Lancaster 7-LX-150B, 7-LXC-100B, 7-LX-200B, 7-LX-75B, 7-LX-300B Installation, Operating And Service Manual

...Page 1

INSTALLATION, OPERATING AND

SERVICE MANUAL

DIAMOND LINE LX

ELECTRONIC WATER SOFTENER WITH

THE X-FACTOR CONTROL VALVE

PROGRAMMED FOR PRE-FILL BRINING OPTION

7-LXC-50B

7-LXC-75B

7-LXC-100B

7-LX-75B

7-LX-100B

7-LX-150B

7-LX-200B

7-LX-300B

Congratulations on purchasing your new Lancaster Water Softener. This unit is designed to give

you many years of trouble free service. When installed in accordance with the following instructions

and if given reasonable care, clear-soft water will be the result. For servicing and future inspection

purposes, please le this booklet with your important documents.

In the event that you need assistance for servicing your water softener, please rst contact the

professional contractor who installed the system.

PAGE 1

Page 2

TABLE OF CONTENTS

Job Specications ......................................................................................................................... 2

General Installation and Service Warnings .................................................................................. 3

Pre-Installation Review ................................................................................................................. 4

Bypass Valve Operation ............................................................................................................... 5

Installation Instructions, Diagrams ................................................................................................ 6-8

Placing Softener into Service ....................................................................................................... 9

General Operation ........................................................................................................................ 9

Set Time of Day ............................................................................................................................ 10

Adjust Hardness, Days Between Regenerations or Time of Regeneration .................................. 10-11

Low Battery.................................................................................................................................... 11

Contact Screen Programming ...................................................................................................... 11

Specications ............................................................................................................................... 12-15

Parts Diagrams ............................................................................................................................. 16-23

Service Instructions ...................................................................................................................... 24-26

Troubleshooting ............................................................................................................................ 27-30

JOB SPECIFICATIONS

MODEL NO.

INSTALLATION DATE

SERIAL NUMBER

INSTALLER NAME PHONE

ADDRESS

WATER TEST AT TIME OF INSTALLATION

Hardness CaCo3 (gpg)

Iron (ppm)

pH

SIZING INFORMATION

All Water is Softened Except:

Rear Hose Bib Front Hose Bib Kitchen Cold Toilets All Cold

Other

The average family uses 50 gallons per person daily for all water uses in the home.

Daily Water Usage (Gallons/Person)

x Family Size (Number of people in family)

= Total Gallons Per Day

x Grains Per Gallon of hardness

Other:

(Note: Add 4 grains per gallon of hardness for each ppm iron for total compensated hardness)

= Total Grains per Day

PAGE 2

Page 3

GENERAL INSTALLATION AND SERVICE WARNINGS

The control valve, ttings and/or bypass are designed to accommodate minor plumbing misalignments but are not designed to support

the weight of a system or the plumbing.

HYDROCARBONS SUCH AS KEROSENE, BENZENE, GASOLINE, ETC., MAY DAMAGE PRODUCTS THAT CONTAIN O-RINGS OR

PLASTIC COMPONENTS. EXPOSURE TO SUCH HYDROCARBONS MAY CAUSE THE PRODUCTS TO LEAK. DO NOT USE THE

PRODUCT(S) CONTAINED IN THIS DOCUMENT ON WATER SUPPLIES THAT CONTAIN HYDROCARBONS SUCH AS KEROSENE,

BENZENE, GASOLINE, ETC.

THIS WATER METER SHOULD NOT BE USED AS THE PRIMARY MONITORING DEVICE FOR CRITICAL OR HEALTH EFFECT

APPLICATIONS

Do not use Vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may be used on black o-rings but

is not necessary.

The nuts and caps are designed to be unscrewed or tightened by hand or with the special plastic wrench. If necessary a pliers can be

used to unscrew the nut or cap. Do not use a pipe wrench to tighten or loosen nuts or caps. Do not place a screwdriver in the slots on

caps and/or tap with a hammer.

Do not use pipe dope or other sealants on threads. Use Teon tape on the threaded inlet, outlet and drain ttings. Teon tape is not

necessary on the nut connection or caps because of o-ring seals.

After completing any valve maintenance involving the drive assembly or the drive cap assembly and pistons unplug power source jack

from the printed circuit board (black wire) and plug back in or press and hold NEXT and REGEN buttons for 3 seconds.

This resets the electronics and establishes the service piston position. The display should ash all wording, then ash the software version

and then reset the valve to the service position.

All plumbing should be done in accordance with local plumbing codes. The pipe size for the drain line should be a minimum of ½”.

Backwash ow rates in excess of 7 gpm or length in excess of 20’ require ¾” drain line.

Solder joints near the drain must be done prior to connecting the drain line ow control tting. Leave at least 6” between the drain line

control tting and solder joints when soldering pipes that are connected on the drain line control tting. Failure to do this could cause

interior damage to the drain line ow control tting.

When assembling the installation tting package (inlet and outlet), connect the tting to the plumbing system rst and then attach the nut,

split ring and o-ring. Heat from soldering or solvent cements may damage the nut, split ring or o-ring. Solder joints should be cool and

solvent cements should be set before installing the nut, split ring and o-ring. Avoid getting primer and solvent cement on any part of the

o-rings, split rings, bypass valve or control valve.

Plug into an electrical outlet. Note: All electrical connections must be connected according to local codes. (Be certain the outlet is

uninterrupted.)

Install grounding strap on metal pipes.

This glass lled Noryl (or equivalent) fully automatic control valve is designed as the primary control center to direct and regulate all cycles

of a water softener or lter. The control valve can be set to regenerate on demand (consumption of a predetermined amount of water) and/

or as a time clock (passage of a particular number of days). The control valve can be set so that a softener can meet the Water Quality

Association (WQA) Standard S100 or NSF/ANSI Standard 44 efciency rating.

It is not recommended to change control valves from downow to upow brining or vice versa in the eld. The valve bodies

for downow and upow are unique to the regeneration type and should not be interchanged. A mismatch of valve body and

regeneration piston will result in hard water bypass during service.

The control valve is compatible with a variety of regenerants and resin cleaners. The control valve is capable of routing the ow of water

in the necessary paths to regenerate or backwash water treatment systems. The injector regulates the ow of brine or other regenerants.

The control valve regulates the ow rates for backwashing, rinsing, and the replenishing of treated water into a regenerant tank, when

applicable. The control valve uses no traditional fasteners (e.g. screws); instead clips, threaded caps and nuts and snap type latches are

used. Caps and nuts only need to be rmly hand tightened because radial seals are used. Tools required to service the valve include one

small blade screw driver, one large blade screw driver, pliers and a pair of hands. A plastic wrench is available which eliminates the need

for screwdrivers and pliers. Disassembly for servicing takes much less time than comparable products currently on the market. Control

valve installation is made easy because the distributor tube can be cut ½” above to ½” below the top of tank thread. The distributor tube

is held in place by an o-ring seal and the control valve also has a bayonet lock feature for upper distributor baskets.

The AC adapter comes with a 15 foot power cord and is designed for use with the control valve. The AC adapter is for dry location use

only. The control valve remembers all settings until the battery power is depleted if the power goes out. After the battery power is depleted,

the only item that needs to be reset is the time of day; other values are permanently stored in the nonvolatile memory. The control valve

battery is not rechargeable but is replaceable.

Allow one foot of clearance to service the valve.

PAGE 3

Page 4

PRE-INSTALLATION REVIEW

WATER QUALITY: If sand or sediment is present in the water supply, a sediment lter should be installed ahead of the water softener.

Your water softener has been designed to adequately reduce hardness from levels up to 100 grains per gallon. Ferrous bicarbonate iron

levels up to 0.5 ppm can also be reduced. This is iron that is dissolved in water and not visible to the eye in a freshly drawn sample. After

standing in contact with air, the ferrous iron will become oxidized to the ferric state and start to precipitate as a reddish brown oc. It can

be seen and may cause discolored water. Air must not come in contact with water until after it has passed through the water softener. In

some cases, additional treatment equipment may be needed to treat water having special characteristics, such as: ferric hydroxide iron,

iron bacteria, low pH, tastes and odors, etc. Consult your dealer if you have any questions. This water softener is not to be used for

treating water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after treatment.

WATER PRESSURE: A minimum of 20 pounds of water pressure (psi) is required for regeneration. Maximum 100 psi. CAUTION: the

softener cannot be subject to a vacuum due to loss of pressure (such as a water main break or submersible well pump check valve failure).

WATER TEMPERATURE: The range of water temperature is 40°F to 100°F. DO NOT install any water softener with less than 10 feet of

piping between its outlet and the inlet of a water heater.

AMBIENT TEMPERATURE: DO NOT locate softener where it or its connections (including the drain and overow lines) will ever be

subject to room temperatures under 33°F.

ELECTRICITY: An uninterrupted 120 volt 60Hz source is required. Make sure electrical source is not on a timer or switch. All electrical

connections must be connected according to local codes. The plug-in transformer is for dry locations only. Surge protection is recommended

with all electrical connections.

DRAIN: All plumbing should be done in accordance with local plumbing codes. The distance between the drain and the water softener

should be as short as possible. The pipe size for the drain line should be a minimum of 1/2” (inside diameter of pipe).

SOFTENING: It is recommended that the softener be installed to soften both the hot and cold water supply. A separate hard water faucet

may be plumbed for drinking purposes if desired. Outside faucets should be left on hard water.

BYPASS: A bypass valve should be installed so that water will be available if it should be necessary to shut off the pressure in order to

service the softener.

PAGE 4

Page 5

BYPASS VALVE

The bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure in order to perform control

valve repairs or maintenance. The X-Factor bypass valve is particularly unique in the water treatment industry due to its versatility

and state of the art design features. The 1” full ow bypass valve incorporates four positions, including a diagnostic position that

allows service personal to work on a pressurized system while still providing untreated bypassed water to the facility or residence. Its

completely non-metallic, all-plastic design allows for easy access and serviceability without the need for tools.

The bypass body and rotors are glass lled Noryl® (or equivalent) and the nuts and caps are glass lled polypropylene. All seals are

self-lubricating EPDM to help prevent valve seizing after long periods of non-use. Internal o-rings can easily be replaced if service is

required.

The bypass consists of two interchangeable plug valves that are operated independently by red arrow-shaped handles. The handles

identify the ow direction of the water. The plug valves enable the bypass valve to operate in four positions.

