Page 1

Quick Reference for End Users

Lambda Transmitter LT2-K

Lambda Probe LS2-K/LS2KV

Sensors and Systems for Combustion Engineering

www.lamtec.de

Page 2

Page 3

Table of Contents

Table of Contents

1 Important Information about the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Validity of these Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Information on Using this Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 For Your Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Classification of the Safety Instructions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Proper Use - Conditions of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Permissible Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Safety Equipment/Safety Measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Protection Against Emissions from Gas Carrying Channels . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Commissioning/Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6.1 Decommissioning, Storage and Commissioning . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6.2 Environmental Protection, Waste Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Technical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 LT2-K LS2-K Structure in Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 LT2-K LS2-KV Structure in Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 LS2-K / LS2-KV Lambda Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 LT2-K Lambda Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 LT2-K Lambda Transmitter Type 657R102 with Display and Operating Unit. . . . . . . . . 16

3.6 Display and Operating Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.7 Cold-start Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.8 Analogue Outputs 0/4 … 20 mA, 0/2 … 10 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.9 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.10 Analogue Inputs (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.11 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Commissioning/Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Display and Operating Unit of the LT2-K Lambda Transmitter. . . . . . . . . . . . . . . . . . . . 21

4.2 Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 Internal Display and Operating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4 Display and Operating Unit Type 657R0831 (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.2 Menu Function 'meas' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.3 Menu Function 'cal' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.4 Menu Function 'par' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4.5 Menu Function 'psw' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4.6 Menu Function 'view' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4.7 Menu Function 'change'. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.8 Menu Function 'diag' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.9 Limit values display and resetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4.10 Display of the Limit Value Crossing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.11 Brightness, Contrast and Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4.12 Customer Password Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.5 Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.1 LT2-K Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.2 LT2-K Diagnosis Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.5.3 LT2-K Measurement Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

Page 4

Table of Contents

4.5.4 LT2-K Parameter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.6 Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.6.1 Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.6.2 Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.7 Measurement Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.7.1 Measurement with LS2-K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.7.1.1 Adjust the Amount of the Reference Air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.7.1.2 Performing an offset calibration to ambient air . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.7.1.3 Performing an Offset Calibration with Compressed Air . . . . . . . . . . . . . . . . . . . 46

4.7.1.4 Perform a Calibration with Reference Measurement . . . . . . . . . . . . . . . . . . . . . 47

4.7.1.5 Perform a Calibration with Test Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.7.2 LS2-KV Measurement (Fully-automatic Calibration) . . . . . . . . . . . . . . . . . . . . . 49

4.7.2.1 Adjust the Amount of the Reference Air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.7.2.2 Performing an offset calibration to ambient air . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.7.2.3 Reference measurement - Performing a Test Calibration . . . . . . . . . . . . . . . . . 52

4.7.2.4 Performing a Combined Offset and Test Gas Calibration . . . . . . . . . . . . . . . . . 53

4.8 Probe Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.9 Setting up Service Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.10 Decommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5 Test Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.1 Measurement During Distinct Pressure Surges at the Measuring Site . . . . . . . . . . . . . 57

6.2 Operational Failure, Switching On and Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.3 Liquid Purification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7 Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.1 Checking the O2 Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.1.1 Calibrating the Air Voltage (Offset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.1.2 Checking (Calibration) with Reference Measurement /Test Gas . . . . . . . . . . . . 58

7.1.3 Fully-automatic Combined Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.2 Checking the Measurement Input of LT2-K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.3 Checking the Probe's Internal Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . 59

7.4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.4.1 Checking the Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.4.2 Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.4.3 Cleaning/Replacing the Sintered Metal Pre-filter. . . . . . . . . . . . . . . . . . . . . . . . 60

7.4.4 Replacing the O2 Measuring Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8 Fault Analysis/Trouble-shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.1 Faults/Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.2 Internal Fault Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.3 Warning Indication by LED Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.4 Resetting Faults/Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.5 Faults - Causes and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.5.1 Probe voltage too low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.5.2 Probe Heating Defective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.5.3 Broken Wire Probe/Defective Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.5.4 No Probe Dynamics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.5.5 Fault Analogue Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3

Page 5

Table of Contents

8.5.6 O2 Value Is Incorrect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.5.7 Reference Air Is Missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.6 Warnings - Causes and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.6.1 LT2-K Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.6.2 Offset Voltage out of range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.6.3 Reference Air Is Missing (Indication as a Warning in Parameter 395). . . . . . . . 69

8.6.4 Delta-P Offset/Test Gas Calibration is Insufficient - Too less Gas . . . . . . . . . . . 70

8.6.5 Delta-P Offset or Test Gas Calibration too High - Filter Clogged. . . . . . . . . . . . 70

8.6.6 Amount of Calibration Gas Insufficient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.6.7 Test Gas Calibration Is Invalid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.6.8 Test Gas Calibration Is Invalid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.6.9 Analogue Inputs 1/2/3/4 Input Value too Large/too Small . . . . . . . . . . . . . . . . . 71

8.6.10 Configuration Error at Analogue Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.6.11 Service Warning 1/Service Warning 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.1 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.2 Connection Diagram for LT2-K/LS2-K (semi automatic calibration). . . . . . . . . . . . . . . . 74

10.3 Connection Diagram for LT2-KV/LS2-KV (fully automatic calibration) . . . . . . . . . . . . . . 75

10.4 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.5 Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.6 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.7 LT2 Power Electronic Type 657E1882. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.8 Wet/Dry Measurement Deviations, Conversion Table . . . . . . . . . . . . . . . . . . . . . . . . . . 81

11 EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4

Page 6

1 Important Information about the Manual

1 Important Information about the Manual

1.1 Validity of these Instructions

This manual describe the Lambda Transmitter LT2 with all required components. The information in this document applies to the software version 1V61. If you utilise a different version, this

can lead to other effects to your device than those described in this manual.

The devices apply to the following standards and directives:

• DIN EN 61326-1: 2013-07

• DIN EN 61010-1: 2013-07

• 2014/35/EU Low Voltage Directive

• 2014/30/EU EMC Electromagnetic Compatibility

• 2011/65/EU RoHS

1.2 Information on Using this Operating Manual

1.3 Glossary

NOTICE

Before starting work, you absolutely must read these instructions!

Carefully observe all warning notes!

They contain important data and information, the compliance with which will ensure the function of the device and, in turn, reliable measurement results.

The device described here corresponds with the standard configuration.

Particular attention must be paid to information and warnings. These are indicated by respective pictograms. They serve to safeguard your personal safety and help you to avoid operating errors.

This manual for end users contains the information required to operate and maintain the system.

Abbreviations

GED Gas extraction device

PCB Probe connection box

PIF Probe installation fitting

Li Limit values

IP Protection class for example IP54

5

Page 7

2 For Your Safety

2 For Your Safety

2.1 Classification of the Safety Instructions and Warnings

The following symbols are used in this document to draw the user's attention to important safety information. They are located at points where the information is required. It is essential that

the safety information is observed and followed, and that applies particularly to the warnings.

DANGER!

This draws the user's attention to imminent danger. If it is not avoided, it will result in death or

very serious injury. The plant including its surroundings could be damaged.

WARNING!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in death or very serious injury. The plant including its surroundings could be damaged.

CAUTION!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in minor injuries. The plant including its surroundings could be damaged.

NOTICE

This draws the user's attention to important additional information about the system or system

components and offers further tips.

The safety information described above is incorporated into the instructions.

Thus, the operator is requested to:

1 Comply with the accident prevention regulations whenever work is being carried out.

2 Do everything possible within his control to prevent personal injury and damage to prop-

erty.

6

Page 8

2 For Your Safety

2.2 Proper Use - Conditions of Use

The Lambda Transmitter LT2 in combination with the Lambda Probe LS2-K, is a universal system for a direct detection of combustible gas constituents (CO/H2), displayed as an equivalent

of CO (COe) in combustion systems in superstoichiometric range ( > 1).

The system is designed for semi-automatic calibration with air and test gas.

If the system should be used in a different way and the device function can not be accurately

determined for this application, you must consult the manufacturer before.

Prerequisites

All planning, mounting, installation, commissioning, maintenance, and repair work must be

carried out by adequately trained personnel only and checked by experts.

Correct handling

in particular, it is necessary to ensure that

• the application must conform to the technical data and details of the permitted use, terms

and conditions with regards to mounting, connection, environment and operation (to be

taken from order documents, device’s user information, rating plat, etc) as well as the delivered documentation

• the local regulations and facility-specific and technical hazards must be noted and followed.

• all necessary measures are taken to ensure value conservation, e.g. for transport and

storage as well as maintenance and inspection.

Observing the operating instruction

Intended use also includes:

• Observing all the information in the operating instructions.

• Carrying out all inspection and maintenance work.

2.3 Permissible Users

Qualified personnel

The person responsible for safety absolutely must guarantee that

• only qualified personnel perform work on the system parts.

Due to their training, education, experience, or instruction and due to their knowledge of

pertinent standards, provisions, accident prevention regulations, and system conditions,

qualified personnel are authorized to perform these tasks by the person responsible for

the safety of people and the system. It is decisive that this personnel must be able to recognise and prevent risks on time.

Experts are considered to be people according to DIN VDE 0105 or IEC 364 or directly

comparable standards like DIN 0832.

• These persons must have access to the provided operating manual and any pertinent order-related documentation during all work and observe these documents within the scope

of preventing risks and damage.

7

Page 9

2 For Your Safety

User groups

For the handling of the Lambda Transmitter LT2, three user groups are required:

• Service technicians of LAMTEC or its OEM customers and/or trained customer personnel:

– Qualified technicians/engineers have very good knowledge of the device.

– SERVICE access level - password-protected

• Operators, customer fitters, technicians for instrumentation and control technology, electricians, and electronic engineers have introductory knowledge of the device.

– CUSTOMER access level - password-protected

• Operating personnel with basic knowledge

– OPERATION access level - no password

2.4 Safety Equipment/Safety Measures

Hazards from electrical equipment

The LT2 Lambda Transmitter and the Lambda Probe is equipment for use in industrial electrical power installations. Always switch off the power when working on mains connections or

mains voltage. If shrouding (for electrical safety) has been removed, reattach it before switching on the power supply again. Damage to health or equipment may result from improper use

or improper handling.

NOTICE

To avoid damage, always observe the respective security notices.

Preventive measures for improving operating safety

If the LT2 is used in conjunction with control and monitoring technology, the operator must ensure that any breakdown or failure of the LT2 device does not cause inadmissible damage or

dangerous operating states. To avoid faults which could cause direct or indirect personal or

material damage, the operator must ensure that:

• the responsible maintenance personnel can be reached at any time and as quickly as possible

• the maintenance personnel are trained to correctly respond to faults with the LT2 Lambda

Transmitter and the associated malfunctions

• in the case of doubt, the faulty equipment can be switched off immediately

• A switch-off does not lead to direct follow-up problems.

Avoiding consequential damages

To avoid consequential damages in the event of failure, which could cause direct or indirect

personal or material damage, the owner must ensure that qualified personnel can assess the

faults and initiate appropriate measures to tackle them.

8

Page 10

2 For Your Safety

2.5 Protection Against Emissions from Gas Carrying Channels

Protect against gas leakage from the gas-bearing channel

The Lambda Probe LS2-K is fitted directly to the gas-bearing channel via a counterflange. If

the Lambda Probe LS2-K is dismantled, depending on the plant but particularly in the case of

excess pressure, aggressive and / or hot gas can seep out of the channel and this could pose

a serious health hazard to an unprotected operator if suitable safety measures have not be

taken previously. For prevention, suitable protective measures must be taken in advance.

WARNING!

Discharge of hot, corrosive gases!

In the event of high pressure and temperatures higher than 200 °C in the gas duct, gas escapes when the LS2-K Lambda Probe is removed.

Switch OFF the application before opening.

Wear protective clothing and a protective mask.

Affix appropriate warnings near by.

Close aperture immediately after finishing work.

WARNING!

Danger from electrical shock

The device contains live parts and touching these parts could cause electric shock.

Before opening the housing, disconnect the mains plug!

9

Page 11

2 For Your Safety

2.6 Commissioning/Decommissioning

2.6.1 Decommissioning, Storage and Commissioning

The Lambda Transmitter and the Lambda Probe form a high quality electronic system. Treat

them with care at all times, including during shut-down, transport and storage.

Shut-down

NOTICE

Do not switch the Lambda Transmitter off as long as the Lambda Probe is mounted; including

when the relevant facility has been shut down. Residual gases cause corrosion and may damage system parts.

Do not store the instruments outdoors without protection!

Always store in a dry place, if possible in the original packaging.

When dismantling, protect cable ends and plugs against corrosion and dirt. Corroded

plugs may cause malfunction.

If possible, transport in the original packaging.

WARNING!

Danger of burns!

If the probe is operated when removed, there is a danger of burns on the

probe housing.

Never lay the probe on flammable material and heat it up.

Wear protective gloves

Return to service

According to chapter 4 Commissioning/Decommissioning.

2.6.2 Environmental Protection, Waste Disposal

The design of Lambda Transmitter and LS2-K is also based on environmental considerations.

The modules can easily be separated and sorted into distinct types, and recycled accordingly.

