Page 1

2020 ClearTrace

In-line Turbidity System

Code 5-0113-24V

Code 5-0113-110V

Page 2

Page 3

Preface

This instruction manual serves to explain the use of the LaMotte 2020 ClearTrace

Inline Turbidity System and is written to cover as many applications as possible.

Please do not hesitate to contact LaMotte or an authorized LaMotte representative

with questions or concerns.

The information presented in this instruction manual is subject to change without

notice as improvements are made, and does not represent any commitment

whatsoever on the part of LaMotte.

LaMotte cannot accept any responsibility for damage or malfunction of the sensor

due to improper use.

Contact Information

Mail: LaMotte Company • PO Box 329 • Chestertown, MD 21620

Phone: 800-344-3100 • 410-778-3100

Fax: 410-778-6394

Email: csr@lamotte.com

Website: www.lamotte.com

2

Page 4

Safety Information

The LaMotte 2020 ClearTrace Turbidity System shall

be installed and operated only in the manner specified.

Only a skilled, trained or authorized person should

carry out installation, setup and operation of the

system.

Before using the system, make sure that is connected as

specified. Failure to do so may result in permanent

damage to the system of its components.

Protection against electric shock will be achieved only

by observance of the corresponding installation rules.

3

Page 5

Table of Contents

Preface ................................. 2

Contact Information ..........................2

Safety Information ........................... 3

1. Introduction ............................5

1.1 General Information .......................5

1.2 Intended Use ...........................6

1.3 Safety Instructions ........................ 6

1.4 Removal from Service/Correct Disposal .............6

2. Product Description ........................ 7

2.1 Drinking Water Turbidity ....................7

2.2 Calibration Kits .......................... 7

2.3 Replacement Parts ........................ 8

3. Mounting, Wiring, and Plumbing ................. 9

3.1 Mounting ............................. 9

3.2 Plumbing............................. 10

3.3 Valve Position for Operation ..................10

3.4 Wiring For 24 VDC and 110VAC Power ............11

3.5 Sample Chamber Details .................... 14

4. Measure Screen Overview .................... 15

5. Menu Structure.......................... 16

6. Calibration ............................ 19

6.1 Span Calibration ........................ 19

6.2 Zero Calibration ......................... 22

6.3 Temperature Calibration ....................24

7. Configuration ...........................26

8. DataStick Comms Menu .....................27

9. Analog Output(s)......................... 27

11. Help Menu ............................30

12. Reset AV 38 ........................... 31

13. Performance Specifications ................... 31

14. Limited Warranty ........................33

4

Page 6

1. INTRODUCTION

1.1. General Information

Thank you for purchasing the LaMotte 2020 ClearTrace Inline Turbidity

System.

The product is designed for continuous use in industrial process

applications and complies with safety regulations currently in force.

Improper use could lead to hazards for the user or a third-party, and/or

adverse effects to the plant or other equipment.

LaMotte does not accept any liability for damage that may arise if

information in this manual is not followed. Therefore, the operating

instructions and specifications must be read and understood by all persons

involved in installation and operation of this equipment.

This manual identifies safety instructions and additional information by

means of the following symbols:

This symbol draws attention to safety

instructions and warnings of potential

danger, which if neglected, could result in

injury to persons and/or damage to property.

This symbol identifies additional

information and instructions, which if

neglected, could lead to inefficient

operation and possible loss of production.

It is recommended that this manual be made accessible to everyone who

may need it as a reference.

Please contact LaMotte or an authorized LaMotte representative with any

questions.

5

Page 7

1.2. Intended use

The LaMotte 2020 ClearTrace Inline Turbidity System is used for

continuous monitoring of low-range turbidity in drinking water

applications. The system also measures water temperature.

Data is reported through a local display and a scalable 4-20 milliamp

current output.

Any other use, or use not mentioned here, that is incompatible with the

technical specifications is deemed inappropriate. The operator is solely

responsible for any damage arising from such use.

Other prerequisites for appropriate use include:

Observing the instructions, notes and requirements set out in this

•

instruction manual.

Observing all local safety regulations.

•

Observing all warnings and cautions in the documentation regarding

•

all products used in this measurement system, including the sensor,

mounting hardware, AV38 electronics and cabling.

Observing the prescribed environmental and operational conditions.

•

Observing chemical compatibility with all wetted materials.

•

1.3. Safety Instructions

The Turbidity System should be installed and operated

only by personnel familiar with the sensor and qualified for

such work.

A defective Turbidity System should be returned to

LaMotte for repair or replacement. Contact LaMotte to

obtain a Return Material Authorization (RMA) number.

No modifications to the Turbidity System are allowed. The

manufacturer/supplier accepts no responsibility for damage

caused by unauthorized modifications. The risk is borne

entirely by the user.

1.4. Removal from Service / Correct Disposal of the

Turbidity System

Removal from Service

•

Disconnect the cable wiring from the controller terminal block.

•

Remove the Turbidity System from the mounting hardware.

Correct Disposal of Unit

•

When the Turbidity System is taken out of service, observe the local

environmental regulations for correct disposal.

6

Page 8

2. PRODUCT DESCRIPTION

2.1 Drinking Water Turbidity

The LaMotte 2020 ClearTrace Inline Turbidity System continuously

monitors low-range turbidity and temperature in drinking water

applications.