OPERATION:

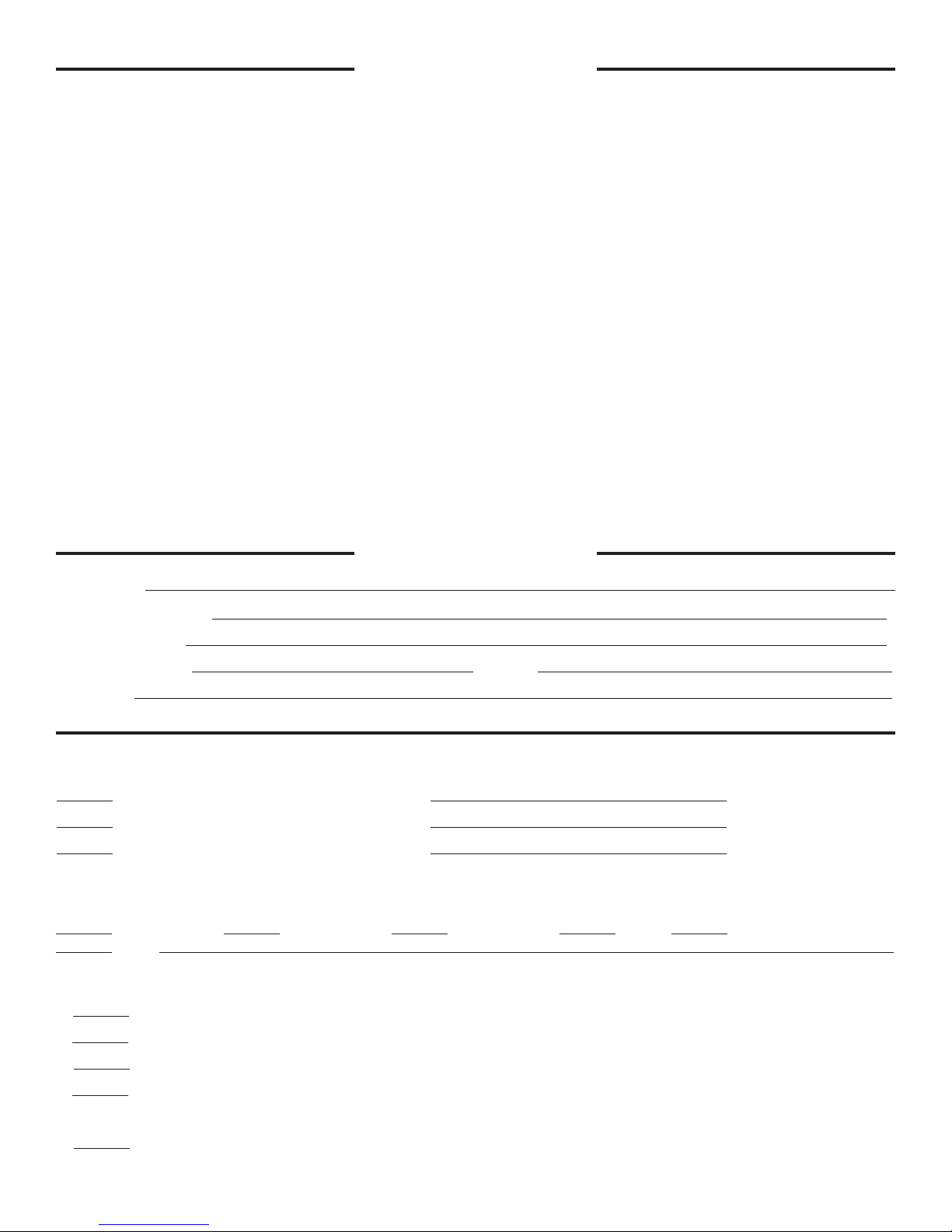

1. Normal Operation Position: The inlet and outlet

handles point in the direction of ow indicated by the

engraved arrows on the control valve. Water ows

through the control valve during normal operation and

this position also allows the control valve to isolate the

media bed during the regeneration cycle. (see gure

1)

2. Bypass Position: The inlet and outlet handles

point to the center of the bypass, the control valve

is isolated from the water pressure contained in the

plumbing system. Untreated water is supplied to the

plumbing system. (see gure 2)

3. Diagnostic Position: The inlet handle points in

the direction of ow and the outlet handle points to

the center of bypass valve, system water pressure is

allowed to the control valve and the plumbing system

while not allowing water to exit from the control valve

to the plumbing. (see gure 3)

4. Shut Off Position: The inlet handle points to the

center of the bypass valve and the outlet handle

points in the direction of ow, the water is shut off

to the plumbing system. If water is available on the

outlet side of the softener it is an indication of water

bypass around the system (i.e. a plumbing connection

somewhere in the building bypasses the system).

(see gure 4)

The working parts of the bypass valve are the rotor assemblies that are contained under the bypass valve caps. Before working on the

rotors, make sure the system is depressurized. Turn the red arrow shaped handles towards the center of the bypass valve and back

several times to ensure rotor is turning freely.

The nuts and caps are designed to be unscrewed or tightened by hand. If necessary a pliers can be used to unscrew the nut or cap. Do

not use a pipe wrench to tighten or loosen nuts or caps. Do not place screwdriver in slots on caps and/or tap with a hammer. To access

the rotor, unscrew the cap and lift the cap, rotor and handle out as one unit. Twisting the unit as you pull it out will help to remove it

more easily. There are three o-rings: one under the rotor cap, one on the rotor stem and the rotor seal. Replace worn o-rings. Clean

rotor. Reinstall rotor.

When reinstalling the red arrow handles be sure that:

1. The handle pointers are lined up with the control valve body arrows, and the rotor seal o-ring and retainer on both rotors face to the

right when being viewed from the front of the control valve; or

2. Arrows point toward each other in the bypass position.

Since the handles can be pulled off, they could be accidentally reinstalled 180° from their correct orientation. To install the red arrow

handles correctly, keep the handles pointed in the same direction as the arrows engraved on the control valve body while tightening the

bypass valve caps.

gure 1 gure 2

gure 3 gure 4

PAGE 5

Page 6

INSTALLATION INSTRUCTIONS

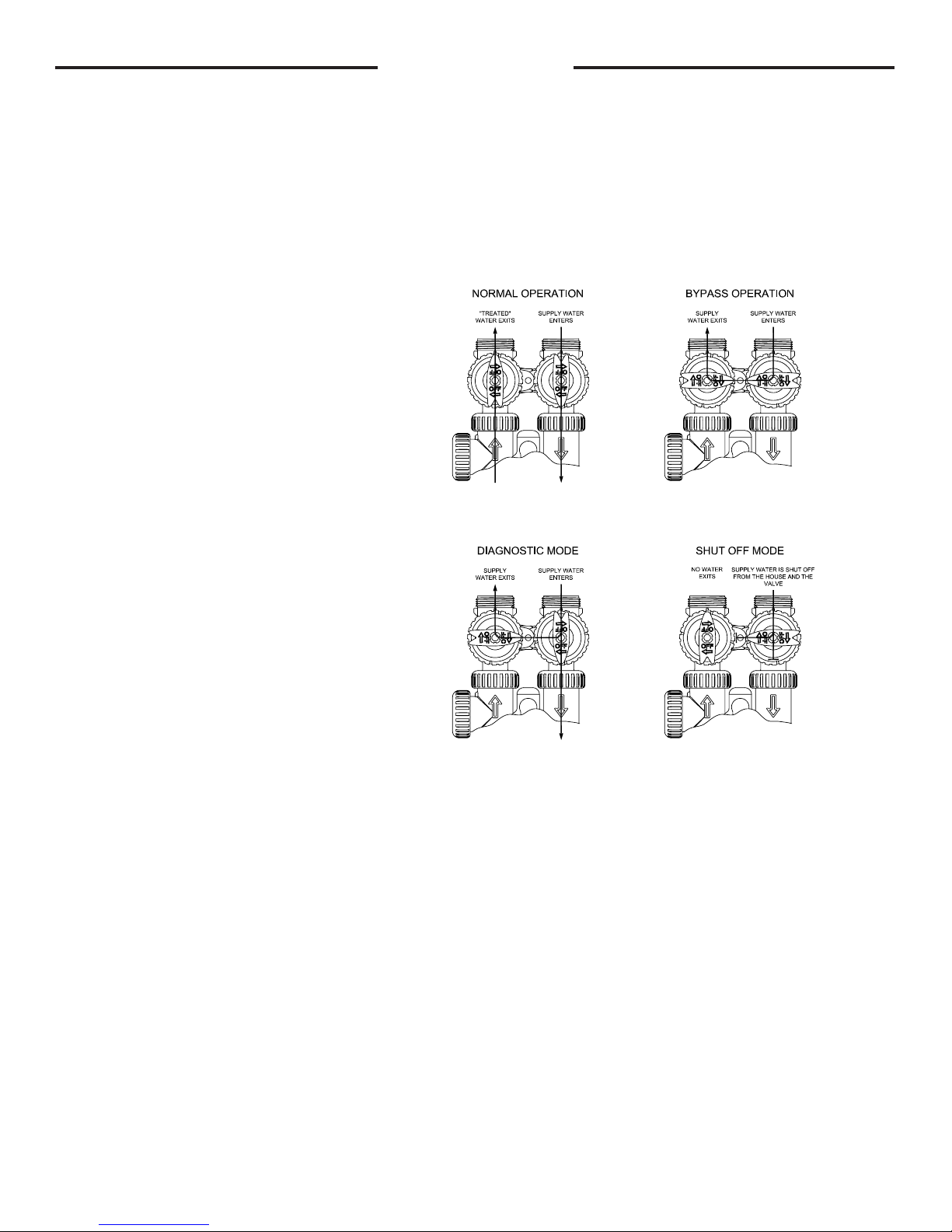

BRINE LINE FITTING CONNECTIONS

DRAIN LINE FITTING CONNECTION USING 5/8" POLY TUBE

Click to buy NOW!

P

D

F

-

X

C

H

A

N

G

E

w

w

w

.

d

o

c

u

-

t

r

a

c

k

.

c

o

m

(All electrical & plumbing should be done in accordance to all local codes)

1. Place the softener where you want to install it, making sure it is on

a clean, level and rm base.

2. Do all necessary plumbing (inlet to inlet, outlet to outlet, and drain

line to drain). The control valve, ttings and/or bypass are designed to

accommodate minor plumbing misalignments but are not designed to

support the weight of a system or the plumbing.

3. When assembling the installation tting package (inlet and outlet),

connect the tting to the plumbing system rst and then attach the

nut, split ring and o-ring. Heat from soldering or solvent cements may

damage the nut, split ring or o-ring. Solder joint should be cool and

solvent cements should be set before installing the nut, split ring and

o-ring. Avoid getting primer and solvent cement on any part of the

o-rings, split rings, bypass valve or control valve.

4. A jumper ground wire should be installed between the inlet

and outlet pipe whenever the metallic continuity of a water

distribution piping system is interrupted. Install grounding strap

on metal pipes.

POLYTUBE

5. The drain connection may be made using either 5/8” polytube (see below) or a 3/4” female adapter. The polytube insert

is shipped attached to the drain line elbow’s locking clip. Press the insert into the drain line tubing (tubing not provided).

Loosen the nut of the drain line elbow. Press the 5/8” polytube with insert into the drain line elbow until it seats on the back

of the tting. Tighten the nut. If soldering, joints near the drain must be done prior to connecting the drain line ow control

tting. Leave at least 6” between the drain line control tting and solder joints when soldering pipes that are connected on

the drain line control tting. Failure to do this could cause interior damage to the drain line ow control tting. Never insert a

drain line into a drain, sewer line, or trap. Always allow an air gap between the drain line and the wastewater to prevent the

possibility of sewage being back-siphoned into the softener.

