Page 1

Barrilitos Beverage Tower

Operation Manual

Lancer Corporation

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

“Lancer” is the registered trademark of Lancer © 2018 by Lancer, all rights reserved.

330

Tech Support/Warranty: 800-729-1550

email: custserv@lancercorp.com

®

web: lancercorp.com

Lancer PN: 28-1004/02

Revision: August 2018

Page 2

TABLE OF CONTENTS

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product.

Please carefully read the guidelines and warnings contained

herein as they are intended to provide the user with essential

information for the continued safe use and maintenance of the

product. In addition, it provides GUIDANCE ONLY to the user

on the correct services and site location of the unit.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with

up-to-date safety and hygiene knowledge and practical experience, in accordance with current regulations.

IMPORTANT SAFETY INSTRUCTIONS..........................3

Intended Use Warning................................................3

CO2 Warning...............................................................3

Electrical Warning.......................................................3

Water Notice...............................................................3

PRE-INSTALLATION....................................................4-5

Specications & Features...........................................4

General System Overview..........................................5

Pre-Installation Checklist............................................5

INSTALLATION.............................................................6-9

Unpacking the Dispenser...........................................6

Selecting/Preparing the Counter Location..................6

Dispenser Installation..............................................7-8

Adjust Water Flow Rate & Syrup/Water Ratio............8

MODES OF OPERATION...........................................9-10

Normal Operation Mode.............................................9

Technician Mode...................................................9-10

LED Saver Mode......................................................10

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly

inspected before shipment. At the time of shipment, the carrier

accepts responsibility for the unit. Upon receiving the unit,

carefully inspect the carton for visible damage. If damage exists,

have the carrier note the damage on the freight bill and le a

claim with carrier. Responsibility for damage to the dispenser

lies with the carrier.

CLEANING & SANITIZING.......................................11-12

General Information..................................................11

Cleaning & Sanitizing Solutions................................11

Scheduled Maintenance & Cleaning...................11-12

Cleaning & Sanitizing Nozzle...................................12

Cleaning & Sanitizing Syrup Lines - BIB..................12

TROUBLESHOOTING..............................................13-15

ILLUSTRATIONS & PART LISTINGS.......................16-20

Main Unit Assembly..................................................16

Faucet Housing Assembly........................................17

Button Panel Assembly.............................................18

Wiring Diagram.........................................................19

DIP Switch Settings..................................................20

Plumbing Diagram....................................................21

SAFETY NOTICES

READ ALL SAFETY INSTRUCTIONS BEFORE USING THIS UNIT.

This manual contains important safety information and all applicable safety precautions must be observed. To reduce

the risk of re, electric shock, damage to the equipment or personal injury when using this unit all instructions/warnings

on the product being used must be followed:

! WARNING

Text following the Warning signal indicates a

hazardous situation, which if not avoided, will result

in death or serious injury. Be sure to read all Warning

statements before proceeding with the installation.

! CAUTION

Text following the Caution signal indicates a

hazardous situation, which if not avoided, could result

in death or serious injury. Be sure to read the Caution

statements before proceeding with the installation

2

! ATTENTION

Text following the Attention signal addresses a

situation that if not followed could potentially damage

the equipment. Be sure to read the Attention

statements before proceeding

NOTE

Text following the Note signal provides you with

information that may help you more eectively perform

the installation procedures within this manual.

Disregarding information will not cause damage or

injury, however it may limit the performance of the

dispenser.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

! Intended Use

• The dispenser is for indoor use only

• This appliance is intended to be used in commercial

applications such as restaurants or similar.

• This appliance should not be used by children or

inrm persons without supervision.

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

• This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

• Cleaning and user maintenance shall not be

performed by children without supervision.

• This unit is not a toy and children should be advised

not to play with the appliance.

• The min/max ambient operating temperature for the

dispenser is 40°F to 75°F (4°C to 24°C).

• Do not operate unit below minimum ambient operation

conditions.

• Should freezing occur, cease operation of the unit and

contact authorized service technician.

• The maximum tilt for safe operation is 5°.

• This appliance must be installed and serviced by a

professional.

5 Carbon Dioxide (CO2)

• WARNING: Carbon Dioxide (CO

noncombustible gas with a light pungent odor. High

percentages of CO2 may displace oxygen in the

blood.

• WARNING: Prolonged exposure to CO

Personnel exposed to high concentrations of CO2 gas

will experience tremors which are followed by a loss

of consciousness and suocation.

• WARNING: If a CO

ventilate the contaminated area before attempting to

repair the leak.

gas leak is suspected, immediately

2

• WARNING: Strict attention must be observed in the

prevention of CO2 gas leaks in the entire CO2 and soft

drink system.

) is a colorless,

2

can be harmful.

2

F Power

• Follow all local electrical codes when making

connections.

• Check the dispenser name plate label, located behind

the front panel, for the correct electrical requirements

of unit. DO NOT plug into a wall electrical outlet

unless the current shown on the serial number plate

agrees with local current available.

• Each dispenser must have a dedicated electrical

circuit.

• DO NOT use extension cords with this unit. DO NOT

‘gang’ together with other electrical devices on the

same outlet.

• WARNING: Always disconnect electrical power to the

unit to prevent personal injury before attempting any

internal maintenance.

• The resettable breaker switch should not be used as

a substitute for unplugging the dispenser from the

power source to service the unit.

• Only qualied personnel should service internal

components of electrical control housing.

• WARNING: Make sure that all water lines are tight and

units are dry before making any electrical connections

• If this dispenser is installed in an area that is

susceptible to more than 10% variation of the nominal

line voltage, consider installing a surge protector or

similar protection device.

! Water Notice

• Provide an adequate, potable water supply. Water

pipe connections and xtures directly connected to

a potable water supply must be sized, installed, and

maintained according to federal, state, and local

codes.

• The water supply line must be at least a 3/8 inches

(9.525 mm) pipe with a minimum of 25 psi (0.172

MPa) line pressure, but not exceeding a maximum

of 65 psi (0.448 MPa). Water pressure below 25 psi

(0.172 MPa) will require the use of a water booster,

(82-3401 or MC-163172). Water pressure exceed-

ing 65 psi (0.448 MPa) must be reduced by way of a

water regulator (18-0253/02).

• Use a lter in the water line to avoid equipment

damage and beverage o-taste. Check the water lter

periodically, as required by local conditions.

• CAUTION: The water supply must be protected by

means of an air gap, a backow prevention device

(located upstream of the CO2 injection system)

or another approved method to comply with NSF

standards. A leaking inlet water check valve will

allow carbonated water to ow back through the pump

when it is shut o and contaminate the water supply.

