Page 1

DO 6

Instruction Manual

Economy Hand-held Dissolved Oxygen Meter

Code 5-0107

Page 2

Page 3

PREFACE

WARNING! This set contains chemicals

that may be harmful if misused. Read

cautions on individual containers

carefully. Not to be used by children

except under adult supervision

This manual serves to explain the use of the Dissolved Oxygen hand-held meter

DO 6.

This manual functions in two ways: first as a step by step guide to help you

operate the meter; second, it serves as a handy reference guide. This manual is

written to cover as many anticipated applications of the DO 6 hand-held

meter as possible. The information presented in this manual is subject to

change without notice.

Page 4

TABLE OF CONTENTS

1 Introduction.............................

5

2 Display & Keypad Functions ....................5

2.1 Display ................................ 5

2.2 Keypad ................................

6

3 Preparation ............................. 7

3.1 Inserting & Removing Rubber Boot ................. 7

3.2 Inserting the Batteries ........................ 8

3.3 Battery Replacement ......................... 8

3.4 Dissolved Oxygen Probe Information................. 9

3.5 Connecting the Probe to Meter ................... 10

3.6 Switching the Meter On....................... 11

3.7 Measurement Mode Selction:-Percentage Saturation (%),

Concentration (mg/L) (ppm) and Temperature (T) ........12

4 Calibration ............................ 13

4.1 Important Information on Meter Calibration ........... 13

4.2 Preparing the Meter for Calibration ................. 14

4.3 Temperature Calibration ...................... 15

4.4 Dissolved Oxygen Calibration in % Saturation ...........16

4.4.1 To calibrate 100% Saturation ................. 16

4.4.2 To calibrate 0% Saturation .................. 17

4.5 Dissolved Oxygen Calibration in mg/L or ppm Concentration

Mode................................ 18

4.5.1 To calibrate in mg/L (ppm) Concentration mode: ......18

5 Measurement ........................... 19

5.1 With Automatic Temperature Compensation (ATC) .......19

5.2 Manual Temperature Compensation ................ 20

5.3 Taking Measurements ........................ 21

5.3.1 To take measurements: .................... 21

5.4 Taking Pressure/Salinity Compensated DO Measurements .....21

5.4.1 Pressure Setting Adjustment ................. 22

5.4.2 Salinity Setting Adjustment.................. 23

6 Hold Function ...........................25

7 Advanced Setup Funtions ..................... 25

7.1 Advanced Setup Overview ..................... 25

7.1.1 To enter the % Saturation or Temperature Set Up menu: . . 25

7.1.2 To enter the mg/L (ppm) Concentration Set Up menu: . . . 26

3

Page 5

7.2 (COF.1) Configuration Menu .................... 28

7.2.1 Selection of Automatic Temperature Compensation .....28

7.2.2 Selection of mg/L or ppm mode ................ 29

7.3 (CAL.2) Calibration Data...................... 30

7.3.1 Viewing the % Saturation calibration data ..........30

7.3.2 Viewing the mg/L (ppm) Concentration calibration data . . 30

7.4 (ELE.3) Electrode Properties .................... 30

7.4.1 Viewing the electrode Slope Factor .............. 31

7.4.2 Viewing the % Saturation Offset (only available in % Saturation

or Temperature Set up menu): ................... 31

7.4.3 Viewing the 100% Saturation mV value ........... 31

7.4.4 Viewing the 0% Saturation mV value ............ 31

7.5 (A

TO.4) Automatic Off ....................... 33

7.6 (

RST.5) Reset to Factory Default .................. 33

7.6.1 Calibration Reset ....................... 34

7.6.2 User Reset ........................... 35

7.7 (OFS.5) % Saturation Offset Adjustment.............. 36

7.8 (DP

R.7) Dissolved Oxygen Parameters ............... 37

7.8.1 Pressure Setting Adjustment ................. 37

7.8.2 Salinity Setting Adjustment ................. 39

8 Probe Care and Maintenance ................... 39

8.1 Probe Care .............................. 40

8.2 Pre-Membraned Caps Replacement .................40

8.3 To Replace the Probe Pre-Membraned Cap............. 40

8.4 Electrolyte Solution ......................... 41

9 Trouble-Shooting Guide ..................... 42

10 Error Messages ...........................43

11 Factory Default Settings ......................44

12 Specifications ...........................46

13 Accessories ............................ 48

14 Additional Information......................48

14.1 Dissolved Oxygen ......................... 48

14.1.1 General Information ..................... 48

14.1.2 Measurement Units ..................... 49

14.1.3 What is Being Measured ................... 49

14.1.4 Air Calibration........................ 50

14.1.5 Applications ......................... 51

15 Limited Warranty .........................51

16 Return of Items ..........................52

4

Page 6

1 INTRODUCTION

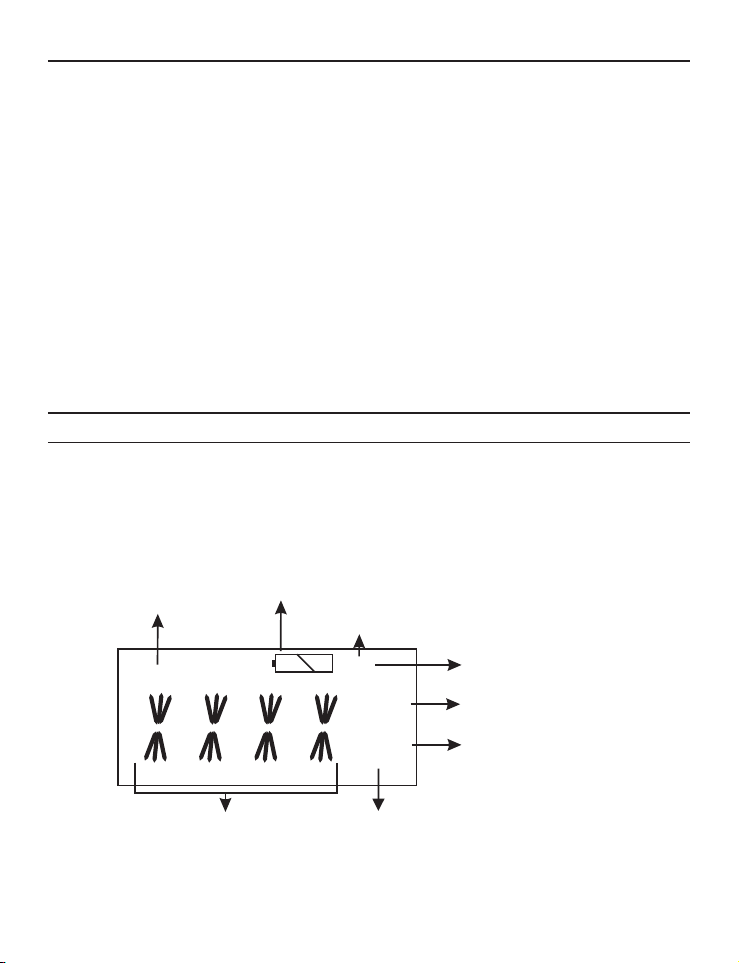

CAL

TA

Low Battery annunciator

Calibration Mode

Annunciator

14-segment Liquid Crystal Display

Percentage

(Percentage Saturation

Mode)

parts per million

milligram per litre

(Concentration Mode)

ATC annunciator

Temperature Mode

mg/L

ppm

%

+

-

8.8.8.8

Thank you for purchasing the DO 6 Dissolved Oxygen palm-top meter. This

economy microprocessor-based hand-held meter has a large custom LCD

(Liquid Crystal Display) for clear and easy reading.

The DO 6 offers the measurement of dissolved oxygen in the percentage

saturation mode and in the concentration mode. Temperature measurement is

also available in degrees Celsius. The meter ensures accurate measurement of

the Dissolved Oxygen values through its temperature, barometric pressure and

salinity compensation features.

Your meter includes a dissolved oxygen probe, refill solution, a rubber boot, 4

alkaline “AAA” batteries, and instruction manual.

Please read this manual thoroughly before operating your meter.

To order other accessories and standard solutions, please refer to the Section

on Accessories for more information.

2 DISPLAY & KEYPAD FUNCTIONS

2.1 Display

The meter has a large custom LCD that consists of 14-segment 4 digit display

and operation annunciators for Percentage Saturation measurement mode (%),

Concentration measurement mode (mg/L or ppm) and Temperature

measurement mode in degrees Celsius (T). Other annunciators include “A”

(when the ATC function is activated), “CAL” (when meter is in calibration

mode) and battery diagram for low battery condition. See Figure 1.

Figure 1, Active LCD display for DO6

5

Page 7

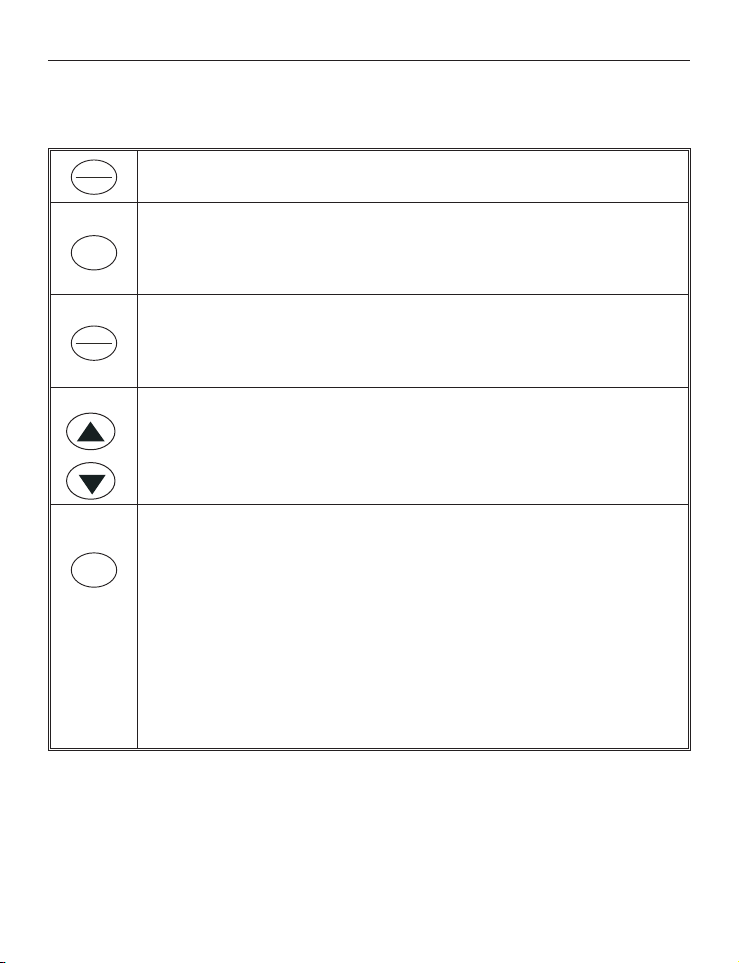

2.2 Keypad

ON

OFF

CAL

HOLD

ENTER

MODE

The DO 6 meter has 6 keys on its splash-proof keypad; ON/OFF,

HOLD/ENTER CAL, MODE,

p and q keys. Some buttons have several

functions depending on its mode of operation.

