Page 1

Model S/DuoSoft

with ColorQ

water quality

DEMO OUTFIT

AT-Q

38/40

Page 2

o

Page 3

Table of Contents

Safety Information .................................................................... 4

Testing Hints ............................................................................. 4

Analytical T echnique ...................................................................... 5

Water Softeners ......................................................................... 6

Introduction .................................................................................... 6

Instructions for Use

Procedure A - Use of the Softeners ................................................. 7

Procedure B - Replacing the Media in the Softeners ....................... 8

Procedure C - Regenerations of the Media .................................... 9

Soap Demonstration ................................................................. 10

Precipitation Demonstration ..................................................... 11

ColorQ DW Photometer ........................................................... 12

Introduction ................................................................................... 12

Blank ............................................................................................. 13

pH .................................................................................................. 13

Hardness ........................................................................................ 14

Iron ................................................................................................ 15

Chlorine ......................................................................................... 16

Sulfi de ........................................................................................... 17

Nitrate ........................................................................................... 18

ColorQ User Tips ...................................................................... 19

TDS Meter (Optional) ............................................................. 20-21

Replacement Parts .................................................................... 22

AT-38 & AT-40 Diagram Layout .............................................. 23

Page 4

Safety Information

Read the instruction manual thoroughly to familiarize yourself with the test procedures before you begin.

Make note of any precautions in the instructions.

Read the labels on all LaMotte reagent containers prior to use. Some containers include precautionary notices

and fi rst aid information. Certain reagents are considered hazardous substances and are designated with a * in

the instruction manual. Material Safety Data Sheets (MSDS) are available at www.lamote.com. Read the MSDS

before using these reagents. Additional emergency information for all LaMotte reagents is available 24 hours

a day from the Poison Control Center listed in the front of the phone book. Be prepared to supply the name and

four-digit LaMotte code number found on the container label or at the top of the MSDS. LaMotte reagents are

registered with a computerized poison control information system available to all local poison control centers.

Keep equipment and reagent chemicals out of the reach of young children.

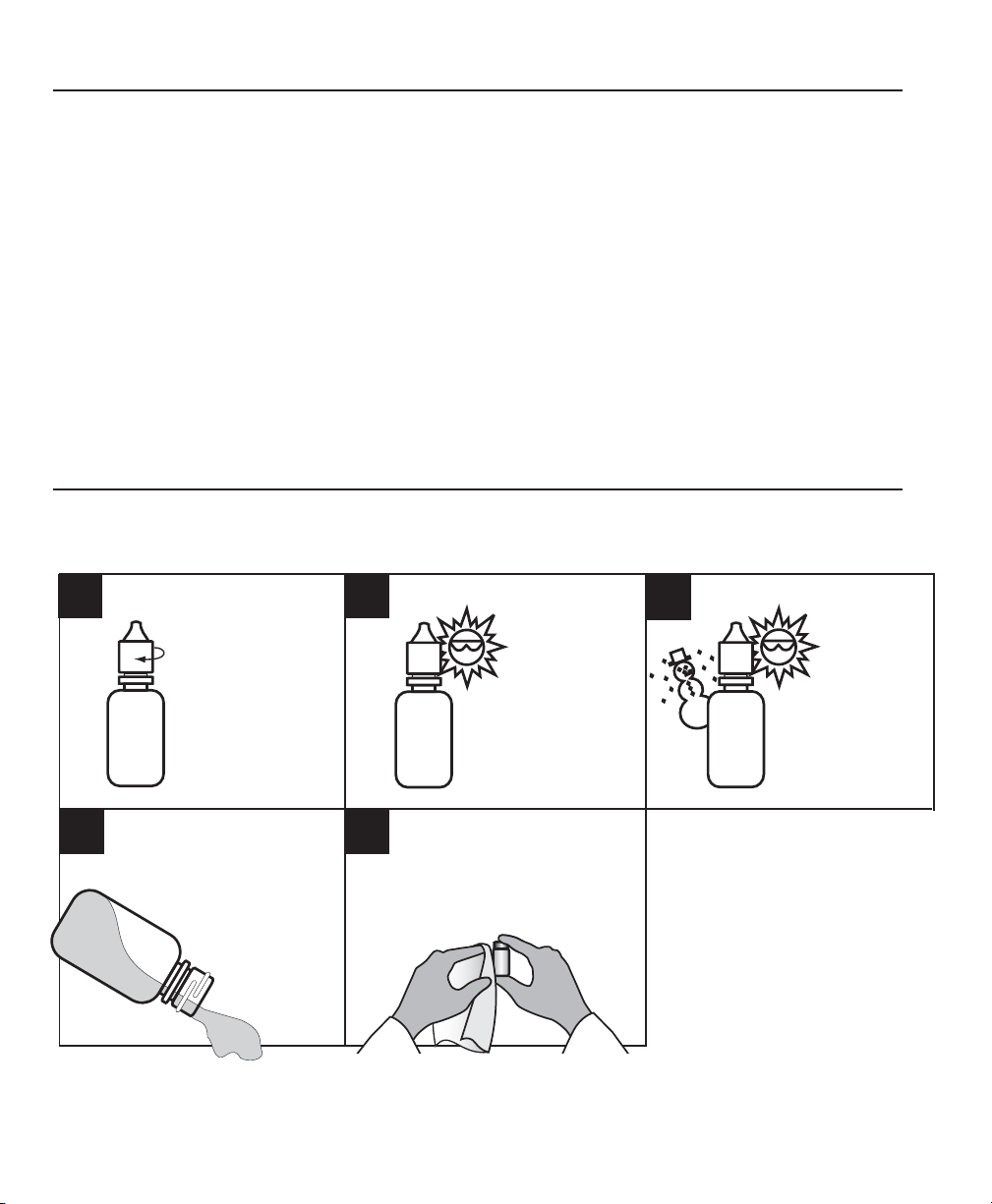

Protect Yourself and Equipment: Use Proper Analytical Techniques

Testing Hints

1. 2. 3.