• CAUTION: Ensure the backow prevention device

complies with ASSE and local standards. It is the

responsibility of the installer to ensure compliance.

3

Page 4

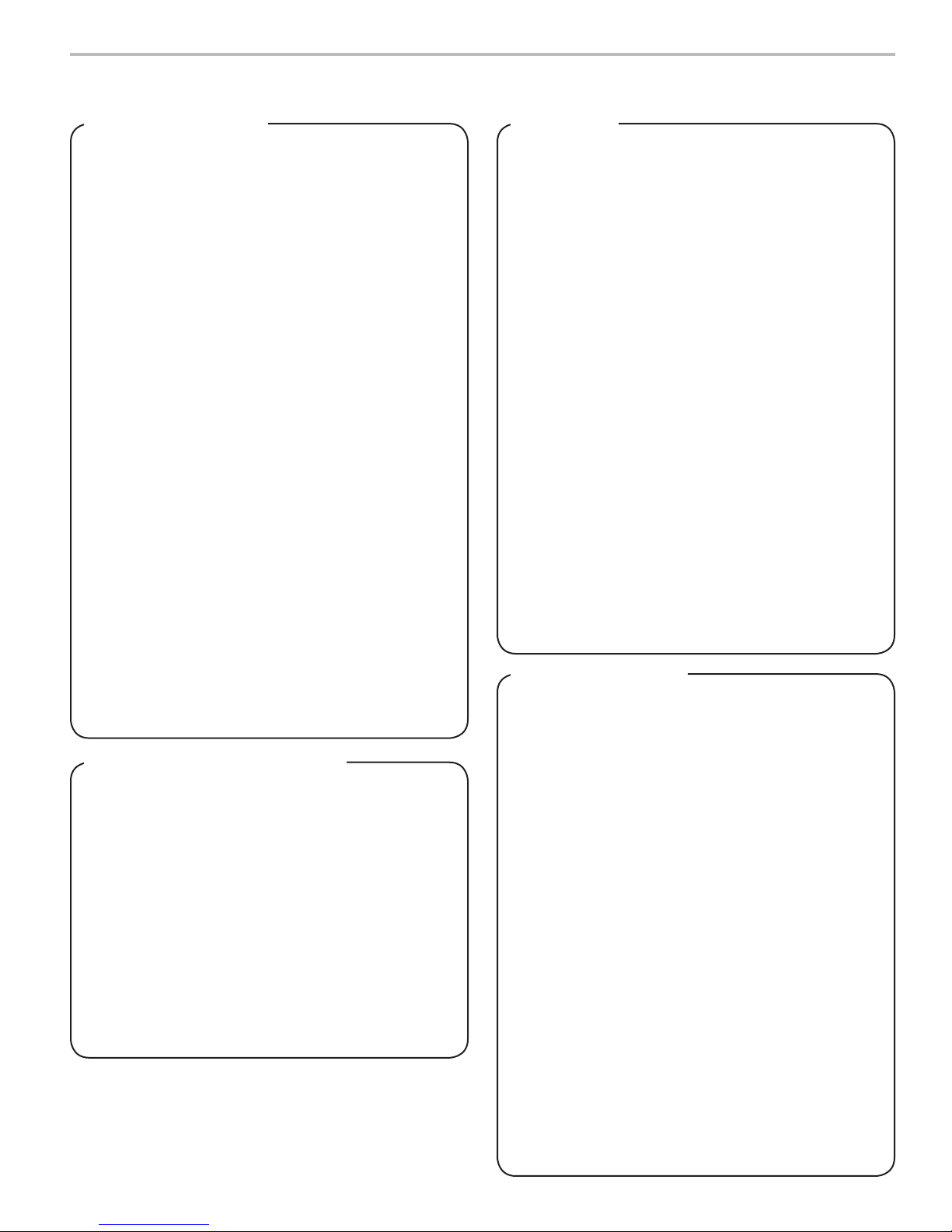

Specications & Features

PRE-INSTALLATION

B

C

22.75 in.

D

E

F

15.5 in.

10.0 in.

A

A. Brand Select

B. Pour Handle

C. Nozzle

D. Front Panel

E. Cup Rest

F. Drip Tray

DIMENSIONS

Width: 10.00 inches (254 mm)

Depth: 15.50 inches (393.7 mm)

Height: 22.75 inches (577.85 mm)

WEIGHT

Shipping: 32.0 lbs (14.5 kg)

Operating: 19.0 lbs (8.6 kg)

ELECTRICAL

24 VDC / 2.0 Amps

FLOW RATE

2.0 ounces per second

This unit emits a sound pressure level below 70 dB

4

PLAIN WATER SUPPLY

Min Flowing Pressure: 25 psi (0.172 MPa)

Max Static Pressure: 65 psi (0.448 MPa)

CARBON DIOXIDE (CO2) SUPPLY

Min Pressure: 70 psi (0.483 MPa)

Max Pressure: 80 psi (0.552 MPa)

