Page 1

•

COD

••••••••••••••••••••••••••••••••••••••••••••••

PLUS

Colorimeter

OPERATOR’S

MANUAL

CODE 1922/1922-EX2

Page 2

Page 3

T ABLE OF CONTENTS

GENERAL INFORMATION

Packaging & Delivery ······································································ 5

General Precautions ········································································ 5

Safety Precautions ··········································································· 5

Limits of Liability ············································································ 5

Specifications ·················································································· 6

Contents and Accessories ································································ 7

EPA Compliance ············································································· 7

CE Compliance ················································································ 8

CHEMICAL TESTING

Water Sampling for Chemical Analysis ··········································· 9

Filtration ························································································· 10

An Introduction to Colorimetric Analysis ······································ 11

Reagent Blank ················································································· 12

Colorimeter Tubes ··········································································· 12

Selecting an Appropriate Wavelength ············································ 12

Calibration Curves ·········································································· 13

Standard Additions ········································································· 15

Sample Dilution Techniques & Volumetric Measurements ············ 16

Interferences ··················································································· 17

Stray Light Interference ·································································· 17

OPERATION OF THE COD PLUS COLORIMETER

Overview ························································································· 18

Power Source ··················································································· 18

Components ···················································································· 19

Quick Start ····················································································· 20

GENERAL OPERATING PROCEDURES

The Keypad ····················································································· 22

Sample Holders ················································································ 22

The Display & the Menus ······························································· 23

Looping Menus ················································································ 25

TESTING

Testing Menu ·················································································· 26

Sequences of Tests ··········································································· 27

General Testing Procedures ····························································· 28

Testing With the LaMotte Pre-Programmed Tests ·························· 28

Calibrating With the LaMotte Pre-Programmed Tests····················· 30

Measuring in the %T/ABS Mode ···················································· 32

COD PLUS COLORIMETER 4/03 3

Page 4

T ABLE OF CONTENTS (cont.)

EDITING MENU

Edit a Sequence ·············································································· 34

Adding or Deleting Tests ································································· 35

Edit User Tests ················································································ 38

Naming the Test ·············································································· 39

Selecting the Vial and Wavelength ················································· 41

Entering a New Calibration ···························································· 42

Selecting the Numerical Format of the Result ································ 44

Selecting Units of Concentration····················································· 45

Setting the Clock ············································································· 46

Turning the Data Logger On and Off ·············································· 47

Factory Setup ··················································································· 48

Setting the Power Saver Function···················································· 48

PC LINK

Output ···························································································· 49

Computer Connection ····································································· 49

BATTERY OPERATION

Replacing the Battery······································································· 49

MAINTENANCE

Cleaning ·························································································· 50

TROUBLESHOOTING GUIDE

Error Messages ················································································· 50

Helpful Hints ··················································································· 50

SMART REAGENT SYSTEMS

······································································································· 51

COD PLUS COLORIMETER TEST INSTRUCTIONS

APPENDIX

4 COD PLUS COLORIMETER 4/03

Page 5

GENERAL INFORMATION

PACKAGING & DELIVERY

n

Experienced packaging personnel at LaMotte Company assure adequate

protection against normal hazards encountered in transportation of shipments.

After the product leaves the manufacturer, all responsibility for its safe delivery

is assured by the transportation company. Damage claims must be filed

immediately with the transportation company to receive compensation for

damaged goods.

Should it be necessary to return the instrument for repair or servicing, pack

instrument carefully in suitable container with adequate packing material. A

return authorization number must be obtained from LaMotte Company by

calling 1-800-344-3100. Attach a letter with the authorization number to the

shipping carton which describes the kind of trouble experienced. This valuable

information will enable the service department to make the required repairs

more efficiently.

GENERAL PRECAUTIONS

n

Before attempting to set up or operate this instrument it is important to read

the instruction manual. Failure to do so could result in personal injury or

damage to the equipment.

The COD PLUS Colorimeter should not be stored or used in a wet or corrosive

environment. Care should be taken to prevent water or reagent chemicals from

wet colorimeter tubes from entering the colorimeter chamber.

NEVER PUT WET TUBES IN COLORIMETER.

SAFETY PRECAUTIONS

n

Read the labels on all LaMotte reagent containers prior to use. Some

containers include precautionary notices and first aid information. Certain

reagents are considered hazardous substances and are designated witha*inthe

instruction manual. Material Safety Data Sheets (MSDS) are supplied for these

reagents. Read the accompanying MSDS before using these reagents.

Additional information for all LaMotte reagents is available in the United

States from the Poison Control Center listed in the front of the phone book or

by calling 1-800-222-1222. Call 1-813-248-0585 to contact the International

Poison control Center. LaMotte reagents are registered with a computerized

poison control information system available to all local poison control centers.

Be prepared to supply the name and four-digit LaMotte code number found on

the container label , listed in the test procedures, or at the top of the MSDS.

Keep equipment and reagent chemicals out of the reach of young children.

Protect Yourself and Equipment: Use Proper Analytical Techniques

LIMITS OF LIABILITY

n

COD PLUS COLORIMETER 6/02 5

Page 6

Under no circumstances shall LaMotte Company be liable for loss of life,

property, profits, or other damages incurred through the use or misuse of its

products.

SPECIFICATIONS

n

n

INSTRUMENT TYPE: Colorimeter

Readout Graphical 4 line, 16 character per line LCD

Wavelengths 430nm, 620 nm

Wavelength Accuracy ±2nm

Readable Resolution Determined by reagent system

Wavelength

10 nm typical

Bandwidth

Photometric Range -2to+2A

Photometric Precision ± 0.001A

Sample Chamber Accepts 25 mm diameter flat-bottomed test tubes, 10

mm square cuvettes, 16 mm COD test tubes

Light Sources 2 LEDs

Detectors 2 silicon photodiodes with integrated interference

filters

Modes Absorbance, pre-programmed tests

Pre-Programmed Tests YES, with automatic wavelength selection

User Defined Tests Up to 10 user tests can be input

RS232 Port 8 pin mini-DIN, 9600b, 8, 1, n

Power Requirements Battery Operation: 9 volt alkaline

Line Operation: 110/220V AC;

50/60 Hz with adapter, 6V 500 mA DC

Dimensions (LxWxH) 8.5 x 16.2 x 16.7 cm, 3.4 x 6.4 x 2.6 inches

Weight 312 g, 11 oz (meter only)

Data Logger 350 test results stored for download to a PC

6 COD PLUS COLORIMETER 6/02

Page 7

CONTENTS AND ACCESSORIES

n

n

CONTENTS

COD PLUS Colorimeter

Test Tubes, with Caps (4)

COD Adapter

Power Supply, 110V or 220V

COD PLUS Colorimeter Manual

n

ACCESSORIES

COD Reactor, 8 Vial Capacity, 110V Code 5-0069

COD Reactor, 8 Vial Capacity, 220V Code 5-0070

COD Reactor, 25 Vial Capacity, 110/220V Code 5-0094

COD Safety Shield for 8 Vial Reactor Code 5-0071

Small Field Carrying Case Code 1919-GCS150

Large Field Carrying Case Code 1919-BCS440

SMARTLink 2 Program & Interface Cable (3.5 disk) Code 1912-3

SMARTLink 2 Program & Interface Cable (CD) Code 1912-CD

EPA COMPLIANCE

n

The COD PLUS Colorimeter is an EPA-Accepted instrument. EP A-Accepted

means that the instrument meets the requirements for instrumentation as

found in test procedures that are approved for the National Primary Drinking

Water Regulations (NPDWR) or National Pollutant Discharge Elimination

System (NPDES) compliance monitoring programs. EPA-Accepted

instruments may be used with approved test procedures without additional

approval.

COD PLUS COLORIMETER 6/02 7

Page 8

CE COMPLIANCE

n

The COD PLUS Colorimeter has earned the European CE Mark of

Compliance for electromagnetic compatibility and safety.

DECLARATION OF CONFORMITY

Standards to which

Conformity Declared:

Manufacturer's Name:

Manufacturer's Address:

Type of Equipment:

Model Name:

Year of Manufacture:

Testing Performed By:

Chestertown, Maryland

Place

EN61326:1998, IEC61326:1997,

IEC61000-4-2:1995, IEC61000-4-3:1995

IEC61000-4-4:1995, IEC61000-4-5:1995

IEC61000-4-6:1996, IEC61000-4-11:1994,

EN61000-3-2:1995, EN61000-3-3:1994-12,

EN55011/CISPR11, FCCCFR47 Part 15,

EN61558

LaMotte Company

802 Washington Avenue

PO Box 329

Chestertown, MD 21620

Colorimeter

COD Plus

2001

Windermere

2000 Windermere Court

Annapolis, MD 21401

I, the undersigned, hereby declare that the equipment specified above

conforms to the above Directive and Standards.

Signature

1/15/02

Date

8 COD PLUS COLORIMETER 6/02

Scott H. Steffen

Name

VP New Products & Quality

Position

Page 9

CHEMICAL TESTING

WATER SAMPLING FOR CHEMICAL ANALYSIS

n

n

Taking Representative Samples

The underlying factor to be considered for any type of water sampling is

whether or not the sample is truly representative of the source. To properly

collect a representative sample:

l

Sample as frequently as possible.

l

Collect a large sample or at least enough to conduct whatever tests are

necessary.

l

Make a composite sample for the same sampling area.

l

Handle the sample in such a way as to prevent deterioration or

contamination before the analysis is performed.

l

Perform analysis for dissolved gases such as dissolved oxygen, carbon

dioxide, and hydrogen sulfide immediately at the site of sampling. These

factors, as well as samples for pH, cannot be stored for later examination.

l

Make a list of conditions or observations which may affect the sample.

Other considerations for taking representative samples are dependent

upon the source of the sample. Taking samples from surface waters

involves different considerations than taking samples from impounded and

sub-surface waters.

n

Sampling of Open Water Systems

Surface waters, such as those found in streams and rivers, are usually well

mixed. The sample should be taken downstream from any tributary, industrial

or sewage pollution source. For comparison purposes samples may be taken

upstream and at the source of the pollution before mixing.

In ponds, lakes, and reservoirs with restricted flow, it is necessary to collect a

number of samples in a cross section of the body of water, and where possible

composite samples should be made to ensure representative samples.

To collect samples from surface waters, select a suitable plastic container with a

tight fitting screw cap. Rinse the container several times with the sample to be

tested, then immerse the container below the surface until it is filled to

overflowing and replace the cap. If the sample is not to be tested immediately,

pour a small part of the sample out and reseal. This will allow for any

expansion. Any condition which might affect the sample should be listed.

Sub-surface sampling is required to obtain a vertical profile of streams, lakes,

ponds, and reservoirs at specific depths. This type of sampling requires more

sophisticated sampling equipment.

For dissolved oxygen studies, or for tests requiring small sample sizes, a Water

Sampler (LaMotte Code 1060) will serve as a subsurface or in-depth sampler.

COD PLUS COLORIMETER 6/02 9

Page 10

This weighted device is lowered to the sampling depth and allowed to rest at

this depth for a few minutes. The water percolates into the sample chamber

displacing the air which bubbles to the surface. When the bubbles cease to rise,

the device has flushed itself approximately five times and it may be raised to

the surface for examination. The inner chamber of the sampling device is lifted

out and portions of the water sample are carefully dispensed for subsequent

chemical analysis.

A Snap-Plunger Water Sampler (LaMotte Code 1077) is another “in-depth”

sampling device which is designed to collect large samples which can be used

for a multitude of tests. Basically, this collection apparatus is a hollow cylinder

with a spring loaded plunger attached to each end. The device is cocked above

the surface of the water and lowered to the desired depth. A weighted

messenger is sent down the calibrated line to trip the closing mechanism and

the plungers seal the sample from mixing with intermediate layers as it is

brought to the surface. A special drain outlet is provided to draw off samples for

chemical analysis.

n

Sampling of Closed System

To obtain representative samples from confined water systems, such as pipe

lines, tanks, vats, filters, water softeners, evaporators and condensers, different

considerations are required because of chemical changes which occur between

the inlet and outlet water. One must have a basic understanding of the type of

chemical changes which occur for the type of equipment used. Also,

consideration should be given to the rate of passage and retaining time for the

process water.

Temperature changes play an important part in deciding exactly what test

should be performed. Process water should be allowed to come to room

temperature, 20–25°C, before conducting any tests.

When drawing off samples from an outlet pipe such as a tap, allow sample to

run for several minutes, rinsing the container several times before taking the

final sample. Avoid splashing and introduction of any contaminating material.

FILTRATION

n

When testing natural waters that contain significant turbidity due to suspended

solids and algae, filtration is an option. Reagent systems, whether EPA,

Standard Methods, LaMotte or any others, will generally only determine

dissolved constituents. Both EPA and Standard Methods suggest filtration

through a 0.45 micron filter membrane, to remove turbidity, for the

determination of dissolved constituents.** T o test for total constituents,

organically bound and suspended or colloidal materials, a rigorous high

temperature acid digestion is necessary.

**LaMotte offers a filtering apparatus: syringe assembly (Code 1050) and membrane

filters, 0.45 micron, (Code 1103).

10 COD PLUS COLORIMETER 6/02

Page 11

AN INTRODUCTION TO COLORIMETRIC ANALYSIS

n

Most test substances in water are colorless and undetectable to the human eye.

