Instruction Manual

LAMI CORPORATION INC.

1

Preface

Thank you for purchasing our 【 】.

This Instruction Manual (document) includes details for safe use of this product.

Please read this document thoroughly before using the product.

Also, carefully store this document for immediate use whenever necessary.

■ Preface P 1

┗ Table of Contents........................................................................................................................................ P

1

■ Precautions Before Use P 2

┣ List of Labels Attached to the Product and Meaning of Symbols............................................................... P 2

┣ Precautions for Handling ............................................................................................................................ P 3

┗ Place for Installation................................................................................................................................... P 4

■ Characteristics and Confirmation of Parts P 5

■ Installation of the Machine P 6

┣ Stand Assembly Method ............................................................................................................................. P 6

┣ Foot Switch Installation Method................................................................................................................. P 6

┣ Power Connection for re-winding Device ................................................................................................. P 6

┗ Fuse Installation Method............................................................................................................................. P 7

■ Name of Each Part P 8

┣ Main Body of Freesia 55C.......................................................................................................................... P 8

┣ Operation Panel........................................................................................................................................... P 9

┗ Foot Switch.................................................................................................................................................. P 10

■ Before Processing Laminate P 11

┗ About Laminate Film................................................................................................................................... P 1

1

■ Cold Laminate Processing P 12

┗ Installation and Processing of Cold Laminate Film..................................................................................... P 12

■ Maintenance P 15

┣ Cleaning of Roller........................................................................................................................................ P 15

┣ Cleaning of paper tube holder...................................................................................................................... P 15

┗ Cover the product with cloth after use......................................................................................................... P 15

■ Troubleshooting P 16

┣ Power does not turn on · machine does not function ................................................................................... P 16

┣ Product malfunctions or power is immediately turned off........................................................................... P 16

┣ Wrinkles are formed in the processing material........................................................................................... P 16

┗ Processing material cannot be inserted · does not come out........................................................................ P 16

■ Others P 17

┣ Product Specifications .................................................................................................................................P 17

┗ Contact......................................................................................................................................................... P 17

Table of Contents

2

Precautions before Use

▼Nameplate label (porting)

▼Rated label

▼Cover switch restriction label

▼Jamming and entangling warning

label

▼Grounding instruction label

Ground connection must be done.

▼Fuse label

▼Emergency stop switch label

▼Tension control label

This document uses symbols to explain the degree of harm and damage caused by incorrect use of the product and to

prevent harm on customers and others or damage on properties.

Warning

If this symbol is neglected and the product is handled incorrectly, serious injury or death may

occur.

Caution

If this symbol is neglected and the product is handled incorrectly, human injury or physical

damage on properties may occur.

This symbol indicates matters to be followed

to avoid injury.

This symbol prohibits disassembly of the

device for safety.

This symbol instructs the user to remove

power plug from the outlet for safety.

This symbol prohibits touching of the

product with wet hands.

This symbol instructs the user to connect

grounding for safety.

This symbol prohibits wetting of the

product by water.

This symbol warns the user about the risk of

hands rolling into the roller.

This symbol shows concern for electric

shock under improper handling.

This symbol shows concern for smoke and

ignition under improper handling.

Meaning of

Symbols

List of Labels Attached to the Product

3

Warning

Power cable included in the product must be used. Do not use power supply not indicated on the product.

Do not place heavy objects on power cable, place cables nearby heating devices, or complex wiring.

Do not process power cable or use damaged power cable.

Accurately insert to the end of electrode.

When inserting power cable, the plug must be held. Excessive bending, twisting or pulling can damage the cable interior

and cause electric shock, fire, and failure.

※ Contact our company or store when power cord is damaged.

Regularly remove power cable from the outlet to clean the root and gap of electrode. Do not insert cable with foreign

substances such as dust attached.

Do not install the product in places with high temperature and humidity or poor ventilation, places with combustible and explosive gas

or poisonous gas, places covered with dust, and on top of easily burnt objects. When installing against a wall, the product should be

placed at least 50cm away from the wall.

Do not approach the product to firearms, high temperature, metals, and easily burnt objects. Do not put liquids into the

machine.

Do not disassemble or remodel the machine.

Do not use the product in abnormal state such as smoke, strange odor, and noise. If such condition is found, immediately

turn off the power switch and remove power cable from the outlet before contacting the store or our company. The product

must never be repaired by the customer for safety purpose.