FITTINGS AT UNIT

Plain Water Inlet: 3/8 inch (9.5 mm) barb

Brand Syrup Inlets: 3/8 inch (9.5 mm) barb

Drain Fitting: 5/8 inch (15.9 mm) barb

Page 5

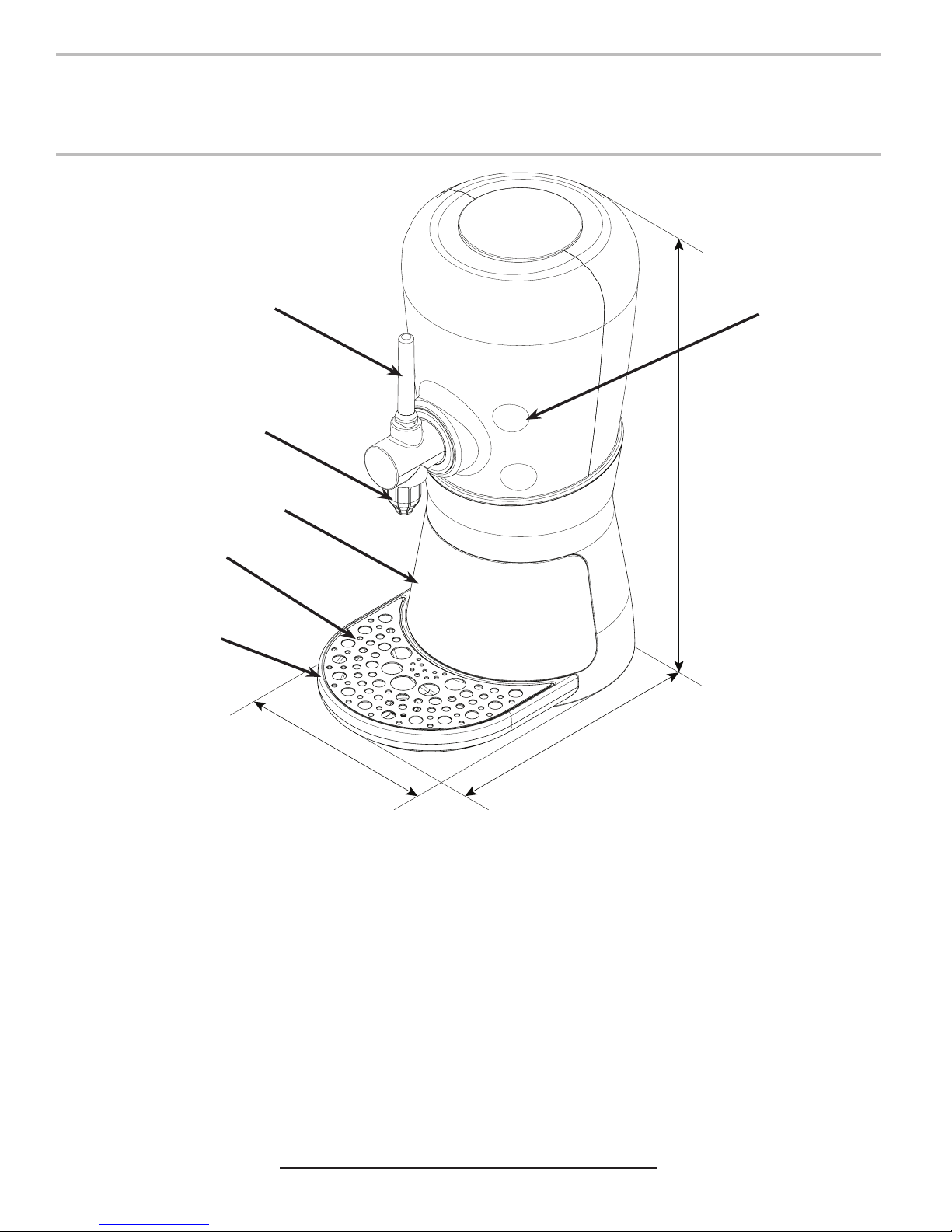

General System Overview - Remote Syrup Pumps

G

F

E

J

H

I I I I

H H H

Syrup Line

CO2 Line

Plain Water Line

Drain Line

Electrical

D

75

C

A. Water Source

B. Water Filter

C. CO2 Source

D. High Pressure CO2

Regulator

E. Electrical Outlet

F. Counter

B

A

G. Tower (Dispenser)

H. Syrup Pump

I. BIB Syrup Containers

J. Floor Drain

Pre-Installation Checklist

TOOLS REQUIRED:

Oetiker Pliers

Tubing Cutters

Wrench

Slotted Screwdriver

Phillips Screwdriver

Drill

BIB SYSTEM:

BIB Rack

BIB Syrup Boxes

BIB Regulator Set

BIB Connectors

POST MIX ACCESSORIES:

CO2 Regulator

CO2 Supply

Chain for CO2 Tank

Beverage Dispenser

Beverage Tubing

Oetiker Clamp Fittings

Water Booster (Lancer PN:

82-3401 or MC-163172

CONSIDER THE FOLLOWING

BEFORE INSTALLATION:

Location of Water Supply Lines

Location of Drain

Location of Electrical Outlet

Location of Heating and Air

Conditioning Ducts

Do you have enough space to

install the dispenser?

Does the counter height meet

ADA requirements?

Is countertop level?

Can the countertop support the

weight of the dispenser? (Include

the weight of an ice machine plus

weight of ice, if necessary)

Is dispenser located away from

direct sunlight or overhead

lighting?

5

Page 6

INSTALLATION

Read This Manual

This manual was developed by Lancer Corporation as a reference guide for the owner/operator and installer of this dispenser.

Please read this manual before installation and operation of this dispenser. Please see pages 13-15 for troubleshooting or service

assistance. If the service cannot be corrected please call your Service Agent or Lancer Customer Service. Always have your

model and serial number available when you call.

Unpacking the Dispenser

1. Cut package banding straps and remove.

2. Open the box and remove the accessory kit and loose

parts.

3. Carefully lift the unit out of the box and place on a at

surface taking care to not scratch the plastic covers.