To test for their presence we must find a way to “see” them. The COD PLUS

Colorimeter can be used to measure a test substance that is itself yellow or

green to blue, or can be reacted to produce these colors. In fact a simple

definition of colorimetry is “the measurement of color” and a colorimetric

method is “any technique used to evaluate an unknown color in reference to

known colors”. In a colorimetric chemical test the intensity of the color from

the reaction must be proportional to the concentration of the substance being

tested. Some reactions have limitations or variances inherent to them that may

give misleading results. Many such interferences are discussed with each

particular test instruction. In the most basic colorimetric method the reacted

test sample is visually compared to a known color standard. However, accurate

and reproducible results are limited by the eyesight of the analyst,

inconsistencies in the light sources, and the fading of color standards.

To avoid these sources of error, a colorimeter can be used to photoelectrically

measure the amount of colored light absorbed by a colored sample in reference

to a colorless sample (blank).

White light is made up of many different colors or wavelengths of light. A

colored sample typically absorbs only one color or one band of wavelengths

from the white light. Only a small difference would be measured between white

light before it passes through a colored sample versus after it passes through a

colored sample. The reason for this is that the one color absorbed by the

sample is only a small portion of the total amount of light passing through the

sample. However, if we could select only that one color or band of wavelengths

of light to which the test sample is most sensitive, we would see a large

difference between the light before it passes through the sample and after it

passes through the sample.

The COD PLUS Colorimeter passes one of two colored light beams through

one of two optical filters which transmits only one particular color or band of

wavelengths of light to the photodectector where it is measured. The difference

in the amount of colored light transmitted by a colored sample is a

measurement of the amount of colored light absorbed by the sample. In most

colorimetric tests the amount of colored light absorbed is directly proportional

to the concentration of the test factor producing the color and the path length

through the sample. However, for some tests the amount of colored light

absorbed is inversely proportional to the concentration.

The choice of the correct wavelength for testing is important. It is interesting

to note that the wavelength that gives the most sensitivity (lower detection

limit) for a test factor is the complementary color of the test sample. For

example the Nitrate-Nitrogen test produces a pink color proportional to the

nitrate concentration in the sample (the greater the nitrate concentration, the

darker the pink color). A wavelength in the green region should be selected to

analyze this sample since a pinkish-red solution absorbs mostly green light.

COD PLUS COLORIMETER 6/02 11

Page 12

REAGENT BLANK

n

Some tests will provide greater accuracy if a reagent blank is determined to

compensate for any color or turbidity resulting from the reagents themselves. A

reagent blank is performed by running the test procedure on 10 mL of

demineralized water. Use sample water to SCAN BLANK. Insert the reagent

blank in the colorimeter chamber and select SCAN SAMPLE. Note result of

reagent blank. Perform the tests on the sample water as described. Subtract

results of reagent blank from all subsequent test results. NOTE: Some tests

require a reagent blank to be used to SCAN BLANK.

COLORIMETER TUBES

n

Colorimeter tubes which have been scratched through excessive use should be

discarded and replaced with new ones. Dirty tubes should be cleaned on both

the inside and outside. Fingerprints on the exterior of the tubes can cause

excessive light scattering and result in errors. Handle the tubes carefully,

making sure the bottom half of the tube is not handled.

LaMotte Company makes every effort to provide high quality colorimeter

tubes. However, wall thicknesses and diameter of tubes may still vary slightly.

This may lead to slight variations in results (e.g. if a tube is turned while in the

sample chamber, the reading will likely change slightly). To eliminate this error

put the tubes into the sample chamber with the same orientation every time.

The tubes that are included with the colorimeter have an index mark to

facilitate this. If possible, use the same tube to SCAN BLANK and SCAN

SAMPLE.

SELECTING AN APPROPRIATE WAVELENGTH

n

The most appropriate wavelength to use when creating a calibration curve is

usually the one which gives the greatest change from the lowest reacted

standard concentration to the highest reacted standard concentration.

However, the absorbance of the highest reacted standard concentration should

never be greater than 2.0 absorbance units. Scan the lowest and highest reacted

standards at different wavelengths using the absorbance mode to find the

wavelength which gives the greatest change in absorbance without exceeding

2.0 absorbance units. Use this wavelength to create a calibration curve.

12 COD PLUS COLORIMETER 6/02

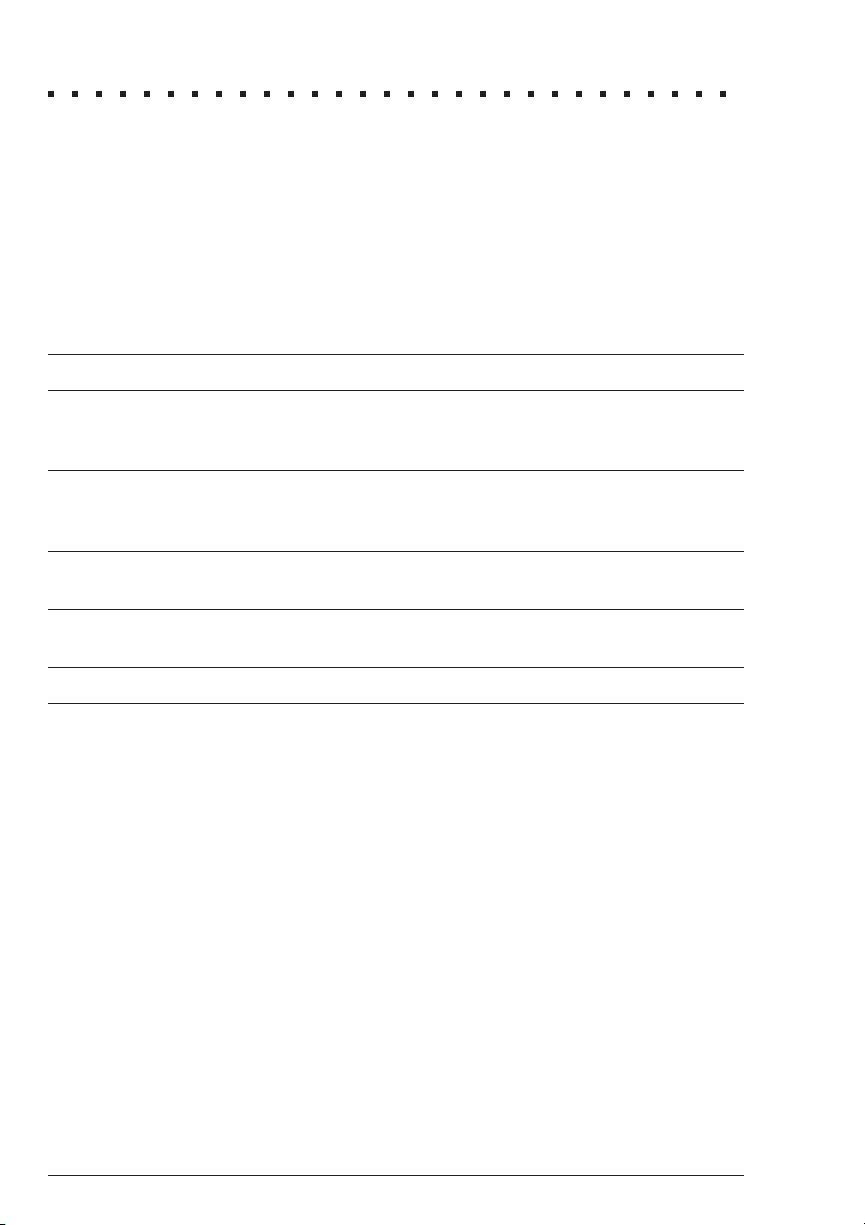

Page 13

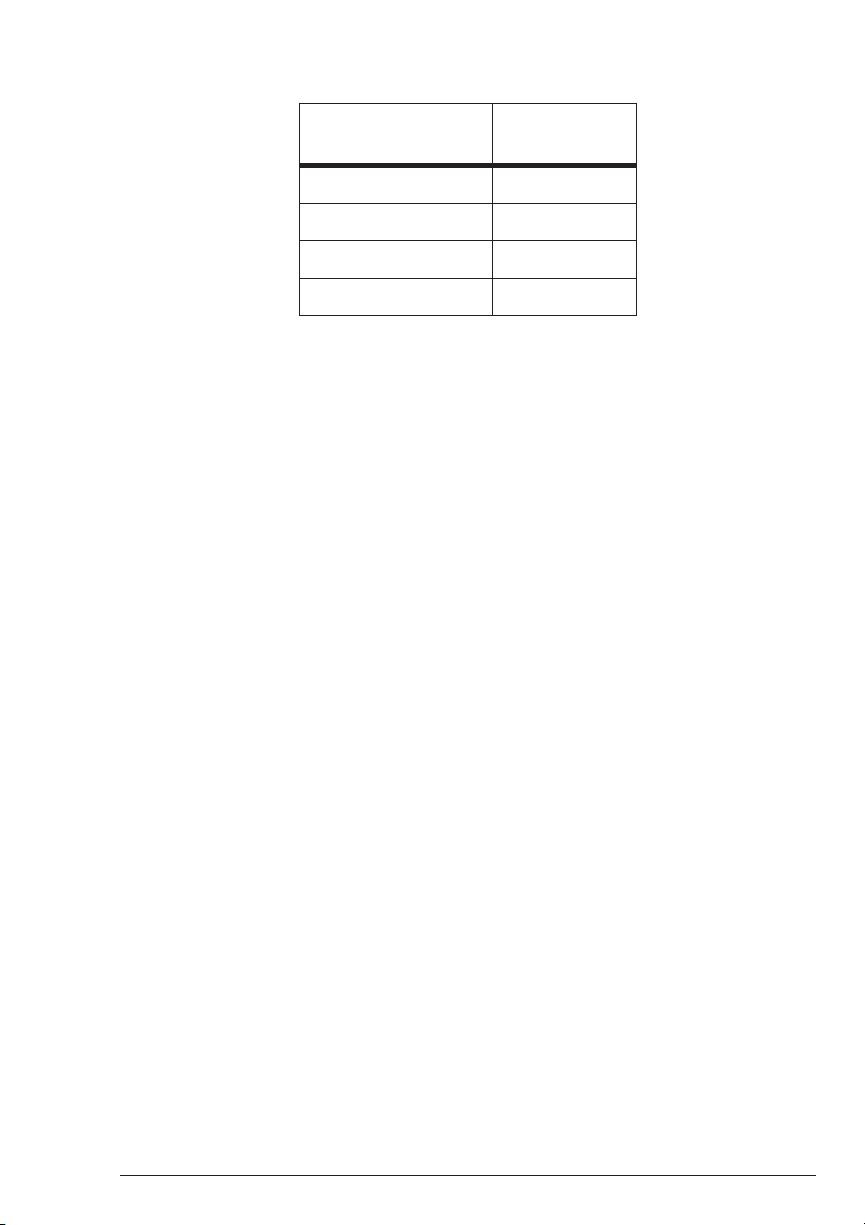

Below is a list of suggested wavelengths for the color of the reacted samples.

Use these as a starting point.

Sample

Color

Yellow 430

Pink 520

Red 570

Green and Blue 620

Wavelength

Range

NOTE: Available wavelengths in the COD PLUS are 430 nm and 620 nm

only.

CALIBRATION CURVES

n

The COD PLUS Colorimeter contains precalibrated tests for the LaMotte

reagent systems (p. 49). The first step in using a non-LaMotte reagent system

with your COD PLUS Colorimeter is to create a calibration curve for the

reagent system. To create a calibration curve, prepare standard solutions of the

test factor and use the reagent system to test the standard solutions with the

COD PLUS Colorimeter. Select a wavelength for the test as described above.

Plot the results (in ABS or %Transmittance) versus concentration to create a

calibration curve. The calibration curve may then be used to identify the

concentration of an unknown sample by testing the unknown, reading

Absorbance or %T, and finding the corresponding concentration from the

curve. The linear range of the reagent system can be determined and this

information can be used to input a User Test into the COD PLUS Colorimeter

(see EDIT USER TESTS, p. 36).

n

PROCEDURE

1. Prepare 5 or 6 standard solutions of the factor being tested. The

concentration of these standards should be evenly distributed throughout

the range of the reagent system, and should include a 0 ppm standard

(distilled water). For instance, the solutions could measure 0, 10%, 30%,

50%, 70%, and 90% of the system’s maximum range.

2. Turn on the COD PLUS Colorimeter . Select the appropriate wavelength

from the absorbance mode. Be sure to select the appropriate wavelength for

the color produced by the reagent system.

3. Use the unreacted 0 ppm standard to standardize the colorimeter by using it

to scan blank.

4. Following the individual reagent system instructions, react each standard

solution beginning with 0 ppm. Continue with standards in increasing

concentration. Record the reading and the standard solution concentration

on a chart. Readings can be recorded as percent transmittance (%T) or

absorbance (A).

COD PLUS COLORIMETER 6/02 13

Page 14

5. Plot results on graph paper or computer using any available plotting

program. If results are as %T versus concentration, semilog graph paper

must be used. Plot the standard solution concentrations on the horizontal,

linear axis, and the %T on the vertical, logarithmic axis. If results are as

absorbance versus standard solution concentration, simple linear graph

paper can be used. Plot the standard solution concentration on the

horizontal axis, and the absorbance on the vertical axis.

