Page 1

Bar Bridge

DRAFT

Lancer Corporation

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

Operation Manual

“Lancer” is the registered trademark of Lancer © 2014 by Lancer, all rights reserved.

Technical Support/Warranty

800-729-1550

custserv@lancercorp.com

lancercorp.com

PN: 28-0941/01

Page 2

TABLE OF CONTENTS

DRAFT

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product and

should be handed over to the operator after the installation and

preserved for any further consultation that may be necessary.

Please read carefully the guidelines and warnings contained

herein as they are intended to provide the user with essential

information for the continued safe use and maintenance of the

product. In addition, it provides GUIDANCE ONLY to the user

on the correct services and site location of the unit.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with

up-to-date safety and hygiene knowledge and practical experience, in accordance with current regulations.

IMPORTANT SAFETY INSTRUCTIONS..........................3

Intended Use..............................................................3

Power Warning...........................................................3

CO2 Warning...............................................................3

Water Notice...............................................................3

SPECIFICATIONS AND FEATURES...............................4

General Systems Overview........................................5

PRE-INSTALLATION CHECKLIST...............................5-6

INSTALLATION................................................................6

Unpacking the Dispenser............................................6

Selecting/Preparing a Counter Location.....................6

Dispenser/Chiller Installation...................................7-8

Installing Remote Syrup Pumps.................................9

Installing CO2 Supply...........................................10-11

Connecting to Syrup Supply......................................11

Dispenser Setup..................................................11-12

Adjust Water Flow Rate & Syrup/Water Ratio.....12-13

Merchandiser Installation..........................................13

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly

inspected before shipment. At the time of shipment, the

carrier accepts responsibility for the unit. Upon receiving the

unit, carefully inspect the carton for visible damage. If

damage exists, have the carrier note the damage on the freight

bill and le a claim with carrier. Responsibility for damage to the

dispenser lies with the carrier.

MAINTENANCE.............................................................14

Scheduled Maintenance...........................................14

CLEANING AND SANITIZING.......................................14

General Information..................................................14

Cleaning and Sanitizing Solutions............................15

Cleaning and Sanitizing Product Lines.....................15

Cleaning and Sanitizing Nozzle...........................15-16

TROUBLESHOOTING...............................................16-18

DISPENSER DISPOSAL................................................18

ILLUSTRATIONS AND PART LISTINGS.......................19

Main Unit Assembly..................................................19

Unit Plumbing Diagram.............................................20

Unit Wiring Diagram..................................................21

READ ALL SAFETY INSTRUCTIONS BEFORE USING THIS UNIT.

This manual contains important safety information and all applicable safety precautions must be observed. To reduce

the risk of re, electric shock, damage to the equipment or personal injury when using this unit all instuctions/warnings

on the product being used must be followed:

! WARNING

Text following the Warning signal indicates a

hazardous situation, which if not avoided, will result

in death or serious injury. Be sure to read all Warning

statements before proceeding with the installation.

! CAUTION

Text following the Caution signal indicates a

hazardous situation, which if not avoided, could result

in death or serious injury. Be sure to read the Caution

statements before proceeding with the installation

2

SAFETY NOTICES

! ATTENTION

Text following the Attention signal addresses a

situation that if not followed could potentially damage

the equipment. Be sure to read the Attention

statements before proceeding

NOTE

Text following the Note signal provides you with

information that may help you more effectively perform

the installation procedures within this manual.

Disregarding information will not cause damage or

injury, however it may limit the performance of the

dispenser.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

DRAFT

! Intended Use F Power

• The dispenser is for indoor use only

• This appliance is intended to be used in commercial

applications such as restaurants or similar.

• This appliance should not be used by children or

inrm persons without supervision.

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

• This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

• Cleaning and user maintenance shall not be

performed by children without supervision.

• This unit is not a toy and children should be advised

not to play with the appliance.

• The min/max ambient operating temperature for the

dispenser is 4°C to 32°C (40°F to 90°F).

• Do not operate unit below minimum ambient operation

conditions.

• Should freezing occur, cease operation of the unit and

contact authorized service technician.

• The maximum tilt for safe operation is 5°.

• This appliance must be installed and serviced by a

professional.

5 Carbon Dioxide (CO2)

• WARNING: Carbon Dioxide (CO

noncombustible gas with a light pungent odor. High

percentages of CO2 may displace oxygen in the

blood.

• WARNING: Prolonged exposure to CO

Personnel exposed to high concentrations of CO2 gas

will experience tremors which are followed by a loss

of consciousness and suffocation.

• WARNING: If a CO

ventilate the contaminated area before attempting to

repair the leak.

• WARNING: Strict attention must be observed in the

prevention of CO2 gas leaks in the entire CO2 and soft

drink system.

gas leak is suspected, immediately

2

) is a colorless,

2

can be harmful.

2

• Follow all local electrical codes when making

connections.

• Check the dispenser serial number plate for

correct electrical requirements of unit. DO NOT plug

into a wall electrical outlet unless the current shown

on the serial number plate agrees with local current

available.

• Each dispenser must have a separate electrical

circuit.

• DO NOT use extension cords with this unit.

• DO NOT ‘gang’ together with other electrical devices

on the same outlet.

• WARNING: Always disconnect electrical power to the

unit to prevent personal injury before attempting any

internal maintenance.

• The resettable breaker switch should not be used as

a substitute for unplugging the dispenser from the

power source to service the unit.

• Only qualied personnel should service internal

components of electrical control housing.

• WARNING: Make sure that all water lines are tight and

units are dry before making any electrical connections

• If this dispenser is installed in an area that is

susceptible to ±10% variation of the nominal line

voltage, consider installing a surge protector or similar

protection device.

! Water Notice

• Provide an adequate, potable water supply. Water

pipe connections and xtures directly connected to

a potable water supply must be sized, installed, and

maintained according to federal, state, and local

codes.

• The water supply line must be at least a 9.525 mm

(3/8 inches) pipe with a minimum of 20 PSI (0.137

MPA) line pressure, but not exceeding a maximum of

50 PSI (0.345 MPA). Water pressure exceeding 50

PSI (0.345 MPA) must be reduced to 50 PSI (0.345

MPA).

• Use a lter in the water line to avoid equipment

damage and beverage off-taste. Check the water lter

periodically, as required by local conditions.

