Page 1

TECHNICAL MANUAL

820 LX / 910 LX / 1300 LX

Page 2

LANCER reserves the right to modify, constantly its documentation for its improvement.

The values of adjustments indicated in the displays of this manual are given as an indication

and do not have to be taken for reference.

Page 3

PRECAUTIONS TO BE TAKEN BEFORE USE

• Users must be trained before using the washer-dryer.

• The staff that use or repair this washer-dryer must have followed a complete

training referring its use and maintenance. This training must include the

selection and understanding of the washing cycle, the loading and unloading of

the baskets and the handling of the washing products.

• The staff in contact with the detergent products and its emanations, which

could be used in this washer-dryer, must have knowledge of the safety data

sheet of the used products as well as the detailed instructions about the

dangers and the detection of toxic product leaks.

• The training of the users and technicians must be done regularly and always

before the first use of the washer-dryer. A written register of these trainings

must be kept in order to prove the presence and the understanding of the

interested parties.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

1

Page 4

Page 5

SUMMARY

SUMMARY

CHAPTER 1 INTRODUCTION..................................5

1. INTRODUCTION TO THE TECHNICAL MANUAL 6

2. INTRODUCTION TO THE ACCESS CODES 7

3. DESCRIPTION OF KEYPAD 8

CHAPTER 2 ACCES TO TECHNICIAN MENU ................9

1. ACCES TO TECHNICIAN MENU 10

2. THE MACHINE TEST 11

3. CALIBRATION OF TEMPERATURE PROBES 13

4. MAINTENANCE HOURS RESET 15

5. CHANGING CARD 16

5.1 MEMORY READING OF THE ELECTRONIC BOARD TO BE CHANGED 16

5.2 MEMORY WRITING 18

6. RETURN TO THE INITIAL DISPLAY 20

CHAPTER3 ACCES TO SUPERVISOR MENU...............21

1. ACCES TO SUPERVISOR MENU 22

2. MACHINE CONFIGURATION 23

3. THE COMMON TIMES 28

4. THE CHOICE OF MACHINE NAME 34

5. UPDATE CYCLES 35

6. UPDATE HOURS 36

NT_820_910_1300_LX_ANG_V1 04_2007.doc

3

Page 6

SUMMARY

7. UPDATE MAINTENANCE HOURS 37

8. PRINT PROGRAM / COMMON SETTING PARAMETERS 39

9. PRINT CONFIGURATION PARAMETERS 40

10. CHANGING CARD 41

11. RETURN TO THE INITIAL STATE 41

CHAPTER 4 FAULT ALARMS................................43

1. WARNINGS 44

1.1 - LACK OF SALT * : 44

1.2 - LACK OF PRODUCTS 44

1.3 HOT CHAMBER 44

1.4 FULL BASIN 45

1.5 MAINTENANCE REMINDER 45

1.6 PREVENTATIVE MAINTENANCE REQUIRED 45

2. FAULT ALARMS 46

2.1 FAULT N°1 PROBE FAULT. 46

2.2 FAULT N°2 EMPTYING FAULT. 46

2.3 FAULT N°3 HEATING EXCESS. 47

2.4 FAULT N°4 HEATING FAULT. 47

2.5 FAULT N°5 NO WATER. 48

2.6 FAULT N°6 DOOR FAULT 48

2.7 FAULT N°7 LEVEL FAULT. 49

2.8 FAULT N°8 PRESSURESTAT FAULT. 49

NT_820_910_1300_LX_ANG_V1 04_2007.doc

4

Page 7

CHAPTER 1 INTRODUCTION

CHAPTER 1 INTRODUCTION

You have in your possession a LANCER washer-dryer.

Its good working and your entire satisfaction depend on the attention you pay

when reading this guide.

You will find here some advices about the use, the loading and the maintenance.

Follow them, as they have been written in your interest.

Before using your washer-dryer, you should become fully acquainted with it and

learn how to use it properly so it will give you many years’ service.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

5

Page 8

CHAPTER 1 INTRODUCTION

1.INTRODUCTION TO THE TECHNICAL MANUAL

This manual is intended to facilitate the operations of programming, testing,

maintenance and repairing, of your washer-dryer.

It is only addressed to people in possession of an access code of technician or

supervisor.

Before executing any operation, do read carefully these advices and

recommendations, they have been written in your interest.

Do respect the using precautions; the washer-disinfector must be only used for

the washing operations described in this manual.

This manual is made up of 4 chapters.

You have started chapter 1 , which introduces the specifications of the

washer-dryer from the point of view of the people authorised to the access

technicians and supervisors levels.

Chapter 2 will familiarize you with the operations which can be made by an

owner of a technician code.

Chapter 3 is a description of the configuration machine and of the different

parameters of the programs, only changeable by the owner of a supervisor

code.

You will find in chapter 4 the solutions to the different incidents which you

could find when using your washer-dryer.

All through this manual, we have placed brief comments and icons to help you

locate the important information.

When you see this icon, it means :

: ATTENTION ! ! PAY SPECIAL ATTENTION ! !

NT_820_910_1300_LX_ANG_V1 04_2007.doc

6

Page 9

CHAPTER 1 INTRODUCTION

2.INTRODUCTION TO THE ACCESS CODES

The codes give access to the developed menu which enables you to define the

adjustments of the washer-dryer.

There is a hierarchy inside these codes which enables the reduction of the rights

of access to the adjustment data, according to the different users (user’s level,

technician level, supervisor level).

The assigning of the access levels to the different users is a responsibility of the

client.

