Page 1

INSTALLATION AND SERVICE MANUAL

LANCER SERIES 4500

85-4562H, ICE BEVERAGE DISPENSER

44 INCH WIDE, 12 VALVE, 115V/60Hz

SPECIFICATIONS

DIMENSIONS

HEIGHT: 34.00 Inches (864 mm)

WIDTH: 44.00 Inches (1118 mm)

DEPTH: 30.50 Inches (775 mm)

TOTAL ICE CAPACITY: 360 Pounds (163.29 kg)

DISPENSABLE ICE CAPACITY: 300 Pounds (136.08 kg)

COUNTER WEIGHT (WITHOUT ICE): 400 Pounds (181.44 kg)

SHIPPING WEIGHT: 460 Pounds (208.66 kg)

ELECTRICAL

VOLTAGE: 115

AMPS: 6.0

Hz: 60

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

This manual supersedes Installation and Service Manual 28-0420/01, Dated 05/21/04,

and is being published on the Lancer Web Site only.

DATE: 02/15/06

P.N. 28–0420/02

• FAX ENGINEERING: • 210-310-7096 •

• "Lancer" is the registered trademark of Lancer •

• Copyright — 2006 by Lancer, all rights reserved •

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

FAX SALES

• NORTH AMERICA – 210-310-7245 • INTERNATIONAL SALES – 210-310-7242 • CUSTOMER SERVICE – 210-310-7242 •

• LATIN AMERICA – 210-310-7245 • EUROPE – 32-2-755-2399 • PACIFIC – 61-8-8268-1978 •

W

ARNING

THIS UNIT IS EQUIPPED WITH AUTOMATIC AGITATION. IT MAY ACTIVATE UNEXPECTEDLY. DO NOT

PLACE HANDS, OR FOREIGN OBJECTS IN THE ICE STORAGE COMPARTMENT.

WHEN UNIT IS BEING SERVICED, CLEANED, OR SANITIZED, UNPLUG DISPENSER FROM THE

POWER SOURCE.

NOTE

Lancer does not recommend the use of shaved, flake, nugget, or pellet ice in the dispenser. Dispenser will

only operate with cube ice.

Page 2

TABLE OF CONTENTS

SPECIFICATIONS ...................................................................................................................................COVER

TABLE OF CONTENTS .....................................................................................................................................1

1. INSTALLATION ...........................................................................................................................................1

1.1 RECEIVING........................................................................................................................................1

1.2 UNPACKING ......................................................................................................................................1

1.3 SELECTING COUNTER LOCATION .................................................................................................1

1.4 INSTALLING THE DISPENSER .........................................................................................................2

2. CLEANING AND SANITIZING INSTRUCTIONS ........................................................................................3

2.1 GENERAL INFORMATION ................................................................................................................3

2.2 REQUIRED CLEANING EQUIPMENT...............................................................................................4

2.3 DAILY CLEANING..............................................................................................................................4

2.4 ICE BIN CLEANING – START UP AND MONTHLY ..........................................................................4

2.5 CLEANING AND SANITIZING BEVERAGE COMPONENTS - FIGAL SYSTEMS............................5

2.6 CLEANING AND SANITIZING BEVERAGE COMPONENTS - BAG-IN-BOX SYSTEMS.................6

3. TROUBLESHOOTING.................................................................................................................................6

4. LIGHT EMITTING DIODES .........................................................................................................................7

5. AUTOMATIC AGITATION AND LOW ICE ALARM CONTROL..................................................................8

6. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS............................................................9

6.1 DECALS AND LABELS.................................................................................................................9-10

6.2 FINAL ASSEMBLY, POST-MIX IBD AND ICE DISPENSER .......................................................11-12

6.3 FAUCET PLATE AND ICE CHUTE SUB-ASSEMBLY, POST-MIX, IBD .....................................13-14

6.4 ELECTRICAL BOX AND GEAR MOTOR SUB-ASSEMBLY, POST-MIX, IBD............................15-16

6.5 WIRING DIAGRAM - 115V/60HZ .....................................................................................................17

6.6 AGITATION - CONTROLS, EXPANDED VIEW ...............................................................................18

1. INSTALLATION

1.1 RECEIVING

Each unit is completely tested under operating conditions and thoroughly inspected before

shipment. At the time of shipment the carrier accepts the unit, and any claim for damage must be

made with the carrier. Upon receiving units from the delivering carrier, carefully inspect carton for

visible indication of damage. If damage exists, have carrier note the same on bill of lading and file

claim with carrier.

1.2 UNPACKING

A. Set shipping carton upright on the floor.

B. Cut band and remove.

C. Open top of carton and remove interior packing.

D. Lift carton up and off of the dispenser.

E. Remove wood shipping base from the bottom of the dispenser. (Support dispenser while

removing shipping base to prevent damage to the dispenser.)

