Page 1

Operating Instructions

Ignition and Pilot Burner

GFI 48 / 70 / 89 and Ex Variants

Sensors and Systems for Combustion Engineering

www.lamtec.de

Page 2

Page 3

Table of Contents

Table of Contents

1 Important Information about the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Purpose/Applicability of the Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Safekeeping of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Classification of the Safety Instructions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Product-specific Dangers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Proper Use - Conditions of Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Scope of Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Installation and Connection Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Important Information about the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5.1 Life Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6.1 Technical data for the GFI 48 pilot burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6.2 Technical data for the GFI 70 pilot burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6.3 Technical data for the GFI 89 pilot burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6.4 Common technical data for GFI 48/70/89 pilot burner. . . . . . . . . . . . . . . . . . . . 17

3.6.5 Special version thermal rating with high power versions. . . . . . . . . . . . . . . . . . 21

3.6.6 Technical Data external Housing Ex-Zone I. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6.7 Technical data for NW48/70/89 sliding flange . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Design and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.1 Electrically Connecting the GFI Pilot Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3.1 Adjusting the GFI 48 Flame Quality and Flame Stability. . . . . . . . . . . . . . . . . . 40

5.3.2 Adjusting the GFI 70 Flame Quality and Flame Stability. . . . . . . . . . . . . . . . . . 41

5.3.3 Adjusting the GFI 89 flame quality and flame stability. . . . . . . . . . . . . . . . . . . . 42

5.3.4 Connect Pressure-Measuring Equipment for Gas and Air. . . . . . . . . . . . . . . . . 43

5.3.5 Evaluate the Flame Stability using the Ionisation Current. . . . . . . . . . . . . . . . . 43

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.1 Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Maintenance Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3 Perform Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.4 Customer Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.5 Warranty and Delivery Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2

Page 4

Table of Contents

7 Correcting Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.1 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.2 Fault Finding and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.3 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4 Information About the Repair Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8 Decommissioning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.1 Decommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9 Disposal Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10 EU Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11 Order Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3

Page 5

1 Important Information about the Manual

1 Important Information about the Manual

1.1 Purpose/Applicability of the Document

These instructions facilitate the safe and efficient handling of the pilot burner GFI and its

variants.

1.2 Target Group

These instructions must have been read carefully and completely before commencing with

any work. The basic prerequisite for working safely is compliance with all the specified safety

instructions.

NOTICE

All assembly , commissioning, troubleshooting and maintenance work may only be carried

out by authorised and trained personnel.

The device may be operated and maintained only by those who are capable of doing so

in terms of their level of knowledge and training.

For safety reasons, access to parameter settings must be restricted to authorised and

trained personnel.

Ensure that personnel have the proper qualifications when it comes to mounting,

commissioning and maintaining the Ex variants.

NOTICE

During the mounting, commissioning and maintenance of the Ex variant, it must be ensured

that only personnel familiar with explosion protection regulations who are qualified and authorised to perform this week work on and with this device.

1.3 Safekeeping of the Manual

Look after the manual and all the associated documents carefully.

The manual is part of the product and must be kept safe and be accessible to personnel at all

times.

Moreover, it is important that the manual:

• Is available when required.

• Is kept for the entire service life of the device.

• Is available to its next operator.

4

Page 6

2 General Safety Instructions

2 General Safety Instructions

2.1 Classification of the Safety Instructions and Warnings

The following symbols are used in this document to draw the user's attention to important safety information. They are located at points where the information is required. It is essential that

the safety information is observed and followed, and that applies particularly to the warnings.

DANGER!

This draws the user's attention to imminent danger. If it is not avoided, it will result in death or

very serious injury. The plant including its surroundings could be damaged.

WARNING!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in death or very serious injury. The plant including its surroundings could be damaged.

CAUTION!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in minor injuries. The plant including its surroundings could be damaged.

NOTICE

This draws the user's attention to important additional information about the system or system

components and offers further tips.

The safety information described above is incorporated into the instructions.

Thus, the operator is requested to:

1 Comply with the accident prevention regulations whenever work is being carried out.

2 Do everything possible within his control to prevent personal injury and damage to

property.

5

Page 7

2 General Safety Instructions

2.2 Product Safety

WARNING!

This product is state-of-the-art technology and complies with the generally accepted

safety-related rules and regulations.

Every device is tested before delivery to ensure that it is working properly and safely.

Only use this product when it is perfect condition and in accordance with the manual, the

prevailing regulations and guidelines and the applicable safety and accident prevention

regulations.

WARNING!

The risk of danger in the event of external fire, traffic and wind, flood waves and earthquakes

depend on the installation situation and the installation site to be assessed separately where

appropriate.

6

Page 8

2 General Safety Instructions

2.3 Product-specific Dangers

Installation and commissioning

WARNING!

All following warnings must be observed to avoid personal injury and damage to

property and the environment.

WARNING!

During the operation of electrical devices, certain parts inevitably have dangerous

voltage. If the following notices are not observed, severe bodily injury and property

damage could thus occur.

WARNING!

The integrated flame scanner is not provided with a direct switch-off of the fuel valves.

The subsequent signal processing must be carried out in the control system, which is

adapted to suit the combustion plant. The device may only be used with burner controllers which comply with local standards.

WARNING!

The integrated flame scanner is a safety device. Only specialist staff of the manufacturer or people approved by the manufacturer may intervene. No interventions by anyone

else are permissible. This applies, in particular, in the event of a defective fuse.

7

Page 9

2 General Safety Instructions

NOTICE

The integrated flame scanner of the pilot burner is a safety component for gaseous and liquid

fuels. When gas consumers according to EN 298 are used, they are subject to the Gas Appliances Directive 2009/142/EC.

• The applicable national safety regulations and standard notes are to be observed

in each case.

• The installation of the device must be carried out precisely according to the directions in

these operating instructions.

• Only connect the device when the technical data of the device matches the data of the

peripheral equipment.

• The device may only be operated in an environment for which it is specified in accordance

with the technical data.

• None of the safety labelling or markings may be removed from the device.

• No unauthorized modifications or attempts to repair the device

are permitted.

• Make sure that no spliced strands can come into contact with any of the adjacent connections. Use appropriate end splices.

• Make sure that the power cables are not interchanged between L and N.

• The plug connectors X13, X14, X15 and X16 do not have a secure disconnection from the

mains voltage.

• To replace or disconnect the plug connectors, all poles of the plant must be disconnected

from the mains.

• Measuring circuits must feature a secure disconnect according to EN 61140 "Protection

against electric shock " for active parts; for this reason, use only measurement and

evaluation devices which have a double or reinforced insulation.

• In order to provide for operating safety , make sure when installing the output contacts that

the circuitry of the radio interference suppression to be provided by the user is carried out

in such a way that there is no risk of shorting out the relay contact output (flame signal) by

defective component parts of the suppressor circuitry

• Work on electrical systems or equipment may be performed only by a certified electrician

or trained personnel managed and supervised by a certified electrician according to the

electrical engineering regulations.

• Machine and plant parts on which inspection, maintenance, and repair work is performed

must be de-energised and secured against reactivation. First make sure the enabled parts

are de-energised, then earth and short-circuit them. Secure adjacent, live parts against

accidental contact by covering them.

• The electrical equipment of the system must be checked regularly. Defects must be

reported immediately and remedied.

• If work on live parts is necessary, a second person must be involved who can press the

emergency stop or main switch if required. Block off the working area with a red-and-white

safety chain and a warning sign. Use only voltage-insulated tools.

• In case of fire in electrical systems, do not extinguish with water under any circumstances.

Only the provided fire extinguishers may be used.

8

Page 10

2 General Safety Instructions

2.4 Proper Use - Conditions of Use

Intended use

The ignition burner is utilised in industrial ovens, thermal processing systems and heating boilers for gas, oil and solid fuels.

It is used for the following purposes:

• Preheating the system

• Igniting the main burner

• Supporting the main burner flame

The ignition burner is intended only for the described use.

Any use going beyond the intended use shall be deemed improper.

The LAMTEC GmbH & Co KG shall not be liable for damage caused by the non-compliance.

2.5 Installation Notes

WARNING!

All following warnings must be observed to avoid personal injury and damage to

property and the environment..

Supply the feed cable with L, N and PE only. The neutral conductor may not have any

potential difference to PE.

Phase and neutral conductors may not be interchanged (this would lead to dangerous

malfunctioning, loss of protection against contact, etc.).