6. After plotting the results, draw a line, or curve, of best fit through the

plotted points. The best fit may not connect the points. There should be

approximately an equal number of points above the curve as below the

curve. Some reagent systems will produce a straight line, while others

produce a curve. Many computer spreadsheet programs can produce the

curve of best fit by regression analysis of the standard solution data.

NOTE: Only reagent systems which produce a straight line can be used for a

User Test.

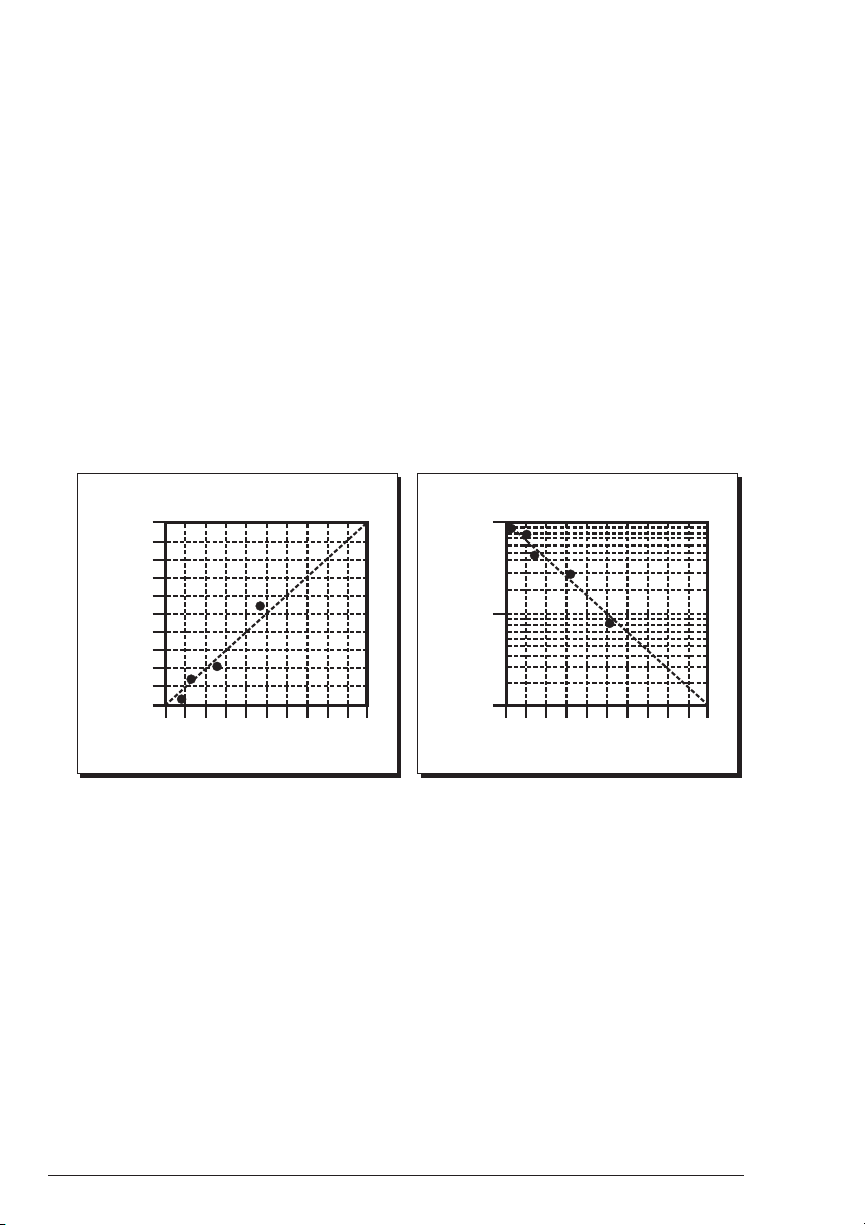

A sample of each type of graph appears below:

CALIBRATION CURVE

Absorbance vs. Concentration

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

Absorbance

0.4

0.2

0.0

123456

Concentration in ppm

CALIBRATION CURVE

%T vs. Concentration

100

10

%T Transmission

1

0

89107

123456

Concentration in ppm

891070

14 COD PLUS COLORIMETER 6/02

Page 15

n

PREPARING DILUTE STANDARD SOLUTIONS

Standard solutions should be prepared to create a calibration curve. Standard

solutions can be prepared by diluting a known concentrated standard by

specified amounts. A chart or computer spreadsheet can be created to

determine the proper dilutions. Use volumetric flasks and volumetric pipets for

all dilutions.

1. In Column A – Record the maximum concentration of test as determined

by the range and path length.

2. In Column B – Record the percent of the maximum concentration the

standard solution will be.

3. In Column C – Calculate the final concentration of the diluted standard

solutions by multiplying the maximum concentration (In Column A) by the

% of maximum concentration divided by 100. (C=Ax

B

).

100

4. In Column D – Record the final volume of the diluted sample (i.e. volume

of volumetric flask).

5. In Column E – Record the concentration of the original standard.

6. In Column F – Calculate the milliliters of original standard required

D

(C x

= F).

E

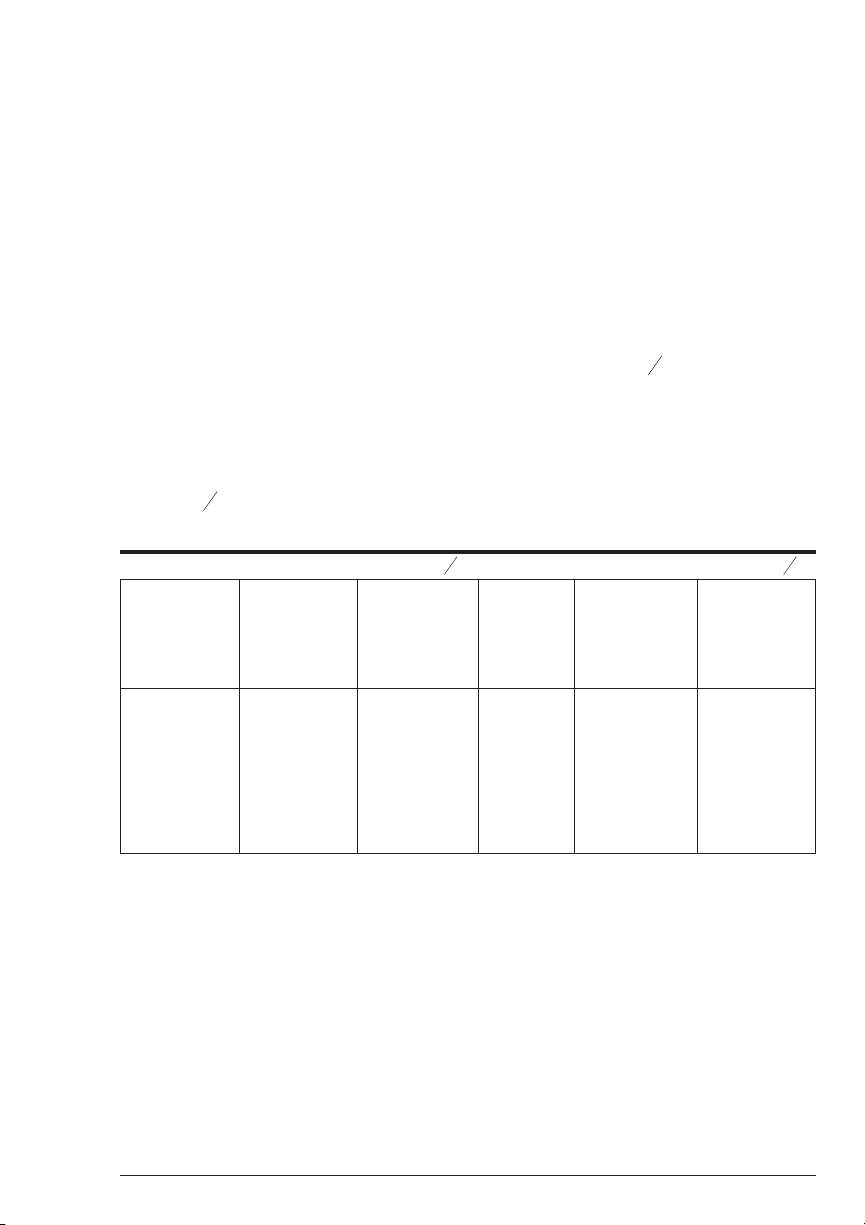

A sample chart appears below:

A B C=Ax

B

I00

D E F=Cx

Final

Maximum

concentration

of test

%of

Maximum

concentration

concentration

of Diluted

Standard

Volume of

Standard

Concentration

of Original

Standard

Standard

Required

10.0 ppm 90 9.0 ppm 100 mL 1000 ppm 0.90 mL

10.0 ppm 70 7.0 ppm 100 mL 1000 ppm 0.70 mL

10.0 ppm 50 5.0 ppm 100 mL 1000 ppm 0.50 mL

10.0 ppm 30 3.0 ppm 100 mL 1000 ppm 0.30 mL

10.0 ppm 10 1.0 ppm 100 mL 1000 ppm 0.10 mL

10.0 ppm 0 0 ppm 100 mL 1000 ppm 0 mL

mL of

Original

D

E

STANDARD ADDITIONS

n

A common method to check the accuracy and precision of a test is by standard

additions. In this method a sample is tested to determine the concentration of

the test substance. A second sample is then “spiked” by the addition of a

known quantity of the test substance. The second sample is then tested. The

determined concentration of the spiked sample should equal the concentration

of the first plus the amount added with the spike. The procedure can be

repeated with larger and larger “spikes.” If the determined concentrations do

not equal the concentration of the sample plus that added with the “spike”,

then an interference may exist.

COD PLUS COLORIMETER 6/02 15

Page 16

For example, a 10.0 mL water sample was determined to contain 0.3 ppm iron.

To a second 10.0 mL sample, 0.1 mL of 50 ppm iron standard was added. The

concentration of iron due to the “spike” was (0.10 mL x 50 ppm)/10.0 mL =

0.50 ppm. The concentration of iron determined in the spiked sample should

be 0.3 + 0.5 = 0.8 ppm iron. (Note: any error due to the increased volume from

the “spike” is negligible).

LaMotte offers a line of calibration standards which can be used to generate

calibration curves and perform standard additions.

SAMPLE DILUTION TECHNIQUES

n

& VOLUMETRIC MEASUREMENTS

If a test result using the COD PLUS Colorimeter gives an OVERRANGE message

then the sample concentration could be over range or under range. If it is over

range, the sample must be diluted. Then the test should be repeated on the

diluted sample to obtain a reading which is in the concentration range for the

test. (Note: This is not true for colorimetric determination of pH.)

Example:

Measure 5 mL of the water sample into a graduated cylinder. Add

demineralized water until the cylinder is filled to the 10 mL line. The sample

has been diluted by one-half, and the dilution factor is therefore 2. Perform the

test procedure, then multiply the resulting concentration by 2 to obtain the

test result.

The following table gives quick reference guidelines on dilutions of various

proportions. All dilutions are based on a 10 mL volume, so several dilutions

will require small volumes of the water sample. Graduated pipets should be

used for all dilutions.

Size of Sample

10 mL 0 mL 1

5mL 5mL 2

2.5 mL 7.5 mL 4

1 mL 9 mL 10

0.5 mL 9.5 mL 20

Deionized W ater to Bring

Volume to 10 mL Multiplication Factor

If the above glassware is not available, dilutions can be made with the

colorimeter tube. Fill the tube to the 10 mL line with the sample then transfer

it to another container. Add 10 mL volumes of demineralized water to the

container and mix. T ransfer back 10 mL of the diluted sample to the tube and

follow the test procedure. Continue diluting and testing until a reading, which

is in the concentration range for the test, is obtained. Be sure to multiply the

concentration found by the dilution factor (the number of total 10 mL volumes

used).

Example:

10 mL of sample is diluted with three 10 mL volumes of demineralized water;

the dilution factor is four.

16 COD PLUS COLORIMETER 6/02

Page 17

INTERFERENCES

n

LaMotte reagent systems are designed to minimize most common interferences.

Each individual test instruction discusses interferences unique to that test. Be

aware of possible interferences in the water being tested.

The reagent systems also contain buffers to adjust the water sample to the ideal

pH for the reaction. It is possible that the buffer capacity of the water sample

may exceed the buffer capacity of the reagent system and the ideal pH will not

be obtained. If this is suspected, measure the pH of a reacted distilled water

reagent blank using a pH meter. This is the ideal pH for the test. Measure the

pH of a reacted water sample using the pH meter. If the pH is significantly

different from the ideal value, the pH of the sample should be adjusted before

testing.

Interferences due to high concentration of the substance being tested, can be

overcome by sample dilution (p. 16).

STRAY LIGHT INTERFERENCE

n

When scanning samples in 16 mm tubes, such as COD, the sample chamber lid

can not be closed. The COD adapter minimizes stray light. To further reduce

stray light interference, do not scan sample in direct sunlight.

COD PLUS COLORIMETER 6/02 17

Page 18

OPERA TION OF THE

COD PLUS COLORIMETER

OVERVIEW

n

The COD PLUS Colorimeter is a portable, microprocessor controlled, direct

reading colorimeter. It has a graphical 4 line, 16 character liquid crystal display

for graphical, alphabetical and numerical messages. The operation is controlled

with the keypad through menu driven software in response to selections shown

on the display.

