Page 1

12

0

0

COL ORIMETER

.................

Instruction

MANUAL

Page 2

Page 3

TABLE OF CONTENTS

GENERAL INFORMATION

PackagingandDelivery...............................4

General Precautions ................................4

Safety Precautions .................................4

Limits of Liability ..................................4

Specifications....................................5

Parts&Accessories.................................6

EPACompliance..................................7

CEStatement....................................7

CHEMICALTESTING........................8

WaterSamplingforChemicalAnalysis.....................8-9

Filtration ......................................9

AnIntroductionToColorimetricAnalysis..................10-11

Reagent Blank ...................................11

ColorimeterTubes.................................11

SampleDilutionTechniques&VolumetricMeasurement...........12

Interferences....................................13

StrayLightInterference..............................13

GENERALOPERATINGINFORMATION.............14

Overview....................................14-15

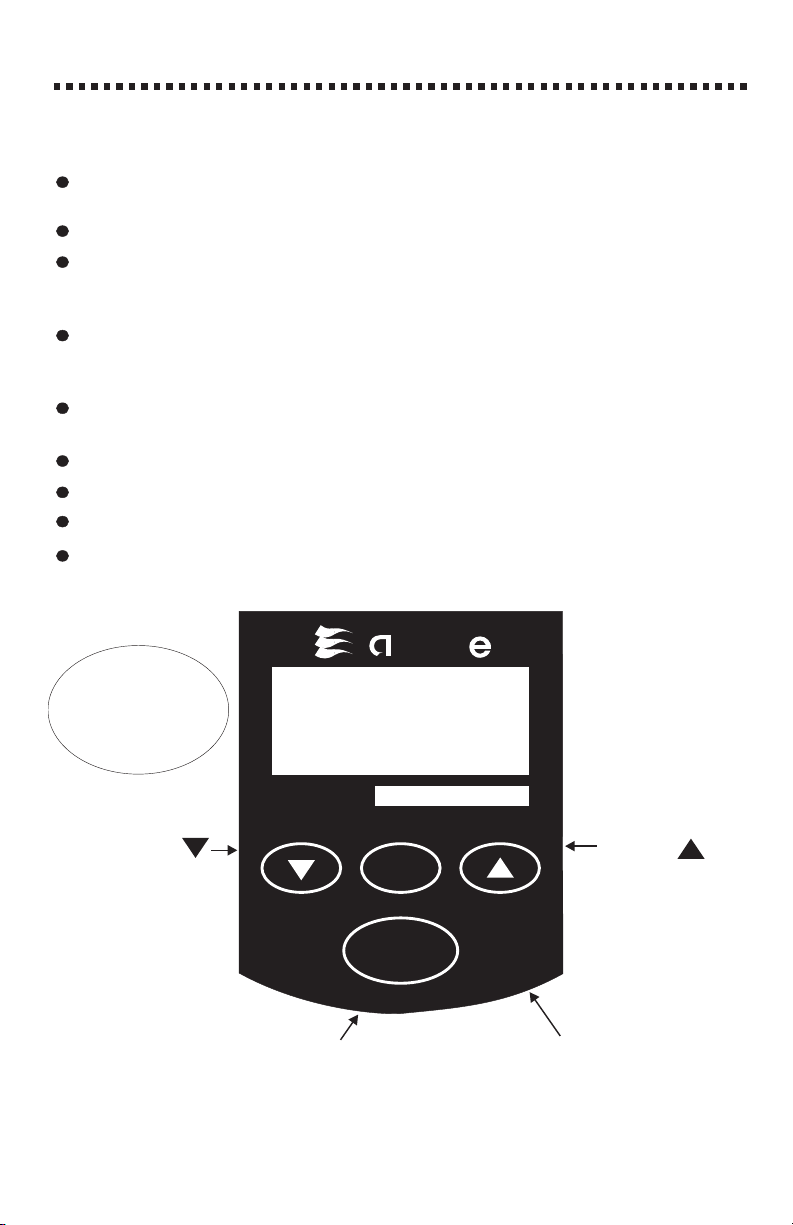

TheKeypadandDisplay .............................16

TestingTips....................................17

CALIBRATIONPROCEDURE..................18-19

ANALYSISPROCEDURE....................20-21

AVAILABLETESTKITS ......................22

TROUBLESHOOTINGGUIDE...................23

RS232PORT ...........................24

MAINTENANCE OF THE 1200 ..................25

ReplacingtheBattery...............................25

Repairs.......................................25

MeterDisposal...................................25

WARRANTY............................26

Limitations.....................................26

Page 4

GENERAL INFORMATION

PACKAGING & DELIVERY

Experienced packaging personnel at LaMotte Company assure adequate

protection against normal hazards encountered in transportation of shipments.

After the product leaves the manufacturer, all responsibility for safe delivery is

assured by the transportation company. Damage claims must be filed immediately

with the transportation company to receive compensation for damaged goods.

Should it be necessary to return the instrument for repair or servicing, pack the

instrument carefully in a suitable container with adequate packing material. A

return authorization number must be obtained from LaMotte Company by

calling 1-800-344-3100 or faxing 1-410-778-6394. Attach a letter with the

authorization number to the shipping carton which describes the reason for the

return. This information will enable the service department to make the required

repairs more efficiently.

GENERAL PRECAUTIONS

Read the instruction manual before attempting to set up or operate this

instrument. Failure to do so could result in personal injury or damage to the

instrument.

The 1200 Colorimeter should not be stored or used in a

wet or corrosive environment. Care should be taken to

prevent water from wet colorimeter tubes from entering

the colorimeter light chamber.

NEVER PUT WET TUBES IN THE COLORIMETER.

SAFETY PRECAUTIONS

Read labels on all reagent containers. Some labels include precautionary notices

and first aid information. Certain reagents are considered hazardous and are

designated with a * in the instruction manual. To view or print a Material Safety

Data Sheet (MSDS) for these reagents see MSDS CD or our web site. To obtain a

printed copy, contact us by e-mail, phone or FAX. Additional information for all

LaMotte reagents is available in the United States, Canada, Puerto Rico, and the

US Virgin Islands from Chem-Tel by calling 1-800-255-3924. For other areas,

call 813-248-0585 collect to contact Chem-Tel’s International access number.

Each reagent can be identified by the four digit number listed on the upper left

corner of thereagent label, in the contents list and in the test procedures.

LIMITS OF LIABILITY

Under no circumstances shall LaMotte Company be liable for loss of life,

property, profits, or other damages incurred through the use or misuse of their

products.

4

Page 5

SPECIFICATIONS

Instrument Type Single wavelength, direct reading colorimeter

Measurement Wavelengths: 420 nm, 460 nm, 510 nm, 530 nm, 570 nm or

605 nm

Readable Resolution: Determined by test factor

Photometric Precision: ±0.001 Absorbance Unit

Range: 0 - 2.00 absorbance units

Display: 3 ½ digits

Response Time: 2 seconds

Warm-up Time: Not required

Lamp: LED

Detector: Silicon Photodiode

Sample: 10 mL in capped tube

Sample Chamber: Accepts 25mm diameter flat-bottomed tubes

(capped)

Power Source: Battery Operation: 9 Volt Alkaline

Line Operation: 110V/60Hz, 220V/50Hz, with available adapter

Size (L X W X H): 8.5 x 16.2 x 6.7 cm, 3.4 X 6.4 X 2.6 inches

Shipping Weight: 11 oz (312 g) meter only

Serial Interface: RS232, 8 pin mDIN, 9600b, 8, 1, n

5

Page 6

PARTS & ACCESSORIES

Included in the Model 1200 Colorimeter Kit :

1200 Colorimeter

Colorimeter tubes, set of 6

Water Sample Collecting Bottle

Reagent System

Optional Accessories

AC Adapter, 110V/60Hz Code 1726-110

AC Adapter, Universal Code 1754

Colorimeter Tubes, set of 6 Code 0290-6

6

Page 7

EPA COMPLIANCE

CE

EUROPEAN

MARK

Application of Council Directives:

Standards to which Conformity Declared:

Manufacturer's Name:

Manufacturer's Address:

Importer's Name:

Importer's Address:

Type of Equipment:

Model Number:

Year of Manufacture:

89/336/EEC

EN55022, EN50082-1, En600950

802 Washington Avenue

PO Box 329

Chestertown, MD 21620

Reagecon Diagnostics Ltd

Water Quality Meters

2020/1200

1997

13 A/D Shannon Free Zone

Shannon, Co. Clase. Ireland

LaMotte Company

I, the undersigned, hereby declare that the equipment specified above

conforms to the above Directive and Standards.

Place

Chestertown, Maryland

Date

3-19-97

Signature

Name

James K. Trumbauer

Position

V.P., Director of Research & Development

DECLARATION OF CONFORMITY

NOTE: The device complies to the product specifications for the

Low Voltage Directive when furnished with the 220V AC Adapter (Code 1774).

The 1200 Chlorine Colorimeter is an EPA Accepted instrument.

EPA Accepted means that the instrument meets

requirements for colorimeters as found in test procedures

that are approved for the National Primary Drinking

Water Regulations (NPDWR) or National Pollutant

Discharge Elimination Systems (NPDES) compliance

monitoring programs. EPA Accepted instruments may be

used with approved test procedures without additional

approval.

CE COMPLIANCE

The 1200 Colorimeter has

been independently tested

and has earned the European

CE Mark of Compliance for

electromagnetic compatibility

and safety.

7

Page 8

CHEMICAL TESTING

WATER SAMPLING FOR CHEMICAL ANALYSIS

Taking Representative Samples

The underlying factor to be considered for any type of water sampling is whether

or not the sample is truly representative of the source. To properly collect a

representative sample:

Sample as frequently as possible.

•

Collect a large sample or at least enough to conduct whatever tests are

•

necessary.

Makeacompositesampleforthesamesamplingarea.

•

Handle the sample in such a way as to prevent deterioration or contamination

•

before the analysis is performed.

Perform analysis for dissolved gases such as dissolved oxygen, carbon dioxide,

•

and hydrogen sulfide immediately at the site of sampling. These factors, as well

as samples for pH, cannot be stored for later examination.

Make a list of conditions or observations which may affect the sample. Other

•

considerations for taking representative samples are dependent upon the

source of the sample. Taking samples from surface waters involves different

considerations than taking samples from impounded and sub-surface waters.

SamplingofOpenWaterSystems

Surface waters, such as those found in streams and rivers, are usually well mixed.

The sample should be taken downstream from any tributary, industrial or sewage

pollution source. For comparison purposes samples may be taken upstream and at

the source of the pollution before mixing.

In ponds, lakes, and reservoirs with restricted flow, it is necessary to collect a

number of samples in a cross section of the body of water, and where possible

composite samples should be made to ensure representative samples.

To collect samples from surface waters, select a suitable plastic container with a

tight fitting screw cap. Rinse the container several times with the sample to be

tested, then immerse the container below the surface until it is filled to

overflowing and replace the cap. If the sample is not to be tested immediately,

pour a small part of the sample out and reseal. This will allow for any expansion.

Any condition which might affect the sample should be listed.

Sub-surface sampling is required to obtain a vertical profile of streams, lakes,

ponds, and reservoirs at specific depths. This type of sampling requires more

sophisticated sampling equipment.

8

Page 9

For dissolved oxygen studies, or for tests requiring small sample sizes, a Water

Sample Bottle (LaMotte Code 1060) will serve as a subsurface or in-depth

sampler. This weighted device is lowered to the sampling depth and allowed to

rest at this depth for a few minutes. The water percolates into the sample

chamber displacing the air which bubbles to the surface. When the bubbles cease

to rise, the device has flushed itself approximately five times and it may be raised

to the surface for examination. The inner chamber of the sampling device is

lifted out and portions of the water sample are carefully dispensed for subsequent

chemical analysis.

A Snap-Plunger Water Sampler (LaMotte Code 1077) is another “in-depth”

sampling device which is designed to collect large samples which can be used for

a multitude of tests. Basically, this collection apparatus is a hollow cylinder with a

spring loaded plunger attached to each end. The device is cocked above the

surface of the water and lowered to the desired depth. A weighted messenger is

sent down the calibrated line to trip the closing mechanism and the plungers seal

the sample from mixing with intermediate layers as it is brought to the surface. A

special drain outlet is provided to draw off samples for chemical analysis.