• CAUTION: The water supply must be protected by

means of an air gap, a backow prevention device

(located upstream of the CO2 injection system)

or another approved method to comply with NSF

standards. A leaking inlet water check valve will

allow carbonated water to ow back through the pump

when it is shut off and contaminate the water supply.

• CAUTION: Ensure the backow prevention device

complies with ASSE and local standards. It is the

responsibility of the installer to ensure compliance.

3

Page 4

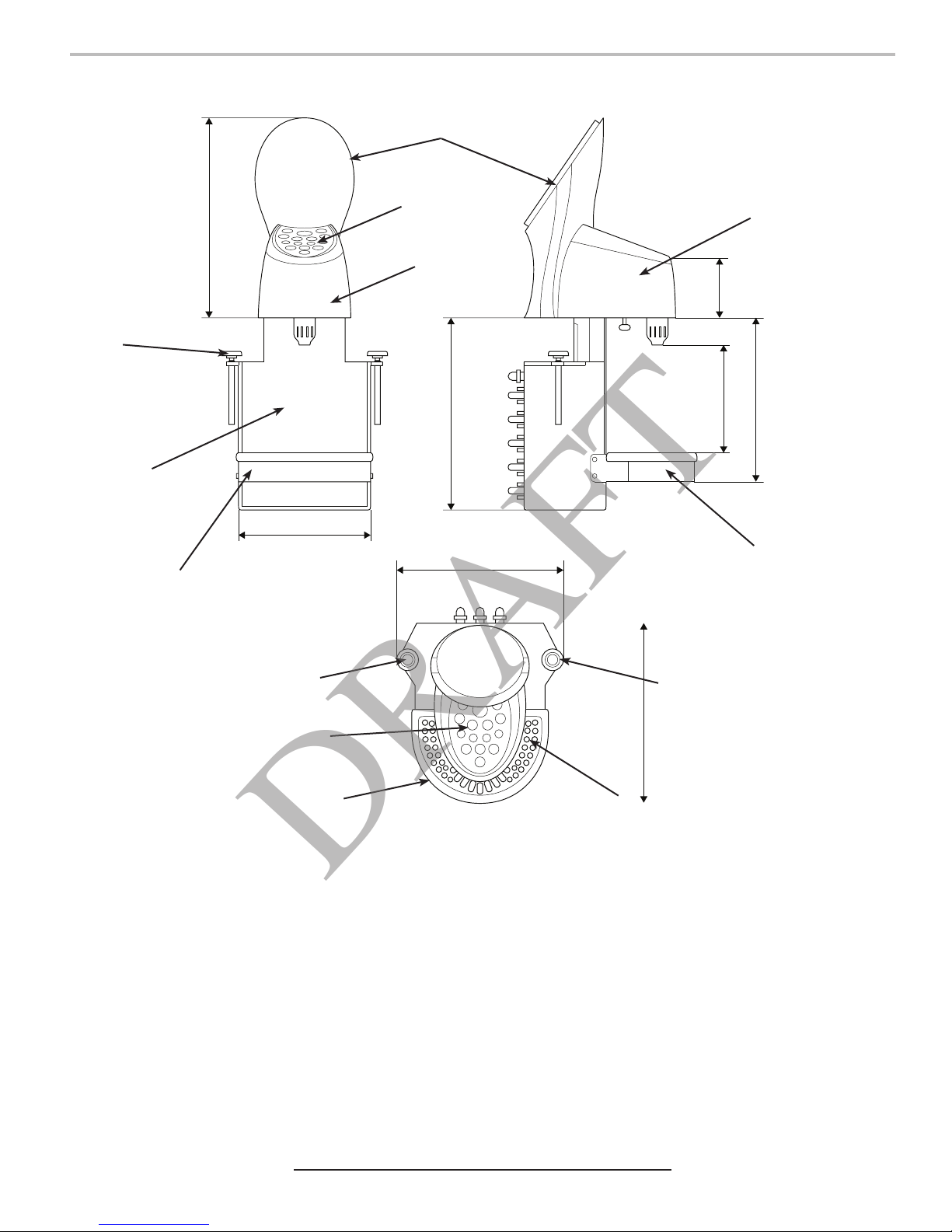

SPECIFICATIONS AND FEATURES

DRAFT

A

G

361.5 mm

D

C

244 mm

E

F

344.5 mm

310 mm

F

110 mm

195.23 mm 295.24 mm

C

G

E

C

DIMENSIONS

Width: 310 mm (XX inches)

Depth: 335.8 mm (XX inches)

Height: 706 mm (XX inches)

WEIGHT

Shipping: XX kg (XX lbs)

Operating: XX kg (XX lbs)

ELECTRICAL

XXX VAC / XX Hz / X Amps

FLOW RATE

1.5 ounces per second

4

This unit emits a sound pressure level below 70 dB

G

A. Tower

B. Drip Plate

C. Drip Tray

D. Splash Housing

E. Keypad

B

PLAIN WATER SUPPLY

Min Flowing Pressure: 20 PSIG (0.137 MPA)

Max Static Pressure: 50 PSI (0.345 MPA)

CARBON DIOXIDE (CO2) SUPPLY

Min Pressure: 70 PSIG (0.483 MPA)

Max Pressure: 80 PSIG (0.552 MPA)