Caution

Power cable must be removed from the outlet when the product is not used for long time.

Do not insert power cable with wet hands.

Grounding must be connected before connecting power to power cable. Power cable must be removed before grounding

disconnection.

Especially, keep the product away from children.

Do not ride the product or put heavy objects on top.

Do not place the product in unstable places (oscillating place, slanted place, and place with vibration of other

machineries). The product may fall down or over to injure persons nearby.

Avoid direct wind from air conditioner.

Never block the air vent. Blocked air vent can cause failure or fire from accumulation of internal heat.

During operation or insertion of laminate, be careful about clothes such as neck tie and necklace and body parts from entering the

device.

When film glue is attached to the laminate roller, squeeze cloth stained with neutral detergent and wipe out. (※ Do not

clean with benzene, thinner, or sponge.)

Lift the roller for laminate processing.

When the machine is not used, cover with a cloth to keep away from direct light or fluorescent light. Light can result in

rapid degeneration of the laminate roller rubber.

For safety, transport this product after turning the power switch off and removing power cable from the outlet.

Precautions for Handling

4

This device shall be installed in the following places.

●Horizontal and stable place

Use as slanted or in unstable state may result in adverse effects such as paper return.

Also, unexpected accidents can occur.

●Place where exclusive power outlet is available

Do not use power types other than the rated voltage regulated on this Manual.

Grounding and earth leakage breaker must be installed.

●Place with low humidity and sound ventilation

Installation of this product in place with high humidity can result in short circuit or failure.

Avoid outdoor places and places with direct light or air conditioner wind.

●Workability

Secure sufficient space for workability.

Do not install the product too close to walls. If possible, space between the product and wall should be wide

enough to allow human passage.

Place for Installation

1000mm or more

500mm

or

more

500mm or more

500mm or more

5

Characteristics

●Pressure can be adjusted in 8 steps automatically

●Speed of laminate processing can be adjusted step by step

●Rotation and stopping of the roller can be done using foot switch

●Transparent safety cover

Confirmation of Parts

The following parts and documents are included in the main body.

If there is a missing part, contact a nearby business office of our company or store from which the product was

purchased.

`

Freesia-55C main body

Film shaft

Branch paper tube holder (3-inch)

Stand (assembly type)

Foot switch

Instruction Manual

(this document)

Hex wrench

(For paper tube holder)

3 EA

6 EA

Film shaft

Branch paper tube holder (3-inch)

3 EA

4 EA

6

Installation of the Machine

Stand is assembly type. Use hex wrench to install the stand while being careful about left and right directions.

※ ③ with re-winding power switch should be installed on the right stand when looked from the front.

When looked from the front, there is an insertion hole of foot switch at

the center of the right surface.

Convex surface prevents insertion in incorrect direction. Check the

shape of the insertion hole before inserting.

(Excessive force causes damage the part.)

When disconnect the cable, Remover lock by pulling it.

When looked from the front, insert the cable sticking out from the rear

side of the main body into the power insertion hole of the re-winding

device.

※ Do not insert power re-winding device cable into other power

holes. It may cause device failure.

Power Connectio

n for Re

-

Winding Device

Foot Switch Installation Method

Stand Assembly Method

①

M6 screw

(4

EA

x 2

places)

②M6 screw 2 EA

③M6 screw 2 EA

Power switch

Fuse box

Power inlet

Re-Winding device

7

Fuse is placed nearby the power switch on the rear of right surface and power switch of the Re-winding device.

(Spare fuse is only included in the Re-winding device.)

Take out the fuse using flat-head driver to check disconnection of the fuse.

If it is disconnected, replace with a new fuse before supplying power again.

Fuse Installation Method

Power switch

Fuse

Fuse disconnection check

Re-Winding device

Rear-R

ight

Fuse

(spare fuse)

Fuse box

Visually check whether this part is

disconnected

8

Name of Each Part

① Stand

③ Film shaft for under-film

⑤ Front signboard

⑦ Laminate roll

⑨ Film shaft for release liner

⑪ Idle roller (top)

⑬ Re-winding film shaft

② Media holder shaft

④ Idle roller (front)

⑥ Finger jamming prevention cover

⑧ Stay bar (reinforcement bar)

⑩ Laminate film shaft

⑫ Back signboard

.

