PILOT'S

OPERATING

HANDBOOK

AND

AIRPLANE FLIGHT MANUAL

®

ES-P

Manufacturer: Heizer IJ

Serial No: 001

Model: ESP

Lancair Kit No: 120

This aircraft is FAA Approved in the EXPERIMENTAL

category based on FAR 23. This document must be carried in

the aircraft.

Originally Published by

Lancair International Inc.

2244 Airport Way

Redmond, Oregon 97756

Adapted for Heizer IJ ESP Serial Number 001 by

Isaac Heizer

Woodinville, Washington

98072

WARNING

This is an experimental aircraft having

experimental documentation. No aspect

of this documentation can be assumed

correct. The pilot must accept all risk and

responsibility associated with being

anywhere near this airplane – do not fly in

this aircraft if you do not personally agree

and accept all responsibility!

INTRODUCTION

This Pilot’s Operating Handbook is in the format and contains most

data recommended in the GAMA (General Aviation Manufacturers

Association) Handbook Specification Number 1.

Use of the Terms Warning, Caution and Note

The following conventions will be used for the terms, Warning,

Caution, and Note.

WARNING

The use of a Warning symbol means that

information which follows is of critical

importance and concerns procedures and

techniques which could cause or result in

personal injury or death if not carefully

followed.

CAUTION

The use of a Caution symbol means that

information which follows is of significant

importance and concerns procedures and

techniques which could cause or result in

damage to the airplane and/or its

equipment if not carefully followed.

NOTE

The use of the term “NOTE” means the

information that follows is essential to emphasize.

Lancair ES-P

HANDBOOK

SECTION 2 GENERAL

SECTION 3 LIMITATIONS

SECTION 4 EMERGENCY PROCEDURES

SECTION 5 NORMAL PROCEDURES

SECTION 6 WEIGHT & BALANCE

SECTION 7 SYSTEMS DESCRIPTIONS

SECTION 8 HANDLING, SERVICING &

MAINTENANCE

SECTION 9 SUPPLEMENTS

SECTION 10 SAFETY INFORMATION

SECTION 11 ADDENDUM

SECTION 2 GENERAL

TABLE OF CONTENTS

IMPORTANT NOTICE......................................................................2

DESCRIPTIVE DATA........................................................................4

GENERAL AIRSPEED TERMINOLOGY AND SYMBOLS........7

METEOROLOGICAL TERMINOLOGY....................................... 8

POWER TERMINOLOGY................................................................ 9

ENGINE CONTROLS / INSTRUMENTS........................................9

PERFORMANCE AND FLIGHT PLANNING TERMINOLOGY

.............................................................................................................10

WEIGHT AND BALANCE TERMINOLOGY.............................. 11

This is a state-of-the-art, high performance general aviation aircraft.

Its performance is spectacular and its life almost beyond measure when

given reasonable care. You must become familiar with this handbook

as well as the FARs that are applicable to its operation. The

combination will provide you with safe and sound knowledge for

operation of your personally manufactured Lancair.

IMPORTANT NOTICE

This handbook must be read carefully by the owner or operator(s) of

this aircraft in order to become familiar with its operation and to obtain

all it has to offer in terms of both speed and reliability. Herein are

suggestions and recommendations to help you obtain safe performance

without sacrificing economy. You are encouraged to operate your

machine in accordance with and within the limits identified in this

Pilot's Operating Handbook as well as any placards located in the

airplane.

Again, the operator should be familiar with the Federal Aviation

Regulations as applicable to the operation and maintenance of

experimental airplane and FAR Part 91 General Operating and Flight

Rules. The aircraft must be operated and maintained in accordance

with any FAA Airworthiness Directives that may be issued against it.

It is also prudent and mandatory to operate within any established

limits or Service Bulletins.

The FARs place the responsibility for the maintenance of this airplane

on the owner and the operator who must ensure that all maintenance is

accomplished by the owner or qualified mechanics in conformity with

all airworthiness requirements established for this airplane.

All limits, procedures, safety practices, time limits, servicing, and

maintenance requirements contained in this handbook are considered

mandatory for the continued airworthiness of this airplane, in a

condition equal to that of its original manufacture.

