Page 1

1

2020t/i

Turbidity Meter

Medidor de turbidez

Turbidimètre

Code/ Código 1974-T/1974-I

1

Page 2

CONTENTS

GENERAL INFORMATION

∆ Packaging and Delivery ......................................................................................... 4

∆ General Precautions ..............................................................................................4

∆ Safety Precautions................................................................................................. 4

∆ Limits of Liability .................................................................................................... 4

∆ Specifi cations ......................................................................................................... 4

∆ Statistical & Technical Defi nitions .................................................................... 6

∆ Contents and Accessories .................................................................................... 7

∆ EPA Compliance ......................................................................................................8

∆ ISO Compliance .......................................................................................................8

∆ CE Compliance ........................................................................................................ 8

∆ IP67 Compliance ....................................................................................................8

∆ Warranty ................................................................................................................... 8

∆ Register Your Meter ............................................................................................... 8

COMPUTER CONNECTION

∆ Output ....................................................................................................................... 8

∆ Computer Connection ........................................................................................... 9

BATTERY/AC OPERATION ................................................................................................. 9

TURBIDITY

∆ What is Turbidity? ................................................................................................10

∆ How is Turbidity Measured? ...............................................................................10

∆ Turbidity Units .......................................................................................................11

∆ Taking Turbidity Water Samples .......................................................................12

∆ Sample Dilution Techniques ..............................................................................13

OPTIONS & SETUP

∆ Factory Default Settings.....................................................................................13

∆ Turbidity Options

Selecting a Turbidity Calibration Curve ....................................................... 14

Selecting Turbidity Units................................................................................. 16

∆ Averaging ................................................................................................................18

∆ Setting Clock .........................................................................................................19

∆ Setting Power Save ..............................................................................................21

∆ Setting Backlight Time ........................................................................................22

∆ Selecting Language .............................................................................................24

∆ PC Link ....................................................................................................................25

DATA LOGGING .................................................................................................................25

2

Page 3

CALIBRATION & ANALYSIS

∆ Calibration ..............................................................................................................27

Turbidity Standards ......................................................................................... 27

Tubes ................................................................................................................... 27

Turbidity Calibration Procedure .................................................................... 27

∆ Analysis without Blanking Procedure ..............................................................32

∆ Analysis with Blanking Procedure ...................................................................33

∆ Dilution Procedure ...............................................................................................36

∆ Preparation of Turbidity-Free Water ................................................................36

∆ Testing Tips ............................................................................................................38

TROUBLESHOOTING GUIDE

∆ Troubleshooting ....................................................................................................39

∆ Stray Light ..............................................................................................................39

GENERAL OPERATING INFORMATION

∆ Overview..................................................................................................................40

∆ The Keypad .............................................................................................................40

∆ The Display and Menus .......................................................................................40

∆ Negative Results ...................................................................................................42

∆ Tubes and Chambers ...........................................................................................42

MAINTENANCE

∆ Cleaning ..................................................................................................................43

∆ Repairs ....................................................................................................................43

∆ Meter Disposal ......................................................................................................43

Refer to the Quick Start Guide for simplifi ed Calibration and Analysis procedures.

Refer to the Testing Guide for detailed Calibration and Analysis procedures for improving

the accuracy of low range turbidity measurements.

3

Page 4

Refer to the Quick Start Guide for simplifi ed Calibration and Analysis procedures.

Refer to the

Testing Guide for detailed Calibration and Analysis procedures for improving

the accuracy of low range turbidity measurements.

GENERAL INFORMATION

PACKAGING AND DELIVERY

Experienced packaging personnel at LaMotte Company assure adequate protection

against normal hazards encountered in transportation of shipments.

After the product leaves LaMotte Company, all responsibility for safe delivery is assured

by the transportation company. Damage claims must be fi led immediately with the

transportation company to receive compensation for damaged goods.

GENERAL PRECAUTIONS

READ THE INSTRUCTION MANUAL BEFORE ATTEMPTING TO SET UP OR OPERATE THE METER.

Failure to do so could result in personal injury or damage to the meter. The meter should

not be used or stored in a wet or corrosive environment. Care should be taken to prevent

water from wet tubes from entering the meter chamber.

NEVER PUT WET TUBES IN THE METER.

SAFETY PRECAUTIONS

*WARNING: Reagents marked with an * are considered to be potential health hazards. To

view or print a Safety Data Sheet (SDS) for these reagents go to www.lamotte.com.

Search for the four digit reagent code number listed on the reagent label, in the contents

list or in the test procedures. Omit any letter that follows or precedes the four digit code

number.

For example, if the code is 4450WT-H, search 4450. To obtain a printed copy, contact

LaMotte by email, phone or fax.

Emergency information for all LaMotte reagents is available from Chem-Tel: (US, 1-800255-3924) (International, call collect, 813-248-0585).

Ensure that the protection provided by this equipment is not impaired. Do not install or use

this equipment in a manner that is not indicated in this manual.

LIMITS OF LIABILITY

Under no circumstances shall LaMotte Company be liable for loss of life, property, profi ts,

or other damages incurred through the use or misuse of their products.

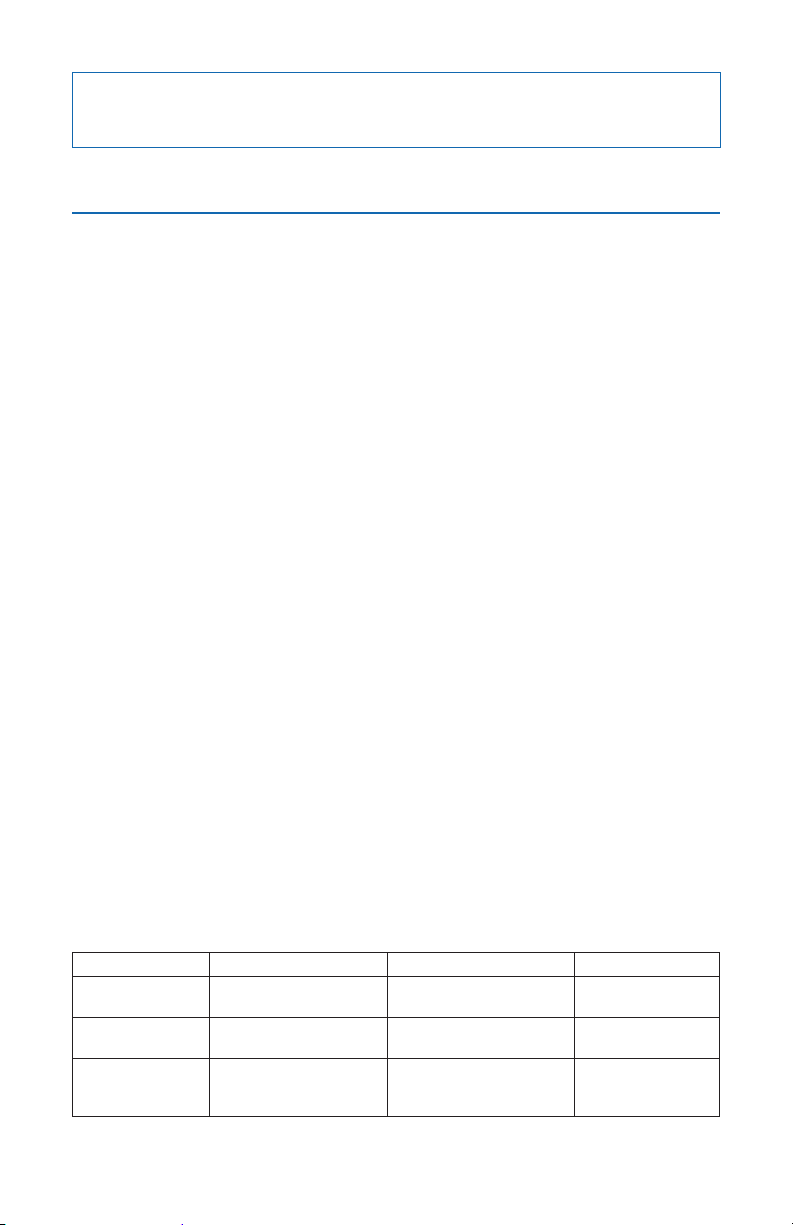

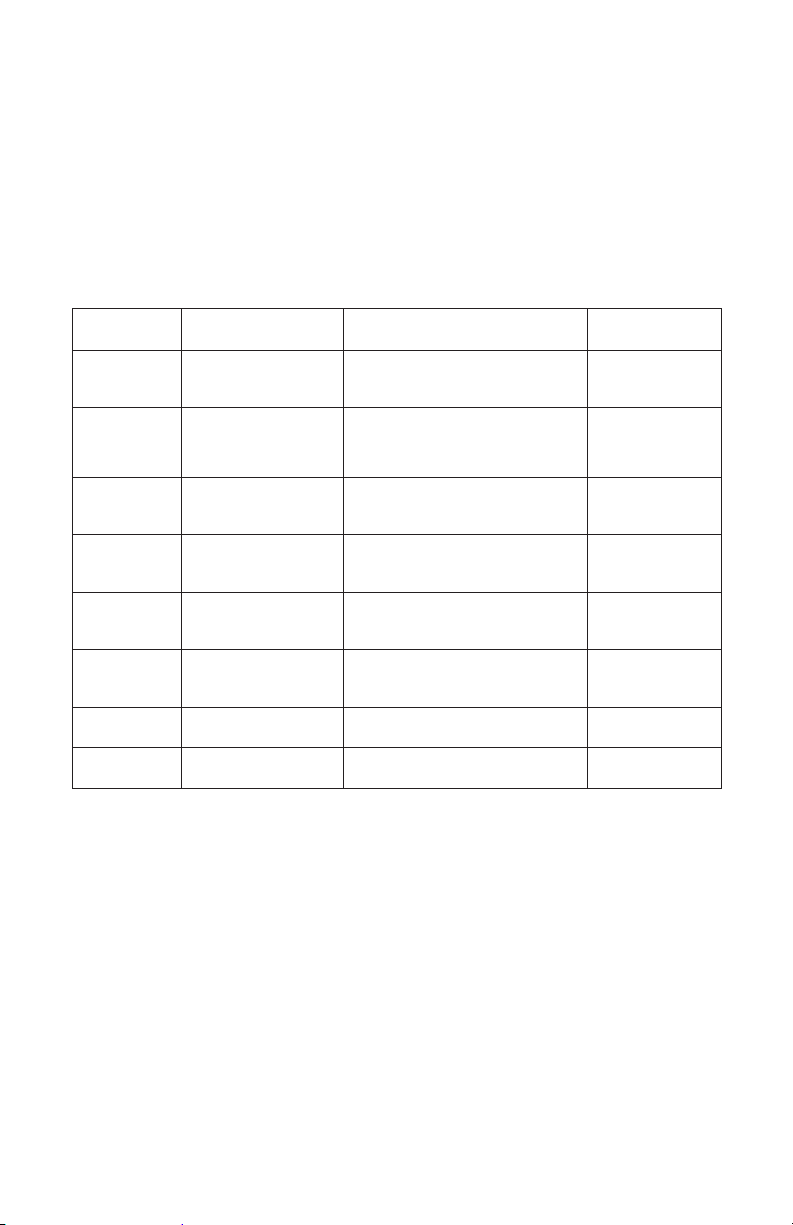

SPECIFICATIONS - 2020t/i

Mode Nephelometric Ratiometric Attenuation

Unit of Measure

2020t

Unit of Measure

2020i

Range 0-100 NTU/FNU

NTU, ASBC, EBC NTU, NTRU, ASBC, EBC NTU, AU, ASBC, EBC

NTU, FNU, ASBC, EBC NTU, FNRU, ASBC, EBC NTU, FAU, ASBC,

0-1,750 ASBC

0-25 EBC

0-1,000 NTRU/FNRU

0-17,500 ASBC

0-250 EBC

EBC

0-2,000 AU/FAU

0-70,000 ASBC

0-1,000 EBC

4

Page 5

Resolution 0–10.99 NTU/FNU: 0.01

NTU/FNU,

11.0–100.0 NTU/FNU: 0.1

NTU/FNU

Accuracy 0-2.5 NTU/FNU:

±0.05 NTU/FNU,

2.5-100 NTU/FNU: ±2%

Detection Limit 0.05 NTU/FNU 0.05 NTRU/FNRU 10 AU/FAU

Reproducibility 0.02 NTU/FNU or 1% 0.02 NTRU/FNRU or 1% 1%

Range Selection Automatic

Light Source 2020t: Tungsten lamp 2300 °K ±50 °K, 2020i: IR LED 860 nm ±10 nm,

spectral bandwidth 50 nm

Detector 2020t: Photodiode, centered at 90° and 180°, maximum peak 400-600 nm

2020i: Photodiode, centered at 90° and 180°

Response Time: <2 seconds

Signal Averaging: Yes

Sample Chamber: Accepts 25 mm fl at-bottomed test tubes

Sample: 10 mL in capped tube

Display: Graphic Liquid Crystal Display with Backlight

Software: Auto Shut-off : 5, 10, 30 min, disabled

Calibration: Field adjustable, blank and 1 point

Data Logging: 500 points

Languages: English, Spanish, French, Portuguese, Italian, Chinese, Japanese (Kana)

0–10.99 NTRU/FNRU: 0.01

NTRU/FNRU, 11.0–109.9

NTRU/FNRU: 0.1 NTRU/

FNRU,

110–1000 NTRU/FNRU: 1

NTRU/FNRU

0-2.5 NTRU/FNRU:

±0.05 NTRU/FNRU,

2.5-100 NTRU/FNRU: ±2%,

100-1000 NTRU/FNRU:

±3%.

0–2000 AU/FAU:

1 AU/FAU

0-2000 AU/FAU:

±10 AU/FAU or 6%

whichever is greater

Temperature: Operation: 0–50 °C; Storage: -40–60 °C

Operation

Humidity Range:

Auto Shut-off : 5, 10, 30 min, disabled

Power Source: USB wall adapter, USB computer connection or Lithium ion rechargeable

Battery: Charge Life: Approximately 380 tests with backlight on to 1000 tests with

Electrical Ratings: Rated voltage (5V), Rated power of input current (1.0A) at mini-USB input

Data Logger: 500 test results stored

Waterproof: IP67 with USB port plug in place.

Dimensions: (W x L x H) 8.84 x 19.05 x 6.35 cm; 3.5 x 7.5 x 2.2 inches

0–90 % RH, non-condensing

battery

backlight off . (Signal averaging disabled).

Battery Life: Approximately 500 charges.

port

5

Page 6

Certifi cations:

Weight: 362 g, 13 oz (meter only)

USB Interface: mini B

CE Mark Safety: Low Voltage Directive (2006/95/EC)

IEC 61010-1:2001, EN 601010-1:2001,

2nd edition

EU EMC: EMC Directive (2004/108/EC)

EN 61326-1:2006, EN 61000-4-2:1995

including A1:1998 and A2:2001, EN

61000-4-3:2002, EN 61000-4-4:2004,

EN 61000-4-5:1995 including A1:2001,

EN 61000-4-6:1996 and A1:2001, EN

61000-4-11:2004, EN 55011:2007, IEC

61000-3-2:2005, EN 61000-3-2:2006,

IEC 61000-3-3:1994, EN 61000-3-3:1995

including A1:2001 and A2:2005

US EMC CFR 47, Part 15 Subpart B:2007

CAN EMC ICES-003, Issue 4, February 2004

AU/NZ EMC AU/NZ: CISPR 11:2004

STATISTICAL & TECHNICAL DEFINITIONS RELATED TO PRODUCT

SPECIFICATIONS

Method Detection Limit (MDL): “The method detection limit (MDL) is defi ned as the

minimum concentration of a substance that can be measured and reported with 99%

confi dence that the analyte concentration is greater than zero and is determined from

analysis of a sample in a given matrix containing the analyte.”

Horwitz once stated, ‘In almost all cases when dealing with a limit of detection or limit of

determination, the primary purpose of determining that limit is to stay away from it.’”

Accuracy: Accuracy is the nearness of a measurement to the accepted or true value.3

The accuracy can be expressed as a range, about the true value, in which a measurement

occurs (i.e. ±0.5 ppm). It can also be expressed as the % recovery of a known amount of

analyte in a determination of the analyte (i.e. 103.5 %).

Resolution: Resolution is the smallest discernible diff erence between any two

measurements that can be made.

