Page 1

02 - DRIVING TORQUES

Workshop manual - Diablo 6.0

02-1

Page 2

CONTENTS

Engine

Engine control unit

Clutch

Gearbox

Propeller shaft

Front differential

Rear differential

Brakes

Suspension and steering

Bodywork

Workshop manual - Diablo 6.0

02-2

Page 3

Engine

Workshop manual - Diablo 6.0

No. Description

1 Screws securing timing chain shoes on crankcase 30

2 M8 nuts securing engine stands to crankcase 28

3 Main oil duct closing caps 70

4 Screws securing connecting rod caps Engine oil

Clamping: torque + angle

Check: elongation torque at 60°

5 Oil pump filter M8 nuts 30

6 M8 nuts securing front cover to oil pump 30

7 M12 nuts securing crankshaft lower support on crankcase

first tightening

full tightening

8 M8 nuts securing crankshaft lower support on crankcase 30

9 M8 screw securing crankshaft lower support to crankcase (timing side) 30

Torque

15 + 60°

± 0.015 mm

0.115

55

40

90

[Nm]

Notes

± 10%

± 2°

÷ 85

± 7%

± 3% Molycote 1000

± 10% Molycote 1000

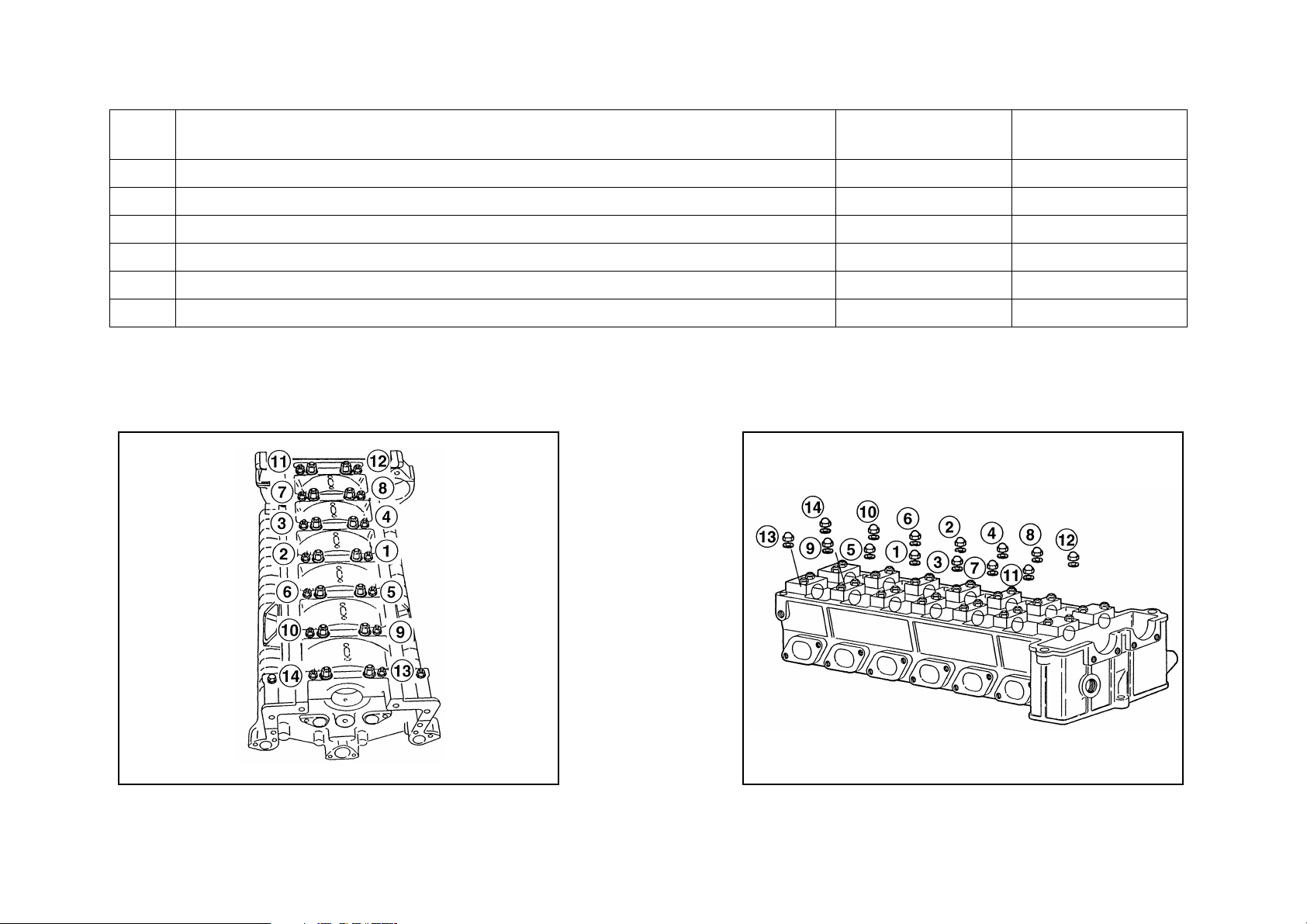

See figure 1 for

tightening order

± 10%

10 M8 nuts securing timing box to crankcase 30

11 Timing box to crankshaft screws 28

12 Cylinder head nuts 108 Molycote 1000

13 Not used

14 Driving pulley to crankshaft screw 140

15 Not used

16 Spark plug caps 80

02-3

± 10%

± 10%

See figure 2 for

tightening order

Page 4

Workshop manual - Diablo 6.0

No. Description

Torque

[Nm]