The test library consists of 29 LaMotte tests and 10 “User Tests”. The LaMotte

tests are precalibrated for LaMotte reagent systems. The colorimeter displays

the results of these tests directly in units of concentration. The 10 “User Tests”

may be used to enter additional calibrations. All of these tests may be arranged

in any of 3 sequences. These sequences can be modified a limitless number of

times to meet changing testing needs.

The optics feature 2 different colored LEDs. Each LED has a corresponding

silicon photodiode with an integrated interference filter. The interference

filters select a narrow band of light from the corresponding LED for the

colorimetric measurements. The microprocessor automatically selects the

correct LED/photodiode combination for a test.

A RS-232 serial port on the back of the colorimeter, and optional software,

allows the COD PLUS to be interfaced with an IBM compatible personal

computer for real time data acquisition and data storage. This port also allows

an interface with a RS-232 serial printer.

Due to its portability, alternate power sources, and rugged construction, the

COD PLUS Colorimeter is ideal for lab and field use.

POWER SOURCE

n

The COD PLUS Colorimeter uses a 6V 500 mA AC adapter. Please refer to

the Parts List for the code number for the correct adapter.

USE OF ANY AC ADAPTER OTHER THAN THE ONE SPECIFIED

FOR USE WITH THE COD PLUS COLORIMETER MAY DAMAGE

THE METER AND WILL VOID THE WARRANTY.

To use the adapter, slide the connector pin from the AC adapter into the small

hole on the left side of the meter. Plug the AC adapter into an appropriate wall

socket or power source.

18 COD PLUS COLORIMETER 6/02

Page 19

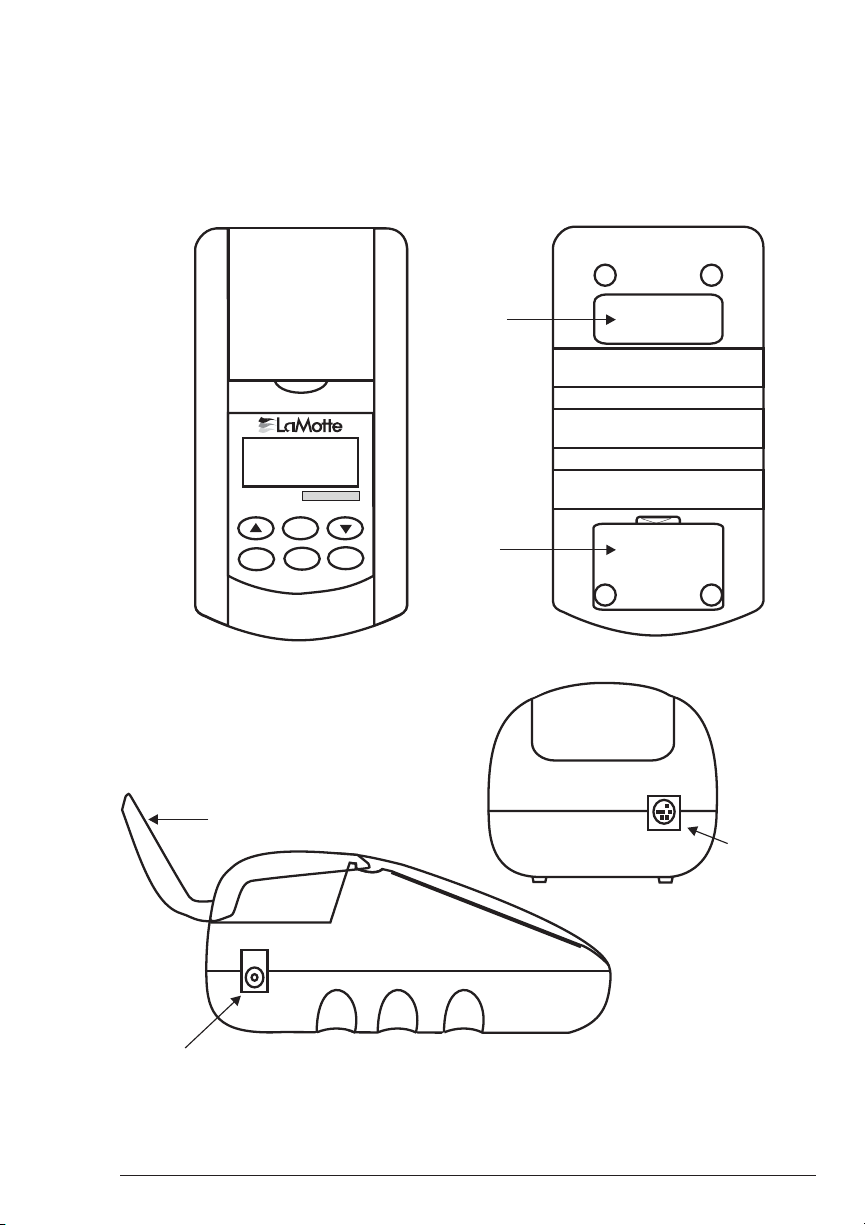

COMPONENTS

n

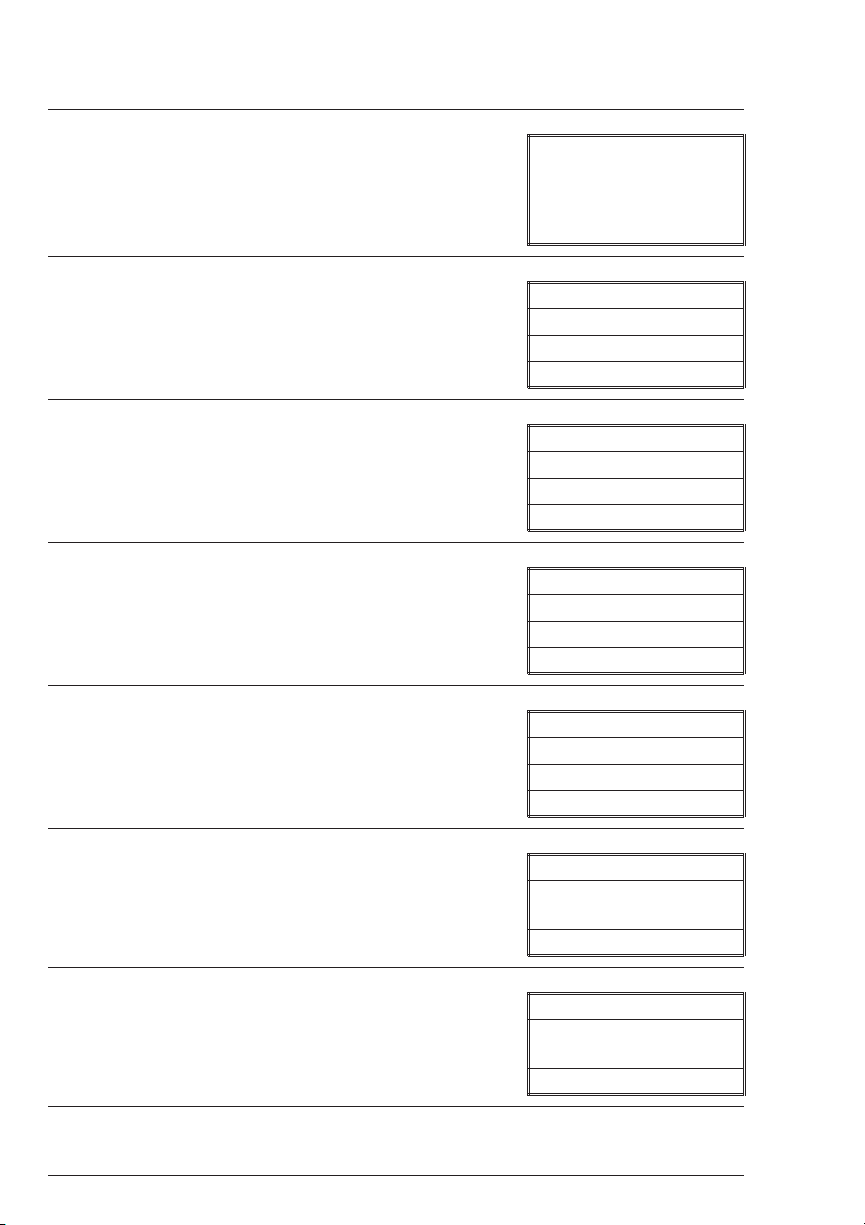

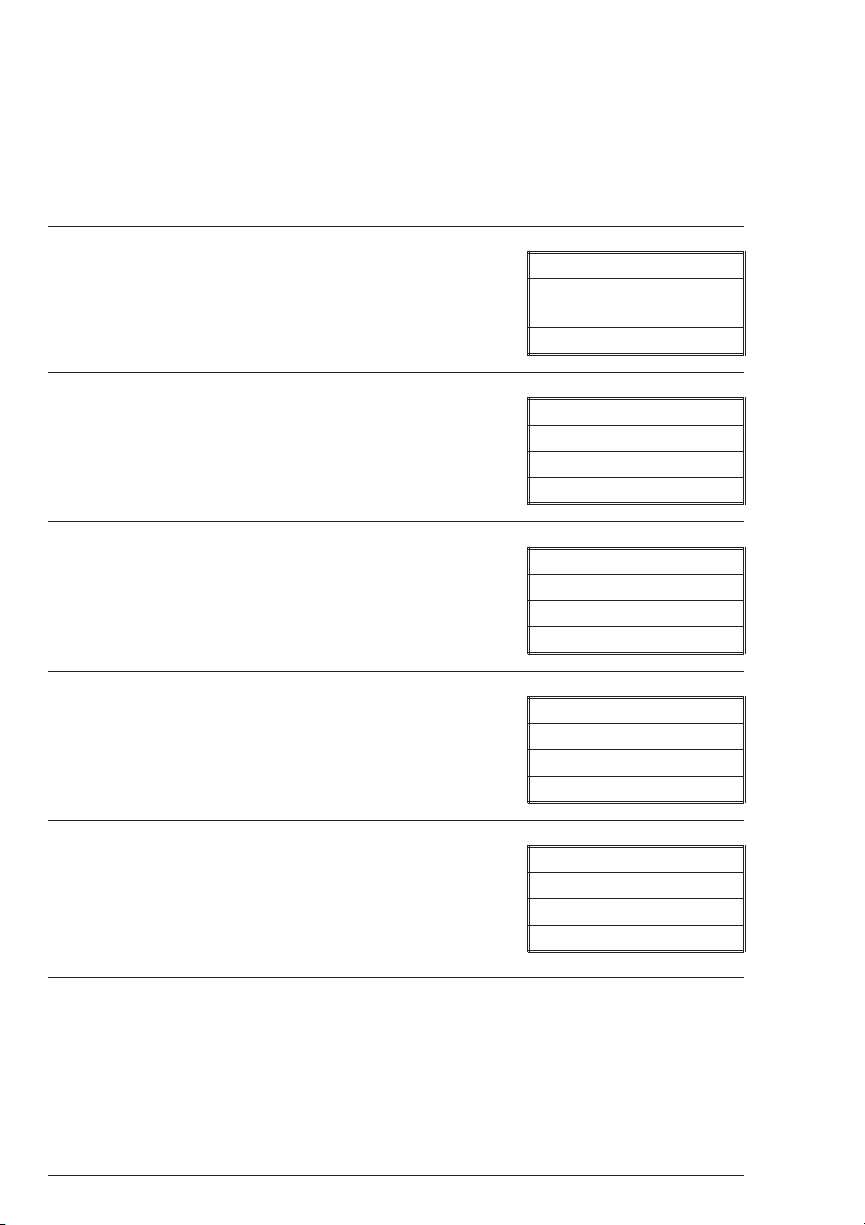

Figure 1 shows a diagram of the COD PLUS Colorimeter and its components.

