Gasket &

Fastener

Handbook

A Technical Guide To

Gasketing & Bolted Flanges

About Lamons

Lamons is one of the largest gasket and bolt suppliers in the world,

commied to quality and local service. We have 6 manufacturing and 21

sales and services branches posioned all around the world combined

with many licensees and distributors.

We are strategically located to provide customers with the widest

selecon of gasket materials and fastener stock ready for immediate

delivery. Lamons’ various locaons feature leading technology and state

of the art manufacturing facilies capable of producing engineered

products to custom specicaons serving the rening, chemical,

power generaon, oshore, subsea, petrochemical (upstream and

downstream), and pulp and paper industries, among others.

www.lamons.com

Sealing Global - Servicing Local

Table of Contents

Introduction

Why Gaskets are Used • Effecting A Seal • Gasket Seating

Flange Types • Flange Finish • Material Considerations

Chapter 1 : Gasket Selection

Section 1: Non-Metallic Gaskets

Elastomers 17

PTFE Products 19

Compressed Non-Asbestos 23

High Temperature Sheet Products 38

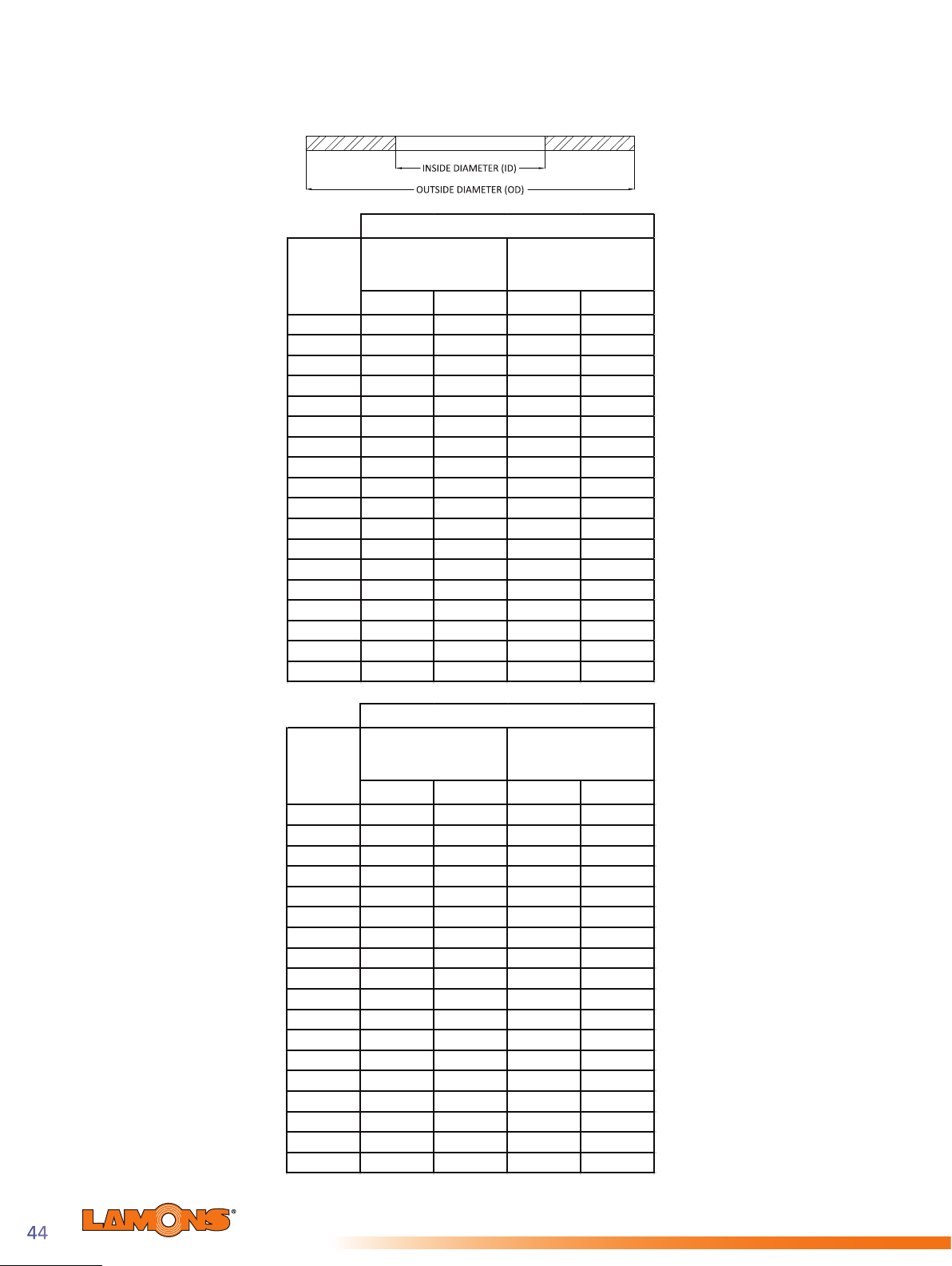

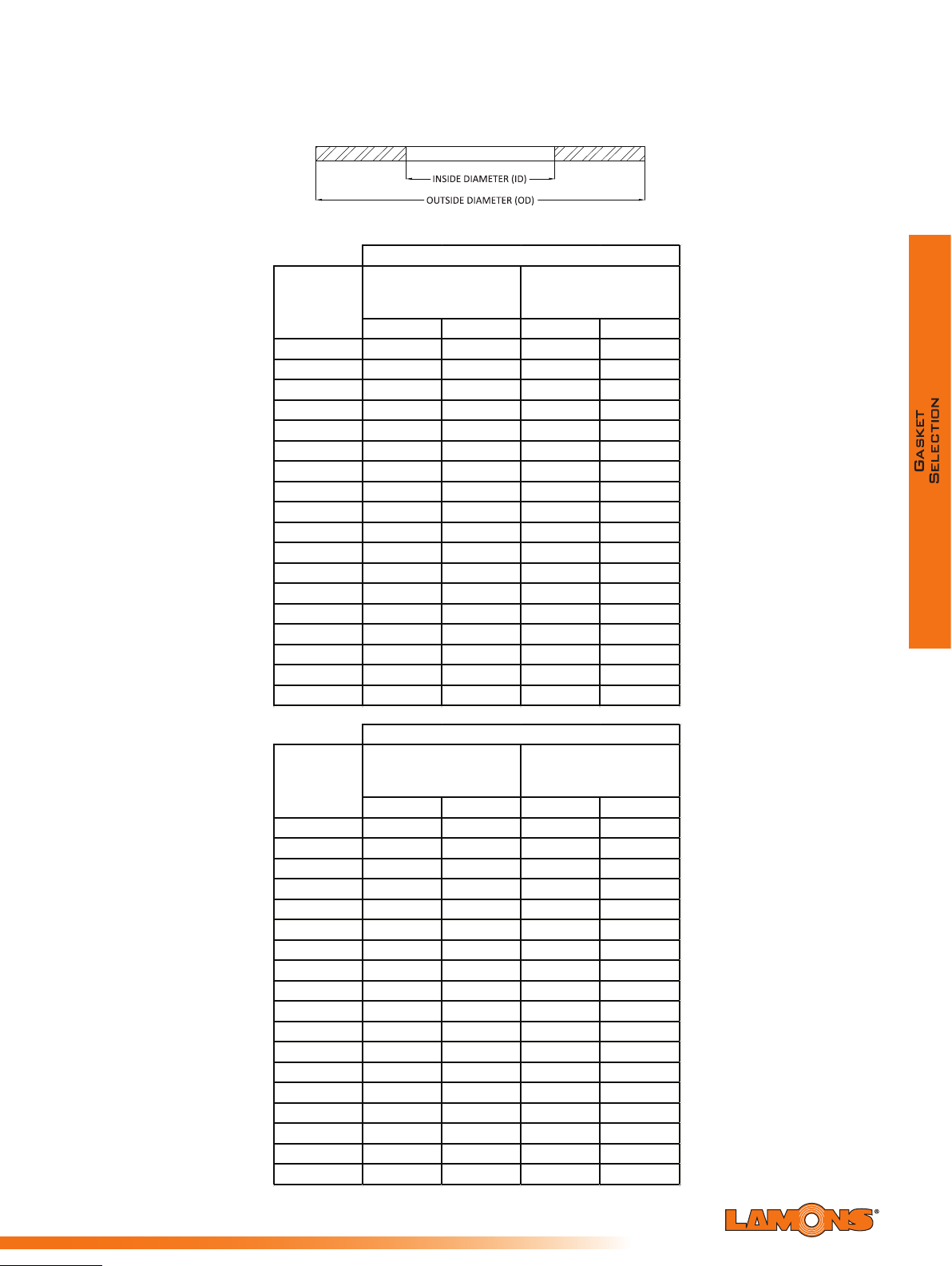

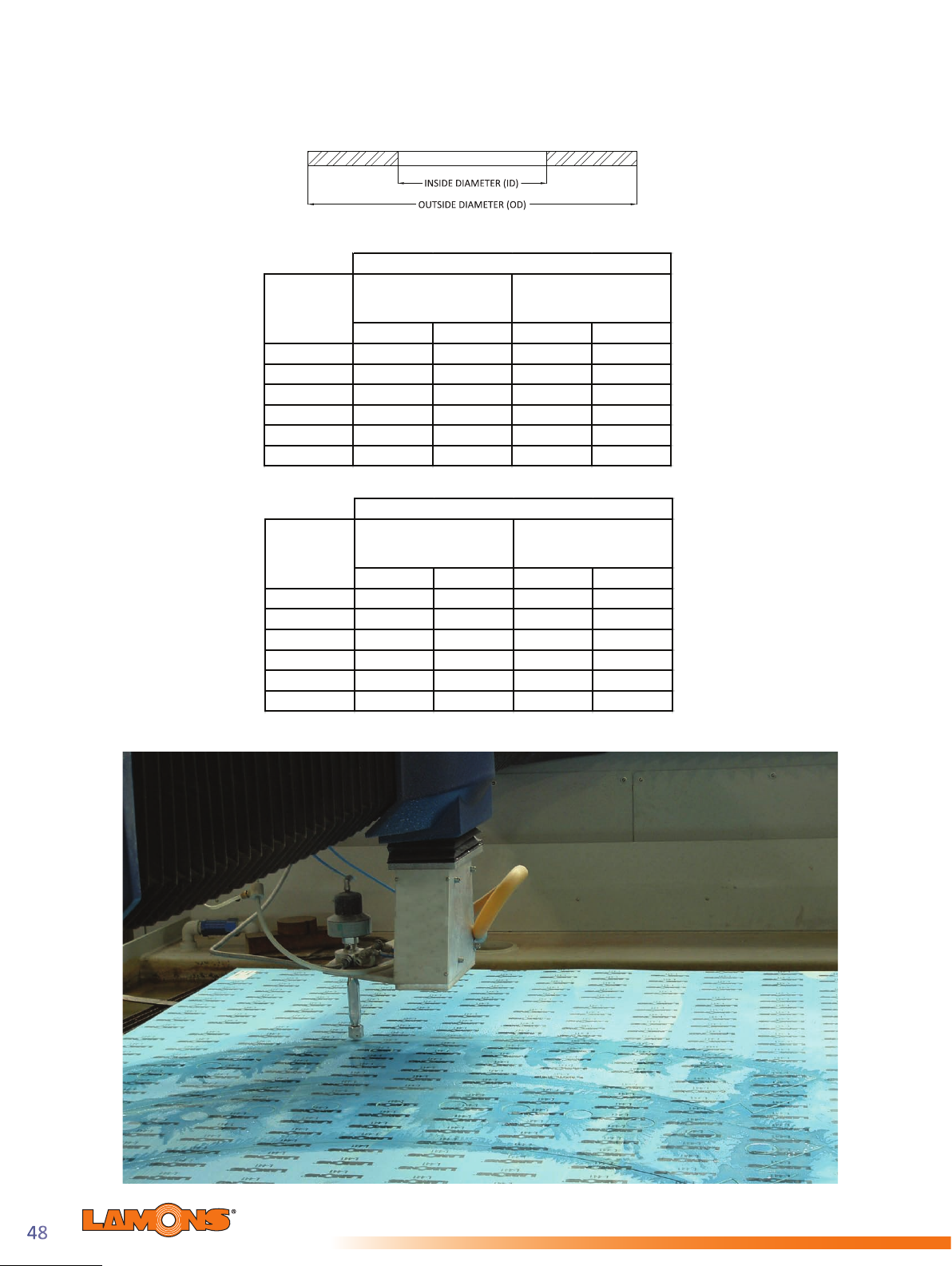

Soft Gasket Dimensions 39

Section 2: Semi-Metallic Gaskets

CorruKammTM Gaskets & Dimensions

TM

Kammpro le

Spiral Wound Gaskets & Dimensions 65

Corrugated Metal Gaskets & Dimensions

Metal / Double Jacketed Gaskets & Dimensions 109

Section 3: Metallic Gaskets

Ring Joints & Dimensions 115

Lens Ring Dimensions 126

Specialty Machined Products 127

Gaskets & Dimensions 53

5

51

105

Section 4: IsoTekTM Isolation Gaskets & Kits

Defender

Defender

IsoGuard

IsoMate

Sleeves and Washers 141

Installation • Torque Values • Sugested Media

TM

Sealing - Isolating Gasket 128

TM

FS Sealing - Isolating Gasket 131

TM

Sealing - Isolating Gasket 136

TM

Sealing - Isolating Gasket 139

145

Chapter 2: Gasket Installation

Installation and Bolting Practices 153

Bolt Torque Sequence 160

Trouble Shooting Leaking Joints 165

Chapter 3: Technical & Design

ASME Section VIII, Design Consideration for Bolted Flange Connections 169

Bolt Load Formulas 172

Notation Symbols and De nitions 173

Common Metals Description 177

Bolt Reference Charts for ASME B16.5 Flanges 180

Bolt Reference Charts for ASME B16.47 A and B Flanges

Torque Chart 184

182

Chapter 4: Appendix

Chemical Resistance • Galvanic Corrosion • Temperature Conversion

Hardness Conversion • Pipe Dimensions & Weights • Circumferences &

Areas of Circles • Fastener Details

187

4

Lamons Gasket Company makes no expressed or implied warranty or representation

whatsoever concerning the statements and information set forth in this handbook and

expressly disclaims any liability for direct, incidental or consequential damages arising from

injury to persons or products resulting directly or indirectly from the use of, or reliance upon,

any statement or information set forth in this handbook.

The content of this handbook is the property of Lamons Gasket Company and is not to be

reproduced in any form without permission of Lamons.

Lamons is a Company of

Revision Febuary 2016

Sealing Global - Servicing Local

Sealing Global - Servicing Local

Introduction

The cost of leaky joints in industry today is staggering. Out-of-pocket costs run into billions of

dollars annually in lost production, waste of energy, loss of product and, most recently, impact

on the environment. These problems are increasing, not decreasing. It behooves all of us to

consolidate our knowledge and experience to solve or at least minimize these problems.

This publication is being produced because we, as gasket and fastener manufacturers and

suppliers, are constantly called upon to solve sealing problems after the fact. Too often we nd

insufcient time and attention has been given to:

• Proper design of anged joint;

• Installation procedures; and,

• Selection of the optimum gasket material required to solve a particular sealing

problem.

We will endeavor to outline in this publication those areas we believe to be essential in a

properly designed, installed and maintained gasketed joint.

We believe most people involved with the design, installation, and maintenance of gasketed

joints realize that no such thing as “zero” leakage can be achieved. Whether or not a joint

is “tight” depends on the sophistication of the methods used to measure leakage. In certain