NOTE

Except as noted, all airspeeds quoted in this

handbook are Indicated Airspeeds (IAS) in Knots

and assume zero instrument error.

The owner/operator should frequently refer to all supplements, whether

STCs (Supplemental Type Certificate) or Lancair Supplements direct

from Lancair, for appropriate placards, limitations, normal, emergency

and other operational procedures for proper operation of their Lancair

with any optional equipment installed.

WARNING

When this handbook is used for airplane

operational purposes, it is the pilot's responsibility

to maintain it in current status.

DESCRIPTIVE DATA

ENGINE

This aircraft is fitted with a Continental TSIO-550E (3) six cylinder

fuel injected twin-turbocharged engine.

PROPELLER

This aircraft is equipped with an MT MTV-9-D/198-58a 3 blade

hydraulic constant speed propeller with a McCauley C290D3-R/T43

propeller governor. The propeller is 77.9 inches diameter.

FUELS

100 or 100LL (Minimum grade Aviation Gasoline conforming to

ASTM D0-76 & MLG-5572, latest revision).

SYSTEMS CAPACITIES

Fuel capacity 105 US gallons

Oil Capacity 12 quarts

FILTERS

Oil Filter CH48109-1

WEIGHTS

Empty weight 2480 lbs.

Max gross take-off 3600 lbs.

Max landing weight 3550 lbs.

Max weight in baggage compartment 175 lbs.

CABIN DIMENSIONS

Length 74 inches

Height (max) 47 inches

Width

Front seat 45 inches

Rear seat 42 inches

BAGGAGE

Length 40 inches

Width (Front) 37 inches

Width (Rear) 22.5 inches

Height (Front) 29.5 inches

Height (Rear) 23 inches

SPECIFIC LOADING (max take-off weight)

Wing area 140 ft2

Wing loading 25.7 lb./ft2

Power loading (350 HP) 10.3 lb./h.p.

