LAMBORGHINI Vela XN 24 MB/IT Installation And Maintenance Manual

CALDAIA MURALE A GAS CON BOLLITORE AD ACCUMULO - ALTO RENDIMENTO - MODULANT

EWALL-HUNG GAS BOILER WITH HOT WATER STORAGE TANK - HIGH EFFICIENCY - MODULATING UNIT

CALDERA MURAL A GAS CON ACUMULADOR - ALTO RENDIMIENTO - MODULANTE

CALDEIRA DE PAREDE A GÁS COM TERMOACUMULADOR - ALTO RENDIMENTO - MODULANTE

MANUALE DI

INSTALLAZIONE E

MANUTENZIONE

PREGASI CONSEGNARE

L'INSERTO "MANUALE D'USO"

AL SIG. UTENTE

TENGAN LA AMABILIDAD

DE ENTREGARLE AL USUARIO

EL FOLLETO “MANUAL DE USO”

PLEASE MAKE SURE THAT

THE “USE MANUAL” IS

HANDED OVER TO THE USER

FAVOR ENTREGAR O

“MANUAL DE USO”

AO SR. UTENTE

INSTALLATION

AND MAINTENANCE

MANUAL

MANUAL PARA

LA INSTALACIÓN Y EL

MANTENIMIENTO

MANUAL DE

INSTALAÇÃO E

MANUTENÇÃO

N

24 MB/IT

Read carefully all warnings and instructions contained in this manual as they give

important instructions regarding safety, installation and maintenance. Keep this manual

for future reference. Installation must be carried out by qualified personnel who will

be responsible for respecting existing safety regulations.

GB

ENGLISH

24

Congratulations....

......on an excellent choice. We thank you for the preference accorded to our products.

LAMBORGHINI CALORECLIMA has been actively present in Italy and throughout the world

since 1959 with a widespread network of agents and concessionary agents to constantly

guarantee the presence of our product on the market.

Alongside this is the support of a technical service, “LAMBORGHINI SERVICE”, which is

entrusted with the qualified servicing of the product.

For the installation and positioning of the boiler:

CAREFULLY OBSERVE THE LOCAL REGULATIONS IN FORCE

INDEX PAGE

GENERAL INSTRUCTIONS _____________________________________________ 25

DESCRIPTION _______________________________________________________ 26

MAIN COMPONENTS ________________________________________________ 27

DIMENSIONS _______________________________________________________ 28

TECHNICAL FEATURES ________________________________________________ 28

GAS - NOZZLE CALIBRATION __________________________________________ 29

ELECTRICAL CONNECTIONS - WIRING DIAGRAMS _______________________ 30

MALFUNCTIONS AND ADJUSTMENTS __________________________________ 32

WATER CONNECTION _______________________________________________ 33

WATER CIRCUIT ______________________________________________________ 34

INSTALLATION_______________________________________________________ 35

START-UP ___________________________________________________________ 35

FLUE EXHAUST CONNECTION _________________________________________ 36

ADJUSTMENTS ______________________________________________________ 37

SWITCHING OFF ____________________________________________________ 38

MAINTENANCE _____________________________________________________ 38

KNOB ASSEMBLY INSTRUCTIONS ______________________________________ 39

OPERATION WITH DIFFERENT TYPES OF GAS ____________________________ 41

FAULT-FINDING CHART _______________________________________________ 42

25

GENERAL INSTRUCTIONS

● This booklet constitutes an integral and essential part of the product.

Read carefully the instructions contained in this booklet as they provide important directions

regarding the safety of installation, use and maintenance. Preserve this booklet with care for any

further consultation. The installation of the boiler must be carried out in compliance with current

regulations, according to the instructions of the manufacturer and by qualified personnel. An

incorrect installation can cause injury or damage to persons, animals and objects, for which the

manufacturer cannot be held responsible.

● After removing the packaging materials, check the content integrity. In case of doubt, do not use

the unit and contact the supplier. The packaging material (wooden crates, nails, clips, plastic

bags, foam, etc.) must not be left within reach of children as they are potential sources of danger.

● This boiler is designed to heat water to a temperature below boiling (atmospheric pressure). It

must be connected to a heating system compatible with its performances and output.

● This appliance should be destined only for the use for which it has been expressly envisaged. Any

other use is to be considered improper and therefore dangerous. The manufacturer cannot be

considered responsible for any damages caused from improper, erroneous or unreasonable use.

