Page 1

WaterLink

El futuro del análisis del agua

L’avenir de l’analyse de l’eau

nSp

Touch

The Future of Water Testing

®

Compatible with Android® and iOS® devices

Compatible con dispositivos Android® y iOS

Compatible avec les appareils Android® et iOS

For Code/ Para el código / Pour les codes 3580/3581/3582

®

®

Page 2

2

Page 3

SETUP

BEFORE FIRST USE

¬ Fully charge battery using the Spin Touch USB cable and adapter plug in AC

outlet.

¬ Ensure your Spin Touch has the latest fi rmware:

1. Download and install the WaterLink

http://softwarecenter.lamotte.com/.

2. Plug meter into the computer with the provided USB cable and launch

WaterLink

®

Connect application from the Start Menu.

3. Any fi rmware updates will automatically be applied to the meter.

METER

1. The meter can be powered from an AC outlet, a computer or the internal battery.

2. Use the USB cable and the adapter to plug the meter into an AC outlet.

3. Use the USB cable to connect the meter to the USB port of a computer.

CHARGE THE BATTERY

1. Use the USB cable and the adapter to plug the meter into an AC outlet or use the

USB cable (included) with a car charger (not included) to charge the battery. (Anker

PowerDrive 2, DC 12/24V, 5V = 4.8A, Part Number A2310 recommended.)

2. The battery icon on the screen will show the battery status. Charge the battery until

the battery indicator is full.

FIRMWARE UPDATES

Occasionally, the fi rmware in the Spin Touch will require updates. To do so:

1. Visit

2. Plug the Spin Touch into the computer using the included USB cable.

3. Open the WaterLink

Once the update is complete, it is safe to close WaterLink

After updating fi rmware it is recommended that the Alignment Procedure on page 15 be

performed.

http://softwarecenter.lamotte.com/ and download the WaterLink® Connect

application for Windows.

®

Connect desktop application and wait for the update to

complete.

®

Connect application for Windows® at

®

Connect and unplug the lab.

SETUP PC CONNECTION DEVICE CONNECTION

PC CONNECTION

When the WaterLink® Spin Touch® is connected to a computer via USB, the onboard

touchscreen becomes disabled and operation of the lab is performed using the WaterLink

Connect application for Windows

softwarecenter.lamotte.com/

from the Spin Touch can be transferred to a water analysis program such as WaterLink

Solutions

™

.

®

. This application is available for free at http://

. Via the WaterLink® Connect desktop application, results

®

DEVICE CONNECTION

The WaterLink® Spin Touch® supports connections to a Windows® based PC (over USB) and

to Android and iOS mobile devices (via Bluetooth).

3

®

Page 4

CONNECTING VIA USB

Using the provided USB cable, the WaterLink® Spin Touch® can be connected to a Windows®

based PC. Before connecting a meter via USB, download and install the free WaterLink

Connect Windows

WaterLink

will be disabled and operation of the meter is performed using the WaterLink

application. LaMotte off ers robust water analysis programs as well, such as WaterLink

Solutions

™

more about LaMotte software products at

®

®

application from http://softwarecenter.lamotte.com. When the

Spin Touch® is connected to the PC via USB, the onboard touch screen controls

®

Connect

, to collect test results and off er detailed treatment recommendations. Learn

http://softwarecenter.lamotte.com.

DEVICE CONNECTION

CONNECTING VIA BLUETOOTH

The WaterLink® Spin Touch® is capable of connecting to a Bluetooth enabled device, such

as a phone or tablet. The Spin Touch is also compatible with a LaMotte Bluetooth Printer

[Code 5-0066]. Other Bluetooth printers are not supported.

Transferring results over Bluetooth to a mobile device requires that a mobile app is

installed on the device and an active account for the associated software program. For

example, with an active WaterLink

mobile app on a phone or tablet, results can be transferred from the meter into the

application. Mobile apps for LaMotte software products are available from iTunes (for

iOS devices) and Google Play (for Android devices). Learn more about LaMotte software

products at

http://softwarecenter.lamotte.com.

To transfer results from the WaterLink

app:

1. Log into the LaMotte software product mobile app.

2. Search for a customer or Site record. You may need to create one before you can

begin testing.

3. Start a Water Test in the mobile app.

4. Perform a water test from the Spin Touch onboard touchscreen normally. The Spin

Touch and the Bluetooth enabled mobile device will connect automatically.

5. When the connection is available the

dim, the meter and device are not connected. Tap the

mobile app.

Whenever the

appears on the touch screen the Spin Touch is capable of connecting

to the Mobile Bluetooth Printer (Code 5-0066). The

connected and dim when not connected.

The Spin Touch cannot connect to both mobile device and the printer at one time. (See the

Save, Print and Send, page 9)

®

Solutions™ account and the WaterLink® Solutions™

®

Spin Touch® to a LaMotte software product mobile

will light on the touch screen. When the is

to transfer results to the

button will be highlighted when

®

®

USING BLUETOOTH LOW ENERGY

The WaterLink® Spin Touch® will automatically connect to the nearest Bluetooth enabled

phone or tablet or printer. It is not necessary to pair the Spin Touch to the Bluetooth

enabled device. Barriers to wireless signals can reduce the range of wireless devices.

The WaterLink Spin Touch will work best if there are no walls between it and the receiving

devices.

4

Page 5

FILLING: Single-Use Disks

When the syringe is placed in the water sample, and the plunger is

pulled all the way up, the syringe will hold more than enough water

sample to adequately fi ll the disk. Hold the syringe vertically and

insert the tip into the fi ll hole in the disk. Press the plunger slowly and

smoothly to fi ll the disk.

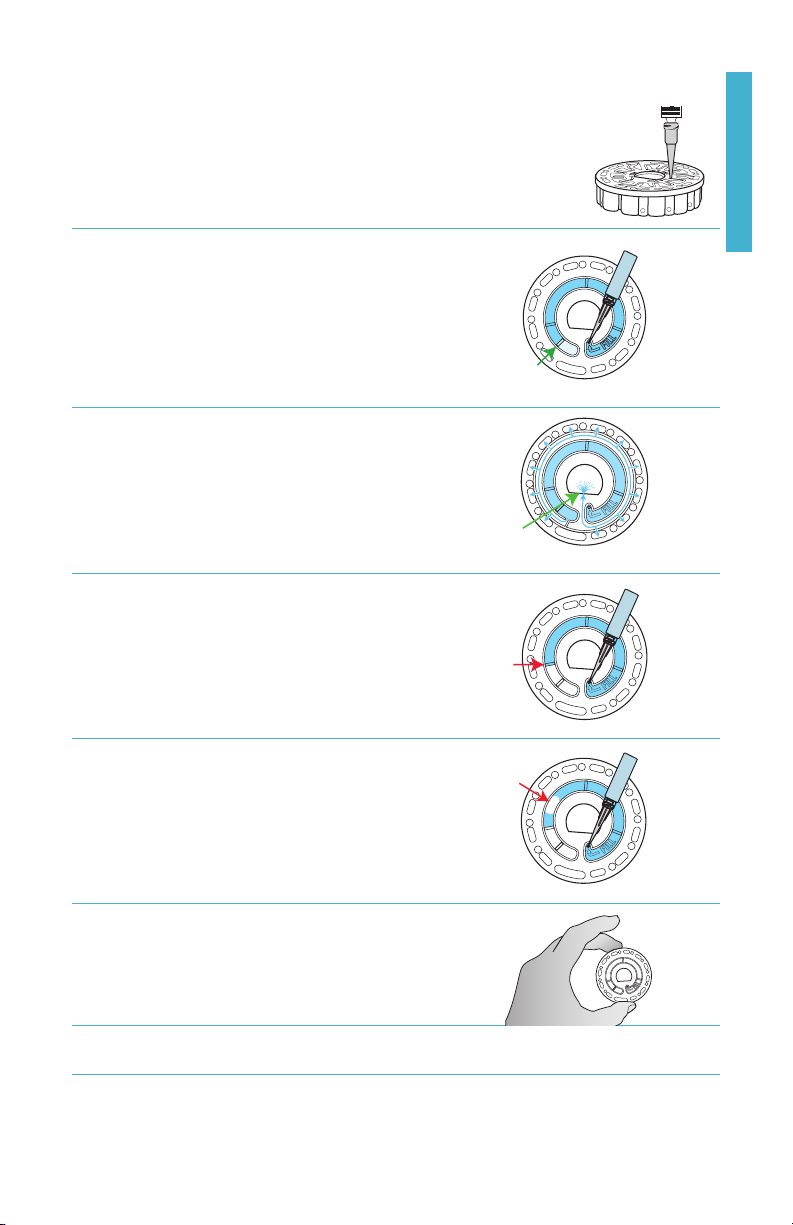

1. Fill the disk using slow, even pressure. The

sample water will fi ll the spaces between

the baffl es in a counterclockwise order.

Each space will fi ll from the bottom to the

top. Sample water should be added until the

sample water in the fourth chamber fi lls to the

top of the chamber slightly past the embossed

fi ll line. It is OK to fi ll slightly past the fi ll line.

Correct Fill

(Fill line)

2. Do not overfi ll the disk. If the disk is overfi lled,

sample water will fl ow out of the overfl ow

hole in the center of the disk. The disk is not

leaking. Dry the disk and run the test.

Over

Filled

(Dry disk before placing in meter)

3. Do not under fi ll the disk. If the disk is under

fi lled, the reagent chambers will not fi ll entirely

and results will be inaccurate.

Under

Filled

FILLING

4. Do not introduce air bubbles into the disk.

The reagent chambers will not fi ll entirely

Air

Bubble

and results will be inaccurate. As soon as a

bubble starts to form, pull back on the plunger

to draw the bubble out of the disk. Begin the

fi lling process again.

5. Wet disks should be dried thoroughly with a

lint free wipe. The disk should be handled by

the edges.

6. Disks should be fi lled and used within 10 minutes. They cannot be fi lled ahead of

time.

For fi lling and troubleshooting tips go to:

www.lamotte.com/spin

5

Page 6

FILLING: Multiple-Use Disks

When the syringe is placed in the water sample, and the plunger is

pulled all the way up, the syringe will hold more than enough water

sample to adequately fi ll the disk. Hold the syringe vertically and

insert the tip into the fi ll hole in the disk. Press the plunger slowly and

FILLING

smoothly to fi ll the disk..

1. Fill any unused section of the disk using slow, even

pressure. Add the sample water until the Blank

Chamber is full and the Over Flow Chamber is partially

fi lled.

2. Do not overfi ll the disk. If the disk is overfi lled, sample

water will fl ow out of the vent hole in the center of the

disk. The disk is not leaking. Dry the disk and run the

test.

3. Do not under fi ll the disk. If the disk is under fi lled, the

blank chamber will not be full. The reagent chambers

will not fi ll entirely and results will be inaccurate.

