Page 1

Quick Reference for Endusers

Lambda Transmitter LT3-F

Combination Probe KS1D

Application only in Connection with

BT300/ETAMATIC/FMS/VMS to CO/O

-Control

2

Sensors and Systems for Combustion Technology

www.lamtec.de

Page 2

Page 3

Table of Contents

Table of Contents

1 Important Information about the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Validity of these Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Information on Using this Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Classification of the Safety Instructions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Proper Use - Conditions of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Permissible Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Safety Equipment/Safety Measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Mounting and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Designs and Accessories of the KS1D Combination Probe. . . . . . . . . . . . . . . . . . . . . . 17

4.2 Connection Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Display and Operational Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.1 Password Entry Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.2 Information Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.3 Calibration Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.4 Settings Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Status Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4.1 Main Menu - Password Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.2 Main Menu - Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4.3 Main Menu - Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4.4 Main Menu - Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3 Measurement Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.1 Enter the Password for the Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.2 Activate/deactivate Maintenance Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.3 Response of the Internal Resistance Regulation. . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.4 Premature Cold Start Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3.5 Reading the Measured Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4 Calibrating the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.1 Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.2 Calibrating the O

Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2

6.4.3 Perform a Calibration of the CO/H2 Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5.1 Maintenance Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5.2 Filter Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5.3 Analogue Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.5.4 Replacing a Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2

Page 4

Table of Contents

6.5.5 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.5.6 Limit Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.6 Test Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.7 Probe Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1 Checking/Calibrating the KS1D Combination Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1.1 Checking/Calibrating the Air Voltage (Offset) . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1.2 Checking/Calibrating the O2 Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1.3 Checking/Calibrating the CO/H2 Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1.4 Checking/Calibrating with Test Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.1.5 Checking/Calibrating with Reference Measurement . . . . . . . . . . . . . . . . . . . . . 56

7.1.6 Simple Function Test of the CO/H2 Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.1.7 Wear-and-Tear Parts of the KS1D Combination Probe . . . . . . . . . . . . . . . . . . . 56

7.2 Replacing a Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3 Sensor Replacement KS1D-HT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8 Correcting Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.1 Faults and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.1.1 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.1.2 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1.3 Call of the Fault History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.1 Decommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.1.1 Protection Against Emissions from Gas Carrying Channels . . . . . . . . . . . . . . . 71

10 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.1 Analogue Outputs via LSB Module Current, alternative Voltage, LSB address 19 . . . . 72

10.1.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.1.2 Factory Setting of Analogue Outputs via LSB Module. . . . . . . . . . . . . . . . . . . . 73

10.1.3 Conversion of the Output Range via the User Interface . . . . . . . . . . . . . . . . . . 74

10.2 Digital Outputs via LSB Module, LSB Address 03 and 51 . . . . . . . . . . . . . . . . . . . . . . . 75

10.2.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.2.2 Factory Setting of the Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.2.3 Diagnosis of the Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3 Digital Inputs via the LSB Module, LSB Address 11 and 55. . . . . . . . . . . . . . . . . . . . . . 78

10.3.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.3.2 Factory Settings of the Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.3.3 Diagnosis of the Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.4 LSB Module for Calculating Combustion Efficiency. . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.4.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.5 External Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.5.1 Commissioning of the Additional Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11.1 Storage Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12 Disposal Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

12.1 Environmental Protection, Waste Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3

Page 5

Table of Contents

13.1 LT3-F spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

13.2 Spare Parts Combination Probe KS1D in Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

13.3 Spare Parts Combination Probe KS1D without Housing . . . . . . . . . . . . . . . . . . . . . . . . 87

13.4 Spare Parts KS1D-HT Combination Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.5 Wet/Dry Measurement Deviations, Conversion Table . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4

Page 6

1 Important Information about the Manual

1 Important Information about the Manual

1.1 Validity of these Instructions

This manual describe the Lambda Transmitter LT3-F with all required components. The information in this document applies to the software version 1.0.0.0. If you utilise a different version, this can lead to other effects to your device than those described in this manual.

The CO/O2 control described in this document must be activated in the burner control units

stated above and the required measurement equipment must be connected.

The basic documentation to this commissioning supplement is:

• Manual of BurnerTronic BT300, BT320 ... BT340 (publication no. DLT1201)

• Manual of Lambda Transmitter LT3-F KS1D (publication no. DLT3140)

The lambda transmitter LT3-F must be operated with the CO/O2 control option.

For this purpose, the following LAMTEC burner control systems can be used:

• BT300

• ETAMATIC/ETAMATIC S

• ETAMATIC OEM/ETAMATIC S OEM

• ETAMATIC V/ETAMATIC VS

• FMS

• VMS

The description of the CO/O2 control can be found in the following documents:

• Commissioning supplement for the CO/O2 control in connection with BT300 (publication

no. DLT1209)

• Commissioning supplement for the CO/O2 control in connection with FMS/VMS/ETAMATIC (publication no. DLT5015)

NOTICE

The current publications are available for download from the LAMTEC Website,

www.lamtec.de.

5

Page 7

1 Important Information about the Manual

1.2 Information on Using this Operating Manual

NOTICE

Before starting work, you absolutely must read these instructions!

Carefully observe all warning notes!

They contain important data and information, the compliance with which will ensure the function of the device and, in turn, reliable measurement results.

The device described here corresponds with the standard configuration.

Particular attention must be paid to information and warnings. These are indicated by re-

spective pictograms. They serve to safeguard your personal safety and help you to avoid operating errors.

This operating manual contains the information required for the product to be used in a manner that is compliant with its intended use. It is intended for technically qualified personnel who

are appropriately trained and who possess the relevant knowledge in the area of measurement, control and steering technology.

This operating manual is an inherent part of the delivery. For reasons of clarity, it is not possible to cover all possible designs of the described system. Please contact us if you wish to set

up, operate, or maintain the device differently from the instructions given here.

6

Page 8

2 General Safety Instructions

2 General Safety Instructions

2.1 Classification of the Safety Instructions and Warnings

The following symbols are used in this document to draw the user's attention to important safety information. They are located at points where the information is required. It is essential that

the safety information is observed and followed, and that applies, in particular, to the warnings.

DANGER!

This draws the user's attention to imminent danger. If it is not avoided, it will result in death or

very serious injury. The plant or something in its surroundings could be damaged.

WARNING!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in death or very serious injury. The plant or something in its surroundings could be damaged.

CAUTION!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in minor injuries. The plant or something in its surroundings could be damaged.

NOTICE

This draws the user's attention to important additional information about the system or system

components and offers further tips.

The safety information described above is incorporated into the instructions.

In this connection, the operator is requested to:

1 Comply with the accident prevention regulations whenever work is being carried out.

2 Do everything possible in the circumstances to prevent personal injury and damage to

property.

7

Page 9

2 General Safety Instructions

2.2 Proper Use - Conditions of Use

Operation

The LT3-F lambda transmitter is an electronic data interpreting device which is used in conjunction with the KS1D combination probe for the continuous measurement of the O2 concentration and the oxidising components (CO/H2) in non-combustible gases in the

superstoichiometric area.

Prerequisites

It is assumed that plant planning, mounting, installation, commissioning, maintenance, and

service work will be carried out by sufficiently trained personnel and that this work will be

checked by responsible skilled personnel. It must be particularly noted that

• the operation complies with the technical data and specifications regarding permissible

use, mounting, connection, and environment and operating conditions (refer to the contract documents, the device user information, rating plates, etc.).

• work will be carried out in accordance with the local, plant-specific circumstances and with

regard to the operational risks and directives.

• all the measures required to preserve the value, e.g. for transportation and storage as well

as maintenance and service, are maintained.

