Page 1

Manual

BT300 BurnerTronic

Sensors and Systems for Combustion Engineering

www.lamtec.de

Page 2

Page 3

Table of Contents

Table of Contents

1 Important Information about the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Validity of these Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Standards, Directives and Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Classification of the Safety Instructions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Product-specific Dangers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Commissioning Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1.1 Fuel/Air Ratio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1.2 Basic Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.2 Tasks fulfilled by "authority on the subject" during Approval Test . . . . . . . . . . . 11

2.2.2.1 Checking for Correct Parameter Setting in System . . . . . . . . . . . . . . . . . . . . . . 11

2.2.2.2 Checking the Fuel/Air Ratio Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.2.3 Checking Burner Sequencer Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Security Advice - Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Electrical Connection Flame Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Life Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 BT300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3.2.1 Actuators 662R550... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3.2.2 Actuators 662R5001... / 662R5003... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.3 Flame Sensor/Flame Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Mounting and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Connecting Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.1 Optional Connections for the Fuel Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.2 Optional Connections for the Flame Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.3 LSB Module Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3 Flame Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.3.1 Integral Flame Monitoring (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.3.2 Flame Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.3.2.1 KLC 20/KLC 2002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.3.2.2 KLC 10/KLC 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.4 Process Sequence Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.5 Leakage Test for Main Gas Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.5.1 Calculation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.5.2 Leakage Test Process Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.5.3 Reaction on Gas Deficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.5.4 Valve Leakage Test Venting Over the Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.6 Staged Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.7 Flue Gas Recirculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.8 Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.8.1 Operation after Power ON/Long RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2

Page 4

Table of Contents

4.8.2 Direction of Rotation/Position Damper Closed . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.8.3 Detection of Actuators with Transposed Connections . . . . . . . . . . . . . . . . . . . . 56

4.8.4 Adjusting of Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5 Operating Control and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.1 User Interface UI300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.1.1 UI300 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.1.2 Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.1.3 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.1.4 Information Menu Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.1.4.1 Burner Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.1.4.2 Recalling Fault History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.1.4.3 Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.1.4.4 Display of Check Sums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.1.4.5 Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.1.4.6 Positions of Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.1.4.7 Check Digital Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.1.5 Manual Menu Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1.6 Fault Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.1.7 Settings Menu Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.1.7.1 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.1.7.2 Program Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.1.7.3 Configuration of the Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.1.7.4 Set Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.1.7.5 Deleting Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.1.7.6 Adjusting Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.1.7.7 UI300 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.1.7.8 Edit Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.1.8 Menu Path Dataset Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.2 Other Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.3 LSB Remote Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.3.1 Functional Description, Connecting USB-CAN Module . . . . . . . . . . . . . . . . . . . 82

5.3.1.1 Installation Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.3.1.2 Install Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.3.1.3 Install Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.3.1.4 First Connection with the End Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5.3.1.5 Release Codes/Release Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5.3.2 Offline/Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.3.2.1 Offline Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.3.2.2 Online Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.3.2.3 Connecting the BT 300 with the PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.3.3 Read Out Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.3.4 BT300 Curve Dialogue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.3.4.1 Setpoint Graphic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

5.3.4.2 Curve Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

5.3.4.3 Set Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.3.5 Programming of Fuel/Air Ratio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.3.6 Programming a Staged Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5.3.7 Software Interface LSB Remote Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

5.3.7.1 File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3

Page 5

Table of Contents

5.3.7.2 Access Rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

5.3.7.3 BurnerTronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

5.3.7.4 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

5.3.7.5 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

6.1 BT300 Data Back-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

6.2 Firmware Update BT300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

6.3 Firmware Update UI300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

6.4 Replacing of BurnerTronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

7 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

7.1 Firing-Rate Controller Module LCM100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

7.1.1 Range Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

7.1.2 Enter Setpoint of Firing Rate Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.1.3 Operating Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

7.1.4 Control by atmospheric conditions and external setpoint presetting . . . . . . . . 148

7.1.5 Setpoint Changeover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

7.1.6 Start-up Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

7.1.7 Thermostat and Control Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

7.1.8 Control Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

7.1.9 Checking the Safety Limiter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

7.1.10 Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

7.1.11 Aides for Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

7.1.12 External/Manual Firing-rate Presetting (Terminals 16 - 19) . . . . . . . . . . . . . . . 154

7.1.13 DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

7.1.14 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

7.1.15 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

7.1.15.1 Galvanic Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

7.1.15.2 Terminal Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

7.1.16 Technical data LCM100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7.2 Dual Fuel Module DFM300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

7.2.1 DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

7.2.2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

7.2.3 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

7.2.3.1 Galvanic Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

7.2.3.2 Terminal Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

7.2.4 Technical Data DFM300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

7.2.5 Adapter System Rast5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

7.2.5.1 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

7.2.5.2 Technical Data Rast5-Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

7.3 Variable Speed Drive Module VSM100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

7.3.1 DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

7.3.2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

7.3.3 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

7.3.3.1 Galvanic Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

7.3.3.2 Terminal Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

7.3.4 Technical Data VSM100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

7.4 Expansion Module for LSB - LEM100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

7.4.1 DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

4

Page 6

Table of Contents

7.4.2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

7.4.3 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

7.4.3.1 Galvanic Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

7.4.4 Technical Data LEM300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

7.5 Field Bus Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

7.5.1 Field Bus Module for PROFIBUS PBM100 . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

7.5.1.1 DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

7.5.1.2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

7.5.1.3 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

7.5.1.4 PROFIBUS Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

7.5.1.5 Technical Data PBM100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

7.5.2 Field Bus Module for MODBUS TCP EBM100 . . . . . . . . . . . . . . . . . . . . . . . . 194

7.5.2.1 IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

7.5.2.2 DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

7.5.2.3 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

7.5.2.4 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

7.5.2.5 Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

7.5.2.6 Technical Data EBM100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

7.5.3 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

8 Disposal Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

9 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

10 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

10.1 Display Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

10.2 Indication Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

5

Page 7

1 Important Information about the Manual

1 Important Information about the Manual

1.1 Validity of these Instructions

This manual is valid for the burner control system BurnerTronic BT300 in any configuration.

The information contained in this document refer to the software versions BT300 v3.5 and

UI300 v3.8. If you use any other software version as mentioned previously some of the described functions may not be available or not all available functions work as described in this

document.

1.2 Standards, Directives and Approvals

BT300 applies to the following standards and directives:

European Directives:

2004/108/EU EMC Directive

2014/35/EU Low Voltage Directive

2009/142/EU Gas Appliance Directive

2014/68/EU Pressure Equipment Directive, Conformity Assessment cat. IV mod. B and D

2011/65/EU RoHS

Harmonised European Standards:

EN 298

EN 13611

EN 1643 Integrated valve leakage check, gas line DIN DVGW PÜZ N6-2510 ASO 324

EN 12067-2

ISO 23552-1

EN 50156-1, no. 10,5

SIL 3 DIN EN 61508 part 1-7 (BT331, BT341)

USA and Canada:

MH48669 Controls, Primary Safety Certified for Canada - Component

UL 372

UL 1998

Australia:

AGA AS 4625 - 2008

EN 298 - 2012

South Africa:

SAGA Act 85 of 1993

PER R 734 -2009

Russia/Belarus/Kazakhstan:

EAC

6

Page 8

2 General Safety Instructions

2 General Safety Instructions

2.1 Classification of the Safety Instructions and Warnings

The following symbols are used in this document to draw the user's attention to important safety information. They are located at points where the information is required. It is essential that

the safety information is observed and followed, and that applies particularly to the warnings.

DANGER!

This draws the user's attention to imminent danger. If it is not avoided, it will result in death or

very serious injury. The plant including its surroundings could be damaged.

WARNING!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in death or very serious injury. The plant including its surroundings could be damaged.

CAUTION!

This draws the user's attention to the possibility of imminent danger. If it is not avoided, it may

result in minor injuries. The plant including its surroundings could be damaged.

NOTICE

This draws the user's attention to important additional information about the system or system

components and offers further tips.

The safety information described above is incorporated into the instructions.

Thus, the operator is requested to:

1 Comply with the accident prevention regulations whenever work is being carried out.

2 Do everything possible within his control to prevent personal injury and damage to prop-

erty.

7

Page 9

2 General Safety Instructions

2.2 Product-specific Dangers

Please observe the safety instructions to avoid personal injury and damage to property and

the environment!

The BT300 is a safety device! The device must not be opened, interfered with or modified.

LAMTEC assumes no liability for damages arising as a result of unauthorised interference!

• After commissioning and after each maintenance action check the exhaust gas values

across the entire power range.

• Qualified specialist staff are required to carry out all activities (assembly, installation, servicing, etc.).

• The burner or boiler manufacturer will ensure that the BT300 base unit is compliant with

protection class IP40 or IP54 for outdoor use in accordance with DIN EN 60 529.

• Before working in the connection area, switch off the power supply to the plant from all

poles. Ensure that it cannot be switched back on and that the plant is voltage-free. There

is a risk of electric shock when the plant is not switched off.

• Place and secure the protection against contact on the BT300 and on all connected electrical parts. The cover must fulfil the design, stability and protection requirements of

EN 60730.

• Plug connectors X30 - X34 have no protective separation from the mains voltage. To replace or disconnect the plug connectors, all poles of the plant must be disconnected from

the mains.

• After each activity (e.g. assembly, installation, servicing, etc.) check wiring and

parameters to make sure it is in good working condition.

• If the equipment is dropped or suffers impact, you should no longer commission it. The

safety functions may also be impaired but fail to show any obvious external damage.

• When the ratio curves are being programmed, the adjuster will continually monitor the

quality of the plant's combustion (e.g. using an exhaust gas analysis station). In the event

that the combustion values are inadequate or the conditions are potentially harmful, the

adjuster will take suitable action, e.g. switch off the system manually.

• These operating instructions describe many possible applications and functions and

should be used as guidelines. Carry out functional tests on the test bench and/or in the

plant application to ensure correct functioning and document the results.

Follow additional instructions to guarantee safety and reliability while operating the BT300:

• Condensation and humidity are to be avoided. If necessary, make sure that the installation

is sufficiently dry before you switch it on.

• Avoid static charge having a destructive effect in case of touching the device's electronic

components.

NOTICE

LAMTEC recommends that you use ESD equipment while working on electrics/electronics.

8

Page 10

2 General Safety Instructions

2.2.1 Commissioning Notes

• Check all safety functions during commissioning!

• There is no feature to prevent RASTx connector plugs being transposed. Therefore ensure the correct assignment of the plant's plugs prior to commissioning.

• Check electromagnetic emissions specific to the application.

• While installing and commissioning the plant, the person in charge of the plant/heating

technician needs to document the following:

– Parameter set values

– Setting values (e.g. curve progressions)

– Values describing the fuel/air ratio control.

This data can be printed using LSB remote software or alternatively being kept as a hand-

written note.

Retain this documentation and have it checked by the ’authority on the subject’.

WARNING!

For BT300 parameter settings which deviate from the application standards can be carried out

in access level 2. For this reason, check whether the parameter settings are consistent with

the corresponding application standards (e.g. EN 298, EN 230, EN 676, EN 267, etc.) or the

respective plant has to be approved separately.

WARNING!

While unlocking the safety interlock chain in the mode ’BURNER OFF’ BT300 does not lock

the system. BT300 prevents a burner start-up until safety interlock chains are locked.

In case your application needs an interlock of the plant while unlocking the safety interlock

chain also in ’BURNER OFF’ mode you must take suitable measures at the plant.

NOTICE

Should the safety times be changed, these changes must be documented on the devices

Bring an additional sticker for the device.

Note the changed safety times on this sticker.

The details on this sticker must be clear for reading and non-smudge.

2.2.1.1 Fuel/Air Ratio Control

• Guarantee proper operation by ensuring adequate excess air.

