Page 1

Manual

F200K Compact Flame Scanner

Sensors and Systems for Combustion Engineering

www.lamtec.de

Page 2

Page 3

Table of Contents

Table of Contents

1 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Validity of these Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Safekeeping of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 How to Use the Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Product-specific Dangers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Mode of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Basic circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Life Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Selection Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Information for Mounting and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Mounting - Basic Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.2 UL Listed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.3 Basic mounting instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.1 External Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.2 Device Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Instructions on Commissioning and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1 Display and Operational Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.1 Intensity Indicator Including the 'Adjust' Function . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.2 Operating State - Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.3 Operating Mode - Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.4 Sensitivity - Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.5 Frequency - Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.6 Service - Switch Serv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.7 Adjust - Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.8 Start-up Suppression - Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.9 Measuring Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2.1 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2.1.1 'Flame Out' State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2.1.2 'Flame In' State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2.1.3 Operating mode switchover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2

Page 4

Table of Contents

7.2.2 Special Points to Note When Using the Device in Explosion-proof Areas. . . . . 25

7.2.3 Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2.3.1 Checking the Compact Flame Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2.3.2 Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2.3.3 Optics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2.4 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.4.1 Sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.4.2 Alignment with Adjustment Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.4.3 Measuring Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.4.4 Frequency Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.2.4.5 Start-up Suppression. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.2.5 Switch-off test - check the correct setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2.6 Fault on Flame Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2.6.1 1. Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2.6.2 2. Exceeding the permissible ambient temperature. . . . . . . . . . . . . . . . . . . . . . 31

7.2.7 Faults During Ignition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2.8 Faults During Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.4 Commissioning Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.5.1 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.5.2 Instructions on Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.5.3 Flame Scanner Testing Device replace Battery. . . . . . . . . . . . . . . . . . . . . . . . . 36

8 Warranty and Delivery Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1 Layout of the Operational Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.1 F200K1 ... in the State as Delivered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.2 F200K2... (Ex-proof), in the State as Delivered. . . . . . . . . . . . . . . . . . . . . . . . . 40

9.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.2.1 F200K and F200K Ex-II (Hazardous Area 2.22) Compact Flame Scanner. . . . 41

9.2.2 F200K2 ... Ex Compact Flame Detector (Hazardous Area 1, 21) . . . . . . . . . . . 42

9.2.3 Connection Housing FG 24 Ex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.3 Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.3.1 Circuit Diagram F200K1 ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.3.2 Circuit Diagram F200K2 ... EX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.4 Examples of Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.4.1 Interfacing with ETAMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.4.2 Interfacing with FMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1 FN20, FN30-20 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.1 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.2 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.3 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.2 Weather Shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.3 Adjustable Holding Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10.3.1 FH30-10 (for IR and UV, without Ball-and-socket-joint with Purge Air Connec-

tion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10.3.2 FH40-10 (for IR and UV, with Ball-and-socket-joint and Purge Air Connection) . 55

3

Page 5

Table of Contents

10.3.3 FV30-10 (for IR and UV, without Ball-and-socket-joint with Purge Air Connec-

tion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.3.4 FV40-10 (for IR and UV, with Ball-and-socket-joint and Purge Air Connection) . 56

10.3.5 Cooling Air Housing FS50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.3.6 Cooling Air Housing with Ball-and-Socket Joint FS51. . . . . . . . . . . . . . . . . . . . 59

10.3.7 FS56 (Adjustable, Demountable, with Cooling Air Housing) . . . . . . . . . . . . . . . 60

10.4 Installation in the Cooling Air Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.5 Flame Scanner Testing Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.6 Connection Cable AK01. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.6.1 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.6.2 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.7 Fiber Optic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11 Commissioning Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

12 EU Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4

Page 6

1 General Information

1 General Information

1.1 Validity of these Instructions

This document is valid for the F200K Compact Flame Scanner with hardware version 2.0 until

2.2

The devices correspond to the following directives and standards:

• DIN EN 298: 2012

• DIN EN 60730-2-5: 2015

• DIN EN 746-2: 2011

• 2014/68/EU Pressure Equipment Directive

• 2009/142/EG Gas Appliance Directive

• EU/2016/426 Gas Appliance Regulation (GAR)

• 2014/30/EU Electromagnetic Compatibility Directive

• 2014/35/EU Low Voltage Directive

• DIN EN 61508: 2011, part 2 (requirements SIL 3)

• DIN EN ISO 9001:2008 Quality Management Systems

• ISO/IEC 80079-34:2011 Potentially explosive areas - Quality Management System

(QAR)

• 2011/65/EU (RoHS2 Directive)

• UL372

1.2 Purpose

Product-Identification-Number: CE-0085 BO 0005

NOTICE

LAMTEC retains the right to make changes to this document at any time, without notice.

LAMTEC makes no warranty of any kind, expressed or implied, with regard to any

information contained in this document, including, but not limited to, the implied warranties of

merchantability or fitness for any particular purpose.

Further LAMTEC does not warrant the accuracy or completeness of the information, text,

graphics, or other items contained within this document.

In single-burner and multiple-burner furnaces, the flame scanner performs a high-safety monitoring of the burner flame. When the flame goes out, the safe control state’ Flame ’ is reached.

The flame scanner is mainly used in large-scale power plants, thermal power stations and

chemical plants as well as for monitoring furnaces which are operated from.

– oil

– gas

– bio-mass

– dust coal

– chemicals and other waste products

5

Page 7

1 General Information

1.3 Target Group

These instructions must have been read carefully and completely before commencing with

any work. The basic prerequisite for working safely is compliance with all the specified safety

instructions.

NOTICE

All assembly , commissioning, troubleshooting and maintenance work may only be carried

out by authorised and trained personnel.

The device may be operated and maintained only by those who are capable of doing so

in terms of their level of knowledge and training.

For F200K, the covers must be removed for commissioning, but then only by authorised

personnel. Any further opening or disassembly is not permitted.

The open flame scanner must be protected from ingress of dust and moisture.

Contact with the electronics is only permitted if ESD measures are observed.

Opening the devices is not permitted under any circumstances except for commissioning

(F200K).

For safety reasons, access to parameterisation must be restricted to authorised

personnel.

1.4 Safekeeping of the Manual

Look after the manual and all the associated documents carefully.

The manual is part of the product and must be kept safe and be accessible to personnel at all

times.

Moreover, it is important that the manual:

• Is available when required.

• Is kept for the entire service life of the device.

• Is available to its next operator.

6

Page 8

2 Safety

2 Safety

2.1 For Your Safety

The following symbols are used in this document to draw the user's attention to important safety information. They are located at points where the information is required. It is essential that

the safety information is observed and followed, and that applies particularly to the warnings.

This draws the user's attention to imminent danger. If it is not avoided, it will result in death or

very serious injury. The plant including its surroundings could be damaged.

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in death or very serious injury. The plant including its surroundings could be damaged.

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in minor injuries. The plant including its surroundings could be damaged.

DANGER!

WARNING!

CAUTION!

NOTICE

This draws the user's attention to important additional information about the system or system

components and offers further tips.

The safety information described above is incorporated into the instructions.

Thus, the operator is requested to:

1 Comply with the accident prevention regulations whenever work is being carried out.

2 Do everything possible within his control to prevent personal injury and damage to prop-

erty.

2.2 How to Use the Information

The necessary data for correct mounting, wiring, installation, operation and maintenance of

the device are to be taken from the relevant instructions for the burner or combustion in the

official language of the country.

7

Page 9

2 Safety

2.3 Product Safety

WARNING!

This product is state-of-the-art technology and complies with the generally accepted

safety-related rules and regulations.

Every device is tested before delivery to ensure that it is working properly and safely.

Only use this product when it is perfect condition and in accordance with the manual, the

prevailing regulations and guidelines and the applicable safety and accident prevention

regulations.

WARNING!

The risk of danger in the event of external fire, traffic and wind, flood waves and earthquakes

depend on the installation situation and the installation site to be assessed separately where

appropriate.

2.4 Product-specific Dangers

DANGER!

The F200K is not designed to switch off the fuel valves.

The subsequent signal processing must be carried out in the control system, which is

adapted to suit the combustion plant.

WARNING!

The F200K is a safety device. Only specialist staff of the manufacturer or people approved by

the manufacturer may intervene. No interventions by anyone else are permissible. This applies, in particular, in the event of a defective fuse.

WARNING!

Radio interference suppression of the output contacts

In the interests of safety, ensure when installing the output contacts that:

The user suppresses radio interference in such a way that the contacts of the safety relay

contact output cannot be shorted by defective components of the suppressor circuitry.

WARNING!

The power supply of the flame scanner and the user interface with 24 VDC must be ensured

by an external power supply unit, which supplies SELV or PELV.

8

Page 10

3 Functional Description

3 Functional Description

3.1 Design

The compact-type flame detector is composed of a cylindrical casing comprising an axial light

incidence aperture, a processing status indicator at the rear of the unit and operational controls which can be accessed by removing the cover.

When closed the flame detector complies with the requirements of IP 67 (F200K) or IP66

(F200K..EX) protection degree.

The detector is installed at the burner by optionally using the FH30, FV30, FH40, FV40 adjustable holding devices or with an air-cooled housing of types FS50, FS51 or FS56.