Main Body of Freesia

-

55C

Right Side of

Main Body

9

LCD Display Panel

RUN

Displayed during laminate processing

STOP

Displayed when laminate processing is stopped

FORWARD

If 【FORWARD】 is shown on the LCD panel, the roller rotates in forward direction.

REVERSE

If 【REVERSE】 is shown on the LCD panel, the roller rotates in reverse direction.

EMEGENCY

When emergency stop button is pressed, 【EMERGENCY】 pops up on the LCD panel.

All functions come to stop. Emergency stop can be released by turning the emergency stop button to the right.

When 【EMERGENCY】 is displayed, only vertical control is allowed for the roller.

One emergency stop switch is placed on left and right sides of the top of the main body.

Rotate the button clockwise to release emergency stop.

Operation Panel

Speed

Forward and reverse rotation of roller

Current status

Thickness

10

Buttons on the operating panel

【℃℃℃℃/℉℉℉℉】 button

This button is not used.

【TEMPERATURE】 button

This button is not used.

【SPEED】 button

Rotational speed of the laminate roller

can be adjusted within 0 ~ 1.9 m/min.

【THICKNESS】 button

This button is not used.

【MEMORY】 button

This button is used during maintenance

to display appropriate mileage

When pressed once, mileage from

previous reset until now is displayed.

(Press 【RUN/STOP】 button while

pressing 【MEMORY】 to reset.)

When pressed once again, total

mileage until now is displayed. (This

cannot be reset)

When pressed again, it returns to the

original display.

【PRESS/RELEASE】 button

【REVERSE】 button

When pressed once, the laminate roller

rotates in reverse direction

When pressed once again, it returns to

forward rotation.

【RUN/STOP】 button

This button starts and stops roller

rotation.

The roller rotates when the button is

pressed with the roller at stop, and the

roller stops when the button is pressed

again.

Caution

Do not operate 2 or more buttons simultaneously.

The following buttons cannot be used on the product.

【℃/℉】 button, 【TEMPERATURE】 button, 【THICKNESS】 button, 【PRESS/RELEASE】 button

This device can be operated by operation panel as well as foot switch included.

Foot Sw

itch

This is button to adjust pressure of

rollers.

Set the value according to the paper

and film to be processed.

: The roller begins to rotate when the foot switch is pressed. (About 2seconds)

: The roller stops rotating when the foot switch is p

ressed

. (

About 2seconds)

:

The roller can up &down when the foot

switch

is pressed (More and 3 seconds)

11

Before Processing Laminate

There are two types of laminate film including 「roll type」 and 「pack type」.

This product uses 「cold roll film」 type.

※ 「Pack type」 and 「hot roll film」 cannot be used.

Thickness (µ)

Thickness of the laminate film is selected according to the use.

Thickness of the cold roll film used by this product ranges from 20 µ to 300 µ.

Paper core holder Size

(Inner Diameter)

Size of installable paper tube differs according to the laminate structure.

This product uses a 3-inch (about 77 mm) paper core holder.

Type of Roll Film

Hot roll film

Apply heat to melt glue and attach the film.

Cold film

Parting paper (release paper) is attached on the surface applied with glue.

Release the film with the Re-winding device and compress with the roller for use.

About Laminate Film

Precautions for Handling Laminate Film

Do not place the laminate film in places with high temperature and humidity.

When lamination is not being done, store the film on the exclusive film shelf or in a box.

Use film appropriate for the laminator.

If a problem is found in the film before use, do not use and contact the store. Reckless use may result in

failure of the laminator.