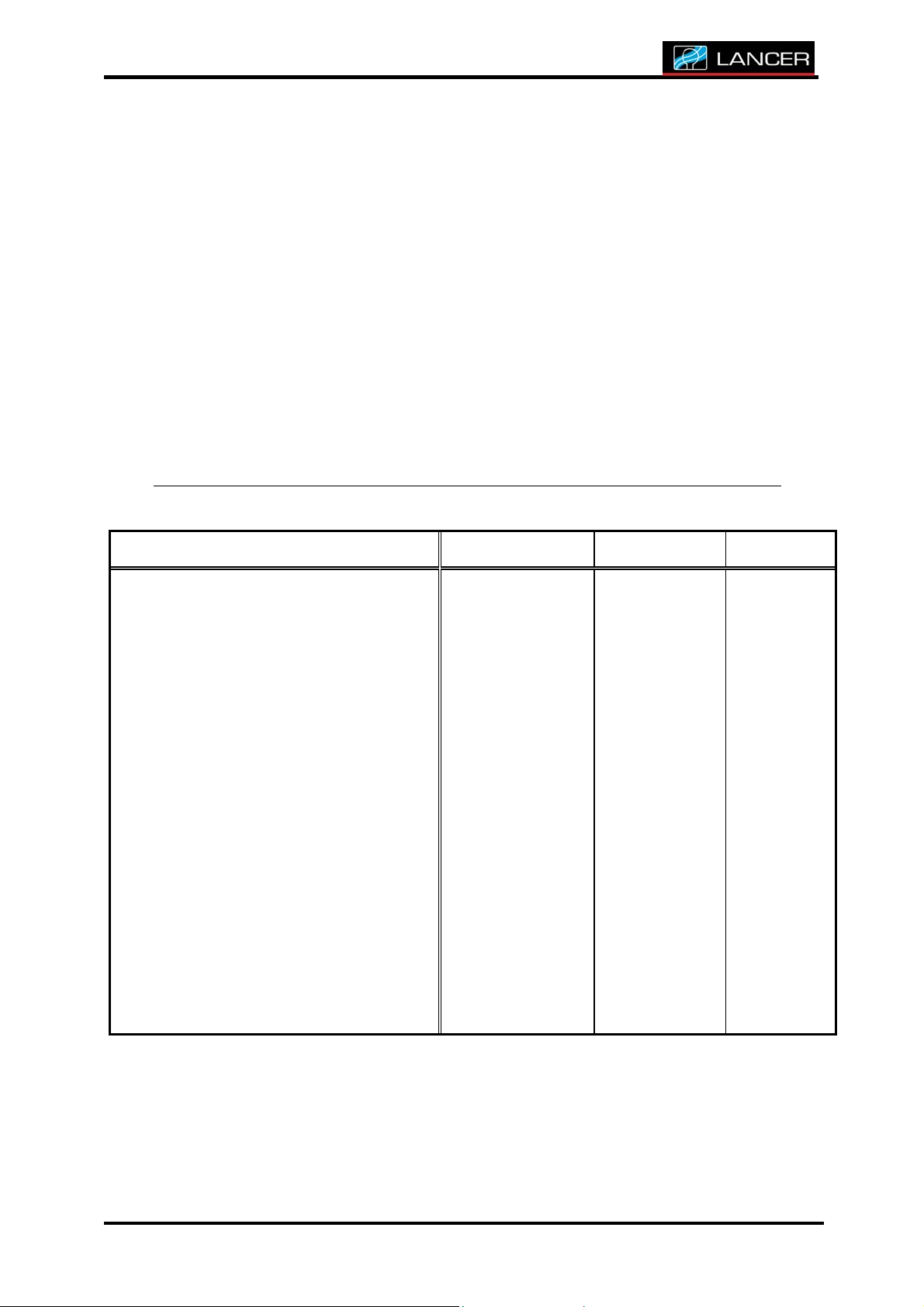

SUMMARY BOARD OF AVAILABLE FUNCTIONS ACCORDING THE ACCESS LEVEL

FUNCTIONS

Configurations

Common times

Machine name

Update cycles

Update hours

Update maintenance hours

Programme parameter printing

Configuration parameter printing

Changing card

Test Machine

Probe calibration

To zero maintenance hours

Printer parameters.