FITTINGS

Carb Water Recirc.: 9.5 mm (3/8 inch) barb

Plain Water Inlet: 9.5 mm (3/8 inch) barb

Brand Syrup Inlets: 9.5 mm (3/8 inch) barb

Flavor Injector Inlets: 6.4 mm (1/4 inch) barb

CO2 Inlet: 9.5 mm (3/8 inch) barb

F. Plastic Housing

G. Clamp

Page 5

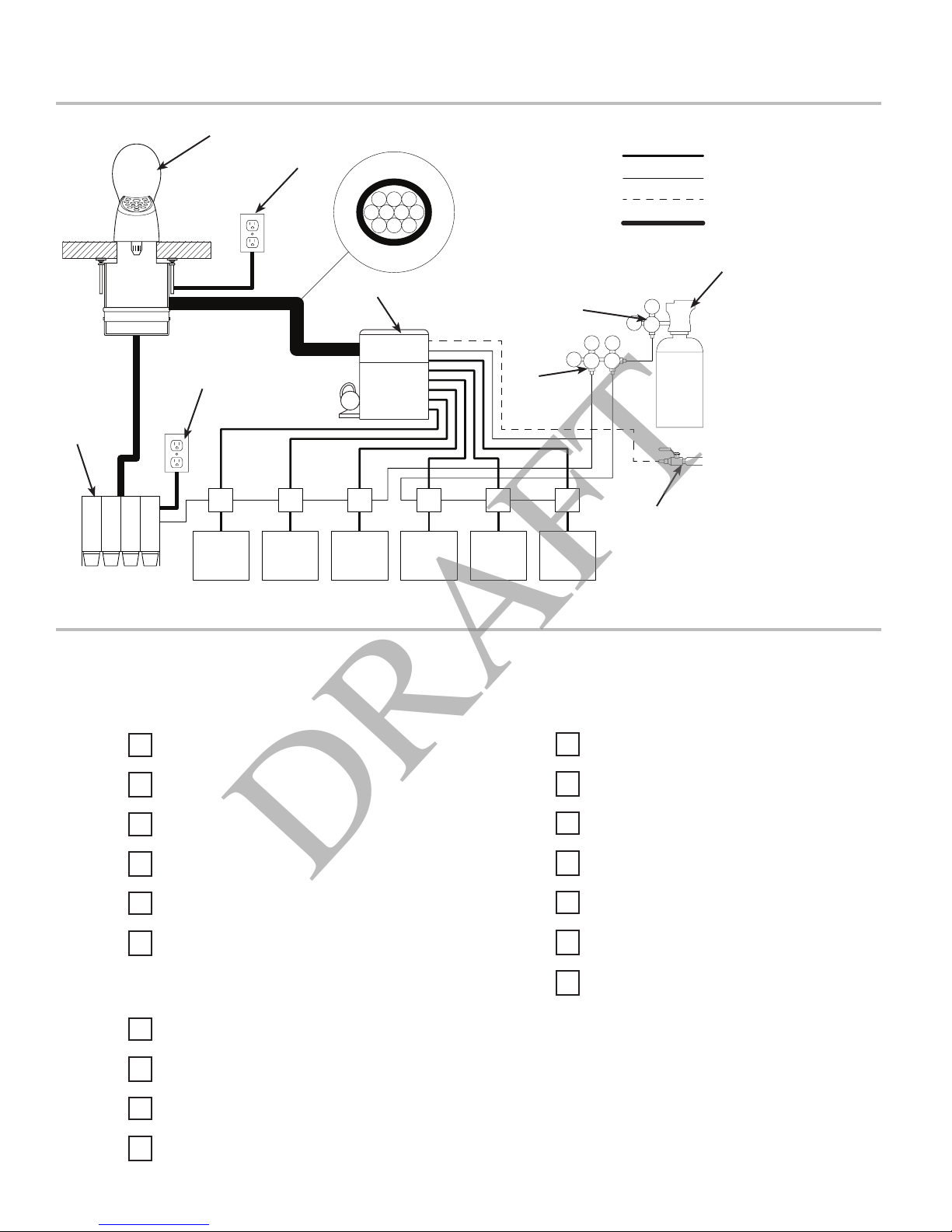

General System Overview

DRAFT

F

E

123

4 567

8910

G

E

K

H H H H HH

I I I JJ J

1. Brand Syrup 1

2. Brand Syrup 2

3. Brand Syrup 3

4. Brand Syrup 4

5. Carb Water Line

6. Carb Water Return

7. Brand Syrup 5

8. Brand Syrup 6

9. Plain Water Line

10. N/A

C

D

Syrup Line

CO2 Line

Plain Water Line

Electrical

B

A. Water Source

357575

A

B. CO2 Source

C. High Pressure CO2

Regulator

D. Low Pressure CO2

Regulator Manifold

E. Electrical Outlet

F. Tower (Dispenser)

G. Recirculation Unit

H. Syrup Pump

I. BIB Non-Diet Syrup

Containers

J. BIB Diet Syrup

Containers

K. Flavour Extension

Syrup Module

PRE-INSTALLATION CHECKLIST

TOOLS REQUIRED:

Oetiker Pliers

Tubing Cutters

Wrench

Slotted Screwdriver

Phillips Screwdriver

Drill

BIB SYSTEM:

BIB Rack

BIB Syrup Boxes

BIB Regulator Set

POST MIX ACCESSORIES:

High Pressure CO2 Regulator

Low Pressure CO2 Regulator Manifold

CO2 Supply

Chain for CO2 Tank

Beverage Dispenser

Beverage Tubing

Oetiker Clamp Fittings

BIB Connectors

5

Page 6

BEFORE INSTALLATION:

DRAFT

Do you have enough space to install the

dispenser?

CONSIDER LOCATION OF THE

FOLLOWING BEFORE THE INSTALL:

Water Supply Lines

Is the countertop level?

Can the countertop support the weight of

the dispenser?

Is dispenser located away from direct

sunlight or overhead lighting?

Electrical Outlet

Heating and Air Conditioning Ducts

Read This Manual

This manual was developed by Lancer Corporation as a reference guide for the owner/operator and

installer of this dispenser. Please read this manual before installation and operation of this

dispenser. Please see pages XX-XX for troubleshooting or service assistance. If the service cannot

be corrected please call your Service Agent or Lancer Customer Service. Always have your model

and serial number available when you call.

INSTALLATION

Unpacking the Dispenser

1. Cut package banding straps and remove.

2. Open the box and carefully remove the dispenser from

the corrugated shipping carton and place on a at surface

taking care to not scratch the plastic covers.

3. Leave the merchandiser in the box until the installation of

the dispenser is complete.

NOTE

Inspect unit for concealed damage. If evident, notify

deliveringcarrierandleaclaimagainstthesame.

! ATTENTION

DO NOT LAY UNIT ON ITS SIDE OR BACK

Selecting/Preparing a Counter Location

1. Select a location that is in close proximity to a properly

grounded electrical outlet and a water supply that meets the

requirements shown in the Specications section found on

page 4.

! ATTENTION

Inspect the counter location where the unit is to be

installed. Verify the selected counter is strong enough

to safely support the weight of the installed unit. The

ideal counter for installation should measure at least

25 mm (1 in) thick (Maximum of 60 mm, 2.36 in).

6

2. Select a location for the remote chiller system or carbonator

(if nessesary), syrup pumps, CO2 tank, product containers,

avour syrup module, and water lter (recommended).

