Page 1

Commissioning FMS Firing Management System

TÜV type-approval

0085 AS 0254

DIN DVGW Test mark NG-2510 AS 0324

Sensors and Systems

for Combustion Engineering

Page 2

Table of Contents

2

Access levels 19

General Information 5 - 15

Entering the password 19

Validity of these instructions 5

Changing password 20

Standards 5

Changing parameters 20

For your safety 6

List of parameters

Follow the legislation on safety of appliances 6

(level 0 and 1 parameters only) 21 - 29

Purpose 7 - 8

Leakage test 30 - 31

Intended purpose of FMS 4 / FMS 5 7 - 8

Mode of operation

Application-internal output regulator (optional) 8

Integrated leakage test (option)

Application-internal O regulator (optional) 10

2

Leakage test flow chart 30

Integrated leakage test (option) 30

Using these instructions 9 - 10

Purpose of these instructions 9

Venting

Preliminary clarification 9

Leakage test line over-roof 31

Finding the appropriate section 9

Calculation formula 31

Conventions 9 - 10

Suggested circuit for venting the gas line

Fault correction 10

over-roof in conjunction with the

combustion management system 31

FMS Operating principle 11 - 15

FMS digital inputs 11

Output regulator (optional) 32 - 38

FMS operating sequence 11 - 12

Pre-ventilation suppression

Method of operation 32 - 34

through an external signal 12

Procedure description 32

Automatic pre-ventilation suppression 12

Weather control 32

Setting the pilot burner, serving mode 13

Set-point switch-over 33

Program monitoring time 13

Startup circuit 33

Restarting 13

Thermostat and control region 34

Leakage test (option) 13

Manual control 34

4 curve sets (option) 13

Flying curve change (option) 13

Setting the regulator 35 - 38

Automatic fuel change 13

Interpreting the display 35

Range limits 13

Control region 35

Internal load 14

Regulator behaviour 36 - 38

Manual operation 14

Examples 38

Parameterisation 14

Correction 14

Before commissioning 39

Facility for direct connection

of Namur transmitter (option) 14

Adjusting motor limit switch 39

Freedom from error of feedback signals 14

Pre-ventilation limit 14

FMS Commissioning 40 - 72

Energy-saving mode for running text display 15

Function test 40 - 41

Separate ignition point 15

Significance of FMSdigital input display 41

Integrated power control unit (option) 15

Integrated O regulation 15

2

Setting control elements 42

Operation of control elements for potentiometer

Settings 16 - 30

adjustment and limit switch settings 42

Inputs 16 - 18

Programming curves 43 - 48

Significance of ID number 16

Programming the compound 43

Inputs 16

Entirely new curve, clear memory 43

Configuration sticker 16

st

Programming 1 point

Configuration number 16

(separate ignition point) 44

Condition on delivery 17 - 18

Programming with burner running 44 - 45

Assignment of sockets to inputs 17

Programming with burner stationary 45

Configuration cards (examples) 17

nd th

Programming 2 to 19 point 45

Processor card 18

Programming last top point 46

Power supply card 18

Store curve 46

Plug-in p.c. card for a continuous output 18

Check monitoring values 46

Adding points 47

Parameters 19 - 20

Changing curve point 48

Parameter setting 19

Page 3

Table of Contents

3

Instrumentation for commissioning 72

O regulation 49 - 62

2

Adjusting load ratings individually 73

Automatic functions control

Entering an initial curve 73

during operation 49 - 50

Approaching control elements from one side 74

Adjusting the integrated O regulator (optional) 49

2

Entering settings 74

Checks during burner start-up 49

Entering top setting 74

O monitoring bands 49

2

Ignition delay when setting 74

O boundary curves 49

2

Pre-setting load automatically 74

Dynamic probe test 50

Entering the compound curves

Probe blockage 50

with the burner stationary 75

Correction output monitoring 50

Keeping the re-circulation damper

Regulation strategy 51 - 53

closed in pre-ventilation 75

With pre-setting for load changes 52

Setting the pilot burner (servicing mode) 75

Extended regulation strategy (air shortage) 53

Switching the burner on again

via the target value 75

Connection to O meter 54

2

Via analogue interface 54

Operator controls and display 55 - 56

System Operation 76 - 89

Mode switching 55

Mode display 76 - 78

Calling up O regulation text messages 56

2

Significance of modes on the FMS 76 - 77

O regulator modes 77

Commissioning 57 - 61

2

"ES" Mode progress (set-control) 78

Setting the correction range 57

Continue programming 78

Inputting the O target value curve 58

2

Calling up the correction range set 59

Calculation and setting of

4 Curve sets FMS (option) 79

control parameters-(manual) 59

Interconnection with 4 curve sets option 79

Lag time (parameters 898/900) 60

P-factor (parameter 899) 60

Checksums

Setting base value for "Deactivated

Running time meter 80

control” and "Air shortage” 61

Recalling the checksums

Calling up the base value for O regulation

2

and the safety times 80

deactivated/air shortage 61

Calling up running time meter 80

Automatic 61

Operation 62

Messages / Faults 81 - 89

The meaning of the additional modes 62

What happens in the event of FMS fault 81

Calling up O regulation text messages 62

2

Reading off a fault 81

Resetting a fault 81

Correction 63 - 66

Calling up fault history 81

Set correction input 63 - 65

O regulation perturbed 82

2

Setting the correction range 65

Air shortage perturbation 82

Recall set correction range 65

Resetting O errors 82

2

Altering the correction range 66

Calling up O regulation error history 82

2

Correction modes 66

Fault codes 83 - 89

Run to shut-off limits 67 - 70

FMS Fault Correction

Run to shut-off limits 67

Aids 90 - 115

Checking the shut-off limits at the

General Faults (A) 90 - 94

three/point step output of the FMS 67

Three-point step control output (B) 95 - 96

Checking the shut-off limits at

continuous output of the FMS 68

Continuous output (C) 97

Tolerance limits direction air deficiency 69

Load signal (D) 98 - 99

Indication for an example protocol 69

Feedback (E) 100 - 103

Checking the O influence 69

2

Correction input (F) 104 - 105

Example protocol 70

Digital inputs (G) 106

Control unit faults (H) 107

Tips & Tricks 71 - 75

Leakage test 108

Programming 1st point

(ignition load point) 71

Parameters (P) 109 - 118

Programming with burner running 71 - 72

Programming with burner stationary 72

Reversing the programming 72

Page 4

Table of Contents

4

with leakage test 131

FMS Fault Correction

Oil operation with pilot burner

Aids O regulation 117 - 118

and ignition flame monitor 132

2

Oil poeration without pilot burner 133

Parameter (P) 117 - 118

Relay module R16 134 - 137

Servicing 119 - 120

Circuit diagram type 660 R 0016 V3 134

Changing EPROMs 119

Block diagram type 660 R 0016 V4 135

Changing a data EPROM

Contact plan, relay module type 660 R 0016 V3 136

or a program EPROM 119

Contact plan, relay module type 660 R 0016 V4 137

Re-entering range limits 119

Installing new software version 120

Safety interlock chain 138

Example safetz interlock chain 230V 138

Procedure for installation of

Wiring of the analogue inputs 139

new software in the FMS 120

Replacing the relais module 660 R 0016 120

FMS 4 / FMS 5

Connection diagram 140 - 144

Appendix 121 - 147

Type 664 F 0010 / Type 665 F 0010 140

EMC of wiring 121

Type 664 F 0020 / Type 665 F 0020 141

Connection of screening 121

Type 664 F 0030 / Type 665 F 0030 142

PE bus bar 121

Type 664 F 0040 / Type 665 F 0040 143

Switch cabinet wiring 121

Type 664 F 0050 / Type 665 F 0050 144

Screening of leads from the field 121

FMS 4 / FMS 5

Feedback on TPS channels 122

Connection diagram

Positive connection 122

with output regulator 145

Example of positive

potentiometer connection 122

Direct connection of

Error-proof feedback 122

Examples of potentiometers 122

Namur transmitter (option) 146 - 147

Examples of servomotors 122

Extract from circuit diagram 146

External switching of the fuel control element 123

Technical data 146

Selecting a suitable sensor

for rev. speed monitoring 147

Replacing a servomotor,

replacing a potentiometer 124 - 125

Relay module

Replacing a servomotor with LAMTEC

connection diagram 148

precalibration 124

Type 660 R 0013 / Type 660 R 0131 148

Replacing a complete servomotor 125

Type 660 R 0019 148

Replacing the potentiometer in a servomotor 125

Connection diagram

Switch and key combinations

Modem for remote control 149

on the VMS / FMS front panel 126

Switch and key combinations

General Notes 150

O regulation 127

2

Technical data 151 - 152

Notes on air pressure monitor

Accessories

Not on operation with

and Spare Parts 156 - 157

re-circulation control elements 128

Accessories and Spare Parts for

Interconnection of the air pressure monitor 128

FMS Combustion Management System 156 - 157

Paramterisation of the

re-circulation pre-ventilation time 128

Interconnection of monitors

Declaration of Conformity 158 - 159

of the re-circulation ducts 128

EC Declaration of Conformity 158

Notes on start without pre/ventilation 129

Appendix to the EC Declaration of

Conformity or EC Manufacturer's Declaration 159

Process sequence charts 130 - 133

Gas operation with pilot burner,

Protocol example 160

leakage test and ignition flame monitor 130

O target value curves 161

2

Gas operation without pilot burner

Page 5

5

General Information Validity of these Instructions

Validity of these instructions These instructions apply to the FMS 4 and FMS 5 Combustion Management

System in any configuration.

The software-related information relates to the software version V3.1

(recognisable from the sticker inscription on the program EPROM).

Standards The units conform to the following standards and regulations:

FMS EN 298

EN 230

where applicable

where applicable

where applicable

where applicable

EMC Directive, Low Voltage Directive

Gas Appliance Directive

Integral leakage test:

EN 1643

Test mark

gas side DIN DVGW PÜZ NG-2510 AS 0324

CE-0085 AS 0254

EN 676

EN 267

EN 12 952-8 u.-11

EN 12 953-7 u.-9

Page 6

6

General Information For your safety

Follow the legislation The legislation on safety of appliances states:

on safety of appliances Follow the instructions !

Proceed only in accordance with this FMS commissioning supplement

(booklet No. D LT 6079)

Use the appliance solely for the specified purpose.

It must be operated only by trained personnel. The appliance must be

operated and serviced only by persons with the required knowledge and

training. Follow the burner manufacturer's safety rules.

Associated automatic flame guard

The unit is approved for use only with an external automatic flame guard.

The automatic flame guard type F 250 made by Hartmann & Braun is used

for testing purposes.

However, any other automatic flame guard tested in accordance with

DIN EN 298 and/or DIN EN 230 and approved for continuous operation may

be used instead of this.

Electrical connection to appliances not mentioned in these instructions

Only after consultation with the manufacturers or a qualified expert.

If an automatic flame guard not approved for continuous operation is

connected, approval of the system for continuous operation will lapse.

Liability for proper functioning of the appliance passes to the owner

or operator.

Liability for correct functioning of the appliances in every case passes to the

owner or operator, should the appliance be incorrectly operated, serviced or

repaired by persons without the requisite knowledge, or if operation is

inconsistent with the specified intended purpose.

In the event of modifications to the unit the type approval lapses. The unit's

inputs and outputs and associated modules must only be wired according

to the specifications in these instructions.

LAMTEC GmbH & Co KG will not be liable for damage or injury arising out of

a failure to observe the instructions above. The warranty and liability provisions

of the terms and conditions of sale and supply of LAMTEC GmbH & Co KG

shall not be extended by virtue of the instructions above.

Where reference is made to legislation, government regulations and

standards, these are based on the legal system of the Republic of Germany.

To be used only in a grounded power line network!

Page 7

7

General Information Purpose

Intended purpose The FMS 4 / FMS 5 Combustion Management System is a control unit for

FMS 4 / FMS 5 combustion systems.

Brief description

The FMS 4 adjusts up to four control elements as a function of a control

variable (generally the burner load) according to freely programmable

curves.

The FMS 5 adjusts up to 5 control elements as a function of a control

variable according to freely programmable curves).

2 sets of curves (e.g. for oil or gas) can be filed as standard, with the

option for 4 or 8 sets of curves.

Examples of possible control elements:

- Combustion air damper - Re-circulation fan

- Combustion air fan - Flue gas damper

- Fuel quantity - Flue gas fan

- Atomiser steam

Up to 20 points can be programmed for each channel. The display is

relative between 0 and 999.

The FMS has two correction inputs for shifting the setting curves, allowing

a feedback control (e.g. O control unit) to be connected up.

2

Each output is freely configurable, either three-point step control element

output for direct actuation of a motor or constant output (on the FMS 5

th

the 5 channel is always constant). The constant output can be set to any

of the following variables:

- Current signal 0 … 20 mA

- Current signal 4 … 20 mA

- Voltage signal 0 … 10 V

The FMS 4 also has a so-called monitor output. In addition an internal

value (such as the load position of the burner or position of the gas control

element) can be outputted by means of 4 … 20 mA signal).