Faulty cycles

Name of programme

Dosing pump test

Reading programme

Programme parameters

Launching cycle

SUPERVISOR TECHNICIAN USER

X

X

X X

X

X

X

X

X

X X

X

X

X

X

X

X

X

X

X

X

NT_820_910_1300_LX_ANG_V1 04_2007.doc

7

Page 10

CHAPTER 1 INTRODUCTION

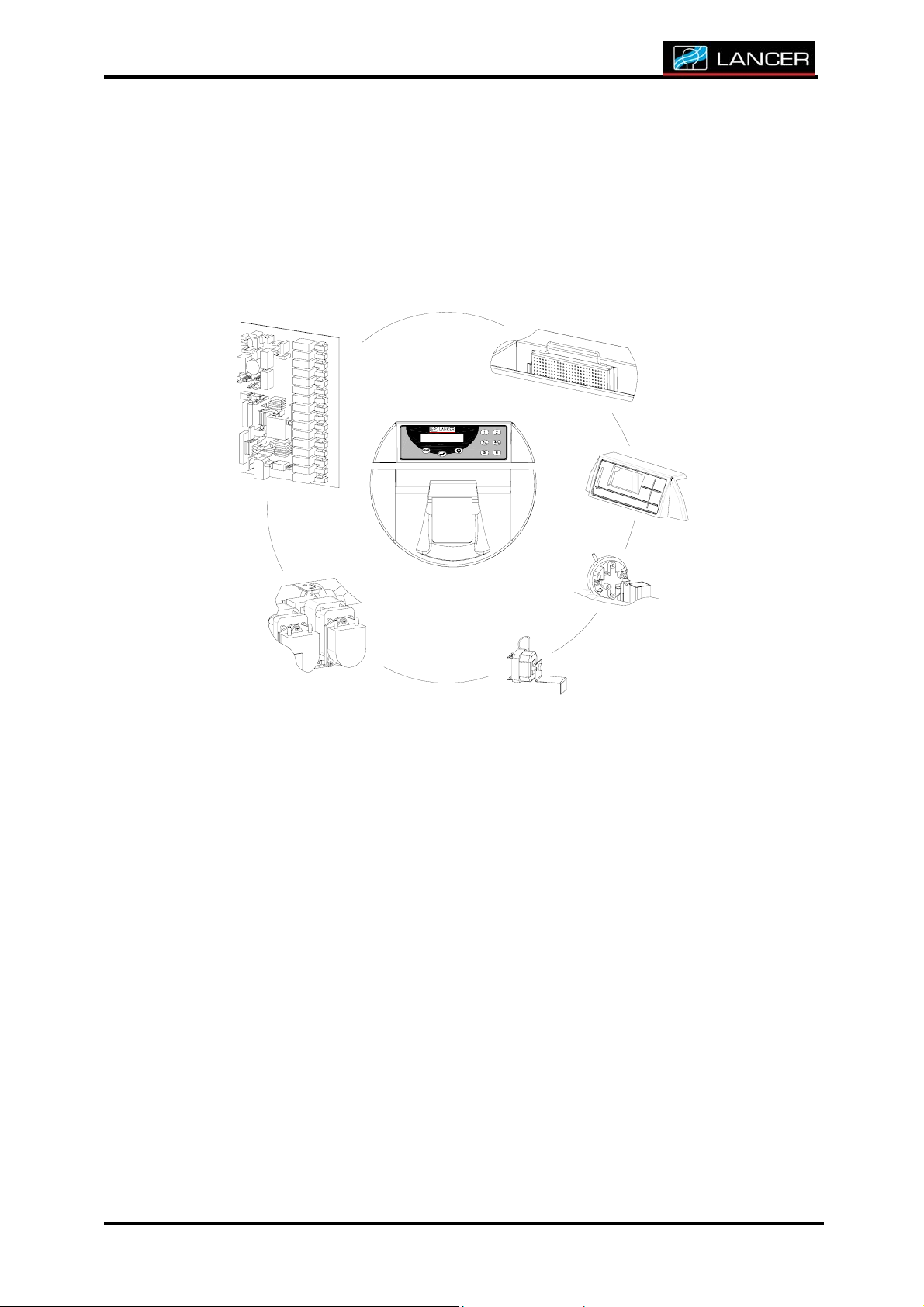

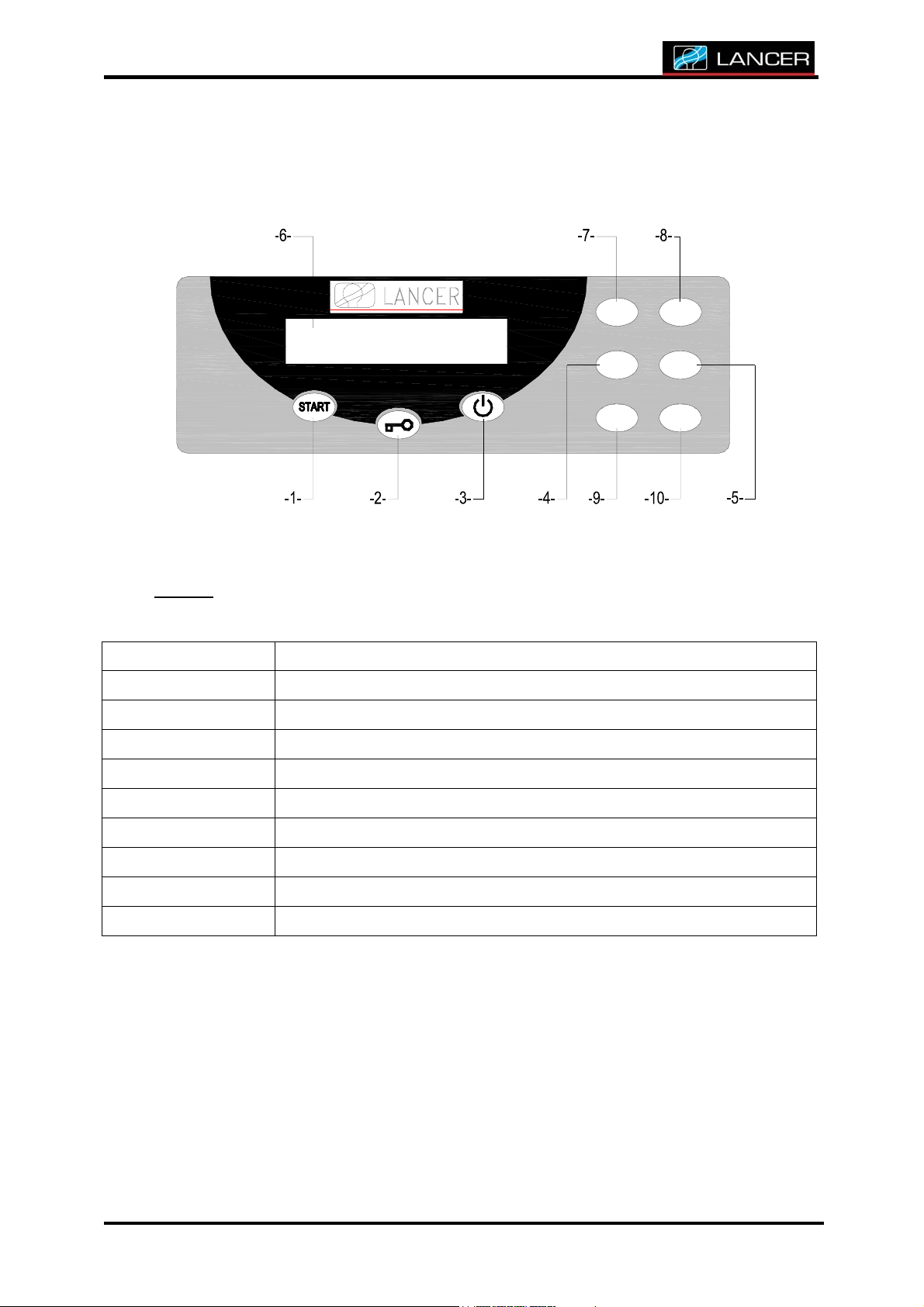

3. DESCRIPTION OF KEYPAD

Legend :

1 START" BUTTON

2 ENTER BUTTON (FOR PROGRAMMING) / DOOR UNLOCK

3 WASHER POWER ON/OFF BUTTON

4 BUTTON 3 / "-" FUNCTION BUTTON

111111111111

1111

33333333333333

3

3

//////////////

/

/

-

-

---------------

-

-

5555555555555

555

2222

2222222222

2

2

4444444444444444

//////////////

/

/

++++++++++++++

+

+

6666

6666666666

6

6

5 BUTTON 4 / "+" FUNCTION BUTTON

6 LIQUID CRYSTAL DISPLAY UNIT

7 BUTTON 1

8 BUTTON 2

9 BUTTON 5

10 BUTTON 6

NT_820_910_1300_LX_ANG_V1 04_2007.doc

8

Page 11

CHAPTER 1 INTRODUCTION

CHAPTER 2 ACCES TO TECHNICIAN MENU

This chapter provides information to check that your washer operates properly.

Using the LEVEL 2 / TECHNICIAN Access code, you can operate the output relays,

verify input status, and perform calibration of temperature probes, reset

maintenance hours counter as well as the recording of the various parameters of

the washer before an electronic board swapping

NT_820_910_1300_LX_ANG_V1 04_2007.doc

9

Page 12

CHAPTER 2 ACCES TO TECHNICIAN MENU

1.ACCES TO TECHNICIAN MENU

Switch on the machine by pressing .

The display indicates the number of the last cycle performed.

P r o g r a m n ° 0 1

L A N C E R x x x x L X

Press and hold button for 3 seconds to validate.

A C C E S S C O D E

----

Enter the access code - TECHNICIAN -.

If an incorrect code is entered, the following error message is displayed.

A C C E S S C O D E

I N C O R R E C T C O D E

Press and hold

button for 3 seconds to validate.

You must enter the correct access code.

Otherwise you access to technician menu.

T E C H N I C I A N M E N U

T e s t m a c h i n e

Note :

If the access code is not entered within 30 seconds, the display unit

returns to its initial state.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

10

Page 13

CHAPTER 2 ACCES TO TECHNICIAN MENU

2.THE MACHINE TEST

After accessing to technician menu, you must select TEST MACHINE with

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

electronic card

Accept with button.

Choose the relay number to be checked.

Choose the relay number with

Each press on button activates or inactivates the relay.

To leave the relay test, select relay 0 and validate with button.

33333333333333

3

3

and

buttons to test the relay state and the inputs of the

//////////////

/

/

-

-------------

-

-

T E C H N I C I A N M E N U

T e s t m a c h i n e

44444444444444

4

4

33333333333333

3

3

and

//////////////

/

/

++++++++++++++

+

+

buttons.

//////////////

/

/

-

-------------

-

-

T e s t m a c h i n e

R e l a y N ° 0 1 : O F F

Particular case :

The "ON" position of relay 14 is limited to 5 seconds to avoid damaging

the heating element if heating without water.

It is necessary to have a quantity of water in the bottom of the basin to

check the functioning of the heaters.

The following display enables to control the state of inputs.

Conformity of the inputs :

INPUT 1 and 2 : CHAMBER FULL

INPUT 3 : CHEMICAL TANKS FULL

INPUT 4 : DOOR LOCKING

INPUT 5, 6 and 7 : N/A

A value of "1" indicates that the switch is closed and the input is

connected to ground (On). A value of "0" indicates that the switch is

open and that the input is not connected to ground (Off).

Press button to get out.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

11

Page 14

CHAPTER 2 ACCES TO TECHNICIAN MENU

I n p u t s : 7 6 5 4 3 2 1

S t a t e : 0000110

The following display gives the total functioning time of the machine and

the number of cycles performed.

Accept with button.

N b r c y c l e s : x x

T i m e m a c . : x h

The following display allows to know time remaining before carrying out

maintenance actions on washer.

Accept with button.

M a i n t enance

i n x x h o u r s

The following display shows the memory version.

Accept with button.