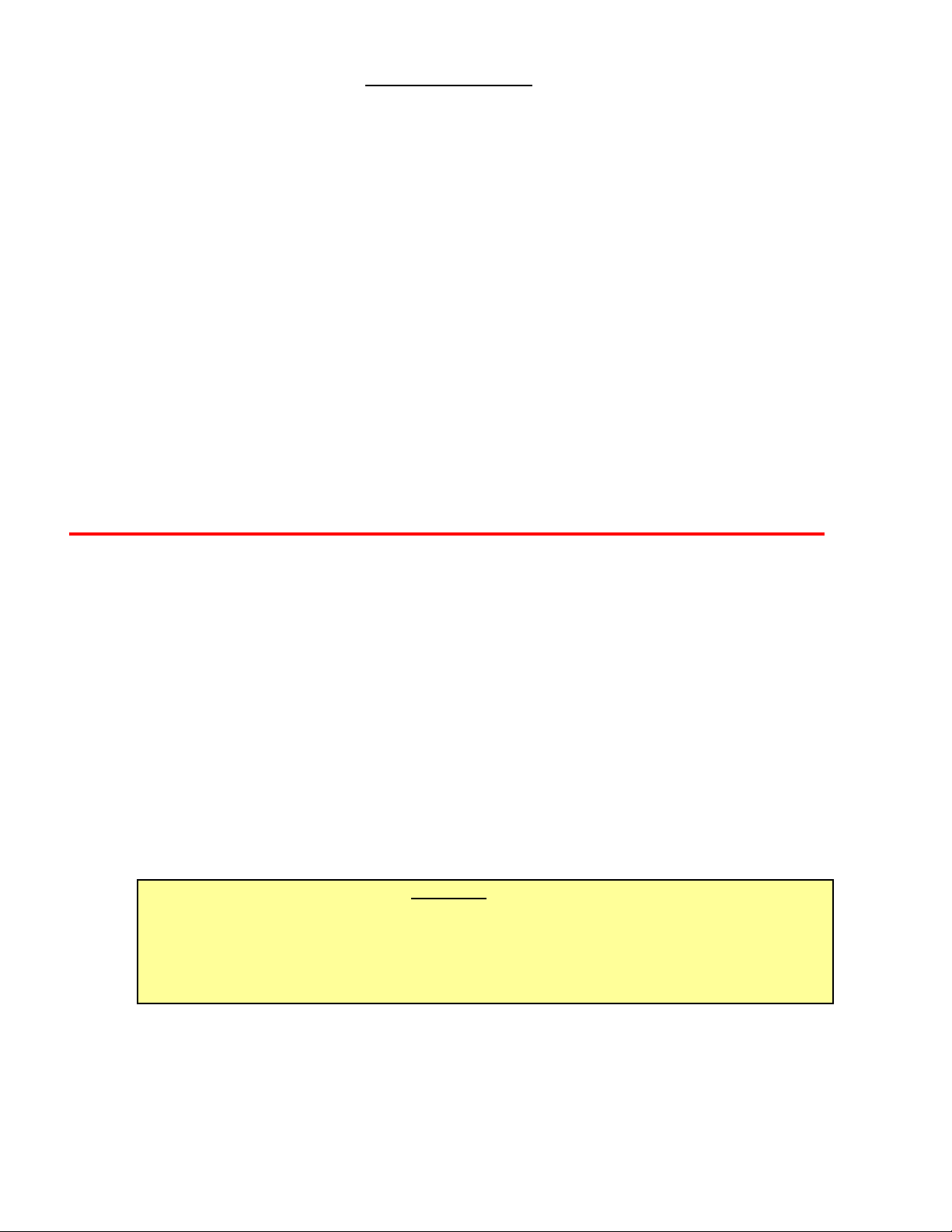

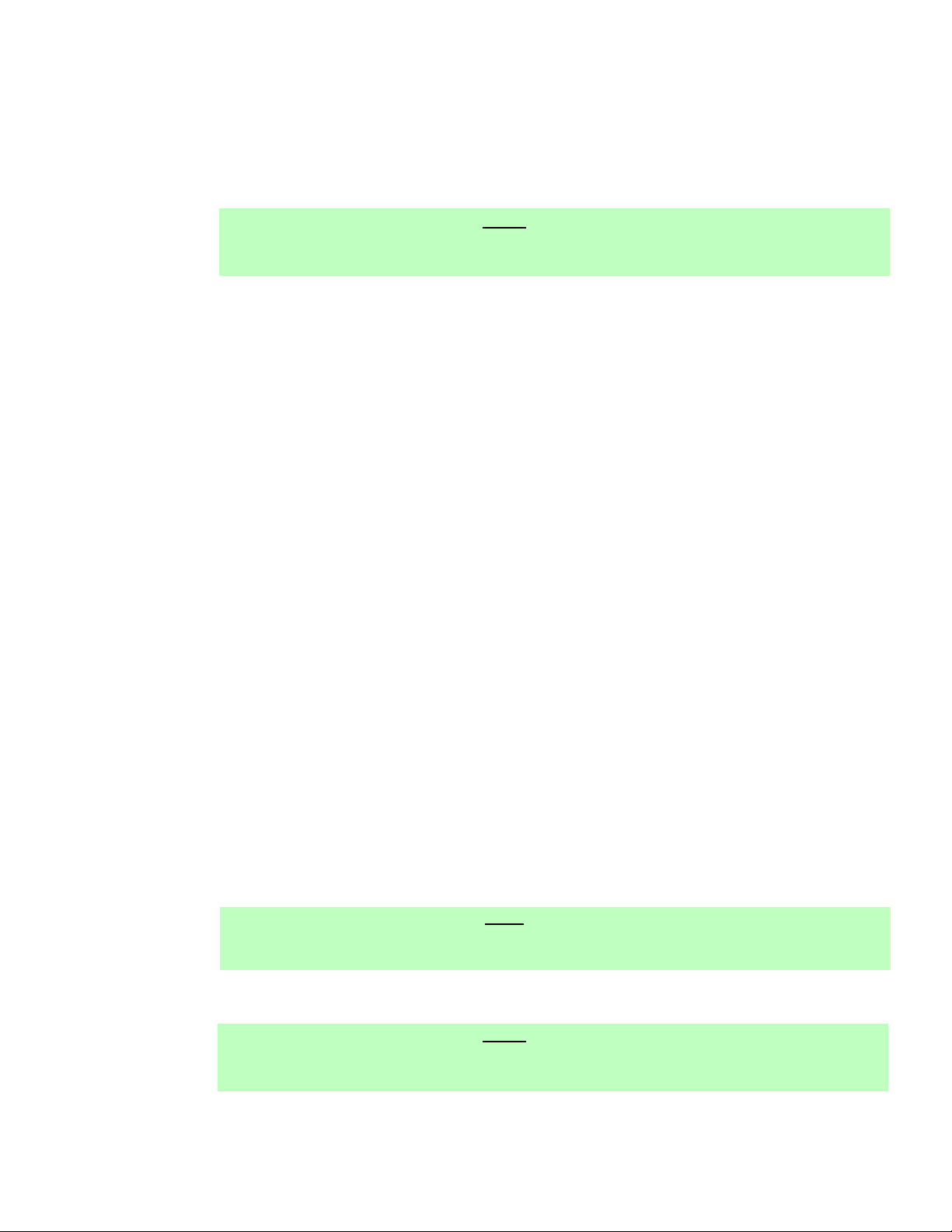

1.3 SELECTING COUNTER LOCATION (SEE FIGURE 1)

W

ARNING

THIS APPLIANCE MUST BE EARTHED. THIS DISPENSER MUST BE ELECTRICALLY

GROUNDED TO AVOID DANGER TO THE OPERATOR. THE POWER CORD PROVIDED HAS

A THREE PRONG GROUNDED PLUG. IF A THREE HOLE GROUNDED ELECTRICAL OUTLET

IS NOT AVAILABLE, USE AN APPROVED METHOD OF INSURING A PROPER GROUND TO

THE DISPENSER.