10

Page 12

3 Technical Description

3 Technical Description

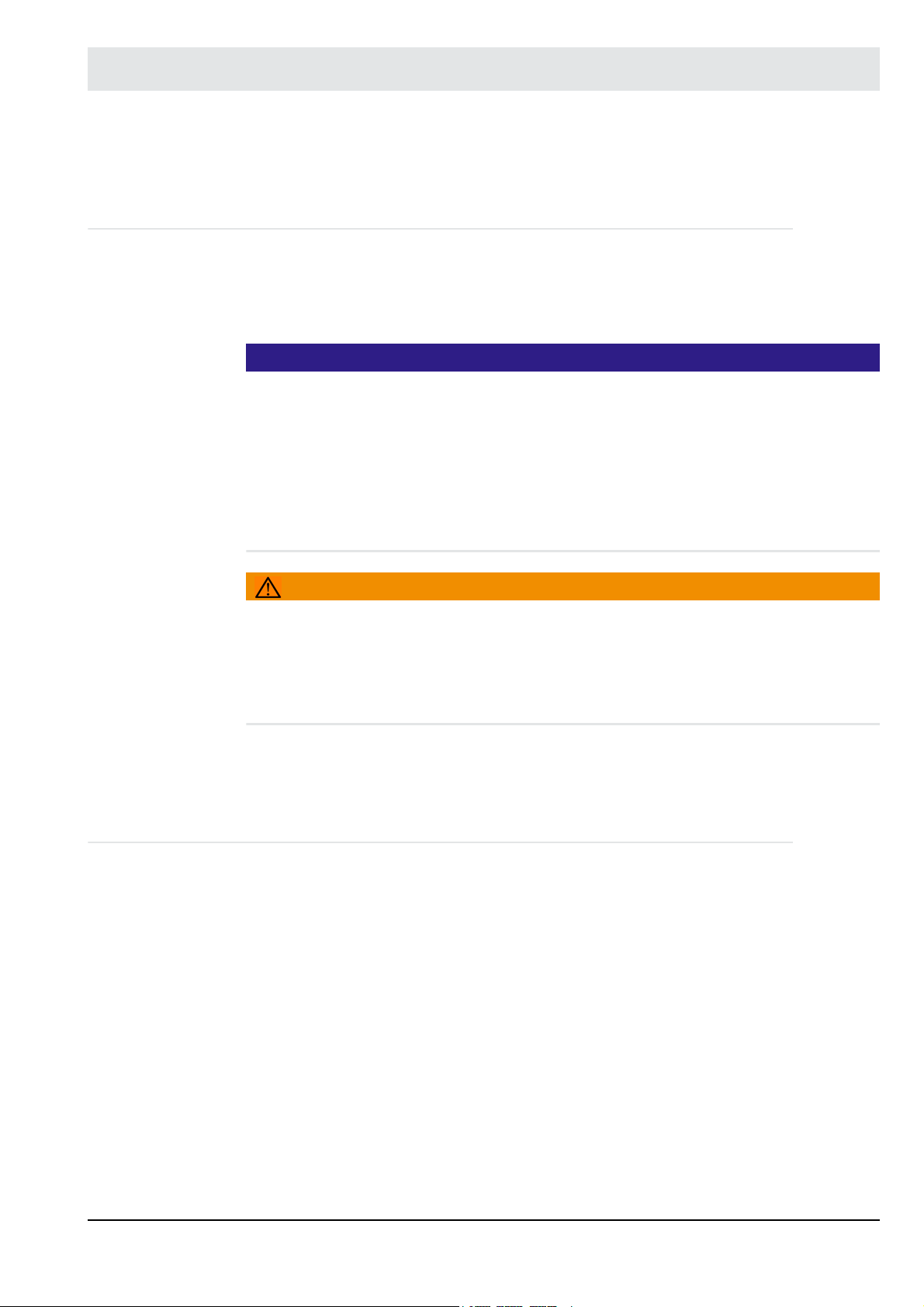

3.1 LT2-K LS2-K Structure in Principle

Fig. 3-1 LT2 LS2-K system components.

1 Pre-filter type 650R2055

2 Counter flange DN65PN6 type 655R0179/0180

3 Lambda Probe LS2-K with semi-automatic calibration unit type 656R1030/1031/1032

4 Probe connection box (PCB)

5 Connection for offset/test gas calibration – 0.3 bar instrument air, test gas for example:

3 vol. % O2 200 ppm CO 100 ppm H2 in N

6 Outlet port reference air

7 Reference air inlet, pressure reducer (on site) instrument air 0.3 bar or reference air pump 40 ... 60 l/h

8 Probe heater

9 Probe signal and pressure sensor

10 Flange seal Klinger Sil C-4400 type 655P4209

11 Measuring gas max. 400 °C/752 °F

Lambda Transmitter LT2-K type 657R102/103/104 in version 3K semi-automatic calibration

• A = in Wall mounting housing

In the case of the design with semi-automatic calibration device, the instrument air for offset

adjustment and the test gas must be connected to the probe by hand, one after the other, and

the necessary quantity must be set as well.

Pressure sensors are installed in the probe connection box and included in delivery.

A pump unit for reference air is available on request as an option if instrument air is not available.

2

NOTICE

A pump unit for reference air is necessary only if instrument air is not available!

11

Page 13

3 Technical Description

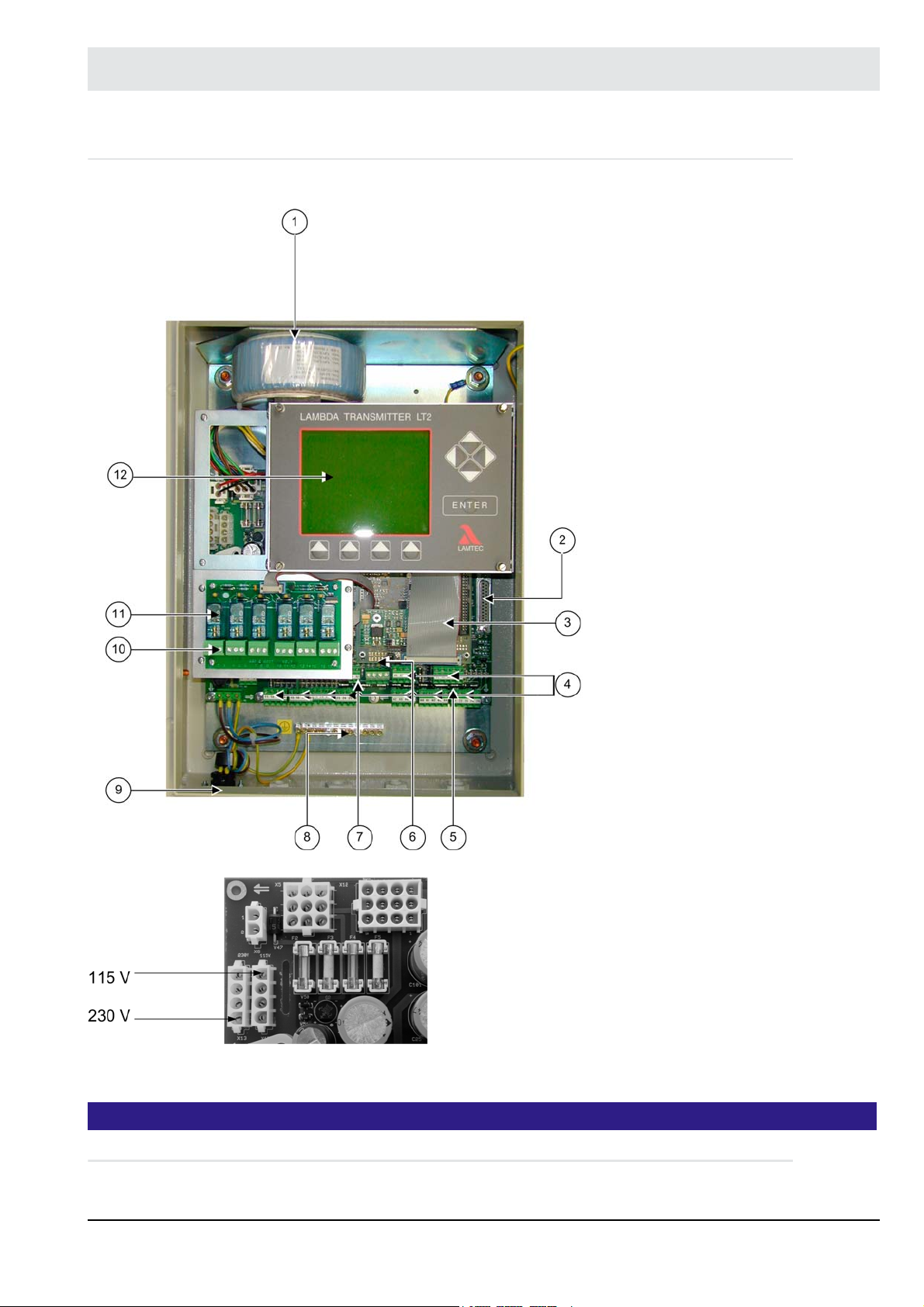

3.2 LT2-K LS2-KV Structure in Principle

Fig. 3-2 System overview LT2-K LS2-KV

A Complete probe with counter flange and PCB

B LT2-KV Lambda Transmitter in wall mounting housing IP65 with integrated reference air pump (option),

type 657R102, steel sheet

1 LS2-KV Lambda Probe with fully automatic calibration unit type 650R2050/2051/650R2052

2 Sintered metal pre-filter type 650R2055

3 Counter flange DN65PN6 type 655R0179/0180

4 Flange seal Klinger Sil C-4400 type 655P4209

5 Reference air pump (option) type 657R1060, only necessary if there is no instrument air available.

6 Display and Operating Unit

7 Relay module, option for fully automatic calibration

With the fully automatic calibrating unit, the instrument air (test gas 1) and the test gas (test

gas 2) can be permanently connected to the probe at 0.3 bar upstream pressure.

12

Page 14

3 Technical Description

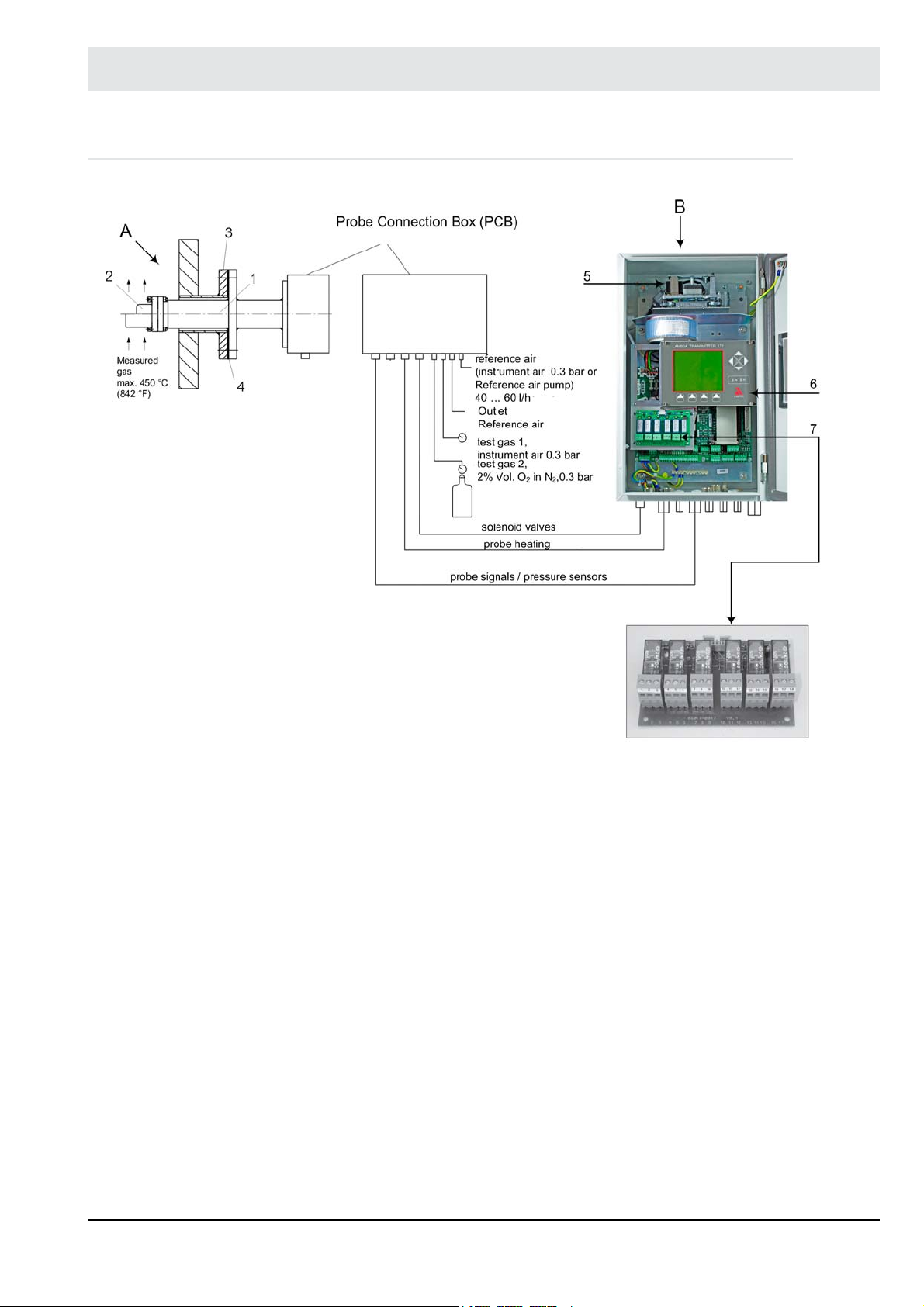

3.3 LS2-K / LS2-KV Lambda Probe

The wiring between the LS2-K / KV Lambda Probe and the LT2-K Lambda Transmitter is done

with conventional, screened cables over terminal blocks; see the wiring diagram in chapter