Top View

COD PLUS

••••••••••••••••••

ENTER

OFF EXIT

Lid

*

ON

Side Views

Bottom View

Serial

Number

Battery

Compartment

Rs232

Serial Port

AC

Adapter Socket

Figure 1

COD PLUS COLORIMETER 6/02 19

Page 20

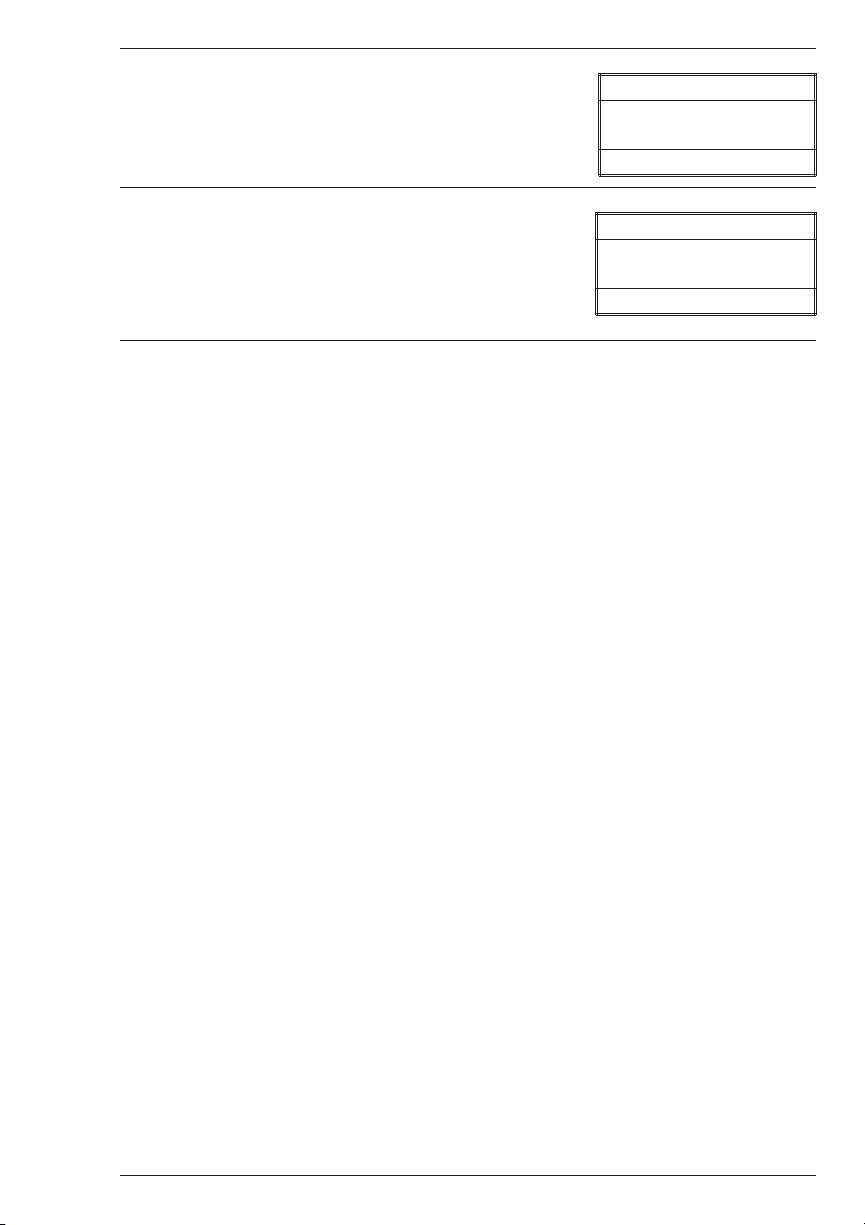

QUICK START

n

Some quick instructions to get into testing.

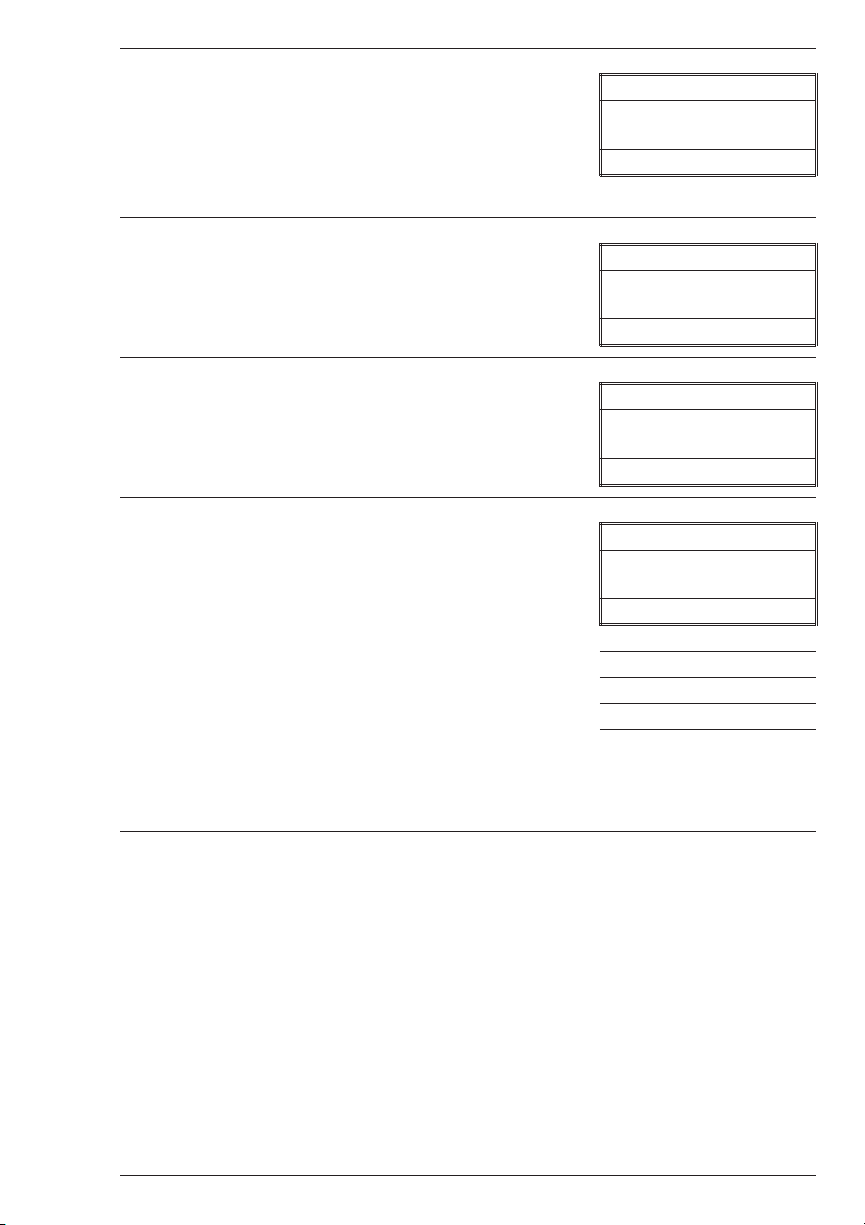

1. Press ON to turn on the COD PLUS. The

LaMotte logo screen will appear for about 2

seconds and then the Start screen appears. Press

Q/ENTER to start testing.

2. The Main Menu will appear. Press

Q/ENTER to select TESTING MENU.

3. Press Q/ENTER to select All Tests.

4. Press t or s to move the * to the desired

test.

5. Press Q/ENTER to select test.

VER 1.0

COD PLUS

* Start

MAIN MENU

* Testing Menu

Editing Menu

PC Link

TESTING MENU

* All Tests

Sequence 1

Sequence 2

ALL TESTS

* 001 COD LR

002 COD SR

003 COD HR

ALL TESTS

* 002 COD SR

003 COD HR

004 Ammonia-N LF

6. Insert blank, press Q/ENTER to scan blank.

7. The screen will display Blank Done for about

1 second.

20 COD PLUS COLORIMETER 6/02

002 COD SR

* Scan Blank

002 COD SR

Blank Done

* Scan Blank

Page 21

8. Insert the reacted sample. Press Q/ENTER to

scan sample. The COD PLUS will scan the

sample and display the concentration.

002 COD SR

* Scan Sample

9. After recording test result, scroll with t or s

and make another selection with Q/ENTER.

Press EXIT to escape to previous menus.

002 COD SR

722 mgL

* Scan Sample

COD PLUS COLORIMETER 6/02 21

Page 22

GENERAL OPERATING PROCEDURES

The operation of the COD PLUS Colorimeter is controlled by a

microprocessor. The microprocessor is programmed with menu driven software.

A menu is a list of choices. This allows a selection of various tasks for the

colorimeter to perform, such as, scan blank, scan sample, and edit test

sequences. The keypad is used to make menu selections which are viewed in

the display. There are three selections accessible from the MAIN MENU:

Testing Menu, Editing Menu and PC Link.

THE KEYPAD

n

The keypad has 6 buttons which are used to perform specific tasks.

ON

t This button will cause the display to scroll down through a list of

s This button will cause the display to scroll up in a list of menu

ENTER

Q

EXIT

OFF

SAMPLE HOLDERS

n

The sample chamber is designed for 25 mm round tubes, and a sample holder

for 16 mm COD tubes is included. A 1 cm square UDV cuvette sample holder

is available for the COD PLUS Colorimeter.

Position the COD adapter in the SMART 2 chamber so that the grooves in the

adapter are aligned with the ridges located at the rear of the chamber. The

adapter should be inserted with the small hole, containing the ball plunger, at

the top. The ball plunger can be adjusted with a small screwdriver to control

the tightness of the fit of the tube in the adapter.

This button is used to turn the colorimeter on.

menu choices. It will move through a list viewed in the display . It

will auto scroll when held down.

choices. It will move through a list viewed in the display. It will

auto scroll when held down.

This button is used to select the menu choice adjacent to the “*”in

a menu viewed in the display.

This button is an exit or escape button. When pressed, the display

will exit from the current menu and go to the previous menu.

This button turns the colorimeter off.

22 COD PLUS COLORIMETER 8/02

Page 23

THE DISPLAY & THE MENUS

n

The display allows menu selections to be viewed and chosen. These choices

instruct the colorimeter to perform specific tasks. The menus are viewed in the

display using two general formats which are followed from one menu to the

next. Each menu is a list of choices or selections.

There are four lines in the display. The top line in each menu is a title or

pertinent instruction. The top line does not change unless a new menu is

selected. The second and third lines are used in two ways. One way is to display

menu choices. The second way takes advantage of the graphical capabilities of

the display. Both lines are used to display important messages, such as test

results, in a large, easy to read format. The fourth line is used for menu choices.

DISPLAY

TESTING MENU

* FIRST CHOICE

SECOND CHOICE

ANOTHER

AND ANOTHER

AND SO ON

TITLE or INSTRUCTION

MENU CHOICE WINDOW

Think of the menu choices as a vertical list in the display which moves up or

down each time an arrow button is pressed. This list or menu is viewed through

a window, the menu choice window, in the display. The menu choice window

is the lower 2 or 3 lines of the display. Pushing the arrow buttons brings

another portion of the menu into menu choice window. This is referred to as

scrolling through the menu.

TESTING MENU

* FIRST CHOICE SECOND CHOICE ANOTHER

SECOND CHOICE * ANOTHER AND ANOTHER

ANOTHER AND ANOTHER * AND SO ON

AND ANOTHER AND SO ON LAST CHOICE

AND SO ON LAST CHOICE

LAST CHOICE

t

TESTING MENU

t

TESTING MENU

An asterisk, “*”, will start in the far left position of the top line in the menu

choice window. As the menu is scrolled through, different choices appear next

to the “*”. The “*” in the display corresponds with the Q/ENTER button.

Pushing the Q/ENTER button selects the menu choice which is adjacent to

the “*” in the menu choice window.

COD PLUS COLORIMETER 6/02 23

Page 24

The second general format of the display takes advantage of the graphics

capabilities of the display. The top line of the display is still a title line. The

middle two lines of the display are used to display important messages, results or

graphics in a large, easy to read format. The menus work in the same way as

described previously but only one line of the menu is visible at the bottom of

the display.

TESTING MENU

TESTING MENU

t

TESTING MENU

t

Result or Message Result or Message Result or Message

* ANOTHER * AND ANOTHER * AND SO ON

AND ANOTHER AND SO ON LAST CHOICE

AND SO ON LAST CHOICE

LAST CHOICE

As described previously, the EXIT button allows an exit or escape from the

current menu and a return to the previous menu. This allows a rapid exit from

an inner menu to the main menu by repeatedly pushing the

Pushing

OFF at any time will turn the colorimeter off.

EXIT button.

24 COD PLUS COLORIMETER 6/02

Page 25

LOOPING MENUS

n

Long menus, such as All Tests, incorporate a looping feature which allow

the user to quickly reach the last choice in the menu from the first choice. In a

looping menu the last choices in the menu are above the first choice and

scrolling upward moves through the menu in reverse order. Scrolling downward

moves through the menu from first choice to last but the menu starts over

following the last choice. So all menu choices can be reached by scrolling in

either direction. The diagrams below demonstrate a looping menu.

AND SO ON AND ANOTHER ANOTHER

: : : AND SO ON AND ANOTHER

: : : : : : AND SON ON

THIRD TO LAST : : : : : :

SECOND TO LAST THIRD TO LAST : : :

LAST CHOICE SECOND TO LAST THIRD TO LAST

TESTING MENU

* FIRST CHOICE * LAST CHOICE * SECOND TO LAST

SECOND CHOICE FIRST CHOICE LAST CHOICE

ANOTHER SECOND CHOICE FIRST CHOICE

AND ANOTHER ANOTHER SECOND CHOICE

AND SO ON AND ANOTHER ANOTHER

: : : AND SO ON AND ANOTHER

: : : : : : AND SO ON

LAST CHOICE : : : : : :

TESTING MENU

s

TESTING MENU

s

COD PLUS COLORIMETER 6/02 25

Page 26

TESTING

TESTING MENU

n

The Testing Menu is used to run all LaMotte pre-programmed tests, USER

TESTS and Absorbance test at two wavelengths. Testing from any of three

sequences can also be done.