In order to do this, set the values for fuel and combustion air in such a way that

– combustion chamber pressure

– fuel pressure

– temperature and pressure of the combustion air

can ensure proper operation through the entire range of burner firing rate until next peri-

odic inspection.

• Pay attention to wear and tear of actuators and actuator elements.

• Measure characteristic values of combustion process to document proper operation.

9

Page 11

2 General Safety Instructions

2.2.1.2 Basic Device

Check the following items prior to commissioning:

• Valves must be assigned correctly to valve outputs on BT300.

• Correct setting of time parameters (especially safety and pre-purge times).

• Flame sensor functioning well in case of:

• flame blow-off during operation (incl. flame-out response time)

• parasitic light is present during pre-purge period

• at a missing flame formation while end of safety period starts

• Activation of the valve leakage control function of gas valves and correct leakage measurement, when required by an application.

2.2.2 Tasks fulfilled by "authority on the subject" during Approval Test

By specifying the assigned DIN registration number and product ID number the manufacturer

confirms that model BT300 burner control system is consistent with type-tested system.

The connection between actuators and actuator elements for fuel and combustion air and also

to any additional actuator elements used must be form-fit.

2.2.2.1 Checking for Correct Parameter Setting in System

While installing and commissioning the plant the person in charge of the plant/heating technician needs to document the following:

• Parameter set values

• Setting values (e.g. curve progressions)

• Values describing fuel/air ratio control.

This data can be printed using LSB Remote Software or alternatively being kept as a handwritten note.

Retain this documentation and have it checked by the ’authority on the subject’.

NOTICE

For BT300 parameter settings which deviate from application standards can be carried out in

access level 2. For this reason, check whether the parameter settings are consistent with the

corresponding application standards (e.g. EN 676, EN 267, etc.) or the respective plant has

to be approved separately.

10

Page 12

2 General Safety Instructions

2.2.2.2 Checking the Fuel/Air Ratio Control System

Save setting values (curve parameters) for actuator elements, fuel and combustion air through

the complete range of burner firing rate in sufficient number.

Select setting values of fuel and combustion air considering combustion chamber pressure,

fuel pressure, temperature and pressure of the combustion air in order to guarantee proper

operation with adequate excess air through the entire range of burner firing rate.

The burner/boiler manufacturer has to document this by measuring reference values of the

combustion process.

2.2.2.3 Checking Burner Sequencer Part

Check the following:

• Correct setting of time parameters (especially safety and pre-purge periods).

• Whether an ionisation flame sensor or a corresponding flame scanner is used since only

these are capable of running in continuous operation.

• Functioning of flame sensor

– in case of flame blow-off during operation

– parasitic light being present during pre-purge period

– missing flame formation at the end of the safety-period

• Check the performance of all available and/or essential incoming signals, such as:

– Air pressure

– Gas pressure - min./oil pressure - min.

– Safety interlock chain (e.g. STB)

• Activated Leakage control function for gas valves if required for application purposes.

– If necessary, ensure a correct leakage quantification.

2.3 Security Advice - Mounting

• Compliance with national safety regulations and standards is obligatory at all times.

• During the assembly and installation process, you must meet the standard requirements

of DIN VDE 0100, 0550 and DIN VDE 0722

• To mount the BT300 basic unit, use screw fittings with an M4 thread (UNC32) and a maximum tightening torque of 1.8 Nm for fastening all four fixing points. Keep in mind that

housings have improved mechanical stability when connected on surrounding contact surfaces.

Generally connect to an even mounting surface.

NOTICE

Deterioration of the 0.8 Nm servomotor through opening.

Opening the servomotor in a different position other than the cap of the electrical connection,

destroys the servomotor.

The warranty expires.

Open the servomotor at the cap of the electrical connection only.

11

Page 13

2 General Safety Instructions

NOTICE

Damaging the servomotors with 1.2 Nm and 9.0 Nm through opening.

Opening the servomotor destroys the servomotor.

The warranty expires.

2.4 Installation Notes

• Lay high-voltage ignition cable always separately and in safe distance from device and

other cables.

• Only trained, qualified personnel may open the BurnerTronic’s cover.

• Observe local and national regulations when wiring the electric cables inside the burner.

• Tighten the screw terminals of the BT300 using a tightening torque of > 0.5 Nm.

• Supply the feed cable with L, N and PE only. The N neutral conductor must not have potential difference to the PE protective conductor.

• The pre-fuse for the BT300 should be max.10 A slow-blow.

• Phase, neutral and central point conductors must not be interchanged (this would lead to

dangerous malfunctioning, loss of protection against contact, etc.).

• The strain relief for the connected cables must comply with standards (e.g. DIN EN 60730

and DIN EN 60335).

• Make sure that no spliced strands can come into contact with any of the adjacent connections. Use appropriate end sleeves.

• The burner manufacturer is obligated to supply unused connections on the BT300 with

dummy plugs.

• To replace or disconnect the plug connectors, all poles of the plant must be disconnected

from the mains.

• Make a form-fit connection between the actuators and actuating elements for fuel and

combustion air, as well as a form-fit connection for any additional actuator element.

• Optional components with safety extra low voltage (SELV) must be safely separated from

the mains. Otherwise this can cause an electrical shock or damage the device due to a

short-circuit.

• You may connect only passive devices or devices without feedback effects at the 230V

outputs of the BT300 (like relays without additional voltage connection). In case of error it

must be guaranteed that BT300 is not fed with 230 V by this terminals.

• To avoid disruption of the UI300’s display during ignition, a damping resistor of 1 ... 5 k

must be installed in the high-voltage ignition line.

• To avoid disturbance on the Bus, the termination must be active on the first and the last

device connected to the bus must be terminated (see chapter 4.2.3 LSB Module Integra-

tion).

12

Page 14

2 General Safety Instructions

2.5 Electrical Connection Flame Sensor

Interruptions and losses in signal transmission need to be minimised:

• Do not wire the sensor cable with other cables.

Flame signal is reduced through line capacities. Use a separate 7-pole cable.

• Consider the permitted length of sensor cables.

• The ionisation flame sensor supplied from the mains is not protected against contact. Protection against accidental contact is therefore obligatory.

• Ground the burner according to instructions – grounding the boiler itself is not sufficient!

• Position ignition electrode and ionisation flame sensor where spark cannot hit ionisation

flame sensor (risk of electrical overloading).

13

Page 15

3 Product Description

3 Product Description

3.1 Functional Description

BT300 combines the benefits of an electronic fuel/air ratio control system with up to three motorised actuator elements and optional modules like an analogue output for speed control of

the combustion air fan with an electronic burner control unit. The leakage test, flame monitoring system, power control unit and (optional) CO/O2 controller for control and optimisation of

an oil or gas-fired forced-draught burner are all integrated.

BT300 is suitable for virtually all combustion plants. Safety interlock chains, monitors (e.g. gas

and air pressure) and sensors are wired directly to the BT300. This greatly reduces the cost

of additional relays and wiring. The BT300 is designed to be attached to the burner. The short

wiring paths also save money. As a result, BT300 is particularly suitable as standard equipment for monoblock burners.

The compact design of BT300 burner control system also has its advantages during commissioning. Standardisation of wiring and operator interface minimises sources of errors right

from the start. Moreover, intelligent display information is making search for errors much easier.

The BT300 is available in five designs:

• BT320 2 motorised control outputs

1 continuous output 0 ... 10 V, 0/4 ... 20 mA for speed control of the

combustion air fan using VSM100 (optional)

intermittent operation

• BT330 3 motorised control outputs

1 continuous output 0 ... 10 V, 0/4 ... 20 mA for speed control of the

combustion air fan using VSM100 (optional)

Approved for continuous operation only in combination with

flame sensors capable of running continuously

• BT331 Same range of functions as BT330 but including following certificates:

DIN EN 61508:2002 parts 1-7 for SIL 3

Performance Level PLE according DIN EN ISO 13849-1

• BT340 3 motorised control outputs

Oil-gas dual-fuel operation via DFM300

1 continuous output 0 ... 10 V, 0/4 ... 20 mA for speed control of the

combustion air fan using VSM100 (optional)

approved for continuous operation only in combination with

flame sensors capable of running continuously

• BT341 Same range of functions as BT340 but also including following certificates:

DIN EN 61508:2002 parts 1-7 for SIL 3

Performance Level PLE according DIN EN ISO 13849-1

Burner sequencer and fuel/air ratio control can be adjusted for a wide range of combustion

conditions by setting parameters. The BT300 for oil and gas can be set to start with and without pilot burner. The integrated leakage test can be run before ignition or after shutting down

the burner.

Starting without pre-purge using gas is available in accordance with EN676.

The setting of fuel/air ratio curves can be optimised using optional CO/O2 control during op-

eration. This helps to counteract conditions that interfere with combustion. This ensures a permanent burner operation at the greatest possible efficiency.

Operating and fault messages are displayed by symbols and numbers on UI300 User Interface. Plant-specific configurations and settings of fuel/air ratio control curves are operated via

menu of UI300 User Interface.

14

Page 16

3 Product Description

An operating and start-up counter is integrated.

The optional LCM100 power control unit with two setpoints, external setpoint shift (control by

atmospheric condition) and start-up control is also available.

3.2 Life Cycle

BurnerTronic BT300 burner management system has a designed lifetime * of 250,000 burner

start-up cycles, which, under normal operating conditions in heating mode, correspond to approx. 10 years of usage (starting from the production date given on the type plate).

This lifetime is based on the endurance tests specified in standard EN230/EN298 and the table containing the relevant test documentation as published by the European Association of

Component Manufacturers (Afecor) (www.afecor.org).

The designed lifetime is based on use of BT300 according to the manufacturer’s basic documentation. After reaching designed lifetime in terms of number of burner start-up cycles, or

the respective time of usage, the BT300 must be replaced by authorized personnel.