applications the degree of leakage may be perfectly acceptable if one drop of water per

minute is noted at the gasketed joint. Another requirement is that no bubbles would be

observed if the gasketed joint was subjected to an air or gas test underwater. A still more

stringent inspection would require passing a mass spectrometer test. The rigidity of any test

method would be determined by:

• The hazard of the material being conned;

• Loss of critical materials in a process ow;

• Impact on the environment should a particular uid escape into the atmosphere; and,

• Danger of re or of personal injury.

All of these factors dictate proper attention must be given to:

• Design of ange joints or closures;

• Proper selection of gasket type;

• Proper gasket material; and,

• Proper installation procedures.

Care in these areas will ensure that the best technology and planning goes into the total

package and will minimize operating costs, pollution of the environment and hazards to

employees and the general public.

5

Why Gaskets are Used

Gaskets are used to create a static seal between two stationary members of a mechanical

assembly and to maintain that seal under operating conditions, which may vary dependent

upon changes in pressures and temperatures. If it were possible to have perfectly mated

anges and if it were possible to maintain an intimate contact of these perfectly mated anges

throughout the extremes of operating conditions, a gasket would not be required.

This is virtually impossible either because of:

• The size of the vessel and/or the anges;

• The dif culty in maintaining such extremely smooth ange nishes during handling and

assembly;

• Corrosion and erosion of the ange surface during operations; and,

• The sheer number of anged joints in a typical industrial setting, and commercial

implications.

As a consequence, relatively inexpensive gaskets are used to provide the sealing element in

these mechanical assemblies. In most cases, the gasket provides a seal by utilizing external

forces to ow the gasket material into the imperfections between the mating surfaces. It

follows then that in a properly designed gasket closure, three major considerations must be

taken into account in order for a satisfactory seal to be achieved.

• Suf cient force must be available to initially seat the gasket. Stated this way, adequate

means must be provided to ow the gasket into the imperfections in the gasket seating

surfaces.

• Suf cient forces must be available to maintain a residual stress on the gasket under

operating conditions to ensure that the gasket will be in continuous intimate contact

with the gasket seating surfaces to prevent leakage.

• The selection of the gasket material must be such that it will withstand the pressures

exerted against the gasket, satisfactorily resist the entire temperature range to which the

closure will be exposed and withstand corrosive attack of the con ned medium.

Effecting a Seal

A seal is affected by compressing the gasket material and causing it to ow into the

imperfections on the gasket seating surfaces so that intimate contact is made between the

gasket and the seating surfaces.

There are four different methods that may be used either singly or in combination to achieve

this unbroken barrier:

1. Compression

This is the most common method of effecting a seal on a ange joint and the compression

force is normally applied by bolting;

2. Attrition

Is a combination of a dragging action combined with compression, such as in a spark plug

gasket where the spark plug is turned down on a gasket that is both compressed and

screwed in to the ange;

3. Heat

An example is the case of sealing a ball and valve joint on cast iron pipe by means of

molten lead. Molten lead is poured, then is tamped into place using a tamping tool and a

hammer; and,

4. Gasket Lip Expansion

This is a phenomenon that would occur due to edge swelling when the gasket would

be affected by con ned uid. Elastomeric compounds affected by con ned uids, such

Sealing Global - Servicing Local

Sealing Global - Servicing Local

as solvents, cause the gasket material to swell and increase the interaction of the gasket

against the ange faces.

Generally, gaskets are called upon to effect a seal across the faces of contact with the anges.

Permeation of the media through the body of the gasket is also a possibility depending on

material, conned media, and acceptable leakage rate.