Over Flow

Chamber

Blank

Chamber

Over Flow

Chamber

Blank

Chamber

Correct Fill

Over

Filled

(Dry disk before placing in meter)

Blank

Chamber

Under Filled

4. Do not introduce air bubbles into the disk. The reagent

chambers will not fi ll entirely and results will be

inaccurate. As soon as a bubble starts to form, pull

back on the plunger to draw the bubble out of the disk.

Begin the fi lling process again.

Air Bubble

5. Wet disks should be dried thoroughly with a lint free

wipe. Handle the disk by the edges. Between tests

store the disk on a fl at surface. Do not agitate a

partially fi lled disk to avoid leaking and contamination.

Partially used disks should be discarded at the end of

the day.

6. Disks should be fi lled and used within 10 minutes. They cannot be fi lled ahead of

time.

For fi lling and troubleshooting tips go to: www.lamotte.com/spin

6

Page 7

GENERAL OPERATING PROCEDURES

METER

When a fi lled disk is placed in the chamber and the lid is closed, the meter spins at high

speed to distribute the sample to the test wells. Next the meter slows to maximize the

pumping action of the stainless steel mixing beads as the reagents mix with the sample

water. Each reaction is then read at the proper time and wavelength for that reagent

system.

The button located in the lower center of the top of the meter turns the

instrument on and off .

The Blue indicator light of the on/off button indicates the status of the instrument.

Steady blue light – the blue LED will remain steady to indicate that the meter is on and

ready to run a test.

Blinking blue light (three blinks/second) – a test is in progress and the disk is spinning. Do

not open the lid when the disk is spinning.

Care should be taken when closing the lid. Do not slam the lid. Wiring between the lid and

the body of the photometer passes through the hinge. The meter will not run with the lid

open.

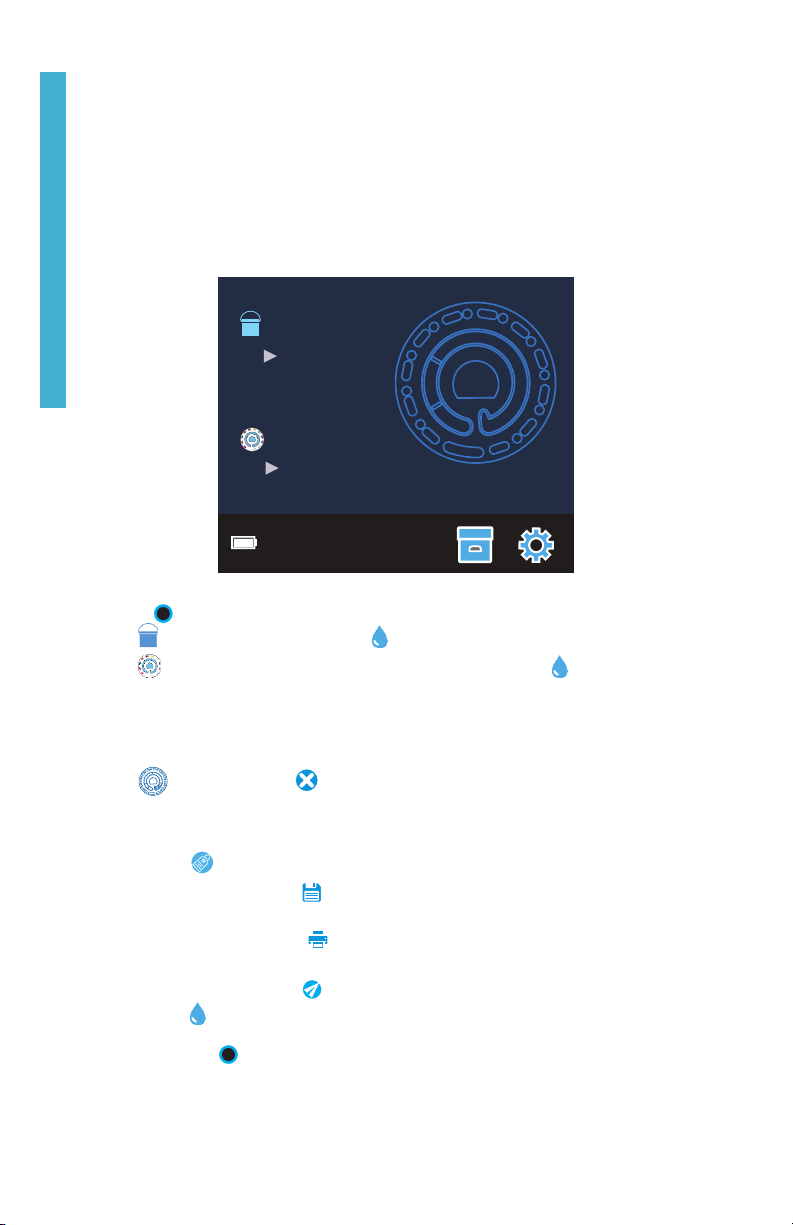

TOUCHSCREEN DISPLAY

When the button is pressed to turn the meter on, the Test Screen will be displayed.

GENERAL OPERATING PROCEDURES

Sanitizer

Selection

Start

Test

SaniƟzer

Disk

Type

Salt

Disk Series

Tap to

Start Test

203

Power/

Battery

Status

The display screen is touch-activated. To make a selection, tap the icon or word on the

screen with a fi ngertip, fi ngernail, pencil eraser, or stylus.

30-Oct-18

12:14 PM

Date &

Time

Test

Settings

History

7

Page 8

¬ Gently wipe smudges from the screen with the Cloth Wipe (3580-WIPE).

¬ Do not touch the screen with a sharp object.

¬ Do not place objects on the screen that will scratch or damage it.

¬ Avoid touching the screen with wet fi ngers.

TESTING

SaniƟzer

Salt

GENERAL OPERATING PROCEDURES

Tap to

Start Test

Disk Series

203

30-Oct-18

12:14 AM

1. Press and hold until the meter turns on.

2. Tap . Select a sanitizer type. Tap to confi rm.

3. Tap

4. Remove a disk from the packaging.

5. Use the syringe (1189) to fi ll the disk with the pool or spa water sample.

6. Insert the disk. Cover the disk with the Universal Disk Cover. Close the lid.

7. Tap

8. The results will be displayed.

9. Choose an option.

. Select a disk series (found on disk packaging). Tap to confi rm.

NOTE: Disk Series are limited by Sanitizer Type selection.

to start test. Tap to cancel the test.

¬ Tap

¬ Tap the highlighted

¬ Tap the hightlighted

¬ Tap the highlighted

¬ Tap

10. Press and hold

NOTE: For water samples over 100 °F (38 °C) subtract 0.3 from pH result or, for the most accurate

result, wait until water sample is below 90 °F (32 °C) to test.

to add a tag.

to save the test results to the test log if Auto Save is

not enabled.

to send the results to the enabled Mobile Bluetooth

Printer.

to send the results to a Bluetooth enabled device.

to return to the Test Screen.

for 2 seconds to turn the meter off .

8

Page 9

SAVE, PRINT, AND SEND TEST RESULTS

Test results can be saved, transferred to the WaterLink Connect mobile app via Bluetooth,

and sent to the Mobile Bluetooth Printer (Code 5-0066).

Test Results

Test Time 05:30:06 30-Oct-2018

FCL - 1.31

TCL - 1.31

CCL - 0.00

PH - 7.8

ALK - 100

HARD - 230

Save

Tagging

Results

CYA - 2

COPPER - 0.1

IRON - 0.1

PHOS - 0

SALT - 489

Print

Results

via

Bluetooth

Transfer

Results

via

Bluetooth

Return

to Test

Screen

Test History Settings

The WaterLink Spin Touch can log test results for 250 water samples in the Test History.

The results for the most recent sample will be located at the top of the list. All results can

be logged automatically or results for an individual sample can be logged after the sample

has been tested.

To turn on automatic logging, tap

and oto return to the test screen. When Auto Save is selected will not be

Tap

highlighted on the Test Results screen.

To manually log results for one sample at a time, Auto-Save Tests must be disabled. If

Auto-Save Tests is disabled

has been run, tap

to save the results for that water sample to the Test History.

A user defi ned identifi cation tag can be assigned to an individual sample result. The tag

can be up to 4 hexadecimal characters. It cannot begin with a zero. To tag a test result,

tap

on the bottom of the Test Results screen and use the buttons to enter up to four

characters. Tap

Results screen. Tap

to erase a character. Tap to save the tag and return to the Test

to return to the Test Results screen without saving the tag. The

tagged result will appear on the Test Results screen and the Test History screen. The tag

will be preceded by “T-“.

on the Test Screen. Tap . Select Auto-Save Tests.

will be highlighted on the Test Results screen. After the test

GENERAL OPERATING PROCEDURES

Test History

12:02A 30-Oct-2018 Salt 401

12:01A 30-Oct-2018 Salt 301

12:00A 30-Oct-2018 T-4650 Chlorine 100

12:00A 30-Oct-2018 Chlorine 300

11:57A 30-Oct-2018 T-ABC7 Chlorine 300

11:49A 30-Oct-2018 Biguanide 400

Select All/

De-Select All

View

Selected

Results

Delete

Selected

Results

History

Settings

Select

Auto Save

9

Home

Go to Top

Scroll up

or down

the test

list by 5

entries

Go to Bottom

Page 10

Logged results are viewed in Test History. Controls for viewing and managing single or

multiple test records are located on the Test History screen. Tap the checkbox next to a

test record to select it, then tap one of the buttons along the bottom to perform an action

with the selected records.

Print or Send Results to a Bluetooth Phone or Tablet

The WaterLink Spin Touch can print to the Mobile Bluetooth Printer or send test results to a

Bluetooth-enabled device such as a phone or a tablet. The highlighted

which function is active. The Spin Touch cannot connect to the printer and connect to a

phone or tablet at the same time.

There are two modes of operation for connecting to the printer and a phone or tablet – Fast

Printer Connect ON and Fast Printer Connect OFF. The default mode is Fast Printer Connect

ON. Fast Printer Connect can be turned on or off from the Bluetooth Menu that is located in

the Settings Menu.

If Fast Printer Connect is ON, the meter will connect immediately to the printer upon

GENERAL OPERATING PROCEDURES

recognizing it. It will also connect to a phone or tablet but priority is given to the printer

connection. The printer will start printing immediately when

in intensity while the printer is printing. Fast Printer Connect should be ON if results will

be printed more frequently than results will be sent to a phone or tablet. It can remain

selected if results will only be sent to a phone or tablet. If Fast Print Connect is ON, and the

printer is on, the printer will have to be turned off before results can be sent to a phone or

tablet.