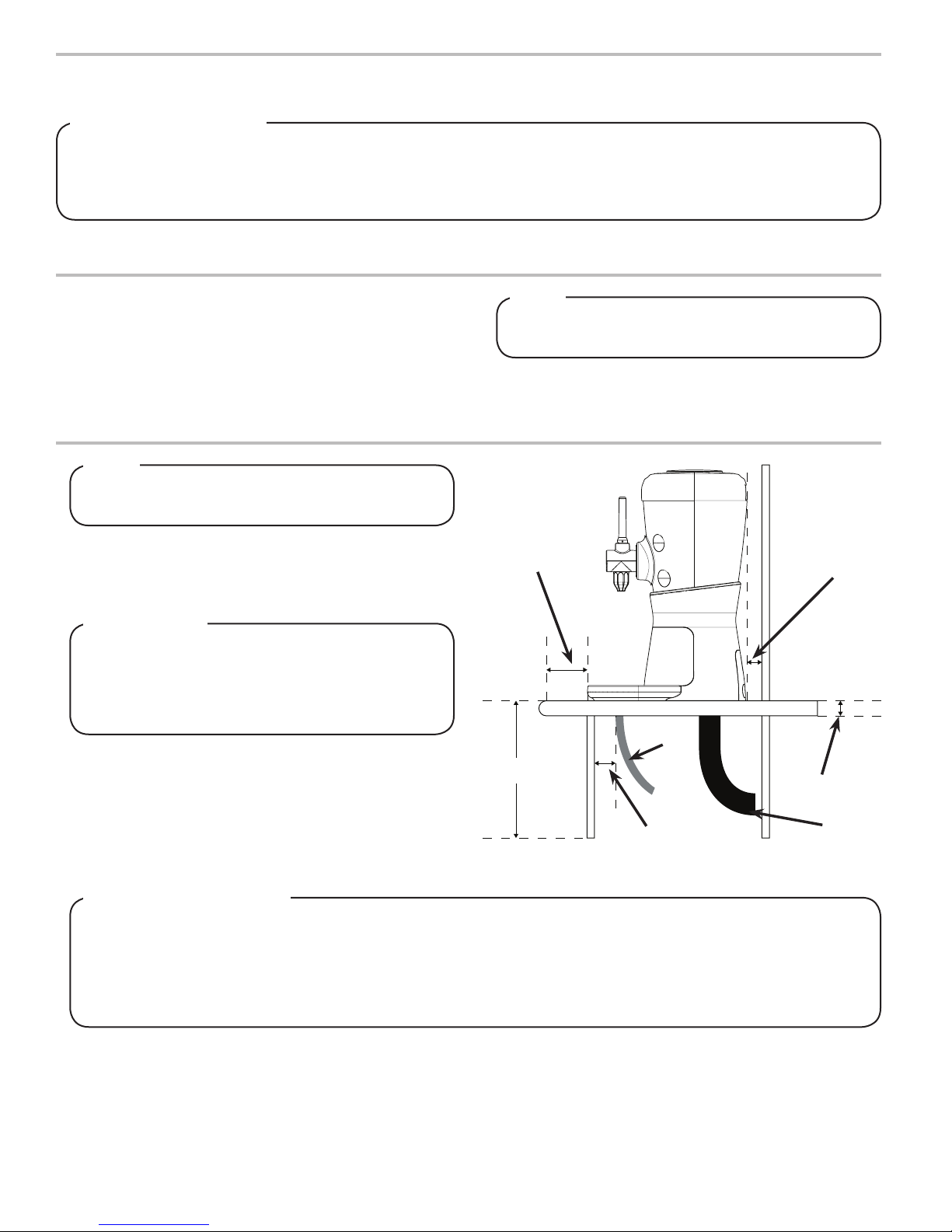

Selecting/Preparing a Counter Location

NOTE

The dispenser should only be installed in a location

where it can be overseen by trained personnel

1. Select a location that is in close proximity to a properly

grounded electrical outlet, within ve (5) feet (1.5 m) of

a drain, and a water supply that meets the requirements

shown in the Specications section found on page 4.

! ATTENTION

Inspect the counter location where the unit is to be

installed. Verify the selected counter is strong enough

to safely support the weight of the installed unit, after

the cutout for the unit is made. The ideal counter for

installation should measure at least one (1) inch thick.

2. Select a location that utilizes the clearances/space required

for installation.

3. Select a location for the syrup pumps, CO2 tank, syrup

containers, and water lter (recommended).

4. Using the base of the tower as a template, cut out required

opening for the tower installation in the designated location.

NOTE

Inspect unit for concealed damage. If evident, notify

delivering carrier and le a claim against the same.

Max: 2.75 in

A

Max: 48.0 in

Min: 2.0 in

Min: 0.75 in

Max: 1.5 in

A. Drain Tube

B. Inlet Tubes

B

Accessibility - ADA

To assure that beverage service is accessible to all customers, Lancer recommends that counter height and

equipment selection be planned carefully. The 2010 ADA Standards for Accessible Design states that the maximum

reach height from the oor should be no more than 48” if touch point is less than 10” from the front of the counter, or

a maximum of 46” if the touch point is more than 10” and less than 27” from the front of the counter. For more

information about the customer’s legal requirements for the accessibility of installed equipment, refer to 2010 ADA

Standards for Accessible Design - http://www.ada.gov.

6

Page 7

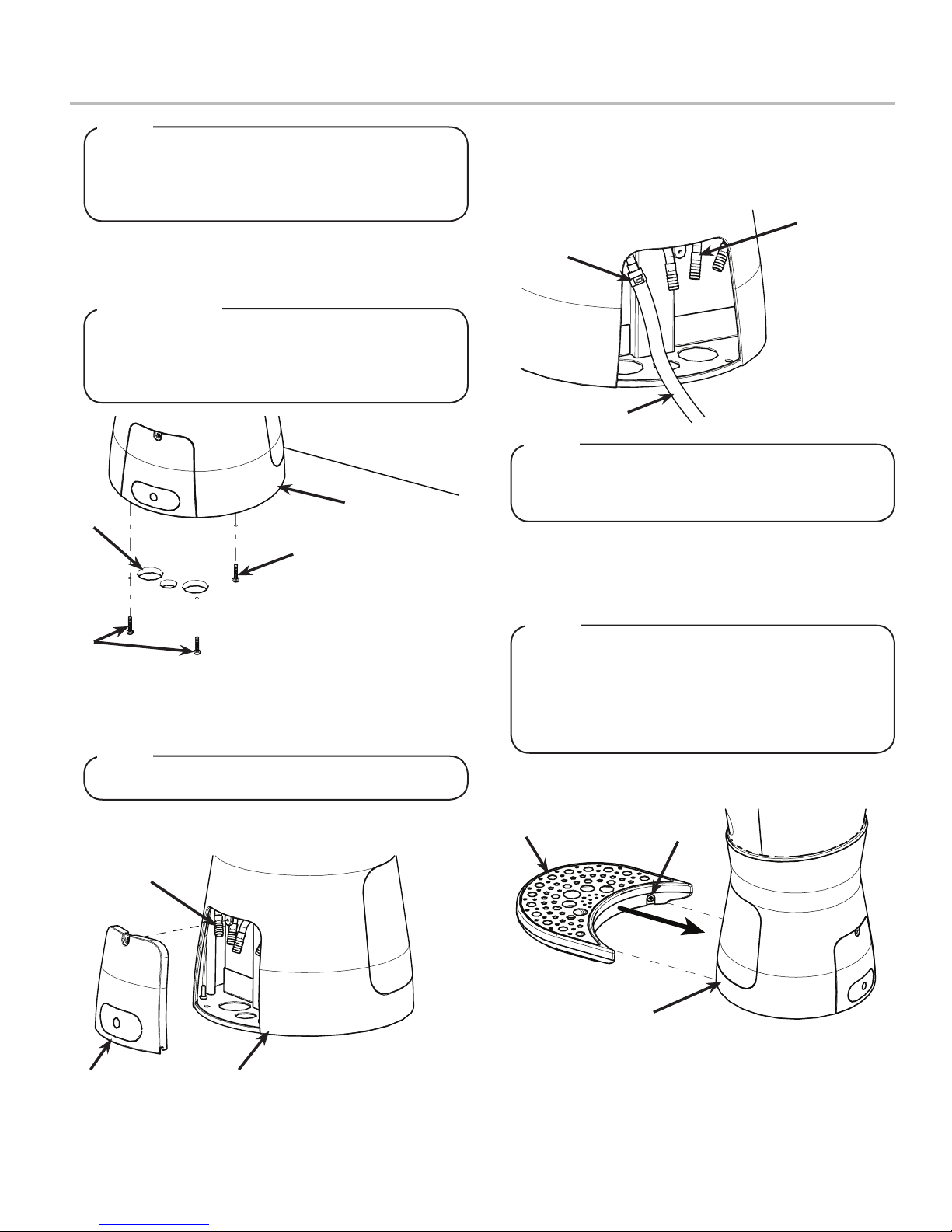

Dispenser Installation

NOTE

The installation, and relocation if necessary, must

be carried out by qualied personnel with up-to-date

knowledge and practical experience, in accordance

with current regulations.