3. Once the location for the dispenser and the remote chiller

have been determined, route the 10-line python and cut/

trim to length.

Page 7

Dispenser/Chiller Installation

DRAFT

1. Connect appropriate tubing for the soda recirculation lines,

located in the 10-line python and routed from the remote

chiller, to the unit inlets. Repeat for plain water line (See the

Plumbing Diagram on page 20 for reference).

D

C

B

2. Connect appropriate tubing for all syrup lines located in the

10-line python and routed from the remote chiller, to the unit

inlets.

3. Connect appropriate tubing for all avour lines, routed from

the remote avour syrup module, to the unit inlets.

4. Once all connections to the unit have been made, loosen

the clamp nuts and lower the two (2) clamps on either side

of the unit.

A

A

A. Water Inlet

B. Syrup Inlet

C. Tubing

D. Oetiker Pliers

6. Using a wrench, raise the two (2) clamps underneath the

counter and tighten the clamp nuts to secure the unit in

place.

C

B

7. Remove the drip plate from the drip tray.

8. Remove the drip tray from the drip bracket.

9. Using a screwdriver, remove the drip bracket by unscrewing

the four (4) side screws (two (2) on each side).

A. Counter

B. Wrench

C. Clamp

A

A

B

A

5. Slide the unit onto the counter in the designated location.

A

A. Clamp Nut

B. Clamp

B

C

B

C

10. Remove the splash housing by removing the two (2) front

screws. Pull forward at the bottom of the plate to release

from the three (3) locating tabs at the top of the housing.

A

A. Unit

B. Drip Bracket

C. Screwdriver

B

A. Front of Unit

B. Screwdriver

A. Unit

B. Counter

C. Clamp

7

Page 8

11. Unscrew the key lock rod located underneath the keypad

DRAFT

and behind the nozzle.

15. Plug in power cord to power supply then route power supply

cord to the designated grounded electrical outlet.

! ATTENTION

DO NOT pull down on key lock rod, only loosen rod

enough to release the keypad.

A

A. Key Lock Rod

B. Nozzle

12. Once released, gently lift up on the front of the keypad

and slide forward to release from the two (2) locating tabs,

remove the keypad and gently set down on the bar next to

the dispenser.

A

! WARNING

DO NOT PLUG UNIT INTO GROUNDED ELECTRICAL

OUTLET AT THIS TIME. Make sure that all water lines

are tight and unit is dry before making any electrical

connections

A

B

B

A. Power Cord to Unit

B. Power Supply

NOTE

Unit is designed to be supported by a remote chiller

system or remote ice cooled system. Please see the

manufacturer’sspecicationsandinstructionsfor

installation. The following are the instructions for

plumbing the remote chiller system to the tower.

B

A. Keypad

B. Keypad Shroud

13. Remove the keypad shroud by rst removing the two

screws located underneath next to the keylock rod. Then

remove the shroud by sliding up and out and then place on

the bar next to the dispenser.

14. Reattach the keypad using the key lock rod, paying

attention to not over-tighten. This will hold the keypad in

place while setting ow rates.

16. Route appropriate tubing from the syrup pump location to

the syrup inlets at the remote chiller. Repeat for all syrup

connections.

17. Route appropriate tubing from the water source to the water

inlet at the remote chiller and only connect tubing to the

water source.

18. Turn on the water and ush the water line thoroughly.

19. Turn off the water and connect water line to the plain water

inlet at the remote chiller.

20. Route appropriate tubing from the designated CO2 source

to the CO2 inlet at the back of the remote chiller and

connect tubing to inlet.