If Fast Printer Connect is OFF, the meter has the opportunity to connect to a phone or

tablet at all times other than when the printer is actually printing a test. The meter will

connect to the printer only after

seconds while the connection to the printer is being established. The

intensity while the printer is printing. After printing, the meter will automatically reconnect

to the phone or tablet. Fast Printer Connect should be OFF if results will be sent to a phone

or tablet most frequently and printed less often.

has been tapped so printing will be delayed a few

is tapped. The will dim

or will show

will dim in

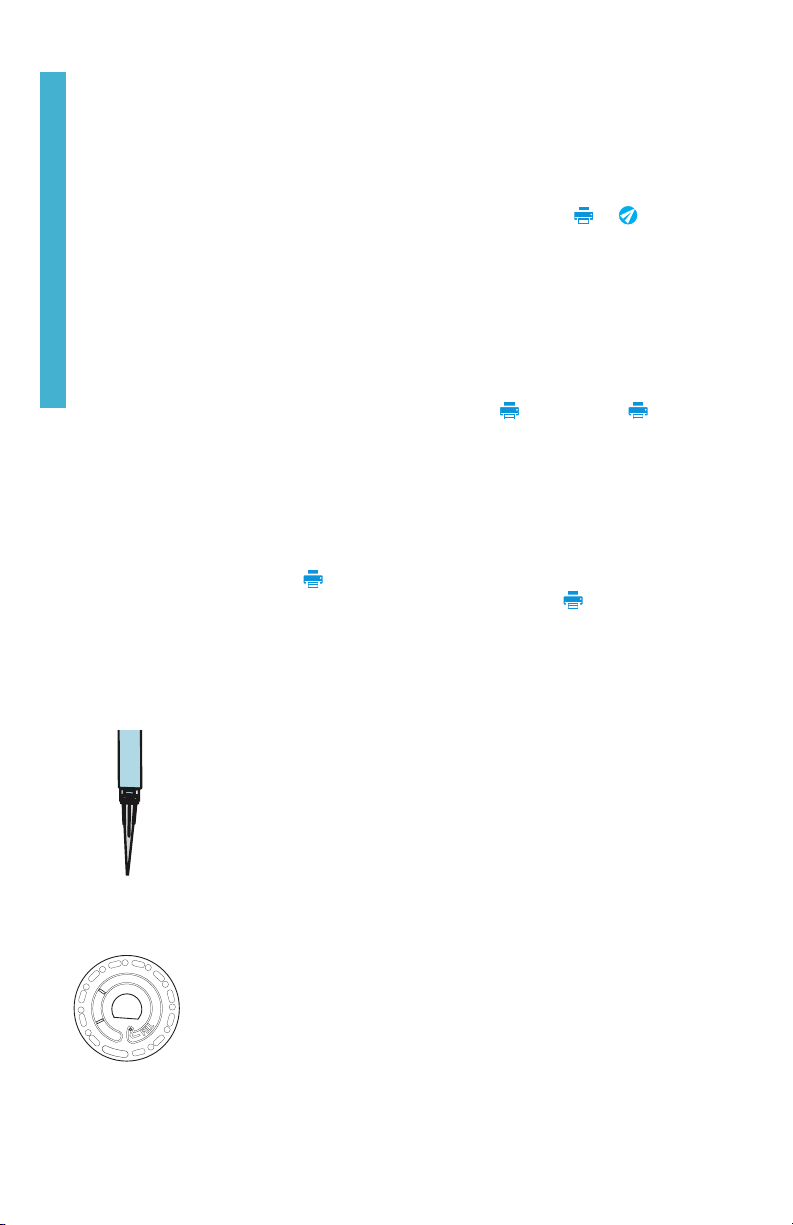

SYRINGE

REAGENT DISK

A plastic 3 mL syringe (Code 1189) is used to fi ll the disks. A precision

tip on the syringe fi ts into the fi ll hole on the disk. The syringe tip should

not be removed from the syringe. Syringes should be cleaned between

water samples. Pump air in and out of the syringe a few times to clear

the previous sample or rinse the syringe with a small amount of the

next water sample before fi lling it with the next sample.

The WaterLink® Spin Touch® uses a disk reagent system. The dried

reagents are packaged in single test amounts in a sealed, polystyrene

disk. Stainless steel mixing beads in the reaction chambers mix the

sample water and the dried reagents. Tests for all factors in the series

are performed at one time. It is not possible to isolate the well for a

single factor and perform a test for one test factor only. Single-use

disks contain reagents for a single series. Multiple-use disks contain

reagents for repetitions of a series. Disks should not be fi lled in the

meter chamber.

10

Page 11

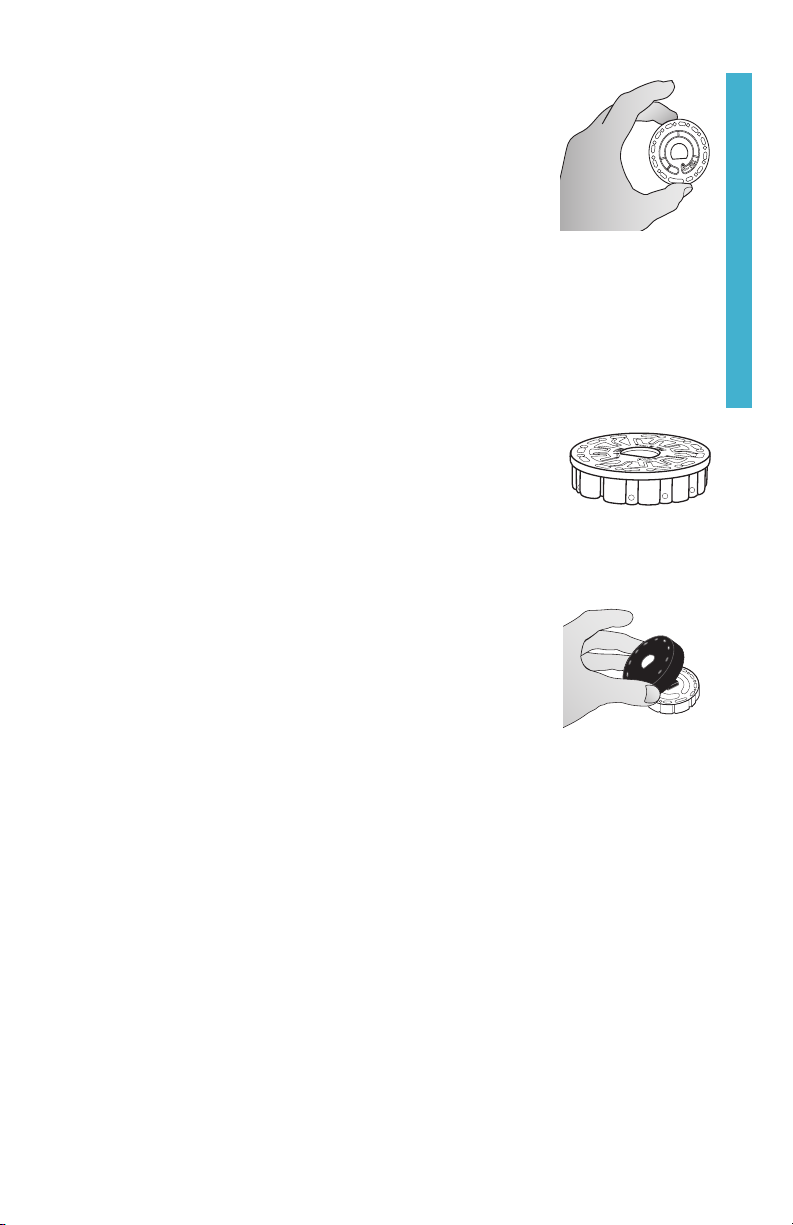

DISK HANDLING

The disk should be handled only by the edges. Avoid touching the

top or bottom of the disk. The light passes through the non-frosted

areas of the disk so these areas must be kept free of smudges and

fi ngerprints. Wet disks should never be placed in the meter. Wet

disks should be dried with a lint free cloth before placing them into

the chamber.

The disk is positioned in the chamber by aligning the D-shaped hole in the center of the

disk over the D-shaped hub in the photometer chamber. The disk should be placed gently

on the hub. There is no need to fi rmly press the disk down onto the hub.

DISK STORAGE

Disks are sensitive to moisture. Avoid opening more packs than are needed. Disks

have a limited shelf life and should not be exposed to the humidity in the air more than

necessary.

Between tests store multiple-use disks fl at. Do not agitate a

partially fi lled disk. It could leak or contaminate unused sections

of the disk. Multiple-use disks that are partially used should be

discarded at the end of the day. Do not transport the meter with a

disk in the chamber.

Store disks at 70-80 °F/21-27 °C. Disks with Salt reagent should be

stored and used at room temperature (68-74 °F/20-23 °C).

DISK COVER

The black disk cover is placed over the disk in the photometer

chamber to reduce interference from stray light. The disk cover is

positioned over the disk by aligning the D-shaped hole in the center

of the disk over the D-shaped hub in the photometer chamber. The

disk cover should be placed gently on the hub. There is no need

to fi rmly press the disk cover down onto the hub. The test will be

aborted if the disk cover is not used.

Only the Universal Disk Cover (Code 1719) that is included with the

WaterLink

®

Spin Touch® can be used with the multi-use disks.

GENERAL OPERATING PROCEDURES

METER CHECK DISK

The Meter Check Disk serves two purposes:

¬ When the Meter Check Disk (MCD) is run as an option from the Disk Series menu, the

values on the display are compared to the values on the chart on the Meter Check

Disk package to determine whether the meter is reporting results in the expected

ranges.

¬ If the Meter Check Disk is inserted in the meter and Rotary Calibration is chosen from

the Settings Menu, the alignment of the hub and disk is evaluated. The results are

analyzed and reported as Pass or Fail.

For use of the Meter Check Disk see page 14.

11

Page 12

USB CABLE

A USB cable connects the Waterlink® Spin Touch® to a Windows®-based PC. When used with

the AC Power Adapter, it connects the meter to an AC outlet.

WARNING: only use the USB cable and wall adapter that are supplied with the kit. Make no

substitutions.

BATTERY

A fully charged battery will last for approximately 150 tests under average conditions. The

battery life will vary based on usage patterns. The meter should be turned off after testing

to prolong the battery life. The standard life cycle of a lithium ion battery is 500 cycles.

The battery will fully charge in approximately 10-12 hours. The battery is designed to be

charged overnight and should be charged indoors only. The battery is rated at 12 V and 8.1

AH capacity. Power the meter from the battery pack or from AC power. The USB cable and

AC adapter are used to plug the meter into an AC outlet. WARNING: only use the AC adapter

GENERAL OPERATING PROCEDURES

supplied with this equipment. Do not substitute.

The battery charge status is indicated by the battery icon on the display. The

battery icon will indicate when the battery charge is full, partial, low, empty or

charging. The empty battery icon will fl ash to indicate that meter should be

connected to AC power source. If the meter continues to be used at low battery

power without connecting it an AC power source, the meter will go into an autoshutdown mode. In this mode the meter will be locked until meter is connected

to an AC source and the battery is charged to a suffi cient voltage.

While charging, the charging battery icon will be displayed. The meter should

remain plugged in until the battery is fully charged. When the battery is

completely charged, the charging icon will change to the full battery icon.

SETTINGS

Tap to enter the SETTINGS menu. Tap to return to the test screen at any time.

Brightness

Date/Time

Set Language

Calibration

Power

Options

Bluetooth

The brightness level of the display can be adjusted from 00 to 10. Tap and

to adjust the brightness. Tap to exit to the Settings menu.