10.2 Connection Diagram for LT2-K/LS2-K (semi automatic calibration)10.3 Connection Diagram for LT2-KV/LS2-KV (fully automatic calibration)

1 Probe connection box (PCB)

Fig. 3-3 Lambda Probe LS2-K with semi-automatic

calibration

1 Absolute pressure sensor

2 Differential pressure sensor

3 Throttle for calibration gas

4 Throttle for reference air

5 Stop cock for calibration gas

6 Hose connection for test gas

(instrument air 0.3 bar)

7 Air outlet

8 Hose connection for reference air

(instrument air 0.3 bar)

9 Electrical connection probe to LT2

probe connection

10 Electrical connection

absolute pressure sensor to LT2,

analogue input 2

11 Electrical connection

differential pressure sensor to LT2

analogue input 1

Fig. 3-4 Interior view of probe connection box LS2-K with semi-automatic calibration

13

Page 15

3 Technical Description

Fig. 3-5 Lambda Probe LS2-KV with connection

for fully-automatic calibration

1 Probe connection box (PCB)

1 Absolute pressure sensor

2 Differential pressure sensor

3 Solenoid valve 2 (shut-off valve)

4 Throttle for calibration gas

5 Solenoid valve 1 (shuttle valve)

6 Throttle for reference air

7 Hose connection for reference air

(instrument air 0.3 bar)

8 Outlet for reference air

9 Hose connection for test gas 1

(instrument air 0.3 bar)

10 Hose connection for test gas 2

(test gas 0.3 bar)

11 Electrical connection of probe

12 Electrical connection of

solenoid valves

13 Electrical connection of

differential pressure sensor

14 Electrical connection of absolute

sensor

Fig. 3-6 Interior view of probe connection box Lambda Probe LS2-KV with fully-automatic calibration

14

Page 16

3 Technical Description

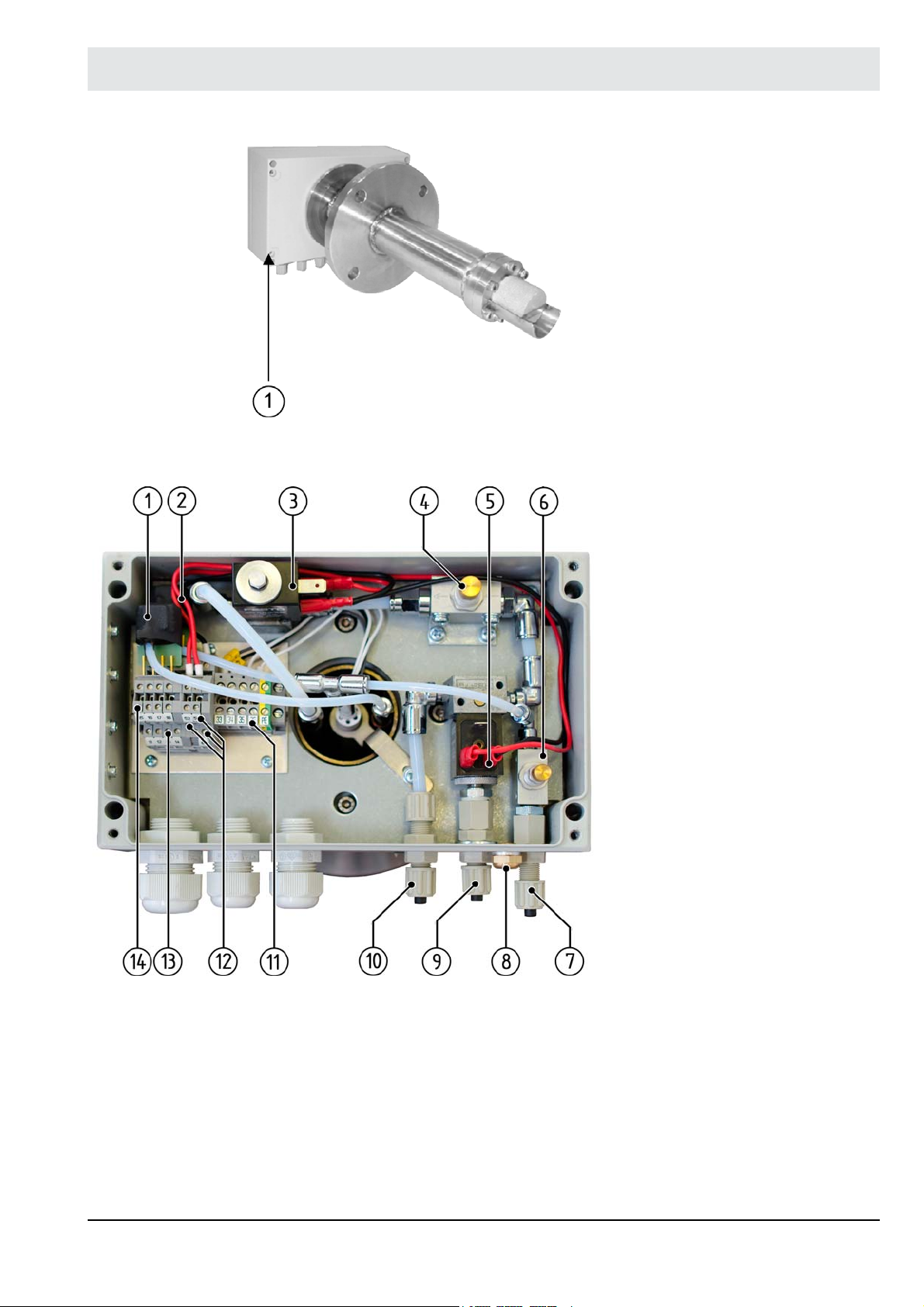

3.4 LT2-K Lambda Transmitter

The LT2 Lambda Transmitter is the analysing unit for the LS2-K Lambda Probe. It contains all

the components required in order to operate the LS2-K Lambda Probe and to evaluate the

measurement signal. It also has additional analogue and digital inputs and outputs for sending

out measurement signals and for operating, status and limit value messages as well as serial

interfaces for connecting to a PC and for connecting to other LAMTEC devices. A universal

BUS interface for connecting to customers control systems is available as an option.

The following basic design is available:

• Wall-mounted housing made of sheet steel, lockable door at the front with impact-resistant

inspection window, IP65

Fig. 3-7 LT2 Lambda Transmitter in wall-mounted housing

in the following variant:

-Semi-automatic calibration and Display and operating

unit type 657R102

15

Page 17

3 Technical Description

3.5 LT2-K Lambda Transmitter Type 657R102 with Display and Operating Unit

1 Transformer probe and elec-

tronic

2 Connection for Remote-Dis-

play-Software (Option)

3 Connecting cable with plug for

display and operating unit

4 Electrical connections

5 BUS-interface alternative

LAMTEC SYSTEM BUS

(CAN-BUS)

6 Operating mode display

multifunction push button

maintenance switch

7 Monitor output

8 Protective earth terminal for

cable screening

9 Mains connection (plug)

10 Terminal bar x2

11 Relay module type 660R0017

12 Display and operating unit

Fig. 3-8 Lambda Transmitter LT2-K Type 657R102

Accessible after removing the front

panes with the main switch

POWER.

Fig. 3-9 Selection of the power supply

NOTICE

Fuse replacement F1/F3 when changeover 230/115 VAC necessary !

16

Page 18

3 Technical Description

Fig. 3-10 Connector for power supply

NOTICE

The dimensions of the wall mounting housing changes with the selection of the option ’with

reference air pump’.

3.6 Display and Operating Unit

1 - L

2 - N

3 -

4 - PE

Fig. 3-11 Connector

1 = Cursor keys

2 = ENTER key

3 = Menu keys

Standard for LT2-K in wall mounting housing type 657R102

17

Page 19

3 Technical Description

3.7 Cold-start Delay

Coldstart delay is used for suppressing incorrect measured values while the probe is heating

up. A cold start delay is activated always after ’Power off’ or the replacement of a probe.

The cold start delay can be aborted at any time:

• by using the multi-function pushbutton

• by the display and operating unit (optional), see separate publication

• by using the remote display software, see separate publication

During the cold start delay or in fault condition the following values are output:

• a default value (factory setting of O

• the ’current measurement value’ (factory setting parameter 362)

The internal resistance of the zirconium dioxide measuring cell is monitored during the cold

start delay. It is only allowed to measure at the end of a specified time if the value is below a

threshold value of 200 Ω.

3.8 Analogue Outputs 0/4 … 20 mA, 0/2 … 10 V

2

0 Vol. %, parameter 361)

by plug-in cards on processor card of LT2-K (max. 4) – can be plugged in at any time

• Type 657R0050 non-floating (1 channel)

Fig. 3-12 Analogue output card Fig. 3-13 X-Jumpers for voltage output 0/2 ... 10 V

Y- Jumpers for current output 0/4 ... 20 mA

The jumpers switch only the hardware between current output and voltage output

The selection of 0 ... 20 mA or 4 ... 20 mA and 0 ... 10 V or 2 ... 10 V is set in parameter 531.

Type 657R0051 is floating with a maximum potential difference of 20 V (only possible with

output 1 and output 2).

Fig. 3-14 plug in card for floating

output type 657R0051

18

Page 20

3 Technical Description

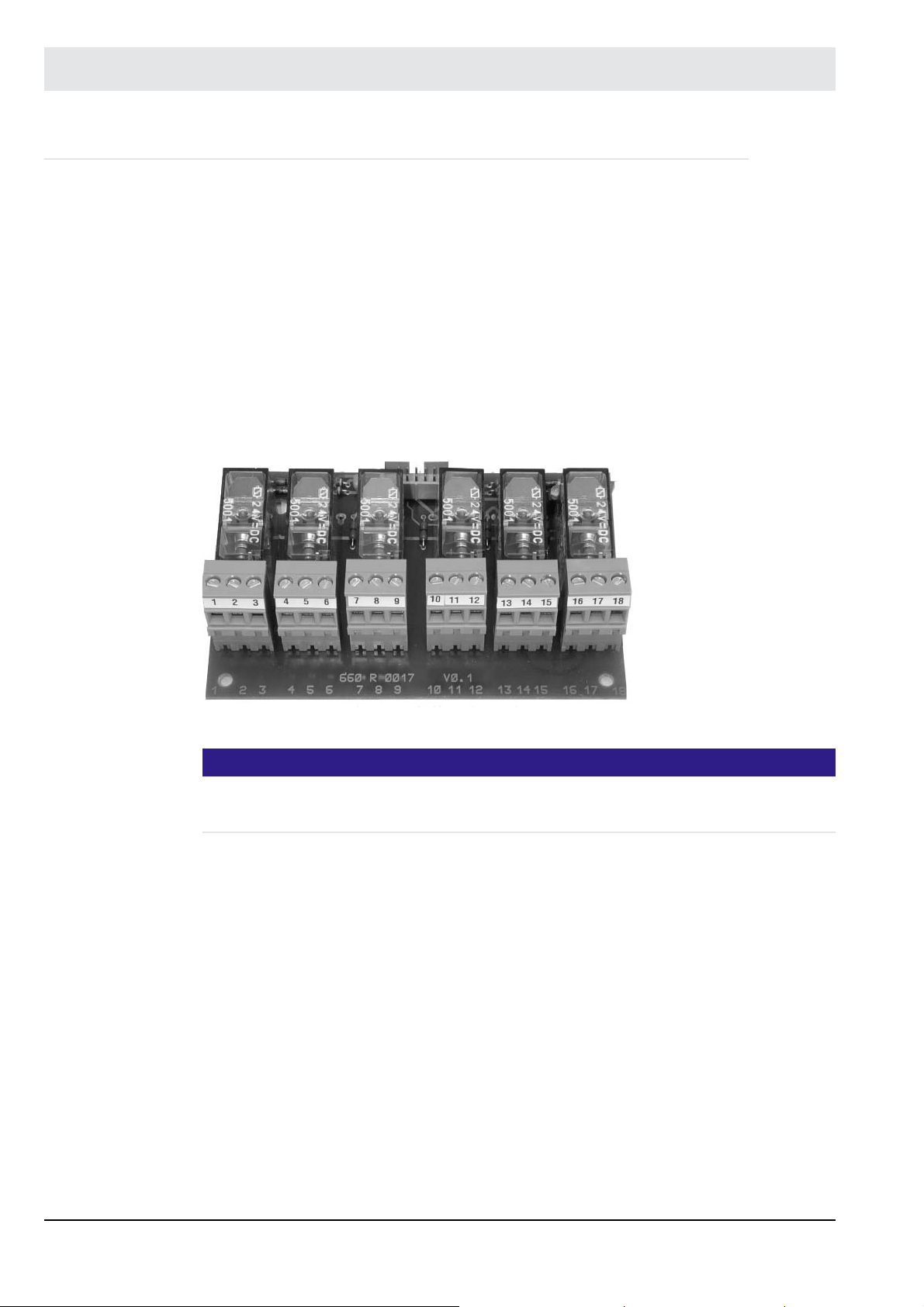

3.9 Digital Outputs

Parameter group 1030 to 1099

Digital output 1: Via internal relay (1 switch over) to LT2supply section

Digital output 2 to 7:

type 660R0857

(optional)

The outputs can be configured arbitrarily via the (optional) display and operating unit and the

Remote Display Software. (parameter 1030 ... 1099)

electronics

1 ... 48 VDC/AC, 3 A

as standard

0 ... 230 VAC, 2 A

Via internal relay module

6 relays (1 switch over), switching capability

max. 230 VAC, 4 A

alternative (on request)

Fig. 3-15 Relay module type 657R0857

NOTICE

To avoid EMC faults shield the branch lines of the relay modules.