4

For meters this is usually how many decimal places are

displayed. (i.e. 0.01). Note that the resolution many change with concentration or range. In

some cases the resolution may be less than the smallest interval, if it is possible to make a

reading that falls between calibration marks. A word of caution, that resolution has very little

relationship to accuracy or precision. The resolution will always be less than the accuracy

or precision but it is not a statistical measure of how well a method of analysis works. The

resolution can be very, very good and the accuracy and precision can be very bad! This is not

a useful measure of the performance of a test method.

Repeatability: Repeatability is the within-run precision.

set up to clean up. Generally, one run occurs on one day. However, for meter calibrations, a

single calibration is considered a single run or data set, even though it may take 2 or 3 days.

Reproducibility: Reproducibility is the between-run precision.

Detection Limit (DL): The detection limit (DL) for the 2020t/i is defi ned as the minimum

value or concentration that can be determined by the meter, which is greater than zero,

independent of matrix, glassware, and other sample handling sources of error. It is the

detection limit for the optical system of the meter.

1

Note that, “As Dr. William

5

A run is a single data set, from

6

2

6

Page 7

1

CFR 40, part 136, appendix B

2

Statistics in Analytical Chemistry: Part 7 – A Review, D. Coleman and L Vanatta, American Laboratory, Sept 2003, P.

31.

3

Skoog, D.A., West, D. M., Fundamental of Analytical Chemistry, 2nd ed., Holt Rinehart and Winston, Inc, 1969, p. 26.

4

Statistics in Analytical Chemistry: Part 7 – A Review, D. Coleman and L Vanatta, American Laboratory, Sept 2003, P.

34.

5

Jeff ery G. H., Basset J., Mendham J., Denney R. C., Vogel’s Textbook of Quantitative Chemical Analysis, 5th ed.,

Longman Scientifi c & Technical, 1989, p. 130.

6

Jeff ery G. H., Basset J., Mendham J., Denney R. C., Vogel’s Textbook of Quantitative Chemical Analysis, 5th ed.,

Longman Scientifi c & Technical, 1989, p. 130

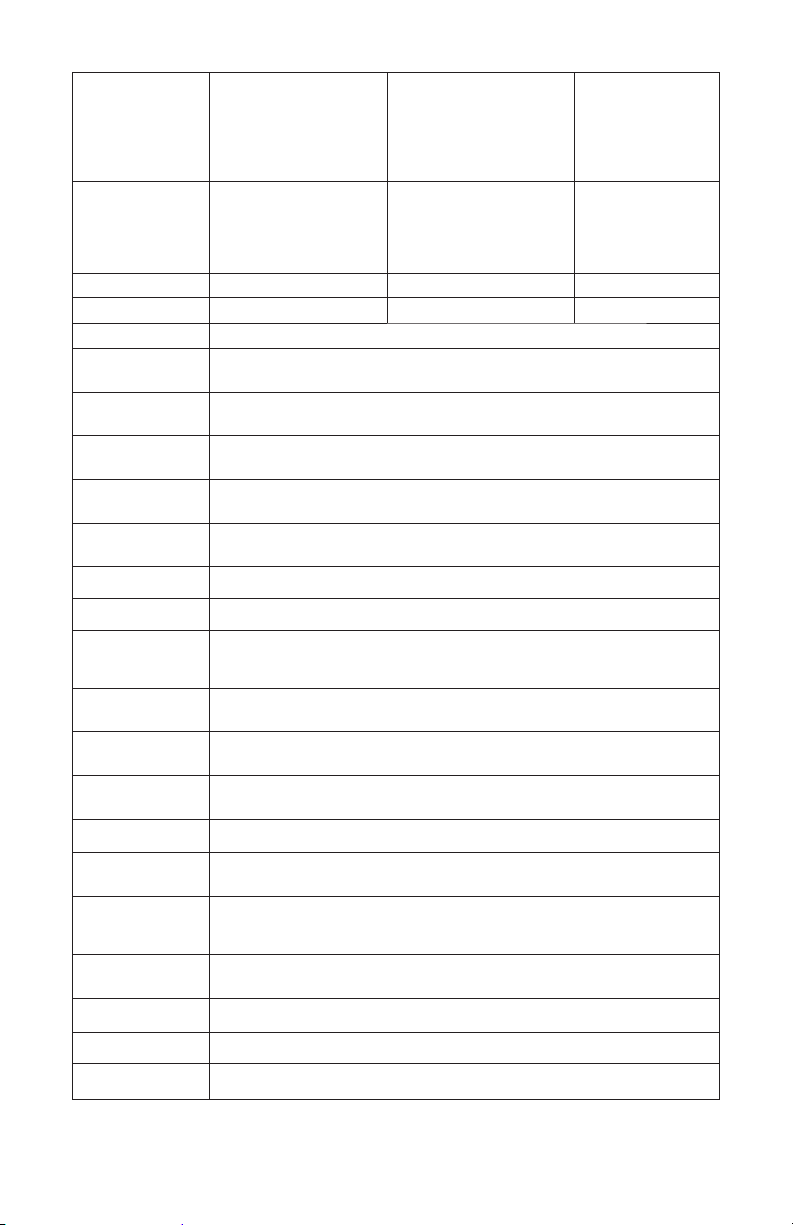

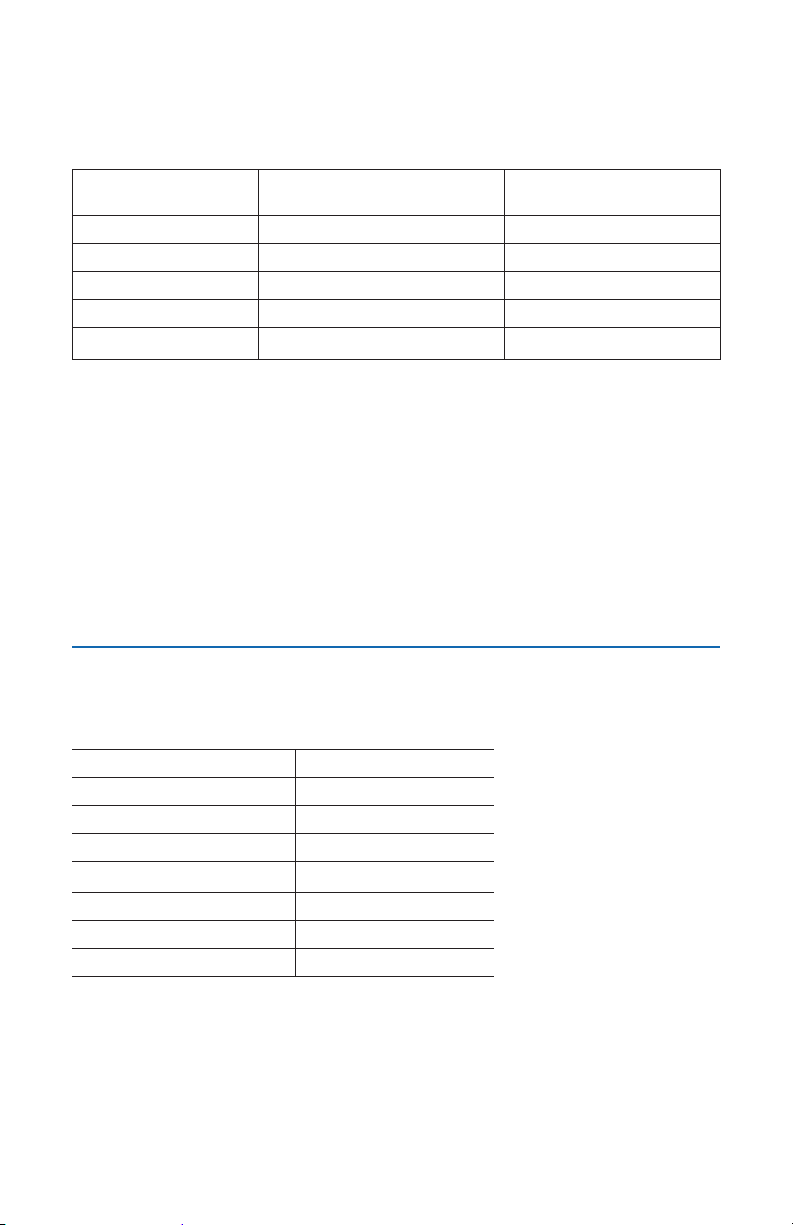

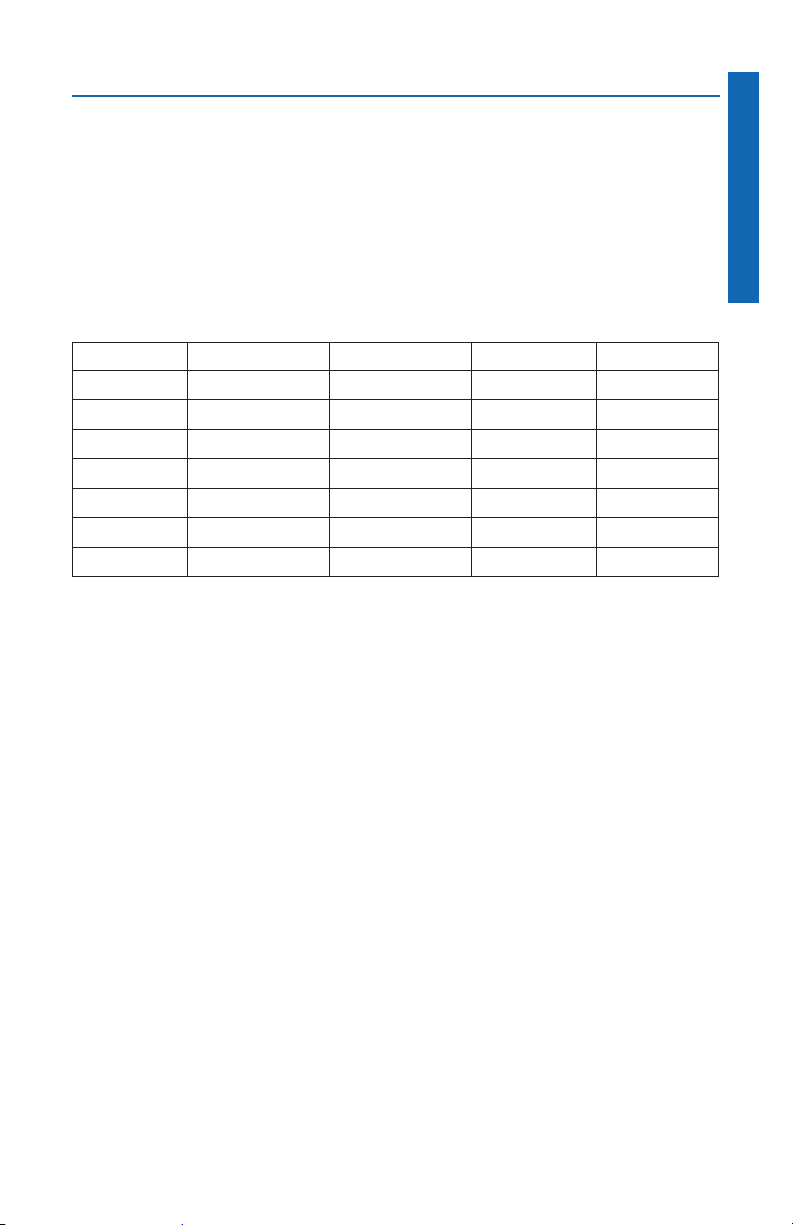

CONTENTS & ACCESSORIES

2020t Kit

EPA Version/

Code 1974-T

2020i Kit

ISO Version/

Code 1974-I

Contents Code Code

2020t/i Turbidimeter

0 NTU Standard, 60 mL 1480 1480

1 NTU Standard, 60 mL 1441

10 NTU/FNU Standard, 60 mL 1442 1447

100 FNU Standard, 60 mL 1444

Water Sample Bottle, 60 mL 0688 0688

Test Tubes, with Caps 0260 (6) 0260 (6)

Cable, USB 1720 1720

USB Wall Adapter 1721 1721

2020t/i Manual 1974-MN 1974-MN

2020t/i Quick Start Guide 1974-QG 1974-QG

2020t/i Testing Guide 1974-TG 1974-TG

Accessories

Code Description

0260-6 Test tubes, with Caps

1446 1 FNU Standard, 60 mL (ISO)

1443 100 NTU Standard, 60 mL (EPA)

6195-H Formazin Standard Solution, 4000 NTU, 60 mL

3-0038 Replacement Chamber

0943 Syringe, 60 mL, plastic

2-2097 Filters, 0.1 micron, Pack of 50

5-0132 Car Charger

7

Page 8

EPA COMPLIANCE

The 2020t meter meets or exceeds EPA design specifi cations for NPDWR and NPDES

turbidity monitoring programs as specifi ed by the USEPA method 180.1.

ISO COMPLIANCE

This 2020i meter meets or exceeds ISO design criteria for quantitative methods of turbidity

using optical turbidimeters as specifi ed by ISO 7027.

CE COMPLIANCE

This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interferences in which case the user will be required to

correct the interference at his own expense.

IP67 COMPLIANCE

The 2020t/i meets IP67 standards for protection against dust and immersion only when

the USB port plug is in place. Documentation is available at www.lamotte.com.

WARRANTY

LaMotte Company warrants this instrument to be free of defects in parts and workmanship

for 2 years from the date of shipment. If it should become necessary to return the

instrument for service during or beyond the warranty period, contact our Technical

Service Department at 1-800-344-3100 for a return authorization number or visit

www.lamotte.com for troubleshooting help. The sender is responsible for shipping

charges, freight, insurance and proper packaging to prevent damage in transit. This

warranty does not apply to defects resulting from action of the user such as misuse,

improper wiring, operation outside of specifi cation, improper maintenance or repair, or

unauthorized modifi cation. LaMotte Company specifi cally disclaims any implied warranties

or merchantability or fi tness for a specifi c purpose and will not be liable for any direct,

indirect, incidental or consequential damages. LaMotte Company’s total liability is limited

to repair or replacement of the product. The warranty set forth above is inclusive and no

other warranty, whether written or oral, is expressed or implied.

REGISTER YOUR METER

To register your meter with the LaMotte Service Department, go to www.lamotte.com and

choose SUPPORT on the top navigation bar.

COMPUTER CONNECTION

OUTPUT

USB

8

Page 9

COMPUTER CONNECTION

USB Type A, USB mini B, Order Cable Code 1720.

BATTERY/AC OPERATION

The 2020t/i may be operated on battery power or using the USB wall adapter or USB

computer connection. If using the meter as a bench top unit, use the wall adapter if

possible to extend the battery life. The meter will remain on when the USB adapter is used.

To charge the lithium ion battery with the wall adapter, plug the smaller end of the USB

cable (USB mini B connector) into the meter and the larger end of the USB cable (USB Type

A connector) into the wall adapter. Plug the wall adapter into an AC outlet. Reinsert the USB

port plug after charging.

To charge the battery from a computer, plug the smaller end of the USB cable (USB mini B

connector) into the meter and the larger end of the USB cable (USB Type A connector) into

a USB port on a computer. Reinsert the USB port plug after charging.

The battery icon will show no bars and fl ash when the unit fi rst turns on. Then the indicator

will indicate the battery status by showing 0, 1, 2, 3 or 4 bars.

It will take 5 hours to fully charge a low battery. The battery icon will fl ash when the battery

is charging. The battery icon will show four bars and stop fl ashing when it is fully charged.

The charging circuit will automatically switch to a fl oat charge when the battery is fully

charged. The charger may remain connected. Some computers will NOT supply power to

the USB ports during standby operation. The wall adapter will charge the unit continuously.

The battery icon will show no bars and continuously fl ash if the battery is getting low but

the unit will still operate normally. A “Low Battery” message on the status bar of the display

will replace the time when the battery voltage is too low for proper operation and accuracy

may be degraded. A “Shutdown Low Batt” message on the display will appear for a few

seconds before the power is switched off when the battery is too low to operate the unit.

To extend the battery life:

• Shut down the unit with the power switch when not taking measurements

or use the power save option to have the unit automatically turn off after 5

minutes.

• Store the unit in a cool dry place.

• Fully charge the battery before storing the unit for extended periods of time.

• Limit backlight use. The unit consumes three times the normal power with the

backlight on. Set the backlight time option to 10 seconds, or select “Button

Control” and keep the backlight off .

Battery replacement: The lithium-ion battery used in this unit should last for many

years with normal use. When it no longer powers the unit long enough to meet testing

requirements it will need to be replaced. Lithium-ion batteries that are properly charged

and stored do not usually lose all capacity; they just have less capacity after hundreds

of charge cycles. This unit uses a custom battery assembly that is only available from

LaMotte Company. Battery replacement must be performed at a LaMotte authorized

repair facility. The water resistant housing of this meter should not be opened by the user.