17 Nuts securing camshaft supports on cylinder head 9

18 Not used

19 Gear to exhaust timing shaft screws 120

20 Phase variator on intake timing shaft 90

21 Phase variator screws 7

22 Hydraulic tensioners on cylinder head 45

Notes

030201

Fig. 1 – Tightening order for M8 nuts on crankshaft

support

030202

Fig. 2 – Tightening order for cylinder head nuts

02-4

Page 5

Engine control unit

Workshop manual - Diablo 6.0

No. Description

1 Lambda sensor on exhaust 58.8

2 Spark plugs 17.6

3 Delivery couplings on fuel manifold 25

4 Outlet couplings on fuel manifold 25

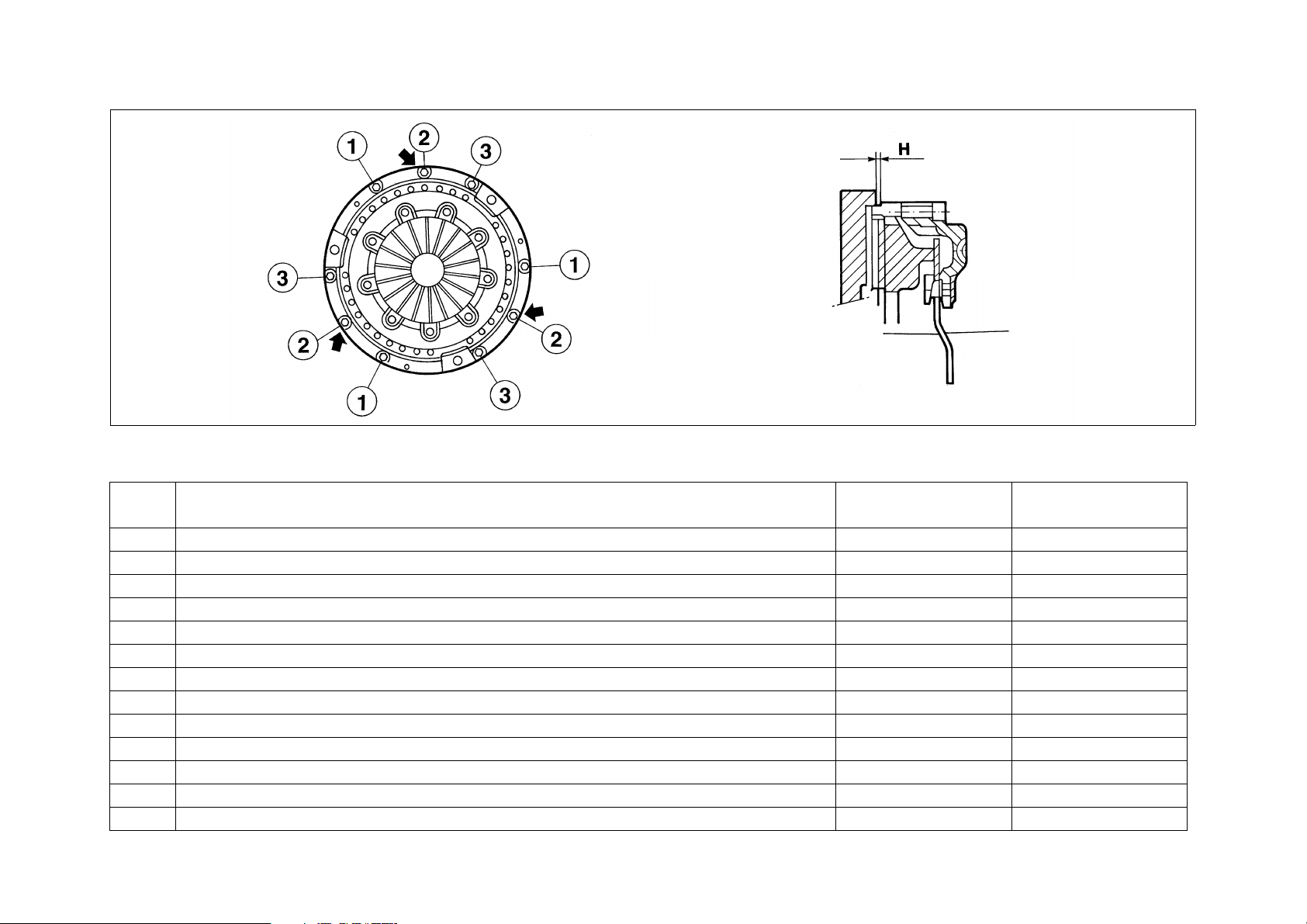

Clutch

No. Description

1 Mechanism to flywheel securing screws

approach –

tightening 15.5

Torque

[Nm]

Notes

± 2

± 2

Torque

[Nm]

(arrow) to obtain H

Notes

Do not lubricate

See figure 3:

tighten screws 2

÷ 2 mm

H = 1

± 5% See figure 3 for

tightening order

2 Thrust block support sleeve nuts 9.25

3 Flywheel securing screws 39.2

02-5

Page 6

Workshop manual - Diablo 6.0

030203

Fig. 3 – Flywheel mechanism tightening

Gearbox

No. Description

Torque

[Nm]

Notes

1 Shift lever housing screws 20

2 Fork and ratchet screws 29.4

3 Main /driven shaft idle gear ring-nut 230 Molycote 1000

4 Screws securing clutch bell to engine 25

5 Transmission gear ring-nut 180

6 Clutch oil seal flange nuts 9.3

7 Screws securing clutch bell to gearbox 25

8 Screws securing gearbox oil pump cover 29.4

9 Screws securing gearbox oil filter 29.4

10 Rear driving shaft bearing ring-nut 245

11 Turret upper support bolt 140

12 Gearbox upper cover screws 25

13 Front driving flange nut 176

02-6

Page 7

Propeller shaft

Workshop manual - Diablo 6.0

No. Description

Torque

[Nm]

Notes

1 Propeller shaft flange fastening screws 39

2 Front differential axle shaft joint fastening screws 39

3 Rear wheel/differential axle shaft joint fastening screws 69

Front differential

No. Description

Torque

[Nm]

Notes

1 Differential crown fastening screws 70 Loctite 52A70

2 Differential cover fastening screws 30

3 Box hub fastening nuts 30

4 Propeller shaft flange fastening ring 150 Molycote 1000

Rear differential

No. Description

Torque

[Nm]

