Page 1

Dissolved

Dissolved

Oxygen

Oxygen

Water Quality Test Kit

Instruction Manual

Code 5860-01

Page 2

Introduction ............................................................................ 3

Dissolved Oxygen

General Safety Precautions

Use Proper Analytical Techniques

Kit Contents

Test Procedure

...................................................................4

...................................................... 8

............................................. 9

........................................................................... 10

....................................................................... 11

Part 1: Collecting a Water Sample ........................................... 11

Part 2: Adding the Reagents ..................................................... 12

Part 3: Titration ........................................................................ 13

Percent Saturation .................................................................. 15

BOD

...................................................................................... 16

EPA Compliance

Short Form Instructions

.................................................................... 17

......................................................... back

WARNING! This set contains chemicals

that may be harmful if misued. Read

cautions on individual containers

carefully. Not to be used by children

except under adult supervision.

Page 3

INTRODUCTION

Aquatic animals need dissolved oxygen to live.

Fish, invertebrates, plants, and aerobic bacteria

all require oxygen for respiration. Oxygen

dissolves readily into water from the atmosphere

until the water is saturated. Once dissolved in the

water, the oxygen diffuses very slowly and

distribution depends on the movement of the

aerated water. Oxygen is also produced by aquatic

plants, algae, and phytoplankton as a by-product

of photosynthesis.

This test kit uses the azide modifi cation of the

Winkler method for determining dissolved oxygen.

3

Page 4

DISSOLVED OXYGEN,

PERCENT SATURATION & BOD

Oxygen is critical to the survival of aquatic plants and animals, and a shortage of

dissolved

species are more sensitive to oxygen depletion than others, but some general

guidelines to consider when analyzing test results are:

Because of its importance to the fi sh’s survival, aquaculturists, or “fi sh farmers,” and

aquarists use the dissolved oxygen test as a primary indicator of their system’s ability

to support healthy fi sh.

WHERE DOES THE OXYGEN COME FROM?

The oxygen found in water comes from many sources, but the largest source is oxygen

absorbed from the atmosphere. Wave action and splashing allows more oxygen to be

absorbed into the water. A second major source of oxygen is aquatic plants, including

algae; during photosynthesis plants remove carbon dioxide from the water and replace

it with oxygen.

Absorption

Oxygen is continuously moving between the water and surrounding air. The direction

and speed of this movement is dependent upon the amount of contact between the

air and water. A tumbling mountain stream or windswept, wave-covered lake, where

more of the water’s surface is exposed to the air, will absorb more oxygen from the

atmosphere than a calm, smooth body of water. This is the idea behind aerators: by

creating bubbles and waves the surface area is increased and more oxygen can enter

the water.

oxygen is not only a sign of pollution, it is harmful to fi sh. Some aquatic

5–6 ppm Suffi cient for most species

<3 ppm Stressful to most aquatic species

<2 ppm Fatal to most species

Photosynthesis

In the leaves of plants, one of the most important chemical processes on Earth is

constantly occurring: photosynthesis. During daylight, plants constantly take carbon

dioxide from the air, and in the presence of water convert it to oxygen and carbohydrates,

which are used to produce additional plant material. Since photosynthesis requires

light, plants

the photosynthesis

do not photosynthesize at night, so no oxygen is produced. Chemically,

reaction can be written as:

Light + nCO2 + nH2O (C2HO)n + nO

2

Light + Carbon + Water Carbohydrate + Oxygen

Dioxide

4

Page 5

WHERE DOES THE OXYGEN GO?

Once in the water, oxygen is used by the aquatic life. Fish and other aquatic animals

need oxygen to breathe or respire. Oxygen is also consumed by bacteria to decay, or

decompose, dead plants and animals.

Respiration

All animals, whether on land or underwater, need oxygen to respire, grow and survive.

Plants and animals respire throughout the night and day, consuming oxygen and

producing carbon dioxide, which is then used by plants during photosynthesis.

