Page 1

Manual

F300K Compact Flame Scanner

Sensors and Systems for Combustion Engineering

www.lamtec.de

Page 2

Page 3

Table of Contents

Table of Contents

1 Important Information about the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Purpose/Applicability of the Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Safekeeping of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Classification of the Safety Instructions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Product-specific Dangers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Structure of the F300K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Basic variants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Life Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Proper Use - Conditions of Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4.1 UL Listed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6 Selection Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.7 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.7.1 FB30 External User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.7.2 F300K Remote Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.7.3 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7.3.1 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7.3.2 FN20, FN30-20 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7.3.3 FN30 power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7.4 Coupling relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7.5 Adjustable Holder, Cooling-air Housings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7.6 FG30 connection housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.7.7 Flame Scanner Testing Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.7.8 Connection Cable AK05. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.7.9 Fiber Optic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Design and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Operating and display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Menu tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.1 Safety When Putting the Device Into Operation . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.2 Electrical Safety – Requirements to Be Met by Third-party Manufacturers. . . . 27

6.1.3 Special Points to Note When Using the Device in Explosion-proof Areas. . . . . 28

6.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.1 Prerequisite for Mounting the Device Properly . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.2 Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.3 Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2

Page 4

Table of Contents

6.3 Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4 Putting the Device into Operation for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.2 Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.3 Adjusting F300K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.4 Setting Monitoring Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.4.1 Automatic setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.4.2 Hand optimization of the automatically determined trigger thresholds (levels) . 43

6.4.4.3 Manual setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.4.5 Switch-off Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5 Acceptance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1 Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2 Enter Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3 Reading information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.1 Read mode 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.2 Reading the device setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.3 Reading the signal of the flame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.3.1 Reading the signal values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.3.2 Signal simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.3.4 Displaying faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.3.4.1 Reading the cause of a problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.3.4.2 Reading the fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4 Automatic setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.5 Manual setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.5.1 Changing the switch-on/startup parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.5.2 Changing switch-off parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.5.3 Resetting the factory settings (up load). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.5.4 Save parameters (down load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.5.5 Load parameters (up load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.5.5.1 Load operating mode parameters (up load) . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.5.5.2 Device parameters load (up load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.5.5.3 Transfer parameters to an other F300K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.6 Changing the device settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.6.1 Parameterising the flame scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.6.2 Parameterising the User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.6.3 Resetting the device parameter factory settings . . . . . . . . . . . . . . . . . . . . . . . . 73

7.6.3.1 Resetting the flame scanner factory settings. . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.6.3.2 Resetting the factory settings of the User Interface. . . . . . . . . . . . . . . . . . . . . . 74

7.6.4 Changing Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.6.4.1 Changing the level 1 password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.6.4.2 Changing the level 2 password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.7 Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.1 Maintenance Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.1.1 Flame Scanner Testing Device replace Battery. . . . . . . . . . . . . . . . . . . . . . . . . 79

8.2 Customer Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.3 Warranty and Delivery Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3

Page 5

Table of Contents

9 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10 Correcting Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.1 Fault Finding and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.1.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.1.2 F300K Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.1.3 Error codes at the level of the operating unit. . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.2 Information About the Repair Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11 Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13 Disposal Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

14 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

14.1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

14.1.1 F300K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

14.1.2 FB30 External User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

14.1.3 Power Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

14.1.3.1 FN20, FN30-20 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

14.1.3.2 FN30 power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

14.1.4 FG30 connection housing and FG30-21 stainless steel . . . . . . . . . . . . . . . . . 102

14.1.5 M12 - Mounting box for front / screw mounting with M16 thread. . . . . . . . . . . 105

14.1.6 Flame Scanner Testing Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.1.7 Connection Cable AK05. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

14.2 Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

14.2.1 F300K With Power Pack FN20, FN30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

14.2.2 F300K With ETAMATIC, FMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

14.3 EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

14.4 Order Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

4

Page 6

1 Important Information about the Manual

1 Important Information about the Manual

1.1 Purpose/Applicability of the Document

This manual enables users to handle the F300K compact flame scanner system safely and

efficiently.

The manual is valid for all F300K systems in any configuration.

The information in this document applies to software version F300K V1.3.0.0 and User Inter-

face V1.4.0.0. If you have a different version of the software, you may find that some of the

functions described are not available or that not all of the available functions are described.

The F300K system complies with the following standards and directives:

• DIN EN 298:2012

• DIN EN 60730-2-5:2015

• DIN EN 50156:2016, Section 10.5

• DIN EN 746-2:201 1 (Industrial thermoprocessing equipment – Part 2: Safety requirements

for combustion and fuel handling systems)

• 2014/68/EU (Pressure Equipment Directive)

• 2009/142/EC (Gas Appliances Directive)

• EU/2016/426 Gas Appliance Regulation (GAR)

• 2014/35/EU (Low Voltage Directive)

• 2014/30/EU (EMC Directive)

• DIN EN 61508:2011, parts 1-7 (SIL 3 requirements)

• ISO/IEC 80079-34:201 1 Potentially explosive areas - Quality Management System (QAR)

• 2011/65/EU (RoHS2 Directive)

• UL372

1.2 Purpose

In single-burner and multiple-burner furnaces, the flame scanner performs a high-safety monitoring of the burner flame. When the flame goes out, the safe control state’ Flame ’ is reached.

The flame scanner is mainly used in large-scale power plants, thermal power stations and

chemical plants as well as for monitoring furnaces which are operated from.

– oil

– gas

– bio-mass

– dust coal

– chemicals and other waste products

5

Page 7

1 Important Information about the Manual

1.3 Target Group

These instructions must have been read carefully and completely before commencing with

any work. The basic prerequisite for working safely is compliance with all the specified safety

instructions.

NOTICE

All assembly , commissioning, troubleshooting and maintenance work may only be carried

out by authorised and trained personnel.

The device may be operated and maintained only by those who are capable of doing so

in terms of their level of knowledge and training.

For F200K, the covers must be removed for commissioning, but then only by authorised

personnel. Any further opening or disassembly is not permitted.

The open flame scanner must be protected from ingress of dust and moisture.

Contact with the electronics is only permitted if ESD measures are observed.

Opening the devices is not permitted under any circumstances except for commissioning

(F200K).

For safety reasons, access to parameterisation must be restricted to authorised

personnel.

1.4 Safekeeping of the Manual

Look after the manual and all the associated documents carefully.

The manual is part of the product and must be kept safe and be accessible to personnel at all

times.

Moreover, it is important that the manual:

• Is available when required.

• Is kept for the entire service life of the device.

• Is available to its next operator.

6

Page 8

2 General Safety Instructions

2 General Safety Instructions

2.1 Classification of the Safety Instructions and Warnings

The following symbols are used in this document to draw the user's attention to important safety information. They are located at points where the information is required. It is essential that

the safety information is observed and followed, and that applies particularly to the warnings.

DANGER!

This draws the user's attention to imminent danger. If it is not avoided, it will result in death or

very serious injury. The plant including its surroundings could be damaged.

WARNING!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in death or very serious injury. The plant including its surroundings could be damaged.

CAUTION!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in minor injuries. The plant including its surroundings could be damaged.

NOTICE

This draws the user's attention to important additional information about the system or system

components and offers further tips.

The safety information described above is incorporated into the instructions.

Thus, the operator is requested to:

1 Comply with the accident prevention regulations whenever work is being carried out.

2 Do everything possible within his control to prevent personal injury and damage to prop-

erty.

7

Page 9

2 General Safety Instructions

2.2 Product Safety

WARNING!

This product is state-of-the-art technology and complies with the generally accepted

safety-related rules and regulations.

Every device is tested before delivery to ensure that it is working properly and safely.

Only use this product when it is perfect condition and in accordance with the manual, the

prevailing regulations and guidelines and the applicable safety and accident prevention

regulations.

WARNING!

The risk of danger in the event of external fire, traffic and wind, flood waves and earthquakes

depend on the installation situation and the installation site to be assessed separately where

appropriate.

2.3 Product-specific Dangers

DANGER!

The F300K is not designed to switch off the fuel valves.

The subsequent signal processing must be carried out in the control system, which is

adapted to suit the combustion plant.

WARNING!

The F300K is a safety device. Only specialist staff of the manufacturer or people approved by

the manufacturer may intervene. No interventions by anyone else are permissible. This applies, in particular, in the event of a defective fuse.

WARNING!

Radio interference suppression of the output contacts

In the interests of safety, ensure when installing the output contacts that:

The user suppresses radio interference in such a way that the contacts of the safety relay

contact output cannot be shorted by defective components of the suppressor circuitry.

WARNING!

The power supply of the flame scanner and the user interface with 24 VDC must be ensured

by an external power supply unit, which supplies SELV or PELV.