Notes

1 Differential box cover nuts 50 Molycote 1000

2 Not used

3 Pinion-pinion set flange fastening screws 30 Loctite 52A70

4 Axle shaft flange fastening screws 91.4 Loctite 641

Molycote 1000

5 Differential crown fastening screws 102

6 Crown beaaring pre-load flange fastening nuts 40 Molycote 1000

02-7

Page 8

Brakes

Workshop manual - Diablo 6.0

No. Description

1 Not used

2 Brake shoe fastening screws 115

3 Hydraulic control fitting on shoe 18.5

4 Brake disc to hub fastening screws

5 Male ABS control unit hydraulic fitting 12

6 Female ABS control unit hydraulic fitting 16

Suspension and steering

No. Description

1 Front axle shaft to hub fastening nut 345

2 Front suspension upper arm fastening nut 85

3 Front/rear shock absorber fastening screws 85

4 Rear suspension upper arm fastening nuts 85

5 Front hub bearing fastening ring 490 Loctite 242

Torque

[Nm]

Notes

± 5 Loctite 222

± 1.5 Brake oil

± 1 Lubricating oil

± 2 Lubricating oil

Torque

[Nm]

Notes

± 5

± 5

± 5

± 5

6 Suspension arm ball joint housing on pillar 175

7 Steering arm joint fastening nut 44

8 Front pillar upper/lower joint fastening nut 69

9 Steering arm joint housing on pillar 62.5

10 Lifting system flow separator valve unit fittings 37

11 Steering box fastening screws 45

02-8

± 0.5

± 5 Loctite 270

± 2.5 Loctite 270

Page 9

Bodywork

Workshop manual - Diablo 6.0

No. Description

1 Windscreen wiper arms

Tighten

Settle

Torque

[Nm]

35

30

Notes

02-9

Page 10

10 - ENGINE

Workshop manual - Diablo 6.0

10-1

Page 11

CONTENTS

Workshop manual - Diablo 6.0

DESCRIPTION P. 3

Cylinder numbering and direction of crankshaft rotation

SPECIFICATIONS AND DATA P. 5

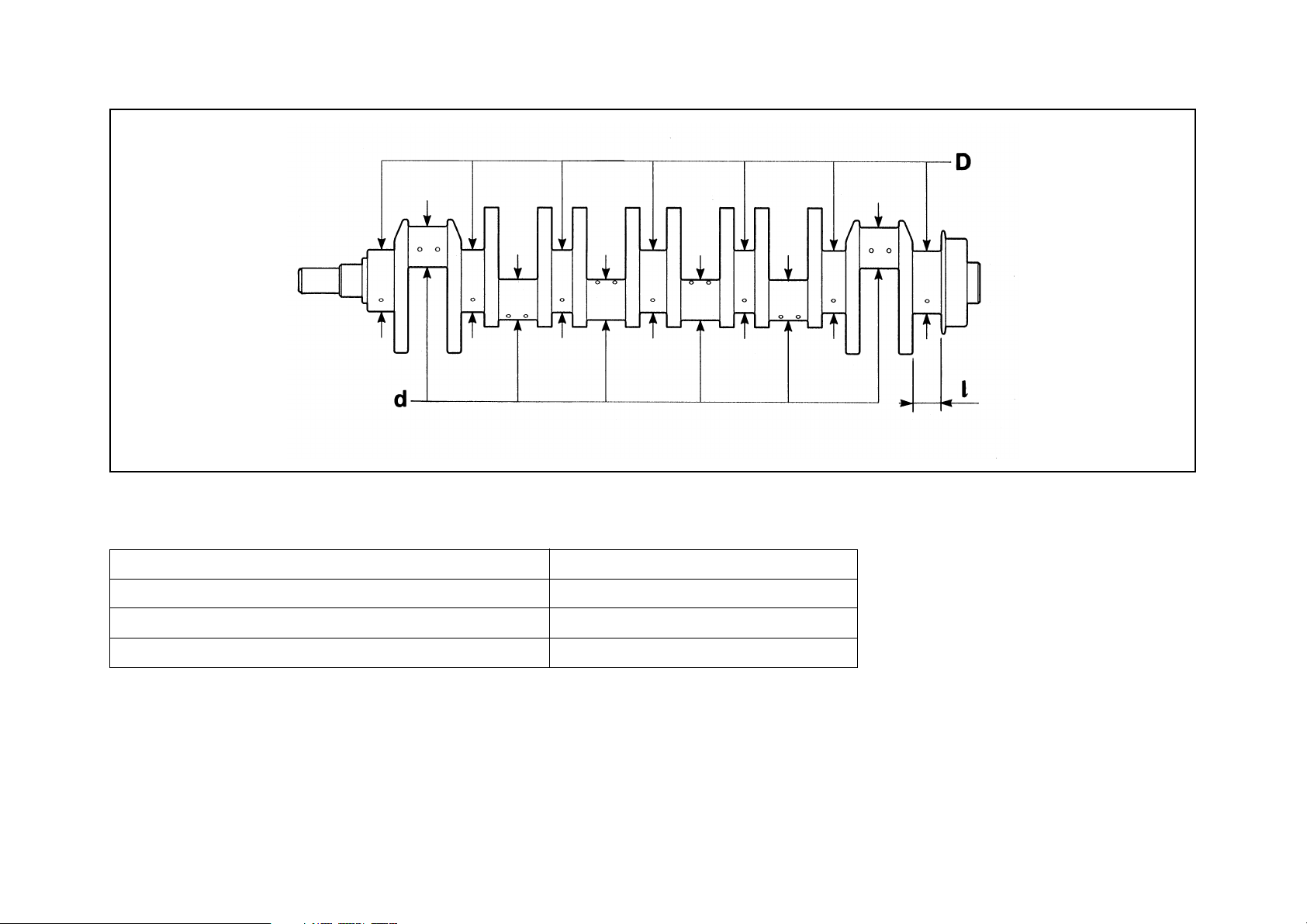

Crankshaft

Connecting radius R

Crankcase

Piston liners

Pistons

Piston pin

Piston rings

Tappets

Valve guides (intake and exhaust)

Fitting between valve stem and relevant guide

Valve springs (intake and exhaust)