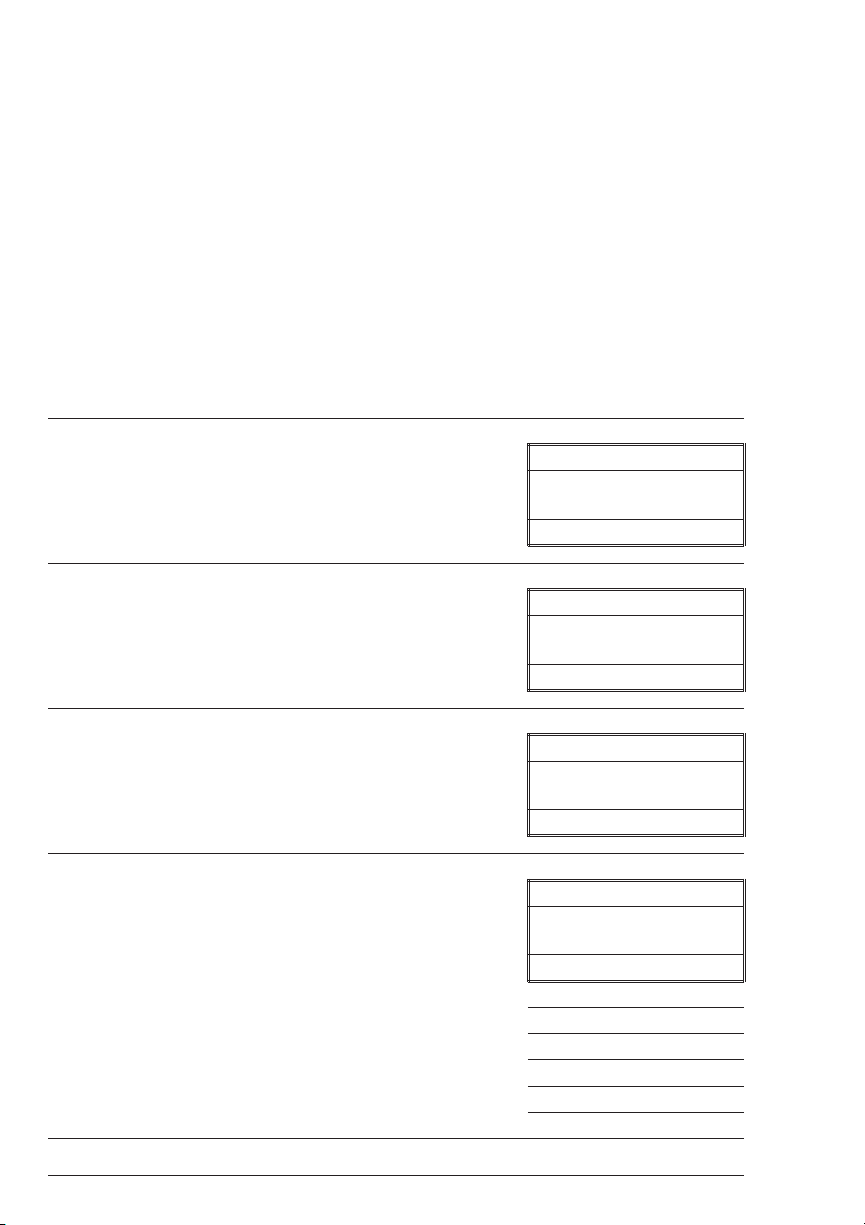

1. Press the ON button to turn on the

COD PLUS Colorimeter. The LaMotte logo will

appear for about 2 seconds and the the Start screen

appears. Press the Q/ENTER button to begin testing.

2. The MAIN MENU will appear. Press the

Q/ENTER button to select Testing Menu.

3. Scroll with the t or s buttons and make

a selection with the Q/ENTER button. All

Tests has all the available tests. The three

sequences have selected tests and

Absorbance has %T/ABS tests.

VER 1.0

COD PLUS

* Start

MAIN MENU

* Testing Menu

Editing Menu

PC Link

TESTING MENU

* All Tests

Sequence 1

Sequence 2

Sequence 3

Absorbance

26 COD PLUS COLORIMETER 6/02

Page 27

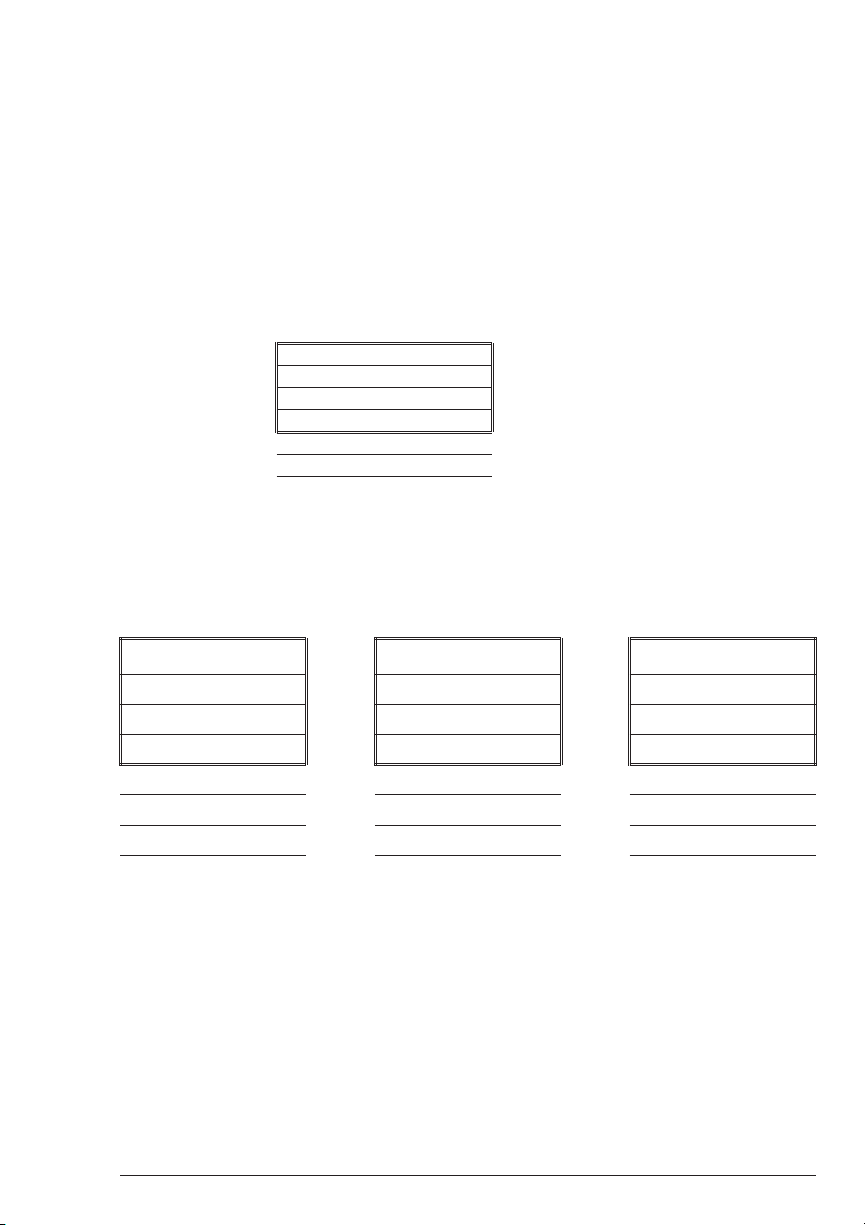

SEQUENCES OF TESTS

n

SEQUENCE 1, SEQUENCE 2, and SEQUENCE 3 are alterable sequences. They

may be edited using the Editing Menu. Any of the LaMotte

pre-programmed tests or User T ests may be placed in these sequences in

whatever testing order that is preferred. Some examples of typical sequences are

given below.

SEQUENCE 1 SEQUENCE 2 SEQUENCE 3

* 004 Ammonia-N LF * 008 Cobalt * 001 COD LR

005 Ammonia-N LS 010 Cu Cuprizone 002 COD SR

006 Ammonia-N H 011 Cu - DDC 003 COD HR

007 Boron 015 Hydrazine

001 COD LR 016 Moly HR

002 COD SR 017 Nickel

003 COD HR 018 Ozone-LR

009 Color 021 Phosphate-H

013 DO 022 Potassium

014 Fluoride 023 Silica-Lo

018 Ozone-LR 024 Silica-Hi

020 Phosphate-L 027 Tannin

025 Sulfate-HR 029 Zinc-LR

026 Sulfide-LR

028 Turbidity

These alterable sequences allow a series of tests to be setup that are run

frequently. The order of the individual tests in the sequence is determined by

the user. After running a test, use the t button to scroll to the next test and

press the Q/ENTER button to select the next test in the sequence. Continue

this pattern until the entire sequence has been completed.

All Tests is a fixed sequence containing the LaMotte pre-programmed tests,

User Tests, and Absorbance tests.

Modification of the alterable sequences is accomplished through the Editing

Menu. This menu is explained in greater detail in EDITING MENU (p. 32).

Pressing the EXIT button while in a sequence menu will escape back to the

Testing Menu.

Pressing the OFF button at any time will turn the colorimeter off.

COD PLUS COLORIMETER 6/02 27

Page 28

GENERAL TESTING PROCEDURES

n

The following are some step by step examples of how to run tests from the

Testing Menu. These test procedures are designed to be used with LaMotte

SMART Reagent Systems.

TESTING WITH THE LaMOTTE

n

PRE-PROGRAMMED TESTS

Press ON to turn on the COD PLUS Colorimeter.

The LaMotte logo will appear for about 2 seconds

and then the Start screen appears. Press the

Q/ENTER button to start testing.

The MAIN MENU will appear. Press the Q/ENTER

button to select Testing Menu.

Press the Q/ENTER button to select All Tests.

Press the t button to move to the 001 COD LR to

*.

VER 1.0

COD PLUS

* Start

MAIN MENU

* Testing Menu

Editing Menu

PC Link

TESTING MENU

* All Tests

Sequence 1

Sequence 2

ALL TESTS

* 001 COD LR

002 COD SR

003 COD HR

Press the Q/ENTER button to select 001 COD LR.

28 COD PLUS COLORIMETER 6/02

ALL TESTS

* 001 COD LR

002 COD SR

003 COD HR

Page 29

The COD PLUS Colorimeter is ready to scan at the

correct wavelength. Place the blank in the sample

chamber, close the lid and press the Q/ENTER

button to scan blank.

NOTE: Do not keep the button depressed.

001 COD LR

* Scan Blank

The screen will display Blank Done for about 1

second. Scan Sample will be positioned next to *.

Place the reacted sample in the chamber, close the

lid and press the Q/ENTER button to scan sample.

The colorimeter will scan the sample and the results

screen will appear.

Record test result. To repeat the test, press the

Q/ENTER button to scan the sample again. The

last blank scanned is used to zero the colorimeter for

repeated scans. A different blank can be used by

pressing the s button to scroll back to Scan

Blank and then scanning another blank. Scroll with

the t or s buttons and make another selection

with the Q/ENTER button. The %T or Absorbance

of the last test can be viewed by choosing %T/Abs.

Press the EXIT button to escape to previous menus.

NOTE: The menus loop in this screen so either the

s or t buttons will lead to the menu selection

needed.

001 COD LR

Blank Done

* Scan Blank

001 COD LR

* Scan Sample

001 COD LR

100 mgL

* Scan Blank

Next Test

Previous Test

%/Abs

Scan Blank

COD PLUS COLORIMETER 6/02 29

Page 30

CALIBRATING LaMOTTE PRE-PROGRAMMED TESTS

n

The LaMotte Pre-Programmed T ests have been pre-calibrated. Recalibration of

the pre-programmed tests by the user is not possible. However, a procedure to

standardize the calibration can be performed to obtain the most accurate

readings or to meet regulatory requirements.

The LaMotte Pre-Programmed tests are standardized with one standard

solution. To standardize over the full range of the test, the concentration of the

standard should be chosen from the high end of the range. Alternatively , if

samples do not cover the full range of the test, a standard should be chosen that

is close to the concentration of the samples.

The standardization procedure should be followed as often as required by

regulations and laws for compliance monitoring.

In the example below the Aluminum calibration will be standardized.

Prepare a standard solution to be tested. Use 0.10 ppm aluminum.

Use the s or t button to scroll to 002 Aluminum.

Follow instructions in the COD PLUS Manual for

testing the aluminum standard. Scan the blank.

The screen will display Blank Done for about 1

second. Scan Sample will be positioned next to *.

Place the reacted sample in the chamber, close the

lid and press Q/ENTER to scan sample. The result

will be displayed.

The displayed result can now be standardized. Use

the s or t buttons to scroll to Calibrate. Press

Q/ENTER to select.

002 Aluminum

* Scan Blank

002 Aluminum

Blank Done

* Scan Sample

002 Aluminum

* Scan Sample

002 Aluminum

0.09 ppm

* Scan Sample

Next Test

Previous Test

%T/Abs

Calibrate

Scan Blank

30 COD PLUS COLORIMETER 4/03

Page 31

A reverse font (dark background with light

characters) will appear to indicate that the reading

can be adjusted. Use s or t to scroll to the

concentration of the sample, 0.10 ppm in this

example.

002 Alumninum

0.09

* Calibrate

Set the calibration by pressing Q/ENTER to select

Calibrate.

Two menu choices will be offered, Set

Calibration and Factory Setting. Set the

calibration by pressing Q/ENTER to select Set

Calibration;oruses or t to scroll to and select

Factory Setting to revert to the factory

calibration.

The meter will display the message “Storing” and

return to 002 Aluminum test.

The calibration for 002 Aluminum has now been

standardized and can be used for testing. The

standardization can be removed by repeating the

calibration and selecting Factory Setting.