Intended use

The product described here has left the factory in a flawless, safe and checked condition and

it must be maintained exclusively in the manner that is described by the manufacturer. Equally,

the proper transportation, correct storage and setup as well as the careful operation and maintenance, are critical for the flawless and safe operation of the device. Sufficiently qualified personnel must be used to install and operate this product. They must be familiar with the security

advice and warnings specified here and ensure they can be implemented flawlessly. Unqualified persons working on the device or the warning information provided here or on the device

not being observed could result in serious personal injury and / or damage to property. The

device is being used as intended if the device is being used solely for the application specified

in the technical description. Auxiliary devices or those from other manufacturers must be recommended or authorised by LAMTEC. Provided the safety information and operating directives specified in this manual are observed, this device should not present any risks in terms

of damage to property or the health of personnel.

8

Page 10

2 General Safety Instructions

2.3 Permissible Users

Qualified personnel

The person responsible for safety absolutely must guarantee that

• only qualified personnel perform work on the system parts.

Due to their training, education, experience, or instruction and due to their knowledge of

pertinent standards, provisions, accident prevention regulations, and system conditions,

qualified personnel are authorized to perform these tasks by the person responsible for

the safety of people and the system. It is decisive that this personnel must be able to recognise and prevent risks on time.

Experts are considered to be people according to DIN VDE 0105 or IEC 364 or directly

comparable standards like DIN 0832.

• These persons must have access to the provided operating manual and any pertinent order-related documentation during all work and observe these documents within the scope

of preventing risks and damage.

User groups

For the handling of the lambda transmitter LT3-F, three user groups are required:

• Service technicians of LAMTEC or its OEM customers and/or trained customer personnel:

– Qualified technicians/engineers have very good knowledge of the device.

– SERVICE access level - password-protected

• Operators, customer fitters, technicians for instrumentation and control technology, electricians, and electronic engineers have introductory knowledge of the device.

– CUSTOMER access level - password-protected

• Operating personnel with basic knowledge

– OPERATION access level - no password

9

Page 11

2 General Safety Instructions

2.4 Safety Equipment/Safety Measures

Hazards from electrical equipment

The Lambda Transmitter LT3-F combination probe is equipment for use in industrial electrical

power installations. Always switch off the power when working on mains connections or mains

voltage. If contact protection has been removed, reattach it before switching on the power supply again. Damage to health or equipment may result from improper use or improper handling.

NOTICE

To avoid damage, always observe the respective security notices.

Preventive measures for improving operating safety

If the LT3-F is used in conjunction with control and steering technology, the operator must ensure that any breakdown or failure of the LT3-F device does not cause inadmissible damage

or dangerous operating states. To avoid faults which could cause direct or indirect personal

or material damage, the operator must ensure that:

• the responsible maintenance personnel can be reached at any time and as quickly as possible

• the maintenance personnel are trained to correctly respond to faults with the Lambda

Transmitter LT3-F and the associated malfunctions

• in the case of doubt, the faulty equipment can be switched off immediately

• A switch-off does not lead to direct follow-up problems.

Avoiding consequential damages

To avoid consequential damages in the event of failure, which could cause direct or indirect

personal or material damage, the owner must ensure that qualified personnel can assess the

faults and initiate appropriate measures to tackle them.

Protect against gas leakage from the gas-bearing channel

The combination probe KS1D is fitted directly to the gas-bearing channel via the probe installation fitting (PIF). If the combination probe KS1D or the probe installation fitting (PIF) are dismantled, depending on the plant but particularly in the case of excess pressure, aggressive

and / or hot gas can seep out of the channel and this could pose a serious health hazard to

an unprotected operator if suitable safety measures have not be taken previously. For prevention, suitable protective measures must be taken in advance.

WARNING!

In the case of excess pressure and temperatures in excess of 200 °C in the gas channel, gases could escape when dismantling the combination probeKS1D or the probe installation fitting

(PIF).

Always switch off the plant prior to opening. If this is not possible, wear protective clothing

and a mask.

Fix respective warning information in close proximity to the mounting site.

Immediately seal the opening again.

WARNING!

Danger from electrical shock

The device contains live parts and touching these parts could cause electric shock.

Before opening the housing, disconnect the mains plug!

10

Page 12

2 General Safety Instructions

Decommissioning/recommissioning

The LT3-F Lambda Transmitter and the KS1D combination probe are a high-quality,

electronic measuring system. It therefore requires careful handling in all situations - decommissioning, transport, and storage.

NOTICE

Do not switch off the LT3-F Lambda Transmitter as long as the KS1D combination probe is

mounted. Not even if the associated plant has been brought to a standstill. Residual gases will

cause corrosion and could damage the probe.

Do not store the device outside without any protection!

Always store in a dry location and, if possible, keep in the original packaging.

When uninstalling, protect the ends of cables and the connectors from corrosion and soil-

ing. Corroded connectors can cause malfunctions.

If possible, always transport in the original packaging.

11

Page 13

3 Product Description

3 Product Description

3.1 Applications

The LT3-F lambda transmitter has been developed to use in conjunction with the KS1D combination probe for the simultaneous measurement of the O2 concentration and oxidising components (CO/H2), displayed as CO equivalents (COe), usually in the flue gases from

combustion systems in the superstoichiometric area (>1).

Application only in connection with CO/O2 control. The fail-safe function is only valid for the

hole system, not for single components.

12

Page 14

3 Product Description

3.2 Declaration of Conformity

13

Page 15

3 Product Description

14

Page 16

4 Mounting and Functions

4 Mounting and Functions

4.1 Designs and Accessories of the KS1D Combination Probe

The KS1D combination probe permits a simultaneous measurement

of the O2 concentration and combustible, oxidising gas components (CO/H2) displayed as

CO equivalent (COe), in the flue gases from combustion systems in the superstoichiometric area

(>1) in situ (directly in the flue gas).

Fig. 4-1 Standard design of the KS1D combination probe

1 KS1D combination probe in standard housing

Standard cable length 2 m, PTFE, with connecting plug

2 Probe installation fitting (PIF)

3 Measuring gas extraction device (GED)

Fig. 4-2 KS1D combination probe without housing

Alternatively:

Fig. 4-3 KS1D combination probe in HT design

1 KS1D combination probe in high-temperature housing

Standard cable length 2 m, PTFE, with connecting plug

2 Flue gas bypass tube

15

Page 17

4 Mounting and Functions

4.2 Connection Extension

Extension via probe terminal box

In preparation.

Extension via extension cable

For distances > 2 m, extension cables in lengths of 2 m and 5 m are available.

NOTICE

The maximum distance between LT3-F and combination probe KS1D may not exceed 10 m.

With longer distances the approval of the system for continuous operation expires.

For distances longer than 10 m the risk of EMC increases.

LAMTEC assumes no responsibility for correct, error-free functions.

16

Page 18

5 Display and Operational Controls

5 Display and Operational Controls

To display and operate LT3-F, the user interface is integrated into the front door of LT3-F (included in the standard scope of supply).

Functions:

• Reading of the O

• Password entry

• Information regarding the probe, fuel, warnings, faults, software version,

CRC, and serial number

• Calibration of measurement

• Settings maintenance, filter time, analogue output, probe replacement, display,

limit values, and digital outputs

and COe measured values

2

Fig. 5-1 LT3-F user interface

Fig. 5-2 Housing with user interface

17

Page 19

5 Display and Operational Controls

5.1 Operation

Using the arrow keys you can navigate within the menus.

In the process, move the keys and to the right or left by one to make a selection.

ENTER ENTER takes you to menu entries or to the edit mode in the case of selected pa-

rameters or values.

With the keys and the currently selected value can be changed accordingly Hold

down the respective key and the value will count automatically up or down.

BACK BACK leaves the window, menu, or edit mode.