The Year, Month, Day, Format, Hour, Minute, AM/PM can be set. Tap or

to adjust the displayed value. Tap to move to the next value. After the

last value has been chosen (minutes for 24 hour format, AM/PM for 12 hour

format) tap to return to the Settings menu. Tap to exit to the Settings

menu at any time.

There are ten language options – English, French, Italian, Portuguese,

Spanish, Chinese, German, Dutch, Swedish, Turkish. Tap selection. Tap to

exit to the Settings menu.

Tap to run an angle calibration to evaluate the alignment of the hub and disk.

Tap to exit to the Settings menu.

There are three power options: Auto Dim Time, Auto Off Time, and Power. Tap

the options then tap a selection. Tap selection. Tap to exit to the Settings

menu.

There are two Bluetooth options: Bluetooth Enabled and Fast Printer Connect

that are used to transfer and print test results. Tap to exit to the Settings

menu.

12

Page 13

Market Type

Other Settings

Tap to select the market type. Select Pool/Spa. Tap to exit to the Settings

menu.

About…lists the Serial Number, Firmware Version, Bluetooth MAC address,

Bluetooth Version and Test Count. The Test Count shows the number of

complete tests that have been performed over the lifetime of the meter. Tap

to return to the Settings menu.

Ranges Enabled allows the option of having test results that are out of range

of the reagent system displayed in red. The default setting is off .

When Show Market Type is selected, the market type will be displayed on the

Testing Screen. The default setting is OFF. Tap to return to the Settings

menu.

Select Disk Detection to display an error message and abort the test when

improper testing conditions, such as No Disk, No Disk Cover, Used Disk or

Meter Check Disk, are present that would result in inaccurate or no test

results. The default setting is OFF. Tap to return to the Settings menu.

TROUBLESHOOTING

TROUBLESHOOTING GUIDE

Problem Reason Solution

“No Disk, Test Aborted” No disk in chamber

Empty chamber

“No Disk Cover, Test

Aborted”

Disk cover was not used Use disk cover. Select OK. Start test.

Place fi lled disk in chamber. Cover

with disk cover. Select OK. Start test.

Insert fi lled disk. Cover with disk

cover. Select OK. Start test.

GENERAL OPERATING PROCEDURES

“Lid Open, Test Aborted” Lid opened Close lid. Select OK. Start test.

“Used Disk” Reacted disk in chamber Select “Continue” to go to Test

Meter Check Disk Meter Check Disk in chamber

“Source” appears on

test screen instead of

“Sanitizer”

!

on Test History

screen

Range Error Raw data out of range Contact Support

Output Error Decreased light intensity.

instead of reagent disk

Wrong Market Type was chosen Go to Settings. Change Market Type

Meter is using the default blank

due to under fi lled disk or air

bubble.

Possibly dirty lens

Results screen. Select “Abort” to go

to Testing screen and run test with

new disk.

Select “Continue” to go to Test

Results screen. Select “Abort” to go

to Testing screen and run test with

reagent disk.

to Pool/Spa

Solution: Fill disk correctly (see

FILLING)

Clean lens (see CLEANING). Follow

Range Check Procedure. If error

message persists, contact Support.

13

Page 14

High pH results Water sample temperature

MC

Salt results not as

expected

Disk not spinning Lid open, meter not powered

above 100 °F (38 °C) interferes

with pH reagent

Water sample not between

68-74 °F (20-23 °C). Sample

disk temperatures above or

below this will also cause

artifi cially low or high readings

respectively.

on, low battery, disk or disk

cover pressed down too tightly

on hub

GENERAL OPERATING PROCEDURES

Fast electrical transients may

disrupt operation of the Spin

Touch meter

Trouble connecting to

Bluetooth device

Trouble connecting to

computer by USB

Results not printing Printer not on

Bluetooth not enabled

Too many Bluetooth devices

near the meter

Printer power is ON and Fast

Printer Connection is ON

Broken connection Press and hold power button for 1

The Spin Touch will only print

to the Mobile Bluetooth Printer

(Code 5-0066)

For water samples over 100 °F

(38 °C) subtract 0.3 from pH result

or, for the most accurate result, wait

until water sample is below 90 °F

(32 °C) to test

Run salt test with sample water and

disk between 68-74 °F (20-23 °C).

Close lid, power on meter, charge the

battery or plug meter into a stable

power source, remove the disk/disk

cover and place back in the chamber

more gently

Restart the test to resume normal

operation

Enable Bluetooth

Have only one device near the meter

Turn printer power OFF. Or turn Past

Printer Connection OFF.

second.

Turn printer on

Connect to Mobile Bluetooth Printer

(Code 5-0066)

TROUBLESHOOTING WITH THE METER CHECK DISK

Do not attempt to separate the components of the Meter Check Disk (Code 1705). The

Meter Check Disk consists of a disk with a permanently attached cover.

Do not fi ll the Meter Check Disk with water. Water is not used during the meter check

procedure.

Range Check Procedure

The Meter Check Disk is used to verify the performance of a meter. It is not used to

recalibrate the meter. Meters are calibrated at the time of manufacture. The meter is

performing satisfactorily if readings using the Meter Check Disk are within the ranges

provided on the Meter Check Disk pouch. Range specifi cations are specifi c to the disk

identifi ed by the serial number on the pouch. The range specifi cations will vary from disk to

disk. The exact readings from a specifi c disk may vary from meter to meter.

1. Follow the Cleaning procedure on page 20 to clean the light chamber and optic lenses.

2. Tap

3. Tap MCD to select Meter Check Disk.

4. Tap

select Disk Series.

to return to the test screen.

14

Page 15

5. Remove the Meter Check Disk from the foil pouch. DO NOT remove the black cover

from the disk.

6. Insert the Meter Check Disk. Close the lid.

7. Tap

to start test.

8. Results will be displayed.

9. Compare the results on the display to the values on the chart shown on the pouch. If

the results are not within the range shown on the pouch, contact Support.

10. Replace the Meter Check Disk in the foil pouch for storage.

Alignment Procedure

The Meter Check Disk is inserted in the meter and Calibration is chosen from the Settings

Menu to perform an angle calibration which checks the alignment of the hub and disk. The

results are analyzed and reported as Pass or Fail. If the measurements pass, the settings

will be saved. If the analysis fails, contact Support.

1. Follow the Cleaning procedure on page 20 to clean the light chamber and optic lenses.

2. Tap

3. Tap Calibration.

4. Remove the Meter Check Disk from the foil pouch. DO NOT remove the black cover

5. Insert the Meter Check Disk. Close the lid.

6. Tap

7. If the meter is performing satisfactorily, “Angle Calibration Successful” will be

8. Tap

to go to Settings.

from the disk.

Start to begin the meter check procedure.

displayed and the settings will be saved. If the meter is not performing satisfactorily,

“Angle Calibration Unsuccessful. Contact Support.” will be displayed.

to return to the Testing Menu and resume testing.

email: softwaresupport@lamotte.com

phone: 800-344-3100 option 3 | Mon-Fri 9am-5pm EST

HELPFUL HINTS

¬ Do not touch top or bottom of disk. Handle disk by the edge.

¬ Do not fi ll disk while in the meter. Fill disk on clean, dry surface.

¬ Fill the disk on a dark surface to more easily see the sample water.

¬ The disk should not contain any large air bubbles. Air bubbles will result in erroneous

results.

¬ Always use the disk cover.

¬ Only the Universal Disk Cover (Code 1719) can be used with the WaterLink

Touch

®

.

¬ Empty syringe of old sample before fi lling with next sample.

¬ Remove fi lled disk from meter after testing. Do not travel with fi lled disks in meter.

They may leak.

15

®

Spin

Page 16

RANGES AND SPECIFICATIONS

Test Factor Range Test Factor Range

Alkalinity, Total 0–250 ppm Copper 0.0–3.0 ppm

Biguanide 0–70 ppm Cyanuric Acid 5–150 ppm

Biguanide Shock 0–250 ppm Hardness, Calcium 0–800 ppm

Borate 0–80 ppm Iron 0.0–3.0 ppm

Bromine (DPD) 0.00–33.00 ppm pH 6.4–8.6

Chlorine, Free (DPD) 0.00–15.00 ppm Phosphate 0–2000 ppb

Chlorine, Combined 0,00–15.00 ppm Salt 0–5000 ppm

Chlorine, Total (DPD) 0.00–15.00 ppm

Test results that are out of range of the reagent system wil be RED. RED test results may

not be accurate. Go SETTINGS>Other Settings to turn the Ranges Enabled feature OFF.

Copper concentrations over 4 ppm will result in low total hardness results.

Instrument Type Centrifugal Fluidics Photometer

Wavelengths

(interference fi lters)

Display Color Capacitive Touchscreen,

Wavelength Accuracy ±2 nm

Wavelength Bandwidth 10 typical

Photometric Range -2 to 2 AU

Photometric Precision ±0.01 AU at 1.0 AU

Photometric Accuracy ±0.01 AU at 1.0 AU

Sample Chamber Accepts prefi lled disk

Light Source 6 LEDS

Detectors 6 silicon photodiodes

Pre-Programmed Tests Yes, with automatic wavelength selection

Languages English, French, Spanish, German, Dutch, Swedish, Portuguese,

Temperature Operation: 0-50 °C; storage – 40-60 °C

Operation Humidity Range 0- 90 % RH, non-condensing

Communication USB-C, Bluetooth low energy technology (BLE)

Calibration Factory set, fi eld calibration via internet connection

Firmware Internet updateable (New Test, New Test Calibrations, etc.)

Software Android & iOS Apps, DataMate® Web, DataMate®10

Power Requirements USB wall adapter, USB computer connection or internal lithium ion

Battery Type Lithium ion

390 nm, 428 nm, 470 nm, 525 nm, 568 nm, 635 nm

3.5 in, 320 x 240 pixel resolution

Italian, Chinese, Turkish

rechargeable battery

16

Page 17

Minimum Capacity 12 V/2.6 AH

Charge Life Approximately 150 tests

Battery Life Approximately 500 charges

Full Charge 10-12 hours

Water Resistance Rubber over-molded base, rubber USB Port Plug, gasketed display

Electrical Rating Rated voltage (5V), Rated power of input current (1.6 A) at USB C

Auto Off Yes, default 15 (only with battery power)

Power Save Yes, default OFF

Data Logger 250 test results stored for download to PC or transfer by Bluetooth

Certifi cations

and hinge.