3.3 Technical Data

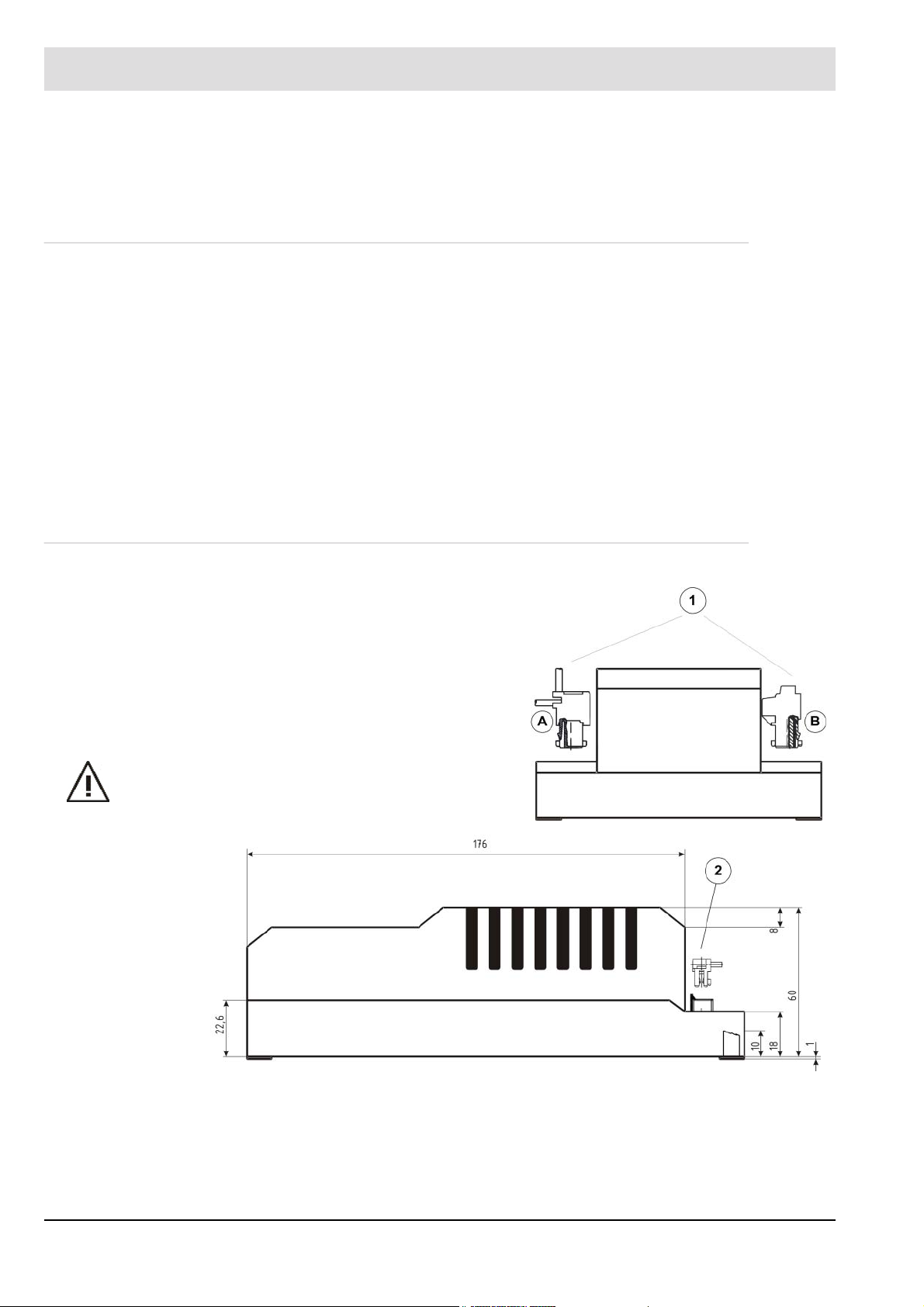

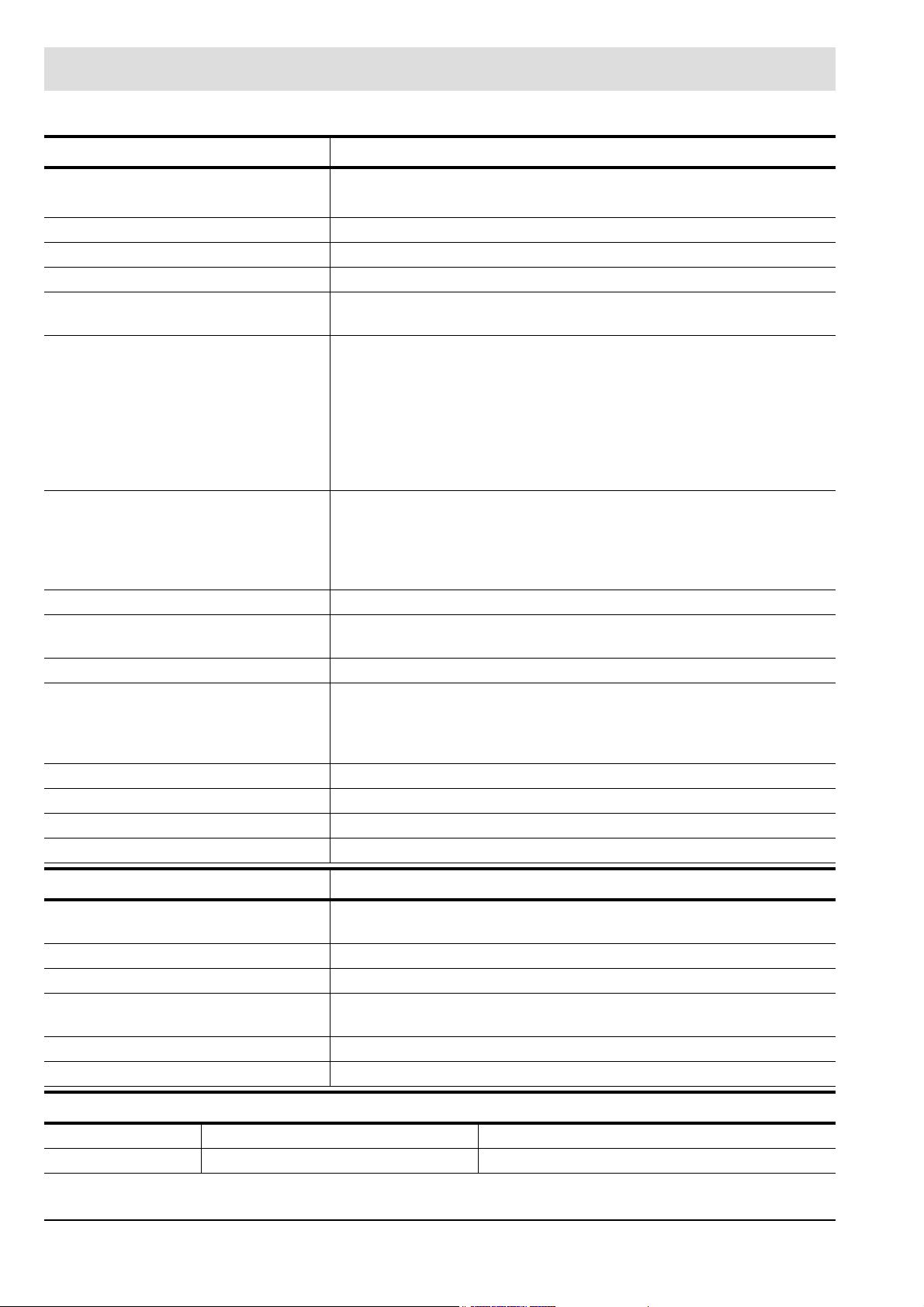

3.3.1 BT300

1 RAST5 plug connector optionally

A cutting and clamping technique (SKT) *

B screw terminals *

2 RAST2.5 plug connector for actuator,

User interface and LAMTEC SYSTEM

BUS in cutting and clamping technique

* please note plug-in direction

*

The designed lifetime is not the warranty time specified in the Terms of Delivery

15

Page 17

3 Product Description

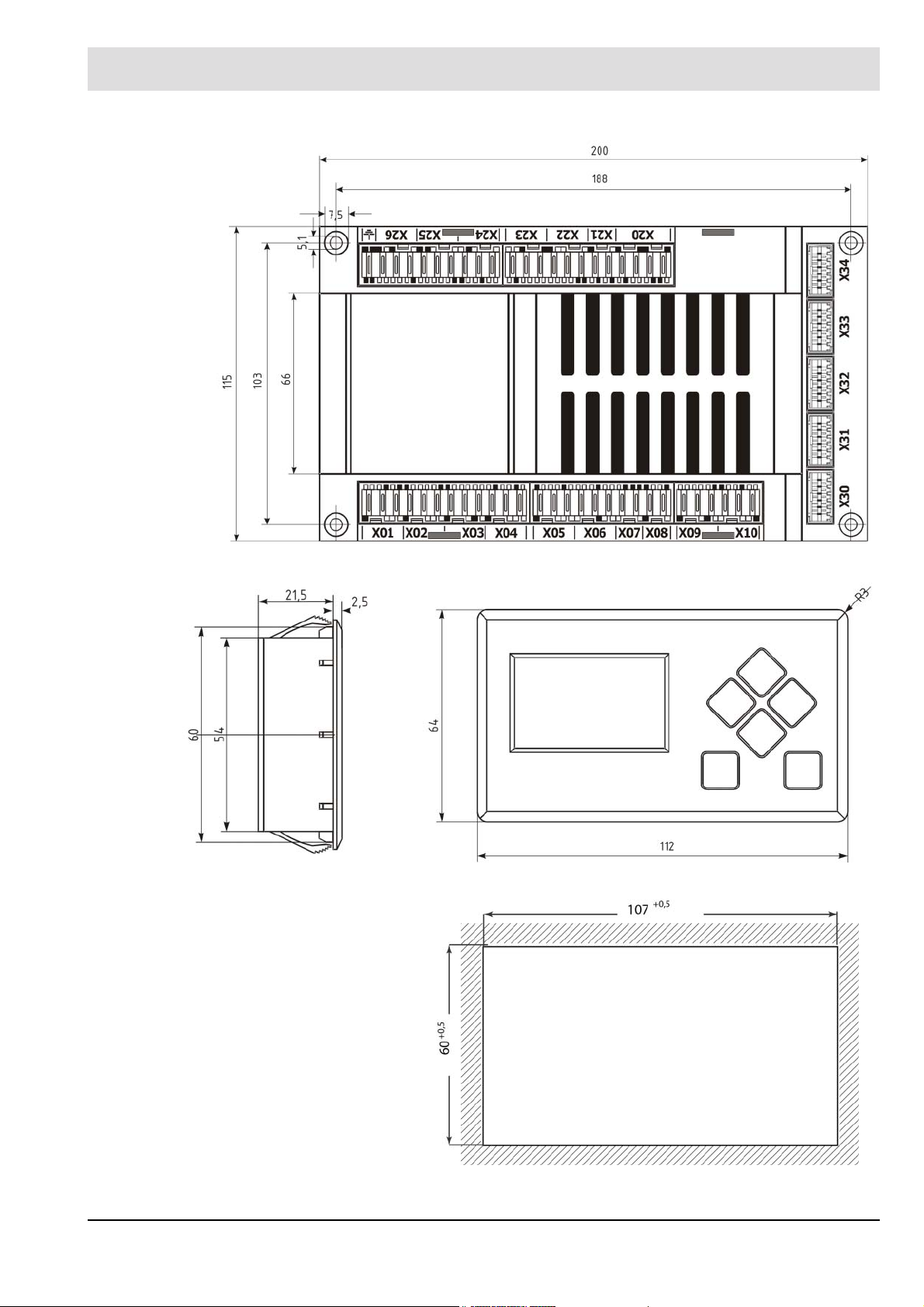

Fig. 3-1 Dimensions BT320 ... 340 (terminal assignment BT330/BT340 only)

Fig. 3-2 UI300 side view

Fig. 3-3 UI300 front view

Fig. 3-4 UI300 panel cut-out

16

Page 18

3 Product Description

Function

Power supply: 230 V +10/-15 % 47-63 Hz

115 V +10/-15 % 47-63 Hz (on request)

Maximum backup-fuse: 10 A slow-blow

To be used only in a grounded power line network!

