Page 1

Instruction Manual For

L

M

o

tt

Page 2

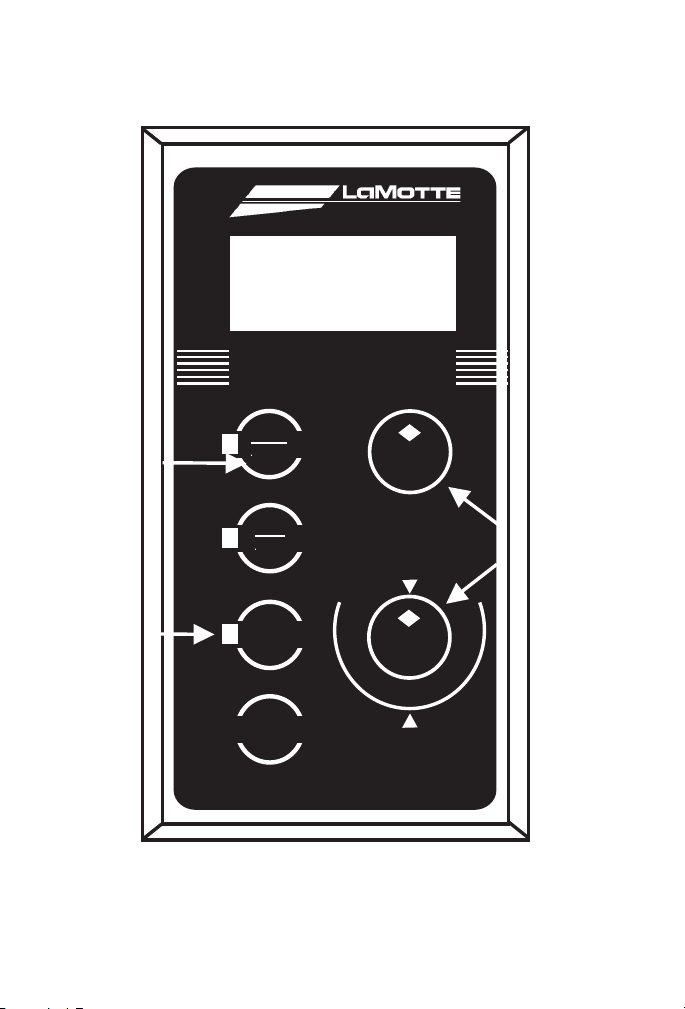

DIGITAL DISPLAY

CDS 5000

CONDUCTIVITY/TDS

.5

.6

.7

.8

.9

uS

ppm

mS

ppt

°C

OFF

SLOPE

CONDUCTIVITY

TDS

Controls Used

To Calibrate

Light

Indicates

Currently

Active Mode

Press Button

To Select

Operating

Mode

2

Page 3

CDS 5000

L

Mott

CONDUCTIVITY/TDS METER

CODE 1752-01

TABLE OF CONTENTS

Conductivity.......................................................................................... 4

Meter Basics ........................................................................................... 5

Meter Specifications............................................................................... 6

Calibrating ............................................................................................. 7

Testing Water......................................................................................... 8

Testing Salinity ...................................................................................... 9

Testing Soil........................................................................................... 12

Maintaining the Meter......................................................................... 13

Warranty Information .......................................................................... 15

3

Page 4

CONDUCTIVITY

Conductivity is defined as the ability of a solution to conduct an electrical

current, or the reciprocal of the solution’s ability to resist the current. This

current is conducted by electrically charged particles called ions, which

are present in almost all solutions. Different solutions have different kinds

and amounts of ions: distilled water has very few ions, and therefore a low

conductivity, while sea water has a large number of ions, and a high

conductivity.

