Page 1

STORMWATCH

DRAIN MONITORING KIT

Code 7446-01

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

OVERVIEW

According the U.S. Census Bureau, the world’s population went from 2.5 billion in

1950 to 6 billion in 2000 and is on pace to exceed 9 billion by 2050. We will soon

have 3 times the global population we had only in 1950, and with this growth

comes enormous impacts on the surface of our globe. As buildings and pavement

expand so do our obligations to control stormwater euents. Urban development

creates new pollution, which can either be washed or directly dumped into storm

sewer systems, and ultimately into our waterways and coastal areas. Storm runo

leaving developed urban areas is signicantly greater in inorganic content than

runo from the same area prior to development.

Stormwater is typically dened as water that is created as a result of a

precipitation event. This water may ow through any path (gully, stream,

conduit, channel, etc.) or adjacent area that is subject to overow or ood water

generated from that event. This water passes through a wide variety of natural

or articial environments, often sweeping organic and inorganic constituents

into the watercourse through

municipal storm drain systems.

These environments can include

pipeline projects, construction

sites, landscaped areas,

agricultural runo, irrigation

ditches, industrial sites, and a

variety of other sources. In most

cases this material is eventually

fed into a stream, river, or other

waterway, contributing to the

overall pollutant load in that body

of water.

While onsite sampling and osite

testing can be completed over the

course of a number of days, the source of this outfall continues to contaminate

the watercourse with both inorganic and organic constituents during subsequent

precipitation events. A means is required by which to screen the outfall to

potentially determine its source, the contribution it is making to the pollutant load,

and the proper course of action to take.

Instrumentation and reagent systems are currently available to make

measurements necessary to provide a preliminary screening of the outow, and

determine whether it is contributing to the overall pollutant load as it relates to

inorganic constituents. In many cases these measurements can be made near the

source, using handheld instrumentation and test kits, which may provide some

indication as to the source and content of the outow, or provide some indication

of what additional testing is required.

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

EXAMPLES OF OUTFLOWS

Outows attributable to a rainwater event can occur across a number of dierent

environments.

These include:

• Agricultural runoff

• Industrial sites

• Construction sites

• Irrigation runoff

• Parking lots and pavement

• Other

While illicit discharges of various chemical constituents into stormwater drains

represent a portion of the overall problem, these are not normally dened as

stormwater events. These outows can contain a wide variety of both inorganic

and organic contaminants, and must be considered when characterizing the

source of outow. Inorganic constituents can often provide an indicator of such

outows when used in a manner that takes all indicators into account.

Where there are questions and concerns, either generated through the use

of inorganic indicators, or when there are suspicions regarding organic

contaminants, samples should be sent for further analysis.

While individual test measurements can be eectively used for screening outows,

long term trends are important after establishing baseline values for inorganic

indicators (and organic indicators as needed).

MAKING MEASUREMENTS

Colorimetric

Colorimetric methods are based on the intensity of color produced by a chemical

reaction. The color of the reaction is matched to a precision matched color bar

using an Octa-Slide 2 Comparator.

Turbidimetric

The turbidity concentration is determined by the degree to which black lines on

the tube are obscured when compared to calibrated targets.

Detergent

Anionic surfactants are extracted with toluene and break up an ion pair, releasing

bromphenol blue into a water layer.

Electrometric pH

When the TRACER is immersed in the sample, the meter measures the dierence

in electrical potential between the electrode and the reference electrode. The

electronic measurement is converted from millivolts to pH units, and the result

appears on the display.

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

INDICATORS

Chlorine

Chlorine is used throughout the country to disinfect tap water, except where

private wells provide the water supply. Unfortunately, chlorine is extremely volatile,

and even moderate levels of organic materials can cause chlorine levels to drop

below detection levels. Because chlorine is unstable, it is not a reliable indicator,

although if very high chlorine levels are measured, it is a strong indication of a

water line break, swimming pool discharge, or industrial discharge from a chlorine

bleaching process.

Copper

Copper can arise from the corrosive actions of water leaching copper from copper

pipes in building condensate systems and heat exchangers. High concentrations

of copper can come from a variety of other sources including vehicle brake pads,

pesticides and soil erosion, plating operations, vehicle uid leaks and dumping.

Phenols

Phenols are used in heavy or industrial cleaning solutions, plating operations, coal

coking and renery operations. They are also a product of plating operations and

are used as an anticaking ingredient in road salts.