When using unshielded cables loop them twice trough the provided ferrite ring.

Options for LAMTEC Combination Probes

– Semi-automatic calibration (available for probes with attribute ’K’ )

– Pump for reference air (available for probes with attribute ’K’ and ’Ex’)

– Purging unit in combination with bypass tube (available for probes with attribute ’HT’)

– Purging of the preliminary filter (available for KS1D-KA and KS1D-KAF)

– Automatic regeneration of the ZrO2 measuring cell by short feeding with air for biomass

19

Page 21

3 Technical Description

3.10 Analogue Inputs (Optional)

Parameter groups 570 ... 609

By plug-in card on the electronic unit of the LT2-K power supply (max. 2)

• Analogue input card 0/4 ... 20 mA type 663P6001

• Analogue input card 0/4 ... 20 mA with 24 VDC supply for transmitter for LT1/LT2

type 663P6002

• Analogue input card for potentiometer 1 ... 5 ktype 657P6000

• Temperature input for Pt100

measurement range alternatively 0 ... 320 °C or 0 ... 850 °C (must be specified by order)

type 657R0890

• Additional pressure sensors for:

– absolute pressure

– differential pressure on request

– other modules on request

3.11 Digital Inputs

Parameter group 1170 to 1249

8 digital inputs to LT2 supply section electronics, 24 VDC, 6 mA either referenced to instrument potential or floating (see chapters 10.1 Electrical Connection to 10.4 Electrical Connec-

tion), arbitrarily configured via (optional) display and operating unit and service and diagnostic

software.

20

Page 22

4 Commissioning/Decommissioning

4 Commissioning/Decommissioning

4.1 Display and Operating Unit of the LT2-K Lambda Transmitter

The LT2's operation and the display of measured values, operational and error messages take

place by the (optional) display and operating unit, or by a PC in combination with the Remote

Display Software. The LT2 itself has only limited operating capabilities, which do not allow LT2

to display or process all the functions necessary for operation, maintenance and servicing.

1 Display of operating

mode

2 Warning /

Fault display

3 Maintenance switch

4 Multifunction key

Fig. 4-1 Internal display and operating elements on the processor

board

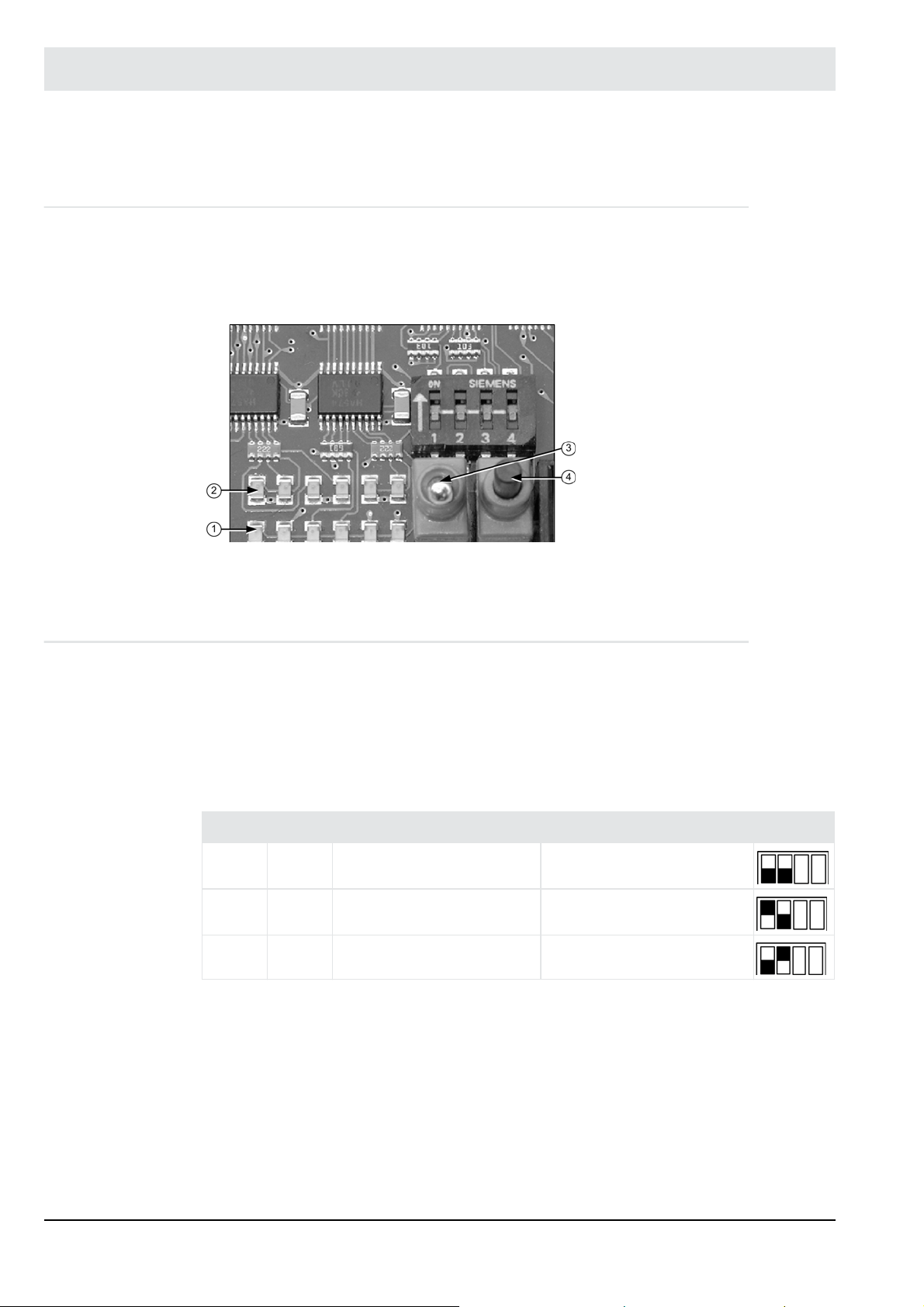

4.2 Monitor Output

The monitor output (terminals 31 (-) and 32 (+)) makes it possible to connect a multimeter for

example. The device indicates the following values by the monitor output:

–O2 measured value

– Probe voltage [U]

– The measuring cell's AC internal resistor [Ri]

DIP switch processor card

SW 1 SW 2 Monitor output function

OFF OFF O2 measured value 0 ... 2.5 V = 0 ... 25 % vol O

ON OFF O2 probe voltage (U-O2) 0 ... 2.5 V = 0 ... 250 mV

OFF ON O2 cell’s internal resistance 0 ... 2.5 V = 0 ... 250

Input resistance of the connected measuring device greater than 10 k.

2

21

Page 23

4 Commissioning/Decommissioning

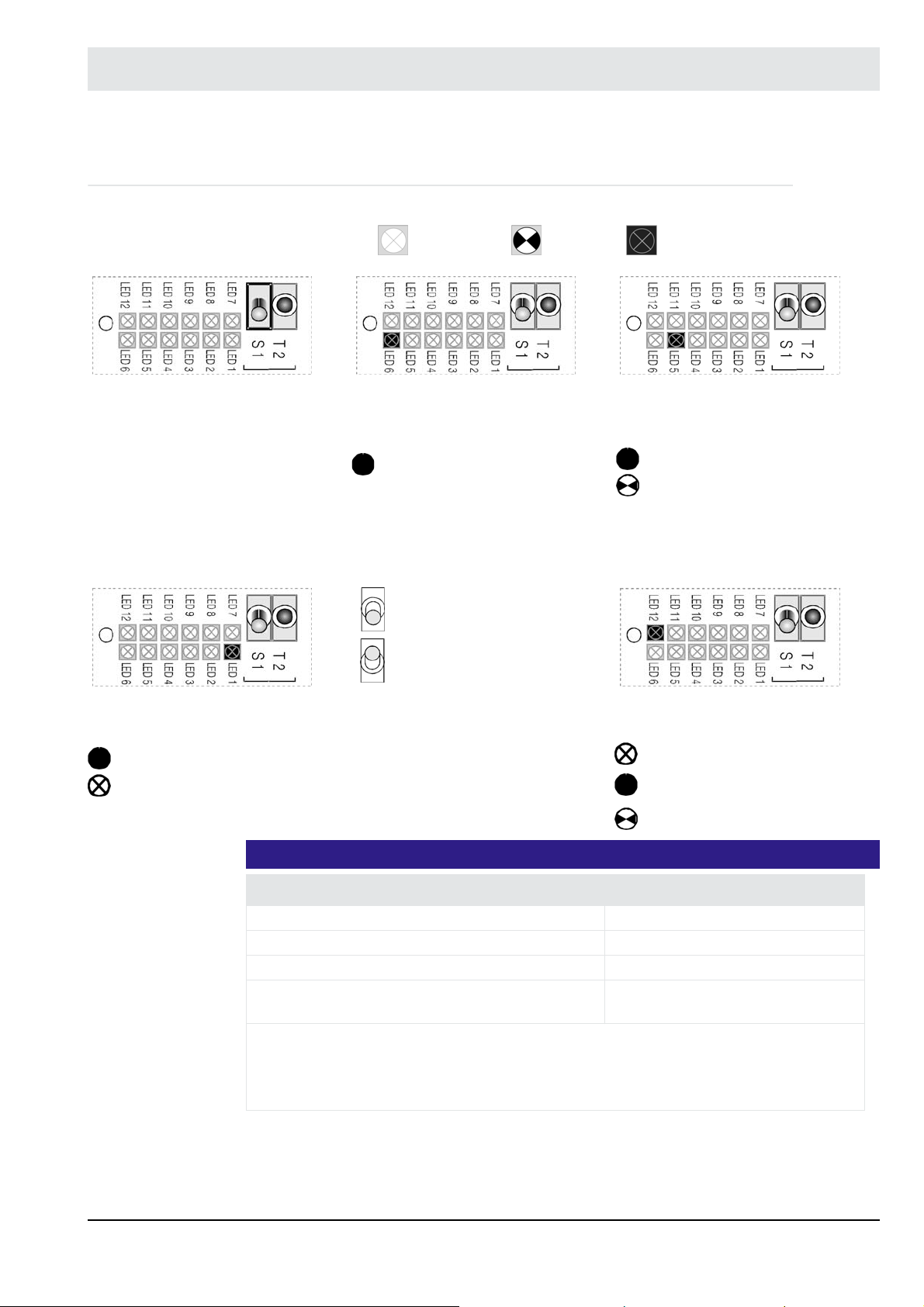

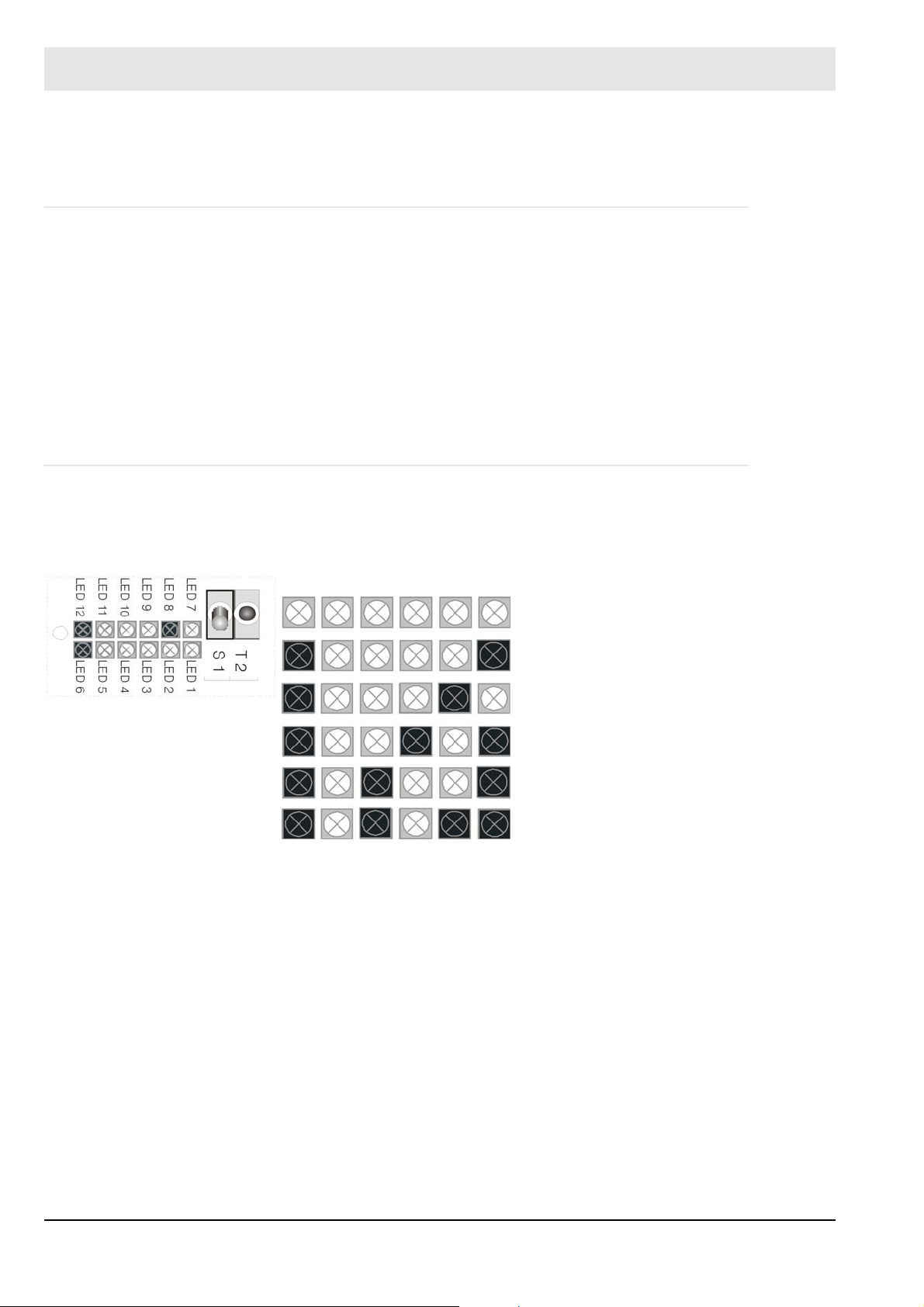

4.3 Internal Display and Operating Elements

Multifunction key T 2

Maintenance switch S 1

Legend: LED

is off

Operation (green) LED 6 Operating mode (green) LED 5

Operation Measurement

Maintenance mode off

Maintenance mode on

flashes

lights up

Calibration

Offset compensation (flashes slowly)

With test gas/comparative measurement (flashes quickly)

Maintenance (orange) LED 1 Warning/fault (red) LED 12

Maintenance mode active

Normal operation

NOTICE

Function Key operation

Toggle the displayed warning/ fault Press briefly

Reset the displayed warning/fault Press for longer than 3 sec*

Abort cold-start Press for longer than 3 sec**

Trigger an offset calibration to ambient air Press key for longer than 3 sec

* Some warnings and faults cannot be reset if the error is still present or the routine is

still running.

