISEZ PAS

DE JAVELLISANTS OU DEDÉTERGENTS FORTS; CEUX-CI PEUVENT DÉCOLORER ET CORRODER DIVERS

MATÉRIAUX. N’UTILISEZ PAS DE RACLEURS EN MÉTAL, D’OBJETS POINTUS, DE LAINE D’ACIER, DE TAMPONS À

RÉCURER, D’ABRASIFS OU DE SOLVANTS SUR LE DISTRIBUTEUR. N’UTILISEZ PAS DE L’EAU CHAUDE DE PLUS

DE 140 DEGRÉS F (60 DEGRÉS C). CECI PEUT ENDOMMAGER LE DISTRIBUTEUR.

15

Page 18

4.2 CLEANING AND SANITIZING SOLUTIONS

CLEANING SOLUTION: Mix a mild, non-abrasive detergent (e.g. Sodium Laureth Sulfate, dish

soap) with clean, potable water at a temperature of 90°F to 110°F (32°C to 43°C). The mixture

ratio is one ounce of cleaner to two gallons of water. Prepare a minimum of ve gallons of cleaning

solution. Do not use abrasive cleaners or solvents because they can cause permanent damage to

the unit. Ensure rinsing is thorough, using clean, potable water at a temperature of 90°F to 110°F.

Extended lengths of product lines may require additional cleaning solution.

SANITIZING SOLUTION: Prepare sanitizing solutions in accordance with the manufacturer’s

written recommendations and safety guidelines. The solution must provide 100 parts per million

(PPM) chlorine (e.g. Sodium Hypochlorite or bleach). A minimum of ve gallons of sanitizing solution should be prepared. Any sanitizing solution may be used as long as it is prepared in accordance with the manufacturer’s written recommendations and safety guidelines, and provides 50 to

100 parts per million (PPM) chlorine.

4.3 DAILY CLEANING

A. Wear sanitary gloves throughout the process. Prepare the Cleaning Solution.

B. Use a damp cloth soaked in Cleaning Solution to clean the Top Cover, all exterior stainless

steel surfaces and the tower.

C. Remove Cup Rest. Wipe clean Cup Rest, Drip Tray and all splash areas.

D. Replace the Cup Rest.

4.4 MONTHLY MAINTENANCE AND CLEANING

A. To remove the front panel, locate and remove the two (2) screws located under the front door.

B. Remove the magnetic air lter.

C. Clean the air lter with the cleaning solution (Section 4.1). Rinse and dry the magnetic air lter.

D. Reinstall the magnetic air lter.

E. Pull out the air compressor assembly. Do not disconnect wiring.

F. Turn the air compressor switch from AUTO to OFF.

A

D

B

E

C

F

16

Page 19

4.4 MONTHLY MAINTENANCE AND CLEANING (CONTINUED)

G. Open the manual relief valve by turning counter-clockwise and wait until the air tank is empty.

H. Close the manual relief valve by turning the valve clockwise.

I. Turn the switch from OFF to AUTO. The air compressor will start and ll the tank until a

pressure of 105 PSI (0.724 MPA) is reached.

J. Slide the air compressor assembly back into the place. DO NOT disconnect the wiring.

K. Reinstall the front panel and fasten the two (2) screws.

G

J

4.5 SIX WEEKS PREVENTATIVE MAINTENANCE

After every 6 weeks of operation, maintenance and sanitization must be performed by a qualied

agent in the eld.

5. TROUBLESHOOTING GUIDE FOR END USER

TROUBLE CAUSE REMEDY

5.1 Too much foam when beer dispensed A. Beer is not cold enough

B. Tap not fully open

H

K

I

A. Cool the keg for at least 12 hours.

Refer to Section 2.2. Connecting the

Kegs.

B. The beer only ows properly when

the tap is completely open. Pull the tap

handle all the way open.

C. Pouring ritual not executed correctly

D. Glass not clean or too warm

E. Pressure is too high

F. Beer tubing partially blocked

17

C. Refer to The Pouring Ritual. Refer to

Section 3.

D. Always use a clean, cold glass. Small

impurities inside the glass or warm glass

will cause excessive foaming.