L 6 X X X X X V : x . x x

x x - x x - x x x x x x : x x

E n d o f m e n u

The display returns to technician menu.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

12

Page 15

CHAPTER 2 ACCES TO TECHNICIAN MENU

3.CALIBRATION OF TEMPERATURE PROBES

After accessing to technician menu, you must select CALIBR. PROBE with

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

Accept with button.

33333333333333

3

3

and

buttons to calibrate the probes.

//////////////

/

/

-

-------------

-

-

T E C H N I C I A N M E N U

C a l i b r . p r o b e

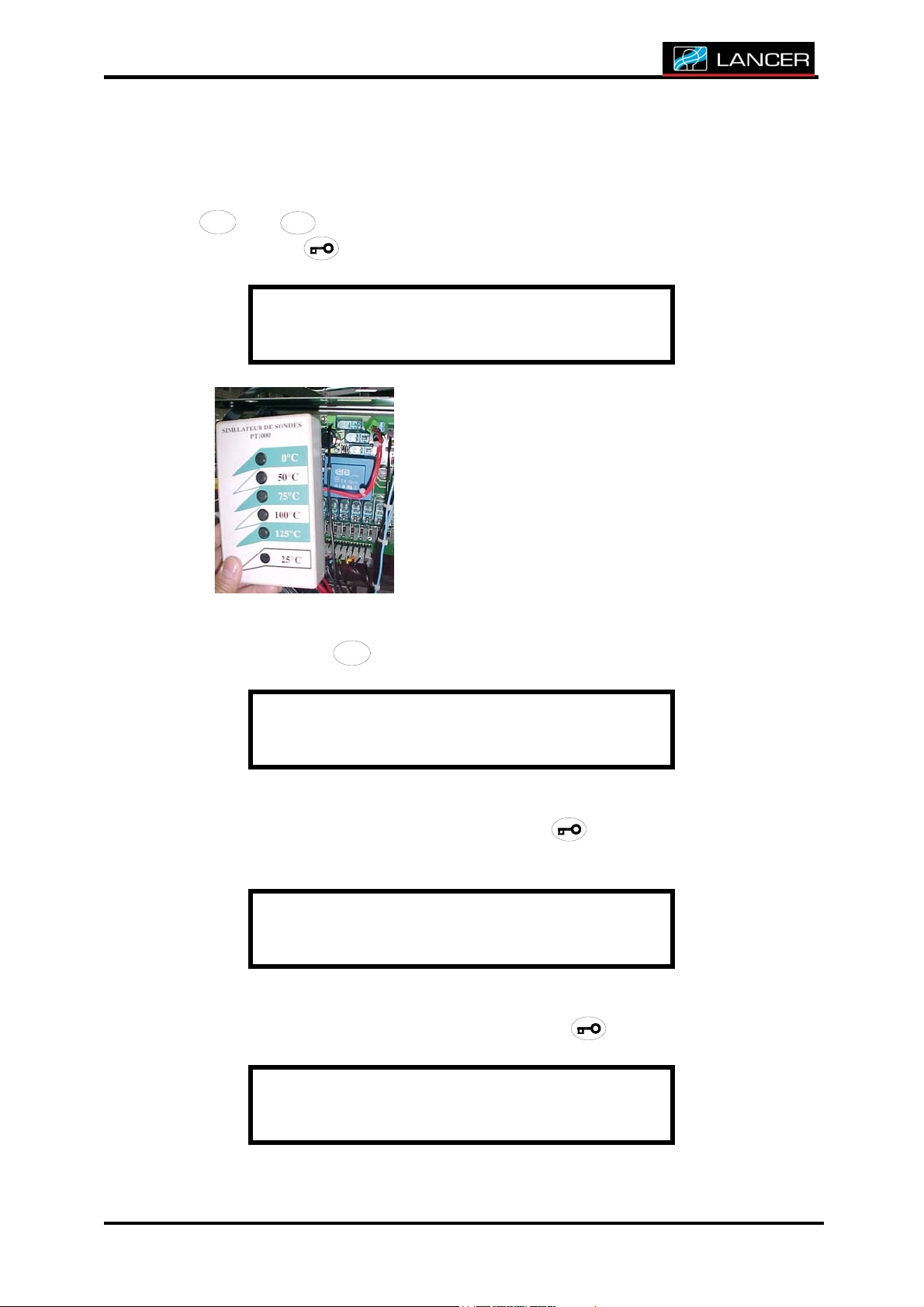

Connect probe simulator box on plug K49 of

the electronic board.

Calibrate electronic board probe outlet

(slope of the probe) using probe simulator

box.

Display indicates temperature of the probe.

6666

6666666666

6

Press on button

6

to calibrate the probe.

Wa t e r p r o b : 3 4 . 9 °

Press on button 0°C of the simulator.

Keep pressed button 0°C and accept with button.

C a l i b r a t e s l o p e

S i m P T 1000 -> 00°

Press on button 100°C of the simulator.

Keep pressed button 100°C and accept with button.

C a l i b r a t e s l o p e

S i m P T 1 0 0 0 - > 1 0 0 °

NT_820_910_1300_LX_ANG_V1 04_2007.doc

13

Page 16

CHAPTER 2 ACCES TO TECHNICIAN MENU

The slope of the probe is set.

Disconnect the probe simulator from the electronic board then connect

temperature probe on plug K49 of the electronic board.

The following display enables calibration of the temperature probe of

the chamber.

Calibration of the probe must be done inside a full water chamber, then

deep the probe of the calibrated standard inside the sump and verify

both values (washer probe and calibrated standard probe).

Probe is blinking. Validate with

Adjust the value of the offset with

the calibrated standard.

Accept with button.

If the display reads 120°C, the probe is not connected or is faulty.

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

//////////////

/

/

-

-------------

-

-

and

buttons.

33333333333333

3

3

buttons in regard to

//////////////

/

/

-

-------------

-

-

Wa t e r p r o b : 3 4 . 9 °

Of f s e t : + 0.1

Temperature of the electronic board inside the cabinet.

This value is given as an indicative value and does not have to be

modified.

Accept with button.

Ma i n box : 42. 7°C

Do not modify the value of the offset. Set in factory.

Accept with button.

Ma i n box : 42. 7°C

Of f s e t : + 0.1

F i n du menu

The display returns to technician menu.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

14

Page 17

CHAPTER 2 ACCES TO TECHNICIAN MENU

4.MAINTENANCE HOURS RESET

After having reached to the small technician, you must, to allow a new

calculation of the hours before completing work of maintenance

After accessing to technician menu, you must, to allow a new calculation

of the hours before completing work of maintenance, select Reset

44444444444444

4

Maint. HRS with

Accept with

4

//////////////

/

/

++++++++++++++

+

+

button.

T E C H N I C I A N M E N U

R e s e t M A I N T . H R S

Choose yes or no with

Accept with button.

and

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

and

buttons.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

//////////////

/

/

-

-------------

-

-

buttons

R e s e t M A I N T . H R S

C o n f i r m a t i o n : Y e s

E n d o f m e n u

The display returns to technician menu.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

15

Page 18

CHAPTER 2 ACCES TO TECHNICIAN MENU

5.CHANGING CARD

After accessing to technician menu, it is possible, before changing

electronic board of the washer, choose Changing card using buttons

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

keyboard must be still existing).