Turbidity

Turbidity in water is caused by suspended particles or colloidal matter that

obstructs light transmission through the water. It may be caused by inorganic or

organic matter or a combination of the two. Microorganisms (bacteria, viruses and

protozoa) are typically attached to particulates. Turbidity in some groundwater

sources is a consequence of inert clay or chalk particles or the precipitation of

nonsoluble reduced iron and other oxides . Turbidity in surface waters may be the

result of particulate matter of many types and is more likely to include attached

microorganisms that are a threat to health.

Detergents

In many countries, persistent types of anionic detergent have been replaced by

others that are more easily biodegraded, and hence the levels found in water

sources have decreased substantially. The concentration of detergents should

not be allowed to reach levels giving rise to either foaming or taste problems.

The presence of any detergent may indicate contamination of source water with

sewage or ingress of detergent solution into the distribution system, as a result of

back-ow, for example.

pH

Most discharge ow types are neutral, having a pH value around 7, although

groundwater concentrations can be somewhat variable. pH is a reasonably good

indicator for liquid wastes from industries, which can have very high or low pH

(ranging from 3 to 12). The pH of residential wash water tends to be rather basic

(pH of 8 or 9). Although pH data is often not conclusive by itself, it can identify

problem outfalls that merit follow-up investigations. Normal rainwater has a pH of

approximately 5.6

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Test Factor Methodology Action Level

Total Residual

Chlorine

Total Copper Copper ions form a yellow colored chelate with

Total Phenol 4-Aminoantipyrine is oxidized in the presence of

Turbidity The turbidity is determined by comparing the degree

Detergents

(Surfactants)

pH An ion specic electrode is used to measure

Combined forms of chlorine react with DPD in the

presence of potassium iodide to produce a red color.

Color is compared to a known standard using a

comparator.

diethyldithiocarbamate around pH 9-10 in

proportion to the concentration of copper in the

sample. Color is compared to a known standard

using a comparator.

all ortho- and meta-substituted phenols to form

a colored complex in proportion to the amount

of phenol present. Color is compared to a known

standard using a comparator.

to which black lines on a tube are obscured by the

sample when compared to targets ina comparator.

The presence of LAS (Linear Alkylbenzene Sulfonate)

in the water sample causes the transfer of

bromphenol blue dye from the organic reagent layer

to the aqueous layer. The amount of color in the

aqueous layer is proportional to the concentration

of the LAS in the sample.

potential across the salt bridge created by an

electronic meter with a probe.

≥0.30 ppm

≥0.50 ppm

≥1.00 ppm

Non specied

≥0.40 ppm

<6 or >9

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

USE OF THE OCTA-SLIDE 2 VIEWER

The Octa-Slide 2 Viewer should be held so nondirect light enters through the back of the Viewer.

Insert the reacted sample into the top of the

Viewer. Slide the Octa-Slide 2 Bar into the Viewer

and match the color of the reaction to the color

standards.

GLASSWARE CLEANING PROCEDURE

It is important to rinse test tubes with Deionized Water, three times in succession,

after each test procedure is completed. At the end of each day, all sampling

and test glassware should be brushed with a test tube brush (0514) and dilute

dishwashing detergent and rinsed three times with Deionized Water.

To avoid possible detergent test interference, do not use detergent to clean

Detergent Bottle (0800), rinse three times with Deionized Water only.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

FIELD TEST PROCEDURES

1

2

3

4

5

6

TOTAL RESIDUAL CHLORINE

QUANTITY CONTENTS CODE

50 Chlorine DPD #4R Tablets 6899A-J

2 Test Tube, 2.5-5-10 mL, plastic, w/caps 0106

1 Chlorine Octa-Slide 2 Bar, 0.2-3.0 ppm 3401-01

*WARNING: Reagents marked with an * are considered to be potential health hazards. To view or

PROCEDURE

Insert Chlorine

Octa-Slide 2

Bar (3401-01)

into the

Octa-Slide 2

Viewer (1101).

Cap and mix

until tablet

disintegrates.

Fill a test tube

(0106) to the 5

mL line with the

water sample.

Insert test

tube into

OctaSlide 2

Viewer.

Add one

Chlorine DPD

#4R Tablet

(6899A).

Match

sample color

to a color

standard.

Record as

ppm Total

Residual

Chlorine.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

COPPER

QUANTITY CONTENTS CODE

30 mL *Copper 1 *6446-G

2 Test Tube, 2.5-5-10 mL, plastic, w/caps 0106

1 Copper Octa-Slide 2 bar, 0-4.0 ppm 3435-01

*WARNING: Reagents marked with an * are considered to be potential health hazards. To view or

PROCEDURE

1

Insert the

Copper OctaSlide 2 bar

(3435-01) into

the OctaSlide 2 Viewer

(1101).