The FMS has one serial interface for remote control/ display via PC

(Windows software available separately) and for connection to other

system components via BUS (e.g. fault message system, O control).

2

Connections for Interbus-S, Profibus, Modbus and CANBUS are available as options. Other BUS systems on request.

The FMS constantly monitors its own functioning and that of the control

elements connected.

Each analog input (control variable and feedback or correction) is freely

configurable via plug-in cards.

Alternatively:

- Potentiometer (1 5kS) - Step input (DPS)

- Current signal 0/4 … 20 mA - Namur transmitter as a two-wire system

- PT 100 - inductive sensor with switch terminals in

three-wire system

The unit is of error-proof construction.

Page 8

General Information Purpose

Application - internal

output regulator

(optional)

Application - internal

O regulator

2

(optional)

The FMS contains a burner control unit with process control program.

Outputs:

- actuation of gas valves

- actuation of oil valves

- actuation of the ignition valve and ignition transformer

- fan release

- oil pre-heating

- fault signal

- signal outputs for oil and gas operation

(in the off condition, oil operation is always indicated)

The external signals to the control unit are via floating contacts or chains of

contacts.

The following signals can be pre-set:

- 3 separate safety interlock circuits

- fault unlocking

- air pressure monitor

- gas pressure monitor (min.)

- flame signa

This software option makes it possible to calculate the burner's required load

setting continuously for a specified target value (referred e.g. to temperature or

pressure), through comparison with the actual value. This load setting can be

notified internally to the electronic compound as the specified value.

This software function makes it possible to regulate one or several actuators

independently of a switched-on O actual value. By using a self-optimising

2

regulator strategy, it is also possible to regulate burners with frequent load

changes.

l (pilot flame monitor and ignition flame monitor)

- pre-ventilation and ignition release

- pre-ventilation suppression

- control release

- re-circulation release

- burner on

- fuel selection

8

Page 9

9

General Information Using these instructions

Purpose of these instructions These instructions are concerned exclusively with commissioning and

servicing.

Further information, for example design examples, possible uses, software

settings etc., is given in separate booklets.

Special information dealing with optional equipment on this unit is

explained in separate booklets.

Preliminary clarification To make the best use of these instructions, proceed as follows:

Check whether the settings of your FMS meet the system requirements.

You will find the settings on the sticker on the unit.

- Which physical quantities (current, resistance) and values does your

FMS need on its inputs?

- Which physical quantities (current, voltage, relay signal) and values

does the system expect on the outputs of the FMS ?

- Do the settings of the FMS match your requirements with regard to

operating behaviour (pre-ventilation, feedback etc) ?

Should these matters not be clear, please read the section "Settings”

(page 16-29)

Finding the appropriate section Determine what operation you wish to perform on the FMS.

When initially putting into operating or tracing the cause of a fault, a

function test is first recommended. You must then decide whether you

wish to program with the burner stationary or running and whether or not an

entire curve is to be programmed.

Identify your current requirement from the table of contents and turn to the

appropriate page.

Conventions Sub-headings

Serve as a guide if you can already handle the FMS and merely want to

refer to certain information again.

Lines in italics after the sub-headings

describe what the current state of the system should be. If this is not the

case, the subsequent operations will not show the desired result.

Lines in bold type

indicate an action which you are to perform.

Page 10

10

General Information Using these instructions

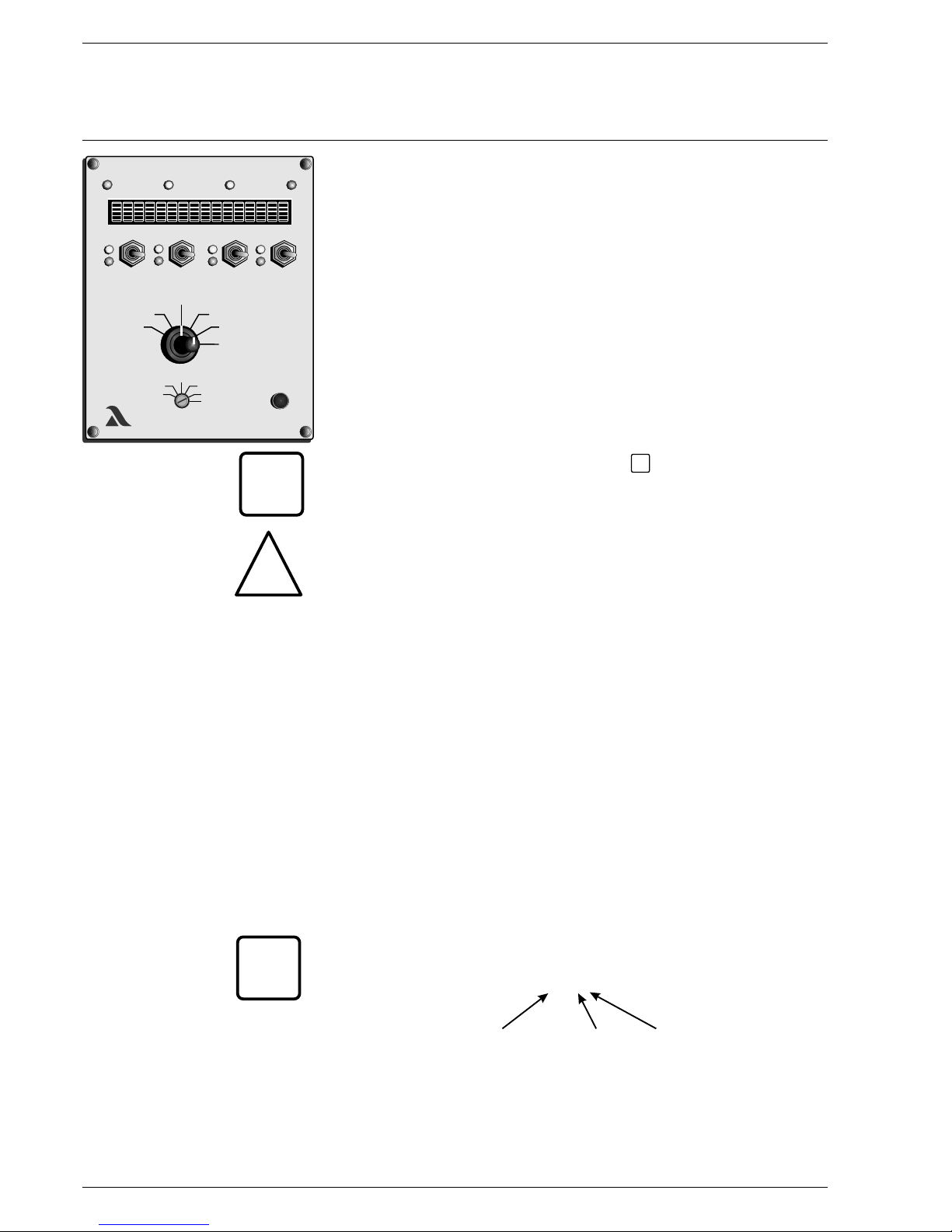

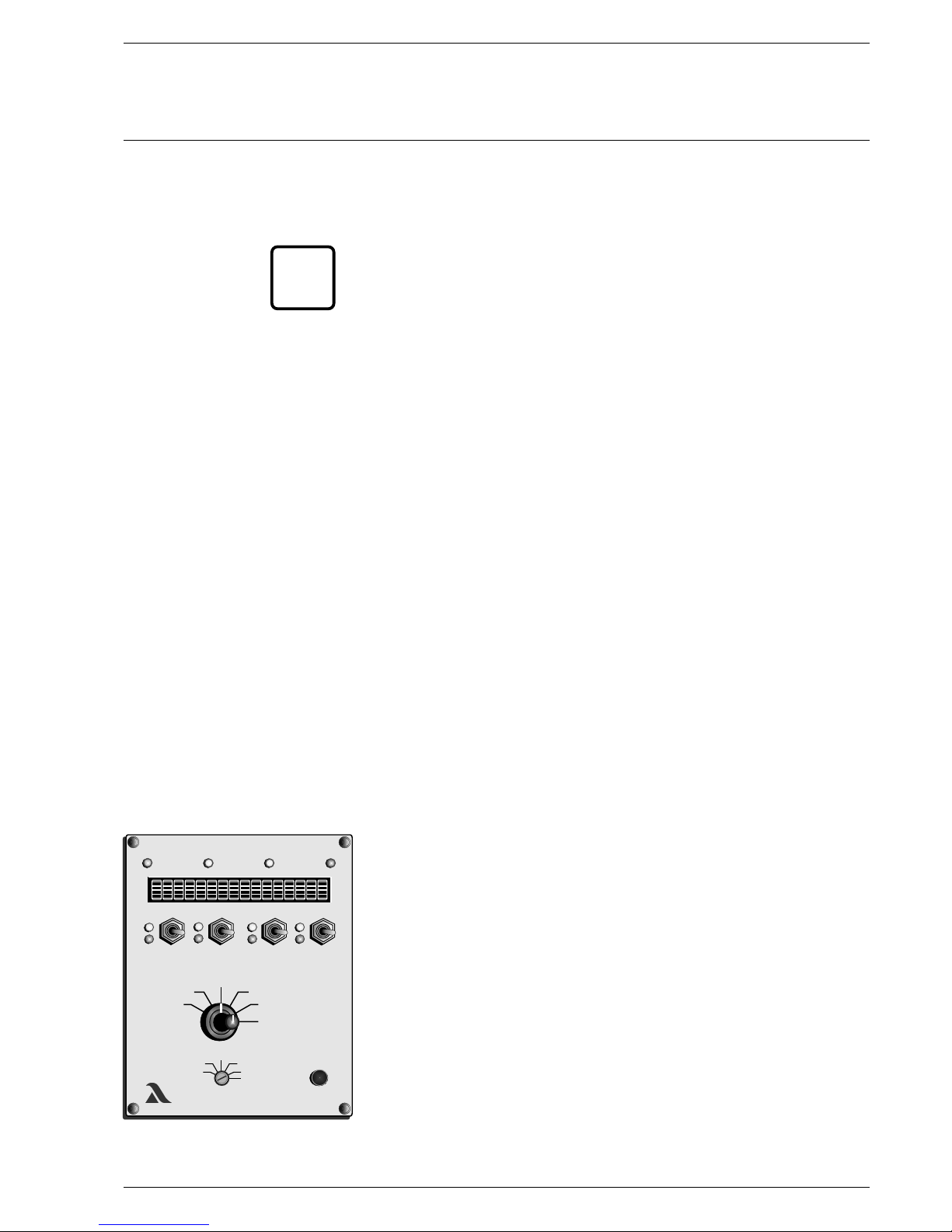

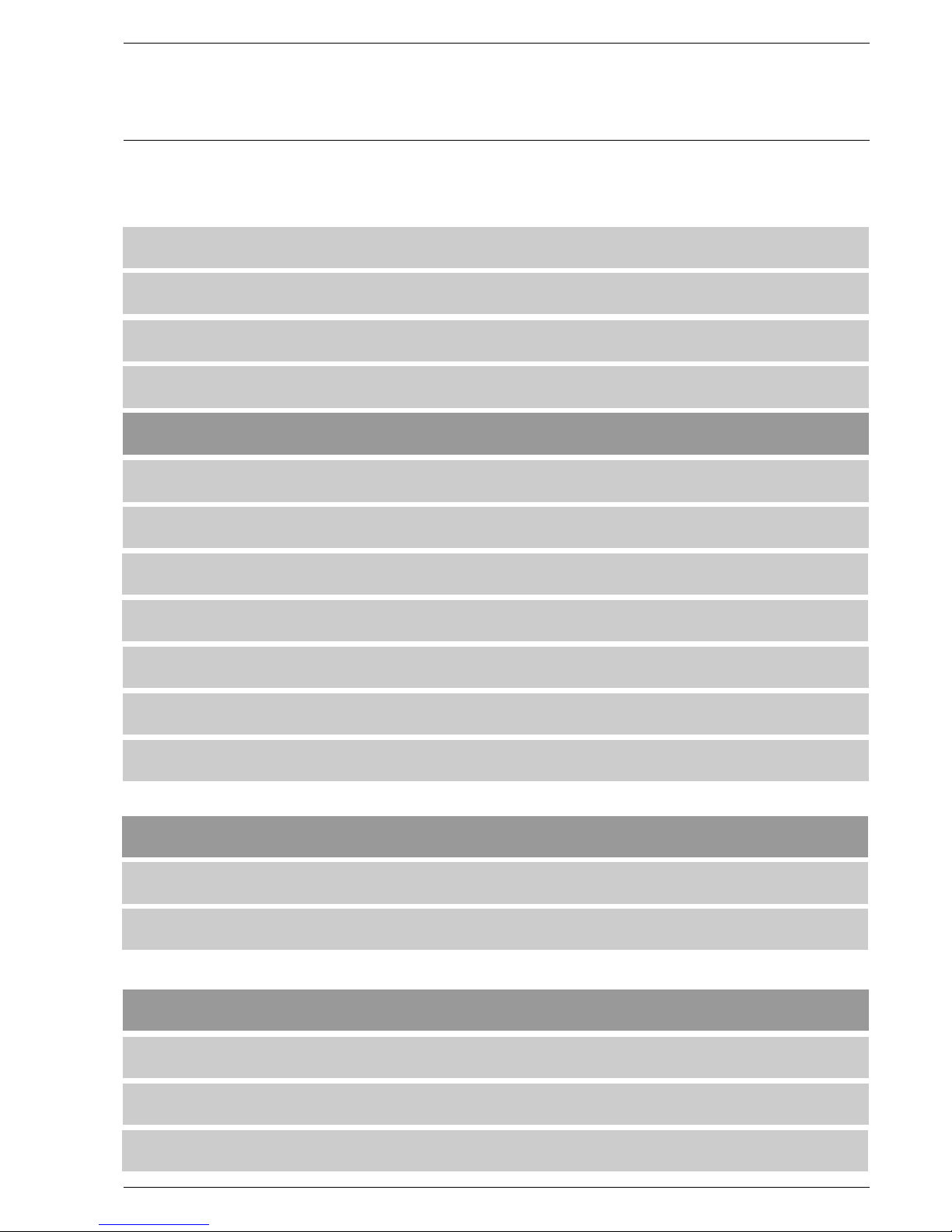

The figures and letters in brackets (1), (2), (3), (4), (5), (6), (7), (8), (A)

and (B) relate directly to the picture of the front panel. They identify the

part on which the specified action is to be performed or on which a reaction

can be seen.

