Page 1

laminaceramics.com

To see how you can realize all these design benefits, to request a sample, or to speak with an engineer

about your design, contact Lamina at 800.808.5822 or 609.265.1401 or visit www.laminaceramics.com.

Bright Lights. Bright Ideas.

TM

•HIGH LUMINOUS FLUX IN SMALL FOOTPRINT

•SUPERIOR THERMAL PERFORMANCE FOR IMPROVED RELIABILITY

•LONG

LIFE AND

HIGH LUMEN MAINTENANCE

•N

O MERCURY OR LEAD

•CUSTOM SIZES AND SHAPES AVAILABLE

As the market leader in the development and manufacture of super-bright LED

arrays, Lamina brings solid state lighting to applications which until now were

only possible with traditional lighting sources.

Lamina’s LED arrays are manufactured by combining high brightness LEDs from

industry-leading LED manufacturers with Lamina's proprietary packaging tech-

nology, multilayer Low Temperature Co-Fired Ceramic on Metal (LTCC-M). LTCC-M

is a breakthrough in thermal performance for LED packaging technology, a key

factor in determining LED life and reliability. Unmatched thermal performance

coupled with package interconnectivity allows Lamina to densely cluster multiple

LEDs to achieve exceptionally high luminous intensity in very small footprints.

Lamina’s arrays are available in white, RGB and monochrome, from 1W to

100W, and also are available in custom packages.

Lamina's new high power RGB LED arrays have independent color control for

dynamic or preset display of colors. Through additive color mixing there is

complete control of the various colors and white which can be displayed.

Lamina BL-3000 LED arrays are configured with 39 cavities, each populated

with multiple LEDs. In the RGB light engine each cavity contains multiple red,

green and blue LED die for optimal color uniformity, a unique feature made

possible with Lamina’s packaging techology.

Brilliant Light!

BL-3000SERIES

ARCHITECTURAL LIGHTING

•DECORATIVE AND ACCENT

•ARCHITAINMENT

•S

TAGE AND STUDIO

•WALLWASHERS

LCD B

ACKLIGHTING

LCD PROJECTORS

S

IGNALS

MACHINE VISION

PHOTOGRAPHY

Lamina Light Engines

BL-3000 RGB

RGB LED L

IGHT ENGINE

Typical Applications

Page 2

laminaceramics.com

To see how you can realize all these design benefits, to request a sample, or to speak with an engineer

about your design, contact Lamina at 800.808.5822 or 609.265.1401 or visit www.laminaceramics.com.

Bright Lights. Bright Ideas.

TM

Technical Data

Part # BL-333F0-00142

Symbol Min Typical Max Unit

Dominant Wavelength R: λ 619 - 629

nm

G:

λ 515 - 535

nm

B:λ 465 - 475

nm

Voltage* R: V

F

- 4.8 - V

G: V

F

-7.2- V

B: V

F

-7.2- V

Test Current R: I

F

-1.17- A

G: I

F

-1.17- A

B: I

F

-1.17- A

Power* R: P - 5.6 - W

G: P - 8.4 W

B: P - 8.4 - W

Luminous Flux* R: Φ

V

-218- lm

G: Φ

V

-114- lm

B: Φ

V

-47-lm

Thermal Resistance** R: T

R

- 0.66 -

ºC

/W

G: T

R

- 0.66 -

ºC

/W

B: T

R

- 0.66 -

ºC

/W

*Note 1. Optical and Electrical specifications are given for the specified drive

current at a 25

ºC junction temperature.