Sampling of Closed System

To obtain representative samples from confined water systems, such as pipe lines,

tanks, vats, filters, water softeners, evaporators and condensers, different

considerations are required because of chemical changes which occur between

the inlet and outlet water. One must have a basic understanding of the type of

chemical changes which occur for the type of equipment used. Also,

consideration should be given to the rate of passage and retaining time for the

process water.

Temperature changes play an important part in deciding exactly what test should

be performed. Process water should be allowed to come to room temperature,

20–25°C, before conducting any tests.

When drawing off samples from an outlet pipe such as a tap, allow sample to run

for several minutes, rinsing the container several times before taking the final

sample. Avoid splashing and introduction of any contaminating material.

FILTRATION

When testing natural waters that contain significant turbidity due to suspended

solids and algae, filtration is an option. Reagent systems, whether EPA, Standard

Methods, LaMotte or any others, will generally only determine dissolved

constituents. Both EPA and Standard Methods suggest filtration through a 0.45

micron filter membrane, to remove turbidity, for the determination of dissolved

constituents.** To test for total constituents, organically bound and suspended or

colloidal materials, a rigorous high temperature acid digestion is necessary.

**LaMotte offers a filtering apparatus: Syringe Assembly (Code 1050) and

Membrane Filters, 0.45 micron (Code 1103).

9

Page 10

AN INTRODUCTION TO

COLORIMETRIC ANALYSIS

Most test substances in water are colorless and undetectable to the human eye.

To test for their presence we must find a way to “see” them. The LaMotte

colorimeter can be used to measure any test substance that is itself colored or can

be reacted to produce a color. In fact a simple definition of colorimetry is “the

measurement of color” and a colorimetric method is “any technique used to

evaluate an unknown color in reference to known colors”. In a colorimetric

chemical test, the intensity of the color from the reaction must be proportional to

the concentration of the substance being tested. Some reactions have limitations

or variances inherent to them that may give misleading results. Many such

interferences are discussed with each particular test instruction. In the most basic

colorimetric method the reacted test sample is visually compared to a known

color standard. However, accurate and reproducible results are limited by the

eyesight of the analyst, inconsistencies in the light sources, and the fading of

color standards.

To avoid these sources of error, a colorimeter can be used to photoelectrically

measure the amount of colored light absorbed by a colored sample in reference to

a colorless sample (blank).

White light is made up of many different colors or wavelengths of light. A

colored sample typically absorbs only one color or one band of wavelengths from

the white light. Only a small difference would be measured between white light

before it passes through a colored sample versus after it passes through a colored

sample. The reason for this is that the one color absorbed by the sample is only a

small portion of the total amount of light passing through the sample. However,

if we could select only that one color or band of wavelengths of light to which

the test sample is most sensitive, we would see a large difference between the

light before it passes through the sample and after it passes through the sample.

A colorimeter passes a white light beam through an optical filter which transmits

only one particular color or band of wavelengths of light to the photodetector

where it is measured. The difference in the amount of colored light transmitted

by a colorless sample (blank) and the amount of colored light transmitted by a

colored sample is a measurement of the amount of colored light absorbed by the

sample. In most colorimetric tests the amount of colored light absorbed is directly

proportional to the concentration of the test factor producing the color and the

path length through the sample. However, for some tests the amount of colored

light absorbed is inversely proportional to the concentration.

The choice of the correct optical filter and therefore the correct color or

wavelength of light is important. It is interesting to note that the filter that gives

the most sensitive calibration for a test factor is the complementary color of the

test sample. For example, the Nitrate-Nitrogen test produces a pink color

proportional to the nitrate concentration in the sample (the greater the nitrate

concentration, the darker the pink color). A green filter is used since a

pinkish-red solution absorbs mostly green light.

10

Page 11

The 1200 Colorimeter has been specially calibrated to read test results directly in

parts per million (ppm) of the test factor. The sensitivity of the response has been

maximized by using a specific, complementary light source for each test.

REAGENT BLANK

Some tests will provide greater accuracy if a reagent blank is determined, to

compensate for any color or turbidity resulting from the reagents themselves. A

reagent blank is performed by running the test procedure on 10 mL of

demineralized water. Use sample water to zero the meter. Insert the reagent blank

in the colorimeter chamber and select READ. Note result of reagent blank.

Perform the tests on the unknown as described. Subtract results of

reagent blank from all subsequent test results.

COLORIMETER TUBES

The handling of the colorimeter tubes is of utmost importance. Scratches,

fingerprints and water droplets on the tube or inside the light chamber can cause

stray light interference leading to inaccurate results. It is imperative that the

tubes and light chamber be clean and dry. The glassware must be clean and

defect-free. Scratches and abrasions will permanently affect the accuracy of the

readings. Tubes can be acid washed periodically. After a tube has been filled and

capped, it should be held by the cap and the outside surface should be wiped with

a clean, lint-free absorbent cloth until it is dry and smudge-free. Handling the

tube only by the cap will avoid problems from fingerprints. Always set the clean

tube aside on a clean surface that will not contaminate the tube.

Variability in the geometry and quality of the glassware is the predominate cause

of variability in results. Orientation of the tube in the chamber will greatly affect

the test results. To obtain the most accurate results, the tubes must be positioned

so that the index line on the tube is aligned with the arrow-shaped index mark t

molded into the housing in front of the light chamber. This will ensure that the

most accurate results are obtained.

11

Page 12

SAMPLE DILUTION TECHNIQUES & VOLUMETRIC

MEASUREMENTS

If a test result using the 1200 Colorimeter gives an ER2 (over range) message, the

sample must be diluted. Then the test should be repeated to obtain a reading

which is in the concentration range for the test. (Note: This is not true for

colorimetric determination of pH.)

Example:

Measure 5 mL of the water sample into a graduated cylinder. Add demineralized

water until the cylinder is filled to the 10 mL line. The sample has been diluted

by one-half, and the dilution factor is therefore 2. Perform the test procedure,

then multiply the resulting concentration by 2 to obtain the test result.

The following table gives quick reference guidelines on dilutions of various

proportions. All dilutions are based on a 10 mL volume, so several dilutions will

require small volumes of the water sample. Graduated pipets should be used for

all dilutions.

Deionized Water to

Bring Volume to 10

Size of Sample

10 mL 0 mL 1

5mL 5mL 2

mL

Multiplication

Factor

2.5 mL 7.5 mL 4

1mL 9mL 10

0.5 mL 9.5 mL 20

If the above glassware is not available, dilutions can be made with the

colorimeter tube. Fill the colorimeter tube to the 10 mL line with the sample

then transfer it to another container. Add 10 mL volumes of demineralized water

to the container and mix. Transfer back 10 mL of the diluted sample to the

colorimeter tube and follow the test procedure. Continue diluting and testing

until a reading, which is in the concentration range for the test, is obtained. Be

sure to multiply the concentration found by the dilution factor (the number of

total 10 mL volumes used).

Example:

10 mL of sample is diluted with three 10 mL volumes of demineralized water; the

dilution factor is four.

12

Page 13

INTERFERENCES

LaMotte reagent systems are designed to minimize most common interferences.

Each individual test discusses interferences unique to that test. Be aware of

possible interferences in the water being tested.

The reagent systems also contain buffers to adjust the water sample to the ideal

pH for the reaction. It is possible that the buffer capacity of the water sample may

exceed the buffer capacity of the reagent system and the ideal pH will not be

obtained. If this is suspected, measure the pH of a reacted distilled water reagent

blank using a pH meter. This is the ideal pH for the test. Measure the pH of a

reacted water sample using the pH meter. If the pH is significantly different from

the ideal value, the pH of the sample should be adjusted before testing.

Interferences due to high concentration of the substance being tested, can be

overcome by sample dilution (see page 12).

STRAY LIGHT INTERFERENCE

Stray light interference can be minimized by always zeroing the meter and

reading a sample with the lid closed. Turbidimetric determinations (i.e. sulfate)

are most likely to exhibit a stray light interference. Colorimetric tests are less

likely to have this problem unless the samples are turbid. If sample turbidity is

causing a stray light interference, filtration may be needed.

13

Page 14

GENERAL OPERATING INFORMATION

OVERVIEW

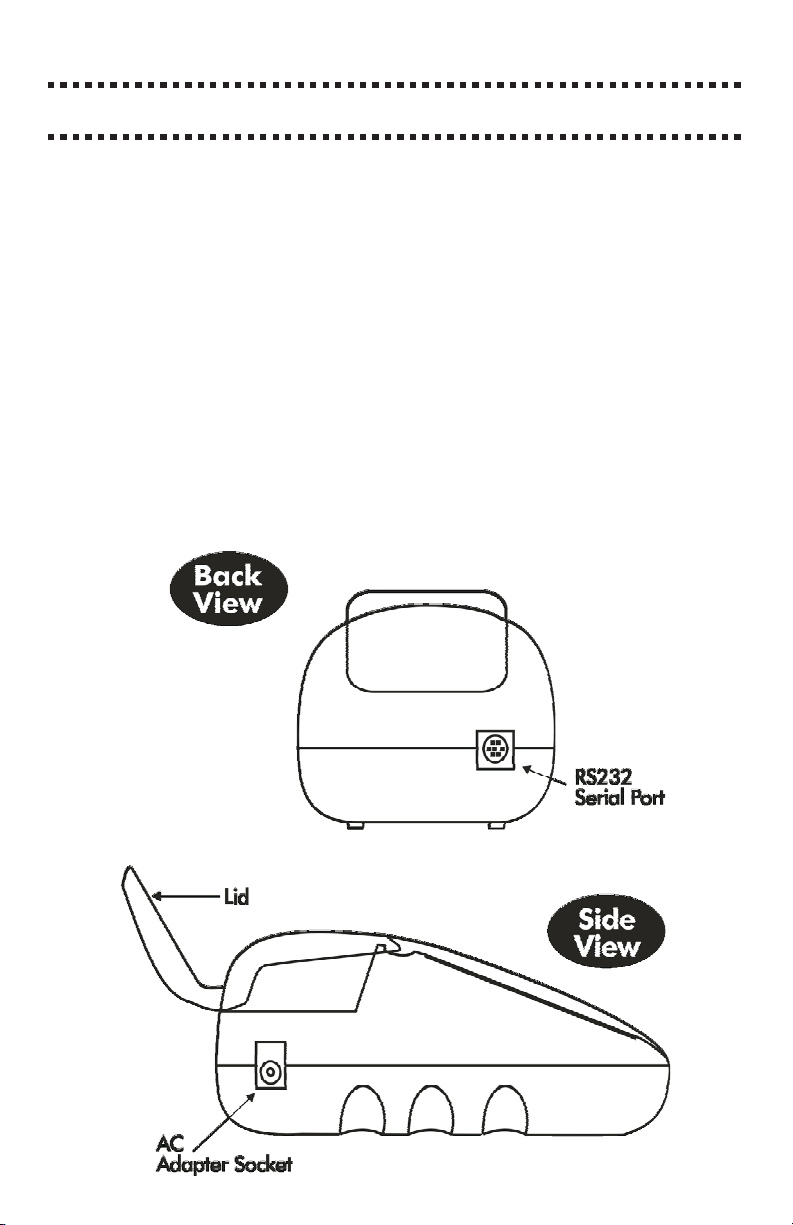

The Model 1200 Colorimeter is a portable, microprocessor-controlled, direct

reading colorimeter. The microprocessor enables factory programmed

calibrations to optimally match non-linear curves. The auto zero feature

eliminates the need to dial in the zero manually. A sealed keypad controls the

operation. The large display presents measurements in ppm concentration and

indicates low battery warnings. The 1200 will turn off automatically after 5

minutes to prolong battery life. This will not affect the user calibration and the

meter will not have to be re-zeroed. The calibration and the last zero reading will

be stored in memory.

The 1200 is supplied with a 9 volt alkaline battery. An optional AC power

adapter is available.

A RS-232 serial port on the back of the meter allows an interface of the

colorimeter with a computer for real time data acquisition and data storage using

the PC. This port also allows an interface with a RS-232 serial printer.