Power consumption: max. 30 VA

Switching threshold of ionisation

current:

Digital signal inputs: Max. line length 10 m/33 ft

Digital outputs: 3 fuel valves max. 1 A cos 0,4

Resolution: 999 digit, 10 bit

Number of curve sets: BT320/33x: 1 curve set (oil or gas)

Number of programs: unlimited (EEPROM)

Field bus-coupling (optional): PROFIBUS DP

Housing: Polycarbonate + ABS

Dimensions: 200x115x61 mm/7.87x4.53x2.4 in

Weight: 1,0 kg/2.20 lb

Flammability: UL-94 V0

1 A

Max. line length 20 m/66 ft for the following signals:

Firing rate+ / firing rateBoiler safety interlock chain (SIC)

Burner ON

Reset

Alarm

Fuel selection DFM

VL fan max. 2 A cos 0,4

oil pump max. 2 A cos 0,4

ignition transformer max. 2 A cos 0,2

alarm output max. 1 A cos 0,3

BT34x: 2 curve sets (oil/gas switchable; DFM300 or LCM100 required)

Modbus TCP

PROFINET

LEM100 or LCM100 always required

Display UI300

Display: 128x64 pixel, monochrome

White backlighting (dimmable)

Dimensions: 112x64x24 mm/4.41x2.52x0.94 in

Weight: 140 g/0.31 lb

Housing: Basic housing: Polyamide glass fibre reinforced

LCD-display window: Polycarbonate

Flammability: UL-94 V0

Cable length: 1 m/3.28 ft

Environmental Conditions

Operation: Climatic conditions Class 3K5 according to DIN EN 60721-3

Mechanic conditions Class 3M5 according to DIN EN 60721-3

17

Page 19

3 Product Description

Environmental Conditions

Temperature range -20 ... +60 °C/-4 °F ... +140 °F

(condensation is prohibited)

Transport: Climatic conditions Class 2K3 according to DIN EN 60721-3

Mechanic conditions Class 2M2 according to DIN EN 60721-3

Temperature range -20 ... +70 °C/-4 °F ... +158 °F

(condensation is prohibited)

Storage: Climatic conditions Class 1K3 according to DIN EN 60721-3

Mechanic conditions Class 1M2 according to DIN EN 60721-3

Temperature range -20 ... +70 °C/-4 °F ... +158 °F

(condensation is prohibited)

Electronic safety: Degree of protection (DIN EN 60529): BT300 – IP00 housing

IP20 (terminals covered)

UI300 – IP40 (clamping)

IP54 (glued assembly)

3.3.2 Actuator

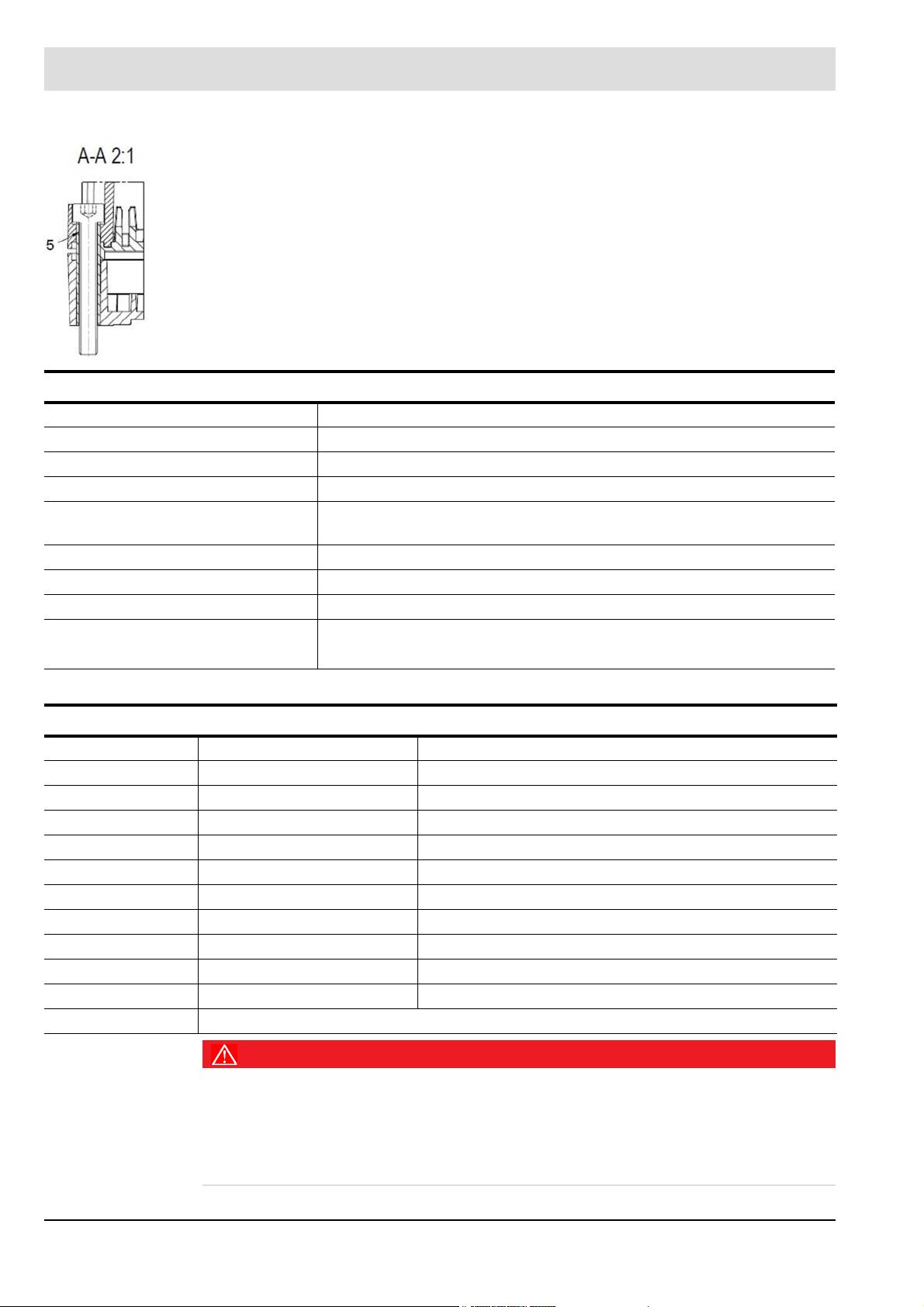

3.3.2.1 Actuators 662R550...

18

Page 20

3 Product Description

1 15.4 (+0.3/-1) including axial play

2 Cap cannot be removed by hand

3 Flexible control cable (black), length 1.5 m

4 Plug connector (RAST 2.5) pole number 6

5 Brass tube and M4 x 30 DIN 912 cylinder bolt fixed with O-ring

Function

Power supply 24 VDC ±20 %

Floating time 5 s / 90° at 180 Hz

Direction of rotation 0° to 90° right

Torque 0.8 Nm (both directions)

Holding torque 0.4 Nm (no power)

0.7 Nm

Permissible radial load 30 Nm (centre of output shaft)

Permissible axial load 5 N

Axial play of drive shaft 0.1 ... 0.2 mm

Cable length securely connected 0.6 m

pluggable max. 3 m

Environmental conditions

Operation Climatic condition Class 3K3 according to DIN EN 60721-3

Mechanical condition Class 3M3 according to DIN EN 60721-3

Temperature range -20 ... +60 °C (condensation is prohibited)

Transport Climatic condition Class 2K3 according to DIN EN 60721-3

Mechanical condition Class 2M2 according to DIN EN 60721-3

Temperature range -20 ... +70 °C (condensation is prohibited)

Storage Climatic condition Class 1K3 according to DIN EN 60721-3

Mechanical condition Class 1M2 according to DIN EN 60721-3

Temperature range -20 ... +70 °C (condensation is prohibited)

Bursting strength Peak voltage 4 kV

Repeat frequency 2,5 kHz

Electrical safety Protection class 2 as per DIN EN 60730

DANGER!

Danger by electrical shock!

Shut BT300 down before opening the cover, otherwise it is possible to get in contact with conducting parts. This may cause an electrical shock. Only open BT300 when it is disconnected

it all-pole.

Disconnect BurnerTronic all-pole.

19

Page 21

3 Product Description

NOTICE

Damaging the 0,8 Nm actuator by opening the actuator.

Do not open the actuator at another part as the cover of the electric connection, otherwise the

actuator will be damaged.

The warranty expires and is invalid.

Do not open the actuator but at the cover of the electric connection.

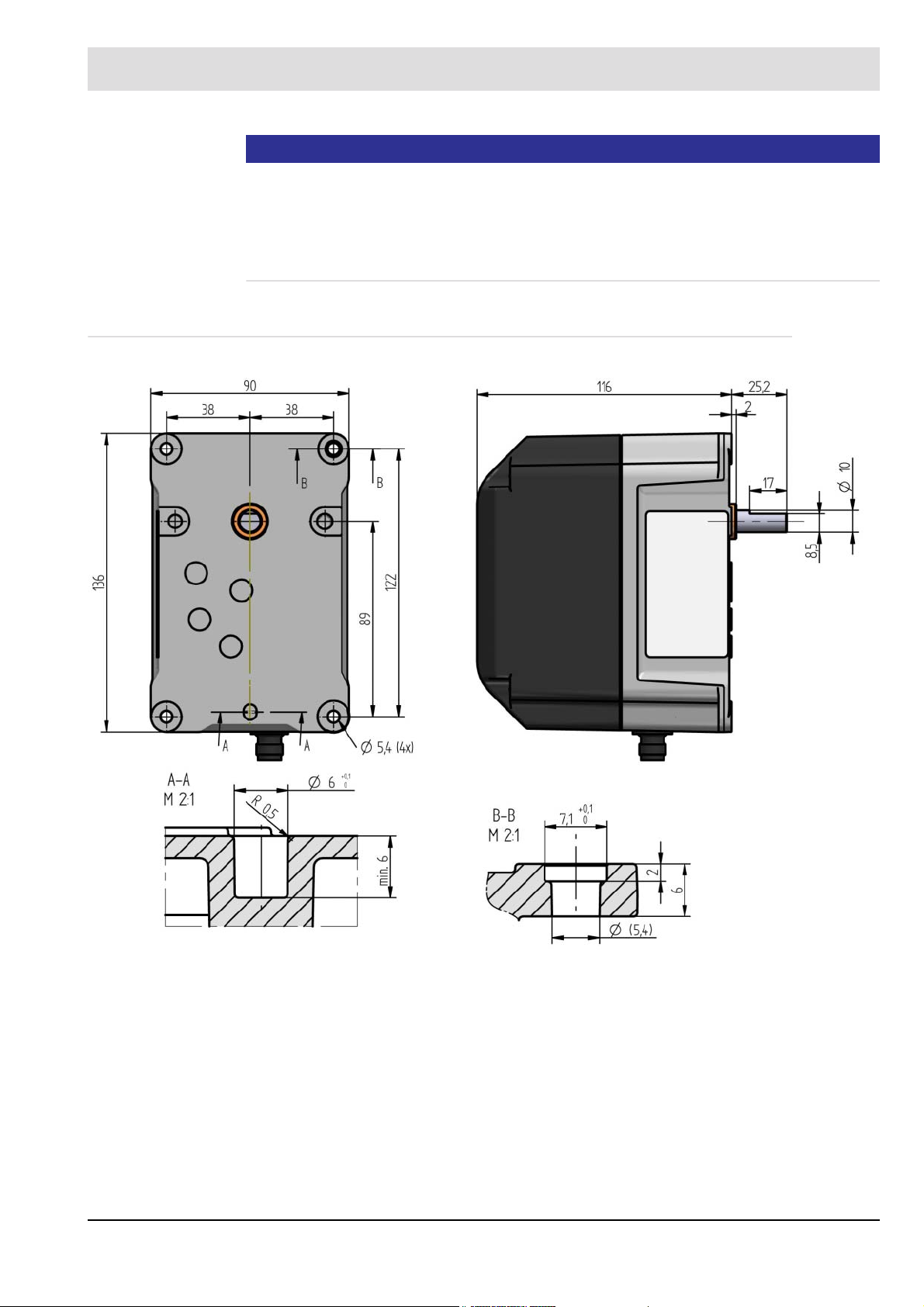

3.3.2.2 Actuators 662R5001... / 662R5003...

Fig. 3-5 Dimensional drawing of motor type 662R5001-0 and 662R5003-0 without cable but with plug

20

Page 22

3 Product Description

Fig. 3-6 Dimensional drawing of motor type 0R5001-1 and type 662R5003-1 with cable

Fig. 3-7 Dimensional drawing of motor type 660R5009-0 without cable but with plug

21

Page 23

3 Product Description

Function 662R5001... 662R5003... 662R5009...