EZ-BLE™ PRoC™

Module,

CYBLE-022001-00

RF Radio:

EMC: EU: ETSI EN 301489-1

Safety: EU: EN61010-1:2010

FCC (USA):

Industry

Canada (IC)

Certifi cation:

CE (Europe): Complies with

MIC (Japan): 005-101007

KC (Korea): MSIP-CRM-

US: FCC PART 15 B

CAN ICES-3 (B)/NMB-3(B)

AS/NZS: CSPR 22

AS/NZS: national diff erences

FCC ID:

WAP2001

License IC:

7922A-2001

Directive

1999/5/EC

Cyp-2001

Dimensions 21.6 X 12.4 X 10.4 cm (L X W X H)

8.5 X 4.9 X 4.2 in

Weight 0.79 Kg, 1.74 lb

17

Page 18

ACCESSORIES AND REPLACEMENT PARTS

Description Code

®

WaterLink

Water Sample Bottle (60 mL) 0688

Water Sample Bottle (30 mL) 0689

Syringe with tips (3) 1189-3

Syringe tips (3) 1189-TIP

Cleaning Tissues 0669

Meter Check Disk (North America) 1705

Meter Check Disk (Europe) 1705-EU

Universal Disk Cover 1719

USB Cable 1712

AC Adapter (North America) 1713

AC Adapter (UK) 27252-PAD-UK

Cloth Wipe 3580-WIPE

Mobile Bluetooth Printer 5-0066

WaterLink

WaterLink

WaterLink

WaterLink

WaterLink

WaterLink

Spin Touch® Meter 1715-METER

®

Spin Touch® Counter Mat 3580-MAT

®

Spin Touch® Manual 3580-MN

®

Spin Touch® Quick Guide 3580-QG

®

Spin Touch® Quick Guide 3581-QG

®

Spin Touch® Banner 3580-BAN

®

Spin Touch® Window Decal 3580-DECAL

For available WaterLink

®

Spin Touch® reagent disks, see page 19.

18

Page 19

DISK DESCRIPTIONS

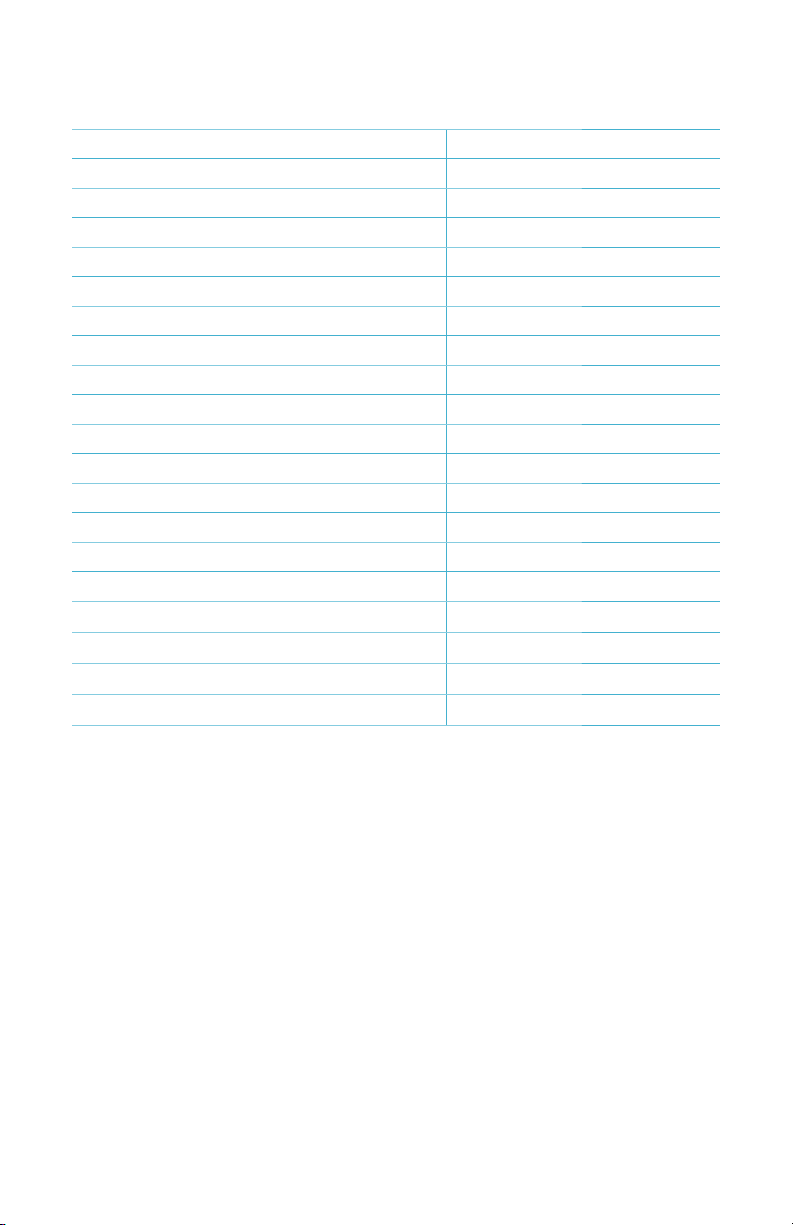

SINGLE USE DISKS

Chlorine/Bromine Disk

(Code 4328)

Free Chlorine

Bromine

Total Chlorine

Total Alkalinity

pH

Salt

Calcium Hardness

Copper

Iron

Cyanuric Acid

Alkalinity

Free Chlorine/

Bromine

Salt

pH

Copper

Calcium

Hardness

Blank

Total

Chlorine

Cyanuric

Acid

Iron

Chlorine/Bromine Plus Phosphate

10 Tests Series Disk

(Code 4329)

Free Chlorine

Bromine

Total Chlorine

Total Alkalinity

pH

Salt

Calcium Hardness

Copper

Iron

Cyanuric Acid

Phosphate

Chlorine/Bromine Plus Borate

10 Tests Series Disk

(Code 4330)

Free Chlorine

Bromine

Total Chlorine

Total Alkalinity

pH

Salt

Calcium Hardness

Copper

Iron

Cyanuric Acid

Borate

Alkalinity

Free Chlorine/

Bromine

Total

Alkalinity

Free Chlorine/

Bromine

Copper

Salt

pH

Copper

Salt

pH

Calcium

Hardness

Blank

Calcium

Hardness

Blank

Total

Chlorine

Cyanuric

Acid

Total

Chlorine

Cyanuric

Acid

Iron

Phosphate

Iron

Borate

NOTE: Colored reagents may be visible in the disk before adding sample water.

NOTE: Disks with Salt reagent should be stored and used at room temperature (68-74 °F/20-23 °C).

19

Page 20

Biguanide Plus Borate Disk

(Code 4331)

Biguanide

Biguanide Shock

Total Alkalinity

pH

Calcium Hardness

Copper

Iron

Borate

Copper

Biguanide

Calcium

Hardness

Biguanide

Shock

Total

Alkalinity

Iron

Borate

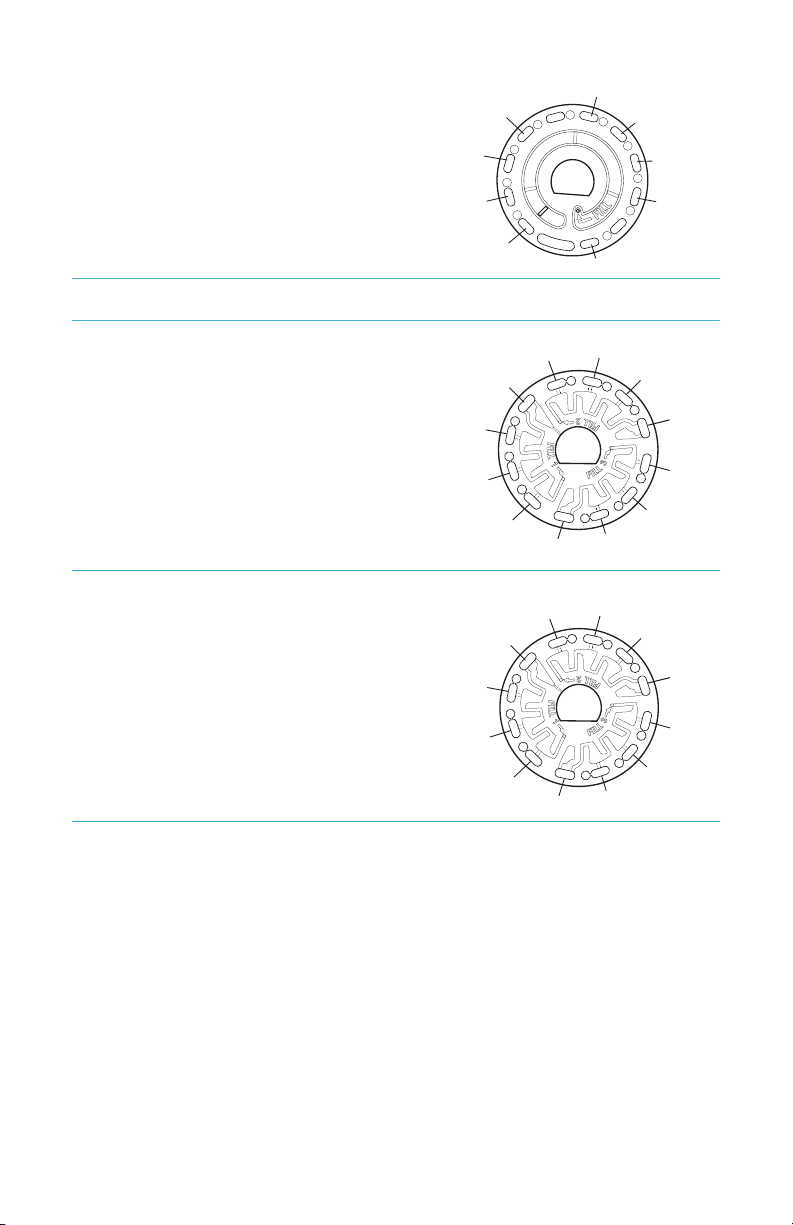

MULTIPLE-USE DISKS

Chlorine/Bromine/pH

(Code 4334)

pH

Free Chlorine

Bromine

Total Chlorine

Chlorine/Bromine/pH/Alkalinity

(Code 4335)

pH

Free Chlorine

Bromine

Alkalinity

Total

Chlorine

Free

Chlorine/

Bromine

Alkalinity

Free

Chlorine/

Bromine

Blank

Blank

pH

pH

pH

pH

Blank

pH

Blank

Blank

Free

Chlorine/

Bromine

Total

Chlorine

Free

Chlorine/

Bromine

Alkalinity

Total

Chlorine

Free

Chlorine/

Bromine

Alkalinity

Free

Chlorine/

Bromine

Blank

pH

Blank

pH

MAINTENANCE

CLEANING

The optical system of the WaterLink® Spin Touch® must be kept clean and dry for optimal

performance. Dry the disk with a lint-free wipe before placing it into the chamber to avoid

introducing moisture. For best results, store the instrument in an area that is dry and free

from aggressive chemical vapors. Clean the exterior housing with a damp, lint-free cloth.

Do not allow water to enter the light chamber or any other parts of the meter. To clean the

light chamber and optic lenses, point a can of compressed air into the light chamber and

the lid and blow the pressurized air into the light chamber and lid. Focus the pressurized

air around the LEDs which are the small round lenses positioned at 2:00, 4:00, 6:00, 8:00,

10:00 and 12:00 in the lid. The photodiodes are located on the bottom of the chamber

around the hub. This area must be kept clean and dry. Use a cotton swab dampened with

®

Windex

window cleaner to gently swab the LED and photodiode lenses. Do not use alcohol;

20

Page 21

it will leave a thin residue over the optics when dry.