In the standard system configuration, data is reported through a local

display and a scalable4–20milliamp current output. All functions can be

accessed through a digital network with or without the local display

interface.

The Turbidity System uses a pre-calibrated turbidity probe mounted in a

DataStick and attached to a sample chamber specifically designed to

prepare water for low-range turbidity measurements. The chamber removes

bubbles from the water sample so that solid particles can be accurately

detected. Because the chamber volume is only 135 milliliters, only a small

amount of a turbidity standard is necessary to perform EPA mandated

calibrations.

A white light source in the chamber lid illuminates suspended particles

with a collimated white light. The chamber lamp will provide collimated

white light for up to two years and is easily changed from the top of the

system.

Measurement data from the turbidity probe is communicated through the

DataStick communication adapter for direct computer communications.

2.2 Calibration Kits

Calibration kits containing calibration standards and accessories are

available for use with the 2020 ClearTrace.

Code 5-0114

1 liter 0.0 NTU, calibration standard

1 liter 20.0 NTU, calibration standard

2 squirt bottles, for standards

2 cleaning swabs

Code 5-0115

1 gallon 0.0 NTU, calibration standard

1 gallon 20 NTU, calibration standard

2 spigots, for dispensing standards

2 squirt bottles, for standards

2 cleaning swabs

7

Page 9

2.3 Replacement Parts

Code 5-0124 Bulb and cable assembly

Code 5-0125 Sample chamber lid, without bulb

Code 5-0126 Replacement sample chamber

Code 5-0127 DataStick

Code 5-0126 Turbidity Probe

Code 5-0116 Turbidity standard, 0.0 NTU, 1 liter

Code 5-0117 Turbidity standard, 0.0 NTU, 1 gallon

Code 5-0118 Turbidity standard, 1.0 NTU, 1 liter

Code 5-0119 Turbidity standard, 1.0 NTU, 1 gallon

Code 5-0120 Turbidity standard, 10.0 NTU, 1 liter

Code 5-0121 Turbidity standard, 10.0 NTU, 1 gallon

Code 5-0122 Turbidity standard, 20.0 NTU, 1 liter

Code 5-0123 Turbidity standard, 20.0 NTU, 1 gallon

8

Page 10

3. MOUNTING, WIRING AND PLUMBING

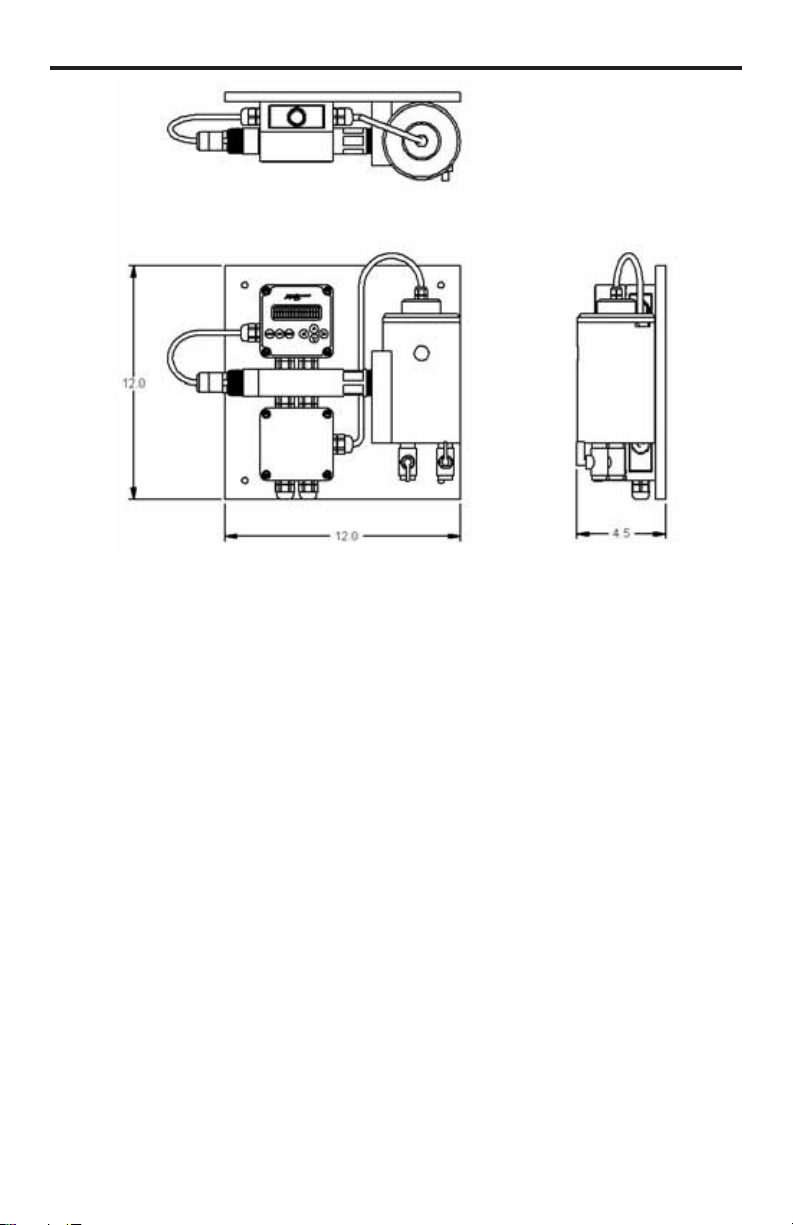

Figure 3.1: Wall mounting Clearances

3.1 Mounting

The 2020 ClearTrace Turbidity System is mounted on a 12 inch x 12 inch

panel with four ¼ inch mounting holes. Use ¼ inch bolts with washers to

mount the panel to a wall. Make sure the sample chamber is level and

plumb to insure proper water levels are maintained in the sample chamber.