002 Aluminum

0.10

* Calibrate

002 Aluminum

0.10

* Set Calibration

Facctory Setting

Storing

002 Aluminum

* Scan Sample

Next Test

Previous Test

%/Abs

Calibrate

Scan Blank

COD PLUS COLORIMETER 4/03 31

Page 32

MEASURING IN THE ABSORBANCE MODE

n

Press ON to turn on the COD PLUS Colorimeter.

The LaMotte logo will appear for about 2 seconds

and then the Start screen appears. Press the

Q/ENTER button to start testing.

The MAIN MENU will appear. Press the Q/ENTER

button to select Testing Menu.

Press the t button to scroll to Absorbance.

Press the Q/ENTER button to select Absorbance.

VER 1.0

COD PLUS

* Start

MAIN MENU

* Testing Menu

Editing Menu

PC Link

TESTING MENU

All Tests

Sequence 1

Sequence 2

Sequence 3

* Absorbance

TESTING MENU

* Absorbance

Press the tor s buttons to move to the desired test.

Press the Q/ENTER button to select test.

32 COD PLUS COLORIMETER 6/02

Absorbance

* 101

102 End of List

103 Abs 430

104 Abs 620

Absorbance

* 103 Abs 430

104 Abs 620

Page 33

Insert blank, press the Q/ENTER button to scan

blank.

103 Abs 430

* Scan Blank

The screen will display Blank Done for about 1

second.

Insert the reacted sample. Press the Q/ENTER

button to scan the sample.

Record test result. To repeat the test, press the

Q/ENTER button to scan the sample again. The

last blank scanned is used to zero the colorimeter for

repeated scans. A different blank can be used by

pressing the s button to scroll back to Scan

Blank and then scanning another blank. Scroll with

t or s and make another selection with

Q/ENTER. The %T or Absorbance of the last test

can be viewed by choosing %T/Abs. Press EXIT to

escape to previous menus.

NOTE: The menus loop in this screen so either t or

swill lead to the menu selection needed.

103 Abs 430

Blank Done

* Scan Blank

103 Abs 430

* Scan Sample

103 Abs 430

0.95

* Scan Sample

Next Test

Previous Test

%T/Abs

Scan Blank

COD PLUS COLORIMETER 6/02 33

Page 34

EDITING MENU

The EDITING MENU allows the user to edit sequences, edit user tests, set the

clock, edit the logging function, and set the power saving function.

EDIT A SEQUENCE

n

The EDIT SEQUENCE menu allows three alterable test sequences (SEQUENCE

1, SEQUENCE 2, and SEQUENCE 3) to be edited.

Press ON to turn on the COD PLUS Colorimeter.

The LaMotte logo will appear for about 2 seconds and

then the Start screen appears. Press the Q/ENTER

button to start testing.

The Main Menu will appear. Press the t button to

scroll to Editing Menu.

Press the Q/ENTER button to select Editing

Menu.

The Editing Menu appears. Press the Q/ENTER

button to select Editing Sequence.

VER 1.0

COD PLUS

*START

MAIN MENU

* Testing Menu

Editing Menu

PC Link

MAIN MENU

*Editing Menu

PC Link

EDITING MENU

* Edit Sequence

Edit User Test

Set Clock

The Edit Sequence menu appears. Press the

Q/ENTER button to scroll to select Edit

Sequence 1.

34 COD PLUS COLORIMETER 6/02

EDIT SEQUENCE

*Edit Sequence 1

Edit Sequence 2

Edit Sequence 3

Page 35

Sequence 1 appears.

ADDING OR DELETING TESTS

n

EDIT SEQUENCE 1

*004 Ammonia-NLF

005 Ammonia-NLS

006 Ammonia-NH

There are three ways to alter a sequence: Insert Before, Insert After,

and Delete. Insert Before adds a new test to the sequence before the

selected test. Insert After adds a new test to the sequence after the selected

test. Delete is used to remove an existing test from a sequence.

Below is a step by step example of how to add a test to SEQUENCE 1 starting

from the EDIT SEQUENCE 1 menu.

Press the t button to scroll to 005 Ammonia-NLS.

Press the Q/ENTER button to select 005

Ammonia-NLS.

Press the Q/ENTER button to select Insert

Before.

The ALL TESTS menu appears. Press the t button

to move the 001 COD LR to *.

EDIT SEQUENCE 1

004 Ammonia-NLF

005 Ammonia-NLS

* 006 Ammonia-NH

EDIT SEQUENCE 1

* 005 Ammonia-NLS

006 Ammonia-NH

007 Boron

EDIT SEQUENCE 1

* Insert Before

Insert After

Delete

ALL TESTS

* 001 COD LR

002 COD SR

003 COD HR

Continued...

COD PLUS COLORIMETER 6/02 35

Page 36

Press the Q/ENTER button to select 001 COD LR.

ALL TESTS

* 001 COD LR

002 COD SR

003 COD HR

Sequence 1 appears in EDIT SEQUENCE 1 menu

and 001 COD LR is now before 005

Ammonia-NLS in the sequence. All changes to

Sequence 1 are automatically saved. Press the EXIT

button to exit the EDIT SEQUENCE 1 menu and

return to the EDIT SEQUENCE menu or continue

editing.

The EDIT SEQUENCE menu appears. Select another

sequence to edit or press the EXIT button to return

to the EDITING MENU. Press the EXIT button

again to return the the MAIN MENU.

EDIT SEQUENCE 1

* 004 Ammonia-NLF

001 COD LR

005 Ammonia-NLS

006 Ammonia-NH

007 Boron

EDIT SEQUENCE 1

* Edit Sequence 1

Edit Sequence 2

Edit Sequence 3

Below is a step by step example of how to delete a test from SEQUENCE 1

starting from the EDIT SEQUENCE 1 menu. The test 001 COD LR, added in

the previous example, will be deleted.

Press the t button to scroll to 001 COD LR.

EDIT SEQUENCE 1

004 Ammonia-NLF

* 001 COD LR

005 Ammonia-NLS

006 Ammonia-NH

007 Boron

Press the Q/ENTER button to select 001 COD LR.

36 COD PLUS COLORIMETER 6/02

EDIT SEQUENCE 1

* 001 COD LR

005 Ammonia-NLS

006 Ammonia-NH

Page 37

Press the t button to scroll to Delete.

EDIT SEQUENCE 1

* Insert Before

Insert After

Delete

Press the Q/ENTER button to select Delete.

Sequence 1 appears in the EDIT SEQUENCE 1

menu and 002 Aluminum has been deleted. All

changes to SEQUENCE 1 are automatically saved.

Press the

EXIT button to exit the EDIT SEQUENCE

1 menu and return to the EDIT SEQUENCE menu

or continue editing.

The EDIT SEQUENCE menu appears. Select another

sequence to edit or press the EXIT button to return

to the EDITING MENU. Press the EXIT button again

to return the the MAIN MENU.

EDIT SEQUENCE 1

* Delete

EDIT SEQUENCE 1

* 004 Ammonia-NLF

005 Ammonia-NLS

006 Ammonia-NH

007 Boron

EDIT SEQUENCE 1

* Edit Sequence 1

Edit Sequence 2

Edit Sequence 3

COD PLUS COLORIMETER 6/02 37

Page 38

EDIT USER TESTS

n

If a test other than the LaMotte programmed tests is performed regularly , a

calibration for it may be entered in one of the 10 User Tests. These tests are

originally named “User Test1-10". It will be possible to rename the test,

select a wavelength, enter a new calibration, select the number of decimal

places used to display the results, and select the units. A User Test may be

added for a reagent system for which no precalibrated test exists. A calibration

of a LaMotte reagent system may also be entered. The calibration of a User

Test can be changed at any time.

The User Tests have the ability to handle 2 data points. The colorimeter will

determine the absorbance of the standards and calculate a response that will be

stored to determine the concentration of future samples of unknown

concentration. These standards should cover all the concentrations for the

range of the test being performed and be scanned beginning with the low

concentration and finishing with the high concentration (for more

information, see CALIBRATION CURVES, p. 13). Prepare these solutions

prior to entering a new calibration.

NOTE: A calibration procedure must be performed before using any of the

User Tests.

The User Tests can be placed in any of the alterable sequences using EDIT

SEQUENCES.

To edit a User Test, start at the EDITING MENU.

Scroll down to Edit User Test.

Press the Q/ENTER button to select the Edit

User Test.

From the EDIT USER TEST menu, select the User

Test to be entered or changed. In this example,

choose 105 User Test 01. Use the t and s

buttons to scroll to other User Tests if desired. Select

the User Test by pressing the Q/ENTER button.

EDITING MENU

* Edit Sequences

Edit User Test

Set Clock

EDITING MENU

* Edit User Test

Set Clock

Edit Logging

EDIT USER TEST

* 105 User Test01

106 User Test02

107 User Test03

108 User Test04

:::

114 User Test10

38 COD PLUS COLORIMETER 6/02

Page 39

NAMING THE TEST

n

A User Test can be up to 11 characters long. The menu choices for each

character are 26 upper case letters A to Z, 26 lower case letters a to z, ten

numerals 0 to 9, a space (SP), a dash (-) and a decimal point (.). The existing

name is displayed on the bottom line of the display. A cursor will be over the

character which is to be edited and that character is also displayed in the

center of the display. The character can be changed by using the t and s

buttons to scroll to other characters. Use the Q/ENTER button to select a

character. The edited name is saved at any time by pressing EXIT or by

pressing the Q/ENTER button after selecting the eleventh character.

From the Edit User Test01 menu press the

Q/ENTER button to select Name The Test and

change the name of User Test 01.

The cursor is over the letter “U”in105 User

Test01 and the letter “U” is displayed in the large

font in the center of the display .

Change the name to H2O. Use the t and s buttons

to scroll to the letter “H” into the center of the

display. Press the Q/ENTER button to select the

letter “H”.

The letter “H” has been entered in the first position

of the name and the cursor has moved to the second

letter “s”.

EDIT USER TEST01

* Name The Test

Select Vial/WL

New Calibration

Decimal Places

Select Units

NAME THE TEST

U

105 User Test01

NAME THE TEST

H

105 User Test01

NAME THE TEST

s

105 User Test01

Use the t and s buttons to scroll to the number

“2” into the center of the display. Press the

Q/ENTER button to select the number “2”.

NAME THE TEST

2

105 Hser Test01

Continued...

COD PLUS COLORIMETER 6/02 39

Page 40

The number “2” has been entered in the second

position of the name and the cursor has moved to

the third letter “e”.

NAME THE TEST

e

105 H2er Test01

Use the t and s buttons to scroll to the letter “O”

into the center of the display. Press the Q/ENTER

button to select the letter “O”.

The letter “O” has been entered in the third position

of the name and the cursor has moved to the fourth

letter “r”. Press the EXIT button to save the name

entered up to this point.

The meter will display the message “Storing” and

return to the EDIT USER TEST01 menu.

NAME THE TEST

O

105 H2Or Test01

NAME THE TEST

r

* 105 H2Or Test01

Storing

EDIT USER TEST01

* Name The Test

Select The Vial/WL

New Calibration

Decimal Places

Select Units

40 COD PLUS COLORIMETER 6/02

Page 41

SELECTING THE VIAL AND WAVELENGTH

n

The COD PLUS Colorimeter uses three different vials (the 25 mm 0290 tube,

UDVs and COD tubes) and 2 different wavelengths (430 and 620 nm). The

colorimeter uses different settings for each of the combinations of vial and

wavelength. These twelve settings are called channels. Choose the channel

with the correct wavelength and vial for the test.

NOTE: 520 nm and 570 nm are not available in the COD PLUS.

Use the t button to scroll to Select Vial/WL

and press Q/ENTER button to select.

Use the t and s buttons to scroll to the

appropriate channel and press Q/ENTER button to

select.

NOTE: This is a looping menu.

The meter will display the message “Storing” and

return to the EDIT USER TEST01 menu.

EDIT USER TEST01

* Name The Test

Select Vial/WL

New Calibration

Decimal Places

Select Units

:::

Ch11 620nm COD

Ch12 570nm COD

SELECT CHANNEL

* Ch1 520nm 25mm

Ch2 430nm 25mm

Ch3 620nm 25mm

Ch4 570nm 25mm

Ch5 520nm UDV

Ch6 430nm UDV

:::

Storing

EDIT USER TEST01

* Select The Vial/WL

New Calibration

Decimal Places

Select Units

COD PLUS COLORIMETER 6/02 41

Page 42

ENTERING A NEW CALIBRATION

n

To enter a new calibration two reacted standards solutions of known

concentration are required: a “low standard” and a “high standard”. These

should be ready to use.

Use the t button to scroll to New Calibration

and press Q/ENTER button to select.

Input the concentration of the LOW STANDARD by

using the t and s buttons to scroll the first digit of

the concentration into the first position on the

display. Press Q/ENTER button to select that digit

(1 for this example).

The number “0” is always the starting point for the

next digit. Continue selecting digits or a decimal

point to enter the concentration (up to seven

characters).

“1.5” has been entered in this example. Press

Q/ENTER button four times to input “0” as the last

four digits. Pressing Q/ENTER after selecting the

last digit saves the concentration.