The supply cable of the integrated flame scanner must absolutely be fused with a 4 A

(slow) fuse. The minimum fusing amounts to 0.5A..

9

Page 11

3 Product Description

3 Product Description

3.1 Scope of Supply

Check the scope of supply

The scope of supply comprises:

• Operating Instructions

• Pilot burner GFI, design A, B, C

Fig. 3-1 Lieferumfang LAMTEC Zündbrenner.tif

Check the scope of supply for completeness and faultless condition.

If parts are missing or there is damage:

• Do not mount the device

• Do not connect

• Do not place into operation

• Submit a claim to the supplier

10

Page 12

3 Product Description

3.2 Rating Plate

Information on the rating plate

The rating plate is located on the pilot burner housing.

Fig. 3-2 Rating plate on the LAMTEC GFI pilot burner

On the rating plate, you will find information on the configuration of your pilot burner:

Rating plate example:

Fig. 3-3 Rating plate example LAMTEC GFI pilot burner

11

Page 13

3 Product Description

3.3 Equipment

With respect to the electrical equipment, the pilot burner is available in 3 versions.

The versions differ as follows:

Fig. 3-4 Pilot burner versions A-B-C

Equipment Design A

Design B Design C

(standard)

1 Ignition electrode X X X

2 Ionisation electrode X X X

3 Ignition transformer X X

4 Flame scanner

1

(IFM)

1

IFM= ionisation flame scanning

2

either ignition transformer or IFM

X X

2

2

GFI 48 / 70 / 89 with optional bar graph

Fig. 3-5 Optional GFI housing with bar graph equipment

NOTICE

The bar graph is optional for versions A and B (if with IFM).

No bar graph available in Ex-area

Differences in the type of cable entry point

The connection cables are fed into the device enclosure either

via a screwed cable gland or via a plug-in connection. The difference is in the flexibility during installation and connection work.

There are no differences in terms of technology or functionality.

In these operating instructions, the device is always depicted

with screwed cable gland.

12

Page 14

3 Product Description

3.4 Installation and Connection Materials

Installation and connection materials are not included in the scope of supply.

The following materials depicted below are required for the installation. See also chapter

Order Information

Fig. 3-6 Feed-through flange with seal

The steps described in chapter Montage are to be adhered to precisely for the installation.

3.5 Important Information about the Product

3.5.1 Life Cycle

The device has a limited lifespan. It is designed for 250,000 switching cycles at nominal load

and thus type-tested. With 50 switching operations per day , this results in a lifespan of approx.

10 years.

Increased load due to extreme operating conditions (e.g. temperature, vibration, contamination, etc.) can significantly reduce the service life.

The system operator is responsible for adapting the frequency of regular safety-related inspections to the operating conditions.

At the end of its service life, the device must be disposed of properly.

13

Page 15

3 Product Description

3.6 Technical Data

3.6.1 Technical data for the GFI 48 pilot burner

Fig. 3-7 Side view of GFI48 pilot burner design A/B

Fig. 3-8 Dimensions of GFI48 pilot burner design A/B

Fig. 3-9 Side view of GFI48 pilot burner Ex-Zone II

Fig. 3-10 Dimensions of GFI48 pilot burner ExZone II

14

Page 16

3 Product Description

Fig. 3-11 Side view of GFI48 pilot burner design C

Fig. 3-12 Dimensions of GFI48 pilot burner design C

1 Dimension outer tube length (customer-specific)

2 Outer tube diameter 48.3 mm x 2 mm (1.90 x 0.078 in)

3 Housing length versions A and B

4 Housing dimensions

5 Air supply connection 1 inch (BSPP inner threads)

6 Gas supply connection 1/2 inch (BSPP inner threads)

7 Distance between housing and connec-

tion flange

15

Page 17

3 Product Description

3.6.2 Technical data for the GFI 70 pilot burner

Fig. 3-13 Side view of GFI70 pilot burner design A/B

Fig. 3-14 Dimensions of GFI70 pilot burner design A/B

Fig. 3-15 Side view of GFI70 pilot burner ExZone II

Fig. 3-16 Dimensions of GFI70 pilot burner

Zone II

16

Page 18

3 Product Description

Fig. 3-17 Side view of GFI70 pilot burner design C

Fig. 3-18 Dimensions of GFI70 pilot burner design C

1 Dimension outer tube length (customer-specific)

2 Outer tube diameter 70 mm x 2 mm ( 2.75 x 0.078 in)

3 Housing length versions A and B

4 Housing dimensions

5 Air supply connection 1 1/2 inch (BSPP inner threads)

6 Gas supply connection 3/4 inch (BSPP inner threads)

7 Distance between housing and connec-

tion flange

17

Page 19

3 Product Description

3.6.3 Technical data for the GFI 89 pilot burner

Fig. 3-19 Side view of GFI89 pilot burner design A/B

Fig. 3-20 Dimensions of GFI70 pilot burner design A/B

Fig. 3-21 Side view of GFI89 pilot burner ExZone II

Fig. 3-22 Dimensions of GFI70 pilot burner ExZone II

18

Page 20

3 Product Description

Fig. 3-23 Side view of GFI89 pilot burner design C

Fig. 3-24 Dimensions of GFI89 pilot burner design C

1 Dimension outer tube length (customer-specific)

2 Outer tube diameter GFI89: 88.9 mm x 2 mm ( 3.5 x 0.078 in)

3 Housing length versions A and B

4 Housing dimensions

5 Air supply connection 2 inch (BSPP inner threads)

6 Gas supply connection 1 1/2 inch (BSPP inner threads)

7 Distance between housing and connec-

tion flange

19

Page 21

3 Product Description

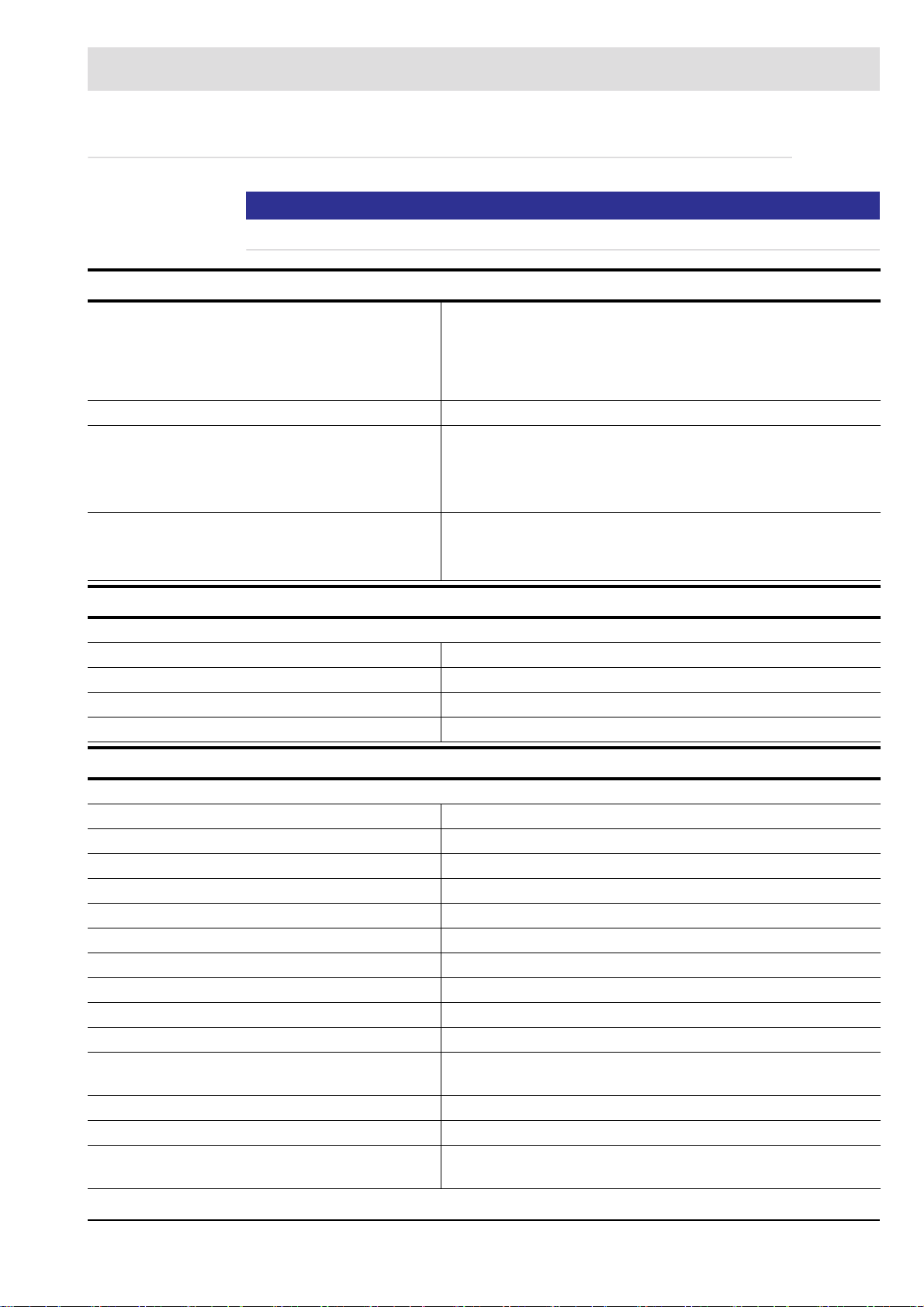

3.6.4 Common technical data for GFI 48/70/89 pilot burner

NOTICE

The electrical data are identical for all devices, only the air and gas volume flows differ.