5.2 Menu Structure

5.2.1 Password Entry Menu Structure

Without access level

Customer access level

Service access level

18

Page 20

5 Display and Operational Controls

5.2.2 Information Menu Structure

5.2.3 Calibration Menu Structure

19

Page 21

5 Display and Operational Controls

5.2.4 Settings Menu Structure

20

Page 22

5 Display and Operational Controls

5.3 Status Line

The status line contains information about LT3-F, including the device family.

Description status line:

Active fault/warning

Operating mode OK

Heat-up (cold start)

Status of limit values 1-4

Active limit value not triggered

Non-active limit value (off)

Active limit value undershot/exceeded

Active maintenance mode

Without access level

Access level 1 - Customer

Access level 2 - Service

Window number

21

Page 23

5 Display and Operational Controls

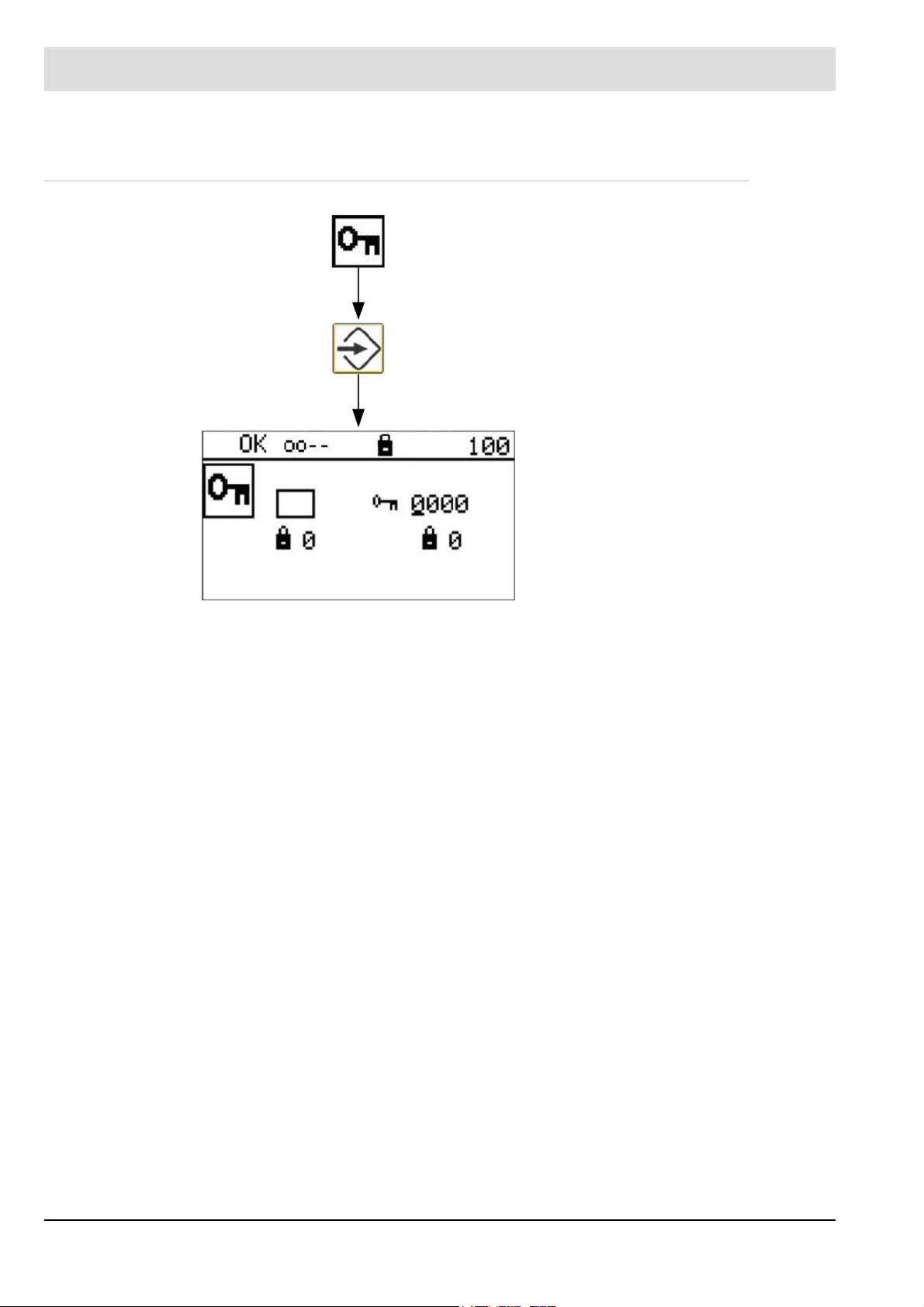

5.4 Main Menu

Main display Main menu

The following values are displayed:

•O

value, resolution 0.1%

2

•COe value (recommended 1,000 ppm), resolution 1 ppm

•COe: Probe signal dynamics

• CO edge signal reached/exceeded

The factory-set reaction threshold lies at 40%. The display shows whether the reaction thresh-

old is reached. When the reaction threshold is reached, the CO edge signal is present and the

CO control becomes active. This is shown through a symbol in the display or can be read

via the LSB remote software in Parameter 444. The desired response threshold be set on the

display or using Parameter 453 of the LSB remote software. Access level 2 is required for service!

Press ENTER to access the main menu.

Meaning of the symbols:

Password entry

Information regarding the probe and fuel, warnings and faults,

software version, CRC, and serial number

Calibration of measurement

Settings (maintenance, filter time, analogue output, probe replacement, display,

limit values and digital outputs)

22

Page 24

5 Display and Operational Controls

5.4.1 Main Menu - Password Entry

23

Page 25

5 Display and Operational Controls

5.4.2 Main Menu - Information

Meaning of the symbols:

Measured values and probe data

Fault/warning history

Software version of LT3-F and display

CRC checksums

Serial number

Manual reset of the limit values if they are set to manual reset

24

Page 26

5 Display and Operational Controls

5.4.3 Main Menu - Calibration

Meaning of the symbols: Required access level

Offset of calibration to 21% O2 (air calibra-

tion)

COe calibration At least 1 (Customer) or higher

O2 calibration At least 1 (Customer) or higher

Fuel changeover At least 1 (Customer) or higher

Without

25

Page 27

5 Display and Operational Controls

5.4.4 Main Menu - Settings

Meaning of the symbols: Required access level

Maintenance mode Without

Filter time of the measured values Without

Analogue outputs At least 1 (Customer) or higher

Triggering of probe replacement At least 1 (Customer) or higher

COe trigger threshold At least 2 (Service)

Display parameters Without

Digital outputs At least 2 (Service)

Limit values At least 1 (Customer) or higher

26

Page 28

6 Commissioning

6 Commissioning

WARNING!

Prior to commissioning, carefully read the manual and heed the instructions.

The measuring system may be operated only by trained and instructed personnel!

Improper working/operation can cause death, serious bodily injury and/or considerable mate-

rial damage.

NOTICE

Before commissioning, the KS1D combination probe and all alarm/signal outputs are connected, as described in Chapter 6.2 Installation in these operating instructions, to the LT3-F Lambda Transmitter.

WARNING!

Before actuating the main switch for the voltage supply, ensure all housings (evaluation electronics and terminal boxes, electrical connection of the probe) are sealed in

accordance with the instructions!

27

Page 29

6 Commissioning

6.1 Operating Conditions

NOTICE

If the LT3 is being used for O2 control or the LT3-F for CO/O2 control, it may happen, that the

connected LSB-modules are not be controlled correctly. The LSB modules start to flash red

and the output values are disturbed.

To avoid this, the ETAMATIC or when FMS/VMS then the connected communications processor board/fieldbus module requires a software update to the latest version.

Please check the version before commissioning.