The detector consists of the following functional units:

– sensor unit providing for digitalisation of the flame signal

– digital frequency evaluation

– self-monitoring

– switching amplifier

The device is connected through an integrated standard plug and using the a connection cable

required for this (8 pins, static shielded) with coupler.

The cable provides for the following connections:

– Infeed of power supply

– connection of the operational earthing FPE

– connection of external power circuits to a failsafe change-over contact to control the con-

trol states ’Flame out’ and ’Flame in’

– connection of the intensity measurement output

– connection for an external sensitivity change-over, only for F200K2

– connection of the screen via the connector housing

The layout of the operational controls is represented in chapter 9.1 Layout of the Operational

Controls.

9

Page 11

3 Functional Description

3.2 Rating Plate

Rating plate F200K (Example):

Information on variants:

a Housing type:

Ex= zone1, EXII=zone2,

empty/0 = Standard,

FO= Fiber optic,

V= screwed

b Electronic type

c Electronic type

d FFTD: 1 ... 4

e Mains frequency: 50, 60,--

f Output current min.: 0, 4

g ERP number

h Serial number

i Hardware version

10

Page 12

3 Functional Description

3.3 Mode of operation

The compact flame detector converts the flame radiation pulsing of the burner flame into electrical signals. These signals are routed to an electronic changeover switch, which alternately

applies them to one of the independently working processing channels, where the signals are

digitised. This reduces the initial signal quantity to the information ’pulse period’ (information

carrier: pulse frequency of the flame radiation).

The digitised signals are compared with the related reference signals by means of a digital

frequency evaluation unit. This ensures that only those flame signals that are within the preselected frequency transmission range will be included in a continued processing, irrespective

of their original amplitude. A control switch (for the F200K2 only) located below the removable

cover allows the operator to change the lower frequency limit if required. After evaluation, the

flame signal is routed to the switching amplifier, which also controls the related shut-down

time.

A safe monitoring of the antivalent control states as well as the response and shut-down periods is performed at the output of the signal processing channels, before an activation of the

output relays at the end of each signal processing channel is carried out. Antivalence faults

and deviation in time delays going beyond the admissible limit values result in the control state

’Flame out’.

The control states ’Flame out’ and ’Flame in’ are indicated on the rear side of the device by

means of a red and/or green LED. The change-over between the two signal processing channels is indicated by pulsing of the green LED during the ’Flame in’ control state.

Additionally one or two six-step control switches provide for a sensitivity adjustment to adapt

the system to the flames to be monitored, this being indicated by means of a six-step chain of

green LEDs designed to be the device's flame intensity indicator.

Miscellaneous

Self-monitoring principle

Signal processing is carried out by means of two transmission channels working independently of each other and alternately triggered. The output levels are permanently checked for antivalence within a given time grid.

Parameter adjustment, combustion system type monitoring equipment

Using the control rotary switch on the F200K/F200K2 compact flame detectors enables between 6 and 12 sensitivity levels to be set. The F200K2 version allows an increased sensitivity

in range II to be set. A six-step green LED indicator indicates the evaluated flame intensity on

the rear side of the device. The transmission range of the digital flame frequency evaluation

allows for signal passage between10 ... 190 Hz (F200K1) and/or 10 / 20 / 30 ... 190 Hz

(F200K2).

11

Page 13

3 Functional Description

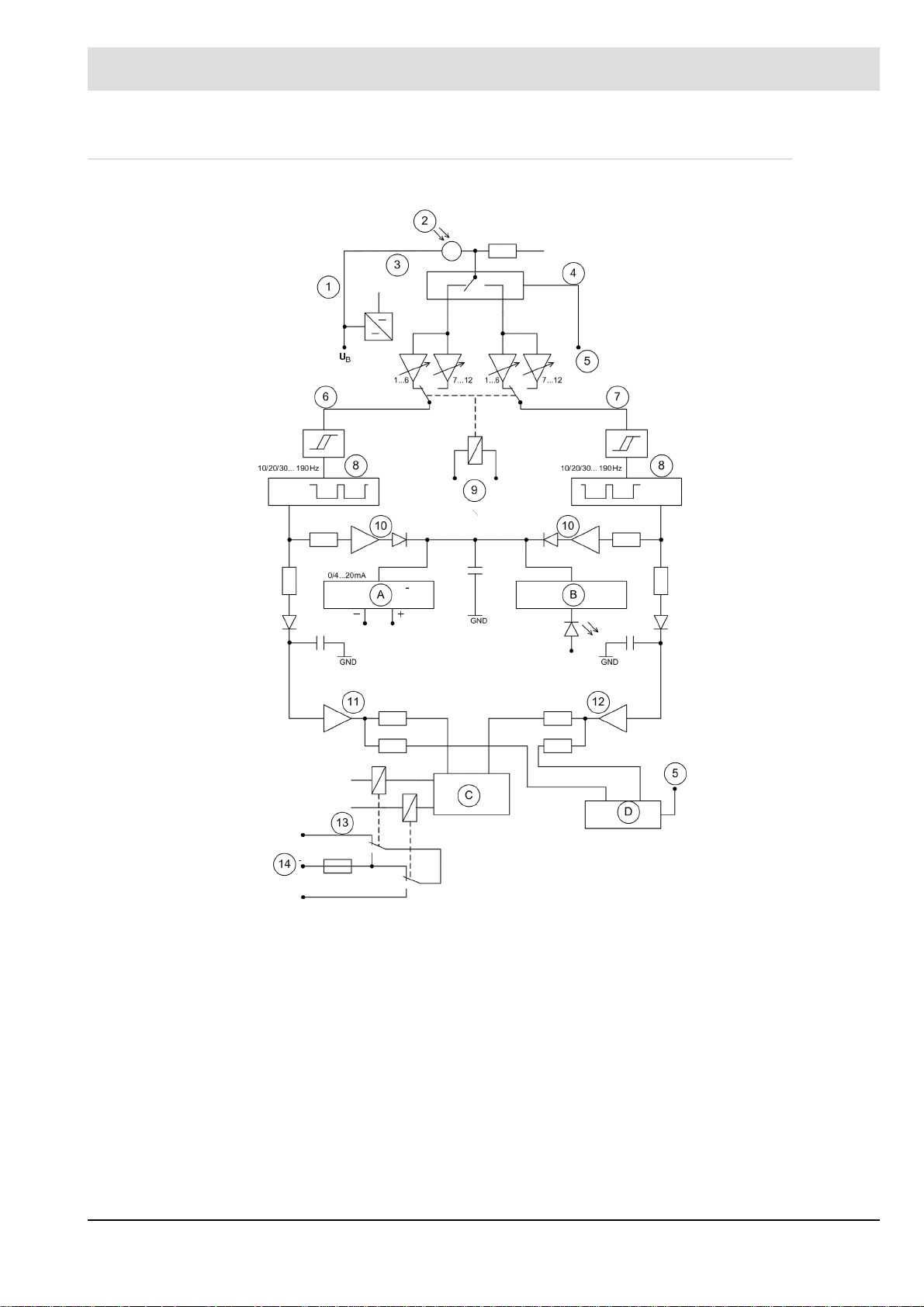

3.4 Basic circuit diagram

Fig. 3-1 Basic circuit diagram

A Intensity remote indicator C Self-monitoring

B Visual intensity indicator D Monitoring cycle

1 Stabilisation 8 Digital band pass

2 Flame sensor 9 Sensitivity selector switch

3 Detector 10 Safe de-coupling

4 Switch-over contact 11 Switching amplifier channel A

5 Cycle 12 Switching amplifier channel B

6 Channel A 13 Output relay

7 Channel B 14 Output contacts

12

Page 14

4 Technical Data

4 Technical Data

4.1 Characteristics

The compact flame scanner is available in 2 basic versions, as well as an ex-proof enclosure

type with several spectral varieties (IR / UV).