The lines in ordinary typeface below the procedural instruction describe

the reaction of the system or unit following the operation.

The figures at the right-hand margin denote a paragraph in the

"Fault Correction” section of these instructions. If the reaction indicated

does not occur, please refer to this. It describes the possible causes of

faults and how to rectify them.

___________________________________________________________________

The word in italics between two lines and the sign

are notes for a better understanding of the operation or notes on how to

avoid incorrect operation.

___________________________________________________________________

___________________________________________________________________

The lines in bold italics between two lines and the triangle

draw attention to dangers. The instructions given there must be followed.

___________________________________________________________________

If you now follow the operations step by step, paying attention to the

instructions, you will automatically be working correctly.

If any of the reactions indicated do not occur, there is a fault with the unit or

the system. You should correct the fault first before proceeding.

Fault correction Follow the instructions identified by the figures given after the fault codes

and after the procedural instructions. You may find the solution to your

problem there.

This section, however, makes no claim to completeness. Should the

actions described there not have the desired effect, the unit or parts of the

unit (e.g. front panel etc.) must be changed. If the fault still occurs you are

dealing with a fault specific to the system.

___________________________________________________________________

Tip: You can download the up-to-date version of these instructions from

http://www.lamtec.de as PDF File.

You will find the version from the letter of the booklet no.

(see the backside of this document).

Example:

DLT 6066 cD

booklet No. version language

___________________________________________________________________

CHANNEL 1 CHANNEL 2 CHANNEL 3 CHANNEL 4

ENTER

POWER OIL GAS ALARM

SETPOINT

FEEDBACK

SETPOINT

FEEDBACK

ACTUAL VALUE

FEEDBACK

ACTUAL VALUE

FEEDBACK

SETPOINT

CHANNEL 5

xxx

xxx

xxx

5

4

6

A

B

7 8

3

SETTING

AUTOMATIC

CLEAR

MEMORY

O -CONTROL

2

PARAMETERISATION

MONITORIN

DISPLAY

FEUERUNGS-MANAGEMENT-SYSTEM FMS

LAMTECLAMTEC

xxx

2

1

DISPLAY CHANNEL 5

(DIGITAL INPUTS)

LOAD RATING

(CORR. INPUT)

STATUS

(CORR. RANGE)

SETPOINT

ii

i

!

i

Page 11

11

General Information FMS Operating Principle

FMS Digital Inputs For the FMS to function according to the requirements of a combustion

system, the condition signals from the system must be relayed to the FMS.

These signals include:

Pre-ventilation suppression Air pressure monitor

Gas safety interlock circuit Gas pressure > min.

Oil safety interlock circuit Ignition flame

Boiler safety interlock circuit Burner on

Ignition position acknowledgement Fault reset

High firing rate acknowledgement Re-circulation On

Fuel selection Control release

Flame signal Set-point switch over

(only with integral load control unit)

For use in burner control, the FMS emits 9 digital signals, which are

converted by relay module (type 6 60 R 0016) into twelve output signals

for 230 V:

Main gas 1 Ignition valve

Main gas 2 Ignition transformer

Oil Release ignition gas line

Heated oil distribution Fan

Oil operation signal Pre-ventilation / post-ventilation

Gas operation signal Fault signal

___________________________________________________________________

FMS operating sequence The operating sequence described relates to a usual configuration of the

(for diagram of example, unit. The various parameter settings can result in a somewhat different

see appendix) sequence.

___________________________________________________________________

A signal is first sent to terminal 2 (burner ON), indicating when the burner is

to start. The FMS then interrogates the safety interlock chain for the

selected fuel and the air pressure monitor contact. If the fuel is selected via

the fuel safety interlock circuits, the FMS performs a plausibility check. If it

does not detect a satisfactory condition, a corresponding text message is

emitted and the process control stops.

If all signals are OK, the fan output is activated and the ducts run to their

bottom stop as a check. The "pre-ventilation/post-ventilation” output is

activated. Once all ducts have reached their bottom stop, they open for

aeration. Any leakage test configured runs in parallel.

In the case of control elements, aeration is used to enter and to check the

range limits. The fuel control element, after reaching its top position, runs

back into the ignition position. All other ducts remain in the open position.

The FMS now interrogates the high firing rate acknowledgement and the air

pressure monitor. If these signals are OK, the parameterised aeration time

runs. If a duct is configured for re-circulation, this opens with a time delay.

On reaching the parameterised re-circulation delay time, the pre-ventilation

time stops. As soon as the re-circulation duct has reached the aeration

position, the aeration time continues. Once this time has elapsed the

ducts run into the programmed ignition position (re-circulation fully

closed). Once all ducts have reached ignition position, the FMS

interrogates the ignition position acknowledgement. In gas operation the

gas pressure monitors must also be in a satisfactory condition prior to

ignition.

The ignition transformer is now activated alone for the duration of the

pre-ignition time (transformer start-up time).

Page 12

12

General Information FMS Operating Principle

Start without pilot burner:

The main valves open and remain activated together with the ignition

transformer for the duration of the safety period. During this time the flame

signal appears.

Start with pilot burner:

The ignition valve and main gas 1 are opened. The pilot flame forms and

st

the flame signal appears. Once the 1 safety period has elapsed, the pilot

burner burns on its own. The main gas 2 then opens and remains activated

nd

in parallel with the ignition valve for the duration of the 2 safety period.

When this period has elapsed the ignition valve closes again.

When ignition is completed the re-circulation duct and the flue gas damper

run to the programmed point. Correction is activated. All ducts may run to

the programmed base load point (depending on the setting selected).

The FMS remains in the base load position until control release (terminal 4)

is given.

Following control release the FMS follows the prevailing external load.

A current signal proportional to the position of the compound is emitted as

internal load (not on FMS 5).

Withdrawal of the signal/control release during operation allows the

compound to run at base or ignition load (configurable).

Withdrawal of the terminal 2 signal is followed by shutting off. The main

valves close. (In gas operation, main gas 1 first, followed by main gas 2

with an approx. 5-second delay, in order to allow the monitoring line

between the solenoid valves to burn out. In the event of a fault shut-off,

however, they both close immediately).

If configured for post-ventilation, the air ducts open again for this period.

After the configured after-burning time the FMS again checks for a period

of 5 seconds whether the flame has gone out. If not, a fault shut-off

occurs.

The FMS then goes into "OFF” mode.

Pre-ventilation suppression The pre-ventilation range can be skipped by means of the pre-ventilation

through an external signal suppression signal (terminal 1). If the signal is present straight away at

burner start-up (terminal 2 signal), the control elements run directly to the

ignition position. In order to enter the range limits, however, pre-ventilation

should be performed once after "Clear Memory”.

Pre-ventilation suppression can only occur, however, if this function is

activated via parameters.

Automatic pre-ventilation When activated by parameters, the FMS starts after regulator switch-off

suppression automatically without pre-ventilation. Pre-ventilation is only carried out now after

fault switch-off or power failure. Using this function is subject to the regulations

applicable to the facility.

Page 13

13

General Information FMS Operating Principle

Setting the pilot burner,

servicing mode

Program monitoring time

Restarting

Leakage test (option)

4 curve sets (option)

Automatic fuel change

Flying curve change

(option)

Range limits

A so-called servicing mode can be set via parameters. The control unit then

runs until the stabilisation period. In this mode 5 successive starts are

possible without the need for pre-ventilation and without a leakage test.

th

The 5 start is automatically followed by pre-ventilation and/or a leakage test.

It can be determined by way of parameters how long the FMS may take

after a start signal (terminal 2) until ignition occurs. If this length of time is

exceeded, a fault shut-off occurs. If the content of the parameter is set to

0, no fault occurs (= program monitoring time = T).

Automatic restart can be activated via parameters. The control unit attempts

a one-off restart in the event of any fault marked with * after a factory-set

period (standard: 10 sec). This restart can be prevented by setting the period

to 0.

n the case of firing systems according to EN 676 the parameter must

be set to "0”.

The standard setting is without restart.

The control unit may optionally also perform the leakage test on the gas

valves. The leakage test can per performed before ignition and/or after

shut-off

The leakage test is performed by way of the main valves. The use of filling

and discharge valves is also possible by means of relay switching.

The FMS offers the facility for using two curve sets for each fuel

(e.g. summer/winter operation) or a mode with and without speed.

When using Option 4: Curve sets, it is possible to switch within one fuel

selection from one curve-set to the other (flying curve change). Fuel

change can only be performed via "Off”.

When switching the fuel selection switch over (terminal 75), the FMS first

moves automatically to the base load position. Then the system switches

off. Only then are the fuel selection and thus the curve set changed over. If

the "Burner on” signal is still present, the burner starts with the new fuel.

(This function is not available with Option 4: Curve sets).

st

In the 1 pre-ventilation after "Clear memory”, the FMS determines the

maximum range of travel for each control element and stores this

automatically. If no ranges limits have yet been determined, the setting (in

the case of constant outputs the feedback setting) in pre-ventilation

stands at 0 and 999 points respectively. At all further starts a check is

made to see that these range limits are correct. Should the limit switches

be shifted or the frequency converter setting changed after programming,

the range limits must be re-entered.

If the range limits cannot be determined automatically, they can also be

entered manually by way of parameters. If the FMS has no existing range

limits, it automatically takes the top and bottom point of the curve as the

limit. It then does not go beyond this.

____________________________________________________________

I

____________________________________________________________

!

Page 14

14

General Information FMS Operating Principle

The internal load is the load value at which the compound currently stands.

It therefore corresponds indirectly to the output of the burner.

The internal load is displayed in addition to the external load signal.

In the "load value” position therefore both the external load (left-hand) and

the internal load (right-hand) are displayed.

The value of the internal load can be outputted via the monitor output, in

order to connect further units (e.g. O control, only on FMS 4). When

2

connecting other units, it must be remembered that the signal in itself is

not error-proof.

When switching over to "Load value” with the burner running the burner

load can be set via the FMS. The load value can then be adjusted with the

channel 1 toggle switch.

The system follows this load value in the compound.

Operating a switch other than channel 1 causes the unit to exit manual

mode again.

The person commissioning the unit can adjust various functions of the

FMS

by way of parameters (e.g. post-ventilation time). The parameters are

classified into various safety levels. With the exception of the lowest safety

level these are accessible only with a password. The parameterisation can

be undertaken both on the unit itself and by means of a PC and Windows

software.

The FMS has 2 correction inputs. An analog signal (0/4 … 20 mA) can be

connected to these for shifting the set curves (e.g. for O correction or air

2

temperature correction). The assignment of the correction to the individual

output channels and the mode of operation can be adjusted via

parameters.

If the FMS cannot perform a correction because a control element stop has

been reached, it adjusts the internal load and hence the compound until

the correction can take effect as required.

An output for controlling the speed of a combustion air fan or a

re-circulation fan etc. can be monitored by switching the pulse output of a

Namur transmitter directly to the FMS.

Continuous outputs and three-point step outputs have different feedback

requirements. In the case of continuous outputs comparisons are made

between output and feedback values in or to check the plausibility. The

units therefore do not have to be intrinsically error-free in order to form the

feedback signal. For availability reasons (minimisation of interference) the

reproducibility of the values should be as good as possible.

For technical reasons this method cannot be used in the case of

three-point step outputs. For this reason TÜV approved potentiometers

must be connected directly as feedback to the FMS. These

potentiometers must positively render the position of the damper.