Contact LaMotte Company by phone (1-800-344-3100) or email (tech@lamotte.com) for

a return authorization number.

9

Page 10

TURBIDITY

WHAT IS TURBIDITY?

Turbidity is an optical property that results when light passes through a liquid sample

and is scattered by particulate matter. The scattering of light results in a change in the

direction of the light passing through the liquid. If the turbidity is low, the particles may

be invisible to the naked eye and much of the light will continue in the original direction.

As the quantity of particles increases in samples with greater turbidity, the light strikes

particles in solution and is scattered backward, sideways and forward. Light scattered by

the particles allows the particles in the solution to be ”seen” or detected just as sunlight

allows dust particles in the air to be seen. At high concentrations, turbidity is perceived as

cloudiness, haze or an absence of clarity. Turbidity is not specifi c to the types of particles in

the sample. The particles may be suspended or colloidal and can have inorganic, organic or

biological origins.

In drinking water, turbidity may indicate a treatment problem or signal conditions with an

increased risk of gastrointestinal diseases. Because pathogens such as Cryptosporidium

and Giardia cause measurable amounts of turbidity, turbidity monitoring can hold the

key to assuring adequate water fi ltration. In 1998, the EPA published the IESWTR (interim

enhanced surface water treatment rule) mandating turbidities in combined fi lter effl uent

should read at or below 0.3 NTU. By doing so, the EPA hoped to achieve a 2 log (99%)

removal of Cryptosporidium. There is presently consideration to lower this to 0.1 NTU. The

trend has been to check the calibration of on-line turbidimeters used to monitor drinking

water with hand-held fi eld units. The optical design and low detection limit of the 2020t/i

allows very accurate readings for such calibrations. Drinking water that is turbid is not

always harmful to human health but does impart an unpalatable appearance.

Turbidity in environmental waters reduces the amount of benefi cial sunlight that reaches

submerged aquatic vegetation, raises surface water temperature, buries eggs and bottom

dwelling creatures, and can carry sediment and pesticides through the water system.

HOW IS TURBIDITY MEASURED?

Turbidity is measured by detecting and quantifying the scattering of light in a solution. The

amount of light that is scattered is infl uenced by particulate properties of color, shape, size

and refl ectivity. Turbidity can be measured by various methods including visual methods

and instrumental methods. Visual methods are more suitable for samples with high

turbidity. Instrumental methods can be used for samples with turbidity at all levels.

Examples of visual methods are the Secchi Disk method and the Jackson Candle method.

The Secchi Disk method is often used in natural waters. A Secchi Disk with black and white

quadrants is lowered into the water until it can no longer be seen. It is then raised until

it can be seen again. The average of these two measurements is known as the “Secchi

Depth”. The Jackson Candle method uses a long glass calibrated tube placed over a

standardized candle. Water is added or removed from the tube until the candle fl ame

becomes indistinct. The height of the water in the tube is measured with a calibrated scale

and is reported as Jackson Turbidity Units (JTU). The lowest level of turbidity that can

accurately be determined with this method is about 25 JTU.

Instrumental methods for measuring turbidity involve a combination of detection angles

and light sources to optimize accuracy in various samples and to meet regulatory

requirements. The 2020t and 2020i turbidimeters off er the option of three calibration

curves for measuring turbidity that is based on the characteristics of the sample.

In the nephelometric mode, which is the default mode, the detector that is located

90-degrees from the light source measures the scattered light from a light beam passing

through a sample. In the 2020t, this confi guration and the tungsten lamp, with a color

temperature of 2,200–3,000 °K, meet the requirements of EPA method 180.1. The 2020i,

10

Page 11

which has an IR LED light source at 860 nm, uses the 90-degree detector to meet the

requirements of the ISO 2027 Standard. The nephelometric mode is best used for meeting

regulatory requirements on samples, such as drinking water, that are in the range of 0.00

to 40.00 Nephelometric Turbidity Units (NTU) for the 2020t or 0.00 to 10.00 Formazin

Nephelometric Units (FNU) for the 2020i. A signal averaging option improves the stability

of readings on low turbidity samples.

The ratiometric mode is typically used for natural waters and storm waters, or other

samples in the 0 – 1000 NTU/FNU range, to minimize interference from color in the

sample. The ratiometric mode takes readings from both the 90-degtree detector and the

180 degree detector. Results are reported as Nephelometric Turbidity Ratio Units (NTRU,

2020t) or Formazin Nephelometric Ratio Units (FNRU, 2020i).

In the attenuation mode, the detector is located 180-degrees from the light source. It

measures the attenuation of the light beam due to absorption and scatter. This mode

is best used to measure samples with high turbidity levels in the range of 40 – 2000

Attenuation Units (AU, 2020t) or Formazin Attenuation Units (FAU, 2020i).

TURBIDITY UNITS

Traditionally, turbidimeters designed for use in the United State were made to the

specifi cations of EPA Method 180.1. This method defi ned the NTU, nephelometric turbidity

unit, as a unit that measured turbidity in the range of 0 – 40 NTU using a nephelometer.

According to the EPA a nephelometer was a turbidimeter that measures turbidity with

a 90° detector. If a sample had a turbidity that was greater than 40 NTU, a dilution was

necessary to bring the sample into the 0 – 40 NTU range. Today, many turbidimeters have

additional detectors which increase the range of the turbidity measurement, eliminate

interferences and generally improve the performance. Currently, many turbidimeters

are capable of measuring above 40 NTU by using detectors other than a 90° detector.

Even though they may use a 180° detector, which does not meet the defi nition of a

nephelometer, the results are often be reported as NTU.

Since the position of the detector and the light source is important information to include

when reporting and comparing turbidity results, there has recently been an eff ort by the

ASTM to use turbidity units which include this information. For EPA compliant meters,

measurements made with a 90° degree detector and an incandescent white light source

are reported as Nephelometric Turbidity Units (NTU). When an attenuation measurement

is made with a 180°detector, using the same light source, the results are reported as

Attenuation Units (AU). If a ratio of the measurements from both detectors is used to

calculate the turbidity, the results are reported in Nephelometric Turbidity Ratio Units

(NTRU).

ISO Method 7027, which specifi es an 860 nm light source, reports results in four turbidity

units. When the 90° degree detector is used, the results are reported as Formazin

Nephelometric Units (FNU). With an attenuation measurement made with a 180° detector,

the results are reported as Formazin Attenuation Units (FAU). And results that are a ratio

of measurements from the two angles are reported in Formazin Nephelometric Ratio

Units (FNRU). It is also possible to report the readings from each of the three ISO modes in

Nephelometric Turbidity Units (NTU).

It should be noted that all units are numerically equivalent if the meters are calibrated to

formazin. The units diff erentiate which detector and light source was used to make the

measurement. For example, 1 NTU = 1 AU = 1 NTRU = 1 FNU =1 FAU = 1 FNRU.

11

Page 12

Each turbidity calibration mode has a default unit:

Nephelometric Mode: NTU (2020t) or FNU (2020i)

Ratiometric Mode: NTRU (2020t) or FNRU (2020i)

Attenuation Mode: AU (2020t) or FAU (2020i)

The meter will permit the user to choose to report results in any of the other available

calibration units (NTU, FNU, AU, FAU, NTRU or FNRU) other than the default unit. It also

allows the brewing industry to check process water in the nephelometric mode and choose

to have results reported in American Society of Brewing Chemists (ASBC) or European

Brewery Convention (EBC) units.

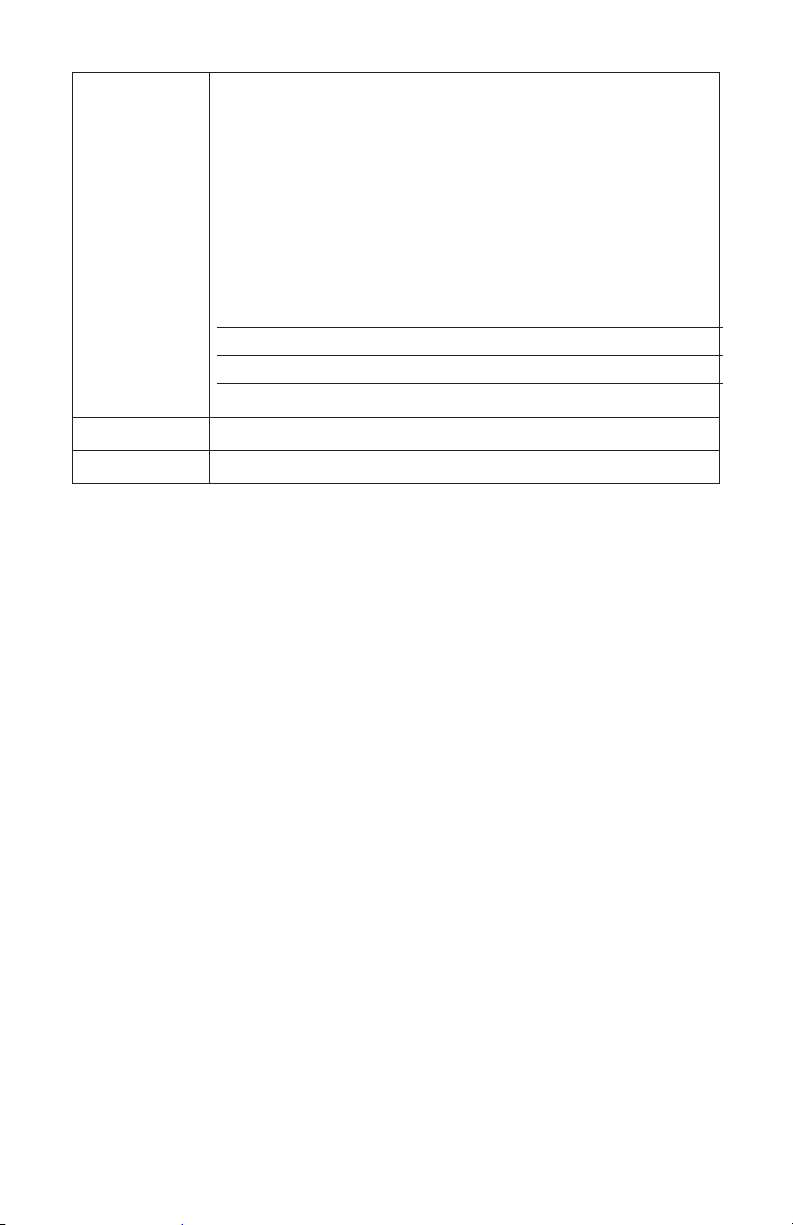

Acronyms Defi nitions Notes

NTU Nephelometric

Turbidity Units

FNU Formazin

Nephelometric Units

Incandescent white light between

400 and 600 nm, 90° detection,

2020t

IR LED (usually) 860 nm, bandwidth

less than 60 nm, 90° detection,

2020i

Regulatory

Method

EPA 180.1

ISO 7027

AU Attenuation Units Incandescent white light between

FAU Formazin Attenuation

Units

NTRU Nephelometric

Turbidity Ratio Units

FNRU Formazin

Nephelometric Ratio

Units

ASBC American Society of

Brewing Chemists

EBC European Brewery

Convention

For more information see ASTM 07726-4 Standard Guide for the Use of Various Turbidimeter Technologies for the

Measurement of Turbidity in Water.

400 and 600 nm, 180° detection,

2020t

IR LED (usually) 860 nm, bandwidth

less than 60 nm, 180° detection,

2020i

Incandescent white light between

400 and 600 nm, 90° and 180°

detection, 2020t

IR LED (usually) 860 nm, bandwidth

less than 60 nm, 90° and 180°

detection, 2020i

2020t/i Not applicable

2020t/i Not applicable

Not applicable

ISO 7027

EPA 180.1

Not applicable

TAKING TURBIDITY WATER SAMPLES

Clean plastic or glass containers may be used for turbidity samples. Ideally, samples should

be tested soon after collection and at the same temperature as when collected.

12

Page 13

SAMPLE DILUTION TECHNIQUES

If a test result is out of the range of the meter, as indicated by an over range message

on the display, the sample must be diluted and retested.The following table gives quick

reference guidelines for dilutions of various proportions.

Amount of Sample

10 mL 0 mL 1

5 mL 5 mL 2

2.5 mL 7.5 mL 4

1 mL 9 mL 10

0.5 mL 9.5 mL 20

Deionized Water to Bring Final

Volume to 10 mL Multiplication Factor

All dilutions are based on a fi nal volume of 10 mL, so several dilutions will require small

volumes of the water sample. Graduated pipets should be used for all dilutions. If

volumetric glassware is not available, dilutions can be made with the colorimeter tube. Fill

the tube to the 10 mL line with the sample and then transfer it to another container. Add

10 mL volumes of deionized water to the container and mix. Transfer 10 mL of the diluted

sample to the colorimeter tube and follow the test procedure. Repeat the dilution and

testing procedures until the result falls within the range of the calibration. Multiply the test

result by the dilution factor. For example, if 10 mL of the sample water is diluted with three

10 mL volumes of deionized water, the dilution factor is four. The test result of the diluted

sample should be multiplied by four.

OPTIONS & SET UP

FACTORY DEFAULT SETTINGS

Settings that have user options have been set at the factory to default settings.

The factory default settings are:

Turbidity Calibration Curve Nephelometric (N)

Turbidity Units Default

Turbidity Measurement Turbidity-No Blank (NB)

Averaging Disabled

Date Format MM-DD-YYYY

Power Save 5 minutes

Backlight 10 seconds

Language English

13

Page 14

TURBIDITY OPTIONS

Three calibration curves are available: Nephelometric, Ratiometric and Attenuation. For

the 2020t, Nephelometric is the default calibration curve and the available units are NTU,

NTRU, ASBC and EBC. For the 2020i, Nephelometric is the default calibration curve and the

available units are FNU, NTU, FNRU, ASBC and EBC for the 2020i.

The 2020t in Nephelometric mode with the default NTU units should be used for testing

public drinking water for compliance with the EPA 180.1 rule.

Once a calibration curve and turbidity units have been selected, they will remain selected

until the calibration curve and turbidity units are changed by performing the following

procedures.

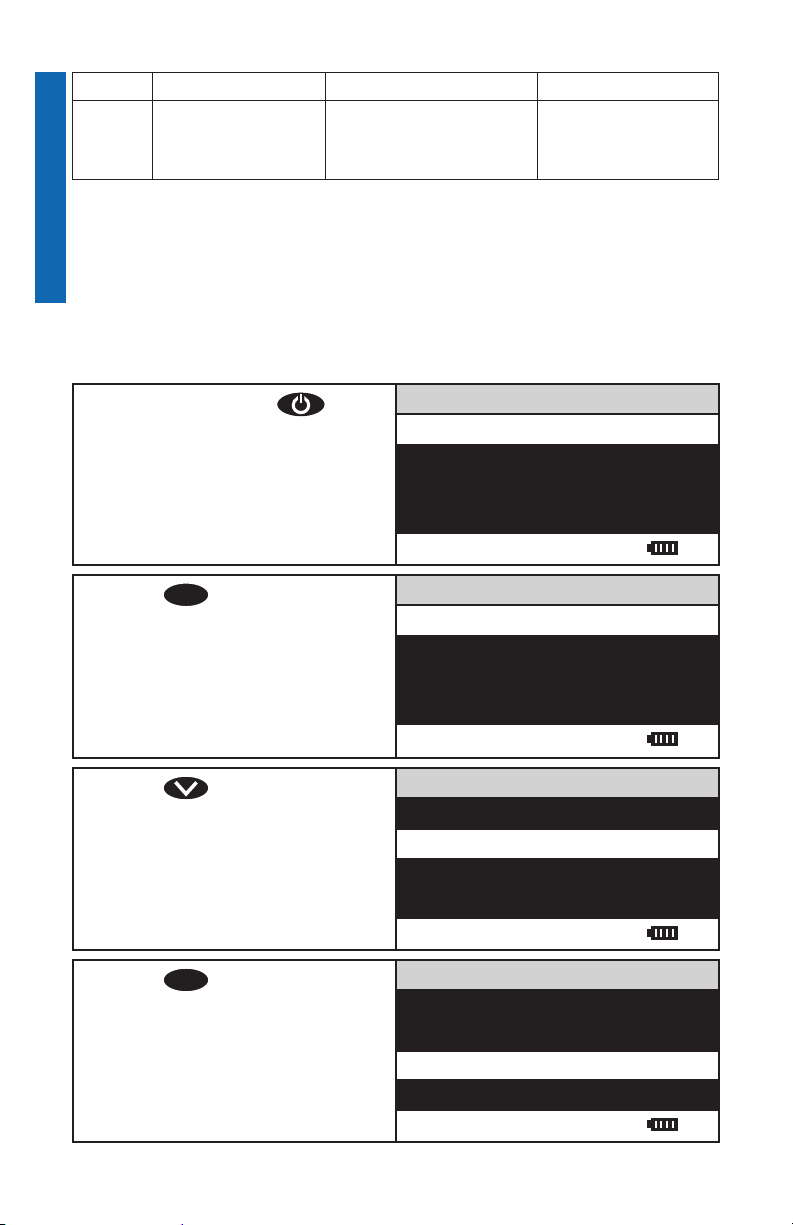

SELECTING A TURBIDITY CALIBRATION CURVE

Three calibration curves are available: Nephelometric, Ratiometric and Attenuation. The

default calibration curve is Nephelometric. The calibration curve should be chosen that

suits the type of sample being tested.