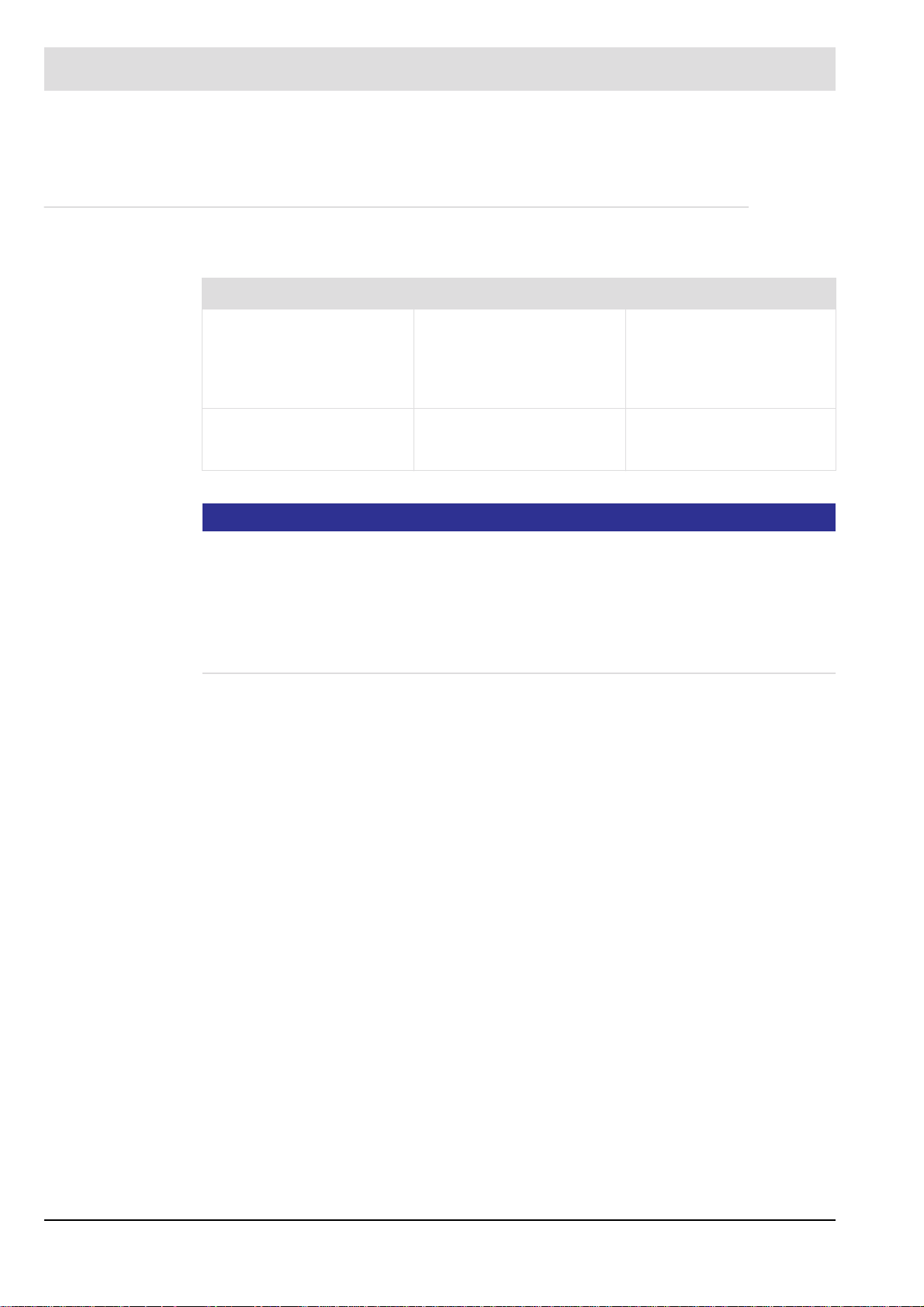

Design type F200K1 F200K2

Sensitivity range 1 sensitivity range

6 levels

Frequency range 10 ...190 Hz* *10/20/30 ... 190 Hz

* Special versions with regard to the lower limit frequencies are available on request

NOTICE

Signals lying in the mains frequency range or its multiples are suppressed for 50 Hz mains

generally. For 60 Hz application, please indicate separately in your order form. The related

stop ranges are changed in factory.

LAMTEC offers a version without mains frequency suppression for special applications.

This design requires additional measures during installation.

Please contact LAMTEC Support for further information

The compact flame scanner is accordingly marked by a rating plate.

2 sensitivity range

increased sensitivity in

range II, can externally be

switched over, 6 levels

each

can be adjusted on the

device

13

Page 15

4 Technical Data

4.2 Operating conditions

Input parameters

Auxiliary energy, input

- Supply voltage 24 VDC ± 20 %, protection class III

- Power consumption 4 W, 380 mA (100 ms peak)

- Switch ON current 28.8 V 750 mA (100 ms peak)

spectral radiation range and sight angle

- F200K1 UV-2 and F200K2 UV-2(Ex) 210 ... 380 nm about 8°

- F200K1 UV-3 and F200K2 UV-3(Ex) 210 ... 380 nm about 8°

- F200K2 UV-6(Ex) 215 ... 360 nm about 10°

- F200K1 IR-2 and F200K2 IR-2(Ex) 850 … 1200 nm about 50°

- F200K1 IR-1 and F200K2 IR-1(Ex) 1200 ... 2800 nm about 60°

Response sensitivity 25 mV AC

Range remote switch-over (F200K2 only) floating-contact, can be controlled by means of

the supply voltage (refer to chapter 9.3 Circuit Diagrams and 9.4.2 Interfacing with FMS).

- Input control current ca. 10 mA

Output parameters

Output contact Change-over contact (floating)

- Permissible switching voltage max. 50 VDC, protection class II

(250 VAC by main supply

FN 20)

min. 6 VAC/DC

- Permissible switching current max. 0,5 A at < 60°C/+140 °F

0,4 A at < 75 °C/+167 °F

min. 1 mA, at a limit load of 50 mA

- Switching capacity min. 0,1 W

max. 30 W

- Internal fuses 2,5 A slow IEC or

3,5 A slow UL

- Safety time ’FFDT’ t

- Start-up delay t

1 s or 2 ... 4 s, factory set

VAus

FFDT

VEin

NOTICE

The output contacts of the flame detector have no radio interference suppression. The user is

required to take the appropriate radio interference suppression measures on the basis of the

overall installation design.

In order to ensure the required safety, carry out the installation circuitry in such a way as to

avoid shorting-out of the contacts by defective components of the interference suppression

unit.

14

Page 16

4 Technical Data

Measuring output for intensity

- Output continuous current 0/4 ... 20 mA, there is no insulation of

- Maximum working resistance 200

- Floating DC voltage 6,6 V

- Basic error 2 %

Dynamic characteristics

Self-monitoring cycle t

Cable length

Maximum extension via the connection cable

3 m/9,84 ft addition, at a supply voltage 20,5 V

Deviating cable lengths p. ex.

(main criteria is the compliance to limitations of the

supply voltage the compact flame scanner and thus

the loss of voltage on the supply line)

potential towards the supply voltage

ca. 3,0 s for safety time

TAKT

t

1 s

VAus

t

ca. 7,0 s for safety time

TAKT

t

3 s

VAus

2

Wire 0.5 mm

/20 AWG length: 50

m/164 ft

Wire 1.0 mm2/18 AWG length:

100 m/328 ft

Wire 2.5 mm

2

/14 AWG length:

250 m/820 ft

length: 150 m/492 ft

Wire: 0.5 mm² / 20 AWG

150 : 0.5 x 0.0131 +19.2 = 23.13 V

The supply voltage must be

> 23.13 V

NOTICE

Only a cross-section of 0.5 mm²/20 AWG is possible for the F200K Ex.