**Note 2. Values for operating all colors at rated current.

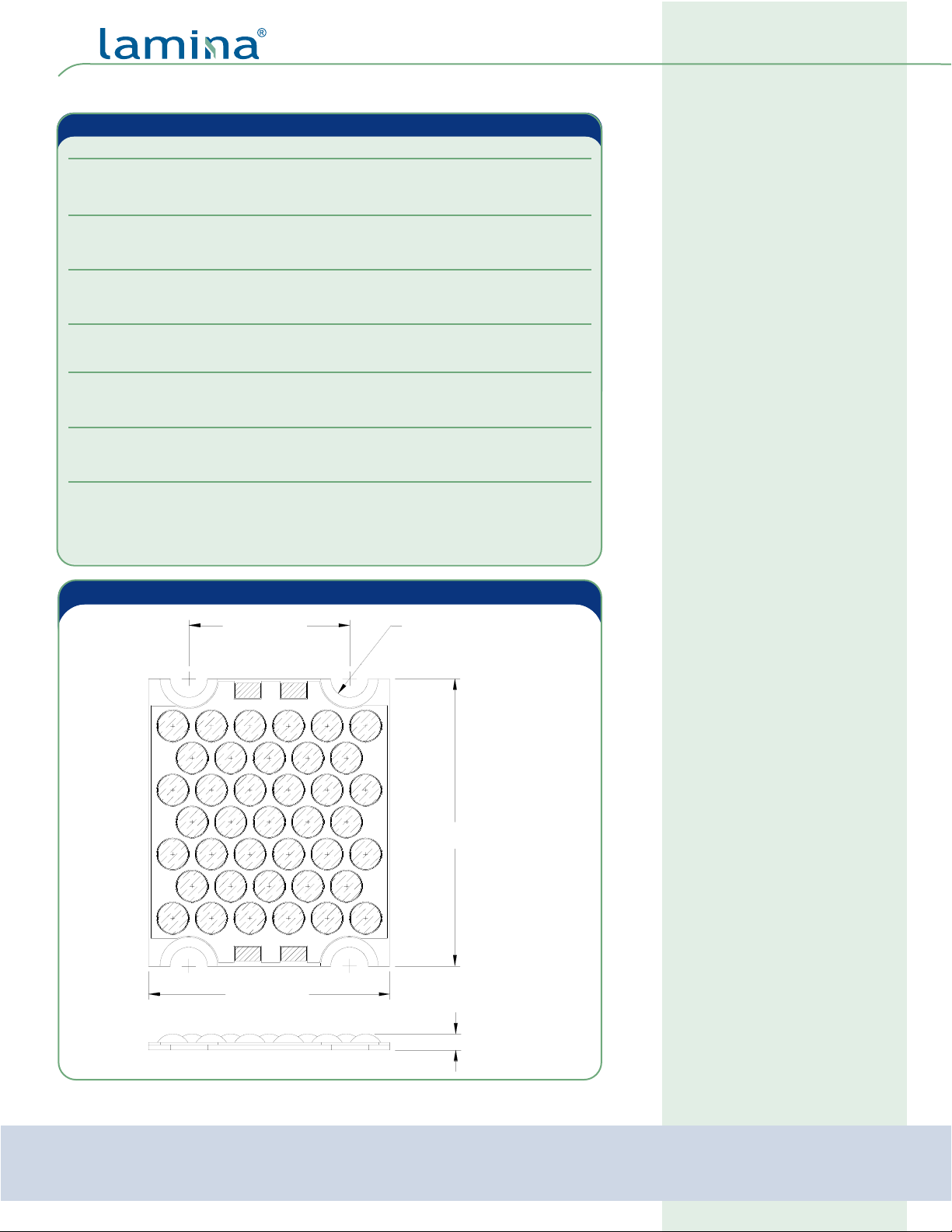

1.050 [26.67]

1.250 [31.75]

0.700 [17.78]

0.090 [2.29] MAX

4X MOUNTING HOLE

FOR 6-32 SCREW

1

4

2

3

Mechanical Specifications

ATTACHMENT

RECOMMENDATIONS

Lamina’s BL-3000 Series is

configured with solder pads

compatible with Sn63 or Sn62

solder. As with many electrical

devices, non-acid RMA type solder flux should be used to prepare the solder pads before

application of solder. If wire

attachment is performed with a

soldering iron, care must be

taken to minimize heat transfer

to the die and minimize leaching of the solderable pads.

ASSEMBLY

RECOMMENDATIONS

Lamina's BL Series Light

Engines, are designed for

attachment to heatsinks with

conductive epoxy or screw

down for flange mount devices

with thermal grease in the

joint.

For attachment using screws, a

6-32 UNC fillister head slotted

machine screw, 18-8 SS is recommended. Maximum torque

is 4 inch pounds (45 newton

centimeter). Required flatness

of surface light engine is

mounted to is 0.001 inch/inch.

Page 3

laminaceramics.com

To see how you can realize all these design benefits, to request a sample, or to speak with an engineer

about your design, contact Lamina at 800.808.5822 or 609.265.1401 or visit www.laminaceramics.com.

Bright Lights. Bright Ideas.

TM

1

2

4

3

Electrical Connections

GREEN

APPLY (V-) VOLTAGE

BLUE

APPLY (V-) VOLTAGE

RED

APPLY (V-) VOLTAGE

APPLY (V+) VOLTAGE

Typical Beam Pattern

H

EAT SINK

R

ECOMMENDATIONS

Lamina LED arrays provide efficient transfer of heat from the

individual LED die to a customer supplied heat sink. All

Lamina LED arrays must be

operated at or below 125ºC. A

heat sink must be attached to

the array with sufficient cooling

capacity to keep the die junction below 25ºC. The temperature rise from the array base to

the die junction may be determined by calculating the product of the maximum package

thermal resistance and the

desired operating power level.

The appropriate heat sink may

then be determined by:

O

PTICAL

RECOMMENDATIONS

Lamina LED arrays project a

Lambertian radiation pattern,

with projection angles built into

the package cavity at approximately 125º. It will be necessary for users to create an optical reflector and lens structure

that meets their light dispersion requirements. Please contact Lamina Application

Engineering for support with

your optical needs.

Junction Temperature Rise (Tj

(rise)) = Operating Power (P) x

Lamina Array Thermal

Resistance (Tr)

Heat Sink Thermal Resistance

(ºC/W) = (125 - Tj (rise) Maximum Ambient

Temperature)/P

Page 4

laminaceramics.com

To see how you can realize all these design benefits, to request a sample, or to speak with an engineer

about your design, contact Lamina at 800.808.5822 or 609.265.1401 or visit www.laminaceramics.com.