PAGE 6

Page 7

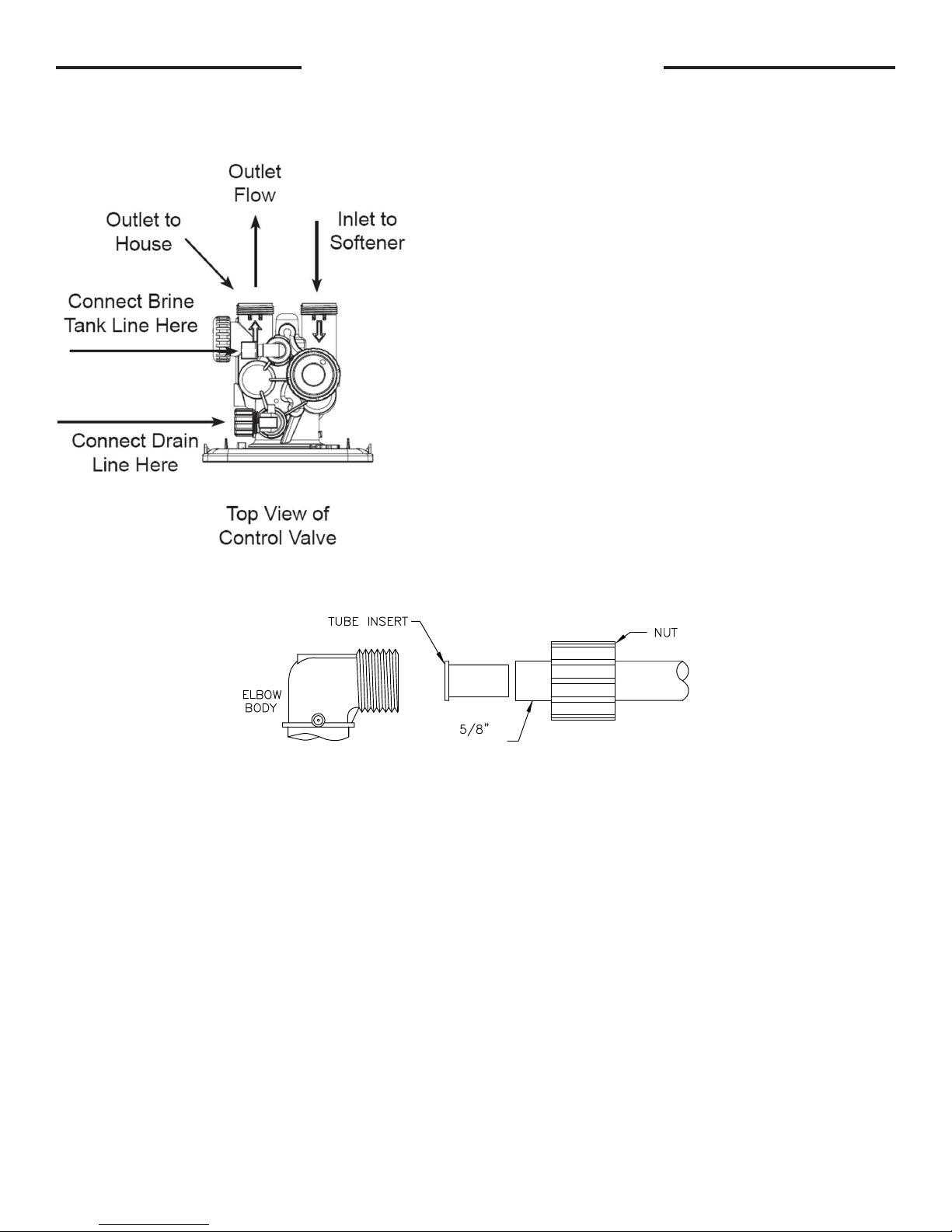

BRINE LINE FITTING CONNECTIONS

Click to buy NOW!

P

D

F

-

X

C

H

A

N

G

E

w

w

w

.

d

o

c

u

-

t

r

a

c

k

.

c

o

m

INSTALLATION INSTRUCTIONS CONT’D

(All electrical & plumbing should be done in accordance to all local codes)

A

E

C

B D

6. Assemble the brine tank. Install a brine well cap (Item A)

on the bottom of the brine well (Item B). Remove the brine

valve assembly (Item C) from the brine well by removing the

nut (Item D). Attach the brine well to the brine tank with the

two-piece overow (Items E & F) using the lower holes in

both pieces, as shown. Reinstall the brine valve assembly.

Push brine line polytube (Item G) through the upper holes in

F

the brine tank and brine well and press the polytube into the

elbow tting.

G

A

7. The brine rell ow control assembly is installed in an easy to access rell elbow located on top of the control valve. The

rell ow control assembly is attached to the control valve with a locking clip. The locking clip allows the elbow to rotate 270

degrees so the outlet can be oriented towards the brine tank.

8. Connect the brine line polytubing found with the brine tank to the brine connection on the control valve. The control valve

has a standard rell elbow to which a 3/8” exible tube can be connected, see below. Press the polytube into the brine elbow

tting. Make sure the oor is clean beneath the brine tank and that it is level and smooth.

POLYTUBE

9. A 1/2” (inside diameter, not provided) gravity drain line should be connected to the overow tting on the side of the brine

tank. This overow is in case of a malfunction in the brine shut off. If the unit is installed where water may ow in the event of

an overow and cause water damage, connect a length of exible tubing and run to a drain below the level of the overow.

(Do not connect the tubing to the drain line on the control valve. Do not run tubing above overow height at any

point.)

PAGE 7

Page 8

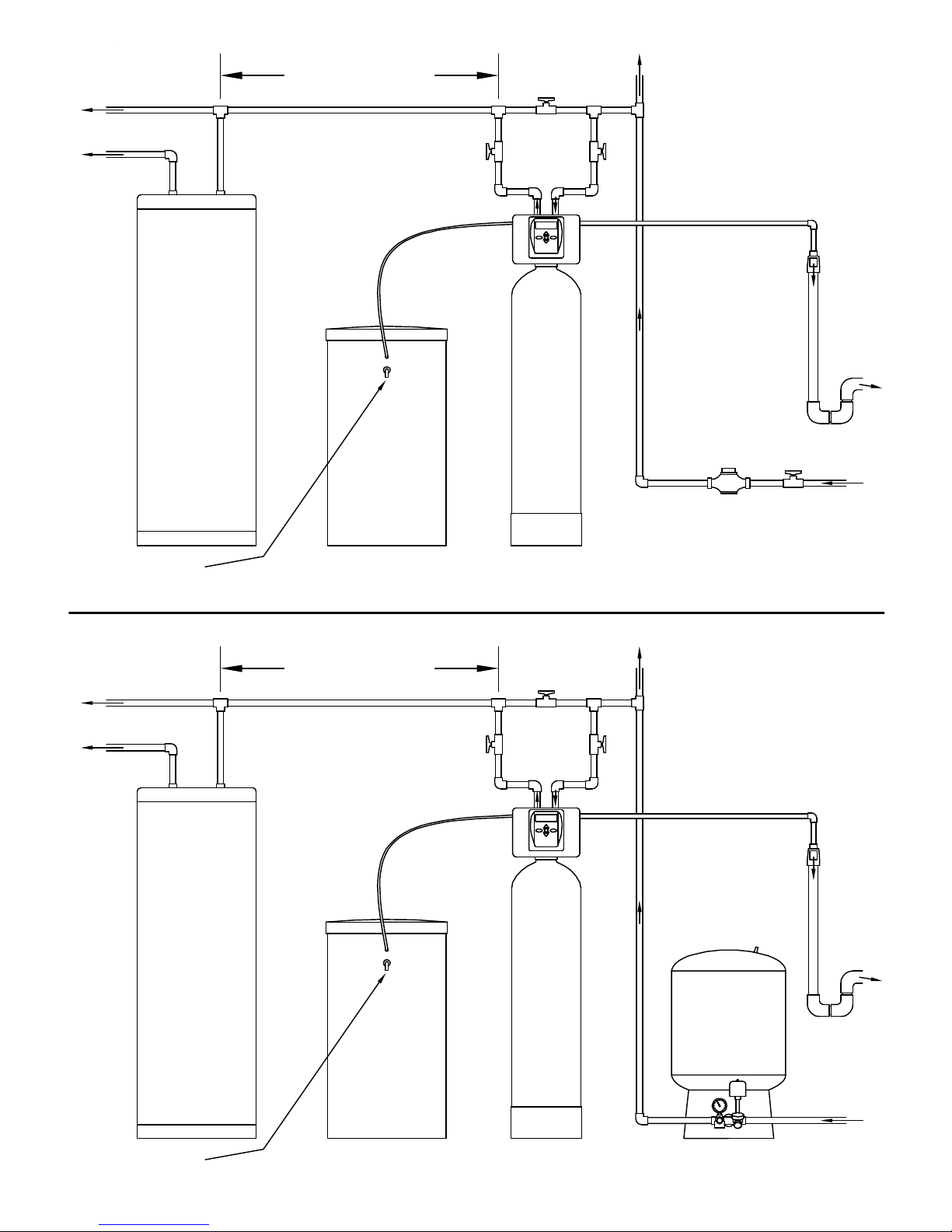

COLD

Click to buy NOW!

P

D

F

-

X

C

H

A

N

G

E

w

w

w

.

d

o

c

u

-

t

r

a

c

k

.

c

o

m

Click to buy NOW!

P

D

F

-

X

C

H

A

N

G

E

w

w

w

.

d

o

c

u

-

t

r

a

c

k

.

c

o

m

HOT

MINIMUM 10 FEET

BETWEEN

WATER SOFTENER OUTLET

AND

WATER H EATER INLET

A SIX FOOT LENGTH OF 3/8" O.D.

BRINE LIN E POLYTUBE

SUPPLIED WITH BRINE TANK.

LOCATE WATER SOFTENER

AS CLOSE AS POSSIBLE

TO BRIN E TANK.

BYPASS PLUMBING

RECOMMENDED

IF

OPTIONAL BP2000

BYPASS VALVE

IS NOT USED.

TO

OUTSIDE

TAP

LOCATE WATER SOFTEN ER CLOSE TO A DRAIN.

AVOID OVERHEAD DRA IN LINES IF POSSIBLE TO

PREVEN T BACK P RESSURE ON BRINE INJECTOR.

IF OVER HEAD D RAIN LIN E IS USED AND EXCEEDS

5 FEET ABOVE CON NECT ION ON CONTROL VALVE

IF DRAIN LINE EXC EEDS 20 FEET IN LENGTH,

DRAIN LINE PIPE SIZ E SHOU LD BE MINIMUM 3/4".

OR

DRAIN LINE

AIR GAP

ADAPTER

WATER

HEATER

TO

DRAIN

CITY WATER

INSTALLATION

WATER

METER

BRINE TANK

OVERFLO W GRAVITY DRAIN - ON LY USED IN CASE O F MALFU NCTIO N IN TH E BRINE SHUTOFF. DO NOT CONNECT TO CONTROL VALVE DRAIN LINE.

IF UNIT IS INST ALLED WH ERE OVER FLOW C OULD CAUSE W ATER D AMAGE, CONNEC T TU BING AND RUN TO FLOOR DRAIN. DO NOT RUN TUBING ABOVE OVERFLOW HEIGHT.

