Page 1

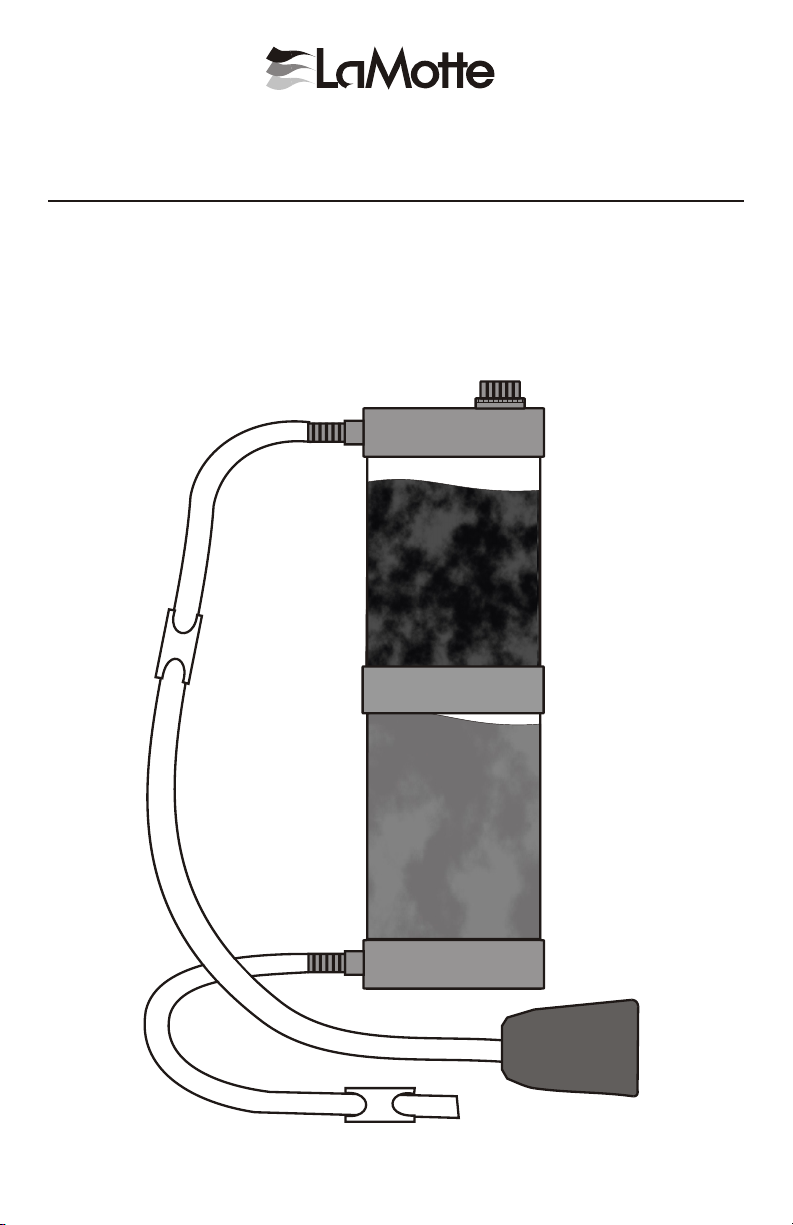

DUO-SOFT

PLUG

INLET

HOSE

CLAMP

CHAMBER

CHAMBER

CLAMP

FAUCET

ADAPTER

OUTLET

HOSE

IN TRO DUC TION

The DuoSoft Water Softener is designed to produce high quality treated water. Each

unit has a faucet adapter that easily connects to any standard faucet. The two chambers

may be filled with the media of choice for specific problem water. Water passes through

both chambers and is treated by both types of media.

READ ALL INSTRUCTIONS BEFORE USE.

NOTE: This softener DOES NOT yield water suitable for drinking.