Design A: Power supply voltage connection

Electrical data 120/127/220/230 VAC; -15/+10% (within the scope of the EU

Gas Appliances Directive), cf. rating plate

240 VAC; -20/+5% (outside the scope of the EU Gas Appli-

ances Directive), cf. rating plate

Mains frequency 50/60 Hz

Power consumption 10 V A flame scanner when UN = 230 V, 230 VA ignition trans-

former,

10 V A flame scanner when UN = 120 V, 192 VA ignition trans-

former,

Ignition transformer duty cycle ED= 50% on 2 min. (1’ on; 1’ off) 45 °C when UN=230V

ED= 15% on 1 min. (9”on; 51” off) -20°C<Ta<60°C when

UN=120V

Design A: connection to relays

Electrical data

NO contact NO contact (flame on)

Switching voltage

Switching current

1

1, 2

230 V or 48 VDC

max. 0.5 A cos 0.4 min 10 mA

Contact fusing (internal, soldered): 0.5 AT

Versions A and B: Integrated flame scanner

Ionisation input

Ionisation current from 1 ADC flame ON

Operating mode Continuous operation capable

Flame signal output contact

Contact type Safety-oriented, floating contact

Contact type NO, for "flame on", the contact is closed

Level of protection SKII, base isolation for the status signal

Permissible switching voltage

Permissible switching current

1

1, 2

230 VAC 48 VDC

Max. 0.5 A cos 0.4 Min. 10 mA

Contact fusing 0.5 AT (internal, soldered)

Safety time (FFDT)

Response time in the event of the flame going

tV off 1 s

out

Switch-on time tV on 1 s

Measuring shunt runs mains potential

Transmission ratio of measurement voltage to

10 mV (DC) = 1 A (DC)

ionisation current

20

Page 22

3 Product Description

Versions A and B: Integrated flame scanner

Intrinsic error 2%

Electrical safety Contact protection by means of protective impedances

Min. impedance of the connected

measuring device

1

The product is not permitted to be transported, stored or operated outside the specified range.

Doing so will invalidate any guarantees with regard to safety relevant functions.

2

Provide external spark quenching for inductive loads, do not connect any capacitive loads.

NOTICE

Use device manufacturer recommended silicone shielded cable. The device manufacturer will

only guarantee proper functioning if this cable is used. This cable is available in any length up

to the maximum cable length.

Design B: Connection of external flame scanner to the ionisation electrode

Recommended cable specifications

Cable type RG62 coaxial cable

Cable lengths

1 M

< 10 m/32,8 ft

Inner conductor Solid copper-plated steel wire, uninsulated Ø: 0.64 ± 0.025

mm (0.025 ± 0,00098 in)

Wire insulation PE hollow space insulation (helix made from PE strands with

PE hose on top) Ø: 3.7 mm (0.14 in)

Shield Braided from bare Cu wires, 96 % coverage

(nominal value)

Outer shell PVC, black outside diameter: 6.15 ± 0.18 mm (0.24 ± 0.0070

in)

Conductor resistance max. 144 Ohm/km

Operating capacity max. 43 pF/m (1 kHz)

Rated voltage 0.8 kV (50 Hz)

Test voltage 2 kV

Temperature range -40 °C to 80 °C (-40 °F to 176 °F)(fixed installation)

Design B and C: Power supply voltage connection to the external ignition transformer

Recommended cable specifications

Cable lengths Max. 200 m (656.168 ft)

Cable cross-section 3 x 1.0 mm2 (3 x 17 AWG)

Isolation PVC

Temperature range -40 °C ... +90 °C (-40 °F ... 194 °F)

Design C: Connection of external ignition transformer to the ignition electrode

Electrical data

Ignition voltage to earth max. 8 kV (at UN=230 V)

max. 7 kV (at UN=120 V)

Recommended cable specifications

21

Page 23

3 Product Description

Design C: Connection of external ignition transformer to the ignition electrode

Cable lengths max. 20 m (65.62 ft)

Cable cross-section 1 x 1.0 mm

Isolation Silicone, red-brown

Temperature range -60 ... +180 °C (-76 ... 356 °F)

Design C: Connection of external flame scanner to the ionisation electrode

(same procedure as for B)

Design C: Ground cable

Recommended cable specifications

Cable lengths Max. 200 m (656.168 ft)

Cable cross-section 1 x 1.5 mm

regulation

DANGER!

High voltage on the bare ignition electrode!

Pilot burner is only permitted to be operated with correct earthing.

With version C in particular there is a danger of death when removing or omitting the earthing, the housing earthing must be connected directly to the ignition transformer earthing!

In the event of damage to the earthing insulation, the device should be shut down; further

operation without repair is not permitted.

2

(1 x 17 AWG)

2

(1 x 15 AWG) and/or according to regional

Connection: GFI48 gas

Gas type Natural gas or propane

Flow rate (gas quantity) Natural gas: 8.0...15.0 m3/h (10.46 ... 19.61 yd3/h)

Propane: 3.2...6.0 m3/h (4.18 ... 7.84 yd3/h)

Operating pressure Min. 50 mbar (0.725 psi)

Max. 200 mbar (2.90 psi)

Connection: GFI70 gas

Gas type Natural gas or propane

Flow rate (gas quantity) Natural gas: 15.0 ... 30.0 m3/h (19.61 ... 39.23 yd3/h)

Propane: 6 ... 12.0 m3/h (7.84 yd3/h ... 15.69 yd3/h)

Operating pressure Min. 50 mbar (0.725 psi)

Max. 200 mbar (2.90 psi)

Connection: GFI89 gas

Gas type Natural gas or propane

Flow rate (gas quantity) Natural gas: 35.0...70.0 m3/h (45.77 ... 91.55 yd3/h)

Propane: 14...28.0 m3/h (18.31 ... 36.62 yd3/h)

Operating pressure Min. 50 mbar (0.725 psi)

Max. 200 mbar (2.90 psi)

NOTICE

Higher pressure ratings can be realised by connecting a restrictor upstream.

22

Page 24

3 Product Description

Connection: Air

Air type Combustion air

Operating pressure GFI48/70: min. 15 mbar (0.217 psi) + 6 mbar (0.087psi) per

metre of tube length

GFI89: min. 15 mbar 0.217 psi) + 5 mbar (0.087psi) per metre

of tube length

Air temperature max. 80 °C (176 °F)

Rel. air humidity max. 70 %

Air quality Free of dust, oil, grease and aerosols

The quality for the compressed air supply should conform to

ISO 8573-1:2010 class ( 7 : 4 : 4 ). Non-observance can

result in short-circuits due to material deposits in the housing.

Air ratio 0.3...0.5 (the remaining air quantity must be provided by the

combustion chamber)

Flow rate (air quantity) GFI48: max. 50 m3/h (65.39 yd3/h)

GFI70: max. 150 m3/h (196.19 yd3/h)

GFI89: max. 250 m3/h (326.98 yd3/h)

NOTICE

At temperatures in the combustion chamber of over 500 °C (932 °F), if the pilot burner is off,

a cooling air supply of 50% of the max. combustion air should be provided.