Nephelometric

Mode:

Ratiometric

Mode:

Attenuation

Mode:

Ratiometric methods typically minimize color interference.

The 2020t in Nephelometric mode with the default NTU units should be used for testing

public drinking water for compliance with the EPA 180.1 rule.

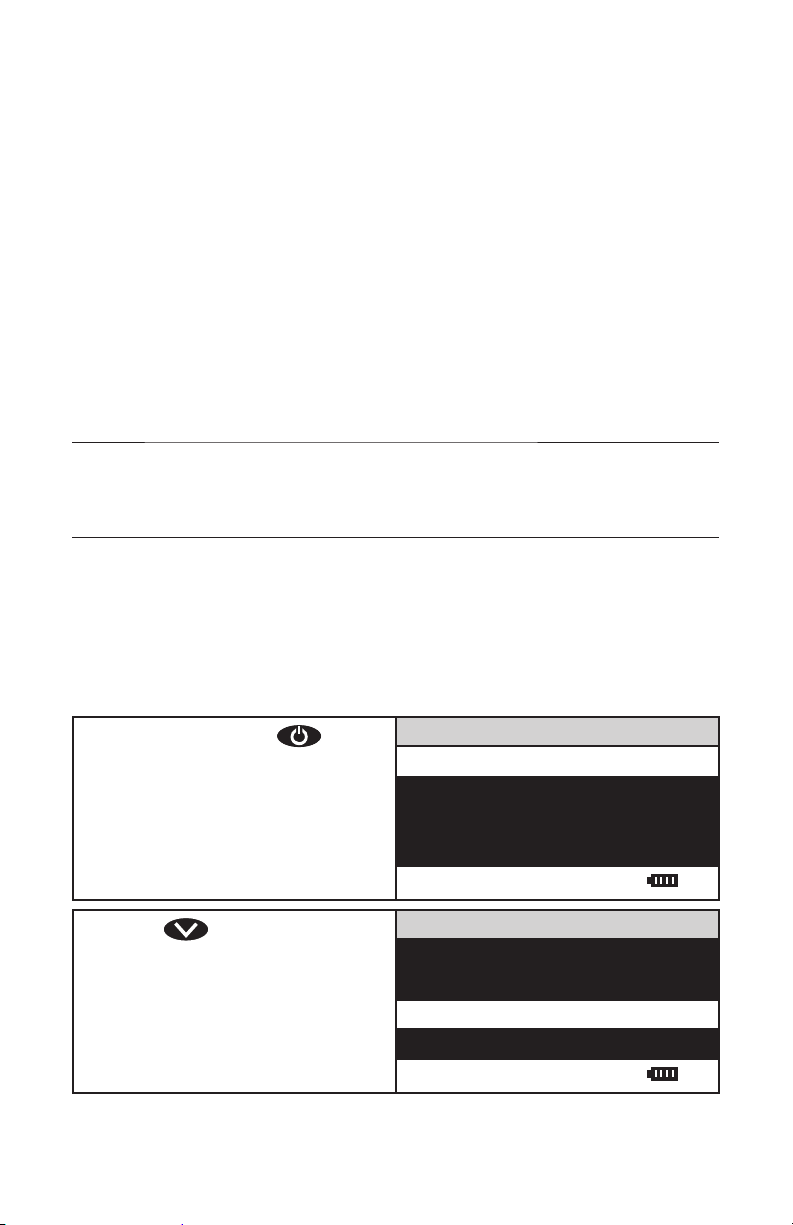

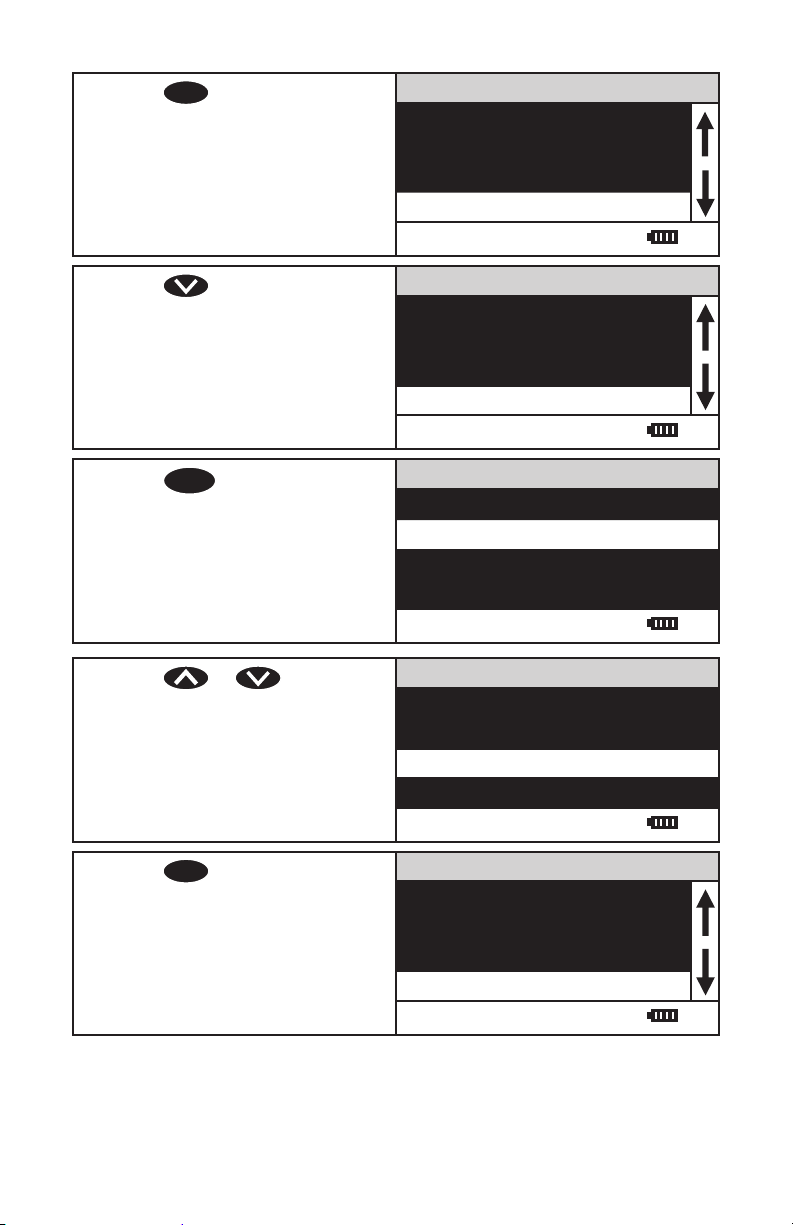

The Nephelometric mode will be used in the example. To change the calibration curve:

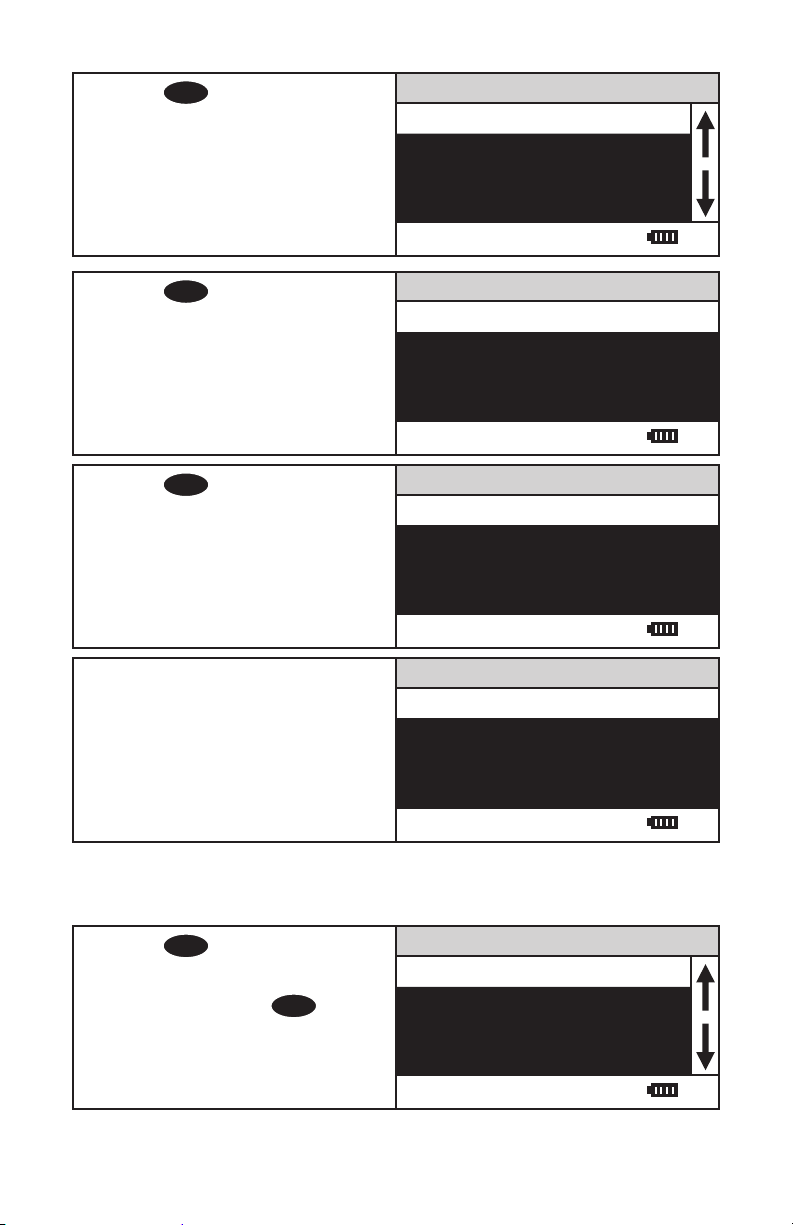

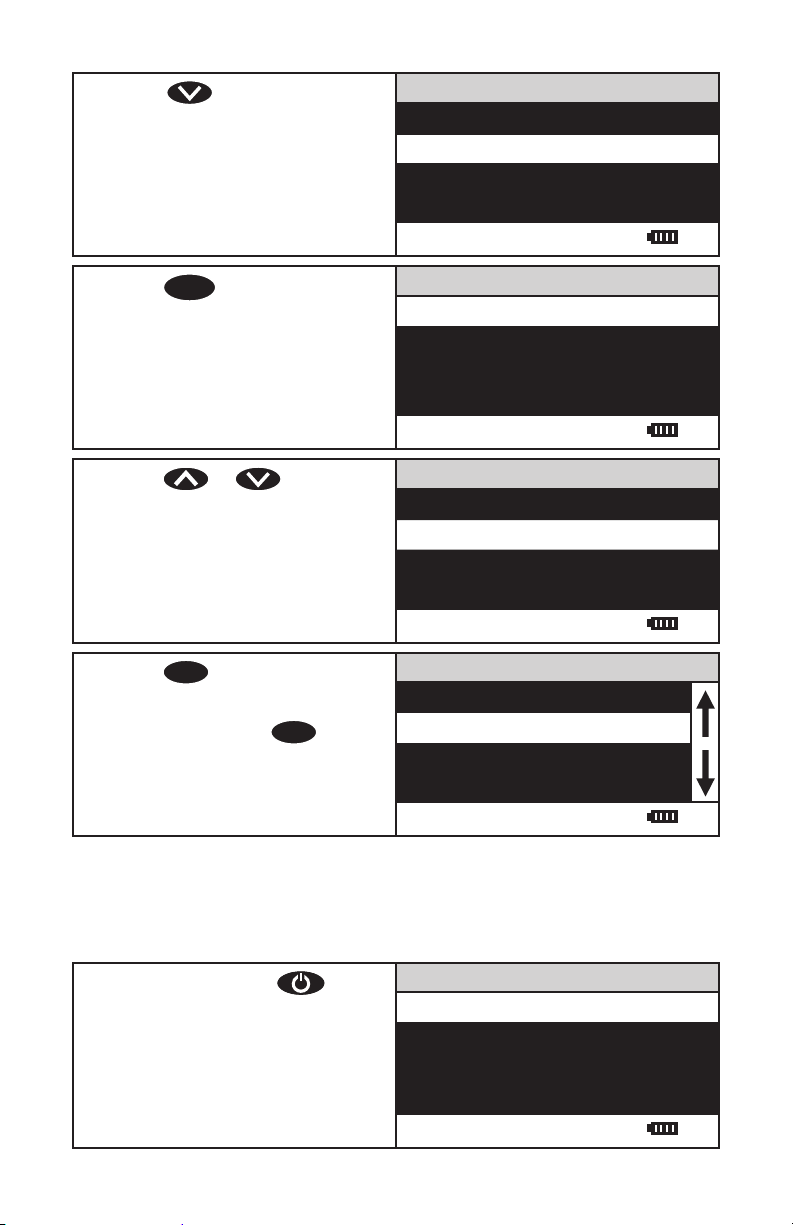

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

2. Press to scroll to Options.

90° Detector 0 – 100 NTU/FNU Range, for Drinking Water

90° and 180°

Detectors

180° Detector 0 – 2000 NTU/AU/FAU Range, for High

Samples

0 – 1000 NTU/NTRU/FNRU Range, for

Drinking Water, Natural Water

Samples, Storm Water Samples, and Colored

Samples

Turbidity Samples

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

14

Page 15

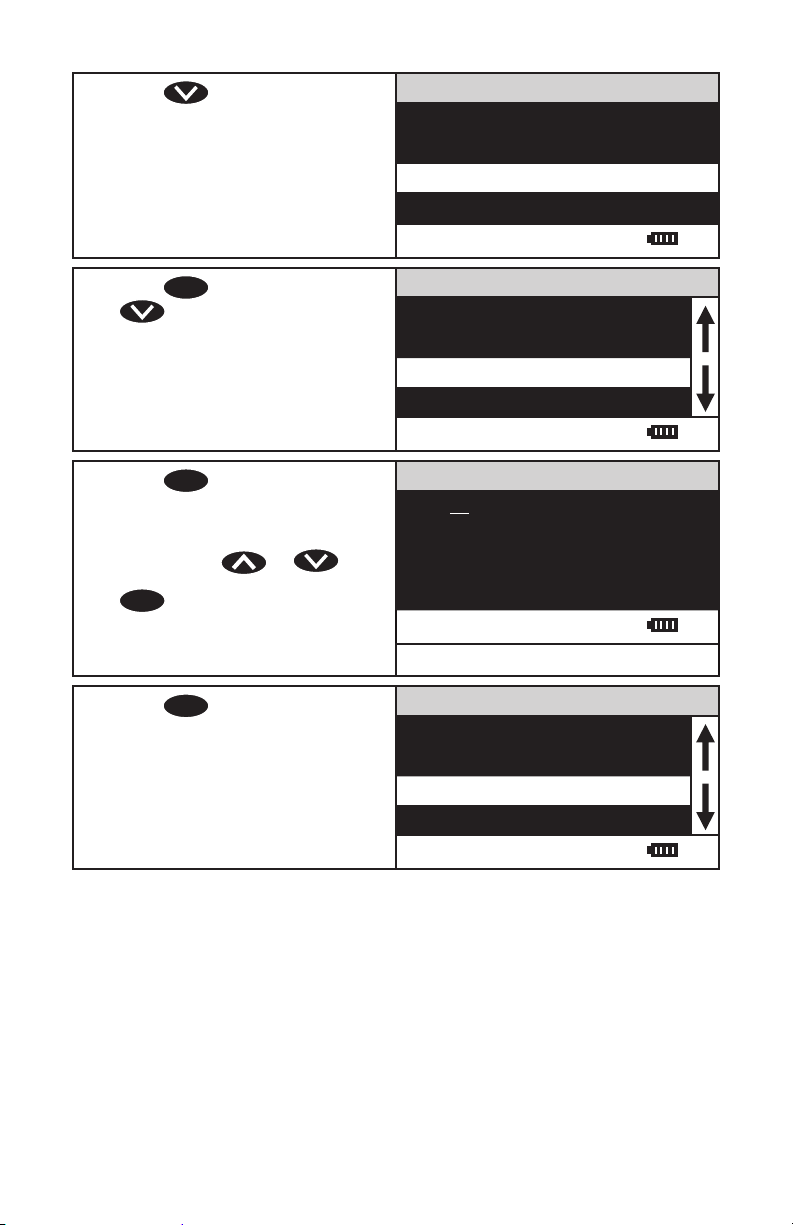

3. Press

ENTER

to select Options.