Remove smudges due to routine use from the touchscreen with the Cloth Wipe

3580-WIPE). Use a cloth dampened with alcohol for more thorough cleaning when

necessary. Do not use Windex

®

window cleaner, or similar cleaners, on the touchscreen.

(Code

REPAIRS

Should it be necessary to return the meter for repair or servicing, pack the meter carefully

in a suitable container with adequate packing material. A return authorization number

must be obtained from LaMotte Company by calling 800- 344-3100, ext. 3 (US only) or

410-778-3100, ext. 3, faxing 410-778-6394, or emailing softwaresupport@lamotte.

com. Often a problem can be resolved over the phone or by email. If a return of the meter

is necessary, attach a letter with the return authorization number, meter serial number, a

brief description of problem and contact information including phone and FAX numbers

to the shipping carton. This information will enable the service department to make the

required repairs more effi ciently.

METER DISPOSAL

Waste Electrical and Electronic Equipment (WEEE)

Natural resources were used in the production of this equipment. This

equipment may contain materials that are hazardous to health and the

environment. To avoid harm to the environment and natural resources, the

use of appropriate take-back systems is recommended. The crossed out

wheeled bin symbol on the meter encourages the use of these systems

when disposing of this equipment.

Take-back systems will allow the materials to be reused or recycled in a

way that will not harm the environment. For more information on approved

collection, reuse, and recycling systems contact local or regional waste

administration or recycling services. Do not incinerate the equipment.

DISK DISPOSAL

The disks cannot be reused. Over time, the water in reacted disks will evaporate. Disks

can be recycled. Warning: Recyclers should check with the local authorities. Some states

may require that no chemical residue remains on the plastic or may not be able to accept

plastic waste with stainless steel mixing beads. Used disks may be returned, at the

customer’s expense, to LaMotte for recycling.

GENERAL INFORMATION

PACKAGING AND RETURNS

Experienced packaging personnel at LaMotte Company assure adequate protection against

normal hazards encountered in transportation of shipments. After the product leaves

the manufacturer, all responsibility for its safe delivery is assured by the transportation

company. Damage claims must be fi led immediately with the transportation company to

receive compensation for damaged goods. Should it be necessary to return the instrument

for repair or servicing, pack the instrument carefully in a suitable container with adequate

packing material. A return authorization number must be obtained from LaMotte Company

by calling 1-800-344-3100 or 1-410-778-3100, ext. 3 or emailing tech@lamotte. com.

Attach a letter with the authorization number to the shipping carton which describes the

kind of trouble experienced. This valuable information will enable the service department to

make the required repairs more effi ciently.

21

Page 22

GENERAL PRECAUTIONS

Read the instruction manual before attempting to set up or use the instrument. Failure to

do so could result in personal injury or damage to the meter. The WaterLink

should not be stored or used in a damp or excessively corrosive environment. Care should

be taken to prevent water or reagents from entering the photometer chamber. Wet disks

should never be put into the photometer chamber.

®

Spin Touch®

SAFETY PRECAUTIONS

Read the safety precautions on the labels of all reagent containers and packaging prior to

use. Safety Data Sheets (SDS) can be found at

information for all LaMotte reagents is available 24 hours a day from the National Poison

Control Center at 1-800-222-1222 or by contacting the 24 hour emergency line for

ChemTel at 1-800-255-3924 (USA, Canada, Puerto Rico). For locations outside of the

North American continent call 813-248-0585 collect.

Ensure that the protection provided by this equipment is not impaired. Do not install or use

this equipment in a manner that is not indicated in this manual.

www.lamotte.com. Additional emergency

LIMITS OF LIABILITY

Under no circumstances shall LaMotte Company be liable for loss of life, property, profi ts,

or other damages incurred through the use or misuse of its products.

CE MARK

The WaterLink® Spin Touch® meter has been independently tested and has earned the

European CE Mark of compliance for electromagnetic compatibility and safety. To view

certifi cates, go to the LaMotte website at

This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

residential environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

¬ Reorient or relocate the receiving antenna.

¬ Increase the separation between the equipment and receiver.

¬ Connect the equipment into an outlet on a circuit diff erent from that to which the

receiver is connected.

¬ Consult the dealer or an experienced radio/TV technician for help.

www.lamotte.com.

22

Page 23

NSF CERTIFICATION

The NSF/ANSI 50 certifi cation mark on a water quality testing device

(WQTD) used in recreational waters, such as pools and spas, means

that the product was reviewed and certifi ed by NSF International to

meet applicable American National Standards for product design and

performance. NSF tests and re-tests products to confi rm that they comply

with all requirements of certifi cation for performance, accuracy and

operating range. Certifi cation levels of L1, L2, and L3 are possible with L1

being the highest rating. Go to

Test Factor Application

pH Pool 6.4–8.6 L1

Spa/Hot Tub 6.4-8.6 L1

Free Chlorine Pool 0–15 ppm L1

Spa/Hot Tub 0–7 ppm L1

Chlorine,

Combined

Cyanuric Acid Pool 5–50 ppm L1

Other test factors not evaluated by NSF.

www.nsf.org for a current listing of LaMotte NSF certifi ed products.

Go to

See Disk Descriptions (page 19) for NSF Certifi ed Disks.

Pool 0-1 ppm L1

Spa/Hot Tub 0-1 ppm L1

www.nsf.org for more information.

NSF Level

NSF Certifi ed

Range

Accuracy/

Overall

WARRANTY

LaMotte Company warrants this instrument to be free of defects in parts and workmanship

for 2 years from the date of shipment. If it should become necessary to return the

instrument for service during or beyond the warranty period, contact our Technical Service

Department at 1-800-344-3100 or 1-410-778-3100, ext. 3 or softwaresupport@lamotte.

com for a return authorization number or visit

The sender is responsible for shipping charges, freight, insurance and proper packaging to

prevent damage in transit. This warranty does not apply to defects resulting from action

of the user such as misuse, improper wiring, operation outside of specifi cation, improper

maintenance or repair, or unauthorized modifi cation. LaMotte Company specifi cally

disclaims any implied warranties or merchantability or fi tness for a specifi c purpose and

will not be liable for any direct, indirect, incidental or consequential damages. LaMotte

Company’s total liability is limited to repair or replacement of the product. The warranty

set forth above is inclusive and no other warranty, whether written or oral, is expressed or

implied.

To register your meter with the LaMotte Service Department, go to

www.lamotte.com and choose SUPPORT on the top navigation bar.

Serial Number ______________________________________________________

www.lamotte.com for troubleshooting help.

23

Page 24

24

Page 25

CONFIGURACIÓN

ANTES DEL PRIMER USO

¬ Cargue completamente la batería con un cable USB Spin Touch y un adaptador

conectados a una toma de CA.

¬ Asegúrese de que está instalada la última versión de fi rmware de Spin Touch:

1. Descargue e instale la aplicación de escritorio WaterLink

Windows

2. Conecte el medidor al ordenador con el cable USB suministrado y abra la

aplicación de escritorio WaterLink

®

en http://softwarecenter.lamotte.com/.

®

Connect desde el menú Inicio.

3. Se aplicarán automáticamente al medidor las actualizaciones de fi rmware

disponibles.

MEDIDOR

1. El medidor se puede alimentar con una toma de corriente, un ordenador o la batería

interna.

2. Utilice el cable USB y el adaptador para conectar el medidor a una toma de corriente.

3. Utilice el cable USB para conectar el medidor al puerto USB de un ordenador.

CARGA DE LA BATERÍA

1. Use el cable USB y el adaptador para conectar el medidor a una toma de CA o use el

cable USB (incluido) con un cargador de coche (no incluido) para cargar la batería.

(Anker PowerDrive 2, DC 12/24V, 5V = 4.8A, n.

o

pieza A2310 recomendado.)

2. El icono de la batería de la pantalla indicará el estado de la batería. Cárguela hasta que

el indicador señale que está llena.

ACTUALIZACIONES DE FIRMWARE

De vez en cuando hay que actualizar el fi rmware del Spin Touch. Para hacerlo:

1. Visite

2. Conecte el Spin Touch al ordenador usando el cable USB suministrado,

3. abra la aplicación de escritorio WaterLink

Una vez fi nalizada, para mayor seguridad, cierre WaterLink

laboratorio. Tras actualizar el fi rmware se recomienda realizar el Proceso de alineación

descrito en la página 38.

http://softwarecenter.lamotte.com/ y descárguese la aplicación WaterLink®

Connect para Windows.

®

Connect y espere a que fi nalice la

actualización.

®

Connect y desconecte el

®

Connect para

CONFIGURACIÓN

CONEXIÓN AL PC

Cuando se conecta el WaterLink® Spin Touch® a un ordenador a través de USB, la pantalla

táctil del dispositivo se desactiva y el laboratorio se maneja a través de la aplicación

WaterLink

®

Connect para Windows®. Esta aplicación está disponible de forma gratuita en

http:// softwarecenter.lamotte.com/. Mediante la aplicación de escritorio WaterLink®

Connect, se pueden transferir los resultados del Spin Touch a un programa de análisis del

agua como WaterLink

®

Solutions™.

CONEXIÓN A DISPOSITIVO

El WaterLink® Spin Touch® es compatible con conexiones a un PC con Windows® (a través

de USB) y a dispositivos móviles Android e iOS (a través de Bluetooth).

25

CONEXIÓN AL PC

Page 26

CONEXIÓN A TRAVÉS DE USB

Mediante el uso del cable USB suministrado, puede conectarse el WaterLink® Spin Touch® a

un PC con sistema Windows

e instale de forma gratuita la aplicación para Windows

softwarecenter.lamotte.com

de USB, los controles de la pantalla táctil del dispositivo se desactivan y el fotómetro se

maneja a través de la aplicación WaterLink

programas de análisis del agua, como WaterLink

de los análisis y ofrecer recomendaciones detalladas de tratamiento. Obtenga más

información acerca de los productos de software de LaMotte en

lamotte.com

CONEXIÓN A DISPOSITIVO

.

®

. Antes de conectar un fotómetro a través de USB, descargue

®

WaterLink® Connect desde http://

. Cuando se conecta el WaterLink® Spin Touch® al PC a través

®

Connect. LaMotte también ofrece sólidos

®

Solutions™, para recoger los resultados

http://softwarecenter.

CONEXIÓN A TRAVÉS DE BLUETOOTH

El WaterLink® Spin Touch® puede conectarse a un dispositivo con Bluetooth habilitado,

como un teléfono o una tablet. El Spin Touch también es compatible con la impresora

Bluetooth de LaMotte [Código 5-0066]. No es compatible con otras impresoras Bluetooth.