Technical conditions

Operating mode DB – continuous operation

Intermittent operation

72h Operation according to TRD604

Creepage distances and clearances IEC 60730-1:2010, ÜK III, VG 2

Interference susceptibility IEC 60730-1:2010, EN 61000-4

Emitted interference DIN EN 55011/A1, class B

15

Page 17

4 Technical Data

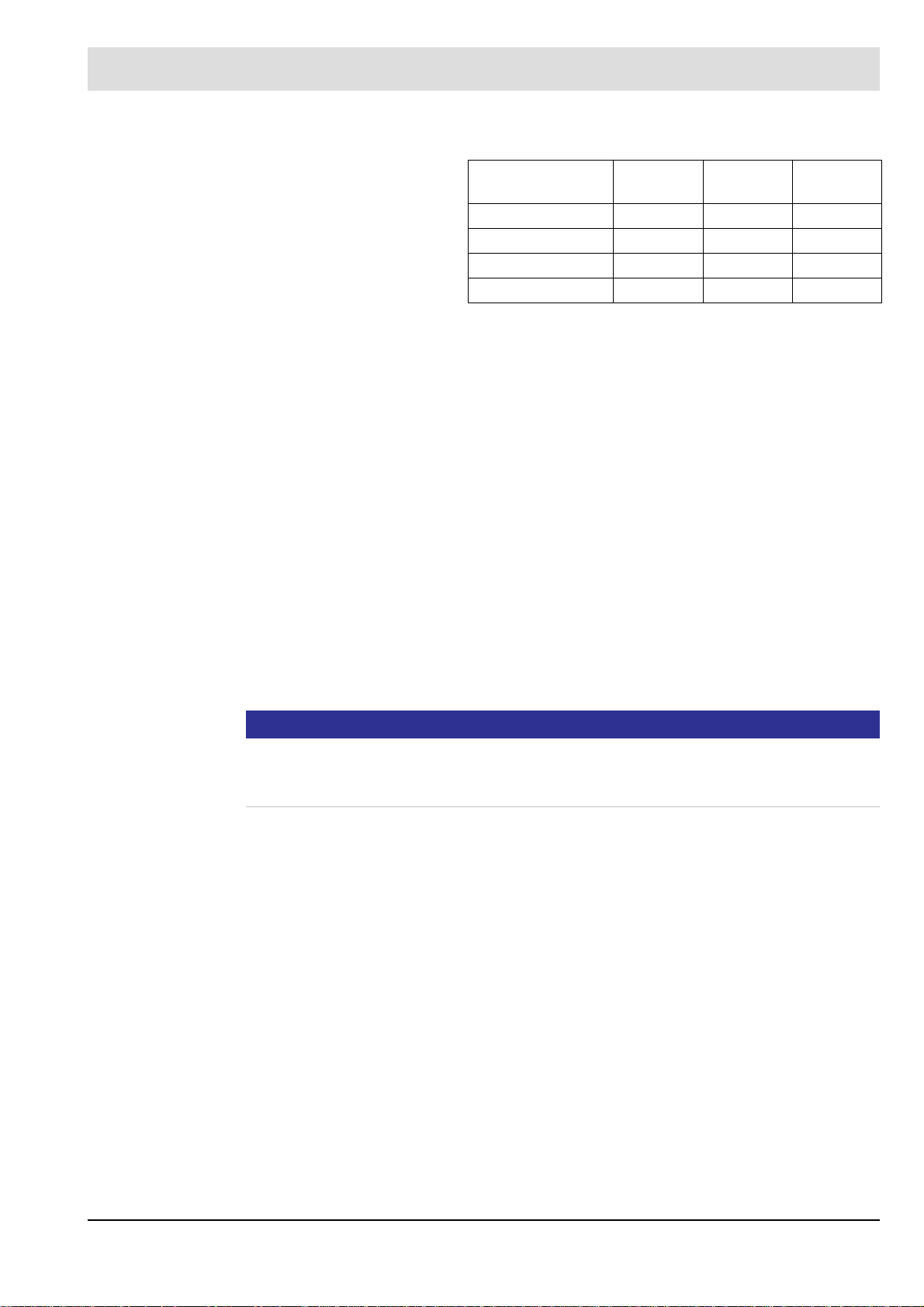

Climatical conditions

Operating class temperature

F200K

Operating class temperature LiYCY moving - 5 °C/+23 °F ...

Cable fixed - 20 °C/-4 °F ...

Relative humidity 0 ... 95% non-condensing

Sensor IR-1 IR-2 UV1, UV-6

UV-2, UV-3

- 40 °C/-40 °F*/** X X X

- 20 °C/-4 °F X X X

+ 60 °C/+140 °F X X X

+ 75 °C*/+167 °F* X X

* - in preparation for F200K…Ex… (See Ex approval)

** - not valid for FFDT 4s

+ 70 °C/+158 °F

+ 80 °C/+176 °F

LiYCY A moving - 5 °C/23 °F ...

+ 70 °C/+158 °F

fixed - 40 °C/-40 °F ...

+ 80°C/+176 °F

Silikon moving - 25 °C/-13 °F ...

+ 150°C/+302 °F

fixed - 40 °C/-40 °F ...

+ 150°C/+302 °F

protected - 60 °C/-76 °F ...

+ 150 °C/+302 °F

NOTICE

If the connection cable is subjected to particular stress caused by UV radiation, the connection

cable protective tubes provided for this purpose must be used.

Order no. 659N990/0/1/2 available in 3/5 and 10 m lengths

Vibration fatigue limit

according to GL2003-12/VI-7-2 4 g/0.14 oz

Protection type IP67; in closed state

IP66 (only F200K Ex), in closed state

NEMA 4X

Mass 0.6 kg/1.322 lb (F200K, F200K Ex-II)

Storage conditions (in original packing)

Storage location enclosed premises

Air temperature - 40 ... +75 °C/-40 ... +167 °F

Type IR-1 +65 °C/ +149 °F

Air humidity 0 ... 95 % not condensing

Transport conditions (in original packing)

Type of transport enclosed holds

Air temperature - 40 ... + 75 °C/-40 ... +167 °F

16

Page 18

4 Technical Data

Temperature - humidity - coupling 0 ... 95 % not condensing

Wear and tear parts none

Application in hazardous areas F200K .... Ex-II

Device group/category of

hazardous area, certificate

Marking Ex nA nC IIC T6...T5 Gc X

Standards IEC 60079-0, EN 60079-0

Operating temperature range

Ambient temperature T5 -40°C/-40 °F ... Ta ... +75°C/+167 °F

Additional Information Follow the section "Special Points to

[Ex] II 3G, Zone 2,

[Ex] II 3D, Zone 22

IECEx IBE 15.0012X

Class I Division 2

File-No. E488138

Ex tc IIIC T85°C Dc X

Cl I Div2 Gr A T5

ANSI/ISA-12.12.01,

CAN/CSA C22.2 No. 213

T6 -40°C/-40 °F ... Ta ... +65°C/+149 °F

Note When Using the Device in Explosionproof Areas".

Application in hazardous areas F200K .... Ex

Device group/category of

hazardous area, certificate

Certificate IECEx EPS 14.0042X,

Marking Ex db IIC T6...T5 Gb

Standards IEC 60079-0 , EN 60079-0

Operating Temperature range T5 -40 °C/-40 °F ... Ta ... +75 °C/+157 °F

Ambient temperature T6-40 °C/-40 °F ... Ta ... +60 °C/+140 °F

Additional information Follow the section "Special Points to note

[Ex] II 2G, Zone 1

[Ex] II 2D, Zone 21

EPS 14 ATEX 1 696 X

Ex tb IIIC T80°C, T95°C Db

(UV Version)

T6 -40 °C/-40 °F ... Ta ... +65 °C/+149 °F

(UV Version)

(IR Version)

when using the device in explosion-proof

areas".

17

Page 19

4 Technical Data

4.3 Life Cycle

The F200K’s and FN20’s lifetime is rated for 10 years or 250.000 working cycles. The probability of failure is considered on this basis. The real lifetime of F200K and FN20 is influenced

among others by the ambient temperature. Particularly operation in high temperatures reduces the lifetime.

18

Page 20

5 Selection Criteria

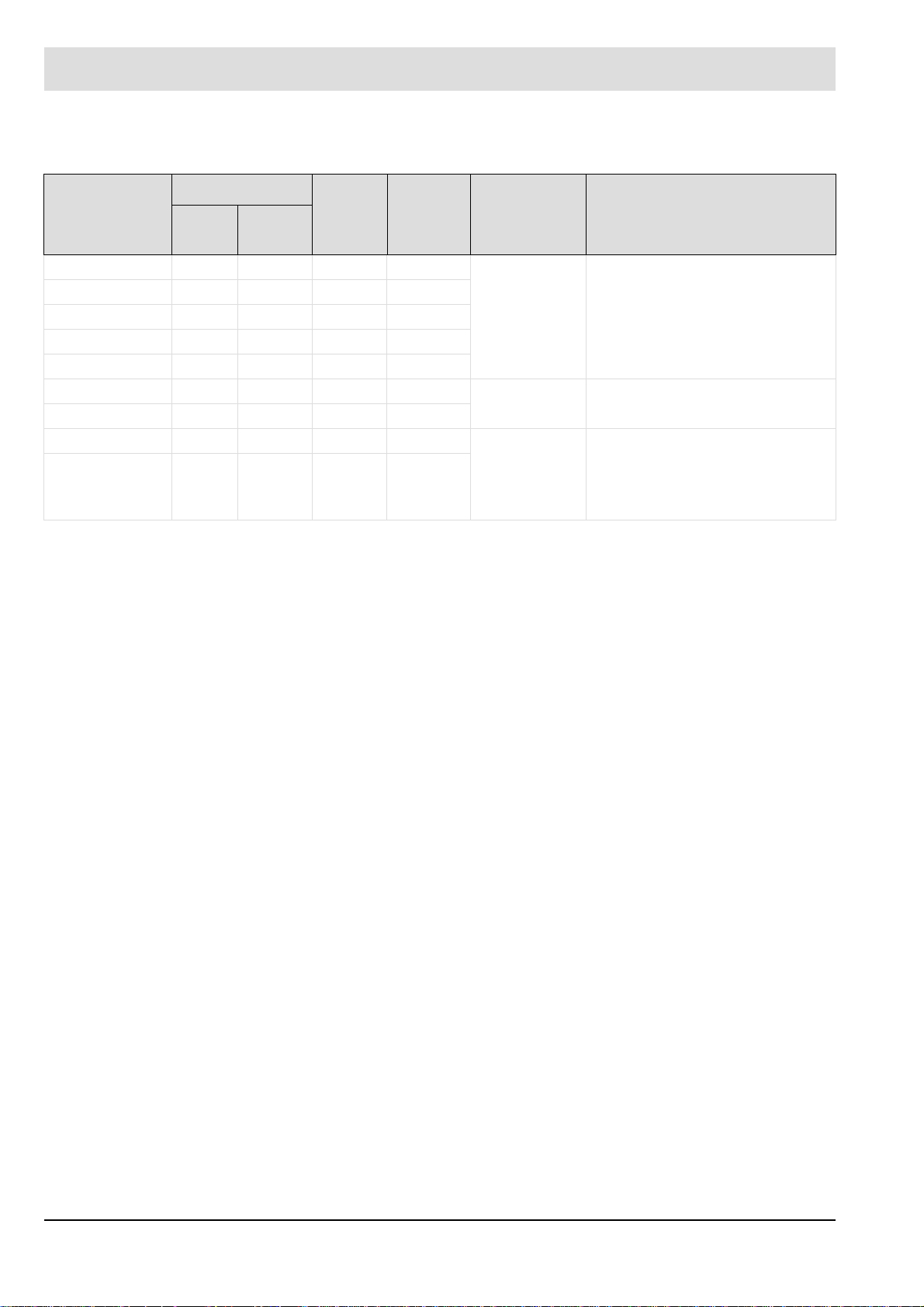

5 Selection Criteria

Hazardous Area

Typ Ex-II Ex

Fiberoptic

Sensitivity

F200K1 UV-2

F200K2 UV-2

XX X ++

F200K1 UV-3 F200K2 UV-3

F200K2 UV-6

XX O

X X X +++

F200K1 IR-2

F200K2 IR-2

F200K1 IR-1

F200K2 IR-1

XX * ++

* in preparation

++

Spectralrange

[nm]

+

210 ... 380

+

850 ... 1100

+

1100 ... 2800

Application - Fuel type

Oil, gas (special gasses such as

refinery and blast furnace gases) and

highly selective monitoring

Monitoring of combustion chambers

and burn edges (coal, wood)

Oil, gas, wood, coal, furnaces with

heavy flue gas recirculation, waste

gases with yellowish colour without

UV radiation and/or screening of the

UV portions by vapour, dust etc.