Engine cooling

REMOVAL AND REFIT P. 22

ASSEMBLY P. 23

COOLING CIRCUIT P. 33

Description

Radiators and electric fans

Thermostatic valve

Radiator removal

Filling up the system

LUBRICATION CIRCUIT P. 36

Description

Thermostatic valve

Oil pump check

Level check and oil replacement

PNEUMATIC UTILITY CONNECTIONS P. 40

CHECKS AND ADJUSTMENTS P. 25

Valve clearance

Locking the phase variator

Position check

Positioning

Timing regulation

Adjustment

Checking

Locking check on phonic wheel for engine timing sensor

10-2

Page 12

Workshop manual - Diablo 6.0

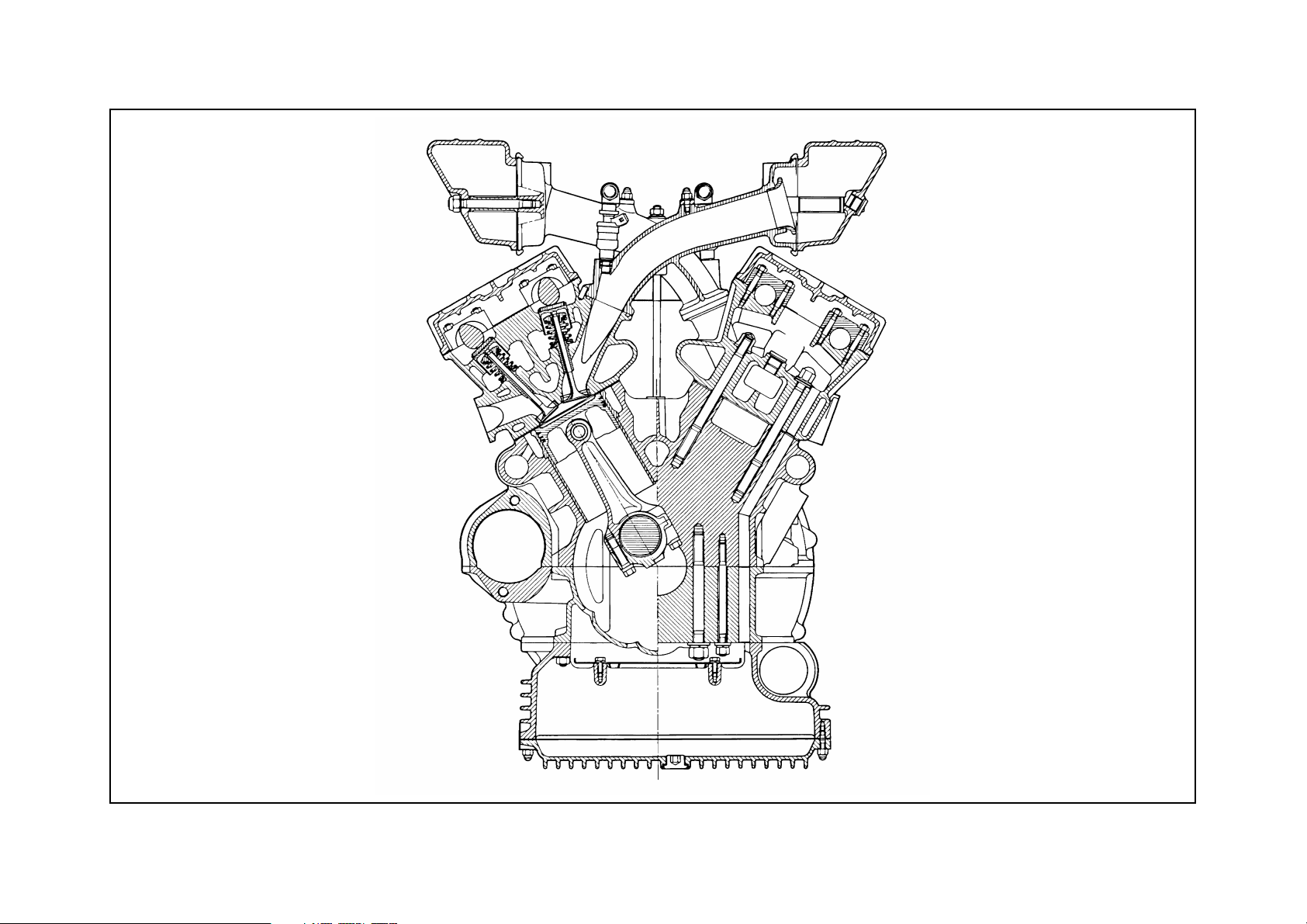

DESCRIPTION

Otto cycle – 4 intake stroke engine, 12 V cylinders at 60°; timing system with 4 valves for each cylinder, double overhead camshaft

controlled by double chain, phase variator on intake, indirect MPI injection (one injector for each cylinder), static electronic ignition

(one coil per cylinder), liquid cooling with double radiator, forced lubrication with oil radiator, exhaust six in two in one with catalyst.

Aluminium alloy and H+T silicon “open deck” type crankcase with wet inserted liners.

Steel alloy liners with Nikasil treated internal surfaces. This treatment ensures a very high surface hardness.

This type of liner cannot be lapped.

Cr Mo hardened and tempered steel crankshaft, the working surfaces are hardened by gaseous nitriding. The crankshaft bearings

are smooth. The main bearing caps are integrated in a block structure to give maximum stiffness.

Each time the crankshaft is undersized, it is most important to restore the surface hardness by the special heat treatment.

Titanium alloy connecting rods with modular head, smooth bearings at big and small ends.

The pistons are in pressed light alloy with three rings, two seals and one oil scraper.

The cylinder heads are aluminium alloy and H+T silicon, with bronze valve guides and cast iron valve seats.

The timing system consists of two overhead camshafts for each cylinder bank, controlled by double chains with phase variator on

the intake shafts.

Motion is transmitted directly from the crankshaft to two gear wheels by means of a double chain. Each of these gear wheels in its

turn controls the two camshafts of each head by means of double chains.

The chain tension is ensured by hydraulic chain tighteners that operate with the lubrication circuit oil.

The cooling system with two cooling radiators is a closed loop system with forced circulation by a centrifugal pump belt driven by

the crankshaft.

The lubrication is forced by a gear pump with a vented gas recycling system and radiator to cool the oil.