Tightly close all

reagent containers

immediately after

use. Be sure not to

interchange caps

and pipets from

different containers.

Avoid

prolonged

exposure of

equipment

and reagents

to direct

sunlight.

Protect reagents

and components

from extreme

heat and cold.

4. 5.

Wipe up any reagent chemical

spills, liquid or powder, as

soon as they occur. Refer to

label and accompanying

MSDS for proper

reagent disposal.

4

Use care when dispensing or

handling all reagents due to

safety reasons. Some

chemicals also may cause

permanent stains if spilled.

Page 5

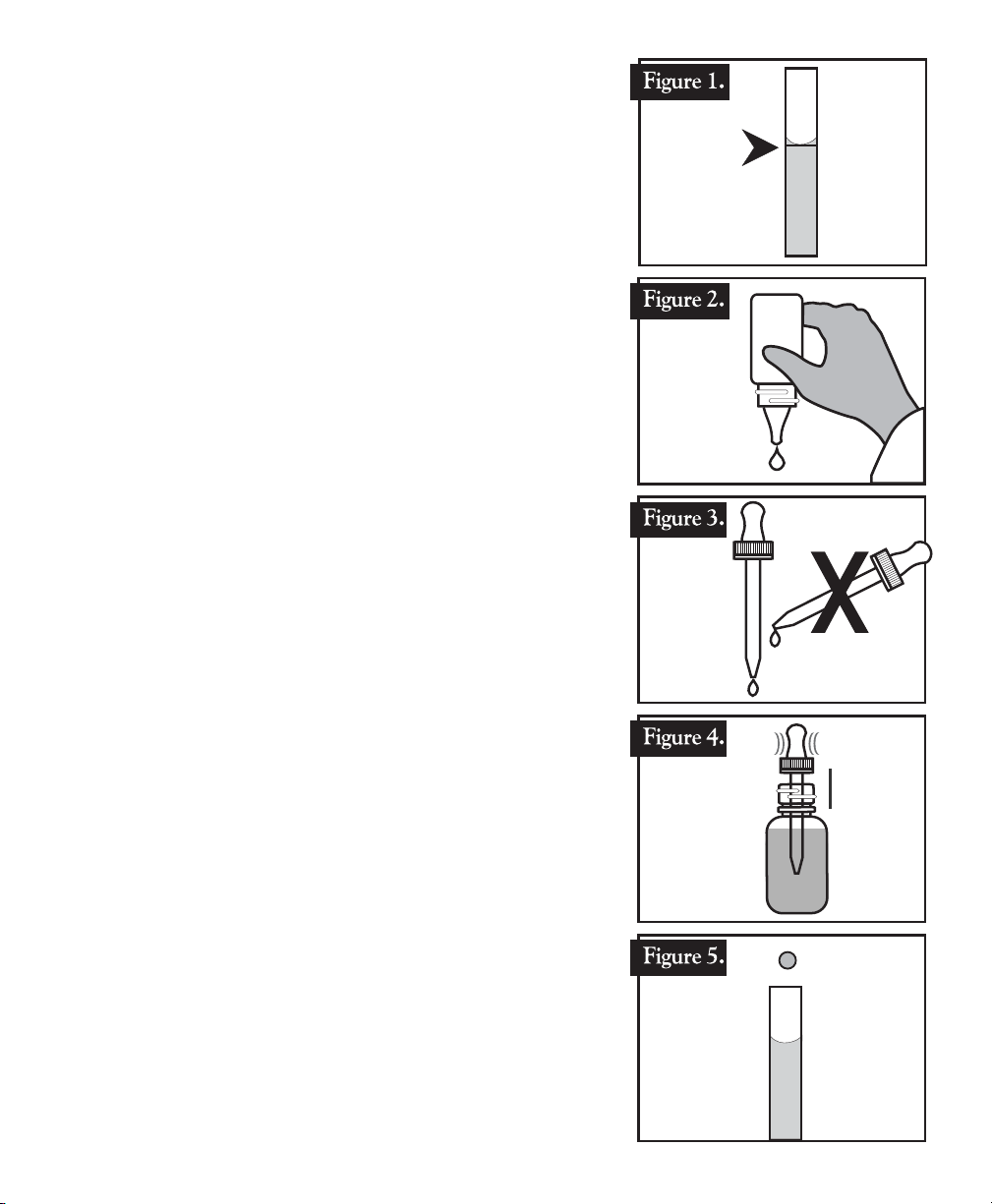

ANALYTICAL TECHNIQUE

1. Clean glassware is a must for accurate results. Thoroughly rinse

test tubes before and after each test. Caps and stoppers should

also be cleaned after each use.

2. Use test tube caps or stoppers, not your fi ngers, to cover test

tubes and fl asks during shaking or mixing.

3. When adding sample to calibrated test tube, be sure vial is fi lled

to the appropriate mark. The bottom of the liquid (meniscus)

should be level with the desired mark. (Figure 1)

4. When dispensing reagents from bottles fi lled with dropper plug

and cap, be sure to hold bottle vertically and gently squeeze to

dispense the appropriate number of uniform drops. (Figure 2)

5. For those reagents to be added with the screwcap pipet assemblies

enclosed, remove polyseal cap on bottle and replace with the

screwcap pipet.

NOTE: Place the polyseal caps back on the reagent bottles for

longer periods of storage. Be sure that both pipet assemblies

and polyseal caps are thoroughly cleaned before placing on

bottles to avoid contamination.