TM

WA TER SOFTENER

CODE 1022

Page 2

Page 3

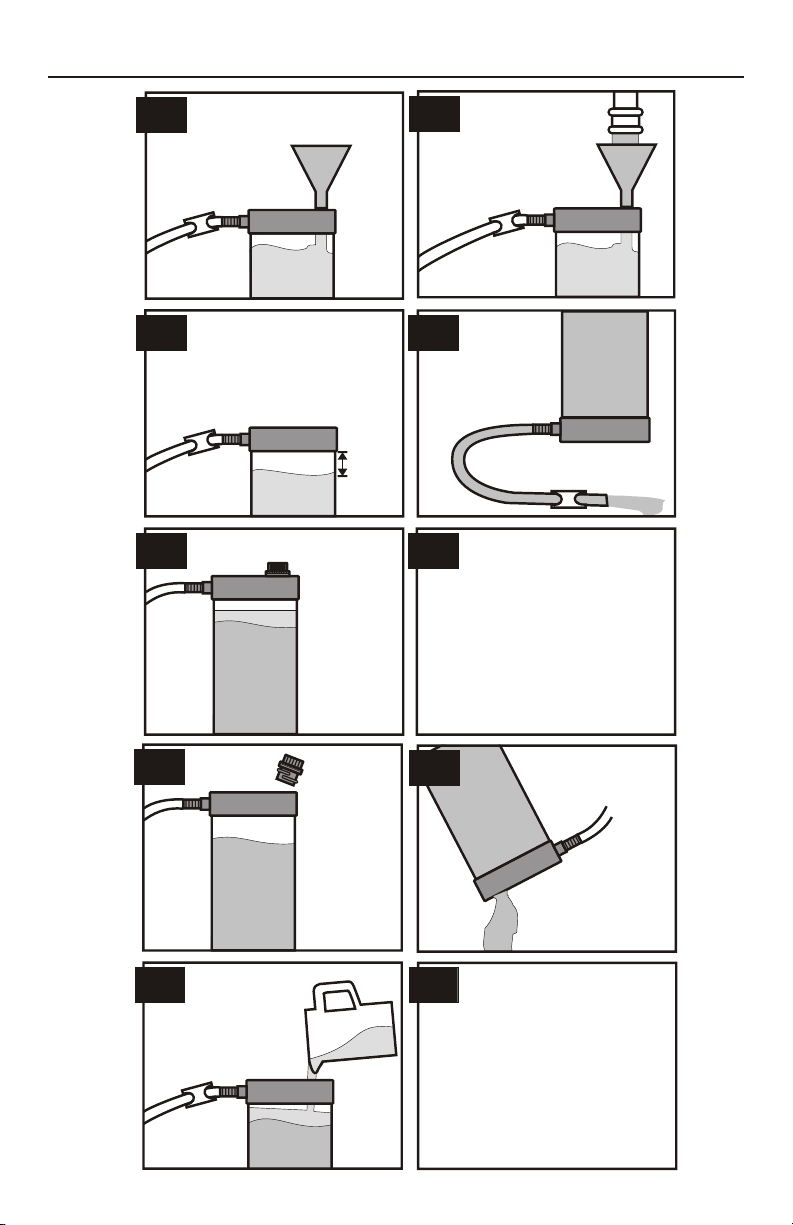

PROCEDURE A - AD DI TION AND RE MOVAL OF RESIN

Allow excess

water to drain

from outlet hose.

4.

Clean

threaded

area

completely

and replace

the black

plug in the

top of

column.

5.

To replace

resin,

remove

black plug

from the top

of dispenser.

1.

By adding more

water to the

3.

column and shaking,

the remaining resin

can be easily removed.

1.

With the aid of a funnel,

add the fresh resin to the

column.

2.

Tap water may

be added to the

resin in the funnel

to facilitate filling of

the column.

Continue adding resin to

the column until the resin is

about 2" from the top of the

column.

2"

3.

Unclamp outlet

hose and turn

softener upside

down.

Allow exhausted

resin and water to

run to waste.

2.

4.