8

Page 10

3 Product Description

3 Product Description

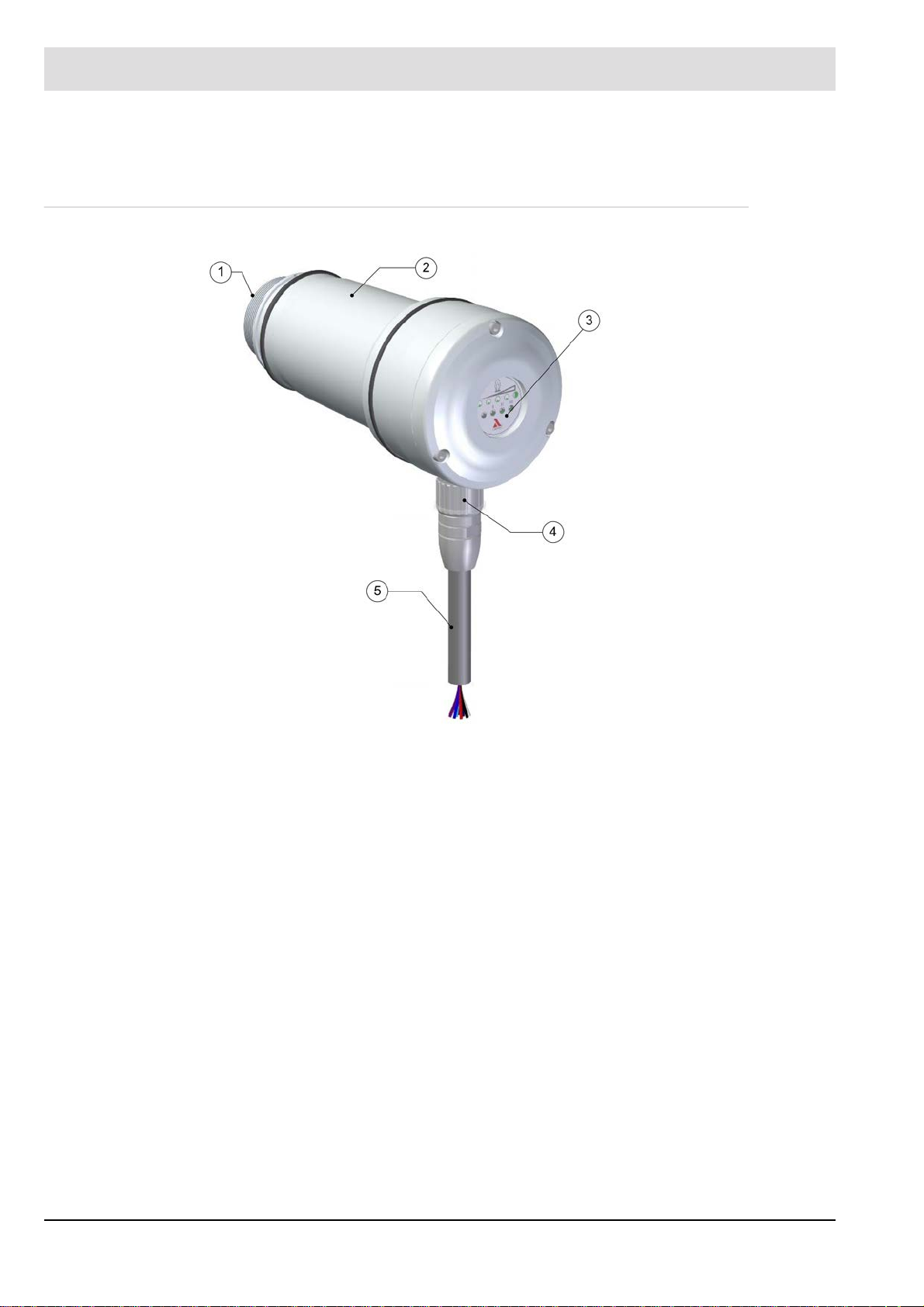

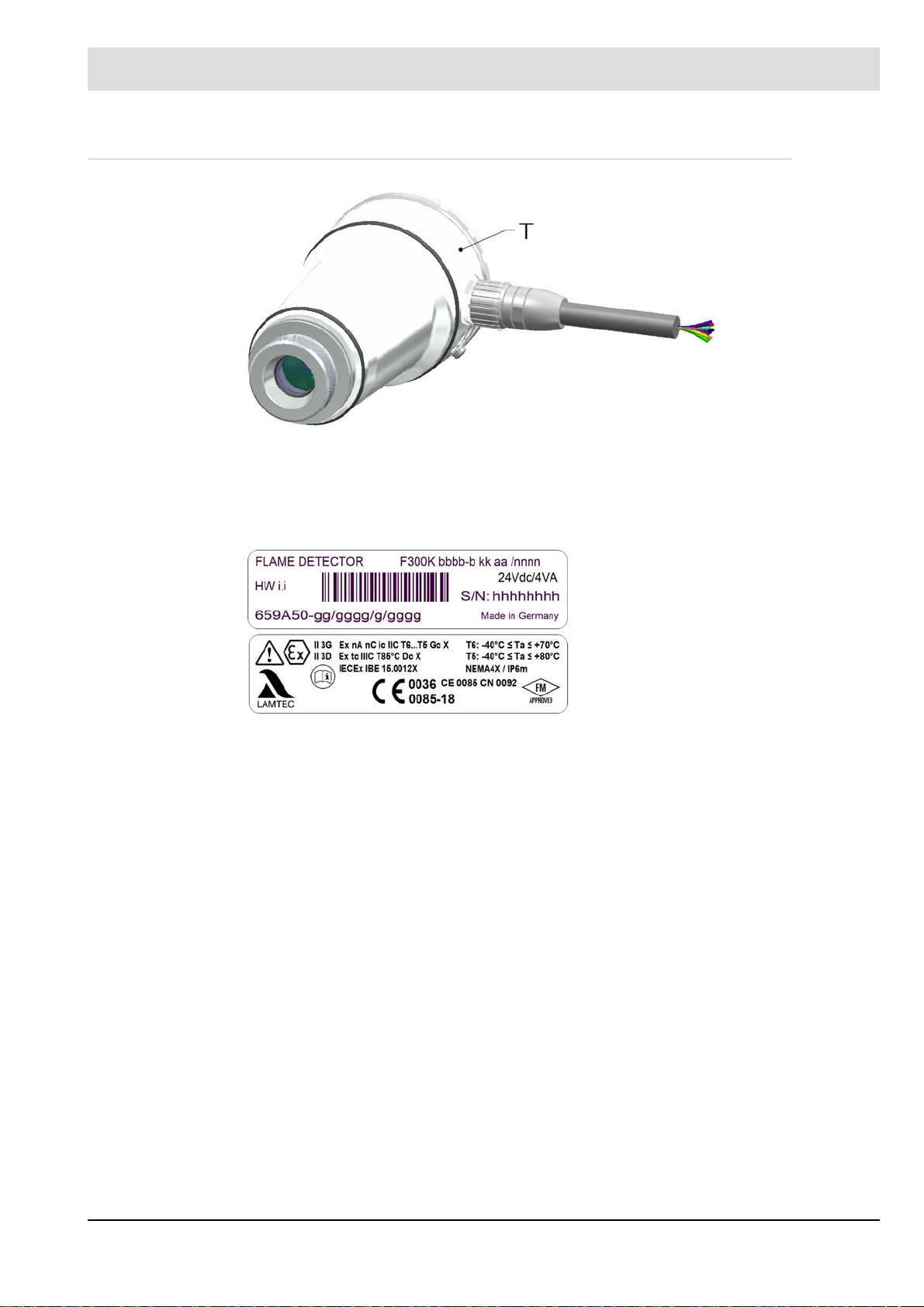

3.1 Structure of the F300K

1 Lens holder

2 F300K housing

3 Cover with operating unit

UI (user interface) or

LED display

4 Device connector

5 Connecting cable

Fig. 3-1 The components of the F300K

9

Page 11

3 Product Description

3.2 Basic variants

There are two basic variants of the F300K

NOTICE

The basic functions of the variants are identical. The differences lie merely in how they are

operated and their displays.

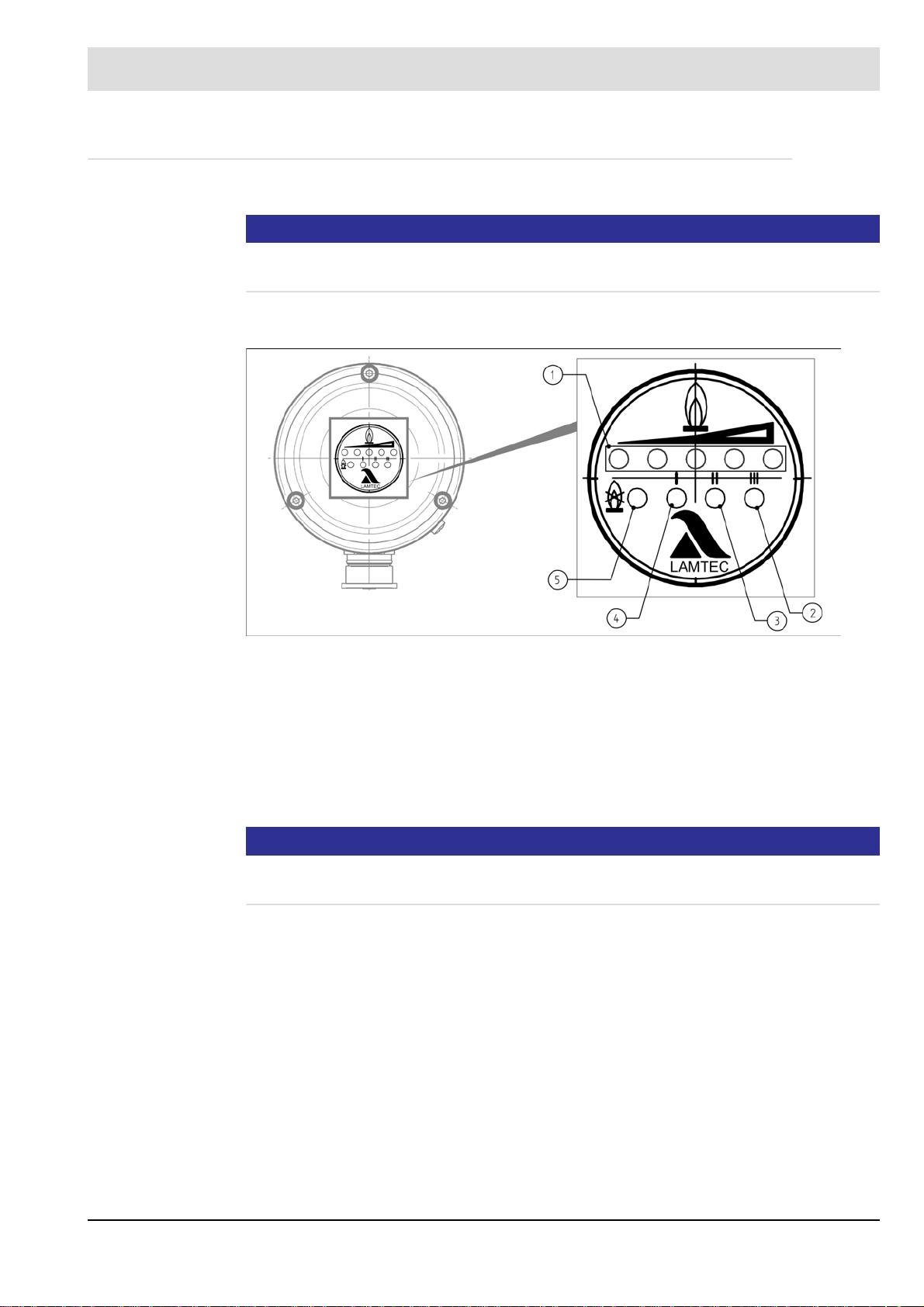

F300K with LED display

Fig. 3-2 F300K display unit with LED display

1 LEDs in the display strip show the intensity of the flame: a series of two yellow and three

green LEDs; point display for intensity, flashing for a warning

2 Green LED: mode 3

3 Green LED: mode 2

4 Green LED: mode 1

5 Red LED: Flame OFF/stand-by – flashes in the event of a fault

NOTICE

For operation of F300K (with LED display) you need an external User Interface UI or the

F300K Remote Software.