Normally during pre-ventilation each control element runs as far as ist

uppermost stop. Now, by means of parameters, a limit can be set for each

channel that is not exceeded during pre-ventilation.

Internal load

Manual operation

Parameterisation

Correction

Facility for direct connection

of Namur transmitter

(option)

Freedom from error

of feedback signals

Pre-ventilation limit

Page 15

15

General Information FMS Operating Principle

Energy-saving mode for The brightness of the display can be adjusted to the ambient light

running text display conditions by means of parameters.

In addition the display can be set to automatically revert to the lowest

brightness level if not operated within a given period of time.

Separate ignition point In the standard version the ignition point is situated outside the accessible

range in order to set a separate fuel/air ratio. By means of parameters,

however, the ignition point can be adjusted so that it lies on the compound

curve.

Integrated power control unit An integrated power control unit is also available as an option. Where this

(option) is used the actual temperature or the actual pressure is directly switched

instead of the load signal. The control parameters are adjusted via

parameters. It is also possible to change the setting (daytime/night time

The integral output regulator is a PID controller with special combustion

technology functions. It can be used as a fixed-value regulator or as a

weather-dependent regulator. The following signals can be set:

- Actual value (analogue)

- External temperature or some other analogue signal for target value shifting

(only in weather-dependent regulators)

- Target value switching (via zero-potential contact)

Combustion enabling by the output regulator takes place internally in the FMS

Boundary values that switch the burner on and off, need to be set via parameter

regulation - optimises combustion systems

2

- saves fuel

- minimises pollutants

The main purpose of O regulation is to compensate for perturbations that

2

affect combustion. In addition, the O regulation system monitors the

2

combustion's fuel/air ratio. A message is output at once if it strays outside

the permitted limits.

The following are the main perturbing factors that affect combustion:

Air: Temperature Contamination: Burner

Pressure Boiler

Humidity

Fuel: Calorific value Mechanical systems:

Temperature Mechanical

Viscosity hysteresis

Density (free play)

Gas pressure fluctuations

The O control unit is implemented as a free-standing software module.

2

The unit compares the residual oxygen content in the exhaust gas of a

combustion system measured by means of the LT1/LT2 Lambda

transmitter (actual value) with the optimum residual oxygen content (target

value). The target values are stored in the instrument in the form of an

installation-specific curve. The control unit applies a correction until the

actual value corresponds to the target. The calculated output value of the

O control module is transmitted to the compound module as a correction

2

input signal.

operation) and to control the atmospheric conditions by switching in the

outside temperature.

setting. In this case, the startup signal is removed internally from the FMS via the

output regulator module.

The operator is alerted by the display (running text) that the output regulator

refuses to enable a startup.

Integrated O

Page 16

16

Settings Inputs

Significance of ID number The ID number comprises 8 characters, e.g. 664 V 0010

The two figures before the letter denote the unit, in this case a FMS 4.

The letter denotes whether the unit is a VMS or a FMS. The penultimate

figure provides information on the unit hardware.

It also determines which connection diagram applies (see appendix).

Inputs The inputs can be configured on the backplane by means of plug-in

configuration cards. Any of the following can be connected up to each

input:

- a potentiometer in the range from 1-5 kS

- a current signal 0 … 20 mA or 4 … 20 mA

- a step signal ("OPEN CLOSE" commands)

- a frequency signal (Namur transmitter), for details see appendix

- a PT 100 element

- flame sensor module (in preparation)

- a potentiometer module (in preparation)

There is a plug-in card for each configuration. This is inserted into the

respective socket in order to configure the input.

Configuration sticker The factory setting is entered on a sticker on the side of the unit.

This corresponds either to the customer data or, if nothing was specified,

the standard setting (see condition on delivery).

The EEPROM checksums and thereby the software version are also

entered on this sticker, together with the configuration number and hence

the hardware setting.

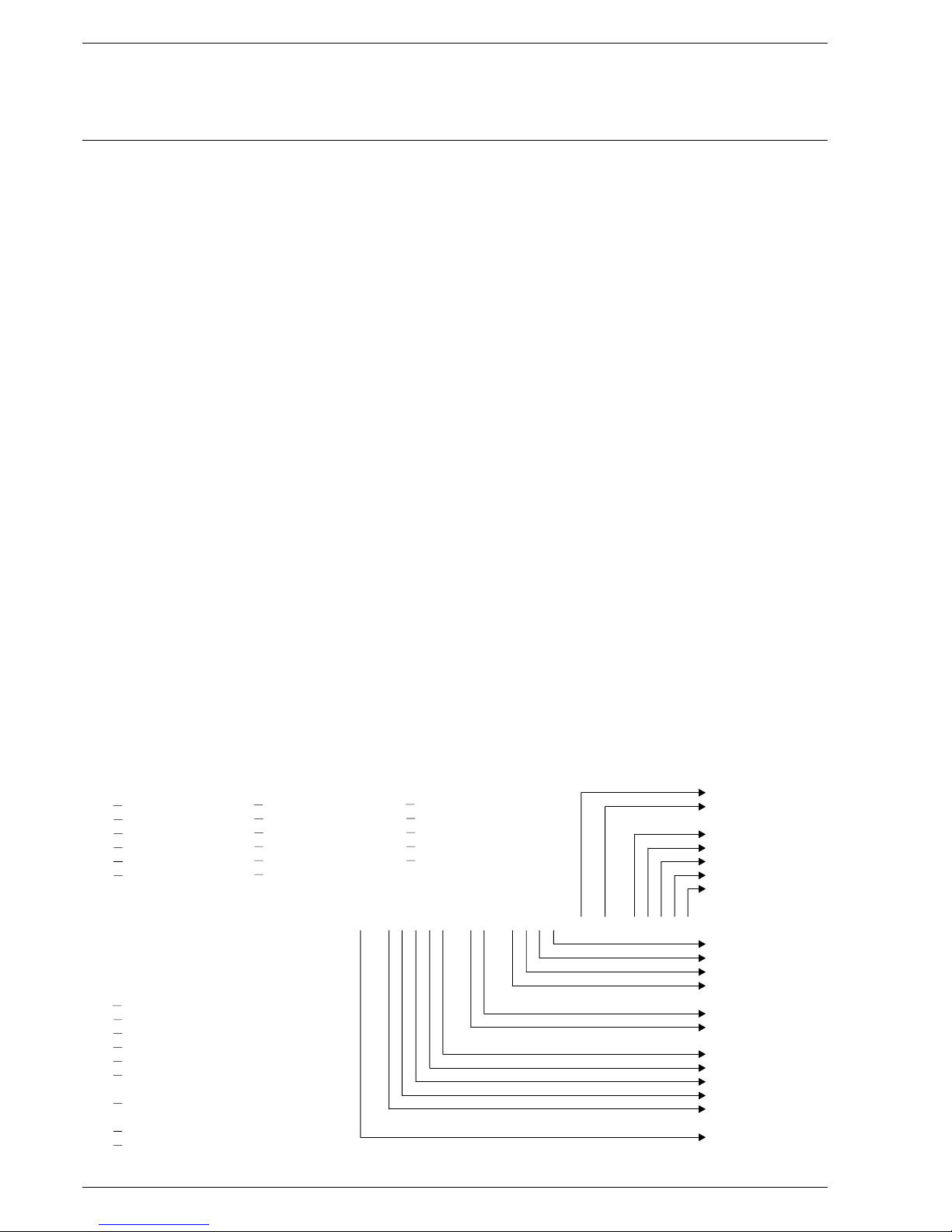

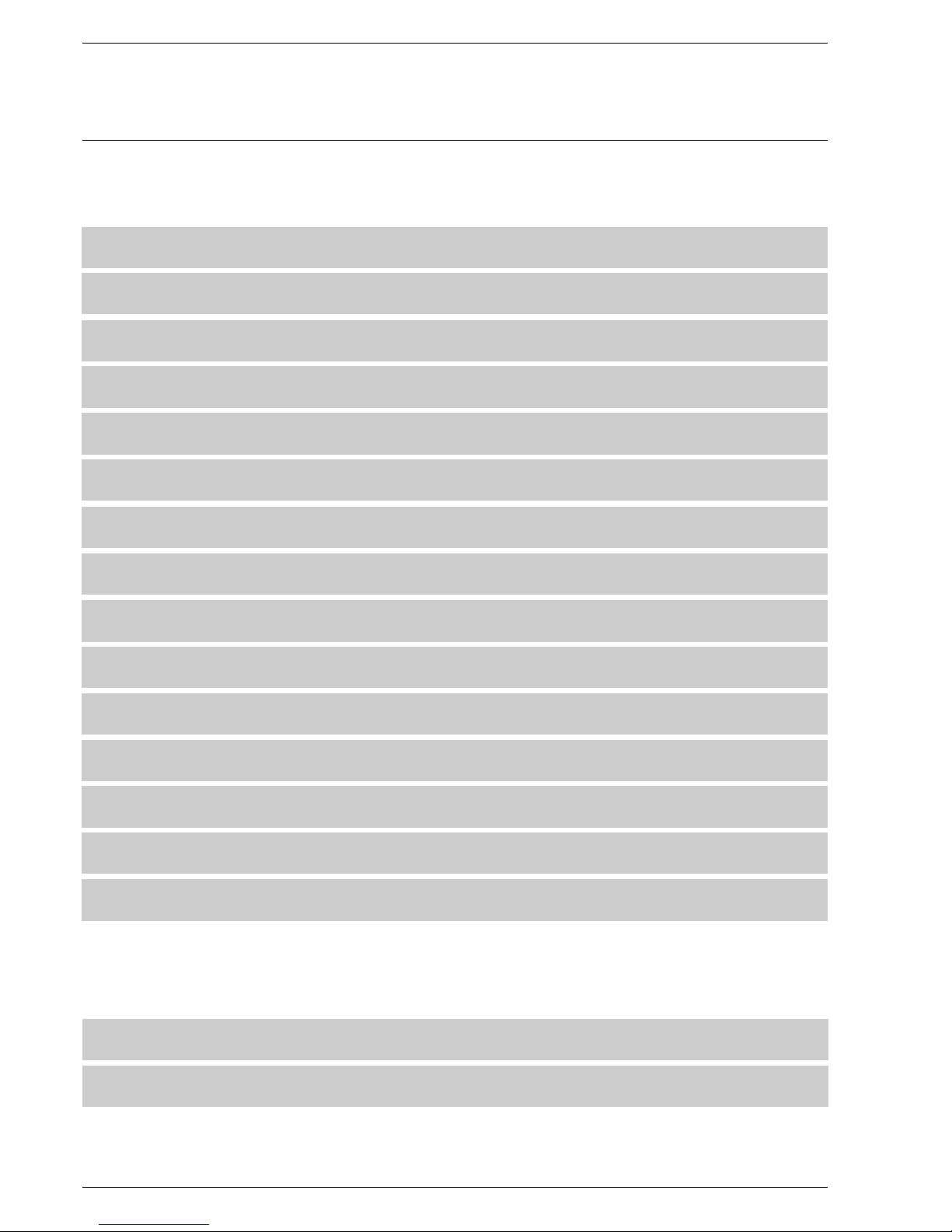

Configuration number The configuration number is a 15-digit number, constructed according

to a fixed code.

BUS-card

input voltage

Channel 1 assignment

red. feedback channel 4

red.

red.

red.

Correction input 1

Channel 5 feedback

Load input

Channel 2 assignment

Channel 3 assignment

Channel 4 assignment

Channel 5 assignment

feedback channel 3

feedback channel 2

feedback channel 1

Correction input 2

Channel 4 feedback

Channel 3 feedback

Channel 2 feedback

Channel 1 feedback

a x b x x x x x c x x d x x x x e x f x K y y y y y

BUS-card

x = 1 ^ Interbus-S

2 ^ SUCOnet K-Bus

3 ^

4 ^ Profibus

5

0 ^ not present

CAN-Bus

^ Modbus

K = Channel assignment

y = 1 ^ Recirculation

2 ^ Fuel

3 ^ Air

4 ^ Flue gas

5 ^ mech. Compound

6 ^ Steam

a, b, c or d =

Feedback, correction and load

x = 1 ^ Potentiometer input 1kW...5kW

2 ^ continuous signal 0/4...20mA

3 ^ TPS input

4 ^ Pulse input (Namur)

5 ^ PT 100-input

6 ^ Flame sensor input

(only on red. feedback channel 4)

7 ^ continuous signal 0/4...20mA

potential separated

8 ^

0 ^ unoccupied

constant signal with 24 V supply

Input voltage

x = 1 ^ 230 VAC

2 ^ 115 VAC

3 ^ 24 ACV

4 ^ 24 VDC

5 ^ Special voltage

Page 17

Settings Condition on delivery

Condition on delivery All units are set according to the order. Settings not evident from the

ID number or configuration number must be indicated separately.