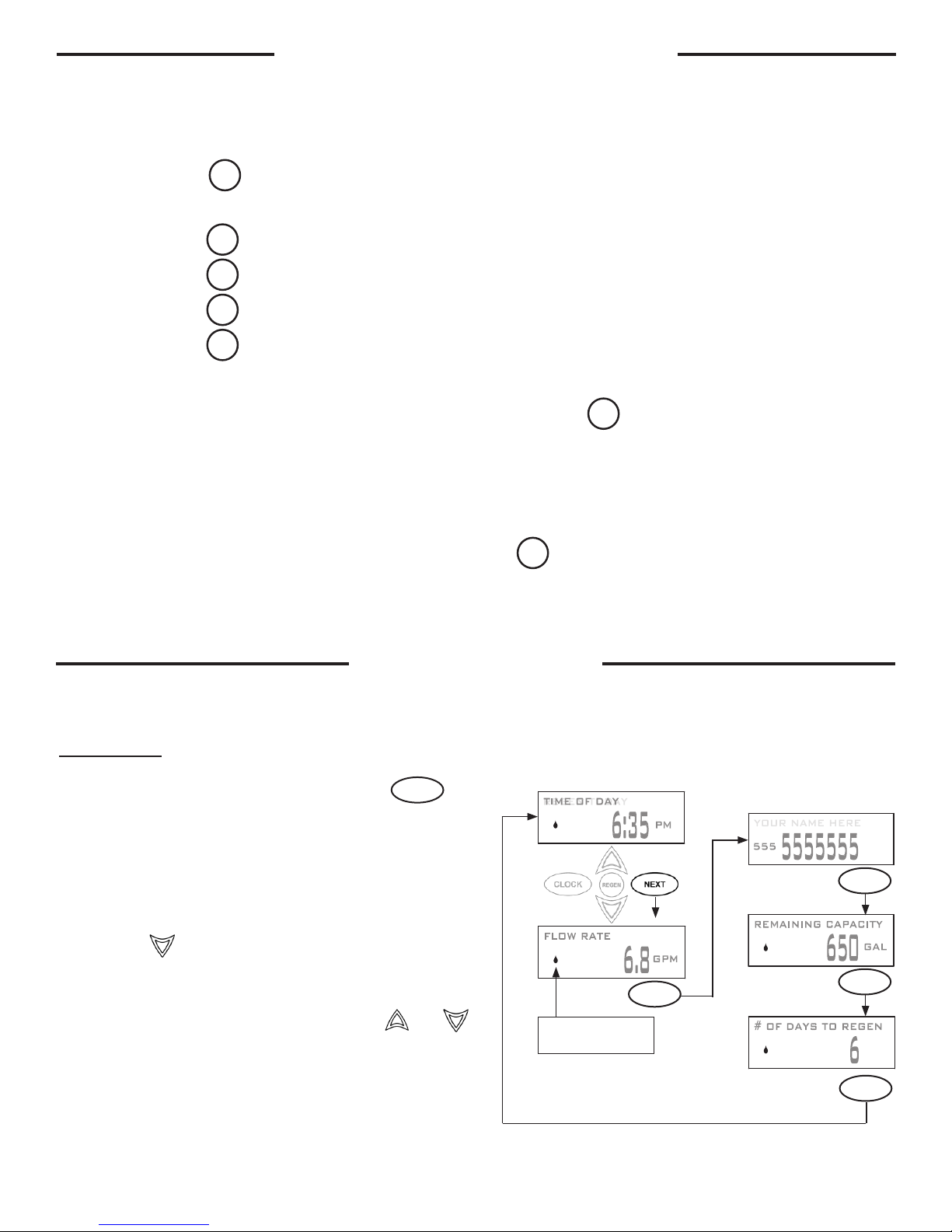

MINIMUM 10 FEET

BETWEEN

WATER SOFTENER OUTLET

AND

WATER H EATER INLET

COLD

HOT

A SIX FOOT LENGTH OF 3/8" O.D.

BRINE LIN E POLYTUBE

SUPPLIED WITH BRINE TANK.

WATER S OFTENER

BYPASS PLUMBING

RECOMMENDED

IF

OPTIONAL BP2000

BYPASS VALVE

IS NOT USED.

TO

OUTSIDE

TAP

LOCATE WATER SOFTEN ER CLOSE TO A DRAIN.

AVOID OVERHEAD DRA IN LINES IF POSSIBLE TO

PREVEN T BACK P RESSURE ON BRINE INJECTOR.

IF OVER HEAD D RAIN LIN E IS USED AND EXCEEDS

5 FEET ABOVE CON NECT ION ON CONTROL VALVE

IF DRAIN LINE EXC EEDS 20 FEET IN LENGTH,

DRAIN LINE PIPE SIZ E SHOU LD BE MINIMUM 3/4".

OR

FROM

WATER MAIN

WATER

HEATER

OVERFLO W GRAVITY DRAIN - ON LY USED IN CASE O F MALFU NCTIO N IN TH E BRINE SHUTOFF. DO NOT CONNECT TO CONTROL VALVE DRAIN LINE.

IF UNIT IS INST ALLED WH ERE OVER FLOW C OULD CAUSE W ATER D AMAGE, CONNEC T TU BING AND RUN TO FLOOR DRAIN. DO NOT RUN TUBING ABOVE OVERFLOW HEIGHT.

LOCATE WATER SOFTENER

AS CLOSE AS POSSIBLE

TO BRIN E TANK.

BRINE TANK

PAGE 8

WATER S OFTENER

WELL WATER

INSTALLATION

PRESSURE

TANK

DRAIN LINE

AIR GAP

ADAPTER

TO

DRAIN

FROM

WELL PUMP

Page 9

PLACING SOFTENER INTO SERVICE

Do not add salt to the brine tank yet. Do not plug the transformer into the receptacle yet. Make sure inlet and outlet valves are to their

closed positions. If using optional bypass, place in bypass position. Turn on main water supply. Open a cold water faucet. This will clear

the line of any debris (solder, pipe dope, etc.) that may be in the line. Let water run at faucet for a couple minutes, or until clear. Turn

off faucet. Manually add 1 ½ gallons of water to the brine tank. Now plug the transformer into a 120 volt receptacle (be certain the

receptacle is uninterrupted). Within 5 seconds the control display and buttons will illuminate and the time of day screen will appear.

• Press and hold the

REGEN

button for approximately 5 seconds until the motor starts.

• Wait until display reads FILL and numbers start counting down.

• Momentarily press

• Momentarily press

• Momentarily press

• Momentarily press

REGEN

again. Valve is now in the SOFTENING position.

REGEN

again. Valve is now in the BACKWASH position. (NA for model 7-LXC-50, -100)

REGEN

again. Valve is now in the REGENERANT DRAW position.

REGEN

again. Valve is now in the second BACKWASH position. (NA for model 7-LXC-50, -100)

If using optional bypass SLOWLY turn bypass valve to DIAGNOSTIC position (See gure 3 on page 5) or slowly open inlet valve to

allow water to slowly enter Softener.

When water is owing steadily to drain without the presence of air, momentarily press

REGEN

again. Display will read RINSE. Open

the outlet valve of the softener, or if using optional bypass place to NORMAL OPERATION MODE (see gure 1 on page

5). Allow control to nish the RINSE cycle. Allow the control to automatically advance to the SOFTENING position. Now

load the brine tank with salt. Solar Salt is recommended. The brine tank salt level should be checked every couple of

weeks to determine salt usage. Keeping the brine tank salt level at least 1/2 full is recommended.

SANITIZING: Use 2 oz. of 5 ¼% unscented household chlorine bleach for each cubic foot of resin. Pour bleach directly into the 4”

diameter white brine well located inside the brine tank. Press and hold the

system to complete the regeneration automatically. Check for other local and state codes which may also specify sanitation methods.

Note: The rst step of the regeneration process is to ll the brine tank with the proper amount of water. The brine tank will

only have a very slight amount of water in it after the regeneration cycles are completed.

REGEN

for 5 - 6 seconds until the motor starts running. Allow

GENERAL OPERATION

Note: As an energy saving feature, the control will automatically turn off all SOLID BLUE or SOLID GREEN display

illumination and keypad illumination after about 5 minutes of the last keypad button push. Any further keypad touch will

cause the re-illumination of the display and keypad, and re-activate keypad control.

User Displays

When the system is in normal service mode, one of up to ve

available User Displays will be shown. Pressing

alternate between the following displays:

• Current time of day

• Treated water ow rate

• Service contact name and phone number (if entered)

• Remaining Capacity of treated water available

• Remaining days to regeneration (if Day Override is

programmed)

Pressing the button while in the Capacity Remaining or

Days Remaining displays will decrease the capacity remaining

in ten gallon increments or the days remaining in one day

increments.

To clear the Service Call reminder, press the and

buttons simultaneously while the number and banner text

screen is displayed.

If the system has called for a regeneration that will occur at

the preset time of regeneration, the words REGEN TODAY will

alternate with the header on the display.

Utilizing the control valve’s built-in water meter, a water drop

ashes on the display when water is being treated (i.e. water is

owing through the system).

NEXT

will

Drop will ash while water

is being treated.

Contact Screen

NEXT

NEXT

NEXT

NEXT

PAGE 9

Page 10

SET TIME OF DAY

Current time of day needs to be entered during initial installation, and adjusted when daylight saving time begins or ends.

If an extended power outage occurs and depletes the on-board non-rechargeable coin cell battery, when power resumes

the time of day should be reset and battery replaced.

STEP 1

STEP 2

STEP 1 – Press

STEP 2 - Current Time (hour): Set the hour of the day using or buttons. AM/PM toggles

after 12. Press

STEP 3

STEP 3 - Current Time (minutes): Set the minutes of the day using or buttons. Press

NEXT to exit Set Time of Day. Press

RETURN TO NORMAL MODE

ADJUST HARDNESS, DAYS BETWEEN REGENERATIONS,

CLOCK

NEXT

to go to Step 3.

to return to previous step.

REGEN

OR TIME OF REGENERATION

STEP 1

STEP 2

STEP 3

STEP 4

STEP 1 - Press

NEXT

and simultaneously for 3 seconds to access Installer Display Settings.

STEP 2 – Hardness: Set the amount of hardness in grains of hardness as calcium carbonate per

gallon using the or buttons. The default is 20 with value ranges from 1 to 150 in 1 grain

increments. Note: The grains per gallon can be increased if soluble iron needs to be reduced. Press

NEXT

to go to step 3. Press

to exit Installer Display Settings.

REGEN

STEP 3 – Day Override: Set the maximum number of days between regenerations. If value set to

“OFF”, regeneration initiation is based solely on volume used. If value is set as a number (allowable

range from 1 to 28) a regeneration initiation will be called for on that day even if sufcient volume of

water were not used to call for a regeneration. Set Day Override using or buttons:

• number of days between regeneration (1 to 28); or

• “OFF”.

Press

NEXT

to go to step 4. Press

REGEN

to return to previous step.

STEP 4 – Next Regeneration Time (hour): Set the hour of day for regeneration using or

buttons. AM/PM toggles after 12. The default time is 2:00 AM. Press

REGEN

to return to previous step.

to go to Step 5. Press

NEXT

PAGE 10

Page 11

STEP 5

STEP 5 – Next Regeneration Time (minutes): Set the minutes of day for regeneration using

or buttons. Press

NEXT

to return to normal operation. Press

REGEN

to return to

previous step.

RETURN TO NORMAL MODE

LOW BATTERY

A non-rechargeable coin cell battery is located on the circuit board, used only to maintain the time of day during power

outages (all other information will be stored in memory no matter how long the power outage). The screen displays LOW

BATTERY when the battery needs to be replaced. The screen will remain illuminated solid blue when LOW BATTERY is

displayed. Initially LOW BATTERY display will alternate with the User display, nally displaying only LOW BATTERY. User

displays are still accessible by pressing

NEXT

.

CONTACT SCREEN PROGRAMMING

STEP 1

STEP 2

STEP 3

STEP 4

STEP 1 - Press

NEXT

and simultaneously for 3 seconds to access Installer Display

Settings.

STEP 2 - Press

STEP 3 - Press

NEXT

to go to step 3.

NEXT

to go to step 4.

From Step 4, while hour is ashing, press and hold both the

change phone number and banner text.

CLOCK

and button to

Phone Number - Set phone number using the or arrow. Press

to the next digit. Press

Banner Text - Set the banner text up to a maximum of 44 characters. Use the or

to select letters of the alphabet, numbers, ampersand (&), or a space in the banner text.

Press

REGEN

to return to previous digit.

NEXT

to forward to the next character or to exit the Installer Display Settings.

PAGE 11

NEXT

to forward

Page 12

X FACTOR SERIES

GENERAL SPECIFICATIONS

1” Control Valve Size;

W” x L” x H”

Inlet/Outlet Fitting

Options; inches

Drain Pipe NPT (OD

Poly Tube) Size; inches

Working Pressure;

Min to Max (PSI)

Water Operating Temp;

Min to Max (°F)

AC Adaptor Input;

Voltage - Hertz

AC Adaptor Output;

Voltage - Current

3 Volt Lithium Coin Cell

Battery; type

PC Board Relay Terminal

Block DC Output; Voltage

** Relay Specications: 12V DC Relay with a coil resistance not less than 80 ohms. If mounting the relay under the control

valve cover, check for proper mounting location dimensions on the backplate.