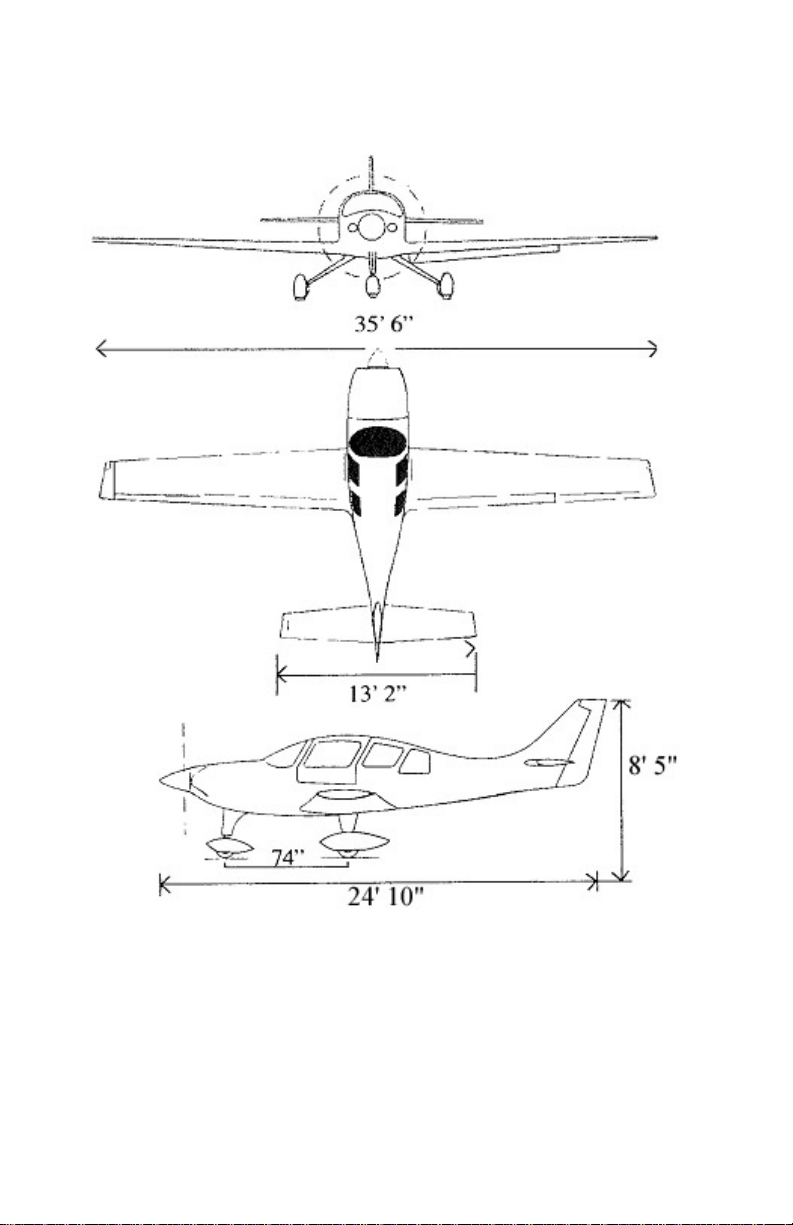

Basic Airframe Dimensions

GENERAL AIRSPEED TERMINOLOGY

AND SYMBOLS

CAS

GS

IAS

KCAS

KIAS

TAS

VA

VFE

Calibrated Airspeed is the indicated speed of an

airplane, corrected for position error and

instrument error. Calibrated Airspeed is equal to

true airspeed in standard atmosphere at sea level.

Ground Speed is the speed of an airplane relative

to the ground.

Indicated Air Speed is the speed of an airplane as

shown on the airspeed indicator when corrected for

instrument error. IAS values published in this

handbook assume zero instrument error.

Calibrated Airspeed expressed in knots.

Indicated Airspeed expressed in knots.

True Airspeed is the airspeed of an airplane

relative to undisturbed air which is the CAS

corrected for altitude, temperature and

compressibility.

Maneuvering Speed is the maximum speed at

which application of full available aerodynamic

control will not over stress the airplane.

Maximum Flap Extend Speed is the highest speed

permissible with wing flaps in a prescribed

extended position.

VN

VNE

VNO/VC

VS

VSO

Maximum Level Speed at full power.

Never Exceed Speed is the speed limit that may

not be exceeded at any time.

Maximum Structural Cruising Speed is the speed

that should not exceeded except in smooth air, and

then only with caution.

Stalling Speed or the minimum steady flight speed

at which the airplane is controllable.

Stalling Speed or the minimum steady flight speed

at which the airplane is controllable in the landing

configuration.

VX

Best Ange-of-Cimb Speed is the airspeed that

delivers the greatest gain of altitude in the shortest

possible horizontal distance.

VY

MMO

Best Rate-of-Climb Speed is the airspeed that

delivers the greatest gain in altitude in the shortest

possible time.

Maximum Mach number.

METEOROLOGICAL TERMINOLOGY

ISA International

Standard

OAT (Outside Air

Temperature)

Atmosphere in which:

1) The air is a dry perfect gas;

2) The temperature at sea level is 15

Celsius (59° Fahrenheit);

3) The pressure at sea level is 29.92

in. Hg. (1013.2 millibars);

4) The temperature gradient from sea

level to the altitude at which the

outside air temperature is -56.5ºC (-

69.7ºF) is -0.00198°C (-0.003566ºF)

per foot and zero above that altitude.

The free air static temperature,

obtained either from inflight

temperature indicators adjusted for

instrument error and compressibility

effects, or ground meteorological

sources.

Indicated Pressure

Altitude

The number actually read from an

altimeter when the barometric

subscale has been set to 29.92 in Hg

or 1013.2 millibars.

Pressure Altitude

Altitude measured from standard sealevel pressure (29.92 in Hg) by a

pressure or barometric altimeter. It

is the indicated pressure altitude

corrected for position and instrument

error. In this handbook altimeter

instrument errors are assumed to be

zero. Position errors may be

obtained from the Altimeter

Correction Graph.

Station Pressure

Wind

Actual atmospheric pressure at field

elevation.

The wind velocities recorded as

variables on the charts of this

handbook are to be understood as the

headwind or tailwind components of

the reported winds.

POWER TERMINOLOGY

Takeoff /Maximum

Continuous

Cruise Climb

The highest power rating not limited

by time.

The power recommended for cruise

climb.