6. When dispensing reagents from pipets, hold pipet vertically

to assure uniform drop size. This is extremely important when

performing drop count titrations. (Figure 3)

7. To fi ll pipets, squeeze rubber bulb and immerse into reagent.

Release bulb to fi ll. (Figure 4)

8. To add tablets, place over test vial with silver plastic side facing

up. Press tablet through the foil into the tube. (Figure 5)

5

Page 6

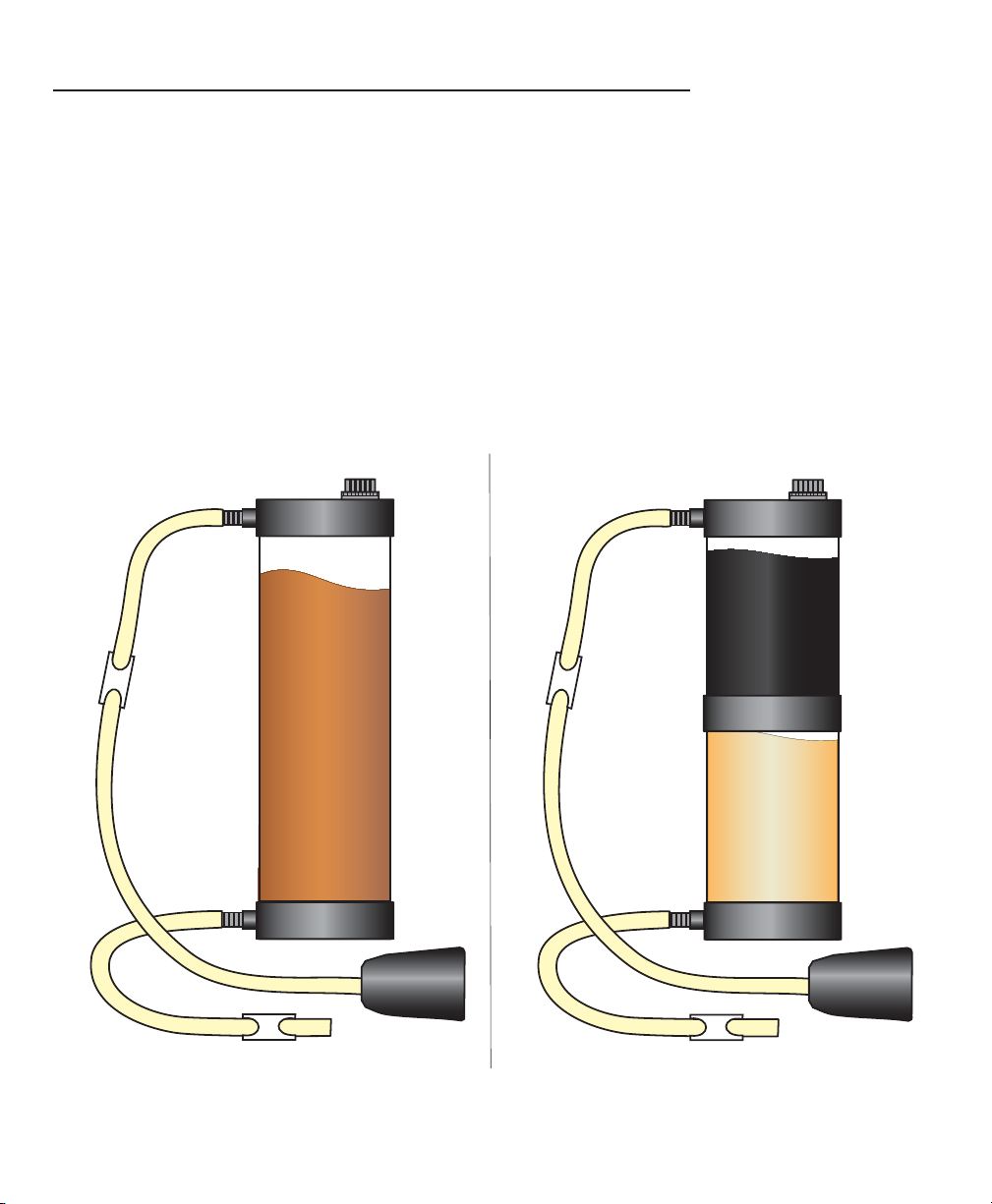

Model S and DuoSoft Softeners

INTRODUCTION

The Model S and the DuoSoft Water Softeners are designed to produce high quality softened water. As water

passes through the Model S chamber, the resin column causes scale-forming calcium and magnesium ions to be

exchanged for non-scale-forming sodium ions. When the resin is exhausted it must be replaced or regenerated.

Inexpensive

In the DuoSoft, water passes through both chambers and will be treated by both types of media. The two chambers of the DuoSoft may be easily fi lled with the media of choice for specifi c problem water.

NOTE: These softeners DO NOT yield water suitable for drinking .

READ INSTRUCTIONS BEFORE USE.

resin refi ll packages are available, or the original resin can be regenerated by chemical treatment.