Compression Attrition

Gasket Seating

There are two major factors to be considered with regard to gasket seating:

First, the gasket itself. The ASME Unred Pressure Vessel Code Section VIII, Division 1 denes

minimum design seating stresses for a variety of gasket types and materials. These design

seating stresses range from zero psi for so-called self-sealing gasket types such as low

durometer elastomers and O-rings to 26,000 psi (179 MPa) to properly seat solid at metal

gaskets. Between these two extremes there is a multitude of types and materials available to

the designer enabling them to make a selection based upon the specic operating conditions

under investigation.

Second, the other major factor to take into consideration must be the surface nish of the

gasket seating surface. As a general rule, it is necessary to have a relatively rough gasket

seating surface for elastomeric and PTFE gaskets on the order of magnitude of 500 micro

inches. Solid metal gaskets normally require a surface nish not rougher than 63 micro inches.

Semi-metallic gaskets, such as spiral wound gaskets, fall between these two general types.

The reason for the difference is that with non-metallic gaskets such as rubber, there must be

sufcient roughness on the gasket seating surfaces to bite into the gasket, thereby preventing

excessive extrusion and increasing resistance to gasket blowout. In the case of solid metal

gaskets, extremely high unit loads are required to ow the gasket into imperfections on

the gasket seating surfaces. This requires that the gasket seating surfaces be as smooth as

possible to ensure an effective seal. Spiral wound gaskets require some surface roughness

to prevent excessive radial slippage of the gasket under compression. The characteristics of

the type of gasket being used dictate the proper ange surface nish that must be taken into

consideration by the ange designer, and there is no such thing as a single optimum gasket

surface nish for all types of gaskets. The problem of the proper nish for gasket seating

surface is further complicated by the type of the ange design. For example, a totally enclosed

facing such as tongue and groove will permit the use of a much smoother gasket seating

surface than can be tolerated with a raised face.

Flange Types

A ange is used to join pipe, valves, or a vessel within a system. The most common anges

used in industrial applications follow. When applying gasket and sealing components to these

anges, the user must take into consideration sizing limitations, available clamp load, optimum

surface nish, and gasket placement to minimize ange rotation. Pressure ratings for ASME

standard anges are classied by pressure class of 150, 300, 400, 600, 900, 1500 and 2500.

The most common terminology used is the pound reference, although the more formal

reference is by class, such as class 150 ange. ASME requires that each ange be stamped with

7

the manufacturer’s name, nominal pipe size, pressure classi cation, ange facing, bore, material

designation, ring gasket number (when using a ring type joint ange facing) and heat number or

code.

Raised Face Flange

Raised Face anges are the most common type used in industrial applications due to their

versatility in gasket compatibility, robust construction that prevents ange rotation under

load and the unitized design.

Flat Face Flange

Mating faces of both anges are at across the entire face both inside and outside the bolts.

These uncon ned gaskets require a mechanical stop to control compression height, such as

a spiral wound gasket, should be designed with this consideration.

Sealing Global - Servicing Local

Sealing Global - Servicing Local

Tongue and Groove Flange

Compressibility characteristics of the conned design need to be taken into consideration

when applying gaskets to this ange style to ensure ange surfaces do not meet and prevent

over-compression on the gasket. The groove width is typically not wider than 1/16” (1.5 mm)

over the tongue width to control gasket compression and creep relaxation due to gasket

migration. The gasket dimensions will typically match the tongue dimensions.

Male - Female or Recessed Groove Flange

Compressibility characteristics need to be taken into consideration when applying gaskets

to this ange style to ensure ange surfaces do not meet and prevent over compression on

the gasket.

9

Lap Joint and Slip on Flange

A lap joint ange and slip on ange are very similar in that they are typically associated

with non-critical applications and systems that require frequent dismantling for inspection.

The slip on ange is bored slightly larger than the OD of the matching pipe. The pipe slips

into the ange prior to welding both inside and outside to prevent leaks. The lap joint has a

curved radius at the bore and face to accommodate a lap joint stub end.

Lap Joint Flange

Slip On Flange

Sealing Global - Servicing Local

Sealing Global - Servicing Local

Socket Welding Flange

The ange is similar to the slip on ange, except it has a bore and a counter bore. The counter

is slightly larger than the OD of matching pipe, allowing the pipe to be inserted. A restriction

is built into the bottom of the bore, which acts as a shoulder for the pipe to rest on, and has

the same ID of the matching pipe. The ow is not restricted in any direction.

Ring Type Joint (RT J)

Very often used for high pressure applications, ring type joints utilize octagonal or oval shaped

ring gaskets that are ideally softer than the ange material. The gasket is conned in the joint,

where surface nish is critical for the traditional metal to metal seal.

11

The Impact of Flange Finish on Gasket Performance

L

A

M

O

N

S

W

R

I

2

1

5

0

3

1

6

L

F

G

3

1

6

L

I

R

3

1

6

L

O

R

A

S

M

E

B

1

6

.