Shown on the ETAMATIC: Using PC software for remote control view version

„Software Version Communication Processor’“

Software-EPROM on processor board in ETAMATIC

Shown on the FMS/VMS:

or

Using PC software for remote control view version

Function up from software version for communication processor for LSB:

When ETAMATIC / ETAMATIC OEM: B9w001, up from April 2015

When communication processor / PROFIBUS connection

for FMS/VMS

When MODBUS connection RTU for FMS/VMS: M9xxx, up from April 2015

When MODBUS connection TCP for FMS/VMS: E9xxx, up from June 2011

If you have any questions, please contact support@lamtec.de or phone +49 6227 605233.

Check on the label ‘Software’ printed on the outside of the

housing of communications processor board / fieldbus module

"Software Version Secondary Communication Processor“

Software-EPROM in communications processor board/fieldbus

A9xxx, up from November

2011

28

Page 30

6 Commissioning

6.2 Installation

Danger of falling!

The mounted probe may not be used as a step. The maximum permissible bending moment

lies at 100 kg. In case of non-observance, the probe can be destroyed.

A fall can result in severe injury or death.

Do not step on the probe! Use appropriate work equipment.

NOTICE

Do not pull on cables or pneumatic connections. The maximum permissible tensile force lies

at 10 kg.

NOTICE

The maximum distance between LT3-F and combination probe KS1D may not exceed 10 m.

With longer distances the approval of the system for continuous operation expires.

For distances longer than 10 m the risk of EMC increases.

LAMTEC assumes no responsibility for correct, error-free functions.

WARNING!

6.3 Measurement Start-up

NOTICE

If it is not possible to switch off the system, the probe can be installed only after a successful

offset calibration and the GED has been aligned.

Commissioning the probe

1. Connect the probe electrically.

2. Switch on the voltage.

3. Enter the password for access level 2 (Service); see Chapter 6.3.1 Enter the Password for

the Access Level.

4. Activate maintenance mode; see Chapter 6.3.2 Activate/deactivate Maintenance Mode.

5. Heat up the probe (10 min. cold start and 30 min. faultless measurement operation)

6. Cold start is displayed.

7. The device automatically changes over to measurement operation.

8. The probe voltages stabilised to (-20 ... + 10mV).

9. The internal resistance stabilised to 15 ... 25 W

10. Calibrate the probe; see Chapter 6.4 Calibrating the Probe.

29

Page 31

6 Commissioning

6.3.1 Enter the Password for the Access Level

In the main menu PASSWORD ENTRY

select

Enter password via and

ENTER .

Access level 1:

Factory setting:

Access level 2: Service level

Customer Level

0000 – access to customer functions only

Customers can change the password for access level 1. For details ask

the burner manufacturer/supplier

Password: customer specific

Access to customer and service functions

30

Page 32

6 Commissioning

6.3.2 Activate/deactivate Maintenance Mode

In maintenance mode, the majority of test routines are disabled. It is advantageous to activate

the maintenance mode during probe calibration. Substitute values can be given as an output

during active maintenance mode.

In the main SETTINGS menu, select

In the MAINTENANCE MODE settings,

select

Menu 460 ACTIVATE/DEACTIVATE MAINTENANCE MODE is opened.

Select with the key and ENTER to

activate/deactivate the maintenance mode.

Activate maintenance mode

Deactivate maintenance mode

If both parameters (LT3 and UI300) are equal

confirm the procedure with ENTER

31

Page 33

6 Commissioning

• The symbol appears in the status line.

• The probe heats up (approx.10 min.).

• LD 603 green OPERATION lights up.

• COLD START is displayed.

The cold start serves to suppress incorrect measured values while the probe is heating

up. A cold start delay is always activated after MAINS ON and a fault reset. Premature

termination via the CALIBRATION menu possible (see Chapter 6.3.4 Premature Cold

Start Termination).

• After a concluded COLD START (approx. 10 minutes), the device switches to measuring

mode.

• The probe voltages U-O2 and U-COe stabilise to values between +10 ... -20 mV.

• The internal resistances of the sensor Rki O2 and Rki CO stabilise to values between

15 ... 25 .

For the analogue outputs, a replacement value can be set via the LSB remote software while

the maintenance mode is active.

Parameter 2035 and Parameter 2042 for analogue output 1

Parameter 2075 and Parameter 2082 for analogue output 2

Wait for transmission end indication.

Return to the SETTINGS menu with the

BACK and repeat the procedure.

In case of cancelling or timeout, this display

appears. Return to the SETTINGS menu

with the BACK .

WARNING!

Danger of burns!

Probe becomes hot during operation.

If the probe is operated when removed, there is a danger of burns on the probe housing.

Never lay the probe on flammable material and heat it up.

Wear protective gloves

32

Page 34

6 Commissioning

6.3.3 Response of the Internal Resistance Regulation

The internal ceramic resistance between the reference and O2 electrodes (Rki O2) is a function of the sensor temperature, which is constantly regulated for a perfect function

of the probe.

NOTICE

The optimum operating point of the KS1D probe lies at a Rki O2 of about 20

This value must be reached before the first offset calibration or after a probe replacement is

triggered.

If the measured R

(see Menu 213), the installation situation of the probe must be changed for optimum operation:

Rki O2 > 25

• The probe does not become hot enough:

– The probe was installed in a cold spot and is thus cooled.

Determine a new installation site.

– If necessary, check whether aRki O2 of 20 is reached when it is disassembled.

If a too high Rki O2 is assumed by the internal resistance regulation, the probe functions outside of its optimum operating point.

Rki O2 < 20

• The internal resistance regulation automatically sets the Rki setpoint value to 20:

- After 30 minutes in fault-free measurement operation and subsequent offset

calibration

- After 120 minutes in fault-free measurement operation without an offset calibration

deviates too strongly from the optimum setpoint value Rki S = 20

ki O2

33

Page 35

6 Commissioning

6.3.4 Premature Cold Start Termination

Occasionally, it might be necessary to terminate the COLD START prematurely, e.g., after a

short-term power failure, but not before a minimum waiting period of 120 seconds has expired.

NOTICE

A premature cold start termination leads directly into measurement operation without

an additional prompt. If the probe does not reach its optimum operating point, falsified

measured values and, possibly, faults and warnings are the result.

In the main menu, select for the calibration of the probe.

Terminating the cold start prematurely.

By selecting with the cursor key and

ENTER the cold start is terminated prematurely.

The system returns to the main menu automatically.

34

Page 36

6 Commissioning

6.3.5 Reading the Measured Values

In the main menu, select the INFORMATION

menu with .

In the INFORMATION menu, select measured values and probe data with .

In measured values and probe data, select:

Display of the O2 measured values

Display of the COe measured values

Display of the R

resistances

Display of the current fuel

selection

The O2 probe voltage U-O2 stabilises to values between +10 ...-20 mV.

The CO probe voltage U-CO stabilises to

values between +10 ...-20 mV.

internal probe

ki

35

Page 37

6 Commissioning

The Rki internal probe resistance values

lie between 15 ... 25 .

Display of whether the internal probe

resistance regulation is active!

Display of the current heating capacity

P

h

R

S Display of the setpoint value for the

ki

internal resistance regulation.

O2-CO: Evaluates the cross-talk response

between the O2 and CO electrodes.

If the influence is too large (>15 %), the sensor signals overwrite each other. This leads

to measurement faults and triggers Fault

FH007/10 after 30 seconds. A basic influence always exists due to the common GND

of the electrodes.

Currently selected fuel.

36

Page 38

6 Commissioning

6.4 Calibrating the Probe

A correct and regular probe calibration increases measuring precision.

The probes can be calibrated by

• reference measurement or

• test gas

For calibration using a reference measurement, an flue gas analyser is required. The probes

can then be calibrated when installed / whilst combustion is taking place.

For the test gas calibration, the KS1D-HT is be provided with a test gas connection. It can then

be calibrated when installed / whilst combustion is taking place. A testing device is available

for the test gas calibration of the KS1D standard (type 656R2000)(see Chapter 7.1 Checking/

Calibrating the KS1D Combination Probe). Calibration must take place when the probe is disassembled.