EDIT USER TEST01

* Select Vial/WL

New Calibration

Decimal Places

Select Units

LOW STANDARD

0______

* Continue

LOW STANDARD

10_____

* Continue

LOW STANDARD

1.50___

* Continue

Input the concentration of the HIGH STANDARD by

using the same method as for the low standard.

42 COD PLUS COLORIMETER 6/02

HIGH STANDARD

0______

* Continue

Page 43

Place a clear blank in the sample chamber. Press the

Q/ENTER button to scan the blank.

The screen will display Blank Done for about 1

second.

Insert Blank

* Continue

Blank Done

* Scan Blank

Place the reacted low standard in the sample

chamber. Press Q/ENTER to scan the low standard.

Place the reacted high standard in the sample

chamber. Press Q/ENTER to scan the high

standard.

The meter will display the message “Storing” and

return to the EDIT USER TEST01 menu.

Insert Lo Standard

* Continue

Insert Hi Standard

* Continue

Storing

EDIT USER TEST01

* New Calibration

Decimal Places

Select Units

COD PLUS COLORIMETER 6/02 43

Page 44

SELECTING THE NUMERICAL FORMAT OF THE RESULT

n

To input tests with very different ranges, the number of decimal places

displayed for a result can be selected. A test which ranges from 20 to 1000 ppm

should not be displayed with three decimal places. A test with a range from

0.010 to 0.500 needs three decimal places (the microprocessor will always

calculate the concentration to many more significant figures than will be

displayed). Menu choices of 0, 1, 2, or 3 decimal places will be given for the

display.

Use the t button to scroll to Decimal Places

and press Q/ENTER button to select.

Use the t button to scroll to the number of decimal

places to be shown and press Q/ENTER to select.

The meter will display the message “Storing” and

return to the EDIT USER TEST01 menu.

EDIT USER TEST01

* New Calibration

Decimal Places

Select Units

DECIMAL PLACES?

* None 0

One 0.0

Two 0.00

Three 0.000

Storing

EDIT USER TEST01

* Decimal Places

Select Units

44 COD PLUS COLORIMETER 6/02

Page 45

SELECTING THE UNITS OF CONCENTRATION

n

The COD PLUS Colorimeter has seven options for units of concentration.

They are No Units, ppm, pH, FTU, ppb, ppt and mgL.

Use the t button to scroll to Select Units and

press Q/ENTER to select.

Use the t button to scroll to the appropriate unit

and press Q/ENTER to select.

The meter will display the message “Storing” and

return to the EDIT USER TEST01 menu.

EDIT USER TEST01

* Decimal Places

Select Units

SELECT UNITS

* No Units

ppm

pH

FTU

ppb

ppt

mgL

Storing

EDIT USER TEST01

* Select Units

COD PLUS COLORIMETER 6/02 45

Page 46

SETTING THE CLOCK

n

Setting the clock allows the correct time and date stamp to be stored with each

reading in the data logger and with each reading sent out the serial port.

From the EDITING MENU use the t button to scroll

to Set Clock. Press Q/ENTER to select.

The current date and time are displayed as month day - year on the first line and as hours : minutes :

seconds on the second line. A two-digit number is

displayed for each setting. Use the t and s buttons

to scroll to the appropriate number and press

Q/ENTER to select. The cursor will move to the

next digit. Set all subsequent numbers in the same

manner. Selecting the final digit in the seconds field

stores the date and time and returns to the EDITING

MENU.

NOTE: These are looping menus.

EDITING MENU

* Edit Sequences

Edit User Test

Set Clock

Editing Logging

Factory Setup

Set PWR Save

SET TIME

MM-DD-YY

HH:MM:SS

EDITING MENU

* Set Clock

Editing Logging

Factory Setup

Set PWR Save

46 COD PLUS COLORIMETER 6/02

Page 47

TURNING THE DATA LOGGER ON AND OFF

n

The default setting for the datalogger is “Enabled” or turned off. If there is no

need for data logging, this setting is suggested. If data logging is needed, the

data logger can be “Enabled” or turned on.

From the EDITING MENU use the t button to

scroll to Edit Logging. Press

Q/ENTER to

select.

The current setting is always displayed next to the *.

To change the setting, use the t or s buttons to

scroll to the other setting. Press Q/ENTER to select.

The meter will display the message “Storing” and

return to the EDITING MENU.

EDITING MENU

* Edit Sequences

Edit User Test

Set Clock

Editing Logging

Factory Setup

Set PWR Save

EDIT LOGGING

* Enabled

Disabled

Storing

EDITING MENU

* Editing Logging

Factory Setup

Set PWR Save

COD PLUS COLORIMETER 6/02 47

Page 48

FACTORY SETUP

n

The Factory Setup menu is used in the manufacturing of the COD PLUS

Colorimeter. This menu is not for use by the operator in the field.

SETTING THE POWER SAVING FUNCTION

n

The COD PLUS Colorimeter has a power saving function that turns the meter

off after an interval of inactivity. If no buttons have been pressed during that

interval the meter will turn itself off. This interval can be disabled or set for 5,

15, 30 or 60 minutes. The default setting is 5 minutes.

From the EDITING MENU use the t button to

scroll to Set PWR Save. Press Q/ENTER to select.

The current setting is always displayed next to the *.

To change the setting, use the t or s buttons to

scroll to the appropriate setting. Press Q/ENTER to

select.

The meter will display the message “Storing” and

return to the EDITING MENU.

EDITING MENU

* Edit Sequences

Edit User Test

Set Clock

Editing Logging

Factory Setup

Set PWR Save

Disabled

AUTO SHUTOFF

* 5 Minutes

15 Minutes

30 Minutes

60 Minutes

Storing

EDITING MENU

* Set PWR Save

48 COD PLUS COLORIMETER 6/02

Page 49

PC LINK

The COD PLUS Colorimeter may be interfaced with any Windows-based

computer by using the LaMotte SMARTLink2 Program and Interface Cable

(Order Code 1912-3 [3.5 disk] or 1912-CD [compact disk]). The program

stores customer information and test data in a database. It can be used to

download data stored in the COD PLUS datalogger for each test site.

The colorimeter may also be interfaced with an RS-232 serial printer, using an

interface cable (Order Code 1772) and setting the printer configuration to the

Output as described below.

Choose PC Link from the Main Menu. The user can download the entire

datalogging buffer. Downloading does not delete or empty the datalogger.

OUTPUT

n

RS-232 compatible, asynchronous serial, 9600 baud, no parity, 8 data bits, 1

stop bit.

COMPUTER CONNECTION

n

RS-232 interface connection, 8 pin mini-DIN/9 pin F D-submin. (Order Code

1772).

BA TTERY OPERA TION

The colorimeter may be run on battery power or AC using the AC adapter. If

using the meter as a benchtop unit, keep it plugged in if possible. If used on

only battery power, always have a spare battery on hand.

If the battery power is low , the COD PLUS will

display “LOW BATT” and turn off.

REPLACING THE BATTERY

n

The COD PLUS Colorimeter uses a standard 9-volt alkaline battery that is

available worldwide. The battery compartment is located on the bottom of the

the case.

To replace the battery:

1. Open the battery compartment lid.

2. Remove the battery and disconnect the battery from the polarized plug.

3. Carefully connect the new battery to the polarized plug and insert it into the

compartment.

4. Close the battery compartment lid.

COD PLUS COLORIMETER 6/02 49

LOW BATT

Page 50

MAINTENANCE

CLEANING

n

Clean with a damp, lint-free cloth.

DO NOT ALLOW WATER TO ENTER THE COLORIMETER

CHAMBER OR ANY OTHER PARTS OF THE METER.

TROUBLESHOOTING GUIDE

ERROR MESSAGES

n

n

OVER RANGE

If the message OVERRANGE is displayed when scanning a sample, the sample

may be over range or under range. If the sample is over range the sample should

be diluted and tested again (see Sample Dilution Techniques and Volumetric

Measurements, p. 16).

If OVERRANGE is displayed, press the Q/ENTER

button to continue testing on diluted samples.

HELPFUL HINTS

n

n

STRAY LIGHT

The COD PLUS Colorimeter should have no problems with stray light. Make

sure that the sample compartment lid is always fully closed, except when

testing COD with the adapter.

015 Chlorine

OVERRANGE

* Continue

50 COD PLUS COLORIMETER 6/02

Page 51

COD PLUS COLORIMETER

REAGENT SYSTEMS

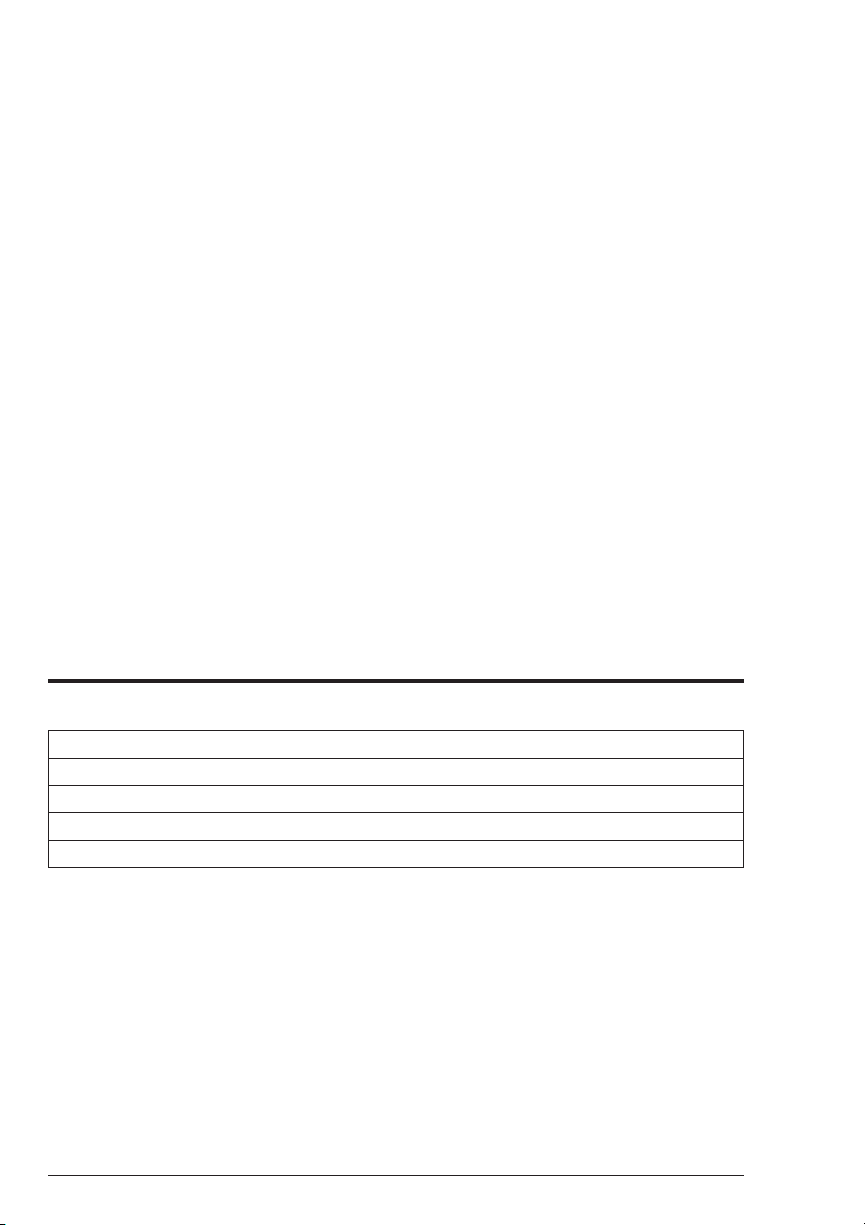

COD PLUS REAGENT SYSTEMS LIST

n

Test # Test Factor Range(ppm) Test Method (# of Reagents)

1 COD-Low Range 5-150 Digestion (1) 25

2 COD-Standard Range 0-1500 Digestion (1) 25

3 COD-High Range 0-15000 Digestion (1) 25

4 Ammonia Nitrogen-

Low Range, Fresh Water

5 Ammonia Nitrogen-

Low Range, Salt Water

6 Ammonia Nitrogen-

High Range

7 Boron 0.00-0.80 Azomethine-H (2) 50

8 Cobalt 0.00-2.00 PAN (3) 50

9 Color 0-1000 Platinum Cobalt (0) ¥

10 Copper-Cuprizone 0.00-2.00 Cuprizone (2) 50

11 Copper-DDC 0.00-6.00 Diethyldithiocarbamate (1) 100

12 Cyanuric Acid 5-200 Melamine (1) 50

13 Dissolved Oxygen 0.0-11.0 Winkler colorimetric (3) 300

14 Fluoride 0.00-2.00 SPADNS (2) 50

15 Hydrazine 0.00-1.00 P-dimethylaminobenzaldehyde (2) 50

16 Molybdenum-High Range 0.0-50.0 Thioglycolate (3) 50

17 Nickel 0.00-8.00 Dimethylglyoxime (6) 50

18 Ozone-Low Range 0.00-0.40 Indigo (3) 100

19 Ozone-High Range 0.00-2.50 Indigo (3) 50

20 Phosphate-Low Range 0.00-3.00 Ascorbic Acid Reduction (2) 50

21 Phosphate-High Range 0.0-70.0 V anodomolybdphosphoric Acid (1) 50