14

Page 15

READ

ZERO

Top

View

Bottom

View

2.55

Serial

Number

Battery

Compartment

I200

••••••••••••••••••

15

Page 16

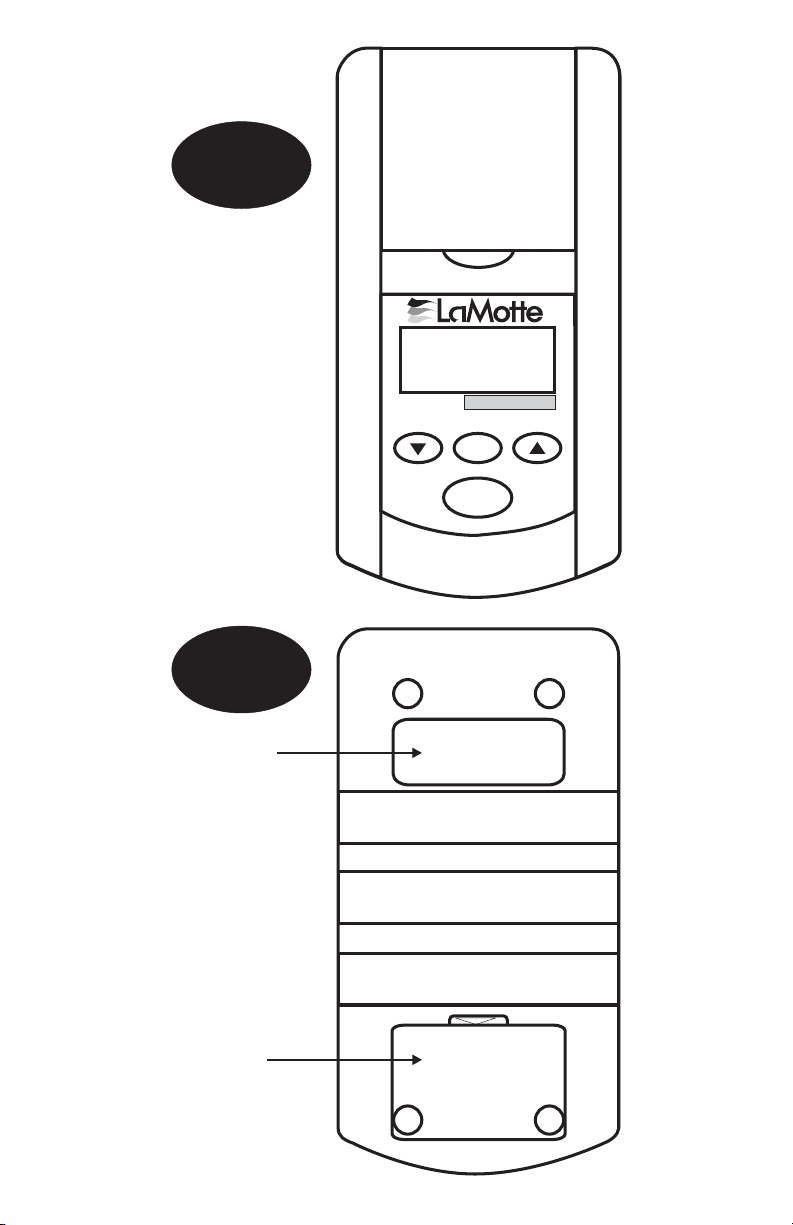

THE KEYPAD and DISPLAY

The button is used to turn the meter

ON and to take readings. Pressing the button

for 2 seconds will cause the meter to display

OFF. Releasing the button when OFF is

displayed turns the meter OFF.

The button is used

to zero the meter and for

calibration procedures.

The DOWN

ARROW will

the

numerical value

of the display.

The UP

ARROW will

the numerical

valueofthe

display.

See

TROUBLE

SHOOTING

GUIDE

page 23

The DISPLAY :

When the button is first pushed, a number will be briefly displayed that

indicates the software version number.

A walking dash ( ) will be displayed when reading is taking place.

(blank) will be displayed after the button has been pushed and held

for 2 seconds. If the button is released while is displayed, a zero or

blank reading will be taken.

(calibrate) will be displayed after the zero button has been pushed and held

for 5 seconds. If the button is released while is displayed, the

calibration mode will be entered as indicated by a flashing display.

will be displayed after the button has been held down for 2 seconds.

The meter will turn off when the button is released.

will be displayed when the battery voltage is very low.

will be displayed when concentration is over range.

will be displayed when the bulb has burned out.

will be displayed when the battery voltage is getting low. Readings are

reliable. Replace battery as soon as possible.

-

READ

ZERO

I200

••••••••••••••••••

L

Mott

DECREASE

READ

ZERO

INCREASE

READ

ZERO

ZERO

ZERO

READ

Bla

BLA

cal

CAL

OFF

Er1

Er2

Er3

BAT

16

Page 17

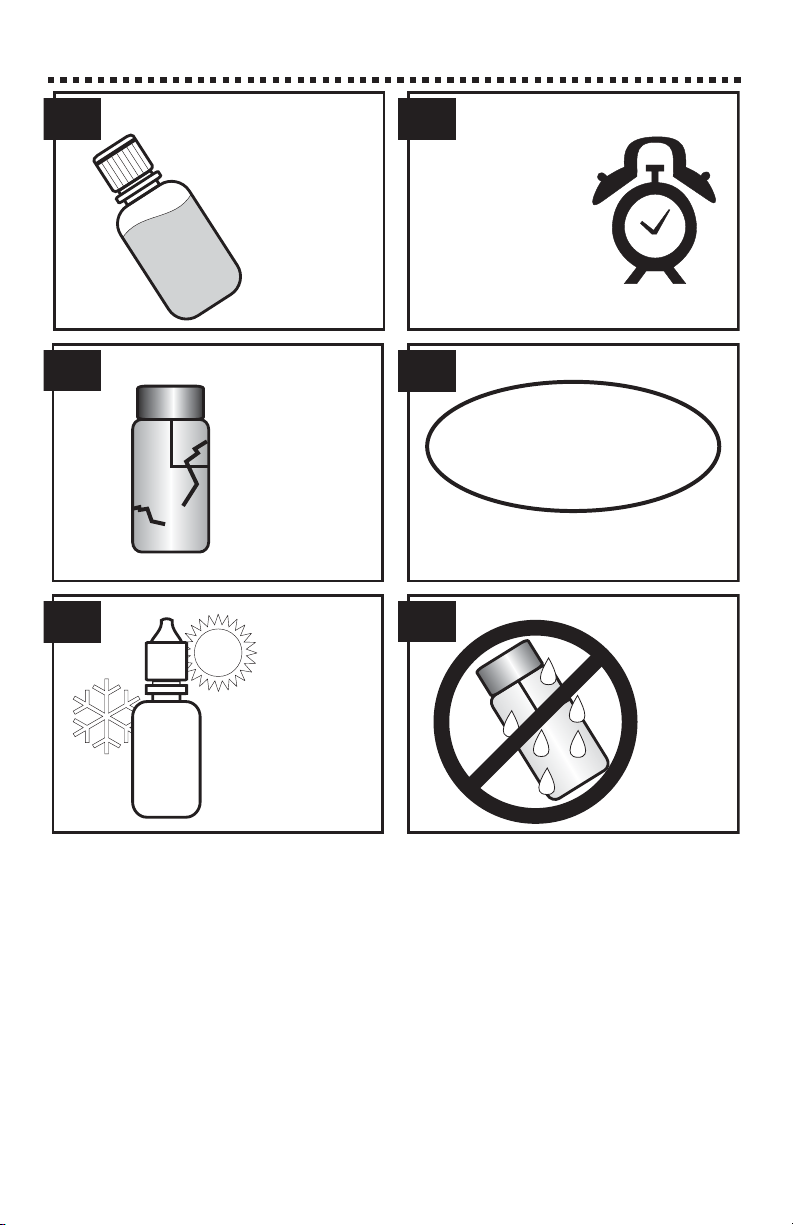

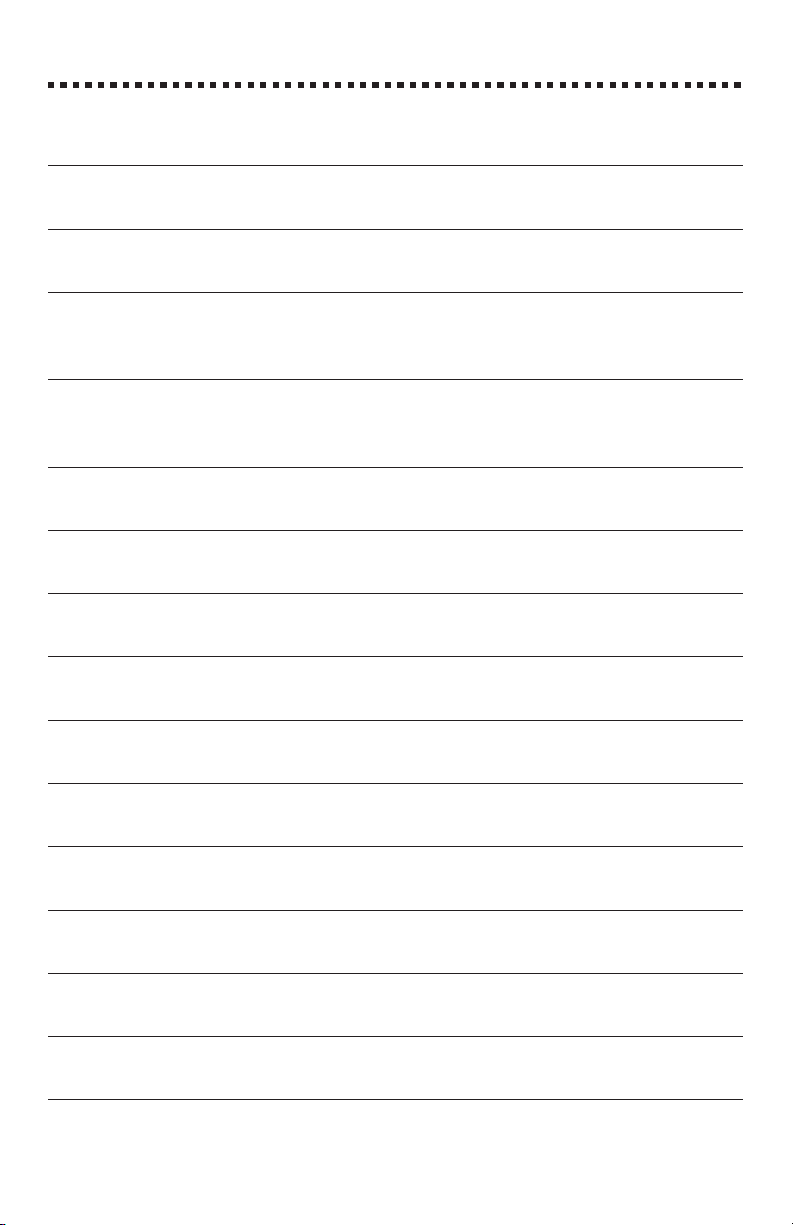

TESTING TIPS

Samples should

be collected in a

clean glass or

polyethylene

container.

Observe the shelf-life

recommendations for reagents.

Samples should be

analyzed as soon as

possible after

collection.

5.

3.

1. 2.

4.

6.

Protect reagents

and components

from extreme heat

and cold.

Never put

wet tubes in

colorimeter.

Discard tubes

that are badly

scratched.