In particular:

Outputs

- whether continuous or three-point step

- whether 0 … 10 V, 0/4 … 20 mA

- position of the outputs in the event of fault

Inputs, load, feedback

- Whether potentiometer or 0/4 … 20 mA or step

- Whether inputs are used doubled (redundant) and if so, which

(possible only if the integrated power control unit is not used)

- Whether special plug-in configuration cards

(PT 100, Namur transmitter) are used

Correction input

- Whether 0 … 20 or 4 … 20 mA or direct temperature connection

- Mode of operation, on which channel, upward or downward shift

(modifiable only via software)

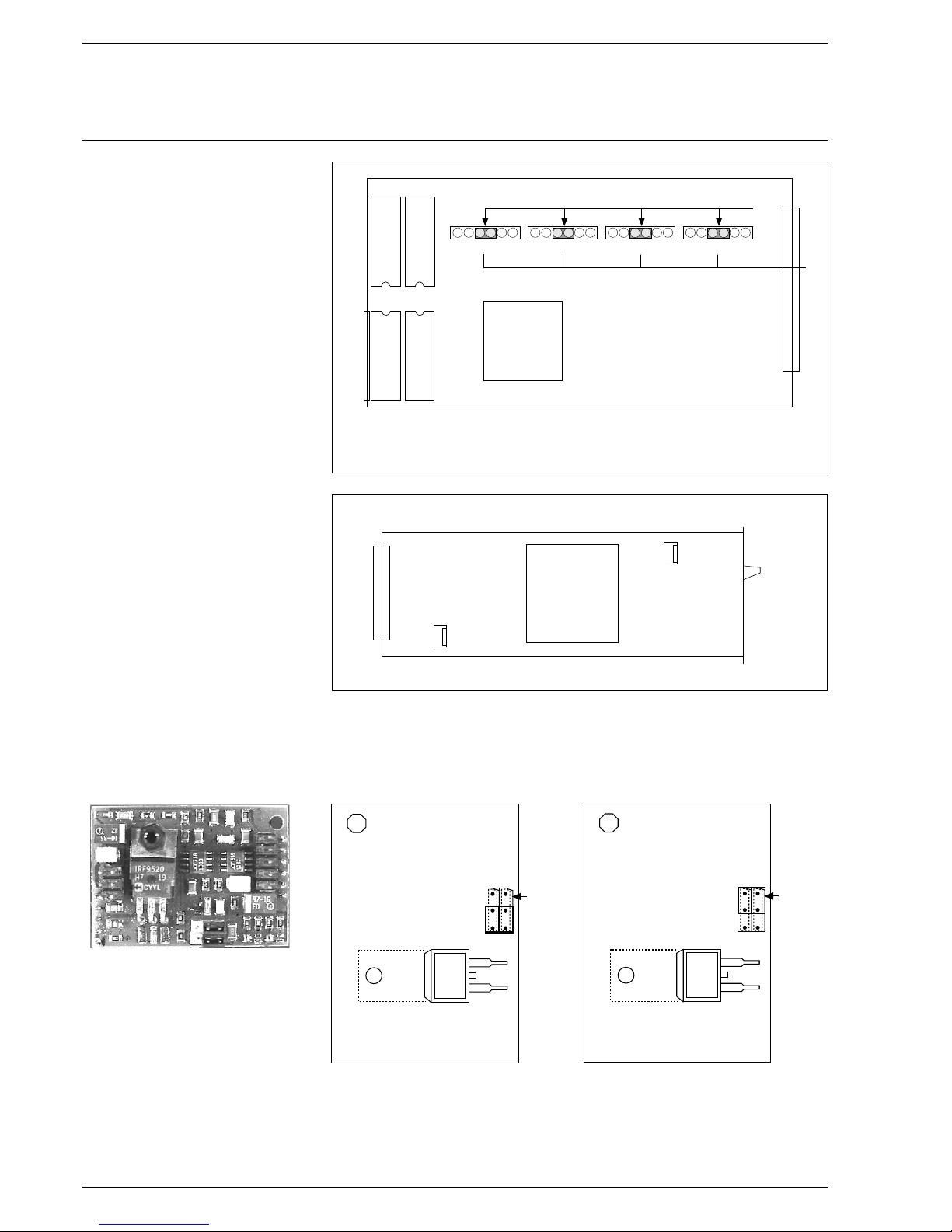

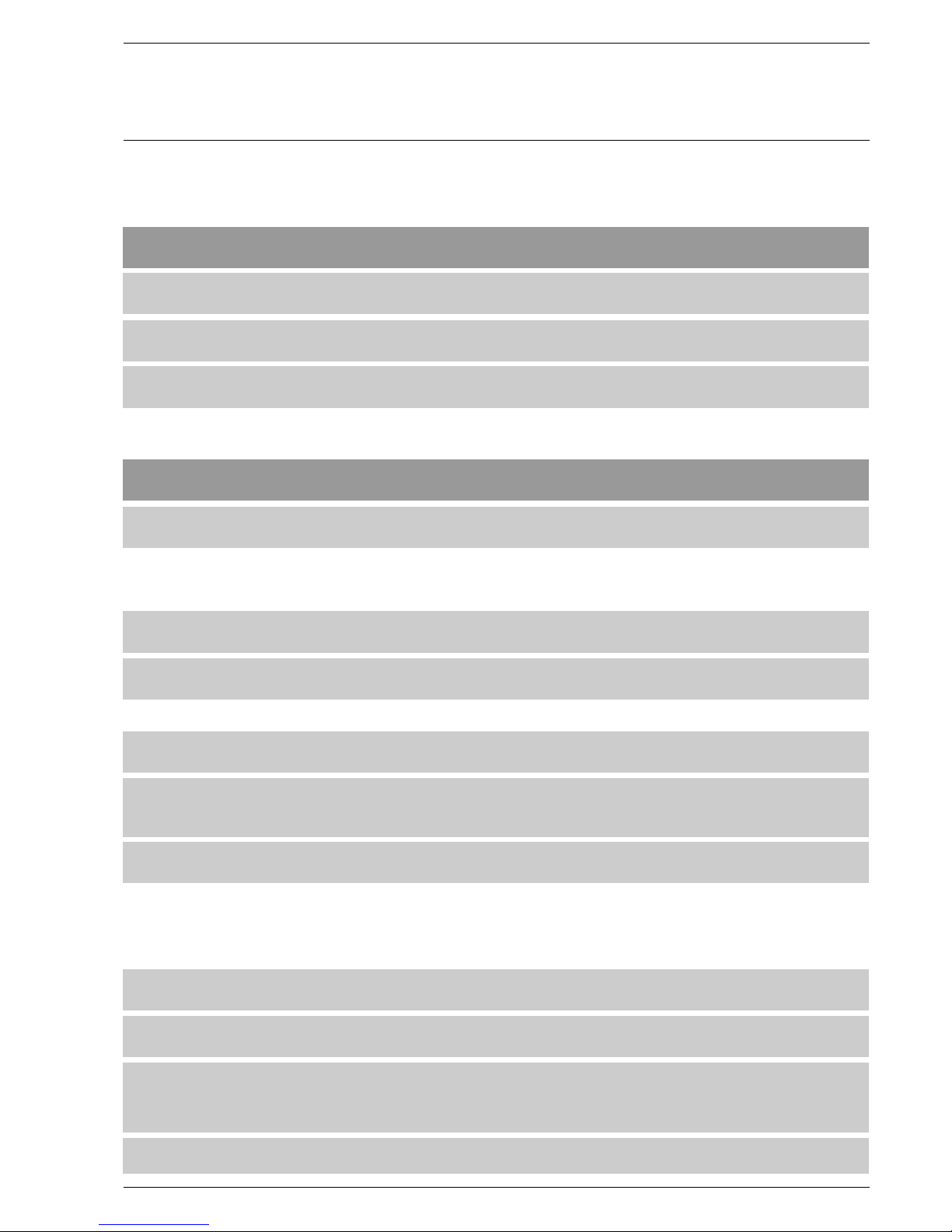

Assignment of Backplane

sockets to inputs

Configuration cards

(examples)

Feedback 1

Corr. Input 1

Corr. Input 2

Load input or load

control unit value

Feedback 2

Feedback 3

Feedback 4

Feedback 5

Red. Feedback 1

Red. Feedback 2

Red. Feedback 3

Red. Feedback 4

or atmosphere control

or flame sensor module

17

R4 = 0W

R4 = 0W

R4 = 0W

R8 = 2K2

R10 = 2K2

R15 = 0W

R12 = 0W

R12 = 0W

R11 = 0W

R16 = 0W

R17 = 0W

R15 = 0W

Potentiometer

Configuration

TPS

configuration

0/4 … 20mA

configuration

TM1

R17

R18

R16

R13

R14

R15

R5

R11

R12

R10

R7

R9

R8

R4

D1

T1

C1

R6

R2

R3

D2

R1

D2

D1

R10

R12

R16

R4

R15

R8

R11

R18

R9

R7

R13

R14

R17

R1

R3

R5

R2

R6

C1

TM1

T1

TM1

R10

R12

R11

R5

R16

R18

R17R13

R15

R14

R9

R7

R4

R8

R2

R6

C1

T1

D1

D2

R3

R1

Page 18

Settings Condition on delivery

Processor card

Note:

Continuous channels must all be fitted with additional cards from

channel 1 onwards

Power supply card

Plug-in p.c. card for The standard control outputs are three-point step

a continuous output (except for a possible 5-channel. This is always continuous).

Each TPS output can be reconfigured to make it continuous by plugging in

an additional card.

The jumpers serve only for hardware switching between current output

and voltage output.

The selection of 0 or 4 … 20 mA is done through the software by means

of parameters.

18

T 902

EEprom for curves

and parameters

Monitoring processor

EEprom for curves

and parameters

Main processor

Program processor

Main processor

Program EPROM

Over-voltage

processor

Sockets for contiuous additional cards

TPS

Configuration

Channel 1

Transformer

Fuse 2

1 AT mA

80 C 537

Channel 2 Channel 3 Channel 4

Bridge

voltage

output

0 … 10V

Bridge

current

output

0/4...20mA

T 902

Page 19

Settings Parameters

Parameter setting The parameter level can be accessed by turning to the "Parameter”

selector switch position. When working on level 1-4, this works only with

the burner stationary (i.e. no signal on the digital inputs). Only level 0 is

accessible with the burner running.

___________________________________________________________________

As a rule, the factory parameter settings are precisely tuned for the

installation for which the unit has been designed. Therefore, it is only

necessary to change parameter settings in exceptional cases.

___________________________________________________________________

Access levels The parameters are divided into four different access levels according to

function and safety classification:

Operating level (Level 0)

! Accessible without password, non-critical parameters that may possibly

have to be altered during operation.

Customer level (Level 1)

! Accessible with modifiable password (on delivery set at "0000”), access

to parameters, adjustment of which calls for technical knowledge, which

are tailored to the system and which are not altered during operation.

Service level (Level 2)

! Accessible with a fixed password, but only to personnel specially trained

in parameterisation. Access to all parameters that are not fixed on the

basis of standards and technical regulations.

Production levels (Levels 3 and 4)

! Access to all parameters (only possible through LAMTEC)

Each parameter level is protected by its own checksum. This checksum

serves to show that no changes have been made (see page 78).