ON/OFF – Powers on and shuts off the meter. The meter will start in

the measurement mode it was in when last switched off.

CAL – Activates the calibration mode for Percentage Saturation,

Concentration and Temperature calibrations.

Deactivates calibration or setup without confirming a value in

calibration mode.

HOLD -Activates/Deactivates freezing of the measured reading while

in measurement mode.

ENTER - Confirms the calibration values in Calibration mode and

the selections in the SETUP menu.

pq – Sets the calibration values during the Concentration and

Temperature calibration.

Scrolls through each SETUP and its sub group menu.

Set offset adjustments and configuration settings.

MODE - Selects the measurement option between DO Percentage

Saturation measurement; DO Concentration measurement and

Temperature measurement.

When pressed together with ON/OFF key during power on, SETUP

mode is selected. This menu allows meter customization with

preferences such as activating ATC selection, DO concentration

measurement unit selection, viewing of the last calibration data,

viewing of the electrode properties, selecting the auto power off,

resetting calibration data or meter settings back to factory default,

setting the offset adjustments, setting barometric pressure in Hg or PA

for barometric pressure compensation and setting of the salinity value

for salinity compensation.

6

Page 8

3 PREPARATION

3.1 Inserting & Removing Rubber Boot

1. To remove meter from rubber boot, push out from the bottom edges of

meter until it is completely out of boot. Ensure that the cables of Dissolved

Oxygen electrode or temperature probe are not connected

2.. To insert meter into rubber boot, slide in from the top of meter before

pushing the bottom edges of meter down to set it into position. Lift up the

stand at the back of meter for bench top applications if necessary.

Figure 2: Inserting or removing the rubber boot

7

Page 9

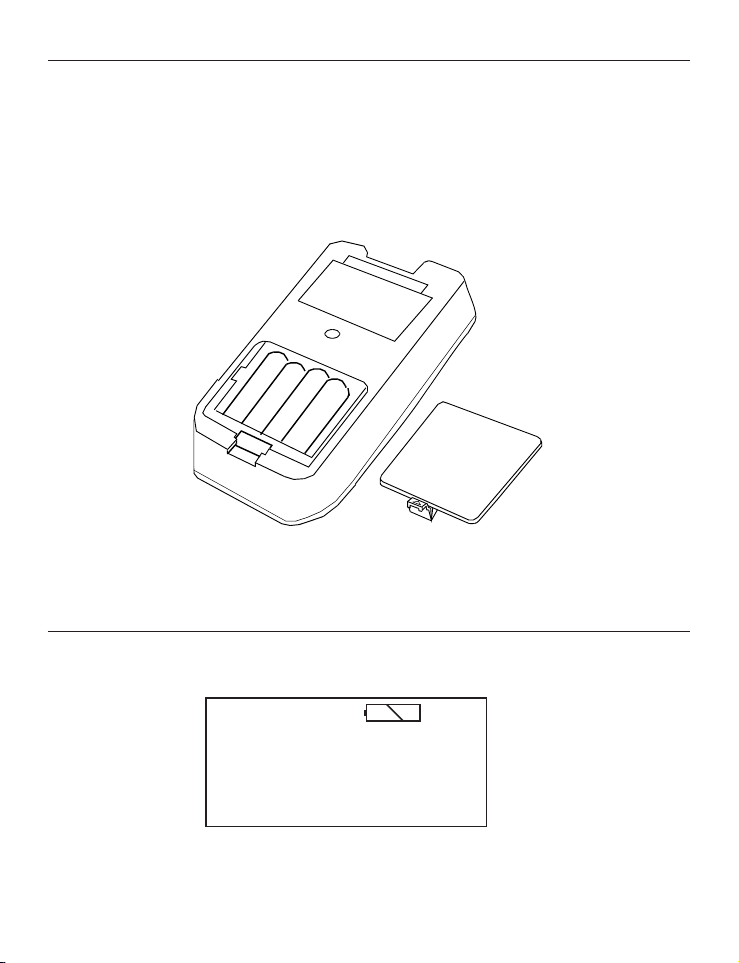

3.2 Inserting the Batteries

3.0

%

+

-

The battery compartment is found at the back of instrument as shown in

Figure 3. To open the battery compartment first remove protective rubber

boot/stand then:

1. Push in the direction of arrow and lift up the cover.

2. Note the polarity of battery before inserting into position.

3. After replacement, place cover back and press down until it locks tight.

Figure 3: Inserting the batteries

3.3 Battery Replacement

A low battery annunciator in the LCD alerts you when battery power is

running low. See Figure 4. Replace with the same type as recommended by the

manufacturer.

Figure 4: Low Battery Condition

Caution: Power off the meter when changing battery.

8

Page 10

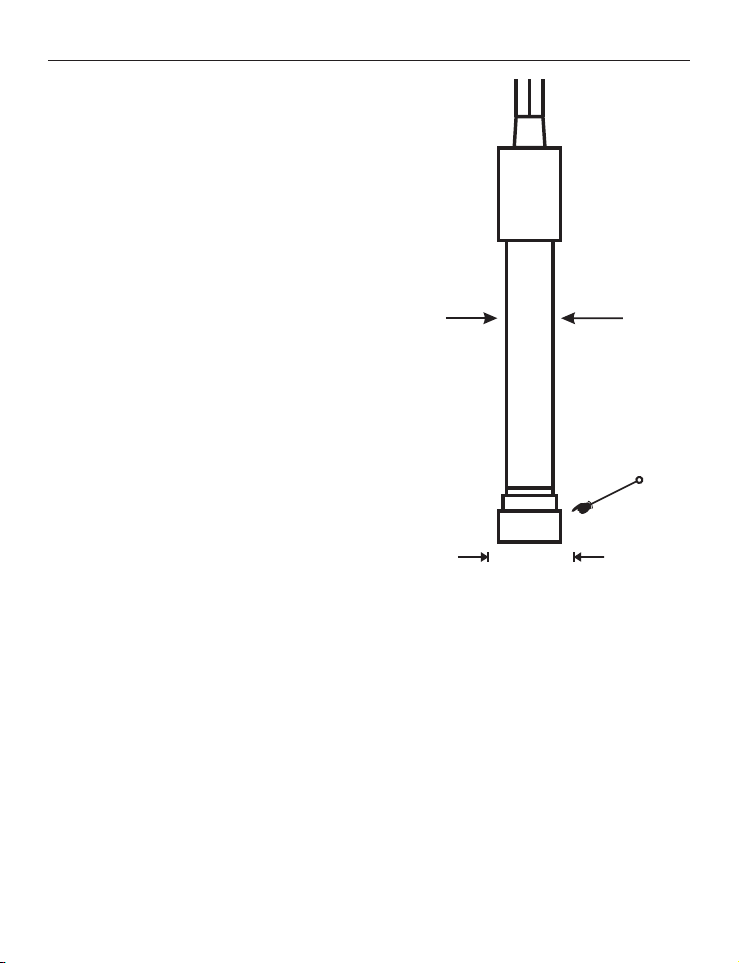

3.4 Dissolved Oxygen Probe Information

16 mm

12 mm

Detachable

Pre-membraned Cap

(Probe Sensing Area)

Figure 5: 12 mm Galvanic DO probe

The DO 6 hand-held meter is supplied with

a Dissolved Oxygen Probe that works on

galvanic principle, that is, it does not require

any polarising voltage from your meter.

Rather it will generate a millivolt signal

proportional to the amount of oxygen in the

solution.

Your DO Probe has a twin cable, one with a

BNC connector for the DO measurement

input, and the other with a phono jack plug

for the temperature measurement input. Its

sensing area consists of a cathode, anode, and

an inner electrolyte which is separated from

your sample solution by an oxygen permeable

membrane pre-membraned to the probe’s

detachable cap. Reconditioning of your

probe is made easy with the introduction of

this specially designed detachable

pre-membraned cap.

This light weight probe has a built-in

temperature sensor for Automatic

Temperature Compensation (ATC) with

12mm diameter epoxy body housing and 16

mm diameter Noryl detachable cap. Its

compact sensing area reduces air entrapment

which makes it easy to obtain fast, accurate

and stable readings. Simply stir the probe in

the solution being measured. Shaking will aid to remove bubbles if needed

before taking a reading. Also, always ensure to remove water drops from the

membrane when calibrating in air.

Proper use of probe is essential to ensure that the optimum measurement is

taken in a short time. Always immerse the probe beyond the pre-membraned

cap. The minimum water flow rate is 2 inch/second across membrane. The

temperature range for use is within 0 to 50 °C.

Always ensure that the probe’s membrane is protected against any scratches or

dents. The whole pre-membraned cap has to be replaced if the

membranedamaged. It is also important to keep the membrane clean so as to

produce an optimum and accurate measurement.

See Section 8 - "Probe Care and Maintenance" for more information.

9

Page 11

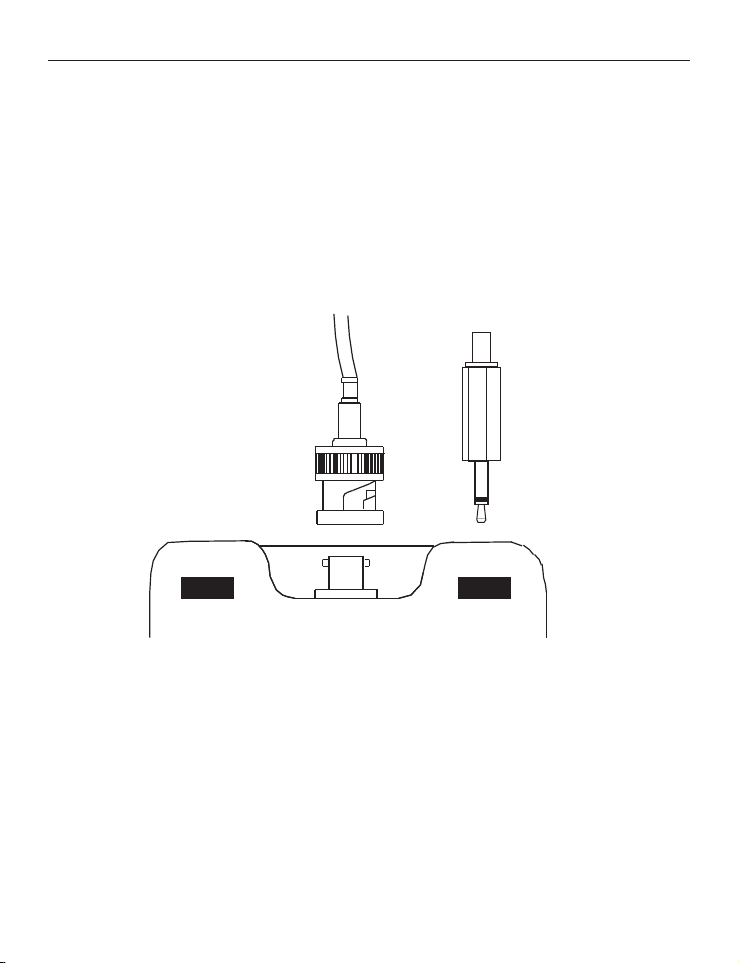

3.5 Connecting the Probe to Meter

BNC Connector for

DO probe

Phono jack for

Temperatureprobe

1. Insert the BNC connector from the electrode to the BNC connector socket

on the meter accordingly and rotate connector clockwise until it locks. See

Figure 6 below.