Decomposition

All plant and animal waste eventually decomposes, whether it is from living animals

or dead plants and animals. In the decomposition process, bacteria use oxygen to

oxidize, or chemically alter, the material to break it down to its component parts.

Some aquatic systems may undergo extreme amounts of oxidation, leaving no oxygen

for the living organisms, which eventually leave or suffocate.

PERCENT SATURATION

The oxygen level of a water system is not only dependant on production and consumption.

The potential dissolved oxygen capacity of water is limited by atmospheric pressure

(altitude), salinity, and temperature. These factors determine the highest DO level

possible. The percent saturation value expresses the quantity of dissolved oxygen in

the sample as a percent of the theoretical potential.

When water holds all of the dissolved oxygen that it can hold at a given altitude,

temperature, and salinity, it is said to be 100% saturated. If it holds a quarter as much as it

could possibly hold under those conditions it is 25% saturated. It is possible to get percent

saturation values over 100% when water becomes highly aerated by tumbling over

rapids and dams. It can also become supersaturated on a sunny day when dense areas

of plants or algae produce oxygen through photosynthesis.

Low atmospheric pressure found at higher altitudes slightly decreases the solubility of

oxygen in water so the dissolved oxygen value must be corrected for altitude.

The various minerals dissolved in water lower the capacity of the water to hold oxygen.

A correction factor can also be applied to dissolved oxygen measurements in saline

waters. In fresh water, where the salinity is very low, this effect is insignifi cant when

compared to the effect of temperature. Therefore, a correction for salinity is not

incorporated into the calculation.

Cold water can hold more oxygen than warm water. That is why fi sh that require higher

levels of oxygen, like trout, are found in cold water and dissolved oxygen concentrations

are usually higher in the winter than they are in the summer at the same location. The

percent saturation concentration can be corrected for water temperature.

Percent saturation levels from 80 to 120 percent are considered to be excellent. Levels

between 60 and 79 percent are adequate. Above 125 percent and below 60 percent

saturation, levels are poor. Fish and invertebrates that can move will leave areas with

low dissolved oxygen and move to areas with higher levels. Slow moving, trapped

or non-mobile aquatic animals may perish if levels become too low. Extremely high

dissolved oxygen concentrations are harmful to fi sh even for very short periods of

time. Gas bubble disease, which is characterized by the rupturing of capillaries in the

gills due to supersaturated water, is usually fatal.

5

Page 6

MEASURING BOD (BIOCHEMICAL OXYGEN DEMAND)

Biochemical oxygen demand is determined by measuring the dissolved oxygen

concentration in a freshly collected water sample and comparing it to the dissolved

oxygen level in a sample that was collected at the same time but incubated under

specifi c conditions for a specifi c length of time. The difference between the two

oxygen levels represents the amount of oxygen required for the decomposition of

organic material and the oxidation of chemicals in the water during the storage period,

a measurement known as the BOD.

Unpolluted, natural waters will have a BOD of 5 ppm or less. Raw sewage may have

levels of 150 to 300 ppm. Wastewater treatment plants must reduce BOD to levels

specifi ed in their discharge permits, usually between 8 and 150 ppm BOD.

TESTING DISSOLVED OXYGEN

The fi rst step in a DO titration is the addition of Manganous Sulfate Solution (4167) and

Alkaline Potassium Iodide Azide Solution (7166). These reagents react to form a white

precipitate, or fl oc, of manganous hydroxide, Mn(OH)2. Chemically, this reaction can

be written as:

MnSO4 + 2KOH Mn(OH)2 + K2SO

4

Manganous + Potassium Manganous + Potassium

Sulfate Hydroxide Hydroxide Sulfate

Immediately upon formation of the precipitate, the oxygen in the water oxidizes

an equivalent amount of the manganous hydroxide to brown-colored manganic

hydroxide. For every molecule of oxygen in the water, four molecules of manganous

hydroxide are converted to manganic hydroxide. Chemically, this reaction can be

written as:

4Mn(OH)2 + O2 + 2H2O 4Mn(OH)

3

Manganous + Oxygen + Water Manganic Hydroxide

Hydroxide

After the brown precipitate is formed, a strong acid, such as Sulfamic Acid Powder

(6286) or Sulfuric Acid, 1:1 (6141) is added to the sample. The acid converts the

manganic hydroxide to manganic sulfate. At this point the sample is considered

“fi xed” and concern for additional oxygen being introduced into the sample is reduced.