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

4. Press

Options.

ENTER

to select Turbidity

Turbidity Calibration

Turbidity Options

Turbidity Units

12:00:00 001/500

5. Press

Calibration.

ENTER

to select Turbidity

Nephelometric NTU

Turbidity Calibration

Ratiometric NTRU

Attenuation AU

12:00:00 001/500

6. Scroll to the desired calibration

option.

Nephelometric NTU

Turbidity Calibration

Ratiometric NTRU

Attenuation AU

12:00:00 001/500

NOTE: Stablcal® standards below 50 NTU should not be used to calibrate the 2020t/i. The

diluent has a diff erent refractive index than traditional formazin standards and will aff ect

the results.

7. Press

ENTER

to save the selection.

The screen will display Storing... for

about 1 second and return to the

Options menu. Press

EXIT

to a previous menu.

to return

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

15

Page 16

SELECTING TURBIDITY UNITS

The results for each calibration curve will be reported in the default units for that

calibration curve unless diff erent units are chosen. The default unit is shown after the

calibration curve name. The default units are:

Calibration Curve Default Unit

2020t Nephelometric NTU (Nephelometric Turbidity Units)

Ratiometric NTRU (Nephelometric Turbidity Ratio Units)

Attenuation AU (Attenuation Units)

2020i Nephelometric FNU (Formazin Nephelometric Units)

Ratiometric FNRU (Formazin Nephelometric Ratio Units)

Attenuation FAU (Formazin Attenuation Units)

It is possible to choose to have the results reported in an alternative unit instead of the

default unit for each mode. When ASBC (American Society of Brewing Chemists) and EBC

(European Brewery Convention) units are desired the Nephelometric calibration curve

should be used.

For the 2020t, the available units are: NTU, NTRU, AU, ASBC, EBC

For the 2020i, the available units are: FNU, NTU, FNRU, FAU, ASBC, EBC

NTRU, AU, FNU, FNRU and FAU are numerically equivalent to NTU. The units diff erentiate

which detector and light source was used to make the measurement. See page 12 for the

defi nition of turbidity units.

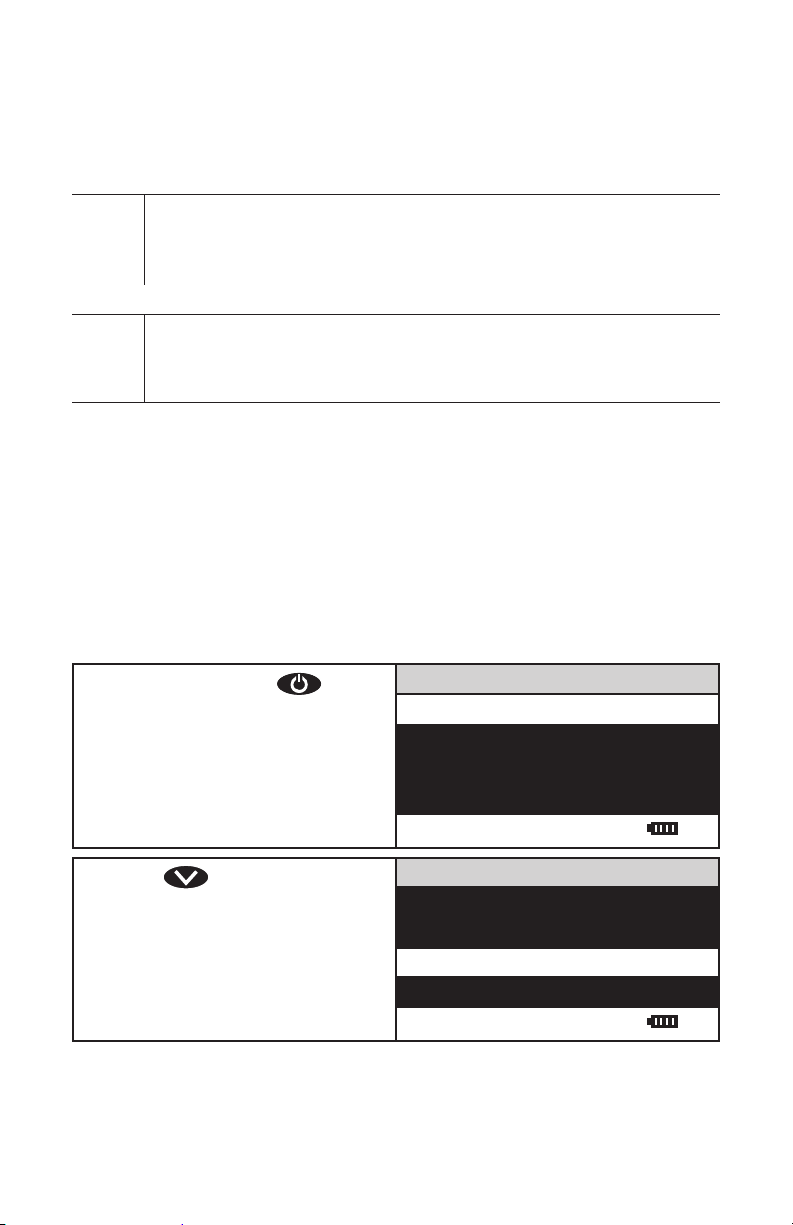

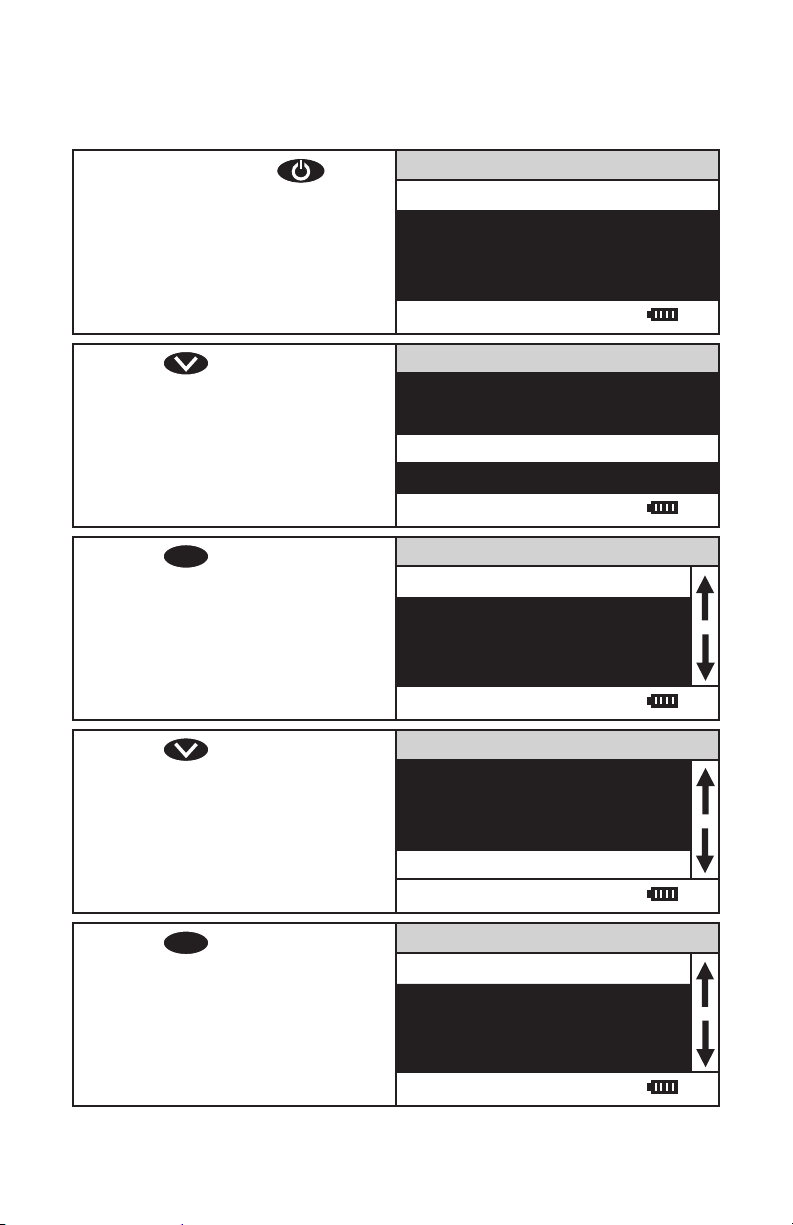

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

2. Press to scroll to Options.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

16

Page 17

3. Press

ENTER

to select Options.

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

4. Press

ENTER

to select Turbidity

Options.

5. Press to scroll to Turbidity

Units.

6. Press

ENTER

to select Turbidity Units.

7. Press or to scroll to

the desired units.

Turbidity Options

Turbidity Calibration

Turbidity Units

12:00:00 001/500

Turbidity Options

Turbidity Calibration

Turbidity Units

12:00:00 001/500

Set Turbidity Units

Default

NTU

ASBC

EBC

12:00:00 001/500

Set Turbidity Units

Default

NTU

ASBC

EBC

12:00:00 001/500

17

Page 18

8. Press

ENTER

to save the selection.

The screen will display Storing... for

about 1 second and return to the

Options menu. Press

EXIT

to a previous menu.

to return

Turbidity Options

Averaging

Set Clock

Options Menu

Set PWR Save

12:00:00 001/500

AVERAGING

The averaging option allows the user to average multiple readings. This option will improve

the accuracy of samples with readings that may tend to drift with time. When the two, fi ve

or ten measurement option has been selected the fi nal average is displayed. The default

setting is Disabled. To change the setting:

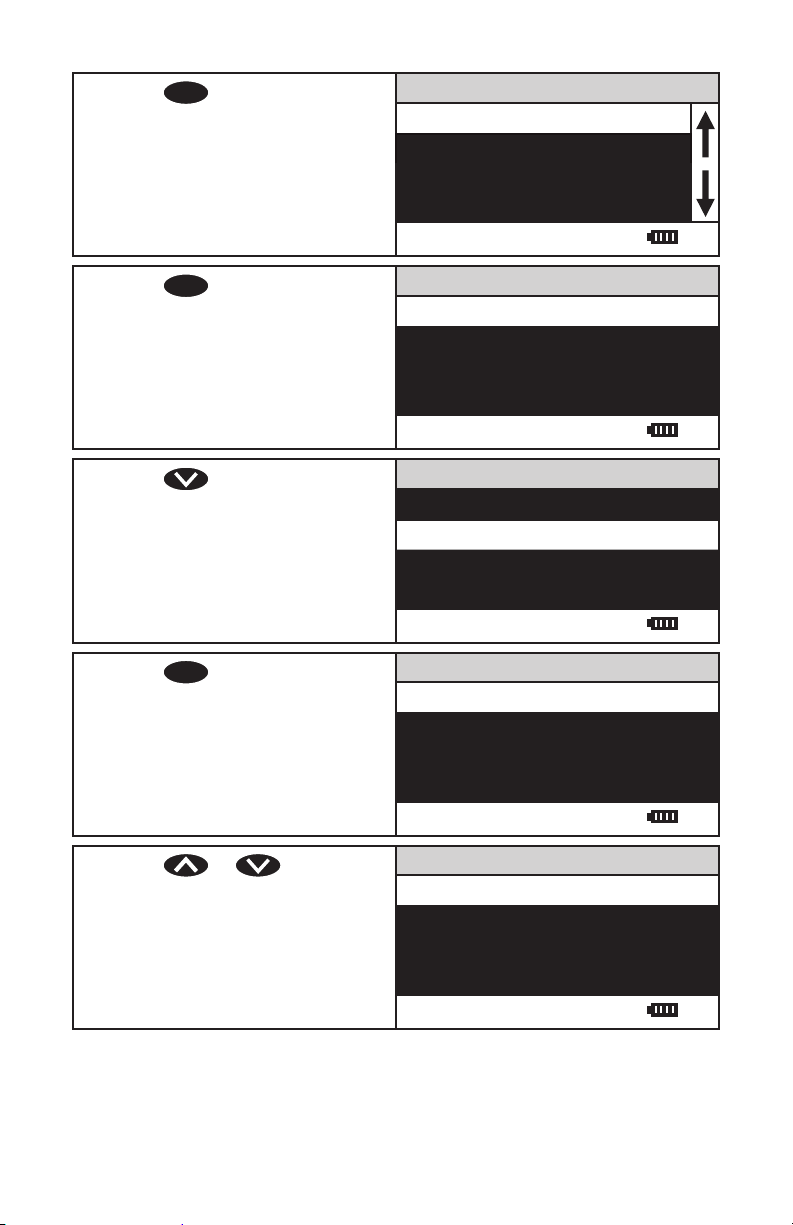

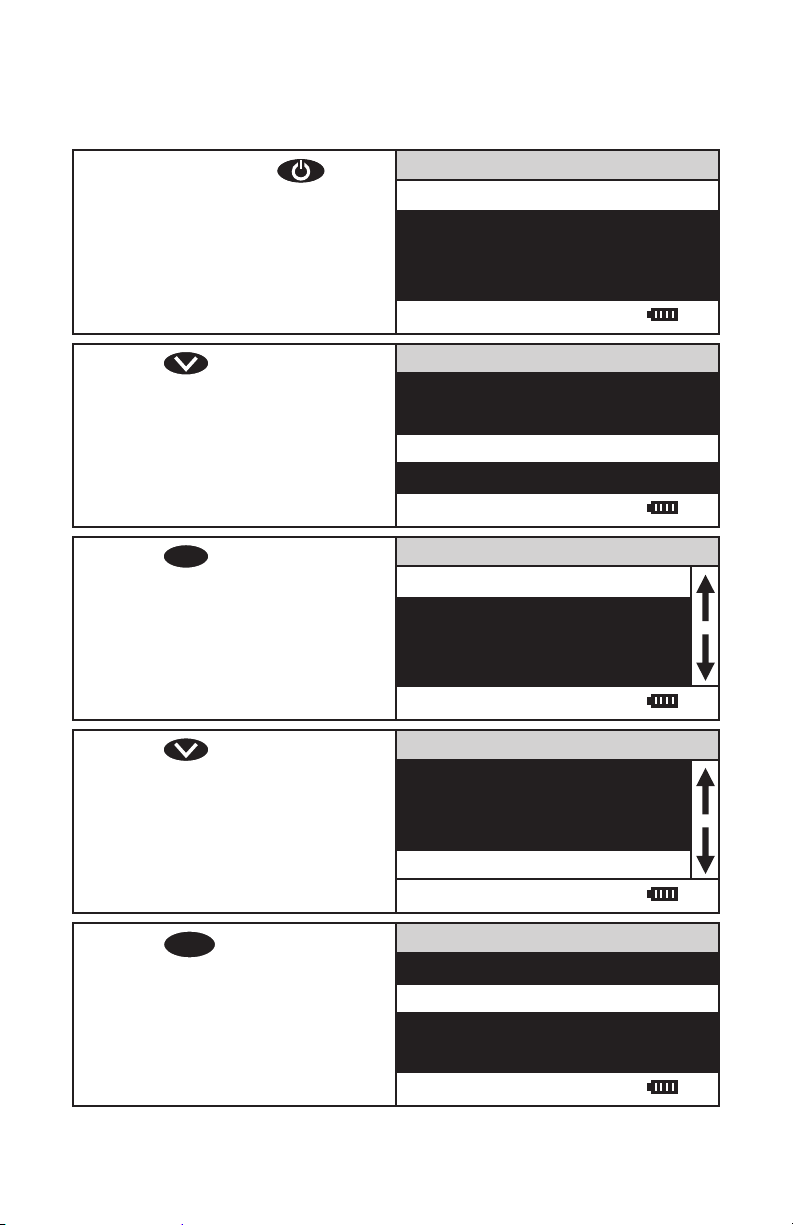

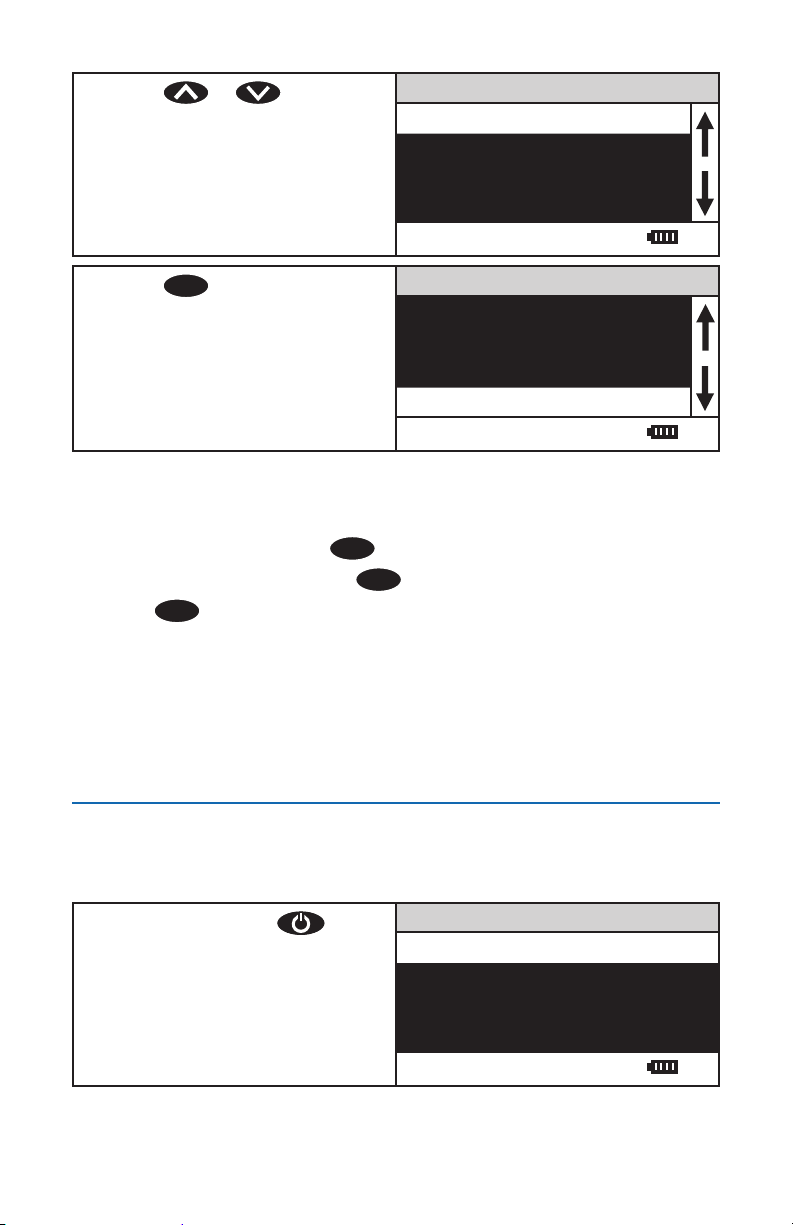

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

2. Press to scroll to Options.

3. Press

ENTER

to select Options.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

18

Page 19

4. Press to scroll to

Averaging.

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

5. Press

ENTER

to select Averaging.

Averaging Menu

Disabled

2 Measurements

5 Measurements

10 Measurements

12:00:00 001/500

6. Press or to scroll to

the desired option.

Disabled

Averaging Menu

2 Measurements

5 Measurements

10 Measurements

12:00:00 001/500

7. Press

ENTER

to save the selection.

The screen will display Storing... for

about 1 second and return to the

Options menu. Press

EXIT

to a previous menu.

to return

Turbidity Options

Averaging

Set Clock

Options Menu

Set PWR Save

12:00:00 001/500

NOTE: When the Averaging option is enabled, more time will be required to display a reading

and more power will be used.

SETTING THE CLOCK

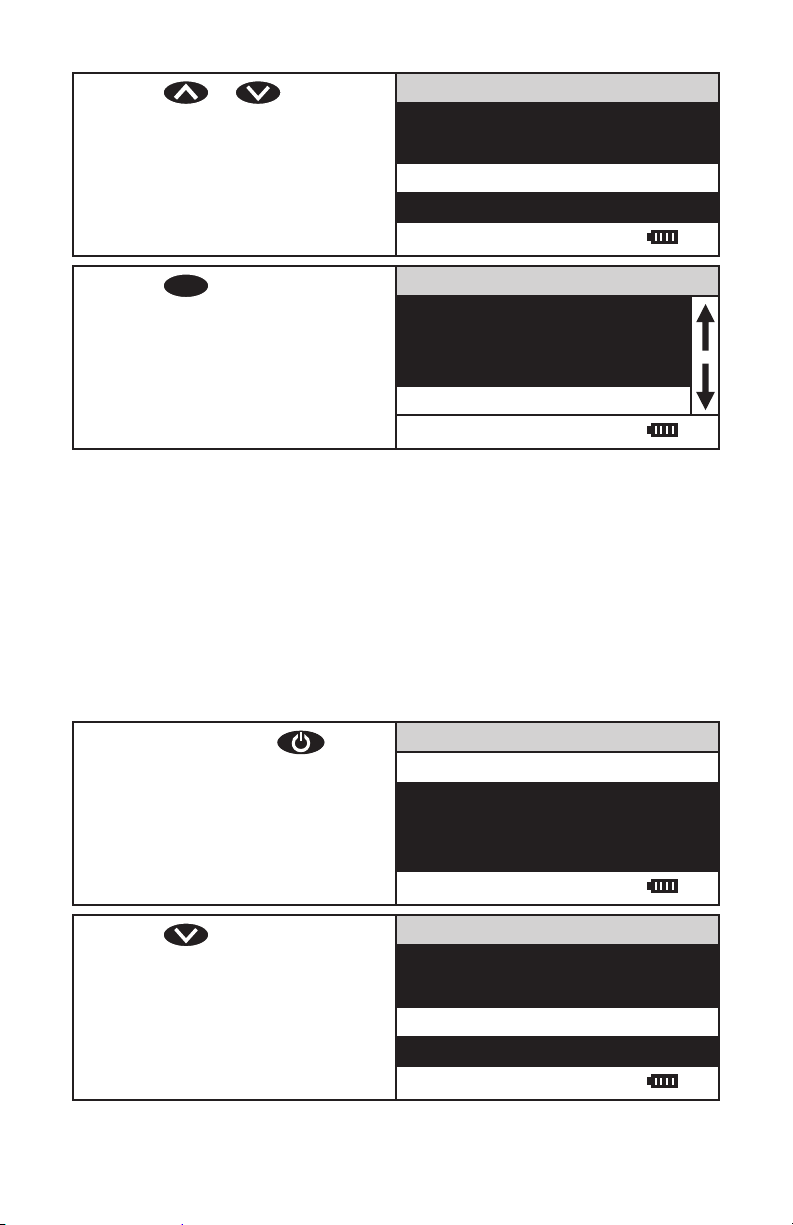

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

19

Page 20

2. Press to scroll to Options.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

3. Press

ENTER

to select Options. Press

to scroll to Set Clock.

4. Press

ENTER

to select Set Clock.

The date is displayed as monthday-year. The time is displayed as

hours:minutes:seconds

AM/PM. Press

or to

the appropriate character and press

ENTER

to select. The cursor will

move to the next character. Set all

characters in the same manner. This

is a scrolling menu.

5. Press

ENTER

to select the fi nal

character. The time and date will be

saved and the screen will return to

the Options Menu.

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

Set Time

Date: 07-09-2018

Time: 02:09:08 PM

12:00:00 001/500

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

20

Page 21

SETTING POWER SAVE

The power saving Auto Shutoff feature will turn the meter off when a button has not been

pushed for a set amount of time. The default setting is 5 minutes. To change the setting:

6. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

7. Press to scroll to Options.

8. Press

ENTER

to select Options.

9. Press to scroll to Set PWR

Save.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

10. Press

ENTER

to select PWR Save.

Auto Shutoff

Disable

5 Minutes

15 Minutes

30 Minutes

12:00:00 001/500

21

Page 22

11. Press or to scroll to

desired setting.

Auto Shutoff

Disable

5 Minutes

15 Minutes

30 Minutes

12:00:00 001/500

12. Press

ENTER

to save the selection.

The screen will display Storing... for

about 1 second and return to the

Options Menu.

Turbidity Options

Averaging

Options Menu

Set Clock

Set PWR Save

12:00:00 001/500

SETTING THE BACKLIGHT TIME

The backlight illuminates the display for enhanced viewing. If Button Control is chosen the

backlight button on the key pad will act as an on/off switch and the backlight will remain on

or off when the meter is being used. When one of the other settings – 10, 20 or 30 seconds

– is chosen, the display will be illuminated for the specifi ed amount of time after any button

is pressed. As a precaution, the backlight will not illuminate during turbidity measurements

to avoid interference from stray light.

NOTE: The backlight feature uses a signifi cant amount of power. The longer the backlight is

on, the more frequently the battery will have to be charged if the USB/Wall Charger is not

being used.

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

Measure

Data Logging

Options

Main Menu

2. Press to scroll to Options.

12:00:00 001/500

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

22

Page 23

3. Press

ENTER

to select Options.

Options Menu

Averaging

Set Clock

Set PWR Save

Set Backlight Time

12:00:00 001/500

4. Press to scroll to Set

Backlight Time.

5. Press

ENTER

to select Set Backlight

Time.

6. Press or to scroll to

desired setting.

Options Menu

Averaging

Set Clock

Set PWR Save

Set Backlight Time

12:00:00 001/500

Backlight Time

Button Control

10 Seconds

20 Seconds

30 Seconds

12:00:00 001/500

Backlight Time

Button Control

10 Seconds

20 Seconds

30 Seconds

12:00:00 001/500

7. Press

ENTER

to save the selection.

The screen will display Storing... for

about 1 second and return to the

Options Menu.

Options Menu

Averaging

Set Clock

Set PWR Save

Set Backlight Time

12:00:00 001/500

23

Page 24

SELECTING A LANGUAGE

There are seven languages available in the 2020t/i: English, Spanish, French, Portuguese,

Italian, Chinese, and Japanese (Kana).

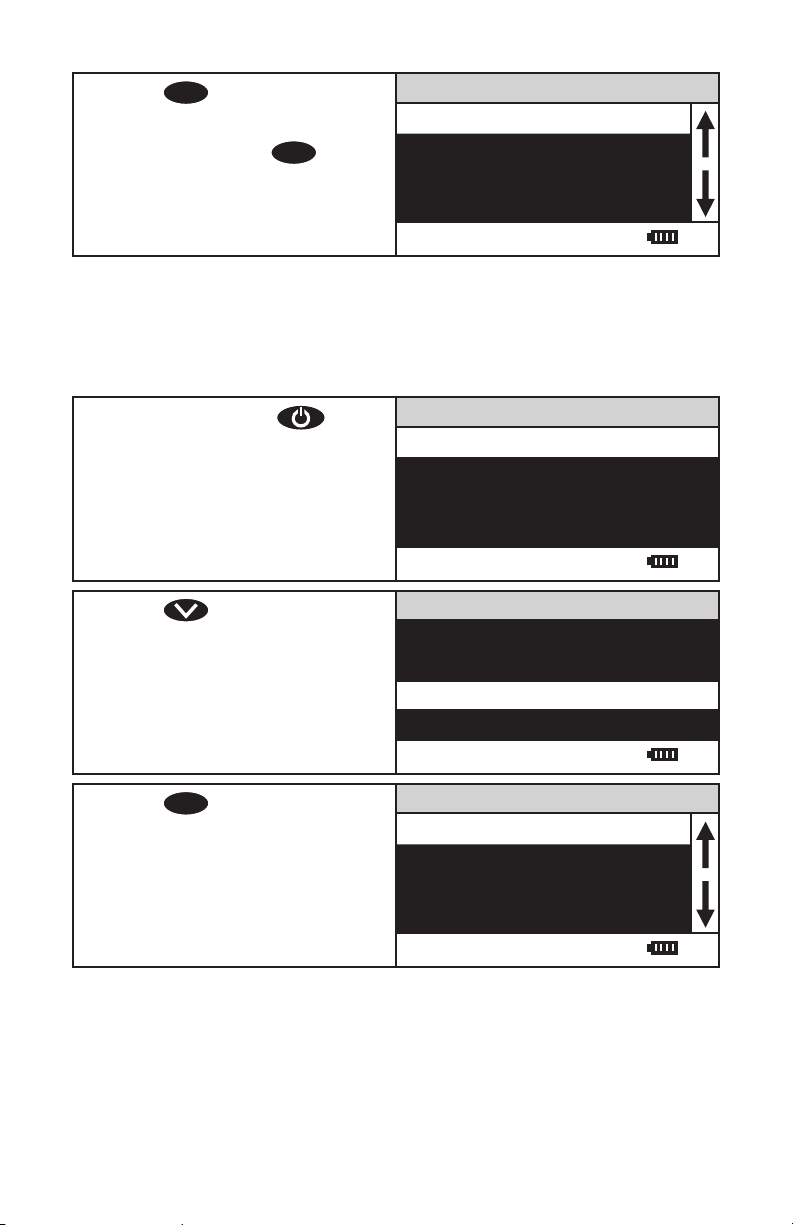

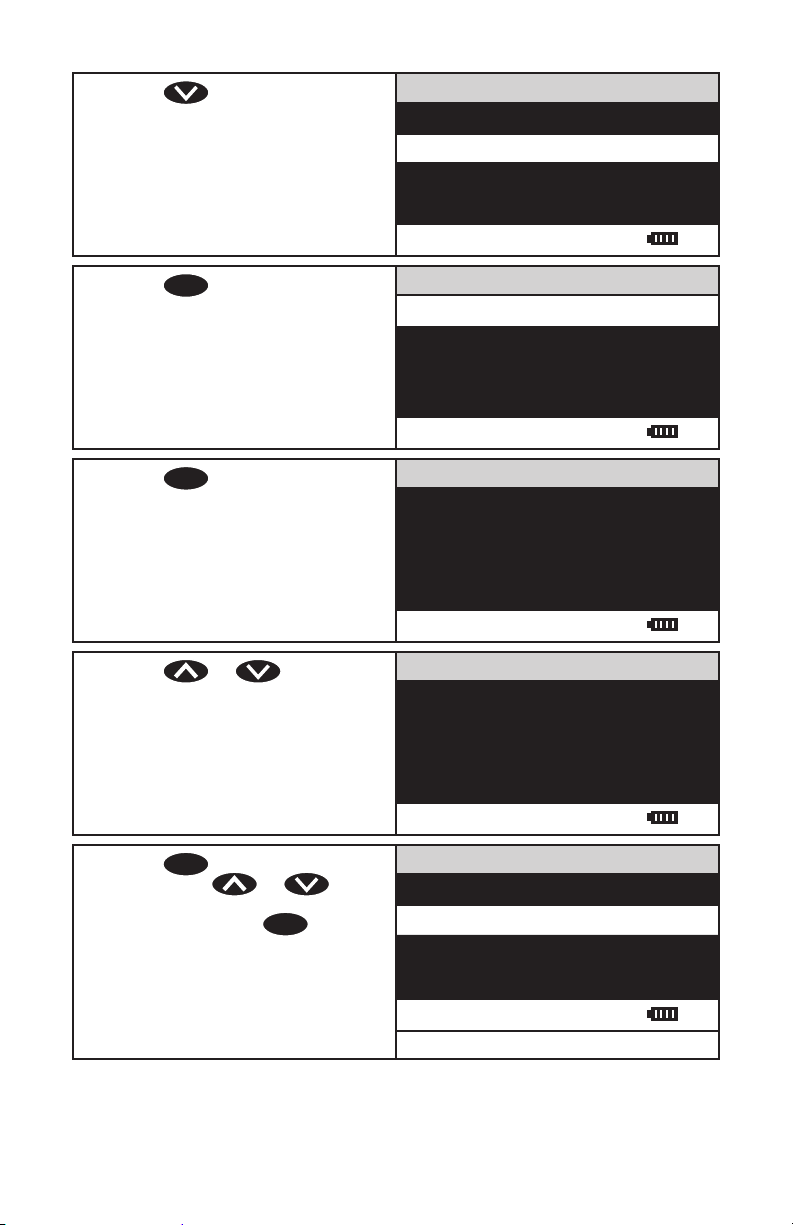

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

2. Press to scroll to Options.

3. Press

ENTER

to select Options.