OUTLET

HOSE

INLET

HOSE

CLAMP

CLAMP

PLUG

CHAMBER

FAUCET

ADAPTER

OUTLET

HOSE

INLET

HOSE

CLAMP

CLAMP

PLUG

TOP

CHAMBER

BOTTOM

CHAMBER

FAUCET

ADAPTER

6

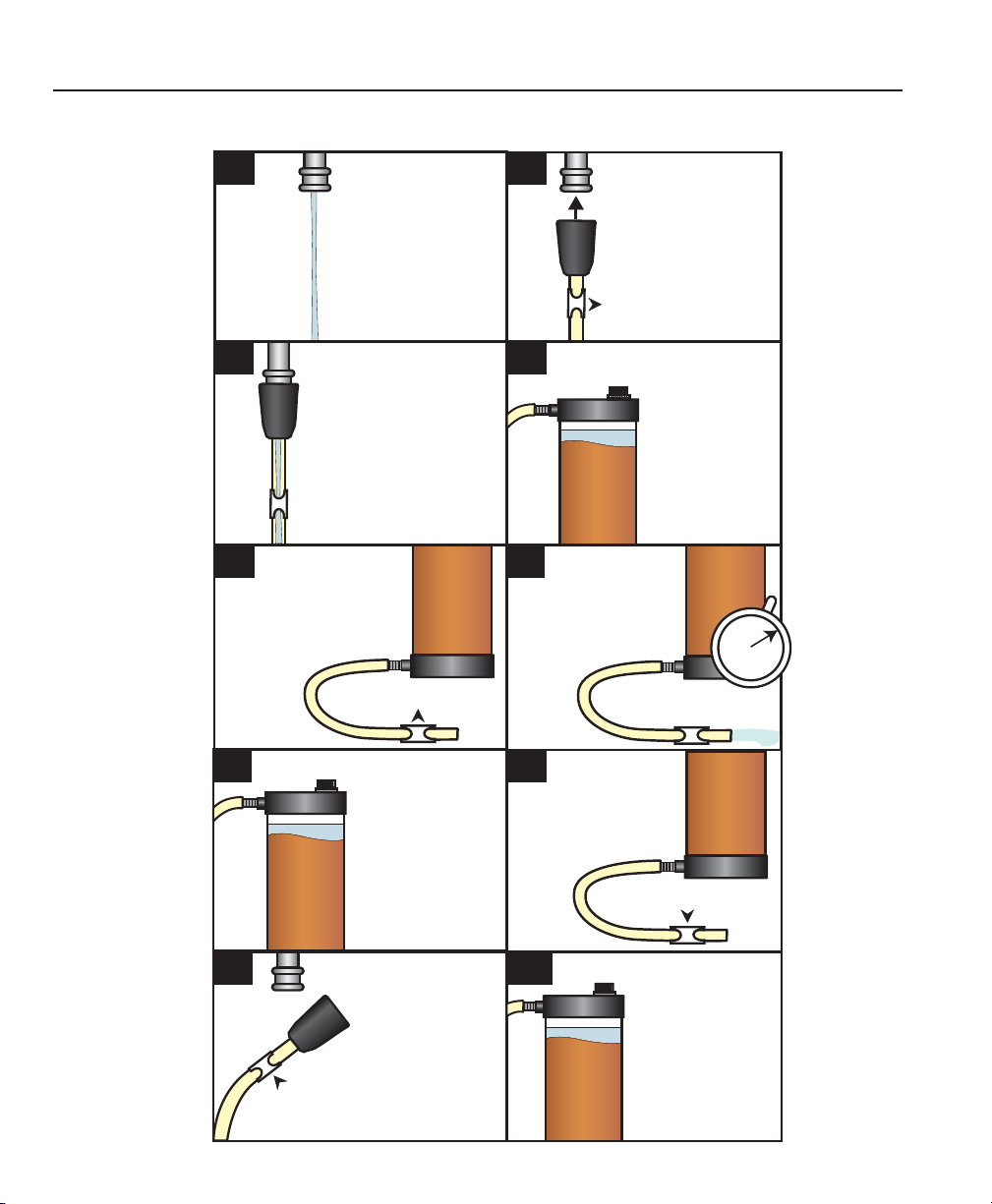

Page 7

Instructions for Use

PROCEDURE A — Use of the Softeners

1. 2.

Allow water

to run from

faucet briefl y to

visually gauge

pressure.

Attach adapter

on inlet hose

to faucet.

Fully open

clamp on inlet

hose.

3. 4.

5. 6.

7.

SLOWLY turn on

faucet and adjust the fl ow

of water into softener

until

the stream of water

is about 1/8” in diameter.

Maintain

prevent excessive pressure

in the adapter

Unclamp outlet

hose at bottom

of softener.

a gentle fl ow t

Adjust fl ow to

maintain the 1”

layer of water

over the media.

o

.

Let effl uent run

to waste for about

3 minutes to wash

out residue from

the previous

sample.

8.

After enough

softened water has

been collected, turn

off faucet and clamp

outlet hose.

Fill chamber

until a 1” layer

of water is

visible over

the media.

3

minutes

9. 10.

When

softener is

disconnected

from faucet,

clamp inlet

hose.

If softener will be stored

unused for any

length of time,

keep a 1” layer

of water over

resin column to

prevent drying

and cracking.