La transferencia de resultados a través de Bluetooth a un dispositivo móvil requiere que

se instale una aplicación móvil en el dispositivo y una cuenta activa para el programa

de software asociado. Por ejemplo, con una cuenta activa de WaterLink

la aplicación móvil WaterLink

®

Solutions™ instalada en un teléfono o una tablet, pueden

transferirse los resultados del fotómetro a la aplicación. Las aplicaciones móviles para los

productos de software de LaMotte están disponibles en iTunes (para dispositivos iOS) y

Google Play (para dispositivos Android). Obtenga más información acerca de los productos

de software de LaMotte en

Para transferir los resultados del WaterLink

http://softwarecenter.lamotte.com.

®

Spin Touch® a la aplicación móvil para

productos de software de LaMotte:

1. Acceda a la aplicación móvil del producto de software LaMotte.

2. Busque un registro de un cliente o de un Sitio. Es posible que tenga que crear uno

antes de comenzar a realizar análisis.

3. Inicie un análisis del agua en la aplicación móvil.

4. Realice un análisis del agua desde la pantalla táctil del Spin Touch del dispositivo

como de costumbre. El Spin Touch y el dispositivo móvil con Bluetooth habilitado se

conectarán automáticamente.

5. Cuando la conexión esté disponible,

sea tenue, el fotómetro y el dispositivo no estarán conectados. Pulse

se iluminará en la pantalla táctil. Cuando

transferir los resultados a la aplicación móvil.

Cuando aparezca

móvil Bluetooth (Código 5-0066). El botón

en la pantalla táctil, el Spin Touch podrá conectarse a la impresora

será brillante cuando esté conectado y

tenue cuando no lo esté.

El Spin Touch no puede conectarse a ambos dispositivos móviles y a la impresora al mismo

tiempo. (Consulte el apartado Guardar, imprimir y enviar, página 31)

®

Solutions™ y

para

USO DE BLUETOOTH DE BAJA ENERGÍA

El WaterLink® Spin Touch® se conectará automáticamente al teléfono, la tablet o la

impresora con Bluetooth habilitado más cercano. No es necesario conectar el Spin Touch

a su dispositivo con Bluetooth habilitado. Las barreras de las señales inalámbricas pueden

reducir el rango de los dispositivos inalámbricos. El WaterLink Spin Touch funcionará mejor

si no hay paredes entre el fotómetro y los dispositivos receptores.

26

Page 27

LLENADO: discos de un solo uso

Cuando se introduce la jeringa en la muestra de agua y el émbolo

está arriba del todo, la jeringa contiene muestra de agua más

que sufi ciente para rellenar bien el disco. Sostenga la jeringa

verticalmente e inserte la punta en el orifi cio de llenado del disco.

Presione el émbolo lenta y suavemente para llenar el disco.

1. Llene el disco ejerciendo lentamente una

ligera presión. La muestra de agua llenará los

espacios entre los separadores en el sentido

contrario a las agujas del reloj. Cada espacio

se llenará de abajo hacia arriba. Añada más

agua de muestra hasta que la cuarta cámara

se llene de agua hasta arriba superando

ligeramente la línea de llenado marcada en

relieve. No pasa nada si se llena sobrepasando

un poco la línea.

2. No llene excesivamente el disco. Si llena el

disco en exceso, la muestra de agua saldrá

por el orifi cio de desbordamiento situado en

el centro del disco. El disco no gotea. Seque el

disco y ejecute el test.

3. No llene el disco por debajo del nivel indicado.

Si llena el disco por debajo del nivel adecuado,

las cámaras de reactivos no se llenarán por

completo y los resultados no serán precisos.

(Linea de

llenado)

Llenado correcto

Llenado

excesivo

(Seque el disco antes de ponerlo en el medidor.)

CONEXIÓN A DISPOSITIVO

Llenado

insuficiente

4. No llene el disco por debajo del nivel indicado.

Si llena el disco por debajo del nivel adecuado,

Cámara

vacía

la cámara vacía no se llenará. Tan pronto

como una burbuja comienza a formarse, tire

hacia atrás del émbolo para sacar la burbuja

del disco. Inicie de nuevo el proceso de

llenado.

5. Seque bien los discos húmedos con un trapo

sin pelusas. Agarre el disco por los bordes.

6. Llene el disco y úselo en los próximos 10 minutos. No llene discos con antelación.

Si quiere obtener consejos sobre llenado y resolución de problemas, visite:

www.lamotte.com/spin

27

Page 28

LLENADO: discos de múltiples usos

Cuando se introduce la jeringa en la muestra de agua y el émbolo está

arriba del todo, la jeringa contiene muestra de agua más que sufi ciente

para rellenar bien el disco. Sostenga la jeringa verticalmente e inserte

LLENADO

la punta en el orifi cio de llenado del disco. Presione el émbolo lenta y

suavemente para llenar el disco.

1. Llene las secciones no utilizadas del disco ejerciendo

lentamente una ligera presión. Añada la muestra de

agua hasta que la Cámara vacía se llene y la Cámara

de fl ujo excesivo se llene parcialmente.

2. No llene excesivamente el disco. Si llena el disco en

exceso, la muestra de agua saldrá por el orifi cio de

purga situado en el centro del disco. El disco no gotea.

Seque el disco y ejecute el test

3. No llene el disco por debajo del nivel indicado. Si llena

el disco por debajo del nivel adecuado, la cámara vacía

no se llenará. Tan pronto como una burbuja comienza

a formarse, tire hacia atrás del émbolo para sacar

la burbuja del disco. Inicie de nuevo el proceso de

llenado.

4. No introduzca burbujas de aire en el disco. Las

cámaras de reactivos no se llenarán por completo y

los resultados no serán precisos. Retire la muestra de

agua con la jeringa y rellene.

Cámara

de flujo

excesivo

Cámara

vacía

Llenado correcto

Cámara

de flujo

excesivo

Cámara

vacía

Llenado excesivo

(Seque el disco antes de ponerlo en el medidor.)

Cámara

vacía

Llenado insuficiente

Burbuja

de aire

5. Seque bien los discos húmedos con un trapo sin

pelusas. Agarre el disco por los bordes. Entre prueba

y prueba almacene el disco sobre una superfi cie

plana. No agite el disco lleno para evitar que gotee y

se contamine. Los discos parcialmente usados deben

descartarse al fi nal del día.

6. Llene el disco y úselo en los próximos 10 minutos. No llene discos con antelación.

Si quiere obtener consejos sobre llenado y resolución de problemas, visite: www.lamotte.com/spin

28

Page 29

PROCEDIMIENTOS DE FUNCIONAMIENTO GENERAL

MEDIDOR

Cuando se coloca un disco lleno en la cámara y se cierra la tapa, el medidor gira a alta

velocidad para distribuir la muestra a los depósitos de prueba. A continuación, el medidor

maximiza la acción de bombeo de las perlas de acero inoxidable al mismo tiempo que los

reactivos se mezclan con el agua de la muestra. Entonces se lee cada reacción a su debido

momento y en la longitud de onda oportuna para ese sistema de reactivos.

El botón situado en la parte central inferior de la parte superior del

medidor enciende y apaga el instrumento.

El indicador luminoso azul del botón de encendido/apagado señala el estado del

instrumento.

Luz azul fi ja: la LED azul permanecerá fi ja para indicar que el medidor está encendido y

listo para realizar un análisis.

Luz azul intermitente (tres parpadeos/segundo): hay un análisis en marcha y el disco está

girando. No abra la tapa cuando el disco esté girando.

Tenga cuidado al cerrar la tapa. No la cierre de golpe. Los cables que conectan la tapa con

el cuerpo del fotómetro pasan por la bisagra. El medidor no funcionará con la tapa abierta.

PANTALLA TÁCTIL

Al pulsar el botón para encender el medidor, se muestra la pantalla Test.

LLENADO

Selección del tipo

de desinfectante

Iniciar

el test

Desinfectante

Sal

Tipo de

disco

Encendidoapagado/

Estado de

la batería

La pantalla se activa al tocarla. Para hacer una selección, pulse el icono o la palabra en

pantalla con la punta de un dedo, una uña, una goma de un lápiz o un lápiz óptico.

¬ Limpie suavemente las manchas de la pantalla con la toallita (3580-WIPE).

Disco

203

30-Oct-18

12:14 PM

Fecha y

hora

29

Pulse para

Iniciar análisis

Historial

de tests

Ajustes

Page 30

¬ No limpie la pantalla con un objeto afi lado.

g

g

g

g

¬ No coloque sobre la pantalla objetos que la puedan rayar o dañar.

¬ Evite tocar la pantalla con los dedos mojados.

ANÁLISIS

Desinfectante

Sal

Pulse para

iniciar análisis

Disco

203

PROCEDIMIENTOS DE FUNCIONAMIENTO GENERAL

1. Mantenga pulsado hasta que se encienda el medidor.

2. Pulse

3. Pulse

Pulse

NOTA: las series de discos están limitadas por la selección del tipo de desinfectante.

4. Extraiga un disco del embalaje.

5. Use la jeringa (1189) para llenar el disco con una muestra de agua de la piscina o spa.

6. Inserte el disco. Cubra el disco con la Cubierta de disco universal. Cierre la tapa.

7. Pulse

8. Aparecerán los resultados en pantalla.

9. Elija una opción.

10. Mantenga pulsado

NOTA: para muestras de agua de más de 100 °F (38 °C) restar 0,3 al resultado del pH o, para un

resultado más preciso, esperar hasta que la muestra de agua esté por debajo de 90 °F (32 °C) para

realizar la prueba.

. Seleccione el tipo de desinfectante. Pulse para confi rmar.

. Seleccione una serie de discos (la encontrará en el embalaje del disco).

para confi rmar.

para iniciar test. Pulse para cancelar test.

¬ Pulse

¬ Pulse

cuando no esté habilitada la opción de Guardado automático.

¬ Pulse

¬ Pulse

habilitado.

¬ Pulse

30-Oct-18

12:14 AM

para añadir una etiqueta.

resaltado para guardar los resultados del análisis en el registro

resaltado para enviar los resultados a la impresora móvil Bluetooth.

resaltado para enviar los resultados al dispositivo con Bluetooth

para regresar a la pantalla Test.

durante 2 segundos para apagar el medidor.

30

Page 31

GUARDAR, IMPRIMIR Y ENVIAR RESULTADOS DEL TEST

Los resultados del test pueden guardarse, transferirse a la aplicación móvil WaterLink

Connect a través de Bluetooth y enviarse a la impresora móvil Bluetooth (Código 5-0066).

Resultados

Tiempo de prueba 05:30:06 04-Jan-2018

FCL - 1,31

TCL - 1,31

CCL - 0.00

PH - 7,8

ALK - 100

HARD - 230

CYA - 2

COPPER - 0,1

IRON - 0,1

PHOS - 0

SAL T- 489

PROCEDIMIENTOS DE FUNCIONAMIENTO GENERAL

Etiquetas

Guardar

los

resultados

Imprimir

resultados

a

través de

Bluetooth

Transferir

esultados a

través de

Bluetooth

los

Volver

a la

pantalla

Test

Ajustes del historial de análisis

El WaterLink Spin Touch puede guardar resultados de test de 250 muestras de agua en

el Historial de tests. Los resultados de la muestra más reciente se situarán en la parte

alta de la lista. Pueden guardarse automáticamente todos los resultados o guardarse los

resultados de una sola muestra después de haberla analizado.