It is important to note that the system must be fixed securely to the wall to

insure the chamber does not move when handled or touched.

Mounting tools and equipment:

•

½ inch Drill with drill bit for appropriate wall anchor.

•

Four ¼ diameter bolts – 1.5 inches long.

•

Four ¼ inch ID flat washers

•

Wrench to turn bolts

•

Level to insure the system is level when mounted

General Mounting Instructions:

1. Place the 12x12 inch panel on the wall where it is to be mounted and

mark the placement of the upper left hole.

2. Drill a mounting hole for the upper left corner with a masonry drill

bit.

3. Mount the Turbidity System with the upper left bolt.

4. Using a level, rotate the system until level, then mark the other three

mounting holes.

9

Page 11

5. Rotate the Turbidity System out of the way and drill the other three

Measure

• Inlet valve open

• Drain valve closed

Water goes in the

INLET and out the

OUTLET. The sample

chamber should be full

Drain Sample Chamber

• Inlet valve closed

• Drain valve open

Drain sample chamber

and wipe clean prior

to calibration.

Calibration

• Inlet valve closed

• Drain valve open

When sample chamber

is empty and clean, pour

in 20 NTU standard until

it overflows to the

OUTLET (approx.

135 mL).

mounting holes.

6. Place all four bolts with washers and tighten. Use shims if necessary

to insure the sample chamber is level.

3.2 Plumbing

The Turbidity System has an INLET, an OUTLET and a DRAIN.

Barb fittings are provided for the INLET and OUTLET in the event that

3/8 inch ID tubing is used.

When piping is used instead of tubing, remove the barb fittings to install ¼

inch NPT threaded pipe for the INLET, OUTLET and DRAIN.

OUTLET and DRAIN Plumbing Recommendations: Use straight ¼ inch

NPT threaded pipe that extends to a vented drain. Pipe restrictions that

result in back pressure for OUTLET and DRAIN are not allowed.

INLET Plumbing Recommendations: Use 3/8 ID tube or ¼ inch NPT

threaded pipe from sample source.

Flow rate must be between 250 to 750 ml/min (4 to 12 gph). If the source

is under pressure, use an appropriate flow or pressure valve to obtain

consistent flow. The turbidity sample chamber has an overflow weir that

must not be restricted.

3.3 Valve Position for Operation

10

Page 12

3.4 Wiring For 24 VDC and 110 VAC Power

T urbidity User

Junction Box

Lamp assembly

screws into sample

chamber lid

Lamp cable connection

Terminal Connection to AV38

USER Terminal Connections:

See next page for wiring tables

24 VDC

or

110 VAC

Lamp

24 VDC or 110 VAC

Access to all User wiring is through the ¼ DIN junction box in the lower

left on the mounting panel.

The standard on-line turbidimeter requires 24 VDC for power and typically

draws 270 mA (6.5 watts) or optionally requires 100-240 VAC at 50/60 Hz

for power and typically draws up to 250 mA (10 watts).

Pg11 and Pg16 punch out conduit holes are provided for user terminal

connections. We supply Pg11 cord grips that can be removed.

Note: Loop 2 and Relay options are not currently available on 2020

ClearTrace System.

11

Page 13

USER WIRING FOR: 1 Current Loop without Host Communications

100-240 VAC Power Cable Wiring:

1. 100-240 VAC, 50/60 Hz power is wired to the wider-spaced

strip on left side of terminals.

2. Typically Black wire to 'LINE', White wire to 'NEUTRAL',

and Green wire to 'EARTH'

Lamp cable connection.

Red wire to 'LAMP+'

Black wire to 'LAMP-'

Terminal Connections

to AV38; .

Red wire to '+24V' terminal

Black wire to 'GND'

24 VDC power

Terminal Wiring

1 24VDC or 110 VAC from Power Supply

2 Ground from Power Supply

3

4

5 Earth Ground from Power Supply

6 Current Loop 7 Current Loop +

8

9

10

11

12

Note: Current Loop Requires 24 VDC or 110 VAC supply.

USER WIRING FOR: 24 VDC or 110 VAC Power

AC-Powered Models:

The AC-powered ClearTrace Tubidimeter comes with a Junction Box below the two

terminal blocks when ordered with one or two 4-20 mA analog outputs and/or host

comminications. If relays are ordered, a third terminal block is present.