The following calibrations must be performed with the probe after commissioning and/or probe

replacement:

1 Offset calibration (required; see Chapter 6.4.1 Offset Calibration)

– Adapts the O2 measured value to the ambient conditions. In the process, a known environment with 21 vol.% O2 must be present.

2O2 calibration (recommended; see Chapter 6.4.2 Calibrating the O2 Electrode)

– Adapts the O2 measured value to the operating conditions around a typical operating

point.

3COe calibration (recommended; see Chapter 6.4.3 Perform a Calibration of the CO/H2

Electrode)

– Adapts the COe measured value to the operating conditions of the combustion system.

NOTICE

For good measuring precision, it must be guaranteed that the correct fuel curve is set for the

system (e.g., BS1 = light fuel oil EL or BS2 = natural gas) during operation and for calibration

with a reference measurement. The factory set fuel curve is natural gas.

NOTICE

For the greatest possible measuring precision, an own burner and fuel specific characteristic

curve can be determined and stored. In order for the generally valid fuel curves BS1 and BS2

not to have to be changed, BS3 is unassigned for this purpose.

Before start the calibration you have to activate maintenance mode. This prevents mishandling faults and deactivate probe faults. The maintenance mode have to be disabled after successful calibration.

37

Page 39

6 Commissioning

6.4.1 Offset Calibration

Before offset calibration, check whether Rki O2 value is equivalent to 20 (see chapter 6.3.5

Reading the Measured Values).

Otherwise, proceed as described in chapter 6.3.3 Response of the Internal Resistance Regulation

Also check the probe voltage U-O2. It must be in the range of +10 ... -20 mV.

To perform an offset calibration, the probe must be located in the ambient air and should run

for at least 30 minutes in a fault-free measuring mode.

No access level is required!

NOTICE

In case of the KS1D-HT (type 656R2015), the offset calibration can also be performed in an

installed state whilst combustion is running. For this purpose, air (dry and oil-free air, instrument air or ambient air) must be fed at connection 10 with a volume of 40 ... 60 l/h for the duration of the calibration.

Activate maintenance!

In the MAIN MENU, select for the calibration of the probe.

In PROBE CALIBRATION, select for the

offset calibration.

38

Page 40

6 Commissioning

Selecting with the cursor key and

ENTER triggers an offset calibration.

Within 10 s, confirm the setting with ENTER

otherwise the value is not assumed.

The U-O2 value stabilises to values between

+10 ... -20 mV.

The Rki internal probe resistance values

lie between 15 ... 25 .

Display of whether the internal probe

resistance regulation is active!

Ph Display of the current heating capacity

R

S Display of the setpoint value for the

ki

internal resistance regulation.

O2-CO: Evaluates the cross-talk response

between the O2 and CO electrodes.

If the influence is too large (>15 %), the sensor signals overwrite each other. This leads

to measurement faults and triggers Fault

FH007/10 after 30 seconds. A basic influence always exists due to the common GND

of the electrodes.

• The offset calibration takes place automatically once triggered

• After a successful calibration, the O2 value is at 21 vol.% O2,

whilst the COe value is at 0 ppm.

• Deactivate maintenance mode; see Chapter 6.3.2 Activate/deactivate Maintenance

Mode.

39

Page 41

6 Commissioning

6.4.2 Calibrating the O2 Electrode

• Activate Maintenance mode.

NOTICE

Access level 1 or 2 required!

NOTICE

When calibrating the O2 electrode in CO containing flue gas the O2 sensors’ Kelvin value

moves outside the permissible range (< 800 ... >1200 K). The warning WH004 or WH104 is

indicated CO temperature is too high/too low.

The calibration have to be repeated on another point of O2 without CO in the flue gas.

The calibration can be performed by reference measurement using an external measuring device or by using test gas at a known O

gas adapter is required.

For the KS1D-HT (Type 656R2015), a hose connection for calibration gas through which the

test gas (40 ... 60 l/h) can be input is available.

A special test gas adapter is not required for this type.

Recommended test gas: 3 vol.% O

concentration. For KS1D type 656R2000 a special test

2

in N2.

2

NOTICE

When performing a reference measurement using an external measuring device, check if the

measuring device is measuring wet or dry. In the case of devices with an upstream measuring

gas cooler, it always concerns a dry measurement. This also applies to devices which remove

the moisture by means of a chemical substance. The KS1D probe measures wet. The difference between a wet to dry measurement is evident from the graphic in the appendix under

13.5 Wet/Dry Measurement Deviations, Conversion Table.

NOTICE

Calibration / checking with a reference measurement functions only

with O2 values < 15 vol. % and > 1 vol. %.

In the Main Menu, select for probe calibration.

40

Page 42

6 Commissioning

• Deactivate MAINTENANCE mode.

6.4.3 Perform a Calibration of the CO/H2 Electrode

• Activate maintenance mode.

NOTICE

Access level 1 or 2 required!

In Probe Calibration, select for O

cali-

2

bration.

With , , , change the O

val-

2

ues of the probe.

Within 5 s, confirm the calibration with

otherwise the calibration is not assumed.

The calibration can be performed by reference measurement using an external measuring device or using test gas in combination with a testing device (type 650R1015) of test gas at a

known COe concentration.

For KS1D type 656R2000, a special adapter for test gas is necessary. (For the required test

gas adapter for the KS1D (Type 656R2000), see Chapter 7.1.4 Checking/Calibrating with Test

Gas).

Recommended test gas: 3 vol.% O2, 200 ppm CO, 100 ppm H2, in N

2

COe value to be set: 300 ppm

A test gas without O2 cannot be used for the calibration. The test gas must always contain O2

in the % area.

For the KS1D-HT (Type 656R2015), a hose connection for calibration gas through which the

test gas (40 ... 60 l/h) can be input is available.

NOTICE

Calibration / checking with a reference measurement functions only with COe values

>100 ppm.

41

Page 43

6 Commissioning

In the MAIN MENU, select for the calibration of the probe.

In PROBE CALIBRATION select for

COe calibration.

With the keys , , , change the

COe values.

Within 5 s, confirm the calibration with

otherwise the calibration is not assumed.

The probe is now ready for operation.

Deactivate maintenance mode; see Chapter 6.3.2 Activate/deactivate Maintenance Mode.

42

Page 44

6 Commissioning

6.5 Settings

According to which access level you are located, you can make various settings. In access

level 2 (Service), all settings can be made.

In the MAIN MENU, select to make settings.

SETTINGS, offers the following setting possibilities:

Maintenance mode (Level 0); see Chap-

ter

6.5.1 Maintenance Mode

Filter time of the measured values

(Level 0).

Analogue outputs (Level 1); see

Chapter 5 Display and Operational Con-

trols

Probe replacement (level 1).

COe response threshold (Level 2).

Display (Level 0).

Limit values (Level 1).

Digital outputs (Level 2).

6.5.1 Maintenance Mode

In SETTINGS select (see Chapter 6.3.2 Activate/deactivate Maintenance Mode.)

6.5.2 Filter Time

Filter time of the measured values:

No access level is required to make this set-

ting.

Time over which the measured values are

determined

(in an integrated manner).

Factory setting:

O2 measured value 2 seconds

COe measured value 10 seconds

43

Page 45

6 Commissioning

6.5.3 Analogue Outputs

In SETTINGS select for analogue outputs (see Chapter 10.1.3 Conversion of the Output

Range via the User Interface).

6.5.4 Replacing a Probe

Probe replacement:

A minimum of access level 1 is required for

triggering.

(See Chapter 7.2 Replacing a Probe.)

6.5.5 Display

Display:

No access level is required to make this set-

ting.

