Lance TDC-100 Installation And Operation Manual

TDC-100

TD’S DISK CONTROLLER

Installation and Operation Manual

Software Version 3.4

September 2007

Lance Design / 27 Fairview Avenue / Ridgefield, Connecticut 06877

Tel: 203-894-8206 / Fax: 203-894-8207

www.lancedesign.com

WARRANTY STATEMENT

This equipment is warranted to be free of defects in materials and workmanship for

a period of two years from date of delivery. Any necessary repairs resulting from

defects in materials or in manufacture will be made free of charge provided that the

equipment has not been subjected to mechanical or electrical abuse, or modification,

as determined by Lance Design, and also that the equipment is returned to Lance

Design with prior authorization.

No liability whatsoever is assumed for consequential damages resulting from the use

or failure of this equipment. This warranty is in lieu of all other warranties,

expressed or implied, including any implied warranty of fitness for purpose.

COPYRIGHT

All software and hardware designs are copyrighted to Lance Design,1999-2007.

CAUTION! HAZARDOUS VOLTAGES ARE EXPOSED WHEN THE TOP

COVER OF THE RACK FRAME IS REMOVED. DO NOT APPLY POWER

WITH THE UNIT DISASSEMBLED.

2

Table of Contents

Quick Operation Guide Page 4

General Description Page 7

Control Panel Description Page 7

Menu Items Page 9

General Operation Page 14

Trigger Function Numbers Page 15

Multi-Device Control Rules Page 17

Auto-dub From VTR Page 18

Multi-Point Loops Page 19

TBC Adjustment Control Page 20

Installation Page 21

GPI Inputs and Outputs Page 22

Dipswitch Functions and Connector Pinouts Page 22

3

QUICK OPERATION GUIDE

To enable a device press the corresponding ‘device enable’ button

To enable more than one device, press multiple ‘device enable buttons at the

same time. The first one pressed will be the displayed machine, and will flash

To manually learn the ‘device enable’ data (gang) into the current register, select

the devices as above, and while still holding the ‘device enable’ buttons down, press

SET on the keypad. The display will say “Now Enabled: XXXX”, indicating the

enabled machines for this register.

To select a register, press REG #, then enter three digits on the keypad (000-299).

You can also press and hold the REG # key, and use the ‘+’ and ‘-’ keys to scroll

through the registers. The register number is indicated in the lower right corner of

the display.

To clear the current register, press and hold the REG # key, and press CLR. The

display will say ‘Register Cleared’. This clears all data from the current register.

To clear ALL registers (or a group of registers), press and hold the REG# button,

the MARK IN button, and the MARK OUT button at the same time (3 buttons at

once). The display will say ‘CLR To Clear All!’. If you press the CLR key (while

holding down the above three buttons) the TDC-100 will start clearing registers at

the current register, and ascending until you either press the STOP button, or it

reaches the last register (299). This operation is deliberately awkward in order to

minimize the chance of doing it accidentally. This function may be inhibited by

turning on Dipswitch #1 on the rear of the rack mount frame.

To copy the current register to another, press REG #, then SET. The display will

say “Copy Reg To?”. Enter three digits for the destination register. All register data

will be copied from the current register to the new register.

To mark an in time, press MARK IN. All enabled machines will be marked from

their current time code (or timer) values.

To mark an out time, press MARK OUT.

To enter an in or out time from the keypad, key in the time, press SET, and press

MARK IN (for in time) or MARK OUT (for out time). Note: if multiple machines are

selected, the time will be entered only on the currently-displayed machine. The

others will not be affected.

(continued)

4

Quick Operation Guide - continued

To recall an in or out time to the display, press FCN, then MARK IN or MARK

OUT. The corresponding time value will be recalled to the display and the

scratchpad register, so you can do arithmetic with it if desired (add and subtract). If

you ‘double-click’ the REG # button it will recall the in time of the current register (or

clip name), for the currently-displayed machine. If there is no value stored in the

register, the display will be all asterisks, indicating no value.

To recall the stored clip name to the display, press FCN, then REG #. If there is

a stored clip name for the current device, it will be recalled to the second line of the

display, for the purpose of checking it.