ONE

year

SHELF

LIFE

17

Page 18

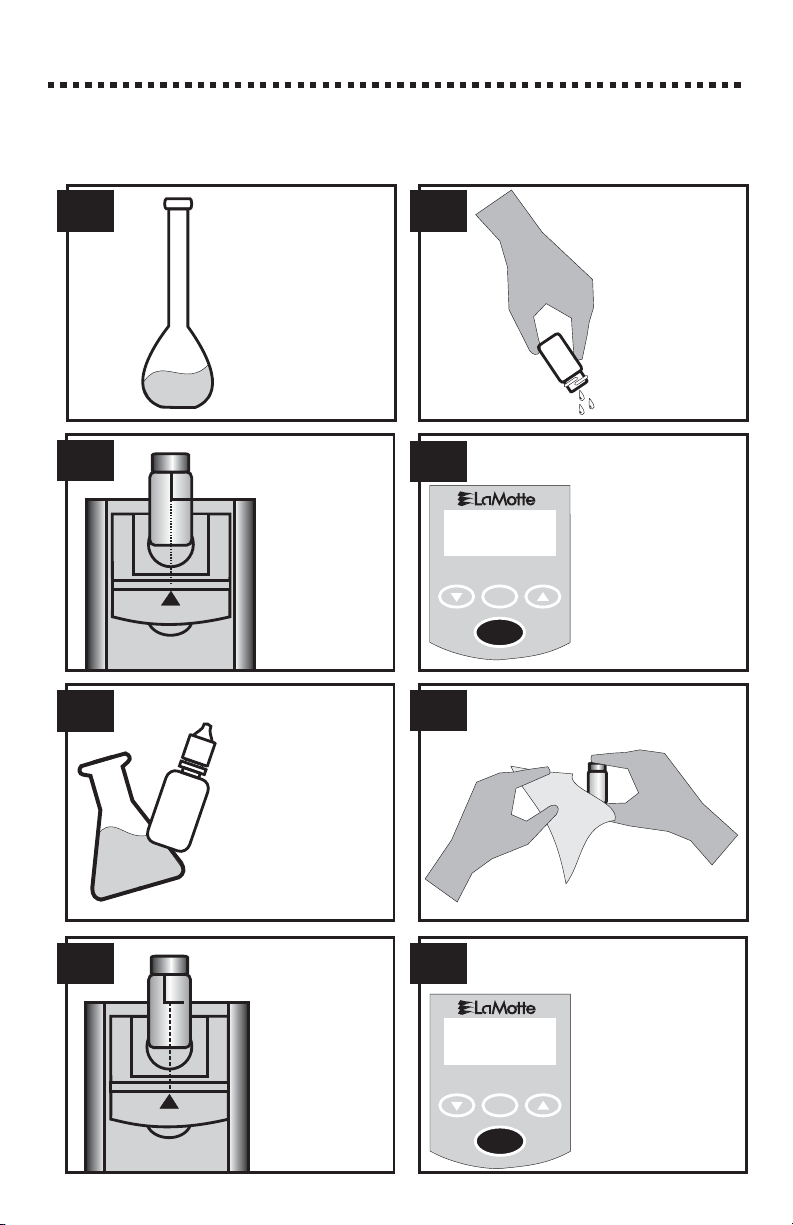

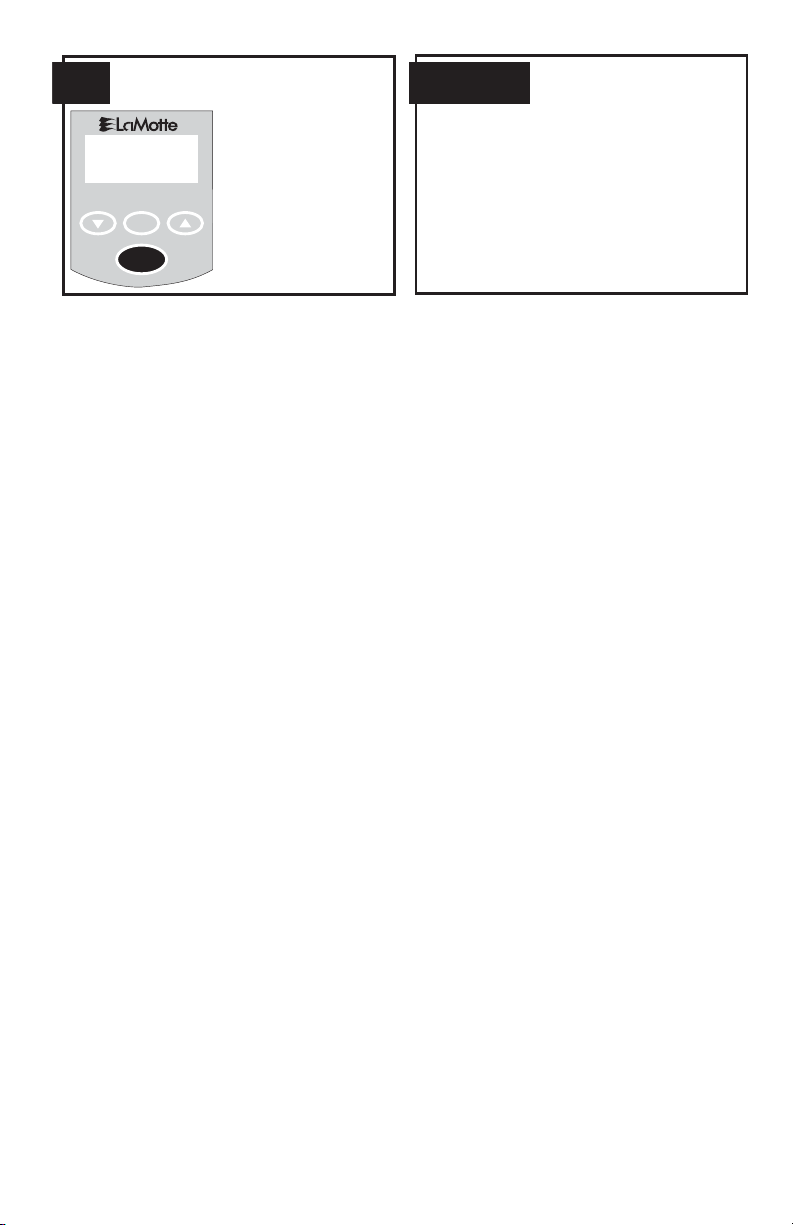

CALIBRATION PROCEDURE

Prepare standard

solutions to be

tested.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

This tube is the

blankorzero.

Rinse and fill a

colorimeter tube

(0290) to the 10

mL line with

standard

solution. Cap

and wipe dry.

7. 8.

5.

3.

1. 2.

4.

6.

React a standard

that is in the range

of the reagent

system, and similar

to the expected

range of the sample.

Follow the

individual test

procedure.

Wipe the tube clean with a

lint-free cloth.

2.50 ppm

Push the

button to turn the

meter on. Press the

button

andholditfor2

seconds until

is displayed.

Release the button

to take a zero

reading (0 ppm).

Insert the

tube into the

chamber,

being sure to

align the

index line

with the

arrow on the

meter. Close

the lid.

Push the button. If the

displayed value is not the same as

thevalueofthe

reacted standard

(within the

specification

limits), continue

with the

calibration

procedure.

I200

••••••••••••••••••

ZERO

COLORIMETER

READ

2.55

I200

••••••••••••••••••

ZERO

COLORIMETER

READ

bla

READ

READ

ZERO

bla

The 1200 has been pre-calibrated. Recalibration of the 1200 by the user is not

required. However, a procedure to standardize the calibration (shown below)

should be performed to obtain the most accurate readings.

18

Page 19

The 1200 can be calibrated with two prepared standards. The concentrations of

Push the

button again to

memorize the

calibration. The

1200 display will

stop flashing.

Calibration is

complete.

ZERO

Turn the unit off by

holding the

button down for at

least 2 seconds, or

proceed to measure

the test samples

following the

procedure on page

20.

READ

9. 10.

11 .

Push and hold the

button for 5

seconds until is

displayed. Release

the button. The

display will flash.

Adjust the display

with the and

buttons until the

value of the standard

is displayed.

ZERO

CAL

I200

••••••••••••••••••

ZERO

COLORIMETER

READ

“

“

“

“

2.55

I200

••••••••••••••••••

ZERO

COLORIMETER

READ

2.50

I200

••••••••••••••••••

ZERO

COLORIMETER

READ

the standards should be chosen from the low and high ends of the range of the

meter. The low standard must be less than 5% of over range. To calibrate the

meter with two standards, follow steps 1-11 of the calibration procedure for one

reacted sample. Repeat steps 1-11 of the calibration procedure with the second

reacted standard.

•

The calibration procedure should be followed as often as required by

regulations and laws for compliance monitoring.

•

To reset the calibration to the factory calibration: with the meter off, hold

down the t and push READ. The meter will turn on and the calibration

will be reset.

19

Page 20

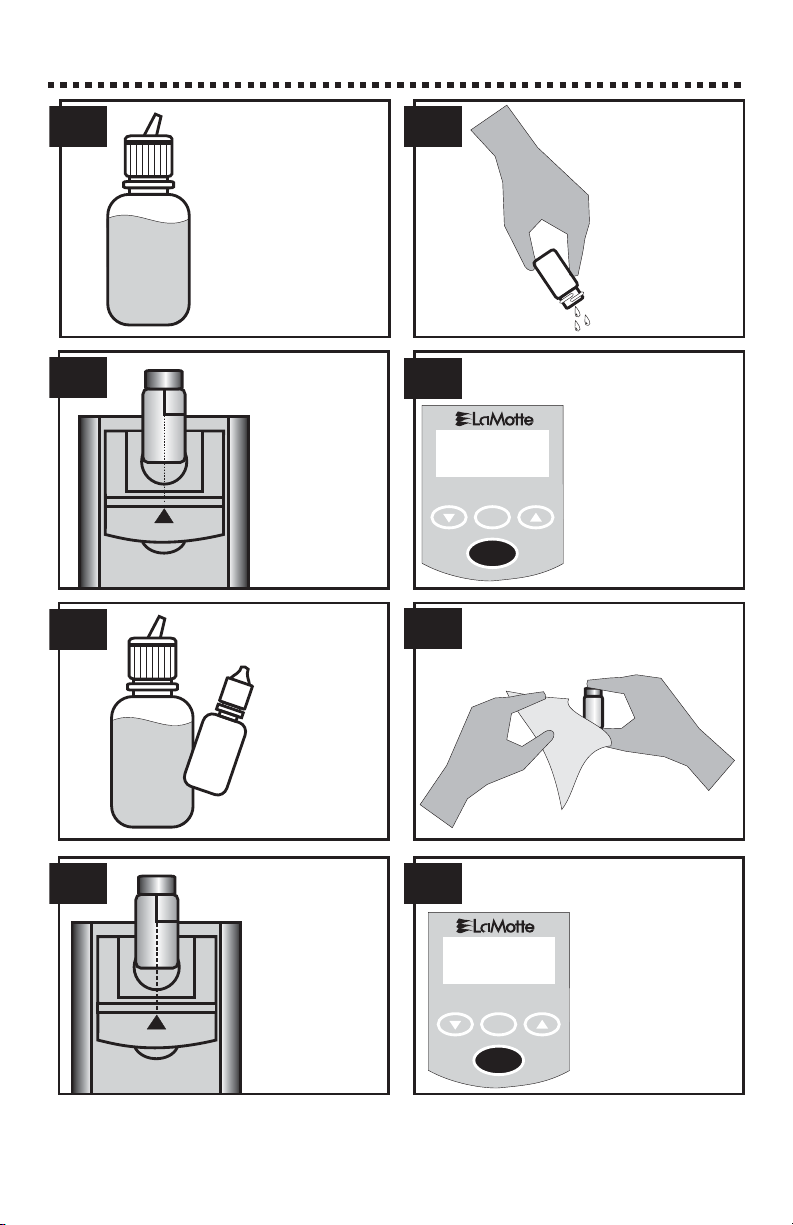

ANALYSIS PROCEDURE

Fill the Water

Sample Collecting

Bottle (0688) with

sample water. This

will be used to

dispense sample

water for the tests.

Push the

button to turn the

meter on. Press the

button and

hold it for 2 seconds

until is

displayed. Release

the button to take a

zero reading (0

ppm).

READ

ZERO

bla

Rinse and fill a

colorimeter tube

(0290) to the 10

mL line with

sample water.

Cap and wipe

dry.

7. 8.

5.

3.

1. 2.

4.

6.

React a sample

following the

individual test

procedure.

Wipe the tube clean with a

lint-free cloth.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

This tube is the

blankorzero.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

Push the

button. The

concentration in

ppm will be

displayed within

2 seconds.