ENGINE CONTROLS / INSTRUMENTS

Throttle Control

Used to control power by introducing

fuel-air mixture into the intake

passages of the engine. Settings are

reflected by readings on the manifold

pressure gauge.

Propeller Control

Mixture Control

This control requests the propeller to

maintain engine / propeller rpm at a

selected value by controlling blade

angle.

This control is used to set fuel flow in

all modes of operation and cuts off

fuel completely for engine shutdown.

CHT (Cylinder

Head Temperature)

The indicator used to identify the

operating temperature of the engines'

cylinder(s).

TIT

Tachometer

Propeller Governor

The temperature of the exhaust gases

as they enter the respective

turbocharger.

Indicates the rpm of the

engine/propeller.

Regulates the rpm of the

engine/propeller by increasing or

decreasing the propeller pitch

through a pitch change mechanism in

the propeller hub.

PERFORMANCE AND FLIGHT PLANNING

TERMINOLOGY

Climb Gradient

Demonstrated

Crosswind Velocity

The ratio of the change in height

during a portion of a climb, to the

horizontal distance traversed in the

same time interval.

The demonstrated crosswind velocity

is the velocity of the crosswind

component for which adequate

control of the airplane during takeoff and landing was actually

demonstrated. The value shown is

considered to be limiting. The value

in this handbook is that demonstrated

by Lancair test pilots and considered

safe.

MEA

Route Segment

GPH

Minimum enroute IFR altitude.

A part of a route. Each end of that

part is identified by

1) a geographical location; or

2) a point at which a definite radio

fix can be established.

Gallons per hour fuel flow.

WEIGHT AND BALANCE TERMINOLOGY

Reference Datum

Station

Arm

Moment

Airplane Center of

Gravity (CG)

CG Arm

An imaginary vertical plane from

which all horizontal distances are

measured for balance purposes.

A location along the airplane fuselage

usually given in terms of distance from

the reference plane.

The horizontal distance from the

reference datum to the center gravity

(CG) of an item.

The product of the weight of an item

multiplied by its arm. (Moment

divided by a constant may be used to

simplify balance calculations by

reducing the number of digits).

The point at which an airplane would

balance if suspended. Its distance

from the reference datum is found by

dividing the total moment by the total

weight of the airplane.

The arm obtained by adding the

airplane's individual moments and

dividing the sum by the total weight.

CG Limits

Usable Fuel

Unusable Fuel

Standard Empty

Weight

Basic Empty

Weight

The extreme center of gravity

locations within which the airplane

must be operated at a given weight.

The fuel available for flight planning

purposes.

Fuel remaining after a run out test has

been completed in accordance with

governmental regulations.

Weight of a standard airplane

including unusable fuel, full operating

fluids and full oil.

Standard empty weight plus any

optional equipment.

Payload Weight

Weight of occupants, cargo and

baggage.

Useful Load

Difference between take-off weight or

ramp weight (if applicable) and basic

empty weight.

Maximum Ramp

Weight

Maximum weight approved for ground

maneuvering. (It includes weight of

start, taxi and run up fuel).

Maximum TakeOff Weight

Maximum Landing

Weight

Zero Fuel Weight

Tare

Maximum weight approved for the

start of the take-off run.

Maximum weight approved for the

landing touchdown.

Weight exclusive of usable fuel.

The weight of chocks, blocks, stand,

etc. used on the scales when weighing

an airplane.

Jack Points

Points on the airplane identified by the

manufacturer as suitable for

supporting the airplane for weighing

or other purposes.

Section 3 LIMITATIONS

TABLE OF CONTENTS

AIRCRAFT OPERATING SPEEDS.................................................2

ALTITUDE LIMITATION...............................................................3

POWERPLANT OPERATING LIMITATIONS.............................. 3

OIL SPECIFICATION......................................................................4

POWERPLANT INSTRUMENT MARKINGS................................4

MAXIMUM WEIGHTS (LBS)......................................................... 4

CENTER OF GRAVITY LIMITS .................................................... 4

FLIGHT LOAD FACTOR LIMITS .................................................. 5

KINDS OF OPERATION LIMITS AND PILOT REQUIREMENTS

...........................................................................................................5

ICING CONDITIONS.......................................................................5

COMMERCIAL OPERATIONS ...................................................... 5

FUEL MANAGEMENT ................................................................... 5

SEATING CAPACITY..................................................................... 5

WINTER OPERATIONS.................................................................. 5

AIRCRAFT OPERATING SPEEDS

The airspeed is shown on both the PFD and backup airspeed indicator.