4

Cap and mix.

2

5

Fill a test tube

(0106) to the

10 mL line with

sample water.

Insert test

tube into

OctaSlide 2

Viewer.

3

6

Add 5 drops

of *Copper 1

(6446).

Match

sample color

to a color

standard.

Record as

ppm Copper.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

PHENOLS

QUANTITY CONTENTS CODE

10 g Aminoantipyrine Reagent 7825-D

60 mL *Ammonia Hydroxide Solution *7826-H

2 x 100 mL Potassium Ferricyanide Solution 7827-J

1 Spoon, 0.1 g 0699

1 Pipet, plain, glass, w/cap 0344

1 Pipet Assembly, 1.0 mL, plastic, w/cap 0330

2 Test Tube, plastic, w/caps 0106

1 Phenols Octa-Slide 2 bar, 0-5 ppm 3434-01

1 Sample Reaction Tube 0837

*WARNING: Reagents marked with an * are considered to be potential health hazards. To view or

PROCEDURE

1

Insert the

Phenols

Octa-Slide 2

bar (3434-01)

into the OctaSlide 2 Viewer

(1101).

4

Use the

unmarked

pipet (0344) to

add 4 drops of

*Ammonium

Hydroxide

Solution (7826).

Cap and mix.

2

Fill Sample

Reaction Tube

(0837) to

the line with

sample water.

5

Use the 1.0 mL

pipet (0330) to add

2 mL (2 measures)

of Potassium

Ferricyanide

Solution (7827).

Cap and mix.

Solution will turn

orange/pink

if phenols are

present.

9

3

Use 0.1 g spoon

(0699) to add

1 measure of

Aminoantipyrine

Reagent (7825).

Cap and mix.

6

Fill test tube

(0106) to 10

mlL line with

solution. Cap.

Insert tube

into OctaSlide Viewer

(1101). Match

sample color

to a color

standard.

Record as

ppm Phenols.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

TURBIDITY

1

2

3

4

5

QUANTITY CONTENTS CODE

2 Test Tube, 2.5-5-10 mL, plastic, w/caps, with line 0106-WL

1 Turbidity Octa-Slide 2 bar, Low-Med-High 3436-01

PROCEDURE

Insert Turbidity

Octa-Slide 2

Bar (3436-01)

into the OctaSlide 2 Viewer

(1101).

Match sample

with the

standards by

comparing

the degree

to which the

black lines are

obscured by

the turbidity

(cloudiness)

of the sample.

Low 0-50 FTUs

Medium 75-150 FTUs

High 200-500 FTUs

Fill a test tube

(0106-WL) to

the 10 mL line

with sample

water.

Disregard any

differences in

color between

the sample

and the

standards.

The test is

based on the

degree of

turnidity, not

color. Record

as Low,

Medium or

High.

Insert test

tube into the

Octa-Slide 2

Viewer with

the printing

on the tube

facing away

from the

operator.

NOTE:

Throughly

clean tubes

after each use.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

10

Page 11

DETERGENT

QUANTITY CONTENTS CODE

60 g Detergent Reagent #1 7444-H

3 x 100 mL *Detergent Reagent #2 *6037-J

100 mL *Detergent Reagent #3 *7445-J

1 Pipet, 0.5 mL, glass, w/cap 0335

1 Spoon, 1.0 g 0697

1 French Bottle, Calibrated to 65 & 75 mL 0800

*WARNING: Reagents marked with an * are considered to be potential health hazards. To view or

PROCEDURE

1

4

Fill bottle

(0800) to 65

mL line with

sample water.

Fill to 75

mL line with

Detergent

Reagent #2.

2

5

Use the 1.0 g

spoon (0697)

to add 2

measures

of Detergent

Reagent #1

(7444).

Use pipet (0335) to add 0.5 mL *Detergent

#3 (7445). Shake vigorously for 15 seconds.

Wait until layers separate (20-30 seconds).

If the top layer is light blue, less that 0.1 mL

detergent is present and no further testing is

necessary. If top layer is colorless, continue

adding *Detergent Reagent #3 , 0.5 mL at a

time, shaking vigorously for 15 seconds after

each addition, allowing the layers to separate

until the top layer is light blue. Count the

number of additions of 0.5 mL of *Detergent

Reagent #3 required to change the top layer

from colorless to light blue.

3

Shake until

dissolved.