Bright Lights. Bright Ideas.

TM

Specifications subject to change

without notice.

Lamina Ceramics

120 Hancock Lane

Westampton, NJ 08060

REV.10.01.04

© 2004 Lamina Ceramics

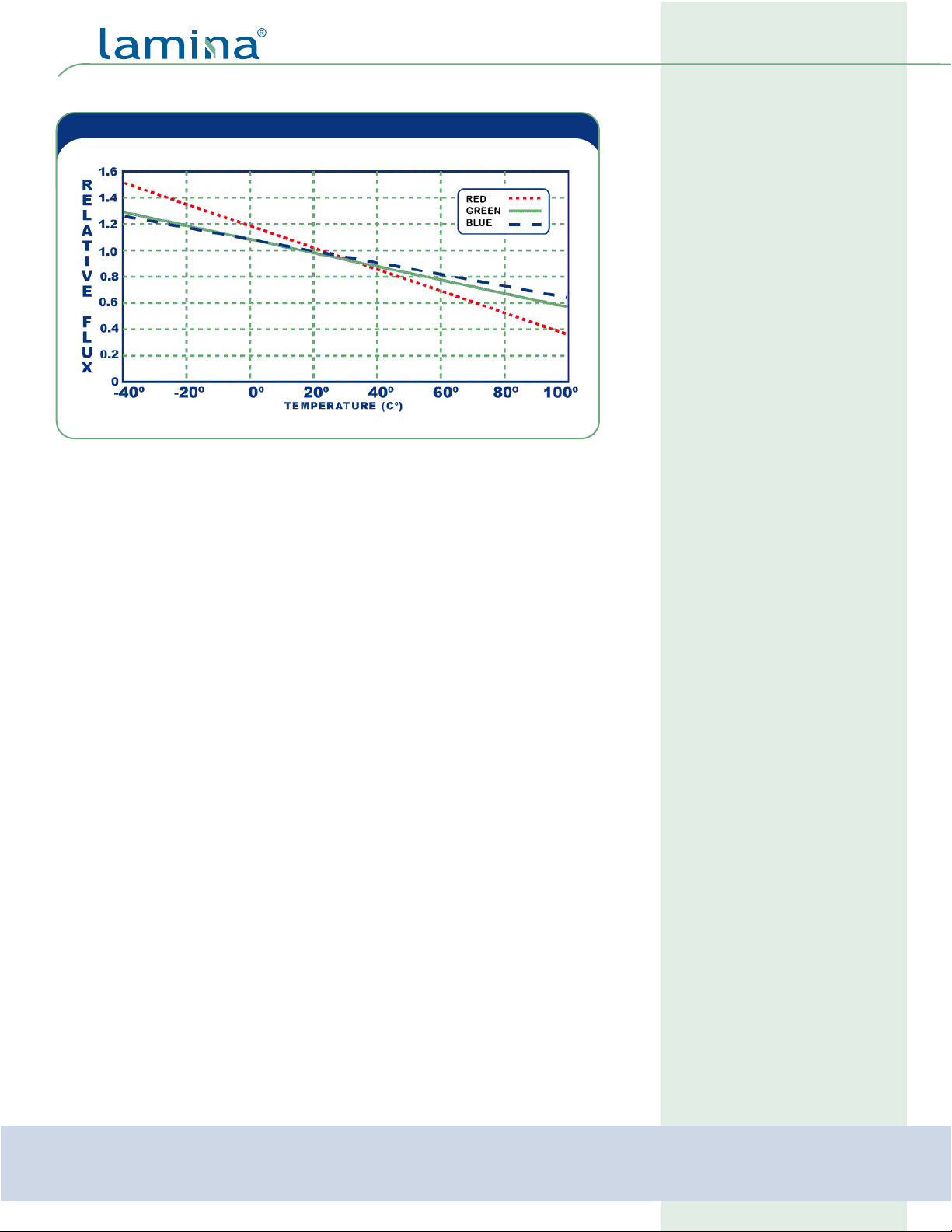

Luminous Flux with Junction Temperature

L

IGHT OUTPUT VS

.

J

UNCTION TEMPERATURE

Light output from LED die will

decrease with increasing junction temperature. This effect is

particularly acute for die in the

580 to 750 nm range. As a

result we recommend that the

LED array heat sink design be

optimized to maintain the die

junction temperature as low as

possible.

ESD PROTECTION

LEDs are static sensitive and

susceptible to Electrostatic

Discharge (ESD) damage.

Lamina LED arrays must be

handled using ESD damage

control precautions.

HANDLING PRECAUTION

Contact with the silicone based

encapsulant on the surface of

the light engine must be avoided to prevent damage. Do not

apply pressure to the silicone

based encapsulant or allow it to

come into contact with sharp

objects. Lamina LED arrays

must be handled from the

sides.

Loading...

Loading...