1. Place tower on counter in designated location and position

over counter cutout.

2. Attach tower to counter using the three (3) screws provided.

! ATTENTION

When attaching the tower to the counter, make sure

the screws do not extend more than 0.75 in (19 mm)

from the top of the mounting plate. These could

damage the valves when installing the dispenser.

A

B

C

A. Tower

B. Counter Cutout

C

3. After the tower is permanently bolted to the counter top, the

tower base must be sealed to the counter top with a bead

of clear silicone caulk or sealant which provides a smooth

and easily cleanable bond to the counter.

C. Connecting Screws

(Underneath Counter)

NOTE

NSF listed units must be sealed to the counter.

5. Route appropriate tubing from the syrup pump location to

the syrup inlets on the tower. Connect tubing to inlets using

the oetiker pliers and ttings. Repeat for all syrup

connections. (See Plumbing Diagram on page 21 for

reference)

A

C

A. Syrup/Water Inlets

B. Tubing

B

C. Oetiker Fitting

NOTE

The Barrilitos Tower syrup and water lines can either

be routed through the counter cutouts or out through

the back panel of the tower.

6. Route appropriate tubing from the water source to the plain

water inlet at the tower.

7. Cut water line, using tubing cutters, and install water lter to

water line.

NOTE

If the water source is above 65 psi (0.448 MPa), cut

tubing assembly and install Water Regulator Kit (PN

18-0253/02, sold separately) as shown in kit

instruction sheet. Once installed, use a test gauge

assembly (PN 22-0138, sold separately), to set

regulator at a maximum of 65 psi (0.448 MPa).

8. Slide drip tray into opening in tower until magnets engage

and lock drip tray in place.

4. Using a screwdriver, remove the back panel on the tower to

reveal the syrup/water inlets.

C

A

B

A. Back Panel

B. Tower

C. Syrup/Water Inlets

A

B

B

A. Drip Tray

B. Magnet

7

Page 8

9. If a drain line is to be utilized, place gasket at the bottom of

the drain then attach drain tting to drip tray.

B

A. Seal

B. Drip Tray

C

F

E

10. Using two hands, rmly lift the back panel up until the

magnet connection is released and removed from the unit.

C. Counter

D. Upper Drain Fitting

E. Lower Drain Fitting

F. Washer

AD

A

11. Route power cord either up through designated counter

cutout or through back panel, (See step 5) and connect

power cord to unit control board connection.

A

B

A. Power Cord Connection

B. Counter Cutout/

Back Panel Access

12. Plug in power cord to power supply then route power supply

cord to the designated grounded electrical outlet.

! WARNING

The dispenser must be properly electrically grounded

to avoid serious injury or fatal electrical shock. The

power cord has a three-prong grounded plug. If a

three-hole grounded electrical outlet is not available,

use an approved method to ground the unit. Follow

all local electrical codes when making connections.

Each dispenser must have a separate electrical circuit.

Do not use extension cords. Do not connect multiple

electrical devices on the same outlet.

A. Back Panel

To congure the light ring to a specic color for each

Adjust Water Flow Rate & Syrup/Water Ratio

1. Remove the front panel from the tower by pulling away from

the unit and disengaging the magnets.

B

A

A. Front Panel

B. Water/Syrup Valves

2. Use the brand buttons to enter the Technician Mode, (see

section Technician Mode, on page 9, for reference).

3. Perform a 8 second water pour (see page 10) and using a

4. Use the chart below to determine the proper ow of water

NOTE

brand, see DIP Switch Settings on page 20.

graduated cylinder, verify water ow rate.

B

A

A. Graduated Cylinder

B. Nozzle

needed according to the ratio of the products being used.

8

Page 9

5. Use a screwdriver to adjust the ow if needed, (See

plumbing diagram on page 19 for reference). Repeat Steps

3-5 until proper ow of water is achieved.

B

A

Increase Decrease

A. Flow Control

C

B. Solenoid

C. Valve Body

6. Perform a 8 second syrup pour (see page 10) of the rst

syrup line and using a graduated cylinder, verify syrup ow

rate.

7. Use the chart below to determine the proper ow of syrup

needed according to the ratio of the syrup being used.

8. Use a screwdriver to adjust if needed. Repeat Steps 6 - 8

until proper ow of syrup is achieved.

9. Repeat Steps 6 - 8 for remaining syrup lines.

Target Flow Rate

Ratio (X:1) 4.00 4.25 4.50 4.75 5.00 5.25 5.50 5.75 6.00

Plain Water Volume

(8 sec.)

Volume of Syrup

(8 sec.)

12.80 oz

(378.51 ml)

3.20 oz

(94.64 ml)

12.95 oz

(382.98 ml)

3.05 oz

(90.20 ml)

Normal Operation Mode

Starting a Normal Pour

when no Brand is Selected.

Starting a Normal Pour with

Lever , when Brand is

Already Selected.

13.09 oz

(387.12 ml)

2.91 oz

(86.06 ml)

13.22 oz

(390.96 ml)

2.72 oz

(80.44 ml)

13.33 oz

(394.22 ml)

2.67 oz

(78.96 ml)

13.44 oz

(397.47 ml)

2.56 oz

(75.71 ml)

13.54 oz

(400.43 ml)

2.46 oz

(72.75 ml)

13.63 oz

(403.09 ml)

2.37 oz

(70.09 ml)

13.72 oz

(405.75 ml)

2.28 oz

(67.43 ml)

MODES OF OPERATION

1. The lever is in the OFF state and no brand is selected.

2. Pull the lever down, all brand button LEDs will illuminate for 3 seconds.

3. Touch the brand button to select and initiate pour. The selected brand LED will turn ON

and all others will turn OFF. Light ring will turn ON and match the color specied by the

associated DIP switch conguration.

4. Pour stops when lever is released (or after 15 seconds)

1. The lever is in the OFF state and a brand is already selected. The brands’ LED is ON and

the light ring matches the color specied by the associated DIP switch conguration.

2. Pull the lever down, pour of brand syrup and water begins.

3. Pour stops when lever is released (or after 15 seconds)

1. The selected brands’ LED is ON and the light ring matches the color specied by the as-

Deselecting a Brand

Dispense/Settle Mode

2. Brand button is automatically deselected after 30 seconds of inactivity. Brand LED turns

1. Once a Normal Pour is activated, the dispenser is in Dispense Mode and a manual pour

2. Once pour stops and the lever is released, the dispenser is in Settle Mode which allows

3. Brand button is automatically deselected after 30 seconds of inactivity. Brand LED turns

sociated DIP switch conguration.