READ

I200

••••••••••••••••••

ZERO

COLORIMETER

READ

2.55

I200

••••••••••••••••••

ZERO

COLORIMETER

READ

bla

20

Page 21

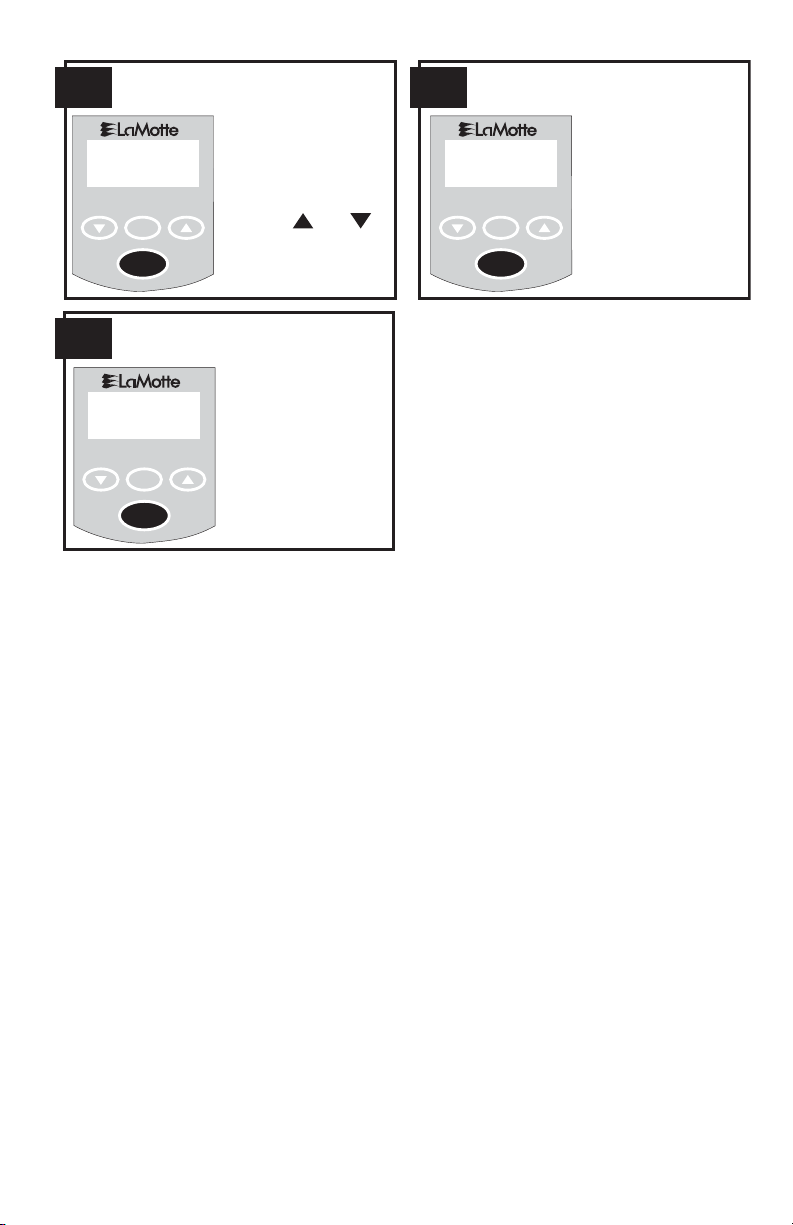

9.

The 1200 will turn

off automatically 5

minutes after the

last button push. To

turn the meter off

manually, hold the

button for 2

seconds. Release the

button when is

displayed.

READ

OFF

If is displayed, the

concentration is over range.

The sample must be diluted

and re-tested. See page 12.

Er2

Note

I200

••••••••••••••••••

ZERO

COLORIMETER

READ

21

Page 22

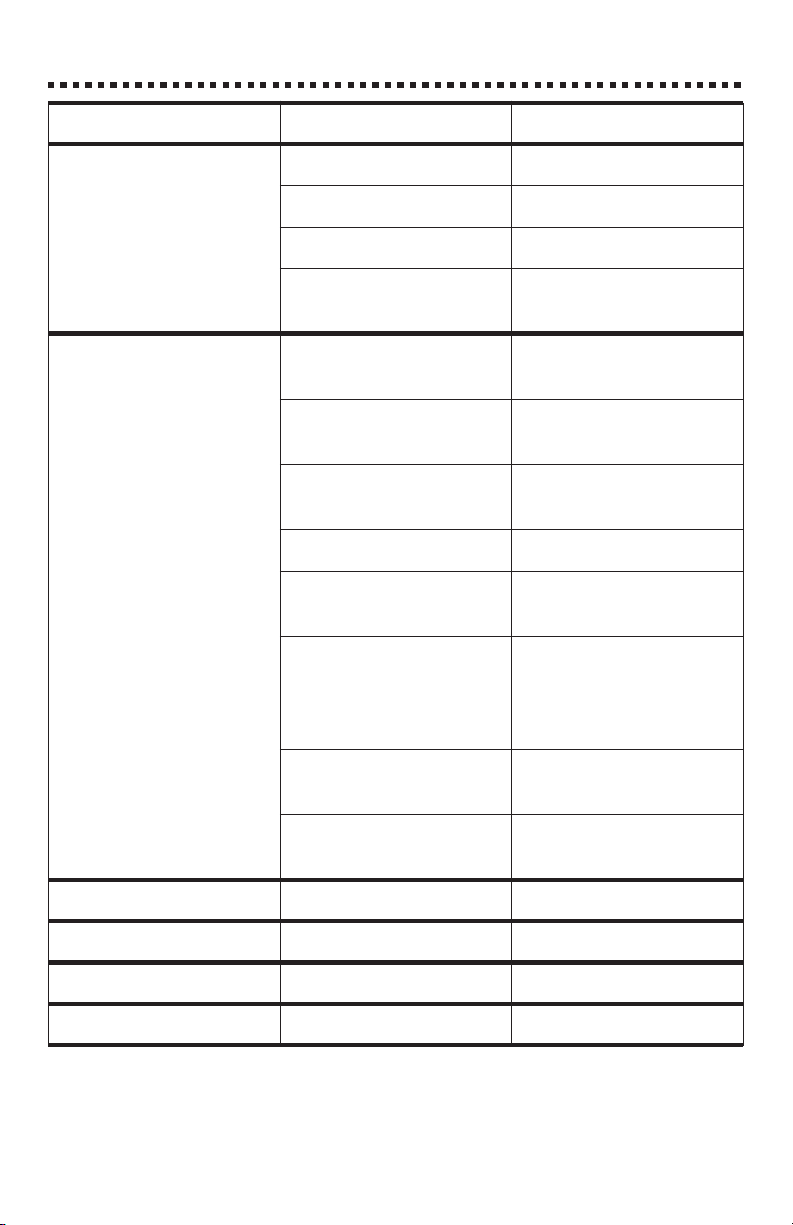

AVAILABLE TEST KITS

TEST

FACTOR

Ammonia

Nitrogen

ORDER

CODE/MODEL

3680-01

DC 1200-NH

Bromine 3672-01

DC 1200-BR

Chlorine

(Free &

3670-01

DC1200-CL

Total)

Chlorine

(Free &

3670-01-LI

DC1200-CL-LI

Total)

Chlorine

Dioxide

3671-01

DC1200-CLO

Copper 3673-01

DC1200-CO

Fluoride 3674-01

DC1200-FL

Iron 3681-01

DC1200-FE

RANGE

(PPM)

DETECTION

LIMIT

TEST METHOD

(# OF REAGENTS)

0-5.00 0.05 Nessler (2)

0-7.00 0.05 DPD Tablets (1)

0-4.00 0.05 DPD Tablets (2)

0-4.00 0.05 DPD Liquid (3)

0-7.00 0.05 DPD with Glycine

Solution (2)

0-8.00 0.03 Diethyldithio-

carbamate (1)

0-2.00 0.03 Aliizarin-Zirconyl

(2)

0-4.00 0.25 1-10

Phenanthroline (2)

Manganese 3682-01

0-0.90 0.01 PAN (3)

DC1200-MN

Molybdenum 3676-01

0-50.0 0.5 Thioglycolate (3)

DC1200-MO

Nitrate

Nitrogen

Ozone 3678-01

3677-01

DC1200-NA

0-3.00 0.05 Cadmium

0-0.40 0.04 Indigo Blue (3)

DC1200-OZ

Phosphate 3679-01

0-3.00 0.07 Ascorbic Acid (2)

DC1200-PLR

Sulfate 3683-01

0-100.0 1.0 Barium Chloride

DC1200-SU

Test kit includes 1200 meter and reagent system.

22

Reduction (2)

(1)

Page 23

TROUBLESHOOTING

er1

er2

er3

PROBLEM CHECK ACTION

Meter won’t turn on Battery Replace

AC Adapter Plug in

AC Wall Outlet Verify power source

Contact LaMotte for

Return Authorization

Suspect Calibration Check calibration with

standards

Verify standard

concentration

Verify with another

meter

Check tube alignment Re-align tube

Check sample tubes for

dirt and scratches

Check to see if internal

meter components are

wet

Reset meter to factory

calibration

Contact LaMotte for

Return Authorization

Return to LaMotte for

repair

Use new standards

Runtestwithalternative

reagent system

Check other meter

calibrations

Check, clean and/or

replace if necessary

Always dry tubes before

inserting. Examine

chamber for visible

moisture.

With meter off, hold

down t and press READ

Return for calibration

check

Very low battery Change battery

Over range Dilute sample

Burnt out bulb Call LaMotte

BAT Low battery Change battery

23

Page 24

RS232 PORT

The 1200 Colorimeter may be interfaced with any IBM compatible computer

using an Interface cable (Code 1772). The meter may also be interfaced with an

RS-232 serial printer, using an appropriate cable and setting the printer

configuration to the output below.

Output: RS232 compatible, asynchronous serial, 9600 baud, no parity, 8 data

bits, 1 stop bit.

Computer Connection: RS232 (Code 1772) interface connection, 8 pin

mini-DIN/9 pin F D-submin.

Pin out:

5 RS-232 TxD

3 RS-232 RxD

4, 6, 8 Digital ground

24

Page 25

MAINTENANCE

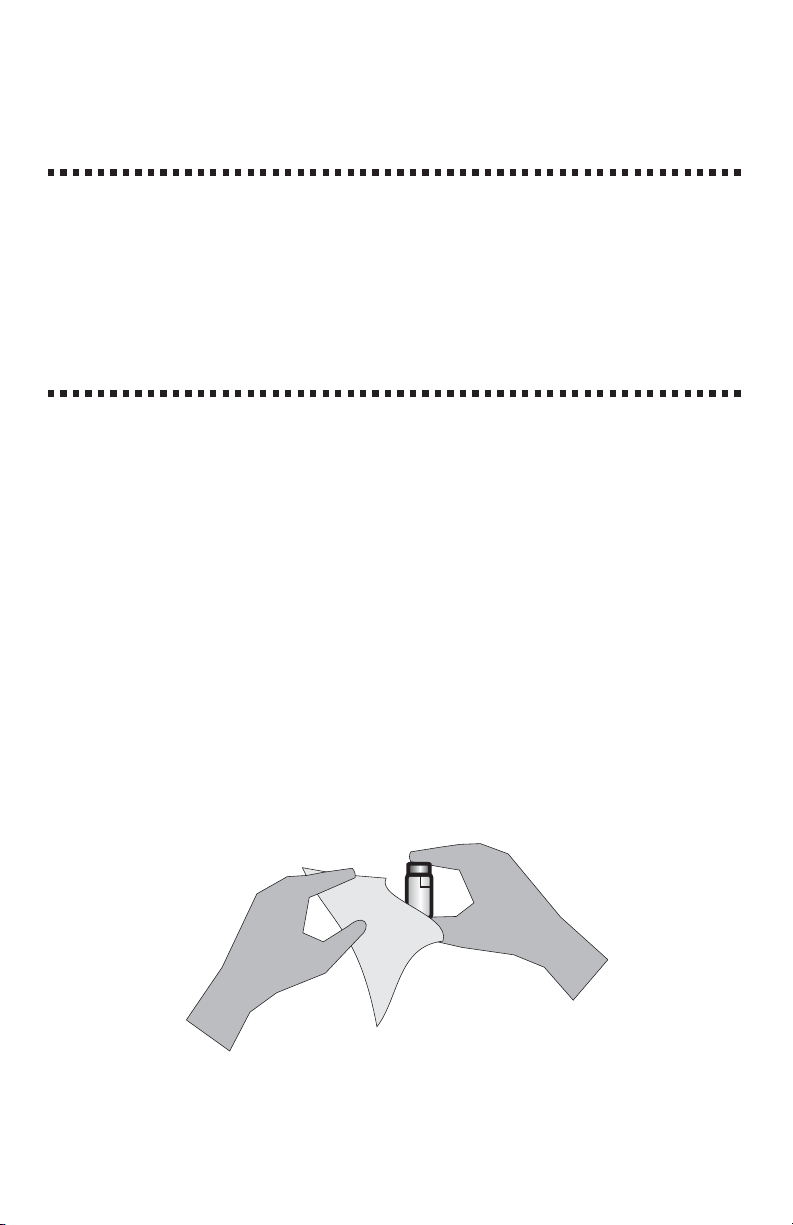

REPLACING THE BATTERY

The LaMotte 1200 uses a standard 9-volt alkaline battery that is available

worldwide. The battery compartment is located on the bottom of the case. To

replace the battery:

1. Open the battery compartment lid.

2. Remove the battery and disconnect the battery from the polarized plug.

3. Carefully connect the new battery to the polarized plug and insert it into

the compartment.