19

Page 21

6 Information for Mounting and Installation

6 Information for Mounting and Installation

6.1 Mounting - Basic Instructions

6.1.1 Safety

WARNING!

For the F200K version without mains frequency suppression, it is mandatory to mount it with

its viewing opening on the burner in such a way that it is protected against the detection of

mains frequency light. This mounting must meet the requirements of a tool mounting.

The LAMTEC mounting brackets FV30 and FV40 meet this requirement.

After attaching the union nut to the F200K /V, tighten the set screws located in this union nut

with an Allen key. This prevents unintentional disconnection of the connection.

Mounting in a cooler housing of the FS50, FS51 series also ensures tool mounting.

Advice on this is available from LAMTEC support.

Warning notice

The flame monitor without mains frequency suppression is provided with a warning: e. g.

6.1.2 UL Listed

WARNING!

WARNING After scanner commissioning tighten set screw

in scanner coupling nut!

Flame monitor without mains frequency suppression!

WARNING!

The fiber optic flame detector versions F200K.. IR-.. FO with IR sensors may only be used with

the LAMTEC IR Fiber optic FOR...-IR or FOF...-IR.

In preparation

NOTICE

For applications within the scope of the UL Listed certification procedure, it must be ensured

that the components used are "Listed" certified. That is, in addition to the flame detector used

must also be the connection cable and if used the power supply "Listed" certified.

The applicable installation rules according to NFPA70 (NEC) must be observed.

20

Page 22

6 Information for Mounting and Installation

6.1.3 Basic mounting instructions

NOTICE

The cables are designed for a special temperature range (see chapter 4 Technical Data).

Do not open the devices in temperatures below -20 °C/-4 °F.

NOTICE

For the installation of an extension cable on site, make sure to use a separate, shielded extensionable. Moreover, provide for good continuity of the shield and make sure that the shield

and functional earthing (FPE) are connected properly.

In order to reduce the risk of electromagnetic interference it is recommended that the supply

cable and extension cable, if used, are installed in separate containment away from any main

wiring (e.g. ignition lines, electrical motors, contactors, frequency inverters). Parallel cable

routing with mains cables should be strictly avoided.

NOTICE

Very high levels of electromagnetic radiated noise may result in sporadic problems in flame

detection, or may even avoid proper detection at all.

NOTICE

The radiation emitted by a flame contains an element of flicker (pulsating).

This characteristic is a result of the processes that occur during combustion. This oscillation

(flame frequency) is used for flame monitoring. The flame detector should be installed at the

burner viewing port using a suitable mounting device to ensure that the burner flame remains

perfectly visible throughout the full modulating/operating range of the furnace. To install a selective monitoring device the viewing port should be located such that the flame sensor can

be aligned to detect the base of the flame adjacent to the burner mouth (perhaps 'head' might

be better). The detector should be aligned so that it cannot 'look' directly into adjacent flames

or flames located on the opposite side of the furnace. Consideration should also be given to

ensure that background flames, such as coal, wood and waste, cannot be detected.

21

Page 23

6 Information for Mounting and Installation

The compact flame detector:

– is to be aligned in such a way as to cover the first third of the flame for single monitoring.

– has to cover the flame root area for a simple selection during the ’Flame in’ control state

(area of high flame frequencies), and during the ’Flame out’ state to only detect the residual radiation caused by the ’offshoots’ of the other flames in the combustion chamber (area of low flame frequencies) or by reflection.

– If possible avoid aligning the compact flame detector parallel with the flame axis, since

in this position, a loss of flame can hardly be detected.

In order to reach a high availability and a high selection quality , it is very important to place the

compact flame detector at the appropriate location.

Make sure in every case that the aperture angle for the UV solutions is only about 8°. For this

reason we recommend to use the FH40, FV40, FS 51and/or FS 56 adjustable holding device

(ball-and-socket joint), unless already in place. Correct alignment is of paramount impor-

tance in particular in such cases where there is an additional viewing tube inside the burner

or where the visibility of the flame is considerably restricted. With increasing length of the

sighting tube is a correspondingly larger cross-section advantageous.

NOTICE

The installation should take place with the holding device provided by LAMTEC.

Otherwise pay attention to an isolated mounting to avoide any interference from compensating currents provoke over the cable shield.

The installation site must be easily accessible to allow a perfect observation of the visual operational controls even during operation of the furnace. When replacing the compact flame detector, make sure to install a device having the same identification marking.

Make sure that the maximum admissible ambient temperature is not exceeded at the installation site. This applies in particular to radiant heat.

22

Page 24

6 Information for Mounting and Installation

6.2 Installation

6.2.1 External Installation

EMC emission

Compliance with the requirements with respect to the EMC emissions are proven for the device as part of the type test. After installing the device in the equipment an extra EMC type

testing is not necessary.

Output contacts

The flame detector ready for operation delivers the ’Flame ON’ or ’Flame OFF’ status message to a floating output contact. Further signal processing has to be carried out by the controller adapted to the related furnace.

T o guarantee a high safety level make sure when installing the output contacts to lay out the

circuitry of the radio interference suppression system to be provided by the user in such a

manner as to avoid shorting-out of the contacts due to faulty components of the radio interference suppression unit.

Power supply, Output contacts

WARNING!

For the power supply of the flame detector and for potential separation of the flame detector

contact use the FN20 power supply. Instead of FN20 a safety power supply must be used to

generate the power supply of the flame detector (eg. According to EN61558-2-6 or

EN 60950-1).

DANGER!

The output contacts of the Flame scanner are approved for use with SELV or PELV only.

Remote switch-over of sensitivity

WARNING!

Use a floating contact which is feeded by the flame detector's 24 V supply for the remote

switching of the F200K2's range. Or use a SEL V or PELV power supply according to 60730-1

or EN 60950-1 (i.e. a safety power supply).

Intensity remote display (4 / 0 - 20 mA current loop)

WARNING!

The current loop for remote indication of the flame intensity must be connected to devices

which have a safe isolation of the measuring circuit to dangerous active parts in accordance

with EN 61140 ( e.g. by double or reinforced isolation in accordance with EN 61010-1). This

can be, for example, passive instruments or isolating transformers with galvanic 3-way isolation.

NOTICE

If the connection cable is subjected to particular stress caused by UV radiation, the connection

cable protective tubes provided for this purpose must be used.

Order no. 659N990/0/1/2 available in 3/5 and 10 m lengths

23

Page 25

6 Information for Mounting and Installation

6.2.2 Device Connection

Refer to connection diagram chapter 9.3 Circuit Diagrams and

9.4 Examples of Application.

24

Page 26

7 Instructions on Commissioning and Maintenance

7 Instructions on Commissioning and Maintenance

7.1 Display and Operational Controls

Represented in chapter 9.1 Layout of the Operational Controls.

NOTICE

The cables are designed for a special temperature range (see chapter 10.1.2 T echnical Data).

Do not open the devices in temperatures below -20 °C/-4 °F.

7.1.1 Intensity Indicator Including the 'Adjust' Function

The flame intensity is represented by a six dot indicator. The indication is delayed in accordance with switch-off time (1s and/or 3s) and fulfils 2 functions.

1 Display of the evaluated intensity / basic setting

With the Adjust switch set in the OFF position the flame intensity, after internal analysis of

amplitude and frequency, is displayed. For a well-established flame signal the state will

display the maximum intensity i.e. the uppermost green LED. In normal operation the signal indication may vary/fluctuate for a short period of time depending on the behaviour of

the flame being monitored. However, if variance/fluctuation occurs too frequently this

might result in a switch-off during prolonged operation.

2 Display of the unevaluated intensity (direct signal at the probe element)

With the Adjust switch set to the ON position the flame intensity is displayed as detected

at the probe element without internal flame frequency analysis processing. This function

allows the compact flame detector to be aligned to detect the maximum flame radiation

value using the ball-and-socket joint adapter (refer to chapter 7.2.4 Settings). Note that

with the Adjust switch set to ON the Serv. switch becomes inactive.

Normally, the display should be in the green LED row. If the flame is stable, a reliable operation may be possible in this function even if the two upper yellow LEDs light up. In this

mode the flame signal indication should only be used to optimise the alignment of the

flame detector and not as an exact indication of flame measurement

7.1.2 Operating State - Indication

This display type only exists in the F200K2 execution type. The display shows the sensitivity

ranges I or II activated by external selection. The range I (normal sensitivity) is mainly used

for high flame intensities, whilst range II (higher sensitivity) is used for weaker flame intensities.