Power supply: 24VDC ±20 %

Floating time 5 s/90° 5 s/90° 15 s/90°

Direction of rotation 0°

to 90°

Effective

output torque

Holding torque 0.82 Nm (currentless) 2.8 Nm (currentless) 6 Nm (currentless)

Permissible

radial load

Permissible axial load 10 N

Axial play of drive shaft 0.1 ... 0.2 mm 0.1 ... 0.2 mm

Motor RDM 51/6 stepper motor

Angular resolution 0.1°/motor step 0.1°/motor step 0.03°/motor step

Rated resolution

encoder monitoring

Monitoring

accuracy

Repeat accuracy 0,1° 0,1° 0,1°

Life cycle 2,000,000 motions forward and back performed on complete actuator range

Degree of protection IP54 according to DIN EN 60529-1

Weight 1400 g

Cable length securely connected

left - view to the drive shaft

1.2 Nm

(both directions of rotation)

100 N (centre of output shaft)

0,7°

0,5° 0,5° 1.3125°

1.5mpluggable max. 3 m

3 Nm

(both directions of rotation)

securely connected

1.5mpluggable max. 3 m

9 Nm

(both directions of rotation)

(corresponds 44 motor

steps)

pluggable max. 3 m

Environmental conditions 662R5001.../662R5003.../662R5009...

Operation Climatic condition Class 3K5 according to DIN EN 60721-3

Mechanical condition Class 3M5 according to DIN EN 60721-3

Temperature range -20 ... +60 °C (condensation is prohibited)

Transport Climatic condition Class 2K3 according to DIN EN 60721-3

Mechanical condition Class 2M2 according to DIN EN 60721-3

Temperature range -20 ... +70 °C (condensation is prohibited)

Storage Climatic condition Class 1K3 according to DIN EN 60721-3

Mechanical condition Class 1M2 according to DIN EN 60721-3

Temperature range -20 ... +70 °C (condensation is prohibited)

Bursting strength Peak voltage 4 kV

Repeat frequency 2,5 kHz

Electrical safety Protection class 2 as per DIN EN 60730

NOTICE

Damage of the actuator with 1.2, 3.0 and 9.0 Nm due to opening the actuators housing.

Opening the actuator’s housing will damage the actuator. The warranty expires.

22

Page 24

3 Product Description

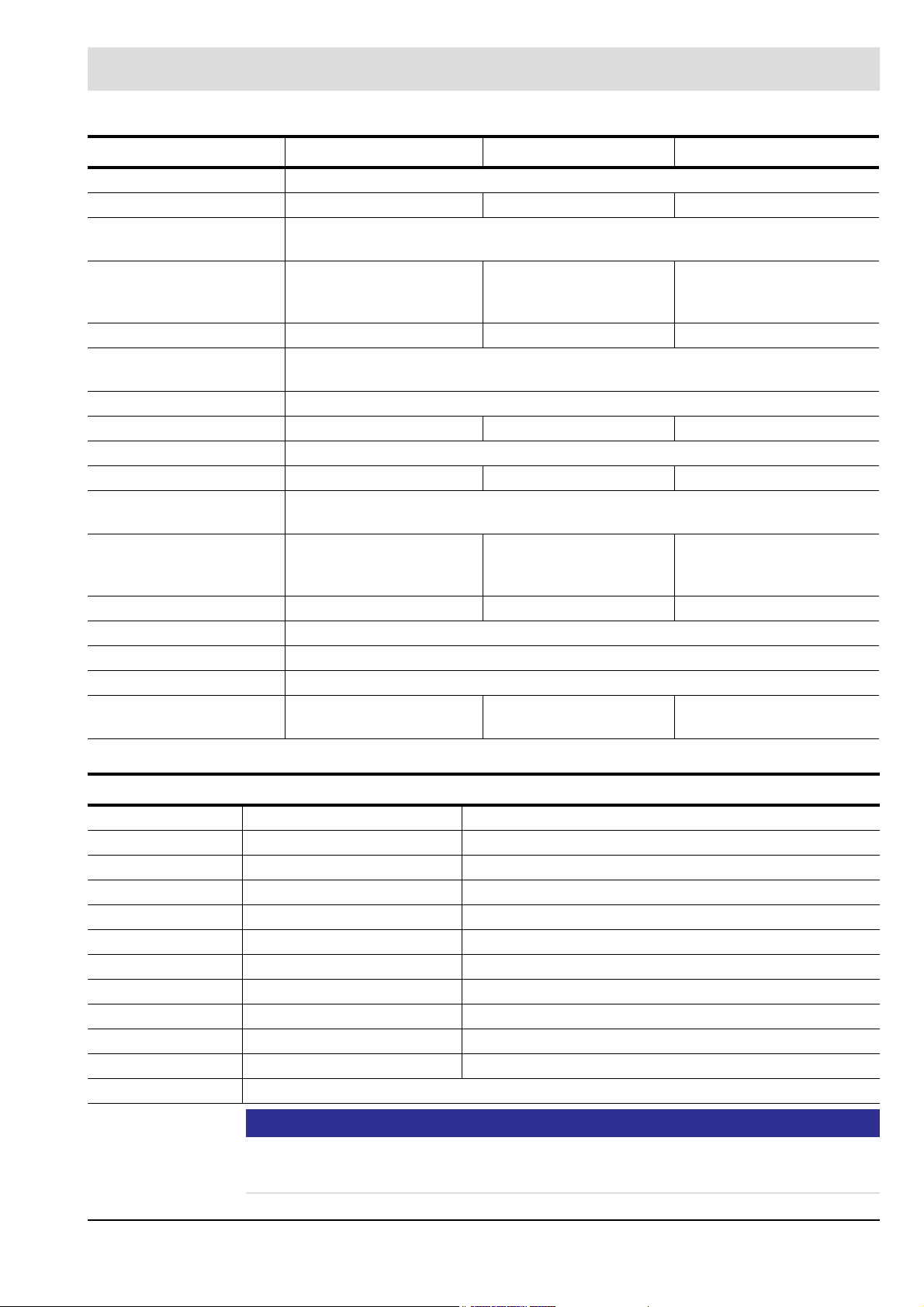

3.3.3 Flame Sensor/Flame Scanner

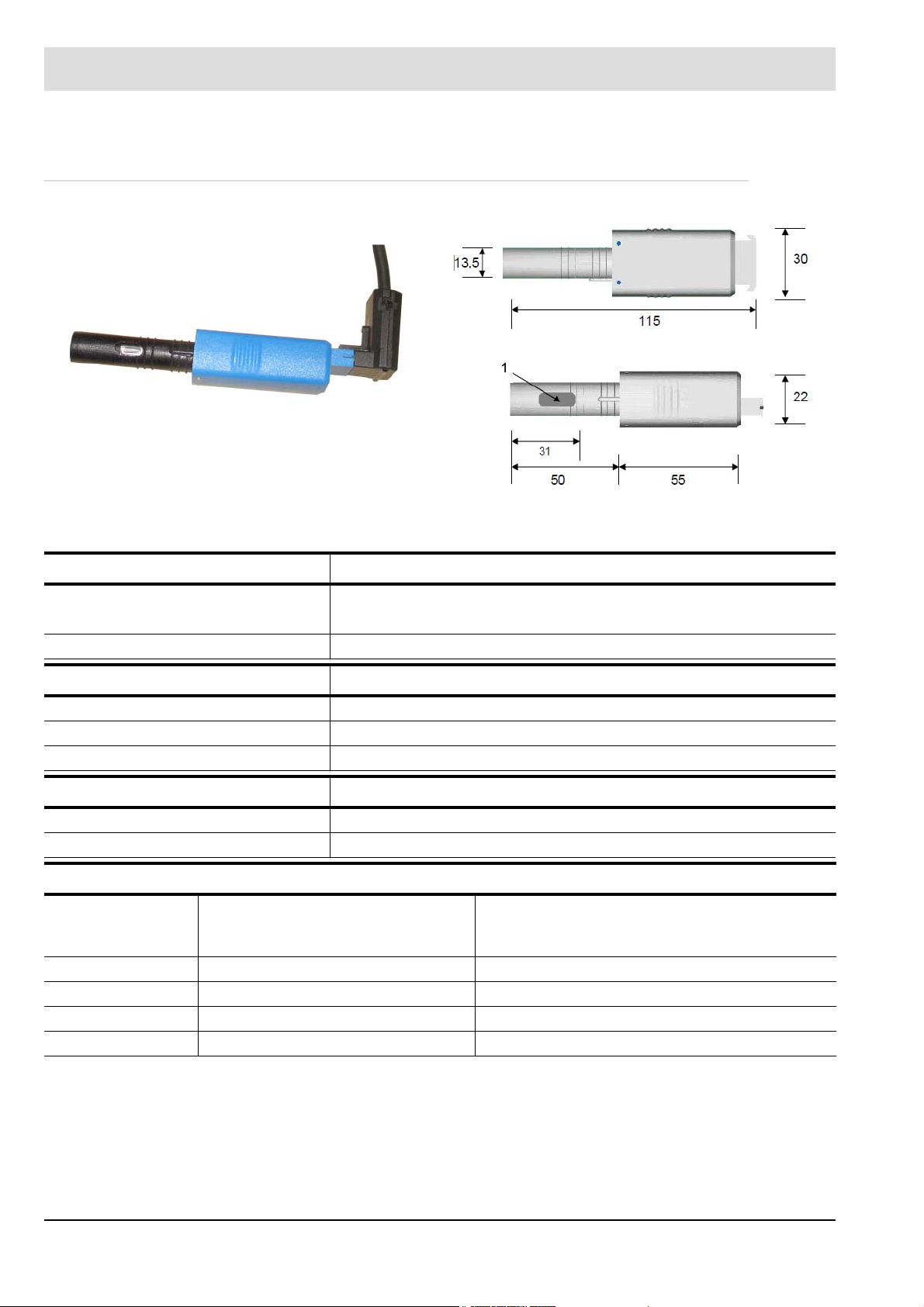

Fig. 3-8 KLC 1000

KLC10/KLC1000

Input Data

Power supply: KLC10: 120 VAC -15/+10 % 50-60 Hz

KLC1000: 230/240 VAC -15/+10 % 50-60 Hz

Current consumption: 5,5 mA

Optical Evaluation

Spectral range: 185 - 260 nm

Tolerable flame signal dips: 200 ms

Alignment to the flame: left

Dimensions

Weight: 0,028 kg (1 oz)

Connecting cable length max.: 1 m (39.4")

Environmental Conditions

Operation: Temperature range -20 ...+60 °C (-4 °F ... 140 °F)

Humidity max. 95 % r. h. (condensation is prohibited)

Electrical safety: Protection category IP41

Protection class II

Protecting against contact DIN EN 60730-2-5

Fig. 3-9 Dimensions KLC 1000 (1 = radial scanning opening)

(temperatures >50 °C (122 °F) will reduce life

cycle of the device)

23

Page 25

3 Product Description

Fig. 3-10 Dimensions of angle adapter for KLC 2002 Fig. 3-11 Dimensions KLC 2002

KLC20/KLC2002

Input Data

Power supply: KLC20: 120 VAC -15/+10 % 50-60 Hz

KLC2002: 230/240 VAC -15/+10 % 50-60 Hz

Current consumption: 3 - 4 mA

Optical Evaluation

Spectral range:

Design with optical filter 380 - 830 nm:

Sensitivity max.: 920 nm

Tolerable flame signal dips: 280 ms

Fading of the parasitic frequency: >35 Hz (option)

Dimensions

Weight: 0,029 kg (1.02 oz)

Connecting cable length: 1 m (39.37")

Mounting position: any

Environmental conditions

Operation: Temperature range -20 ...+60 °C (-4 °F ... +140 °F)

Humidity max. 95 % r. F. (condensation is prohibited)