12

Page 14

USER WIRING FOR: Digital Communications to Host Computer with 2 Outputs

and Relay

Terminal Wiring

1 Red wire from Host Network (+24 VDC or 110 VAC)

2 BLACK wire from Host Network (Network Ground)

3 White wire from Host Network

4 Blue wire from Host Network

5 Shield wire from Host Network

6 OUTPUT 1 (-)

7 OUTPUT 1 (+)

8 OUTPUT 2 (-)

9 OUTPUT 2 (+)

10 Relay – Normally Open Terminal

11 Relay – Common Terminal

12 Relay – Normally Closed Terminal

Note: Output 2 and Relay options are not currently available on 2020

ClearTrace System.

13

Page 15

3.6 Sample Chamber Details

Exterior marker to

align lid with sample

chamber

Sample Chamber Lid with

integral lamp assembly

Alignment hole

The alignment peg

on the Sample Chamber

must line up with the

alignment hole in

the lid.

Alignment peg

Chamber Lid with Lamp

Chamber Body

Sample Chamber

with bubble trap

Sample Chamber

with Lid in Place

Keep aperture dry

Sample Chamber

Bubble Trap

DataStick*with

Optical Sensor

Head can be

removed and

replaced.

TM

Lamp Assembly

The lamp assembly

screws into the lid.

The cable is routed

to the user terminal

box.

Lamp with Cable

Chamber Lid

The sample chamber is designed for easy access and maintenance.

The chamber lid is lifted to gain access to the sample chamber. Set it on

top of the AV38 during chamber maintenance. When replacing the lid, it

should be aligned using the exterior alignment markers on the front edge of

the chamber and the lid.

*DataStick is a registered trademark of Thermo Fisher Scientific Inc. and

its subsidiaries.

14

Page 16

4. MEASURE SCREEN OVERVIEW

0.035 NTU AB

30.8 °C DS1: 6

MENU ESC ENTER

Figure 3.1: The elements of the measure screen

t

t

t

t

Figure 3.2: The measure screen when the Sensor

Head is absent.

Sensor Head

Absent

MENU ESC ENTER

t

t

t

t

Figure 3.3: The measure screen when the

DataStick is absent.

DataStick

Absent

MENU ESC ENTER

t

t

t

t

The AV38 user interface is

shown in Figure 3.1. It

consists of an LCD module

that contains two lines of 16

alphanumeric characters and

seven keys to navigate the

menu. The contrast of the

LCD module can be adjusted

by simultaneously pressing

the escape and up-arrow keys

(for more contrast) or the escape and down-arrow keys (for less contrast).

When the DataStick and

communications adapter are

connected to the AV38

display but the optical sensor

head is absent, the measure

screen indicates the fault as

shown in Figure 3.2.

When the DataStick or

communications adapter are

not connected to the AV38

display, the measure screen

indicates the fault as shown

in Figure 3.2.

15

Page 17

5. MENU STRUCTURE

Pressing the menu key while a measure screen is displayed accesses the

main menu. The items in the main menu are the same regardless of the

type of sensor head that is installed in the DataStick. Table 4.1 shows all

accessible functions including optional features.

Note: Not all optional features are currently available on 2020 ClearTrace

System.

Main Menu Option

Calibrate

(Station Number)

Configure

(Station Number)

DataStick Comms

Chlorine Configure

Hold Outputs

Analog Output 1

Analog Output 2 (option)

PID Controller

Relay A (option)

Relay B (option)

Help

Reset AV38

Exit

The main menu is navigated using the up/down arrows to display a desired

function. The (=) symbol is used to indicate main menu choices.

To select a menu choice, press the ENTER key when the desired choice is

displayed.

To return to the measure screen, press the ESC key.

Whenever there is a value to be entered or a choice to be made, the second

line of the display will be surrounded by parentheses (( )). The name of

the value being entered or choice being made will appear on the upper line

of the screen and be appended with a question mark (?) to indicate that the

user is to provide input. Figure 4.1 shows the list of standard menu choices

and optional menu choices in the context of the AV38 display

presentation.

Function

Sensor calibration choices are automatically available for

installed sensor head.

Enter the MENU from the measure display of interest –

station in lower right.

Configuration choices are automatically available for the

installed sensor head.

Enter the MENU from the measure display of interest –

station in lower right.

Not currently available

Not currently available

Holds the 4-20 mA and Relay outputs

Set 4 mA and 20 mA values. Calibrate and test the current

output with a meter.

Not currently available

Not currently available

Not currently available

Not currently available

Indicates AV38 software version

Resets AV38 configuration to default current output, relay

and PID settings.

Returns to the measure screen

16

Page 18

Main Menu

Calibrate

MENU ESC ENTER

Configure

DataStick Comms

Analog Output 1

Analog Output 2

Relay A

Relay B

Help

Reset AV38

Exit

Main Menu

Optional Features

t

t

t

t

t

ttttttt

t

Main Menu

Calibrate

MENU ESC ENTER

Configure

DataStick Comms

Analog Output

Help

Reset AV38

Exit

Main Menu

Standard

t

t

t

t

t

ttttt

t

Main Menu

Calibrate

MENU ESC ENTER

t

t

t

t

t

Main Menu

Configure

MENU ESC ENTER

t

t

t

t

t

Main Menu

DataStick Comms

MENU ESC ENTER

t

t

t

t

t

ESC

Figure 4.1: The main menu (standard and optional feature lists)

To illustrate navigation through the main menu the following sequence of

down arrow key presses is shown. The up arrow can always be used to scroll

up through the list.