Brightness

Contrast

Time in seconds until the

background lighting extinguishes

Switchover °C/°F

44

Page 46

6 Commissioning

6.5.6 Limit Values

NOTICE

Access level 1 or 2 required!

Limit values

Proceed with the key.

Control of the entry with the following key

sequence:

, , , .

Limit value off

Monitoring of exceeding

Monitoring of undershooting

Setting of limit value

Setting of trigger time of limit value

NO - limit value resets automatically

YES - manual acknowledgement of limit value required (see Chapter 5.4

Main Menu

45

Page 47

6 Commissioning

If a limit value is undershot/exceeded, this is indicated in the status line by a down/up arrow

(see Chapter 5.3 Status Line).

In addition, the following message appears on the display:

Limit value 1:

• Factory setting: Exceeding of 400 ppm CO

Limit value 2:

• Factory setting: Undershooting of 0.5% O2, 30 s

Key returns to the main display

, 60 s

e

46

Page 48

6 Commissioning

6.6 Test Certificate

Each probe is accompanied with a test certificate. This means that you can compare the current measured values against test bench values at any time.

47

Page 49

6 Commissioning

6.7 Probe Certificate

A probe certificate is included with each probe. This should be completed during commissioning. The probe certificate must always be enclosed in the event of complaints and for repairs.

NOTICE

No probe certificate included with the probe, no goodwill!

Fig. 6-1 Probe certificate for the KS1D probe

48

Page 50

7 Maintenance

7 Maintenance

As a result of extensive self-diagnosis, the measuring system is essentially maintenance-free.

Maintenance is restricted to the calibration and the cleaning of dust or other deposits; as well

as the cyclic replacement of the ZrO2 measuring element.

7.1 Checking/Calibrating the KS1D Combination Probe

The checking / calibration should (advantageously installed) be built in at normal operating

temperature and carried out under operating conditions.

Recommended time spans (cycles):

• 6 hours after commissioning

• 12 months for natural gas combustion systems

7.1.1 Checking/Calibrating the Air Voltage (Offset)

1. Switch off the plant.

If you cannot switch off the plant, the probe must be dismantled. Observe the safety no-

tices!

2. Pre-ventilate, until there is no longer any flue gas at the measuring point (about 1 minute).

3. End the pre-purge.

4. Perform the offset calibration of the O2 (U-O2) and CO/H2 (U-CO) electrodes.

See Chapter 6.4.1 Offset Calibration.

7.1.2 Checking/Calibrating the O2 Electrode

See Chapter 6.4.2 Calibrating the O2 Electrode.

7.1.3 Checking/Calibrating the CO/H2 Electrode

See Chapter 6.4.3 Perform a Calibration of the CO/H2 Electrode.

49

Page 51

7 Maintenance

7.1.4 Checking/Calibrating with Test Gas

WARNING!

Danger of burns!

Probe becomes hot during operation.

If the probe is operated when removed, there is a danger of burns on the probe housing.

Never lay the probe on flammable material and heat it up.

Wear protective gloves

Description of the Testing Device

General Information:

The probe signals are pressure-dependent so they must be tested in a pressure-free environment. The testing device takes this into consideration and guarantees the best results in specific ranges. In exceptional cases, the pressure of the testing device must be adjusted to the

pressure of the measuring point through an additional device.

Choose a test gas combination so that O2 or COe content lies in the usual plant specific range

and within the specified measuring range of the probe. In standard applications in the combustion technology, O2 concentration lies at 2-5 vol.% and COe concentration lies between

100 ... 500 ppm. The following indicated test gas composition guarantees best results.

Description:

The testing device is a device for the task of testing gases on the probes LS1/KS1/KS1D in

standard housing. The probe can be tested or calibrated by means of test gas function.

The testing device can used lying on the table or plugged into the flue gas channel (Fig. 7-1

Testing device laying on the table and Fig. 7-2 Testing device plugged into flue gas channel.

For gas-tight fixing at the flue gas channel, the probe screw joints (clamping ring/screw cap)

can be attached to the plug in nozzle for flue gas channel.

50

Page 52

7 Maintenance

Fig. 7-1 Testing device laying on the table

1 Probe LS2, KS1, KS1D

2 Test gas connection

3 Plug in nozzle for flue gas channel

4 Test gas outlet

Fig. 7-2 Testing device plugged into flue gas channel

51

Page 53

7 Maintenance

Test probe

1. Install probe:

2. Heat up probe:

The testing device with plugged in heated probe would get hot.

Risk of burning!

3. Test gas function:

NOTICE

For test gas usage of 2 bar, test gas pressure lies at 1.6 l/min and increases at 0.6 l/min per

bar increase in pressure.

Push probe into the testing device until stop.

A cold probe should be heated up for at least 45 minutes in the installed condition. Should

an already heated up probe be installed in the testing device, then wait for 15 minutes.

CAUTION!

The test gas connection would be connected to the pressure reducer or the compressed

air supply of the test gas bottle using hose or hose clamp (D

sponding test gas is to be given up with 2 1 bar (pressure behind the bottle pressure

reducer). After 2 minutes, the probe calibration and testing can take place.

=4; Da=6mm). The corre-

i

CAUTION!

With the usage of CO containing test gases C, these must be removed from the test gas outlet

e.g. by the exhaust hose.

4. Calibration/probe testing:

According to table 4, LS2 is to be tested within 2 steps while KS1/KS1D in 3 steps.

a) Offset testing/calibration

Compare oxygen values of probe and test gas A.

Should the deviation of oxygen value be less than or equal to 0.2 vol.% of 21 vol.%,

the probe is fine.

Should the deviation of oxygen value be more than 0.2 vol.%, the probe must be calibrated according to the manual.

b) O2 testing/calibration

Compare oxygen values of probe and test gas B.

Should the deviation of oxygen value be less than or equal to 0.1 vol.% of 3 vol.%, the

probe is fine.

Should the deviation of oxygen value be more than 0.1 vol.%, the probe must be calibrated according to the manual.

c) CO/H2 testing/calibration

If the probe reacts to an increase in probe voltage on test gas C, then the probe is fine.

If the probe does not react, it has to be changed.

Compare CO value of the probe and COe-value of test gas C.

If COe value of the probe lies between 275 … 375 ppm, the estimation of COe value

is fine. Otherwise, calibrate a more precise estimation of the probe according to the

manual. calibrate on 300ppm.

NOTICE

CO/H2 calibration with test gas C has the advantage of determining and compensating the

long term drift of sensitivity. The sensitivity of the CO/H2 electrode usually increases over time

safe direction!

52

Page 54

7 Maintenance

NOTICE

With KS1D HT (item no. 656R2015), the test gas to be tested/calibrated can be connected

directly at the hose connection for calibration gas. A special testing device is not necessary.

The required test gas quantity lies between 40 ... 60 l/h.

Probe calibrated

Test gas matrix for testing or calibrating the respective probe

Functional

Probe

chrck/calibration with test

gas

Probe voltage U-O

Probe voltage U-CO probe voltage U-

2

CO

e

1 Offset A A A

2 OBBB

3 CO/H

2

CCC

Test gas composition

Composition

Test gas

**

A

O2 [Vol.%] COe [ppm]

21 0 Rest

*

N2 [Vol.%]

B 3 0 Rest

C 3 300 Rest

* CO Equivalent COe is the sum of all components in the exhaust gas. In test gases, it is represented

by CO and H2 in proportion of 2:1, e.g. 300ppm COe = 200 ppm CO +100 ppm H2.

** In the test gas device, the probe can be calibrated/tested with oil-free pressure air or synthethic air

from test gas bottle. In a COe-free and defined surrounding, the probe can also be tested/calibrated outside of the test gas device.

Recommendation:

To check the O2 electrode, use a test gas with 3 vol. % O2 in N2.

