Page 1

MOLYBDENUM

1200 COLORIMETER, 0-30 ppm

CODE 3676-01

QUANTITY CONTENTS CODE

60 mL *Mo Buffer *3997-H

2 x 30 mL *Molybdenum Oxidizing Reagent *6485-G

2.5 g *Molybdenum Indicator Powder *6486-S

1 Colorimeter Tubes 10 mL, w/cap, set of 6 0290-6

1 Spoon, 0.05g, plastic 0696

1 Pipets, 1.0 mL, plastic, w/cap 0372

1 Pipet, 1.0 mL 0354

1 Water Sample Collecting Bottle 0688

1 1200 Colorimeter for Molybdenum 26729

*WARNING: Reagents marked with an * are considered to be potential health hazards.

To view or print a Material Safety Data Sheet (MSDS) for these reagents go to

www.lamotte.com. To obtain a printed copy, contact LaMotte by e-mail, phone or fax.

To order individual reagents or test kit components, use the specifi ed code number.

NOTE: After use, return *MO Buffer (3997) to zipper top storage bag to reduce

exposure to corrosive reagent.

INTRODUCTION

Molybdenum occurs naturally in the earth’s crust as molybdenite and wolfenite, and

is an important element in many biochemical reactions, including nitrogen fi xation. In

industrial processes, such as the operation of boilers and cooling towers, molybdenum,

in the form of sodium molybdate, is used as an environmentally safe corrosion

inhibitor.

Page 2

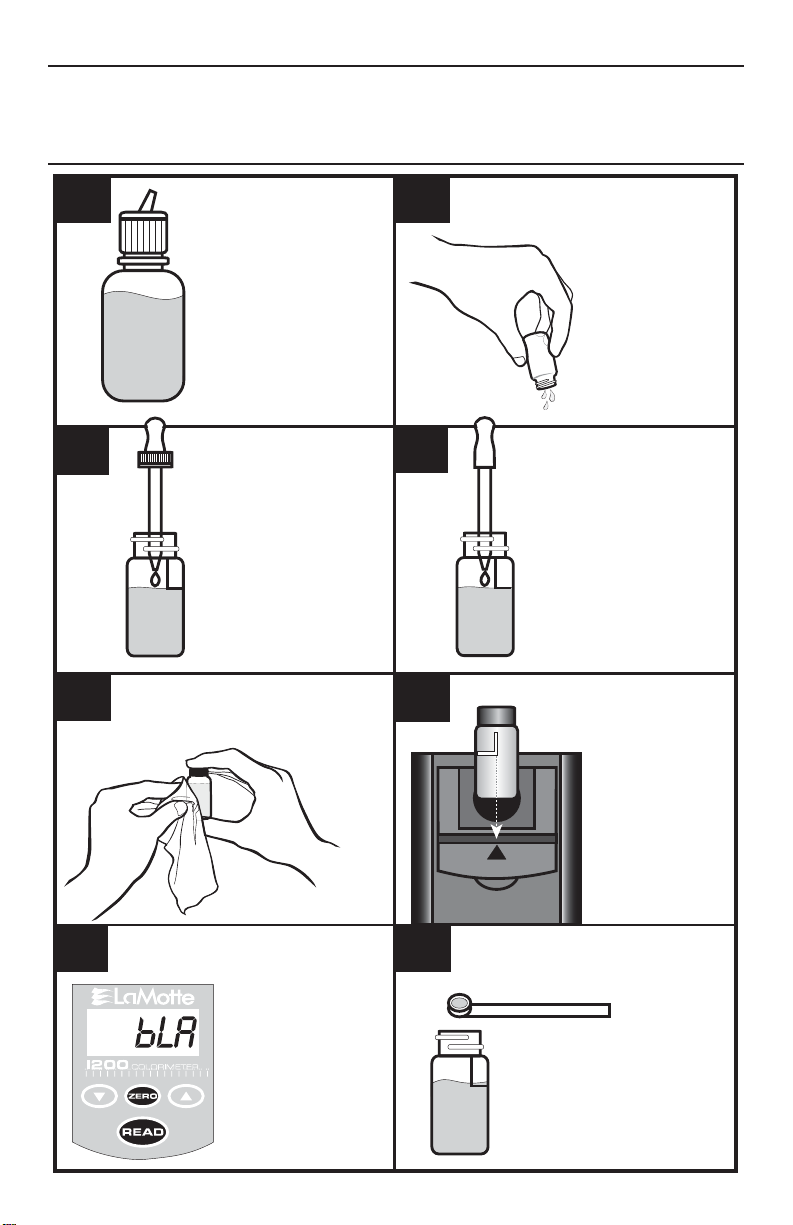

MOLYBDENUM PROCEDURE - Thioglycolate Method

Read the 1200 Colorimeter Manual before proceeding. Carefully wipe tubes dry

before inserting into the colorimeter chamber

MOLYBDENUM

12

Fill theWater Sample

Collecting Bottle

(0688) with sample

water. This will be

used to dispense

sample water for the

tests.

Rinse and fi ll a

colorimeter tube

(0290) to the

10mL line with

sample water.

34

Use the 1.0 mL pipet

(0372) to add1mLof

*Mo Buffer (3997).

Cap and mix.

Use the 1.0 mL pipet

(0354) to add 1mL

of *Molybdenum

Oxidizing Reagent

(6485). Cap and mix.

5

Wipe the tube dry.

7

Push the READ

button to turn the

meter on. Press

the ZERO button

and hold it for 2

seconds until is

displayed. Release

the button to take

a blank reading

(0.0 ppm).

6

8

Insert the tube into the

chamber, being sure

to align the index line

with the arrow

on themeter.

Close the lid.

This tube is the

sample blank.

Use the 0.05 spoon

(0696) to add 0.05g of

*Molybdenum Indicator

Powder (6486).

Page 3

5

Cap and mix

until the powder

dissolves.

Solution will

turn yellow if

molybdenum is

present.

6

Wipe the tube dry.

7

MOLYBDENUM TEST METHOD SPECIFICATIONS

APPLICATION

Boiler and cooling water

RANGE

0 to 30 ppm Molybdenum

METHOD

Calcium thioglycolate reacts with molybdenum to give a yellow color with an

intensity proportional to the amount of molybdenum present.

HANDLING & PRESERVATION

Molybdenum samples may be stored in either plastic or glass containers.

Align the index

line with the

arrow on the

meter, insert tube

into chamber.

Close the lid. Push

the button. Record

results as ppm

Molybdenum.

NOTE: If the molybdenum reading

exceeds 50 ppm, repeat procedure

on diluted sample, and multiply the

result by the appropriate dilution

factor. See 1200 Colorimeter

Instruction Manual for procedure.

INTERFERENCES

Nickel levels less than 50 ppm do not interfere; aluminum levels less than 10 ppm do

not interfere; chromate, at higher concentrations, interferes due to the intense yellow

color. Ferrous iron levels below 50 ppm do not interfere, but low levels of ferric iron

will cause a large blank. Highly buffered samples may exceed the capacity of the

system possibly producing inaccurate results. Add an extra 1.0 mL of *Mo Buffer

(3997) to adjust the pH of the sample to approximately 4.5. Multiply the result in ppm

by 1.08.

Page 4

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

®

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside USA) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

63676-01 7/14

Loading...

Loading...