E. Verify the pressure. Turn down the

knob of the pressure regulator slightly

until pressure is suitable for pouring.

Refer to Section 2.1.

F. Check beer tubing for any obstruction,

untangle the beer tubing. If issue is not

solved, change keg.

Page 20

TROUBLE CAUSE REMEDY

5.2 First glass has a lot of foam A. This is normal A. The beer tubing is primed during the

rst pour and may result in more foam.

5.3 Not enough foam A. Pouring ritual not executed correctly

B. Pressure is too low

5.4 Product jets out from the spout A. Pressure is too high A. Turn the knob of the pressure

5.5 Cannot lock the front door of the

cabinet

A. Kegs not loaded correctly

B. Keg not well connected

C. Air line and/or beer tubing stuck in

between door

A. Refer to Section 3 The Pouring Ritual.

B. Turn the knob of the pressure

regulator slightly until pressure is 21 PSI

(0.145 MPA).

regulator slightly until pressure is 21 PSI

(0.145 MPA).

A. The connected kegs must be loaded

on the top shelf of the refrigerator. Make

sure the kegs are inserted properly and

pushed completely to the back. Refer to

Section 2.2. Connecting the Kegs.

B. The keg connector must be rmly

attached to the keg. Make sure the

locking is done well. Refer to Section 2.2

Connecting the Kegs.

C. Move air line and/or beer tubing

correctly into unit.

5.6 Beer leaks A. Keg not correctly connected

B. Keg connector and/or beer tubing not

correctly tted.

C. Tap not fully closed

D. Keg damaged

A. The keg connector must be rmly

attached to the keg. Make sure the

locking is done well Refer to Section 2.2.

Connecting the Kegs.

B. Make sure the beer tubing tting is

connected well to the keg connector.

Refer to Section 2.2 Connecting the

Kegs.

C. Close the tap completely. If this does

not stop the leakage, disconnect the keg

and contact a service technician.

D. Replace the keg.

18

Page 21

TROUBLE CAUSE REMEDY

5.7 Warm Beer A. Keg is not cooled properly

B. Cabinet door does not close properly

C. Temperature controller is

malfunctioning

A. Cool the keg for at least 12 hours.

Refer to Section 2.2. Connecting the

Kegs.

B. Make sure the kegs, beer tubing and

air lines are placed correctly in the

cabinet and do not obstruct the door

closing. Check that the keg connectors

are well connected to the kegs on the top

rack.

C. Check the temperature display at the

front bottom of the cabinet. If the read out

is ‘E1’, call the hotline.

D. Dispenser cooling failure

5.8 Very low or no beer ow A. No power supply

B. Beer tubing not well connected

or obstructed

C. Air line not well connected or

obstructed

D. Keg (almost) empty

E. Beer tubing is frozen

F. Pressure is too low

D. Call the hotline.

A. Check that the power supply cord is

well connected to the power supply.

B. Check the correct tting of the beer

tubing to the keg connector. Check if the

valve on the beer tubing is in the open

position. Make sure that the beer tubing

is untangled and check for any

obstruction. If issue still persists, please

replace the keg.

C. Check the correct tting of the air line

to the keg connector. Check the correct

position of the valves (refer to Section

1.6). Make sure that the air line is

untangled and check for any obstruction.

D. Check if the keg is empty. Replace the

keg if empty.

E. Check if the beer tubing is frozen, if

frozen the temperature probe is

positioned incorrectly, turn off the

dispenser, open the door, and call the

hotline.

F. Turn the pressure regulator knob

slightly until pressure is suitable for

pouring. Refer to Section 2.1.

G. Keg damaged

H. Dispenser failure

5.9 Unit makes buzzing noise A. Air compressor noises are normal A. The dispenser has an air compressor,

5.10 Unit does not move easily A. Caster brakes are not released A. Release the caster brakes to move the

19

G. Replace the keg.

H. Call the hotline.

which keeps the beer inside the keg

under pressure. A pressure switch turns

the compressor on once the pressure

drops below 72 PSI (0.496 MPA) and

turns off when pressure reaches 101 psi

(0.696 MPA).

unit

Page 22

6. TROUBLESHOOTING GUIDE FOR TECHNICIANS

TROUBLE CAUSE REMEDY

6.1 Air Compressor does not start A. Excessive accumulation of water from

condensation

A. Refer to 4.3 Monthly Maintenance and

Cleaning to manually relieve the

accumulated water from the tank. If still

not functioning, then replace air

compressor assembly.