The airspeed on the PFD is indicated with an airspeed tape and colored

bands. The backup airspeed indicator has four colored arcs on the outer

circumference.

SPEED SYMBOL KIAS

Caution, smooth air only Yellow

174-220

Arc

Never exceed speed

Decrease 4.4 knots for

Red Line,

VNE

220

163 @ FL250

each 1000 ft above

12,000’ pressure altitude

Normal Operating Range Green Arc 67 - 174

Maneuvering Speed

Decrease 3 knots for each

1000 ft. above 1200 feet

pressure altitude

VA 135 @ 2600 lbs

96 @ 2600 (FL250)

158 @ 3600 lbs

119 @ 3600 (FL250)

Max. Structrual Cruising

VNO 174

Speed

Decrease 3.5 knots for

each 1000’ above 12,000’

pressure altitude

Full Flap Operating Range White Arc 56 - 122

Maximum Flap Extended

VFE 122

Speed

Decrease 2.4 knots for

each 1000’ above 12,000’

pressure altitude

Best Angle of climb speed VX 85

Best Rate of climb speed VY 105

Stall Speed clean VS1 74

Stall Speed landing

VSO 61

configuration

Max. Demonstrated x-wind component 15

ALTITUDE LIMITATION

The maximum flight altitude is 25,000 MSL with a working oxygen

system and 14,000 MSL without oxygen available. This is to ensure

backup oxygen is available in the event of pressurization system

failure.

POWERPLANT OPERATING LIMITATIONS

Operating limitations for the TSIO-550E engine in this aircraft are

listed below. In addition, the data and limits shown are for new

specification engines and do not reflect any degradation due to age or

number and quality of overhauls.

Rated max continuous BHP 350 HP @ 2700

RPM

Recommended Max.cruising BHP 262 HP @ 2500

RPM

Max continuous manifold pressure 38.5” Hg.

Cylinder Head Temperatures - °F

Normal flight operation max temperature 420°F

Maximum a llowable 460°F

Turbine Inlet Temperature - °F

Maximum a llowable 1750

1850 for

30 sec

Oil Temperatures - °F

Maximum 240

Minimum for take-off 100

Cruise 160-200

Oil Pressure - PSI

Normal operation at 75oF – 240oF 30-60

Idle, Minimum 10

Max Allowable (cold oil) 100

Fuel Pressure (Unmetered p.s.i.g.)

Idle (700 RPM) 7.0 - 9.0

Takeoff 32 - 34

Fuel Flow (GPH)

Takeoff 41.7 – 43.4

OIL SPECIFICATION

Lubricating oil used must conform to Teledyne Continental Motors’

specification MHS24.

All Temperatures 15W50 or 20W50

Below 40°F ambient (Sea Level) SAE30 or 10W30

Above 40°F Ambient (Sea Level) SAE50 or 20W60

POWERPLANT INSTRUMENT MARKINGS

The engine instrumentation area of the Garmin G900X in this aircraft

contains the following markings:

OIL TEMPERATURE (DEG. F.)

Caution (Yellow region) 210-240

Normal Operating range (Green region) 160-200

Maximum (Red line) 240

OIL PRESSURE (PSI)

Minimum (Idle, Red line) 10

Caution Range (Yellow region) 10-30

Operating Range (Green region) 30-60

Maximum (Red Line ) 100

TACHOMETER (RPM)

Operating Range (Green region) 600-2700

Maximum (Red Line ) 2700

MANIFOLD PRESSURE (IN. HG.)

Operating Range (Green region) 15-38

Maximum (Red Radial) 38-38.5

FUEL PRESSURE (PSIG)

Operating Range (Green region) 10-34

Maximum Pressure (Red Radial) 34

FUEL QUANTITIES

Standard Fuel 105 US Gal.