8

Page 9

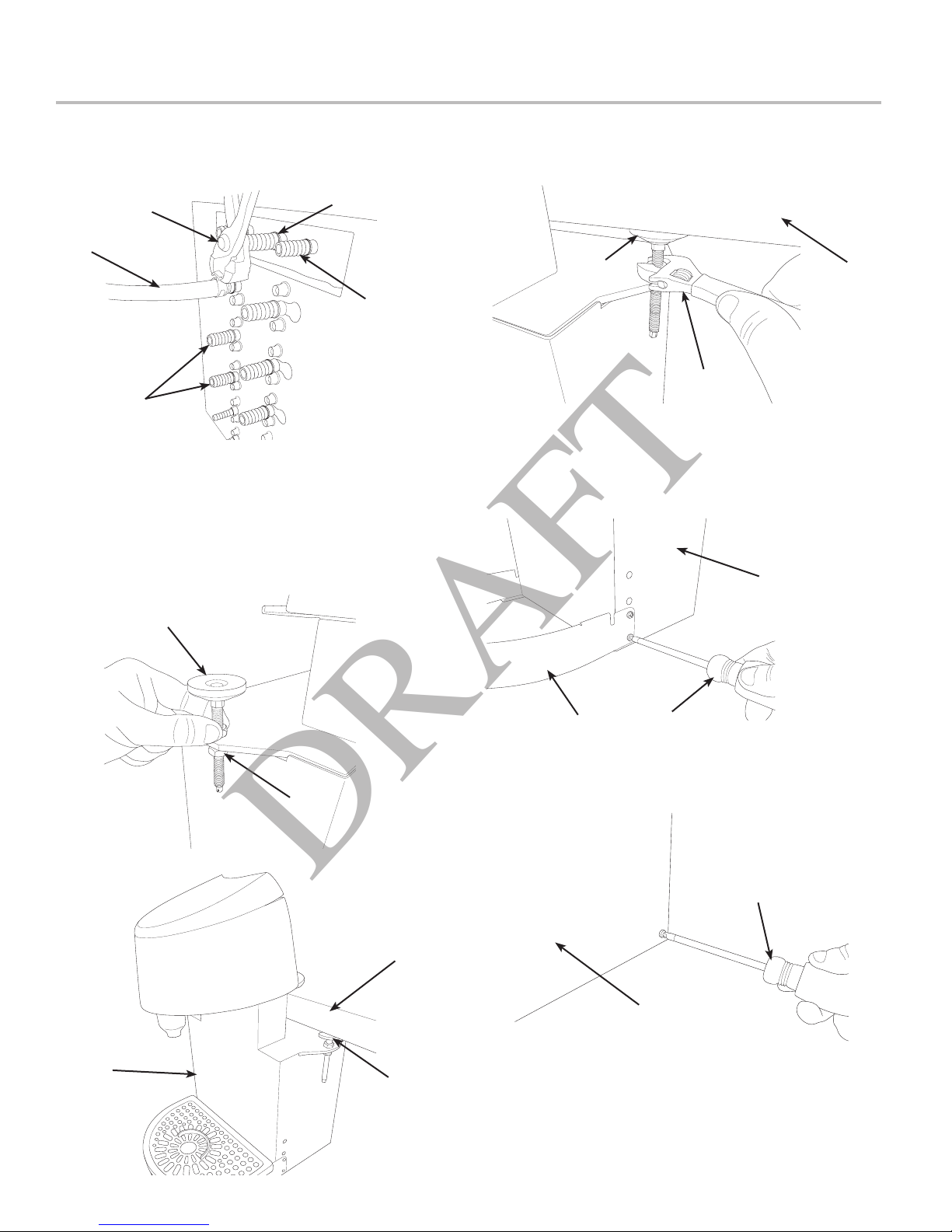

Installing Remote Syrup Pumps

DRAFT

1. Mount pump brackets in pre-determined location.

2. Mount syrup pumps to pump brackets.

B

A

C

3. Measure and cut tubing to length between the pump CO2

inlets, then connect tubing to all pumps.

A. Pump Bracket

B. Syrup Pump

C. CO2 Inlet

5. Cut tubing from CO2 supply to tee tting at syrup pumps

and install another tee tting.

6. Attach line from remote chiller CO2 inlet to tee tting

between syrup pumps and CO2 supply.

D

B

7. Connect tubing from dispenser syrup inlet to the syrup

pump outlet tting. Repeat for each syrup line/pump.

A

A. Tee Fitting

B. Line to Tee at Syrup Pump

C. Line to CO2 Supply

D. Remote Chiller CO2 Inlet

C

B

D

4. Using tubing cutters, cut any pump CO2 supply line and

install tee tting, then route appropriate tubing from the CO2

supply to the tee tting at syrup pumps.

C

B

A

C

A. Syrup Pump

B. CO2 Line

C. Fitting

D. Oetiker Pliers

A. Tee Fitting

B. Line to Syrup Pump

C. Line to CO2 Supply

D. Fitting

B

D

A

B

C

A. Syrup Pump Outlet

B. Syrup Pump

A

C. Fitting

9

Page 10

Installing CO2 Supply

DRAFT

1. Connect high pressure CO2 regulator assembly to CO2

cylinder or bulk system.

! ATTENTION

Before installing regulator, assure that a seal (washer

or o-ring) is present in regulator attachment nut.

A

C

D

B

A. CO2 Regulator

- Thread regulator nut on to tank,

then tighten nut with wrench

2. Connect a 6.35 mm (1/4 in) nut, stem and seal to high

pressure CO2 regulator outlet.

A

B. Outlet

C. Wrench

D. CO2 Supply

A

B

D

A. CO2 Regulator

C

4. Connect tubing routed from the CO2 inlet at the remote

chiller and normal, non-diet syrup pumps to one of the low

pressure CO2 regulator manifold outlets.

5. Connect tubing routed from the diet syrup pumps to the

second outlet of the low pressure CO2 regulator manifold.

B. Fitting

C. Line to CO2 Regulator

Manifold

D. Oetiker Pliers

C

D

B

C

A. CO2 Regulator

B. Wrench

C. 6.35 mm nut, Stem

D. CO2 Supply

3. Route appropriate tubing from the low pressure CO2

regulator manifold location to the 6.35 mm (1/4”) nut, stem

on the high pressure CO2 regulator attached to source and

connect tubing.

! ATTENTION

A dedicated CO2 regulator is required to supply the

CO2 to all normal, non-diet syrup pumps as well as to

all diet syrup pumps.

D

A

A. Line to Non-Diet Syrup

Pumps

B. Line to Diet Syrup Pumps

C. Line to CO2 Regulator

D. CO2 Regulator Manifold

6. Using a wrench, loosen lock nut on high pressure regulator

adjustment screw then using a screwdriver back out lock

nut screw all the way.

B

! WARNING

DO NOT TURN ON CO2 SUPPLY AT THIS TIME

7. Repeat Step 6 for both low pressure regulator adjustment

screws on the regulator manifold

10

Page 11

B

DRAFT

B

A

C

A. CO2 Regulator

B. Wrench

C. Regulator locknut

Connecting to Syrup Supply

1. Install BIB (bag in box) connectors onto the syrup pump

inlet tubing.

! ATTENTION

Use proper connector for syrup manufacturer

A

D

B

A. Syrup Pump Inlet C. BIB Connector

B. Fitting D. Oetiker Pliers

C

A

2. Connect syrup BIBs to connectors. Repeat for each syrup

line/pump and each avor injector line/pump.

A

C

B

A. CO2 Regulator

B. Screwdriver

C. Regulator Adjustment Screw

C

A. Syrup Pump Inlet

B. BIB Connector

C. BIB Syrup Container

Dispenser Setup

1. Turn on the water supply.

2. Verify all Bag-in-Box or Figal tanks contain syrup and check

for leaks.

3. Open the pressure relief valve located on the remote chiller

system by ipping up on the valve cap lever. Hold open

until water ows from the relief valve then close (ip down)

reief valve.

A

A. Carbonator Relief Valve

4. Connect power cord to grounded electrical outlet. Keypad

LEDs will ash in a sequence to validate the electronics and

congure the keypad.

! WARNING

The dispenser must be properly electrically grounded

to avoid serious injury or fatal electrical shock. The

power cord has a three-prong grounded plug. If a

three-hole grounded electrical outlet is not available,

use an approved method to ground the unit. Follow

all local electrical codes when making connections.

Each dispenser must have a separate electrical circuit.

Do not use extension cords. Do not connect multiple

electrical devices on the same outlet.

5. Locate a valve that utilizes plain water brand then close the

syrup line at the backblock for that corresponding valve.

NOTE

Example: Oasis and Schweppes Lemonade both utilize

plain water in their syrups.

11

Page 12

6. Using the keypad, select the brand whose syrup line was

DRAFT

closed in the previous step, then press and hold the pour/

cancel button until a steady ow of water is achieved.