2. To remove, simply rotate the connector in counter-clockwise direction

until it unlocks, and slide the connector off the socket.

3. Plug the phono jack of temperature sensor into the phono socket of the

meter as shown in Figure 6 below.

Caution: Do not pull or force the probe cord or the probe wires might

disconnect.

Note: Keep connectors clean. Do not touch connector with soiled hands.

Figure 6: DO 6 probe to meter connections

10

Page 12

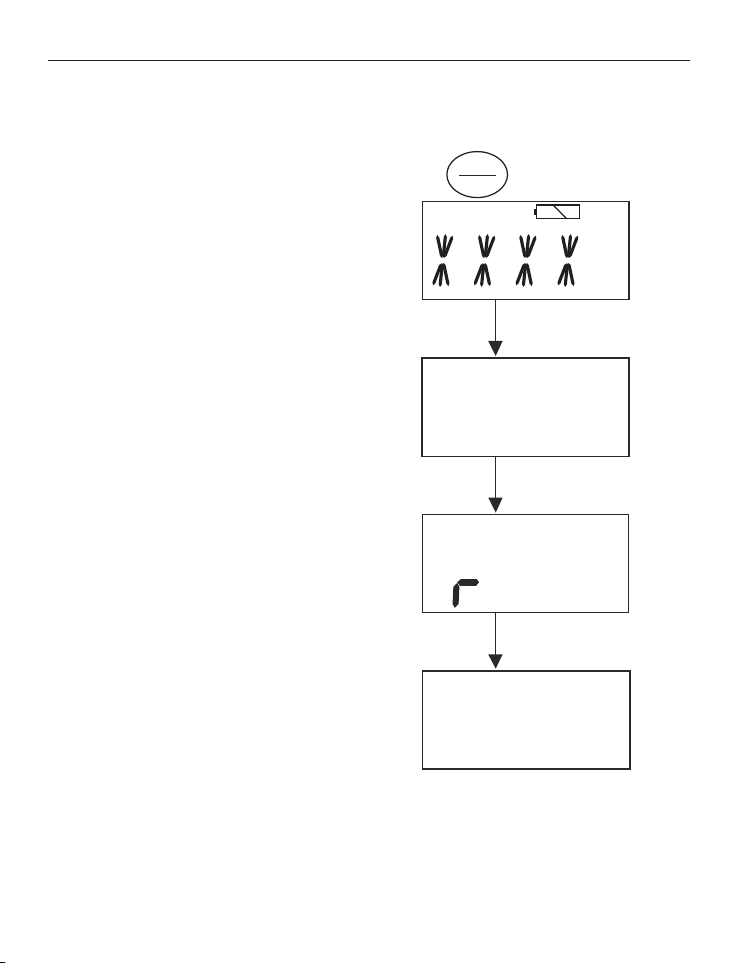

3.6 Switching the Meter On

CAL 13 CAL 24

TAv g

A

1.00

10.00

D06

mg/L

NTU

mg/L

ppm

ppm

%pH

%

%

+

-

8.8.8.8

ON

OFF

When switching the meter on, it will go through a series of display, eventually

showing the revision number of the meter before going to the measurement

mode. The mode of measurement which the meter displays will be similar to

the last measurement mode to

which the meter is switched off.

Press ON/OFF key to power up

your meter.

1. All LCD segments will light up

for 1.5 seconds.

2. The display will then

momentarily show the meter’s

identification “DO 6” with the

annunciators for percentage

saturation mode and

concentration mode.

3. The display continues to switch

to display meter’s revision

number for 1.5 seconds before

finally showing the

measurement mode.

4. Either percentage saturation

measurement mode,

concentration measurement

mode or temperature

measurement mode will be

displayed following the previous

measurement mode to which

the meter is switched off.

Figure7: Power Up sequence

11

Page 13

3.7 Measurement Mode Selection:- Percentage Saturation (%),

10.00

8.24

25.0

MODE

MODE

A

A

TA

mg/L

%

Automatic Temperature

Compensation

Percentage Saturation

Concentration Mode

Temperature Mode

Concentration (mg/L)(ppm) and Temperature(T)

By simply pressing the MODE key, you can select the measurement mode of

percentage saturation measurement, concentration measurement or

temperature measurement.

The customized annunciator shall indicate the selection of the measurement

mode.

Figure 8: Measurement mode selection using the mode key

12

Page 14

4 CALIBRATION

4.1 Important Information on Meter Calibration

Your meter has three measurement modes namely the DO % saturation

measurement mode, the DO mg/L (ppm) concentration mode and the

Temperature measurement mode.

Since the mg/L (ppm) concentration value of dissolved oxygen varies with

temperature, barometric pressure and salinity, the meter with its electrode has

to be calibrated with consideration to these factors to ensure a proper

measurement. Therefore, it is very important to set the proper temperature,

barometric pressure and salinity values in the meter prior to any calibration or

measurement process. Since the dissolved oxygen measurements in %

saturation will linearly affect the mg/L (ppm) concentration measurement, it is

important that the meter has to be first calibrated in the % Saturation mode

and temperature mode before commencing the mg/L (ppm) concentration

mode calibration.

In % saturation calibration mode, the dissolved oxygen calibration values will

vary according to the barometric pressure correction set in the meter.

Therefore it is necessary to set the barometric pressure first before proceeding

to % Saturation calibration. The following table is an example which explains

the acceptance calibration values when % Saturation mode calibration is

attempted under different absolute value and under two different barometric

pressures.

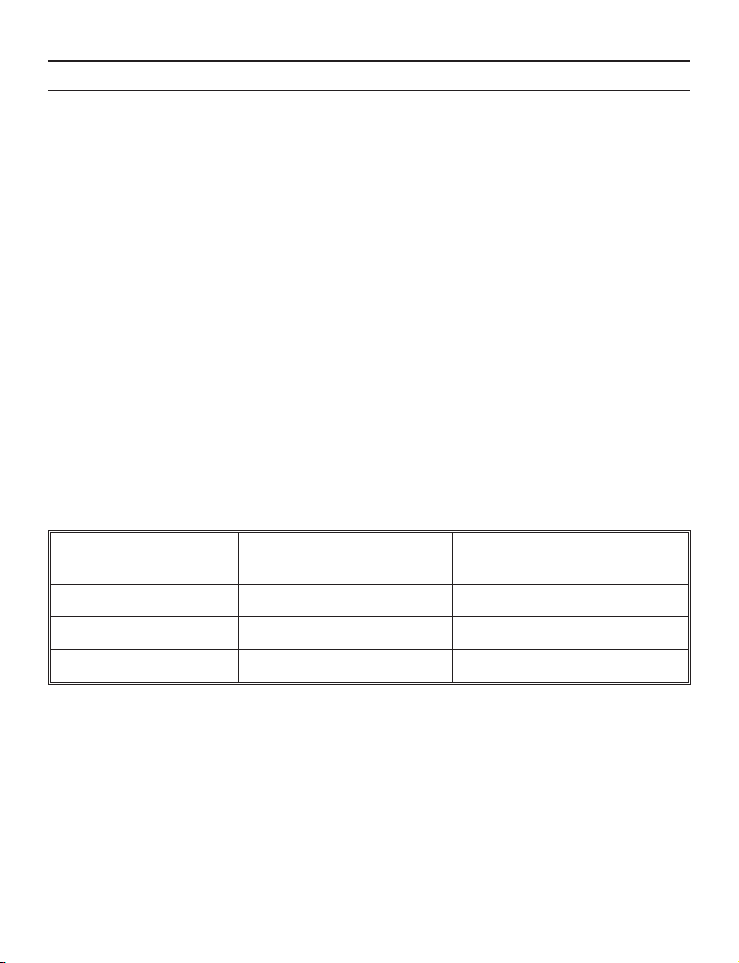

% Saturation factory

default value

less than 10% 0% 0%

10.1% to 49.9% Err.1 (error 1) Err.1 (error 1)

50% to 200% 100% 92.1%

Acceptance Calibration

Value (760mmHg)

Acceptance Calibration

Value (760mmHg)

In the mg/L (ppm) concentration calibration mode, barometric pressure,

salinity and temperature of the calibration sample needs to be set in the meter

prior to calibration. Since the pressure has already been set in the % saturation

calibration which is done earlier and assuming that the calibration is done on

the same barometric pressure and if you are using the temperature sensor in

automatic temperature compensation mode, you only need to input the known

salinity of the calibration sample to the meter. The dissolved oxygen mg/L

(ppm) concentration value can then be calibrated to the known sample

concentration calibration value. Note that the concentration calibration

13

Page 15

window is +/- 40% of the factory default value. However the minimum point of

calibration is 2 mg/L.

When you recalibrate your meter in % saturation mode, old calibrations in %

saturation will be replaced while the % saturation offset adjustment will be

erased. However, recalibration in the mg/L (ppm) concentration mode will

only replace the old calibration in the concentration mode and do not affect

the calibration in the percentage saturation mode.

To completely recalibrate your meter, or when you use a replacement

electrode, it is best to clear all calibration data. To erase all the old calibration

data completely, see Section 7.6 (rSt.5) Reset to Factory Default.

4.2 Preparing the Meter for Calibration

Before starting calibration, make sure you are in the correct measurement

mode and in the correct calibration sequence. The temperature and the %

Saturation calibration must be done first before attempting to do the mg/L

(ppm) Concentration calibration.

In % Saturation, the meter is able to perform either a one point calibration or

a 2 point calibration. For one point calibration, it is recommended that you

perform a 100% Saturation calibration in saturated air. If you opt for 2 point

calibration, you can calibrate for 100% Saturation in saturated air and 0%

Saturation using a zero oxygen solution. The meter will take several minutes to

reach 0% Saturation value after submersion into the zero solution.

Rinse the probe well in the de-ionized (DI) water or rinse solution and wipe

the probe carefully taking care of the membrane.

Calibrate the meter in all the modes to ensure the highest accuracy throughout

the DO measurement range. In % Saturation calibration, should there be a

calibration failure for 0% Saturation slope calibration; the meter may have

exceeded the limit of 10% of the factory calibrated absolute value. The sensor

may have to be re- conditioned. Also, note that the DO 6 meter will not

perform 0% or 100% Saturation calibration for absolute value ranging from

10.1% to 49.9%. The meter also will not perform the mg/L (ppm)

Concentration calibration for an absolute value of less than 2.00 mg/L (ppm)

or calibration which is out of its window tolerance of +/- 40% from the factory

default value. An error message of “Err.1” will be indicated and will return the

meter to the measurement mode.

All new calibration values will automatically override the existing data. It is

recommended to calibrate the meter periodically and or if it is suspected to be

inaccurate.