MAXIMUM WEIGHTS (LBS)

Max gross take-off 3600

Max landing weight 3550

Max weight in baggage compartment 175

CENTER OF GRAVITY LIMITS

The allowable Center of Gravity (CG) range is from Fuselage Station

(FS) 95.4 to (FS) 105 or 6.6 to 26% MAC.

The aft CG limit must be considered a firm limit. Loads that place the

CG further aft are dangerous and must not be accepted. A “Weight

and Balance" sheet must be completed and carried in the aircraft at all

times.

REFERENCE DATUM

The Datum is located at FS “0.” This can be located by measuring

51.25” forward from the bottom forward face of the firewall.

FLIGHT LOAD FACTOR LIMITS

Flaps Up +4.4, to -2.2 g's.

Flaps Down +2.2, to -0 g's

KINDS OF OPERATION LIMITS AND PILOT REQUIREMENTS

The airplane has the necessary equipment available for daytime and

nighttime VFR and IFR operations with only one pilot. The operational

minimum equipment and instrumentation for the kinds of operation are

detailed in Part 91 of the FARs.

ICING CONDITIONS

Flight into known icing is prohibited.

COMMERCIAL OPERATIONS

Flight operations with passengers for hire are prohibited.

FUEL MANAGEMENT

Do not take off with less than 10 gallons in each tank. There is no

interconnection between the wing tanks.

SEATING CAPACITY

This aircraft has capacity for four persons (one pilot and three

passengers).

WINTER OPERATIONS

Winter Operations are acceptable with proper oil grades for the

operating temperatures. Engine pre-heating is recommended when the

engine has been exposed to temperatures below 20 degrees Farenheit in

excess of two hours.

Section 4 EMERGENCY PROCEDURES

TABLE OF CONTENTS

EMERGENCY AIRSPEEDS ............................................................. 2

ENGINE FAILURE ............................................................................ 3

ENGINE FAILURE DURING TAKE-OFF (NOT ARIB ORNE)..... 3

ENGINE FAILURE IMMEDIATELY AFTER TAKEOFF (Below

400 Feet AGL)................................................................................... 3

ENGINE FAILURE DURING FLIGHT........................................... 3

IN-FLIGHT RESTART.....................................................................4

ROUGH RUNNING ENGINE.......................................................... 4

TURBOCHARGER FAILURE......................................................... 5

HIGH CYLINDER HEAD TEMPERATURE.................................. 7

HIGH OIL TEMPERATURE............................................................7

LOW OIL PRESSURE...................................................................... 8

ENGINE FIRE IN FLIGHT..............................................................8

ENGINE FIRE DURING START.....................................................9

EMERGENCY DESCENT ............................................................... 9

MAXIMUM GLIDE CONFIGURATION........................................ 9

FORCED LANDING........................................................................9

SYSTEMS EMERGENCIES............................................................10

ELECTRICAL SYSTEM PROBLEMS.......................................... 10

CIRCUIT BREAKERS AND FUSES......................................... 10

ELECTRICAL SYSTEM OVERCHARGING ........................... 11

ALTERNATOR FAILURE......................................................... 11

FLIGHT WITH ONE FAILED ELECTRICAL SYSTEM ......... 11

ELECTRIC TRIM / AUTOPILOT FAILURE............................12

MULTI-FUNCTION DISPLAY.................................................13

PRIMARY FLIGHT DISPLAY..................................................13

CARBON MONOXIDE ALERT....................................................13

WING FIRE IN FLIGHT................................................................13

PROPELLER OVERSPEED........................................................... 13

PROPELLER DAMAGE................................................................ 14

SPEED BRAKES............................................................................14

UNLATCHED DOOR IN FLIGHT................................................ 14

SPINS..............................................................................................14

EMERGENCY SPEED REDUCTION........................................... 15

LOSS OF PRESSURIZATION....................................................... 15

CRASH AX..................................................................................... 15

NOTE

All airspeeds quoted in this section are indicated

airspeeds (KIAS) and assume zero instrument

error.