7

Page 8

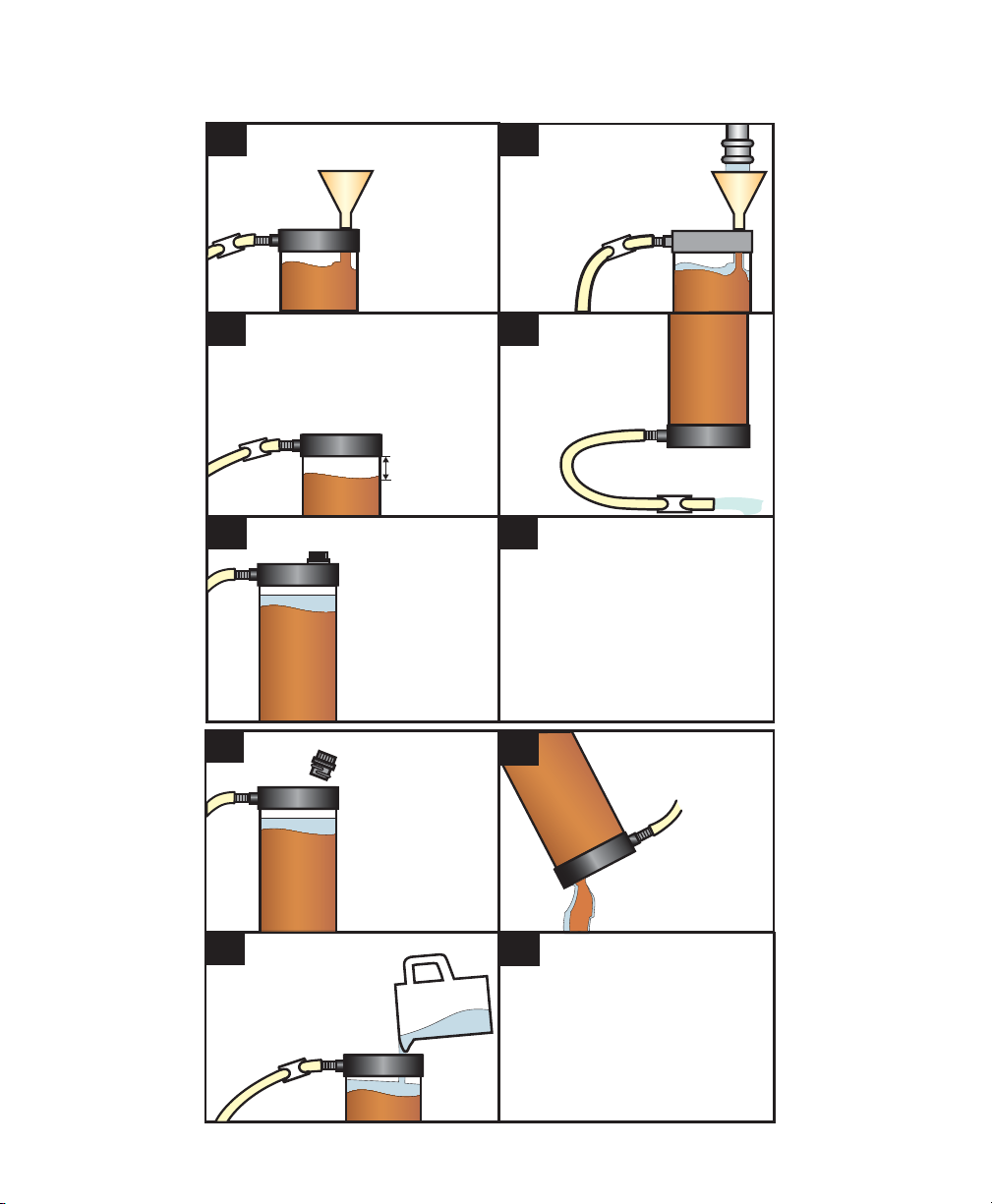

PROCEDURE B — Replacing the Media in the Softeners

1. 2.

With the aid

of a funnel,

add the fresh

media to the

column.

3. 4.

Continue adding media to

the column until the resin is about

2” from the top of the column.

2”

ADDITIONREMOVAL

5. 6.

Clean threaded

area completely

and replace the

black plug in the

top of column.

Tap water may be

added to the media in the

funnel to facilitate fi lling

of the column.

Allow excess water

to drain from outlet

hose.

DuoSoft Unit

To add the media in the

bottom chamber, turn unit upside

down and repeat Addition Steps

1-5. When media has been added

to both chambers, proceed with

Procedure A. When using carbon

media, it is suggested that it be

used in the top chamber.

1.

T o replace media,

remove black

plug from the top

of dispenser.

3. 4.

By adding more

water to the column

and shaking, the

remaining media can

be easily removed.

2.

T o remove the media in the

bottom chamber, turn unit up-

side down and repeat Removal

Steps 1-3. To add new media,

follow Addition Steps 1-5 for

Unclamp outlet hose

and turn softener

upside down.

Allow exhausted

media and water to

run to waste.

DuoSoft Unit

both chambers.

8

Page 9

PROCEDURE C — Regeneration of Media

Follow manufacturers’ instructions for regeneration of media. Cation exchange resin may be regenerated in the

following manner. NOTE: Due to build up of air pressure, it is not possible to regenerate both chambers of the

DuoSoft unit at the same time. Follow steps 1-8 to regenerate top chamber, then see step 9 to regenerate bottom

chamber.

1. 2.

Prepare salt

solution by

dissolving about

½ pound of

salt (sodium

Chloride) in 1

quart of water.

3. 4.

Clamp

outlet tube.

Add salt

solution

top chamber is

completely full.

until

5. 6.

Unclamp outlet

tube and allow salt

solution to run to

waste.

Remove black

plug from top

of softener.

Allow to stand for about 30

minutes.

30

MINUTES

Clean threaded

area completely

and replace

black plug in

top of softener.

7.

Attach adapter

to faucet.

9.

For the DupSoft unit; turn unit upside down and repeat steps 1-8.

8.

Wash resin with

approximately

1 gallon of tap

water.

9

Page 10

Soap Demonstration

Calcium and Magnesium ions present in a water supply are the principle contributors to the total hardness.

Hard water tends to consume excessive quantities of soap and forms curds and deposits on glassware, fabrics, etc.

*WARNING: Reagents marked with an * are considered to be potential health hazards. To view or print a

Material Safety Data Sheet (MSDS) for these reagents go to www.lamotte.com. To obtain a printed copy,

contact LaMotte by e-mail, phone or fax.

TEST PROCEDURE

1. 2. 3.

Thoroughly rinse

the “SOFT”

water fl ask

(0453) with

softened water.

Thoroughly rinse

the “HARD”

water fl ask

(0452) with

untreated water.

4. 5. 6.

With the pipet

Fill the “SOFT”

fl ask (0453) with

softened water to

the same level.

7. 9.8.

A thick lather will form

in the softened water.

(0392), add 4

drops of *Soap

Reagent #4

(4767) to each

fl ask.

Continue to add

*Soap Reagent #4

(4767), one drop at a

time, to the untreated

“HARD” water,

shake periodically

until a lather forms.

Count the number

of drops added.

Fill the “HARD”

fl ask (0452) with

untreated water

until the bottom

surface is covered

with a layer of

water about ½”

deep.

Cap and shake

the fl ask.

Extremely hard

water may require

30, 40, or even 60

drops of *Soap

Reagent #4 to

produce a lasting

lather.