14

Page 16

Always rinse the probe with either DI water or rinse solution before and after

CAL

HOLD

ENTER

co

24.3

TA

25.0

TA

“CO” will display for

1.5 seconds

24.3

TA

CAL

25.0

TA

CAL

Factory default

Temperature

Measurement

Figure 9: Temperature Calibration Sequence

each calibration/sample measurement. When calibrating in air, make sure that

any water droplets from the probe’s membrane are removed.

For details please refer to Section 8 - PROBE CARE AND MAINTENANCE.

Note: The DO 6 factory calibrated default value is in respect to 760mm Hg or

101.3 kPa barometric pressure (sea level). To set the barometric pressure to

different value, see Section 5.4.1 Pressure Setting Adjustment.

4.3 Temperature Calibration

DO mg/L (ppm) Concentration

measurement is dependent on the

temperature of the sample to be

measured. Most users will choose

to have the DO 6 automatically

compensate for temperature using

the temperature sensor that is

built into the DO probe.

However, it is possible to

manually enter a known

temperature to the meter

(manual temperature

compensation). The built-in

temperature sensor of the DO 6

probe is factory calibrated.

However, the temperature can be

re-calibrated if needed and is

recommended when a

replacement probe is used.

Before calibration, ensure that

the meter displays annunciator

“A” to indicate that it is in

automatic temperature

compensation mode. Please see

Set Up menu on page 36 for its

activation procedure.

1. Switch the meter on. Press

MODE to select temperature

mode. The display should

show the annunciator “T” for

temperature mode and“A”

for automatic temperature compensation mode.

15

Page 17

2. Dip the probe to a solution of known temperature (i.e. a temperature

CAL

HOLD

ENTER

co

83.0

A

CAL

100.0

A

“CO” will display for

1.5 seconds

A value with respect to the

factory default calibration

will be displayed

100.0

85.2

CAL

Calibration point will be

displayed for 1.5 seconds

Figure 10: 100% Saturation Calibration

%

%

%

%

bath).Allow some time for the reading to stabilize.

3. Press the CAL key. The CAL indicator will appear and blinks above the

display. The temperature value displayed is with respect to the factory

default calibration.

4. Press the p andq keys to adjust the meter reading to the correct

temperature value (i.e. the temperature of the temperature bath)

5. Press the HOLD/ENTER key to confirm temperature calibration and

return to measurement mode.

NOTE: To exit from Temperature Calibration mode without confirming the

calibration, press CAL instead of HOLD/ENTER. Temperature calibration is

restricted to ± 5°C from the factory

default temperature measurement

displayed during calibration.

4.4 Dissolved Oxygen Calibration in

% Saturation

You can calibrate this meter quickly and

easily in air. The exact calibration value

depends on barometric pressure. The

meter is set to a factory default of 760 mm

Hg, which results in a calibration value of

100% Saturation in air.

NOTE: If the barometric pressure setting

has been changed from 760 mm Hg, the

calibration value in air will automatically

adjust to a value other than 100%. The

adjusted value will be correct for the new

barometric pressure setting.

See Section 5.4.1 Pressure Setting

Adjustment on page 26 to change the

pressure setting.

4.4.1 To calibrate 100% Saturation:

1. Rinse the probe well with DI water or

rinse solution. Do not touch the

membrane.

2. Press the MODE key to select the %

Saturation mode.

16

Page 18

3. Hold the probe in the air with the sensor facing downwards. Wait for the

CAL

HOLD

ENTER

co

3.0

A

CAL

0.0

A

“CO” will display for

1.5 seconds

A value with respect to the

factory default calibration

will be displayed

0.0

5.2

CAL

Calibration point will be

displayed for 1.5 seconds

Figure 1: 0% Saturation Calibration

%

%

%

%

reading to stabilize.

4. Press the CAL key. The display will show the intended percentage

calibration point (100%) with a CAL indicator at the top corner for 1.5

seconds. The CAL indicator will then blink and the display will show a

value which is with respect to the factory default calibration. When

calibration is attempted on a factory calibrated absolute value measurement

of 10.1% to 49.9%, the display will show the absolute value measurement

for 1.5 seconds before displaying Err.1 and goes to the measurement mode.

5. Press the HOLD/ENTER key to confirm the calibration. The meter

displays “CO” for 1.5 seconds and automatically calibrates to 100.0% air

saturation and returns to measurement

mode.

Note: You can offset your % DO

calibration. See Section 7.7 (OFS.6) %

Saturation Offset Adjustment for

directions.

6. Press the HOLD/ENTER key to confirm

the calibration. The meter displays

“CO” for 1.5 seconds and automatically

calibrates to 0.0% Saturation and

returns to measurement mode.

4.4.2 To calibrate 0% Saturation

1. Rinse the probe well with DI water or

2. Press the MODE key to select the %

3. Dip the probe into the zero oxygen

4. Press the CAL key. The display will

Note: When calibration is attempted on a

factory calibrated absolute value

rinse solution.

Saturation mode, if necessary.

solution. Wait for the reading to

stabilize.

show the intended percentage

calibration point (0%) with a CAL

indicator at the top corner for 1.5

seconds. The CAL indicator will then

blink and the display will show a value

which is with respect to the factory

default calibration.

17

Page 19

measurement of 10.1% to 49.9%, the

CAL

HOLD

ENTER

co

8.1 6

A

8.24

A

mg/L

“CO” will display for

1.5 seconds

9.00

mg/L

mg/L

8.24

mg/L

Factory default

Temperature

Measurement

Figure 9: Temperature Calibration Sequence

CAL

CAL

display will show the absolute value

measurement for 1.5 seconds before

displaying Err.1 and goes to the

measurement mode.

5. Press the HOLD/ENTER key to

confirm the calibration. The meter

displays “CO” for 1.5 seconds and

automatically calibrates to 0.0%

Saturation and returns to

measurement mode.

4.5 Dissolved Oxygen Calibration in

mg/L or ppm concentration mode :

Calibrating the meter to 100% Saturation

will also calibrate the concentration mode

at the value in mg/L corresponding to

100% Saturation. This should produce

acceptable results in most applications.

This meter also lets you make a

calibration adjustment in mg/L (ppm)

Concentration mode without affecting

your % Saturation calibration.

To select between mg/L and ppm units,

see page 38

mode"

.

4.5.1 To calibrate in mg/L (ppm)

Concentration mode:

1. Calibrate 100% Saturation as per

Section 4.4.

2. Rinse the probe well with DI water or

rinse solution. Wipe the outside of the

probe carefully (do not touch the

membrane).

3. Dip the probe into a sample of known

oxygen concentration. Wait for the

reading to stabilize.

4. Press the MODE key to select the

mg/L (ppm) Concentration mode.

, "Selection of mg/L or ppm

18

Page 20

5. Press the CAL key. The display will show a value which is with

83.0

%

A

Automatic Temperature

Compensation activated

Figure 8: Automatic Temperature Compensation

respect to the factory default calibration with a CAL indicator

blinking at the corner of the display.

6. Press the p andq keys to adjust the reading to the known oxygen

concentration of the sample.

7. Press the HOLD/ENTER key to confirm the calibration. The meter

will display “CO” for 1.5 seconds and automatically calibrates to the

value you have entered and returns to the measurement mode.

NOTES: The concentration calibration window is +/- 40% of the factory

default value. However, the minimum point of calibration is 2 mg/L. In

an event where the default measured value is less than 2 mg/L and a

calibration is attempted, the display will show “2.00” and then error

message “Err.1” will be displayed momentarily before returning to

measurement mode.

You can change the barometric pressure value and salinity value in the

mg/L (ppm) Set Up menu (see Section and for and ). Please refer to

page if you are intending to use manual temperature compensation.

5 MEASUREMENT

The DO 6 meter is capable of taking measurements with automatic or

manual temperature compensation.

5.1 With Automatic Temperature Compensation (ATC)

For Automatic temperature compensation, make sure the phono jack of

the probe (see Figure 6 in Section 3.5) is securely inserted. The ATC

annunciator “A” will be blinking if the ATC probe is disconnected.

Activate the “A.ATC” mode in the set up menu, if necessary. See page

36.

19

Page 21

5.2 Manual Temperature Compensation

CAL

HOLD

ENTER

co

25.0

T

25.5

T

“CO” will display for

1.5 seconds

25.0

T

CAL

25.5

mg/L

CAL

Last set manual

temperature setting

Figure 3: Manual Temperature

Compensation value selection sequence.

For manual temperature

compensation, simply deactivate the

“A.ATC” mode as explained in the

set up menu on page . The

automatic temperature

compensation annunciator “A” will

not be displayed to represent that

the meter is in manual temperature

compensation mode.

To use manual temperature

compensation, you need to enter the

temperature value of your process

into the meter. You can select any

temperature between 0 and 50 °C.

Default value is 25 °C.

1. Switch on the meter and if

2. Press CAL key to start

3. The “CAL” indicator will start

4. Check the temperature of your

5. Press the HOLD/ENTER key to

necessary, press MODE key to

select temperature measurement

mode.

temperature calibration process.

blinking and the display will

show the last manual set

temperature value.

sample using an accurate

reference thermometer. Wait for

the thermometer value to

stabilize. Press the p or q key

of your meter to manually set its

temperature value according to

the value of the reference

thermometer used.

confirm the manual temperature

setting made. The “CO”

indicator will appear for 1.5

seconds before the display

returns to the measurement mode.

20

Page 22

5.3 Taking Measurements

70.5

5.80

24.3

MODE

MODE

A

A

TA

mg/L

%

Figure 4: Measurement mode

During measurement, care must be taken

to ensure that the probe’s membrane

surface does not touch anything. Stir

around the solution to prevent any air

bubbles from being trapped on the

membrane before taking a reading.

IMPORTANT: Since the DO probe

consumes oxygen from the sample, the

sample must constantly flow past the

membrane to achieve more accurate

readings. You can use a stirrer to

accomplish this.

5.3.1 To take measurements:

1. Rinse the probe well with DI water or

rinse solution.

2. Select the appropriate measurement

mode. Press the MODE key to toggle

between modes:

a. Percentage Saturation (%)

b. Concentration (mg/L) or (ppm)

c. Temperature (T)

3. Dip the probe into the sample. Stir

the solution gently to homogenize

the sample. Make sure that the

sample is continuously flowing past

the membrane sensor.

4. Take your measurements once your meter reading has stabilized.

Note: “Ur”/”Or” will be displayed if the instruments exceeds the specified

measuring range. See Section for range specification.

To select between mg/L and ppm units, see Set Up menu on page 38.

5.4 Taking Pressure/Salinity Compensated DO Measurements

In taking pressure and salinity compensated DO measurements, the pressure

and salinity values of your measurements need to be adjusted from the Set Up

menu. The pressure setting adjustment feature is available when Set Up menu

is derived from the % Saturation mode, mg/L (ppm) Concentration mode or

21

Page 23

Temperature mode. Salinity setting feature, on the other hand, will only be

available when Set Up menu is derived from the mg/L (ppm) Concentration

mode. See Section - Advanced Setup Overview for more information.