OFF and the light ring returns to the white color.

of brand syrup and water is initiated.

for a top-o of the selected brand.

OFF and the light ring returns to the white color.

9

Page 10

Technician Mode

Enter Technician Mode

Timed Pour of Water and

Syrup

1. Technician mode can only be entered within one (1) minute after startup. If the unit has

been powered on for more than one minute, cycle power then begin the process to enter

the Technician Mode.

2. Press and hold the top two brand buttons simultaneously for two (2) seconds.

• The top two brand buttons must be pressed within 1 minute of unit power up.

3. After the two (2) seconds, the top two brand button LEDs will turn ON. Release the top

two brand buttons then press and hold the bottom two brand buttons for two (2) seconds.

• The bottom two brand buttons must be pressed within 10 seconds of releasing the

top two brand buttons.

4. After the two (2) seconds, the bottom two brand button LEDs will turn ON. Release the

bottom two brand buttons to activate Technician Mode.

• The bottom two brand buttons must be released within 1 second of brand button

LEDs turning ON.

• If successful, the four button LEDs will blink 4 times.

• If the user is unsuccessful in entering the Technician Mode, re-cycle power and

repeat the process.

1. The lever is in the OFF state and no brand is selected.

2. Pull and release lever 4 times within a span of 4 seconds.

• Pulls must be within 1 second of each other.

3. Select and release any brand within one second to begin pour.

• Pull lever or press any button to cancel pour in progress.

Timed Pour of Syrup

Timed Pour of Water

Exit Technician Mode

(Manually)

1. The lever is in the OFF state and no brand is selected.

2. Pull and release lever 5 times within a span of 5 seconds.

• Pulls must be within 1 second of each other.

3. Select and release any brand within one second to begin pour.

• Pull lever or press any button to cancel pour in progress.

1. The lever is in the OFF state and no brand is selected.

2. Pull and release lever 6 times within a span of seconds.

• Pulls must be within 1 second of each other.

3. Select and release any brand within one second to begin pour.

• Pull lever or press any button to cancel pour in progress.

1. The lever is in the OFF state, no brand is selected, and dispenser is in Technician Mode.

2. Press and hold the top two brand buttons simultaneously for two (2) seconds.

3. The top two brand button LEDs will turn ON, release the top two brand buttons then press

and hold the bottom two brand buttons for two (2) seconds.

• The bottom two brand buttons must be pressed within 10 seconds of releasing the

top two brand buttons.

4. The bottom two brand button LEDs will turn ON, release the bottom two brand buttons to

exit Technician Mode.

• The bottom two brand buttons must be released within 1 second of brand button

LEDs turning ON.

• If successful, the four button LEDs will blink twice.

Exit Technician Mode

(Automatically)

1. The dispenser will automatically exit the Technician Mode and return to the Normal

Operation Mode after 3 minutes of inactivity.

10

Page 11

LED Saver Mode

Enter LED Saver Mode

Exit LED Saver Mode (Brand

Button)

1. With the dispenser in the Normal Operation Mode, the LEDs and light ring will turn o

after 2 hours of inactivity.

2. After the dispenser is in the LED Saver Mode and the LEDs and light ring have been o

for 1 minute, the light ring will begin a color ramp sequence.

1. With the dispenser in the LED Saver Mode, touch any brand button to change to Normal

Operation Mode.

2. The selected brand LED will turn ON and all others will turn OFF. Light ring will turn ON

and match the color specied by the associated DIP switch conguration.

Exit LED Saver Mode

(Activate Lever)

1. With the dispenser in the LED Saver Mode, pull the lever down to change to Normal

Operation Mode.

2. The brand button LEDs remain o and the light ring turns white.

CLEANING AND SANITIZING

General Information

• Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized in accordance with NSF guidelines.

The operator of the equipment must provide continuous maintenance as required by this manual and/or state and local health

department guidelines to ensure proper operation and sanitation requirements are maintained.

NOTE

The cleaning procedures provided herein pertain to the Lancer equipment identied by this manual. If other

equipment is being cleaned, follow the guidelines established by the manufacturer for that equipment.

• Cleaning should be accomplished only by trained personnel. Sanitary gloves are to be used during cleaning operations.

Applicable safety precautions must be observed. Instruction warnings on the product being used must be followed.

! ATTENTION

• Use sanitary gloves when cleaning the unit and observe all applicable safety precautions.

• DO NOT use a water jet to clean or sanitize the unit.

• DO NOT disconnect water lines when cleaning and sanitizing syrup lines, to avoid contamination.

• DO NOT use strong bleaches or detergents; These can discolor and corrode various materials.

• DO NOT use metal scrapers, sharp objects, steel wool, scouring pads, abrasives, or solvents on the dispenser.

• DO NOT use hot water above 140° F (60° C). This can damage the dispenser.

• DO NOT spill sanitizing solution on any circuit boards. Insure all sanitizing solution is removed from the system.

Cleaning and Sanitizing Solutions

Cleaning Solution

Mix a mild, non-abrasive detergent (e.g. Sodium Laureth

Sulfate, dish soap) with clean, potable water at a temperature of

90°F to 110°F (32°C to 43°C). The mixture ratio is one ounce of

cleaner to two gallons of water. Prepare a minimum of ve

gallons of cleaning solution. Do not use abrasive cleaners or

solvents because they can cause permanent damage to the

unit. Ensure rinsing is thorough, using clean, potable water at a

temperature of 90°F to 110°F. Extended lengths of product lines

may require additional cleaning solution.

Sanitizing Solution

Prepare the sanitizing solution in accordance with the

manufacturer’s written recommendations and safety guidelines.

The type and concentration of sanitizing agent recommended

in the instructions by the manufacturer shall comply with 40

CFR §180.940. The solution must provide 100 parts per million

(PPM) chlorine (e.g. Sodium Hypochlorite or bleach) and a

minimum of ve gallons of sanitizing solution should be

prepared.

11

Page 12

Scheduled Maintenance and Cleaning

As Needed

Daily

Weekly

Every Six Months

• Keep exterior surfaces of dispenser (include drip tray and cup rest) clean using a clean, damp

cloth.

• Remove each nozzle and rinse well in warm water. DO NOT use soap or detergent. This will

cause foaming and o taste in nished product.

• Using a soft cloth and cleaning solution, clean the nozzle injectors. See Cleaning and Sanitizing

Nozzle section on page 12 for reference.

• Remove cup rest and wash in warm soapy water.

• Pour warm soapy water into the drip tray and wipe with a clean cloth.

• With a clean cloth and warm water, wipe o all of the unit’s exterior surfaces. DO NOT USE

ABRASIVE SOAPS OR STRONG DETERGENTS.