ALL INSTALLATION, MAINTENANCE AND GAS CONVERSION OPERATIONS MUST BE CARRIED OUT

BY AUTHORISED SKILLED TECHNICIANS.

TO ENSURE THAT BOILER IS INSTALLED CORRECTLY AND THAT IT FUNCTIONS PROPERLY, WE

RECOMMEND THAT ONLY LAMBORGHINI ACCESSORIES AND SPARE PARTS BE USED.

ON NOTICING THE SMELL OF GAS DO NOT TOUCH ANY ELECTRIC SWITCH. OPEN DOORS AND

WINDOWS. SHUT OFF THE GAS TAPS.

INSTALL THE BOILER ON WALLS WHICH ARE AS WIDE AS OR WIDER THAN THE BOILER ITSELF.

26

DESCRIPTION

These boilers are fully automatic and gas control is effected by an electronic control unit having the

following characteristics:

- continuous modulation mode on both circuits;

- possibility to adjust the heating output;

- possibility to adjust the slow ignition;

- “anti-Legionnaire’s” function

They are equipped with:

- Safety flow-switch;

-Total safety thermostat;

- High efficiency flue gas exchanger;

- 60-liter tank in stainless steel for plenty of hot water

- Electric 3-way valve

VELA X N 24 MB W TOP

Electronic ignition with ionisation flame control.

Combustion and fume discharge are of the atmospheric type. Fitted with FLUE CONTROL fume evacuation device.

FLUE CONTROL THERMOSTAT

VELA X N MB boilers are fitted with the FLUE CONTROL device to control evacuation of fumes. An

increase in fume temperature in the down-draught diverter indicates an anomaly in fume evacuation.

The FLUE CONTROL probe in the down-draught diverter detects variations in temperature and shuts

down the boiler. Efficient operation of this safety system depends on observance of the following:

- Do not deactivate the FLUE CONTROL thermostat.

- Inspect the boiler and the flue immediately if the FLUE CONTROL device trips frequently.

- If the FLUE CONTROL device is changed make sure you observe assembly and probe positioning

instructions carefully and use only original LAMBORGHINI spare parts.

If there is a fume evacuation anomaly act quickly to prevent the formation of Carbon Monoxide, a

poisonous gas that causes intoxication and potentially fatal harm to both humans and animals.