Chemically, this reaction can be written as:

2Mn(OH)3 + 3H2SO4 Mn2(SO4)3 + 6H2O

Manganic + Sulfuric Manganic + Water

Hydroxide Acid Sulfate

6

Page 7

Simultaneously, iodine from the potassium iodide in the Alkaline Potassium Iodide

Azide Solution is oxidized by manganic sulfate, releasing free iodine into the

water. Since the manganic sulfate for this reaction comes from the reaction between

the manganous hydroxide and oxygen, the amount of iodine released is directly

proportional

to the amount

of oxygen present in the original sample. The release of

free iodine is indicated by the sample turning a yellow-brown color. Chemically, this

reaction can be written as:

Mn

(SO4)

2

+ 2KI 2MnSO

3

4

+ K2SO

+ I

4

2

Manganic + Potassium Manganous + Potassium + Iodine

Sulfate Iodide Sulfate Sulfate

The fi nal stage in the Winkler titration is the addition of sodium thiosulfate. The

sodium

thiosulfate reacts with the free iodine to produce sodium iodide. When all of the

iodine has been converted the sample changes from yellow-brown to colorless. Often a

starch indicator

is added to enhance the fi nal endpoint. Chemically, this reaction can be

written as:

2Na2S2O3 + I2 Na2S4O6 + 2NaI

Sodium + Iodine Sodium + Sodium

Thiosulfate Tetrathionate Iodide

7

Page 8

GENERAL SAFETY PRECAUTIONS

1. 2.

Store the test kit in a

cool dry area.

3. 4.

Material

Safety

Read the labels on

all reagent bottles.

Note warnings and

fi rst aid information.

Read all Material

Safety Data Sheets.

Avoid contact between reagent

chemicals and skin, eyes, nose,

and mouth.

Data

Sheet

6.5.

Read all instructions

and note precautions

before performing

the test procedure.

Instruction

Manual

Keep all

equipment

and reagent

chemicals

out of the

reach of

young children.

Wear safety glasses when

performing test procedures.

7.

In the event of an accident or suspected poisoning, immediately call

the Poison Center phone number in the front of your local telephone

directory or call a physician. Additional information for all LaMotte

reagents is available in the United States, Canada, Puerto Rico, and

the US Virgin Islands from Chem-Tel by calling 1-800-255-3924.

For other areas, call 813-248-0585 collect to contact Chem-Tel’s

International access number. Each reagent can be identifi ed by

the four digit number listed on the upper left corner of the

reagent label, in the contents list and in the test procedures.