During measurement, the DO meter will automatically compensate for salinity

and pressure based on the values entered in the Set Up Menu. The meter is

factory set at 760 mm Hg (101.3 kPa) barometric pressure setting and a salinity

factor of 0.0 ppt.

5.4.1 Pressure Setting Adjustment

(See Figure 16 for flow chart explanation)

1. Switch off your meter in mg/L (ppm) Concentration mode.

2. While pressing and hold the MODE key, switch on the meter by pressing

the ON/OFF key.

3. Once the ON/OFF key is released, the meter will enter the Set Up menu

by displaying “SEt.P”. By releasing the MODE key, the display will show

the configuration menu “COF.1”. See section – Advanced Setup

Functions

4. Press the p and q keys to scroll through the Set Up main group menu till

the display shows “DPr.7”.

5. Press the HOLD/ENTER key and the meter will enter the barometric

pressure units selection menu with the display showing one of two; either

“A.HG” for mm Hg or “A.PA” for kilo Pascal, depending on what the

meter’s last set up was.

6. Use the p and q keys to toggle between the two units of pressure

measurement and press the HOLD/ENTER key to confirm selection.

7. Use the p and q keys to set the pressure value and press the

HOLD/ENTER to confirm the setting. A confirmation indicator “CO” will

be displayed for 1.5 seconds before the meter shows the next display of

Salinity setting “b.SAL”. If the Set Up menu is derived from other than the

mg/L (ppm) Concentration mode, the meter will return to the Set Up

main group menu “DPr.7”.

8. Press CAL key to return to measurement mode, or continue to make a

salinity setting adjustment.

.

22

Page 24

5.4.2 Salinity Setting Adjustment

.sal

HOLD

ENTER

HOLD

ENTER

0.0

45.2

co

“CO” will display

for 1.5 seconds

Display will return back to “DPr.7”

subgroup menu

Figure 5: Salinity Setting Adjustment Sequence

NOTE: This mode is available

only from the mg/L (ppm)

Concentration Set Up menu.

1. Repeat steps 1 to 5 as in the

steps of Pressure Setting

Adjustment.

2. Press the HOLD/ENTER key

twice till the meter displays the

Salinity setting mode “b.SAL”.

3. Press the HOLD/ENTER key

to enter the Salinity setting

mode.

4. Use the p and q keys to enter

5. Press HOLD/ENTER key to

6. Press CAL key to return to the

the salinity of your solution in

parts per thousand (ppt).

Factory default is 0.0. Salinity

values up to 50 ppt can be

entered.

confirm the value. A

confirmation indicator “CO”

will be displayed for 1.5

seconds before returning to the

main group menu “DPr.7”.

measurement mode.

23

Page 25

HOLD

ENTER

HOLD

ENTER

HOLD

ENTER

HOLD

ENTER

.7

.

.

760

HOLD

ENTER

co

750

101.3

co

105. 2

“CO” will display

for 1.5 seconds

“CO” will display

for 1.5 seconds

Display will continue to

Salinity setting menu

“b.SAL” if Set Up menu is

entered from mg/L (ppm)

mode. Otherwise display will

return back to “DPr.7”

Display will continue to

Salinity setting menu

“b.SAL” if Set Up menu is

entered from mg/L (ppm)

mode. Otherwise display will

return back to “DPr.7”

Figure 16: Pressure Setting Adjustment Sequence

24

Page 26

6 HOLD Function

70.5

A

Annunciator Blinks when

meter is in “HOLD” mode

Figure 68: Unit in HOLD mode

%

This feature lets you freeze the display for a delayed observation. HOLD can be

used in any measurement mode.

1. To hold a measurement, press the HOLD/ENTER key while in

measurement mode. The %, mg/L, ppm or T annunciator in the display

will start blinking to indicate that the measurement is being held.

2. To release the held value, press the HOLD/ENTER again. The

annunciator will stop blinking to indicate that the held value has been

released.

3. Continue to take measurements.

Note: This meter has a selectable auto off feature which when activated will

shut the meter off automatically after 20 minutes of non use.

If the meter is shut off either automatically or manually, the HOLD value will

be lost.

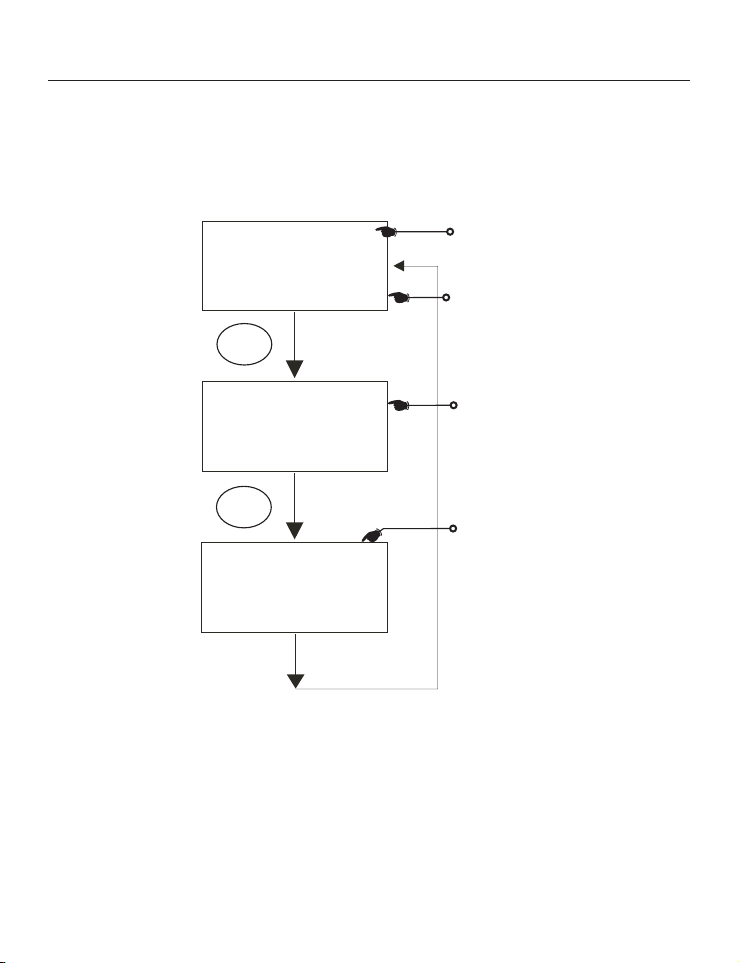

7 ADVANCED SETUP FUNCTIONS

7.1 Advanced Setup Overview

The advanced setup mode lets you customize your meter’s preferences and

defaults. There are two Set Up menus: - one which is derived from the %

Saturation or Temperature mode and the other is derived from the mg/L (ppm)

Concentration mode.

7.1.1 To enter the % Saturation or Temperature Set Up menu:

1. Make sure that the meter is switched-off while in the % Saturation or

Temperature measurement mode.

25

Page 27

2. With the MODE key pressed, power the unit on by pressing the ON key.

COF.1

ELE.3

CA L.2

Release the ON key before releasing the MODE key.

3. “SEt.P” indicator will appear momentarily and “COF.1” will appear next.

4. You are now in the % Saturation or Temperature Set Up menu.

7.1.2 To enter the mg/L (ppm) Concentration Set Up menu:

1. Switch off the meter in the mg/L (ppm) Concentration measurement

mode.

2. Repeat steps 2 to 3 as above and you will be in the mg/L (ppm)

Concentration Set Up menu.

The following table combines the explanation for the features available in

both Set Up menus. Figures 19 and 20 give an overall view of the Set Up

sequence for the % Saturation or Temperature Set Up menu and the mg/L

(ppm) Concentration Set Up menu.

SEt.P - Enter Set Up Menu

COF.1 – Enter Configuration Menu

A.ATC –Selection for automatic temperatur

b.DO – Selection of mg/L or ppm of the concentration mode

measurement. (Only available in Concentration Set Up menu)

CAL.2 – Viewing the latest Calibration data

‘View only’ parameter for the latest calibration data of the DO

% Saturation calibration and the DO mg/L (ppm)

Concentration calibration. Calibration data will be viewed

according to its respective Set Up menu.

ELE.3 – Viewing the Electrode properties

FACT – Viewing the Slope Factor

OFS – Viewing the % Saturation offset adjustment. (Only

available in % Saturation Set Up menu)

HI.mV – Viewing the mV value for 100% Saturation

LO.mV – Viewing the mV value for 0% Saturation

AtO.4 – Selection of automatic power off (20 minutes from the

last key press)

26

Page 28

rSt.5 – Enter Reset Menu

OF5.6

p

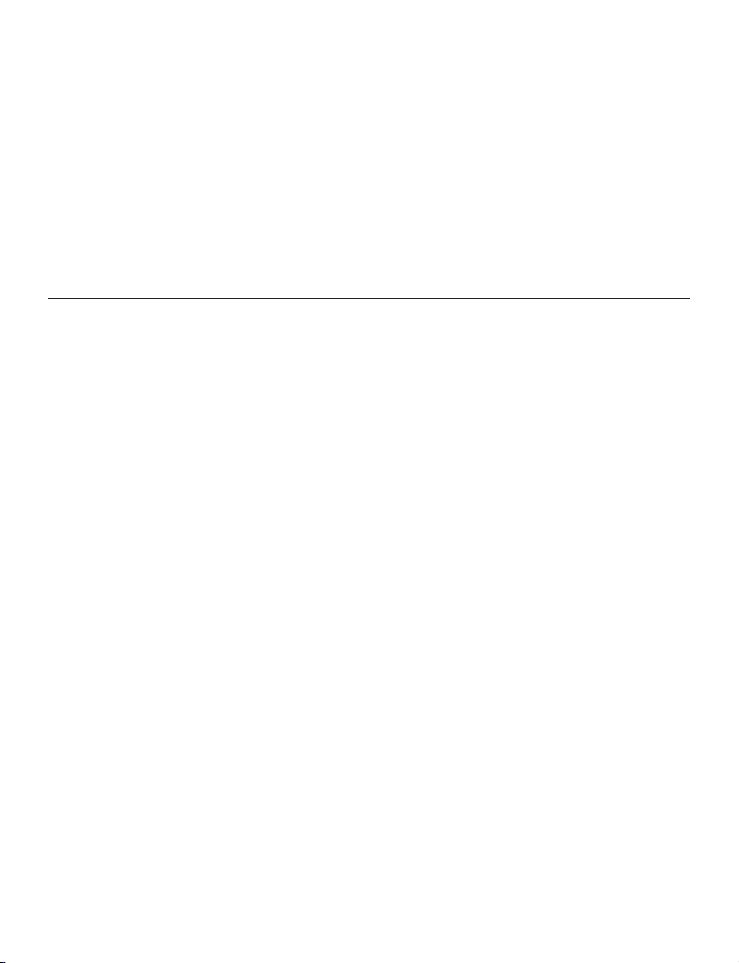

Figure 79: Overview of DO 6% Saturation or Temperature Setup Menu

Switch off from % Saturation

or Temperature measurement

mode. Press and hold MODE

key and then switch on.