Accept with button.

Using buttons

“writing memory”.

33333333333333

3

3

, (communication between electronic board, display and

//////////////

/

/

-

-------------

-

-

T E C H N I C I A N M E N U

C h a n g i n g c a r d

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

., you have to select: “reading memory” or

//////////////

/

/

-

-------------

-

-

5.1 MEMORY READING OF THE ELECTRONIC BOARD TO BE CHANGED

“Memory reading ” makes it possible to keep in memory washer

configurations, programming tables, counters for cycles, hours or

maintenance…

All these parameters are stored inside memory 24c256.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

16

Page 19

CHAPTER 2 ACCES TO TECHNICIAN MENU

C h a n g i n g c a r d

R e a d i n g m e m o r y

Accept with button.

C h a n g i n g c a r d

C o n f i r m a t i o n : Y e s

Accept with button.

C h a n g i n g c a r d

[ . . . . . . . . . . ] 9 9 %

Once 100% is reached, all the datas are now stored in the memory.

E n d o f m e n u

The display returns to technician menu.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

17

Page 20

CHAPTER 2 ACCES TO TECHNICIAN MENU

5.2 MEMORY WRITING

“Memory writing ”.makes it possible to transfer on the memory from the

washer all the parameters which were safeguarded in reading mode, thus

avoiding having with all to reprogram.

C h a n g i n g c a r d

W r i t i n g m e m o r y

Accept with button.

C h a n g i n g c a r d

C o n f i r m a t i o n : Y e s

NT_820_910_1300_LX_ANG_V1 04_2007.doc

18

Page 21

CHAPTER 2 ACCES TO TECHNICIAN MENU

C h a n g i n g c a r d

[ . . . . . . . . . . ] 9 9 %

Once 100% is reached, all the datas are now written in the memory.

E n d o f m e n u

The display returns to technician menu.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

19

Page 22

CHAPTER 2 ACCES TO TECHNICIAN MENU

6. RETURN TO THE INITIAL DISPLAY

44444444444444

4

Select END REGLAGE ? with

technician menu.

Accept with button.

E n d o f r e g l a g e ?

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons to leave the

//////////////

/

/

-

-------------

-

-

NT_820_910_1300_LX_ANG_V1 04_2007.doc

20

Page 23

CHAPTER3 ACCES TO SUPERVISOR MENU

CHAPTER3 ACCES TO SUPERVISOR MENU

Using the SUPERVISOR Access code enables adaptation of the configuration and

programming parameters of your washer-dryer to meet the requirements of the

facility in which it will be used.

The operation of your machine can be adversely

affected by the settings in this section. Do not

randomly modify parameters!

NT_820_910_1300_LX_ANG_V1 04_2007.doc

21

Page 24

CHAPTER3 ACCES TO SUPERVISOR MENU

1.ACCES TO SUPERVISOR MENU

Switch on the machine by pressing .

The display indicates the number of the last cycle performed.

P r o g r a m n ° 0 1

L A N C E R x x x x L X

Press and hold button for 3 seconds to validate.

A C C E S S C O D E

----

Enter the access code - SUPERVISOR -.

If an incorrect code is entered, the following error message is displayed.

A C C E S S C O D E

I N C O R R E C T C O D E

Press and hold

button for 3 seconds to validate.

You must enter the correct access code.

Otherwise you access to supervisor menu.

S U P E R V I S O R M E N U

C o n f i g u r a t i o n s

Note :

If the access code is not entered within 30 seconds, the display unit

returns to its initial state.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

22

Page 25

CHAPTER3 ACCES TO SUPERVISOR MENU

2.MACHINE CONFIGURATION

After accessing the supervisor menu, you must select CONFIG. MACHINE

44444444444444

4

with

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with button.

S U P E R V I S O R M E N U R

C o n f i g u r a t i o n s

Select the language : French, English, German…

Select the language with

button.

33333333333333

3

3

buttons to configure the machine.

//////////////

/

/

-

-------------

-

-

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons. Accept with

//////////////

/

/

-

-------------

-

-

C h o o s e t e x t

F rancai s

Choose the type of water of your washer according to its equipment:

- LX WITHOUT REGE for standard washers

- LX REGE 1 for washers equipped with softener option

- LX REGE 1+2 for washers equipped with softener option (no purified

water available)

- SP1 (not applicable)

Select with

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

44444444444444

4

C h o i x d e s e a u x

L X W I T H O U T R E G E

Select the machine model : 820 LX, 820 SP1, 820 MD, 910 LX, 1300 LX,

1400 LX.

Select the model with

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

44444444444444

4

T y p e o f m a c h i n e

L A N C E R 9 1 0 L X

If the washer is equipped with softener option (regeneration), select YES

44444444444444

4

with

4

//////////////

/

/

++++++++++++++

+

+

Accept with

NT_820_910_1300_LX_ANG_V1 04_2007.doc

or

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

button.

23

Page 26

CHAPTER3 ACCES TO SUPERVISOR MENU

R E G ENERAT I ON

YES

This washer is equipped with a drying device as a standard, you must

select YES with

Accept with

4

//////////////

/

/

++++++++++++++

+

+

button.

or

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

44444444444444

4

D RYING

YES

This washer is equipped with a door lock device (during the washing

cycle) as a standard (except 820 LX), you must select YES with

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

Accept with button.

44444444444444

4

4

or

//////////////

/

/

++++++++++++++

+

+

D O O R L O C K E D

YES

If the washer is equipped with an additional dosing pump option, select

YES with

4

//////////////

/

/

++++++++++++++

+

+

or

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

44444444444444

4

Accept with button.

P R ODUCT 2

YES

Not applicable on 910 LX / 1300LX washers, select NO with

4

//////////////

/

/

++++++++++++++

+

+

or

33333333333333

3

3

//////////////

/

/

-

-------------

-

-

44444444444444

4

buttons.

Accept with button.

E M P T Y I N G 2

YES

This washer is equipped with a door lock device (during the washing

cycle) as a standard (except 820 LX),, you must select YES with

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

Accept with button.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

24

44444444444444

4

4

or

//////////////

/

/

++++++++++++++

+

+

Page 27

CHAPTER3 ACCES TO SUPERVISOR MENU

M O T O R L O C K E D

YES

Not applicable on laboratory range washers, select NO with

buttons.

Accept with button.

L U BRICANT

YES

44444444444444

4

Select YES with

4

//////////////

/

/

++++++++++++++

+

+

Accept with button.

or

33333333333333

3

3

//////////////

/

/

-

-------------

-

-

buttons.

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

or

33333333333333

3

3

//////////////

/

/

-

-------------

-

-

H O T W A T . NETWORK

YES

If the washer is equipped with effluent neutralization option, select YES

with

4

//////////////

/

/

++++++++++++++

+

+

or

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

44444444444444

4

Accept with button.

N E U T R A L I Z A T I O N

YES

The HYSTERESIS is the temperature difference between switching

heating on and off during regulation.

Choose with

4

or

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

, hysteresis temperature between 1 and

//////////////

/

/

-

-------------

-

-

44444444444444

4

10°C.

Accept with button.

H Y STERISIS

3°C

NT_820_910_1300_LX_ANG_V1 04_2007.doc

25

Page 28

CHAPTER3 ACCES TO SUPERVISOR MENU

Choose if the fast advance is allowed.