7.1.3 Operating Mode - Display

The red LED shows the ’Flame OUT’ operating state. Whilst indicating 'Flame IN' the green

LED pulses in intensity to indicate the self-monitoring operation of the system. The pulse frequency is the same as the self-monitoring cycle time (1.5 or 3.0 seconds). If the green LED

does not pulse then this could be symptomatic of electromagnetic interference (EMC) or a defect of the compact flame scanner. (refer to chapters from 7.2.6 Fault on Flame Detection to

chapter 7.2.8 Faults During Operation and chapter 7.3 Troubleshooting).

25

Page 27

7 Instructions on Commissioning and Maintenance

7.1.4 Sensitivity - Switch

Depending on the model (F200K1 or F200K2), there are 1 or 2 sensitivity selector switches.

The sensitivity selector switches can be set in 6 steps. The switches are used to adapt the

device to the existing flame intensity. (refer to 7.2.4 Settings).

CAUTION!

The settings of the sensor sensitivity of the model F200K2 must carried out so that the sensitivity in region II is higher than in the region I. Switch position I-5, I-6 overlaps with II-7, II-8.

7.1.5 Frequency - Switch

The frequency switches are only included in the F200K2 solution.

They are used to set the lower frequency limits of the digital filters. This allows to improve the

selectivity in flame detection. In the F200K1 solution, only the lower frequency limit of 10 Hz

is factory-set principally. (refer to chapter 7.2.4 Settings).

CAUTION!

In connection with the frequency setting is important to note that both channels (A and

B) ON and/or OFF mode switched on same position.

(refer to chapter 9.1.2 F200K2... (Ex-proof), in the State as Delivered )

7.1.6 Service - Switch Serv.

The Serv. service switch is issued to suppress the indication during start-up and starting time

of the flame detector. The flame detector is supplied with the Serv. switch in the ON position

as default. This function does not display any short flame signals of other radiation sources

(e.g. adjacent burners or background fire), which are not to result in a switch-on of the flame

detector.

For commissioning it is recommendable to set the Serv. switch to OFF. Short flame signal of

other sources are thus indicated even during the start-up phase. This information is important

for a probably required change of the start-up suppression setting (refer to chapter 7.2.4

Settings).

7.1.7 Adjust - Switch

The Adjust switch is issued to feed in the unevaluated flame intensity (i.e. the direct signal

at the probe element) to the intensity display of the compact flame detector. The activation of

the Adjust switch (ON position) suppresses the function of the Serv. switch (refer to 7.2.4 Set-

tings).

7.1.8 Start-up Suppression - Potentiometer

The potentiometer is issued to vary the setting of the start-up (switch-on) behaviour of the

flame detector. This setting has an influence on the switch-on behaviour of the flame detector

with regard to the flame to be monitored. (refer to chapter 7.2.4 Settings).

26

Page 28

7 Instructions on Commissioning and Maintenance

7.1.9 Measuring Points

These measuring points are used to directly measure the flame signals at the probe element

and can be used to determine the optimum alignment, apart from intensity indication.

(refer to chapter 7.2.4 Settings)

7.2 Commissioning

7.2.1 General Information

Check the compact flame detector for correct positioning on the burner. Before switching on

the supply voltage, check the connections on the basis of the pin configuration as specified

herein. Refer to chapter 9.4 Examples of Application.

The switches of the compact flame detector as delivered are set according to chapter 9.1

Layout of the Operational Controls, unless otherwise agreed,. The potentiometer for start-up

suppression is set to 50 %.

7.2.1.1 'Flame Out' State

After switching on the power supply, the flame scanner is ready for operation after approximately 5 seconds. The following display has to be shown:

- Display ’Flame out’ ’Red’ LED lights up

- Sensitivity range I or II ’Yellow’ LED lights depending on external pre-selec-

7.2.1.2 'Flame In' State

T o check the monitoring parameters, install the compact flame scanner in the specified mounting place before starting the operation of the furnace. If the flame burns naturally , the display

should change as follows:

’Red’ LED Goes out

’Green’ LED Lights up, changing its radiation intensity antivalently

7.2.1.3 Operating mode switchover

Two preselectable operating modes

The compact flame scanner F200K offers users two operating modes for selection. This

makes it possible to select two different settings in the range of gain levels. The individual operating modes can be switched during operation.

tion f. range I or II (for F200K2 only)

to the cycle rhythm of the self-monitoring system.

Intensity indicator (lighting point) should reach 100%.

27

Page 29

7 Instructions on Commissioning and Maintenance

7.2.2 Special Points to Note When Using the Device in Explosion-proof Areas

The following applies when using the F200K Ex-II, F200K Ex in explosion-proof areas:

• For use only in approved explosion protection zones.

• To protect its aperture, only mount the F200K Ex-II, F200K Ex on a burner or boiler using

one of its holders: the FV30, FH30 or FS50.

• Use only the types of cable specified by the manufacturer when extending cables.

• When extending cables in the potentially explosive area, use only terminal housings that

are approved for this area. LAMTEC recommends the connection housing FG24 Ex for

this purpose.

• Check if cable connections fit tightly. Should there be a need to loosen the cable connection, it is to be ensured that the cables do not turn while loosening and tightening the cable

connection.

• Note, in particular, the information on setup in EN 60079-14, section 12.2 (cables and

earthing).

• Only remove the connector of the F200K Ex-II, F200K Ex or any other cable connections

when it is deenergised.

See the warning on the device:

WARNING – DO NOT DISCONNECT WHEN ENERGISED.

• In particular, seperation has to be in accordance with EN 60079-14 'Appendix:

Instructions for procedures to work safely in an explosive gas atmosphere', only permitted

after the release by personnel in charge of the explosion protection of the operating

company.

• Opening the device is required during commissioning!

Should there be any risk of danger to the surroundings in an opened device, a clearance

measurement as described above should be done before the opening.

• A transformer for generating the supply voltage must be carried out according to

IEC 61558-2-6.

• You must use a current limiter with a limit on the rated voltage.

• When using the device in the ambient temperature range, you must keep the temperature

in accordance with the temperature class:

See Ex marking on the device

• If devices are so damaged that they no longer meet the requirements of the protection

class, you must replace them.

Special instructions for use in Hazardous Area Class I Division 2 (valid for F200K Ex-II)

• During installation, the rules of the NEC (National Electrical Code) must be considered.

UL Listed Version:

• The plug of the connecting cable must be secured against self-loosening after mounting

on the flame detector. There are screws on the union nut of the connector.

28

Page 30

7 Instructions on Commissioning and Maintenance

Marking on the device: e.g.

Marking information on the device:Example

F200K Ex-II

F200K Ex + Rating Plate BARTEC

Warning: e.g. WARNUNG - NICHT UNTER SPANNUNG ÖFFNEN

DO NOT OPEN WHEN ENERGIZED

29

Page 31

7 Instructions on Commissioning and Maintenance

7.2.3 Preparations

7.2.3.1 Checking the Compact Flame Scanner

The flame detector can be checked for proper functionality without a flame being present.

1 Carry out the complete electrical installation of the flame detector and connect it to the

supply voltage.

A LAMTEC test emitter of the FFP30 type (IR + UV) can be used as an auxiliary means

for flame simulation.

2 Simulation of flame radiation in front of the flame detector's viewing port. This can be

achieved using a lighter or any other type of a modulated-light source (do not use the

mains frequency) having a sufficiently high intensity . For example the light from a lamp can

be modulated by moving splayed fingers to and fro in front of the bulb. However, start-up

suppression requires a stable signal to do this. If necessary and if the signal is not sufficient, the switch (see chapter 9.1 Layout of the Operational Controls) should be

set to OFF in order to make the reaction to the simulated flame signal visible.

The flame detector will switch on its output contacts if the flame signal is simulated for a sufficient period of time. This is indicated by the extinction of the red LED and the pulsating light

of the green LED. The 6-level intensity indicator illuminates.

If no flame signal is indicated despite apparent correct functionality then check the output contact (refer to chapter 7.3 Troubleshooting).

7.2.3.2 Alignment

7.2.3.3 Optics

The following information applies analogous to the process optics of Fiber optic.

IR- flame detectors should be installed / aligned in such a way that possible reflections from

the combustion chamber are already largely suppressed by constructive measures. A balland-socket joint for the alignment of the sensor to the flame is normally not required, since the

optics of the flame detector is characterised by a wide viewing angle.

UV- flame detectors should generally be used with a ball-and-socket joint only, since the optics of the flame detector has a narrow viewing angle. For this reason an optimum alignment

towards the flame is of utmost importance.

There are no special requirements for locking discs or similar components when using IR-

flame scanners. Small accumulations of dirt due to dust and similar materials are generally

not critical for flame detection.

In UV- flame scanners, the requirements for locking discs are more critical. Ensure that materials, such as quartz, that allow UV light to pass through freely are used. These materials

are used in the LAMTEC UV adjustable holding devices (FH30, FV30, FH40 and FV40) Small

accumulations of dust, water and other contaminants are much more likely to affect the performance of flame detection than when using an IR scanner.

WARNING!

When using an F200K without mains frequency suppression, it must be ensured that it is protected against the detection of mains frequency light. The mounting of the sight opening on

the burner must meet the requirements of a tool mounting. Unintentional loosening of the

F200K must be prevented.