10

Page 12

3 Product Description

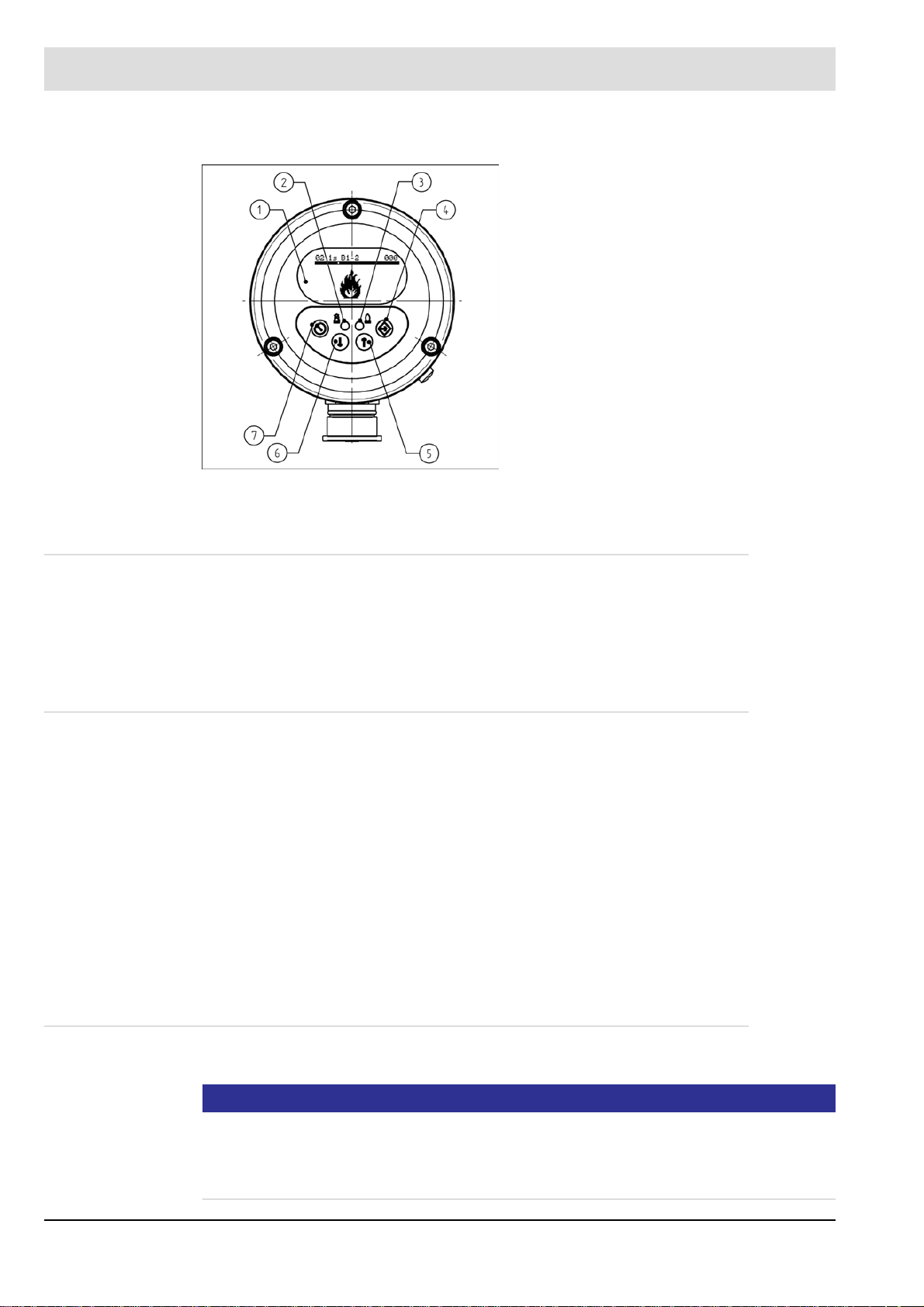

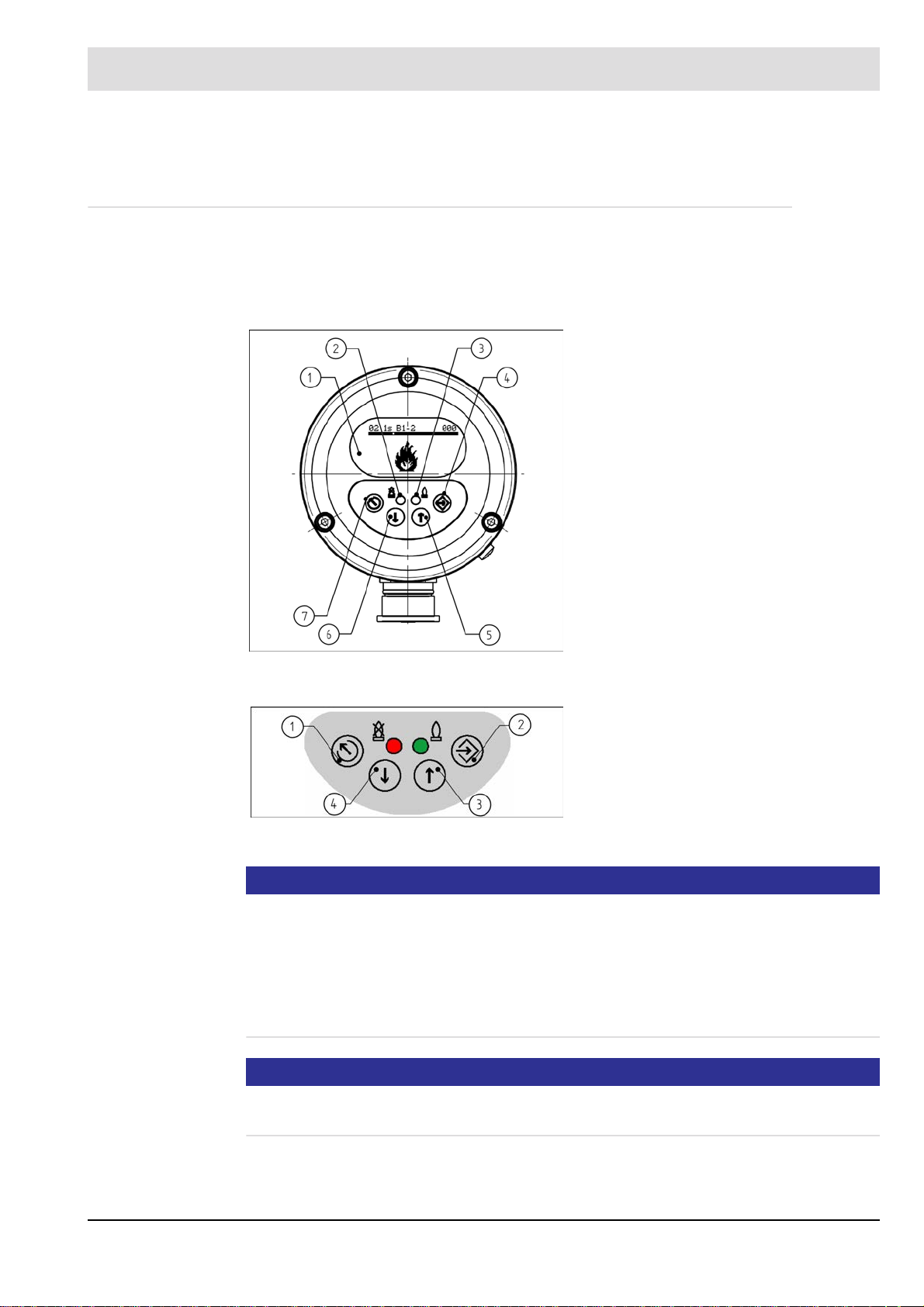

F300K with user interface

Fig. 3-3 F300K operating and display unit with UI

1 Display

2 LED shines red: Flame OFF/ready for

operation

LED flashes red: fault

3 LED shines green: flame ON

LED flashes green: warning

4 ENTER key

5 UP key

6 DOWN key

7 ESC/BACK key

3.3 Life Cycle

The device is designed to have a service life of 10 years or 250,000 cycles. The functional

safety calculations are based on these values.

The actual service life of the F300K depends on the ambient temperature among other factors.

In particular, operation at high temperatures reduces the actual service life.

3.4 Proper Use - Conditions of Use

The F300K is designed to monitor the safety of burner flames in single- and multi-burner combustion plants and in combustion chambers for dust- and grate-fired systems.

As an explosion-proof device, the flame scanner can be used in potentially explosive atmospheres (up to Zone 2).

Any other usage going beyond this is considered to be improper use. The plant operating company is liable for any damages that resulting from this.

The table in Section 3.6 Selection Criteriashows the applications to which the various device

types are suited.

Please heed the following information when operating the F300K:

• The safety information in this manual

• Section 14.1 Technical Data in this manual

3.4.1 UL Listed

In preparation

NOTICE

For applications within the scope of the UL Listed certification procedure, it must be ensured

that the components used are "Listed" certified. That is, in addition to the flame detector used

must also be the connection cable and if used the power supply "Listed" certified.

The applicable installation rules according to NFPA70 (NEC) must be observed.

11

Page 13

3 Product Description

3.5 Rating Plate

Fig. 3-4 Position of the rating plate

T = position of the type plate

On the rating plate you will find information on the configuration of your flame sensor:

Rating plate example:

12

Page 14

3 Product Description

3.6 Selection Criteria

The spectral sensitivity of the flame scanners determines their suitability for specific fuels.

NOTICE

LAMTEC guarantees that the flame sensor is in perfect working order but cannot offer any

guarantees if it is used improperly.

Note the specific requirements of your plant when selecting the flame sensors. We will be

pleased to answer any questions you may have in relation to LAMTEC products.

The following table provides an overview:

Type Fiber

Optic

F300K UV-4 X ++ 215 ... 360 8° • Oil

F300K UV-4.6

F300K IR-2 * ++ 850 … 1200 • Combustion chamber monitoring

F300K IR-3 * ++ 1000 … 1700 60° • Oil-, gas-, wood-, coal- and dust-fired

F300K IR-4

F300K UVIR-1

X

*

X

*in preparation, use may only be made with LAMTEC IR fiber optic system

The suitability of the device types may differ from that indicated in the table depending on particular circumstances.

Sensi

tivity

+++

+++

++ 215 ... 360

Spectral

range

in nm

215 ... 360

1000 ... 2200

Sight

angle

approx

10°

60°

8°

Preferred area of application/fuels

• Gas

• Special gases such as refi nery gases,

blast furnace gases and hydrogen

furnaces with a high level of flue-gas

recirculation

• Yellowish waste gases without UV radiation or with shielding of the UV spectrum by water vapour and dust

• as F300K UV-4

• as F300K IR-3(double sensor) ++ 1000 ... 1700

Fig. 3-5 Spectrum of the flame

13

Page 15

3 Product Description

3.7 Accessories

NOTICE

When installing electrical accessories you must ensure that the necessary protection class is

reached.