Although a conductivity reading provides an overall measurement of the

ionic content of a solution, it is not possible to distinguish the specific

amounts of individual ions. For this reason, conductivity is often used to

measure the total dissolved solids (TDS) of a solution. TDS is defined as

the amount of solids which will pass through a 45 micron filter. Rather

than filtering a solution, the TDS can be estimated by multiplying the

conductivity measurement by a predetermined factor. This factor, which is

determined gravimetrically, will fall between 0.55 and 0.9; 0.7 is a

commonly used factor.

The conductivity measurement can also be used to estimate the salinity of

water, or the total amount of all salts dissolved in the water. Typically, the

conductivity reading is converted to salinity using charts, such as the one

found on page 10. These charts are based on water containing the same

amount and proportion of ions as standard seawater, so this form of

measurement is most effective for low concentrations and dilutions of

seawater.

Conductivity is measured in microsiemens per centimeter (msiemens/cm).

Siemens are also called mhos. In waters of higher conductivity,

msiemens/cm may be mul million. Therefore, using the information

discussed above:

msiemens/cm x 0.7 = ppm TDS

Salinity is usually measured in parts per thousand (ppt). The chart on page

10can be used to convert conductivity readings to salinity.

Because it is a quick, reliable, and inexpensive way of monitoring the

ionic content of a solution, conductivity measurements are widely used in

many areas of water testing, from environmental monitoring to municipal

water supplies to many industrial applications.

4

Page 5

METER BASICS

Conductivity is measured using a probe which contains two electrodes,

separated by a fixed distance. When a voltage is applied from the meter

across the electrodes, the ions in solution conduct a current, which flows

between the electrodes. The greater the concentration of ions in the

solution, the larger the current generated and the higher the conductivity.

Likewise, the smaller the concentration of ions, the lower the

conductivity. The meter converts the current measured to a conductivity

reading.

Over time the electrodes may become dirty or fouled with contaminants

from the sample. For specific probe cleaning instructions for the CDS

5000 see Maintaining The Meter on page 13.

Conductivity measurements are very dependent on temperature. The

ability of the ions to move through the solution, and conduct the current,

is related to the temperature of the solution. As the temperature rises, the

ions move more quickly through the solution, increasing the conductivity;

likewise as the temperature decreases the ions move more slowly and the

conductivity decreases. Since the conductivity of the same solution can

change by as much as 2%/°C, accurate temperature measurements must

be made simultaneously to the conductivity reading. The CDS 5000

includes a temperature probe to measure the temperature.

To make conductivity readings taken at different times and places

comparable, measurements are often converted to what the conductivity

of the solution would be at 25°C. The CDS 5000 automatically makes this

conversion before providing a final reading.

5

Page 6

METER SPECIFICATIONS

Range 1-199.9 mS/cm

200-1999 mS/cm

2-19.99 mS/cm

20-199.9 mS/cm

0to50°C

Resolution ±0.1

±1

±10

±100

Readout 3

1

digit LCD

2

Controls SLOPE

CONDUCTIVITY

mS/ppm

mS/ppt

°C

OFF

Temperature

Automatic by separate probe

Compensation

Probe Carbon electrodes; 3 ft. cable

Power 1604A Alkaline Battery (9 volt)

3.5 mm jack adapter

7

1

Size 5

“x3

8

3

”x1

“(15cmx8cmx5cm)

4

4

ACCESSORIES

Description Code #

AC Adapter 1708

Funnel 0459

Filter Paper 0465

Cond. Std., 0.0005M KCl, 74 mmhos/cm 6416-L

Cond. Std., 0.005M KCl, 718 mmhos/cm 6417-L

Cond. Std., 0.01M KCl, 1,413 mmhos/cm 6354-L

Cond. Std.,0.05M KCl, 6,668 mmhos/cm 6418-L

Cond. Std., 0.5M KCl, 58,640 mmhos/cm 6419-L

6

Page 7

CALIBRATING

The CDS 5000 is precalibrated at the factory; set both the TDS knob and

the SLOPE knob to the 12 o’clock position and proceed. This procedure

will give results within ±10% of the actual reading. For more accurate

results, follow the procedure below.