8

Page 9

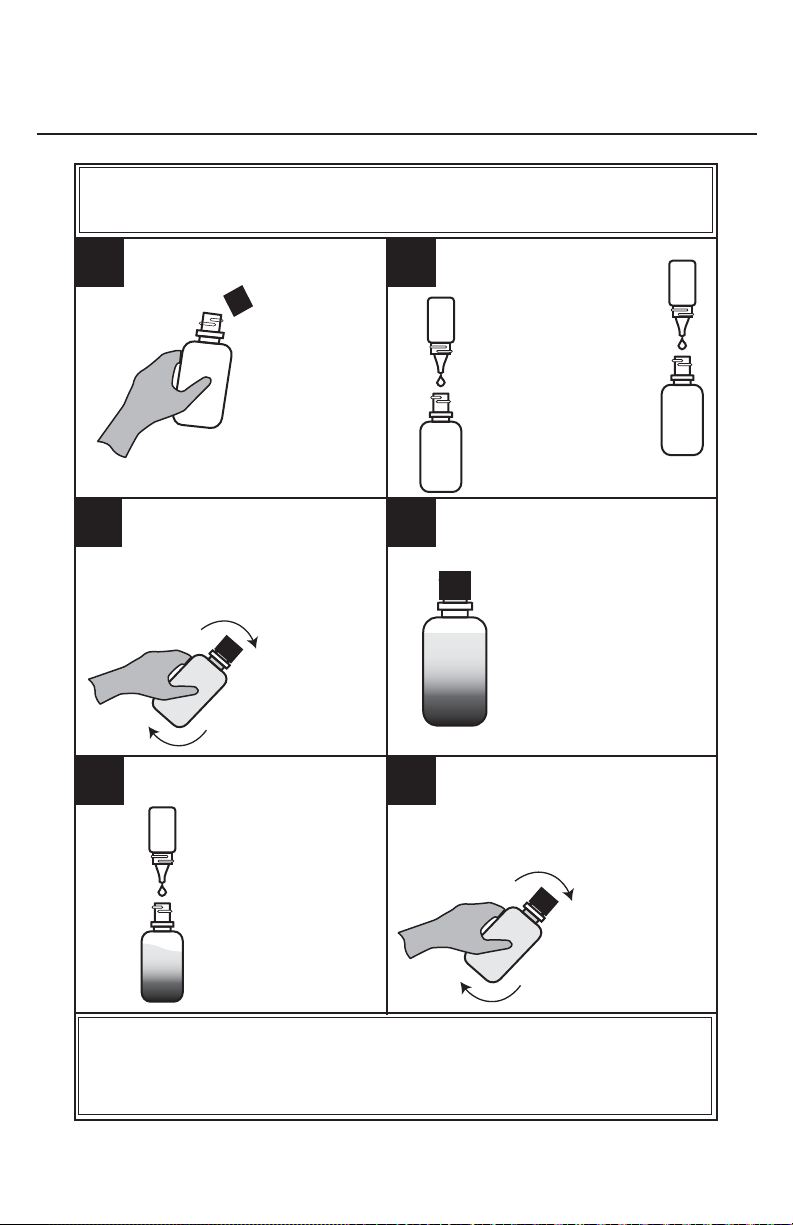

USE PROPER ANALYTICAL TECHNIQUES

1. 2.

Use test tube caps or

stoppers, not your

fi ngers, to cover tubes

during shaking or

mixing.

3. 4.

Wipe up any reagent

chemical spills

immediately.

Tightly close all

containers

immediately

after use. Do not

interchange caps

from containers.

Hold dropper bottles

vertically upside-down, and not

at an angle,

a reagent. Squeeze

the bottle gently to

dispense the

reagent one drop

at a time.

6.5.

when dispensing

Thoroughly rinse test

tubes before and after

each test.

Avoid prolonged exposure

of equipment

and reagents

to direct

sunlight. Protect

reagents from

extremes of

temperature.

9

Page 10

DISSOLVED OXYGEN

CODE 5860-01

QUANTITY CONTENTS CODE

30 mL *Manganous Sulfate Solution *4167-G

30 mL *Alkaline Potassium Iodide Azide *7166-G

30 mL *Sulfuric Acid, 1:1 *6141WT-G

60 mL *Sodium Thiosulfate, 0.025N *4169-H

30 mL Starch Indicator Solution 4170WT-G

1 Direct Reading Titrator 0377

1 Test Tube, 5-10-12.9-15-20-25 mL, glass, w/cap 0608

1 Water Sampling Bottle, 60 mL, glass 0688-DO

*WARNING: Reagents marked with an * are considered to be potential health hazards.