10

Page 11

Precipitation Demonstration

Again, Calcium and Magnesium ions are the major contributors to water hardness. The chemical reagents in this

demonstration pull the Calcium and Magnesium ions out of solution to form a cloudy precipitate in hard water.

The water that has been run through the ion exchange column has had these ions removed, therefore, the sample

should remain clear.

NOTE: This portion of the AT-38/40 Water Quality Demo Kit is ONLY a visual demonstration illustrating the

removal of Calcium and Magnesium ions from tap water after treatment by the ion exchange process. The

results should not be interpreted beyond the intent of the demonstration.

*WARNING: Reagents marked with an * are considered to be potential health hazards. To view or print a Material Safety Data Sheet (MSDS) for these reagents go to www.lamotte.com. To obtain a printed copy, contact

LaMotte by e-mail, phone or fax..

TEST PROCEDURE

1. 2. 3.

Thoroughly rinse

the “SOFT”

water Demo Tube

(0298) with

softened water.

Thoroughly rinse

the “HARD”

water Demo Tube

(0297) with

softened water.

4. 5. 6.

Fill the “HARD”

Demo tube

(0297) to the line

with untreated

water.

Add 7 drops of

*Precipitation

Reagent A

(4542WT)

to each tube.

7. 9.8.

Cap and mix.

Add 7 drops of

*Precipitation

Reagent B

(4543WT)

to each tube.

Fill the “SOFT”

Demo tube

(0298) to the line

with softened

water.

Cap and mix.

Place tubes in the

Precipitation Rack (0879)

and allow the tubes to

stand for

5 minutes.

Heavy

Precipitate

Remains

clear

11

Page 12

Color

Q

DW

ColorQ Photometer for Drinking Water

For software Version 5.73 or higher

To insure proper testing results.

• Insert tubes into ColorQ with line

and arrow facing forward.

• Brush and rinse all tubes

promptly after use.

• Rinse tablet crusher between test

factors.

• Allow tubes to dry before

returning to case.

• Replace reagent caps securely.

• Use only LaMotte replacement

reagents and ColorQ test tubes

Code 0201.

• If unit should auto-off during

testing rinse and fi ll one tube to

Blank and return to testing.

12

• To skip test in the sequence press

button to advance past that test

factor.

• To turn meter off at any time,

press and hold the button until

“off” is displayed.

• bAt = battery is low.

WARNING! This set contains chemicals that may be harmful

if misused. Read cautions on individual containers carefully.

Not to be used by children except under adult supervision.

Page 13

BLANK (CALIBRATION)

1

BLA

A

L

Color

Q

1. Fill sample bottle with water sample. Replace cap.

2. Fill clean tube (#0201) to the 5mL line with water sample.

3. Insert tube into ColorQ as shown.

4. Press button to turn meter on. When “bLA” appears press button to

“Blank” the meter, and go to pH. Remove tube.

pH ColorQ Range: 4.0-9.0

2

pH

pH - Code 7059-E

5

1. Add 5 drops Wide Range pH Reagent (7059) to the same tube.

2. Cap. Invert 3 times to mix. Insert tube into ColorQ.

3. Press button to read “pH” pH. Remove tube.

* Reagent is a potential health hazard. Read MSDS at www.lamotte.com.

h

p

Color

Q

13

Page 14

HARDNESS ColorQ Range: 1-41 GPG

*Hardness 1 Buffer: Code 7045-G

3

hb

*Hardness 2 Indicator: Code 7046-G

Color

Q

5 5

+

1. Press button to go to “Hd” Hardness.

2. Fill a clean tube (0201) to the 5 mL line with water sample.

3. Add 5 drops Hardness 1 Buffer (7045) and Hardness 2 Indicator (7046)

to same tube.

4. Cap. Invert 3 times to mix. Insert tube into ColorQ.

5. Press button to read “Hd” Hardness in gpg. Remove tube.

DILUTION

Samples with hardness concentrations above 41 gpg must be diluted. The

meter will display “Hi”.

A. Use the 1 mL pipet (0354) to add 2 measures (2mL) water

sample to a clean test tube (0201).

B. Dilute to the 5 mL line with distilled or deionized water. Cap and mix.

C. Blank with the diluted sample from Step B. Follow test procedure Step

3-5 with dluted sample. Multiply the displayed result by 2.5

Color

Q

14

NOTE: To convert from GPG to ppm; Multiply GPG by 17.1

* Reagent is a potential health hazard. Read MSDS at www.lamotte.com.

Page 15

TOTAL IRON ColorQ Range: 0.0-3.0 ppm

4

i

Color

i

Q

*Ir - Code 3725A-H

1

1. Press button to go to “Ir” Iron.

2. Fill a clean tube (0201) to the 5 mL line with water sample.

3. Add 1 IRON (3725) Tablet. Crush with tablet crusher (0175).

4. Cap. Invert 3 times to mix. Tablet will not disslve completely.

Insert tube into Color Q.

5. Press button to read “Ir” Total Iron in ppm. Remove tube.

DILUTION

Samples with iron concentrations above 3 ppm must be diluted. The meter

will display “Hi”.

A. Use the 1 mL pipet (0354) to add 1 mL water sample to a test tube.

B. Dilute to the 5 mL line with distilled or deionized water. Cap and mix.

C. Blank with the diluted sample from Step B. Follow Steps 3-5 of the test

procedure with the diluted sample.. Multiply the displayed result by 5.

i

Color

Q

* Reagent is a potential health hazard. Read MSDS at www.lamotte.com.