10-3

Page 13

Workshop manual - Diablo 6.0

Fig. 1 - Engine cross section

031001

10-4

Page 14

Workshop manual - Diablo 6.0

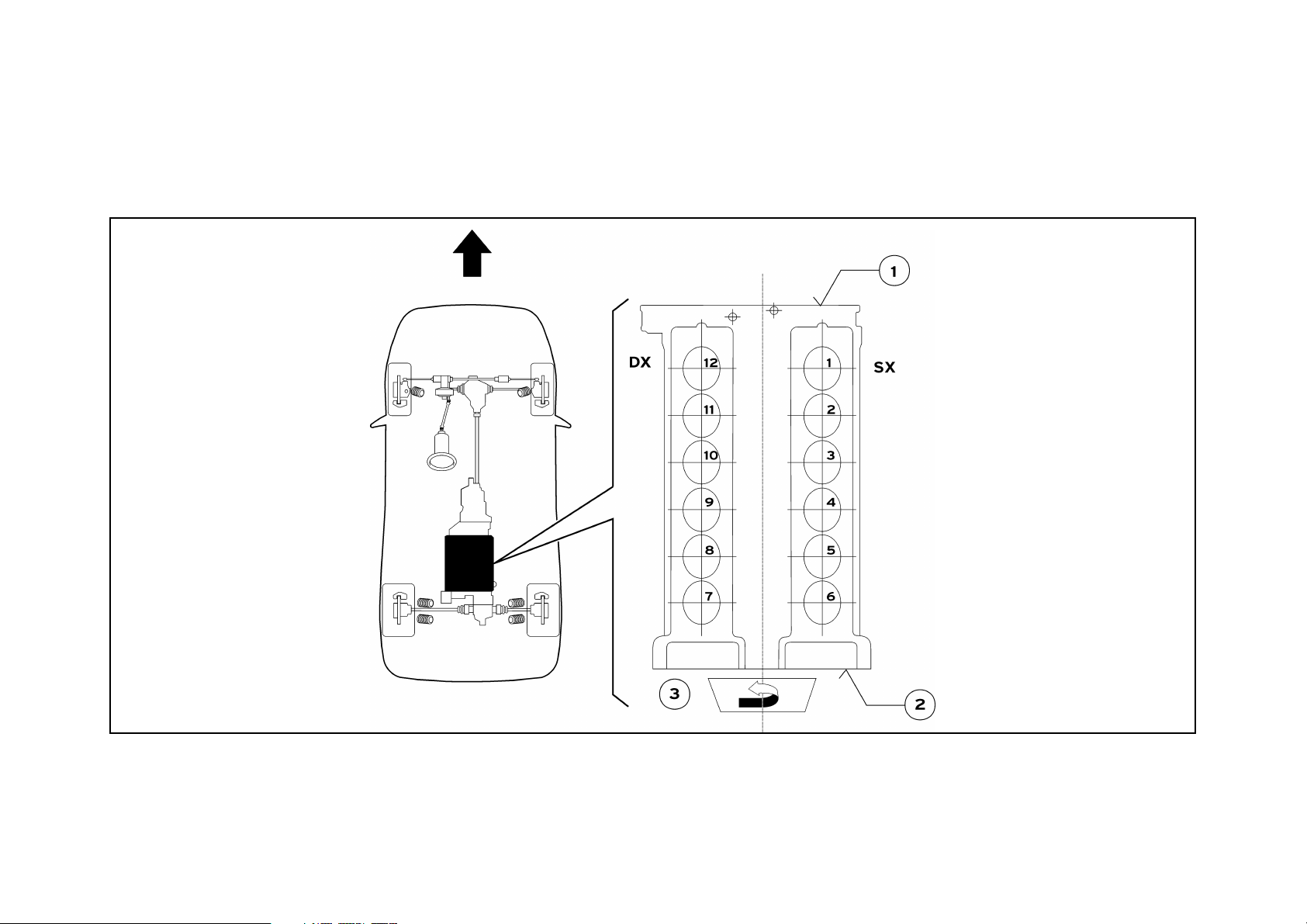

Cylinder numbering and direction of crankshaft rotation

The engine rotation is anticlockwise (as seen from the timing side).

The engine cylinder banks are defined as right and left hand as seen from the flywheel.

The No. 1 cylinder is the first of the left hand cylinder bank near the flywheel, the numbering continues following a U towards the

right hand cylinder bank.

Fig. 2 – Numbering of cylinders

1 Engine flywheel side

2 Timing side

3 Direction of rotation

(counterclockwise from timing side)

181002

4 Travel direction

SX = Left hand cylinder bank (cylinder bank 1-6)

DX = Right hand cylinder bank (cylinder bank 7-12)

10-5

Page 15

Workshop manual - Diablo 6.0

SPECIFICATIONS AND DATA

Crankshaft

Crankshaft end float 0.155 to 0.315

Crankpin and conrod journals surface hardness

HV1 630

Crankpin and conrod journals surface finish 0.2 mm

Crankpins:

Rated diameter D

2nd undersizing

Conrod journals:

Rated diameter d

2nd undersizing

62.966 to 62.979

62.712 to 62.722

45.482 to 45.500

45.236 to 45.246

Shoulders:

Rated width

Oversized thickness

The 1st undersizing is no longer available.

Whenever crankshaft undersizing is performed, it is most important to restore the surface hardness with special treatment of the NITREG type, attaining to these specifications:

temperature: 530 °C

times: rising 4 hours

holding 40 hours

descent 4 hours

depth of nitriding : 0.35 to 0.40 mm

hardness: HV1: 600 to 680

HV10: 550 to 630

white sheet thickness: < 10 microns

40.070 to 40.100

40.578 to 40.608

10-6

Page 16

Fig. 3 – Crankshaft

Workshop manual - Diablo 6.0

031003

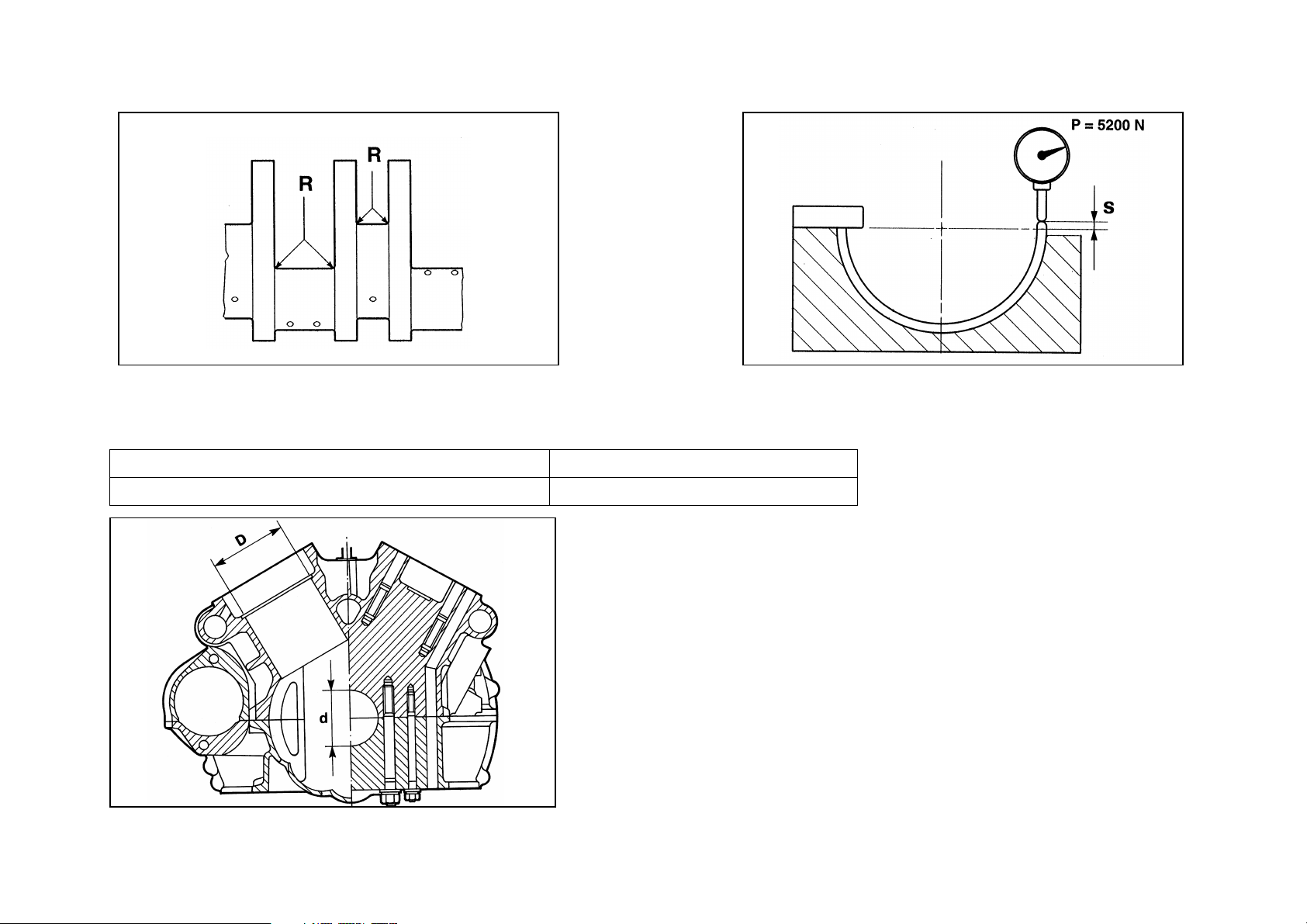

Connecting radius R

Crankpins 2.0 to 2.2

Conrod journals 2.0 to 2.2

Protrusion from crankcase edge (bushing) s 0.125 to 0.150 (*)

Bushing/shaft clearance 0.010 to 0.050

(*) apply a force P=5200 N as indicated in the figure.