SEt.P will display for

1 second

MODE

ON

OFF

COF.1

CA L.2

ELE. 3

OF5.6

p

A.CAL – Selection of Calibration Reset (Clear only Calibration

and its Data back to factory default condition)

b.USR – Selection of User Reset (Clear all user setting back to

factory default condition)

OFS.6 - % Saturation Offset Adjustment (Only available in %

Saturation Set Up menu)

DPr.7 – Enter Barometric Pressure Selection Menu

A.HG – Selection of Barometric Pressure Setting Adjustment in

mmHg

A.PA - Selection of Barometric Pressure Setting Adjustment in

Kilo Pascal

b.SAL – Enter the Salinity Setting Adjustment Menu (Only

available in mg/L (ppm) Concentration Set Up menu)

27

Page 29

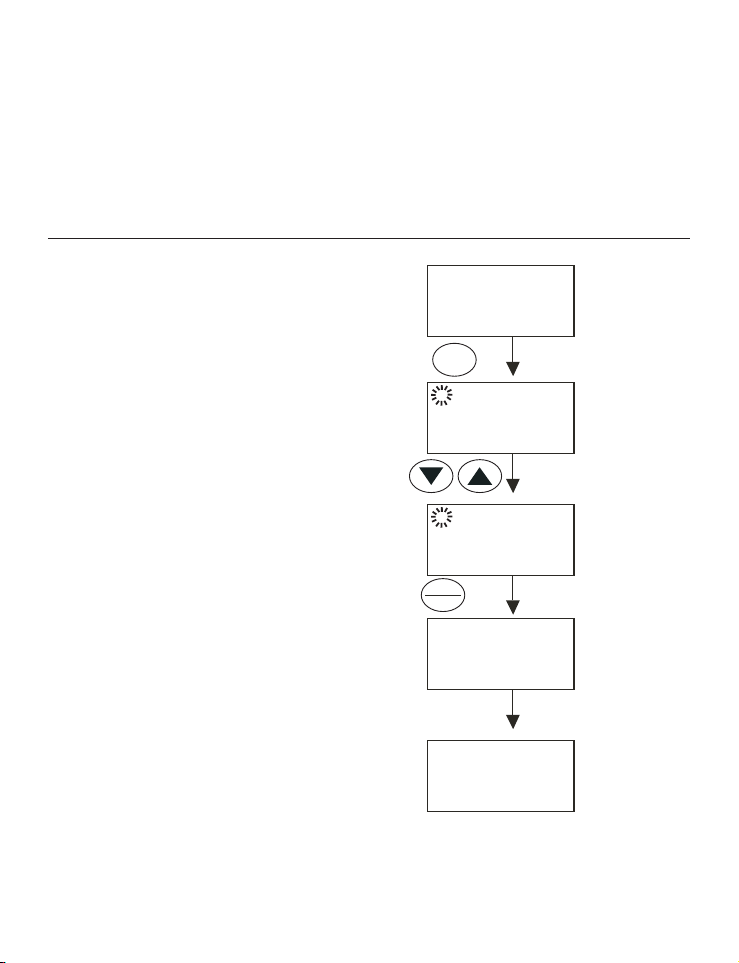

Figure 19: Overview of DO6 Concentration Set up Menu

Switch off from Concentration

measurement mode. Press

and hold MODE key and then

switch on.

SEt.P will display for

1 second

MODE

ON

OFF

COF.1

CA L.2

ELE. 3

p

Figure 20: Selection of Automatic or

Manual Temperature

Compensation

COF.1

A.AT c

yes

HOLD

ENTER

HOLD

ENTER

7.2 (COF.1) Configuration

Menu

In this menu, the meter lets you

configure the selection of

automatic temperature

compensation (A) and the

selection of mg/L or ppm mode for

the mg/L (ppm) Concentration

measurement mode. (Second

feature is only available in mg/L

(ppm) Concentration Set Up

menu)

7.2.1 Selection of Automatic

Temperature Compensation

From "COF".1" of any Set Up

menu.

28

Page 30

1. 1.Press the HOLD/ENTER key for the display to show the Automatic

Figure 21: Selection of mg/L or ppm

mode

mg/L

ppm

Temperature Compensation selection menu “A.ATC”.

2. Press the HOLD/ENTER key to enter the ATC selection menu.

3. Use the p and q keys to either activate or deactivate the ATC feature.

a. YES – activates the ATC

b. NO – deactivates the ATC and activates the Manual temperature

compensation

4. Press the HOLD/ENTER key to confirm your selection.

Note: The meter will either return to the main group menu “COF.1” if %

Saturation or Temperature Set Up menu is used or will continue to the mg/L

or ppm mode configuration if mg/L (ppm) Concentration Set Up menu is used.

7.2.2 Selection of mg/L or ppm

mode

From the “COF.1” of the mg/L (ppm)

Concentration Set Up menu,

1. Press the HOLD/ENTER key thrice

to enter the mg/L or (ppm) mode

selection menu “b.DO”.

2. Use the ? and ? keys to select the

desired mode of measurement.

3. Press the HOLD/ENTER key to

confirm the selection made and to

return to the subgroup menu.

4. Press the CAL key to return to the

measurement mode.

29

Page 31

7.3 (CAL.2) Calibration Data

10.00

8.24

CAL

CAL

Figure 22: Viewing the last calibration

data for each measurement range.

CA L.2

HOLD

ENTER

Display will show the latest % saturation

Calibration if set up menu is selected from the

DO%Saturation Mode

Display will show the latest mg/L or ppm

calibration if set up menu is selected from the

DO mg/L (ppm) Concentration Mode

You can view the latest

calibration data for the %

Saturation and the mg/L (ppm)

Concentration calibrations. The

calibration data from each mode

can be viewed in the Set Up

menu respectively.

7.3.1 Viewing the %

Saturation calibration dat

From the % Saturation or

Temperature Set Up menu,

1. Press the p and q keys to

scroll through the main

group to enter the viewing

menu “CAL.2” for the latest

calibration data.

2. Press HOLD/ENTER key to

view the latest % Saturation

calibration data.

To exit to the main group

menu, press the

HOLD/ENTER key or the

CAL key

3. To exit to the main group

menu, press the HOLD/ENTER key or the CAL key.

4. Press the CAL key to return to the measurement mode.

7.3.2. Viewing the mg/L (ppm) Concentration calibration data

From the mg/L (ppm) Concentration Set Up mode,

1.. Repeat process 1 to 4 above to view the latest mg/L (ppm) Concentration

calibration data.

at steps 1-5 until all points have been calibrated.

7.4 (ELE.3) Electrode Properties

This menu features data of the electrode properties for diagnostic purposes.

The “view only” parameters such as the electrode Slope Factor, % Saturation

Offset setting, 100% Saturation mV value and 0% Saturation mV value are

30

Page 32

very useful in determining the life efficiency of the electrode. These electrode

properties can be examined through its data in % Saturation and mg/L (ppm)

Concentration which is available in their Set Up menu respectively.

7.4.1 Viewing the electrode Slope Factor

This parameter lets you view and gives an indication of the probe’s efficiency.

The value displayed is the ratio of the actual value produced by the probe to

the theoretical value. The higher the number, the lower the mV output from

the probe. The ratio displays from 0.5 to 1.999.

From the % Saturation or Temperature Set Up menu,

1. Enter the Set Up menu & scroll by using the p and q keys until the

meter displays the Electrode Properties menu “ ELE.3”

2. Press the HOLD/ENTER key to enter the menu and view the Slope Factor

of the electrode..

3. The display will momentarily shows “FACT” before displaying the slope

factor value.

7.4.2 Viewing the % Saturation Offset (Only available in % Saturation

or Temperature Set Up menu):

This parameter shows you the amount of the % Saturation Offset entered in

the other parameter “OFS” (refer to Section for instructions).

From Step 3 above,

4. Press the HOLD/ENTER key to enter the % Saturation Offset viewing

menu

5. The meter will display “OFS” momentarily before displaying the last offset

adjustment made.

7.4.3 Viewing the 0% Saturation mV value

This parameter show the sensor's mV output corresponding to 100%

Saturation. From Step 5 above,

6. Press the HOLD/ENTER key. The display will show "HI.mV" momentarily

before displaying the sensor's mV output with respect to 100% Saturation.

7.4.4 Viewing the 0% Saturation mV value

This parameter lets you view the sensor’s mV output corresponding to 0%

Saturation. From step 6 above.

31

Page 33

7. Press the HOLD/ENTER key. The display will show “LO.mV”

HOLD

ENTER

HOLD

ENTER

HOLD

ENTER

HOLD

ENTER

“LO.mV” will display

for 1.5 seconds

“FACT”displays

for 1.5 seconds

“OFS” displays

for 1.5 seconds

“HI.mV” displays

for 1.5 seconds

Viewing of the offset

percentage adjustment will be

available only if set up menu is

selected from the DO%

Saturation of the Temperature

Mode. Otherwise, this menu

will be skipped.

Figure 23: Viewing electrode data sequence

%

momentarily before displaying the sensor’s mV output value with respect to

0% Saturation.

8. Press the HOLD/ENTER key again to exit to the main group menu. Press

CAL to return to the measurement mode.

Note: To view the electrode properties in the mg/L (ppm) Concentration

mode, repeat the whole steps above using the mg/L (ppm) Concentration Set

Up menu. Viewing of the % Saturation Offset will be skipped in this menu.

32

Page 34

7.5 (AtO.4) Automatic Off

HOLD

ENTER

Figure 24: Selection of Automatic

Off function

This feature is useful for batteries energy

conservation. The meter automatically

shuts off 20 minutes from the last key

press.

From any Set Up Menu,

1. Scroll the Set Up main group menu

by using the ? and ? keys until the

meter displays the Automatic Off

menu “AtO.4”.

2. Press the HOLD/ENTER key to enter

the menu.

3. Use the p and q keys to activate or

deactivate the automatic off selection.

a. YES – activates Automatic Off

b. NO – deactivates Automatic Off

4. Press the HOLD/ENTER key to

confirm the selection.

5. Press the CAL key to exit the Set Up menu to return to the measurement

mode.

7.6 (rSt.5) Reset to Factory Default

This mode lets you reset all parameters to factory default settings. There are

two levels of reset:

1. Calibration Reset: - Reset only the calibration values. This clears all

previous calibrated values and reset to factory default. See Section for

factory default settings.

2. User Reset: - Clears all data including calibration and other customized

setup functions and reset it to factory default. See Section 11 for factory

default settings.

33

Page 35

7.6.1 Calibration Reset

HOLD

ENTER

HOLD

ENTER

Figure 25: Calibration reset

selection

Calibration

Reset

From any Set Up menu:

1. Scroll the Set Up main group menu by

using the p and q keys until the meter

displays the Reset to Factory Default

menu “rSt.5”.

2. Press the HOLD/ENTER key to enter

the menu.

3. Press the HOLD/ENTER key to enter 4.

Use the p and q keys to activate or

deactivate the Calibration Reset

selection.

a. YES – activates Calibration Reset

b. NO – deactivates Calibration Reset

5. Press HOLD/ENTER key to confirm the

selection made.