1. Press “°C” button to turn the meter on.

2. Set TDS knob to the 12 o’clock position.

1

3. Insert temperature and conductivity probes at least

conductivity standard.

“into

2

4. Gently stir with conductivity probe until reading stabilizes. Press

“mS/ppm” or “mS/ppt” button.

5. Adjust SLOPE knob until display reads conductivity of chosen

standard. The CDS 5000 is now calibrated and ready for use.

LaMotte offers several ranges of conductivity standards. Choose the

standard most appropriate for your testing needs and order using the four

digit code number listed.

STANDARDS

Description Code #

Cond. Std., 0.0005M KCl, 74 mmhos/cm 6416-L

Cond. Std., 0.005M KCl, 718 mmhos/cm 6417-L

Cond. Std., 0.01M KCl, 1,413 mmhos/cm 6354-L

Cond. Std.,0.05M KCl, 6,668 mmhos/cm 6418-L

Cond. Std., 0.5M KCl, 58,640 mmhos/cm 6419-L

7

Page 8

TESTING WA TER

CONDUCTIVITY

1. Press “°C” button to turn the meter on.

2. Set TDS and SLOPE knobs to the 12 o’clock position.

NOTE: If meter was calibrated according to procedure on page 7,

leave SLOPE knob set in the same position.

3. Insert temperature and conductivity probes at least 1/2" into sample.

4. Gently stir with conductivity probe until reading stabilizes. Press

“mS/ppm” button. Record reading as msiemens/cm.

5. If a 1 appears on the far left side of the display, the reading is out of

range. Repeat procedure using “mS/ppt” button. Record as

msiemens/cm. To convert to msiemens/cm, multiply reading by 1000.

Record as msiemens/cm.

6. Press “OFF” button when finished testing. Rinse probe with distilled

water and dry thoroughly before storing.

TOTAL DISSOLVED SOLIDS

1. Set TDS knob to desired multiplication factor.

NOTE: 0.7 is a commonly used multiplication factor.

2. Press “°C” button to turn the meter on.

3. Set SLOPE knob to the 12 o’clock position.

NOTE: If meter was calibrated according to procedure on page 7,

leave SLOPE knob set in the same position.

4. Insert temperature and conductivity probes at least 1/2" into sample.

5. Gently stir with conductivity probe until reading stabilizes. Press

“mS/ppm” button. Record reading as msiemens/cm.

6. If a 1 appears on the far left side of the display, the reading is out of

range. Repeat procedure using “mS/ppt” button. Record as

msiemens/cm. To convert to msiemens/cm, multiply reading by 1000.

Record as msiemens/cm.

7. Press “OFF” button when finished testing. Rinse probe with distilled

water and dry thoroughly before storing.

8

Page 9

TESTING SALINITY

1. Press “°C” button to turn the meter on.

2. Set TDS and SLOPE knobs to the 12 o’clock position.

NOTE: If meter was calibrated according to procedure on page 7,

leave SLOPE knob set in the same position.

3. Insert temperature and conductivity probes at least 1/2" into sample.

4. Gently stir with conductivity probe until reading stabilizes. Press

“mS/ppt” button. Record reading as msiemens/cm.

5. Using chart on the following page, convert conductivity reading to

salinity . Record as ppt Salinity.

6. Press “OFF” button when finished testing. Rinse probe several times

with distilled water and dry thoroughly before storing.