9.3 x 10.5 x 7.0

3/4 to 1.25

3/4 (5/8)

20 to 100

35 to 100

120V AC - 60 Hz

12V AC - 500 mA

2032

12V DC **

8.50 215.9

9.3

186.17.33

7.0

10.15 257.9

10.5

3.39 86.1

General Notes for estimating only.

PAGE 12

Page 13

X FACTOR SERIES

LX SPECIFICATIONS

MODEL NUMBER 7-LX-75B 7-LX-100B 7-LX-150B 7-LX-200B 7-LX-300B

Service Flow (GPM)

at 15 PSI Pressure Drop

Resin Tank Size;

Diameter x Height (inches)

Resin; Cu. Ft. 0.75 1 1.5 2 3

Brine Tank Size; (inches) 15 x 17 x 36 15 x 17 x 36 15 x 17 x 36 18 x 40 18 x 40

Brine Tank Capacity;

Lbs NaCl

Drain Line Flow Control;

GPM

Brine Line (Re-Fill)Flow

Control; GPM

Injector; color 1C - Violet 1E - White 1E - White 1F - Blue 1H - Green

13 17 16 18 19

8 x 44 10 x 40 10 x 54 12 x 48 14 x 65

275 275 275 450 450

1.0 1.7 1.7 2.7 4.2

0.5 0.5 0.5 0.5 0.5

X FACTOR SERIES

LXC SPECIFICATIONS

MODEL NUMBER

7-LXC-50B

(PACKED BED)

7-LXC-75B

7-LXC-100B

(PACKED BED)

Service Flow (GPM)

at 15 PSI Pressure Drop

Resin Tank Size;

Diameter x Height

(inches)

Resin; Cu. Ft. 0.5 0.75 1

Cabinet Size (including

top cover); W” x L” x H”

Cabinet Capacity (with

grid); Lbs NaCl

Drain Line Flow Control;

GPM

Brine Line (Re-Fill) Flow

Control; GPM

Injector; color 1D - Red 1E - White 1E - White

14 18 17

9 x 18 10 x 35 10 x 35

13.5 x 22.5 x 27.25 13.5 x 22.5 x 44 13.5 x 22.5 x 44

75 225 225

0.7 1.7 1.7

0.5 0.5 0.5

PAGE 13

Page 14

X FACTOR SERIES

LX SPECIFICATIONS

MODEL NUMBER 7-LX-75B 7-LX-100B 7-LX-150B 7-LX-200B 7-LX-300B

CYCLES*

(Downow Regenerant,

Prell)

1st: Fill; Lbs NaCl 6.0 8.0 12.0 16.0 24.0

2nd: Softening; Minutes

(Regenerant Production)

3rd: Backwash; Minutes 10 10 10 10 10

4th: Regenerant Draw

DN; Minutes

(Draw & Slow Rinse)

5th: Backwash; Minutes 10 10 10 10 10

6th: Rinse; Minutes

(Fast Rinse)

7th: End - - - - -

GRAINS

CAPACITY

LBS NaCl

Per

Regeneration

(Re-) FILL

Minutes

GALLONS¹

WATER TO

DRAIN

at

40/50/60

PSI

Inlet Pressure

Low 12,750 17,000 25,500 34,000 51,000

Medium* 18,000 24,000 36,000 48,000 72,000

High 24,000 32,000 48,000 64,000 96,000

Low 3.4 4.5 6.75 9.0 13.5

Medium* 6.0 8.0 12.0 16.0 24.0

High 11.3 15.0 22.5 30.0 45.0

Low 2.3 3.0 4.5 6.0 9.0

Medium* 4.0 5.3 8.0 10.7 16.0

High 7.5 10.0 15.0 20.0 30.0

Low 38.4/39.6/40.4 60.8/62.5/63.8 61.5/63.3/64.5 94.5/96.3/98.0 142.5/145.5/148.0

Medium* 39.3/40.5/41.3 61.9/63.7/64.9 63.3/65.0/66.3 96.8/98.6/100.3 146.0/149.0/151.5

High 41.0/42.3/43.0 64.3/66.0/67.3 66.8/68.5/69.8 101.5/103.3/105.0 153.0/156.0/158.5

60 60 60 60 60

50 50 50 50 50

5 5 5 5 5

WATER²

USAGE

% Efciency

at

10 GRAINS

per GALLON

and

40 PSI

Inlet Pressure

* Factory Setting.

1

Gallons to Drain = (Backwash Min. x DLFC Gal./Min.) + (Fast Rinse Min. x DLFC Gal./Min.) + (Regenerant Draw DN Min. x Slow

Rinse Gal./Min.) + (LBS. NaCl x 1 Gal./3 LBS. NaCl)

Note: Slow Rinse Gal./Min. is obtained from injector charts for each color injector at various pressures.

2

Water Usage % Efciency =

Low 97.1 96.5 97.6 97.3 97.3

Medium* 97.9 97.5 98.3 98.0 98.0

High 98.3 98.0 98.6 98.4 98.4

Gallons Treated

Gallons Treated + Gallons to Drain

X 100

PAGE 14

Page 15

X FACTOR SERIES

LXC SPECIFICATIONS

MODEL NUMBER

CYCLES*

(Downow Regenerant,

Prell)

1st: Fill; Lbs NaCl 4.0 6.0 8.0

2nd: Softening; Minutes

(Regenerant Production)

3rd: Backwash; Minutes NA 10 NA

4th: Regenerant Draw

DN; Minutes

(Draw & Slow Rinse)

5th: Backwash; Minutes NA 10 NA

6th: Rinse; Minutes

(Fast Rinse)

7th: End - - -

7-LXC-50B

(PACKED BED)

60 60 60

50 50 50

5 5 5

7-LXC-75B

7-LXC-100B

(PACKED BED)

GRAINS

CAPACITY

LBS NaCl

Per

Regeneration

(Re-) FILL

Minutes

GALLONS¹

WATER TO

DRAIN

at

40/50/60

PSI

Inlet Pressure

WATER²

USAGE

% Efciency

at

10 GRAINS

per GALLON

and

40 PSI

Inlet Pressure

Low 8,500 12,750 17,000

Medium* 12,000 18,000 24,000

High 16,000 24,000 32,000

Low 2.3 3.4 4.5

Medium* 4.0 6.0 8.0

High 7.5 11.3 15.0

Low 1.5 2.3 3.0

Medium* 2.7 4.0 5.3

High 5.0 7.5 10.0

Low 18.5/20.0/21.3 60.4/62.1/63.4 26.8/28.5/29.8

Medium* 19.0/20.6/21.8 61.2/63.0/64.2 27.9/29.7/30.9

High 20.3/21.8/23.0 63.1/64.8/66.1 30.3/32.0/33.3

Low 97.9 95.5 98.4

Medium* 98.4 96.7 98.9

High 98.8 97.4 99.1

* Factory Setting.

1

Gallons to Drain = (Backwash Min. x DLFC Gal./Min.) + (Fast Rinse Min. x DLFC Gal./Min.) + (Regenerant Draw DN Min. x Slow

Rinse Gal./Min.) + (LBS. NaCl x 1 Gal./3 LBS. NaCl)

Note: Slow Rinse Gal./Min. is obtained from injector charts for each color injector at various pressures.

2

Water Usage % Efciency =

Gallons Treated + Gallons to Drain

Gallons Treated

X 100

PAGE 15

Page 16

Click to buy NOW!

P

D

F

-

X

C

H

A

N

G

E

w

w

w

.

d

o

c

u

-

t

r

a

c

k

.

c

o

m

SOFTENER ASSEMBLY

Click to buy NOW!

P

D

F

-

X

C

H

A

N

G

E

w

w

w

.

d

o

c

u

-

t

r

a

c

k

.

c

o

m

Dwg.

1

No.

2

1 LXCV1 (detailed components shown in this manual) Metered Control Valve 1

3

2 D1203 Top Distributor 1

4

5

FG844VT, D1130-12 Ft. (cut for 44 in.), R-DIP1050 Tank, Pipe, Connector, Assy for Model 7-LX-75B 1

Order No. Description Qty

FG1040VT, D1130-12 Ft. (cut for 40 in.), R-DIP1050 Tank, Pipe, Connector, Assy for Model 7-LX-100B 1

3,4,5

FG1054VT, D1130-12 Ft. (cut for 54 in.), R-DIP1050 Tank, Pipe, Connector, Assy for Model 7-LX-150B 1

FG1248VT, D1130-12 Ft. (cut for 48 in.), R-DIP1050 Tank, Pipe, Connector, Assy for Model 7-LX-200B 1

FG1465VT, D1130-12 Ft. (cut for 65 in.), R-DIP1050 Tank, Pipe, Connector, Assy for Model 7-LX-300B 1