Operating modes

Permitted operating modes Intermittent operation/continuous operation

Ambient conditions during operation

Permissible ambient temperatures -20 ... +60 °C (-4 ... 140 °F)(without bar graph) 0 ... +60 °C

(32 ... 140 °F) (with bar graph)

Rel. air humidity Max. 85 % (non-condensing)

Ambient conditions for storage

Ambient temperature -20 ... +60 °C (-4 ... 140 °F)

Rel. air humidity Max. 85 % (non-condensing)

Thermal rating

Thermal rating GFI48: 70 ... 150 kW

GFI70: 150 ... 300 kW

GFI89: 400 ... 700 kW

SIL classification

Level SIL 3

Electrical safety

Protection class IP 65 / NEMA 4 / NEMA 4X

IEC

for integrated power unit Ex zone II: Ex ec IIB+H2 T4 Gc

23

Page 25

3 Product Description

3.6.5 Special version thermal rating with high power versions

NOTICE

The following technical data relates exclusively to the scope of the NFPA.

Connection: GFI48 gas

Flow rate (gas quantity) Natural gas: 25 ... 40 m3/h (32.69 ... 52.31 yd3/h)

Propane: 9.5 ... 15 m3/h (12.42 ... 19.61 yd3/h)

Operating pressure Natural gas: 500 ... 1000 mbar (7.25 ... 14.50 psi)

Propane: 400 ... 800 mbar (5.80 ... 11.60 psi)

Connection: GFI70 gas

Flow rate (gas quantity) Natural gas: 50 ... 80 m3/h (65.39 ... 104.63 yd3/h)

Propane: 19 ... 31 m3/h (24.85 ... 40.54 yd3/h)

Operating pressure Natural gas: 500 ... 1000 mbar (7.25 ... 14.50 psi)

Propane: 500 ... 1000 mbar (7.25 ... 14.50 psi)

Connection: GFI89 gas

Flow rate (gas quantity) Natural gas I: 230 ... 300 m3/h (300.82 ... 392.38 yd3/h)

Natural gas II: 460 ... 600 m3/h (601.65 ... 784.76 yd3/h)

Propane: 90 ... 115 m3/h (117.71 ... 150.41 yd3/h)

Operating pressure Natural gas I: 700 ... 1000 mbar (10.15 ... 14.50 psi)

Natural gas II: 700 ... 1000 mbar (10.15 ... 14.50 psi)

Propane: 700 ... 1000 mbar (10.15 ... 14.50 psi)

Thermal rating with high power versions

GFI 48 Natural gas: 250 ... 400 kW

Propane: 250 ... 400 kW

GFI70 Natural gas: 500 ... 800 kW

Propane: 500 ... 800 kW

GFI89 Natural gas I: 2300 ... 3000 kW

Natural gas II: 4600 ... 6000 kW

Propane: 2300 ... 3000 kW

NOTICE

This is not a control range as for a burner as the appropriate air volume must be set accordingly when changing the gas pre-pressure.

Connection: Air

Air type Combustion air

Operating pressure GFI48/70: min. 15 mbar + 6 mbar (0.217 psi + 0.087psi ) per

metre of tube length

GFI89: min. 15 mbar + 5 mbar (0.217 psi + 0.072 psi) per

metre of tube length

Air temperature max. 80 °C (176 °F)

Rel. air humidity max. 70 %

24

Page 26

3 Product Description

Connection: Air

Air quality Free of dust, oil, grease and aerosols

The quality for the compressed air supply should conform to

ISO 8573-1:2010 class ( 7 : 4 : 4 ). Non-observance can

result in short-circuits due to material deposits in the housing.

Air ratio 0.3...0.5 (the remaining air quantity must be provided by the

combustion chamber)

Flow rate (air quantity) GFI48: max. 50 m3/h (65.39 yd3/h)

GFI70: max. 150 m3/h (196.19 yd3/h)

GFI89: max. 250 m3/h (326.98 yd3/h)

NOTICE

At temperatures in the combustion chamber of over 500°C (932 °F), if the pilot burner is off, a

cooling air supply of 50% of the max. combustion air should be provided.

25

Page 27

3 Product Description

3.6.6 Technical Data external Housing Ex-Zone I

Fig. 3-25 External power unit Ex-Zone I

Fig. 3-26 Dimensions of the External power unit - Ex-Zone I

Technische Daten

Explosion protection: II 2 G Ex db IIB + H2 T6/T5 GbII 2 D Ex tb IIIC T80 °C...T95 °C Db

Material: copper-free aluminium, stainless steel 1.4404/316

Certificates/Test certificates: ITS 15 ATEX 18302X, IECEx ITS 15.0041X

Electrical safety: IP 66 according to EN 60529

Impact resistance: 7 Joule according to EN 60079-0

Temperatureinsatzbereich: -20 °C ... +60 °C (-4 ... 140 °F)

26

Page 28

3 Product Description

3.6.7 Technical data for NW48/70/89 sliding flange

Technical data for NW48/70/89 sliding flange

Fig. 3-27 Dimensions of the sliding flange of the GFI pilot burner

The flange is equipped with 4 grub screws to fix the outer tube in a defined

position. The pipe leadthrough contains an EPDM O-ring seal.

Material

Flange 1.4571 stainless steel, galvanized steel

O-ring seal EPDM

Temperature range -40 ... +120 °C (-40 °F ... 248 °F)

Pressure 1.0 bar (14.50 psi)

Weight NW48: 1.24 kg (2.73 lb)

NW70: 1.5 kg (3.30 lb)

NW89: 2.4 kg (5.29 lb)

Dimensions

b Flange plate thickness NW48: 10 mm (0,39 in)

NW70: 10 mm (0,39 in)

NW89: 15 mm (0,47 in)

D Flange diameter NW48: 140 mm (5,51 in)

NW70: 160 mm (6,29 in)

NW89: 190 mm (7,48 in)

d1 Outside collar diameter NW48: 70 mm (2,75 in)

NW70: 90 mm (3,54 in)

NW89: 115 mm (4,33 in)

d2 Hole diameter NW48: 14 mm (0,55 in)

NW70: 14 mm (0,55 in)

NW89: 18 mm (0,70 in)

h Total height NW48: 25 mm (0,98 in)

NW70: 25 mm (0,98 in)

NW89: 30 mm (1,18 in)

k Hole circle diameter NW48: 110 mm (4,33 in)

NW70: 130 mm (5,11 in)

NW89: 150 mm (5,90 in)

DN Nominal diameter 48/70/89

27

Page 29

4 Design and Functions

4 Design and Functions

4.1 Design

Construction of pilot burner versions A and B

Fig. 4-1 Main components of LAMTEC GFI pilot

burner

Connections: Gas and air supply

1 Outer tube

2 Air housing

3 Gas block

4 Connection enclosure

Fig. 4-2 Gas and air supply connections

Connections: Measurement sockets

Fig. 4-3 Connections of the measurement sockets for gas and air

Connections: test sockets

1 Air supply connection

2 Gas supply connection

1 Measurement socket - air

2 Measurement socket - gas

Fig. 4-4 Test socket connections

28

1 and 2 test sockets for the temporary

connection of a measurement device

for

flame setting

Page 30

4 Design and Functions

4.2 Functional Description

Operating mode of the pilot burner

Fig. 4-5 Pilot burner versions A-B-C

1 Ignition electrode 3 Ionisation electrode 5 System control

2 Ignition transformer 4 Flame scanner

DANGER!

High voltage on the bare ignition electrode!

Pilot burner is only permitted to be operated with correct earthing.

With version C in particular there is a danger of death when removing or omitting the earthing; the housing earthing must be connected directly to the ignition transformer earthing!

In the event of damage to the earthing insulation, the device should be shut down; further

operation without repair is not permitted.

The ignition electrode is connected to the ignition transformer. The ignition transformer is supplied from the system control.

The ionisation diode in the flame area of the pilot burner is connected to the flame scanner.

The flame scanner measures the ionisation current and evaluates it.

The amount of the ionisation current can also be determined via a shunt measuring principle

using a multimeter. The measured voltage is to be converted as follows into the ionisation current: 10 mVDC = 1 ADC

When the flame is detected, the flame scanner activates the relay and the pilot light indicates

"flame on".

The system control detects the relay activity and implements this into system-specific actions.

WARNING!

Both analogue outputs have supply voltage reference!

Contact protection must be observed.

Measuring circuits must be safely separated from dangerous active components to

EN 61140 "Protection against electric shock".

Only use measurement and data interpreting devices that have double or reinforced insu-

lation.