2

0

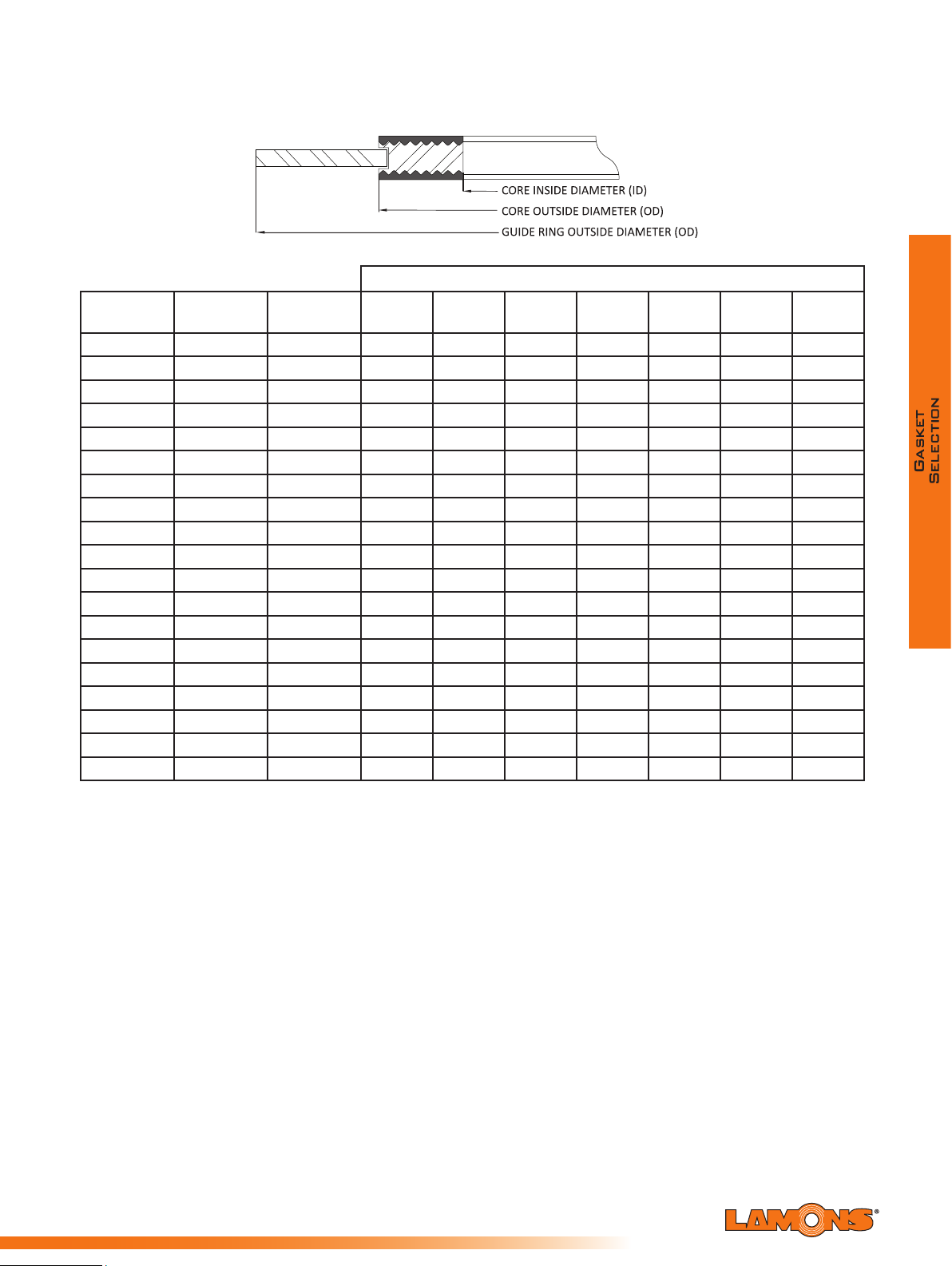

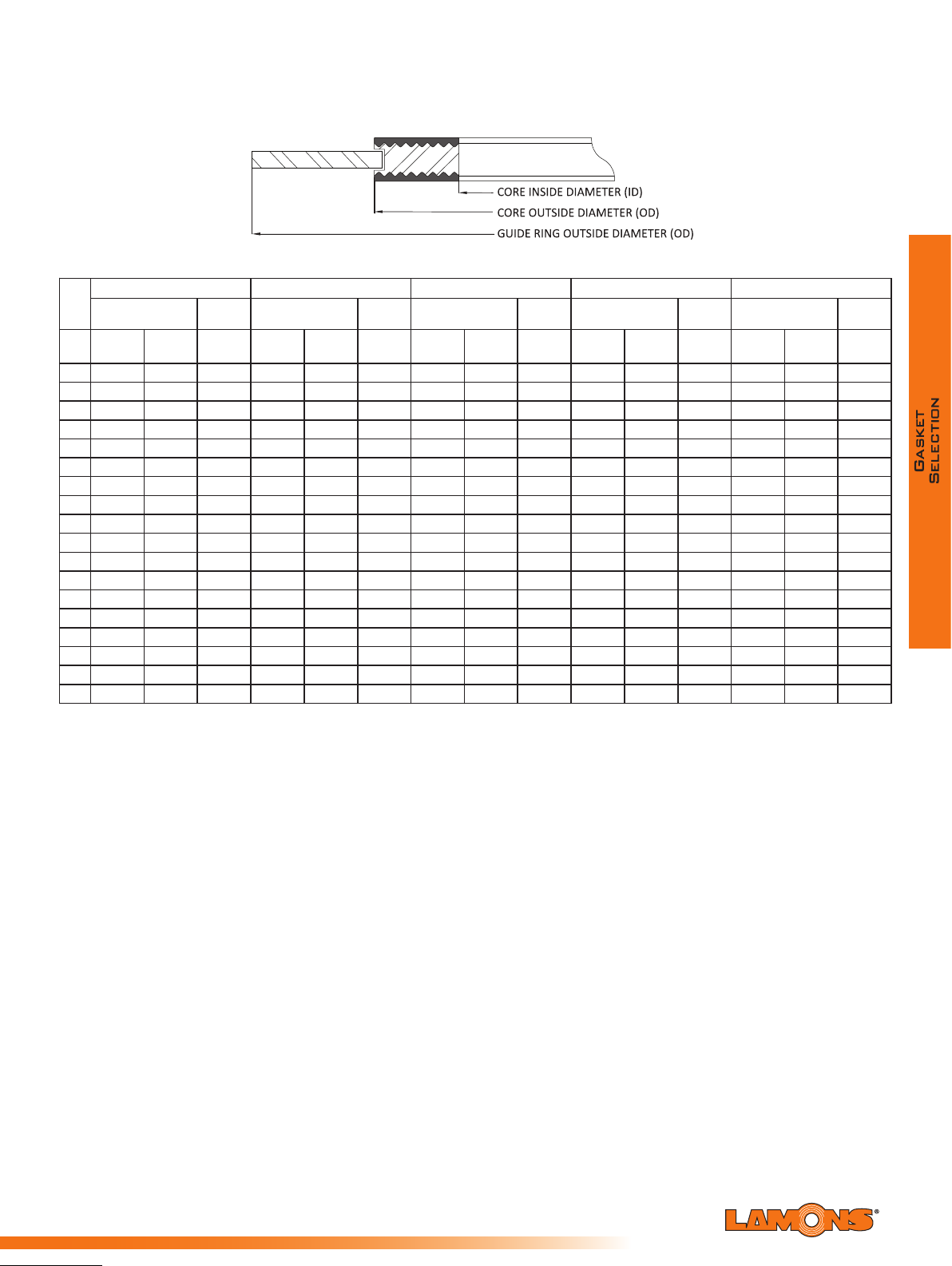

Inner Ring

Outer Ring

Winding Metal

Filler Material

ASME B16.20

or applicable

specication

L

A

M

O

N

S

L

P

3

2

1

5

0

3

1

6

L

F

G

3

1

6

L

O

R

E

N

-

1

2

5

6

0

-

6

A critical and fundamental aspect of sealing is the level of friction between the ange and

gasket surfaces. The level of roughness characteristic of the ange faces can have a dramatic

effect on gasket creep relaxation, blow out resistance and bolted joint tightness. Dependent

upon the type of gasket that is being used in the connection, different surface nishes can be

utilized to optimize gasket performance.

As a general rule, metal gaskets and those that have less conformable surfaces require a

very smooth surface nish. Given the creep resistance and structural stability of most metal

gaskets, the two mating surfaces can create a very tight and reliable seal. Alignment, parallelism

and ange nish must be within speci ed limits in order to achieve an optimal result. Metal

gaskets such as solid metal and jacketed designs offer very little forgiveness in regards to

ange nish, and bolting and assembly de ciencies. A typical surface nish recommendation

for these types of metal contact seals is 64 AARH/RMS or smoother.

Soft gaskets such as compressed ber sheet, that are more compressible, can be more

forgiving in regards to alignment and parallelism of the ange. However, these designs are

more susceptible to creep relaxation and movement while under a load. The ange surface

nish can play a critical role in the gasket’s service life and long term reliability. A smooth

surface nish will not create the necessary friction between these mating surfaces, allowing a

non-reinforced gasket design to be more susceptible to creep under load. This creep would

translate to a loss in bolted joint tightness and potential leakage. A rougher surface nish is

generally recommended for soft, non-reinforced materials to create this necessary friction,

which lends to stability and tightness between the mating surfaces. A typical surface nish

recommendation for soft, non-reinforced materials is 125-250 AARH/RMS or rougher.

Flange Finish Definition and Common Terminology

Raised and at ange facings are machined with serrations; serrations may be either

phonographic or concentric. The industry standard is a phonographic serrated nish. The

facing nish is judged by visual comparison with Roughness Average (Ra) standards. Ra is

stated in microinches (µin) or micrometers (µm) and is shown as an Arithmetic Average

Roughness Height (AARH) or Root Mean Square (RMS). AARH and RMS are different

methods of calculation giving essentially the same result and are used interchangeably. The

more common nishes are represented in the illustration below. Normally the manufacturer

furnishes the “Stock Finish” unless the purchaser speci es otherwise.

De ned on following page, anges are available in many different surface textures that can

affect gasket performance.

1 2

Sealing Global - Servicing Local

4 3

Sealing Global - Servicing Local

1. Stock Finish: This is a continuous spiral groove. Suitable for practically all ordinary

service conditions, this is the most widely used of any gasket surface nish. The AARH/

RMS microinch nish for this typically ranges from a 125 to 250 value. This nish is suitable

for gaskets that have a soft conformable face. Under compression, the soft face will embed

into this nish which helps create a seal. A high level of friction is generated between the

mating surfaces due to this aspect. The stock nish for 12” (305 mm) and smaller anges

is generated by a 1/16” (1.59 mm) radius round nosed tool at a feed of 1/32” (0.79 mm)

per revolution. For sizes above 12” (305 mm) the tool nose is 1/8” (3.17 mm) radius and

the feed is 3/64” (1.19 mm) per revolution.

2. Spiral Serrated: This, too, is a continuous spiral groove but it differs from the stock

nish in that the groove is generated using a 90 degree tool which creates a “V” geometry

with 45 degree angled serration.

3. Concentric Serrated: (Not depicted) As the name suggests this nish is comprised of

concentric grooves. A 90 degree tool is used and the serrations are spaced evenly across

the face. This is a non-standard custom nish which must be specied.

4. Smooth Finish: This nish show no denite signs of tool markings apparent to the

naked eye. These nishes are typically utilized for gaskets with metal facings such as double

jacketed at steel. The smooth surfaces mate to create a seal and depend on the atness

of the opposing faces to effect a seal. AARH/RMS Microinch nish values are typically

better than a 64 value.

5. Lapped Finish (Cold Water Finish): Produced by using a wide tool at high speeds, this

nish is equivalent to a ground surface. It is mirror like in appearance. Surfaces such as this

are typically intended to be used without a gasket.

The concepts of surface roughness, waviness, and lay are illustrated schematically below.

RMS microinch value is dened as the root mean square (square root of the mean square)

of an innite series of distances measured in miroinches from the hypothetical nominal or

mean surface line to the actual irregular surface contour. For all practical purposes, the RMS

microinch value is a weighted average unit of surface roughness that is affected to a greater

extent by the highest and lowest deviation from the nominal surface that is by the minor

deviation. AARH is calculated by obtaining the average roughness height of the irregular

surface .

Flow

(unspecied)

Nominal surface

Normal secon

Total prole

(includes error in

geometric form)

Lay

Waviness prole

(roughness, heights

aenuated)

Roughness prole

(waviness heights

aenuated)

13

Mean Roughness

=

1

n

)

∀

∈ ℝ

i = 1

n

(

∑

∀ ∈ ℝ

i = 1

( )

Arithme cal mean devia on (Ra)Root-mean-square devia on (Rq)

1

y = y (x)

∑

Ra = ,

n

1

Rq =

n

mean of the distribu on (average)

n

∑

y (xi) - y

(y (xi) - y)

2

,

R

q

0 X

Calculations for statistical parameters of pro lometry data.

One microinch equals one millionth of an inch (0.000001”).

Mean line

R

a

Material Considerations

A most important factor in selecting the proper gasket is selecting the suitable material that

will be compatible with the application service.

The optimum gasket material would have the following characteristics:

• It would have the chemical resistance of PTFE;

• The heat resistance of Flexible Graphite;

• The strength of steel;

• It requires a zero seating stress, such as with soft rubber; and,

• Be cost effective.

Obviously there is no known gasket material that has all these characteristics, and each

material has certain limitations that restrict its use. It is possible to overcome limitations

partially by several methods such as:

• Including the use of reinforcing inserts;

• Utilizing combination of materials;

• Varying the construction and/or density; and,

• Designing the joint itself to overcome some of the limitations.

Sealing Global - Servicing Local

Evidently, mechanical factors are important in the design of the joint but the primary selection

of a gasket material is in uenced by different factors:

1. The temperature of the uid or gas in the service

Gaskets are affected in two ways by temperature. Gross physical characteristics are

determined by temperature, including material state, oxidation point, and resilience.

Also the mechanical (creep or stress relaxation) and chemical properties are highly

temperature dependent.

Sealing Global - Servicing Local

2. The pressure of the uid or gas in the service.

Internal pressure acts in two ways against a gasket. First, the hydrostatic end force, equal

to the pressure multiplied by the area of pressure boundary, tends to separate the anges.

This force must be opposed by the ange clamp force. The difference between the initial

ange clamp force and the hydrostatic end force is residual ange load. The residual

load must be positive to prevent joint leakage. The magnitude of the residual ange load

required to prevent leakage is dependent upon the style of gasket selected and its material

of construction. Second, the internal pressure acts to blow out the gasket across the

gasket ange interface.