To view or print a Material Safety Data Sheet (MSDS) for these reagents go to

www.lamotte.com. To obtain a printed copy, contact LaMotte by e-mail, phone or fax.

To order individual reagents or test kit components, use the specifi ed code number.

Kit Diagram

0688-DO

0608

4167-G

4170WT-G

10

7166-G

4169-H

614WT-G

0377

0377

Page 11

DISSOLVED OXYGEN TEST PROCEDURE

Part 1 - Collecting the Water Sample

1. 2.

Rinse the Water

Sampling Bottle

(0688-DO) with

the sample water.

Tightly cap the bottle, and

submerge it to the desired depth.

3. 4.

Remove the cap and allow

the bottle to fi ll.

Replace the cap while the

bottle is still submerged.

Tap the sides of the bottle to

dislodge any air bubbles.

6.5.

Retrieve the bottle

and make sure that

no air bubbles are

trapped inside.

11

Page 12

DISSOLVED OXYGEN TEST PROCEDURE

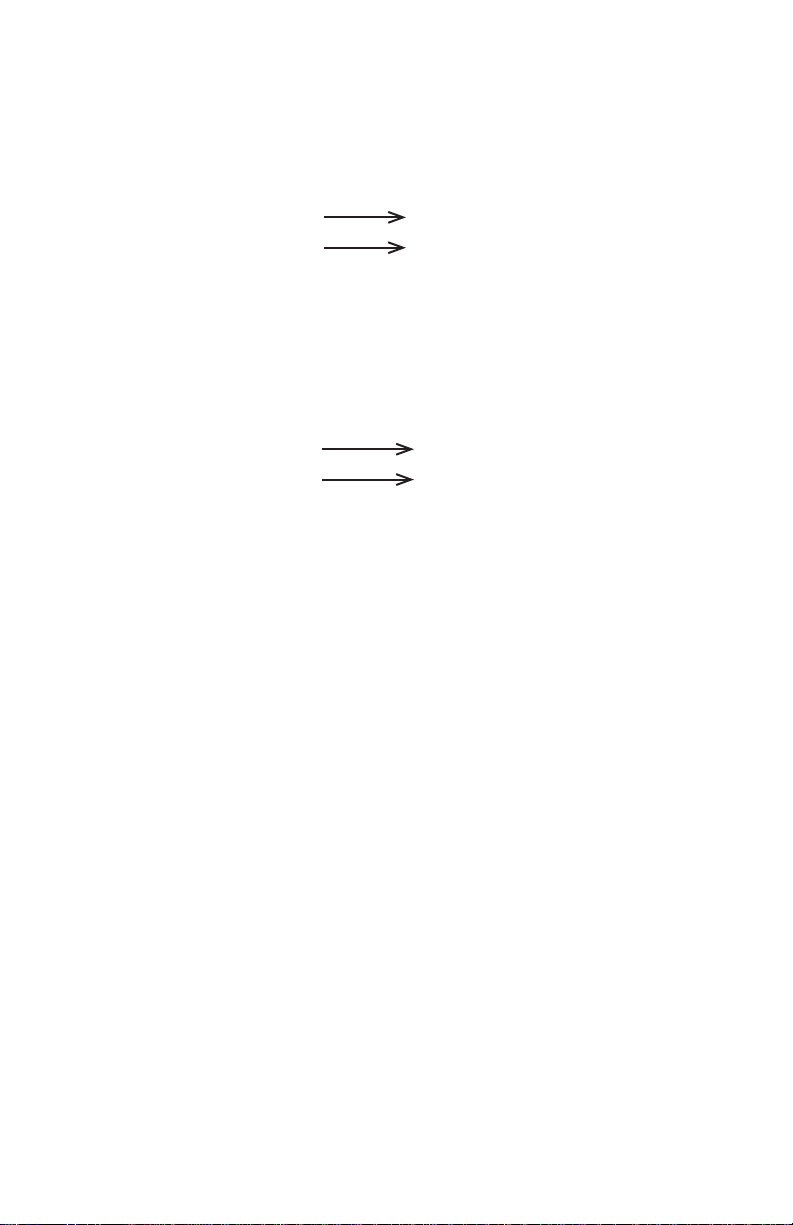

Part 2 - Adding the Reagents

NOTE: Be careful not to introduce air into the sample while adding

the reagents.