3.7.1 FB30 External User Interface

The FB30 external operating unit offers the same range of functionality as the internal UI built

into the F300K. It can be used with an F300K (without an integrated operating unit) or a F300K

UI (with an integrated operating unit).

Y ou can connect the FB30 directly to the FG30 connection housing using its plug-in connector .

The FB30 is then supplied with 24 VDC from the power supply of the F300K.

You will find the technical specifications for this device in section 14.1.2 FB30 External User

Interface.

3.7.2 F300K Remote Software

NOTICE

LAMTEC provides a CAN/USB adapter with the F300K Remote Software. You can use this

with a specific adapter cable to connect your PC to the CAN bus of the F300K.

The F300K Remote Software allows you to do all the parameterisation of an F300K. In addition, it also offers analysis, data backup and recording functions.

In addition to the data of the F300K, you can also record external, analogue and/or digital data

by means of CAN modules. All of the data is synchronised.

Fig. 3-6 Remote PC software

You will find further information in a separate description F300K-Remote-Software

(DLT-No. 7652).

14

Page 16

3 Product Description

3.7.3 Power Supply

3.7.3.1 Power Supplies

Y ou can use a commercially available power supply with an output voltage of 24 V that meets

the protective separation requirements. See section 6.1.2 Electrical Safety – Requirements to

Be Met by Third-party Manufacturers.

3.7.3.2 FN20, FN30-20 Power Supply

NOTICE

The FN20 (115 V) is UL Listed approofed.

WARNING!

Instalation

The wires must be installed/attached in such a way that, if a wire is unintentionally loosened,

a sufficient distance is still maintained between SELV/PELV and the other voltages.

WARNING!

Secure output contact and secure indicator contact

Danger due to electric shock! This may result in personnel injury.

Basic insulation is used for protective separation, i.e. you may not use SEL V (safety extra

low voltage) and mains voltage at both of the contacts at the same time.

You can use the FN20 power supply to operate the F300K at mains AC voltage. The power

supply is designed for top-hat rail mounting (for F300K can be supplied as an option with built

in an IP65 housing).

Fig. 3-7 FN20 for top-hat rail mounting

Fig. 3-8 FN20 as a built-in unit

The power supply is equipped with safety output relays (to EN 298) for mains AC voltage. The

power supply complies with SIL 2 (Safety Integrity Level) to EN 61508.

When you connect the F300K to the FN20 power supply, you do not connect all of the wires

of the connecting cable to the terminals. You have to connect the surplus wires to separate

terminals. These terminals are part of the F300K's IP65 housing.

Y ou will find the technical specifications for this power supply in section 14.1.3.1 FN20, FN30-

20 Power Supply.

15

Page 17

3 Product Description

3.7.3.3 FN30 power supply

The power supply unit FN30 can only be used to operate the F300K on an AC mains voltage

within the scope of EN 60950 or UL 60950.

The power supply is available in two versions:

• For top-hat rail mounting

• As a built-in unit in a housing

Fig. 3-9 FN30-00 top-hat rail mounting

When connecting the F300K to the FN30-00 power supply , not all wires of the connection cable are connected to the power supply connections. Surplus wires must be connected to separate terminals. These terminals are part of the housing.

Technical data for this power supply unit can be found in section 14.1 Technical Data.

3.7.4 Coupling relays

To connect the contact outputs of the F300K to voltages higher than 42 V or voltages without

protective separation, you have to use coupling relays. These must met the protective separation requirements. See section 6.1.2 Electrical Safety – Requirements to Be Met by Third-

party Manufacturers.

In addition, you also require appropriate certification for the coupling relay with a safety contact output (flame signal) for the purpose for which it is to be used (e.g. to EN 298 and/or to

EN 61508 with SIL III or SIL II).

The LAMTEC FN20 and FN30-20 power supply has coupling relays for the flame signal.

These meet EN 298 und EN 61508-2 SIL 2 requirements.

If you want suitable coupling relays or have any questions, please contact our support staff at

vertrieb@lamtec.de or on +49 (0) 6227 6052-33.

3.7.5 Adjustable Holder, Cooling-air Housings

Fig. 3-10 FN30-10 as a built-in unit

You will find a complete overview of the holders and cooling-air housings for LAMTEC flame

scanners in the document "Flame Monitoring Systems and Accessories" (DLT7673).

16

Page 18

3 Product Description

3.7.6 FG30 connection housing

Regard the applicable rules and regulations for mounting and installation, note also the additional requirements described in section 6.1.1 Safety When Putting the Device Into Operation

Fig. 3-11 FG30-00 connection housing

LAMTEC offers two versions of the FG30 connection housing:

• FG30-00 with cable glands and an M12 circular connector for FSB

• FG30-20 Ex-II for use in potentially explosive atmospheres with cable glands and an M12

circular connector for FSB

Y ou will find technical specifications for the housings in section 14.1.4 FG30 connection hous-

ing and FG30-21 stainless steel.

Fig. 3-12 FG30-20 Ex-II connection housing

17

Page 19

3 Product Description

3.7.7 Flame Scanner Testing Device

Fig. 3-13 Toggle switch UV/IR

Fig. 3-15 Positions of the internal jumper UV + IR

You can use the FFP30 to test that your flame scanner is working properly.

The testing device simulates a variable flame frequency.

If the internal jumper(1) is plugged on IR, UV or IR can be chosen via the toggle switch.

If the internal jumper is plugged on IR+UV, the switch position IR as well as UV rays can be

detected simultaneously. The latter can be interesting for flame scanner with dual sensor.

Flame scanner testing device is off in the average position of the toggle switch. The flame

scanner testing device switches off automatically after a preset time of approximately 4 min to

reserve the battery resource.

The testing device is screwed onto the flame scanner.

For the recognition of the flame simulation, the F300K must be set to sufficiently sensitive (increase, trigger threshold and frequency).

To change the battery, see chapter 8.1.1 Flame Scanner Testing Device replace Battery

Fig. 3-14 FFP30 flame-scanner testing device

WARNING!

After a possibly necessary modification of the F300K setting for the test, the original

settings must be set back and controlled through the CRC manual of the operating

mode parameter.

DANGER!

Explosion hazard!

Flame sensors must not be tested in a potentially explosive atmosphere.

You will find the technical specifications for this device in section Fig. 14-27 Dimensioned

drawing of the FB30.

18

Page 20

3 Product Description

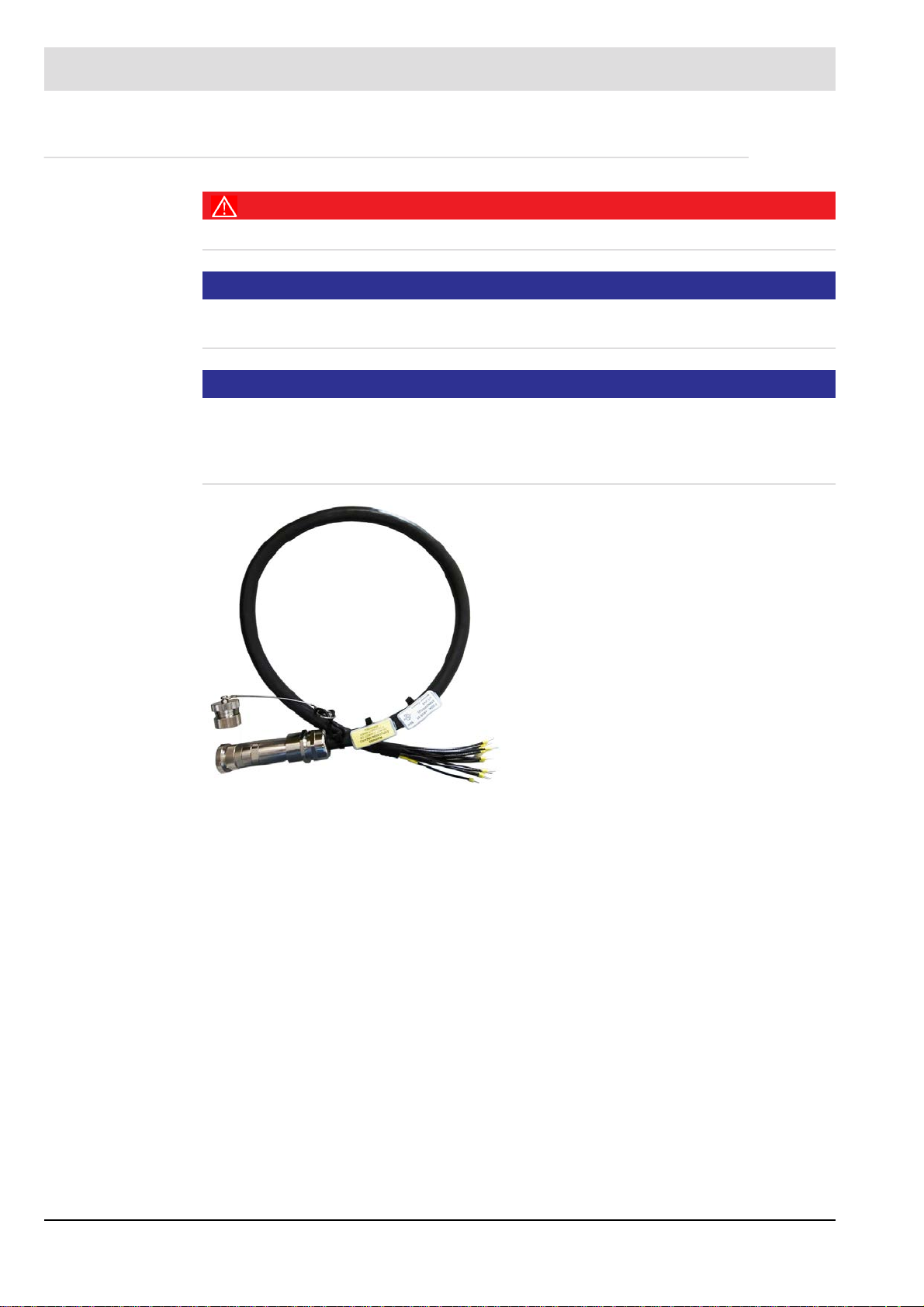

3.7.8 Connection Cable AK05

DANGER!

The Connection Cable are approved for use with SELV or PELV only.

NOTICE

For special requirements it may be necessary to protect cable additionally.

The specific installation rules are to be observed.

NOTICE

Only the Connection Cable AK05-51 is UL Listed approofed. For the use of the Flame scanner as UL Recognized approofed, the other Connection Cable can be used.

Devices shall be wired in accordance with NEC field wiring requirements for the

location.