29

Page 31

5 Commissioning

5 Commissioning

5.1 Transport

NOTICE

Depending on the version, the device can be heavy and bulky.

The following regulations should be observed during transport:

Always transport the device in the original protective packaging.

Depending on the weight and situation, use lifting gear and/or obtain assistance from an-

other person

5.2 Assembly

Observe the safety regulations!

NOTICE

Fragile!

Isolators installed in the pilot burner are ceramic and may break.

Do not allow pilot burners to drop or suffer impact.

CAUTION!

Loose, unfastened pilot burner!

Risk of injury due to falling pilot burners.

Secure the pilot burner against falling for the duration of the assembly process by hand or

using a suitable device.

WARNING!

All activities described in this chapter must only be performed by qualified, authorised personnel observing all safety requirements.

Select mounting location

The mounting location must meet the following requirements:

• Space requirement for mounting and removal: See section "Space requirement for mounting and removal".

• Remaining clearance after mounting: See section "Remaining clearance after mounting".

• Ambient conditions: For more details, see chapter 3.6 Technical Data

• The mounting surface must be torsion-resistant, stable and even.

• Distance to external components and to the system control: For more details, see chapter

3.6.1 Technical data for the GFI 48 pilot burner

30

Page 32

5 Commissioning

Mounting position

Due to the pilot burner falling due to vibrations for overhead assembly with sliding

flange!

Overhead assembly is only permitted with welded flange!

DANGER!

Fig. 5-1 Possible installation situations

1 Mounting angle in relation to the hori-

zontal 0…90°. A corresponding adapter

for angled assembly must be present

on-site.

2 Upright or vertical mounting position 4 Level or horizontal mounting position

Plan supply lines

Control devices are to be provided for the gas and air supply.

3 Not permissible with sliding flange.

Overhead assembly is permissible

solely with a welded flange!

31

Page 33

5 Commissioning

The following materials are required for the installation.

Fig. 5-2 Feed-through flange with seal and screws

Designation Specification

1 Feed-through flange Appropriate to the pilot burner, with radially

1 Seal

4 x M12 screws (GFI48/GFI70)

4 x M16 screws (GFI89)

4 washers

4 screw nuts

arranged grub screws for securing the outer tube.

The following material is required for the electrical connection.

Designation Specification

Terminal lug Ring terminal

Ground cable

Ignition cable

Ionisation cable

Specific cable specifications, see chapter 3.6 Technical Data

32

Page 34

5 Commissioning

Space requirement for mounting and removal

Fig. 5-3 LAMTEC GFI pilot burner space requirement for mounting and removal

For the insertion of the device, at least the full device length in axial extension of the outer tube

is to be kept clear. For maintenance and servicing, there must be the possibility of being able

to completely remove the device again.

Subsequently attached system components in the surrounding environment must be easily removable.

Remaining clearance after mounting

Care must be taken to ensure that the following clearance on the rear side of the device remains clear at all times even after mounting:

Fig. 5-4 Remaining clearance after mounting the pilot burner

1 Space for

cable connection

2 Working space for

connecting of the

measurement device plugs

3 View area for the

detection of the

pilot lamp

33

Page 35

5 Commissioning

Before the installation: Check the ionisation electrode

High voltage on the bare ionisation electrode.

Risk of death from contact.

Only allow qualified electricians to perform the electrode test.

Wear face protection and insulating protective gloves.

Switch off and secure additional aggregates, burners and gas valves.

Inertise the gas line completely.

Line breaks and earth short circuits can be determined with the electrode test. Testing principle: An existing flame is simulated by connecting an inspection diode.

An inspection diode is required for the electrode test: Item number: 646R0100

DANGER!

Fig. 5-5 Inspection diode for ionisation electrode test

Depending on the pilot burner design, the following components are to be temporarily

connected:

Version External flame scanner Power supply

A X

B X X

C X X

34

Page 36

5 Commissioning

Perform the electrode test as follows:

NOTICE

Disconnect the pilot burner during the test from subordinate burner control.

Simulating the flame switches the flame relay.

1. Deactivate the flame scanner.

2. Clamp the red clamp of the inspection diode to

attach the ionisation electrode.

3. Activate the flame scanner.

4. Using the yellow/green clamp, connect to

earth, e.g. connect to the outer tube.

5. Check with contact to earth whether the

flame scanner activates.

If the flame scanner activates, the electrode is

functional, and the pilot burner can be installed.

If the flame scanner does not activate, the electrode is not functional, and the pilot burner may

not be installed.

Fig. 5-6 Test of the ionisation electrode

Check possible causes of error:

1. No power supply voltage applied to the flame scanner.

2. Polarity of the inspection diode is reversed.

3. The ceramic insulators are moist, contaminated or broken.

4. Accidental earth of the ionisation electrode present.

5. Line break between ionisation electrode and flame scanner present.

If one of these faults is present, it must be rectified.

Then perform the test again.

If the flame scanner activates after repeating the test, the pilot burner

can be installed. Otherwise the pilot burner must be inspected by the manufacturer.

35

Page 37

5 Commissioning

Mount the pilot burner

Fig. 5-7 Mount the pilot burner

Loosen the grub screws on the feed-through

flange and insert the pilot burner up to the

desired position in the feed-through flange.

Tighten the

grub screws in a cross-wise pattern to secure the

pilot burner.

Fig. 5-8 Tighten the grub screws

NOTICE

If the combustion chamber overpressure is greater than 200 mbar (2.90 psi) , the attachment

of the pilot burner to the feed-through flange must be secured by additional means against detaching due to vibration or other forces.

An additional possibility would be to dispense with the sliding flange altogether and for an appropriate mounting flange to be factory-fitted.

NOTICE

For this, the precise installation length must be specified in advance as it will not possible to

adapt later on site.

36

Page 38

5 Commissioning

Connect gas and air supply

NOTICE

The quality for the compressed air supply should conform to ISO 8573-1:2010 class ( 7 : 4 : 4

). Non-observance can result in short-circuits due to material deposits in the housing.

NOTICE

At temperatures in the combustion chamber of over 500°C (932 °F), if the pilot burner is off, a

cooling air supply of 50% of the max. combustion air should be provided.

Fig. 5-9 Connect gas and air supply

1. Conduct the gas and air supply lines

through

to the pilot burner through the control

devices.

2. Remove the transport safety devices

from the connections.

3. Connect air supply to "A" (Air).

4. Connect gas supply to "G" (Gas).

5. Observe the torques from the table

when tightening the screw connections!

Thread Torque Thread Torque

1/8" 5 Nm 1" 15 Nm

1/4" 7 Nm 1 1/2" 20 Nm

1/2" 10 Nm 2" 25 Nm

3/4" 15 Nm

37

Page 39

5 Commissioning

5.2.1 Electrically Connecting the GFI Pilot Burner

Design A: Electrically connect the pilot burner

Fig. 5-10 Connect pilot burner version A

Connect the pilot burner

cables as follows

No. Wire colour Function

1 bl Phase

2 bl Neutral conductor

3 bl Ignition transformer NTR-N

4 bl Ignition transformer LTR-L

5 bl COM

6 bl NO

PE gn/ye Protective conductor

Design B: Electrically connect the pilot burner

No. Wire colour Function

1 bl Phase

2 bl Neutral conductor

3 bl Ignition transformer NTR-N

4 bl Ignition transformer LTR-L

5 bl COM

6 bl NO/ionisation electrode

PE gn/ye Productive conductor

Fig. 5-11 Electrically connect the pilot burner

design B

NOTICE

Version B has the same connection as version A.

For version B however, the following applies:

If only the ignition transformer is used, only connect wires 3,4 and PE.

With an external flame scanner, the ionisation cable should be connected to wire 6

The remainder is without function. If only the IFM is used, only connect wires 1,2,5,6 and PE.

38

Page 40

5 Commissioning

Design C: Connect earth cable

Fig. 5-12 Connect version C earth cable

Design C: Ignition and ionisation cables

1 Connection thread

2 Ring terminal lug

3 Spring washer

4 Earthing bolt

Fig. 5-13 Electrical connection of GFI89 version C

1 Ignition cable 2 Ionisation cable 3 Ground connection

DANGER!

High voltage on the bare ignition electrode!

Pilot burner is only permitted to be operated with correct earthing.

With version C in particular there is a danger of death when removing or omitting the earthing, the housing earthing must be connected directly to the ignition transformer earthing!