4. Press to scroll to Select

Language.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Options Menu

Turbidity Options

Averaging

Set Clock

Set PWR Save

12:00:00 001/500

Options Menu

Set Clock

Set PWR Save

Set Backlight Time

Select Language

12:00:00 001/500

5. Press

Language.

ENTER

to select to Select

Select Language

English

Spanish

French

Portuguese

12:00:00 001/500

24

Page 25

6. Press or to scroll to

desired language.

Select Language

English

Spanish

French

Portuguese

12:00:00 001/500

7. Press

ENTER

to select desired

language. The screen will

momentarily display, Storing...for

about 1 second and return to the

Options Menu.

Set Clock

Set PWR Save

Set Backlight Time

Options Menu

Select Language

12:00:00 001/500

NOTE: If the meter unintentionally switches to another language, use the procedure above

to reset the meter to the desired language. For example, to reset the meter to English:

1. Turn the meter on.

2. Press down arrow twice. Press

3. Press down arrow six times. Press

4. Press

ENTER

.

ENTER

.

ENTER

.

PC LINK

Run PC Link is used in the manufacturing of the meter. This menu is not for use by the

operator in the fi eld.

DATA LOGGING

The default setting for the data logger is enabled. The meter will log the last 500 data

points. The counter in the center bottom of the display will show how many data points

have been logged. The display will show 500+ when the data logger has exceeded 500

points and the data points are being overwritten.

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

25

Page 26

2. Press to scroll to Data

Logging.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

3. Press

4. Press

ENTER

to select Data Logging.

ENTER

to display the last data

point and the time that it was logged.

5. Press or to scroll

through the data points in the log.

6. Press

EXIT

menu. Press

to return to the Logging

or to

scroll to disable the logging options or

erase the log. Press

ENTER

to select

the option. The screen will display

Storing... for about 1 second and

return to the Logging Menu.

Logging

Display Test Log

Enable Logging

Disable Logging

Erase Log

12:00:00 001/500

Record Number 2

Turbidity - WB (N)

655 AU

12:26:58 PM 08-03-2018

12:00:00 001/500

Record Number 1

Turbidity - WB (R)

95.4 NTU

12:26:44 PM 08-03-2018

12:00:00 001/500

Logging

Display Test Log

Enable Logging

Disable Logging

Erase Log

12:00:00 001/500

26

Page 27

CALIBRATION & ANALYSIS

CALIBRATION

Turbidity Standards

Only use AMCO or formazin standards with the 2020t/i. StablCal® standards below 50 NTU

should not be used to calibrate the 2020t/i .The diluent used in the StablCal

has a diff erent refractive index than traditional formazin standards and will aff ect the

results. The concentration of the calibration standard should be similar to the expected

concentrations of samples that will be tested. The standard should never be poured from

the tube back into the bottle. The standards will not have the same turbidity value in all

three modes.

The following standards are available from LaMotte Company:

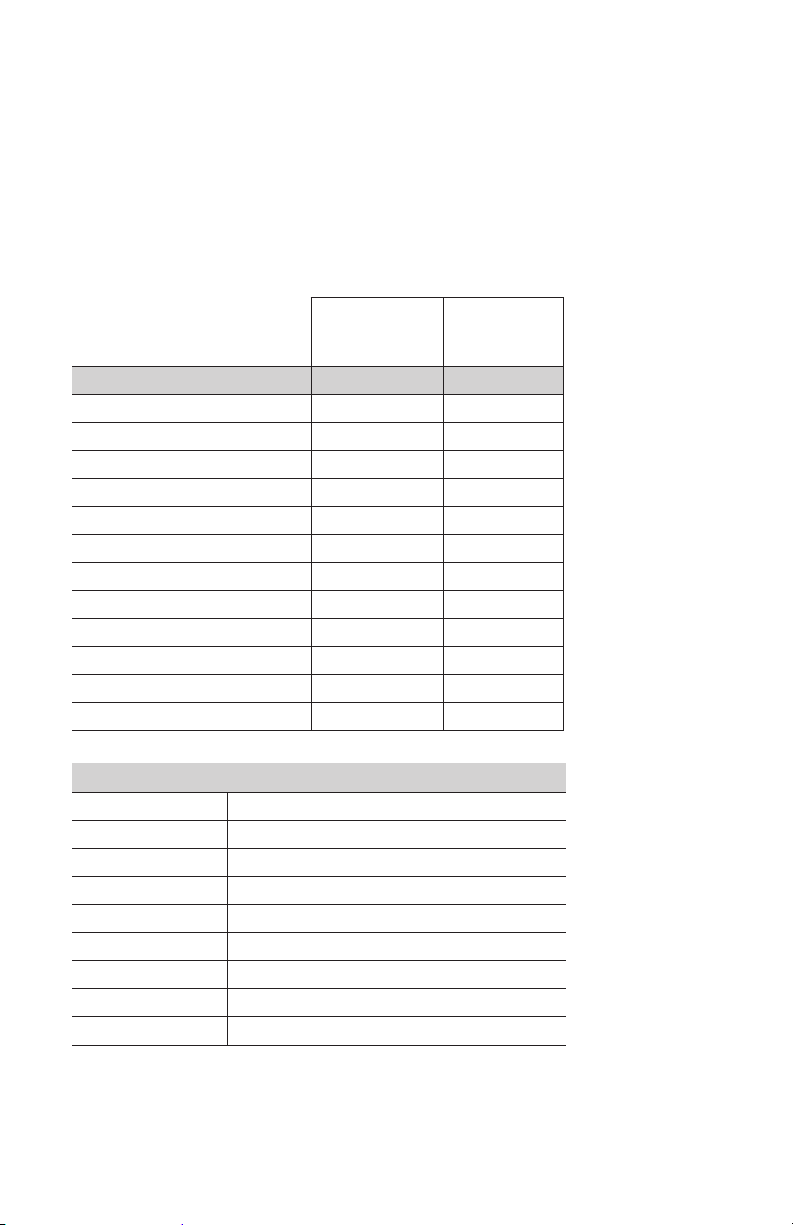

Mode Units Nephelometric (N) Nephelometric (N) Ratiometric (R) Ratiometric (R)

Meter

Code 1480 0 NTU 0 FNU 0 NTRU 0 FNRU

Code 1441 1 NTU - 1 NTRU Code 1446 - 1 FNU - 1 FNRU

Code 1442 10 NTU - 10 NTRU

Code 1447 - 10 FNU - 10 FNRU

Code 1444 - 100 FNU - 100 FNRU

Standards may vary slightly from lot to lot for the ratiometric mode. Standard values for

the nephelometric mode and ratiometric mode are located on the standard bottle label.

Use the value on the turbidity standard bottle label as the target value when calibrating

the meter in the nephelometric mode and the ratiometric mode. Standards for calibration

in the attenuation mode should be prepared from Formazin.

2020t 2020i 2020t 2020i

Tubes

Use turbidity tubes (0260) that are free of scratches and imperfections in the light zone

between the bottom of the tube and the fi ll line. Discard scratched tubes. When reading

very low turbidity samples, do not use tubes or caps that have been used previously with

high turbidity samples. See page 38 for additional information.

Turbidity Calibration Procedure

The default calibration curve is nephelometric as indicated by (N) in the Menu bar. The

default units are NTU (2020t) and FNU (2020i). Other calibration curve options are

ratiometric and attenuation. The ratiometric calibration curve is indicated by (R) and the

attenuation calibration curve is indicated by (A). A user calibration should be performed for

each mode with standards that are appropriate for the meter and range.

For the most accurate results, a user calibration should be performed over the smallest

range possible. Use a calibration standard that, along with the blank, brackets the range

of the samples that will be tested. For example, if the samples that are to be tested are

expected to be below 1 NTU, more accurate results will be obtained by calibration with a

blank and a 1 NTU standard as opposed to a blank and a 10 NTU standard.

The number of measuring ranges for each mode varies.

®

standards

CALIBRATION

27

Page 28

Mode Nephelometric (N) Ratiometric (R) Attenuation (A)

Ranges 0-11 NTU/FNU

10-110 NTU/FNU

0-11 NTRU/FNRU

10-110 NTRU/FNRU

100-510 NTRU/FNRU

500-1000 NTRU/FNRU

0-1010 AU/FAU

1000-2000 AU/FAU

Each range can be calibrated with one point per range plus a blank. New calibration points

will replace old calibration points independently for each range. If one range is recalibrated,

CALIBRATION

the meter will retain the old calibration data for the other ranges. It is recommended that

the meter be calibrated for each range that will be used. The value of the standards chosen

for the calibration should not be at the extremes of the ranges. The meter is auto-ranging

and will automatically select the appropriate range for the sample being tested.

It is recommended that the meter be calibrated daily.

A 2020t in the nephelometric mode with NTU standards will be used in the following

examples.

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

2. Press

ENTER

to select Measure.

3. Press to scroll to Turbidity -

With Blank.

4. Press

ENTER

to select Turbidity -

With Blank.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Measure Menu (N)

Turbidity - No Blank

Turbidity - With Blank

12:00:00 001/500

Measure Menu (N)

Turbidity - No Blank

Turbidity - With Blank

12:00:00 001/500

Turbidity WB (N)

Scan Blank

Scan Sample

12:00:00 001/500

28

Page 29

5. Rinse a clean tube (0260) three

times with the blank. If samples are

expected to read below 1 NTU the

meter should be blanked with a 0

NTU Primary Standard or prepared

turbidity-free (<0.1 NTU) water. For

the most accurate results, use the

same tube for the blank and the

sample.

6. Fill the tube to the fi ll line with the

blank. Pour the blank down the inside

of the tube to avoid creating bubbles.

Cap the tube.

7. Wipe the tube thoroughly with a lintfree cloth.

8. Open the meter lid. Insert the tube

into the chamber. Align the index line

on the tube with the index arrow on

the meter. Close the lid.

CALIBRATION

9. Press

ENTER

to select Scan Blank

and scan the blank. The screen

will display Blank Done for about

1 second and then return to the

Turbidity - With Blank Menu.

10. Rinse a clean tube (0260), or the

same tube, three times with the

turbidity standard.

Turbidity WB (N)

Scan Blank

Scan Sample

12:00:00 001/500

29

Page 30

11. Fill the tube to the fi ll line with the

turbidity standard. Pour the standard

down the inside of the tube to avoid

creating bubbles. Cap the tube.

CALIBRATION

12. Wipe the tube thoroughly with a lintfree cloth.

13. Open the meter lid. Insert the tube

into the chamber. Align the index line

on the tube with the index arrow on

the meter. Close the lid.

14. Press

15. Press to scroll to Calibrate.

ENTER

and scan the standard. The screen

will display Reading for about 1

second. The result will appear on the

screen.

“Overrange” will be displayed if

the reading is out of range. Dilute

the sample or select a mode that

is appropriate for the range of the

sample.

to select Scan Sample

Turbidity WB (N)

0.99 NTU

Scan Blank

Scan Sample

12:00:00 001/500

Turbidity WB

0.99 NTU

Scan Sample

Calibrate

12:00:00 001/500

30

Page 31

16. Press

ENTER

A reverse font (light background

with dark characters) will appear

to indicate that the reading can be

adjusted.

to select Calibrate.

Turbidity WB

CALIBRATION

0.99 NTU

Scan Sample

Calibrate

12:00:00 001/500

17. Press or to scroll to

the concentration of the standard,

1.00 in the example. Use the value

on the turbidity standard bottle label

as the target. Note: The allowable

adjustment is ±25%. If the allowable

adjustment limit is reached,

“overrange” wil be displayed.

18. Press

19. Press

ENTER

menu choices will be off ered, Set

Calibration and Factory Setting.

and save the calibration. Press

Factory Setting to revert to the

factory calibration. The meter will

momentarily display Storing... and

return to the Turbidity-Without Blank

menu. The calibration has now been

saved and the meter can be used for

testing. The standard should never be

poured from the tube back into the

bottle.

to select Calibrate. Two

ENTER

to select Set Calibration

or to scroll and select

Turbidity WB (N)

1.00 NTU

Scan Sample

Calibrate

12:00:00 001/500

Calibrate Menu (N)

1.00 NTU

Set Calibration

Factory Setting

12:00:00 001/500

Turbidity WB

Scan Blank

Scan Sample

12:00:00 001/500

NOTE: For the greatest accuracy during the calibration procedure, be sure that after the

meter is blanked and the blank is scanned as a sample, the reading is 0.00. If not, reblank

the meter and scan the blank again until it reads 0.00. When scanning the calibration

standards as the sample, scan the calibration standard three times removing the tube

from the chamber after each scan and reinserting the tube in the chamber with the same

orientation. The readings should be consistent. Use the last consistent reading to calibrate

the meter. If the readings are not consistent, avoid using an aberrant reading to calibrate

the meter.

31

Page 32

ANALYSIS WITHOUT BLANKING PROCEDURE

To obtain the most accurate results the meter should be blanked before measuring a

sample. The blanking step is not as critical for samples above 10 NTU. The meter should

always be blanked before reading samples below 10 NTU.

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

2. Press

ENTER

to select Measure.

ANALYSIS WITHOUT BLANKING PROCEDURE

3. Press

ENTER

to select Turbidity - No

Blank.

4. Rinse a clean tube (0260) three times

with the sample.

Main Menu

Measure

Data Logging

Options

12:00:00 001/500

Measure Menu (N)

Turbidity - No Blank

Turbidity - With Blank

12:00:00 001/500

Turbidity NB (N)

Scan Blank

Scan Sample

12:00:00 001/500

5. Fill the tube to the fi ll line with the

sample. Pour the sample down the

inside of the tube to avoid creating

bubbles. Cap the tube.

32

Page 33

6. Wipe the tube thoroughly with a lintfree cloth.

7. Open the meter lid. Insert the tube

into the chamber. Align the index line

on the tube with the index arrow on

the meter. Close the lid.

ANALYSIS WITHOUT BLANKING PROCEDURE ANALYSIS WITH BLANKING PROCEDURE

8. Press

ENTER

and scan the sample. The screen will

display Reading for about 1 second.

The result will appear on the screen.

to select Scan Sample

10.22 NTU

Scan Blank

Scan Sample

12:00:00 001/500

Turbidity NB (N)

ANALYSIS WITH BLANKING PROCEDURE

To obtain the most accurate results the meter should be blanked before measuring a

sample. The blanking step is not as critical for samples above 10 NTU. The meter should

always be blanked before reading samples below 10 NTU.

1. Press and briefl y hold to

turn the meter on. The LaMotte

logo screen will appear for about

3 seconds and the Main Menu will

appear.

2. Press

ENTER

to select Measure.

Measure

Data Logging

Options

12:00:00 001/500

Turbidity - No Blank

Turbidity - With Blank

Main Menu

Measure Menu (N)

12:00:00 001/500

33

Page 34

3. Press to scroll to Turbidity -

With Blank.

Measure Menu (N)

Turbidity - No Blank

Turbidity - With Blank

4. Press

ENTER

to select Turbidity -

With Blank.

ANALYSIS WITH BLANKING PROCEDURE

5. Rinse a clean tube (0260) three

times with the blank. If samples are

expected to read below 1 NTU the

meter should be blanked with a 0

NTU Primary Standard or prepared

turbidity-free (<0.1 NTU) water. For

the most accurate results, use the

same tube for the blank and the

sample.

6. Fill the tube to the fi ll line with the

blank. Pour the blank down the inside

of the tube to avoid creating bubbles.

Cap the tube.

7. Wipe the tube thoroughly with a lintfree cloth.

Turbidity WB (N)

Scan Blank

Scan Sample

12:00:00 001/500

34

Page 35

8. Open the meter lid. Insert the tube

into the chamber. Align the index line

on the tube with the index arrow on

the meter. Close the lid.

ANALYSIS WITH BLANKING PROCEDURE

9. Press

ENTER

to select Scan Blank

and scan the blank. The screen

will display Blank Done for about

1 second and then return to the

Turbidity - With Blank menu.

10. Rinse a clean tube (0260), or the

same tube, three times with the

sample.

11. Fill the tube to the fi ll line with the

sample. Pour the standard down the

inside of the tube to avoid creating

bubbles. Cap the tube.