15

Page 16

FREE / TOTAL CHLORINE ColorQ Range: 0.0-10.0 ppm Chlorine

5

+

Color

Fcl

L

C

Q

/

+cl

/

*DPD 1 - Code 6903A-H

*DPD 3 - Code 6197A-H

1

Free Chlorine and Total Chlorine

1. Press button to go to “FCL” Free Chlorine.

2. Fill a clean tube (0201) to the 5 mL line with water sample.

3. Add 1 DPD 1(6903A) Tablet. Cap. Shake for TEN seconds. Invert

slowly 5 times.

4. Press button to read “FCL” Free Chlorine in ppm. Remove tube.

1. Press button to go to “tCL” Total Chlorine.

2. Remove cap from reacted FCL tube.

3. Add 1 DPD 3(6197A) Tablet. Cap. Shake for TEN seconds. Invert

slowly 5 times.

4. Insert tube into ColorQ.

5. Press button to read “tCL” Total Chlorine in ppm. Remove tube.

C

+

Color

L

Q

16

Total Chlorine Only

1. Press button past “FCL” Free Chlorine to go to “tCL” Total Chlorine.

2. Fill a clean tube (0201)to the 5 mL line with water sample.

3. Add 1 DPD 1(6903A) Tablet. Cap. Shake for TEN seconds. Invert slowly

5 times.

4. Remove cap. Add 1 DPD 3(6197A) Tablet. Cap. Shake for TEN seconds.

Invert slowly 5 times.

5. Insert tube into ColorQ.

6. Press button to read “tCL” Total Chlorine in ppm. Remove tube.

*Reagent is a potential health hazard. Read MSDS at www.lamotte.com.

Page 17

FREE / TOTAL CHLORINE ColorQ Range: 0.0-10.0 ppm Chlorine

*Sulfi de Reagent A: Code V-4458LWT-G

6

Color

Q

*Sulfi de Reagent A: Code V-4458LWT-G

*Sulfi de Reagent A: Code V-4458LWT-G

+

5

3

Color

Q

5

1. Press button to go to “SuL” Sulfi de.

2. Fill a clean tube (0201) to the 5 mL line with water sample.

3. Add 5 drops of SULFIDE REAGENT A (4458).

4. Add 3 drops of SULFIDE REAGENT B (4459).

5. Cap and invert 3 times to mix. Allow tube to sit for ONE minute.

6. Add 5 drops of SULFIDE REAGENT C (4460).

7. Cap. Invert 3 times to mix. Insert tube into ColorQ.

8. Press button to read “SuL” Total Sulfi de in ppm. Remove tube.

DILUTION

Samples with sulfi de concentrations above 3 ppm must be diluted. The meter

will display “Hi”.

A. Use the 1 mL pipet (0354) to add 1 mL water sample to a test tube.

B. Dilute to the 5 mL line with distilled or deionized water. Cap and mix.

C. Blank with the diluted sample from Step B. Follow the test procedure,

steps 3 - 8, with the diluted sample. Multiply the displayed result by 5.

* Reagent is a potential health hazard. Read MSDS at www.lamotte.com.

17

Page 18

NITRATE-NITROGEN ColorQ Range: 0-15 ppm

7

Color

Q

*Nitrate - Code 3884A-H

1

1. Press button to go to “nit” Nitrate.

2. Fill a clean tube (0201) to the 5 mL line with water sample.

3. Add 1 NITRATE (3884A) Tablet. Crush with tablet crusher.

4. Cap. Invert 30 times per minute for TWO minutes.

5. Wait FIVE minutes. Insert tube into Color Q.

6. Press button to read “nit” Nitrate-Nitrogen in ppm. Remove tube.

Color

Q

18

*Reagent is a potential health hazard. Read MSDS at www.lamotte.com.

Page 19

Color

Q

User Tips

Testing Tips

• Read all instructions before testing.

• If not testing all tests in the sequence, follow

blanking procedure and then press button

until desired test factor is shown. Follow test

procedure.

• In one complete inversion, the tube will be

turned cap down and then right side up. The air

bubble will move slowly to the bottom of the

tube and back again to the cap end.

• If small bubbles form after adding reagents,

tap bottom of tube sharply once or twice to

dislodge bubbles. Bubbles will interfere with

the test results.

• Be sure the outside of the tubes are dry before

putting them into the ColorQ. This is best

accomplished by dispensing the water sample

from the sample bottle.

Low pH Low pH levels can signifi cantly

lower the hardness results.

Error Messages

Er 3 = Insuffi cient light is reaching the detector.

Sample may be too dark, or tube may be in

sideways. Turn off meter and retest.

Er 7 = The blank was not properly set. Turn

off meter and retest blank making sure the black

arrow on the tube is facing forward, toward the

user (not left or right).

SUN = Extremely bright sunlight is penetrating

the chamber. Turn your back to the sun to shade

the meter from bright sunlight.

Lo = Result is below the effective measuring

range for the system (e.g. < 4.0 pH for Code

7059 reagent.)

Hi = Result is above the effective measuring

range for the system (e.g. >9.0 pH for Code 7059

reagent.)

bAt = Battery is low.

Maintenance

• Clean ColorQ optics with a damp cotton swab.

Avoid abrasive cleaners that can damage

plastic.

• Replace stained or scratched tubes (0201).

Battery Replacement

Use a small Phillips head screwdriver to remove

all 5 screws in the base. Gently pull the battery

holder from the inside and replace TWO AA

style batteries. Replace screws securely but do

not over-tighten screws which can tear the rubber

base.

8/11 62059-01

19

Page 20

TDS • CODE 5-0080 • Dual Range TDS Pocketester

BEFORE FIRST USE: Soak electrodes for a few minutes in alcohol to remove oils. Rinse well with distilled

water and shake dry.

CALIBRATION

(To Be Done Once a Month)

Use a calibration standard between 900 ppm and 5,000 ppm for low range testing. LaMotte conductivity standard #6354 (989 ppm TDS) is most commonly used.

Pour ½” to 1”

1. 2. 3.

of a Calibration

Standard into 2

containers, and

tap or deionized

water into a

third container.