Fig. 3-16 Connection Cable AK05-51

19

Page 21

3 Product Description

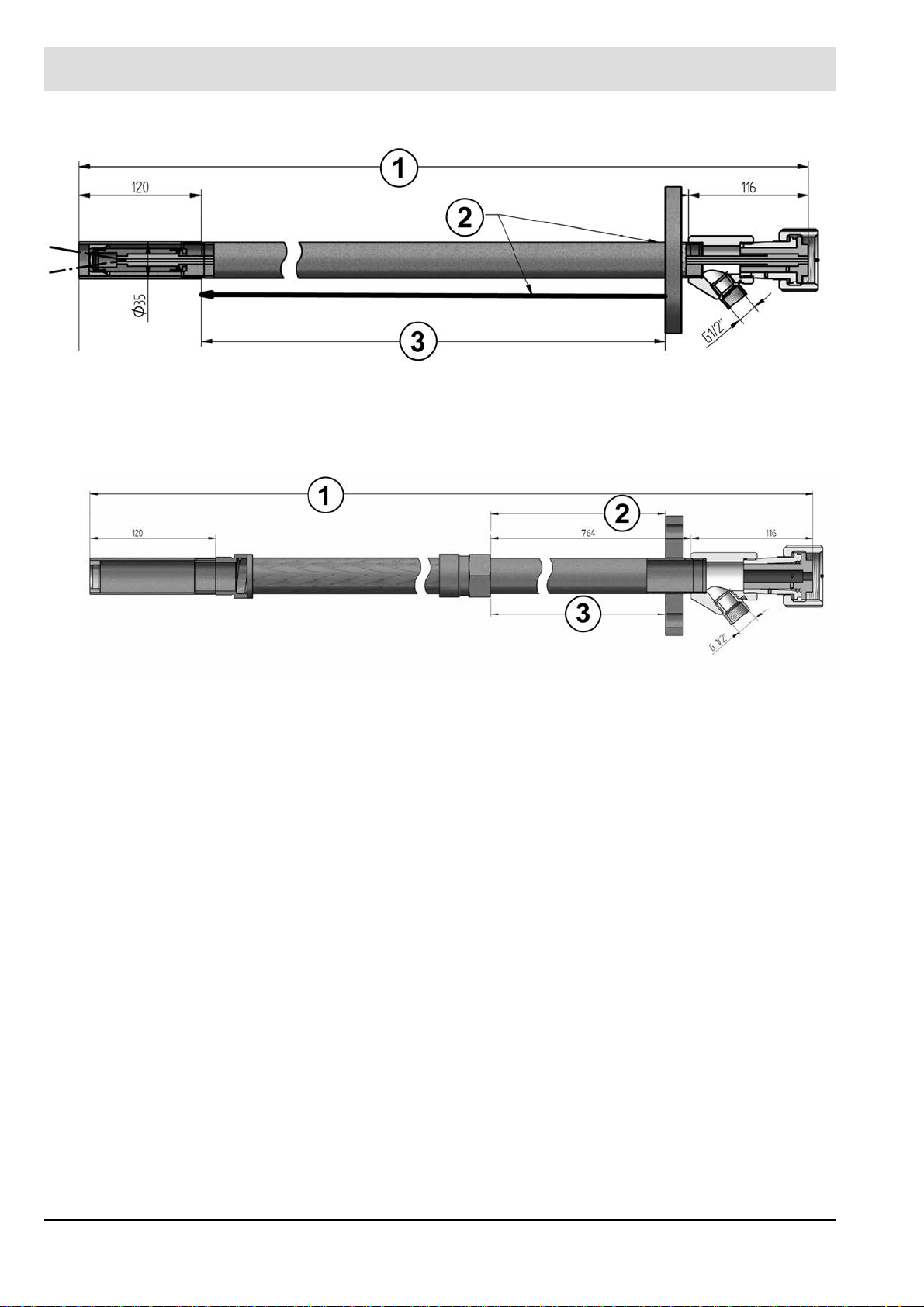

3.7.9 Fiber Optic

The LAMTEC Fiber Optic System is available with 2 spectral sensitivities and 2 basic

mechanical constructions.The spectral sensitivity is matched to the LAMTEC flame detector.

WARNING!

F300K IR-x FO

The flame detector F300K FO in the IR version (IR-2..4) may only be used with the

LAMTEC Fiber Optic in the IR version. The Fiber Optic IR version includes the required

spectral sensitivity limitation.

Visible is the Fiber Optic IR version on the process optics (see Fig. below).

The viewing port to the flame is not a lens, but covered with a black filter.

Fig. 3-17 Fiber optic with Flame scanner

1 Component Group Process Optics 3 Component Group rigid housing

1.1 Optic UV 4 Component Group burner mounting assembly

1.2 Optic IR 5 Component Group Flamescanner holder

assembly FV30-FO

2 Fiber bundle (customer-specific length)

Fiber Optic with enclosure - Type key: FOabb-cc-dd

a - enclosure type: R - starr, F - flexibel

b - enclosure series: e.g. 10

c - lenght: e.g. 25 - (2,5 m)

d - optic: UV - uv/vis/nir, IR - nir

20

Page 22

3 Product Description

Fig. 3-18 Fiber optic rigid, FOR10-XX-XX

1 Minimum total length 1000 mm / 3,28 ft 3 Adjustment length 740 mm / 2,43 ft

2 Mounting flange positionable

Fig. 3-19 Fiber optic flexible, FOF10-XX-XX, in preparation

1 Minimum total length 1500 mm / 4,92 ft

21

Page 23

4 Design and Functions

4 Design and Functions

4.1 Design

Structure:

The compact flame scanner consists of a cylindrical housing with an axial aperture and an

LED status display at the back or an integrated operating unit with an UI (user interface).

Connection:

The connection is made via the serial connector on the F300K and the required connecting

cable (14-pin with static shielding) with coupling.

The cable offers the following connections:

• Supply of auxiliary power

• Flame contact

• Ready contact

• Measuring output for intensity

• FSB (Bus)

• Shield

22

Page 24

4 Design and Functions

4.2 Functional Description

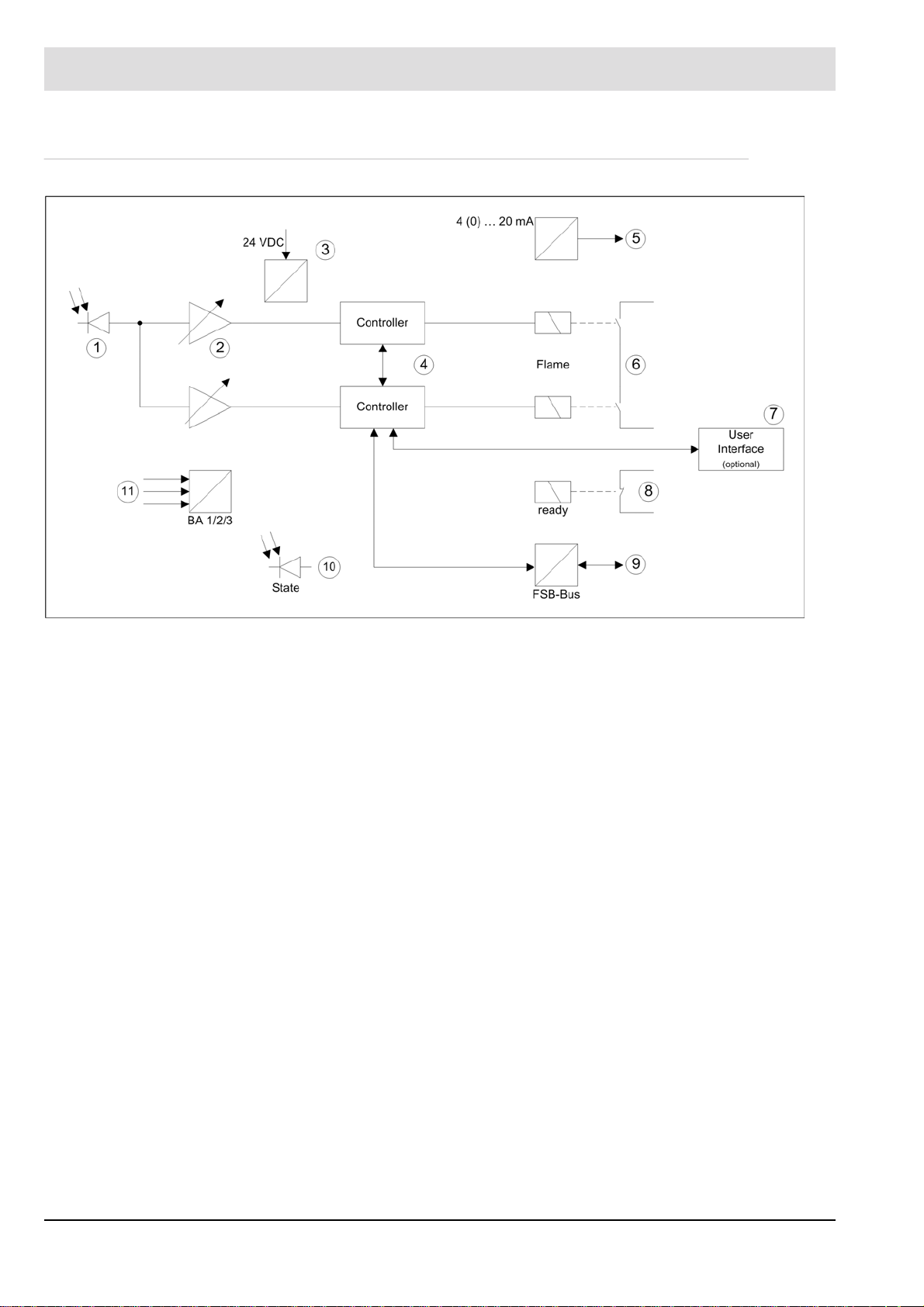

1 Semiconductor sensor 5 Measuring output for intensity 9 FSB bus for parameterisation and mes-

sages

2 Amplifiers 6 Flame relay 10 LED status display

3 Power supply 7 Integrated operating unit (UI) 11 Mode selector

4 Microcontrollers 8 Ready

The F300K analyses the flickering of the flame in the UV or IR range. For preparation for signal

processing there is a semiconductor sensor (1) on a button strip. For each sensor signal,

the level is adjusted by means of two adjustable amplifiers (2). These two amplifiers are located on the main board, as are the two microcontrollers (4). Due to the amplitude and the

course taken by the signal to be evaluated over time, both microcontrollers detect the existence of the flame.

The safety of the device is monitored by means of both software and hardware diagnostics.

The ready contact (8) indicates that the flame scanner is ready for operation.