12

Cold Laminate Processing

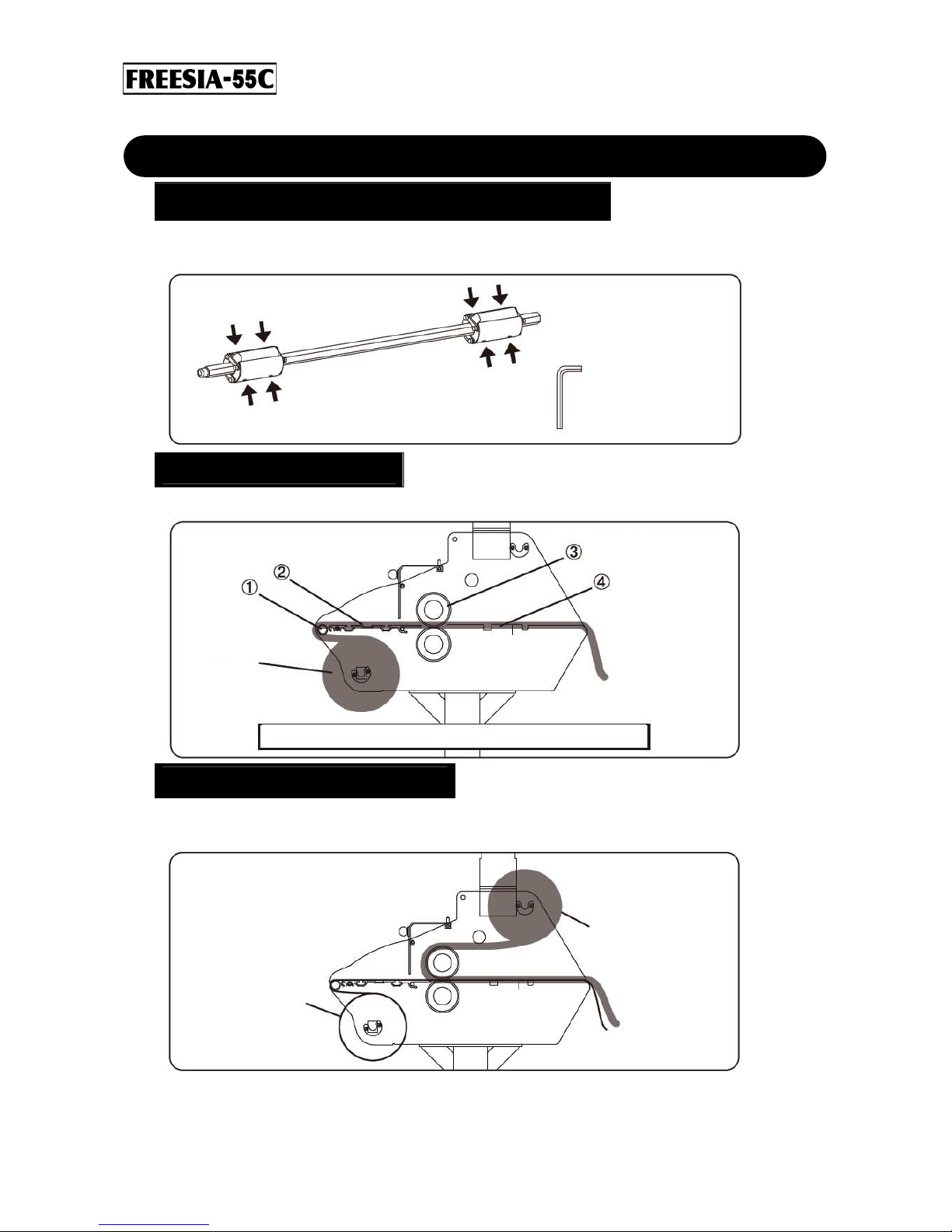

【1】 Install the paper tube holder on the film shaft.

All 6 film shafts are common parts.

Use hex wrench to move or fixate the branch pipe holder.

【2】 Install the under-film.

Refer to the figure below to pass the under-film while laminate roller (top) is lifted.

【3】 Install the laminate film.

Pass the laminate roller through the under roller with the release paper attached and then put down the laminate

roller.

Installation and Processing of C

o

ld Laminate Film

Fixate 4 sides of each

branch pipe holder.

Under-film

Laminate f

ilm

① Idle roller (front)⇒② front signboard⇒③ laminate roll⇒④ back signboard

Under-film

13

Only cut the release paper on the laminate film and rotate the laminate roller until the cross section of the release

paper cut touches the re- winding paper tube.

Here, hold the release paper so that it does not get entangled.

When the release paper touches the re-winding paper tube, attach it using cellophane tape to finish installation.