4. Close the battery compartment lid.

REPAIRS

If it is necessary to return the instrument for repair, telephone LaMotte Company

at 1-800-344-3100 or fax 1-410-778-6394 for a return authorization number.

METER DISPOSAL

Waste Electrical and Electronic Equipment (WEEE)

Natural resources were used in the production of this equipment. This equipment

may contain materials that are hazardous to health and the environment. To

avoid harm to the environment and natural resources, the use of appropriate

take-back systems is recommended. The crossed out wheeled bin symbol on the

meter encourages you to use these systems when disposing of this equipment.

Take-back systems will allow the materials to be reused or recycled in a way that

will not harm the environment. For more information on approved collection,

reuse, and recycling systems contact your local or regional waste administration

or recycling service.

25

Page 26

WARRANTY

This Instrument is guaranteed to be free from defects in material and workmanship for a

period of one (1) year from the original purchase date. In the event that a defect is found

during the warranty time frame, LaMotte Company agrees that it will be repaired or

replaced without charge except for the transportation costs. This guarantee does not cover

batteries.

This product can not be returned without a return authorization number from LaMotte

Company. For warranty support or a Return Authorization Number, contact LaMotte

Company at 1-800-344-3100 or tech@lamotte.com.

Limitations

This guarantee is void under the following circumstances:

Damage due to operator negligence, misuse, accident or improper application.

•

Damage or alterations from attempted repairs by an unauthorized

•

(non-LaMotte) service.

Damage due to improper power source, AC adapter or battery.

•

Damage caused by acts of God or natural disaster.

•

Damage occurred while in transit with a shipping carrier.

•

LaMotte Company will service and repair out-of-warranty products at a nominal

charge.

26

Page 27

27

Page 28

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside U.S.A.) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

®

626728 • 4.09

Page 29

1200 COLORIMETER

CHLORINE

DPD TABLET TEST

MODEL 1200-CL · CODE 3670-01

QUANTITY CONTENTS CODE

100 *Chlorine DPD #1 Instrument Grade Tablets *6903A-J

100 *Chlorine DPD #3 Instrument Grade Tablets *6197A-J

1 Colorimeter Tubes, w/caps,set of 6 0290-6

2 Tablet Crushers 0175

1 Water Sample Collecting Bottle 0688

1 1200 Colorimeter for Chlorine DPD 26728

*WARNING: Reagents marked with an * are considered to be potential health hazards. To view

or print a Material Safety Data Sheet (MSDS) for these reagents see MSDS CD or

www .lamotte.com. To obtain a printed copy, contact LaMotte by e-mail, phone or fax.

To order individual reagents or test kit components, use the specified code number.

INTRODUCTION

Chlorine is added to water to kill bacteria and other disease-producing organisms,

control algae, and remove undesirable odors and colors. Chlorine added to water quickly

forms hypochlorous acid, HClO, also known as Free Available Chlorine, the active

ingredient responsible for chlorine*s sanitizing capabilities. Free Available Chlorine

combines with impurities in the water to form chloramines and other organic nitrogen

compounds. In combined form, its sanitizing capability diminishes, and higher levels of

chlorine are necessary to achieve effective sanitation.

Therefore, it is essential to chlorinate to the point of establishing a Free Available

Chlorine Residual, and then to maintain that residual at a recommended level. The

LaMotte DPD tablet test method distinguishes levels of Free Available Chlorine,

Combined Chlorine, and Total Residual Chlorine, using a single test sample.

Page 30

CHLORINE TEST PROCEDURE - DPD METHOD

7. 8.

5.

3.

1. 2.

4.

6.

I200

COLORIMETER

••••••••••••••••••

READ

READ

ZERO

CAL

••••••••••••••••••

bla

COLORIMETER

I200

Fill the Water

Sample Collecting

Bottle (0688) with

sample water. This

will be used to

dispense sample

water for the tests.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

This tube is the

blankorzero.

Empty all but a few

drops of sample from

tube. Add one

*Chlorine DPD #1

IG T ablet (6903A) and

crush with tablet

crusher (0175).

NOTE: T o insure

accurate results, tablet

must be crushed before

filling tube.

Align the index line with the

arrow on the meter, insert tube

into chamber.

the lid. Push the

READ button.

Record results as

ppm Free A vailable

Chlorine. Save

sample for the T otal

Residual Chlorine

test.

Rinse and fill a

colorimeter tube

(0290) to the

10 mL line with

sample water.

Cap and wipe

dry .

Push the

READ

button to turn the

meter on. Press the

ZERO button and

hold it for 2 seconds

until is displayed.

bla

Release the button to

take a zero reading

(0.00 ppm).

Fill to 10 mL line

with sample. Cap

and mix until tablet

disintegrates. Make

readings within 30

seconds after

disintegration of the

tablet.

Add one Chlorine

DPD #3 IG T ablet

(6197A) to the sample

from Step 6. Crush

tablet.

READ

Read the 1200 Colorimeter Manual before proceeding. Carefully

wipe tubes dry before inserting into the colorimeter chamber.

FREE AVAILABLE CHLORINE

Page 31

er2

TOTAL RESIDUAL CHLORINE

11.

9. 10.

12.

••••••••••••••••••

READ

2.55

ZERO

COLORIMETER

I200

Cap and mix

until tablet

disintegrates.**

Push the

READ button.

Record reading

as ppm Total

Residual

Chlorine.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

Subtract the Free Available

Chlorine reading from the

Total Residual Chlorine

reading to determine ppm

Combined Chlorine

(Monochloramine,

Dichloramine, and Nitrogen

Trichloride) present in the

water sample.

If either chlorine reading displays , repeat procedure on diluted sample, and

multiply the result by the appropriate dilution factor. See 1200 Colorimeter Instruction

Manual for procedure.

Levels of chlorine above 10 mg/L will cause a bleaching effect on the DPD indicator, and

may give a false indication that no chlorine is present. If it is possible that the chlorine

concentration is greater than 10 mg/L (e.g. after shock treatment), perform test on a

diluted sample and multiply the result by appropriate dilution factor.

CAUTION: DO NOT leave reacted DPD samples in test tubes. Discard sample and

thoroughly rinse tubes. If allowed to remain, DPD will stain tubes, significantly

impairing the operation of the 1200 Colorimeter. If necessary, acid wash, and vigorously

clean glassware with test tube brush and detergent.

**For wastewater samples, Standard Methods for the Examination of Water and Wastewater

recommends waiting 2 minutes for full color development.

Page 32

DPD CHLORINE

TEST METHOD SPECIFICATIONS

APPLICATION

Drinking water supplies and distribution systems, swimming pool and spas, sewage and

chlorinated waste waters, process waters and sanitizing solutions.

RANGE

0 to 4.0 mg/L Chlorine (may be extended by dilution)

METHOD

In the absence of Iodide, Free Available Chlorine reacts instantly with the buffered

diethyl-p-phenylenediamine indicator (DPD) to produce a red color in proportion to the

amount of chlorine present. Subsequent addition of potassium iodide produces a rapid

color response from the combined forms of chlorine (chloramines).

HANDLING & PRESERVATION

Chlorine in aqueous solutions, particularly weak solutions, is not stable. Exposure to

sunlight or agitation will accelerate the reduction of chlorine. Fill sample containers to

the top and cap tightly. Analyze samples as soon as possible after collection.

INTERFERENCES

The only interfering substance likely to be encountered is oxidized manganese. The

extent of this interference can be determined by treating a sample with sodium arsenite

to destroy the chlorine present, so that the amount of interference can be measured.

CALIBRATION

The single test colorimeter is precalibrated. In order to comply with NPDWR or NPDES

reporting regulations, the calibration should be checked periodically by using a set of

reference standards including a 0 mg/L blank and 0.3, 1.0, and 3.5 mg/L chlorine. To

prepare these standards, a LaMotte 1000 mg/L standard chlorine equivalent solution

(Code 3858) is available. Consult with your local regulatory agency to determine

standardization frequency.

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside USA) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

SM

63670-01 · 7/08

Page 33

1200 COLORIMETER

CHLORINE

DPD LIQUID TEST

MODEL 1200-CL-LI • CODE 3670-01-LI

QUANTITY CONTENTS CODE

30 mL DPD #1A Free Chlorine Reagent P-6740-G

30 mL *DPD #1B Free Chlorine Reagent *P-6741-G

30 mL *DPD #3 Total Chlorine Reagent *P-6743-G

1 Colorimeter Tubes, with caps 0290-6

1 Water Sample Collecting Bottle 0688

1 1200 Colorimeter for Chlorine DPD 26728

*WARNING: Reagents marked with a * are considered to be potential health hazards. To view or

print a Material Safety Data Sheet (MSDS) for these reagents see MSDS CD or

www .lamotte.com. To obtain a printed copy, contact LaMotte by email, phone or fax.

To order individual reagents or test kit components, use the specified code number.

INTRODUCTION

Chlorine is added to water to kill bacteria and other disease-producing organisms,

control algae, and remove undesirable odors and colors. Chlorine added to water quickly

forms hypochlorous acid, HClO, also known as Free Available Chlorine, the active

ingredient responsible for chlorine's sanitizing capabilities. Free Available Chlorine

combines with impurities in the water to form chloramines and other organic nitrogen

compounds. In combined form, its sanitizing capability diminishes, and higher levels of

chlorine are necessary to achieve effective sanitation.

Therefore, it is essential to chlorinate to the point of establishing a Free Available

Chlorine Residual, and then to maintain that residual at a recommended level. The

LaMotte DPD method distinguishes levels of Free Available Chlorine, Combined

Chlorine, and Total Residual Chlorine, using a single test sample.

Page 34

CHLORINE TEST PROCEDURE - DPD METHOD

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

This tube is the

blank or zero.

8.

5.

3. 4.

Fill the Water

Sample Collecting

Bottle (0688) with

sample water. This

will be used to

dispense sample

water for the tests.

Rinse and fill a

colorimeter tube

(0290) to the 10

mL line with

sample water.

Cap and wipe

dry .

1. 2.

I200 COLORIMETER

••••••••••••••••••

READ

bla

ZERO

7.

CAL

I200COLORIMETER

••••••••••••••••••

READ

Align the index line

with the arrow on

the meter, insert

tube into chamber.

Close the lid. Push

the button.

Record results as

ppm Free Available

Chlorine.

READ

Remove the tube and

add 5 drops DPD #1A

Free Chlorine Reagent

(6740), and 5 drops of

*DPD #1B Free

Chlorine Reagent

(6741).

6.

Cap and invert to

mix. Wipe tube dry .

Make readings

within 30 seconds.

Push the

button to turn the

meter on. Press the

button and

hold it for 2 seconds

until is

displayed. Release

the button to take a

zero reading

(0.00 ppm).

READ

ZERO

bla

Save sample for the

Total Residual

Chlorine T est.

Proceed to Step 9.

Read the 1200 Colorimeter Manual before proceeding. Carefully

wipe tubes dry before inserting into the colorimeter chamber.

FREE AVAILABLE CHLORINE

Page 35

er2

Subtract the Free Available Chlorine reading from the Total Residual

Chlorine reading to determine ppm Combined Chlorine (Monochloramine,

Dichloramine, and Nitrogen T richloride present in the water sample).

11.

9. 10.

12.

Push the

button.

Record reading

as ppm Total

Residual

Chlorine.

READ

Cap and

invert to

mix.**

Insert the tube

into the

chamber, being

sure to align

the index line

with the arrow

on the meter.

Close the lid.