A. Select a location close to a properly grounded electrical outlet, convenient to an open type drain,

and access for soda, water, and syrup lines.

1. If at all possible, location should be away from direct sunlight or other heat sources.

2. Connecting lines may be run through access in back of the unit or extend down through a

counter cut out.

3. The counter must support the weight of the dispenser, ice, and possibly an ice maker. Total

weight may exceed 800 lbs (363.6 kg).

1

Page 3

B. Unit may be installed directly on the countertop or on legs supplied with the unit. If installed

directly on the counter, the unit must be sealed to the counter top with a silicone sealant which

provides a smooth and easily cleanable bond to the counter. If an ice maker is to be

mounted on top of dispenser, do not install dispenser on legs.

NOTE

NSF listed units must be sealed to the counter or have four (4) inch legs installed.

Water pipe connections and fixtures directly connected to a potable water supply must all be

sized, installed, and maintained according to Federal, State, and Local laws.

The water supply must be protected by means of an air gap, a backflow prevention device

(located upstream of the CO2 injection system) or another approved method to comply with

NSF standards. A backflow prevention device must comply with ASSE and local standards.

It is the responsibility of the installer to ensure compliance.

C. Location must insure sufficient clearance on sides, top and back of unit is provided for

ventilation and air circulation (see Figure 1).

D. Additionally, if an ice maker is not top mounted on the unit, sufficient clearance should be

provided [a minimum of 16 inches (406 mm) is recommended] to allow filling the unit with ice

from a five (5) gallon (19 liter) container (see Figure 1).

2

Figure 1

1.4 INSTALLING THE DISPENSER

A. Remove Cup Rest, Drip Tray, Splash Plate, and Top Cover.

B. Remove Cover Plate at rear of unit if not a through the counter installation.

C. Connect soda and water supply lines to 3/8 inch barb fittings at the front of the unit. Check for

leaks. (If dispenser is to operate with all soda valves, connect water line into one of the soda

supply lines.)

D. Connect syrup supply lines to the 3/8 inch barb inlet fittings at the front of the unit. Check for

leaks.

E. Uncoil drain hose from Cold Plate drain and extend to an open type drain.

F. Install Drip Tray and extend hose to open type drain.

G. Both drain lines must be insulated with a closed cell insulation. Insulation must cover the entire

length of the drain hose, including fittings. The drain should be installed in such a manner that

water does not collect in sags or other low points, as condensation will form.

NOTE:

Please refer to specific icemaker

model for proper air intake/exhaust

ventilation with Lancer units.

MINIMUM OF 6" (152 mm)

CLEARANCE ABOVE ICE MAKER

AIR

IN

SUFFICIENT CLEARANCE FOR

FILLING MANUALLY WITH ICE,

WHEN ICE MAKER NOT USED

34" (864 mm)

30 1/2" (775 mm)

WIDTH OF THE 85-4562H DISPENSER IS 44" (1118 mm)

9 3/4" (248 mm)

DISPENSE HEIGHT

30 1/2" (775 mm)

AIR

IN

WALL CLEARANCE

MINIMUM of 6" (152 mm)

Page 4

3

H. Install Cup Rest and Splash Plate.

I. Connect Power Cord to grounded electrical outlet.

J. Test Motor operation by pushing Ice Chute.

K. Clean and sanitize dispenser (see Section 2).

L. Fill unit approximately half full with ice. Push Chute and check for ice delivery.

M. Finish filling unit with ice.

N. Install Top Cover.

NOTE

Lancer does not recommend the use of shaved, flake, nugget, or pellet ice in the dispenser.

Dispenser will only operate with cube ice.

O. Set brix ratio for beverage dispensing valves according to manufacturer’s instructions.

IMPORT

ANT NOTICE

WHEN INSTALLING AN ICEMAKER ON AN IBD UNIT, A BIN THERMOSTAT OR OTHER MEANS

OF CONTROLLING THE ICE LEVEL MUST BE INSTALLED. FAILURE TO DO SO COULD

RESULT IN DAMAGE TO THE DISPENSING MECHANISM AND VOID THE WARRANTY.

DURING THE AUTOMATIC AGITATION CYCLE AND/OR WHILE DISPENSING ICE, THERE

MUST BE ADEQUATE ROOM BETWEEN THE TOP OF THE ICE LEVEL AND THE BOTTOM OF

THE ICEMAKER SO THAT THE ICE CAN MOVE WITHOUT OBSTRUCTION.

CONTACT YOUR ICEMAKER SUPPLIER FOR INFORMATION ON PROPER BIN THERMOSTAT.

2. CLEANING AND SANITIZING INSTRUCTIONS

2.1 GENERAL INFORMATION

A. Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized in

accordance with NSF guidelines. This equipment must be cleaned and sanitized after

installation is complete, and the operator of the equipment must provide continuous

maintenance as required by this manual and/or state and local health department guidelines to

ensure proper operation and sanitation requirements are maintained.

NOTE

The cleaning and sanitizing procedures provided herein pertain to the Lancer equipment

identified by this manual. If other equipment is being cleaned, follow the guidelines established

for that equipment.

B. Cleaning and sanitizing should be accomplished only by trained personnel. Sanitary gloves are

to be used during cleaning and sanitizing operations. Applicable safety precautions must be

observed. Instruction warnings on the product being used must be followed.

C. Water lines are not to be disconnected during the cleaning and sanitizing of syrup lines to avoid

contamination.

D. Do NOT use strong bleaches or detergents. They tend to discolor and/or corrode various

materials.

E. Do NOT use metal scrapers, sharp objects, steel wool, scouring pads, abrasives, solvents, etc.,

on the dispenser.