10-7

Page 17

Workshop manual - Diablo 6.0

031004

Fig. 4 – Crankshaft Fig. 5 – Crankshaft bearings

Crankcase

Crankpin seat diameter d 66.675 to 66.688

Liner seat diameter D 92.000 to 92.035

031005

Fig. 6 – Crankcase

031006

10-8

Page 18

Workshop manual - Diablo 6.0

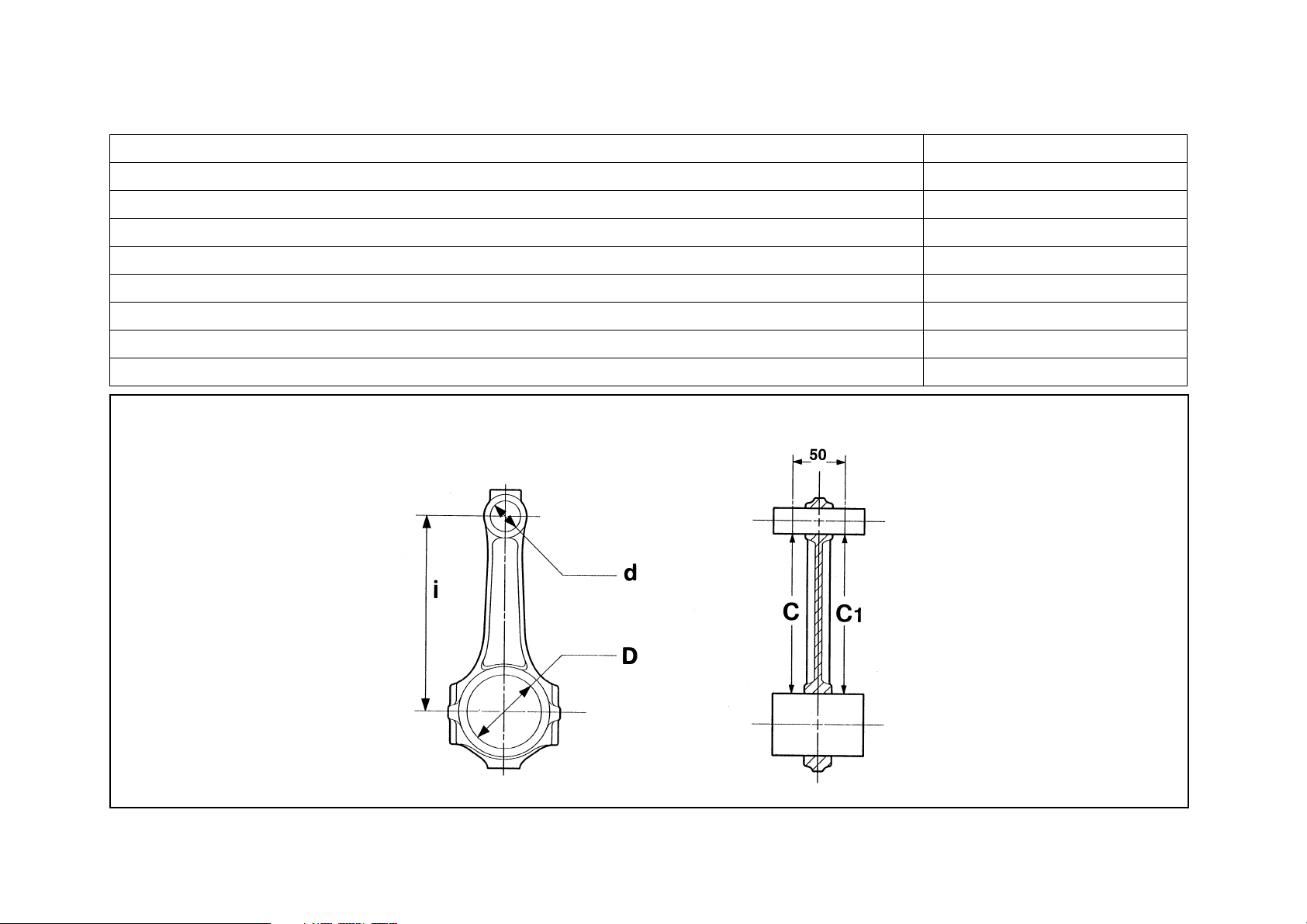

Conrods

Piston pin seat Ø (small end) d 20.020 to 20.030

Conrod bushing seat diameter (big end) D 48.626 to 48.642

Axis parallelism tolerance (piston pin-shaft) C – C1=

± 0.03

Conrod big end width 19.900 to 19.905

Conrod small end width 20.750 to 20.755

Distance between centres i 135.97 to 136.03

Piston pin and conrod small end bushing assembly clearance 0.020 to 0.080

Interference between piston pin bushing and conrod hole 0.050 to 0.096

Conrod journal bearings on crankshaft assembly clearance 0.024 to 0.067

Fig. 7 – Conrods

031007

10-9

Page 19

The big end grooves are to face the crank arms when fitting the conrod-piston group.

If one or more conrods are replaced, it is essential that the spare parts are identical to the originals. (PANKL or LAMBORGHINI).