EMERGENCY AIRSPEEDS

Emergency Descent

Idle Power, Flaps up, Speed Brakes

deployed

Best Glide – Flaps UP

Flaps Down

Speed brakes retracted

Landing Approach (W/O Power)

FLAPS UP 98 – 108 KIAS

FLAPS LANDING POSITION 80 – 90 KIAS

NOTE

The following checklists are presented to capture

in a compact format those pilot tasks requiring

rapid action. The pilot should keep these

checklists handy for ready access, and he should

familiarize him/herself with them before flying the

aircraft. Knowledge of the switches, controls,

gauges, etc. located quickly (even blindfolded) is

highly desirable. “Cockpit, time" prior to ever

flying or after an absence is time prudently spent.

Where more time would likely be available,

rationale will be added and alternative choices

offered. It must be remembered, however, that

each situation will be unique in some manner and

must be treated accordingly.

165 KIAS

100 KIAS

90 KIAS

AOA 2 GREEN

ENGINE FAILURE

ENGINE FAILURE DURING TAKE-OFF (NOT ARIBORNE)

Sufficient Runway remaining:

Throttle IDLE

Brakes APPLY as necessary

Flaps UP

Boost Pump OFF

Mixture CUTOFF

Fuel Selector OFF

Ignition OFF

Master Switches OFF

ENGINE FAILURE IMMEDIATELY AFTER TAKEOFF (Below

400 Feet AGL)

Airspeed 95 with flaps in takeoff

Boost Pump OFF

Mixture IDLE CUT-OFF

Fuel Selector OFF

Ignition OFF

Flaps LANDING position

Master Switches OFF

Maintain directional control and make only shallow turns to avoid

obstacles.

ENGINE FAILURE DURING FLIGHT

Airspeed BEST GLIDE (100

SpeedBrakes RETRACTED

Boost Pump LOW

Mixture RICH

Fuel Selector SWITCH TANKS

Alternate Air OPEN

Ignition VERIFY ON

If power is restored and there is any doubt as to the

cause of the engine stoppage, land at the nearest

airport and determine the cause.

position

100 KIAS with flaps up

KIAS with flaps up)

NOTE

IN-FLIGHT RESTART

CAUTION

Actual shutdown of an engine for practice or

training purposes should not be done. Engine

failure simulation should be done by reducing

power.

1 MASTER switch ON

2 Mixture ¾ FULL RICH

3 Fuel Selector FULLEST TANK

4 Fuel Boost Pump HIGH

5 Magnetos BOTH

6 Throttle NORMAL START POSITION

7 Start Switch START (if propeller is not

8 Throttle

9 Oil Press, Temp,

CHT

10 Power AS REQUIRED.

ROUGH RUNNING ENGINE

(open 1 in.)

turning)

a. Oil Pressure – Within

limits, will probably be

quite low if oil is cold.

If no oil pressure

indicated, engine

damage may occur if

restart is continued.

b. Throttle – Adjust to

15-20 inches manifold

pressure until engine

temperature reaches

operating range. Adjust

mixture as required.

c. Oil Pressure –

STABILIZED

d. Mixture – ¾ FULL

RICH

AS NECESSARY TO PREVENT

OVERSPEED.

Warm up at 15-20” manifold

pressure. Adjust mixture as

required for smoothness.

NORMAL INDICATION

Observe engine for visible damage or evidence of smoke or flame.

Extreme roughness may be indicative of propeller blade problem.

Mixture ADJUST as appropriate to power setting

being used. Do not arbitrarily go to Full

Rich as the roughness may be caused by

an over rich mixture

Magnetos ON

Low Boost ON (if above 10000 feet)

High Boost OFF

If engine roughness does not disappear after the above, the following

steps should be taken to evaluate the ignition system.

Alternate Air OPEN

Throttle REDUCE power until roughness

becomes minimal

Magnetos OFF then ON, one at a time. If engine

smoothes out while running on single

ignition, adjust power as necessary and

continue. Do not operate the engine in

this manner any longer than absolutely

necessary. The airplane should be landed

as soon as practical for engine repairs.

CAUTION

The engine may quit completely when one

magneto is switched off, if the other magneto is

faulty. If this happens, close throttle to idle and

move mixture to idle cutoff before turning

magnetos on. This will prevent a severe backfire.

When magnetos have been turned back on,

advance mixture and throttle to previous setting.

WARNING

If roughness is severe or if the cause cannot be

determined, engine failure may be imminent. In

this case, it is recommended that the emergency

procedures be employed. In any event, further

damage maybe minimized by operating at a

reduced power setting.