Electrical safety: Protection category IP41

Protection class II

Protection against contact DIN EN 60730-2-5

380 - 1150 nm

(temporarily <1 min. up to +75 °C (+167 °F))

24

Page 26

4 Mounting and Functions

4 Mounting and Functions

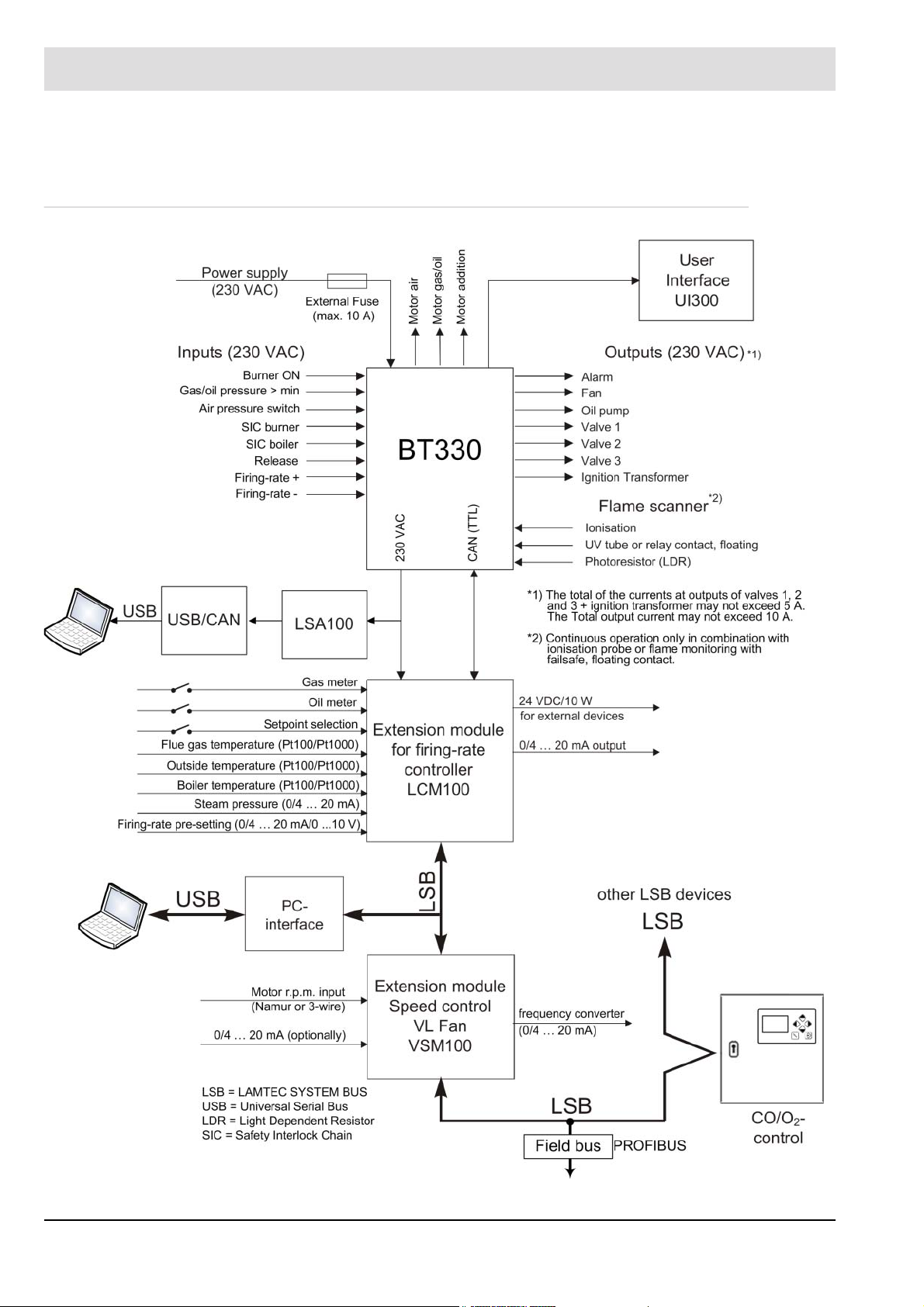

4.1 System Overview

Fig. 4-1 System overview of BurnerTronic BT300

25

Page 27

4 Mounting and Functions

4.2 Connecting Diagrams

X30 = User Interface UI 300

X31 = LSB Option X01-X6+X08: 10 m

X32 = continuous output 1, e.g. air damper X07+X09: 20 m

X33 = continuous output 2, e.g. gas damper X10: 20 m

X34 = continuous output 3 (optional) X20-X21:

(1)

SIC = safety interlock chain

(2)

230 V AC 47 - 63 Hz external fuse protection required (max 10 A slow-blow)

(3)

230 V AC for power supply to external devices

(4)

Fuel selection for dual fuel burners with BT340 + DFM300 see chapter 7.2 Dual Fuel Module DFM300

(5)

Alternative CPI/POC connection see chapter 4.2.1 Optional Connections for the Fuel Line

Maximum cable length

3 m

X22-X23: unlimited X32-X34: 3 m

X24: 20 m X31: 1 m

X25-X26: 10 m X30: 1 m

WARNING!

Conductors with max. 20 m cable length are allowed to have not more than 3 signal transfers

in one cable, otherwise this would lead to dangerous malfunctions.

Safety interlock chain (SIC) is often known as closed.

NOTICE

When running oil-solely burning applications, the function ’Oil pressure > min’ is aligned with

X05.

26

Page 28

4 Mounting and Functions

When running oil/gas burning applications (BT340 in combination with DFM300), the function

’Gas > min’ is aligned with X05.

►Put in oil/gas applications, the pressure monitoring for ’Oil pressure > min.’ in the oil safety

interlock chain (SIC).

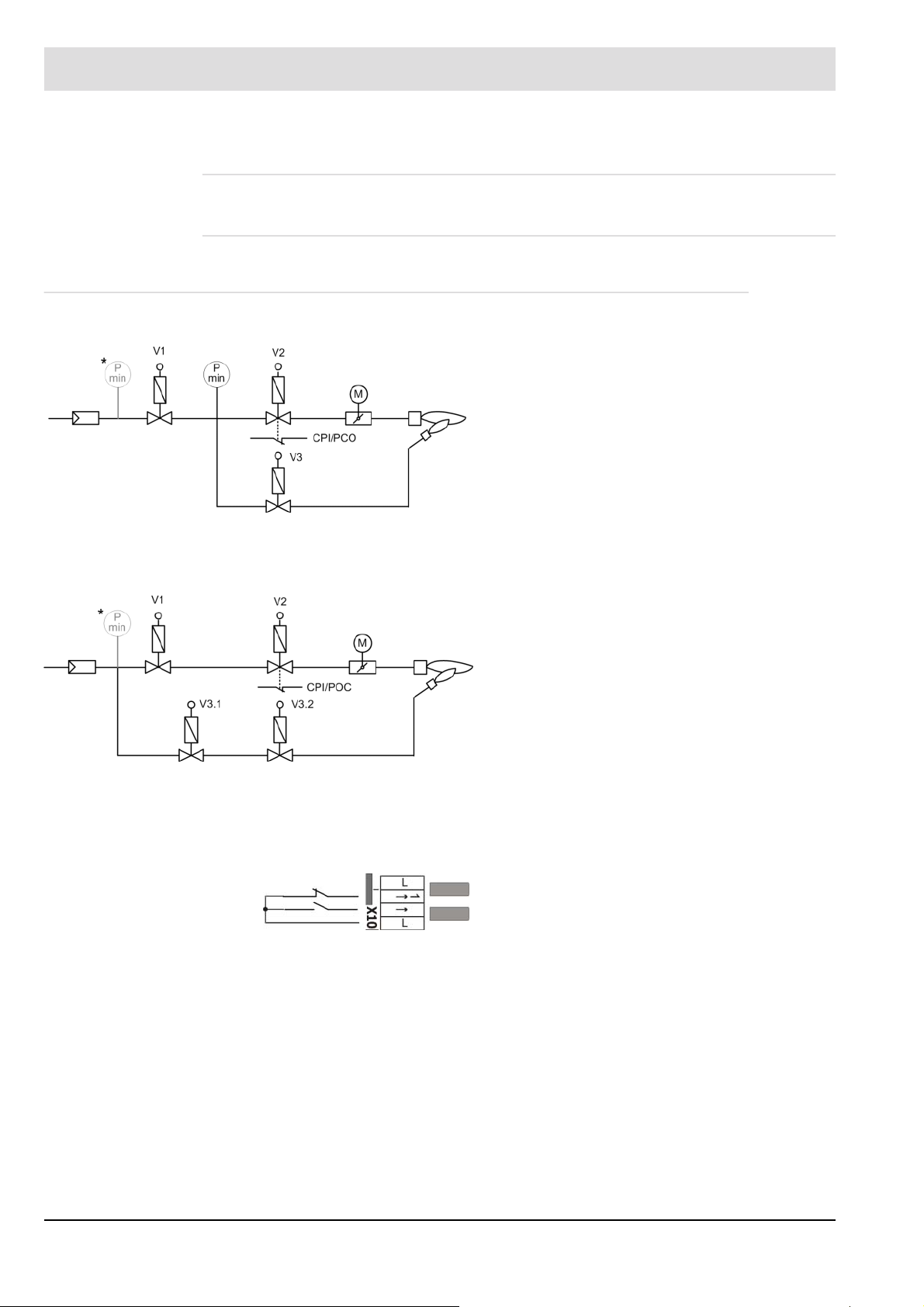

4.2.1 Optional Connections for the Fuel Line

Fig. 4-2 Fuel train - gas modulating

V1 Fuel valve (gas side)

V2 Fuel valve (burner side)

V3 Optional ignition valve

P

min

M Actuator gas damper

*

CPI/

POC

Gas pressure min sensor

Alternative positioning of the pressure monitor P

essary.

Close Position Indicator (UK/AU)

Prove Of Closure (US)

ON switch at gas valve 2 which indicates

that the valve is closed (option)

– if valve leakage check is not nec-

min

Fig. 4-3 Fuel Train - taking pilot gas previous to the main valves (BT300

software version 3.2 or higher)

CPI/POC BT300

Burner ON

V1 Fuel valve (gas side)

V2 Fuel valve (burner side)

V3.1 Ignition valve (gas side)

V3.2 Ignition valve (burner side)

P

min

M Actuator gas damper

*

CPI/

POC

Gas pressure min sensor

Alternative positioning of the pressure monitor P

essary.