A A

A

9. Turn on CO2 at the source then, using a screwdriver, adjust

the high pressure regulator at the source to 75 PSI (0.517

MPA) then tighten locknut with wrench.

B

A

A

A A

C

C C

E

7. Select the soda button then press and hold the pour/cancel

button until a steady ow of water is achieved.

8. Ensure that the pump deck at the remote chiller is turned off

before turning on the CO2.

B

C

D

A. Brand Buttons

B. Soda Button

C. Flavour Injector Buttons

D. Portion Control Buttons

E. Pour/Cancel Button

10. Adjust the low pressure regulator routed from the normal,

11. Adjust the second low pressure regulator routed from the

12. Select the soda button then press and hold the pour/cancel

13. Reactivate the pump deck at the remote chiller.

14. Repeat Step 12 until a steady ow of soda is achieved.

Adjust Water Flow Rate & Syrup/Water Ratio

NOTE

The refridgeration unit should have been running for at

leastone(1)hourbeforeattemptingtosetowrates

on valves. The drink temperature should be no higher

than40°F(4.4°C)whenowratesareset.Thisisbest

done after the remote chiller has already made an ice

bank.

1. Using a Lancer ratio cup verify water ow rate (5 oz. in 4

sec.) by activating the soda module. Remove the protective

cap for the corresponding valve and use a screwdriver to

adjust if needed.

2. Repeat Step 1 for the plain water brand whose syrup was

3. Open the syrup line at the backblock, closed in the previous

4. Once all the water modules have been calibrated, remove

C

non-diet syrup pumps and remote chiller to 75 PSI (0.517

MPA).

diet syrup pumps to 35 PSI (0.241 MPA).

button until gas out.

closed in the previous section.

section.

nozzle by twisting counter clockwise and pulling down.

A. Regulator Adjustment Screw

B. Adjust to 75 PSI (0.517 MPA)

C. Wrench

C

A

Increase Decrease

D

B

12

C

A. Flow Control

B. Valve Retainer

C. Solenoid

D. Valve Body

B

A

A. Nozzle

B. Clamp

C. Counter

5. Install Lancer syrup seperator (PN 82-3458) in place of

nozzle.

Page 13

B

DRAFT

A

A. Syrup Seperator

B. Counter

6. Turn off the soda and plain water backblocks.

7. Purge each syrup line by selecting the brand and pressing

the pour button, until no air is coming from the lines and a

steady ow is achieved.

8. Turn back on the soda and plain water backblocks.

Merchandiser Installation

1. Unplug power to the unit before installing the merchandiser.

2. Remove keypad from key lock rod and set on bar next to

unit.

3. Remove the merchandiser from the box.

4. Plug in the six (6) pin connector and USB cable to the main

tower.

9. Using a Lancer ratio cup, activate syrup valve and capture

a sample. Verify that the syrup level is even with the water

level. Use a screwdriver to adjust if needed.

A

B

A. Syrup Seperator

B. Ratio Cup

10. Repeat Step 8 for each brand/syrup line then remove the

syrup seperator and reinstall nozzle.

A

A

B

C

A. 6-Pin to Unit

B. 6-Pin to Merchandiser

C. Merchandiser

5. Gently slide the merchandiser onto the unit. A 4 mm (0.15

in) screw will designate the front of the main tower.

! ATTENTION

Careful not to pinch any cables or wires when

installing the merchandiser to the unit.

B

A. Merchandiser

B. Main Tower

C. Counter

6. Using a screwdriver and screws provided, attach the

merchandiser to unit.

7. Reinstall keypad shroud to unit.

8. Reattach keypad to key lock rod/keypad shroud.

9. Reinstall splash housing, drip bracket, drip tray, and drip

plate.

13

Page 14

Scheduled Maintenance

DRAFT

As Needed

Daily

Weekly

Monthly

Every Six Months

• Keep exterior surfaces of dispenser (include drip tray and drip plate) clean using a clean,

damp cloth.

• Remove outer nozzle and rinse well in warm water. DO NOT use soap or detergent. This will

cause foaming and off taste in nished product.

• Using the brush provided and cleaning solution, clean the nozzle injectors. See Cleaning and

Sanitizing Nozzle section on the next page for reference.

• Remove drip plate and drip tray and wash both in cleaning solution.

• With a clean cloth and cleaning solution, wipe off all of the unit’s exterior surfaces and splash

areas. DO NOT USE ABRASIVE SOAPS OR STRONG DETERGENTS. DO NOT USE

AMMONIA BASED PRODUCTS WHEN CLEANING THE SCREEN OR SURROUNDING

PLASTICS.

• Replace the drip plate, drip tray, and nozzle.

• Taste each product for off tastes. If off taste occurs clean and sanitize the unit using the

appropriate procedures outlined in the Cleaning and Sanitizing section of this manual.

• Check the water level in the water bath for the remote chiller (if necessary). Replenish as

required.

• Clean and sanitize the unit using the appropriate procedures outlined in the Cleaning and

Sanitizing section of this manual.

• Clean remote chiller according to manufacturer’s instructions (if necessary).

• Clean the entire exterior of the unit.

CLEANING AND SANITIZING

General Information

• Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized in accordance with NSF guidelines.

The operator of the equipment must provide continuous maintenance as required by this manual and/or state and local health

department guidelines to ensure proper operation and sanitation requirements are maintained.

NOTE

ThecleaningproceduresprovidedhereinpertaintotheLancerequipmentidentiedbythismanual.Ifother

equipment is being cleaned, follow the guidelines established by the manufacturer for that equipment.

• Cleaning should be accomplished only by trained personnel. Sanitary gloves are to be used during cleaning operations.

Applicable safety precautions must be observed. Instruction warnings on the product being used must be followed.

! ATTENTION

• Use sanitary gloves when cleaning the unit and observe all applicable safety precautions.

• DO NOT use a water jet to clean or sanitize the unit.

• DO NOT disconnect water lines when cleaning and sanitizing syrup lines, to avoid contamination.

• DO NOT use strong bleaches or detergents; These can discolor and corrode various materials.

• DO NOT use metal scrapers, sharp objects, steel wool, scouring pads, abrasives, or solvents on the dispenser.

• DO NOT use hot water above 60° C (140° F). This can damage the dispenser.

• DO NOT spill sanitizing solution on any circuit boards. Insure all sanitizing solution is removed from the system.