4. 5. 6.

Rinse electrode

in water. Then

rinse in fi rst container

of standard, then dip

into the second.

Open battery compartment lid

(end with lanyard loop). The

two white buttons are Increment

(INC) and Decrement (DEC)

calibration keys.

Turn the meter on, and wait

several minutes

to allow the

display to stabilize.

DEC Key

INC Key

Press in INC or DEC keys to

adjust reading to match the

calibration standard value.

After 3 seconds without a key

positive

+

negative

batteries

Figure #1

plastic

ribbon

press, the display fl ashes 3 times,

then shows “ENT”. The tester

accepts calibration value; returns

to measurements mode.

7.

Replace battery cap.

Rinse the electrode in

the water and proceed

with test procedure.

20

Page 21

PROCEDURE

1. 2. 3.

Remove the cap.

Press ON/OFF

button to turn on.

Dip the electrode end

into the test solution.

Make sure the sensor

is fully covered. Stir

once. Let the reading

stabilize.

4. 5. 6.

7.

Allow time for

the Automatic

T emperature

Compensation to

correct the

readings for

solution

temperature

changes.

Replace the cap.

You can replace the electrode module at the

fraction of the cost of a new Testr. When the

Testr fails to calibrate or gives fl uctuating readings in calibration standards,

you need to change the electrode.

1. With dry hands, grip the ribbed Testr collar with electrode facing you.

Twist the collar counter clockwise. Save the ribbed T estr collar and

O-ring for later use.

2. Pull the old electrode module away from the Testr.

3. Align the four tabs on the new module so they match the four slots

on the Testr.

4. Gently push the module onto the slots to seat in position. Push the

smaller O-ring fully onto the new electrode module. Push the collar

over the module and thread it onto place by fi rmly twisting it clockwise.

Note the reading

once the display

stabilizes. If the

solution is above the

range of the

TDST estr, the

display will show:

Press the ON/OFF

button to turn off Testr.

Note: Testr will

automatically shut

off after 8.5

minutes of

nonuse.

HOLD FUNCTION: Press HOLD key to freeze display. Press HOLD again to release.

MAINTENANCE: To improve performance, clean the stainless steel electrodes by periodically rinsing them

in alcohol for 10-15 minutes. Replace all 4 batteries if the display becomes faint or disappears, or if the readings

are unstable or constant. If drift is detected while electrodes are continuously exposed to solution for longer than

one hour, allow electrode to fully dry off periodically.

CHANGING BATTERIES: Open the battery compartment lid. Remove old batteries and replace with fresh

ones noting polarity as shown in the battery compartment. Recalibrate Testr after battery change.

21

Page 22

Replacement Parts

CODE DESCRIPTION CODE DESCRIPTION

1002 Model “S” softener (AT-38Q) 0688 Sample bottle, 60 mL with fl ip top

1022 DuoSoft softener (AT-40Q) S-0080 Dual Range TDS PockeTester

2050-DW6 ColorQ DW photometer S-0084 Replacement electrode for Dual

Range TDS PockeTester

0452 Flask, 250 mL, “HARD” with cap 6354-J Optional Calibration standard 989

ppm; 100 mL

0453 Flask, 250 mL, “SOFT” with cap 7059-E WR pH ColorQ reagent

0672 Stopper for 250 mL fl ask *7045-G * Hardness 1 Buffer

*4767-H *Soap reagent #4 60 mL *7046-G * Hardness 2 Indicator

*4767-L *Soap reagent #4 500 mL 0354 Pipet, 1 mL plastic

0392 Pipet, plain plastic with cap 3725 A-H * Iron tablet box of 50

0297 Test tube, “HARD” with cap *3725 A-J *Iron tablet box of 100

0298 Test tube, “SOFT” with cap *6903 A-H *DPD #1, instrument grade box of 50

0651 Stopper for test tubes above *6903 A-J *DPD#1, instrument grade box of 100

0879 Precipitation rack, acrylic *6197 A-H *DPD #3, instrument grade box of 50

*4542WT-H *Precipitation reagent A, 60 mL *6197 A-J *DPD #3, instrument grade box of 100

*4542-L *Precipitation reagent A, 500 mL *V-4458 LWT-G *Sulfi de Reagent A, 60 mL

*4543WT-H *Precipitation reagent B, 60 mL *V-4459-E *Sulfi de Reagent B, 15 mL

*4543-L *Precipitation reagent B, 500 mL 4460 LWT-G4 Sulfi de Reagent C, 60 mL

0392 Pipet, plain plastic with cap * 3384A-H *Nitrate ColorQ TesTab, box of 50

0201 ColorQ test tube with cap 0175 Tablet crusher

4-3051CS Case & foam insert

22

WARNING: Reagents marked with an * are considered to be potential

health hazards. To view or print a Material Safety Data Sheet (MSDS)

for these reagents go to www.lamotte.com. To obtain a printed copy,

contact LaMotte by e-mail, phone or fax.

Page 23

AT-38 & AT-40 Diagram Layout

SOFT

SOAP

4767-H

Iron

3725A-H

0201

-NC

0201

-NC

DPD #3

6197A-H

0201

-NC

WT-G

4460L

Sulfide C

6903A-H

0201

-NC

Sulfide B

V-4459-E

DPD #1

3884A-H

0201

-NC

WT-G

Sufide A

V-4458L

Nitrate

0201

-NC

CH2

7046-G

0809-C c addy

& 0354 pipette (1mL)

CH 1

WR pH

7059-E

Single Softener 1002

0688

0879

0298

0297

4543WT-H

7045-G

26905

0688

0453

0452

4542WT-H

HARD

PRECIPITATION

23

Page 24

PO Box 329 • Chestertown • MD • 21620

800-344-3100 • 410-778-3100 • f 410-778-6394

www.lamotte.com

64-3051-WT-01 8.11

Loading...

Loading...