Close Position Indicator (UK/AU)

Prove Of Closure (US)

ON switch at gas valve 2 which indicates that

the valve is closed (option)

– if valve leakage check is not nec-

min

27

Page 29

4 Mounting and Functions

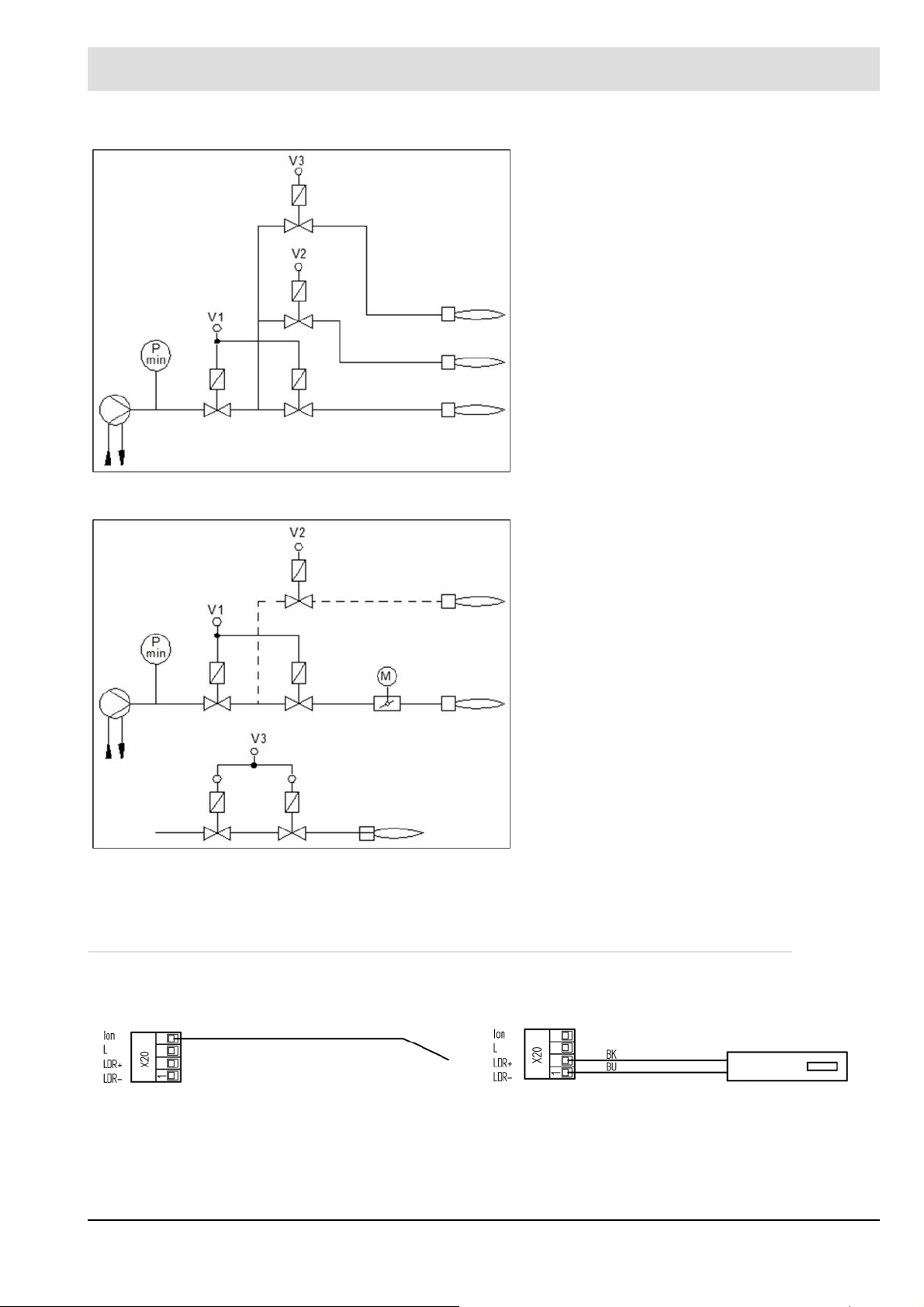

Fig. 4-4 Fuel train - oil 3-stage

P

min

V1 Oil valve 1

V2 Oil valve 2

V3 Oil valve 3

P

min

V1 Oil valve for modulated operation,

V2 Oil valve 2

Oil pressure min sensor

st

stage

nd

stage

rd

stage

Oil pressure min sensor

st

oil valve 1

stage at 2-stage operation

nd

stage at 2-stage operation

V3 Optional ignition valve

M Actuator for control valve oil/modulated opera-

tion

Fig. 4-5 Fuel train - oil modulating - oil 2-stage

Connection of the fuel valves see chapter 7.2 Dual Fuel Module DFM300.

4.2.2 Optional Connections for the Flame Scanner

Electrical connections

Fig. 4-6 Connecting diagram ionisation electrode

28

Fig. 4-7 Connecting diagram photo resistance e.g. Siemens

QRB... or Honeywell MZ770

Page 30

4 Mounting and Functions

Fig. 4-8 Connecting diagram of the sensor Honeywell IRD1020

Colour code BK = black; BN = brown; BU = blue

Fig. 4-10 Connecting diagram F300K via power pack FN20 (also valid for F200K)

Fig. 4-9 Connecting diagram of sensor Honeywell IRD1010,

KLC10, KLC20, KLC1000 or KLC2002

Fig. 4-11 Connecting diagram F152 with FFS07/FFS08

29

Page 31

4 Mounting and Functions

Dimensional Drawings

Fig. 4-12 Dimensional drawing F200K

Fig. 4-14 Dimensional drawing KLC1000/KLC2002 top view

1 Radial opening (with KLC1000 only)

Fig. 4-13 Dimensional drawing F300K

Fig. 4-15 Dimensional drawing KLC1000/KLC2002 side view

30

Page 32

4 Mounting and Functions

4.2.3 LSB Module Integration

1

EBM100 may be

used as an alternative field bus module

instead of PBM100

2

Alternative CO/O2

measurement

3

LEM100 can be used

as an alternative to

LCM100 to connect

LSB to BT100

4

CO/O2 measurement

Fig. 4-16 Connecting diagram LSB module at BT300

31

Page 33

4 Mounting and Functions

NOTICE

Connecting LSB modules to BT300 requires an LCM100 or LEM100 with an external power

supply 24 V SELV.

Connect VSM, DFM and LT3-F as needed on the LSB module.

Only connect H and L of the LCM’s LSB to the LT3-F.

NOTICE

Consider while wiring the LAMTEC SYSTEM BUS (LSB) following notes:

Activate the 120 terminating resistor at first and last device on LSB.

Set dip switch of BT300 module on position 1 (see chapter 7 Options.

When using LT3, pay attention to the device-related manuals.

We recommend for cable length and conductor cross-section with LSB:

Length [m] Cross-section [mm2] Type

0 - 40 m 2x2x0,34 twisted pairs with shielding, impedance 120

40 - 300 m 2x2x0,50 twisted pairs with shielding, impedance 120

300 - 500 m 2x2x0,60 twisted pairs with shielding, impedance 120

Devices on LAMTEC SYSTEM BUS (LSB) must be connected in serial/row (see Fig. 4-17 Se-

rial BUS connection). The first and the last participant on LSB must be terminated with a termination resistor of 120 . All the other BUS participants are not allowed to be connected to

any termination resistor at all. A star wiring is not permitted (see Fig. 4-18 Star BUS connec-

tion).

For activation of the termination resistor, see also technical document LAMTEC SYSTEM

BUS (DLT6095).

Correct: Serial Wiring (in a row)

Fig. 4-17 Serial BUS connection

Incorrect: Star Wiring

Fig. 4-18 Star BUS connection

32

Page 34

4 Mounting and Functions

4.3 Flame Monitoring

4.3.1 Integral Flame Monitoring (Option)

The integral flame monitoring system is designed for standard applications (such as oil and

gas flames in a burner located in a combustion chamber).

The flame monitor has the following tasks in combustion plants:

• Measuring the burner flame, regardless of conditions in the combustion chamber (e.g.

glowing lining)

• Triggering control command internally to shut off fuel feed via burner control unit because

of a flame blow-off.

The following types of flame sensor for intermittent operation (burner switched off at least once

every 24 hours) are valid for use.

Manufacturer Type Settings P 800 Approval

LAMTEC F152 with FFS07 o. FFS08 UV (up to v3.1)

contact (from v3.3)

F200K with FN20 UV (up to v3.1)

contact (from v3.3)

F300K with FN20 UV (up to v3.1)

contact (from v3.3)

Honeywell IRD1010 LDR Intermittent

IRD1020 ION Intermittent

MZ770 LDR Intermittent

SIEMENS QRB1... LDR Intermittent

QRB3... LDR Intermittent

QRA2... UV Intermittent

QRA10... UV Intermittent

QRA4... UV Intermittent

Ionisationselektrode ION Continuous

BST Solutions/

LAMTEC

Continuous = continuous operation

Intermittent = intermittent operation

KLC1000/KLC10 LDR Intermittent

KLC2002/KLC20 LDR Intermittent

Continuous

Continuous

Continuous

NOTICE

For continuous operation, connect following types of flame sensors to BurnerTronic BT330

and BT340:

Flame scanners with ionisation electrode

Flame monitor for continuous operation with potential-free contact e.g. F200K.

The fastening system must be designed in a way that unintentional detachment of the

flame monitor is prevented.

BT320 is despite using these flame sensors approved for intermittent operation only.

33

Page 35

4 Mounting and Functions

WARNING!

Danger from fuel ingress to combustion chamber after loss of flame!

Improper use or configuration of flame sensors not approved for continuous operation can result in hazardous situations and possible cause of explosion leading to loss of life and property. Failure to detect the loss of flame may result in an ingress of fuel into the combustion

chamber and subsequent explosive condition.

Make sure during setting of P300 to the approval of the scanner.

Only set P300 to the value 0 if the flame sensor and the BT300 is approved for continuous

operation.

NOTICE

The flame sensor QRA53 …, 55 …, 73 … and 75 are not authorized together with BT300 for

continuous operation. The test of the UV tube via shutter is not supported by BT300.

4.3.2 Flame Sensors

4.3.2.1 KLC 20/KLC 2002

Brief Description

The wide band flame detector KLC 20/KLC 2002 is a compact flame detector, which is special

designed for blue burning combustion systems. The patented flame signal evaluation is based

on the flicker frequencies of the flame. A RISC-Processor enables evaluation and conversion

of the flame signal into digital information to provide an output signal for burner control boxes.

All flames will be detected by an automatic sensitivity control. Adjustments during commissioning and maintenance are not necessary!

Per international standards, the KLC 20/KLC 2002 will only detect signals caused by the flame

flicker. Signals from continuous radiation and any kinds of constant frequency will be ignored.

Signals caused by disturbing light sources, such as fluorescent tubes or background radiation

from hot refractory will be cut off, so that unwanted influences are not possible.

By using LED-Display as an optical interface, the flame detector is able to read different relevant operating parameters (e.g. monitoring of flame signals, serial number).

Safety Instructions

The KLC 20/KLC 2002 is a safety device. Do not open, modify, or misuse it! Replace the flame

detector in case of any damage, if dropped, exposure to shock, moisture, excessive temperature, or conditions that can destroy the flame detector, even though damage is not obvious.

Repair is strictly prohibited!

Before working on the flame detector, switch off the power supply. Before first commissioning

or replacement of the device, check external wiring!

Mounting Instructions

The KLC 20/KLC 2002 should be mounted close to the flame with straight alignment using the

Mounting Flange KLC or another suitable holder with Ø0.551 inch (14 mm) opening. Mount

the detector with a holder. The best flame signal will be achieved from strong flickering parts

of the flame radiation. The angle of view, especially with sight tubes, must be of appropriate

dimensions to avoid any reduction of flame radiation. Protect the sensor from other light sources.

34

Page 36

4 Mounting and Functions

NOTICE

To avoid any disturbance, do not align the detector direct to the ignition spark. Breakdowns

during pre-purge procedure may occur.

The maximum length of the connection must be in accordance with the technical data. Install

the detector connection cable with most possible distance to the ignition cable or the mains

cable. Avoid to lay the connecting cable in parallel to these cables.

CAUTION!

Due to safety and technical regulations, a control shut down must be done at least once

every 24 hours.

Operating Indicator LED

Via the built-in LED the flame detector KLC 20/KLC 2002 is indicating the following operating

conditions:

LED is OFF KLC is not active.

LED is blinking KLC is active, safety test finished, no flame detected

LED is ON KLC is active, safety test finished, flame detected

Mounting Flange KLC

The Mounting Flange KLC provides attachment and adjustment of the flame detector.

The Mounting Flange KLC can be simply

sealed to the burner housing using an o-ring.

Height = 0.3 in (7 mm).