27

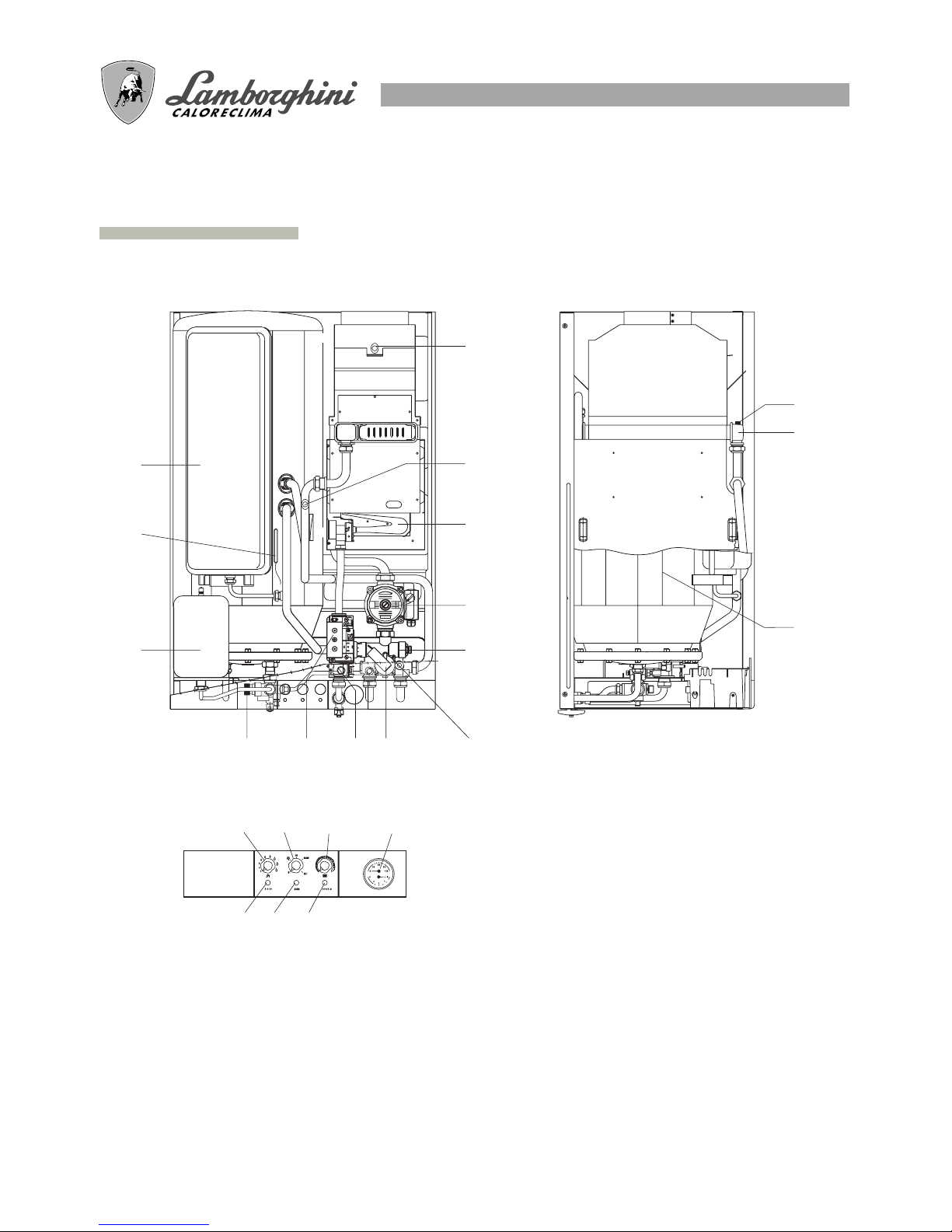

MAIN COMPONENTS

LEGEND

1 Hot water expansion tank

2 Water-heater sensor

3 Heating expansion tank

4 Flue control

5 Delivery sensor

6 Burner

7 Circulator

8 Electric 3-way valve

9 Automatic by-pass

10 Safety flow-switch

11 Modulating coil

12 Gas valve

13 Hot water circuit:

- 8-bar safety valve

- Non-return valve

- Inspection filter

14 Total safety thermostat

15 Fume exchanger

16 Stainless steel water-heater

17 Thermohydrometer

18 Malfunction warning light

19 ON/OFF warning light

20 Lock-out warning light

21 Hot water adjustment potentiometer

22 Function selector

23 Heating adjustment potentiometer

1

2

3

5

P

E

T

S

1

P

E

T

S

1

10 9111213

7

8

4

6

14

15

16

17232221

181920

28

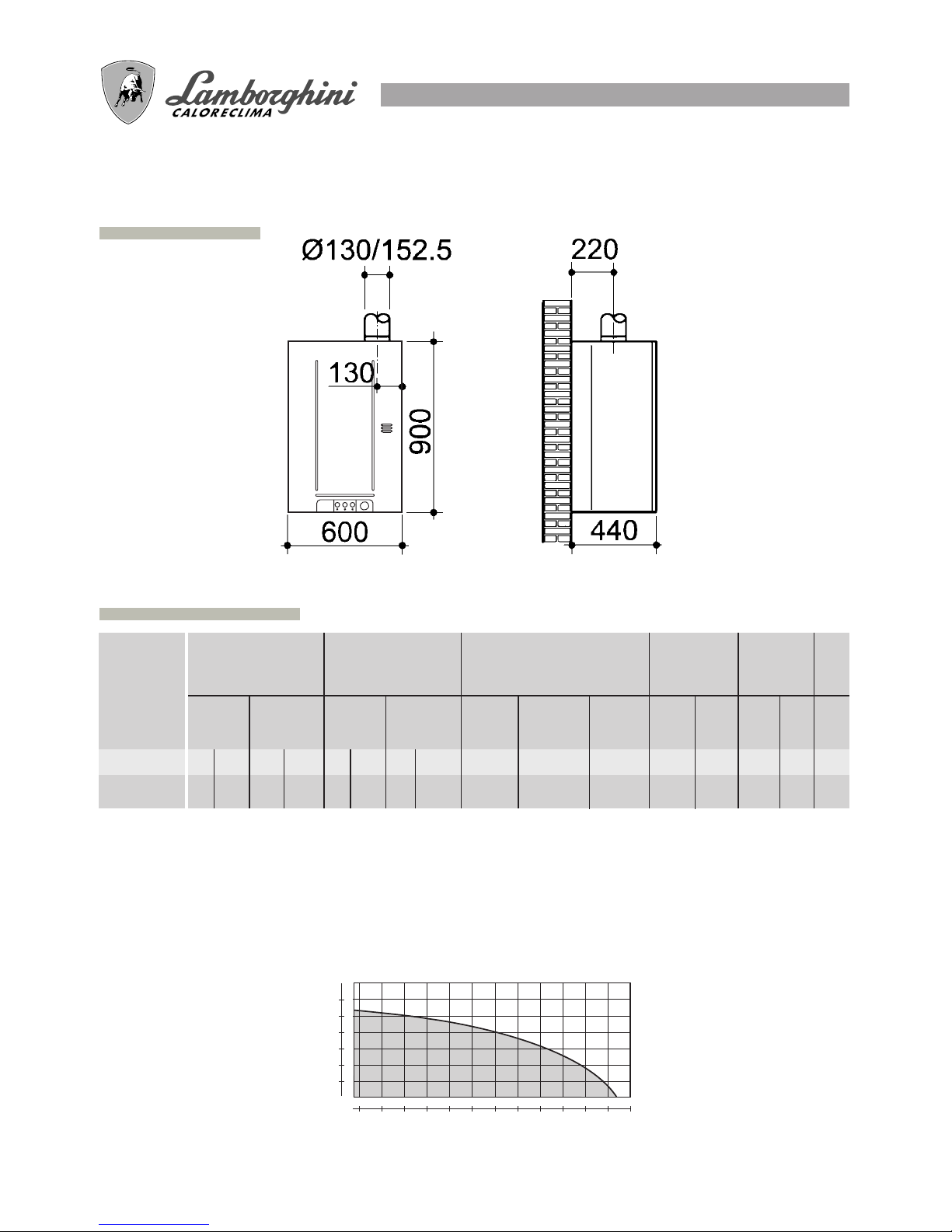

DIMENSIONS mm

CIRCULATING PUMP FEATURES

System delivery/pressure

300 400

500 600 700

800

900 1000 1100 1200

1300 1400 1500

600

500

400

300

200

100

Residual pressure mbarr

Delivery (l/h)

Boiler version: mod. MB type B11 BS Max. water temperature 90°C

Rated gas pressure: Natural gas 20 mbar

Category: II 2H3+ B 28/30 mbar - P 37 mbar

TECHNICAL FEATURES

MODELL

Input Output

kW kcal/h kW kcal/h

l

kg

Hot

water

l

kW

kW

kcal/h

Operating

pressure

Heating

circuit

max.

Hot

water

circuit

bar

bar

Thermal capacity Min. thermal

capacity

Hot water supply

Expansion

tank

Weight

Input

Output

kcal/h

VELA X N 24

26

22360

23,4 20124

12,1

10406

10,43

8970

3

8

8263

Peak output

in first 10

minutes

Supply

∆

30 °C

Water

heater

capacity

ll

l/min

Heating

60

10 150

VELA X N 24 MB W TOP/IT

Operation of safety flow switch: minimum ∆P 1,2 mt.