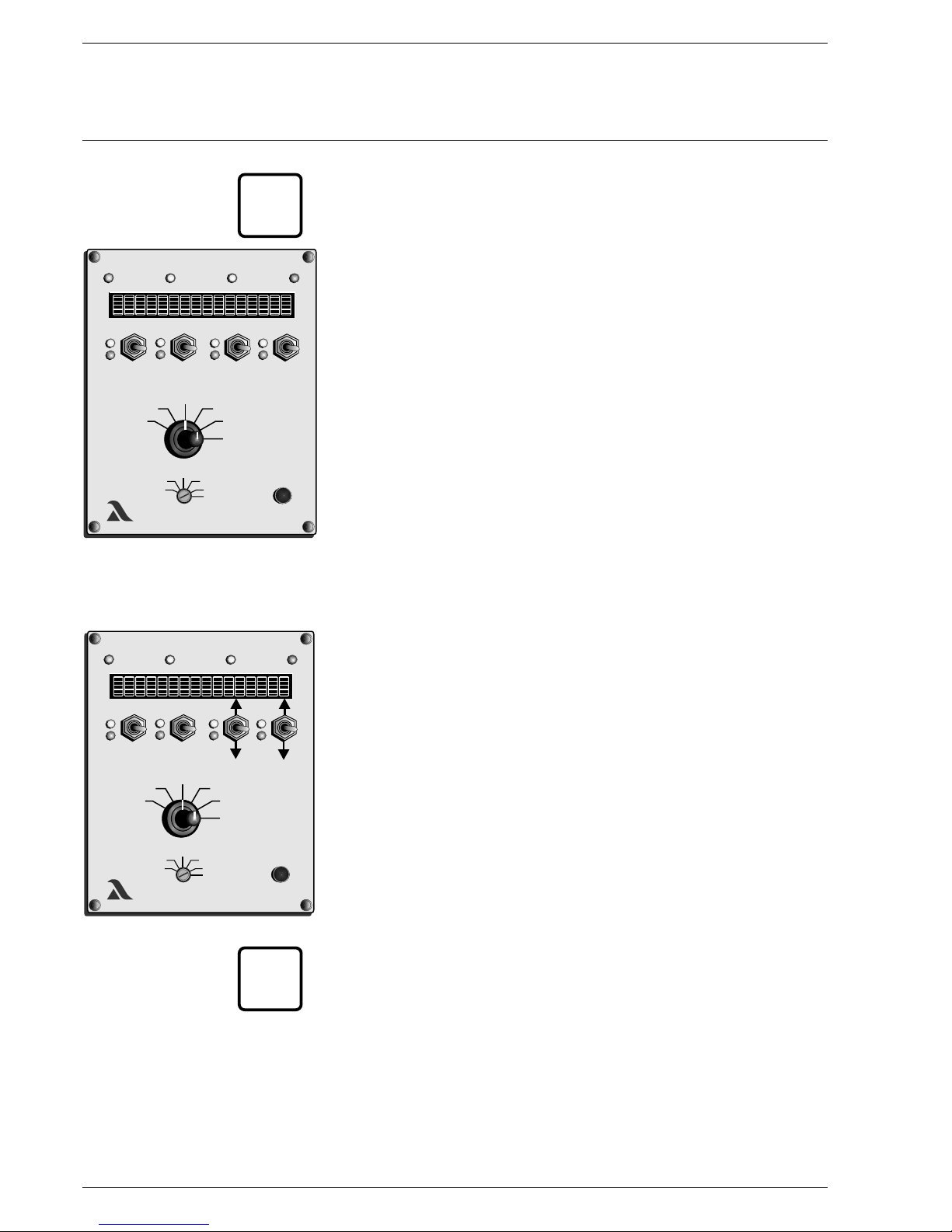

Entering the password Selector switch (1) to status

Push switch (4), channel 2 and 3, up

and at the same time

push switch, channel 4, down

- the input field for the password appears on the display.

Set the appropriate password via the switch.

Acceptance key (3)

Parameters on the corresponding level are released.

Selector switch (2) to parameterisation

xxx

LAMTECLAMTEC

xxx

xxx

xxx

2

3

4

1

19

!

!

!

i

Page 20

Settings Parameters

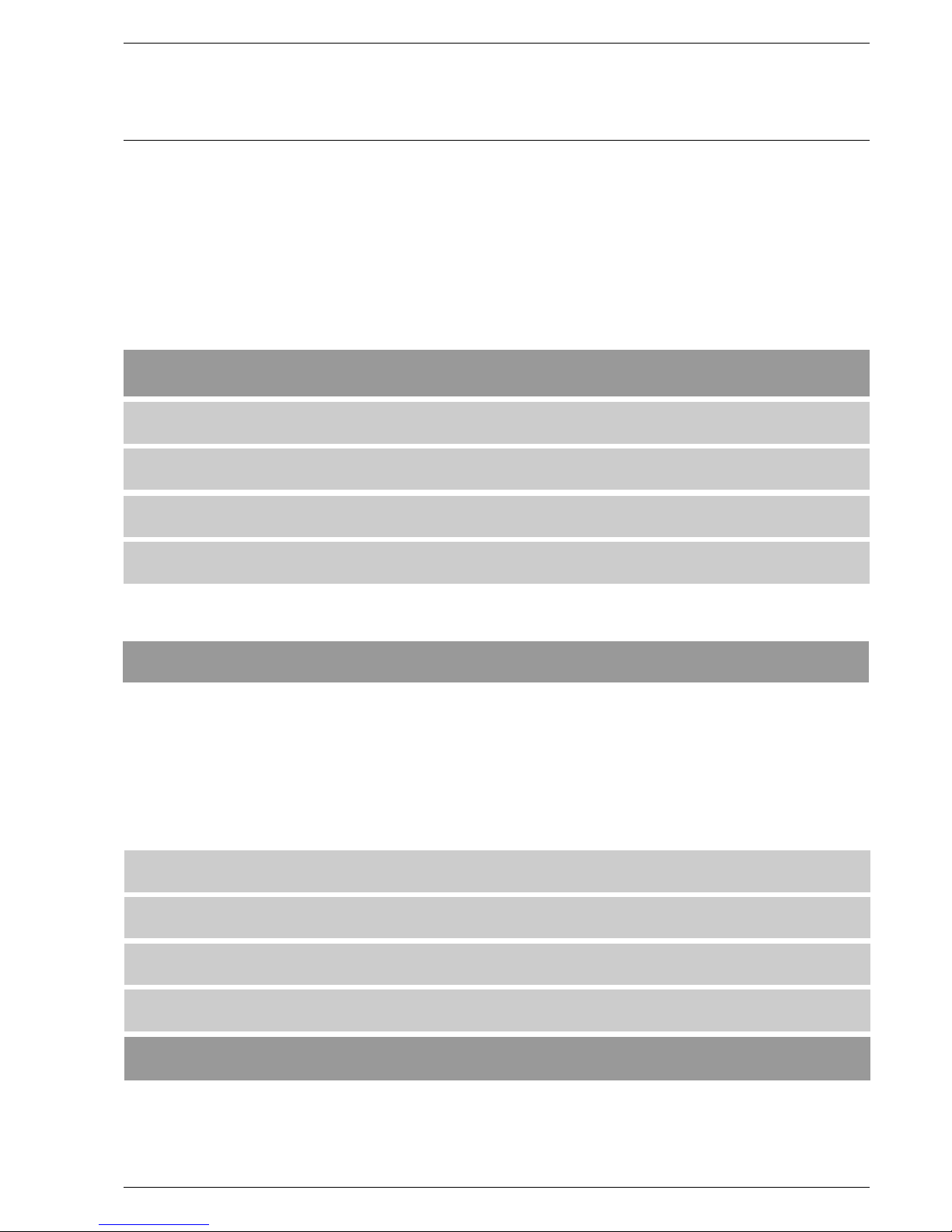

Changing the password ____________________________________________________________

Only possible at customer level (level 1)

____________________________________________________________

From level 1, once accessed:

Turn selector switch (1) to Status

Simultaneously push keys (4) channel 2 and 3 upwards

and channel 4 downwards

- the display shows the password input field

Set the new password for the level

Turn selector switch (1) to Digital inputs

Press the Acceptance key (3)

- new password is set

Changing parameters Select the required parameter with Channel 3 key

Change its value with Channel 4 key

- The values are accepted immediately without further confirmation

An explanatory text for the parameters can be called up by pressing

the Acceptance key (3)

____________________________________________________________

For larger values, changes can be in x100 steps with Channel 1 key and

in x10 steps with Channel 2 key.

____________________________________________________________

xxx

LAMTECLAMTEC

xxx

xxx

xxx

3

4

1

20

i

xxx

LAMTECLAMTEC

xxx

xxx

xxx

3

i

Page 21

Settings List of Parameters

(Level 0 and 1 parameters only)

_____________________________________________________________________________________________________

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

Pre-ventilation

346 VO LimK1 1 0 999 Limit to which pre-ventilation can be 999 P4

terminated, Channel 1

347 VO LimK2 1 0 999 Limit to which pre-ventilation can be 999 P4

terminated, Channel 2

348 VO LimK3 1 0 999 Limit to which pre-ventilation can be 999 P4

terminated, Channel 3

349 VO LimK4 1 0 999 Limit to which pre-ventilation can be 999 P4

terminated, Channel 4

350 VO LimK5 1 0 999 Limit to which pre-ventilation can be 999 P4

terminated, Channel 5

Running direction

374 Laufr.K1 1 0 999 Channel 1 running direction in event or fault 2 P6

375 Laufr.K2 1 0 15 Channel 2 running direction in event or fault 2 P6

376 Laufr.K3 1 0 15 Channel 3 running direction in event or fault 2 P6

377 Laufr.K4 1 0 15 Channel 4 running direction in event or fault 2 P6

378 Laufr.K5 1 0 15 Channel 5 running direction in event or fault 2 P6

427 Vodel R 1 0 999 750 P71

When changing the parameters via interface (by means of optional PC software) a check must then be made on

the spot to ensure that the changes have been properly accepted. This can be done by reading out the

parameters on the unit or by comparing the unit's checksums. See page 78 .

0 = OFF (control element stops)

1 = Control element runs OPEN

2 = Control element runs CLOSED

3 = Control element runs to the setting

6 = Control element runs to its ignition point

8 = Control element runs to base load

Re-circulation delay time (on FMS)

No. of air duct points (VMS)

21

Page 22

22

Settings List of Parameters

(Level 0 and 1 parameters only)

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

Correction

433 K1 Spreiz 1 0 999 10 P22

434 K2 Spreiz 1 0 999 10 P22

517 KB11.1 0 0 999 0 P7

597 KB21.1 1 0 999 0 P7

Monitor output

677 Moni.1 1 0 23 0 P8

678 Moni.2 1 0 25 0 P9

679 Moni.3 1 0 25 0 P9

3

680 Moni.4 1 0 25 0 P9

4

681 Moni.5 1 0 25 0 P9

5

682 Moni.6 1 0 25 0 P9

6

683 Moni.7 1 0 25 0 P9

7

684 Moni.8 1 0 25 0 P9

8

685 Unt.Mo1 1 0 999 0 P10

686 Unt.Mo2 1 0 999 2: 0 P10

687 Unt.Mo3 1 0 999 3: 0 P10

688 Unt.Mo4 1 0 999 4: 0 P10

Spread factor for correction input

(00.0 99.9) 01.0 = no expansion

Spread factor for correction input

(00.0 99.9) 01.0 = no expansion

Correction range, correction input 1

Correction range, correction input 2

Definition of the monitor output

with curve set 1

0= internal load 14= channel 4 actual value

1= channel 1 setting 15= channel 5 actual value

2= channel 2 setting 21= external load

3= channel 3 setting 22= correction input 1

4= channel 4 setting 23= correction input 2

5= channel 5 setting 24=O -actual value

2

11= channel 1 actual value 25=O -setpoint

2

12= channel 2 actual value 26=Flame intensity

13= channel 3 actual value

Definition of the monitor output

with curve set 2

Definition of the monitor output

with curve set

Definition of the monitor output

with curve set

Definition of the monitor output

with curve set

Definition of the monitor output

with curve set

Definition of the monitor output

with curve set

Definition of the monitor output

with curve set

Monitor output, curve set 1:

4 mA correspond to X points

Monitor output, curve set

4 mA correspond to X points

Monitor output, curve set

4 mA correspond to X points

Monitor output, curve set

4 mA correspond to X points

Page 23

Settings List of Parameters

(Level 0 and 1 parameters only)

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

689 Unt.Mo5 1 0 999 Monitor output, curve set 5: 0 P10

4 mA correspond to X points

690 Unt.Mo6 1 0 999 Monitor output, curve set 6: 0 P10

4 mA correspond to X points

691 Unt.Mo7 1 0 999 Monitor output, curve set 7: 0 P10

4 mA correspond to X points

692 Unt.Mo8 1 0 999 Monitor output, curve set 8: 0 P10

4 mA correspond to X points

693 Ob.Mo1 1 0 999 Monitor output, curve set 1: 999. P10

20 mA correspond to X points

694 Ob.Mo2 1 0 999 Monitor output, curve set 2: 999 P10

20 mA correspond to X points

695 Ob.Mo3 1 0 999 Monitor output, curve set 3: 999 P10

20 mA correspond to X points

696 Ob.Mo4 1 0 999 Monitor output, curve set 4: 999 P10

20 mA correspond to X points

697 Ob.Mo5 1 0 999 Monitor output, curve set 5: 999 P10

20 mA correspond to X points

698 Ob.Mo6 1 0 999 Monitor output, curve set 6: 999 P10

20 mA correspond to X points

699 Ob.Mo7 1 0 999 Monitor output, curve set 7: 999 P10

20 mA correspond to X points

700 Ob.Mo8 1 0 999 Monitor output, curve set 8: 999 P10

20 mA correspond to X points

Flying curve change

702 Luftvor 1 0 999 Air advance with flying 0 P11

curve change in points

703 Dauer LV 1 0 999 Duration of air advance with flying 0 P11

curve change in seconds

704 Wirku LV 1 0 999 Effect on air advance 1 P11

0-Load / 1-Setting

Band shift

707 Wirk.Bve 1 0 1 Effect on band shift 0 P2

0-Load / 1-Setting

708 BandV K1 1 0 50 Band shift 4 P3

Channel 1

709 BandV K2 1 0 50 Band shift 4 P3

Channel 2

710 BandV K3 1 0 50 Band shift 4 P3

Channel 3

23

Page 24

Settings List of Parameters

(Level 0 and 1 parameters only)