To Trim an in time, recall time to display as above (FCN, MARK IN), press ‘+’ or ‘-’,

enter the trim value on the keypad, press SET, and press MARK IN to resave it.

Outtimes work the same way, with the MARK OUT key. You can set a known clip

duration the same way: recall the in time, press ‘+’, enter the desired duration, press

‘SET’, press ‘Mark Out’. This takes the in time, adds a duration value to it, and

stores it in the out register.

To display the duration of a register (difference between in point and out point),

press TM key. If either of the registers is clear, the display will be all asterisks,

indicating no value.

To manually learn a speed preset hold down the VAR button and press SET.

The display will confirm that the speed has been learned. This speed will be recalled

when the register is recalled. If you do a learn from the switcher, the current var

speed will be learned into the register.

To Cue Directly to a Keyed-In Time Value enter the time value on the keypad,

press ‘SET’, and press ‘CUE’. The device will cue to the entered time. The time

value will not be stored anywhere. Remember that you must press ‘SET’ before

pressing ‘CUE’. This validates the keypad entry before attempting to send the

machine to that position.

To Adjust TBC Levels press ‘FCN’, then ‘MENU’. This will put the controller into

the TBC adjust mode. Use the ‘+’ and ‘-’ keys to select the function, and the knob to

adjust. To exit this mode, press ‘FCN’ then ‘MENU’ again. The MENU button will

flash when in the TBC adjust mode. If there is no number value displayed after the

function, then the selected device does not support these commands.

(continued)

5

Quick Operation Guide – continued

To Do a Loop Play define the loop by entering an inpoint and an outpoint. The

minimum duration is 1:15 [one and one-half seconds]. The loop play may be

initiated by either Pbus trigger 5, or by pressing <FCN> the <PLAY> on the front

panel. You may simulate the Pbus trigger by pressing <FCN>, then <5> on the

keypad. The loop will run until either a STOP, RECUE or RECALL command is

received. If you turn on LOOP PRESERVE in the menu, only a STOP command

will halt the loop. You can recall another register without disturbing the loop

playback.

To Do a Multi-point Loop Play set the initial start point in the inpoint of a register

number between 000 and 099 (first 100 registers). You may also set an outpoint if

desired, although it isn’t required. The ‘inner loop’ points should be entered in a

register 100 higher. For example, if your ‘outside points’ are in register 25, your

‘inside points’ should be in register 125. Minimum duration for the inside loop is one

and one-half seconds. The multi-point loop play may be initiated by Pbus trigger 8,

or from the front panel by pressing <FCN>, then <8>. The ddr will start at the initial

start point, then loop between the ‘inner loop’ points. If you send a Pbus trigger 9

[<FCN> <9> from the keypad], the controller will stop looping at the first opportunity,

and play to the ‘outside’ outpoint [register 25 outpoint in the above example].

To Do an Automatic Transfer (Dub) from a vtr: Set inpoints for both the vtr

(playback) and the ddr (record) channels. Press and hold the device button for the

ddr, then press the vtr’s device button. Both should be lit, with the ddr’s button

flashing. This is the recorder. Press <FCN>, then <REC>. The vtr will cue back 3

seconds from the inpoint and roll. The ddr will go into record at the proper time.

To Add an Offset to All Registers first select the register number where you’d like

to start [usually 000], and select the channels you want to modify [A, B, C, D] by

lighting up the device buttons. Press <FCN>, then <TM>. The controller will

prompt you to ‘Enter Offset Time’. Enter the time using the keypad. If you want to

offset by a negative number, enter a minus sign first. Press <SET>, then <TM>.

The TDC will start modifying both the inpoints and outpoints of all selected channels.

You can stop the process by pressing STOP.

To Display Pbus Data for diagnostic purposes, turn on Item 30 in the menu, PBUS

DATA DISPLAY. This will cause the ASCII Pbus data to be displayed on line two

of the panel. If the Pbus data is incorrectly formatted (invalid command) a ‘Pbus

Format Error’ message will be displayed. Note that this menu item is turned off each

time the TDC-100 is powered up.