F. Do NOT use hot water above 140°F (60°C). This may damage certain materials.

2.2 REQUIRED CLEANING EQUIPMENT

A. Cleansers (for example, Ivory Liquid, Calgon, etc.) mixed with clean, potable water at a

temperature of 90° to 110°F (32°C - 43°C) should be used to clean equipment. The mixture

ratio, using Ivory Liquid, is one (1) ounce (27.57 ml) of cleanser to two (2) gallons (7.57 liters)

of water. A minimum of five (5) gallons (19 liters) of cleaning mixture should be prepared. Any

equivalent cleanser may be used as long as it provides a caustic based, non-perfumed, easily

rinsed mixture containing at least two (2) percent sodium hydroxide (NaOH). Rinsing must be

thorough and use clean, potable water which is also at a temperature of 90° to 110°F (32°C to

43°C).

NOTE

Extended lengths of product lines may require that an additional volume of cleaning solution be

prepared.

Page 5

4

B. Sanitizing solutions should be prepared in accordance with the manufacturer’s written

recommendations and safety guidelines. The solution must provide 200 parts per million (PPM)

available chlorine. A minimum of five (5) gallons (19 liters) of sanitizing solution should be

prepared. Any sanitizing solution may be used as long as it is prepared in accordance with the

manufacturer’s written recommendations and safety guidelines, and provides 200 parts per

million (PPM) available chlorine. Sanitizing solution is to be purged from line(s) and equipment

by flushing with product only until there is no after taste. Do not rinse with water.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with

the end use product until there is no after taste in the product. This is an NSF requirement.

Extended lengths of product lines may require that an additional volume of sanitizing solution

be prepared.

C. Other:

(1) Clean cloth towels.

(2) Bucket.

(3) Small brush (PN 22-0017) - included with installation kit.

(4) Extra nozzle.

(5) Sanitary gloves.

2.3 DAILY CLEANING

Using a mild detergent solution, clean Top Cover and all exterior stainless steel surfaces. Clean

exterior of dispensing valves and ice chute. Remove Cup Rest, clean Drip Tray and Cup Rest, and

replace Cup Rest. Wipe clean all splash areas using a damp cloth soaked in cleaning solution.

Clean beverage valves as specified by the valve manufacturer.

2.4 ICE BIN CLEANING - START UP AND MONTHLY

A. Disconnect Dispenser from power source.

B. Remove Top Cover.

C. Remove Agitator Pin from Agitator Shaft. Slide Agitator Shaft rearward out of Motor Shaft and

pull out of rear Bearing to remove.

D. Remove Dispensing Wheel from Motor Shaft by sliding rearward.

E. Remove Dispensing Wheel Shroud.

F. Remove Splash Plate Assembly by lifting it up and out from the dispenser face.

G. Using cleaning solution, described in Section 2.2, and a clean cloth or soft brush, clean all

removable parts, sides of Ice Bin, Ice Chute, and surface of aluminum casting.

H. Repeat Step G for all exterior surfaces of the dispenser.

I. Using hot water, thoroughly rinse away the cleaning solution.

J. Wearing sanitary gloves, soak a clean cloth towel in sanitizing solution, described in Section 2.2,

and wash all surfaces of removable parts, sides of Ice Bin, Ice Chute, and surface of aluminum

casting.

K. Repeat Step J for all metal and plastic surfaces (but not labels) of the dispenser exterior.

L. Wearing sanitary gloves, reassemble all removable parts.

M. Fill Unit with ice and replace Top Cover.

NOTE

Lancer does not recommend the use of shaved, flake, nugget, or pellet ice in dispensers not properly

equipped to do so.

N. Reconnect Dispenser to power source.

2.5 CLEANING AND SANITIZING BEVERAGE COMPONENTS - FIGAL SYSTEMS

NOTE

Extended lengths of product lines may require more time for flushing and rinsing lines than

stated below.

A. Disconnect syrup lines from syrup containers (for example, quick disconnects, figal containers,

etc.).

B. Connect hose half of syrup line to a syrup tank filled with clean, potable, room temperature

Page 6

water. Connect CO2 supply hose to tank and pressurize.

C. Activate valve until water is dispensed. Flush and rinse line and fittings for a minimum of

60 seconds to remove all traces of residual product.

W

ARNING

TO AVOID POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE, DO NOT ATTEMPT TO

REMOVE SYRUP TANK COVER UNTIL CO

2 PRESSURE HAS BEEN RELEASED FROM TANK.

D. Disconnect CO2 supply hose from the water filled syrup tank.

E. Following the instructions as described in Section 2.2 above, mix appropriate amount of

cleaning solution. Fill a tank with this solution. Connect hose half of syrup line to the tank.

Connect CO2 supply hose to tank and pressurize.

F. Activate valve and draw cleaning solution through lines for a minimum of 60 seconds. This will

ensure line is flushed and filled with cleaning solution. Allow line to stand for at least

30 minutes.

G. Disconnect CO

2 supply hose from the tank.

H. Connect hose half of syrup line to a tank filled with clean, potable, water at a temperature of 90°

to 110°F (32°C to 43°C). Connect CO

2 supply hose to tank and pressurize.

I. Activate valve to flush and rinse line and fittings for a minimum of 60 seconds to remove all

traces of cleaning solution. Continue rinsing until testing with phenolpthalein shows that the

rinse water is free of residual detergent.

J. Disconnect CO2 supply hose from the tank.

K. Following the instructions as described in Section 2.2 above, mix appropriate amount of

sanitizing solution. Fill a tank with this solution. Connect hose half of syrup line to the tank.

Connect CO2 supply hose to tank and pressurize.

L. Activate valve and draw sanitizing solution through line for a minimum of 60 seconds. This will

ensure line is flushed and filled with sanitizing solution. Allow line to stand for at least 30 minutes.

M. Disconnect CO

2 supply hose from the tank.

N. Reconnect syrup lines to syrup containers (for example, quick disconnects, figal containers, etc.)

and ready unit for operation.

O. Draw drinks to refill lines and flush the sanitizing solution from the dispenser.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with the

end use product until there is no after taste in the product.

P. Test dispenser in normal manner for proper operation. Taste dispensed product to ensure there

is no off-taste. If off-taste is found, additional flushing of syrup system may be required.

Q. Repeat cleaning, rinsing, and sanitizing procedures for each valve and each circuit.

2.6 CLEANING AND SANITIZING BEVERAGE COMPONENTS - BAG-IN-BOX SYSTEMS

NOTE

Extended lengths of product lines may require more time for flushing and rinsing lines than

stated below.