6

Detergent concentrations in ppm = (Number of pipets Detergent # 3 -1) x 0.1

Example: It takes 9 pipets to turn the top layer blue. (9-1) x 0.1 = 0.8. The amount

of detergent is greater than 0.7 ppm but less than 0.9 ppm detergent.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

pH • TRACER

1

2

3

For complete instructions, see the TRACER manual.

Before rst use, hold the meter by the top battery compartment and swiftly tap

the back of the meter downward into your palm (not a hard surface). This assures

that the internal electrolyte moves to the very tip of the electrode. The electrolyte

should ll the circular junction window at the tip of the electrode.

Before rst use or after storage, soak the electrode in tap water or pH buer

solution for about 10 minutes.

For the most accurate results, allow sucient time for the temperature of the

probe to reach the temperature of the sample before calibrating. This will be

indicated by a stable temperature reading on the display.

CALIBRATION

The TRACER can be calibrated at 1, 2 or 3 points. For the most accurate results

with a two point calibration, calibrate the TRACER with a pH 7 buer rst, then

calibrate with either a pH 4 or pH 10 buer whichever is closest to the pH value of

the sample to be tested. When performing a three point calibration, calibrate with

the pH 7 buer rst, followed with the pH 4 buer and then the pH 10 buer.

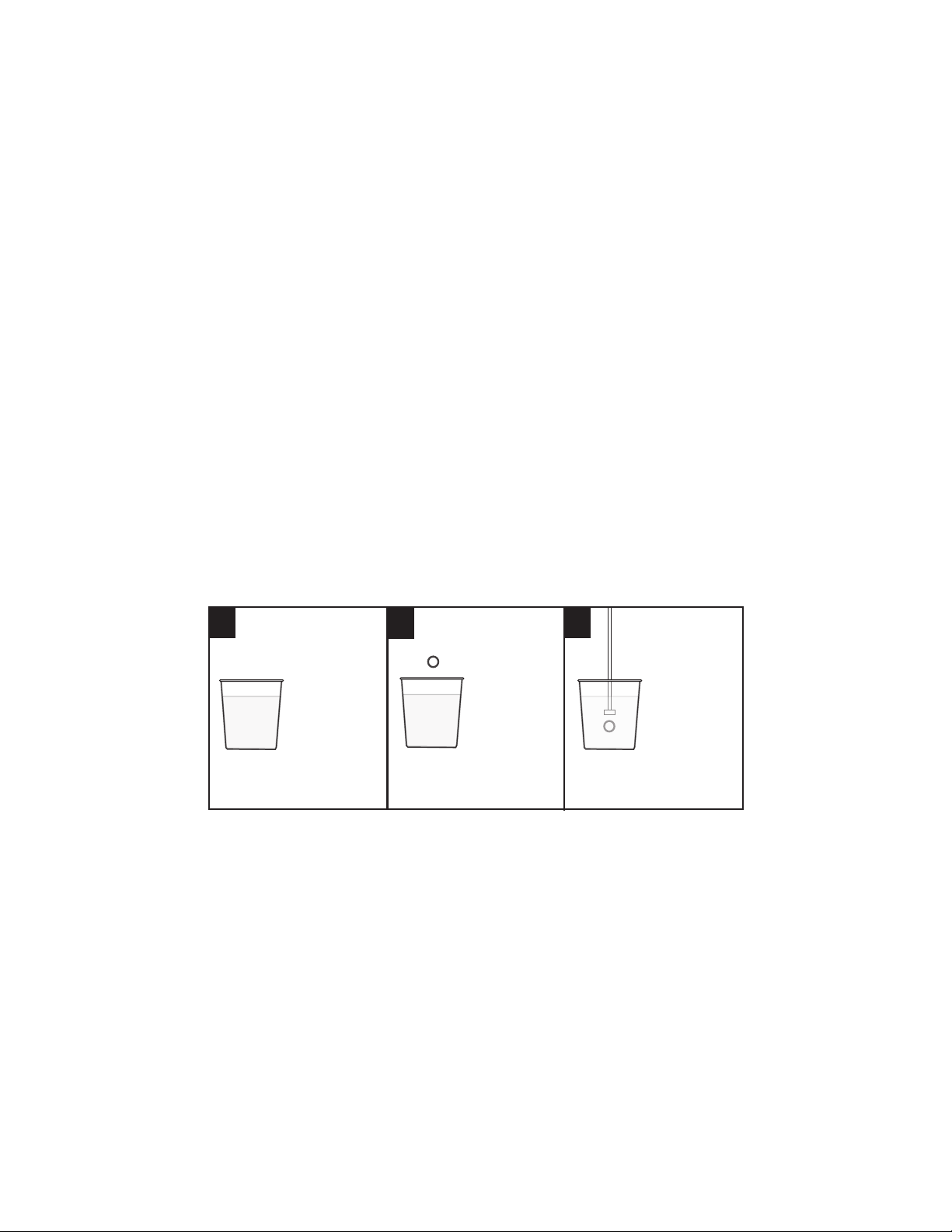

Preparation of Buers

Fill a sample

cup with 20

mL of distilled

or deionized

water.