6

GENERAL DESCRIPTION

The Lance Design TDC-100 is designed to provide control of multiple channels of

video disk recorder(s) or other devices via P-Bus II interface to Grass Valley Group,

Sony, or other production switchers.

This combination allows the user to do the following:

1) Mark playback inpoints when learning an emem effect on the switcher.

2) Recall (cue) the playback device to these cues when effects are recalled.

3) Trigger (roll) the playback device in response to an emem timeline run, loop, or

other trigger.

In addition to these functions which are driven from the production switcher, the

control panel provides full manual control of the devices, providing normal shuttle,

jog, variable play, record, cue, and other commands.

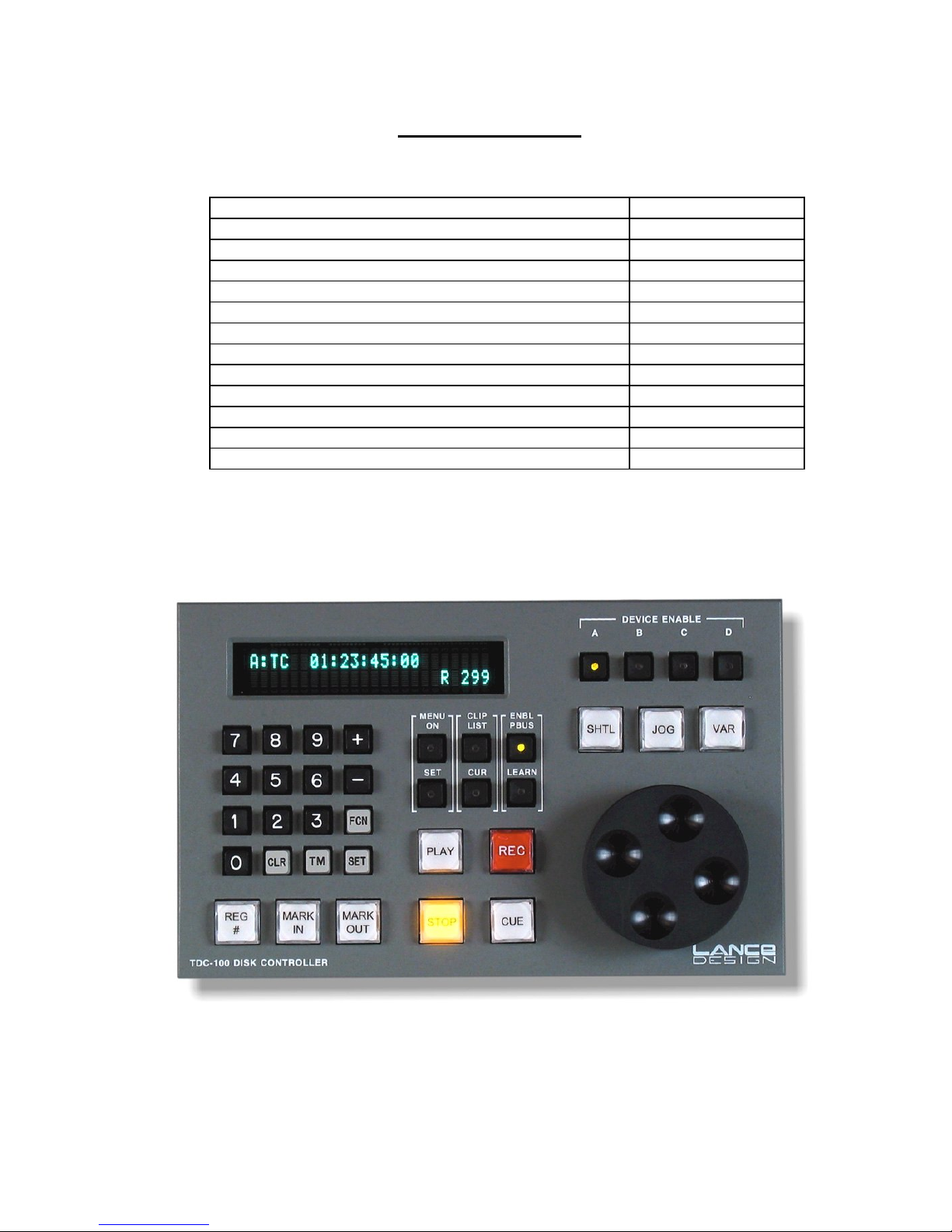

CONTROL PANEL DESCRIPTION

The TDC-100 control panel provides the following controls (left to right on the panel):

Numeric Keypad - for entry of numeric data, register numbers, timecodes, etc.