3. The corrosive characteristics of the uid or gas to be contained

The gasket must be resistant to deterioration from corrosive attack. The severity of

attack and resulting corrosion is dependent upon temperature and time.

Blow-Out

Pressure

Bolt Load

Hydrostac

End Force

Internal pressures

are exerted against both

the ange and the gasket

Gasket

4. Flange Compatibility

The gasket is intended to be the renewable component in the joint system therefore it

should be softer or more deformable than the mating surfaces. It must also be chemically

compatible. For metallic gaskets, this means consideration must be given to galvanic

corrosion. Galvanic effects can be minimized by selecting metals for the gasket and ange

which are close together in the galvanic series, or the gasket should be sacricial (anodic)

to prevent damage to the anges.

Summary

There are charts that are included in the appendix that shows the maximum temperature

limits for non-metal and metal materials. The ratings are based upon hot air constant

temperatures. The presence of contaminating uids and cyclic conditions may drastically

affect the temperature range. Also, there are charts that indicate general recommendations

for non-metallic and metallic materials against various corrosive media. These charts are

general references, as there are many additional factors that can inuence the corrosion

resistance of a particular material at operating conditions. Some of these factors include:

• Concentration of the corrosive agent (full strength solutions are not necessarily more

corrosive than those of dilute proportions and the opposite is also true);

• The purity of a corrosive agent. For example, dissolved oxygen in otherwise pure water

may cause rapid oxidation of steam generation equipment at high temperatures; and,

• The temperature of the corrosive agent. In general, higher temperatures of corrosive

agents will accelerate corrosive attack.

As a consequence, it is often necessary to “eld-test” materials for resistance to corrosion

under normal operating conditions to determine if the material selected will have the

required resistance to corrosion.

15

Sealing Global - Servicing Local

Sealing Global - Servicing Local

Chapter 1

Gasket Selection

Section One: Non- Metallic Gaskets

A “Soft Gasket” material is a term used when referring to a gasket material that is easily

compressed under a low bolt load. This term has been used to distinguish the difference from

a metallic gasket. A soft gasket material can be selected from a large variety of elastomers,

compressed non-asbestos, PTFE, exible graphite and high temperature sheet products. Soft

gaskets are used in a wide range of applications such as for pipe anges, heat exchangers,

compressors and bonnet valves, to name just a few. Soft gasket material can be purchased in

a variety of cut shapes or be provided in sheet or rolls.

As part of Lamons strategy to offer customers a wider range of products, we are pleased to

supply the following soft gasket materials:

• Elastomeric and Fiber Sheet

• Compressed Non-Asbestos Sheet

• Matrix Biaxially Orientated PTFE Sheet

• Matrix L120 Expanded PTFE Sheet

• Matrix L120 PTFE Joint Sealant

• PTFE Envelope Gaskets

• Virgin / Glass-Filled / Reprocessed PTFE Sheet

• Flexible Graphite Sheet

• Mica Sheet

• Ceramic Fiber

Elastomers

An Elastomer is a polymer with the physical property of elasticity. Elastomer is a term derived

from elastic polymer, which is often used interchangeably with the term rubber. Each of the

monomers which link to form the polymer is usually made of carbon, hydrogen, oxygen and/

or silicon. Elastomers are usually thermosets requiring a curing process involving heat and

the addition of sulfur or other equivalent curatives. In addition, elastomers might also be

thermoplastic.

SBR (Styrene-Butadiene)

SBR is a synthetic rubber that has excellent abrasion resistance and has good resistance

to weak organic acids, alcohols, moderate chemicals and ketones. It is not good in ozone,

strong acids, fats, oils, greases and most hydrocarbons. Its temperature range would be from

approximately -65°F to 250°F (-54°C to 121°C).

17

CR-Chloroprene (Neoprene)

Chloroprene is a synthetic rubber that is suitable for use against moderate acids, alkalies

and salt solutions. It has good resistance to commercial oils and fuels. It is very poor against

strong oxidizing acids, aromatic and chlorinated hydrocarbons. Its temperature range would

be from approximately -60°F to 250°F (-51°C to 121°C).

Buna-N/Rubber (Nitrile, NBR)

Buna-N is a synthetic rubber that has good resistance to oils and solvents, aromatic and

aliphatic hydrocarbons, petroleum oils and gasoline over a wide range of temperature. It

also has good resistance to caustics and salts but only fair acid resistance. It is poor in

strong oxidizing agents, chlorinated hydrocarbons, ketones and esters. It is suitable over a

temperature range of approximately -60°F to 250°F (-51°C to 121°C).

EPDM (Ethylene Propylene)

This synthetic material has good resistance to strong acids, alkalies, salts and chlorine

solutions. It is not suitable for use in oils, solvents or aromatic hydrocarbons. Its temperature

range would be between -70°F to 350°F (-57°C to 177°C).

Fluorocarbon (Viton®)

Fluorocarbon elastomer has good resistance to oils, fuel, chlorinated solvents, aliphatic and

aromatic hydrocarbons and strong acids. It is not suitable for use against amines, esters,

ketones or steam. Its normal temperature range would be between -15°F to 450°F (-26°C

to 232°C).

Chlorosulfonated Polyethylene (Hypalon®)

Hypalon® has good acid, alkali and salt resistance. It resists weathering, sunlight, ozone, oils

and commercial fuels such as diesel and kerosene. It is not good in aromatics or chlorinated

hydrocarbons and has poor resistance against chromic acid and nitric acid. It’s normal

temperature range would be between -50°F and 275°F (-46°C and 135°C).

Natural Rubber

Natural rubber has good resistance to mild acids and alkalis, salts and chlorine solutions. It

has poor resistance to oils and solvents and is not recommended for use with ozone. Its

temperature range is very limited and is suitable only for use from -70°F to 200°F (-57°C to

93°C).

Silicones

Silicone rubbers have good resistance to hot air. They are unaffected by sunlight and ozone.

They are not, however, suitable for use against steam, aliphatic and aromatic hydrocarbons.

The temperature range would be between -65°F to 500°F (-54°C to 260°C).

Vegetable Fiber Sheet

Vegetable ber sheet is a tough pliable gasket material manufactured by paper making

techniques utilizing plant bers and a glue-glycerine impregnation. It is widely used for sealing

petroleum products, gases and a wide variety of solvents. Its maximum temperature limit is

250°F (121°C). If a more compressible material is required, a combination cork- ber sheet is

available. The cork- ber sheet has the same maximum temperature limitation as the vegetable

ber sheet.

Note:

Sealing Global - Servicing Local

Viton® and Hypalon® are registered trademarks of DuPont.

Sealing Global - Servicing Local

PTFE Products

PTFE (Polytetrauoroethylene) has emerged as the most common thermoplastic gasket

material. PTFE’s outstanding properties include resistance to temperature extremes from

cryogenic to 500°F (260°C). PTFE is highly resistant to chemicals, solvents, caustics and acids

except free uorine and alkali metals. It has a very low surface energy and does not adhere to

the anges. PTFE gaskets can be supplied in a variety of forms; either as virgin or reprocessed

material, and also with a variety of ller material. The principal advantage in adding llers to

PTFE is to inhibit cold ow or creep relaxation.

Matrix is a premium range of PTFE material that covers the full spectrum of customer

requirements. This product line covers, biaxally orientated lled materials (L100, L104, L110)

for low creep, higher loaded applications. High compression (L120) for applications where

high load values are not achievable but low creep is still required.

Matrix L100, L104 and L110 products are manufactured to the HS10 method which was

developed by DuPont in 1960. The result is a material that has exceptional strength and

stability under load. The resultant biaxial orientation of the PTFE particles creates a unique

strength where both the longitudinal and transverse directions are equally as strong. This

superior matrix orientation and addition of premium llers allows the material to resist

creep and cold ow when subject to load.

Matrix L120 is our range of high quality Expanded PTFE materials, it is offered in both sheet,

cut gaskets and joint sealant form.

Expanded PTFE (ePTFE) is manufactured by heating solid Polytetrauoroethylene, the material

is then stretched up to 800% of its original size and this forms a microporous structure which

consists of around 70% air. This gives the material good compression characteristics, which

allows the ePTFE to seal under low loads.

The Matrix range can be used in its pure form or can be used as facings or llers for our

range of semi-metallic gaskets.

All of our Matrix materials conform to FDA requirements.

Matri

19

Matri

Matri

Matri

A biaxially orientated high quality silica- lled PTFE

sheet for use in sealing most chemicals except

molten alkali metals, uorine gas, and hydrogen

uoride. This material is approved for potable

water service, complies with requirements of FDA

regulations and can be used at all concentrations

of sulfuric acid.

A superior performance, biaxially orientated

sheet material containing PTFE and hollow glass

microspheres for use in sealing most chemicals

except molten alkali metals, uorine gas and

hydrogen uoride. This material is approved for

potable water service, complies with requirements

of FDA regulations and has exceptional compression

characteristics making it good for use in glass lined

anges or where loading problems exist.

A pigment-free biaxially orientated with superior

performance, barium sulfate- lled PTFE sheet for

use in sealing food, pharmaceuticals, and other

general chemical media. This material complies with

requirements of FDA regulations and is acceptable

for use in aqueous hydro uoric acid below 49%, but

is not suitable for sealing molten alkali metals or

uorine gas.