44444444444444

4

Select Active/Non active with

4

Accept with button.

F a s t A v a n c e

Acti ve

If MEMORY OF PROG. is active, the washer will keep in memory the N° of

the last cycle carried out. Otherwise when you switch on the machine,

the number displayed will be 1.

44444444444444

4

Select Active/Not active with

4

Accept with button.

M e m o r y o f p r o g .

//////////////

/

/

//////////////

/

/

++++++++++++++

+

+

++++++++++++++

+

+

and

and

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

Acti ve

If TEST MODE is ON, it is possible to display relay status during the

washing cycle:

555555555555

- button

- button

Select ON/OFF with

5555

will give status for relays 1 to 8

6666

6666666666

6

6

will give status for relays 9 to 16

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

Accept with button.

T e st Mode

Off

If you wish to have a sound effect when pressing buttons on the

keyboard, select ON or OFF with

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

44444444444444

4

Accept with button.

D i s p l a y B i p

Off

The salt alarm is determinate by a counter whose limit is fixed by the

duration of the salt intake and by this setting.

The time of each salt intake is accumulated in memory. When it reaches

the preset value, the automaton asks for the salt intake.

The counter is adjustable from 3 to 20 minutes with

buttons, it goes back to zero as soon as the alarm is cancelled.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

26

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

//////////////

/

/

-

-------------

-

-

Page 29

CHAPTER3 ACCES TO SUPERVISOR MENU

A d j ust sal t

6mn

Select the PROGRAM NUMBER with

Accept with button.

P r o g r . n u m b e r

66

Choose the display type : Type of machine, Machine name or Name of

program.

44444444444444

4

Select the type display with

4

//////////////

/

/

++++++++++++++

+

+

Accept with button.

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

C h o o s e d i s p l a y

T y p e o f m a c h i n e

Note :

MACHINE NAME and NAME OF PROGRAM are respectively configurable

44444444444444

4

The selection of the characters is obtained with the buttons

33333333333333

3

3

.

//////////////

/

/

-

-------------

-

-

A pressure on the key

makes it possible to validate the selected

4

//////////////

/

/

++++++++++++++

+

+

and

character then to pass to following space.

If the chosen name has less of 8 characters fill-in empty blanks by

pressing button.

S eri al nbr

X XXXXXXX

e n d o f m e n u

The display unit returns to its initial state.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

27

Page 30

CHAPTER3 ACCES TO SUPERVISOR MENU

3.THE COMMON TIMES

In this section you can set the Common Times necessary for proper

operation of the machine and define the set point times of the alarms N°

02 and 05.

After accessing to supervisor menu, you must select COMMON TIMES

44444444444444

4

with

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with

S U P E R V I S O R M E N U

C o m m o m t i m e s / T °

33333333333333

3

3

buttons to set the commons times.

//////////////

/

/

-

-------------

-

-

button.

Choose period for emptying : 0 to 6 mn 59 s

During the cycle, if the machine is not entirely emptied at the end of

this period, the alarm "EMPTYING FAULT" will be displayed.

Select the minutes with

Select the seconds with

4

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

44444444444444

4

Accept with button.

E m p t y i n g s t a r t

00m30s

Choose period of 1st regeneration : 0 to 6mn 59s MAXI.

Select the minutes with

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons. Accept with

//////////////

/

/

-

-------------

-

-

44444444444444

4

button.

Select the seconds with

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons. Accept with

//////////////

/

/

-

-------------

-

-

44444444444444

4

button.

Accept with button.

R e g e n e r a t i o n 1

00m18s

NT_820_910_1300_LX_ANG_V1 04_2007.doc

28

Page 31

CHAPTER3 ACCES TO SUPERVISOR MENU

When there is no demi. water available, water inlet for last rinses can be

softened by the washer by programming this function (REGENERATION 2).

During setting of the program (code 3124), it will be possible to select

the filling valve, hot or cold which will feed the softener.

Choose period of 2nd regeneration between 0 and 5mn 59s.

44444444444444

4

Select the minutes with

Select the seconds with

4

and

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with button.

R e g e n e r a t i o n 2

00m00s

Choose period for pump priming : 0 to 6 mn 59 s

Before the pump starts, water flows into the basin, to avoid damaging of

the seal.

44444444444444

4

Select the minutes with

Select the seconds with

4

and

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with button.

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

P u m p p r i m i n g

00m18s

Choose period for filling : 0 to 10 mn 59 s

During the cycle, if the machine has not reached its water level, before

elapsing of this period, the alarm "

44444444444444

4

Select the minutes with

Select the seconds with

4

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

FILLING FAULT" will be displayed.

33333333333333

3

3

and

and

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

Note : Filling of the washer will be 2 min. minimum instead of

programmed time is between 00min00s and 2min00s.

F i l l i n g

04m00s

NT_820_910_1300_LX_ANG_V1 04_2007.doc

29

Page 32

CHAPTER3 ACCES TO SUPERVISOR MENU

Choose period for emptying : 0 to 6 mn 59 s

During the cycle, if the machine is not entirely emptied at the end of

this period, the alarm "EMPTYING FAULT" will be displayed.

44444444444444

4

Select the minutes with

Select the seconds with

4

and

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

E mptyi ng

01m15s

Not applicable on 910 LX / 1300LX washers, this setting must be zero.

44444444444444

4

Select the minutes with

Select the seconds with

4

and

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

E m p t y i n g 2

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

00m00s

Choose duration of recycling : 0 to 6 mn 59 s

This regulation corresponds to the time during which the water will be in

running water rinse, when the pressurestat will be pushed.

Select the minutes with

Select the seconds with

4

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

44444444444444

4

R e c y c l i n g

00m30s

In order to adjust the pH of basic discharged liquids, recirculation period

is increased with an acid intake before draining (function called

“Neutralization”). The adjustment of the acid quantity is carried out

through the working time of the acid dosing pump.

This working time has to be determined by the customer according to

the detergent concentration to be neutralized in the chamber and the

acid concentration.

Choose duration for acid intake: 0 to 6mn59s.

44444444444444

4

Select the minutes with

Select the seconds with

4

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

NT_820_910_1300_LX_ANG_V1 04_2007.doc

30

Page 33

CHAPTER3 ACCES TO SUPERVISOR MENU

R e c y . N e u t r . A c i d e

00m30s

In order to adjust the pH of acid discharged liquids, recirculation period

is increased with an detergent intake before draining (function called

“Neutralization”). The adjustment of the detergent quantity is carried

out through the working time of the detergent dosing pump.

This working time has to be determined by the customer according to

the acid concentration to be neutralized in the chamber and the basic

concentration.

Choose duration for detergent intake: 0 to 6mn59s.

44444444444444

4

Select the minutes with

Select the seconds with

4

and

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

R e c y . N e u t r . B a s i c

00m10s

Choose the pause period : 0 to 6 mn 59 s

At the end of hot demi. water rinse, we define the condenser functioning

time (option).

Select the minutes with

Select the seconds with

4

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

44444444444444

4

Pause

00m00s

Choose door unlocking period: 0 to 2 mn 59 s

Select the minutes with

Select the seconds with

4

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

44444444444444

4

U n l o c k i n g d o o r

00m12s

NT_820_910_1300_LX_ANG_V1 04_2007.doc

31

Page 34

CHAPTER3 ACCES TO SUPERVISOR MENU

Choose period for door lock control: 0 to 2 mn 59 s.