6. If selection is ‘YES’, meter would

immediately return to measurement

mode. Otherwise it will return to the

main group menu. Press CAL to return

to the measurement mode.

Note: When you reset your meter from %

Saturation Set Up menu, both % Saturation

and mg/L (ppm) Concentration calibrations

are reset to factory default. However, calibration reset in the mg/L (ppm)

Concentration Set Up menu will only reset the calibration in the

concentration mode and do not affect the calibration in the percentage

saturation mode.

.

34

Page 36

7.6.2 User Reset

HOLD

ENTER

Figure 26: User Reset Selection

User

Reset

This program clears all data

including calibration and

other customized setup

functions and reset it to

factory default.

You can skip Calibration

Reset and proceed straight to

User Reset

From “rSt.5” menu,

1. Press HOLD/ENTER key

three times until meter

displays the User Reset

menu “b.USR”

2. Press HOLD/ENTER key

to enter the menu.

3. Use the p and q keys to

activate or deactivate the

User Reset selection.

a. YES – activates User

Reset

b. NO – deactivates

User Reset

4. Press HOLD/ENTER key

to confirm the selection

made.

5. If selection is ‘YES’, meter would immediately return to measurement

mode. Otherwise it will return to the main group menu. Press CAL to

return to the measurement mode.

35

Page 37

7.7 (OFS.6) % Saturation Offset Adjustment

HOLD

ENTER

HOLD

ENTER

Figure 27: % Saturation Offset

Adjustment

Measured reading based on last

percentage saturation calibration

is displayed momentarily

HOLD

ENTER

“CO” will display for

1.5 seconds

Display will return to “OFS.6” subgroup menu

%

%

%

This is a useful feature that allows you

to offset meter’s value when cross

referenced with another DO meter.

That way, it can be standardized

without you having to perform manual

calculation. Your DO 6 meter allows %

Saturation Offset adjustment within +/-

10.0% offset and its adjusted offset

value can be viewed in the Electrode

Properties menu “ELE.3”.

From the % Saturation measurement

mode,

1. Dip the DO electrode in the sample

solution and allow the reading to

stabilize.

2. Check the reading of another DO

meter being used as a reference.

This reference meter should have its

probe immersed in the same sample

solution and at the same depth.

3. Switch off your meter and enter the

% Saturation Set Up menu.

4. Scroll the Set Up main group menu

by using the p and q keys until

the meter displays the % Saturation

Offset Adjustment menu “OFS.6”.

5. Press the HOLD/ENTER key to

enter the menu. The display will

momentarily show the measured

reading based on the last calibration

before displaying the last offset

adjusted value.

6. Use the p and q keys to enter the new value.

7. Press the HOLD/ENTER key to confirm the offset adjustment. “CO” will

be displayed for 1.5 seconds before the display returns to the subgroup

menu.

8. Press CAL key to exit the Set UP menu to return to the measurement

mode.

Note: When a user calibration is done, the offset gets reset to zero.

36

Page 38

7.8 (DPr.7) Dissolved Oxygen Parameters

This Set Up menu allows you to set the barometric pressure and the salinity

value of the sample to be measured. You are given the option to use mmHg or

kilo Pascal barometric pressure units. The Salinity value to be entered will be

based on ppt and is available in mg/L (ppm) Concentration Set Up menu.

The Set Up menu for barometric pressure correction is “A.Hg” (for mmHg)

and “A.PA” (for kilo Pascal) whereas the Salinity menu is indicated as

“b.SAL”.

7.8.1 Pressure Setting Adjustment

1. Switch off your meter in mg/L (ppm) Concentration mode.

2. While pressing and hold the MODE key, switch on the meter by pressing

the ON/OFF key.

3. Once the ON/OFF key is released, the meter will enter the Set Up menu

by displaying “SEt.P”. By releasing the MODE key, the display will show

the configuration menu “COF.1”.

4. Press the p and q keys to scroll through the Set Up main group menu till

the display shows “DPr.7”.

5. Press the HOLD/ENTER key and the meter will enter the barometric

pressure unit selection menu with the display showing either the “A.HG”

mode or “A.PA” mode.

6. Use the p and qkeys to toggle between the barometric pressure units and

press the HOLD/ENTER key to confirm selection.

7. Use the p and q keys to set the pressure value and press the

HOLD/ENTER to confirm the setting. A confirmation indicator “CO” will

be displayed for 1.5 seconds before the meter shows the next display of

Salinity setting “b.SAL”. If the Set Up menu is derived from other than the

mg/L (ppm) Concentration mode, the meter will return to the Set Up

subgroup menu “DPr.7”.

8. Press CAL key to return to measurement mode, or continue to make a

salinity setting adjustment.

37

Page 39

HOLD

ENTER

Figure 28: Pressure Setting Adjustment Sequence

HOLD

ENTER

HOLD

ENTER

HOLD

ENTER

“CO” will display for

1.5 seconds

HOLD

ENTER

HOLD

ENTER

HOLD

ENTER

“CO” will display for

1.5 seconds

Display will continue to

Salinity setting menu

“b.SAL” if Set Up menu is

entered from mg/l (ppm)

mode. Otherwise display will

return back to “DPr.7”

Display will continue to

Salinity setting menu

“b.SAL” if Set Up menu is

entered from mg/l (ppm)

mode. Otherwise display will

return back to “DPr.7”

38

Page 40

7.8.2 Salinity Setting Adjustment

.sal

HOLD

ENTER

HOLD

ENTER

0.0

45.2

co

“CO” will display

for 1.5 seconds

Display will return back to “DPr.7”

subgroup menu

Figure29: Salinity Setting Adjustment Sequence

Note: This mode is available only from

the mg/L (ppm) Concentration Set Up

menu.

1. Repeat steps 1 to 5 as in the steps

of Pressure Setting Adjustment.

2. Press the HOLD/ENTER key twice

till the meter displays the Salinity

setting mode “b.SAL”.

3. Press the HOLD/ENTER key to

enter the Salinity setting mode.

4. Use the p and q keys to enter the

salinity of your solution in ppt.

Note: The salinity value is in ppt (parts

per thousand)

5. Press HOLD/ENTER key to

confirm the value. A confirmation

indicator “CO” will be displayed for

1.5 seconds before returning to the

subgroup menu “DPr.7”.

6. Press CAL key to return to the

measurement mode.

8 PROBE CARE AND MAINTENANCE

The DO 6 probe is a galvanic measuring element which produces an output

proportional to the oxygen present in the medium in which it is placed. The

galvanic probe design lets you take measurements immediately – without the

typical 15 minute wait of other dissolved oxygen probes.

The probe consists of two parts:

· An upper part consisting of the anode, a cathode, and the dual cable.

· A lower part consisting of a pre-membraned cap, and electrolyte solution.

Oxygen diffuses through the membrane onto the cathode, where it is

consumed. This process produces an electrical current which flows through the

cable to the meter. The electric current produced is proportional to the oxygen

that passes through the membrane and the layer of electrolyte. This makes it

39

Page 41

possible to measure the partial pressure of oxygen in the sample at a given

temperature.

Since the DO in the sample is consumed by the cathode it is essential that a

new sample must flow past the membrane of the probe to prevent the

occurrence of false readings. The probe uses very little oxygen for its

measurement. This enables it to function correctly with liquid movement as

low as 2 inch/sec across membrane.

The permeability of the membrane to oxygen varies greatly with temperature.

Therefore compensation is needed for this variation. The DO6 probe comes

with an in-built Temperature Compensation for the membrane variation.

8.1 Probe Care

Proper care and maintenance will help you receive the maximum probe life

and ensure more accurate readings.

Since any deposits on the membrane surface act as a barrier to oxygen diffusing

through the membrane, the membrane must be cleaned at regular intervals to

assure maximum reliability.

After using the probe, rinse the probe with clean water and wipe it with a soft

cloth or paper to avoid any hardening of deposits if necessary. If growth

develops on the probe, use a disinfecting chemical to clean.

NOTE: Although the membrane is strong and not easily damaged, wipe it

gently while cleaning it. If the membrane is damaged or torn, the probe will no

longer function.

There are no special probe storage requirements.

8.2 Pre-Membraned Caps Replacement

Replacement of the pre-membraned cap is required only when you cannot

calibrate the probe, or if the membrane is damaged.

Typical membrane damages are punctures or wrinkles caused during

measurements or cleaning.

To order replacement probe components or a replacement probe, see Section

“Accessories” on page 48.

8.3 To replace the probe pre-membraned cap.

1. Unscrew counter clockwise the pre-membraned cap from the probe sensing

tip and discard.

2. Wash the probe under running water.

3. Mount the nozzle tip onto the syringe provided. Fill the syringe with the

refill solution through the tip of the plastic bottle.

40

Page 42

4. Hold the probe upside down. Insert the nozzle tip into one of the 4 holes

surrounding the silver cathode. Inject the fill solution into the probe body

until solution leaks out from the fill hole (approximately 5 mL).

5. Replace pre-membraned cap by tightening clockwise until hand tightened.

6. Allow at least 1 hour for the electrode to equilibrate before usage.

Figure 30: probe pre membraned cap replacement process

8.4 Electrolyte Solution

The electrolyte solution in your probe’s cap will deplete on usage and will need

to be replaced periodically.

Your DO probe comes with replacement electrolyte solution. The replacement

electrolyte comes premixed and ready to use. To order more electrolyte

solution, see “Accessories” section.

41

Page 43

9 TROUBLE-SHOOTING GUIDE

Problem Cause Solution

No

display

when

turned on

a) Batteries not in place

b) Batteries not in

correct polarity (+

and – position).

c) Weak batteries

a. Remove rubber

b) Reinsert batteries

c) Replace batteries.

Unstable

readings

a) Insufficient

electrolyte in probe.

a) Fill probe with

b) Air bubbles trapped

around the probe

b) Stir or tap probe to

c) Dirty or damaged

probe

d) Probe not deep

c) Clean the probe and

d) Make sure sample

enough in sample

e) External noise

pickup or induction

e) Move or switch off

caused by nearby

electric motor.

f) Replace probe.

f) Broken probe.

Slow

response

a) Dirty / Oily probe.

b) Temperature is

a) Clean probe. See

changing.

b) Allow time for

Not

respondin

gtokey

press

a) HOLD operation

indicated by flashing

display.

b) Damaged key pad

a) Cancel HOLD mode.

b) Return to dealer.

c) Reset all internal

c) Internal program

error.

boot/stand. Check

that batteries are in

place and making

good contact.

with correct polarity.

electrolyte & replace

pre-membraned cap

remove bubbles.

re-calibrate

entirely covers the

probe sensors.

interfering motor.

“Probe Care &

Maintenance”.

temperature to

stabilize

programs by

reinserting batteries.

42

Page 44

10 ERROR MESSAGES

+

-

LCD Display Indicates Cause Solution

Low Battery

indicator

Low battery

level

Need new batteries or

battery connection is

bad.

Clean battery contacts.

Replace batteries with

fresh ones, noting

polarity.

"Err 1"

in %

Saturation

Mode

% Saturation

Calibration

error

Calibration is

performed when

factory calibrated

absolute value is out

of calibration range –

10.1% to 49.9%

Check the value of the

calibration solution. If

zero calibration is done,

make sure the limit of

10% is not exceeded.