NOTICE

It is not possible to calibrate the CO/H2 electrode using hydrogen free test gas containing CO.

Recommendation:

To check the CO/H2, use a test gas with 100 ppm H2, 200 ppm CO, and 3 % O2 in N2.

Calibrate to 300 ppm.

For the standard design of the KS1D combination probe, a special testing device is required

(type 650R1015). For calibration adjust the pressure on the pressure gauge between

40 ... 60 mbar.

NOTICE

The pressure gauge is a very sensitive measuring device.

Protect it against overload. Pay attention to the pressure range!

53

Page 55

7 Maintenance

Risk of poisoning by carbon monoxide!

Carbon monoxide is a poisonous gas. Inhalation can cause severe poisoning symptoms an

can be fatal.

Perform the calibration quickly and only in open, well-ventilated rooms, ideally underneath

Do not open the valve on the test gas cylinder until shortly before calibration and close it

Danger of burns!

Probe becomes hot during operation.

If the probe is operated when removed, there is a danger of burns on the probe housing.

Never lay the probe on flammable material and heat it up.

Wear protective gloves

WARNING!

an exhaust hood.

immediately after calibration!

WARNING!

7.1.5 Checking/Calibrating with Reference Measurement

• The system must be in operation (ideally at the desired operating point).

• Perform the calibration as described in Chapters 6.4.2 Calibrating the O2 Electrode and

6.4.3 Perform a Calibration of the CO/H2 Electrode .

7.1.6 Simple Function Test of the CO/H2 Electrode

WARNING!

Danger of burns!

If a dismantled probe is operated, there is a danger of burns if touching the probe’ s housing.

Never lay the probe on flammable material and heat it up.

Wear protective gloves

1. Dismantle the probe

2. Fill isopropyl alcohol in a glass (approx. 1 cm)

Alternatively, use brandy/perfume / etc.

3. Hold the probe without the GED upside down into the glass.

Do not immerse!

NOTICE

An additional possibility is to purge the probe with test gas containing CO, NO, H2, etc.

Some ppm are enough.

If the probe is OK, this immediately reacts with a considerable increase in the probe voltage

(COe value) respective to the probe dynamic response.

54

Page 56

7 Maintenance

7.1.7 Wear-and-Tear Parts of the KS1D Combination Probe

Average life cycle = 2 - 3 years (depending on fuel).

Recommendation:

Exchange the ZrO

A worn measuring gauge could cause errors while calibrating and therefore impede the precision of measurement.

The combination probe KS1D type 656R2000 with housing and type 656R2010 without housing can only be replaced completely

.For combination probe KS1D HT (high temperature) type 656R2015, a replacement kit is

available. Order no. 656R2065.

measuring cell after 5 years at the latest.

2

Probe dynamic response

55

Page 57

7 Maintenance

7.2 Replacing a Probe

A probe must be replaced if:

• The internal resistances Rki-O2 and Rki-CO can no longer be set to values

of 20 Ω (+/- 5 Ω).

To be read at the probe data (Menu 213).

• The probe offset voltages U-O2 and U-CO in the air assume values above +20 mV or

below -30 mV.

To be read at the probe data (Menus 211 and 212).

• The CO/H2 electrode does not response

In the MAIN MENU, select for information.

In INFORMATION select for measured

values and probe data.

In MEASURED VALUES and Probe Data the

following is available for selection:

Display of the O2 measured values

(menu 211)

Display of the CO measured values

(menu 212)

Display of the Rki internal probe

resistances (menu 213)

Display of the current fuel selection

Reading of O2 measured values.

56

Page 58

7 Maintenance

Reading of CO

Reading of the R

ances.

NOTICE

After the exchange of the probe, a probe replacement must be triggered immediately after

reactivation!

• A minimum of access level 1 is required

measured values.

e

internal probe resist-

ki

In the MAIN MENU, select to make settings.

In SETTINGS, select for probe replacement.

57

Page 59

7 Maintenance

After the successful triggering of a probe exchange, the heating capacity and Rki are reset to

the standard values and can be learnt by the system again.

After that, start up the probe as in the initial start-up, as described in Chapter 6 Commission-

ing.

7.3 Sensor Replacement KS1D-HT

To replace the sensor in the KS1D-HT probe a replacement kit type 656R2065 is available.

The replacement kit includes:

• KS1D-HT probe

• Seal for probe

• Filter disc

• Seal Novaphit

By selecting with the cursor key

and ENTER a probe replacement is trig-

gered.

Sensor replacement KS1D-HT (replacement kit 656R2065)

Disconnect the probe and check the connection

Check temperature of probe/sensor and if necessary cool down

Insulation slot screwdriver size 0,4 x 8 x 100 mm

Torque wrench 3,5 Nm with attachment for Allan key

Open-end wrench 24 mm

Allan key 3 mm

1. Loose the connection cable in the probe head Fig. 7-3 Probe head.

2. Loose Allan key and remove them remove probe head Fig. 7-4 Sensor without probe

head

3. Remove sensor and seal Fig. 7-5 Sensor Ein-/Ausbau installation/dismounting and Fig. 7-

6 Ausgebauter Sensor mit Dichtring Dismounted sensor with seal.

4. Unscrew filter cap and remove filter Fig. 7-7 Sensorhalter mit Filterkappe und Filter sensor

holder with filter cap and filter.

5. Replace filter, screw on filter cap.

6. Insert sensor with seal.

7. Put on the probe head and fasten with screws (tightening torque 3.5 Nm

NOTICE

Please note the tightening torque 3.5 Nm!

8. Reconnect connecting cable, see Fig. 7-8 Klemmsockel bei KS1D-HT terminal socket

KS1D-HT

58

Page 60

7 Maintenance

NOTICE

Note the connection diagram and markings on terminal socket!

9. Close probe head.

The probe with a new sensor is ready to use.

Fig. 7-3 Probe head

Fig. 7-5 Mounting/dismounting the sensor

Fig. 7-4 Sensor without probe head

Fig. 7-6 Dismounted sensor with seal

59

Page 61

7 Maintenance

Fig. 7-7 Sensor holder with filter cap and filter

Fig. 7-8 Terminal socket KS1D-HT

1 (-) probe signal O2 (red)

3 (-) probe signal CO (grey)

4 (+) probe signal CO/O2 (black)

5 probe heater (white)

6 probe heater (white)

60

Page 62

8 Correcting Faults

8 Correcting Faults

8.1 Faults and Warnings

Faults are indicated by the red flashing of the ENTER key and shown in the display. After the

ENTER key is pressed, faults can be reset.

NOTICE

In the case of faults that cannot be allocated, data records can be read with LSB remote software and sent to LAMTEC for analysis!

F

Fault

W

Warning

H

Main processor

U

Monitoring processor

001

Fault number

Probe/probe voltage fault

/1

Trigger 1

NOTICE

Each fault can occur as a temporary or permanent fault. Temporary faults reset themselves

automatically when the corresponding values lie within the permissible range again.

If temporary faults are present for longer than 30 minutes or repeat several times within an

hour, they become permanent faults. A permanent fault remains even after switching voltage

off and on again. Permanent faults must be reset manually. After a fault reset, the device resets and starts again in COLD START mode.

Fault 001 Fault 002 - 008 Fault 015 - 016

Number of triggers,

temporary

Time window 60 min 60 min 60 min

Permanent time 30 min 30 min 30 min

10 x for at least 10 s 3 x for at least 10 s Immediately

61

Page 63

8 Correcting Faults

8.1.1 Faults

Deactivation during maintenance: Safety transfer O2, limit values, fault 001, 002, 004,

005, 007, 008.

Fault no. Fault text

001 (HP)

101 (ÜP)

/1 Voltage range of O2 electrode outside of the permissible range.

/2 Voltage range of CO electrode outside of the permissible range.