A. Disconnect syrup quick disconnect coupling from syrup packages and connect coupling to a bag

valve removed from an empty Bag-in-Box (BIB) package.

B. Place syrup inlet line in a clean container filled with clean, potable, room temperature water.

C. Activate valve until water is dispensed. Flush and rinse line and fittings for a minimum of

60 seconds to remove all traces of residual product.

D. Following the instructions as described in Section 2.2 above, mix appropriate amount of

cleaning solution in a clean container. Place syrup inlet line in container filled with cleaning

solution.

E. Activate valve and draw cleaning solution through lines for a minimum of 60 seconds. This will

ensure line is flushed and filled with cleaning solution. Allow line to stand for at least 30 minutes.

F. Place syrup inlet line in a clean container filled with clean, potable, water at a temperature of 90

°

to 110°F (32°C to 43°C).

G. Activate valve to flush and rinse line and fittings for a minimum of 60 seconds to remove all traces

5

Page 7

of cleaning solution. Continue rinsing until testing with phenolpthalein shows that the rinse water

is free of residual detergent.

H. Following the instructions as described in Section 2.2 above, mix appropriate amount of

sanitizing solution in a clean container. Place syrup inlet line in container filled with sanitizing

solution.

I. Activate valve and draw sanitizing solution through line for a minimum of 60 seconds. This will

ensure line is flushed and filled with sanitizing solution. Allow line to stand for at least

30 minutes.

J. Remove bag valve from quick disconnect coupling and reconnect syrup inlet line to syrup

package. Ready unit for operation.

K. Draw drinks to refill lines and to flush the chlorine sanitizing solution from the dispenser.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with the

end use product until there is no after taste in the product. This is an NSF requirement.

L. Test dispenser in normal manner for proper operation. Taste dispensed product to ensure there

is no off-taste. If off-taste is found, additional flushing of syrup system may be required.

M. Repeat cleaning, rinsing, and sanitizing procedures for each valve and each circuit.

3. TROUBLESHOOTING

TROUBLE

CAUSE REMEDY

3.1 Push Chute and A. Dispenser not connected to A. Connect Dispenser to power

nothing happens. power source. source.*

B. Microswitch defective. B. Replace Microswitch.*

C. Wiring Harness not plugged in. C. Plug in Wiring Harness.*

D. PC Board defective. D. Replace PC Board.*

3.2 Push Chute, Trap Door A. Wiring Harness not plugged in. A. Plug in Wiring Harness.*

opens but Motor does B. PC Board defective. B. Replace PC Board.*

not run. C. Motor defective. C. Replace Motor.*

3.3 Push Chute, Motor A. Solenoid not connected to A. Connect Solenoid to PC

runs but Trap Door PC Board. board.*

does not open. B. Solenoid defective. B. Replace Solenoid.*

C. PC Board defective. C. Replace PC Board.*

3.4 Push Chute, Trap Door A. Dispenser is out of ice. A. Fill unit with ice.

opens, Motor runs, B. Agitator Pin is missing or B Replace Agitator Pin.

but no ice dispenses. damaged.

3.5 Valves do not operate. A. Keyswitch is off. A. Turn Keyswitch on.

B. Transformer tripped. B. Reset Transformer.

C. Unit not plugged in. C. Plug in Dispenser.*

3.6 Water in Ice Bin. A. Coldplate Drain is obstructed. A. Remove Drain Hose and

90 degree fitting to obtain

access to Drain.

B. Drain Hose is kinked. B. Replace Drain Hose.

* Light Emitting Diodes (LEDs) are provided on the PC Board to aid in troubleshooting electrical

difficulties. Referring to the wiring diagram included in this manual (also affixed to the electrical box

cover), the following information in Section 4 can be obtained from the LEDs.

NOTES

6

Page 8

4. LIGHT EMITTING DIODES (LEDS)

4.1 LED D3

This light is on when the ice dispense switch is activated. If the chute is depressed and the light does

not turn on, check to see if the wire harness is connected or if the dispense switch is defective.

4.2 LED D4

This light is used on units with lid interlock switches. On the 4500 series ice-beverage dispenser, this

light should always be lit. If it is not, check the Lid Interlock Jumper (black wire with 4 pin white

connector).

4.3 LED D5

This light is on when +5VDC is present at the circuit board. It should be lit whenever the unit is

connected to a power source. If the light is off, check to see if the internal circuit breaker on the

transformer has tripped. If it has tripped, it can be reset by depressing the switch on the top of the

transformer.

4.4 LED D6

This light is on when +32VDC is present at the circuit board. It should be lit whenever the unit is

connected to a power source. If the light is off, check to see if the internal circuit breaker on the

transformer has tripped. If it has tripped, it can be reset by depressing the switch on the top of the

transformer.

4.5 LED D7

This light flashes when there is no ice between the sensors in the ice bin. If the bin is empty and the

light is not flashing, check all wiring harnesses.

4.6 LED D8

This light is on when the solenoid is activated. When the chute is depressed, this light should turn on.

If it does not, check to see if the solenoid leads are connected to the PC board or damaged, check

continuity of solenoid. Replace if defective.

4.7 LED D9

This light is on when the motor is activated. When the chute is depressed, this light should turn on. If

it does not, check to see if the motor harness is connected to the PC board or damaged, check

continuity of motor harness and motor. Replace if defective.

5. AUTOMATIC AGITATION AND LOW ICE ALARM CONTROL

WARNING

THIS UNIT IS EQUIPPED WITH AUTOMATIC AGITATION. IT MAY ACTIVATE UNEXPECTEDLY.

DO NOT PLACE HANDS, OR FOREIGN OBJECTS IN THE ICE STORAGE COMPARTMENT.

WHEN UNIT IS BEING SERVICED, CLEANED, OR SANITIZED, UNPLUG DISPENSER FROM THE

POWER SOURCE.

Each Series 4500 ice beverage dispenser is equipped with automatic agitation for the ice bin. The unit is

shipped with timing set at two (2) seconds ON every 60 minutes. Referring to the tables on the wiring

diagram included in this manual (also affixed to the electrical box cover), the automatic agitation timing can

be changed as follows. (A set of DIP switches is provided to control the timing and low ice control.)