I200 COLORIMETER

••••••••••••••••••

READ

2.55

ZERO

Add 5 drops *DPD

#3 T otal Chlorine

Reagent (6743) to

the sample from

Step 7.

13.

TOTAL RESIDUAL CHLORINE

If either chlorine reading displays , repeat procedure on diluted sample, and

multiply the result by the appropriate dilution factor. See 1200 Colorimeter Instruction

Manual for procedure.

Levels of chlorine above 10 mg/L will cause a bleaching effect on the DPD indicator,

and may give a false indication that no chlorine is present. If it is possible that the

chlorine concentration is greater than 10 mg/L (e.g. after shock treatment), perform test

on a diluted sample and multiply the result by appropriate dilution factor.

CAUTION: DO NOT leave reacted DPD samples in test tubes (0290). Discard sample

and thoroughly rinse tubes. If allowed to remain, DPD will stain tubes, significantly

impairing the operation of the 1200 Colorimeter. If necessary, acid wash, and vigorously

clean glassware with test tube brush and detergent.

**For wastewater samples, Standard Methods for the Examination of Water and Wastewater

recommends waiting 2 minutes for full color development.

Page 36

DPD CHLORINE TEST METHOD SPECIFICATIONS

APPLICATION

Drinking water supplies and distribution systems, swimming pool and spas, sewage and

chlorinated waste waters, process waters and sanitizing solutions.

RANGE

0 to 4.0 mg/L Chlorine (may be extended by dilution)

METHOD

In the absence of Iodide, Free Available Chlorine reacts instantly with the buffered

diethyl-p-phenylenediamine indicator (DPD) to produce a red color in proportion to the

amount of chlorine present. Subsequent addition of potassium iodide produces a rapid

color response from the combined forms of chlorine (chloramines).

HANDLING & PRESERVATION

Chlorine in aqueous solutions, particularly weak solutions, is not stable. Exposure to

sunlight or agitation will accelerate the reduction of chlorine. Fill sample containers to

the top and cap tightly. Analyze samples as soon as possible after collection.

INTERFERENCES

The only interfering substance likely to be encountered is oxidized manganese. The

extent of this interference can be determined by treating a sample with sodium arsenite

to destroy the chlorine present, so that the amount of interference can be measured.

CALIBRATION

The single test colorimeter is precalibrated. In order to comply with NPDWR or NPDES

reporting regulations, the calibration should be checked periodically by using a set of

reference standards including a 0 mg/L blank and 0.3, 1.0, and 4.0 mg/L chlorine. To

prepare these standards, a LaMotte 250 ppm standard chlorine equivalent solution

(Code 6973) is available. Consult with your local regulatory agency to determine

standardization frequency.

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside U.S.A.) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

®

3670-01-LI · 08/08

Page 37

1200 COLORIMETER

CHLORINE DIOXIDE

DPD LIQUID TEST

CODE 3671-01-LI

QUANTITY CONTENTS CODE

30 mL DPD #1A Free Chlorine Reagent P-6740-G

30 mL *DPD #1B Free Chlorine Reagent *P-6741-G

15 mL Glycine Solution 6811-E

1 Colorimeter Tubes, w/caps 0290-6

1 Water Sample Collecting Bottle 0688

1 1200 Colorimeter for Chlorine Dioxide 26731

*WARNING: Reagents marked with a * are considered to be potential health hazards. To view

or print a Material Safety Data Sheet (MSDS) for these reagents see MSDS CD or

www .lamotte.com. To obtain a printed copy, contact LaMotte by e-mail, phone or fax.

To order individual reagents or test kit components, use the specified code number.

INTRODUCTION

Chlorine dioxide is used as a substiture for and an adjunct to chlorine in water

treatment. It is better than chlorine in eliminating taste and odor in certain cases.

Chlorine dioxide, unlike chlorine, does not produce carcinogenic chlorinated organic

compounds when reacted with organic materials. A disadvantage is the higher cost of

producing chlorine dioxide compared to chlorine.

1

Page 38

CHLORINE DIOXIDE TEST PROCEDURE - DPD METHOD

Remove tube.

Add 5 drops

Glycine

Solution

(6811). Cap

and mix.

Cap and invert to

mix. Wipe tube dry.

Make readings

within 30 seconds.

Fill the Water

Sample Collecting

Bottle (0688) with

sample water. This

will be used to

dispense sample

water for the tests.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

This tube is the

blank or zero.

Rinse and fill a

colorimeter tube

(0290) to the

10 mL line with

sample water.

Cap and wipe

dry .

5.

7.

3.

1. 2.

4.

6.

I200 COLORIMETER

••••••••••••••••••

READ

bla

ZERO

Add 5 drops DPD

#1A Free Chlorine

Reagent (6740),

and 5 drops of

*DPD #1B Free

Chlorine Reagent

(6741).

Push the

button to turn the

meter on. Press the

button

andholditfor2

seconds until is

displayed. Release

the button to take a

zero reading

(0.00 ppm).

READ

ZERO

bla

8.

CAL

I200COLORIMETER

••••••••••••••••••

READ

Align the index

line with the arrow

on the meter, insert

tube into chamber.

Close the lid. Push

the

button. Record

results as ppm

Chlorine Dioxide.

READ

Read the 1200 Colorimeter Manual before proceeding.

Carefully wipe tubes dry before inserting into the colorimeter

chamber.

CHLORINE DIOXIDE

2

Page 39

NOTE: If reading displays , repeat procedure on diluted sample, and multiply the

er2

result by the appropriate dilution factor. See 1200 Colorimeter Instruction Manual for

procedure.

CAUTION: DO NOT leave reacted DPD samples in test tubes (0290). Discard sample

and thoroughly rinse tubes. If allowed to remain, DPD will stain tubes, significantly

impairing the operation of the 1200 Colorimeter. If necessary, acid wash, and vigorously

clean glassware with test tube brush and detergent.

CHLORINE DIOXIDE TEST METHOD SPECIFICATIONS

APPLICATION

Drinking and pool waters; domestic and industrial wastewater.

RANGE

0 to 7.0 ppm Chlorine Dioxide

METHOD

Chlorine dioxide reacts with DPD to form a red color in proportion to the

concentration.

HANDLING & PRESERVATION

Test as soon as possible to avoid loss of chlorine dioxide.

INTERFERENCES

Chlorine interference is eliminated by the addition of glycine to the sample before the

indicator.

3

Page 40

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 • Fax 410-778-6394

Visit us on the web at www.lamotte.com

SM

63671-01-LI• 4/08

Page 41

1200 COLORIMETER

BROMINE

DPD TABLET METHOD

MODEL 1200-BR · CODE 3672-01

QUANTITY CONTENTS CODE

100 *Chlorine DPD #1 Tablets (Instrument Grade) *6903A-J

6 Colorimeter Tubes, w/caps 0290-6

1 Tablet Crusher 0175

1 Water Sample Collecting Bottle 0688

1 1200 Colorimeter for Bromine DPD 26730

*WARNING: Reagents marked with a * are considered to be potential health hazards. To view

or print a Material Safety Data Sheet (MSDS) for these reagents see MSDS CD or

www .lamotte.com. To obtain a printed copy, contact LaMotte by e-mail, phone or fax.

To order individual reagents or test kit components, use the specified code number.

INTRODUCTION

Bromine is added to water to kill bacteria and other disease-producing organisms,

control algae, and remove undesirable odors and colors. Bromine added to water, forms

hypobromus acid, the sanitizing form of bromine. Bromine forms free available bromine

and combined bromine or bromamines. Combined bromine is a very active sanitizer.

Page 42

BROMINE TEST PROCEDURE - DPD METHOD

Push the

button to turn the

meter on. Press the

button

andholditfor2

seconds until is

displayed. Release

the button to take a

zero reading

(0.00 ppm).

READ

ZERO

bla

Fill the W ater

Sample Collecting

Bottle (0688) with

sample water. This

will be used to

dispense sample

water for the tests.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

This tube is the

blankorzero.

Rinse and fill a

colorimeter tube

(0290) to the 10

mL line with

sample water.

Cap and wipe

dry .

Align the index line

with the arrow on

the meter, insert

tube into chamber .

Close the lid. Push

the

button. Record

results as ppm

Bromine.

READ

CAL

I200COLORIMETER

••••••••••••••••••

READ

7.

5.

3.

1. 2.

4.

6.

I200

COLORIMETER

••••••••••••••••••

READ

ZERO

Empty all but a few

drops of sample from

tube. Add one

*Chlorine DPD #1

Tablet (6903A) and

crush with tablet

crusher (0175).

To insure

accurate results, tablet

must be crushed before

filling tube.

NOTE:

Fill to 10 mL line

with sample. Cap

and mix until tablet

disintegrates. Make

readings within 30

seconds after

disintegration of the

tablet.

bla

Read the 1200 Colorimeter Manual before proceeding. Carefully

wipe tubes dry before inserting into the colorimeter chamber.

FREE AVAILABLE BROMINE

Page 43

DPD BROMINE

TEST METHOD SPECIFICATIONS

APPLICATION

Drinking, surface, saline waters; swimming pool water; domestic and industrial waters

and wastes.

RANGE

0to7.0mg/LBromine(maybeextendedbydilution)

METHOD

In buffered sample, bromine reacts with disthyl-p-phenylene diamine (DPD) to produce

a pink-red color in proportion to the concentration of bromine present.

HANDLING & PRESERVATION

Bromine is aqueous solutions is not stable, and the bromine content of samples or

solutions, particularily weak solutions, will rapidly decrease. Exposure to sunlight or

agitation will acceslerater the reduction of bromine present in such solutions. For best

results, start analysis immediately after sampling. Samples to be analyzed for bromine

cannot be preserved or stored.

INTERFERENCES

The only interfering substance likely to be encountered in water is oxidized manganese.

The extent of this interference can be dtermined by treating a sample with sodium

arsenite to destroy the bromine present so that the degree of interference can be

estimated.

Iodine and chlorine can also interfere, but these are not normally present unless they

have been added as sanitizers.

Page 44

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside U.S.A.) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

®

63672-01 · 10/08

Page 45

1200 COLORIMETER

COPPER

MODEL 1200-CO · CODE 3673-01

QUANTITY CONTENTS CODE

30 mL *Copper 1 *6446-G

1 Colorimeter Tubes, w/caps 0290-6

1 Water Sample Collecting Bottle 0688

1 1200 Colorimeter for Copper 26732

*WARNING: Reagents marked with a * are considered to be potential health hazards. To view

or print a Material Safety Data Sheet (MSDS) for these reagents see MSDS CD or

www .lamotte.com. To obtain a printed copy, contact LaMotte by email, phone or fax.

To order individual reagents or test kit components, use the specified code number.

INTRODUCTION

The copper content of drinking water generally falls below 0.03 parts per million, but

copper levels as high as 1.0 part per million will give water a bitter taste. W aters testing

as high as 1.0 part per million copper have probably been treated with a copper

compound, like those used in the control of algae, or have become contaminated from

untreated industrial wastes. The addition of copper sulfate to lakes causes an increase in

the copper content of the sediments. Acid waters and those high in free carbon dioxide

may cause the corrosion or “eating away” of copper, brass, and bronze pipes and fittings.

This corrosion results in the addition of copper into the water supply.

Page 46

COPPER TEST PROCEDURE - DIETHYLDITHIOCARBAMATE

Fill the Water

Sample Collecting

Bottle (0688) with

sample water. This

will be used to

dispense sample

water for the tests.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

This tube is the

blank or zero.

Rinse and fill a

colorimeter tube

(0290) to the 10

mL line with

sample water.

Cap and wipe

dry .

5.

3.

1. 2.

4.

6.

I200 COLORIMETER

••••••••••••••••••

READ

bla

ZERO

7.

Align the index line with the

arrow on the meter , insert tube

CAL

I200COLORIMETER

••••••••••••••••••

READ

into chamber.

Close the lid. Push

the

button. Record

resultsasppm

Copper.

READ

Cap and invert to

mix. Wipe tube dry .

Remove tube from

colorimeter. Add 5

drops of *Copper 1

(6446).

Push the

button

to turn the meter

on. Press the

button

and hold it for 2

seconds until

is displayed.

Release the button

to take a blank

reading (0.0 ppm).