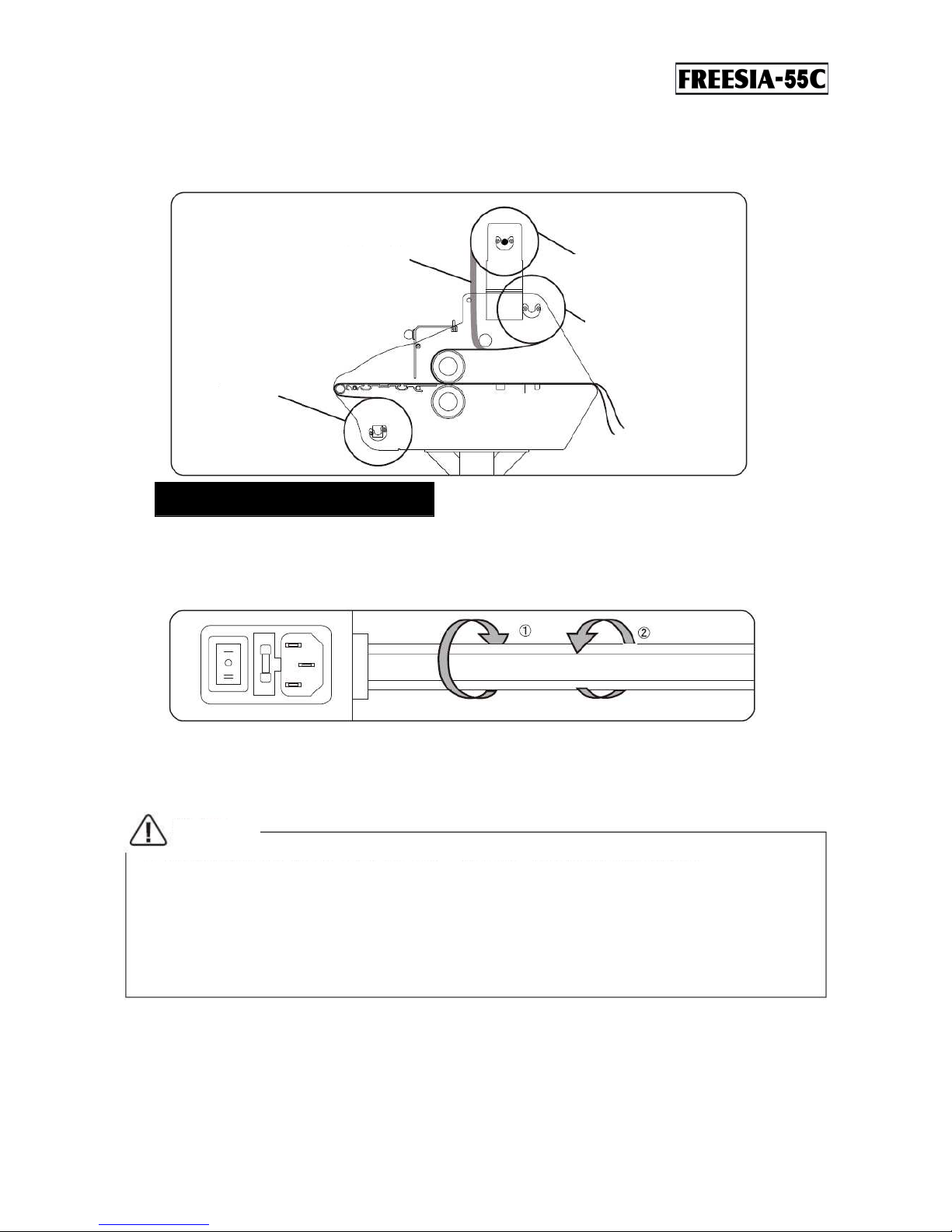

【4】 Use the winding device.

If the optional re-winding device is used, install the device according to the following sequence.

Attach the laminated product to the re-winding paper tube using tape. The motor starts rotating and winding

once the re-winding device switch is turned ON.

The re-winding device switch can be controlled to forward or reverse rotation.

When the switch is turned to ᅳ direction, the re-winding device rotates in direction ①.

When the switch is turned to ○ direction, the re-winding device stops rotation.

When the switch is turned to ᆖ direction, the re-winding device rotates in direction ②.

Caution

The re-winding device (optional) can be winded up to 50 m (about 30 kg).

Standard for the product of our company:

Under-film 【PET 12 µ 1400 mm】

Laminate film 【PVC 80 µ 1350 mm】

Media 【PVC 80 µ 1370 mm】

During cold processing, winding is about 30 kg at 50 m.

Under

-

film

Laminate film

Release liner re-

winding paper

tube.

Release liner

14

【5】 Perform laminate processing.

1 : Use the 【THICKNESS】 button to adjust pressure (gap) according to thickness of processing material

and 【PRESS/RELEASE】 button for up &down of roller

2 : Adjust to the wanted speed using 【SPEED】 button (speed can be adjusted during rotation of the laminate

roller) and press 【RUN/STOP】 button to rotate the laminate roller.