Typical Physical Properties

Style

Color Tan Blue O White

Density

Temperature Limits

MAX Pressure 1235 psi (8.5 MPa) 1235 psi (8.5 MPa) 1235 psi (8.5 MPa)

F36 Compression 7% 35% 6%

F36 Recovery 45% 45% 40%

F152 Tensile Strength 2320 psi (16 MPa) 1885 psi (13 MPa) 2030 psi (14 MPa)

F37 Liquid Leakage <0.3 mL/hr <0.25 mL/hr <0.2 mL/hr

F38 Creep Relaxa on 35% 31% 13%

F149 Dielectric Strength 20 kV/mm 15 kV/mm 21 kV/mm

Residual Stress BS7531 @ 175ºC 4496 psi (31 MPa) 4351 psi (30 MPa) 4351 psi (30 MPa)

Gas Leakage - DIN 3535 <0.01 mg/(s-m) <0.02 mg/(s-m) <0.01 mg/(s-m)

Gas Leakage - BS7531 <0.005 mL/min <0.01 mL/min <0.004 mL/min

ROTT Constant Gb 172 100 146

ROTT Constant a 0.401 0.401 0.375

ROTT Constant Gs 2.76 x 10

Tpmax 24260 33240 60460

m 4 2 2

y 2175 psi (15 MPa) 1595 psi (11 MPa) 1740 psi (12 MPa)

Matrix

L1 0 0

137 lbs/

(2.2 g/cc)

-450ºF (-268ºC) to

500ºF (260ºC)

3

-6

Matrix

L1 0 4

87 lbs/ 3

(1.4 g/cc)

-450ºF (-268ºC) to

500ºF (260ºC)

2.87 x 10

-5

Matrix

L11 0

180 lbs/

(2.9 g/cc)

-450ºF (-268ºC) to

500ºF (260ºC)

3

1.2

Sealing Global - Servicing Local

Sealing Global - Servicing Local

Expanded PTFE Sheet

Matrix L120 effectively lls ange imperfections for a tight, leak-free seal.

Matri

conventional PTFE, which is prone to creep and cold ow, L120 has good

creep resistance and bolt torque retention properties even under higher

compressive force. With L120, it is much more possible to bolt up once and

not have to re-torque later. Most commonly FDA/USDA suitable.

Complies with the requirements of FDA21 CFR 177.1550

Minimum Temperature: -450°F (-268°C)

Maximum Temperature: 500°F (260°C)

Maximum Pressure: 735 psi (5.1 MPa)

Thickness Range: 0.020” (0.5 mm) to 1/4” (6.4 mm)

It is easily compressed under lower

loads, benecial for applications such

as FRP or glass-lined anges. Unlike

Typical Physical Properties

Property ASTM Method Typical Values

Compressibility F36 55%

Recovery F36 15%

Tensile Strength F152 3190 psi (22MPa)

Liquid Leakage F37 <0.1 mL/hr

Creep Relaxaon F38 17%

Density - 59 lbs/3 (0.95 g/cc)

Gas Leakage BS7531 <0.03 mL/min

PTFE Joint Sealant

100% pure, specially processed

PTFE sealant provides soft, highly

Matri

pressure, PTFE sealant provides a very thin and wide ribbon-like joint sealant

so that the smallest possible gasket surface area is exposed to the harmful

effects of corrosive media.

Width (in) Length () Width (in) Length ()

1/8 100 3/4 15

1/4 50 3/4 30

3/8 25 3/4 50

3/8 250 3/4 100

1/2 15 1 15

1/2 30 1 30

1/2 150 1 75

5/8 15

5/8 30

5/8 150

compressible gasketing on a roll for

long-life, trouble-free sealing that cuts

maintenance and storing costs. Under

21

PTFE Envelope Gaskets

Envelope gaskets utilizing PTFE jackets have become popular for use in severely corrosive

services because of their low minimum seating stresses, excellent creep resistance, high

deformability and choice of a variety of ller materials to assure optimum performance on

any speci c application. Fillers such as corrugated metal and rubber sheets are available.

There are three basic designs of envelopes:

1. Slit Type / V Type / Style 800: sliced from cylinders and

split from the outside diameter to within approximately

1/16” (1.5 mm) of the inside diameter. The bearing surface

is determined by the ller dimensions. Clearance is required between the ID of the ller

and the envelope ID. The gasket OD normally rests within the bolt hole circle and the ID

is approximately equal to the nominal ID of pipe. Available in sizes to a maximum OD of

24.

2. Milled Type / Square Cut / Style 820: machined from

cylinder stock. The jacket is machined from the OD to

within approximately 1/32” (0.8 mm) it’s ID. The jacket’s

ID ts ush with pipe bore and its OD nests within the bolts. Available in sizes up to a

maximum OD of 24” (609 mm). Milled envelopes are more expensive than slit type since

considerably more material is lost in machining.

3. Formed Tape Type: large diameter (over 12 NPS) and

irregularly shaped envelopes are formed from tape and

heat sealed to produce a continuous jacket construction.

Virgin / Glass-Filled / Reprocessed PTFE Sheet

Typical Physical Properties

Property Units

Speci c Gravity g/cc D-792 2.14 - 2.20 2.15 - 2.24 2.13 - 2.20

Hardness Shore D D-2240 52 - 65 55 - 58 52 - 65

Tensile Strength psi (MPa)

Elonga on %

Deforma on Under

Load

(73ºF, 2000 psi, 24 hrs.)

Coeffi cient of Linear

Thermal Expansion

(78

ºF - 400ºF)

Thermal

Conduc vity

Dielectric Strength volts/mil D-149a 300 min N/A 500 - 1000

Temperature Range

% D-621 15 - 16 3 - 9 N/A

in/in/ºF D-696 4 - 9 x 10

BTU/hr/

2

/F-in

ºF (°C)

ASTM

Method

D-638

D-1708

D638

D-1708

C-177 1.7 2.5 - 3.5

Typical Values

(Virgin)

2800 min

(19.3 MPa)

270 min 50 - 150 75 - 200

Cryogenic to 450°F

(232°C)

Typical Values

1000 - 2000

-5

Cryogenic to 450°F

(G-F)

(7-14 MPa)

3 - 8 x 10

(232°C)

(10 MPa - 17 MPa)

-5

Cryogenic to 450°F

Typical Values

(Repro)

1500 - 2400

N/A

(232°C)

Sealing Global - Servicing Local

Sealing Global - Servicing Local

Compressed Non-Asbestos

Early efforts to replace asbestos resulted in the introduction and testing of

compressed non-asbestos products in the 1970’s. Many of these products

have seen extensive use since that period, however there have been enough

problems to warrant careful consideration in choosing a replacement

material for compressed asbestos. Most manufacturers of non-asbestos sheet

materials use synthetic bers, like aramid or Kevlar®, in conjunction with

an elastomeric binder. The elastomeric binder makes up a larger percentage

of this sheet and thereby becomes a more important consideration when

determining applications.

Note:

Kevlar® is a registered trademark of DuPont.

L420

L420 is a general purpose sheet jointing material with good mechanical properties.

Constructed with aramid/ organic ber and a high quality nitrile rubber binder.

Creep Relaxation ASTM F-38B (1/32”) 30%

Residual Stress DIN 52913 (50 MPa @ 175°C) 25 MPa

Sealability ASTM F-37A (1/32”) 0.25 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 15%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1500 psi (10 MPa)

Weight Increase

Thickness Increase

Standard Line Callout ASTM F-104 F712111E12M4

Leachable Chlorides FSA Method (Typical) 200 ppm

Density 112 lbs/ft³ (1.8 g/cc)

Color Green

Pressure Range Vacuum to 580 psi (40 Bar) @ 1/16” thickness and below

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Temperature Limits

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C)

ASTM Oil 3, 5 hrs / 300°F (149°C)

ASTM Fuel A, 5 Hrs / 73°F (23°C)

ASTM Fuel B, 5 Hrs / 73°F (23°C)

-40°F to 356°F (-40°C to 180°C)

25% max

0 - 5%

0 - 5%

0 - 5%

0 - 7%

Applications and Characteristics:

• Used successfully in mild organic and

inorganic acids

• Diluted alkalis

• General chemicals

• Synthetic oils

• Petroleum and petroleum derivatives

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

23

L430

L430 is a general purpose sheet jointing material with superior mechanical properties.

Constructed with premium aramid ber and a high quality nitrile rubber binder.

Applications and Characteristics:

• Used successfully in mild organic

and inorganic acids

• Diluted alkalis

• General chemicals

• Synthetic oils

• Petroleum and petroleum

derivatives

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

Creep Relaxation ASTM F-38B (1/32”) 25%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 25 MPa

BS7531 (40 MPa @ 300°C) 16 MPa

Sealability ASTM F-37A (1/32”) 0.25 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 17%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1500 psi (10 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

15% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 5%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 0 - 5%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 5%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 0 - 7%

Standard Line Callout ASTM F-104 F712111E12M4

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 14 kV/mm

Leachable Chlorides FSA Method (Typical) 200 ppm

Density 112 lbs/ft³ (1.8 g/cc)

Color Green

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Temperature Limits

°F to 428°F (-40°C to 220°C)

-40

Maximum Pressure 50 Bar (725 PSI)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering department

for clari cation.engineering@lamons.com

3. Not Suitable.

Sealing Global - Servicing Local

L430 PRESSURE / TEMPERATURE GRAPH

(1160)

80

(1015)

70

(870)

(725)

60

50

3

2

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752) (842)

1

Temperature: Deg C (

Deg F)

Sealing Global - Servicing Local

L433

L433 is a premium sheet gasket material with a reinforcement structure consisting of glass

and aramid bers, it is bound together with a high quality nitrile rubber binder. L433 has excellent resistance to steam due to the addition of glass ber.