** If at least one warning or fault is still present, the key must be pressed for longer than

6 seconds.

No warning / fault

At least one warning present

At least one fault present

during measurement**

22

Page 24

4 Commissioning/Decommissioning

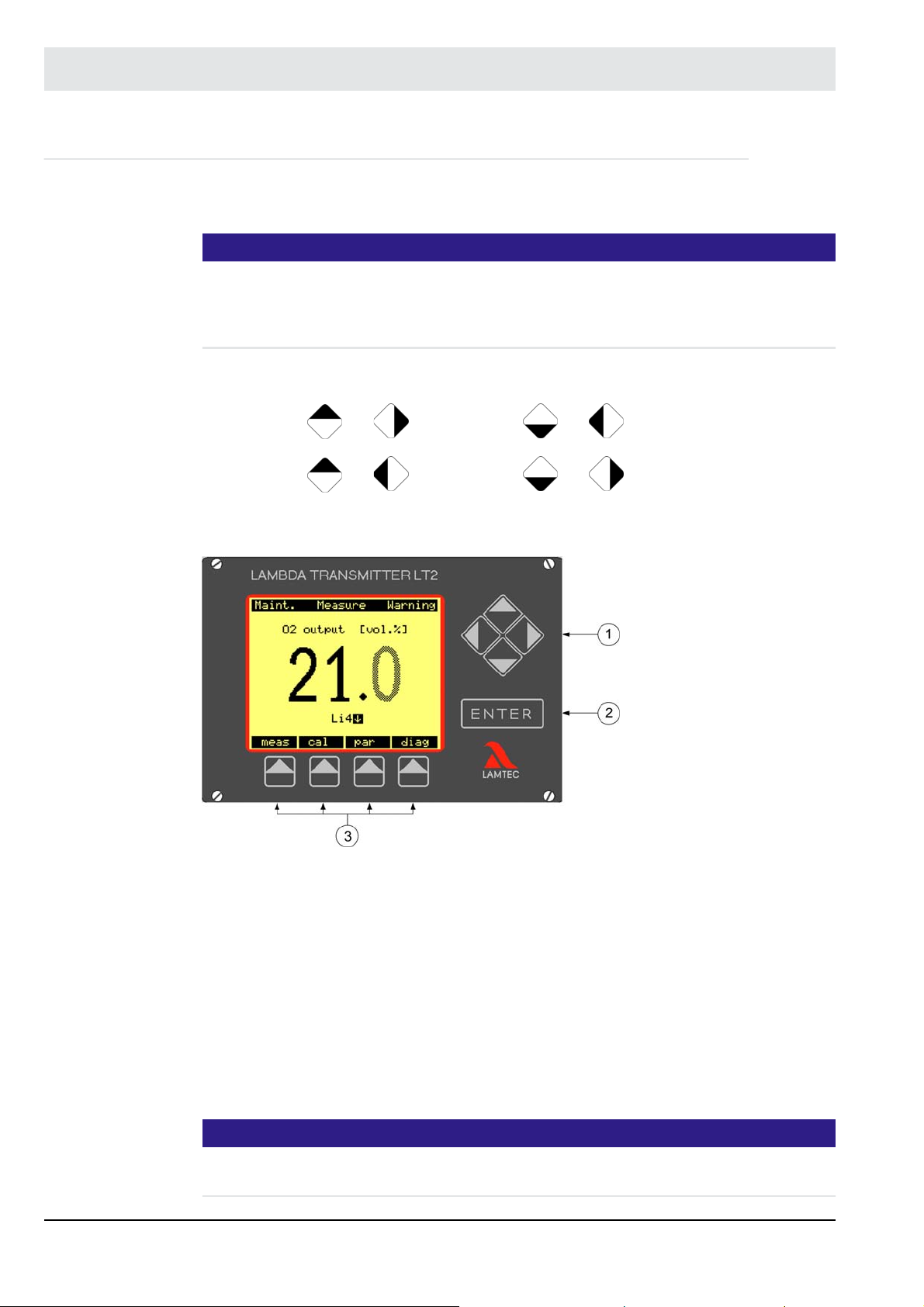

4.4 Display and Operating Unit Type 657R0831 (Option)

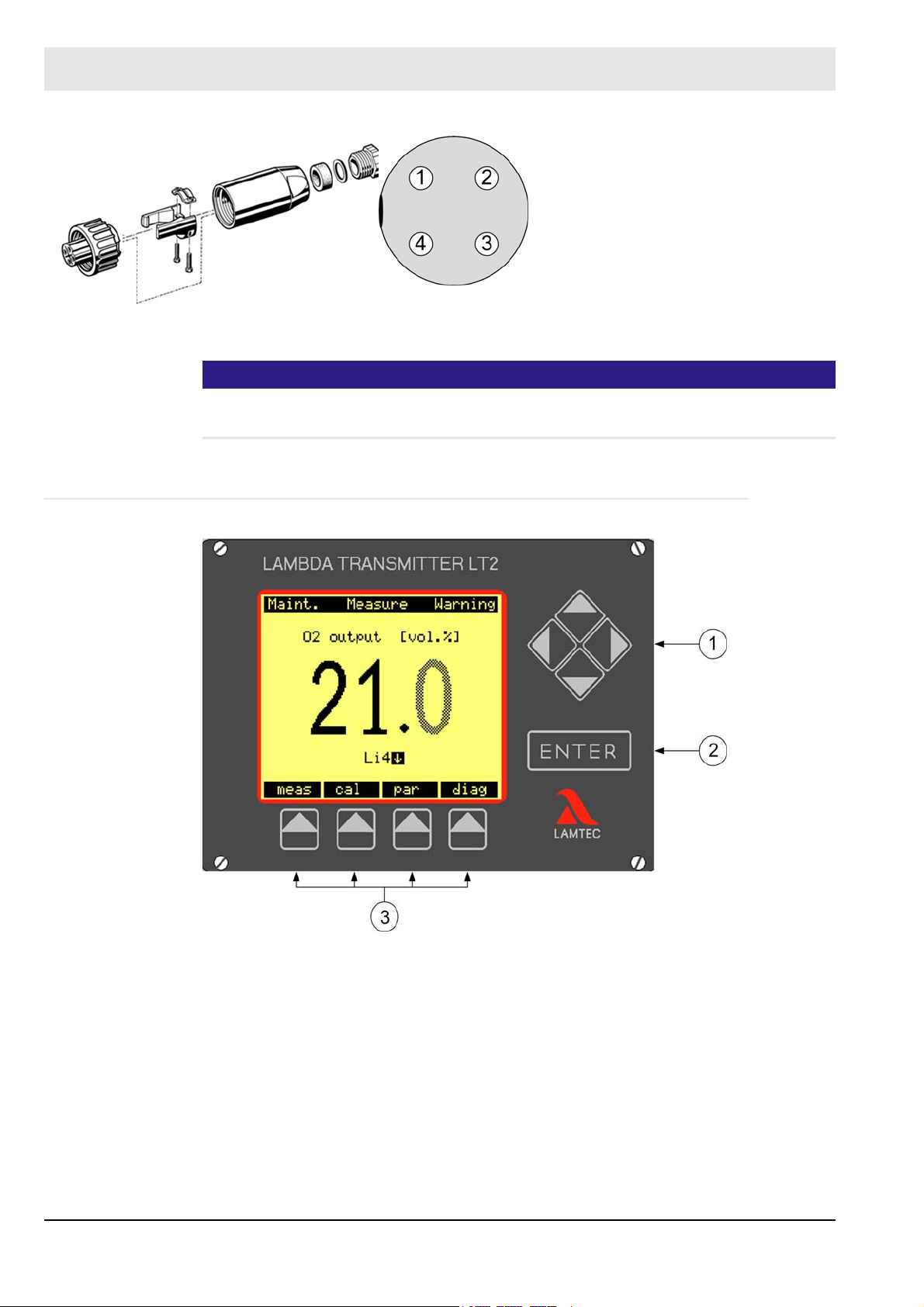

Fig. 4-2 Display of LT2-K with key assignment shows the display of the LT2 Lambda Transmitter. It consists of a LCD display, the cursor keys, the ENTER key, and the menu keys.

NOTICE

- The cursor keys are used to select measurement values, parameters or functions in the

visual area of the display. The keys are also positioning the cursor for entering and editing.

- The ENTER key activates, confirms and ends the editing mode.

- The menu keys are assigned to the menu which is shown in the display

For adjusting brightness and contrast use the cursor keys:

contrast +: + contrast -: +

brightness+: + brightness -: +

The menu keys have the following functions (from left):

measurement [meas] calibration [cal] set parameter [par] diagnoses [diag].

Fig. 4-2 Display of LT2-K with key assignment

1 = Cursor keys

2 = ENTER keys

3 = Menu keys

The menu keys are given in the terms which describe the functions of the LT2 Lambda Transmitter written in an abbreviated form.

Menu keys meas: measurement (measure)

cal: calibration (calibration)

par: parameter setup (parameterise)

diag: diagnosis (Diagnostics)

NOTICE

Only limit values which are activated in parameter 930/940/950/960 are displayed (release

level ’Service’).

23

Page 25

4 Commissioning/Decommissioning

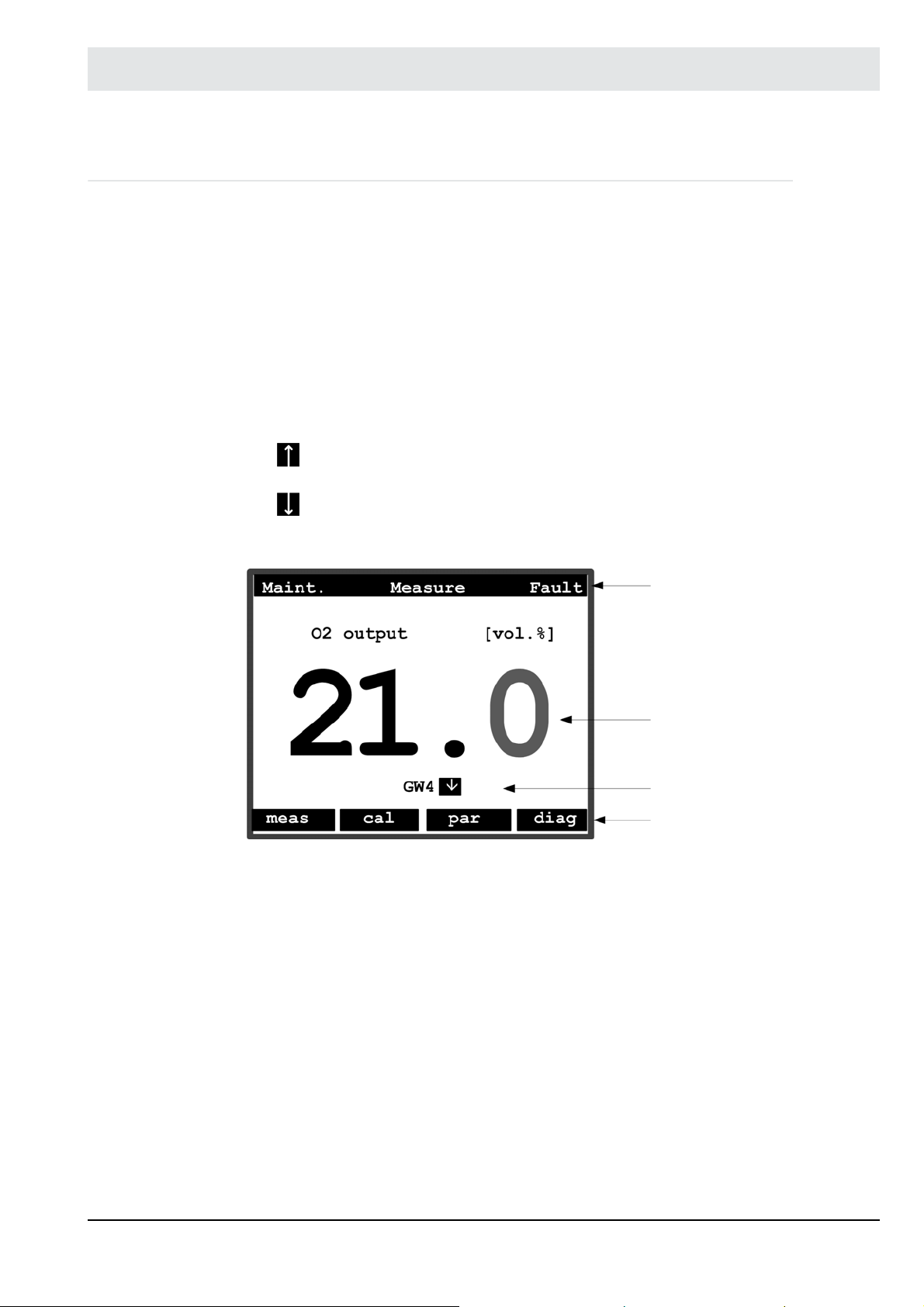

4.4.1 Display

The display is devided into four areas: (see Fig. 4-3 Arrangement of the display):

1. The status line at the top of the display shows the following:

• On the left side, whether the maintenance mode is activated or not

• In the centre, the current operating status

• On the right, if warnings or faults are present in the system

• Faults are also indicated with the flashing of the status light.