Plus and Minus Keys - for timecode arithmetic, and for use as up/down keys for

scrolling through the menu items.

FCN Key - for selecting alternate functions of some keys. Press and release the

FCN key, then press the key whose alternate function you want.

SET Key - operates like an ‘equals’ or ‘enter’ key. To enter a timecode number

from the keypad, for example, you would key in the time, press SET, and press

MARK IN. The SET key tells the controller to use the keypad time instead of

marking from the current disk position

TM Key - used for displaying durations of registers (outpoint minus inpoint). If

you have both an inpoint and outpoint set, pressing TM will show you the duration

between them. This key is also used to enter time values into the timer or timecode

generator of the controlled device, if this capability is supported.

CLR Key - Clear function. Clears numeric entry and other modes. Functions

somewhat like a ‘cancel’ or ‘escape’ key. Also used to clear registers - see below.

7

REG# - used to select the active register from the 300 available registers. Press

this key (it lights), and enter a 3-digit register number on the keypad. The active

register number is displayed in the lower right corner of the display as ‘R 299’, for

example. This key is also used to clear a register (all inpoints and outpoints). Hold

the ‘REG #’ key down and press ‘CLR’. The current register will be cleared.

MARK IN - pressing this key will put the current disk timecode into the IN

register, for all enabled devices. Pressing this key after pressing SET will put the

keyed-in timecode value into the IN register (for the displayed device only).

Pressing FCN, then MARK IN will recall the current in time to the display. The

MARK IN button will be lighted when ever there is an inpoint stored. If the inpoint is

cleared, the button will be dark. If CLIP STORE/RECALL is on in the menu, and

there is a timecode inpoint but no clip name stored in the regitser, the MARK IN

button will flash. This serves as an indicator of the missing clip name.

MARK OUT - same as above for outpoints.

MENU ON - turns on and off the menu mode. Menu items are displayed on the

lower line of the display. Use the knob or the +/- keys to scroll through the items.

Also selects the TBC Adjust function if pressed after the “FCN” key. In this mode,

the menu button light will flash.

MENU SET - used to change the menu items. Pressing this key will toggle the

menu choices if there are only two. If there are more than two, it will step through

them. If you hold this key down, you can use the knob to adjust the menu setting.

CLIP LIST - used to display the clip directory of the disk recorder. If supported

by the disk recorder, the clip names present will be displayed. The numbers on the

left side of the display provide an index, for example 04/12 means this is clip 4 of 12.

The names can be scrolled via the +/- keys or the knob.

CUR CLIP - Loads the displayed clip, when “Clip List” above is active.

ENBL PBUS - when this key is lighted, PBUS control from the production

switcher is enabled. If not lighted, control is inhibited. This button will flash each

time a valid Pbus command is received. If it’s off, it will flash on. If it’s on, it will

flash off.

ENBL LEARN - when this key is lighted, the LEARN function from the production

switcher is active; that is, when an emem effect is learned on the switcher, the disk

inpoints will be marked from the current positions. If you have the disk inpoints set,

and don’t want to mark them each time you learn an emem, you can turn this

function off (key dark). Recall and Trigger functions are not affected. The ENBL

PBUS (above) must be on for this function to operate.

PLAY, RECORD, STOP, CUE, SHTL, JOG, VAR - standard transport controls.

When in variable mode, the speed is displayed in the upper right corner of the

display. When pressed by itself, the REC button will put the device into EE mode.

Pressing REC again, or pressing STOP will cancel EE mode. The REC button

flashes to indicate that the device is in EE mode.

8

Loading...

Loading...