14

Page 15

Cleaning and Sanitizing Solutions

DRAFT

Cleaning Solution

Mix a mild, non-abrasive detergent (e.g. Sodium Laureth

Sulfate, dish soap) with clean, potable water at a temperature

of 32°C to 43°C (90°F to 110°F). The mixture ratio is one

ounce of cleaner to two gallons of water. Prepare a minimum of

ve gallons of cleaning solution. Do not use abrasive

cleaners or solvents because they can cause permanent

damage to the unit. Ensure rinsing is thorough, using clean,

potable water at a temperature of 90°F to 110°F. Extended

lengths of product lines may require additional cleaning solution.

Sanitizing Solution

Prepare sanitizing solutions in accordance with the

manufacturer’s written recommendations and safety guidelines.

The solution must provide 50 to 100 parts per million (PPM)

chlorine (e.g. Sodium Hypochlorite or bleach). A minimum of ve

gallons of sanitizing solution should be prepared. Any sanitizing

solution may be used as long as it is prepared in accordance

with the manufacturer’s written recommendations and safety

guidelines, and provides 50 to 100 parts per million (PPM)

chlorine.

! CAUTION

If a powder sanitizer is used, dissolve it thoroughly with hot water prior to adding to the product system. Ensure

sanitizing solution is removed from the dispenser as instructed.

Cleaning and Sanitizing Product Lines

1. Disconnect product lines from BIB’s or other product supply.

2. Place product lines, with BIB connectors, in a bucket of

warm water.

3. Activate each valve to ll the lines with warm water and

ush out product remaining in the lines.

4. Prepare Cleaning Solution described above.

5. Place product lines, with BIB connectors, into cleaning

solution.

6. Activate each valve until lines are lled with cleaning

solution then let stand for ten (10) minutes.

7. Flush out cleaning solution from the syrup lines using clean,

warm water.

8. Prepare Sanitizing Solution described above.

9. Place product lines into sanitizing solution and activate

each valve to ll lines with sanitizer. Let sit for ten (10)

minutes.

10. Reconnect product lines to BIB’s and draw drinks to ush

solution from the dispenser.

11. Taste the drink to verify that there is no off-taste. If off-taste

is found, ush product system again.

! CAUTION

Following sanitization, rinse with end-use product

until there is no aftertaste. Do not use a fresh water

rinse. This is a NSF requirement. Residual sanitizing

solution left in the system creates a health hazard.

Cleaning and Sanitizing Nozzle

1. Disconnect power, so as to not activate valve while

cleaning.

2. Remove outer nozzle by twisting counter clockwise and

pulling down.

C

A

A. Nozzle

B. Clamp

C. Counter

3. Rinse nozzle with warm water.

4. Wash nozzle with cleaning solution then immerse in

sanitizing solution and let sit for fteen (15) minutes.

5. Set nozzle aside and let air dry. DO NOT rinse with water

after sanitizing.

6. Using the brush provided and cleaning solution, clean the

nozzle injectors.

B

B

A

A. Nozzle Injectors

B. Nozzle Brush

C. Counter

D. Clamp

7. Using the brush provided, sanitize the nozzle injectors and

let air dry.

8. Reconnect nozzle.

C

D

15

Page 16

9. Connect power.

DRAFT

10. Taste the drink to verify that there is no off-taste. If off-taste

is found, sanitize the nozzle and nozzle injectors again.

! CAUTION

Following sanitization, rinse with end-use product

until there is no aftertaste. Do not use a fresh water

rinse. This is a nsf requirement. Residual sanitizing

solution left in the system creates a health hazard.

TROUBLESHOOTING

TROUBLE CAUSE REMEDY

Miscellaneous leakage. 1. Gap between parts.

2. Damaged or improperly installed o-rings.

Insufcient water ow. 1. Insufcient incoming supply water

pressure.

2. Shutoff on mounting block not fully open.

3. Foreign debris in water ow control.

4. Foreign debris in water pump strainer

Insufcient product ow. 1. Insufcent CO2 pressure to BIB pumps.

2. Out of CO2 .

3. Shutoff on mounting block not fully open.

4. Foreign debris in product ow control.

5. Bad product pump.

Erratic ratio. 1. Incoming water and/or product supply not

at minimum owing pressure.

2. Foreign debris in water and/or product ow

controls.

1. Tighten appropriate retaining screws

2. Replace or adjust appropriate o-rings

1. Verify incoming supply water pressure is a

minimum of 25 PSI (0.172 MPA).

2. Open shutoff fully.

3. Remove water ow control from upper

body and clean out any foreign material to

ensure smooth free spool movement.

4. Remove water pump strainer and clean.

1. Adjust CO2 pressure to 80 PSI (0.550

MPA) [minimum 70 PSI (0.480 MPA)] for

BIB pumps.

2. Replace CO2 tank/rell.

3. Open shutoff fully.

4. Remove product ow control form upper

body and clean out any foreign material to

ensure smooth free spool movement.

5. Replace BIB pump.

1. Check pressure and adjust

2. Remove ow controls from upper body and

clean out any foreign material to ensure

smooth free spool movement.

No product dispensed 1. Water and product shutoffs on mounting

block not fully open.

2. The key switch on an electric valve is in

the OFF position.

3. Electric current not reaching valve.

4. Improper or inadequate water or product

supply.

5. Transformer Failure

6. Bad valve solenoid(s)

16

1. Open shutoff fully.

2. Turn key switch to ON position.

3. Check electric current supplied to valve.

If current is adequate, check solenoid coil

and switch, and replace if necessary.

4. Remove valve from mounting block and

open shutoffs slightly and check water and

syrup ow. If no ow, check dispenser for

freeze-up or other problems

5. Reset transformer circuit breaker. If

breaker trips again check for pinched wire

harness at backblocks

6. Replace Solenoid(s)

Page 17

TROUBLE CAUSE REMEDY

DRAFT

Water only dispensed; no

product; or product only

dispensed, no water

Syrup only dispensed. No

water, but CO2 gas dispensed

with syrup.

Excessive foaming. 1. Incoming water or syrup temperature too

1. Water or product shutoff on mounting block

not fully open.

2. Improper or inadequate water or product

ow.

3. BIB supply too far from dispenser.

4. CO2 pressure too low.

5. Stalled or inoperative BIB pump

6. Kinked line.

1. Improper water ow to dispenser.

2. Carbonator pump motor has timed out.

high.