2. The measurement value, shown in the centre of the display area

3. The limited value display shows the following

GW = limit value activated

limit value exceeded

value below the limit value

4. The menu items to which the menu key below is allocated.

Fig. 4-3 Arrangement of the display

1 Status row

2 Measurement value

3 Limit value

4 Menu row

24

Page 26

4 Commissioning/Decommissioning

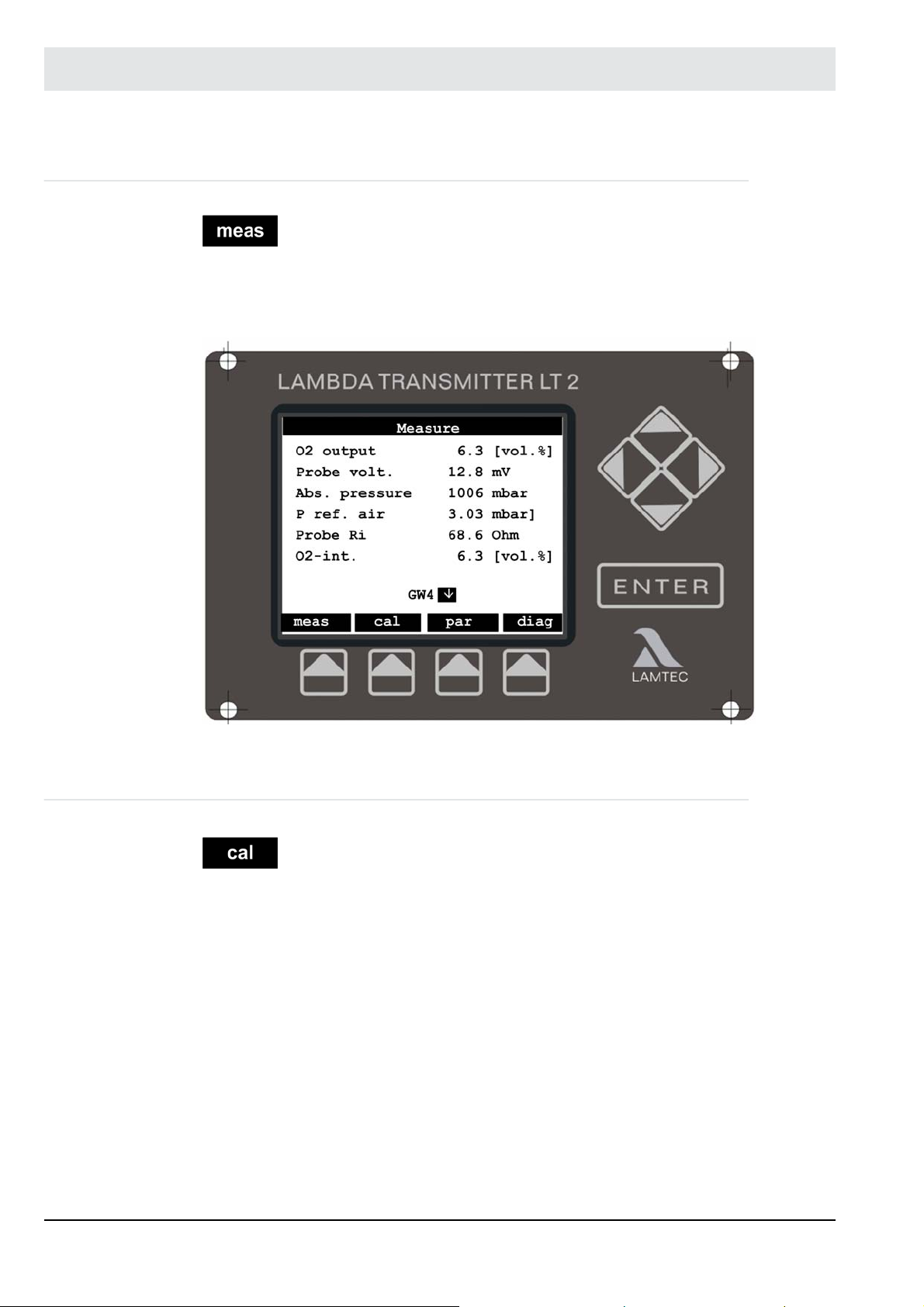

4.4.2 Menu Function 'meas'

When pressing the [ meas ] the display switches to a large representation of the measure-

ment value that has been selected with the cursor keys (up, down) (see 4.4 Display and Op-

erating Unit Type 657R0831 (Option)). Pressing the [ meas ] key repeatedly switches the

display back to a listing of all the measured values.

Fig. 4-4 LT2 display meas

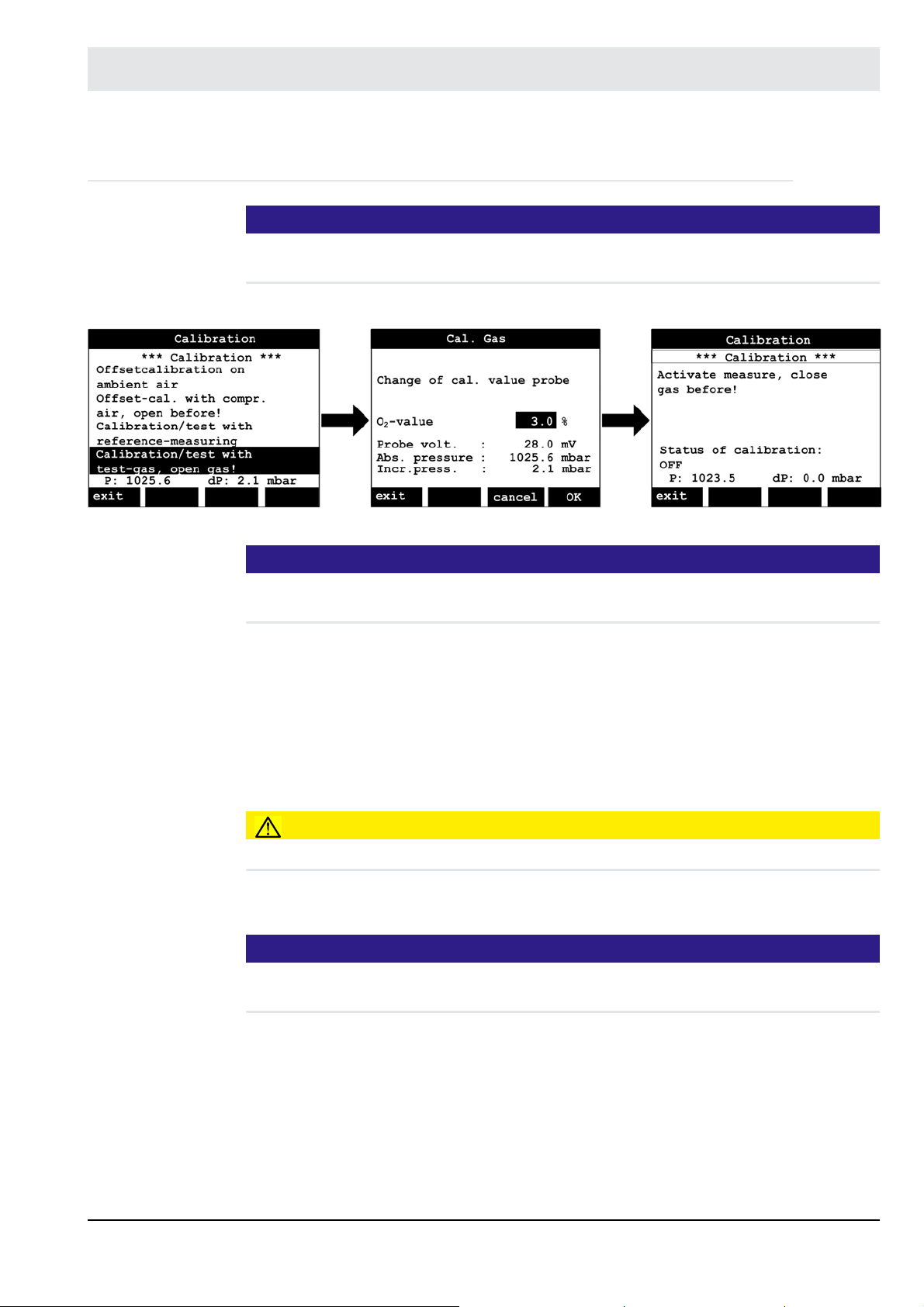

4.4.3 Menu Function 'cal'

Pressing the [cal] menu key, “start calibration” appears on the display. When the calibration

is activated 4 calibration functions are available Fig. 4-5 Calibration functions:

• Start offset calibration in ambient air (see chapter 4.7.1.2 Performing an offset calibration

to ambient air)

• Start offset calibration with compressed air (for semi-automatic calibration open the shutoff valve in the probe connection box, see chapter 4.7.1.3 Performing an Offset Calibration

with Compressed Air).

• Start calibration with a comparative measurement (manual calibration function)

• Start calibration with test gas (for semi-automatic calibration open shut-off valve in the

probe connection box)

Select the required calibration function by the up/down cursor keys. Confirm the selected function with the ENTER key. This triggers the calibration procedure. The automatic calibration

mode can be interrupted by the menu function ’Break’ calibration before end; back to measure’.

25

Page 27

4 Commissioning/Decommissioning

During manual calibration the calibrated value can be change by the menu function ’Change

of calibration value probe LS2-K/LS2-KV’.

Fig. 4-5 Calibration functions Fig. 4-6 Menu functions

After calling up this menu function, the amendment procedure in the displayed sub-menu can

be terminated with the [ cancel ] menu key. Alternatively confirm the O

menu key.

Quit manual calibration with ’Break calibration before end’ (the O2 value is retained).

value with the [ OK ]

2

NOTICE

The manual calibration mode remain active for a maximum of 15 minutes This is followed by

switching automatically back to the measurement mode.

If the [ cal ] is called up during cold start, the cold start can be aborted.

A substitute O2 value is displayed during calibration procedure. Measurement or display of a

meaningful O2 value is only possible in the operational mode, i.e. after completing the calibration.

NOTICE

Check parameter 151 after the offset calibration.

The value must be 40 1 respectively 15 1.

Recommended test gas: 3 % oxygen 97 % nitrogen

26

Page 28

4 Commissioning/Decommissioning

4.4.4 Menu Function 'par'

After calling up the [ par ] menu the menu to set parameters opens.

Fig. 4-7 Parameter menu

Access to the parameter menu is divided into the following authorization levels:

• Operation level

• Customer level requires a password

• Service level requires a password

• Factory level requires a password

NOTICE

The password for the customer level can be individually set by the customer, (see chapter

4.4.12 Customer Password Input).

The display shows the current access level. The following functions can be chosen from the

menu row:

• [ exit ] returns to the start menu

• [ psw ] provides the change of the release level by password

• [ view ] shoes the parameter settings. All parameter are shown regardless of the release

level.

• [ change ] provides the changing of the parameter settings. Only parameters which are

accessible with the actual access level are displayed.

NOTICE

More than 3000 parameters can be changed by the different access levels.Recommendation:

Use the function [ change ] to avoid confusion.

Fig. 4-8 Password entry

27

Page 29

4 Commissioning/Decommissioning

4.4.5 Menu Function 'psw'

[ psw ] calls up the password input menu. The authorization level* is displayed. The functions

which a in the menu are described below:

• [exit] returns to the [ par ] menu.

• [ clear ] resets the access level to ’Operation’ *.

• [ ---- ] shifts to the previous letter in the alphabet.

• [ ++++ ] shifts to the following letter in the alphabet.

The up/down cursor keys act similarly to [ ++++ ] and [ ---- ]. Left/right move the input mark

along the password. Once the correct password is entered, the corresponding authorization

level is displayed and is retained on leaving the menu with [ exit ]. If no key is pressed for

some time, the access level is reset to operation level.*

4.4.6 Menu Function 'view'

[view] opens the parameter menu.