To remove the media in

the bottom chamber,

turn unit upside down

and repeat Removal

Steps 1-3. To add new

media, follow Addition

Steps 1-5 for both

chambers.

ADDITION

REMOVAL

6.

To add the media in the

bottom chamber, turn unit

upside down and repeat

Addition Steps 1-5. When

media has been added to

both chambers, proceed with

Procedure B.

NOTE: When using carbon

it is suggested that the

carbon be used in the top

chamber.

Page 4

PRO CE DURE B - IN STRUC TIONS FOR USE

Adjust flow

to maintain

the 1" layer

of water over

resin.

7.

Let effluent

run to waste

6.

for about 3 minutes to

wash out residue from

the previous sample.

3

M

I

N

U

T

E

S

3.

SLOWLY turn on

faucet and adjust the

flow of water into

softener until the

stream of water is about

1/8” in diameter.

Maintain a gentle flow.

Too much pressure may

cause the adapter to

dislodge from the faucet

and possibly damage the

acrylic cylinder.

Fill chamber

until a 1"

layer of water

is visible over

the resin.

4.

Attach adapter

on inlet hose to

faucet. Fully

open clamp on

inlet hose.

2.

Unclamp outlet

hose at bottom of

softener.

5.

When

softener is

disconnected

from faucet,

clamp inlet

hose.

9.

If softener is to

be stored

unused for any

length of time,

keep a 1" layer

of water over

resin column

to prevent

drying and

cracking.

10.

After enough

softened water

8.

has been collected,

turn off faucet and

clamp outlet hose.

1.

Allow water to

run from faucet

briefly to visually

gauge pressure.

Page 5

PRO CE DURE C - RE GEN ER A TION OF RESIN IN TOP CHAM BER

Clean

threaded area

completely

and replace

black plug in

top of

softener.

6.

At this point the resin in the top chamber should be completely

regenerated.

9.

Wash resin with

approximately 1

gallon of tap water.

8.

Attach adapter

to faucet.

7.

Remove

black plug

from top of

softener.

2.

Prepare salt

solution by

dissolving about

½ pound of salt

(sodium

chloride) in 1

quart of water.

1.

Allow to stand for about 30

minutes.

4.

3

0

M

I

N

UT

E

S

Clamp outlet

tube.

Add salt

solution until

top chamber is

completely

full.

3.

Unclamp outlet tube

and allow salt

solution to run to

waste.

5.

Follow manufacturers’ insstructions for regeneration of media. Cation exchange resin

may be regenerated in the following manner. NOTE: Due to build up of air pressure, it

is not possible to regenerate both chambers at the same time. Follow steps 1-8 to

regenerate top chamber, then procedure D to regenerate bottom chamber.

Page 6

PRO CE DURE D - RE GEN ER A TION OF RESIN IN BOTTOM CHAM BER

At this point the resin in the bottom chamber should be

completely regenerated.

9.

Clean

threaded area

completely

and replace

black plug in

bottom of

softener.

6.

Wash resin with

approximately 1

gallon of tap

water.

8.

Attach adapter

to faucet.

7.

Turn

softener

upside down

and remove

black plug

from bottom

of softener.

2.

Prepare salt

solution by

dissolving

about ½ pound

of salt (sodium

chloride) in 1

quart of water.

1.

Prop up the softener. Allow to

stand for about 30 minutes.

4.

3

0

M

I

NUT

E

S

Clamp inlet

tube.

Add salt

solution until

softener is

completely

full.

3.

Unclamp inlet

tube and allow salt

solution to run to

waste.

5.

Follow manufacturers’ instructions for regeneration of media. Cation exchange resin

may be regenerated in the following manner.

Page 7

Page 8

LaMOTTE COM PANY

Helping Peo ple Solve An a lyt i cal Challenges

PO Box 329 • Chestertown • Mary land • 21620 • USA

800-344-3100 • 410-778-3100 (Out side U.S.A.) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

®

61022-9/11

Loading...

Loading...