※ Here, the re-winding device for release liner automatically rotates. The re-winding device for final

products is controlled by switch. (Refer to the above for switch operation method)

3 : Insert the script towards the laminate roller for laminate processing.

4 : Cut the processing material using cutter after processing.

5 : After completion of all processing works, use the 【PRESS/RELEASE】 button to lift the laminate roller

and cover with a cloth for storage.

Pap

er tube for re

-

winding release liner

Release

li

ner

Under

-

film

Laminate film

Paper tube for product

Re-winding

After setting the re-

winding

shaft, please turn the shaft

holder cover

【

THICKNESS】 is controlled for thickness of sum of script, thickness of under film and thickness of film

15

Maintenance

This product is composed of many rollers, and they must be cleaned according to usage.

The laminate can be maintained in desirable state by cleaning the rollers.

Clean each roller since rollers have paper scraps and dusts attached.

Cleanly wipe the paper tube holder using soft and dry cloth or wipe the contaminated part using cloth with water

completely squeezed out. Here, applying force on wiping or cleaning with materials other than cloth can rip or damage

the pipe.

After using the product, cover the main body with a large cloth to avoid dusts from entering.

Cover the product with cloth after use

Cleaning of Paper Core

Holder

Cleaning of Roller

Caution

The roller must be stopped when cleaning.

Do not clean the roller using hard objects such as steel wool. They can damage the roller.

Do not apply force on the roller for long time.

Do not clean using thick paper, which is sometimes seen in pack type laminator. Thick paper can block the

device and result in damage or failure.

Likewise, do not clean using thin paper. Paper can roll into the roller and the roller cannot be used.

16

Troubleshooting

The following measures are taken for troubleshooting.

Insert outlet plug and check power switch

This product is used at AC 100V~240V. Make sure that the outlet plug is correctly connected.

Check that the power switch on the back of the main body is turned on.

If power cable is disconnected, it must be replaced. Contact our company or store.

Fuse is disconnected

Replace to a new fuse with identical spec. (Refer to P 8 for installation method.)

If the same symptom continues to occur, contact our company or store.

Heater or light projector is used nearby or long drum (cord reel) is used

If such objects are in use, use power from a different system.

If a drum is used, remove the drum before connecting.

Overload

Motor protection circuit may be functioning.

First remove power supply and wait for 10 seconds before resupplying power.

Abnormal noise from the motor

If an abnormal noise is created by the motor, saw-tooth wheel is damaged or screw is loose.

Contact our company or store.

There is a problem in wiring

Contact our company or store.

PCB malfunctions because of static electricity generated inside the machine

Turn the power off and then turn it on again.

Laminate film and under-film are not installed properly

Refer to P 13 ~ 15 of this document to install them properly.

Tension is too weak

Strengthen tension.

The machine is slanted

Reinstall it on a flat surface.

Is the script too thick?

Thickness of the script that can be processed by this product is 8 mm, including thickness of the film. If a thicker material

is inserted, the roller may not rotate or get damaged. Do not try to process anything thicker than the regulated thickness.

Even if thickness is within 8 mm, do not insert hard materials like metals.

Is film or script rolled into the roller?

If the script remains in the insertion hole, press reverse button to pull the script out. Do not pull it too strong because

excessive pulling can cause failure of the machine.

If the script is not caught in the insertion hole, contact our company or store.

Processing material cannot be inserted

·

does not come out

Wrinkles are formed in the processing material

Product malfunctions or power is immediately turned off

Power does not turn on

·

machine does not function

17

Others

Maximum laminate width

(roller width)

1400 mm

Maximum laminate thickness 8 mm (panel can be processed up to 10 mm)

Size of paper core holder 3 inches

Laminate speed 1.9 m/min

Speed conversion method Digital panel, variable type

Laminate temperature Room temperature

Thickness adjustment

Automatically adjustment

Laminator processing: 60μ•160μ•250μ• 400μ• 800μ

Panel processing : 1.2mm · 1.7mm · 2.3mm · 3mm · 5mm· 8mm

Maximum power consumption AC 100V~240V 100W

Dimensions

(width × length × height)

1838 × 591 × 1196 (mm)

Weight 137 kg

※ Specifications may be changed without notice for improvements.

Contact

Product Specifications

LAMI CORPORATION INC.

81-6-6453-1871

Loading...

Loading...