1. 2.

Immediately add 8

drops of *Manganous

Sulfate Solution (4167)

Remove the

cap from the

bottle.

and Add 8 drops of

*Alkaline Potassium

Iodide Azide (7166).

3. 4.

Cap the bottle and mix by

inverting several times.

A precipitate will form.

Allow the precipitate

to settle below the

shoulder of the bottle.

Cap and gently invert the bottle

6.5.

to mix the contents until the

precipitate and the reagent have

Add 8 drops of

*Sulfuric Acid, 1:1

(6141WT).

NOTE: At this point the sample has been “fi xed” and contact between the

sample and the atmosphere will not affect the test result. Samples may be

held at this point and titrated later.

totally dissolved. The solution

will be clear

yellow to

orange if the

sample contains

dissolved oxygen.

12

Page 13

DISSOLVED OXYGEN TEST PROCEDURE

Part 3 - The Titration

1. 2.

0

0

0.1

Fill the titration tube

(0608) to the 20 mL line

with the fi xed sample.

Cap the tube.

0.1

0.2

0.2

Depress plunger of

0.3

0.3

0.4

0.4

the Titrator (0377).

0.5

0.5

0.6

0.6

0.7

0.7

0.8

0.8

0.9

0.9

1.0

1.0

3. 4.

0

1

.

0

0

2

.

3

.

0

0

4

.

5

.

Insert the Titrator into

the plug in the top of the

*Sodium Thiosulfate,

0.025N (4169) titrating

solution.

0

0

.

6

7

.

0

0

8

.

9

.

0

0

1

.

Invert the bottle and

slowly withdraw the

plunger until the large

ring on the plunger is

opposite the zero (0)

line on the scale.

NOTE: If small air bubbles appear in the titrator barrel, expel them by

partially fi lling the barrel and pumping the titration solution back into the

reagent container. Repeat until bubble disappears.

5.

Turn the bottle

upright and remove

the Titrator.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

NOTE: If the sample

is a very pale yellow,

go to Step 9.

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

13

continued . . .

Page 14

DISSOLVED OXYGEN TEST PROCEDURE continued ...

6. 7.

Insert the tip of the Titraror

into the opening of the

titration tube cap.

8. 9.

Carefully remove the

Titrator and cap. Do

not disturb the Titrator

plunger.

11.10.

Cap the titration tube.

Insert the tip of the

Titrator into the opening

of the titration tube cap.

Slowly depress the

plunger to dispense the

titrating solution until

the yellow-brown color

changes to a very pale

yellow. Gently swirl the

tube during the titration

to mix the contents.

Add 8 drops of Starch

Indicator Solution

(4170WT). The sample

should turn blue.

Continue titrating until the blue

color disappears and the solution

becomes colorless.

NOTE: If the plunger ring

reaches the bottom line on

the scale (10 ppm) before the

endpoint color change occurs,

refi ll the Titrator and continue

the titration. Include

of the original

reagent dispensed

when recording the test result.

the value

amount of

(10 ppm)

Read the test result directly from the scale

12.

where the large ring on the Titrator meets

the Titrator barrel. Record as ppm Dissolved

Oxygen. Each minor division on the Titrator

scale equals 0.2 ppm.

NOTE: When testing is complete, discard the

titrating solution in the Titrator. Rinse Titrator

and titration tube thoroughly. DO NOT remove

plunger or adapter tip.

14

Page 15

PERCENT SATURATION

Use the atmospheric pressure reading from a barometer or the local altitude to determine

the correction factor from the chart below. Multiply the dissolved oxygen test result (ppm)

by the correction factor to obtain the corrected dissolved oxygen value.