A4074 (3/4 Cu. Ft. = 39 LBS) Ion Exchange Resin for Model 7-LX-75B 1

A4074 (1 Cu. Ft. = 52 LBS) Ion Exchange Resin for Model 7-LX-100B 1

6

6

A4074 (1 1/2 Cu. Ft. = 78 LBS) Ion Exchange Resin for Model 7-LX-150B 1

A4074 (2 Cu. Ft. = 104 LBS) Ion Exchange Resin for Model 7-LX-200B 1

A4074 (3 Cu. Ft. = 156 LBS) Ion Exchange Resin for Model 7-LX-300B 1

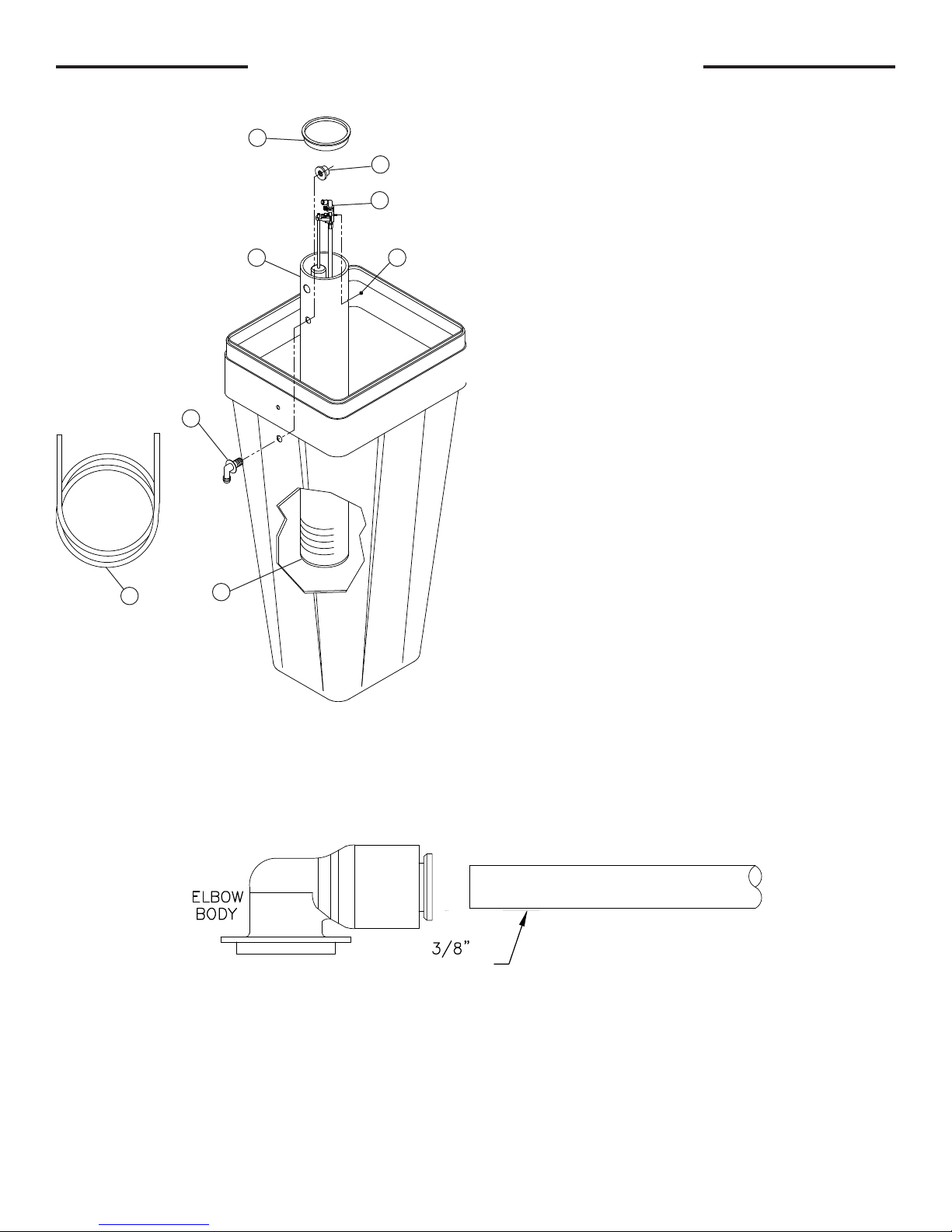

BRINE TANK ASSEMBLY

Dwg. No. Order No. Description Qty

1 G2136 18x40 Brine Tank with Cover for Model 7-LX-200B, -300B 1

2

3 H7016

4 4740

5 H1018 Two Piece Overow Set 1

6

7 H1023 3/8”O.D.x6 Ft. Poly Tubing 1

H1031 4x28 Slotted Brine Well for Model 7-LX-75B, -100B, -150B 1

H1036 4x46 Slotted Brine Well for Model 7-LX-200B, -300B 1

4 inch Brine Well Cap for Model 7-LX-75B, -100B, -150B

(Top Cap Only for Models 7-LX-200B, -300B)

3/8” Brine Valve Assembly

(using 1/2”x24” long air check assy for Model 7-LX-75B, -100B, -150B)

4740-L

(using 1/2”x43” long air check assy for Model 7-LX-200B, -300B)

1640N Nylon Screw (only for Model 7-LX-200B, -300B) 1

6785N Nylon Nut (only for Model 7-LX-200B, -300B) 1

2

(1)

1

L56-40A 18 x 40

Brine Tank Assy.

3

6

5

4

1

2

4740 BRINE VALVE ASSEMBLY

3

Dwg No. Order No. Description Qty

1 H4600 3/8” Safety Brine Valve 1

2 10151 Pin 1

3 H4640-9.5 Float Assembly 1

4 H4500-48

Air Check Assembly (uncut length)

see brine tank assy for cut length

1

3

2

7

J7952 15 x 17 x 36

Brine Tank Assy.

4

1

PAGE 16

Page 17

X-FACTOR FRONT COVER AND DRIVE ASSEMBLY

Drawing No. Order No. Description Quantity

1

2 V3107-01 Motor 1

3 V3106-01 Drive Bracket & Spring Clip 1

4 V3757LP PC Board 1

5 V3110 Drive Gear 12x36 3

6 V3109 Drive Gear Cover 1

V3692-02LW LP Front Cover Assembly

1

When replacing the battery, align

positives and push down to fully seat.

Battery Fully Seated

AC Adapter

Order No.

(Not shown)

V3186

Supply Voltage 120V AC

Supply Frequency 60 Hz

Output Voltage 12V AC

Output Current 500 mA

No user serviceable parts are

on the PC board, the motor, or

the power adapter. The means

of disconnection from the main

power supply is by unplugging

the power adapter from the wall.

Correct

Battery

Orientation

1

Battery replacement is

3 volt lithium coin cell

type 2032.

4

5

After completing any valve maintenance involving the drive assembly or the drive cap assembly and pistons, unplug

power source jack from the printed circuit board (black wire) and plug back in or press and hold

for 3 seconds. This resets the electronics and establishes the service piston position. The display should ash the

software version and then reset the valve to the service position.

PAGE 17

6

2

NEXT

and

3

REGEN

buttons

Page 18

1

2

3

4

5

DRIVE CAP ASSEMBLY, DOWNFLOW PISTON,

REGENERANT PISTON AND SPACER STACK ASSEMBLY

Drawing

Order No. Description Qty

No.

1 V3005 Spacer Stack Assembly 1

2 V3004 Drive Cap Assy 1

3 V3178LP Back Plate 1

4 V3011 Piston Downow Assy 1

5 V3174 Regenerant Piston 1

6 V3135 O-ring 228 1

7 V3180 O-ring 337 1

8 V3105 O-ring 215 (Distributor Tube) 1

Not Shown V3001 Body Assy Downow 1

After completing any valve

maintenance involving the drive

assembly or the drive cap assembly

and pistons, unplug power source jack

from the printed circuit board (black

wire) and plug back in or press and

hold

NEXT

and

REGEN

buttons for 3

2

seconds. This resets the electronics

and establishes the service piston

position. The display should ash the

software version and then reset the

valve to the service position.

Do not use Vaseline, oils, other hydrocarbon lubricants

or spray silicone anywhere. A silicone lubricant may be

used on black o-rings but is not necessary. Avoid any

type of lubricants, including silicone, on the clear

lip seals.

3

5

4

6

1

7

8

INJECTOR CAP, INJECTOR SCREEN, INJECTOR, PLUG AND O-RING

Drawing No. Order No. Description Qty

1 V3176 INJECTOR CAP 1

2 V3152 O-RING 135 1

3 V3177-01 INJECTOR SCREEN CAGE 1

4 V3010-1Z INJECTOR ASSY Z PLUG 1

V3010-1A INJECTOR ASSY A BLACK

V3010-1B INJECTOR ASSY B BROWN

V3010-1C INJECTOR ASSY C VIOLET

V3010-1D INJECTOR ASSY D RED

V3010-1E INJECTOR ASSY E WHITE

5

Not Shown V3170 O-RING 011 *

* The injector plug and the injector each contain one 011 (lower) and 013 (upper) o-ring.

Not Shown V3171 O-RING 013 *

The nut and caps are designed to be unscrewed or tightened by hand or with the service spanner wrench (see page 21).

If necessary a pliers can be used to unscrew the nut or cap. Do not use a pipe wrench to tighten or loosen nuts or caps.

Do not place a screwdriver in slots on caps and/or tap with a hammer.

V3010-1F INJECTOR ASSY F BLUE

V3010-1G INJECTOR ASSY G YELLOW

V3010-1H INJECTOR ASSY H GREEN

V3010-1I INJECTOR ASSY I ORANGE

V3010-1J INJECTOR ASSY J LIGHT BLUE

V3010-1K INJECTOR ASSY K LIGHT GREEN

1

PAGE 18

Page 19

REFILL FLOW CONTROL ASSEMBLY

Drawing No. Order No. Description Quantity

1 V3195-01 WS1 Re ll Port Plug Asy This part is required for backwash only systems

2 H4615 Elbow Locking Clip 1

3 H4628 Elbow 3/8” Liqui t 1

4 V3163 0-ring 019 1

5 V3165-01* WS1 RFC Retainer Asy (0.5 gpm) 1

6 V3182 WS1 RFC 1

7 V4144-01 Elbow 3/8 Liqui t Asy w/RFC 1

Not Shown V3552 WS1 Brine Elbow Asy w/RFC Option

Not Shown H4650 Elbow ½” with nut and insert Option

*Assembly includes V3182 WS1 (0.5 gpm) RFC.

Drawing No. Order No. Description Qty

1 H4615 Elbow Locking Clip 1

2 H4628 Elbow 3/8” Liquit 1

3 V3163 O-ring 019 1

4 V3165-01* RFC Retainer Assy (0.5 gpm) 1

5 V3182 RFC 1

6 V4144-01 Elbow 3/8 Liquit Assy w/RFC 1

*Assembly includes V3182 RFC.

6

2

3

4

5

1

WATER METER

Drawing No. Order No. Description Qty

1 V3151 Nut 1” QC 1

2 V3003* Meter Assy 1

3 V3118-01 Turbine Assy 1

4 V3105 0-ring 215 1

*Order number V3003 includes V3118-01 Turbine

Assy and V3105 O-ring 215.

THIS WATER METER SHOULD NOT BE USED AS THE PRIMARY MONITORING

DEVICE FOR CRITICAL OR HEALTH EFFECT APPLICATIONS.

The nut and caps are designed to be unscrewed or tightened by hand or with the

service spanner wrench. If necessary a pliers can be used to unscrew the nut or

cap. Do not use a pipe wrench to tighten or loosen nuts or caps. Do not place a

screwdriver in slots on caps and/or tap with a hammer.

PAGE 19

Page 20

DRAIN LINE - 3/4”

Dwg

No.

Order No. Description Qty

1 H4615 Elbow Locking Clip 1

2 V3194 Polytube insert 5/8 Option

3 V3192 Nut ¾ Drain Elbow Option

4* V3158 Drain Elbow ¾ Male 1

5 V3163 O-ring 019 1

4

6* V3159 DLFC Retainer Assy 1

V3162-007 DLFC 0.7 gpm for ¾

V3162-010 DLFC 1.0 gpm for ¾

V3162-013 DLFC 1.3 gpm for ¾

V3162-017 DLFC 1.7 gpm for ¾

V3162-022 DLFC 2.2 gpm for ¾

V3162-027 DLFC 2.7 gpm for ¾

V3162-032 DLFC 3.2 gpm for ¾

7

V3162-042 DLFC 4.2 gpm for ¾

V3162-053 DLFC 5.3 gpm for ¾

V3162-065 DLFC 6.5 gpm for ¾

V3162-075 DLFC 7.5 gpm for ¾

One

DLFC

must

be

used

if ¾

tting

is

used

Water

Proper DLFC orientation

directs water ow towards

the washer face with

rounded edge.

Flow

V3162-090 DLFC 9.0 gpm for ¾

V3162-100 DLFC 10.0 gpm for ¾

*4 and 6 can be ordered as a complete assembly V3331 Drain Elbow and Retainer Assy

Do not use pipe dope or other sealants on threads. Teon tape must be used on threads of 3/4” NPT connection (unless

using 5/8” polytubing).

Do not use Vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may be used on

black o-rings but is not necessary.

INSTALLATION FITTING ASSEMBLIES

Description: Fitting 1” PVC Male NPT Elbow

Drawing

Do not use pipe dope or other sealants on threads. Teon tape must be used on threads of 1” NPT connection. Teon

Order No: V3007 (Standard)

Assembly

Order

No.

No.

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3149

Description Quantity

Fitting 1 PVC Male

NPT Elbow

Description: Fitting Vertical Adapter Assembly

2

tape is not necessary on the nut connection nor caps because of o-ring seals.

The nut and caps are designed to be unscrewed or tightened by hand or with the service spanner wrench. If necessary a

pliers can be used to unscrew the nut or cap. Do not use a pipe wrench to tighten or loosen nuts or caps. Do not place a

screwdriver in slots on caps and/or tap with a hammer.

Do not use Vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may be used on

black o-rings but is not necessary.

Order No. V3191-01 (Optional)

Drawing

Order

No.

No.