This parameter allows a door lock control. At beginning of cycle, if door

is not correctly closed, alarm “OPENED DOOR” is displayed.

44444444444444

4

Select the minutes with

Select the seconds with

4

and

//////////////

/

/

++++++++++++++

+

+

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

T . u n l o c k d o o r

00m10s

Choose water temperature for detergent intake with

buttons: 0 to 2 mn 59 s

If temperature is

- set to zero

- higher than programmed temperature for current phase,

detergent intake is done at the beginning of the phase.

Accept with button.

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

33333333333333

3

3

buttons. Accept with button.

//////////////

/

/

-

-------------

-

-

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

//////////////

/

/

-

-------------

-

-

D e t e r g e n t i n t a k e

T e m p e r a t u r e = 4 0 °

Choose water temperature for acid intake with

4

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons: 0

//////////////

/

/

-

-------------

-

-

44444444444444

4

to 2 mn 59 s

If temperature is

- set to zero

- higher than programmed temperature for current phase,

acid intake is done at the beginning of the phase.

Accept with button.

A c i d i n t a k e

T e m p e r a t u r e = 3 0 °

Not applicable on laboratory range washers, must be set to zero with

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

Accept with button.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

32

Page 35

CHAPTER3 ACCES TO SUPERVISOR MENU

L u b r i c a n t i n t a k e

T e m p e r a t u r e = 3 5 °

If the washer is equipped with an additional dosing pump option, choose

water temperature for additive 2 intake with

2 mn 59 s

If temperature is

- set to zero

- higher than programmed temperature for current phase,

additive 2 intake is done at the beginning of the phase.

Accept with button.

P r o d u c t i n t a k e 2

T e m p e r a t u r e = 3 5 °

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons: 0 to

//////////////

/

/

-

-------------

-

-

If the machine is equipped with a condenser, choose with

keys, the condenser temperature between 0 and 60°C.

Accept with button.

C o ndenso r

T e m p e r a t u r e = 5 0 °

E n d o f m e n u

The display unit returns to its initial state.

44444444444444

4

4

//////////////

/

/

++++++++++++++

+

+

or

33333333333333

3

3

//////////////

/

/

-

-------------

-

-

NT_820_910_1300_LX_ANG_V1 04_2007.doc

33

Page 36

CHAPTER3 ACCES TO SUPERVISOR MENU

4.THE CHOICE OF MACHINE NAME

If you choose "CHOOSE DISPLAY = MACHINE NAME" in "machine

configuration " menu of supervisor level (see page 23), the machine can

be identified by a designation particular. A maximum of 16 characters is

available.

After accessing to supervisor menu, you must choose MACHINE NAME

44444444444444

4

with

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with button.

S U P E R V I S O R M E N U

N o m m a c h i n e

33333333333333

3

3

buttons to define the name of the machine.

//////////////

/

/

-

-------------

-

-

The characters selection is got with

4

//////////////

/

/

++++++++++++++

+

+

and

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

44444444444444

4

Press button to accept the chosen character and to pass on next

space.

If the chosen name has less of 16 characters fill-in empty blanks by

pressing button.

m a c h i ne name

█

The program name is recorded in memory after the 16th character is

entered by pressing the button.

E n d o f m e n u

The display unit returns to its initial state.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

34

Page 37

CHAPTER3 ACCES TO SUPERVISOR MENU

5.UPDATE CYCLES

This function is to modify the counter of the number of cycles carried

out.

After accessing to supervisor menu, you must choose UPDATE CYCLE

44444444444444

4

with

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with

S U P E R V I S O R M E N U

U p d a t e s c y c l e s

Select YES/NO with

Accept with button.

33333333333333

3

3

buttons to modify the cycle number.

//////////////

/

/

-

-------------

-

-

button.

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

//////////////

/

/

buttons.

-

-------------

-

-

U p d a t e s c y c l e s

C o n f i r m a t i o n : Y e s

44444444444444

4

If YES, select the cycle number with

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with button.

U p d a t e s c y c l e s

8

E n d o f m e n u

The display unit returns to its initial state.

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

The meter value must be noted before an update.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

35

Page 38

CHAPTER3 ACCES TO SUPERVISOR MENU

6.UPDATE HOURS

This function is to modify the counter of the machine usage time.

After accessing to supervisor menu, you must choose UPDATE HOURS

44444444444444

4

with

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with

S U P E R V I S O R M E N U

U p d a t e s h o u r s

Choose YES/NO with

Accept with button.

33333333333333

3

3

buttons to modify the hour.

//////////////

/

/

-

-------------

-

-

button.

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

U p d a t e s h o u r s

C o n f i r m a t i o n : Y e s

If YES, choose the hours number with

Accept with button.

U p d a t e s h o u r s

5

E n d o f m e n u

The display returns to its initial state.

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

The meter value must be noted before an update.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

36

Page 39

CHAPTER3 ACCES TO SUPERVISOR MENU

7.UPDATE MAINTENANCE HOURS

This function is to modify the counter of hours before carrying out

maintenance.

After accessing to supervisor menu, you must choose Update MAINT. hrs

44444444444444

4

with

4

and

//////////////

/

/

++++++++++++++

+

+

Accept with

S U P E R V I S O R M E N U

U p d a t e M a i n t . h r s

Choose YES/NO with

Accept with button.

33333333333333

3

3

buttons to modify the hours.

//////////////

/

/

-

-------------

-

-

button.

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

U p d a t e M a i n t . h r s

C o n f i r m a t i o n : y e s

Choose frequency of maintenance with

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

44444444444444

4

Accept with button.

The calculation of this frequency is displayed at each starting-up.

M a i n t enance

e v e r y : x x x h

Choose with

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons, the interval of time remaining

//////////////

/

/

-

-------------

-

-

44444444444444

4

before next maintenance so that this time is announced to each

launching of cycle

Accept with button.

M a i n t enance

i n t e r v a l . : x x x h

NT_820_910_1300_LX_ANG_V1 04_2007.doc

37

Page 40

CHAPTER3 ACCES TO SUPERVISOR MENU

This display allows to reset to zero maintenance hours or enter a time

after changing electronic board using

Accept with button.

U p d a t e M a i n t . h r s

xxxx

E n d o f m e n u

The display returns to its initial state.

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons.

//////////////

/

/

-

-------------

-

-

NT_820_910_1300_LX_ANG_V1 04_2007.doc

38

Page 41

CHAPTER3 ACCES TO SUPERVISOR MENU

8.PRINT PROGRAM / COMMON SETTING PARAMETERS

This function allows printing of wash program parameters and common

settings (only for washer equipped with printer option).

TO BE DONE AFTER ANY MODIFICATION OF PROGRAM!

S U P E R V I S O R M E N U

P r i n t p a r a m . p r g

Accept with

button.

P r ogram n°

22

Choose program to be printed.

Accept with

button.

P ri nti ng

I n progress...

Printing of the parameters.

E n d o f m e n u

The display returns to its initial state.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

39

Page 42

CHAPTER3 ACCES TO SUPERVISOR MENU

9.PRINT CONFIGURATION PARAMETERS

This function allows printing of the configuration parameters (only for

washer equipped with printer option).