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

711 BandV K4 1 0 50 Band shift 4 P3

Channel 4

712 BandV K5 1 0 50 Band shift 4 P3

Channel 5

Compound

718 Laufz L 1 0 65535 Running time in pts./min for TPS 9999 P12

Load input

In the event of load via current or

pot, the value must be 0

719 Laufz K1 1 0 65535 Running time in pts./min 9999 P13

for continuous output channel 1

720 Laufz K2 1 0 65535 Running time in pts./min 9999 P13

for continuous output channel 2

721 Laufz K3 1 0 65535 Running time in pts./min 9999 P13

for continuous output channel 3

722 Laufz K4 1 0 65535 Running time in pts./min 9999 P13

for continuous output channel 4

723 Laufz K5 1 0 65535 Running time in pts./min 9999 P13

for continuous output channel 5

729 stopVERB 1 10 100 Minimum compound running time 10 P15

in seconds

730 minTAKT1 1 1 100 Minimum cycle length for channel 1 1 P16

in 20ths seconds per digit (50 ms)

731 minTAKT2 1 1 100 Minimum cycle length for channel 2 1 P16

in 20ths seconds per digit (50 ms)

732 minTAKT3 1 1 100 Minimum cycle length for channel 3 1 P16

in 20ths seconds per digit (50 ms)

733 minTAKT4 1 1 100 Minimum cycle length for channel 4 1 P16

in 20ths seconds per digit (50 ms)

734 minTAKT5 1 1 100 Minimum cycle length for channel 5 1 P16

in 20ths seconds per digit (50 ms)

740 PauseT1 1 1 100 Minimum pause between channel 1 cycles 2 P27

in 20ths seconds per digit (50 ms)

741 PauseT2 1 1 100 Minimum pause between channel 2 cycles 2 P27

in 20ths seconds per digit (50 ms)

742 PauseT3 1 1 100 Minimum pause between channel 3 cycles 2 P27

in 20ths seconds per digit (50 ms)

743 PauseT4 1 1 100 Minimum pause between channel 4 cycles 2 P27

in 20ths seconds per digit (50 ms)

744 PauseT5 1 1 100 Minimum pause between channel 5 cycles 2 P27

in 20ths seconds per digit (50 ms)

24

Page 25

Settings List of Parameters

(Level 0 and 1 parameters only)

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

754 ES aktiv 1 10 100 ES is activated when load 40 P17

falls by X points

755 Verz. ZÜ 1 0 999 Delay time of 0 P19

ignition position relay

756 Verz. GL 1 0 999 Delay time for base load 0 P20

with sep. ignition point

757 Verz. RG 1 0 999 Delay time for control release 0 P21

758 ZEIT NA 1 0 999 Post-ventilation time 0 P18

759 Verz. ZÜ 1 0 30 Ignition delay when setting 0 P29

after actuation of the ignition point

Control unit

768 KuerznLE 1 0 15 Delay time for "Damper open" 5 P72

after fan on

769 D.n.Abs 1 0 1 Leak test 0 P53

0 = Off, 1 = On

772 Dicht Zü 1 0 1 Leak test before starting 1 P53

0 = Off, 1 = On

777 Prgüzeit 1 0 9999 Program monitoring time 4 P40

With content 0 no monitoring occurs

782 VorZüdel 1 2 40 Transformer pre-energise time 3 P51

(pre-ignition time)

783 Stab.zei 1 3 100 Stabilisation time 3 P52

785 ZEIT VO 1 30 999 Pre-ventilation period 30 P54

787 Wartung 1 0 1 Service mode, control unit runs 0 P60

only until stabilisation time

789 Nachbr.z. 1 0 30 Post-combustion time (flame signal 10 P62

irrelevant) in seconds

Power control unit (option)

790 Lasttyp 1 0 2 Load control type 0 P80

0 = off 2 = Atmosphere-controlled unit

1 = Fixed value (possible only where there is

control unit hardware provision for this)

791 Anf.Temp. 0 0 999 Starting maximum temperature 0 P81

792 Anf.Leis 0 0 999 Starting power 0 P82

793 Anf.Zeit 0 0 32767 Starting time in minutes 0 P83

794 ext.Lgre 0 0 1000 External power limit 0 P84

after switching off

25

Page 26

26

Settings List of Parameters

(Level 0 and 1 parameters only)

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

795 SoftStop 0 0 100 D

796 Soll1min 0 0 1000

797 Soll1max 0 0 1000

798 Soll2min 0 0 1000

799 Soll2max 0 0 1000

800 Obergren 0 0 1000

801 Untergren 0 0 1000

802 Regelb.U 0 -999 +999

803 Regelb.O 0 0 999

804 Bren.AUS 0 0 200

805 P-Faktor 0 0 999

806 I-Faktor 0 0 999

807 D-Faktor 0 0 999

808 Nachst.z 0 0 60

809 L-Einheit 1 0 3 0 P94

810 min.Einh. 1 0 999 0 P95

811 max.Einh. 1 0 999 Upper limit 0 P95

Soft stop time Burner after running 0 P85

Control unit setting 1 minimum with P86

atmosphere control/control unit setting 1

Control unit setting 1 maximum P86

with atmosphere control

Control unit setting 2 minimum with P86

atmosphere control/control unit setting 2

Control unit setting 2 maximum P86

with atmosphere control

Load regulator: upper limit P87

with atmosphere control

Load regulator: lower limit P87

with atmosphere control

Control range, bottom P88

Control range, top P89

Burner off P90

P-factor of control unit 3 P91

I-factor of control unit 4 P91

D-factor of control unit 50 P91

Rest time 10 P92

Load regulator actual value input

and setting representation

0 = Display in digits

1 = Display in °C

2 = Display in bar (XX.X)

Lower limit

Pressure (4 mA) correspond to X bar

Pressure (4 mA) correspond to X bar

Page 27

Settings List of Parameters

(Level 0 and 1 parameters only)

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

814 Leist. 1 1 0 1000 1 P91

815 Leist. 2 1 0 1000 2 P91

816 Leist. 3 1 0 1000 3 P91

817 Leist. 4 1 0 1000 4 P91

Interface

822 BaudS 1 1 0 5 4 P23

823 BaudS 2 1 0 5 2 4 P23

0 = 1200 3 = 9600

1 = 2400 4 = 19200

2 = 4800 5 = 38400

826 Adr.S 1 1 0 31 0 P24

827 Adr.S 2 1 0 31 2 0 P24

Display

831 Helligkt 1 0 6 5 P25

0 = 100 % … 6 = 13 %

832 DispOFF 1 0 65535 15 P26

833 Sprache 1 0 6 0

0 = German 4 = Swedish

1 = English 5 =

2 = French 6 = Dutch

3 =

838 Int.L.AU 1 0 999 200

839 LastTotb 1 0 15 10 P14

850 1 0 3 0 P55

851 1 0 3 0 P55

Power output of burner with curve set

Power output of burner with curve set

Power output of burner with curve set

Power output of burner with curve set

Baud rate of serial interfac

Baud rate of serial interface

Network address VMS / FMS se

Network address VMS / FMS ser.

Brightness of display in steps

Display switch-off time in minutes

(0 = none) i.e., time after operation until

switched back to lowest brightness level

Selection of language display

not assigned

not assigned

Value of internal load in AU mode

(for external power display)

Dead band definition +/- this value

does not alter load

Represented unit

steam,

rev speed, quantity

Represented unit channel 2

e 1

r. 1

Einh. Kan.1 channel 1

0 = digits 2 = pressure,

1 = °C (temp.)

3 = mA

Einh. Kan.2

27

Page 28

Settings List of Parameters

(Level 0 and 1 parameters only)

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

852 1 0 3 0 P55

853 1 0 3 0 P55

854 1 0 3 0 P55

860 1 0 999 0 P55

861 1 0 999 0 P55

862 1 0 999 0 P55

863 1 0 999 0 P55

864 1 0 999

0 P55

871 1 0 999 0 P55

872 1 0 999 0 P55

873 1 0 999 0 P55

874 1 0 999 0 P55

880 1 0 3 0 P55

881 1 0 3 0 P55

882 1 0 999 0 P52

883 1 0 999 0 P52

0 P52

0 P52

Einh. Kan.3

Einh. Kan.4

Einh. Kan.5

R4mA K1

R4mA K2

R4mA K3

R4mA K4

R4mA K5

R20 mA K2

R20 mA K3

R20 mA K4

R20 mA K5

Einh. K01

Einh. K02

4mA KOK 1

4mA KOK 2

884 20mA KOK 1 1 0 999

885 20mA KOK 2 1 0 999

Represented unit channel 3

Represented unit channel 4

Represented unit channel 5

4 mA feedback corresponds

to x units channel 1

4 mA feedback corresponds

to x units channel 2

4 mA feedback corresponds

to x units channel 3

4 mA feedback corresponds

to x units channel 4

4 mA feedback corresponds

to x units channel 5

20 mA feedback corresponds

to x units channel 1

20 mA feedback corresponds

to x units channel 2

20 mA feedback corresponds

to x units channel 3

20 mA feedback corresponds

to x units channel 4

20 mA feedback corresponds

to x units channel 5

Represented unit correction input 1

Represented unit correction input 2

4 mA feedback correspond to

X of correction input 1

4 mA feedback correspond to

X of correction input 2

20 mA feedback correspond to

X of correction input 1

20 mA feedback correspond to

X of correction input 2

0 P55

870 R20 mA K1 1 0 999

28

Page 29

Settings List of Parameters

(Level 0 and 1 parameters only)

Para- Short Safety Lower Upper

meter- design- level limit limit Standard

No. nation Description values Aids

_____________________________________________________________________________________________________

1 P30

897 O2Stoer 1 0 2 O

2

0 P31

898 O2-TotZ 0 3 20 15 P32

899 O2-P-Fak 0 1 50 O P-factor 5 P32

2

900 O2 TZ - 0 0 5 O

2

3 P32

901 O2Neutr1 1 0 1000 Correction value output on deactivated

O regulation. Fuel 1 300 P31

2

902 O2Neutr2 1 0 1000 Correction value output on deactivated

O regulation. Fuel 2 300 P31

2

903 O2FWZeit 1 0 9999 O deactivated after fuel

2

change in sec.. 30 P33

904 O2WarteZ 1 0 9999 O regulation active after

2

ignition in sec. 90 P34

910 O2Totbnd 2 0 10 O lag band in 0.1% 2

2

914 O2Aktiv 0 0 999 Activate O regulation from

2

load position X (in pts) 0 P35

915 O2Deakti 0 0 999 Deactivate O regulation from

2

load position X (in pts) 999 P35

917 LftmKor1 1 0 999 Air shortage correction value, fuel 1 150 P31

918 LftmKor2 1 0 999 Air shortage correction value, fuel 2 150 P31

919 O2 4mA 1 0 999 O value 4mA 0 P36

2

920 O2 20mA 1 0 999 O value 20mA 250 P36

2

931 O22UBU1G 1 0 250

100 P37

932 O22UBU1V 1 0 250

100 P37

933 O22UBU2G 1 0 250

100 P37

934 O22UBU2V 1 0 250

100 P37

936 O2SOWert 0 0 65535 2 P38

Parameter for O regulation

2

896 O2Regler 0 0 9 O -Regulator

2

0 = O regulator off 8 = Only display, base value

2

1 = Standard regulator for deact. O regulator

2

2 = Without lag time 9 = Only display, base value

3 = only display for air shortage

neutral value

Error shut-down by regulator

permitted (0=No, 1=on air shortage)

Lag time of the O regulation section

2

Lag time shortening of the regulation

section with full load

Lower 2nd monitoring band, fuel 1

in % of target value, base load

Lower 2nd monitoring band, fuel 1

in % of target value, full load

Lower 2nd monitoring band, fuel 2

in % of target value, base load

Lower 2nd monitoring band, fuel 2

in % of target value, full load

Probe dynamic test

29

Page 30

30

Leakage Test Mode of Operation

Integrated Leakage Test (option)