Atmospheric Pressure (mmHg)

a

775 540 1.02

760 0 1.00

745 542 0.98

730 1094 0.96

714 1688 0.94

699 2274 0.92

684 2864 0.90

669 3466 0.88

654 4082 0.86

638 4756 0.84

623 5403 0.82

608 6065 0.80

593 6744 0.78

578 7440 0.76

562 8204 0.74

547 8939 0.72

532 9694 0.70

517 10,472 0.68

Equivalent Altitude (ft) Correction Factor

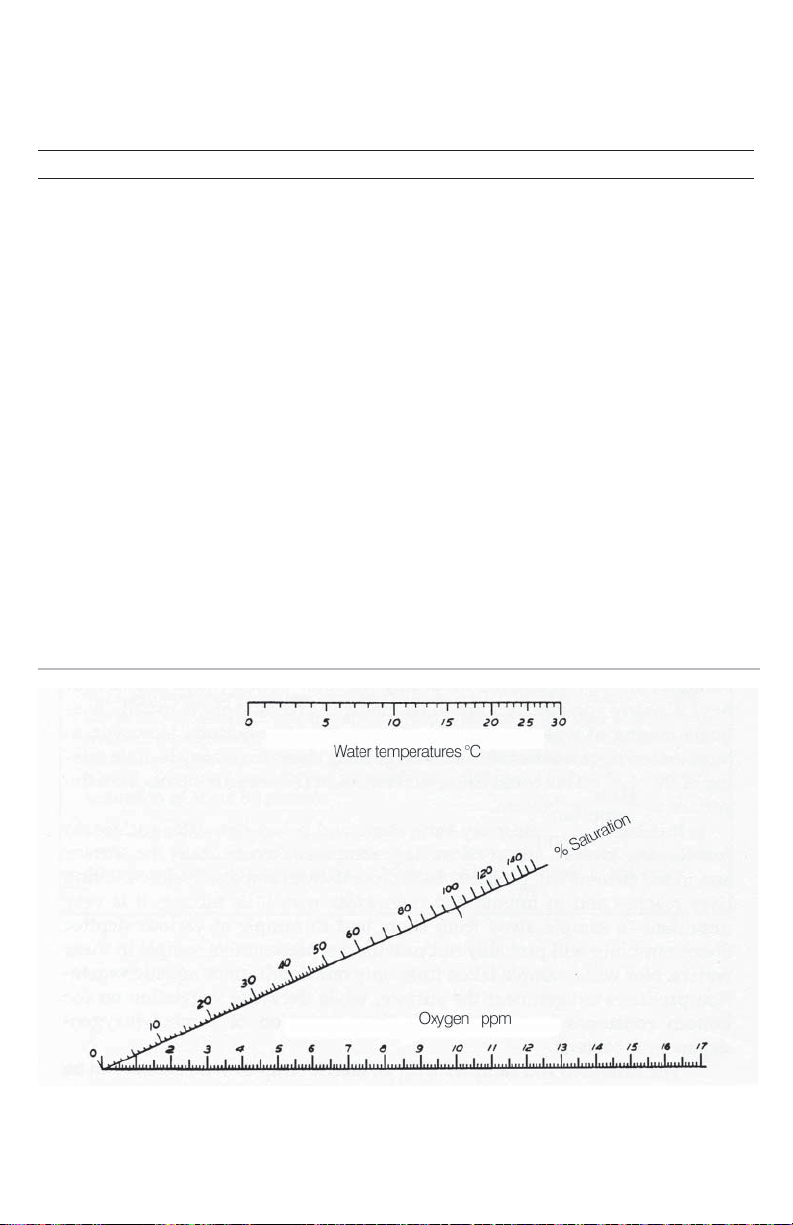

To determine the percent saturation, locate the temperature (°C) of the water sample on

the top scale. Locate the corrected dissolved oxygen concentration (ppm) on the bottom

scale. Draw a straight line between the two points. Read the % saturation where the line

crosses the % saturation scale.