The following functions are available in the menu bar:

• [exit] returns to the menu function [par].

• [s/l] toggles between display formats:

• [group-] scrolls back one parameter group.

• [group+] scrolls forward one parameter group.

Short:

– Only the parameter number and the cur-

rent value are displayed.

Medium:

– The parameter number and the current

value are accompanied by a short

description.

28

Page 30

4 Commissioning/Decommissioning

[ group- ] changes one parameter group back.

[ group+ ] changes one parameter group forward.

All available parameter groups are listed in the appendix. The left/right cursor keys correspond

to the key-function of [ group - ] and [ group + ].

Flashing arrows in the right-hand margin show that not all parameters in a group are visible in

the display. The up/down cursor keys can be used to scroll through the parameters.

As an example, we explain below the status row shown in the Long format:

• If not all the parameters in a group are visible in the readout, this is indicated by flashing

arrows in the right-hand margin. The up/down cursor keys can be used to shift the parameters and make them visible.

• *kw*_30_____[ 12 ; 42 ]_____

The asterisks and underline characters (* and _) are fillers.

• K indicates the customer access level

(b = operation, k = customer, s = service, f = manufacturing)

• W indicates the parameter type

(write = change, read = read only).

• 30 = default value (base value in EPROM)

• [ 12 ; 42 ] is the possible range within which the parameter can be changed

For some parameters no default value and interval is available!

Display long:

– The same as Medium, but with an addi-

tional parameter status line.

29

Page 31

4 Commissioning/Decommissioning

4.4.7 Menu Function 'change'

[ change ] allows parameter values to be amended. The menu bar for the sub-menu is the

same as the [ view ] menu (see chapter 4.4.6 Menu Function 'view').

Unlike this the parameter which should be changed is displayed inversely (bright letters on

dark ground). Select the parameter with the cursor keys (up, down). Confirming with the

ENTER key activates the edit mode. The value flashes during edit mode.

A selected parameter is displayed in three different ways:

The parameter can be changed

The parameter cannot be changed

Edit mode is active

The parameter value can be changed with the cursor keys up/down (left/right for multi-digit

values). Menu row functions:

• [ esc ] returns to the [ change ] menu without saving the changed value in the parameter.

• [ dflt ] sets the default value (factory settings).

• [ OK ] accepts the changes value and returns back to the [ change ] menu or to the

[ ENTER ] menu.

This leads back to the [ change ] menu. Other parameters can be changed.

30

Page 32

4 Commissioning/Decommissioning

4.4.8 Menu Function 'diag'

On pressing the [diag] key, the display switches to warnings and faults. Use the up/down cursor keys to select individual warnings or faults, or limit values.

NOTICE

Limit values are displayed only if they are also activated by parameters 930/940/950/960 (service level).

The selected and inversely displayed warning or fault can only be acknowledged or reset by

the ENTER key.

Fig. 4-9 Displaying faults and warnings

NOTICE

Some faults or warnings cannot be reset by acknowledgement. The cause of the fault or warning must be removed.

If a limit value is selected and confirmed with the ENTER key, the display switches to the limit

value menu.

Fig. 4-10 Limit value menu

31

Page 33

4 Commissioning/Decommissioning

Description:

Limit value 1 is set by parameter to O

Switching point: exceeding 10.0% per volume O

short fall 3.0 % per volume O

Recent O2 measurement value 6.7 % per volume O2

The limit value is not set.

measurement value.

2

2

2

GW2

GW3

Limit value2 has responded. The value is higher than the limit.

Limit value3 has responded. The value is lower than the limit.

Select one limit value after another with the cursor keys. As soon as ’Manual’ or ’Acknowledge’

is selected, the limit value can be reset. Press ’exit’ to leave the limit value menu.

4.4.9 Limit values display and resetting

The current state of the limit values and the reset of the limit values are processed in three

display of the limit values group.

Parameters: 910 ... 9144

The parameters Limit Value 1, Limit Value 2, Limit Value 3 and Limit Value 4 indicate the current settings and state of the limit values.

Parameters: 914 ... 917

The Parameter Reset Li 1, Reset Li 2, Reset Li 3 and Reset Li 4 trigger the reset of the limit

values outputs if the operating modes MANUAL RESET or ACKNOWLEDGE are selected.

To reset a limit value enter ’Reset’ in the respective parameter. In MANUAL RESET mode a

reset is only possible if the monitored reference value is within the limits of Li min. and Li max

Content of Parameters 910 ... 917

0 = Off

1 = enable

2 = acknowledged

3 = disabled.

Off: This indicates either that the limit value in question is not in use or the monitored reference value is within the limits of Li min. and Li max.

Enable: If the display shows ’enabled’ for a limit value the monitored reference value is outside range between Li min. and Li max.

Acknowledged: If the display shows ’acknowledged’ for a limit value the monitored reference

value is outside of the good condition range and the exceeding of the limit value has been acknowledged already.

Disable: The limit value is not parameter set or the limit value is disable via digital inputs or

operating mode (par. 967)

With software version 1V33 and higher the limit values can be deactivated by the digital outputs or by the operating mode (parameter 967).

• Limit value conditions parameter 910…913: 0 = off, 1 = set, 2 = acknowledged,

3 = inactive.

32

Page 34

4 Commissioning/Decommissioning

The condition ’inactive’ is displayed, if the limit value is not set in the parameter or if the

limit value is deactivated by the digital inputs or the operating mode (parameter 967).

• All limit values can be deactivated together depending on the operating mode.

The behaviour can be set in parameter 967 in service level.

Parameter values: 0 = never, 1 = cold start (default), 2 = cold start + maintenance, 3 = no

measurement.

Faults and warnings have no influence of the limit values!

• Each limit value can be deactivated by the function ’Deakt. GWx by the digital inputs

(x={1,2,3,4}).

4.4.10 Display of the Limit Value Crossing

Fig. 4-11 Display LT2 limit values

The limit values are displayed by means of the soft-keys.

When limit value parameters 930/940/950/960 are activated in the access level ’Service’, the

display shows Li1, Li2, Li3 and Li4 depending on the currently activated limit value.

Exceeding the limit values:

Li 1

Li 2

= Li1 has been exceeded (higher than limit value)

= Li2 has been exceeded (lower than limit value)

33

Page 35

4 Commissioning/Decommissioning

4.4.11 Brightness, Contrast and Language

The parameter group ***Display*** controls the LT2 Lambda Transmitter's display and operating unit with the following parameters:

• P 970 Contrast

Adjust the display and operating unit’s contrast.

• P 971 Brightness

Adjust the display and operating unit’s background brightness

• P 972 Language

Select the display language.

NOTICE

Only 2 different languages are available simultaneously. If a language is missing in the language list, a software update may be necessary (Flash).

34

Page 36

4 Commissioning/Decommissioning

4.4.12 Customer Password Input

The password for the customer level can be set individually.

To enter a new password, at least customer access level must be set.

Enter the new password in parameter 1472 (see Fig. 4-12 Password input).

NOTICE

The system accepts the password a few seconds after the input.

The display shows the new password as ’####’. Reading this password is not possible.

Fig. 4-12 Password input

NOTICE

The factory setting of the password is ’0000’.

This corresponds to the default settings of password input.

The customer access level can be activated by switching briefly to password input and leaving

it again without making any changes.

NOTICE

The customer gets the password for service access level by a letter. Only trained personnel

may get this password. OEM customers have their own company-specific password. This is

the same in all LAMTEC devices.

35

Page 37

4 Commissioning/Decommissioning

4.5 Menu Overview

4.5.1 LT2-K Calibration Menu

Fig. 4-13 Overview of the calibration menu cal

36

Page 38

4 Commissioning/Decommissioning

4.5.2 LT2-K Diagnosis Menu

Fig. 4-14 Overview diagnosis (diag)

37

Page 39

4 Commissioning/Decommissioning

4.5.3 LT2-K Measurement Menu

Fig. 4-15 Overview measurement menu (meas)

38

Page 40

4 Commissioning/Decommissioning

4.5.4 LT2-K Parameter Menu

Fig. 4-16 Overview parameter menu (par)

39

Page 41

4 Commissioning/Decommissioning

4.6 Factory Settings

4.6.1 Device Configuration

(unless otherwise specified in the order)

Measurement range: 0. .. 30 % volume of O

2

Resolution: 0.1 % volume of O2 in the range of 0 ... 18 % volume of O2

1.0 % volume of O2 in the range higher than 18 % volume of O

Probe temperature: 1000 K (parameter 141)

Analogue output 1: 4 ... 20 mA = 0...10 % volume of O2 by parameter 531

0 ... 20 mA adjustable

Load: 0 ... 600

– Measurement range by parameters 532 and 533 freely configurable

– Relay outputs closed circuit principle

Relay output 1: Group fault message

Relay output 2: Warning and maintenance

Relay output 3: Measurement

Relay output 4: Limit value 1

Relay output 5: Limit value 2

Relay output 6: LS2-KV calibration

Relay output 7: LS2-KV calibration

– Limit values

Limit value 1: Switched OFF

Limit value 2: Switched OFF

Limit value 3: Switched OFF

Limit value 4: Value falling below < -5 mV,

Trigger delay of 3 s

Reset mode ’automatic’ (for monitoring the probe; air value)

– Digital Inputs

Input 1: Reset fault/warning

Input 2: Reset limit value indications

Input 3: Maintenance ON/OFF

Input 4: PID controller OFF

Input 5: Fully-automatic, combined calibration

Input 6: Fuel 2 (gas)

Input 7: Fuel 3

Input 8: Fuel 4

(1)

(1)

(1)

– RS 232 interface: Device 1

9600 Baud

Parity none

(1)

Parameter 836 - service level - must be set to ’digital inputs’.

without signal specification - domestic fuel EL.

2

4.6.2 Jumpers

see chapter 10.5 Jumpers

40

Page 42

4 Commissioning/Decommissioning

4.7 Measurement Start-up

NOTICE

When installing the probe and during subsequent operation, it is necessary to make sure that

the probe does not get into contact with oil, grease or with agents used to clean the tank.

This belongs to the cell and the connection area!

Poisoning or contamination of the probes is indicated by a potential difference across the air

gap of < -20 mV or > -30 mV. Furthermore, once installed the probe must always be in operation. This will prevent moisture from collecting on the measurement cell which can lead to

measurement errors and to the destruction of the probe!

CAUTION!

The temperature of the aluminium connection housing, should not be higher than +60 °C/

140 °F, because of internal built-in pressure sensors. If necessary use a longer probe with an

intermediate flange.

Do not insulate the counter flange and the housing.

• Install and setup probe

– Mounting flange in design without purge unit DN65 PN6 (through hole 80 mm/

3.15" in)

– Mounting flange in design with purge unit DN80 PN6

(through hole 125 mm/4.921" in)

CAUTION!

Do not forget the gasket between counter and probe flange.

Mounting position probe horizontal Mounting position probe vertical

Fig. 4-17 Mounting position of probe

1 Connection housing (temperature max. 60 °C/140 °F)

2 Baffle plate

3 Flow direction of the flue gas (temperature max. 450 °C/842 °F)

41

Page 43

4 Commissioning/Decommissioning

4.7.1 Measurement with LS2-K

1. Connect the probe electrically and pneumatically, see connecting diagram chapter 10.1

Electrical Connectionand 10.4 Electrical Connection.

2. Supply reference air connection and calibration gas connection with instrument air of

0.3 bar.

NOTICE

If instrument air is not available use regular compressed air for air calibration. If neither instrument air nor compressed air is available proceed one of the following options:

• Switch OFF the plant and ensure that the measuring point is in ambient air.

• Remove the probe.

3. Switch on LT2.

4. Switch to MAINTENANCE alternatively by display and operating unit in the [diag] menu or

by maintenance switch S1.

Using the maintenance switch S1

MAINTENANCE mode OFF MAINTENANCE mode ON

NOTICE

The maintenance key has always priority over the software key in the [diag] menu.

• MAINTENANCE is displayed

– LED1 (orange) is ON

• Probe heats up (10 min.)

• COLDSTART is displayed

– LED5 MEASUREMENT is OFF

– LED6 OPERATION is ON

5. The probe heats up (COLD START)

NOTICE

During the COLD START the cell’s internal resistance Ri is indicated on the display and operating unit or on the monitor output.

NOTICE

The cold start delay can be interrupted from the display and operating unit or by using the multifunction keys:

• Press [cal] key an follow the menu

• Alternatively press multifunction key T2 for longer than 3 s or in warning or fault condition

press T" for longer than 6 s.

42

Page 44

4 Commissioning/Decommissioning

NOTICE

Function Key operation

Toggle the displayed warning/ fault Press briefly

Reset the displayed warning/fault Press for longer than 3 s*

Abort cold-start Press for longer than 3 s**

Trigger an offset calibration to ambient air Press key for longer than 3 during

* Some warnings and faults cannot be reset if the error is still present or the routine is

still running.

** If at least one warning or fault is still present, the key must be pressed for longer than

6 seconds.

• Watch the cell’s inner resistance and read the probe voltage alternatively by:

– Display and operating unit

– Remote Display Software

– Monitor output

measurement**

NOTICE

To read the probe voltage click [meas] key and select the Usprobe voltage on the display.

After a heating up time of 3-5 Min. the probe voltage gets stabilised to values between -5 and

-15 mV and the cell’s inner resistance (Ri probe) gets stabilised to values below 100 . If positive values are indicated in ambient air the probe has been connected reversely. Swap the

probe connections on terminal 33/34.