The mode selector (11) allows you to choose between three different sets of parameters.

These parameters are stored in the EEPROM and influence the analysis of the current sensor

signal of the flame to be monitored.

There is a FSB interface (9) available for operation. The F300K is operated by means of an

external or internal user interface (7) or the PC with F300K-Remote-Software. An LED dis-

play (10) makes the status of the flame scanner visible. The flame intensity is provided as

non-failsafe information with a 4 (0) ... 20 mA current loop (5).

The circuit is supplied with 24 VDC (3) by an external power supply unit with safe separation

(e.g. FN20 or FN30).

An internal temperature sensor monitors the temperature in the device.

23

Page 25

5 User Interface

5 User Interface

5.1 Operating and display elements

You can adjust and operate the F300K compact flame scanner by using either the user interface (integrated in the F300K or as an external device) or the F300K Remote Software.

You will find a description of the F300K Remote Software in a separate manual (publication

no. DLT7652).

1 Display

2 LED shines red: Flame OFF/ready for

operation

LED flashes red: fault

3 LED shines green: flame ON

LED flashes green: warning

4 ENTER key

5 UP key

6 DOWN key

7 ESC/BACK key

Fig. 5-1 F300K operating and display unit with UI

1 ESC/BACK key

2 ENTER key

3 UP key

4 DOWN key

Fig. 5-2 Keypad

NOTICE

To extend the service life of the display, it only remains switched on within a limited temperature range. If the temperature of the display rises to over 70 °C, it is deactivated. In this phase

it is not possible to carry out parameterisation or read out information using the display . In order to get information about the reason (C0013) of the deactivated display , it is activated briefly after pressing a key.. If the temperature of the display drops below 70 °C, it is activated

again. Alternatively, the F300K Remote Software or an external user interface FB30 can be

used to communicate with the F300K from a cooler place.

NOTICE

The accessibility and operation of the different displays depend on the current access level.

See section 7.2 Enter Password.

24

Page 26

5 User Interface

5.2 Menu tree

25

Page 27

6 Commissioning

6 Commissioning

6.1 Safety

6.1.1 Safety When Putting the Device Into Operation

DANGER!

Danger if shock protection is not provided

There is a risk of death or very serious injury from electric shock.

When installing the electrical accessories, do everything necessary to provide shock pro-

tection.

Y ou must comply with the requirements of protection class IP40 or IP54 (for use outdoors)

to EN 60529.

WARNING!

The fiber optic flame detector versions F300K.. IR-.. FO with IR sensors may only be used with

the LAMTEC IR Fiber optic FOR...-IR or FOF...-IR.

NOTICE

Exceeding the maximum permissible operating temperature

Ensure that the maximum permissible operating temperature (see the table in Section 14.1

Technical Data) is not exceeded at the installation location, in particular as a result of radiant

heat.

Take action to ensure sufficient cooling.

LAMTEC offers the FK30 cooling air housing.

NOTICE

Laying of cables

Warning to avoid damage to property

The cables are designed for a special temperature range see chapter 14.1 Technical Data

Lay the connecting cable including its extension apart from the mains and control cables

(don't lay them parallel to each other).

Avoid laying cables near the following components:

- Ignition cables

- Ignition transformers and electric motors

- Contactors or switches and frequency converters that switch high inductive or capacitive

loads

Although the device exceeds the requirements of the applicable EMC standards, in some

cases by a considerable amount, proper wiring is the prerequisite for ensuring that the device and thus the entire plant operates without problems in all cases.

26

Page 28

6 Commissioning

NOTICE

Shielding/extension of connecting cables

Warning to avoid damage to property

Apply shielded cables directly (without any intermediate terminals if at all possible).

If intermediate terminals are necessary, take the shortest route to applying the shielding

to the terminal.

Avoid long connecting wires without shielding.

Use a separate, shielded extension cable to implement an extension on site.

NOTICE

High electromagnetic interference

Excessive electromagnetic interference can lead to sporadic problems with flame detection

and even prevent it.

Connect chassis earth (earthing bolt at the device) to functional earth (FPE).

It is a connection between the mass of the supply voltage and FPE prepared.

NOTICE

EMC emission testing

It was ascertained during the type test that the device meets the EMC emissions requirements. A separate EMC emissions test is not necessary after installation.

27

Page 29

6 Commissioning

6.1.2 Electrical Safety – Requirements to Be Met by Third-party Manufacturers

DANGER!

Supply voltage

The device's supply voltage may only be generated by means of a safety power supply unit of

a different make from the one described in the accessories if safety extra-low voltage is used

(e.g. to EN 61558-2-6 "Safety of transformers" or EN 60950-1 "Information technology equipment – Safety".

DANGER!

"Flame signal" and "ready" relay contact outputs

The potential-free contact connections of the device's relays may only be wired with safety extra-low voltage in accordance with the requirements for supply voltage.

DANGER!

"Mode selector" digital inputs

The digital inputs are controlled only via potential-free contacts.

DANGER!

Communication interfaces

The equipment of other manufacturers connected to the communication interfaces must meet

the requirements of DIN EN 60950-1 "Information technology equipment – Safety".

DANGER!

Analogue output current loop - Protection against electric shock

Measuring circuits must be separated safely to dangerous active parts according to EN 61 140

„Protection against electric shock …“.

You achieve this by double or reinforced isolation according to EN 61010-1 „Safety re-

quirements for electrical equipment for measurement, control and laboratory use“.

WARNING!

Radio interference suppression of the output contacts

In the interests of safety, ensure when installing the output contacts that:

The user suppresses radio interference in such a way that the contacts of the safety relay

contact output cannot be shorted by defective components of the suppressor circuitry.

28

Page 30

6 Commissioning

6.1.3 Special Points to Note When Using the Device in Explosion-proof Areas

The following applies when using the F300K in explosion-proof areas:

• For use only in approved explosion protection zones.

• T o protect its aperture, only mount the F300K on a burner or boiler using one of its holders:

the FV30, FV40, FK41 or FK46.

• Use only the types of cable specified by the manufacturer when extending cables.

• When extending cables in the potentially explosive area, use only terminal housings that

are approved for this area. LAMTEC recommends the connection housing FG30-20 Ex II

for this purpose.

• Check if cable connections fit tightly. Should there be a need to loosen the cable connection, it is to be ensured that the cables do not turn while loosening and tightening the cable

connection.

• Note, in particular, the information on setup in EN 60079-14, section 12.2 (cables and

earthing).

• Only remove the connector of the F300K or FB30 Ex or any other cable connections when

it is deenergised.

See the warning on the device: WARNING – DO NOT DISCONNECT WHEN ENERGISED.

• In particular, seperation has to be in accordance with EN 60079-14 'Appendix: Instructions

for procedures to work safely in an explosive gas atmosphere', only permitted after the release by personnel in charge of the explosion protection of the operating company.

• The F300K and FB30 may only be opened by the manufacturer or authorized personnel.

It is not necessary to open the device when putting it into operation.

• A transformer for generating the supply voltage must be carried out according to

IEC 61558-2-6.

• You must use a current limiter with a limit on the rated voltage.

• When using the device in the ambient temperature range, you must keep the temperature

in accordance with the temperature class: See Ex marking on the device

• If devices are so damaged that they no longer meet the requirements of the IP64 protection class, you must replace them.

Special instructions for use in Hazardous Area Class I Division 2 (valid for F300K)

• Devices shall be wired in accordance with NEC (National Electrical Code) field wiring

requirements for the location.

UL Listed Version:

• The plug of the connecting cable must be secured against self-loosening after mounting

on the flame detector. There are screws on the union nut of the connector.

29

Page 31

6 Commissioning

Marking information on the device: Example

F300K/F300K UI FB30

Warning: e.g.

30

Page 32

6 Commissioning

6.2 Installation

The following sections provide information on:

• What prerequisites have to be met to install the product properly

• How you have to position the product

• How you have to secure the product

6.2.1 Prerequisite for Mounting the Device Properly

NOTICE

Mounting the device using a holder

If at all possible, mount the flame scanner to the burner/boiler using a holder optimised by

LAMTEC for use with flame scanners. Characteristics see chapter 6.1.3 Special Points to

Note When Using the Device in Explosion-proof Areas

If you do not do this, ensure that the device is insulated in order to prevent any interference

from equalising currents (via the cable shield).

NOTICE

Mounting location

Ensure that the mounting location is easily accessible. During operation of the combustion

plant, you should be able to see the optical monitoring elements well.

WARNING!

The fiber optic flame detector versions F300K.. IR-.. FO with IR sensors may only be used with

the LAMTEC IR Fiber optic FOR...-IR or FOF...-IR.

31

Page 33

6 Commissioning

6.2.2 Positioning

The processes that take place in combustion result in pulsing radiation (flickering of the flame).

The series of oscillations (flame frequency) involved are used for monitoring purposes.

Position the aperture used for selective monitoring in such a way that the compact flame

scanner/flame sensor picks up the root of the burner flame to be monitored (near the

mouth of the burner).

NOTICE

The burner flame must be well visible throughout the combustion plant's operating range.

Ensure that the compact flame scanner/flame sensor does not point directly at flame that

is opposite or adjacent.

This is also very important when it comes to background flames (e.g. coal, wood, waste).

1. Mount the compact flame scanner/flame sensor on the burner's viewing opening. Use the

corresponding adjustable holder for this.

The compact flame scanner/flame sensor is now mounted. Pay attention to the following

instructions for alignment.

WARNING!

Overheating of the flame sensor / flame scanner

Ensure that the max. permissible ambient temperature is not exceeded at the installation site.

Due to the location where the flame scanner is installed, increased temperature can occur on

the scanner, especially with the FFS08.

The operating mode of the burner or appropriate cooling measures must prevent the per-

mitted operating temperature from being exceeded.

If the permissible operating temperature has been exceeded, the flame scanner or flame

sensor must be replaced.

Measures must be taken to prevent such a situation.

An overheated flame sensor or flame scanner is operated outside its specification.

As a result, it is possible that the safety function is no longer active.

32

Page 34

6 Commissioning

6.2.3 Alignment

NOTICE

Recommendation

If there is no ball joint available already , we therefore recommend using a LAMTEC adjustable

holder with the FV40-10 ball joint. The viewing direction of the flame detector must cut the

flame (see figure 6-1).

Particularly when there is an additional sight tube in the burner or the view of the flame is

considerably restricted, it is very important to align the flame scanner to optimum effect.

The longer the sight tube, the more advantageous it is that it has a larger cross-section.

NOTICE

Alignment parallel to the axis

In the axially parallel arrangement, it can be difficult to detect that the flame has gone out.

Avoid aligning the F300K in an axially parallel arrangement with the flame.