A pressed key is identified by a gray background, e.g.,.

From the measure screen,

press MENU to display the

list of options. Generally,

Calibration will be the first

option. To select a

calibration function, press

ENTER. Press the down

arrow to scroll through the

list. Press ESC to return to

the measure screen.

Pressing the down arrow from

Calibration will display

Configure. To select

Configure functions, press

ENTER To continue scrolling

the list, press the down arrow.

Press ESC to return to the

measure screen.

Pressing the down arrow from

Configure will display

DataStick Comms. To select

DataStick Comms functions,

press ENTER. To continue

scrolling the list, press the

down arrow. Press ESC to

return to the measure screen.

Note: The DataStick Comms

option is not available on

2020 ClearTrace System.

17

Page 19

Pressing the down arrow from

Main Menu

Help

MENU ESC ENTER

t

t

t

t

t

Main Menu

Exit

MENU ESC ENTER

t

t

t

t

t

Main Menu

Reset AV38

MENU ESC ENTER

t

t

t

t

t

Main Menu

Analog Output

MENU ESC ENTER

t

t

t

t

t

DataStick Comms will display

Analog Output. To select

analog output functions, press

ENTER To continue scrolling

the list, press the down arrow.

Press ESC to return to the

measure screen.

Pressing the down arrow from

Analog Output will display

Help. To select Help

functions, press ENTER To

continue scrolling the list,

press the down arrow. Press

ESC to return to the measure

screen.

Pressing the down arrow from

Help will display Reset AV38.

To select Reset functions,

press ENTER To continue

scrolling the list, press the

down arrow. Press ESC to

return to the measure screen.

To return to the measure

screen press ENTER when in

the EXIT screen. Pressing

ESC from any screen will take

the user up one level. In this

example ESC will also take

the user to the measure

screen. Since this screen is at

the bottom of the main menu

list, the down arrow will not

work here. The up arrow can

be used to go back through

the list.

18

Page 20

6. CALIBRATION

Drain Chamber, Shut off Inlet

Drain and Inlet are shut off:

Ready to calibrate

Sample Chamber

with Lid Removed

Be careful to pour standard directly

into the SAMPLE CHAMBER.

Do not pour standard into the

Bubble trap.

During this operation, water will

remain int he BUBBLE TRAP and

it is not necessary to remove it.

Sample Chamber

Bubble Trap

Calibrate

1-Point Sample

MENU ESC ENTER

Zero

Temperature

Exit

t

t

t

t

t

tt

t

NOTE: The unit should be on for 30

minutes to allow the lamp to warm up

before begining calibrations or taking

measurements.

6.1. Span Calibration

To calibrate the span for the Turbidity

System:

1. Drain the sample chamber.

2. Shut off flow to the sample chamber.

3. Remove the chamber lid and place it

on top of the AV38.

4. Rinse the chamber with clean water and then with a small amount of

calibration solution. (See calibration kit instructions Code-5-0114 or

code 5-0015 for procedure.)

5. Shut off the Drain.

6. Fill the sample chamber with AMCO Clear Turbidity Standard, 20

NTU calibration solution. The standard should overflow the

OUTLET weir located about ¾ of the way to the top of the sample

chamber. As an alternative a formazin 20 NTU calibration standard

may be prepared from a stock solution of 4000 NTU formazin and

used within 24 hours. Refrigerate when stored.

7. After filling the sample chamber with the standard, wait for the

reading to settle (less than a minute depending on the filter setting).

8. Perform a 1-point

sample calibration as

shown in the following

menu tree.

The complete calibrate menu

for the turbidity and

suspended solids is shown.

Figure 5.15: The complete calibrate menu for turbidity

19

Page 21

From the measure screen,

41.32 NTU

Sensor ready?

MENU ESC ENTER

t

t

t

t

40.16 NTU

13.1 °C

MENU ESC ENTER

t

t

t

t

Main Menu

Calibrate

MENU ESC ENTER

t

t

t

t

t

Calibrate

1-Point Sample

MENU ESC ENTER

t

t

t

t

t

1-Point Sample?

( 20.00) NTU

MENU ESC ENTER

t

t

t

t

press MENU.

From the Main Menu, use the

up/down arrows to select

Calibrate. Then press

ENTER.

From the Calibrate Menu, use

the up/down arrows to select

1-Point Sample. Then press

ENTER.

The current sensor value is

dynamically displayed and

asks the user to be sure the

measurement is ready for

calibration before proceeding.

When ready, press the

ENTER key.

The calibration value can be

adjusted with the arrow keys.

Use the up/down arrows for

fine adjust and the left/right

arrows for course adjust.

After the calibration value is

adjusted to the desired value,

press the ENTER key.

NOTE: The display may

default to 40 MTU. Adjust to

20.00 NTU.

20

Page 22

One the actual 1-point sample

Drain Chamber,

Shut off Inlet

Measure: Close Drain,

Open Inlet

Chamber Lid with Lamp

Chamber Body

1-Point Sample

Cal OK

MENU ESC ENTER

t

t

t

t

1-Point Sample

Calibrating...

calibration has been initiated; the

display will indicate that a calculation is

progressing. During this calculation it is

important that nothing disturb the

measurement sample. To abort the

calibration during this calculation, press

ESC.