/3 O2 offset voltage outside of the permissible range during pre-purge

/4 CO offset voltage outside of the permissible range during pre-purge. The

/5 Both offset voltages outside of the permissible range during pre-purge; see

Probe/probe voltage fault

U-O2 must always lie within a range of -25 mV ... +300 mV during measurement operation; tolerance time of 30 seconds.

Help:

- The cold start might have been interrupted therefore the probe is not yet

ready for operation.

- Remove the probe and check with ambient air and test gas.

Compare the values with the test report. Exchange the probe if required.

- If the O2 electrode reacts to CO, the sensor is defective; exchange the

probe.

U-CO must always lie within a range of -25 mV ... +800 mV during measurement operation; tolerance time of 30 seconds.

Help:

- The cold start might have been interrupted therefore the probe is not yet

ready for operation.

- Remove the probe and check with ambient air and test gas.

Compare the values with the test report. Exchange the probe as required.

The offset voltage of the O2 electrode must always lie within a range of

-25 mV ... +5 mV during pre-purge.

Help:

- The cold start might have been interrupted therefore the probe is not yet

ready for operation.

- Remove the probe and check with ambient air and test gas.

Compare the values with the test report. Exchange the probe if required.

- The probe is blown "cold": unfavourable installation site.

offset voltage of the CO electrode must always lie within a range of

-25 mV ... +10 mV during pre-purge.

Help:

- The cold start might have been interrupted therefore the probe is not yet

ready for operation.

- Remove the probe and check with ambient air and test gas.

Compare the values with the test report. Exchange the probe if required.

- The probe is blown "cold": unfavourable installation site.

triggers /3 and /4.

62

Page 64

8 Correcting Faults

/6 CO voltage smaller than O

/7 O2 value over 25%

/8 Dynamism only at O

Help:

- The cold start might have been interrupted therefore the probe is not yet

ready for operation.

- Remove the probe and check with ambient air and test gas.

Compare the values with the test report. Exchange the probe if required.

- The probe is blown "cold": unfavourable installation site.

voltage

2

Offset-adjusted CO probe voltage more than 10 mV smaller than offsetadjusted O2 probe voltage; tolerance time of 28 seconds.

Help:

- Exchange the probe.

- Check the wiring of the sensors, maybe O2 and CO are inverted

The O

value rises to over 25% after the deactivation of the burner;

2

tolerance time of 15 seconds.

Help:

- Wait to see whether the value stabilises at 21%.

- If not, remove the probe and perform an offset calibration in the air.

- Installation site possibly unfavourable; the probe is possibly blown "cold."

electrode

2

The O2 electrode demonstrate dynamism without the CO electrode show-

ing dynamism; tolerance time of 30 seconds.

Help:

- Monitoring active only in case of values < 16 vol. % O2

- The probe no longer reacts to changes.

- Remove the probe and check for soiling of the grille.

- Check the O2 value in the ambient air and/or with test gas.

- If the O2 value is <16% in the ambient air, perform an

offset calibration.

- In case of no changes, exchange the probe.

/9 Missing CO dynamism or U-COe

U-O2 over 200 mV longer than 15 seconds without CO dynamism or UCOe

20 mV

Help:

- Monitoring active only in case of values < 16 vol. % O2

- The probe no longer reacts to changes.

- Remove the probe and check for soiling of the grille.

- Check with ambient air and test gas if pertinent.

- In case of no changes, exchange the probe.

/10 O2 voltage limit value

O2voltage U- O2 > 100 mV for more than 60 seconds.

/11 CO voltage limit value

CO voltage U- CO > 200 mV for more than 120 seconds.

/14 UCOe monitoring

COe voltage U-COe > 300 mV, tolerance time of 27 seconds, up to 117

seconds in case of dropping voltage.

Help:

- Activate maintenance mode in case of a test gas connection.

/15 The O2 voltage does not demonstrate the required dynamism.

Change in the O2 voltage U-O2 less than 2.5% within 24 hours whilst the

O2 or CO controller is running.

63

Page 65

8 Correcting Faults

/16 The CO voltage does not demonstrate the required dynamism.

Change in the CO voltage U-CO less than 2.5% or 8 mV within 24 hours

whilst the O2 or CO controller is running.

002 (HP)

102 (ÜP)

/1 The heater is short-circuited or has a high resistance; tolerance time of 10

/2 Heating power more than 15 s outside of the permitted range

/3 Heater Ri outside of 5 ... 15

/4 OFF current too high

Probe heating fault

seconds

Help:

- Check the wiring.

LT3-F Term. 13 and 14 disconnect the probe - probe heating at LT3-Ex

or in SAK

and measure the heater resistance between wire nos. 13 and 14

on the probe side.

Resistance approx. 9 ... 10 in heated state.

- If not OK, exchange the probe and restart.

- If OK, the fault presumably lies on the motherboard of LT3-F.

If the lines of the probe heating and probe signal are mixed up

during connection (possible in the case of the SAK wiring), the mother

board is destroyed. Disconnect the probe and measure the heating

voltage: approx. 11V

(8W … 25 W)

Help:

Installation site too hot: the heating capacity cannot be further reduced

(current actual value of R

internal resistance Rki of 20 or

Installation site too cold: the heating capacity cannot be further increased

(current actual value of Ri > 20) to reached the setpoint value of the

internal resistance Rki of 20 . Check the value of the internal resistance

Rki in the display.

- Trigger the probe exchange and restart the probe so that the Rki of

20 can be learnt again.

- Check the system temperature at the installation site.

- Check the probe when removed if pertinent.

- Exchange the worn probe if pertinent.

- As a follow-up fault, 002/3 Heater Ri outside of 5 ... 15 might be

displayed.

Internal resistance of heater outside of the interval 5 ... 15

Help:

Installation site too hot: the heating capacity cannot be further reduced

(current actual value of Ri < 20 ) to reached the setpoint value of the

internal resistance Rki of 20 . Check the value of the internal resistance

Rki in the display.

- Trigger the probe exchange and restart the probe so that the Rki of

20 can be learnt again.

- Check the system temperature at the installation site.

- Check the probe when removed if pertinent.

- Exchange the worn probe if pertinent.

As a follow-up fault, 002/2 Heating capacity outside of permissible interval

(8 W ... 25 W) for longer than 15 s might be displayed.

< 20 ) to reached the setpoint value of the

i

64

Page 66

8 Correcting Faults

/5 Heating control circuit open

/6 Temperature of the O

/7 Temperature of the CO sensor too high (Rki-CO too low)

003 (HP)

103 (ÜP)

004 (HP)

104 (ÜP)

/1 R

/2 Rki O2 too low. Internal resistance of ceramics of O2 under 10 , tolerance

005 (HP)

105 (ÜP)

/1 Rki-CO too high. Internal resistance of ceramics of CO for LT3-F over 50 ,

/2 Rki-CO too low. Internal resistance of ceramics of O2 under 10 , toler-

Heater controller at limit stop for longer than 30 seconds.

Help:

Check wiring between probe and LT3-F (check probe signals terminals 10/

11/12)

sensor too high (Rki-O2 too low)

2

For longer than 10 seconds, Rki-O2 is under 10

Heater Ri outside of 5 ... 15

Internal resistance of heater outside of the interval 5 ... 15

For longer than 10 seconds, Rki-CO is under 10

Internal fault of analogue signal processing

Device defective

- Contact the manufacturer. Specify the trigger for diagnostic purposes.

Internal resistance of ceramics of the O

too high. Internal resistance of ceramics of O2 for LT3-F over 50 ,

ki O2

electrode

2

and/or for LT3 over 100 , tolerance time of 30 seconds.

time of 30 seconds.

Help:

If Rki-O2 for LT3-F over 50 , and/or for LT3 over 100 , then

- Probe too cold.

- Internal resistance regulation not active or incorrect setpoint value.