Creep Relaxation ASTM F-38B (1/32”) 20%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 32 MPa

BS7531 (40 MPa @ 300°C) 27 MPa

Sealability ASTM F-37A (1/32”) 0.25 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 17%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1500 psi (10 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

15% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 5%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 0 - 5%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 5%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 0 - 7%

Standard Line Callout ASTM F-104 F712132B3E21M5

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 18 kV/mm

Leachable Chlorides FSA Method (Typical) 200 ppm

Density 100 lbs/ft³ (1.6 g/cc)

Color Red/Brown

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Approvals

Temperature Limits

Meets “BS7531 Grade AX”

API 607 Fire Safe

°F to 800°F (-100°C to 425°C)

-150

Maximum Pressure 80 Bar (1160 PSI)

Applications and Characteristics:

• Excellent sealing ability, high

resistance to creep

• Good steam resistance

• Stronger acids and alkalis, inert

gases, general chemicals, oils and

fuels

• Petroleum and petroleum derivatives

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

(1160)

80

(1015)

70

(870)

60

(725)

50

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

L433 PRESSURE / TEMPERATURE GRAPH

3

2

1

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752)

Temperature: Deg C ( Deg F)

(842)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clari cation.

engineering@lamons.com

3. Not Suitable.

25

L440

L440 is a good quality sheet gasket material with a wide range of application potential. Manu-

factured with a formulation of high quality llers, premium aramid bers and a nitrile rubber

binder, L440 is a cost effective, high performance gasket material.

Applications and Characteristics:

• Excellent sealing ability, good

resistance to creep

• Good chemical resistance

• Inert gases, general chemicals, oils

and fuels

• Great Recovery

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

Creep Relaxation ASTM F-38B (1/32”) 20%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 30 MPa

BS7531 (40 MPa @ 300°C) 24 MPa

Sealability ASTM F-37A (1/32”) 0.2 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 17%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1600 psi (11 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

25% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 5%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 0 - 5%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 5%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 0 - 7%

Standard Line Callout ASTM F-104 F712121B3E22M5

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 17 kV/mm

Leachable Chlorides FSA Method (Typical) 100 ppm

Density 112 lbs/ft³ (1.8 g/cc)

Color Green

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Approvals Meets “BS7531 Grade AY”

Temperature Limits

°F to 752°F (-73°C to 400°C)

-100

Maximum Pressure 65 Bar (943 PSI)

All Pressure / Temperature values are based

on 1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compa bility has to

be considered).

2. Please contact Lamons Engineering

department for clari ca on.

engineering@lamons.com

3. Not Suitable.

Sealing Global - Servicing Local

L440 PRESSURE / TEMPERATURE GRAPH

(1160)

80

(1015)

70

(870)

60

(725)

50

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

0 50 100 150 200 250 300 35 0 400 450

(0) (122) (212) (302 ) (392) (482) (572)

2

1

Temperature: Deg C ( Deg F)

3

(662) (752) (842)

Sealing Global - Servicing Local

L441

L441 PRESSURE / TEMPERATURE GRAPH

Temperature: Deg C ( Deg F)

A general service sheet gasket material with a wide range of application potential. Manufactured

with a formulation of high quality llers, premium aramid bers and nitrile binder, L441 is the

workhorse of the Lamons gasket line

Creep Relaxaon ASTM F-38B (1/32”) 20%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 28 MPa

BS7531 (40 MPa @ 300°C) 20 MPa

Sealability ASTM F-37A (1/32”) 0.25 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 17%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1500 psi (10 MPa)

Weight Increase

ASTM F-146 aer immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

25% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 5%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 0 - 5%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 5%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 0 - 7%

Standard Line Callout ASTM F-104 F712121B3E22M5

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 15 kV/mm

Leachable Chlorides FSA Method (Typical) 100 ppm

Density 112 lbs/³ (1.8 g/cc)

Color Blue

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Temperature Limits

-100°F to 707°F (-73°C to 375°C)

Maximum Pressure 60 Bar (870 PSI)

Applications and Characteristics:

• Excellent sealing ability

• Good chemical resistance

• Creep relaxation minimization

• Great Recovery

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

(1160)

80

(1015)

70

(870)

60

(725)

50

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

3

2

1

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752) (842)

All Pressure / Temperature values are based

on 1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compability has to

be considered).

2. Please contact Lamons Engineering

department for claricaon.

engineering@lamons.com

3. Not Suitable.

27

L443

L443 is a premium sheet gasket material with a reinforcement structure consisting of glass

and aramid bers, it is bound together with a high quality nitrile rubber binder. L443 has

excellent resistance to steam due to the addition of glass ber.

Applications and Characteristics:

• Excellent sealing ability, high

resistance to creep

• Good steam resistance

• Stronger acids and alkalis, inert

gases, general chemicals, oils and

fuels

• Petroleum and petroleum deriva v e s

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

Creep Relaxation ASTM F-38B (1/32”) 20%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 32 MPa

BS7531 (40 MPa @ 300°C) 27 MPa

Sealability ASTM F-37A (1/32”) 0.25 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 17%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1500 psi (10 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

15% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 5%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 0 - 5%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 5%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 0 - 7%

Standard Line Callout ASTM F-104 F712132B3E21M5

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 18 kV/mm

Leachable Chlorides FSA Method (Typical) 200 ppm

Density 100 lbs/ft³ (1.6 g/cc)

Color White/Green

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Approvals

Temperature Limits

Meets “BS7531 Grade AX”

API 607 Fire Safe, ABS, GL

°F to 800°F (-100°C to 425°C)

-150

Maximum Pressure 80 Bar (1160 PSI)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clari cation.

engineering@lamons.com

3. Not Suitable.

Sealing Global - Servicing Local

L443 PRESSURE / TEMPERATURE GRAPH

(1160)

80

(1015)

70

(870)

60

(725)

50

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752) (842)

2

1

Temperature: Deg C ( Deg F)

3

Sealing Global - Servicing Local

L450

L450 is a premium sheet gasket material utilizing carbon and aramid bers, it is bound together

with a high quality nitrile rubber binder. L450 is designed to perform at high temperatures and

pressures. Standardization and consolidation of many other gasket materials can be achieved

by the use of L450.

Creep Relaxation ASTM F-38B (1/32”) 18%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 31 MPa

BS7531 (40 MPa @ 300°C) 26 MPa

Sealability ASTM F-37A (1/32”) 0.3 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 17%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1500 psi (10 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

15% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 5%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 0 - 5%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 5%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 0 - 7%

Standard Line Callout ASTM F-104 F712122B3E22M5

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 5 kV/mm

Leachable Chlorides FSA Method (Typical) 200 ppm

Density 100 lbs/ft³ (1.6 g/cc)

Color Black

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Approvals

Temperature Limits

Meets “BS7531 Grade AX”

API 607 Fire Safe

-150°F to 842°F (-100°C to 450°C)

Maximum Pressure 80 Bar (1160 PSI)

Applications and Characteristics:

• Excellent sealing ability, high

resistance to creep

• Good steam resistance

• Stronger acids and alkalis, inert

gases, general chemicals, oils and

fuels

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

(1160)

80

(1015)

70

(870)

60

(725)

50

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

L450 PRESSURE / TEMPERATURE GRAPH

3

2

1

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752) (842)

Temperature: Deg C ( Deg F)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clarication.

engineering@lamons.com

3. Not Suitable.

* Can be used up to a maximum short term

peak temperature of 900°F (482°C)

29

L460

Temperature: Deg C ( Deg F)

L460 is a premium sheet gasket material utilizing graphite and aramid bers, it is bound to-

gether with a high quality nitrile rubber binder. L460 is designed to perform at high temperatures and pressures. Standardization and consolidation of many other gasket materials can be

achieved by the use of L460.

Applications and Characteristics:

• Excellent sealing ability, high

resistance to creep

• Good steam resistance

• Stronger acids and alkalis, inert

gases, general chemicals, oils and

fuels

• Petroleum and petroleum

derivatives

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

Creep Relaxation ASTM F-38B (1/32”) 19%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 30 MPa

BS7531 (40 MPa @ 300°C) 25 MPa

Sealability ASTM F-37A (1/32”) 0.3 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 11%

Recovery ASTM F-36 J 55% min

Tensile Strength ASTM F-152 1500 psi (10 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

15% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 5%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 0 - 5%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 5%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 0 - 7%

Standard Line Callout ASTM F-104 F712122B3E22M5

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 5 kV/mm

Leachable Chlorides FSA Method (Typical) 200 ppm

Density 100 lbs/ft³ (1.6 g/cc)

Color Black

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Approvals Meets “BS7531 Grade AX”

Temperature Limits

°F to 842°F (-100°C to 450°C)

-150

Maximum Pressure 65 Bar (943 PSI)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clari cation.

engineering@lamons.com

3. Not Suitable.

Sealing Global - Servicing Local

L460 PRESSURE / TEMPERATURE GRAPH

80

(1160)

70

(1015)

60

(870)

50

(725)

40

(580)

Pressure: Bar (PSI)

30

(435)

20

(290)

10

(145)

0

(0)

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752) (842)

2

1

3

Sealing Global - Servicing Local

L540

)

L540 is a compressed sheet gasket material utilizing a high quality Neoprene binder. It is re-

inforced with aramid and inorganic bers. This material has an inherent resistance to oil and

petroleum based solvents

Creep Relaxation ASTM F-38B (1/32”) 25%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 28 MPa

BS7531 (40 MPa @ 300°C) 20 MPa

Sealability ASTM F-37A (1/32”) 0.2 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 17%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1600 psi (11 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

20% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 10%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 15 - 25%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 10%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 10 - 20%

Standard Line Callout ASTM F-104 F712332B4E45M5

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 12 kV/mm

Leachable Chlorides FSA Method (Typical) 500 ppm

Density 106 lbs/ft³ (1.7 g/cc)

Color Dark Gray

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Temperature Limits

-60°F to 572°F (-51°C to 300°C)

Maximum Pressure 60 Bar (870 PSI)

Applications and Characteristics:

• It is chemically stable and possesses

good mechanical properties

• It is an excellent choice for water

and saturated steam

• Refrigerants

• Oils and fuels

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

(1160)

80

(1015)

70

(870)

60

(725)

50

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

L540 PRESSURE / TEMPERATURE GRAPH

3

2

1

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752) (842

Temperature: Deg C ( Deg F)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clarication.

engineering@lamons.com

3. Not Suitable.

31

L640W

L640W is a premium compressed sheet gasket material utilizing a high quality SBR binder. It

is reinforced with an engineered blend of aramid and inorganic bers.