The correct positioning (alignment) of the F300K is a decisive prerequisite for high availability

or for the achievable selection quality. In any case, you should always take into account that

the aperture in the UV and UVIR (double sensor) versions is very restricted due to the lens.

Align the compact flame scanner as follows:

• Align the F300K preferably in such a way that it picks up the first third of the flame to be

monitored (high flame frequencies).

• Also align the F300K in such a way that it picks up only a small part or, even better, none

of the radiation from other burners or the re-radiation from the combustion chamber (low

flame frequencies).

Fig. 6-1 Pulsing of the flame radiation – frequency

33

Page 35

6 Commissioning

6.3 Electrical Connection

NOTICE

It is not required to change to the respective mains frequency.

Periodic signals> 47 Hz are recognised for safety reasons as disorder. This covers the requirements of standards for insensibility in the range of mains frequency (50/60 Hz) and their

multiples. Therefore it is not necessary to change the mains frequency on site.

You will find connection diagrams in the Appendix, Section 14.2 Connection Diagram

6.4 Putting the Device into Operation for the First Time

6.4.1 Requirements

Prerequisites for putting the device into operation for the first time:

• The F300K must be mounted as specified in Section 6.2 Installation.

• The F300K must be aligned as specified in Section 6.2.3 Alignment.

• All electrical installations must have been tested.

• All terminal and plug-in connections must have been tested.

6.4.2 Parameter

NOTICE

Putting the device into operation

To operate the F300K safely, you have to adhere to the following sequence when putting

it into operation for the first time:

1 Release access level 1 or 2 by means of a password: Section 7.2 Enter Password.

2 Set the flame parameters of the F300K: Section 6.4.4 Setting Monitoring Parameters.

3 Set the monitoring parameters of the F300K: Section 6.4.4 Setting Monitoring Parame-

ters.

4 Check the setting of the parameters by means of the switch-off test: Section 6.4.5 Switch-

off Test.

During operation it is possible to change parameters. Parameters have a well-defined 2-digit

numbering and in most cases they are characterised by a symbol.

There are different sorts of parameters:

• Operating mode parameters for the behaviour of flame detections

• Device parameters of the flame scanner (p.ex. BUS-ID or current loop)

• Device parameters of the User Interface (p.ex. light ON time)

34

Page 36

6 Commissioning

6.4.3 Adjusting F300K

Checking the switch-off parameters

There is a risk of death and serious injury.

The switch-off parameters are to be verified through switch-off tests, see chapter 6.4.5

Switch-off Test. Changes made to settings (increase or weighting of doublesensor) do af-

fect the switcht-off parameters and therefore new switch-off tests are to be carried out.

NOTICE

Reliable detection of the flame

Warning to avoid damage to property

Set the parameters in such a way that, across the entire performance range and in all of

the combustion's modes, safe detection of "flame OFF" and stable detection of "flame ON"

are ensured.

WARNING!

NOTICE

Aligning and setting the parameters of the flame scanner

Warning to avoid damage to property

Right from the outset, you must align the flame scanner to optimum effect and optimise its

settings. Any changes alter aspects of how the flame scanner works. Following any

change, it is necessary to check the correct switch-off parameters again by means of corresponding switch-off tests.

You generally start making settings with the flame burning at the burner's base firing-

rate and can then continue for the background signal when the burner to be monitored is

off. It is also possible to do this the other way around.

NOTICE

Note about some basic prerequisites

Y ou must have selected a mode (see the connection diagrams for hardware control). You

generally start with mode 1.

In the delivery state, mode of operation 2 and 3 are occupied with parameters, and in com-

parison to mode of operation 1, they are more insensitive with regards to flame recognition. Should you wish to use mode of operation 2 or 3, you should proceed like mode of

operation 1.

Should you wish to reset the manufacturer's factory settings, you can load that in the cur-

rent mode of operation (see section 7.6.3 Resetting the device parameter factory settings)

NOTICE

You will find a description of the error messages in section 10 Correcting Faults.

35

Page 37

6 Commissioning

Aligning the F300K

Y ou generally start making settings with the flame burning at the burner's base firing-

rate and can then continue for the background signal when the burner to be monitored is

off. It is also possible to do this the other way around.

Aligning the F300K

1. Open the automatically > Align menu.

Fig. 6-2 Open the Parameterize automatically

If there is no sufficient UV signal available in the usage of F300K UVIR-1 (double sensor)

despite the signal reinforcement to level 13, select 'Adjust the Reinforcement Menu

of the IR sensor.

2. Align the F300K mechanically in such a way that the flame to be monitored reaches the

maximum signal strength.

3. During alignment you can read/check the value from the display of the dynamic range.

Fig. 6-3 "Alignment" menu

for the single sensor version

Fig. 6-4 "Aligning UV" menu for the dual sensor

version

1 Current peak value of the signal

2 Minimum and maximum of the optimum

dynamic range

3 Amplification level of the signal

36

Page 38

6 Commissioning

Amplification setting of the F300K

1. In the Align menu you need to adjust the amplification in such a way that the signal is within the optimum amplitude modulation of the amplitude bar (min - max).

a) Press the key to open the "Amplification setting- Ascending steps" menu.

b) Press the key to open the "Amplification setting - Descending steps" menu.

NOTICE

The amplification setting is only possible step by step (1 level). Then you must confirm by

pressing ENTER.

Fig. 6-5 "Amplification setting" menu

2. Press the key to apply the amplification. A countdown of 8 seconds begins. This is

accompanied by flashing. During this countdown, you have to confirm the setting by pressing ENTER. If you do not, an error message appears and the setting is rejected.

Alternatively, use the key to reject the setting.

Fig. 6-6 "Amplification setting" menu after pressing the ENTER key

The F300K is now ideally aligned.

Amplification optimization of the IR sensor in F300K UVIR-1 (double sensor)

Change to the menu and perform the same steps as in the menu .

Fig. 6-7 Menu "Amplification - IR" for the double sensor version

37

Page 39

6 Commissioning

NOTICE

Dual-fuel operation

T wo ranges are marked for dual-fuel operation without mode selection. The fuel with the lower

amplitude remains within the lower range, and the fuel with the higher amplitude uses the entire range.

Monitoring is generally also possible outside the marked ranges, although not ideal.

Icon Name Wert Erklärung

Peak value 0 ... 2500 mV Current peak value of the signal

01

Trigger threshold adaptation

Amplification 1 ... 13 Amplification level of the signal.

Min mark Optimum dynamic range min.

Max1 mark Recommended maximum of the

Marke Max Optimum dynamic range max.

Overload mark Indicates a signal outside the

0 ... 100 mV Information that the trigger

threshold is too low for the

selected Amplification and is

adjusted automatically to the

displayed value (smallest valid).

optimum dynamic range when

monitoring two fuels in the same

mode for the weaker signal (e.g.

for gas).

normal working range.

current trigger

threshold

38

Displays the current trigger

threshold of the flame scanner.

Above in the OFF and down in

the ON state

Page 40

6 Commissioning

Set the Weightings Between UV and IR Signals (Dual Sensor)

Switch to the menu .

Fig. 6-8 Call up the weighting menu

The amplitude bars would be displayed; UV from the menu IR from the menu and the

weighted signals . The percentage value of the amplitude bars gives a relative amount of the

individual signals to the weighted signals.

Fig. 6-9 Weightings Menu

Settings of F300K Weightings

1. In the weightings menu, you can adjust the settings so that the individual signals UV and

IR can be added with the required percentage and be processed further.

a) Control with , to increase the percentage of UV signal to the weighted signal.

b) Control with , to decrease the percentage of UV signal to the weighted signal.

2. Control with to confirm the weightings. A countdown of 8 s starts now. This would be

shown with blinking. During the countdown, you must confirm the settings through ,

otherwise you will get an error message and the settings will not be saved

Alternatively you can discard the process with

WARNING!

The shut-off parameters which are determined by the settings procedure are only valid when

these are verified through corresponding shut-off tests, see chapter6.4.5 Switch-off Test

39

Page 41

6 Commissioning

6.4.4 Setting Monitoring Parameters

6.4.4.1 Automatic setting

This section describes the learning processes for setting the monitoring parameters.

WARNING!

Checking the switch-off parameters

There is a risk of death and serious injury.

The preset switch-off parameters are to be verified through switch-off tests see

Section 6.4.5 Switch-off Test

Recording the signal with the flame ON

Y ou must have aligned the device and set the amplification to optimum effect beforehand.

Select the firing-rate state with the lowest signal amplitude. This is normally the base fir-

ing-rate.

NOTICE

Y ou can open the menus Record flame ON, Record flame OFF and Analyse individually

or process them as a series.

Y ou can also have the monitoring parameters set automatically and/or set them manually.

You can switch to the next menu in the sequence or select the next step "freehand".

1. Open the Automatic flame ON/OFF parameter setting > Record flame ON

menu.

Fig. 6-10 "Record flame ON" display

2. Start the automatic recording of the "Flame ON" parameters by pressing .

Fig. 6-11 The "flame ON" flame data is recorded

40

Page 42

6 Commissioning

3. Once the bar display is fully loaded:

a) Press to open the next menu: Record flame OFF.

b) Alternatively , exit the menu by pressing , and then select the menu Record flame

Fig. 6-12 "Record flame ON" display once the parameters have been learned

The F300K has now automatically learned the parameters for the "flame ON" state.

Icon Name Value Explanation

OFF.

Peak value 0 ... 2,500 mV Current peak value of the signal

Start recording (learn)

Overload Reduces the amplification

Recording the signal of the flame in the OFF state

The F300K has previously learned the flame on/off status automatically in the "Flame ON"

menu.

NOTICE

Optimum recording in the flame OFF state

You will get the best results when analysing the learned/recorded signal if you carry out the

recording in the flame OFF state in the most unfavourable situation for distinguishing between

flame ON and flame OFF.

This is when there is strong interfering radiation coming from the combustion chamber.

With IR flame scanners, it is often the case immediately after the burner is switched off.

1. Open the Automatic parameter setting > Record flame OFF menu.

Duration approx. 30 seconds. A progress bar

indicates the progress

Switches to the next step

Fig. 6-13 "Record flame OFF" view

2. To start automatic parameter setting for "flame OFF", press .

41

Page 43

6 Commissioning

Fig. 6-14 The "flame OFF" flame data is recorded

3. Once the bar display is fully loaded:

a) Press to open the next menu: Analyse.

b) Alternatively, exit the menu by pressing , and then select the menu Analyse.

Fig. 6-15 "Record flame OFF" display once the parameters have been learned

The F300K has now automatically learned the parameters for the "flame OFF" state.