6.2 Air compressor is not providing

enough air ow to achieve desired

pressure through the regulator inside the

cabinet

6.3 Air compressor tank does not reach a

pressure of 101 psi (7 bar), or does not

turn on when the tank pressure falls

below 72 psi (5 bar)

B. Compressor AUTO/OFF knob not

turned to auto position

C. Wire harness may have loose

connections at the system terminal blocks

or at the ground post

D. Faulty Air Compressor Assembly

A. Excessive accumulation of water from

condensation inside the tank

B. Air regulator inside of cabinet is faulty

A. Excessive accumulation of water from

condensation inside the tank

B. Check the knob is on AUTO position

(located on pressure switch of Air

Compressor)

C. Check and ensure all wire connections

are secure.

D. Replace Air Compressor Assembly

A. Refer to 4.3 Monthly Maintenance and

Cleaning to manually relieve the

accumulated water from the tank. If still

not enough air ow, then replace air

compressor, or inspect the air regulator.

B. Replace air regulator.

A. Refer to 4.3 Monthly Maintenance and

Cleaning to manually relieve the

accumulated water from the tank. If it still

does not reach 101 psi (0.696 MPA). then

replace air compressor assembly.

6.4 Miscellaneous leakage of

compressed air

B. Wire harness may have loose

connections at the system terminal blocks

C. Faulty Pressure Switch

A. Loose connection with air line.

B. Damaged ttings connected to the air

lines

C. Air Tank, Manual release valve not

completely closed

D. One way valve is damaged

B. Check and ensure all wire connections

are secure.

C. Replace Air Compressor Assembly.

A. Check and ensure connections are

secure.

B. Replace air line or ttings if required.

C. Ensure release valve is properly

closed.

D. Replace air compressor assembly

20

Page 23

TROUBLE CAUSE REMEDY

6.5 Refrigeration compressor does not

turn on, or stops running

A. Faulty overload, or relay inside

compressor

A. Replace overload and relay inside

compressor.

6.6 Condenser fan does not turn on, or

stops running

6.7 Excessive ice build up around

evaporator area

B. Wires loose on terminal blocks or main

relay, or ground post

C. Temperature controller faulty

D. Temperature controller probe sensor

faulty

E. Faulty main relay

F. Inadequate voltage

A. Wires to compressor and relay may be

loose

B. Faulty fan

C. Faulty main relay

A. 115V machine has a defrost function

which may need adjustment

B. 230V machine does not have a

defrost function

B. Ensure the wires are secure.

C. Check program settings on controller.

Replace controller if necessary.

D. If the Controller sensor is faulty,

display will read ‘E1’. Ensure the wires

are secure or replace probe.

E. Replace main relay.

F. Measure voltage across common and

run terminal on compressor. Voltage

must not drop below 90% of rated

voltage.

A. Ensure the wires are secure.

B. Replace condenser fan.

C. Replace main relay.

A. Defrost can be modied to adjust the

time between defrost cycles, and/or the

time duration of the defrost. Refer to

Section 7.

B. Unplug machine, remove kegs, leave

door open and allow ice to thaw from the

evaporator coils. Door can be closed and

machine plugged in.

6.8 Refrigeration compressor does not

stop

6.9 Compressor cycles on and off

frequently during the initial pulldown

and/or normal operations

A. Possible low charge

B. Refrigeration leak

C. Temperature probe may be

obstructed or out of place

A. Temperature controller malfunctioning

B. Defective probe

C. Air ow blocked

21

A. Repair and recharge.

B. Repair and recharge.

C. Clear the air way path to probe.

Reposition if probe is out of place.

A. Replace temperature controller.

B. If the probe sensor is faulty, display will

read ‘E1’. Ensure the wires are secure or

replace probe.

C. Check to ensure proper air

clearance around machine. Check air

lter for debris.