Advice on this is available from LAMTEC support.

30

Page 32

7 Instructions on Commissioning and Maintenance

7.2.4 Settings

7.2.4.1 Sensitivity

If for the first burner start there is no flame detection then the sensitivity switch (flame amplitude) can be set towards the right-hand stop position to allow a stable flame detection. The

positions 1 - 6 and/or 7 - 12 are allocated to the internal amplification of the flame signal. Position 1 and/or 7 means lowest amplification / sensitivity as well as 6 and/or 12 highest amplification / sensitivity in the related sensitivity range.

NOTICE

Ensure that the flame detector is configured such that the device successfully reacts by indicating 'Flame Out' should the flame be either not burning correctly or be extinguished.

After having carried out a correct burner adjustment, reduce the sensitivity again to such an

extent as to allow for a stable and safe operation. The measurable signals should have at least

2 to 3 times the switching threshold value of 25 mV AC to allow a reliable recognition

7.2.4.2 Alignment with Adjustment Function

To allow an optimum alignment of the compact flame detector towards the flame (maximum

flame amplitude), the intensity indicator of the device can be used by activating the ’Adjust’

function switch. The activation of the ’Adjust’ switch (ON position) suppresses the function of

the Serv. switch. The intensity indicator now represents flame amplitude detected.

If the intensity has already been set to maximum in this function, reduce the sensitivity of the

active sensitivity switch to such a level that a reaction of the intensity indicator can be noticed,

in order to find the best possible view to the flame by alignment.

After having completed the adjustment work and/or before optimisation set the Adjust switch

back to OFF.

The values can slightly tolerate depending on the application

Flame amplitude Measurement

Flame off < ca. 25 mVAC keine < ca. 5%

2 times threshold response 50 mVAC ca. 2. (yellow) ca. 25%

3 times threshold response 75 mVAC ca. 4. (green) ca. 50%

4 times threshold response 100 mVAC ca. 5. (green) ca. 85%

LED lights 20 mA Current loop

points

31

Page 33

7 Instructions on Commissioning and Maintenance

7.2.4.3 Measuring Points

Apart from the Adjust function, the measuring points (refer to chapter 7.1 Display and Operational Controls) of the device can be used. This allows to continuously measure the unevalu-

ated intensity. The measured resistance should be> 5 MOhm.

WARNING!

Connect only potential free measuring equipment/devices to the testing terminals.

The measuring equipment/devices must provide a reliable separation of the measuring circuit

to hazardous active parts, according to EN 61140 e.g. by double or reinforced insulation according to EN 61010-1 (e.g. a standard handheld multi meter).

The trigger threshold for the F200K is at = 25 mV AC, while the measured signal voltage

can amount to maximally 3 VAC.

To allow an optimum suppression of reflections, the measured values should be clearly below the specified value of 25 mVAC of the response threshold after burner switch-off.

See also table in chapter 7.2.4.2 Alignment with Adjustment Function

7.2.4.4 Frequency Settings

An adaptation to the burner flame can additionally be configured in the F200K2 (ex-proof) as

to the lower frequency limit (chapter 9.1.2 F200K2... (Ex-proof), in the State as Delivered).

This frequency allows no remote switch-over. Generally, a low frequency limit means a higher

availability, a reduction of the selectivity. 3 levels are provided for (10, 20 and 30 Hz).

CAUTION!

The setting (changeover to another frequency range) has always to be carried out for both

processing channels A and B in an identical way. Always ensure that only one frequency

range (Channel A + B) is in the ON position is selected each time.

32

Page 34

7 Instructions on Commissioning and Maintenance

7.2.4.5 Start-up Suppression

If during the burner start there are short pulses within the detection range, due to background

radiation or adjacent burners, the start-up suppression function can be used to eliminate detection.

The start-up suppression function allows suppression short pulse rates, which may occur on

burner start in connection with the fan operation (pre-ventilation) and background fire. The values can be set between 0 and 100 % at a continuous start-up delay of 1s, i.e short pulse rates,

which may cause ‘parasitic light detection‘ but no permanent flame signal during the burner

start phase, are ignored (suppressed) with different weighting.When 0% has been set, the

flame detector is activated even on inadequate flame signals, at a setting of 100% however,

an activation requires very proper and stable flame signals.

In case of inadequate starting flames, an excessive start-up suppression impedes a timely

recognition of the flame.

The devices are delivered with start-up suppression factory set to 50 % and the Serv. switch

preset to the ON position (deactivated).

Carry out resetting according to the requirements as follows:

(see the representation of the operational controls in section 9.1 Layout of the Operational

Controls)

– Set the Serv. switch to the OFF position, this allows pulses to be made visible during the

start-up time via the devices' intensity indicator

– Set the start-up suppression (see chapter 9.1 Layout of the Operational Controls) accord-

ing to the amplitude of the pulse rates between 0 and 100 %

After completion of the settings and/or optimisation, reset the Serv. switch to the ON position.

CAUTION!

This setting operation should only be used if the alignment of the flame sensor, as well as sensitivity and frequency settings as to reliability have fully been used.

33

Page 35

7 Instructions on Commissioning and Maintenance

7.2.5 Switch-off test - check the correct setting

WARNING!

Simulate a flame rupture or flame extinction by shunting off the fuel supply to the burner to be

monitored by the flame scanner. Check that the signal for shutting-off the safety valve is triggered off within the period of T

tion of the flame.

’Red’ LED lights

’Green’ LED dark

WARNING!

For the IR compact flame scanners of the F200K1(2) IR-1 and/or F200K1(2) IR-2 types, take

into account the radiation effects characteristic of the combustion chamber. Consequently,

switch-off tests should be carried out when the boiler has reached operating temperature. In

particular, make sure that the sensitivity of the compact flame scanner is increased only to

such a value required to safely and reliably monitor the flame throughout the operating range

of the burner.

< 1 s (on safety period ’Operation’ at tVOff = 1 s) after extinc-

S

7.2.6 Fault on Flame Detection

Check this function according to chapter 7.2.3 Preparations -7.2.3.1 Checking the Compact

Flame Scanner.

7.2.6.1 1. Interference

Generally , interference becomes apparent by the fact that the intensity indicator of the device

may indicate 100 %, but the green LED (’Flame in’) does not light up. Or, the green LED lights

up for a moment, but then it does not change its intensity according to the cycle rhythm and

goes out again. This is a cycle synchronisation fault (signal in both evaluation channel present

at the same time). This may chiefly be due to the interference emission of the ignition transformer during ignition.

– Check the shielding and FPE for proper connection to the F200K

– Carry out a proper grounding of the ignition transformer

– Check the cables for laying and if required untangle / separate them spatially

7.2.6.2 2. Exceeding the permissible ambient temperature

Make sure that the maximum allowable ambient temperature of 60 °C/140 °F is not exceeded

at the installation site. In case where the temperature is expected to exceed the limit, take appropriate cooling measures (e.g. cooling air enclosure FS 50, FS 51or FS 56) refer to chapter

10.3.6 Cooling Air Housing with Ball-and-Socket Joint FS51 and chapter 10.3.7 FS56 (Adjust-

able, Demountable, with Cooling Air Housing). Make sure that the flame detector casing does

not heat up beyond this temperature value due to the impact of the heat radiated by the boiler.

Overheating will result in a sensitivity loss in the first line, or will cause damage to the sensor

elements and with it may result in a total failure of the system.

34

Page 36

7 Instructions on Commissioning and Maintenance

7.2.7 Faults During Ignition

Faults occurring during ignition may have 4 causes.

1 In case of additionally monitoring the pilot flame, the pilot flame may not sufficiently be de-

tected.

• Check the pilot flame for stable operation

• Check that the pilot flame is sufficiently visible within the viewing scope of the compact

flame detector, and change pilot burner adjustment if required.

• Realign the flame detector and check for cleanness of the viewing port

• Measure the flame radiation captured by the compact flame detector (chapter 7.2.4

Settings), and optimise alignment if required.

• Increase sensitivity if required.

2 Interference

Refer to chapter 7.2.6 Fault on Flame Detection

3 If the flame has trouble to start-up, a timely recognition of the flame may be hampered by

an excessive start-up suppression.

4 Defect in the device.

7.2.8 Faults During Operation

Faults occurring during operation may have 3 causes.

1 The main flame may not sufficiently be detected.

– Check the main flame for stable operation - provide for visibility throughout the oper-

ating range

– Check the compact flame detector for proper alignment and make sure that the view-

ing port

– Measure the flame radiation detected by the compact flame detector (chapter 7.2.4

Settings), optimise alignment if required

– Increase the sensibility if required

2 Interference

Refer to chapter 7.2.6 Fault on Flame Detection

3 Defect in the device.

35

Page 37

7 Instructions on Commissioning and Maintenance

7.3 Troubleshooting

on apparently immaculate functioning according to the indicator elements

1 Check the output contact fuse and the contact

– Disconnect the flame detector from the supply voltage

– Check the normally closed output contact at the 1st clamping point behind the flame

detector between the brown (BR) and the white (WH) connection wire (avoid low re-

sistance continuity check - fuse 500 mA)

– Connect the flame detector to the supply voltage

– Check with simulated flame between the brown (BR) and the green (GN) connection

wire

2 Check the supply voltage

– Connect the flame detector to the supply voltage

– Check the supply voltage at the 1st clamping point behind the flame detector between

the red and the blue connection wire for compliance with the voltage limits (in particu-

lar the lower limit)

– Repeat test with simulated flame

– If the supply voltage is too low , this may be due to excessive lengths of the supply lines

which core sections are too small, apart from other faults.