42

Page 44

6 Commissioning

Analysis of the optimum switching thresholds (levels)

The analysis is carried out on the basis of the learned data in the user interface or the

F300K remote software.

NOTICE

With effect from V ersion 1.1 of the F300K software, the set frequency band S or T is included

in the analysis. If the frequency band is changed after the learning data is entered, analysis is

no longer possible. The F300K outputs the error message L1007 in this case.

When the analysis starts, the optimum switching threshold is determined for the change from

flame OFF to flame ON (switch-on level) and from flame ON to flame OFF (switch-off level).

In addition to these two levels, the so-called process reliability (distance between OFF and

ON) is displayed in the result.

NOTICE

To save the parameters of the analyzing result, you need to send it to the flame scanner

When you confirm the parameters transferred, the CRC in the flame scanner changes. Parameter changes after the switch-off test and the associated change to the CRC necessitate

a new switch-off test (see Section 6.4.5 Switch-off Test

WARNING!

1. Open the Automatic parameter setting > Analyse menu.

1 "Flame ON" data recorded by operating

hours

2 "Flame OFF" data recorded by operat-

ing hours

3 "Flame OFF" data factory setting (no rel-

evant background radiation exists)

Fig. 6-16 "Analyse" display

2. Press to display the learned parameters and the process reliability.

Icon Name Value Explanation

Switch-off level 0 ... 2,500 mV Trigger threshold "flame OFF"

1 Parameter trigger threshold for flame off

2 Process reliability,

max. fault- useful signal distance

between flame OFF and ON

Fig. 6-17 "Switch-off parameters" display

43

Switch-off parameters:

Trigger threshold switch-off process

Page 45

6 Commissioning

3. Press to display the switch-on parameters and the process reliability.

Icon Name Value Explanation

Fig. 6-18 "Switch-on parameters" display

4. To send the data from the level of the operating unit to the flame scanner, press .

Alternatively, press to reject it.

Switch-on level 0 ... 2,500 mV Trigger threshold "flame ON"

1 Parameter trigger threshold for flame on

2 Process reliability,

max. fault- useful signal distance

between flame OFF and ON

Switch-on parameters:

Trigger threshold switch-on process

B1 Mode 1

CRC CRC checksum of the data set

Fig. 6-19 Data sent to the flame scanner

5. Compare the data sent to the flame scanner with the data at the level of the operating unit.

Then:

a) Press within 8 seconds to save the data. A countdown of 8 seconds begins. This

is accompanied by flashing. During this countdown, you have to confirm the setting by

pressing ENTER. If you do not, an error message appears and the setting is rejected.

b) Alternatively, press to reject the data.

Line 1 Data to be sent from the level of the

operating unit

Line 2 Data received by the flame scanner

(flashing)

Fig. 6-20 Data received from the flame scanner

44

Page 46

6 Commissioning

The data has now been determined and sent to the flame scanner.

Fig. 6-21 Successful transfer

45

Page 47

6 Commissioning

6.4.4.2 Hand optimization of the automatically determined trigger thresholds (levels)

WARNING!

Checking the switch-off parameters

There is a risk of death and serious injury.

The preset switch-off parameters are to be verified through switch-off tests, (see Section

6.4.5 Switch-off Test).

The change of the trigger threshold, the gain of the weighting (UV/IR) and/or the frequency

setting affects the switch-off parameters and therefore requires renewed switch-off test.

The manual optimisation of the trigger threshold is based on the last point of the data transmitted by "Automatic Optimisation" through the User Interface or F300K-Remote-Software.

If the automatic optimisation is finished, a symbol of manual optimisation would appear in the

higher level menu screen 300 .

In manual optimisation menu, a manual optimisation can be performed before or after saving

the evaluation results from the "Automatic Optimisation".

Screens for the display of evaluation results from the "Automatic Optimisation" pop up, and

they can be edited through DOWN or UP buttons.

Other procedures such as "Browse" and "Save"comply with automatic optimisation

NOTICE

The positions of the displayed trigger threshold corresponds to activation of menus which are

currently active in F300K available and could deviate from evaluation results. The displayed

limits corresponds to the evaluation results.

1 Parameter trigger threshold for flame

OFF

2 Process reliability, is the max. fault or

useful signal distance between flames

OFF and ON.

Shut-down parameter:- trigger threshold

power down

Fig. 6-22 Display "switch-off parameters "

With DOWN, the trigger threshold would be

reduced and process reliability would be

reduced.

The deviation from automatic determined

process reliability would be displayed in %.

In case of failure to achieve pre-determined

limits of the process reliability, an error mes-

Fig. 6-23 With DOWN the trigger threshold would

be reduced

sage would be displayed.

46

Page 48

6 Commissioning

Fig. 6-24 With UP the trigger threshold would be increased.

6.4.4.3 Manual setting

You can further optimise the parameterisation by making settings manually.

You will find information on manual parameterisation in section 7.5 Manual setting.

With UP the trigger threshold would be

increased and process reliability would be

reduced.

47

Page 49

6 Commissioning

6.4.5 Switch-off Test

Checking the safety-related parameters by means of a switch-off test

Y ou must check the safety-related parameters of the F300K to ascertain whether they are set

in accordance with the requirements for the furnace to be monitored and to ensure compliance

with the relevant standards.

Check the parameters for adherence to the flame failure detection time

(FFDT) by means of switch-off tests in the relevant performance range and the relevant

modes of the furnace.

Make the flame go out. To do this, you have to shut off the fuel supply of the burner mon-

itored by the F300K (preferably using the quick-action valve).

Check after the flame goes out that the signal for closing the

safety shut-off device within the necessary timescale is triggered.

NOTICE

Check beforehand that the parameter for the flame failure detection time (FFDT) is set cor-

rectly on the display of the F300K (siehe Fig. 6-25 Main menu).

You have to carry out this switch-off test for every single operating mode.

WARNING!

Fig. 6-25 Main menu

1 Safety time

48

Page 50

6 Commissioning

6.5 Acceptance

NOTICE

Obligation to provide evidence

Due to the obligation to provide documentary evidence to testing authorities, for quality management systems or to clarify liability issues and so on, we urgently recommend that you document your checks of the parameter settings. This documentary evidence can be included in

the burner's settings log.

This can be done by reading out the parameters and/or the CRC of the safety-related parameter sets of modes 1, 2 and 3 for the "flame ON" state by means of the user interface.

We recommend that you use the F300K Remote Software to save or make a note of the software version number at the time of the check and the individual parameters as a data set.

49

Page 51

7 Operation

7 Operation

7.1 Main Menu

This section gives you an overview of the displays and menus of the F300K.

Initial images

Fig. 7-1 Initial image 1

NOTICE

Has the user interface complete the high start-up phase and is in the home screen, the contrast of the display can be changed using the key combination ESC / UP or ESC / DOWN.

• Software version of the User Interface

• Manufacturer

Selection of the device at FSB (Bus)

NOTICE

The following view is only displayed with the external user interface if more than one device

is connected to the BUS

Selection symbol

01 Bus ID (Device number)

F300K Model

UV-4 Spektrum

03 Selection of other LAMTEC

device

Fig. 7-2 Initial image 2

Start window flame ON / OFF

Fig. 7-3 View with flame ON Fig. 7-4 View with flame OFF

50

Page 52

7 Operation

Main menu

1 Password entry

2 Information menu

3 Device setting

Fig. 7-5 Main menu without access via password (access level 0)

Fig. 7-6 Main menu with access via password (access level 1)

No.Name Value Explanation

1 Flame detection Current state: flame OFF or ON

2 BUS ID 01 ... 32 F300K subscriber number on the bus

3 Safety time 1 ... 5 sec-

onds

4 Operating mode 1, 2, 3 Active mode

5 Frequency band S, T Active frequency band

6 Frequency range 1 ... 7 Active frequency range

7 Fault/cause of

problem

8 Image number 000 ... 999 Current image number

9 Bar display Flame intensity – evaluated signal with indication

10 Set monitoring parameters

11 Set and align parameters automatically

12 Information menu

13 Password entry

14 Device settings

Hxxx, Uxxx Fault that led to the problem (cause of switch-off)

FFDT , maximum time before the flame relays are

switched off after the non-appearance of the

flame OFF signal in the current operating mode.

of the current switching threshold for flame ON/

OFF

• Approx. 70 % switching threshold: flame ON

• Approx. 30 % switching threshold: flame

OFF

51

Page 53

7 Operation

7.2 Enter Password

The operating menu is protected by passwords. If you do not enter a password:

• You can only display information.

• You cannot change safety-related parameters.

When you enter a password, this gives you time-limited access to the associated password

level. When you enter a valid password, you get access to additional information and parameters that you can change.

Entering a password and accessing the standard level (level 1)

Access is available to password level 0.

Access is now available to password level 1.

NOTICE

The following password levels are available:

• Password level 1: standard level – entry of 0000 (state on delivery - should changed after

commissioning

– limited manual parameterisation possible

• Password level 2: expert level – entry of XXXX (state on delivery - you should change it

to customer password after commissioning )

– extensive manual parameterisation possible

• Password level 4: entry via the LAMTEC hotline only (factory level)

– full manual parameterisation possible

52

Page 54

7 Operation

7.3 Reading information

The following sections describe how to get to the various information menus.

Fig. 7-7 Overview of the information menu

7.3.1 Read mode 1-3

1 Devices

2 Signal of the flame

3 Fault

4 Mode 1-3 monitoring parameters

Calling the information on the mode

1 Information on mode 1

2 Information on mode 2

3 Information on mode 3

Use the arrow keys to scroll up and down.

You will find more information on the values in the following table:

53

Page 55

7 Operation

Icon Name Value Explanation

70:

20:

05:

07:

08:

12:

06:

11:

10:

09:

24:

25:

AC signal 0 ... 2,500 mV Current effective value of amplified signal

Switch-on

level

Switch-off

level

Amplification

Sensor 1

Amplification

Sensor 2

Weighting 0 … 100% Signal part of sensor 1 (UV)

Frequency 10 ... 110 Hz

Safety time 1 ... 5 sec FFDT, maximum time before the flame

Switch-off

time

Recovery

time (integration time)

Switch-on

time

Level of suppression

0 ... 2,500 mV Switching threshold for "flame ON"

0 ... 2,500 mV Switching threshold for "flame OFF"

1 ... 13 Amplification level of the signal

-Single sensor UV or IR

-Double UV sensor

1 ... 13 Amplification level of the signal IR- Double

sensor only

- Double sensor only

Lower limit frequency as of which the signal

5 ... 160 Hz

0,3 ... 5 s Time before the flame relays are switched

0,2 ... 5 sec Time for the development of the full switch-

0.2 ... 5.0 sec Switch-on time of the flame relays after the