• Replace the cup rest and nozzle

• Taste each product for o tastes. If o taste occurs, clean and sanitize the unit using the

appropriate procedures outlined in the Cleaning and Sanitizing section of this manual.

• Clean and sanitize the unit using the appropriate procedures outlined in the Cleaning and

Sanitizing section of this manual.

Cleaning and Sanitizing Nozzle

1. Disconnect power, so as to not activate valve while cleaning.

2. Remove outer nozzle by twisting clockwise and pulling

down.

A

A

A. Front Panel

B. Water/Syrup Valves

3. Rinse nozzle with warm water.

4. Thoroughly wash the nozzle using a clean soft cloth and

cleaning solution described on previous page.

5. Using the nozzle brush (Lancer PN: 22-0017) included with

the unit and cleaning solution described on the previous

page, thoroughly clean the vent located on the nozzle.

A. Nozzle Vent

6. Immerse the nozzle in sanitizing solution and let sit for

fteen (15) minutes.

7. Set nozzle aside and let air dry. DO NOT rinse with water

after sanitizing.

8. Using a soft, clean cloth and cleaning solution, clean the

nozzle injectors.

9. Using a soft, clean cloth, sanitize the nozzle injectors and

let air dry.

10. Reconnect nozzle.

11. Connect power.

12. Taste the drink to verify that there is no o-taste. If o-taste

is found, sanitize the nozzle and nozzle injectors again.

! CAUTION

Following sanitization, rinse with end-use product

until there is no aftertaste. Do not use a fresh water

rinse. This is a NSF requirement. Residual sanitizing

solution left in the system creates a health hazard.

12

Page 13

Cleaning and Sanitizing Syrup Lines - BIB

1. Disconnect syrup lines from BIB’s

2. Place syrup lines, with BIB connectors, in a bucket of warm

water.

3. Activate each valve to ll the lines with warm water and

ush out syrup remaining in the lines.

4. Prepare Cleaning Solution described above.

5. Place syrup lines, with BIB connectors, into cleaning

solution.

6. Activate each valve until lines are lled with cleaning

solution then let stand for ten (10) minutes.

7. Flush out cleaning solution from the syrup lines using clean,

warm water.

8. Prepare Sanitizing Solution described above.

9. Place syrup lines into sanitizing solution and activate each

valve to ll lines with sanitizer. Let sit for ten (10) minutes.

10. Reconnect syrup lines to BIB’s and draw drinks to ush

solution from the dispenser.

11. Taste the drink to verify that there is no o-taste. If o-taste

is found, ush syrup system again.

! CAUTION

Following sanitization, rinse with end-use product

until there is no aftertaste. Do not use a fresh water

rinse. This is a NSF requirement. Residual sanitizing

solution left in the system creates a health hazard.

TROUBLESHOOTING

TROUBLE CAUSE REMEDY

Water leakage around nozzle. 1. O-ring is damaged or missing. 1. Replace o-ring.

Miscellaneous leakage. 1. Gap between parts.

2. Damaged or improperly installed o-rings.

1. Tighten appropriate retaining screws

2. Replace or adjust appropriate o-rings

Insucient water ow. 1. Insucient incoming supply water

pressure.

2. Shuto on mounting block not fully open.

3. Foreign debris in water ow control.

4. Foreign debris in water pump strainer

Insucient syrup ow. 1. Insucient CO2 pressure to BIB pumps.

2. Out of CO2 .

3. Shuto on mounting block not fully open.

4. Foreign debris in syrup ow control.

5. Bad syrup pump.

Erratic ratio. 1. Incoming water and/or syrup supply not at

minimum owing pressure.

2. Foreign debris in water and/or syrup ow

controls.

1. Verify incoming supply water pressure is a

minimum of 25 psi (0.172 MPa).

2. Open shuto fully.

3. Remove water ow control from upper

body and clean out any foreign material to

ensure smooth free spool movement.

4. Remove water pump strainer and clean.

1. Adjust CO2 pressure to 80 psi (0.550 MPa)

[minimum 70 psi (0.480 MPa)] for BIB

pumps.

2. Replace CO2 tank/rell.

3. Open shuto fully.

4. Remove syrup ow control form upper

body and clean out any foreign material to

ensure smooth free spool movement.

5. Replace BIB pump.

1. Check pressure and adjust

2. Remove ow controls from upper body and

clean out any foreign material to ensure

smooth free spool movement.

13

Page 14

TROUBLE CAUSE REMEDY

No syrup dispensed 1. Water and syrup shutos on mounting

block not fully open.

2. Electric current not reaching valve.

3. Improper or inadequate water or syrup

supply.

4. Transformer Failure

5. Bad valve solenoid(s)

Water only dispensed; no

syrup; or syrup only dispensed,

no water

1. Water or syrup shuto on mounting block

not fully open.

2. Improper or inadequate water or syrup

ow.

3. BIB supply too far from dispenser.

4. CO2 pressure too low.

5. Stalled or inoperative BIB pump

6. Kinked line.

1. Open shuto fully.

2. Check electric current supplied to valve.

If current is adequate, check solenoid coil

and switch, and replace if necessary.

3. Remove valve from mounting block and

open shutos slightly and check water and

syrup ow. If no ow, check dispenser for

freeze-up or other problems

4. Reset transformer circuit breaker. If

breaker trips again check for pinched wire

harness at backblocks

5. Replace Solenoid(s)

1. Open shuto fully.

2. Remove valve from mounting block, open

shutos slightly and check water and

syrup ow. If no ow, check dispenser for

freeze-up or other problems. Ensure BIB

connection is engaged.

3. Check that BIB supply is within six (6) feet

of the dispenser.

4. Check the CO2 pressure to the pump

manifold to ensure it is between 70 and 80

psi (0.483 and 0.552 MPa).

5. Check CO2 pressure and/or replace pump.

6. Remove kink or replace line.

Syrup only dispensed. No

water, but CO2 gas dispensed

with syrup.

Excessive foaming. 1. Incoming water or syrup temperature too

Warm drinks. 1. Restricted airow.

1. Improper water ow to dispenser.

2. Carbonator pump motor has timed out.

high.

2. CO2 pressure too high.

3. Water ow rate too high.

4. Nozzle not installed correctly.

5. Nozzle and nozzle injectors not clean.

6. Air in BIB lines.

7. Poor quality ice.

8. High beverage temperature.

2. Dispenser connected to hot water supply.

3. Dispenser capacity exceeded.

1. Check for water ow to dispenser (see

Insucient Water Flow on previous page).

2. Reset by turning the unit OFF and then

ON.

1. Correct prior to dispenser. Consider larger

dispenser or pre-cooler.

2. Adjust CO2 pressure downward, but not

less than 70 psi (0.483 MPa).