Viewing Angel Adapter KLC

for radial adjustment

Radial adjustment of the KLC2002 to the

flame axis is possible with the optional viewing angle adapter, which can replace the

Mounting Flange KLC. An optionally available

angle adapter provides the radial adjustment

to the flame axis of KLC2002 by an optimally

shaped reflector surface. A special flame

scanner type is not necessary. During handling, avoid touching the reflector surface

and, if necessary, clean with a dry, soft and

lint-free cloth.

Maintenance

To maintain the detector, just keep the sight glass clean by using a dry cloth. Do not use any

kind of cleaning sprays or liquids. The flame scanner may only be touched at the lateral, corrugated regions when inserting or withdrawing it from the mounting flange.

Due to internal checks of the KLC 20/KLC 2002 no more tests are necessary. The flame scanner’s make circuit/break circuit can be checked easily by holding the flame scanner to an AC

operating light source (no torch or similar).

35

Page 37

4 Mounting and Functions

KLC 20/KLC 2002 switches the flame relay ON – the red LED is permanently ON. After 9 sec.

the switching output is disconnected – the red LED flashes.

NOTICE

Due to the safety function of the disturbance frequency cut-off, a flame simulation is not possible by means of a simple art source of light. If a flame simulation, such as during the final

inspection of the burner without a real flame is needed, a source of light with a modulating frequency between 60 and 150 cycles per second.

Disposal Information

The flame detector is equipped with electrical and electronic components and must be disposed separate from household waste. Follow the local and actual regulations for waste disposal.

4.3.2.2 KLC 10/KLC 1000

Brief Description

The KLC 10/KLC 1000 is a compact UV flame detector, which has been developed for single

flame combustion which produces little light or radiation in the visible spectrum and has very

low flame modulation/flicker frequency. The design of the UV sensor ensures that the flame

detector does not react to background radiation from hot refractory or from any other infra-red

light source.

Flame intensity can be easily recognised by an optical LED display.

The flame detector KLC 10/KLC 1000 has been developed to meet the requirements of Euro-

pean Standards EN230 and EN298 for burner management control units which make a ‘noflame’ check after normal burner shut down when the flame amplifier is permanently energised.

Safety Instruction

The KLC 10/KLC 1000 is a safety component, and repair or adjustment must never be attempted. Replacement of the flame detector is recommended in all cases of damage, due to

impact shock, excessive moisture, or other problems rendering it inoperable. Repair work

must never be attempted and is strictly forbidden by the relevant European Standards.

WARNING!

Prior to commissioning the unit; carefully check that the wiring connections have been made

correctly. Also, before removing or checking the flame detector make sure the power supply

is switched off.

Mounting Instructions

The KLC 10/KLC 1000 should be mounted as close as practical to the flame and on the same

axis. The flame detector is compact and should be mounted with the KLC mounting flange or

other suitable holder having a 14mm Ø opening. Fix the detector in the holder taking care to

protect the sensor from other light sources.

To avoid any problems at start-up; please avoid alignment of the KLC detector with the ignition

spark electrode as the flame detector may react with the ignition spark and cause burner shutdown during the air pre-purge/ignition start-up sequence. The maximum length of the connection cable must be in accordance with the technical data. Please ensure that the flame detector connection cable is kept well apart and is completely separated from high-energy igniterand power cables to avoid electrical interference problems.

36

Page 38

4 Mounting and Functions

CAUTION!

For safety reasons and within the technical regulations, a controlled burner shut-down

of the burner must occur and be guaranteed to happen at least once in every 24 hours

of operation.

Operating Indicator LED

The flame detector KLC 10/KLC 1000 indicates the following operating conditions and flame

signal strengths via the built-in LED.

LED is OFF KLC is not switched on – no power supply or ‘no flame’ is detected

LED is FLASH-

ING

LED is ON KLC has detected the strongest level of flame signal.

KLC has detected a flame; the quality of the flame signal is indicated by

the intensity of the flashing of the LED – fast flashing indicates a healthy

flame signal and vice versa - slow flashing indicates a weak flame signal.

Mounting Flange KLC

The mounting flange allows the detector to be

held and adjusted in a suitable position to

view the flame. An O-ring seal is available

which will give the mounting flange an air tight

seal to the burner housing if required.

Height = 7 mm.

Maintenance

The installation and commissioning must be done by qualified personnel only. Before energizing the KLC flame detector, check the cable and wiring connections if they are in accordance

to the diagram of the burner manufacturer. For good maintenance which will ensure trouble

free operation of the KLC flame detector; keep the sight glass clean by wiping with a soft dry

clean cloth. During commissioning and after any cleaning maintenance, the flame detector

should be checked, as the UV tube is subject to a natural ageing process and towards the end

of its life span (ca. >10.000 h at an ambient temperature of <50 °C) it is prone to malfunction.

To check that the flame detector is sound, we recommend the following procedures be followed:-:

• When starting the burner sequencer, the flame scanner must be shaded - after ending of

the safety time the burner sequencer must run to fault condition!

• When starting the burner sequencer, the flame scanner must be lighted up by an external

UV radiation e.g. pocket lighter or gas flame (ambient light/room illumination is not sufficient) – the burner sequencer must run to fault condition during pre-purge period!

• In BURNER OPERATION the flame scanner must be shaded – depending on the burner

sequencer’s type, the burner sequencer must run to fault condition either after restarting

at the end of the safety time or directly after shading the flame scanner.

Disposal Instructions

The flame detector is equipped with electrical and electronic components and must be disposed separately from household waste. Follow the local authority regulations for electrical

component waste disposal.

37

Page 39

4 Mounting and Functions

4.4 Process Sequence Charts

Key to process sequence charts

Any condition

t1 Waiting for safety interlock chain gas, scan of air pressure monitor min. any

t2 Time for pressure build-up in the gas test line (available with activated leakage test) 2,4 s

t3 Actuator running time 30 s - 60 s

t4 Delay of the recirculation damper 0 - t5

t5 Pre-purge period adjustable

t6 Pre-ignition time adjustable

st

t7 1

t8 Stabilisation period adjustable

t9’ 2

t10 Operating phase any

t11 Control mode any

t12 Time for pressure relief in the gas test line 3 s

t13 Post-purge period adjustable

t14 Control elements at base load/firing rate

t15 After burning time adjustable

t16 Checking flame extinction 5 s

t17 Leakage test, gas valve 2 30 s

** Recirculation is released as soon as the flue gas threshold P322 is reached and the

CPI Close Position Indicator (UK/AU)

POC Prove Of Closure (US)

safety period 3 s gas/5 s oil

nd

safety period 3 s gas/5 s oil

delay time in P331 has expired after reaching operation position (base firing-rate/

control).

Limit switch on gas valve 2 which indicates that gas valve 2 is closed.

Limit switch on gas valve 2 which indicates that gas valve 2 is closed.

38

Page 40

4 Mounting and Functions

Fig. 4-19 Oil with pilot burner BT300

39

Page 41

4 Mounting and Functions

Fig. 4-20 Oil without pilot burner BT300

40

Page 42

4 Mounting and Functions

Fig. 4-21 Gas with pilot burner and leakage test BT300

41

Page 43

4 Mounting and Functions

Fig. 4-22 Gas without pilot burner and leakage test BT300

42

Page 44

4 Mounting and Functions

Fig. 4-23 Leakage test BT300

4.5 Leakage Test for Main Gas Valves

4.5.1 Calculation Example

With BT300 the gas pressure monitor is also applicable to the monitoring of minimal gas pressure. Therefore the minimal gas pressure of the burner must be set.

The valve leakage test time t3 (P 311) would be set by BT300. The time t2 for BT300 is fixed

to 2s. The time t3 (P 311) must be set in a way that the maximum allowable leakage rate Q

can be securely detected. The maximum leakage rate stated in EN1643 and ISO23551-4 is

0.1% of the nominal volumetric flow of the gases or a minimum of 50l/h.

43

Leck

Page 45

4 Mounting and Functions

Example 1

Burner capacity =1000 KW

Fuel = natural gas H, calorific value = 10 kW/m

Nominal volumetric flow of the gases = 100 m3/h

Leakage rate max. = 0,1 m3/h or 100l/h

Example 2

Burner capacity =1000 KW

Fuel = propane, calorific value = 25,9 kW/m

Nominal volumetric flow of propane = 38,6 m3/h

Leakage rate max. = 50 l/h (not 38,6 l/h)

Calculation

3

3

Fig. 4-24 Principle scheme

The test volume V

must be calculated with tube diameter and valve volume. The value vol-

test

umes are provided by the valve manufacturer. If valve 1 and valve 2 are be used as a double

valve, the test volume would be provided by the valve manufacturer.

The leakage test V

is calculated according to the Boyle-Mariotte principle.

Leak

p1 V1 = p2 V2

p = absolute pressure

V = gas volume

This is valid for the test of valve 1 V1:

Should t3 be negative, at least 1s must be set.

If the calculation of t3 for valve 2 is higher than t3 for valve 1, the value for the calculation of

valve 2 must be adjusted.

44

Page 46

4 Mounting and Functions

Q

leak

p

sw

Leakage rate in l/h

Absolute pressure on the switching point of pressure monitor (adjusted over-

pressure + atmosphere pressure)

p

p

p

V

sw e

out e

Atm

test

Adjusted overpressure on switching point of pressure monitor

Output pressure on gas valve V2 during purge

Atmospheric pressure (average of 101,3 kPa at sea level)

Test volume between the valves

t2 Settling time is always 2 s

t3 Adjusted leakage check time

NOTICE

p

must always be higher than p

Schalt

out.

Otherwise V1 would be recognised as leaking even if it is not.

This is valid for the test of valve 2 V2:

If t3 is negative, at least 1 s must be set.

If the calculated t3 value of valve 1 is higher than t3 for valve 2, the calculated value of valve

1 must be adjusted.

Q

leak

p

sw

Leakage rate in l/h

Absolute pressure on switching point of pressure monitor (adjusted overpres-

sure + atmosphere pressure)

p

p

p

p

V

sw e

in

in e

Atm

test

Adjusted overpressure on the switching point of pressure monitor

Absolute input pressure on gas valve V1

Overpressure at gas valve V1 input

Atmosphere pressure (average of 101,3 kPa at sea level)

Test volume between the valves

t2 Settling time is always 2 s

t3 Adjusted leakage check time

45

Page 47

4 Mounting and Functions

4.5.2 Leakage Test Process Flow

The valve leakage test checks if the main gas valves are sealed. For this purpose the gas

pressure of the supply is analysed.

As valve leakage test section (space between the two main valves) burns empty whenever

the burner is switched off, this part is usually pressureless at start-up (gas pressure > min =

0). This is checked by BT300. At this point, main gas 1 opens briefly and gas flows into test

section (gas pressure > min switches from 0 to 1). While main gas 1 valve is open gas pressure must apply.Otherwise BT300. detects gas deficiency. Gas pressure must remain at least

constant during valve leakage test period (2 s + P 311). The valve leakage test is considered

complete then.

If leakage test section is not empty at start-up (e.g. resulting from a previous fault shut down),

main gas valve 2 opens first. The leakage test line is then purged (depending on the plant,

either in the combustion chamber or through the roof – for wiring proposition, see chapter

4.5.4 Valve Leakage Test Venting Over the Roof). During leakage test period section is

checked whether it remains pressureless or not. Apart from that the process is the same as

described above.

The leakage test takes place prior to ignition.

The pressure monitor for the leakage test line must be connected to the ’Gas pressure > min’

input on plug X05. It also monitors the minimum pressure during operation. If a different minimum pressure should be monitored during operation, the pressure monitor must be inserted

into the safety interlock chain gas or into the controller loop (burner ON).

46

Page 48