In the event of damage to the earthing insulation, the device should be shut down; further

operation without repair is not permitted.

39

Page 41

5 Commissioning

Connection Design C to external housing

Fig. 5-14 Connection Design C to external housing Ex-Zone I

Design C: Electrically connect the pilot burner

Connect the pilot burner

cables as follows

No. Wire colour Function

1 bl Phase

2 bl Neutral conductor

3 bl Ignition transformer NTR-N

4 bl Ignition transformer LTR-L

5 bl COM

6 bl NO

PE gn/ye Protective conductor

Fig. 5-15 Connect pilot burner version C

DANGER!

High voltage on the bare ignition electrode!

Pilot burner is only permitted to be operated with correct earthing.

With version C in particular there is a danger of death when removing or omitting the earthing, the housing earthing must be connected directly to the ignition transformer earthing!

In the event of damage to the earthing insulation, the device should be shut down; further

operation without repair is not permitted.

40

Page 42

5 Commissioning

5.3 Commissioning

Observe the safety regulations!

NOTICE

Wear personal safety equipment.

Face protection

Insulating safety gloves

Safety shoes

All activities described in this chapter must be performed by qualified, authorised personnel

only under observance of requirements from the following regulating bodies:

Official Journal of the European Union L 96/309, Directive 2014/34/EU of 26 February

2014 relating to equipment and protective systems intended for use in potentially

explosive atmospheres (recast)

EN 60079-0:2014-06 (VDE 0170-1:2014-06) Explosive atmospheres – Part 0:

Equipment – General requirements

WARNING!

WARNING!

Security relevant functionality.

Risk of death and risk of material damage if commissioned incorrectly.

Commissioning may only be performed by authorised specialist personnel.

DANGER!

For ignition attempts, there is a risk of flashing caused by residual gas in the gas tube

or gases in the environment.

For pilot attempts, secure the hazard area in front of the pilot burner mouth.

Clear the pilot burner with purge air from residual gas as necessary.

The ignition should ideally only be tested in installed status.

Integrate the device into the system control

Integrate the relay switch contacts of the flame scanner into the safety-oriented system control. You must observe and comply with the requirements of the DIN EN 298 and the regional

requirements.

In addition, you must ensure that the function or neutral position of the respective

contact is checked regularly - in accordance with the requirements - by the superordinate control system and/or burner sequencer.

Ensure signal detection

NOTICE

In unfavourable conditions, the energy of the ignition spark can interfere with the ionisation

signal in such a way that it is not possible to perform a measurement.

T o prevent this, a time section of approx. 0.5 s before expiry of the ignition safety time, in which

a secure signal detection can take place, is to be set on the system control.

41

Page 43

5 Commissioning

Perform leak test

NOTICE

The regional requirements for the leak test must be observed and complied with.

Perform functional test

Perform the functional test as follows:

1 Check the pilot light of the of the flame scanner with the fuel feed closed off (flame off).

NOTICE

The flame scanner pilot lamp is only visible with the bar graph option.

If there is no bar graph included with the delivery , alternatively check the flame relay (NO)

for correct function

– The pilot light must be off, and the relay contact must be open.

2 Ignite the flame.

– The pilot light must be lit, and the relay contact must be closed.

3 Extinguish the flame.

– The pilot light must go out, and the relay contact must open again.

If the functional test was successful, the flame scanner has been correctly

commissioned.

- Otherwise, the fuel supply is to be closed immediately.

- Check electrical connections and the configuration of the system control.

- Disconnect the pilot burner from the system control.

- Do not place the pilot burner into operation.

- Contact the manufacturer.

42

Page 44

5 Commissioning

5.3.1 Adjusting the GFI 48 Flame Quality and Flame Stability

The following graphic shows the air volume flow to be adjusted in [m3/h] in dependence on the

desired gas pre-pressure in [mbar] and/or the thermal power in [kW]. The gas pre-pressure is

to be recorded at the measurement socket for gas.

Fig. 5-16 Air volume flow to be set

1 Gas pre-pressure in [mbar] 4 Stability field in free self-sustaining com-

bustion

2 Thermal power in [kW] 5 Ideal line

3 Air volume flow in [m3/h]

Reference value table

The reference value table shows the values of the air pressure in [mbar] for the air volume flow

in [m3/h] determined in the diagram.

Outer tube

length

1,000 mm

(39,37 in)

2,000 mm

(78,74 in)

3,000 mm

(118,11 in)

4,000 mm

(157,48 in)

Combustion air

30 m3/h

(39.23 yd3/h)

6 mbar

(0.087 psi)

8 mbar

(0.11 psi)

10 mbar

(0.14 psi)

12 mbar

(0.17 psi)

40 m3/h

(52.31 yd3/h)

10 mbar

(0.14 psi)

14 mbar

(0.20 psi)

18 mbar

(0.26 psi)

22 mbar

(0.32 psi)

50 m3/h

(65.39 yd3/h)

15 mbar

(0.21 psi)

21 mbar

(0.30 psi)

28 mbar

(0.40 psi)

34 mbar

(0.49 psi)

60 m3/h

(78.47 yd3/h)

20 mbar

(0.29 psi)

28 mbar

(0.40 psi)

37 mbar

(0.53 psi)

45 mbar

(0.65 psi)

43

Page 45

5 Commissioning

5.3.2 Adjusting the GFI 70 Flame Quality and Flame Stability

The following graphic shows the air volume flow to be adjusted in [m3/h] in dependence on the

desired gas pre-pressure in [mbar] and/or the thermal power in [kW]. The gas pre-pressure is

to be recorded at the measurement socket for gas.

Fig. 5-17 Air volume flow to be set for GFI 70

1 Gas pressure in [mbar] 4 Stability field in free self-sustaining com-

bustion

2 Thermal power in [kW] 5 Ideal line

3 Air volume flow in [m3/h]

Reference value table

The reference value table shows the values of the air pressure in [mbar] for the air volume flow

in [m3/h] determined in the diagram.

Outer tube

length

1,000 mm

(39,37 in)

2,000 mm

(78,74 in)

3,000 mm

(118,11 in)

4,000 mm

(157,48 in)

Combustion air

60 m3/h

(78.47 yd3/h)

6 mbar

(0.087 psi)

8 mbar

(0.11 psi)

10 mbar

(0.14 psi)

12 mbar

(0.17 psi)

90 m3/h

(117.71 yd3/h)

10 mbar

(0.14 psi)

14 mbar

(0.20 psi)

18 mbar

(0.26 psi)

22 mbar

(0.32 psi)

120 m3/h

(156.95 yd3/h)

15 mbar

(0.21 psi)

21 mbar

(0.30 psi)

28 mbar

(0.40 psi)

34 mbar

(0.49 psi)

195 m3/h

(255.04 yd3/h)

20 mbar

(0.29 psi)

28 mbar

(0.40 psi)

37 mbar

(0.53 psi)

45 mbar

(0.65 psi)

44

Page 46

5 Commissioning

5.3.3 Adjusting the GFI 89 flame quality and flame stability

The following graphic shows the air volume flow to be adjusted in [m3/h] in dependence on the

desired gas pre-pressure in [mbar] and/or the thermal power in [kW]. The gas pre-pressure is

to be recorded at the measurement socket for gas.

Fig. 5-18 Air volume flow to be set for GFI 89

1 Gas pressure in [mbar] 4 Stability field in free self-sustaining com-

bustion

2 Thermal power in [kW] 5 Ideal line

3 Air volume flow in [m3/h]

Reference value table

The reference value table shows the values of the air pressure in [mbar] for the air volume flow

in [m3/h] determined in the diagram.

Outer tube

length

1,000 mm

(39,37 in)

2,000 mm

(78,74 in)

3,000 mm

(118,11 in)

4,000 mm

(157,48 in)

Combustion air

120 m3/h

(156.95 yd3/h)

5 mbar

(0.07 psi)

8 mbar

(0.11 psi)

10 mbar

(0.14 psi)

12 mbar

(0.17 psi)

160 m3/h

(209.27 yd3/h)

9 mbar

(0.13 psi)

13 mbar

(0.18 psi)

17 mbar

(0.24 psi)

21 mbar

(0.30 psi)

200 m3/h

(261.58 yd3/h)

14 mbar

(0.20 psi)

19 mbar

(0.27 psi)

24 mbar

(0.34 psi)

29 mbar

(0.42 psi)

240 m3/h

(313.90 yd3/h)

20 mbar

(0.29 psi)

26 mbar

(0.37 psi)

32 mbar

(0.46 psi)

38 mbar

(0.55 psi)

45

Page 47

5 Commissioning

5.3.4 Connect Pressure-Measuring Equipment for Gas and Air

Suitable are pressure-measuring instruments with a measuring range from 0......>200 mbar.