29

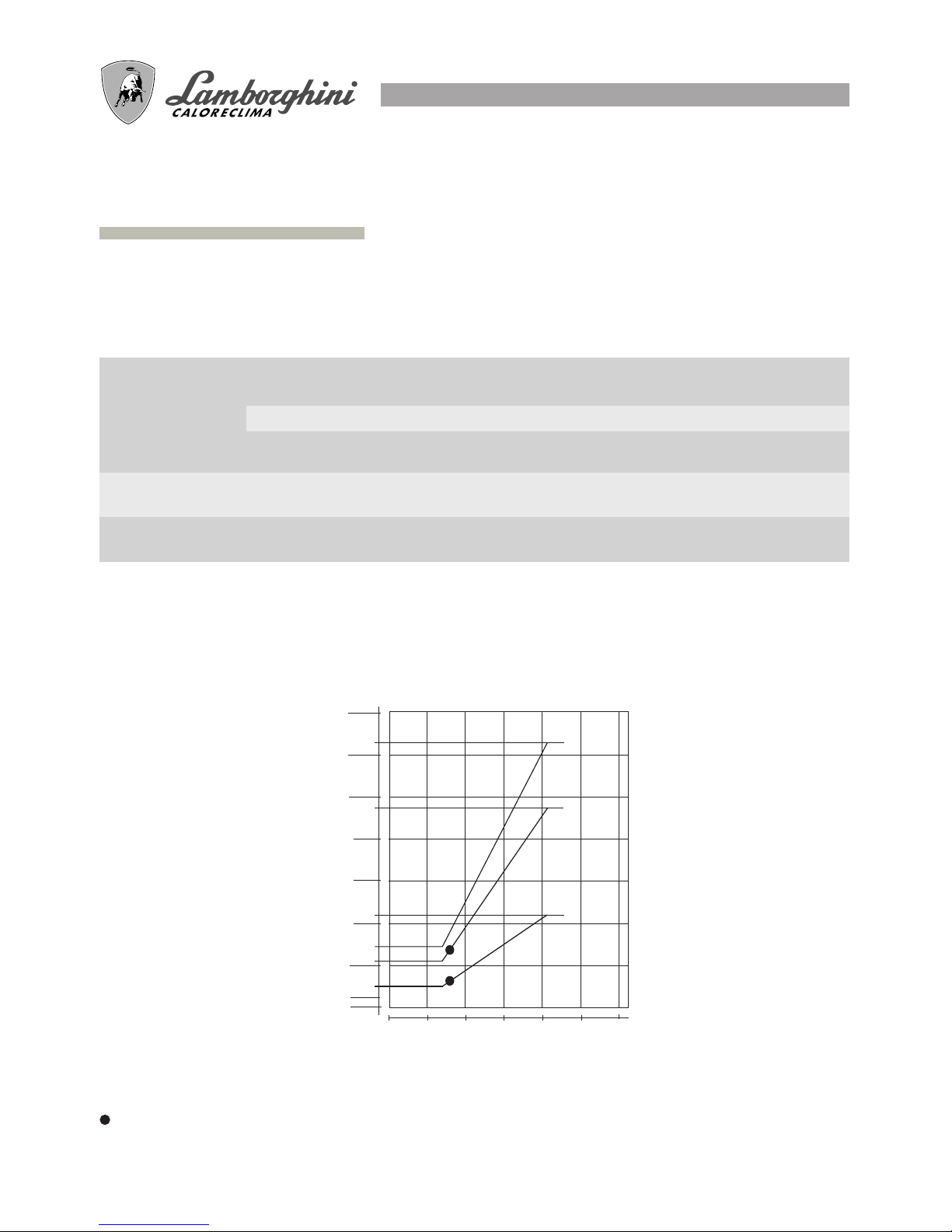

The boilers leave the factory calibrated and ready to operate with NATURAL GAS and LIQUID GAS.

For proper calibration, see the table below:

BURNER PRESSURE CURVES - OUTPUT

GAS - NOZZLE CALIBRATION

Slow ignition adjustment

3 mbars NATURAL GAS

7 mbars LIQUID GAS

VELA X N 24 MB

10

kW

mbar

2,5

11

5,5

23,7

2515 20

10

5

GN 11

0

15

20

25

B 23,7

kPa

30 35

0

30

35

1

0,5

0

1,5

2

2,5

3

3,5

1

31,4

P 31,4

0,1

1009DIS1385

7,2

Jets pressure mbar

Gas type

NATURAL GAS

(G20-20mbar)

LIQUID GAS B

(G30-28/30mbar)

LIQUID GAS P

(G31-37mbar)

Burner jets

L.C.V.

kcal/m

3

8.550

29.330

22.360

Delivery

VELA X N 24

max.

11

23,7

31,4

2,5

5,5

7,2

min. m3/h

2,6

0,76

1

VELA X N 24

Ø mm.

1,25

0,77

0,77

VELA X N 24

30

ELECTRICAL CONNECTIONS - WIRING DIAGRAMS

The boiler must be connected to an earthed, single-phase 230V - 50 Hz mains supply by means of a

three-wire cable, ensuring that connections to the LINE and NEUTRAL terminals are made correctly.

A bipolar switch must be used with contacts opening to at least 3 mm.

The power lead must only be replaced by another with the following characteristics: “HAR H05 vv-F” 3

x 1.00 mm2. (You are strongly advised to use original LAMBORGHINI accessories and spare parts

only).

Installation must be made in compliance with safety REGULATIONS IN FORCE.

Make a good earth connection.