Page 24

TROUBLE CAUSE REMEDY

6.10 Circuit breaker tripping A. Air compressor assembly shorted

A. Disconnect fastons for pump assembly

harness to the terminal blocks and the

ground post and restore power. If circuit

breaker does not trip, then replace air

compressor assembly.

6.11 Excessive condensation appears

B. Possible faulty main relay

A. Damaged or worn door gasket

B. Replace main relay.

A. Replace door gasket.

around the door

6.12 Defrost cycle seems to be too long

for the 115V machine

B. Door hinges loose or need adjusting

A. Machine may have the defrost settings

still set at the defaults from controller

B. Adjust and tighten hinges.

A. Defrost can be modied to adjust the

time between defrost cycles, an/or the

time duration of the defrost. Refer to

Section 7.

6.13 Condenser fan does not shut off A. The dispenser may possibly be in

defrost mode

A. The fan will run for a programmed time

until the defrost time is completed.

Section 7.

6.14 Pressure regulator is malfunctioning A. All subparts of the dispenser are

rated to withstand high pressure,

however this will result in a highly

accelerated beer dispense from tap when

A. Close the beer valve and check the

correct setting of the pressure regulator.

If the problem persists, maintenance is

required.

opened

6.15 Unit is in standby mode A. [Stand-By] pressed for 5 seconds A. Press [Stand-By] for 5 seconds and

units will power on

7. PROGRAMMING THE COOLING PARAMETERS - 115 VOLT MODEL

NOTE: The temperature is preprogrammed per the local requirements. After the dispenser is connected

to power, the controller will automatically regulate the cabinet’s temperature and signal the refrigeration

component if necessary.

Temperature Controller - 115 V

Stand-by ButtonUp Button

SET

Set ButtonDown Button

7.1 ADJUSTING THE TEMPERATURE SET POINT

A. Press the [SET] button once, SEt will display on the screen.

B. Press the [SET] button again to adjust the set point. Use the [UP] and [DOWN] buttons to

increase or decrease the value.

1. SEt is the set point at which the refrigeration compressor shuts off when it reaches the

entered temperature value. Default Value = 32˚F.

C. Press the [SET] button to save the entered value when done.

D. To return to the home screen, press the [Stand-By] button once.

22

Page 25

7.2 ADJUSTING THE REFRIGERATION COMPRESSOR RELAY TRIPPING DIFFERENTIAL

A. Press and hold the [SET] button until PA1 displays on the screen.

B. When PA1 displays, press [SET] once. 0 will now display.

C. When 0 is displayed, press [Up] button once, setting the value to 1. When 1 displays, press

[SET] button. diF will display.

1. diF is the refrigeration compressor relay tripping differential. The refrigeration compressor

shuts off when the temperature reaches the set point and turns back on when the

temperature is equal to the sum of the set point and the diF. Default Value = 6˚F.

D. When diF displays, press [SET] to adjust the differential. Use [UP] and [DOWN] buttons to

increase or decrease the value.

E. Press [SET] button to save the entered value when done.

F. To return to the home screen, press the [Stand-By] button once.

7.3 ADJUSTING THE DEFROST ENDURANCE TIME

A. Press and hold the [SET] button until PA2 is displayed on the screen.

B. Press and hold the [SET] button until diF is displayed on the screen.

C. Scroll by pressing the [DOWN] button until dEt displays on the screen. When dEt displays on

the screen, press the [SET] button.

1. dEt is the defrost endurance time. This is the time interval in minutes for which the unit will

defrost. Default Value = 30 minutes. This can be adjusted by pressing the [UP] or [DOWN]

button.

7.4. ADJUSTING THE TIME INTERVAL BETWEEN DEFROSTING CYCLES

A. Press and hold the [SET] button until PA1 displays on the screen.

B. When PA1 displays, press the [SET] button once. 0 will now display.

C. When 0 displays, press the [UP] button once, setting the value to 1. When 1 displays, press the

[SET] button. diF will display.

D. When diF displays, press the [DOWN] button once. PA2 will display.

E. When PA2 is displayed, press the [SET] button.

F. Scroll by pressing the [DOWN] button until dit is displayed on the screen. When dit displays on

the screen, press the [SET] button.