1 Unscrew grub screws 2...3 revolutions out of the

measuring instrument inlet connection.

2 Connect air pressure measuring device to "A" (Air).

3 Connect gas pressure measuring device to "G"

(Gas).

NOTICE

The test measurement sockets should be closed again once the measurement has been completed.

5.3.5 Evaluate the Flame Stability using the Ionisation Current

General information about Ionisation Flame Monitoring

Following factors are essential regarding the safety of Ionisation Flame Monitoring:

• The reliable monitoring of a gas flame is achieved if the flame monitoring can be optimally

adapted to the gas combustion plant.

• The following must be taken into account. In the ionisation process, flame and burner are

also used as parts of the electrical circuit to form an optimal ionisation current. It is therefore essential that the boiler and burner are properly grounded.

• Of decisive importance for the height of the ionisation current is the fuel, the burner setting

and the electrode arrangement.

• The ionisation current increases with the calorific value of the gas. The prerequisite

for the formation of optimum values is given if, in relation to the setting of the burner:

– a stable flame is created

– the burner is operated with a low excess of air , so that an optimum Combustion occurs.

Flame quality and stability are evaluated by measuring the ionisation current. An ampermeter

is connected to the flame monitor for this purpose.

NOTICE

Measuring circuits must feature a secure disconnect according to EN 61140 "Protection

against electric shock " for active parts; for this reason, use only measurement and evaluation

devices which have a double or reinforced insulation.

NOTICE

Work on electrical systems or equipment may be performed only by a certified electrician or

trained personnel managed and supervised by a certified electrician according to the

electrical engineering regulations.

46

Page 48

5 Commissioning

Measurement sockets with limited designated purpose for short-time measurement.

Risk of explosion if improperly used for continuous measurement.

Do not use measurement sockets for continuous measurements!

Perform short-time measurement only with suitable measuring device and under continuous

supervision.

NOTICE

To improve the evaluation of the flame stability, a needle instrument is more suitable than a

digital measuring device.

An amperemeter with a range of measuring of 0-300 mV is suitable.

10 mV correspond to 1A. .

NOTICE

Sensitive electronics!

Risk if faulty switching when handling measuring device plugs. An accidental contact of a

connected measuring terminal with the enclosure ground or with another contact can occur

here. This can trigger a faulty switching in the system control (e.g. by extinguishing the flame

signal).

For this reason, the flame monitor monitor must be deactivated during connecting and disconnecting of the measuring terminals, e.g. by disconnecting the supply voltage.

DANGER!

47

Page 49

5 Commissioning

Designs A and B: Connect measuring instrument for ionisation current measurement

Use pointer amperemeter with a measuring range of 0-300 mV. 10 mV correspond to 1A.

Fig. 5-19 Connect amperemeter to measuring terminals

Procedure:

1 Deactivate flame monitor.

2 Connect measuring instrument to the flame monitor.

3 Activate flame monitor.

Designs C: Connect measuring instrument for ionisation current measurement

Procedure:

1 Deactivate external flame monitor.

2 Connect measuring instrument to the external flame monitor.

3 Activate external flame monitor.

Perform measurement:

Flame quality and flame stability are set by regulating the gas and air pressure.

An even and stable flame signal is always preferable to a high, but fluctuating flame signal..

Procedure:

1 Ignite the flame.

2 Read the measured values.

3 Set the flame to maximum flame quality while observing the measured value.

– Even needle deflection = high stability

– Uneven needle deflection = low stability

Stop the measurement

Procedure:

1 Deactivate the flame monitor

2 Disconnect measuring instrument.

3 Screw off pressure gauges.

4 Screw grub screws into the measurement sockets up to the limit stop.

5 For versions A and B: Close the protective caps of the measuring sockets.

48

Page 50

6 Maintenance

6 Maintenance

Observe the safety regulations!

NOTICE

Wear personal safety equipment.

Face protection

Insulating safety gloves

Safety shoes

All activities described in this chapter must be performed by qualified, authorised personnel

only under observance of requirements from the following regulating bodies:

Official Journal of the European Union L 96/309, Directive 2014/34/EU of 26 February

2014 relating to equipment and protective systems intended for use in potentially

explosive atmospheres (recast)

EN 60079-0:2014-06 (VDE 0170-1:2014-06) Explosive atmospheres – Part 0:

Equipment – General requirements

WARNING!

DANGER!

For ignition attempts for maintenance purposes, there is a risk of flashing

caused by residual gas in the gas tube or gases in the environment.

For pilot attempts, secure the hazard area in front of the pilot burner mouth.

Clear the pilot burner with purge air from residual gas as necessary.

The ignition should ideally only be tested in installed status.

WARNING!

Opening the housing of the integrated power unit Ex-Zone II is not permitted!

This does not affect the opening of the tube to replace the wearing parts.

49

Page 51

6 Maintenance

6.1 Consumables

Replace wear parts

The replacement of parts that are subject to normal wear is not deemed to be repair work and

may be performed by authorised personnel of the system operator.

The decision as to when wear parts are to be replaced is the responsibility of the system operator.

The following events can make the replacement of wear parts necessary:

• Malfunctions become more frequent.

• Device fails due to a defect.

• Device working under adverse conditions.

• Abnormalities during the course of proper maintenance.

NOTICE

It is not necessary to repair ignition breakdown paths.

NOTICE

Use only original replacement parts when replacing wear parts.

Original replacement parts are available from the manufacturer; for contact data, see chapter

6.4 Customer Service Information

The following is a list of the wear parts that are to be replaced during maintenance and

as needed:

Fig. 6-1 Wear parts on the GFI pilot burner

1 Nozzle for natural gas/propane

2 Electrodes with spacer/centre holder and plug sockets for the electrode rods

3 Spacer and centre holder for the electrode rods

4 Electrode rods

50

Page 52

6 Maintenance

6.2 Maintenance Preparation

Under regular operating conditions, the maintenance is limited to a semi-annual

inspection of the device. With increased load due to extreme operating conditions

(e.g. temperature, vibration, contamination, etc.), the inspection must be performed monthly .

Shut down the system control and secure it against inadvertent or accidental

restarting.

CAUTION!

Residual heat on all parts of the system and the ignition burner.

Risk of contact burns.

Allow the system and ignition burner to cool down before removal.

51

Page 53

6 Maintenance

6.3 Perform Maintenance

Procedure:

CAUTION!

Residual heat on all parts of the system and the pilot burner.

Risk of contact burns.

Allow the system and pilot burner to cool down before removal.

1 Shut down the system and secure it from being switched on again.

2 Allow the pilot burner to cool down completely.

3 Shut off the gas and air supply.

4 Depressurise the gas and air supply systems and disconnect them.

5 Have the closures for the combustion chamber opening ready.

6 Disconnect the electrical connections and ensure that there is no voltage present.

7 Loosen the grub screws.

8 Pull the pilot burner out of the flange.

Remove the device

1 Mark the position in which the outer tube is

inserted in the feed-through flange.

2 Loosen the grub screws of the feed-through

flange.

3 Pull the pilot burner out of the feed-through flange.

NOTICE

If the location conditions permit, it makes sense to remove the device together with the feedthrough flange.

Advantage: The position of the outer tube in the feed-through flange is maintained without any

changes.

Alternatively, the outer tube with feed-through flange and air enclosure can remain on the

combustion chamber so that only the electrodes need to be pulled out of the outer tube.

Requirement for this: The outer tube is short enough that the electrode rods can be removed

from the outer tube without twisting.

Fig. 6-2 Leave outer tube and feed-through flange on the combustion chamber

52

Page 54

6 Maintenance

Replace wear parts

1. Separate air enclosure and gas block, then pull off outer tube.

Fig. 6-3 Step 1 - Replace wear parts on the pilot burner

2. Loosen in-hex screw of the spacer and centre holder.

Fig. 6-4 Step 2 - Replace wear parts on the pilot burner

3. Slide the spacer and centre holder forward so that their plug sockets

release the electrode rods.