5.1 DIP#1

This switch controls the low ice indicator light. With the switch in the ON position, the light operates

when a low ice condition exists. In the OFF position, the light is turned off. The unit is shipped with

the light switch in the ON position.

5.2 DIP#2

This switch controls the low ice audible alarm. With the switch in the ON position, the alarm

operates when a low ice condition exists. In the OFF position, the alarm is turned off. The unit is

shipped with the alarm switch in the OFF position.

7

Page 9

8

5.3 DIP#3 & #4

These switches control the ON time for automatic agitation. By referring to the table and setting the

switches as shown, ON times from one (1) second to four (4) seconds [in one (1) second

increments] can be obtained. EXAMPLE: For three (3) second ON time, switch 3 should be in the

ON position, and switch 4 should be in the OFF position. The unit is shipped with two (2) seconds

ON time.

5.4 DIP#5 through #8

A. These switches control the OFF time for automatic agitation. By referring to the table and

setting the switches as shown, OFF times from 10 minutes to 150 minutes (in 10 minute

increments) can be obtained. EXAMPLE: For 40 minute OFF time, switch 5 should be in the

OFF position, switch 6 should be in the ON position, switch 7 should be in the OFF position, and

switch 8 should be in the OFF position. The unit is shipped with 60 minute OFF time.

B. To turn the agitation completely off, set switches 5 through 8 all OFF.

NOTES

Page 10

6. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS

6.1 DECALS AND LABELS

DANGER

HAZARDOUS MOVING PARTS

SER

VI

CIN

G

OR C

LEAN

ING

UN

IT

D

I

SC

O

N

NE

CT

PO

W

E

R

BEF

O

R

E

UNIT

MA

Y

ACTIVATE

U

N

E

X

PEC

TED

LY

ELECTRICAL SHOCK HAZARD

9

7

E

D

L

E

AN

C

H

T

A

R

U

Z

N

A

I

C

G

I

R

T

A

D

M

L

E

D

O

A

S

I

S

Y

S

U

H

R

E

C

A

S

R

O

O

C

M

V

C

N

T

I

I

C

N

K

O

V

I

E

A

N

V

H

T

C

G

I

E

A

T

N

O

Z

U

P

G

R

A

O

N

P

R

E

W

C

A

X

L

D

E

P

R

E

R

E

A

T

B

C

N

S

E

T

I

N

F

E

G

O

D

R

L

U

Y

E

N

I

T

10

8

1

2

6

3

4

9

6

5

Page 11

10

Item Part No. Description

1 06-1183 Label, Cleaning, Hopper, IBD

2 06-1184/01 Label, Cleaning, Merchandiser, IBD

3 06-2098/01 Label, Plumbing Diagram, IBD44

R 4 06-2099/03 Label, Wiring Diagram, IBD44

5 06-1207 Label, Cold Plate Cleaning, IBD

6 06-1522 Label, Low Ice, IBD

7 06-1139 Label, Warning, Lid, IBD

8 06-1457/01 Panel, Graphics, Coca-Cola, IBD44

9 06-2058/01 Decal, Wrapper, Side, Coca-Cola,

IBD, Round

10 06-1367/01 Decal, Wrapper, Back, Coca-Cola,

IBD44

- 82-2408 Kit, Label, 12 Valve, Coca-Cola, USA,

LEV

®

- 12-0193 Ice Out Indicator

- 27-0056 Lens, Clear, Marquee

R in margin indicates change or revision

6.1 DECALS AND LABELS (CONTINUED)

Page 12

6.2 FINAL ASSEMBLY, POST-MIX IBD AND ICE DISPENSER

11

8

9

7

6

4

5

3

5

4

17

15

10

14

12

13

16

11

3

2

1

18

19

20

21

22

24

23

Page 13

Item Part No. Description

R 1 05-1311/01 Wheel Shroud, IBD44

R 2 82-3650 Dispenser, Wheel Assy, Right Side,

IBD44

R 3 23-1373 Agitator Assy, HEX, IBD

R 4 10-0762 Pin, Agitator, HEX, IBD

5 03-0368 Retainer, RUE-14-S

R 6 82-3556 Dispenser Wheel Assy, Left Side,

HEX, IBD

7 05-1392 Lid, One Piece, 44 Inch IBD

8 82-1980/02 Merchandiser Assy, 44 Inch IBD

9 10-0363/01 Screw, Thumb, IBD

10 12-0128 Lamp, 36 Inch, 30W, CW, 25/R/15

11 23-1038/01 Drain Spider, IBD

12 30-7343/01 Splash Plate, IBD44 (Units

manufactured before December 2003)

- 30-8635 Splash Plate, IBD44 (Units

manufactured after December 2003)

13 03-0300 Clip, Wire, Adhesive, IBD

14 03-0049 Clip, Cord

15 02-0005 O-Ring, 2-010

16 30-6680 Reflector, Merchandiser, Light, IBD44

17 04-0504 Screw, 8 - 18 x 0.375, PHDP

18 04-1089 Screw, 10 - 32 x 1.000, RH, PH/SL

19 82-1871 Drip Tray Assy, IBD44 (Units

manufactured before December 2003)

- 82-3187 Drip Tray Assy, IBD44 (Units

manufactured after December 2003)

20 04-0559 Cap, Protective, Vinyl, VC-375-8

21 04-0529 Screw, 8 - 32 x 0.750, PH

22 10-0364 Spacer, Drip Tray Lock, IBD

23 30-6145 Lock, Drip Tray, IBD

24 06-1580 Label, Patent

R in margin indicates change or revision

6.2 FINAL ASSEMBLY, POST-MIX IBD AND ICE DISPENSER (CONTINUED)

12

Page 14

13

6.3 FAUCET PLATE AND ICE CHUTE SUB-ASSEMBLY, POST-MIX, IBD

10

9

8

6

19

7

11

3

4

5

1

2

HITE

TIE WRAP

W

K

P

C

A

LA

B

R

W

BLACK

IE

T

TRANSFORMER

TO

C

A

L

B

K

TIE WRAP

H

C

IT

W

S

Y

E

K

O

T

TO TRANSFORMER

TO KEYSWITCH

E

IT

H

TIE WRAP

W

K

C

A

L

B

K

C

A

L

B

TIE WRAP

BLACK

TIE WRAP

13

12

Page 15

Item Part No. Description

1 82-2260 Faucet Plate Assy, 12 Valve,

IBD44

2 04-0308 Screw, 10 - 32 x 0.438, PHD

3 30-6145 Lock, Drip Tray, IBD

R 4 10-0364 Spacer, Drip Tray Lock, IBD

R 5 04-0529 Screw, 8 - 32 x 0.750, PHD

R 6 04-0553 Screw, 10 - 24 x 0.750, LG,

PHMS, COMBO, SS

R 7 82-3538 Chute Assy, IBD

R 8 05-0928/02 Trap Door, IBD

9 04-0504 Screw, 8 - 18 x 0.375, PHD

R 10 82-1566/01 Solenoid Assy

R A 03-0086 Ring, Retaining (5304-18)