TURBOCHARGER FAILURE

Turbocharger failure will be evidenced by inability of the engine to

develop manifold pressure above ambient pressure. The engine will

revert to "normally aspirated" and can be operated, but will produce

less than its rated horsepower. If turbocharger failure occurs before

takeoff, do not fly the aircraft. If a failure occurs in flight, readjust

mixture as necessary to obtain fuel flow appropriate to manifold air

pressure and RPM.

WARNING

The cabin pressurization system operates from

bleed air supplied by the turbochargers. Cabin

pressure will quickly fall if the turbochargers fail.

WARNING

If turbocharger failure is a result of a loose,

disconnected or burned-through exhaust, a

serious fire hazard exists. If turbocharger failure

occurs before takeoff, DO NOT fly the aircraft. If

failure occurs in flight, and the choice is made to

continue operating the engine, proceed as follows:

NOTE

At altitudes above 15,000 feet an over rich mixture

may result if the turbocharger fails and the engine

may quit operating. If this occurs, employ the

following procedure:

1 Mixture IDLE CUTOFF

2 Throttle FULL

3 Propeller CRUISE RPM

4 Throttle CRUISE POSITION

5 Mixture Advance slowly. When the

proper mixture ratio is reached,

the engine will start. Continue to

adjust the mixture control unit

until the correct fuel flow for the

manifold pressure and RPM is

obtained.

NOTE

An interruption in fuel flow to the engine can

cause engine power loss due to turbocharger

"run-down". At high altitude, merely restoring

fuel flow may not cause the engine to restart,

because the mixture will be excessively rich. If the

engine does not restart, there will be insufficient

mass flow through the exhaust to turn the turbine.

This condition may give indications similar to a

turbocharger failure. If a power loss is

experienced followed by surging of RPM, fuel

flow, and manifold pressure, the following steps

are recommended:

1 Mixture IDLE CUTOFF

2

Fuel Selector FULLEST TANK

3 Fuel Pump LOW boost

4 Throttle CRUISE POSITION

5 Propeller CRUISE RPM

6 Mixture Enrich slowly from idle

cutoff. Engine starting

will be apparent by a

surge of power. As the

turbocharger begins to

operate, manifold

pressure will increase and

mixture can be adjusted

accordingly.

7 Fuel Pump AS REQUIRED

8 Mixture ADJUST

NOTE

If this procedure does not effect a restart, descend

below 15,000 feet and repeat. If the engine still

will not start, follow the emergency procedures

outlined.

HIGH CYLINDER HEAD TEMPERATURE

Mixture ADJUST to proper fuel flow for power

Oil Door PUSH to open

Airspeed INCREASE

If temperature cannot be maintained within limits, reduce power, land

as soon as possible and have the malfunction evaluated and repaired

before further flight.

HIGH OIL TEMPERATURE

NOTE

Prolonged high oil temperature indications will

usually be accompanied by a drop in oil pressure.

If oil pressure remains normal, a high

temperature indication may be caused by a faulty

gauge or thermocouple. If the oil pressure drops

as temperature increases, proceed as follows:

Oil Door PUSH to open

Airspeed INCREASE

Power REDUCE if previous steps do not lower oil

temperature.

Land As soon as possible if oil temperature

cannot be reduced.

CAUTION

If these steps do not restore oil temperature to

normal, an engine failure or severe damage can

result.

LOW OIL PRESSURE

WARNING

If oil pressure drops below 30 psi, an engine

failure should be anticipated.

If oil pressure drops without apparent reason

from a normal indication of 30 to 60 psi, monitor

temperature and pressure closely, land as soon as

possible, and have the engine inspected.

ENGINE FIRE IN FLIGHT

Determine if fire is electrical (acrid smell) if so:

Master Switches OFF

All Electrical Equipment OFF

If fire/smell clears, turn Master switch ON then each item of equipment

one at a time, waiting long enough to isolate the cause. If no smell,

assume an unknown source and LAND AS SOON AS POSSIBLE

AND CORRECT THE PROBLEM.

If fire continues:

Mixture IDLE CUT-OFF

Fuel Selector OFF

Boost pump OFF

Throttle IDLE

Loading...

Loading...