9

Page 10

FOR CHANGING CONDUCTIVITY INTO SALINITY

CONVERSION TABLE

Conductivity Salinity

0°C 5°C 10°C 15°C 20°C 25°C 30°C

0

1.200 1.400 1.500 1.700 2.000 2.200 2.400 1

2.220 2.500 2.900 3.300 3.700 4.100 4.500 2

3.200 3.700 4.200 4.700 5.300 5.900 6.500 3

4.100 4.700 5.400 6.100

6.900

7.600 8.400 4

5.000 5.800 6.600 7.500 8.400 9.300 10.3005

5.900 6.800 7.900 8.800 9.900 11.000 12.1006

6.700 7.800 8.900 10.100 11.300 12.600 13.9007

7.600 8.800 10.100 11.400 12.800 14.200 15.7008

8.500 9.800 11.200 12.700 14.200 15.800 17.4009

9.300 10.800 12.300 13.900 15.600 17.300 19.10010

10.200 11.800 13.400 15.200 17.000 18.900 20.80011

11.000 12.800 14.500 17.600 18.900 20.400 22.50012

11.900 13.700 15.600 18.900 19.700 21.900 24.10013

12.600 14.600 16.700 20.100 21.100 23.400 25.80014

00

13.400 15.600 17.800 20.100 22.400 24.900 27.40015

14.200 16.400 18.800 21.200 23.800 26.400 29.10016

15.000 17.400 19.800 22.400 25.100 27.800 30.70017

15.800 18.300 20.900 23.600 26.400 29.300 32.30018

16.600 14.200 21.900 24.800 27.700 30.700 33.90019

17.400 20.100 23.000 25.900 29.000 32.200 35.50020

18.200 21.100 24.000 27.100 30.300 33.600 37.00021

Page 11

Conductivity Salinity

0°C 5°C 10°C 15°C 20°C 25°C 30°C

0

19.000 22.000 25.100 28.300 31.600 35.000 38.60022

19.800 22.900 26.100 29.400 32.900 36.500 40.10023

20.600 23.800 27.100 30.600 34.200 37.900 41.70024

21.400 24.700 28.100 31.700 35.400 39.300 43.20025

22.100 25.500 29.100 32.800 36.700 40.700 44.80026

22.800 26.400 30.100 33.900 37.900 42.100 46.30027

23.600 27.300 31.100 35.100 39.200 43.500 47.80028

24.400 28.100 32.100 36.200 40.400 44.800 49.40029

25.200 29.000 33.100 37.300 41.700 46.200 50.90030

00

10

Page 12

FOR CHANGING CONDUCTIVITY INTO SALINITY

CONVERSION TABLE

Conductivity Salinity

0°C 5°C 10°C 15°C 20°C 25°C 30°C

0

00

26.800 30.900 35.100 39.600 44.200 49.000 53.900 32

27.500 31.700 36.100 40.700 45.400 50.300 55.400 33

28.300 32.600 37.100 41.800 46.700 51.700 56.800 34

29.100 33.500 38.100 42.900 47.900 53.000 58.300 35

29.700 34.200 39.000 44.000 49.100 54.400 59.800 36

30.500 35.100 40.000 45.100 50.300 55.700 61.300 37

31.200 36.000 41.000 46.200 51.500 57.100 62.800 38

32.000 36.800 41.900 47.200 52.700 58.400 64.200 39

32.700 37.700 42.900 48.300 53.900 59.700 65.700 40

Data derived from the equation of P.K. Weyl, Limnology and Oceanography;9,75

(1964).

11

Page 13

TESTING SOIL

The Total Dissolved Solids (TDS) level of soil samples can be determined

using the CDS 5000. A soil extraction is made using distilled water, and

the TDS level measured.

1. Fill a 50 mL beaker with sample soil. Tap lightly to eliminate trapped

air. Remove excess soil from the surface.

2. Empty beaker into a 250 mL widemouth flask. Add 100 mL of

distilled water. Stopper and shake vigorously. Wait 30 minutes.

NOTE: During the waiting period, vigorously shake the sample three

or four times.

3. Filter contents of flask, collecting filtrate in a beaker or other suitable

container.

NOTE: LaMotte Company offers a funnel (order code 0459) and

filter paper (order code 0465) which can be used for this filtration.

4. Set TDS knob to desired multiplication factor.

NOTE: 0.7 is a commonly used multiplication factor.