TO BE DONE AFTER ANY MODIFICATION OF

CONFIGURATION!

S U P E R V I S O R M E N U

P r i n t p a r a m . c f g

Accept with

button.

P ri nti ng

I n progress...

Printing of the parameters.

E n d o f m e n u

The display returns to its initial state.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

40

Page 43

CHAPTER3 ACCES TO SUPERVISOR MENU

10. CHANGING CARD

See page 16

S U P E R V I S O R M E N U

C h a n g i n g c a r d

11.RETURN TO THE INITIAL STATE

You must choose END REGLAGE ? with

supervisor menu.

Accept with

button.

44444444444444

4

4

and

//////////////

/

/

++++++++++++++

+

+

33333333333333

3

3

buttons to quit the

//////////////

/

/

-

-------------

-

-

E n d o f r e g l a g e ?

NT_820_910_1300_LX_ANG_V1 04_2007.doc

41

Page 44

Page 45

CHAPTER 4 FAULT ALARMS

CHAPTER 4 FAULT ALARMS

This chapter explains all fault alarms that can occur on the washer-dryer.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

43

Page 46

CHAPTER 4 FAULT ALARMS

1. WARNINGS

1.1 - LACK OF SALT * :

* only for washers with regeneration

(not applicable on 820 LX)

WARNING

L A C K O F S A L T

Lack of salt definition: The following message is displayed at the start

of the cycle when you press the key.

Corrective Action :Fill the salt pot located inside the washer.

1.2 - LACK OF PRODUCTS

WARNING

L A C K O F C H E M I C .

Lack of product definition : The following message is displayed at the

start of the cycle when you press the

Corrective Action :Check level of additive tanks, replace additive low

level tank.

1.3 HOT CHAMBER

W A R N I N G !

H O T C H A M B E R

INCIDENT: the following message is displayed if the temperature inside

the washing chamber is above the safety temperature set point for door

opening.

ACTION: At the end of the cycle, let the washer chamber and contents

cool before opening the chamber door.

key.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

44

Page 47

CHAPTER 4 FAULT ALARMS

1.4 FULL BASIN

W A R N I N G !

F U L L B A S I N :

INCIDENT: If the wash chamber contains water at the beginning of the

cycle, either from the interruption of the previous cycle or due to an

abnormal addition of water to the chamber.

ACTION: The washer is automatically emptied and the cycle then

proceeds normally.

1.5 MAINTENANCE REMINDER

M a i n t e n a n c e

I n X X X H o u r s

INCIDENT: After turning on the machine, the reminder of the upcoming

preventative maintenance is shown on the display.

ACTION: Press the

key to acknowledge the reminder. Schedule a

preventative maintenance service call.

1.6 PREVENTATIVE MAINTENANCE REQUIRED

T i m e f o r P r e v e n T i v e M a i n t e n a n c e

INCIDENT: After starting the wash cycle, the preventative maintenance

message is shown on the display.

ACTION: Press the

maintenance should be performed on the machine.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

key to acknowledge the reminder. Preventative

45

Page 48

CHAPTER 4 FAULT ALARMS

2.FAULT ALARMS

These alarms stop the operation of the washer. To clear the alarm mode, the

washer must be switched off by pressing button.

2.1 FAULT N°1 PROBE FAULT.

F A U LT N°01

P R O B E D E F E C T

Probe Fault Definition :

The probe used to check the temperature of the water in the chamber

is disconnected or defective.

Corrective Action :

CONTACT A MAINTENANCE TECHNICIAN to check the electrical

connection and the condition of the probe.

2.2 FAULT N°2 EMPTYING FAULT.

F A U LT n°02

E M P T Y I N G F A U L T

Emptying Fault Definition :

The washer has not been fully emptied at the end of the normal

emptying time defined in the Common Times menu.

Corrective Action :

Check that there is no restriction on the emptying line, that the

emptying pump (or the valve) and its pipes are not blocked and that the

chamber filters are not clogged.

This message may be displayed at the end of PREWASH 1, PREWASH 2,

WASH, RUNNING WATER RINSE 1, ACID RINSE, RUNNING WATER RINSE 2, COLD DEMI.

WATER RINSE and HOT DEMI. WATER RINSE.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

46

Page 49

CHAPTER 4 FAULT ALARMS

2.3 FAULT N°3 HEATING EXCESS.

F A U LT n°03

H E A T I N G E X C E S S

Heating Excess Definition :

Is displayed if the basin temperature exceeds the programmed

temperature by 20°C.

Corrective Action :

Verify that the incoming water temperature does not exceed the

programmed setpoint temperature.

CONTACT A MAINTENANCE TECHNICIAN.

2.4 FAULT N°4 HEATING FAULT.

F A U LT n°04

H E A T I N G F A U L T

Heating Fault Definition :

This message is displayed during one of the heating phases if the water

temperature has not increased after 8 minutes of heating duration.

Corrective Action :

CONTACT A MAINTENANCE TECHNICIAN TO CHECK :

- the electrical connections,

- the condition of heating elements,

- the safety thermal cut-out with manual reset.

This message may be displayed during the heating phase of

PREWASH 2, WASH, and HOT DEMI. WATER RINSE.

PREWASH 1,

NT_820_910_1300_LX_ANG_V1 04_2007.doc

47

Page 50

CHAPTER 4 FAULT ALARMS

2.5 FAULT N°5 NO WATER.

F A U LT n°05

N O WATER

No Water Definition :

The washer did not reach the required water level by the end of the

normal filling time defined in the Common Times menu.

Corrective Action :

Check that the water inlet valves are open, that the water inlet pipes

are in good condition and that the water inlet filters are clean.

This message may be displayed during filling for PREWASH 1, PREWASH 2,

PREWASH 3, WASH , RUNNING WATER RINSE 1, ACID RINSE , RUNNING WATER RINSE 2,

COLD DEMI. WATER RINSES and HOT DEMI. WATER RINSE.

2.6 FAULT N°6 DOOR FAULT

F A U LT N°06

O P E N E D D O O R

Door Fault Definition :

It displays when the door is opened during the cycle. The cycle is

stopped.

Corrective Action :

Shut the door and start the cycle again.

NT_820_910_1300_LX_ANG_V1 04_2007.doc

48

Page 51

CHAPTER 4 FAULT ALARMS

2.7 FAULT N°7 LEVEL FAULT.

F A U L T N ° : 0 7

F I X TO LEVEL

Fix to Level Definition :

After achieving the proper water level during the Filling Time, the

water level has dropped causing the pressurestat to open times to

indicate fluctuation of the water level in the machine.

Corrective Action :

Check if you have a leak or if the emptying tube is out of location.

2.8 FAULT N°8 PRESSURESTAT FAULT.

F A U L T N ° : 0 8

P R E S S O S T A T F A U L T

Pressostat Fault Definition :

The pressurestat has a N.O. + N.C. contact. This alarm indicates that

the contacts are both closed or both open at the same time which is not

correct.

Corrective Action :

Check the state of the pressurestat

NT_820_910_1300_LX_ANG_V1 04_2007.doc

49

Page 52

CHAPTER 4 FAULT ALARMS

NT_820_910_1300_LX_ANG_V1 04_2007.doc

50

Loading...

Loading...