Para activar el guardado automático, pulse

Guardar tests automáticamente. Pulse

está seleccionado el guardado automático, el icono de

resultados del test.

Para guardar manualmente los resultados de una sola muestra cada vez, la función

Guardar análisis automáticamente debe estar desactivada. Si la opción Guardar test

automáticamente está desactivada, el icono de

test. Después de haber realizado el test, pulse

muestra de agua en el Historial de tests.

Se puede asignar una etiqueta de identifi cación defi nida por el usuario al resultado de

una sola muestra. La etiqueta puede tener hasta 4 caracteres hexadecimales. No puede

comenzar con un cero. Para etiquetar el resultado de un análisis, pulse

inferior de la pantalla Resultados del análisis y utilice los botones para introducir hasta

cuatro caracteres. Toque

para borrar un carácter. Pulse para guardar la etiqueta y

volver a la pantalla Resultados del análisis. Pulse

del análisis sin guardar la etiqueta. El resultado etiquetado aparecerá en la pantalla

Resultados del análisis y en la pantalla Historial de análisis. La etiqueta irá precedida por

«T-».

en la pantalla de tests. Pulse . Seleccione

y para regresar a la pantalla de tests. Cuando

no brillará en la pantalla de

brillará en la pantalla de resultados del

para guardar los resultados para dicha

en la parte

para volver a la pantalla Resultados

31

Page 32

Historial

12:02A 30-Oct-2018 Sal 401

12:01A 30-Oct-2018 Sal 301

12:00A 30-Oct-2018 T-4650 Chloro 100

12:00A 30-Oct-2018 Chloro 300

11:57A 30-Oct-2018 T-ABC7 Chloro 300

11:49A 30-Oct-2018 Biguanidas 400

Ir al principio

Subir o bajar

5 entradas

en la lista

de tests

Ir al final

Seleccionar

todos/

Desmarcar

todos

Los resultados guardados se muestran en el Historial de tests. Los controles para

PROCEDIMIENTOS DE FUNCIONAMIENTO GENERAL

visualizar y gestionar uno o varios registros de tests simultáneamente están situados

Borrar los

resultados

seleccionados

Ver los

resultados

seleccionados

Ajustes del

historial

Seleccionar

Guardado

automático

Inicio

en la pantalla Historial de tests. Pulse la casilla situada junto a un registro de test para

seleccionarlo, después pulse uno de los botones situados en la parte inferior para realizar

una acción con los registros seleccionados.

Imprimir o enviar resultados al teléfono o la tablet con Bluetooth

El WaterLink Spin Touch puede imprimir a través de la impresora móvil Bluetooth o enviar

los resultados del test a un dispositivo equipado con Bluetooth, como un teléfono o una

tablet. Los botones brillantes

puede conectarse a la impresora y a un teléfono o una tablet al mismo tiempo.

Hay dos modos de funcionamiento para conectarse a la impresora y a un teléfono o una

tablet: Conexión rápida a impresora ON y Conexión rápida a impresora OFF. El modo que

viene por defecto es Conexión rápida a impresora ON. La Conexión rápida a impresora

puede activarse o desactivarse desde el menú Bluetooth situado en el Menú de Ajustes.

Si la Conexión rápida a impresora está ON, el medidor se conectará automáticamente a la

impresora en cuanto la reconozca. También se conectará al teléfono o la tablet, pero se da

prioridad a la conexión a la impresora. La impresora comenzará a imprimir de inmediato

en cuanto pulse

. El botón atenuará la intensidad mientras la impresora imprime.

La Conexión rápida a impresora debería estar ON si los resultados se van a imprimir con

más frecuencia que con la que se van a enviar al teléfono o la tablet. Puede permanecer

seleccionada si los resultados solo se van a enviar a un teléfono o una tablet. Si la Conexión

rápida a impresora está ON, y la impresora está encendida, deberá apagar la impresora

antes de que los resultados puedan enviarse a un teléfono o una tablet.

Si la Conexión rápida a impresora está OFF, el medidor podrá conectarse a un teléfono o

una tablet en cualquier momento salvo que la impresora esté imprimiendo un test en ese

momento. El medidor se conectará a la impresora únicamente después de que se pulse

, así que la impresión se retrasará unos segundos mientras se establece la conexión

con la impresora. El botón

Después de imprimir, el medidor volverá a conectarse automáticamente con el teléfono o

la tablet. La Conexión rápida a impresora debería estar OFF si los resultados se van a enviar

a un teléfono o tableta con más frecuencia que con la que se van a imprimir.

o mostrarán qué función está activa. El Spin Touch no

atenuará la intensidad mientras la impresora imprime.

32

Page 33

JERINGA

Para rellenar los discos se utiliza una jeringa de 3 ml de plástico

(código 1189). La punta de precisión de la jeringa encaja en el

agujero de rellenado del disco. No se debe extraer la punta de la

jeringa. Se deben limpiar las jeringas entre distintas muestras de

agua. Bombee aire dentro y fuera de la jeringa unas cuantas veces

para limpiar la anterior muestra o aclare la jeringa con una pequeña

cantidad de la siguiente muestra de agua antes de rellenarla con

esta.

DISCO DE REACTIVOS

El WaterLink® Spin Touch® utiliza un sistema de discos reactivos. Los

reactivos secos se envasan en cantidades para tests individuales

en un disco de poliestireno sellado. Unas perlas de acero inoxidable

colocadas en las cámaras reactivas mezclan el agua de la muestra

con los reactivos secos. Así se realizan los tests de todos los factores

de la serie de una vez. No es posible aislar el depósito de un único

factor y realizar un test sólo de dicho factor. Los discos de un solo uso

contienen reactivos para una serie única. Los discos de múltiples usos

contienen reactivos para repetir una serie. No se deben rellenar los

discos en la cámara del medidor.

MANIPULACIÓN DE DISCOS

Maneje el disco por los extremos. Evite tocar la parte superior o

inferior del disco. La luz pasa a través de las zonas no escarchadas

del disco, por lo que hay que mantener estas zonas libres de

manchas y huellas. Nunca se deben poner discos mojados en el

medidor. Habrá que secarlos con un trapo sin pelusas antes de

ponerlos en la cámara.

El disco se coloca en la cámara alineando el agujero con forma de D en el centro del disco

con el eje en forma de D en la cámara del fotómetro. Hay que colocar suavemente el disco

en el eje. No es necesario apretar con fuerza el disco para encajarlo.

PROCEDIMIENTOS DE FUNCIONAMIENTO GENERAL

ALMACENAMIENTO DE DISCOS

Los discos son sensibles a la humedad. Evite abrir más paquetes de los necesarios. Los

discos tienen una vida útil limitada y no conviene exponerlos a la humedad del aire más

de lo necesario.

Entre pruebas, guarde los discos de múltiples usos en

posición horizontal. No agite un disco parcialmente llenado.

Podría tener una fuga o contaminar las secciones sin usar

del disco. Los discos de múltiples usos que se hayan utilizado

parcialmente deberán ser descartados al fi nal del día. No

desplace el medidor con un disco en la cámara.

Almacene los discos a 70 °-80 ° F / 21 °-27 ° C. Los discos

con el reactivo Sal deben guardarse y utilizarse a temperatura

ambiente (68-74 °F/20-23 °C).

33

Page 34

CUBIERTA DEL DISCO

La cubierta negra del disco se coloca sobre el disco en la cámara

del fotómetro para reducir la interferencia de la luz exterior. La

cubierta del disco se coloca sobre este alineando el agujero con

forma de D en el centro del disco con el eje en forma de D en la

cámara del fotómetro. Hay que colocar suavemente la cubierta

del disco en el eje. No es necesario apretar con fuerza la cubierta

del disco para encajarla. La prueba se detendrá si no se coloca la

cubierta del disco.

Únicamente se puede utilizar la Cubierta de disco universal

(código 1719) que se incluye con el WaterLink

los discos de múltiples usos.

®

Spin Touch® con

DISCO DE COMPROBACIÓN DEL MEDIDOR

El Disco de comprobación del medidor cumple dos funciones:

¬ Cuando se procesa el Disco de comprobación del medidor (MCD) como una opción

del menú Serie de discos, los valores en pantalla se comparan con los valores de la

gráfi ca en el envase del Disco de comprobación para determinar si el medidor está

transmitiendo resultados que se ajustan a los intervalos previstos.

PROCEDIMIENTOS DE FUNCIONAMIENTO GENERAL

¬ Si el Disco de comprobación del medidor se inserta en el medidor y se elige

Calibración rotativa en el menú Ajustes, se evalúa la alineación del eje y el disco. Los

resultados se analizan y notifi can como «Correcto» o «Incorrecto».

Para utilizar el Disco de comprobación del medidor, véase la página 38.

CABLE USB

Un cable USB conecta el Waterlink® Spin Touch® a un PC con Windows®. Cuando se utiliza el

adaptador para CA, se conecta el medidor a un enchufe de CA.

ADVERTENCIA: utilice únicamente el cable USB y el adaptador de pared suministrados con

el kit. No lo cambie por otro.

BATERÍA

Una batería totalmente cargada durará unos 150 tests en condiciones normales. La

vida de la batería variará en función de los patrones de uso. Para alargar la vida de

la batería, hay que apagar el medidor después de realizar los análisis. El ciclo de vida

normal de una batería de litio-ión es de 500 ciclos. La batería se cargará por completo en

aproximadamente 10-12 horas. La batería está diseñada para que se cargue durante la

noche y solo se debe cargar en interiores. La batería está clasifi cada como de 12 V y tiene

una capacidad de 8,1 AH. Alimente el medidor desde el pack de la batería o desde una

fuente de CA. El cable USB y el adaptador para CA se utilizan para conectar el medidor a

una toma de CA. ADVERTENCIA: utilice únicamente el adaptador para CA suministrado con

el equipo. No lo cambie.

El estado de carga de la batería se indica a través del icono de la batería de la

pantalla. Dicho icono indicará cuándo la batería está llena, parcialmente llena,

baja, vacía o cargándose. El icono de la batería vacía parpadeará para indicar que

se debe conectar el medidor a una fuente de CA. Si continúa usando el medidor

con la batería baja y sin conectarlo a un enchufe de CA, el medidor pasará a un

modo de apagado automático. En este modo, el medidor se bloqueará hasta que

se conecte a una fuente de CA y la batería se cargue con un voltaje sufi ciente.

Durante la carga, en pantalla se mostrará el icono de la batería cargándose. El

medidor deberá permanecer enchufado hasta que se cargue del todo. Cuando la

batería esté cargada, el icono de carga pasará a ser el icono de batería llena.

34

Page 35

AJUSTES

Pulse para acceder al menú Ajustes. Pulse para regresar a la pantalla Test en

cualquier momento.

PROCEDIMIENTOS DE FUNCIONAMIENTO GENERAL

Brillo