5. Press “°C” button to turn the meter on.

6. Set SLOPE knob to the 12 o’clock position.

NOTE: If meter was calibrated according to procedure on page 7,

leave SLOPE knob set in the same position.

7. Insert temperature and conductivity probes at least 1/2" into sample.

8. Gently stir with conductivity probe until reading stabilizes. Press

“mS/ppm” button. Record reading as msiemens/cm.

9. If a 1 appears on the far left side of the display, the reading is out of

range. Repeat procedure using “mS/ppt” button. Record as

msiemens/cm. To convert to msiemens/cm, multiply reading by 1000.

Record as msiemens/cm.

10. Press “OFF” button when finished testing. Rinse probe with distilled

water and dry thoroughly before storing.

12

Page 14

MAINTAINING THE METER

Adjust This

Potentiometer

REPLACING THE BATTERY

When “BAT” appears on the display, the battery should be replaced. The

temperature reading will be the first function to be affected by a low

battery.

1. Use a #1 Phillips head screwdriver to remove four screws on the back

of the meter case.

2. Gently lift back panel from meter .

3. Lift battery from bottom of meter. Remove from connector.

4. Snap new battery onto connector.

NOTE: The CDS 5000 uses a type 1604A (9 volt) battery .

5. Lower battery into compartment. Replace back panel and screws.

AC ADAPTER

An AC adapter is available for use with the CDS 5000. Order as code

#1708. Insert connector into small hole next to the probe connector.

CLEANING THE PROBE

Page 15

The graphite probe may occasionally become dirty and need to be

cleaned. After each use the probe should be thoroughly rinsed with

distilled water. If further cleaning is necessary, the probe can be washed

with a mild detergent, and then thoroughly rinsed with distilled water.

Always thoroughly dry the probe before storing.

13

Page 16

REPLACING THE PROBE

If the probe cannot be adequately cleaned, or becomes damaged, it must

be replaced. When a new probe is attached to the meter, the CDS 5000

must be recalibrated using the following procedure. Do not allow the CDS

5000 to contact any conductive surfaces while performing this procedure.

1. Set SLOPE and TDS knobs to the 12 o’clock position.

2. Use a Phillips head screwdriver to remove four screws from back of

meter. Remove back from meter.

3. Follow the Conductivity testing procedure described on page 8 to

measure the conductivity of a chosen standard. Choose the standard

that is closest to the value of the solutions commonly measured.

4. Using a small, flat edge screwdriver, adjust the top potentiometer

(indicated in the diagram) until value of standard solution is

displayed.

NOTE: Only adjust the top potentiometer; adjusting any other

potentiometer voids the meter’s warranty. If these other

potentiometers are adjusted, the meter must be returned to LaMotte

for repair.

5. Replace back on meter and replace the four screws. The CDS 5000 is

now calibrated and ready for use.

14

Page 17

WARRANTY INFORMATION

REPAIRS

If it is necessary to return the instrument for repair, contact LaMotte

Company at 1-800-344-3100 for a return authorization number.

INSTRUMENT GUARANTEE

This instrument, excluding the probe, is guaranteed to be free of defects in

material and workmanship for one year from date of original purchase. If,

in that time, it is found to be defective, it will be repaired without charge,

except for transportation expenses. This guarantee does not cover the

batteries.

This guarantee is void under the following circumstances:

operator’s negligence

•

improper application

•

unauthorized servicing

•

LIMITS OF LIABILITY

Under no circumstances shall LaMotte Company be liable for loss of life,

profits, or other damages incurred through the use of misuse of their

products.

PA CKAGING AND DELIVERY

Experienced packaging personnel at LaMotte Company assure adequate

protection against normal hazards encountered during shipping. After the

product leaves the manufacturer, all responsibility for its safe delivery is

assured by the transporter. Damage claims must be filed immediately with

the transporter to receive compensation for damaged goods.

15

Page 18

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside U.S.A.) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

SM

61752-01 · 10/02

Loading...

Loading...