15

Page 16

BOD

1. 2.

Collect two samples

according to

Part 1 – Collecting

the W ater Sample.

1

3. 4.

Cover the bottle containing

the second sample completely

with aluminum foil to ensure

complete darkness. This will

prevent changes in

concentration caused by

photosynthesis

that may be present in

the sample.

the oxygen

in algae

2

Test one sample immediately

by following the procedures in

Part 2 – Adding the Reagents

and Part 3 – The Titration.

1

Incubate the second sample,

holding the temperature at

20 °C for fi ve days.

After fi ve days, test the incubated

sample by following the

procedures in Part 2 – Adding

the Reagents and Part 3 – The

Titration.

2

5.

Subtract the second dissolved

oxygen reading from the initial

dissolved oxygen reading to

obtain BOD in units of ppm.

16

Page 17

EPA COMPLIANCE

To qualify as an EPA accepted test, and to achieve the greatest accuracy, the Sodium

Thiosulfate Solution, 0.025N (4169) must be standardized daily. This procedure follows

Standard Methods for the Examination of Water and Wastewater. Numbers in ( ) are for

LaMotte products. These products are not included in this kit but can be ordered from

LaMotte Company by using the specifi ed code number.

1.

Use a 10 mL graduated

cylinder (0416) to add 15

mL of Deionized Water

(5115) to the titration tube

(0608).

3.

Add 2 drops of Sulfuric

Acid, 5N (8517WT).

Swirl to dissolve.

Solution will turn

yellowish brown.

2.

Use a Direct Reading

Titrator, 0-1 Range (1.0

mL capacity) (0376) to

add 2 mL of Potassium

Bi-iodate (7346).

4.

Use the 0.1 g spoon

(0699) to add 0.2 g

Potassium Iodide

Crystals (6809).

6.5.

Fill another Direct Reading

Titrator (0376) with Sodium

Thiosulfate Solution, 0.025N

(4169).

17

continued . . .

Page 18

EPA COMPLIANCE continued ...

7. 8.

While gently swirling the

tube, add Sodium

Thiosulfate, 0.025N until

the color fades to pale

yellow. It will be

necessary to refi ll the

Direct Reading Titrator.

9.

Continue adding

Sodium Thiosulfate,

0.025N until the blue

color disappears and

the solution is colorless.

10.

Read the test result directly from the scale

where the large ring on the Titrator meets the

Titrator barrel. Include the value of the original

amount dispensed (1 mL). If the reading is 2.0

+/- 0.1 mL, the Sodium Thiosulfate, 0.025N

(4169) is satisfactory. If not, discard and replace

with new reagent

Add 3 drops of

Starch Indicator

Solution (4170WT).

The solution will

turn blue.

18

Page 19

a

Page 20

SHORT FORM INSTRUCTIONS

Read all instructions before performing test. Use this guide as a quick reference.

1. Fill Water Sampling Bottle (0688-DO).

2. Add 8 drops of *Manganous Sulfate Solution (4167).

3. Add 8 drops of *Alkaline Potassium Iodide Azide (7166).

4. Cap and mix.

5. Allow precipitate to settle.

6. Add 8 drops of Sulfuric Acid, 1:1 (6141WT).

7. Cap and mix until reagent and precipitate dissolve.

8. Fill test tube (0608) to the 20 mL line.

9. Fill Titrator with *Sodium Thiosulfate, 0.025N (4169).

10. Titrate until sample color is pale yellow. DO NOT DISTURB TITRATOR.

11. Add 8 drops of Starch Indicator (4170WT).

12. Continue titration until blue color just disappears and solution is colorless.

13. Read result in ppm Dissolved Oxygen.

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside USA) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

65860-01-MN • 9/11

Loading...

Loading...