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3191 Vertical Adapter 2

3

Description Quantity

2

1

4

PAGE 20

Page 21

BYPASS VALVE

(Order No. BP2000)

Drawing No. Order No. Description Qty

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3145 Bypass 1” Rotor 2

5 V3146 Bypass Cap 2

6 V3147 Bypass Handle 2

7 V3148 Bypass Rotor Seal Retainer 2

8 V3152 O-ring 135 2

9 V3155 O-ring 112 2

10 V3156 O-ring 214 2

SERVICE SPANNER WRENCH

Although no tools are necessary to assemble or disassemble the valve, the wrench (shown in various positions on the

valve) may be purchased to aid in assembly or disassembly.

Loosens Drive Cap

(Order No. V3193)

Loosens Injector And

Bypass Caps

PAGE 21

Page 22

1 1/4 NPT

1 1/4 NPT

1 BSPT

CHANGE

CHANGE

R

BY:

LTR

DATE:

TITLE:

DATE

SCALE:

PART #:

REV.

DWG #:

Clack Corporation

4462 DURAFORM LANE, WINDSOR, WI 53598

TELEPHONE NO. 1-608-846-3010

C

C

1:2

12/1/05

D.A.K.

WS1F1_1-2&Sol1_1-4_0707

MODEL:

DWG:

WS1F1_1-2&Sol1_1-4_0707

CONFIG:

exploded-(artwork)

SHEET:

1 OF 1

WS1 ADAPTER 1 1/2 & 1 1/4 SOLVENT ASSEMBLY

OPTIONAL INSTALLATION FITTING ASSEMBLIES

Description: Fitting ¾” & 1” PVC Solvent 90°

Drawing

No.

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3189

Order No: V3007-01

Assembly

Order

No.

Fitting ¾&1 PVC

Solvent 90

Description Quantity

Description: Fitting 1” Brass Sweat Assembly

Drawing

No.

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3188

2

Do not install in California.

Order No: V3007-02

Order

No.

Fitting 1 Brass Sweat

Assembly

Description Quantity

2

Description: Fitting ¾” Brass Sweat Assembly

Order No: V3007-03

Drawing

Order No. Description Quantity

No.

1 V3151

Nut 1” Quick

Connect

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3188-01

Fitting ¾ Brass

Sweat

Do not install in California.

2

2

Description: Fitting 1” Plastic Male NPT Assembly

Order No: V3007-04

Drawing

No.

Order

No.

Description Quantity

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3164

Fitting 1" Plastic Male

NPT

Description: Fitting 1-¼” Plastic Male NPT Assembly

Order No: V3007-05

Drawing

No.

Order

No.

Description Quantity

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

2

4 V3317

Fitting 1-¼" Plastic

Male NPT

Order No. V3007-07

Description: Fitting 1¼” & 1½” PVC Solvent Assembly

Drawing

No.

Order

No.

Description Quantity

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

2

4 V3352 Fitting 1¼”&1½” PVC

Solvent

4

2

4

4

1

2

3

1 NPT

3

1

2

3

1

2

Description: Fitting 1¼” & 1½” Brass Sweat Assembly

Drawing

No.

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3375

3

Order

No.

1

2

Description Quantity

Fitting 1¼" & 1½"

Brass Sweat

4

Description: Fitting 3/4" Brass SharkBite Assembly

Drawing

No.

1 V3151 Nut 1" Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3628 Ftg 3/4 Brass Shark-

2

3

Order No: V3007-09

Order No. V3007-12

Order

No.

1

2

Bite

Description Quantity

2

4

Description: Fitting 1" Brass SharkBite Assembly

Order No. V3007-13

Drawing

No.

Order

No.

Description Quantity

1 V3151 Nut 1" Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-Ring 215 2

4 V3629 Ftg 1" Brass Shark-

2

Bite

1

4

2

3

Description: WS1 FTG 3/4 JG QC 90 ASY

Order No. V3007-15

Drawing No. Order No. Description Quantity

1 V3151 WS1 NUT 1 QC 2

2 V3150 WS1 SPLIT RING 2

3 V3105 O-RING 215 2

4 V3790 WS1 ELBOW 3/4 QC W/STEM 2

2

3

1

4

Order No. V3007-17

Description: WS1 FTG 1” JG QC ASY

Drawing No. Order No. Description Quantity

1 V3105 O-RING 215 2

2 V3150 WS1 SPLIT RING 2

3 V3151 WS1 NUT 1 QC 2

4 V4045 WS1 FTG 1 INCH QC 2

4

3

2

1

PAGE 22

Page 23

CABINET SOFTENER ASSEMBLY

20

9

16

"

Water Specialist - CWS-18 Cabinet

The Water Specialist - CWS-18 Cabinet

accepts 18” tall mineral tanks.

The Water Specialist – CWS-35 Cabinet

accepts 35” tall mineral tanks up to

a 12” diameter to maximize system

capability.

Water Specialist - CWS-35 Cabinet

27

3

4

"

20

9

16

"

16

1313"

17

5

8

"

5

8

" 20

Water Specialist - CWS-18 Cabinet

The Water Specialist - CWS-18 Cabinet

accepts 18” tall mineral tanks.

20

9

16

"

Order No. Description

G2700T, G2718B Cabinet, Top Cover for Model 7-LXC-50B

G2700T, G2735B Cabinet, Top Cover for Model 7-LXC-75B, -100B

LXCV1 (detailed components shown in this manual) Metered Control Valve

D1203 Top Distributor

FG918VT, D1130-12 Ft. (cut for 18 in.), R-DIP1050 Tank, Pipe, Connector, Assy for Model 7-LXC-50B

FG1035VT, D1130-12 Ft. (cut for 35 in.), R-DIP1050 Tank, Pipe, Connector, Assy for Model 7-LXC-75B, -100B

A4074 (1/2 Cu. Ft. = 26 LBS) Ion Exchange Resin for Model 7-LXC-50B

A4074 (3/4 Cu. Ft. = 39 LBS) Ion Exchange Resin for Model 7-LXC-75B

A4074 (1 Cu. Ft. = 52 LBS) Ion Exchange Resin for Model 7-LXC-100B

7-LXC-50B MINI CABINET

G2700T

17

34

3

27

"

4

5

"

8

5

44

"

8

1

"

2

G2718B

1313"

16

7-LXC-75B, 7-LXC-100B CABINET

G2700T

G2735B

9

20

"

16

13

13

"

16

PAGE 23

20

5

"

8

Page 24

Service Instructions

When servicing the valve, water may leak from

the valve. Water from the valve may create a slip

hazard. Clean up water spills.

Disconnect from electrical power prior to

servicing the valve.

Disconnect from electrical power prior to

servicing the valve.

SERVICE INSTRUCTIONS

When servicing the valve, water may leak

from the valve. Water from the valve may

create a slip hazard. Clean up water spills.

Disconnect from electrical power prior to

servicing the valve.

DRIVE ASSEMBLY:

Remove the valve cover to access the drive assembly.

Disconnect the power source plug (black wire) from the PC board prior to disconnecting the motor or water meter plugs from the PC

board. The power source plug connects to the four-pin jack. The motor plug connects to the two-pin jack on the left-hand side of the PC

board. The water meter plug (gray wire) connects to the three-pin jack on the far right-hand side of the PC board.

The PC board can be removed separately from the drive bracket but it is not recommended. Do not attempt to remove the display panel

from the PC board. Handle the board by the edges. To remove the PC board from the drive bracket, unplug the power, water meter and

motor plugs from the PC board. Lift the middle latch along the top of the drive bracket while pulling outward on the top of the PC board.

The drive bracket has two plastic pins that t into the holes on the lower edge of the PC board. Once the PC board is tilted about 45°

from the drive bracket it can be lifted off of these pins. To reinstall the PC board, position the lower edge of the PC board so that the

holes in the PC board line up with the plastic pins. Push the top of the PC board towards the valve until it snaps under the middle latch,

weave the power and water meter wires into the holders and reconnect the motor, water meter and power plugs.

The drive bracket must be removed to access the drive cap assembly and pistons or the drive gear cover. It is not necessary to remove

the PC board from the drive bracket to remove the drive bracket. To remove the drive bracket start by removing the plugs for the power

source and the water meter. Unweave the wires from the side holders. Two tabs on the top of the drive back plate hold the drive bracket

in place. Simultaneously lift the two tabs and gently ease the top of the drive bracket forward. The lower edge of the drive bracket has

two notches that rest on the drive back plate. Lift up and outward on the drive bracket to disengage the notches.

To reassemble, seat the bottom of the drive bracket so the notches are engaged at the bottom of the drive back plate. Push the top of

the drive bracket toward the two latches. The drive bracket may have to be lifted slightly to let the threaded piston rod pass through

the hole in the drive bracket. Maintain a slight engaging force on top of the drive bracket while deecting the bracket slightly to the left

by pressing on the side of the upper right corner. This helps the drive gears mesh with the drive cap assembly. The drive bracket is

properly seated when it snaps under the latches on the drive back plate. If resistance is felt before latching, then notches are not fully

engaged, the piston rod is not in hole, the wires are jammed between the drive bracket and drive back plate, or the gear is not engaging

the drive cap assembly.

To inspect the drive gears, the drive gear cover needs to be removed. Before trying to remove the gear cover, the drive bracket must

be removed from the drive back plate. (Refer to the instructions above regarding removing the drive bracket from the drive back plate.

The drive gear cover can be removed from the drive bracket without removing the motor or the PC board.) The drive gear cover is held

in place on the drive bracket by three clips. The largest of the three clips is always orientated to the bottom of the drive bracket. With

the PC board facing up, push in and down on the large clip on the drive gear cover. Handle the cover and the gears carefully so that the

gears do not fall off the pegs in the cover.

Replace broken or damaged drive gears. Do not lubricate any of the gears. Avoid getting any foreign matter on the reective coating

because dirt or oils may interfere with pulse counting.

The drive gear cover only ts on one way, with the large clip orientated towards the bottom. If all three clips are outside of the gear

shroud on the drive bracket the drive gear cover slips easily into place.

The drive bracket does not need to be removed from the drive plate if the motor needs to be removed. To remove the motor, disconnect

the power and motor plugs from the jacks on the PC board. Move the spring clip loop to the right and hold. Rotate the motor at least a

¼ turn in either direction so the wires are vertical (up & down) before gently pulling on the wire connectors to remove the motor. Pulling

directly on the wires without rotating the motor may break the wires off the motor.

Replace the motor if necessary. Do not lubricate the motor or the gears. To reinstall the motor, move the spring clip loop to the right and

hold. Gently turn the motor while inserting so that the gear on the motor meshes with the gears under the drive gear cover. Release the

spring clip loop and continue to rotate the motor until the wires are horizontal and the motor housing engages the small plastic bulge

inside the drive bracket motor retainer. Reconnect the motor plug to the two-pronged jack on the lower left side of the PC board. If the

motor will not easily engage with the drive gears when reinstalling, lift and slightly rotate the motor before reinserting. Reconnect the

power plug.

Replace the valve cover. After completing any valve maintenance involving the drive assembly or the drive cap assembly and pistons

unplug power source jack from the printed circuit board (black wire) and plug back in or press and hold NEXT and REGEN buttons for 3

seconds.

This resets the electronics and establishes the service piston position. The display should ash all wording, then ash the software

version and then reset the valve to the service position.