1. dit is the defrost interval time. This is the time interval between the start of two defrost

cycles in hours. Default Value = 12 hours.

G. Use the up and down arrow buttons to increase or decrease the time interval between the start

of two defrost cycles.

1. Value Range = 0 – 250 hours. NOTE: Setting this value to 0 will turn off the defrost cycle.

H. Press the [SET] button to save the entered value when done.

I. To return to the home screen, press the Stand-By button once.

7.5 CHANGING THE CONTROLLER FROM FAHRENHEIT TO CELSIUS.

A. Press and hold the [SET] button until PA2 is displayed on the screen.

B. When PA2 is displayed, press the [SET] button.

C. Scroll by pressing the [DOWN] button. When dro displays, press [SET].

D. The display will now show 1.

NOTE: 1 is the default value for degrees Fahrenheit.

E. Press [DOWN] button once to change value to 0.

NOTE: 0 is the default value for degrees Celsius.)

F. When 0 displays, press [SET]. °C will display in the bottom right corner.

G. To return to the home screen, press [Stand-By] once.

NOTE: Make sure the set point and relay tripping differential have been changed when changing

the unit of temperature.

23

Page 26

8. PROGRAMMING THE COOLING PARAMETERS - 230 VOLT MODEL

NOTE: The temperature is preprogrammed per the local requirements. After the dispenser is connected

to power, the controller will automatically regulate the cabinet’s temperature and signal the refrigeration

component if necessary.

Temperature Controller - 230 V

fnc

SET

Function ButtonUp Button

Set ButtonDown Button

8.1 ADJUSTING THE TEMPERATURE POINT

A. Press the [SET] button once, SEt will display on the screen.

B. Press the [SET] button again to adjust the set point. Use the [UP] and [DOWN] buttons to

increase or decrease the value.

1. SEt is the set point at which the refrigeration compressor shuts off when it reaches the

entered temperature value. Default Value = 0.0˚C.

C. Press the [SET] button to save the entered value when done.

D. To return to the home screen, press the [fnc] button once.

8.2 ADJUSTING THE REFRIGERATION COMPRESSOR RELAY TRIPPING DIFFERENTIAL

A. Press the [SET] button until CP displays on the screen.

B. When CP displays, press [SET] once. diF will display.

1. diF is the refrigeration compressor relay tripping differential. The refrigeration compressor

shuts off when the temperature reaches the set point and turns back on when the

temperature is equal to the sum of the set point and the diF. Default Value = 3.3˚C.

C. Press [SET] to adjust the differential. Use [UP] and [DOWN] buttons to increase or decrease

the value.

D. When diF displays, press [SET] to adjust the differential. Use [UP] and [DOWN] buttons to

increase or decrease the value.

E. Press [SET] to save the entered value when done.

F. To return to the home screen, press the [fnc] button two times.

9. DISPENSER DISPOSAL

To prevent possible harm to the environment from improper disposal, recycle the unit

by locating an authorized recycler or contact the retailer where the product was pur

chased. Comply with local regulations regarding disposal of the refrigerant and

insulation.