Applications and Characteristics:

• It is chemically stable and possesses

good mechanical properties

• It is an excellent choice for water

and saturated steam

• Mild acids and alkalis

• Inert gases.

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

Creep Relaxation ASTM F-38B (1/32”) 20%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 29 MPa

BS7531 (40 MPa @ 300°C) 23 MPa

Sealability ASTM F-37A (1/32”) 0.2 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 17%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1600 psi (11 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

25% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 0 - 15%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 20 - 35%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 0 - 15%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 15 - 25%

Standard Line Callout ASTM F-104 F712541B3E45M5

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 16 kV/mm

Leachable Chlorides FSA Method (Typical) 200 ppm

Density 112 lbs/ft³ (1.8 g/cc)

Color Off White

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Approvals Meets “BS7531 Grade AY”

Temperature Limits

°F to 662°F (-54°C to 350°C)

-65

Maximum Pressure 60 Bar (870 PSI)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clari cation.

engineering@lamons.com

3. Not Suitable.

Sealing Global - Servicing Local

L640W PRESSURE / TEMPERATURE GRAPH

(1160)

80

(1015)

70

(870)

(725)

60

50

3

2

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752) (842)

1

Temperature: Deg C ( Deg F)

Sealing Global - Servicing Local

L740

L740 is a premium compressed sheet gasket material utilizing a high quality EPDM binder. It

is reinforced with an engineered blend of aramid and inorganic bers.

Creep Relaxation ASTM F-38B (1/32”) 24%

Residual Stress

DIN 52913 (50 MPa @ 175°C) 30 MPa

BS7531 (40 MPa @ 300°C) 22 MPa

Sealability ASTM F-37A (1/32”) 0.2 ml/hr

Gas Leakage DIN 3535/6 < 1.0 ml/min

Compressibility ASTM F-36 J 7 - 15%

Recovery ASTM F-36 J 50% min

Tensile Strength ASTM F-152 1600 psi (11 MPa)

Weight Increase

ASTM F-146 after immersion in

Fuel B for 5 Hrs @ 73°F (23°C)

23% max

ASTM F-146

ASTM Oil 1, 5 hrs / 300°F (149°C) 15 - 35%

Thickness Increase

ASTM Oil 3, 5 hrs / 300°F (149°C) 30 - 50%

ASTM Fuel A, 5 Hrs / 73°F (23°C) 10 - 35%

ASTM Fuel B, 5 Hrs / 73°F (23°C) 15 - 35%

Standard Line Callout ASTM F-104

F712690A-

9B4E99L104M9

m & y values 1/16” thickness 1/8” thickness

m 2.5 3.2

y 3800 4100

Dielectric Strength ASTM D149-95a 16 kV/mm

Leachable Chlorides FSA Method (Typical) 200 ppm

Density 112 lbs/ft³ (1.8 g/cc)

Color Off White/Gray

Thickness Range 1/64” (0.4 mm) to 1/8” (3.2 mm)

Sheet Size Availability Max: 120” x 60” (3 m x 1.5 m)

Temperature Limits

-100°F to 707°F (-73°C to 375°C)

Maximum Pressure 65 Bar (943 PSI)

Applications and Characteristics:

• It is chemically stable and possesses

good mechanical properties

• It is an excellent choice for water

and saturated steam

• Mild acids and alkalis

• Inert gases

Note:

Please refer to Lamons Chemical

Compatibility Chart (in the Appendix of

this manual) for more information. All

Lamons sheet gasket materials are supplied

with anti-stick coating as standard. Can be

manufactured with wire insert.

(1160)

80

(1015)

70

(870)

60

(725)

50

(580)

40

Pressure: Bar (PSI)

(435)

30

(290)

20

(145)

10

(0)

0

L740 PRESSURE / TEMPERATURE GRAPH

3

2

1

0 50 100 150 200 250 300 350 400 450

(0) (122) (212) (302 ) (392) (482) (572) (662) (752) (842)

Temperature: Deg C ( Deg F)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clarication.

engineering@lamons.com

3. Not Suitable.

33

Flexible Graphite

This is an all graphite material containing no resins or inorganic llers. It is available with or

without a metal insertion, and in adhesive-back tape form. Flexible Graphite has outstanding

resistance to corrosion against a wide variety of acids, alkalies and salt solutions, organic

compounds, and heat transfer uids, even at high temperatures. There are two proven metal

reinforced exible graphite laminate materials ideal for 95% of all sheet gasket applications.

Lamons exible graphite laminates (LG-SS and LG-TC) are surface branded for easy

identi cation. These gasket materials meet re nery, petrochemical and industrial service

requirements.

Graphite T ape

Rolls of graphite tape can be furnished with a strong self-adhesive

backing strip, to facilitate repair of multiple surfaces, enhancement

of existing design or installation as a form-in-place gasket.

Temperature Limits

Minimum Maximum

In air -320°F (-200°C) 840°F (450°C)

In Steam -320°F (-200°C) 1200°F (650°C)

In Inert or

Reducing Media

-320°F (-200°C) 5400°F (3000°C)

Standard Dimensions

0.005” (0.127 mm), 0.01” (0.254 mm),

Thickness

Width 1/2” (12.7 mm) to 2” (50.8 mm)

Length 20’ (6.1 m), 50’ (15.24 m), 100’ (30.48 m)

Note:

Custom widths and lengths available

0.015” (0.381), 0.02” (0.508 mm),

0.03”(0.762 mm) and 0.04” (1.016 mm)

Sealing Global - Servicing Local

Sealing Global - Servicing Local

Lamons LG -SS

LG-SS is a at metal 316/316L stainless steel reinforced exible graphite sheet material made

with minimum 98% typical carbon content.

Creep Relaxa on

Stability under stress (DIN 52913) 48 N/m

Compressibility

Recovery

ASME code factor “M value”

<4%

2

30%-40%

15%-20%

2

ASME code factor “Y value” 900 psi

Number of inserts

1

Total chlorine (Max) 50 ppm

Density

70 lb/ 3 (1.12 g/cc)

Ash content (Max) 2.0%

Tp max at 15,000 psi gasket stress 3227 psi (22 MPa)

Gb = 816 psi

PVRC design constants*:

a = 0.377 psi

G

= 0.066 psi

s

Gas permeability according DIN 3535 (0.60”) <1.0 ml/min

Nominal Thickness 0.030”-0.120” (0.8 mm - 3 mm)

Typical Thicknesses

1/16” (1.5 mm)

1/8” (3 mm)

316/316L Insert Thickness 0.002” (0.05 mm)

Temperature Limits

*The values are taken from BFG-6.1 and ROTT. Test results are subject to interpreta on

and can lead to di ering design constants.

Cryogenic to 850°F (454ºC)

140

(2030)

120

(1740)

(1450)

100

(1160)

80

(870)

60

Pressure: Bar (PSI)

(580)

40

(290)

20

(0)

0

LG-SS PRESSURE / TEMPERATURE GRAPH

3

2

1

0 50 100 150 200 250 300 350 400 450 500

(0) (120) (210) (300) (390) (480) (570) (660) (750) (850) (930)

Temperature: Deg C ( Deg F)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clari cation.

engineering@lamons.com

3. Not Suitable.

35

Lamons LG -TC

Temperature: Deg C ( Deg F)

LG-TC is a reinforced exible graphite sheet material laminated with tanged 316/316L stain-

less steel insert and made with minimum 98% typical carbon content.

Creep Relaxa on

Stability under stress (DIN 52913) 48 N/m

Compressibility

Recovery

ASME code factor “M value”

<4%

2

30%-40%

15%-20%

2

ASME code factor “Y value” 2500 psi

Number of inserts

1

Total chlorine (Max) 50 ppm

Density

70 lb/ 3 (1.12 g/cc)

Ash content (Max) 1.0%

Tp max at 15,000 psi gasket stress 2287 psi

PVRC design constants*:

(16 MPa)

G

= 1400 psi

b

a = 0.324 psi

G

= 0.010 psi

s

Gas permeability according DIN 3535 (0.60”) <1.0 ml/min

Nominal Thickness 0.030”- 0.120” (0.8 mm - 3 mm)

Typical Thicknesses

1/16” (1.5 mm)

1/8” (3 mm)

316/316L Insert Thickness 0.004”/0.005” (0.1/0.127 mm)

Temperature Limits

*The values are taken from BFG-6.1 and ROTT. Test results are subject to interpreta on

and can lead to di ering design constants.

Cryogenic to 850°F (454ºC)

All Pressure / Temperature values are based on

1/16” (1.5 mm) gasket thickness.

1. Suitable (Chemical Compatibility has to be

considered).

2. Please contact Lamons Engineering

department for clari cation.

engineering@lamons.com

3. Not Suitable.

Sealing Global - Servicing Local

(2030)

(1740)

(1450)

(1160)

Pressure: Bar (PSI)

140

120

100

80

(870)

60

(580)

40

(290)

20

(0)

0

0 50 100 150 200 250 300 350 400 450 500

(0) (120) (210) (300) (390) (480) (570) (660) (750) (850) (930)

LG-TC PRESSURE / TEMPERATURE GRAPH

3

2

1

Sealing Global - Servicing Local

Lamons LG - L

Temperature: Deg C ( Deg F)

Pressure: Bar (PSI)

LG-L homogeneous graphite sheets are manufactured from high carbon content of

minimum 98% natural graphite.

Creep Relaxa on

Stability under stress (DIN 52913) 48 N/m

Compressibility

Recovery