PAGE 24

Page 25

DRIVE CAP ASSEMBLY, MAIN PISTON AND REGENERANT PISTON:

The drive assembly must be removed to access the drive cap assembly. The drive cap assembly must be removed to access the

piston(s). The drive cap assembly is threaded into the control valve body and seals with an o-ring. To remove the drive cap assembly

use the special plastic wrench or insert a ¼” to ½” at blade screwdriver into one of the slots around the top 2” of the drive cap

assembly so it engages the notches molded into the drive back plate around the top 2” of the piston cavity. See below. The notches are

visible through the holes. Lever the screwdriver so the drive cap assembly turns counter clockwise. Once loosened unscrew the drive

cap assembly by hand and pull straight out.

The drive cap assembly contains the drive cap, the main drive gear, drive cap spline, piston rod and various other parts that should not

be dissembled in the eld. The only replaceable part on the drive cap assembly is the o-ring. Attached to the drive cap assembly is the

main piston and if a regenerant is used, a regenerant piston.

The regenerant piston (the small diameter one behind the main piston) is removed from the main piston by pressing sideways and

unsnapping it from its latch. Chemically clean in dilute sodium bisulte or vinegar, or replace the regenerant piston if needed. To remove

the main piston fully extend the piston rod and then unsnap the main piston from its latch by pressing on the side with the number.

Chemically clean in dilute sodium bisulte or vinegar, or replace the main piston.

Reattach the main piston to the drive cap assembly. Reattach the regenerant piston (if needed) to the main piston. Reinsert the drive

cap assembly and piston into the spacer stack assembly and hand tighten the drive cap assembly. Continue to tighten the drive cap

assembly using a screwdriver as a ratchet until the black o-ring on the spacer stack assembly is no longer visible through the drain port.

Excessive force can break the notches molded into the drive back plate. Make certain that the main drive gear still turns freely.

The exact position of the piston is not important as long as the main drive gear turns freely. Reattach the drive assembly to the control

valve and connect all plugs. After completing any valve maintenance involving the drive assembly or the drive cap assembly and

pistons unplug power source jack from the printed circuit board (black wire) and plug back in or press and hold NEXT and REGEN

buttons for 3 seconds.

This resets the electronics and establishes the service piston position. The display should ash all wording, then ash the software

version and then reset the valve to the service position.

REFILL FLOW CONTROL ASSEMBLY:

To clean or replace the rell ow control, pull out the elbow-locking clip and then pull straight up on the elbow. Replace the elbow

locking clip in the slot so that it is not misplaced. Twist to remove the white ow control retainer. The ow control can be removed by

prying upward through the side slots of the retainer with a small at blade screwdriver.

Chemically clean the ow control or the white ow control retainer using dilute sodium bisulte or vinegar. Do not use a wire brush. If

necessary, replace the ow control, o-ring on the ow control retainer, or the o-ring on the elbow.

Reseat the ow control so the rounded end is visible in the ow control. Reseat the white ow control retainer by pushing the retainer

into the elbow until the o-ring seats. Remove locking clip, push down on elbow to reseat and insert locking clip.

Do not use Vaseline, oils, or other unacceptable lubricants on o-rings. A silicone lubricant may be used on the o-ring on the elbow or the

white retainer.

PAGE 25

Page 26

SPACER STACK ASSEMBLY:

To access the spacer stack assembly remove the drive assembly, drive cap assembly and piston. The spacer stack assembly can be

removed easily without tools by using thumb and forenger. Inspect the black o-rings and clear lip seals for wear or damage. Replace

the entire stack if necessary. Do not disassemble the stack.

The spacer stack assembly may be chemically cleaned (dilute sodium bisulte or vinegar) or wiped with a soft cloth.

The spacer stack assembly can be pushed in to the control valve body bore by hand. Since the spacer stack assembly can be

compressed it is easier to use a blunt object (5/8” to 1-1/8” in diameter) to push the center of the assembly into the control valve body.

The assembly is properly seated when at least four threads are exposed (approximately 5/8”). Do not force the spacer stack assembly

in. The control valve body bore interior can be lubricated with silicone to allow for easy insertion of the entire stack.

Reattach the drive cap assembly and piston(s) and the drive assembly.

After completing any valve maintenance involving the drive assembly or the drive cap assembly and pistons unplug power source jack

from the printed circuit board (black wire) and plug back in or press and hold NEXT and REGEN buttons for 3 seconds.

This resets the electronics and establishes the service piston position. The display should ash all wording, then ash the software

version and then reset the valve to the service position.

INJECTOR CAP, SCREEN, INJECTOR PLUG AND INJECTOR:

Unscrew the injector cap and lift off. Loosen cap with special plastic wrench or pliers if necessary. Attached to the injector cap is a

screen. Remove the screen and clean if fouled.

The plug and/or injector can be pried out with a small screwdriver. The plug can be wiped clean. If the plug leaks replace the entire

plug. The injector consists of a throat and a nozzle. Chemically clean the injector with vinegar or sodium bisulte. The holes can be

blown out with air. Both pieces have small diameter holes that control the ow rates of water to insure that the proper concentration

of regenerant is used. Sharp objects, which can score the plastic, should not be used to clean the injector. Scoring the injector or

increasing the diameter of the hole could change the operating parameters of the injector.

Push the plug(s) and/or injectors rmly in place, replace the screen and hand tighten the injector cap.

WATER METER:

The water meter assembly is connected to the PC board by a wire. If the entire water meter assembly is to be replaced, remove the

control valve cover and disconnect the power source and water meter plugs from the PC board. Unlatch the drive assembly and lean it

forward. Unthread the water meter wire from the side of the drive assembly and through the drive back plate. To reinstall, rethread the

water meter wire through the drive back plate and the side of the drive assembly. Reattach the drive assembly and the water meter and

power plugs.

THIS WATER METER SHOULD NOT BE USED AS THE PRIMARY MONITORING DEVICE FOR CRITICAL OR HEALTH EFFECT

APPLICATIONS.

OPERATING PRESSURES: 20 PSI MINIMUM / 125 PSI MAXIMUM • OPERATING TEMPERATURES: 40°F MINIMUM / 110°F

MAXIMUM

If no water meter wire is visible, then a plug is installed, not a water meter.

The water meter wire does not need to be removed from the PC board if the water meter is only being inspected and cleaned. To

remove the water meter assembly, unscrew the meter cap on the left side of the control valve. Pliers may be used to unscrew the nut if

necessary.

With the nut removed, a slot at the top of the water meter is visible. Twist a at blade screwdriver in the slot between the control valve

body and the meter. When the meter is part way out it is easy to remove the water meter from the housing. Once the water meter is

removed from the control valve body, gently pull forward on the turbine to remove it from the shaft. Do not use a wire brush to clean the

turbine. Wipe with a clean cloth or chemically clean in dilute sodium bisulte or vinegar. The turbine can be immersed in the chemical.

Do not immerse electronics. If the turbine is scored or damaged or the bearings on the turbine are worn, replace the turbine.

Do not lubricate the turbine shaft. The turbine shaft bearings are prelubricated. Do not use Vaseline, oils, or other unacceptable

lubricants on the o-ring. A silicone lubricant may be used on the black o-ring.

Snap the turbine on the shaft and reinsert the water meter into the side slot. Hand tighten the nut. Do not use a pipe wrench to tighten

nut.

PAGE 26

Page 27

Problem Possible Cause Solution

1. No Display on PC Board

2. PC Board does not display correct time of

day

3. Display does not indicate that water is

owing. Refer to user instructions for how the

display indicates water is owing

4. Control valve regenerates at wrong time

of day

5. Time of day ashes on and off

6. Control valve does not regenerate

automatically when the REGEN button

7. Control valve does not regenerate

automatically but does when the REGEN

button

TROUBLESHOOTING

a. No power at electric outlet a. Repair outlet or use working outlet

b. Control valve Power Adapter not plugged

into outlet or power cord end not

connected to PC board connection

c. Improper power supply c. Verify proper voltage is being delivered to

d. Defective Power Adapter d. Replace Power Adapter

e. Defective PC Board e. Replace PC Board

a. Power Adapter plugged into electric outlet

controlled by light switch

b. Tripped breaker switch and/or tripped GFI b. Reset breaker switch and/ or GFI switch

c. Power outage c. Reset time of day. If PC Board has battery

d. Defective PC Board d. Replace PC Board

a. Bypass valve in bypass position a. Turn bypass handles to place bypass in

b. Meter is not connected to meter connection

on PC Board

c. Restricted/ stalled meter turbine c. Remove meter and check for rotation or

d. Meter wire not installed securely into three

pin connector

e. Defective meter e. Replace meter

f. Defective PC Board f. Replace PC Board

a. Power outage a. Reset time of day. If PC Board has battery

b. Time of day not set correctly b. Reset to correct time of day

c. Time of regeneration set incorrectly c. Reset regeneration time

d. Control valve set at “on 0” (immediate

regeneration)

e. Control valve set at “NORMAL + on 0”

(delayed and/ or immediate)

a. Power outage a. Reset time of day. If PC Board has battery

a. Broken drive gear or drive cap assembly a. Replace drive gear or drive cap assembly

b. Broken Piston Rod b. Replace piston rod

c. Defective PC Board c. Defective PC Board

a. Bypass valve in bypass position a. Turn bypass handles to place bypass in

b. Meter is not connected to meter connection

on PC Board

c. Restricted/ stalled meter turbine c. Remove meter and check for rotation or

d. Incorrect programming d. Check for programming error

e. Meter wire not installed securely into three

pin connector

f. Defective meter f. Replace meter

g. Defective PC Board g. Replace PC Board

b. Plug Power Adapter into outlet or connect

power cord end to PC Board connection

PC Board

a. Use uninterrupted outlet

back up present the battery may be

depleted. See Front Cover and Drive

Assembly drawing for instructions.

service position

b. Connect meter to three pin connection

labeled METER on PC Board

foreign material

d. Verify meter cable wires are installed

securely into three pin connector labeled

METER

back up present the battery may be

depleted. See Front Cover and Drive

Assembly drawing for instructions.

d. Check programming setting and reset to

NORMAL (for a delayed regen time)

e. Check programming setting and reset to

NORMAL (for a delayed regen time)

back up present the battery may be

depleted. See Front Cover and Drive

Assembly drawing for instructions.

service position

b. Connect meter to three pin connection

labeled METER on PC Board

foreign material

e. Verify meter cable wires are installed

securely into three pin connector labeled

METER

PAGE 27

Page 28

Problem Possible Cause Solution

8. Hard or untreated water is being delivered

9. Control valve uses too much regenerant

10. Residual regenerant being delivered to

service

11. Excessive water in regenerant tank

12. Control valve fails to draw in regenerant

a. Bypass valve is open or faulty a. Fully close bypass valve or replace

b. Media is exhausted due to high water

usage

c. Meter not registering c. Remove meter and check for rotation or

d. Water quality uctuation d. Test water and adjust program values

e. No regenerant or low level of regenerant in

regenerant tank

f. Control fails to draw in regenerant f. Refer to Trouble Shooting Guide number 12

g. Insufcient regenerant level in regenerant

tank

h. Damaged seal/stack assembly h. Replace seal/stack assembly

i. Control valve body type and piston type mix

matched

j. Fouled media bed j. Replace media bed

a. Improper rell setting a. Check rell setting

b. Improper program settings b. Check program setting to make sure

c. Control valve regenerates frequently c. Check for leaking xtures that may

a. Low water pressure a. Check incoming water pressure – water

b. Incorrect injector size b. Replace injector with correct size for the

c. Restricted drain line c. Check drain line for restrictions or debris

a. Improper program settings a. Check rell setting

b. Plugged injector b. Remove injector and clean or replace

c. Drive cap assembly not tightened in

properly

d. Damaged seal/ stack assembly d. Replace seal/ stack

e. Restricted or kinked drain line e. Check drain line for restrictions or debris

f. Plugged backwash ow controller f. Remove backwash ow controller and