24

Page 27

10. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS

10.1 WIRING DIAGRAM

25

Page 28

10.2 EXPLODED VIEW

26

Page 29

10.2 EXPLODED VIEW (CONTINUED)

Item Part No. Description

1 02-0040 Seal,Extrusion

2 02-0114 Grommet,Compressor

3 03-0150 Retainer,Clip,Convert

4 04-0034 Nut,Lck,1/4-20 X 7/17 X

13/16 Wshr

5 04-0059 Scr,8-36 X .375, PHD, LNB,

PH/Sl

6 04-0072 Rivet, .125 Od X .312 Lg, SS

7 04-0297 Nut, Hex, 8-32, Keps, SS

8 04-0357 Scr,10-32 X .375,

PHD,PH,MS,SS

9 04-0406 Scr,8-32 X .375 PH, PH, MS,

SS, PL

10 04-0407 Scr,6-32 X .375, PHD, PH,

Type 23, SS

11 04-0504 Scr,8-18X.375,PHD W/

ELW, PH, AB

12 04-0537 Washer,.467Id X .923 OD

X .060 Thk

13 04-1206 Scr,1/4-20X3/8,Bnh,Hs,Ss

14 04-1453 Screw,3/8-16X1-1/2,

PHD,PH,MS,ZP

15 04-1537 Scr,1/4-20X.500,HH,H/W,

MS, SS, P

16 04-1574 Scr,8-32X1.250, PH, PH/ SL,

RL, SS

17 04-1645 Nut,8-32,TH,NY

18 04-1646 Standoff, 8-32X.375, M-F,

.750 Long, SS

19 05-1502 Plug, Key Hole

20 05-2596 Spacer,Pl,.50Idx1.50odx.625

21 05-3030 Bumpon,Tall Taper

Sq,.81X.30,Black

22 05-3043 Cover,Temp Probe,Liv

23 05-3048 Cover,Electronics

24 05-3130 Deck,Air Prop,Liv

25 05-3141 Bracket,Rack,Left,Liv

26 05-3142 Bracket,Rack,Right,Liv

27 06-0075-01 Nmplt,Vinyl,Pn/Sn/Elec Only

28 06-3316 Label,Wiring Diagram,Liv

29 06-3366 Label,Inside Door,Livingstone

30 07-0211 Washer,Shipping Base

31 08-0184 Tubing, Gry Drain 5/8Id X

7/8Od

32 11-0008 Tie,Wire

33 11-0648 Clamp, Cable, .250/.172,

Black, Nylon

34 12-0524 Relay, Power, 30A, 240Vac

35 12-0562 Terminal Block, Rohs, 1/4”,

6-12 Position

36 13-0008 Bushing,Relief,Heyco 1200

37 15-0223 Grommet,Flex,Slot .085W

X.155D

38 18-0332 Reg,Assy,Liv

39 23-1554 Rack,Liv

40 23-1611 Dryer/Cap Tube Assy,

.031X72”

Item Part No. Description

41 30-11146 Condenser,Ducting,Liv

42 30-11153 Cover,Evap,Liv

43 30-11154 Panel,Front,Liv

44 30-11156 Cup Rest,Liv

45 30-11158 Hinge,Top,Mount,Liv

46 30-11159 Hinge,Bottom,Mount,Liv

47 30-11230 Frame,Support,Liv

48 30-11240 Fan Motor Cover,Cabinet,Liv

49 30-11284 Panel,Rear Access,Liv

50 30-11286 Regulator,Shield,Air

Propulsion,Liv

51 30-11442 Shelf, Bottom, Livingstone

52 30-11463 Rack,3.8L Keg, Backstop,

Livingstone

53 30-11516 Frame,Base-Tray,Liv

54 42-0175 Foamed,Assy,Liner,Liv

55 47-0344 Tube,Process

56 47-2238 Tube,Process,Comp,600

57 47-5699 Evaporator Coil,Liv

58 47-5724 Suction Tube,Comp,Liv

59 47-5725 Tube,One,Comp,Liv

60 47-5726 Tube,Two,Comp,Liv

61 47-5731 Tube,Suction,Liv Deck

62 50-0211 Boot,6”,Delta Ii

63 50-0322 Bafe,Condenser,Side,600

64 50-0640 Foam,Insert,Stage,Liv

65 51-0061 Accumulator,.375Holes

66 51-6427 Shroud,Assy,Fan,Liv

67 52-1258 Fan Mtr Assy, 115V, 9W, 500,

R134a

68 52-3002 Thermostat,Digital,W/Probe

69 52-3368 Lead Assy,18Awg,12”,Blk,W/

Wht Strip

70 52-3369 Harness,Recirc Fan Ext,

Livingstone

71 52-3370 Harness,Main,Livingstone

72 52-3371 Harness,Thermostat

Controller,Livingstone

73 52-3372 Lead Assy, 18Awg, Blk,

Stranded

74 81-0684 Filter,Air,Liv

75 82-4424 Door,Assy,Liv

76 82-4432 Liv,Stage,Assy

77 82-4469 Liv,Air Propulsion Assy,115V

78 82-4473 Fan,Air Recirc,115/60

79 83-0058 Comp Assy,115-60Hz

80 N/A 1 Tower

27

Page 30

Lancer Corp.

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Loading...

Loading...