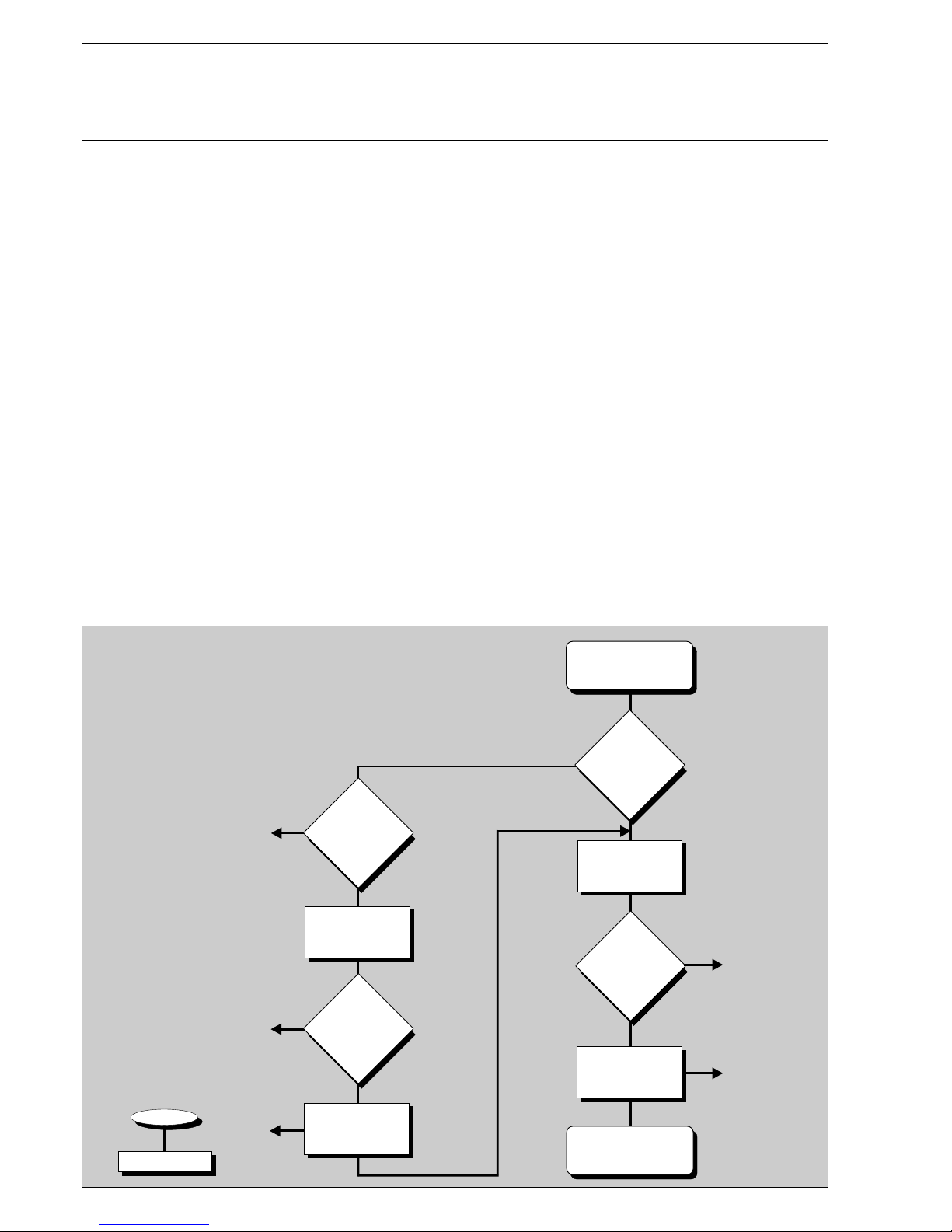

Leakage test flow chart

Integrated leakage test The leakage test checks whether the main gas valves are leak-tight.

(option) The supply gas pressure is used for this purpose. Since the leakage test line

(space between the two main valves) burns empty in the event of a shut-off,

this part is normally pressureless when starting (gas pressure > min. = 0).

The FMS checks this. Main gas 1 is then briefly opened and gas flows into the

test line (gas pressure > min. changes from 0 to 1). This pressure must then

subsist for 30 seconds. The leakage test is then deemed to be completed.

If the leakage test line is not empty at the start (e.g. as a result of a fault shutoff previously), main gas valve 2 is opened first. The leakage test line is thus

vented (into the combustion chamber or over the roof, depending on the

system, for suggested circuit see next page). A check is then conducted to

see whether the line remains pressureless for 30 seconds. Otherwise the

procedure is as described previously.

The leakage test can be performed before ignition and/or after shut-off.

Selection via parameters.

The pressure monitor for the leakage test line must be connected to "Gas

pressure >min” input (terminal 73). It also monitors the minimum pressure

during operation. If another minimum pressure is to be monitored during

operation, however, the pressure monitor is, for this purpose, to be looped into

the gas safety interlock circuit.

The test line, however, must be designed so as to ensure that the test time of

30 sec. per valve is sufficient to reliably detect a leak of 0.1% of the fuel gas

3

consumption at maximum firing heat output, but at least 50 dm /h.

Flow chart

Start

Leak Test

Leak

test line

under pressure

Gas > min = 1

Gas valve 1

(gas line side)

open for 2 sec.

Yes

Yes

1

1

1

1

Pressure

drops again

1

No

No

No

Pressure

rises again

No

Wait 30 sec

and

test pressure

Leak test

successfully

completed

Leak

test line

pressureless ?

Gas > min = 0

Leak

test line

pressureless ?

Parameter

770 = 1

Wait 30 sec

and

test pressure

Fault shut-off

1

Gas valve 2

(burner side)

open for 2 sec.

Yes

Yes

Page 31

Leakage Test Venting

Leakage test line over roof

Calculation formula An (approximate) formula for calculating the leak test facility is compiled

below:

Definitions: GDW gas pressure monitor

V1 gas-side safety shut-off device

V2 burner-side safety shut-off device

barometric air pressure 1000 mbar

lower switch point (falling) of GDW

upper switching point (rising) of GDW

switch difference of GDW

gas flow pressure (supply pressure before V1)

volume of gas line tested

leakage quantity

maximum admissible leakage quantity (limit)

testing time (30 seconds, fixed)

3

That is, for a maximum gas flow rate of 50 m /h the formula is:

inserting the numerical value for in mbar.

For a gas rate of flow Q of >50 m3/h the formula is:

3

inserting the numerical value for Q in m /h and for in mbar.

3

Examples: A. Assuming: = 20 mbar, gas rate of flow < 50 m /h: i.e. the gas line to be

tested must be no

3

greater than 20.8 dm

in order to be able to detect the leakage quantity demanded

3

B. Assuming: = 20 mbar, gas rate of flow = 200 m /h:

i.e. the gas line to be

tested must be no

3

greater than 83.3 dm

3

in order to be able to detect the leakage quantity demanded of 200 dm /h.

Suggested circuit for venting

the gas line over-roof in

conjunction with the

combustion management system

* If after shut-off the test line is not vented over-roof but is to be burned off

into the combustion chamber, a timer relay with a delayed cut-out of

2 … 5 sec is to be used.

PB »

PSU

PSO

DP = P SO - PSU

PG

VP

VL

VLmax

tP

D

P

D

P

D

P

D

P

31

416

30 [s]

1000 [mbar]

7

3

50 dm /h ;

VP

tP

Dp

PB

7

3

50 [dm /h] ; Y

; (3);

.

.

VP

Dp

Y VP

Dp

3

[dm ]

7

.

; (4);

Dp

3

[dm ]

VP

7

.

.

Q

0,12

.

7

7

Y VP

416

20

3

[dm ]

3

[dm ]

;

;

Y VP

20,8

7

7

Y VP

200

20

3

[dm ]

3

[dm ]

;

;

Y VP

83,3

0,12

.

to burner

Roof venting

from gas line

*K 1

P

Gas min.

Gas valve 2

Gas valve 1

82

83

Relay-Modul

6 60 R 0016

Page 32

Output regulator (optional) Method of operation

Procedure description The burner's startup proceeds exactly as already described, except that an

enabling command to start the burner must have been provided by the

output regulator. In other words, the actual value must be smaller than the

set-point by an appropriate amount.

The output regulator only operates once the burner has fired up and the

signal "Enable regulation” (terminal 4) has been given. Load specification

for the compound is then provided via the integral output regulator.

It depends on the difference between the actual value and the set-point,

and on the control parameters set.

If the actual value exceeds the maximum value set, the output regulator

shuts down the burner.

The load regulator is only active in "Automatic” mode.

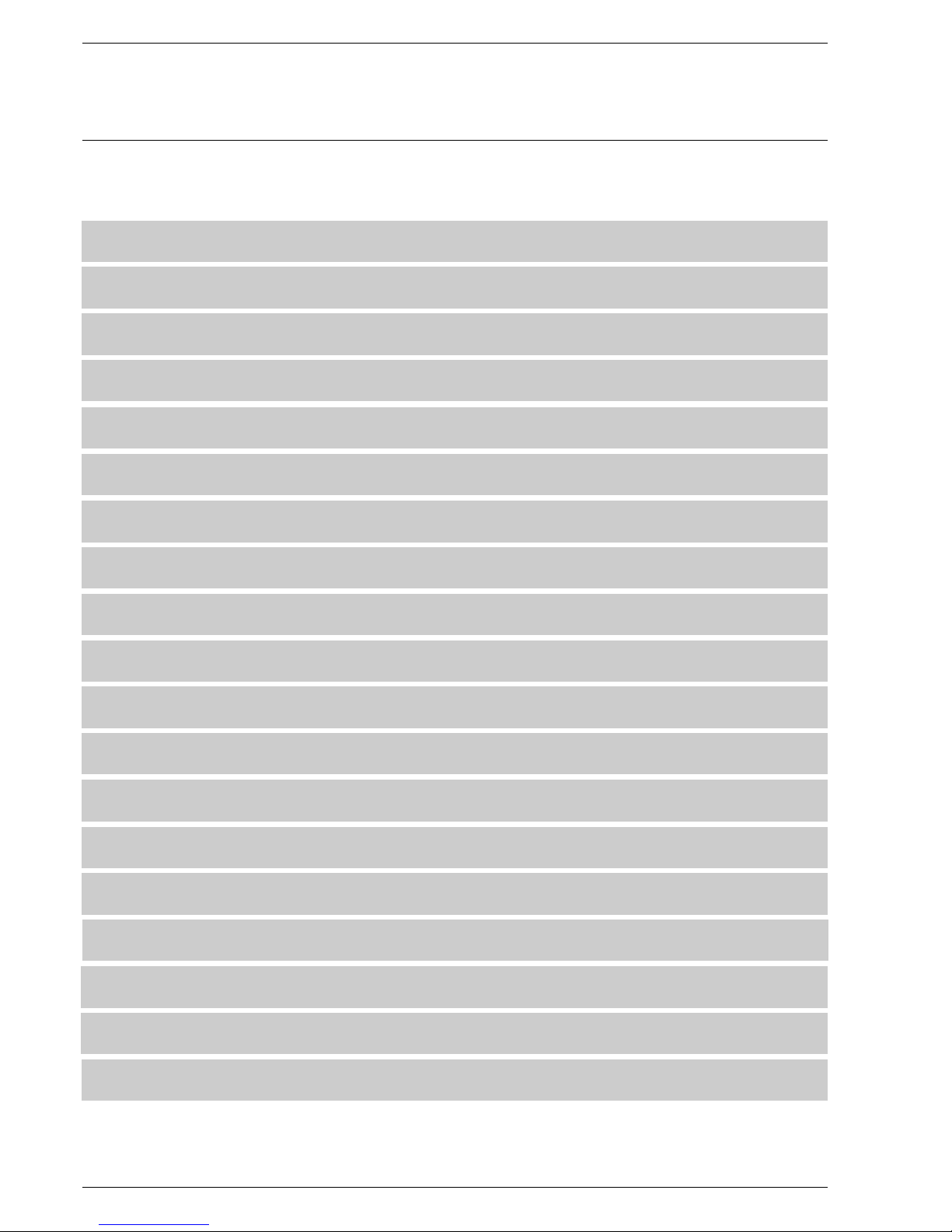

Weather control If the output regulator is configured as "weather controlled”, the set-point

can be shifted between the parameters SetpointMin and SetpointMax by

altering the value at the redundant feedback channel 1.

When the regulator is weather-controlled, the outside temperature is taken

into account when calculating the set-point. The operator can input a

minimum and a maximum set-point, between which the outside

temperature can determine the set-point (see diagram).

With the weather-controlled option activated, an external set-point

specification can also be implemented.

Pre-run temperature

Outside temperature

O

120 C

O

-20 C

O

70 C

O

20 C

O

5C

O

30 C

Set-point max

Set-point min

Lower limit

Upper limit

32

Page 33

Output regulator (optional) Method of operation

Parameterised startup time

Startup circuit

Specified load

Sp

ecif

ed a

di lo

Time

max. load/

or highest

programmed

point

Specified load

Parameterised

startup load

Set-point switch-over The set-point can be switched over via a digital input. In versions with a

fixed set-point, this contact can be used to select between the two values

entered in the parameters list.

If, in addition, weather control is activated, a selection is made between

two pairs of limiting values (see Weather control and Limiting ranges). The

parameters for Set-point 1 (for set-point switch-over) and Set-point min. 1

(for weather control) are equal. Similarly for the parameters Set-point 2 and

Set-point min. 2. The relevant content is assigned in accordance with the

configuration.

Activating the "Weather control” option and adjusting the variable

parameters can also be used to implement external set-point specification.

In other words, the set-point can be altered manually or automatically via a

potentiometer (or switched through resistors). Thus, by connecting a

double-throw switch, night-time reduction could be implemented instead

of weather control. Night-time reduction and weather control can be

achieved simultaneously by combining the weather controller with the setpoint switch-over. When the weather controller is active, the compound's

feedback can no longer proceed completely redundantly.

Startup circuit The load regulator has a startup circuit, in order to brake the burner's start

load. The startup circuit is run during each new burner start. The internal