When the calibration

calculation is complete, the

result will be displayed on the

second line of the display. If

the calibration is successful,

the message will be CAL OK.

If the calibration is not

successful, the message will be

CAL FAIL. In either case,

press ENTER to continue.

If the calibration is successful, pressing ENTER will return to the measure

screen. If the calibration is not successful, pressing ENTER will return to

the beginning of the 1-point sample calibration. Reasons for calibration

failure include a sample that is not in the correct measurement range or is

changing in value too quickly.

After Calibration:

1. Drain the sample chamber.

2. Pour clean water into the chamber

and wipe interior surfaces with a

lint free clean cloth.

3. Rinse with clean water.

4. Close the Drain valve.

5. Open the Inlet Valve to allow

process water to fill the sample

chamber.

6. Replace the sample chamber lid. Be

sure that the alignment post in the

chamber is properly inserted into

the alignment hole in the lid.

21

Page 23

6.2 Zero Calibration

Calibrate

Zero

MENU ESC ENTER

1-Point Sample

Temperature

Exit

t

t

t

t

t

tt

t

Drain Chamber, Shut off Inlet

Drain and Inlet are shut off:

Ready to calibrate

Sample Chamber

with Lid Removed

Be careful to pour standard directly

into the SAMPLE CHAMBER.

Do not pour standard into the

Bubble trap.

During this operation, water will

remain int he BUBBLE TRAP and

it is not necessary to remove it.

Sample Chamber

Bubble Trap

The zero calibration is extremely sensitive and should not be adjusted

unless absolutely necessary. The following criteria must be met to achieve a

successful zero calibration:

1. The chamber must be completely clean and free of particulates.

2. An AMCO CLEAR TURBIDITY STANDARD, 0.0 NTU or water

passed through a 0.2 micron filter must be used.

3. There must be no air bubbles introduced through the inlet to the

chamber.

From the Calibrate menu,

use the UP/DOWN arrows to

display ZERO calibration.

Press ENTER to select.

1. Drain the sample

chamber.

2. Shut off flow to the

sample chamber.

3. Remove the chamber lid and place it

on top of the AV38.

4. Rinse the chamber with clean water

and then with a small amount of

calibration solution. (See calibration

kit instructions Code-5-0114 or code

5-0015 for procedure.)

5. Shut off the Drain.

6. Fill sample chamber with AMCO CLEAR TURBIDITY

STANDARD, 0 NTU calibration solution. The standard should

overflow the OUTLET weir located about 3/4 of the way to the top

of the sample chamber.

22

Page 24

Press ENTER to initiate zero

0.045 NTU AB

13.1 °C DS1: 6

MENU ESC ENTER

t

t

t

t

Zero

Calibrating…

MENU ESC ENTER

t

t

t

t

Zero

Cal Fail

MENU ESC ENTER

t

t

t

t

Zero

Confirm cal ok?

MENU ESC ENTER

t

t

t

t

0.000 NTU AB

13.1 °C DS1: 6

MENU ESC ENTER

t

t

t

t

calibration. A zero calibration

may take some time, as the

zero must be calibrated over a

wide dynamic range. During

this process the calibrating...

message is shown.

When the zero calibration is

complete the user will be

asked to confirm the reult

with the ENTER key.

After pressing ENTER to

confirm Calibration is okay,

the Measure screen will be

displayed.

NOTE: 0.000 NTU may not

be displayed. An acceptable

reading could be as high as

0.015 NTU.

If an error occurs during

calibration, the reason for the

failure is shown.

Press ENTER to acknowledge

the calibration failure and

return to the measure screen.

23

Page 25

6.3 Temperature Calibration

Temperature?

( 25.3) °C

MENU ESC ENTER

t

t

t

t

Calibrate

Temperature

MENU ESC ENTER

t

t

t

t

t

25.3 °C

Sensor ready?

MENU ESC ENTER

t

t

t

t

Temperature?

( 25.0) °C

MENU ESC ENTER

t

t

t

t

Temperature

Calibrating...

MENU ESC ENTER

t

t

t

t

Temperature

Confirm cal OK

MENU ESC ENTER

t

t

t

t

Press the ENTER key from

the TEMPERATURE

calibration menu to initiate

the calibration process.

When the temperature

calibration procedure is

started, the analog output is

placed into hold mode. The

user is prompted to prepare

the sensor. The sensor value

is dynamically updated during

this step.

When the sensor is ready, the

ENTER key is pressed and the

user is presented with a

calibration value for editing.

Please note that it is best to

calibrate temperature when

the sample chamber is full of

flowing process water.

When the value has been

edited as desired, the enter

key is pressed and the

calibration of the point is

started.

During this time, the

calibration procedure can be

aborted by pressing the escape

key.

After the calibration point has

been stored, the user is

prompted to confirm a

successful calibration

procedure.