R B 04-0328 Washer, Rubber

R C 04-0327 Washer, Flat

R D 12-0195 Solenoid, D-90

R E 30-5165/01 Bracket, Solenoid

R F 23-1380 Plunger Assy

R G 10-0496 Pin, Solenoid Assy

R H 03-0110 Spring, Solenoid

R I 03-0111 Ring, Retaining (5133-62)

R J 10-0353 Linkage, Door, IBD

R K 04-0320 Screw, 8 - 32 X 0.187, PHD

6.3 FAUCET PLATE AND ICE CHUTE SUB-ASSEMBLY, POST-MIX, IBD (CONTINUED)

14

R 11 82-1899 Trim Assy, IBD44

R 12 30-6678 Cover, Electric Box, IBD44

R 13 04-0477 Screw, 8 - 32 x 0.375, PHD

R 14 10-0732 Shaft, ice Chute Door

R 15 05-0359 Bushing, Shaft

R 16 03-0113 Ring, Retaining (5144-12)

R 17 05-0546 Lever, Door,

R 18 03-0205 Ring, Retaining (5304-25)

R 19 12-0244 Ice Door Switch

R in margin indicates change or revision

Item Part No. Description

10

18

K

A

E

G

17

7

B

C

D

F

H

I

J

16

15

14

Page 16

15

6.4 ELECTRICAL BOX AND GEAR MOTOR SUB-ASSEMBLY, POST-MIX, IBD

30

19

32

FROM RED

LEADS ON

BALLAST

20

5

19

31

FROM BLUE

LEADS ON

BALLAST

26

27

TO YELLOW

LEADS ON

BALLAST

19

25

24

23

19

28

29

4

5

2

30

3

1

6

2

19

9

8

7

8

22

4

10

21

15

16

18

17

15

16

15

14

10

11

12

13

Page 17

Item Part No. Description

1 82-2315 Foamed Tank Assy, IBD44

2 02-0406 Seal, Shaft, Motor, IBD

3 05-1589 Body, Detector, Sensor, Plug

4 06-2488 Label, Ice Link Tag, IBD

5 52-2450 Harness Assy, Detector, IBD

6 52-2353 Body Assy, Detector, Sensor

7 52-2352 Body Assy, Emitter, Sensor

8 02-0155 O-Ring, 2-015

9 05-1858 Body, Emitter, Sensor, Plug

10 52-2449 Harness Assy, Emitter, IBD

11 90-0975 Board, Shipping, IBD44

12 07-0211 Washer, Shipping Base

13 04-0203 Screw, 3/8 - 16 x 1.000, FHD

R 14 82-3689 Drive Assy, Motor, IBD44, Right Side

15 04-0069 Screw, 10 - 24 x 0.500, PHD

16 30-6147 Cover, Motor, IBD

R 17 82-3688 Drive Assy, Motor, 115V, 1/7 HP, IBD,

Left Side

18 30-6679 Bracket, Merchandiser, Support,

IBD44

19 04-0504 Screw, 8 - 18 x 0.375, PHD

20 52-2181/01 Ballast Assy, 120V, IBD44

21 51-5836 Wrapper Sub Assy, Right Side, IBD44

22 12-0097 Switch, Key Lock, Maintain, Spade

23 51-5331 Wrapper Sub Assy, Back, IBD44

24 04-1106 Screw, 10 - 32 x 0.500, SL, HH, SS,

with Washer

25 82-1897 Wrapper Sub Assy, Left Side, IBD44

R 26* 82-2404 Electrical Box Assy, IBD44*

27 52-2178/01 Harness Assy, Light, Right, White,

IBD44

28 52-2179/01 Harness Assy, Light, Black, Right,

IBD44

29 30-6152 Bracket, Right, Light, IBD

30 04-0237 Screw, 8 - 32 x 0.250, PHD

31 30-6153 Bracket, Left, Light, IBD

32 11-0295 Socket, 660W/600V Max

R REF* Electrical Box Assy Components*

(Not Shown)

R -- 52-1436/05 PCB Assy (Available as Spare Part)

- 25-0039 120V - 24V Transformer (Available as

Spare Part)

- 25-0047 75VA - 24V Transformer (Available as

Spare Part)

R in margin indicates change or revision

6.4 ELECTRICAL BOX AND GEAR MOTOR SUB-ASSEMBLY, POST-MIX, IBD (CONTINUED)

16

Page 18

6.5 WIRING DIAGRAM - 115V/60HZ

17

BLACK

BLACK

WHITE

YELLOW

YELLOW

WHITE

EMITTER

LOW ICE SENSOR

YELLOW

BLUE

WHITE

BLACK

BLACK

SOLENOID

VALV E

KEY

SWITCH

MOTOR

SWITCH

DISPENSE

BLACK

WHITE

WHITE

BLACK

WHITE

BLACK

BLACK

WHITE

WHITE

BLACK

BLACK

BLACK

RED

BLUE

WHITE

BLACK

J2

J7

J3

J6J5J4

62431578

ON

J1

J8

ELECTRICAL BOX BOUNDARY

BLACK

BLACK

J8

J1

J4

J5

87513426

ON

J6

J3

WHITE

WHITE

WHITE

WHITE

J7

WHITE

BLACK

RED

BLUE

J2

WIRING DIAGRAM FOR LANCER ICE DISPENSER WITH LOW ICE SENSING (TYP.)