Add one buffer

tablet:

pH 4.0

Code 3983A

OR

pH 7.0

Code 3984A

OR

pH 10.0

Code 3985A.

Use the tablet

crusher (0175)

to crush the

tablet. Stir until

the tablet has

disintegrated.

NOTE: Buers should be prepared fresh daily.

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Calibration

1

Fill a

sample

cup to

the 20 mL

line with

a buffer

2

Press the

ON/OFF

button to

turn the

MODE

CAL

TRACER

ON

OFF

ON.

solution.

3

Place the electrode in the

buffer solution. Press and

hold the CAL/RECALL button

CAL

until “CAL” appears in the

MODE

CAL

lower display. The meter will

ON

OFF

automatically recognize the

buffer and calibrate itself

to that value. The circled

number on the display will

match the value of the buffer.

During the

4

calibration the pH

value on the display

will ash. When

the calibration

is complete, the

TRACER will display

“SA” and “End” and

return to normal

operation.

The appropriately

5

circled indicator (L, M

or H) will appear on

the display when a

calibration has been

completed within one

power on cycle.

For a two or three

6

point calibration,

repeat steps 1-5 with

the remaining buffers.

When the TRACER

is turned off, the

circled indicator

conguration and the

calibration data will be

memorized.

NOTE: If the buffer solution is more than 1 pH unit off from 4, 7, or 10, or the electrode

slope is low, the meter will assume that there is an error and the calibration will be

terminated. END will be displayed.

MEASUREMENT

For small samples ll

1

a sample cup to the

20 mL line with the

test sample.

Sample depth

must be

greater than

or equal to 1.5

inches.

4

Slowly stir the

sample with

the TRACER

MODE

CAL

to remove air

ON

OFF

bubbles.

2

MODE

CAL

ON

OFF

5

The reading will

ash until it has

stabilized. This may

take

several seconds

depending on the

buffer capacity

sample.

13

Press the

ON/OFF

button.

of the

3

CAL

MODE

CAL

ON

OFF

6

Rinse the electrode

in distilled water.

Replace the cap.

Immerse the

TRACER in

the sample.

Make sure

the electrode

is completely

submersed.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

KIT CONTENTS

Quantity Contents Code

50

30 mL

10 g

60 mL

2 x 100 mL

60 g

3 x 100 mL

100 mL

20

20

20

1

1

1

1

1

2

6

1

1

1

1

1

1

1

1

1

1

1

*WARNING: Reagents marked with an * are considered to be potential health hazards. To view or

Chlorine DPD #4R Tablets 6899A-H

*Copper 1 *6446-G

Aminoantipyrine Reagent 7825-D

*Ammonium Hydroxide Solution *7826-H

Potassium Ferricyanide Solution 7827-J

*Detergent Reagent #1 *7444-H

*Detergent Reagent #2 *6037-J

*Detergent Reagent #3 *7445-J

pH 4.0 MiniBuer Tablets

pH 7.0 MiniBuer Tablets

pH 10.0 MiniBuer Tablets

----

----

----

Spoon, 0.1 g 0699

Spoon, 1.0 g 0697

Pipet, plain, glass, w/cap 0344

Pipet Assembly, 1.0 mL, plastic, w/cap 0330

Pipet Assembly, 0.5 mL, glass, w/cap 0335

Test Tubes, 2.5–10 mL, plastic, w/caps, with line 0106-WL

Test Tubes, 2.5–5–10 mL, plastic, w/caps 0106

Sample Reaction Tube, glass 0837

Bottle, French, calibrated to 65 & 75 mL 0800

Sample Cup, 20 mL, plastic

----

Tablet Crusher 0175

Test Tube Brush 0514

Chlorine Octa-Slide 2 Bar, 0.2–3.0 ppm 3401-01

Copper Octa-Slide 2 Bar, 0–4.0 ppm 3435-01

Phenols Octa-Slide 2 Bar, 0–5 ppm 3434-01

Turbidity Octa-Slide 2 Bar, Low-Med-High 3436-01

Octa-Slide Viewer 1101

TRACER, pH ----

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...