2. CO2 pressure too high.

3. Water ow rate too high.

4. Nozzle and diffuser not installed.

5. Nozzle and diffuser not clean.

6. Air in BIB lines.

7. Poor quality ice.

8. High beverage temperature.

1. Open shutoff fully.

2. Remove valve from mounting block, open

shutoffs slightly and check water and

syrup ow. If no ow, check dispenser for

freeze-up or other problems. Ensure BIB

connection is engaged.

3. Check that BIB supply is within six (6) feet

of the dispenser.

4. Check the CO2 pressure to the pump manifold to ensure it is between 70 and 80 PSI

(0.483 and 0.552 MPA).

5. Check CO2 pressure and/or replace pump.

6. Remove kink or replace line.

1. Check for water ow to dispenser (see

Insufcient Water Flow on previous page).

2. Reset by turning the unit OFF and then

ON.

1. Correct prior to dispenser. Consider larger

dispenser or pre-cooler.

2. Adjust CO2 pressure downward, but not

less than 70 PSI.

3. Re-adjust and reset ratio. Refer to “Adjust

Water Flow Rate & Syrup/Water Ratio”

Section.

4. Remove and reinstall properly.

5. Remove and clean.

6. Bleed air from BIB lines.

7. Check quality of ice used in drink.

8. Check refrigeration system.

Warm drinks. 1. Restricted airow.

2. Dispenser connected to hot water supply.

3. Dispenser capacity exceeded.

BIB pump does not operate

when dispensing valve opened.

BIB pump operated, but no

ow.

BIB pump continues to operate

when bag is empty.

1. Out of CO2, CO2 not turned on, or low CO2

pressure.

2. Out of syrup.

3. BIB connector not tight.

4. Kinks in syrup or gas lines.

5. Bad BIB Pumps.

1. Leak in syrup inlet or outlet line.

2. Defective BIB pump check valve.

1. Leak in suction line.

2. Leaking o-ring on pump inlet tting.

1. Check clearances around sides, top, and

inlet of unit. Remove objects blocking

airow through grill.

2. Switch to cold water supply.

3. Add pre-cooler or replace with larger

dispenser.

1. Replace CO2 supply, turn on CO2

supply, or adjust CO2 pressure to 70-80

PSI (0.483-0.552 MPA)

2. Replace syrup supply.

3. Fasten connector tightly.

4. Straighten or replace lines.

5. Replace BIB pump.

1. Replace line.

2. Replace BIB pump

1. Replace line.

2. Replace o-ring.

17

Page 18

TROUBLE CAUSE REMEDY

DRAFT

BIB pump fails to restart after

bag replacement.

BIB pump fails to restart when

dispensing valve is closed.

No product out light. 1. Burned-out lamp

Low or no carbonation. 1. Low or no CO2.

1. BIB connector not on tight.

2. BIB connector is stopped up.

3. Kinks in syrup line

4. Bad BIB Pumps.

1. Leak in discharge line or ttings.

2. Empty BIB.

3. Air leak on inlet line or bag connector.

2. Faulty wiring or pressure switch in product

line.

2. Excessive water pressure.

3. Worn or defective carbonator pump.

1. Tighten BIB connector.

2. Clean out or replace BIB connector.

3. Straighten or replace line.

4. Replace BIB pump.

1. Repair or replace discharge

2. Replace BIB.

3. Repair or replace.

1. Replace lamp.

2. Repair or replace.

1. Check CO2 supply. Adjust CO2 pressure to

70 PSI (0.483 MPA).

2. Water regulator should be set at 50 PSI

(0.345 MPA)

3. Replace carbonator pump.

Dispenser Disposal

To prevent possible harm to the environment from improper disposal, recycle the unit

by locating an authorized recycler or contact the retailer where the product was purchased.

18

Comply with local regulations regarding disposal of the refrigerant and insulation.

Page 19

ILLUSTRATIONS AND PART LISTINGS

DRAFT

Main Unit Assembly

Item Part No. Description

1 TTCOS-012 MPUpLeg

2 VVSyrupVAssem

3 TTCOS-030 SodaReCirc Assem

4 TTCOS-022 WaterPipeTT

5 TTCOS-007 SplashHousing

6 BonusValveFlipAssem

7 TTCOS-013 ClampBracePlate

8 TTCOS-016 Valve_Bracket

10 TTCOS-008 NewDripBracket

11 TTCOS047 BottomCoverSheet

12 TTCOS-017 WorkTopValveBoxx2BF

13 FoamInsuBlock

14 Valve_InterfaceModule

15 TTCOS-018 Valve_PCB_Bracket

16 TTCOS-005 TTNozzleBracket

17 NozzleAssem

18 TTCOS-015 metal-base-prole-051114

Item Part No. Description

19 1_4syrupLine

20 TTCOS-034 TT_Drip_Plate

21 M4_12mm_PanHead

22 TTCOS-048 ccbb-drip-tray

23 3_8_Elbow_BB

24 3_8_Straight_BB

25 TTCOS-027 Key_Lock_Rod

26 TTCOS-023 Locking Nut

27 Locking Rod O’ Ring

28 TTCOS-030 Soda_Noz_Pipe_Assem

29 SSyrupElbow

30 1_4_Straight_BB

31 TTCOS-035 CupStop

32 ISO 7045 - M4 x 5 - Z -- 5N

33 TTCOS-044 ccbb-external-parts-020315

34 TTCOS-046 RubberFootPad

35 Clamp M8 Locking Bolt

36 TTCOS-015 New_KeyGuide_Plate

19

Page 20

Unit Plumbing Diagram

DRAFT

B1

B2

B3

F3

SR

PW

B4

B5

B6

F1

Item Description

B1 Brand Syrup 1

B2 Brand Syrup 2

B3 Brand Syrup 3

B4 Brand Syrup 4

B5 Brand Syrup 5

B6 Brand Syrup 6

F1 Flavour Injector 1

F2 Flavour Injector 2

F3 Flavour Injector 3

F4 Flavour Injector 4

PW Plain Water Line

SR Soda Recirculation

SD Soda Line

F4

B6

F1

B1

F2

B4

F2

B3

B2

SD

B5

F4

F3

20

Page 21

Unit Wiring Diagram

DRAFT

21

Page 22

Lancer Corp.

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Loading...

Loading...