If message persist,

recondition your probe.

"Err 1" in mg/L

(ppm)

Concentration

Mode

“UR”/”OR”

with blinking

“A”

annunciator in

Temperature

Mode

“——“with

blinking “A”

annunciator in

% Saturation

and

Concentration

Mode

Concentration

Calibration

error

ATC probe

error, Under

Range, Over

Range

ATC probe

error

Calibration is

performed when the

calibration solution

factory absolute

measurement is below

2.00 mg/L or ppm

ATC probe is

removed or broken

while the meter has

the ATC feature

activated.

ATC probe is

removed or broken

while the meter has

the ATC feature

activated

43

Check the calibrating

solution to be above 2

mg/L or ppm.

Check that the correct

temperature and

salinity setting has been

set prior calibration.

Check the probe’s

temperature input

phono jack connection

to the meter. Ensure

probe is not broken or

punctured.

Check the probe’s

temperature input

phono jack connection

to the meter. Ensure

probe is not broken or

punctured.

Page 45

11 FACTORY DEFAULT SETTINGS

Setting

Menu

COF.1 Unit Configuration Parameter Title

A.ATC Selection of

b.DO Selection of mg/L or

CAL.2 Viewing the latest

ELE.3 Viewing the Electrode

FACT View the Slope Factor Viewing Only Viewing Only 1.000

OFS Viewing the %

HI.mV Viewing the mV value

LO.mV Viewing the mV value

AtO.4 Selection of automatic

rSt.5 Reset to factory

A.CAL Selection of

b.USR Selection of User

Function Parameter

Opting Keys

Only

Automatic or Manual

Temperature

Compenstion

ppm of the

concentration mode

calibration data

properties

Saturation offset

adjustment

for 100% Saturation

for 0% Saturation

power off

defaults

Calibration Reset

Reset

p and q YES; NO YES

p and q mg/L or ppm mg/L

Viewing Only Viewing Only ----

Parameter Title

Only

Viewing Only Viewing Only 0.0%

Viewing Only Viewing Only 50 mV

Viewing Only Viewing Only 0 mV

p and q YES; NO

Parameter Title

Only

p and q NO, YES NO

p and q NO, YES 0.0%

Parameter

Optons

Parameter

Title Only

Parameter

Title Only

Parameter

Title Only

Default

Setting

NO

44

Page 46

Setting

Menu

Function Parameter

Opting Keys

Parameter

Options

Default

Setting

OFS.6 Offset Adjustment (%

Saturation

DPr.7 Barometric Pressure

Selection Menu

A.HG Selection of

Barometric Pressure

Setting Adjustment in

mmHg

A.PA Selection of

Barometric Pressure

Setting Adjustment in

Kilo Pascal

b.SAL Salinity Setting

Adjustment

Setting the Manual

Temperature

Compensation

p and q +/-10.0 of

Parameter Title

Only

p and q 500 to 1499

p and q 66.6 to 199.9

p and q 0.0 to 50.0 ppt 0.0 ppt

CAL, p and q 0.0 to 50.0 °C 25.0 °C

measured

reading

Parameter

Title Only

mmHg

kPA

0.0%

760 mm Hg

101.3 kPA

Note: The HOLD/ENTER key is used to confirm every parameter opted.

45

Page 47

12 SPECIFICATIONS

% Saturation Mode

Range

Resolution

Relative accuracy

mg/L (ppm)

Concentration Mode

Range

Resolution

Relative accuracy

Temperature

Range

Resolution

Relative accuracy

Salinity Correction

Range

Resolution

Method

Barometric Pressure

Correction (mm Hg)

Range

Resolution

Method

0.00 – 200.0 %

0.1 %

± 1.5% of Full Scale

0.00 – 20.00 mg/L or ppm

0.01 mg/L; 0.01 ppm

± 1.5% of Full Scale

-5.0 – 105.0 °C

0.1 °C

± 0.5 °C

0.0 – 50.0 ppt

0.1 ppt

Automatic correction after manual

input

500 to 1499 mm Hg or 66.6 to 199.9

kPA

1mmHgor0.1kPA

Automatic correction after manual

input

Automatic Temperature

0.0 to 50.0°C

Compensation

Manual Temperature

0.0 to 50.0°C

Compensation

Probe (DO / Temp) Galvanic / Thermistor

Probe Diameter Body 12 mm, Cap 16 mm

Response Time 60 seconds to achieve 95% of the

reading

46

Page 48

% Saturation Calibration

Points

100% in saturated air or

air-saturated water.

0% in zero oxygen solution

% Saturation Calibration

Limits

Factory calibrated absolute value of

10.0% and below for 0% point &

50% to 200% for 100% point.

Concentration Calibration

Window

+/- 40% from the factory default

measurement value. Minimum

reading allowed is 2.00 mg/L (ppm).

Temperature Calibration

Window

Offset Adjustments (%

Saturation)

+/- 5°C from factory default

measurement

+/- 10.0 of reading in Saturation

mode

HOLD function Yes

Auto-Off function Selectable Auto Off function. (20

minutes after last key press)

Display Customs Single 4 Digit LCD

Inputs BNC for DO & 2.5 mm Phono for

temperature

Operating Range 0 to 50 °C

Power Requirements 4 AAA-sized batteries (included)

Battery Life > 700 hours (Alkaline Batteries)

Dimensions Meter: 14 cm (L)x7cm(W)x3.5

cm (H)

Probe: 115 mm (L) x 12 mm (Dia)

with 3-ft cable.

Probe’s membrane housing: 16 mm

(Dia)

47

Page 49

13 ACCESSORIES

Code

DO 6 meter and probe kit 5-0107

DO probe 26094-65

Replacement caps (2) with

pre-installed membrane and 10-mL

electrolyte

26094-66

14 ADDITIONAL INFORMATION

14.1 Dissolved Oxygen

14.1.1 General Information

Dissolved Oxygen (DO) refers to the volume of oxygen that is contained in

water. There are two main sources of DO in water: from atmosphere and

photosynthesis. Waves and tumbling water mix air into the water where

oxygen readily dissolves until saturation occurs. Oxygen is also produced by

aquatic plants and algae as a by-product of photosynthesis.

The amount of DO that can be held by water depends on 3 factors: water

temperature, salinity, and atmospheric pressure.

1. Amount of DO increases with decreasing temperature (colder water holds

more oxygen);

2. Amount of DO increases with decreasing salinity (freshwater holds more

oxygen than saltwater does);

3. Amount of DO decreases with decreasing atmospheric pressure (amount of

DO absorbed in water decreases as altitude increases).

48

Page 50

Solubility of oxygen in water contact with water saturated air at

standard atmospheric pressure

Solubility mg/L

16

14

12

10

8

6

4

2

0

0 102030405060

Temperature °C

14.1.2 Measurement Units

One measure of DO in water is parts per million (ppm) which is the number of

oxygen molecules (O

the % Saturation is another way to analyze DO levels. % Saturation is the

measured DO level divided by the greatest amount of oxygen that the water

could hold under various temperature and atmospheric pressure conditions

multiplied by 100.

14.1.3 What Is Being Measured?

DO probes respond to the partial pressure of oxygen in liquid or gas being

2) per million total molecules in a sample. Calculating

measured – they measure the “pressure” of oxygen rather than concentration.

All of the oxygen entering the probe is consumed at the cathode where it is

49

Page 51

electrochemically reduced to hydroxyl ions producing an electrical current

within the probe:

O

2 +2H2O+4e

-

à 4OH

–

Since all oxygen entering the probe is chemically consumed, the partial

pressure of oxygen in the electrolyte is zero. Therefore, a partial pressure

gradient exists across the membrane and the rate at which oxygen enters the

probe is a function of the partial pressure of oxygen in the gas or in liquid being

measured.

When a probe is placed in air saturated water, the current it produces will not

be affected by the temperature or salinity of the water. The DO concentration

in the water, however, will vary with temperature and salinity. Because it is

convenient to report DO concentration in mg/L or ppm, it is necessary to adjust

for temperature and salinity of the water to get correct readings in these units.

If DO were to be reported in terms of partial pressure or % Saturation, then

temperature and/or salinity compensation for oxygen solubility would not be

necessary. Most probes are temperature compensated – i.e. they convert the

“partial pressure measurement” to mg/L of DO at whatever temperature the

water happens to be at for a given salinity and barometric pressure.

14.1.4 Air Calibration

Understanding the principle of air calibration is easy, once you know that it is

partial pressure that the probe is responding to. When the probe is in air, it is

measuring the partial pressure of oxygen in air. If water is air saturated, then

the partial pressure of oxygen in the water will be the same as it is in air.

Therefore, all you need to know is the temperature of the air in which the

probe is placed. By consulting solubility tables for oxygen at the particular

barometric pressure and salinity of the water being measured, the

corresponding concentration (mg/L or ppm) can be found for air saturated

water at the air calibration temperature, and the meter can be set accordingly.

Because most meters are temperature compensated, they will still give correct

readings in mg/L even though the actual water temperature may be different to

the air calibration temperature.

Note: The closer the air calibration temperature to the water temperature, the

more accurate is the calibration.

50

Page 52

14.1.5 Applications

Oxygen is essential for fish, invertebrate, plant, and aerobic bacteria

respiration. DO levels below 3 ppm are stressful to most aquatic organisms.

Levels below 2 or 1 ppm will not support fish. Fish growth and activity usually

require 5 to 6 ppm of DO, an important consideration for aquaculture industry.

Low DO indicates a demand on the oxygen of the system. Natural organic

material such as leaves accumulate in the stream and create an oxygen demand

as it is decomposed. Organic materials from human activities also create an

oxygen demand in the system. Micro-organisms consume oxygen as they

decompose sewage, urban and agricultural run-off, and discharge from

food-processing plants, meat-packing plants and diaries. There is an optimum

DO level for this process and if DO level falls too low, the micro-organisms die

and the decomposition ceases. If DO level is too high, more power is used

than necessary for aeration and the process becomes costly.

In boiler water application, presence of oxygen in the water will increase

corrosion and helps build up boiler scale that inhibits heat transfer. In such

instance it is critical to keep DO concentration to a minimum.

Some pollutants such as acid mine drainage produce direct chemical demands

on oxygen in the water. DO is consumed in the oxidation-reduction reactions

of introduced chemical compounds such as nitrate (NO

1+

(NH

4

), sulfate (SO42-), and sulfite (SO32-) and ferrous (Fe2+) and ferric (Fe3+)

1-

3

) and ammonia

ions.

These are important consideration for water and wastewater treatment

industry.

15 LIMITED WARRANTY

LaMotte Company warrants this instrument to be free of defects in parts and

workmanship for 3 years from the date of shipmen and this probe to be free of

defects in parts and workmanship for 6 months from the date of shipment. If it

should become necessary to return the instrument for service during or beyond

the warranty period, contact our Technical Service Department at

1-800-344-3100 for a return authorization number or visit www.lamotte.com

for troubleshooting help. The sender is responsible for shipping charges,