3. Re-adjust and reset ratio. Refer to “Adjust

Water Flow Rate & Syrup/Water Ratio”

Section.

4. Remove and reinstall properly.

5. Remove nozzle and clean injectors.

6. Bleed air from BIB lines.

7. Check quality of ice used in drink.

8. Check refrigeration system.

1. Check clearances around sides, top, and

inlet of unit. Remove objects blocking

airow through grill.

2. Switch to cold water supply.

3. Add pre-cooler or replace with larger

dispenser.

14

Page 15

TROUBLE CAUSE REMEDY

Circuit breaker tripping. 1. Valve wire harness shorted to itself or to

faucet plate.

2. PCB is bad.

3. Secondary wire harness is bad.

4. Transformer failure.

Handle feels loose during

operation

1. Defective or broken handle return spring 1. Un-thread two screws in Faucet Hous-

1. Detect short by disconnecting input fasten

to keylock and single pin connector.

Restore power if breaker doesn’t trip.

Then valve wire harness is shorted. If OK,

reconnect.

2. Detect short by disconnecting J1

connector (24 VAC input) from PCB.

Restore power, if breaker doesn’t trip.

Then replace PCB. If breaker does trip,

then PCB is OK. Reconnect J1 connector.

3. If it does not trip, locate short in secondary

harness between transformer, PCB, and

valve wire harness.

4. Detect short by disconnecting both

transformer fastens and restore power. If

breaker does trip, replace transformer.

ing Assembly and replace upper nozzle/

handle assembly.

2. Remove handle pin then slide up on

handle to replace spring. Re-align the

handle, cam, and actuator then reinstall

handle pin.

BIB pump does not operate

when dispensing valve opened.

BIB pump operated, but no

ow.

BIB pump continues to operate

when bag is empty.

BIB pump fails to restart after

bag replacement.

BIB pump fails to restart when

dispensing valve is closed.

1. Out of CO2, CO2 not turned on, or low CO2

pressure.

2. Out of syrup.

3. BIB connector not tight.

4. Kinks in syrup or gas lines.

5. Bad BIB Pumps.

1. Leak in syrup inlet or outlet line.

2. Defective BIB pump check valve.

1. Leak in suction line.

2. Leaking o-ring on pump inlet tting.

1. BIB connector not on tight.

2. BIB connector is stopped up.

3. Kinks in syrup line

4. Bad BIB Pumps.

1. Leak in discharge line or ttings.

2. Empty BIB.

3. Air leak on inlet line or bag connector.

1. Replace CO2 supply, turn on CO2

supply, or adjust CO2 pressure to 70-80 psi

(0.483-0.552 MPa)

2. Replace syrup supply.

3. Fasten connector tightly.

4. Straighten or replace lines.

5. Replace BIB pump.

1. Replace line.

2. Replace BIB pump

1. Replace line.

2. Replace o-ring.

1. Tighten BIB connector.

2. Clean out or replace BIB connector.

3. Straighten or replace line.

4. Replace BIB pump.

1. Repair or replace discharge

2. Replace BIB.

3. Repair or replace.

Low or no carbonation. 1. Low or no CO2.

2. Excessive water pressure.

3. Worn or defective carbonator pump.

1. Check CO2 supply. Adjust CO2 pressure to

70 psi (0.483 MPa).

2. Water regulator should be set at 65 psi

(0.448 MPa)

3. Replace carbonator pump.

15

Page 16

ILLUSTRATIONS AND PART LISTINGS

Main Unit Assembly

21

19

16

17

18

09

01

11

03

02

04

10

08

14

12 x4

15

13 x4

20

05

06

07

Item Part No. Description

01 30-13230 Cup Rest, BBT

02 01-2994 Drain Fitting, 1/2 NPT

03 02-0677 Seal, Washer, Drain

04 54-0554 Drip Tray Assy, BBT

05 04-1710/01 Washer, Flat

06 01-2991 Coupling, Female

07 82-5000 Drain Kit, BBT

08 05-3719/01 Splash Plate, BBT

09 82-5290 Faucet Housing Assy, BBT

10 54-0557 Nozzle Assy, BBT

16

11 19-0560 Valve Assy, CVM, Water, 2.0 oz

12 19-0559 Valve Assy, CVM, Syrup, 2.0 oz

13 82-2317/01 Mounting Block Assy

14 52-3954 Lever Harness, BBT

15 52-3955 Solenoid Harness, BBT

16 64-5136 PCB Assy, Main Controller

17 52-3953 Power Harness

18 82-5291 Button Panel Assy, BBT

19 12-0666 RGBW LED Strips

20 05-3720 Rear Hatch, BBT

21 82-5272 Rear Jar, BBT

Page 17

Faucet Housing Assembly

01

02

09

04

03

06

05

07

08

Item Part No. Description

01 05-3756 Faucet Handle, BBT

02 05-3757 Faucet Cam, BBT

03 10-1019 Actuator Pin

04 04-0549 Screw, 6-19 x 0.625

05 05-3765 Washer

06 05-3759 Upper Faucet Housing, BBT

07 03-0530 Faucet Spring

08 82-5297 Actuator Assembly w/ Magnet

09 64-5028 PCB Assembly, Hall Sensor

10 04-0699 Screw, 6-19 x 0.250

10

17

Page 18

Button Panel Assembly

01 x4

02

03

Item Part No. Description

01 04-1639/01 Screw, 4-20 x 0.250

02 52-3956 Buttons Harness, BBT

03 05-3726 Button Panel, BBT

04 82-5298 Button PCB Assembly

18

04

Page 19

Wiring Diagram

19

Page 20

DIP Switch Settings

NOTE

The following table shows the DIP switch settings that correlate the 16 colors and Barrilitos brand names available on

the Barrilitos Tower.

DIP Switch Cong Color/Brand Name

Mango Lime **Switch 1 Default Position**

Pear Cucumber **Switch 2 Default Position**

Pineapple **Switch 3 Default Position**

Strawberry Hibiscus **Switch 4 Default Position**

Passionfruit Orange

Watermelon

Guava

Horchata

Tamarindo

Lemonade

Lime

Blueberry

Red

20

Green

Blue

White

Page 21

Plumbing Diagram

S4

S3 S2

S4

S1

S3

PW

S2 S1

Item Description

S1 Syrup Line 1

S2 Syrup Line 2

S3 Syrup Line 3

S4 Syrup Line 4

PW Plain Water Line

Dispenser Disposal

To prevent possible harm to the environment from improper disposal, recycle the unit

by locating an authorized recycler or contact the retailer where the product was

purchased. Comply with local regulations regarding disposal of the refrigerant and

insulation.

21

Page 22

Lancer Corp.

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Loading...

Loading...