24

Page 26

When the enter key is pressed,

0.043 NTU AB

25.0 °C DS1: 6

MENU ESC ENTER

t

t

t

t

0.043 NTU AB

25.0 °C DS1: 6

MENU ESC ENTER

t

t

t

t

the analog output is placed

into active mode and the

monitoring of sensor and

temperature values is resumed.

This successfully completes

the temperature calibration

procedure.

If an error occurs during calibration that causes the procedure to fail, the

reason for the failure will be shown.

When the enter key is pressed,

the calibrate menu is

displayed. This ends the

temperature calibration

procedure. The user has the

option of repeating the

procedure if desired.

25

Page 27

7. CONFIGURATION

Configure

Sensor Filter

MENU ESC ENTER

Temp Filter

Temp Units

Exit

t

t

t

t

t

tt

t

0.038 NTU

14.3 °C

MENU ESC ENTER

t

t

t

t

Main Menu

Configure

MENU ESC ENTER

t

t

t

t

t

Sensor Filter?

( 1) seconds

MENU ESC ENTER

t

t

t

t

Configure

Sensor Filter

MENU ESC ENTER

t

t

t

t

t

The complete configure menu for turbidity is shown.

From the measure screen,

press MENU.

From the Main Menu, use the

up/down arrows to select

Configure. Then press

ENTER.

From the Configure menu,

use the up/down arrows to

select Sensor Filter. Then

press ENTER.

Edit the sensor filter with the

up/down arrows. Press

ENTER to select a new filter

value. Press ESC to abort the

new sensor value. The

temperature filter edit screen

works the same way.

The Temperature units

selection offers °C and °F in

the edit screen.

26

Page 28

8. DATASTICK COMMS MENU

Main Menu

Analog Output

MENU ESC ENTER

t

t

t

t

t

Analog Output

Set Parameter

MENU ESC ENTER

Set 4mA Value

Set 20mA Value

Calibrate

Exit

t

t

t

t

t

ttt

t

Analog Output

Set Parameter

MENU ESC ENTER

t

t

t

t

t

The DATASTICK Comms Menu is currently not operational with the 2020

ClearTrace System.

9. ANALOG OUTPUT(S)

The analog output menu is used to setup the 4milliamp to 20 milliamp

analog output in the AV38. This function allows the following

assignments:

Parameter: Assign either turbidity or temperature to the output.

•

4mA Value: Assign the lowest value of turbidity or temperature to be

•

reported.

20mA Value: Assign the highest value of turbidity or temperature to

•

be reported.

Calibrate: Use an external ammeter to calibrate the output for precise

•

current readings.

When the AV38 is

configured with two current

outputs then the main menu

list shows “Analog Output 1”

and “Analog Output 2” The

menu system for each output

is identical.

Note: During calibration, the

analog output is held at its

present value.

The complete analog output

menu is shown in 8.1.

Figure 8.1 Analog output menu

To configure the Analog

Output, select it from the

main menu by pressing

ENTER.

To view or reassign the

parameter driving the output

(turbidity or temperature),

select “Set Parameter” with

the ENTER key.

27

Page 29

To view or reassign the

Output Param?

(Sensor )

MENU ESC ENTER

(Temperature )

t

t

t

t

Analog Output

Calibrte

MENU ESC ENTER

t

t

t

t

t

Analog Output

Set 4 mA Value

MENU ESC ENTER

t

t

t

t

t

Set 4 mA Value?

( 0.0) NTU

MENU ESC ENTER

t

t

t

t

Analog Output

Set 20 mA Value

MENU ESC ENTER

t

t

t

t

t

parameter driving the output

(turbidity or temperature) use

the up/down arrows to select

Sensor or Temperature.

Accept the displayed

parameter with the ENTER

key. Exit without changing

by using the ESC key.

To set the 4 milliamp value

select “Set 4 mA Value” with

the up/down arrows and the

ENTER key.

Use the up/down arrows for

fine adjustment of the low

sensor or temperature value.

Use the left/right arrows for

course adjustment. Accept

the displayed value with the

ENTER key. Exit without

changing by using the ESC

key.

To set the 20 milliamp value

select “Set 20 mA Value”

with the up/down arrows and

the ENTER key.

Use the up/down arrows for

fine adjustment of the low

sensor or temperature value.

Use the left/right arrows for

course adjustment. Accept

the displayed value with the

ENTER key. Exit without

changing by using the ESC

key.

28

Page 30

To calibrate the current for

Calibrate

20 mA Point

MENU ESC ENTER

t

t

t

t

t

Analog Output

Calibrte

MENU ESC ENTER

t

t

t

t

t

Calibrate

4 mA Point

MENU ESC ENTER

t

t

t

t

t

Cal 4 mA Point?

(2467)

MENU ESC ENTER

t

t

t

t

Cal 20 mA Point?

(12440)

MENU ESC ENTER

t

t

t

t

the current output function

select “Calibrate” in the

Analog Output sub-menu

with the up/down arrows and

the ENTER key. This is a

maintenance function and is

only used when the expected

current at the 4 and 20

milliamp points needs to be

adjusted. To use the

function, remove all current loop

wiring and connect an ammeter to

the current output terminal

blocks.

To calibrate the 4 mA Point,

select the “4 mA Point”

display with the up/down

arrows and press ENTER.