READ

ZERO

bla

L

Mott

L

Mott

Read the 1200 Colorimeter Manual before proceeding. Carefully

wipe tubes dry before inserting into the colorimeter chamber.

COPPER

Page 47

NOTE: If test reading displays , repeat procedure on diluted sample, and multiply

er2

the result by the appropriate dilution factor. See 1200 Colorimeter Instruction Manual

for procedure.

COPPER TEST METHOD SPECIFICATIONS

APPLICATION

Drinking, surface, and saline waters; domestic and industrial wastes.

RANGE

0 to 5.0 ppm Copper

METHOD

Cupric ions form a yellow colored chelate with diethyldithiocarbamate around pH 9-10

in proportion to the concentration of copper in the sample.

HANDLING & PRESERVATION

Copper has a tendency to be absorbed to the surface of the sample container. Samples

should be analyzed as soon as possible after collection. If storage is necessary, 0.5 mL of

20% hydrochloric acid per 100 mL of sample will prevent “plating out.” However, a

correction must be made to bring the reaction into the optimum pH range.

INTERFERENCES

Bismuth, cobalt, mercurous, nickel and silver ions and chlorine (6 ppm or greater)

interfere and must be absent.

Page 48

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside USA) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

®

3673-01 · 6/08

Page 49

1200 COLORIMETER

EPA

COMPLIANT

FLUORIDE

SPADNS METHOD

MODEL 1200-FL · CODE 3674-01

QUANTITY CONTENTS CODE

2 x 100 mL *Acid-Zirconyl-SPADNS Reagent *3875-J

2 x 60 mL *Sodium Arsenite Solution *4128-H

1 Pipet, 0.5 mL, plastic 0353

1 Pipet, 1.0 mL, plastic 0354

1 Colorimeter Tubes, with caps, set of 6 0290-6

1 Water Sample Collecting Bottle 0688

1 1200 Colorimeter for Fluoride 26733

*WARNING: Reagents marked with a * are considered to be potential health hazards. To view

or print a Material Safety Data Sheet (MSDS) for these reagents see MSDS CD or

www .lamotte.com. To obtain a printed copy, contact LaMotte by e-mail, phone or fax.

To order individual reagents or test kit components, use the specified code number.

NOTE: This procedure uses EPA approved SPADNS Reagent System for fluoride found

in method 4500-F-D, 18th Edfition of Standard Methods, page 1-27.

FLUORIDE INTRODUCTION

Fluoride may occur naturally in some ground waters or it may be added to public

drinking water supplies to maintain a 1.0 mg/L concentration to prevent dental cavities.

At higher concentrations, fluoride may produce an objectionable discoloration of tooth

enamel called fluorosis, though levels up to 8 mg/L have not been found to be

physiologically harmful.

Page 50

FLUORIDE TEST PROCEDURE - SPADNS METHOD

Insert the tube

into the

chamber, being

sure to align

the index line

with the arrow

on the meter.

Close the lid.

This tube is

the sample

blank.

5.

Use the 0.5 mL

pipet (0353) to

add 0.5 mL of

*Sodium Arsenite

Solution (4128).

Cap and mix.

3.

This test requires a

reagent blank.

Rinseaclean

colorimeter tube

(0290) with clear,

colorless, fluoride

free water. Fill to

the 10 mL line

with clear,

colorless, fluoride

free water.

2.

Fill the Water

Sample Collecting

Bottle (0688) with

sample water. This

will be used to

dispense sample

water for the tests.

1.

Use the 1.0 mL

pipet (0354) to

add 2 measures of

*Acid-Zirconyl

SP ADNS

Reagent (3875).

Cap and mix

thoroughly . (This

is the reagent

blank.

4.

6.

Push the

button

to turn the meter

on. Press the

button

andholditfor2

seconds until

is displayed.

Release the button

to take a blank

reading (0.0 ppm).

READ

ZERO

bla

I200 COLORIMETER

••••••••••••••••••

READ

ZERO

bla

L

Mott

Read the 1200 Colorimeter Manual before proceeding. Carefully

wipe tubes dry before inserting into the colorimeter chamber.

FLUORIDE

Page 51

FLUORIDE

9.

10 .

Align the index

line with the arrow

on the meter,

insert tube into

chamber. Close

the lid. Push the

button.

Record results as

ppm Fluoride.

READ

CAL

I200COLORIMETER

••••••••••••••••••

READ

18.0

Use the 1.0 mL

pipet (0354) to add

2 measures of

*Acid-Zirconyl

SP ADNS Reagent

(3875). Cap and

mix thoroughly.

8.7.

Rinseaclean

colorimeter tube

(0290) with

sample water. Fill

to the 10 mL line

with sample

water.

Use the 0.5 mL

pipet (0353) to

add 0.5 mL of

*Sodium Arsenite

Solution (4128).

Cap and mix.

L

Mott

er2

NOTE: Zeroing the meter with sample water or an empty chamber will result in an

message. Meter must be zeroed with a reagent blank.

Page 52

FLUORIDE SPADNS TEST METHOD SPECIFICA TIONS

APPLICATION

Drinking and surface waters; domestic and industrial waters.

RANGE

0.0 to 2.0 ppm Fluoride

METHOD

Colorimetric test based upon the reaction between fluoride and zirconium dye lake. The

fluoride reacts with the dye lake, dissociating a portion of it into a colorless complex ion

and dye. As the fluoride concentration increases, the color produced becomes

progressively lighter.

HANDLING & PRESERVATION

Samples may be stored and refrigerated in plastic containers.

INTERFERENCES

The following substances produce a positive interference at the concentration given:

Chloride (Cl

Phosphate (PO

Hexametaphosphate (NaPO

-

) 7000 mg/L

-3

)16mg/L

4

1mg/L

3)6

The following substances produce a negative interference at the concentration given:

Alkalinity (CaCO

Aluminum (Al

+3

Iron (Fe

)10mg/L

Sulfate (SO

) 5000 mg/L

3

+3

)0.1mg/L

-2

) 200 mg/L

4

Color and turbidity must be removed or compensated for in the procedure. Temperature

should be maintained within 5 degrees Celcius of room temperature.

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside USA) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

®

03.08

Page 53

1200 COLORIMETER

MOL YBDENUM

MODEL 1200-MO • CODE 3676-01

QUANTITY CONTENTS CODE

60 mL *Mo Buffer *3997-H

2 x 30 mL *Molybdenum Oxidizing Reagent *6485-G

2.5 g *Molybdenum Indicator Powder *6486-S

1 Colorimeter Tubes 10 mL, w/cap, set of 6 0290-6

1 Spoon, 0.05g, plastic 0696

1 Pipets, 1.0 mL, plastic, w/cap 0372

1 Pipet, 1.0 mL 0354

1 Water Sample Collecting Bottle 0688

1 1200 Colorimeter for Molybdenum 26729

*WARNING: Reagents marked with a * are considered to be potential health hazards. To view

or print a Material Safety Data Sheet (MSDS) for these reagents see MSDS CD or

www .lamotte.com. To obtain a printed copy, contact LaMotte by e-mail, phone or fax.

To order individual reagents or test kit components, use the specified code number.

NOTE: After use, return *MO Buffer (3997) to zipper top storage bag to reduce exposure to

corrosive reagent.

INTRODUCTION

Molybdenum occurs naturally in the earth’s crust as molybdenite and wolfenite, and is

an important element in many biochemical reactions, including nitrogen fixation. In

industrial processes, such as the operation of boilers and cooling towers, molybdenum, in

the form of sodium molybdate, is used as an environmentally safe corrosion inhibitor.

1

Page 54

MOLYBDENUM PROCEDURE - Thioglycolate Method

8.

Fill the Water

Sample Collecting

Bottle (0688) with

sample water. This

will be used to

dispense sample

water for the tests.

Rinse and fill a

colorimeter

tube (0290) to

the 10 mL line

with sample

water.

Use the 0.05 spoon

(0696) to add 0.05g

of *Molybdenum

Indicator Powder

(6486).

1. 2.

Insert the tube

into the

chamber, being

sure to align the

index line with

the arrow on

the meter.

Close the lid.

This tube is the

sample blank.

6.

5.

Wipe the tube dry.

Use the 1.0 mL

pipet (0354) to

add1mLof

*Molybdenum

Oxidizing

Reagent

(6485). Cap

and mix.

4.

Use the 1.0 mL

pipet (0372) to

add1mLof*Mo

Buffer (3997).

Cap and mix.

3.

7.

Push the

button to turn the

meter on. Press the

button

andholditfor2

seconds until is

displayed. Release

the button to take a

blank reading

(0.0 ppm).

READ

ZERO

bla

I200 COLORIMETER

••••••••••••••••••

READ

ZERO

bla

L

Mott

Read the 1200 Colorimeter Manual before proceeding. Carefully

wipe tubes dry before inserting into the colorimeter chamber

MOLYBDENUM

2

Page 55

NOTE: If the molybdenum reading exceeds 50 ppm, repeat procedure on diluted sample,

9.

10 .

Wipe the tube dry .

Cap and mix

until the

powder

dissolves.

Solution will

turn yellow if

molybdenum is

present.

Align the index line

with the arrow on

the meter, insert

tube into chamber.

Close the lid. Push

the

button. Record

results as ppm

Molybdenum.

READ

CAL

I200COLORIMETER

••••••••••••••••••

READ

18.0

11.

L

Mott

and multiply the result by the appropriate dilution factor. See 1200 Colorimeter

Instruction Manual for procedure.

3

Page 56

MOLYBDENUM

TEST METHOD SPECIFICATIONS

APPLICATION

Boiler and cooling water

RANGE

0 to 30 ppm Molybdenum

METHOD

Calcium thioglycolate reacts with molybdenum to give a yellow color with an intensity

proportional to the amount of molybdenum present.

HANDLING & PRESERVATION

Molybdenum samples may be stored in either plastic or glass containers.

INTERFERENCES

Nickel levels less than 50 ppm do not interfere; aluminum levels less than 10 ppm do

not interfere; chromate, at higher concentrations, interferes due to the intense yellow

color. Ferrous iron levels below 50 ppm do not interfere, but low levels of ferric iron will

cause a large blank. Highly buffered samples may exceed the capacity of the system

possibly producing inaccurate results. Add an extra 1.0 mL of *Mo Buffer (3997) to

adjust the pH of the sample to approximately 4.5. Multiply the result in ppm by 1.08.

LaMOTTE COMPANY

Helping People Solve Analytical Challenges

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 (Outside U.S.A.) • Fax 410-778-6394

Visit us on the web at www.lamotte.com

®

06/08

Page 57

1200 COLORIMETER

NITRATE NITROGEN

MODEL 1200-NA · CODE 3677-01

QUANTITY CONTENTS CODE

2 x 120 mL *Mixed Acid Reagent *V-6278-J

10 g *Nitrate Reducing Reagent *V-6279-D

1 Spoon, 0.1 g, plastic 0699

1 Graduated Cylinder 0416

1 Colorimeter Tubes, w/caps 0290-6

1 Water Sample Collecting Bottle 0688

1

*WARNING: Reagents marked with a * are considered to be potential health hazards.

To view or print a Material Safety Data Sheet (MSDS) for these reagents see MSDS CD

or www.lamotte.com. To obtain a printed copy , contact LaMotte by email, phone or fax.

To order individual reagents or test components, use the specified code number.

NITRATE - NITROGEN INTRODUCTION

Nitrogen is essential for plant growth, but the presence of excessive amounts in water

supplies presents a major pollution problem. Nitrogen compounds may enter water as

nitrates or be converted to nitrates from agricultural fertilizers, sewage, industrial and

packing house wastes, drainage from livestock feeding areas, farm manures and legumes.

Nitrates in large amounts can cause “blue babies” (methemoglobinemia) in infants less

than six months of age. Nitrate concentration is an important factor to be considered in

livestock products, where, in addition to causing methemoglobinemia, it is responsible

for many other problems. Nitrates in conjunction with phosphate stimulate the growth

of algae with all of the related difficulties associated with excessive algae growth.

U.S. Public Health Service Drinking Water Standards state that 10 ppm nitrate nitrogen

should not be exceeded. To the sanitary and industrial engineer, concentrations of less

than 1 ppm are acceptable.

1200 Colorimeter for Nitrate Nitrogen

26734

1

Page 58

NITRATE-NITROGEN TEST PROCEDURE -

Insert the tube

into the