12. Wipe the tube thoroughly with a lintfree cloth.

Turbidity WB (N)

Scan Blank

Scan Sample

12:00:00 001/500

13. Open the meter lid. Insert the tube

into the chamber. Align the index line

on the tube with the index arrow on

the meter. Close the lid.

35

Page 36

14. Press

NOTE: The meter will remember the last scanned blank reading. It is not necessary to scan

a blank each time the test is performed. To use the previous blank reading, instead of

scanning a new one, scroll to Scan Sample and proceed. For the most accurate results, the

meter should be blanked before each test and the same tube should be used for the blank

and the reacted sample.

DILUTION PROCEDURES

ANALYSIS WITH BLANKING PROCEDURE

If a sample is encountered that is more than 2000 NTU or FNU, a careful dilution with

0 NTU/FNU or very low turbidity water will bring the sample into an acceptable range.

However, there is no guarantee that halving the concentration will exactly halve the NTU or

FNU value. Particulates often react in an unpredictable manner when diluted.

Turbidity-Free Water

The defi nition of low turbidity and turbidity-free water has changed as fi lter technology

has changed and nephelometric instruments have become more sensitive. At one time

turbidity-free water was defi ned as water that had passed through a 0.6 micron fi lter.

Now 0.1 micron fi lters are available and higher purity water is possible. Water that has

been passed through a 0.1 micron fi lter could be considered particle free and therefore

turbidity free, 0 NTU water. Turbidity is caused by scattered light. Therefore, low turbidity

water is water without any particles that scatter a measurable amount of light. But water

that passed through a 0.1 micron fi lter may still have detectable light scatter with modern

instruments. This light scattering can be the result of dissolved molecules or sub-micron

sized particles that can not be fi ltered out of the water. Because there may still be a small

amount of scattered light from dissolved molecules, high purity water is often called low

turbidity water and assigned a value of 0.01 or 0.02 NTU. However, because this water is

used as a baseline to compare to sample water, the diff erence between the sample and the

low turbidity or turbidity-free water will be the same whether it is called 0.00 NTU or 0.02

NTU. For design simplicity the 2020t/i uses the term turbidity-free water and the value of

0.00 NTU.

ENTER

and scan the sample. The screen will

display Reading for about 1 second.

The result will appear on the screen.

“Overrange” will be displayed if

the reading is out of range. Dilute

the sample or select a mode that

is appropriate for the range of the

sample.

to select Scan Sample

0.99 NTU

Scan Blank

Scan Sample

12:00:00 001/500

Turbidity WB (N)

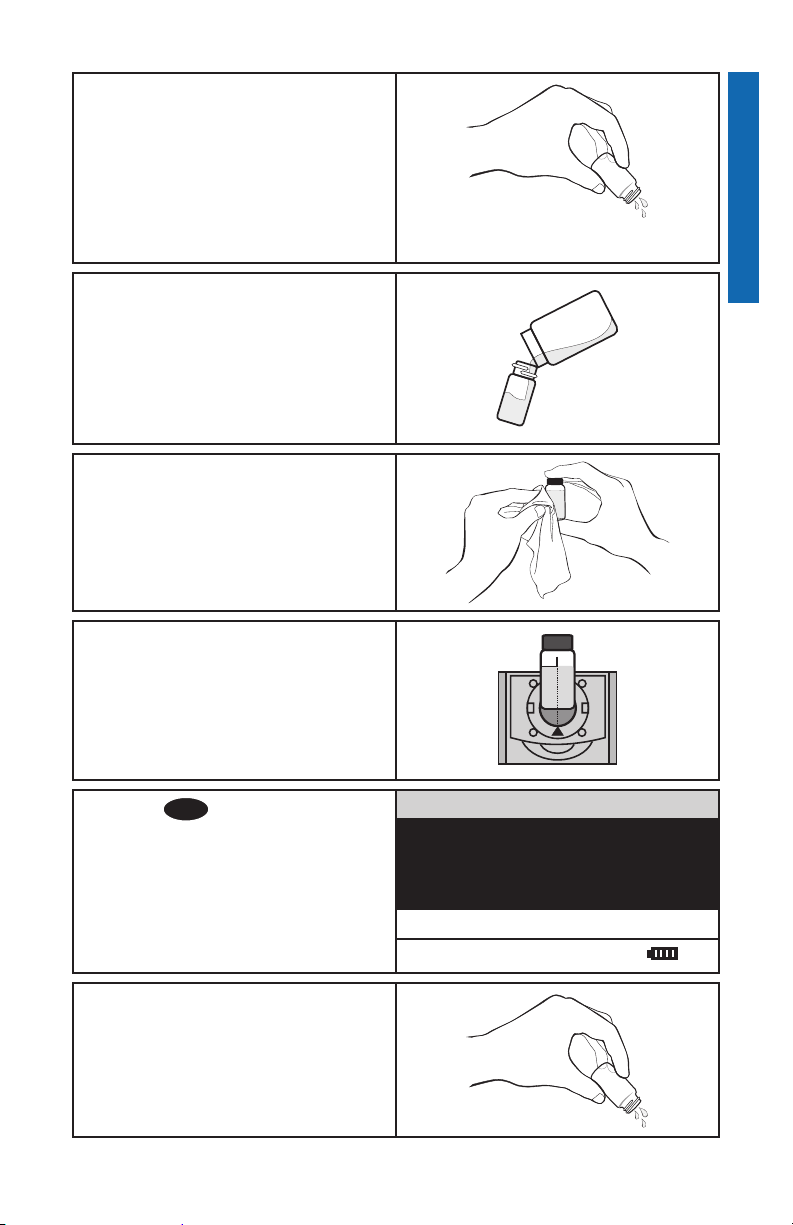

PREPARATION OF TURBIDITY-FREE WATER

A 0 NTU/FNU Standard (Code 1480) is included with the meter. Accessories are available

for preparing turbidity-free water for blanking the meter and dilution of high turbidity

samples.

The preparation of turbidity-free water requires careful technique. Introduction of

foreign matter will aff ect the turbidity reading. A fi ltering device with a special membrane

fi lter is used to prepare turbidity-free water. The fi lter, fi lter holder and syringe must be

conditioned by forcing at least two syringes full of deionized water through the fi ltering

apparatus to remove foreign matter. The fi rst and second rinses should be discarded.

Turbidity-free water as prepared with the following procedure may be stored in the dark

at room temperature in a clean glass bottle with a screw cap and used as required. The

storage container should be rinsed thoroughly with fi ltered deionized water before fi lling.

The water should be periodically inspected for foreign matter in bright light.

36

Page 37

1. Remove the plunger from the syringe

(0943). Attach a fi lter (2-2097) to the

bottom of the syringe.

2. Pour approximately 50 mL of

deionized water into the barrel of

the syringe. Insert the plunger. Exert

pressure on the plunger to slowly

force the water through the fi lter.

Collect water in the clean storage

container. Rinse walls of the container

then discard this rinse water.

3. Remove the fi lter from the syringe.

Remove the plunger from the barrel.

(This step is required to prevent

rupturing the fi lter by the vacuum

that would be created when the

plunger is removed.)

4. Replace the fi lter and repeat step 2

for a second rinse of the syringe and

storage container.

5. Remove the fi lter from the syringe.

Remove the plunger from the

barrel. Replace the fi lter and fi ll the

syringe with approximately 50 mL of

deionized water. Filter the water into

the storage container and save this

turbidity-free water.

37

Page 38

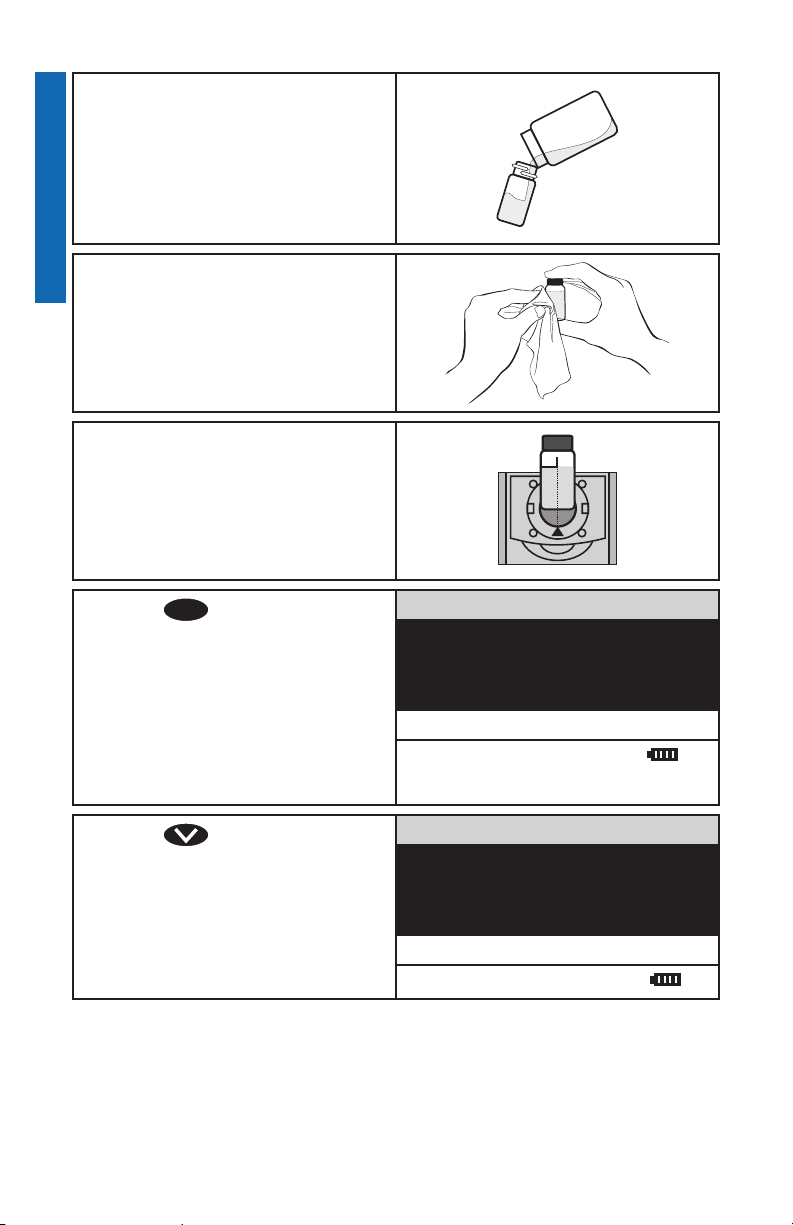

6. Repeat Step 5 until the desired

amount of turbidity-free water has

been collected.

TESTING TIPS

1. Samples should be collected in a clean glass or polyethylene container.

2. Samples should be analyzed as soon as possible after collection.

3. Gently mix sample by inverting before taking a reading but avoid introducing air

bubbles.

4. For the most precise results, follow the recommended procedure for wiping a fi lled

tube before placing it in the meter chamber. Invert tube very slowly and gently three

times to mix the sample. Surround the tube with a clean, lint-free cloth. Press the

cloth around the tube. Rotate the tube in the cloth three times to assure that all areas

of the tube have been wiped. Place tubes in the chamber with the same orientation

each time.

5. Discard tubes that have signifi cant scratches and imperfections in the light pass

zones. (Central zone between bottom and fi ll line).

6. When reading very low turbidity samples, do not use tubes or caps that have been

used previously with high turbidity samples.

7. Use the averaging option for low level measurements of turbidity.

8. The meter should be placed on a surface that is free from vibrations. Vibrations can

cause high readings.

9. Turbidity readings will be aff ected by electric fi elds around motors.

10. Carbon in the sample will absorb light and cause low readings.

11. Excessive color in a sample will absorb light and cause low readings. The user should

verify if a certain level of color will cause a signifi cant error at the level of turbidity

being tested. Use of the Ratiometric calibration curve is recommended for highly

colored samples.

12. Observe shelf life recommendations for turbidity standards.

13. Do not use silicone oil on tubes when testing turbidity with the

2020t/i.

14. When testing at low concentrations use the same tube for the blank and the sample.

15. Always insert tube into the meter chamber with the same amount of pressure and to

the same depth.

16. Occasionally clean the chamber with a damp lint-free wipe, followed by a Windex

dampened wipe. A clean chamber and tubes are essential for reliable results.

17. For the greatest accuracy during the calibration procedure, be sure that after the

meter is blanked and the blank is scanned as a sample, the reading is 0.00. If not,

reblank the meter and scan the blank again until it reads 0.00. When scanning the

calibration standards as the sample, scan the calibration standard three times

removing the tube from the chamber after each scan. The readings should be

®

38

Page 39

consistent. Use the last consistent reading to calibrate the meter. If the readings are

not consistent, avoid using an aberrant reading to calibrate the meter.

18. Calibrate the meter daily.

19. Calibrate the meter with a standard that is closest to the expected range of the

sample being tested. For example, if the sample is expected to be less than 1.0

NTU, calibrate with a 1.0 NTU standard and a blank (0 NTU standard). If the sample

is expected to be around 2 NTU also calibrate with the 1.0 NTU standard but if the

sample is expected to be around 8 NTU calibrate with a 10 NTU standard. If the

sample is expected to be over 30 – 40 NTU it is recommended that the meter be

calibrated with a 100 NTU standard.

20. To maintain a consistent lamp temperature, do not turn the meter on and off when

analyzing samples.

TROUBLESHOOTING GUIDE

TROUBLESHOOTING

PROBLEM REASON SOLUTION

“Blank?” Sample is reading lower

Flashing

“Low Battery” Battery voltage is very low.

“Shut Down Low Batt”

Shut Down

“Over range” Sample is outside of

than the blank.

Low battery. Readings are

reliable.

Readings are not reliable.

Battery is too low to

operate the unit.

acceptable range.

With samples of very low

concentration reblank or

record as zero. On samples of

higher concentration reblank

and read again.

Charge battery or use USB

wall/computer charger.

Charge battery or use USB

wall/computer charger.

Charge battery or use USB

wall/computer charger.

Dilute sample and test again.

“Error1” High readings with 90° and

Unusually large negative

or positive readings when

performing calibration

180° detectors.

Incorrect standards used to

calibrate meter.

Dilute sample by at least 50%

and retest.

Use fresh 0.0 standard in

clean tube. Recalibrate meter.

STRAY LIGHT

The accuracy of readings on the 2020t/i should not be aff ected by stray light. Make

sure that the sample compartment lid is always fully closed when taking readings. The

backlight will interfere with turbidity readings. The meter will temporarily disable the

backlight while turbidity measurements are being taken.

39

Page 40

GENERAL OPERATING INFORMATION

OVERVIEW

The 2020t/i is a portable, microprocessor controlled, direct reading nephelometer. Turbidity

is measured directly according to EPA Method 180.1 or ISO Method 7027, or is calculated

ratiometrically by using a combination of the two measurements. It has a graphical liquid

crystal display and six button keypad. These allow the user to select options from the menu

driven software, to directly read test results or to review stored results of previous tests in

the data logger. The menus can be displayed in seven diff erent languages.

The 2020t/i uses a state of the art, multi-detector optical confi guration that assures long

term stability of calibrations, high precision and accuracy and low detection limits. All

readings are determined by digital signal processing algorithms, minimizing fl uctuations

in readings and enabling rapid, repeatable measurements. The microprocessor and optics

enable a dynamic range and auto-ranging over several ranges. Energy effi cient LED light

sources are used for ISO turbidity. EPA turbidity uses a tungsten fi lament light source that

meets or exceeds EPA specifi cations and is designed for a uniform light spot image and

stable output.

A USB wall adapter, USB computer connection or lithium battery powers the 2020t/i.

GENERAL OPERATING INFORMATION

The operation of the 2020t/i is controlled by the menu driven software and user interface. A

menu is a list of choices. This allows a selection of various tasks for the 2020t/i to perform,

such as, scan blank and scan sample. The keypad is used to make menu selections that are

viewed on the display.

THE KEYPAD

This button will scroll up through a list of menu selections.

ENTER

The button is used to select choices in a menu viewed in the display.

This button controls the backlight on the display.

This button will scroll down through a list of menu selections.

EXIT

This button exits to the previous menu.

This button turns the meter on or off .

ENTER

EXIT

THE DISPLAY & MENUS

The display allows menu selections to be viewed and selected. These selections

instruct the 2020t/i to perform specifi c tasks. The menus are viewed in the display

using two general formats that are followed from one menu to the next. Each menu

is a list of choices or selections.

40

Page 41