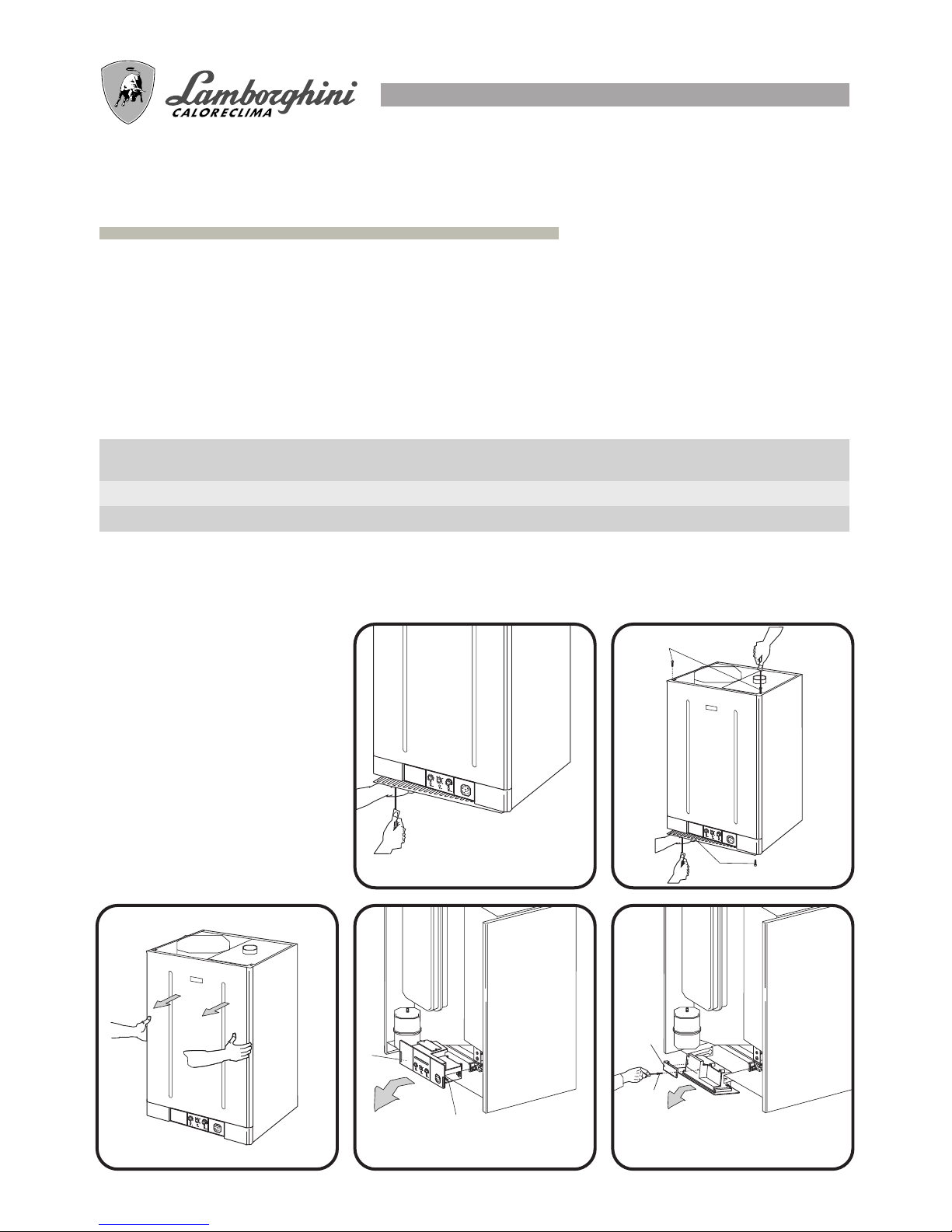

To gain access to the electrical panel which houses the power supply terminal block and any connection to a

room thermostat, proceed as follows:

Voltage

V

230

Frequency

Absorbed power

kW

Hz

Noise level

dB (A)

● Disconnect the boiler power

supply

● Undo the two grating screws

(fig.1)

● Undo the four shell attachment

screws A (fig.2)

● Remove the shell (fig.3)

● To gain access to the electrical

and electronic components

loosen screws B and pull the

entire panel outwards (fig.4).

Tilt it downwards and undo the

screws C on the cover D

fig.3

fig.4

50

fig.1 fig.2

fig.5

VELA X N 24

51

Protection

index

IP

44

VELA X N 24

0,120

D

C

B

B

A

A

Loading...

Loading...