Remove all wiring to the

analog output terminals and

connect a calibrated ammeter

to those terminals. Adjust

the displayed count value

with the up/down arrows until

the meter reads exactly 4.000

mA. Accept the displayed

value with the ENTER key.

Exit without changing by

using the ESC key.

To calibrate the 20 mA

Point, select the “20 mA

Point” display with the

up/down arrows and press

ENTER.

Remove all wiring to the

analog output terminals and

connect a calibrated ammeter

to those terminals. Adjust

the displayed count value

with the up/down arrows until

the meter reads exactly

20.000 mA. Accept the

displayed value with the

ENTER key. Exit without

changing using the ESC key.

29

Page 31

11. HELP MENU

Main Menu

Help

MENU ESC ENTER

t

t

t

t

t

Help

About

MENU ESC ENTER

t

t

t

t

t

About:

AV38, V2.04

MENU ESC ENTER

t

t

t

t

The help menu displays the product name and the firmware version. To

view the current software version of the AV38, press ENTER at each

screen level as shown in the

diagrams below.

30

Page 32

12. RESET AV38

Reset AV38

Done

MENU ESC ENTER

t

t

t

t

Main Menu

Reset AV38

MENU ESC ENTER

t

t

t

t

t

Reset AV38

Are you sure?

MENU ESC ENTER

t

t

t

t

To reset all configuration

information to default

values, select “Reset AV38”

from the main menu.

The AV38 will ask the

question, “Are you sure?” to

notify the user that they are

about to make changes to

the system. Press ENTER to

initiate a reset. Press ESC to

abort the reset.

When the reset is done, the

AV38 will require that the

Enter key is pressed to be

sure the user acknowledges

that a reset has been done.

13. PERFORMANCE SPECIFICATION

Measurement

Range: 0 to 100 NTU (Can range to 200 NTU when necessary).

Resolution: 0.001 NTU

Accuracy: +/-2% of reading or +/-0.015 NTU whichever is greater. +/-5%

of reading above 40 NTU.

Operational Environment

Water Temperature Range: -5°C to 50°C

Air Temperature Range: -20°C to 60°C

Maximum Flow Rate: 500 ml/min (7.9 gal/hr)

Minimum Flow Rate: 250 ml/min (4 gal/hr)

31

Page 33

Power Requirements

Voltage Range: 24 VDC(Line power option available)

Maximum Power: 8W with AV38 and Light Source

Typical Power: 6W with AV38 and Light Source

Note: Class II DC power supply required

Construction

Light Source: White Light (Tungsten)

Sample Chamber Material: ABS plastic

Sample Chamber Volume: 135 ml

Light Source Housing Material: Anodized Aluminum

Mounting Plate: 12x12 inches, 4 mounting holes

Sensor Head Material: Quartz Glass, Anodized Aluminum

Weight: 5.6 lbs

Units of Measure

Measurement Units: NTU

Temperature Units: °C, °F

Calibration

Sample (Span): 1 point

Zero: 1 point

Temperature: 1 point

Interface

Display: 2 lines, 16 characters, 7 key menu navigation

Current Loops: 1 loop standard.

Interface

Sensor Filter: 0 to 100 Seconds

Temperature Filter: 0 to 100 Seconds

Product Safety

cULus Listed 367G E 328889

32

Page 34

14. LIMITED WARRANTY

2020 ClearTrace WARRANTY/REPLACEMENT PLAN

LaMotte warrants its products against material and workmanship defect for a period

of one year from the date of shipment. LaMotte warrants the turbidity lamp to

illuminate for a period of 2 years.

In the event that a defect is discovered during the warranty period, LaMotte agrees,

at its option, to repair or replace the defective product. Any product repaired or

replaced under this warranty will be warranted only for the remainder of the original

product warranty period.

This warranty does not apply to consumable products associated with this product

including, but not limited to, chemical reagents and salt bridges.

Products may not be returned without authorization from LaMotte. To obtain

authorization, please call LaMotte for a return material authorization number.

Limitations:

This warranty does not cover:

1. Damage caused by misuse, neglect (lack of appropriate maintenance),

alteration, accident or improper application or installation.

2. Damage caused by any repair or attempted repair not authorized by

LaMotte.

3. Any product not used in accordance with the instructions furnished

by LaMotte.

4. Damage caused by acts of God, natural disaster, acts of war (declared

or undeclared), acts of terrorism, work actions, or acts of any

governmental jurisdiction.

5. Freight charges to return merchandise to LaMotte.

6. Travel fees associated with on-site warranty repair.

This warranty is the sole expressed warranty made by LaMotte in connection with its

products. All other warranties, whether expressed or implied, including without

limitation, the warranties of merchantability and fitness for a particular purpose, are

expressly disclaimed.

LaMotte's liability shall be limited to the cost of the item giving rise to the claim. In

no event shall LaMotte be liable for incidental or consequential damages.

This warranty is the sole and complete warranty for LaMotte. No person is

authorized to make any warranties or representations on behalf of LaMotte.

33

Page 35

Page 36

PO Box 329 • Chestertown • MD • 21620

LaMotte Company

800-344-3100 • f 410-778-6394 • www.lamotte.com

5-0113-MN • 1.12

Loading...

Loading...