• After COLD START has finished the device switches to MEASUREMENT mode automatically.

43

Page 45

4 Commissioning/Decommissioning

4.7.1.1 Adjust the Amount of the Reference Air

NOTICE

Only oil-free and water-free compressed air can be used as reference air.

Recommendation: Use instrument air if available.

If neither instrument air nor compressed air is available a LT2 with integrated reference air

pump is necessary. The optional internal reference air pump type 657R060 cannot be retrofit

in a wall mounting housing for LT2 type 657R102.

Retrofitting a reference air pump is only possible with an external housing type 657R1061.

NOTICE

Reference air is monitored permanently by a differential pressure sensor which is installed in

the connection box of the LS2-K.

NOTICE

Reference air is monitored by the fault ’No reference air’. Release time: 1 h

• Calibrate the differential pressure sensor to 0.

– Therefore close thee reference air completely. Refer to the display and control unit

menu function [par], [psw], [change] (see chapter 4.4.2 Menu Function 'meas' ff.)

– Open the throttle until a differential pressure of 2 to 3 mbar has been reached (see Fig.

4-18 Display LT2).

Fig. 4-18 Display LT2

44

Page 46

4 Commissioning/Decommissioning

1 Differential pressure sensor

2 Absolute pressure sensor

3 Throttle for calibration gas

4 Throttle for reference air

5 Stopcock for calibration gas

6 Hose connection for test gas (instrument air or

test gas ca. 0.3 bar)

7 Outlet for air

8 Hose connection for reference air (instrument

air ca. 0.3 bar)

9 Electrical connection probe to LT2-K

10 Electrical connection absolute pressure sen-

sor to LT2 analogue input 2

11 Electrical connection differential pressure sen-

sor to LT2 analogue input 1

Fig. 4-19 Internal view of probe connection box LS2-K

4.7.1.2 Performing an offset calibration to ambient air

NOTICE

The probe must be removed or ambient air must be ensured at the measuring point.

• Trigger offset calibration alternatively by:

– Display and operating unit by the [cal] menu

– Remote Display Software by the [cal] menu

– Multifunction key (only with ambient air) see chapter 4.7.1 Measurement with LS2-K If

the system works properly for 20 Min. after finishing the offset calibration repeat the

calibration

Menu function

Pressing the [cal] menu key shows ’Start calibration’ in the display. After the activation of the

calibration 4 functions are available (see chapter 4.7.1.3 Performing an Offset Calibration with

Compressed Air), Use the two upper functions for offset calibration:

• Start offset calibration in ambient air

• Start offset calibration with compressed air (open stopcock in PCB)

• Start calibration with reference measurement

• Start calibration with test gas (open stopcock in PCB)

Press cursor keys up/down to select the required offset calibration.

Press ENTER key to start the selected offset calibration.

Use the menu function ’ Break calibration before end!’ to abort the calibration.

After finishing the automatic calibration procedure in ambient air the LT2 changes to MEASUREMENT mode.

Press the [exit] key to change to the indication of the measurement values.

By multi function key T2 as an alternative (with ambient air only):

45

Page 47

4 Commissioning/Decommissioning

NOTICE

Function Key operation

Toggle the displayed warning/ fault Press briefly

Reset the displayed warning/fault Press for longer than 3 sec*

Abort cold-start Press for longer than 3 sec**

Trigger an offset calibration to ambient air Press key for longer than 3 sec

* Some warnings and faults cannot be reset if the error is still present or the routine is

still running.

** If at least one warning or fault is still present, the key must be pressed for longer than

6 seconds.

• Wait until the offset calibration has finished. The flashing stops. The status line shows

’Measurement’.

Repeat the offset calibration after 20 Min. of failure free operation.

4.7.1.3 Performing an Offset Calibration with Compressed Air

during measurement**

NOTICE

If compressed air (instrument air) is available the offset calibration can be proceeded without

removing the probe. Compressed air (instrument air) of 0,3 bar must be connected to the calibration gas inlet.

CAUTION!

Open the stopcock in the PCB before clicking the ENTER key. Adjust the required rise in pressure of dP = 2 mbar by the calibration gas throttle (see Fig. 4-20 Display of offset calibration).

Fig. 4-20 Display of offset calibration

CAUTION!

Close the stopcock in the PCB after finishing the offset calibration. Measurement mode may

not be activated before closing the stopcock.

46

Page 48

4 Commissioning/Decommissioning

4.7.1.4 Perform a Calibration with Reference Measurement

Select ’Calibration/test with reference-measuring’ in the [cal] menu and confirm with ENTER.

Use the up/down cursor keys to adjust the O2 value of the reference measurement.

Confirm with [OK] key (see Fig. 4-21 Input of the calibration values).

This is valid only for O2 values smaller than 18 %.

Use the [canel] key to quit the calibration process.

Fig. 4-21 Input of the calibration values

47

Page 49

4 Commissioning/Decommissioning

4.7.1.5 Perform a Calibration with Test Gas

NOTICE

The calibration can be proceeded with test gas as an alternative to the reference measurement.

The procedure corresponds to the offset calibration with compressed air.

Fig. 4-22 Display of calibration with test gas

NOTICE

The test gas used must be free of oxidizing components such as CO, NO, etc.Oxidising components are burned at the 700 °C hot Pt electrode catalytically and distort the calibration.

Calibration with test gas

1. Disconnect instrument air of the offset calibration

2. Connect test gas with 2 … 5 Vol. % O2 in N2 and with a primary pressure of 0.3 bar at the

PCB of the LT2

3. Wait for 1 to 2 minutes after supplying test gas until the measuring value has stabilised.

4. Proceed with adjusting the O2 value to the value of the test like the calibration with reference air.

CAUTION!

Close the stopcock before activating the MEASUREMENT mode.

5. Press [exit] key to change to the display of the measurement value.

During the calibration procedure an O2 substitute value can be chosen in parameter 275.

NOTICE

The CALIBRATION mode remains active for a maximum of 15 Min. Afterwards the system

switches to MEASUREMENT mode automatically.

48

Page 50

4 Commissioning/Decommissioning

4.7.2 LS2-KV Measurement (Fully-automatic Calibration)

• Apply instrument air of 0,3 bar at the probe’s reference air connection and test gas 1 connection. Apply test gas of 2 … 5 % volume of O2 in N2 of 0,3 bar on test gas 2 connection.

CAUTION!

The test gas used must be free of oxidizing components such as CO, NO, etc. Oxidising components are burned at the 700 °C hot Pt electrode catalytically and distort the calibration.

• Switch on power

• Probe heats up (COLD START see chapter 4.7.1 Measurement with LS2-K)

• Enter the O

operating unit).

NOTICE

The O2 concentration which is entered in parameter 301 must be the same as the O2 concentration of the connected test gas. Differences caus measuring failures. because the probe is

calibrated to the specified value.

concentration of the connected test gas 2 in parameter 301 (see display and

2

• If the cold start is not aborted the LT2 proceeds a combined offset and test calibration afterwards. The probe is now in measurement condition. A manually triggered calibration

can be abandoned.

49

Page 51

4 Commissioning/Decommissioning

4.7.2.1 Adjust the Amount of the Reference Air

1 Differential pressure sensor

2 Absolute pressure sensor

3 Solenoid valve 2 (shut off valve)

4 Throttle for calibration gas

5 Solenoid valve 1 (shutter valve)

6 Throttle for reference air

7 Hose connection for reference air

(instrument air 0.3 bar)

8 Outlet reference air

9 Hose connection test gas 1

(instrument air 0.3 bar)

10 Hose connection test gas 2

(test gas 0.3 bar)

11 Electrical connection

absolute pressure sensor

12 Electrical connection probe

13 Electrical connection

differential pressure sensor

14 Electrical connection solenoid valve

Fig. 4-23 LS2-KV internal view of PCB

• In combination with calibration unit type 657R2811 as an option.

Proceed as described for LS2-K in chapter Fig. 4-18 Display LT2

50

Page 52

4 Commissioning/Decommissioning

4.7.2.2 Performing an offset calibration to ambient air

Press the [ cal ] menu key to display a choice two calibration variants

Fig. 4-24 Selection menu of offset calibration

NOTICE

To adjust the required rise of the pressure during calibration manual calibration must be selected.

For the further procedure of the manual offset calibration see chapter 4.7.1.2 Performing an

offset calibration to ambient air and 4.7.1.3 Performing an Offset Calibration with Compressed

Air.

The only difference is: A solenoid valve opens and closes the air supply.

For automatic calibration a choice of 3 calibration variants are available.

Fig. 4-25 Quitting the automatic offset calibration

NOTICE

When automatic offset calibration is activated, the required 2 mbar pressure rise must have

already been set. Once the fully automatic sequence has ended, the LT2 automatically switches to measuring mode.

51

Page 53

4 Commissioning/Decommissioning

4.7.2.3 Reference measurement - Performing a Test Calibration

Perform the calibration by:

• Display and operating unit

• Remote Display Software

Press the [cal] menu key to display a choice two calibration variants (see chapter 4.7.2.2 Per-

forming an offset calibration to ambient air).

NOTICE

Selecting the manual calibration in CALIBRATION mode runs a calibration with reference

measurement and test gas as described in chapter 4.7.1.4 Perform a Calibration with Refer-

ence Measurement and 4.7.1.5 Perform a Calibration with Test Gas.

The only difference is: Test gas is connected to the hose connection Test gas 2 and is triggered automatically by solenoid valves.

Selecting the automatic test gas calibration the calibration is performed fully automatically to

the O

value in parameter 301.

2

Fig. 4-26 Test gas calibration menu

After finishing the fully automatic calibration the LT2 switches to MEAUREMENT MODE automatically.

NOTICE

The O2 concentration in parameter 301 must match the test gas witch is connected to Test

gas 2. The probe is calibrated to this value in the automatic test gas calibration process. A

difference between If the value in the parameter and the value of the connected test gas causes incorrect measurement.

52

Page 54

4 Commissioning/Decommissioning

4.7.2.4 Performing a Combined Offset and Test Gas Calibration

Start calibration alternatively by:

• Display and operating unit

• Remote Display Software

• Digital input 5

• Cyclic (parameter 300)

Pressing the [cal] menu key shows a choice of 2 calibration variants. (see figure in chapter

4.7.1.2 Performing an offset calibration to ambient air). The Automatic calibration provides a

choice of 3 variants.

Fig. 4-27 Combined offset and test gas calibration menu

After triggering the combined calibration the automatic offset calibration and the test gas calibration are performed subsequently automatically. After finishing the calibration the LT2

switches to automatically to MEASUREMENT mode.

NOTICE

For performing the combined calibration the notices and instructions in chapters 4.7.1.2 Performing an offset calibration to ambient air and 4.7.1.4 Perform a Calibration with Reference

Measurement.

Parameter 300 activates the cyclic, time controlled trigger, see chapter 4.4 Display and Operating Unit Type 657R0831 (Option), menu functions [par], [psw], [change].

53

Page 55

4 Commissioning/Decommissioning

4.8 Probe Certificate

There is a probe certificate included in every probe. This should be completed as part of the

commissioning work. The probe certificate must always be included in the event of any complaints or repairs.

NOTICE

The settlement of problems on the basis of goodwill requires the submission of the passport.

Fig. 4-28 Probe certificate (example)

54

Page 56

4 Commissioning/Decommissioning

4.9 Setting up Service Warnings

The service warnings are designed to draw attention to regular servicing. The service warnings can be freely defined by the operator, e.g.

Service warning 1 check probe

Service warning 2 replace probe

The appropriate cycle times can be freely configured by the parameters 1260 and 1261.

4.10 Decommissioning

In order to be sure to avoid damaging the probe’s ZrO2 measuring element, the probe must

be dismantled before the system is shut down or immediately after the supply voltage is

switched off.

NOTICE

Dismantle the probe before shutting down the measurement system.

CAUTION!

Hot probe!

The probe may be hot during mounting/demounting! Risk of burns!

Wear appropriate protective clothing.

Be careful.

Do not place the hot probe on flammable material.

NOTICE

Once dismantled, the probe can be stored indefinitely. The zirconium element is only consumed during operation (measuring cell at operating temperature). This also applies where a

probe has already been used previously.

55

Page 57

5 Test Certificate

5 Test Certificate

Each probe has an accompanying production test record.

This means current measurement values can be compared with the bench performance at any

time.

Fig. 5-1 Example test protocol

56

Page 58

6 Operation

6 Operation

6.1 Measurement During Distinct Pressure Surges at the Measuring Site

If the display jumps badly, damping can be increased via the (optional) display and operating

unit and the service and diagnostic software (i.e. by increasing the integration's time-constant); this steadies the display: parameter 360 - Operational release level. However, this

slows down the display in terms of reaching an end state.

NOTICE

Large damping simultaneously leads to an artificial slowing down of the measurement signal.

6.2 Operational Failure, Switching On and Off

In the event of long interruptions during operation, which are lasting for longer than approx. 3

months, it is recommended to switch off the measuring system. The probe should be dismantled to avoid damage (see chapters 8.6.11 Service Warning 1/Service Warning 2, 4.10 Decom-

missioning4 Commissioning/Decommissioning).

NOTICE

Recommendation: Continue with the measurement in case of short service interruptions.

6.3 Liquid Purification

To perform a liquid purification of the boiler is possible, if the probe is dismantled before. Performing a liquid purification to an installed probe, can damage the probe. An error free operation is no longer possible.

NOTICE