BLUE

BLACK

BLUE

RED

WHITE

RED

BLACK

BLACK

RED

WHITE

WHITE

DETECTOR

LOW ICE SENSOR

LOW ICE LIGHT

BLACK

BLACK

RED

BLACK

LOW ICE LIGHT

SOLENOID

WHITE

BLACK

WHITE

SWITCH

DISPENSE

WHITE

GREEN

BLACK

BLACK

WHITE

BLACK

BLACK

KEY

SWITCH

WHITE

MOTOR

VALV E

Page 19

18

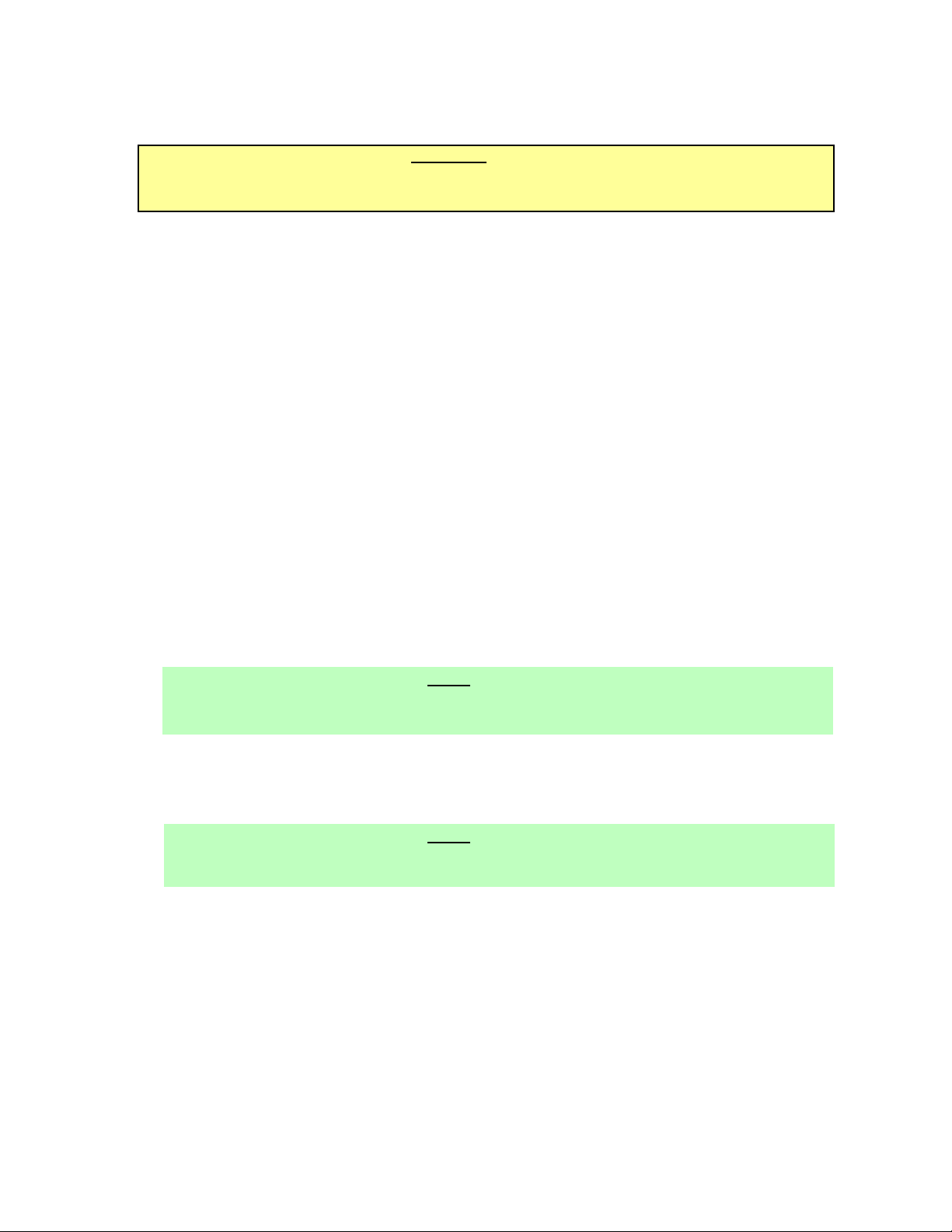

6.6 AGITATION - CONTROLS, EXPANDED VIEW

TES

TES

OFF

=ON=

X

O

4 SECONDS

X

X

3 SECONDS

X

O

2 SECONDS

X

AGITATION TIME

1 SECOND

SWITCH

NUMBER

AGITATION FREQUENCY

O

OO

3

4

SWITCH

150 MINUTES

X

140 MINU

MINUTES

130

X

120 MINUTES

MINUTES

0

11

XX

100 MINU

90 MINUTES

80 MINUTES

X

70 MINUTES

60 MINUTES

50 MINUTES

40 MINUTES

30 MINUTES

20 MINUTES

O

10 MINUTES

OO

NUMBER

X

X

X

X

X

O

XX

OO

O

O

XX

X

X

OOO

O

O

O

OO

5

6

X

X

X

O

X

O

O

O

X

O

XX

X

O

O

OOOO

X

X

X

O

X

X

X

X

X

O

OO O

8

7

62431578

EXPANDED VIEW OF CONTROLS

SWITCHES 3-4 : AGITATION "ON TIME"

SWITCH 2 : "LOW ICE" ALARM

SWITCH 1 : "LOW ICE" LED INDICATOR

LED

INDICATORS

D3-ON WHEN DISPENSE SWITCH IS CLOSED

D4-ON WHEN LID IS CLOSED

ON

SWITCHES 5-8 : AGITATION "OFF TIME"

D9-ON WHEN MOTOR IS ON

D8-ON WHEN TRAP DOOR IS OPEN

D7-FLASHES WHEN ICE IS LOW

D6-ON WHEN +32VDC IS AVAILABLE

D5-ON WHEN +5VDC IS AVAILABLE

SLIDE SWITCH "DOWN" TO TURN "OFF"

SLIDE SWITCH "UP" TO TURN "ON"

SLIDE SWITCHES:

CUBE ICE SETTING:

FREQUENCY: 60 MIN.

AGITATION TIME: 2 SEC.

Page 20

19

NOTES

Please refer to the Lancer web site (www.lancercorp.com)

for information relating to Lancer Installation and Service

Manuals, Instruction Sheets, Technical Bulletins, Service

Bulletins, etc.

Loading...

Loading...