Fig. 6-5 Step 3 - Replace wear parts on the pilot burner

4. Bend the electrode rods to the side slightly. Slide the spacer and centre holder back far

enough

that a socket wrench can be placed on the nozzle.

Fig. 6-6 Step 4 - Replace wear parts on the pilot burner

5. Unscrew nozzle and remove flame stabiliser

53

Page 55

6 Maintenance

Fig. 6-7 Step 5 - Replace wear parts on the pilot burner

NOTICE

During the mounting process, the nozzle with the flame stabiliser must be tightened at 20 Nm.

6. Loosen in-hex screws of all spacer and centre holders.

Pull off all spacer and centre holders from the electrode rods and from the inner tube.

Fig. 6-8 Step 6 - Replace wear parts on the pilot burner

7. Replace all wear parts.

Fig. 6-9 Step 7 - Replace wear parts on the pilot burner

8. Then re-assemble everything and ensure that the distance of the spacer and

centring holder in relation to one another.

Fig. 6-10 Step 8 - Replace wear parts on the pilot burner

54

Page 56

6 Maintenance

9. Make sure the electrodes are in the correct position.

Ignition electrode (short): left

ionisation electrode (long): right

Re-tighten all hexagon screws.

Fig. 6-11 Step 9 - Replace wear parts on the pilot burner

10. Mount the outer tube again and perform electrode test, see chapter 5.2 Assembly check

ionisation electrode.

Mount the device again

Procedure:

1 Install the pilot burner again, see also chapter 5.2 Assembly

2 Connect gas and air supply again.

3 Connect electrical connections again.

4 Perform leak test, see also chapter 5 Commissioning

5 Perform functional test, see also chapter 5 Commissioning

55

Page 57

6 Maintenance

6.4 Customer Service Information

Please contact LAMTEC Service/Support if you have any questions.

LAMTEC GmbH & Co.KG

Sensors and Systems for Combustion

Technology

Wiesenstraße 6

D-69190 Walldorf

Hotline: +49 (0) 6227 / 6052-33

email: support@lamtec.de

6.5 Warranty and Delivery Terms

The manufacturer's warranty conditions apply. Warranty claims are refused if changes have

been made to the device or it has been interfered with in any way during the warranty period.

The device is shipped as specified in the purchase order information. LAMTEC's terms and

conditions of delivery and service and the general terms and conditions of delivery and service

of the electrical and electronic engineering industry apply.

56

Page 58

7 Correcting Faults

7 Correcting Faults

Observe the safety regulations!

NOTICE

Wear personal safety equipment.

Face protection

Insulating safety gloves

Safety shoes

WARNING!

All activities described in this chapter must be performed by qualified, authorised personnel

only under observance of requirements from the following regulating bodies:

Official Journal of the European Union L 96/309, Directive 2014/34/EU of 26 February

2014 relating to equipment and protective systems intended for use in potentially

explosive atmospheres (recast)

EN 60079-0:2014-06 (VDE 0170-1:2014-06) Explosive atmospheres – Part 0:

Equipment – General requirements

For ignition attempts for maintenance purposes, there is a risk of flashing

caused by residual gas in the gas tube or gases in the environment.

For pilot attempts, secure the hazard area in front of the pilot burner mouth.

Clear the pilot burner with purge air from residual gas as necessary.

The ignition should ideally only be tested in installed status.

Opening the housing of the integrated power unit Ex-Zone II is not permitted!

This does not affect the opening of the tube to replace the wearing parts.

7.1 General Data

Act correctly when an error occurs

Critical operating state when an error occurs.

Risk of death from deflagration or explosion.

Shut off the gas supply immediately.

Stop operation.

Shut down the system.

Secure the system against being restarted.

DANGER!

WARNING!

DANGER!

57

Page 59

7 Correcting Faults

7.2 Fault Finding and Troubleshooting

Fault Causes Fault rectification

No ignition flame forms.

There is no combustion air present or the combustion air is insufficient.

Possible cause

- Fan not running. Check fan.

Ensure that the fan is

being activated correctly by the system control.

- An actuator is closed (air

flap, ball valve, valve).

- An actuator is faulty (air

flap, ball valve, valve).

- Air line clogged. Check line air line.

- Air line or fan incorrectly

dimensioned.

- Combustion air is

contaminated.

- Gas does not comply with

the specifications.

- Gas/air ratio does no

comply with the

specifications.

No fuel gas reaches the ignition burner.

Open actuator.

Check/replace actuator.

Correct the dimensioning of the tube length,

tube diameter, fan power.

Clean or replace air filter.

If air filter is missing, retrofit this.

Gas must comply with the specifications of the

ignition burner (see type plate and technical

specifications).

Set the gas and air operating pressures correctly (see chapter 5.3 Commissioning ).

Possible cause

- An actuator is closed (ai

flap, ball valve, valve).

- An actuator is faulty (air

flap, ball valve, valve).

- Gas pressure not

sufficient.

- In the tubing there is

residual inert gas (N2).

Open actuator.

Check/replace actuator.

Correct the dimensioning of the tube length,

tube diameter, fan power.

Flush the gas line by repeating ignition attempt

until flame ignites.

58

Page 60

7 Correcting Faults

Fault Causes Fault rectification

No ignition flame forms.

No ignition sparks occur.

Possible cause

The flame monitor switches to fault

condition during operation.

- No supply voltage on the

ignition burner.

- Ignition electrode is

burnt down.

- Distance between ignition

electrode and ground is

not correct or there is an

accidental ground pres

ent.

- Ignition electrode is

contaminated.

- An insulator is broken. Replace insulator with spacer and centre

- Ignition transformer is

defective.

Ignition flame has been extinguished.

Check supply voltage.

Ensure that the ignition burner is being correctly activated by the system control.

Replace ignition electrode.

Check the distance between ignition electrode

and ground and correct, if necessary.

Rectify contamination using steel wool or sandpaper until the electrode is bare.

holder.

Replace ignition transformer.

Possible cause

- Pressure in combustion

chamber fluctuating.

- Gas and air pressures

fluctuating.

- Main flame is influenced

by flows in the combus

tion chamber or due to

external deflection.

- No combustion air in the

combustion chamber.

Provide for differential pressure control on the

gas and air side.

Correct the installation position and power of

the ignition burner.

59

Page 61

7 Correcting Faults

Fault Causes Fault rectification

The ignition flame forms but goes

out after the ignition safety time

expires.

Ionisation monitoring not functioning

Possible cause

- Ionisation electrode is

burnt down.

- An insulator is broken. Replace insulator with spacer and centre

- Flame monitor is con

nected incorrectly or is

incorrectly activated.

- The distance between the

ionisation electrode and

ground is not correct or

there is an accidental

ground present.

- The insulating property of

the insulators is impaired

due to overheating of the

ignition burner.

- The ignition flame is not

located in the coverage

area of the ionisation

electrode.

- The ignition spark inter

feres with the ionisation

feedback.

- The operating voltage

and basic voltage are

simultaneously switched

on.

Flame monitor is faulty. Have the manufacturer inspect the flame moni-

Replace ionisation electrode

holder.

Check electrical connection of the flame moni-

tor.

Ensure that the flame monitor is being correctly

activated by the system control.

Correct the distance between ionisation electrode and ground by bending the ionisation

electrode or replace the ionisation electrode.

Ensure that the ignition burner is continually

flushed with combustion air to reduce the heat

effect.

Adjust the gas and air operating pressures correctly (see chapter 5.3 Commissioningsection

"Adjust the flame quality and flame stability".

Ensure that the system control

switches off the ignition spark before the ignition safety time expires (-0.5 s).

Ensure that the system control switches on the

operating voltage 5 s after the basic voltage.

tor and replace, if necessary.

60

Page 62

7 Correcting Faults

Fault Causes Fault rectification

The flame monitor switches to fault

condition during operation.

Despite the closed gas valve, the

flame monitor outputs a flame

signal.

The ignition flame has been extinguished.

Possible cause

- Pressure in combustion

chamber fluctuating.

- Gas and air pressures

fluctuating.

- Main flame is influenced

by flows in the combus

tion chamber or due to

external deflection.

- No combustion air in the

combustion chamber.

The gas valve is leaky, so

that a small flame arises.

Provide for differential pressure control on the

gas and air side.

Correct the installation position and power of

the ignition burner.

Replace leaky gas valve.

7.3 Repair

WARNING!

Safety-relevant components!

Risk of malfunction if repaired improperly.