36

Page 38

7 Instructions on Commissioning and Maintenance

7.4 Commissioning Flow Chart

Simple and fast process for commissioning the F200K.

NOTICE

The following steps require that all work in the previously described chapters on installation

and mounting has been carried out correctly and checked again.

1 Set all frequency DIP switches (1) to default as

shown in the drawing.

2 Set rotary switch (8) to position 6.

3 Connect the multimeter to the measuring points

(9) and (6) (the multimeter setting is "AC volt-

age"), for good flame detection a minimum

voltage of ≥ 50 mV AC* required.

4 Start the burner in the lowest load.

5 If the voltage is higher than 100 mV, the rotary

switch (8) must be reduced step by step.

6 If the voltage is less than 50 mV, it is necessary to

switch to range II (switchover by connecting the

yellow and red wires of the connecting cable)

then increase the settings of the rotary switch (7),

(Default is 11, start with 8 here).

*(2 to 3 times the switching threshold value of 25 mV)

Fig. 7-1 Control and operating elements

F200K

The frequency DIP switches (1) are required for existing background radiation with

low frequencies. The low frequencies (below 10/20/30Hz) are faded out depending on the

setting.

NOTICE

The frequency DIP switches (1) A and B must always be adjusted together. (two-channel

system), only one frequency range may be selected, the other two must be set to "Off".

The Serv. switch is issued to suppress the indication during start-up and starting time

of the flame detector. The flame detector is supplied with the Serv. switch in the ON position

as default. For commissioning it is recommendable to set the Serv. switch to OFF.

The Adj switch is for commissioning. In the "ON" position, the sensor signal is displayed with

the intensity display (3) in the range 0... 150 mV

The start-up suppression function (4) (rotary potentiometer 0 ... 100%) allows suppression

short pulse rates, which may occur on burner start in connection with the fan operation

(pre-ventilation) and background fire.

See Chapter 7.2.4.5 Start-up Suppression

37

Page 39

7 Instructions on Commissioning and Maintenance

38

Page 40

7 Instructions on Commissioning and Maintenance

7.5 Maintenance

7.5.1 General Information

Provisions shall be made to ensure that the light entry port of the flame sensor and the viewing

port on the furnace, where the sensor is fitted, are regularly cleaned, i.e. at regular intervals,

which depend on the operating conditions of the furnace. The compact flame scanner needs

no maintenance. The operation of the flame scanner by physically shutting off the flame

should be incorporated into the maintenance cycle for the device.

NOTICE

If it is necessary to clean the optics of fiber optic flame detectors, special care should be taken

to clean the fiber optic surface. Damage to the surface can result in significant signal loss.

7.5.2 Instructions on Troubleshooting

DANGER!

The flame scanner is a safety device.

Any repair work or other changes to the device shall only be carried out by the manufacturer's specialist staff or by some other persons appointed by the manufacturer.

Any other person are not allowed to operate on parts inside the device.

In particular, this concerns the unauthorized exchange of the flame contact fuse.

39

Page 41

7 Instructions on Commissioning and Maintenance

7.5.3 Flame Scanner Testing Device replace Battery

Fig. 7-2 Flame Scanner Testing Device FFP30 replace battery

Battery type: 9-Volt-Block 6LR61

The assembly is carried out in the reverse order

40

Page 42

8 Warranty and Delivery Terms

8 Warranty and Delivery Terms

The manufacturer's terms and conditions of guarantee shall apply. Any modifications or

changes carried out to the device by authorised personnel shall render all warranties and

guarantees void. Inappropriate or use outside the recommenced guidelines set out in this

manual shall also render the warranties and guarantees void.

Delivery will comply with ordering details. The terms of deliveries and services of LAMTEC,

and the general terms of delivery for products and services made or rendered by companies

of the electrical industry, shall apply.

41

Page 43

9 Appendix

9 Appendix

9.1 Layout of the Operational Controls

9.1.1 F200K1 ... in the State as Delivered

Fig. 9-2 Housing cover F200K

Fig. 9-1 Control and operating elements F200K1

1 - Serv. Service switch, according to chapter 7.1.6 Service - Switch Serv.Adj.- Adjust, according to chapter

7.1.1 Intensity Indicator Including the 'Adjust' Function and chapter 7.2.4 Settings

2 - Intensity indicator for flame signal in the range of 0 ... 100 %

3 - Start-up suppression, according to chapter 7.2.4 Settings

4/7 - Measuring points to measure the flame radiation received by the F200K according to chapter 7.2.4 Settings

5 - Sensitivity switch for gradual increase and/or decrease of sensitivity (amplification) of the compact flame

detector in 6 level, according to chapter 7.2.4 Settings

6 - LED (red): Indication ’Flame Out’ state

8 - LED (green): Indication ’Flame In’ state

42

Page 44

9 Appendix

9.1.2 F200K2... (Ex-proof), in the State as Delivered

Fig. 9-4 Housing cover F200K, F200K EX-II

Fig. 9-3 Control and operating elements F200K2

1 Serv. Service switch, according to chapter 7.1.6 Service - Switch Serv.

Adj.- Adjust, according to section chapter 7.1.1 Intensity Indicator Including the 'Adjust' Function and chapter

7.2.4 Settings Frequency switch according to chapter 7.2.4 Settings

Note:

When changing the frequency both switch (A + B) of the respective Range ON or OFF switching and always

one Frequency enable.

2 LED (green): Indication, ’Flame in’ state

3 Intensity indicator for flame signal in the range 0 ... 100 %

4 Start-up suppression, according to chapter 7.2.4 Settings

5/10 LED (yellow), only for F200K2, lights for active range,

Pre-selection according to chapter 9.3.2 Circuit Diagram F200K2 ... EX or chapter 9.4.1 Interfacing with ET A-

MATIC (pin configuration) and chapter 7.2.4 Settings

6/9 Measuring points to measure the flame radiation received by the F200K, according to chapter 7.2.4 Settings

7 Sensitivity switch for range II (range of higher sensitivity), for gradual increase and/or decrease of sensitiv-

ity (amplification) of the compact flame detector in 6 levels, overlapping switching position 5 = 7.6 = 8, s., see

Chapter 7.2.4 Settings.

8 Sensitivity switch for range I (range of normal sensitivity), for gradual increase and/or decrease of sensitiv-

ity (amplification) of the compact flame detector in 6 levels.

11 LED (red): Indication, "Flame out’ state

43

Page 45

9 Appendix

9.2 Dimensions

9.2.1 F200K and F200K Ex-II (Hazardous Area 2.22) Compact Flame Scanner

F200K Ex-II: Ex nA nC II T6...T5 Gc X (IECEx IBE 15.0012X)

Cl I Div2 GrA T5 (UL - E488138)

Fig. 9-5 Compact flame detector F200K/F200K Z2, IP 67

a Permanent joint

b Light entry port

c Coupler for connecting cable

d Indication of the operating state

e Variant/V

Material: Corrosion-resistant aluminium EN A W 6082 (seawater 2*; atmospheric condition 1*),

anodised

Weight: approx. 0.6 kg/1,32 lb

* Comparative evaluation from 1 (very good) to 6 (unsuitable)

Order no. F200K ... : Order no. F200K ... Z2:

F200K1 IR-1

F200K2 IR-1

F200K1 IR-2

F200K2 IR-2

F200K1 UV-2

F200K2 UV-2

F200K1 UV-3

F200K2 UV-3

3 m/9,84 ft cable

5 m/16,4 ft cable

10 m/32,81 ft cable

659R6001

659R6002

659R6007

659R6008

659R6005

659R6006

659R6013

659R6014

659R6112

659R6113

659R6114

F200K2 IR-1/Z2

F200K2 IR-2/Z2

F200K2 UV-2/Z2

F200K2 UV-3/Z2

special lengths on request

659R6002/Z2

659R6008/Z2

659R6006/Z2

659R6014/Z2

Protective Cable Conduit AKS-18 I- Ø 18 mm x 1,5 mm, long 3 m/9,84 ft

Protective Cable Conduit AKS-18 I- Ø 18 mm x 1,5 mm, long 5 m/16,4 ft

Protective Cable Conduit AKS-18 I- Ø 18 mm x 1,5 mm, long 10 m/32,81 ft

44

659N9900

659N9901

659N9902

Page 46

9 Appendix

9.2.2 F200K2 ... Ex Compact Flame Detector (Hazardous Area 1, 21)

Ex db IIC T6, T5 Gb, Ex tb IIIC T80°C Db (IECEx EPS 14.0042X)

Fig. 9-6 Compact flame detector F200K2 Ex, IP 66

a Indication of operating state

b Light entry port

Coupling fixation: Cylindrical pipe Thread DIN ISO 228/1

c Cylindrical bolt DIN 84, cable cross section 2.5 ... 6 mm2/14 AWG ... 11 AWG

d Cable entry (not detachable!), with or without conduit connection 1/2" BSPP