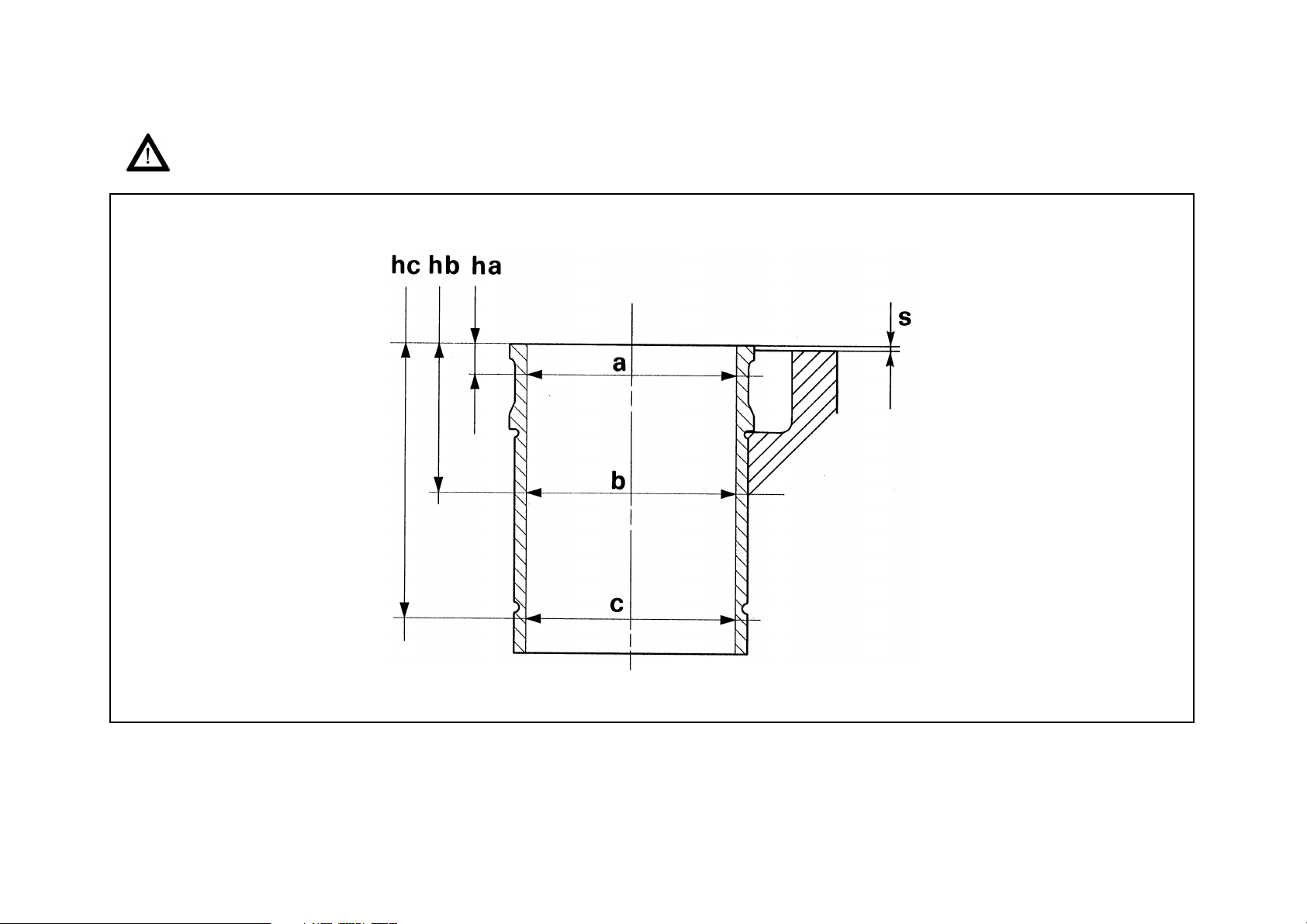

Piston liners

Rated diameter

Group A 86.995 to 86.985

B 87.005 to 86.995

C 87.015 to 87.005

Height ha 5

Diameter a

Group A 86.995 to 86.975

B 87.005 to 86.985

C 87.015 to 86.995

Height hb 60

Diameter b

Group A 89.995 to 86.985

B 87.005 to 86.995

C 87.015 to 87.005

Height hc 110

Diameter c

Group A 87.005 to 86.985

B 87.015 to 86.995

C 87.025 to 87.005

Workshop manual - Diablo 6.0

Liner protrusion from crankcase edge s 0.4 to 0.7 (*)

Maximum taper 0.02

Maximum ovalisation 0.03

Surface roughness 0.3 micron

(*) measure with a liner-stop pre-load P=30 [N]

10-10

Page 20

The liners cannot be shimmed.

Workshop manual - Diablo 6.0

Fig. 8 – Liners

031008

10-11

Page 21

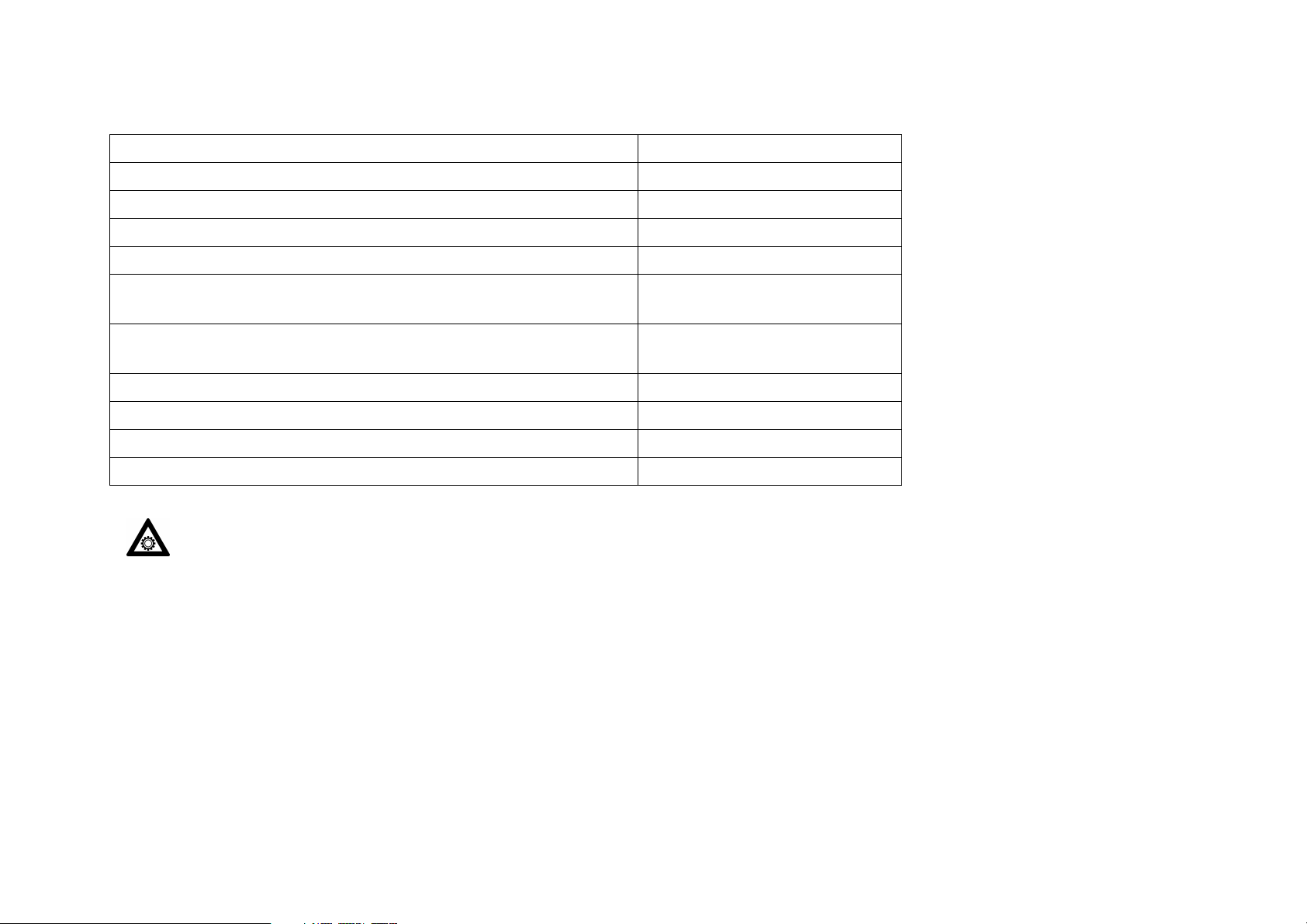

Pistons

Rated diameter

Workshop manual - Diablo 6.0

Group A 86.900

B 86.910

C 86.920

Total height H 47.1

Piston crown-piston pin axis

height H1

Piston pin axis-lower edge

height H2

Step I – slot h height 6.1 to 6.3

Height I slot a 1.230 to 1.250

Height II slot b 1.770 to 1.790

Height III slot c 3.010 to

Pistons must always be coupled with liners belonging to the same group. Pistons and liners belonging to the same

engine must all be of the same group.

29.050 to 29.150

17.8 to 18.0

± 0.009

± 0.009

± 0.009

3.030

10-12

Page 22

Fig. 9 – Pistons

Workshop manual - Diablo 6.0

031009

Piston pin

Diameter 19.995 to 20.000

Seat diameter 20.010 to 20.016

Piston pin-piston clearance 0.010 to 0.020

10-13

Page 23

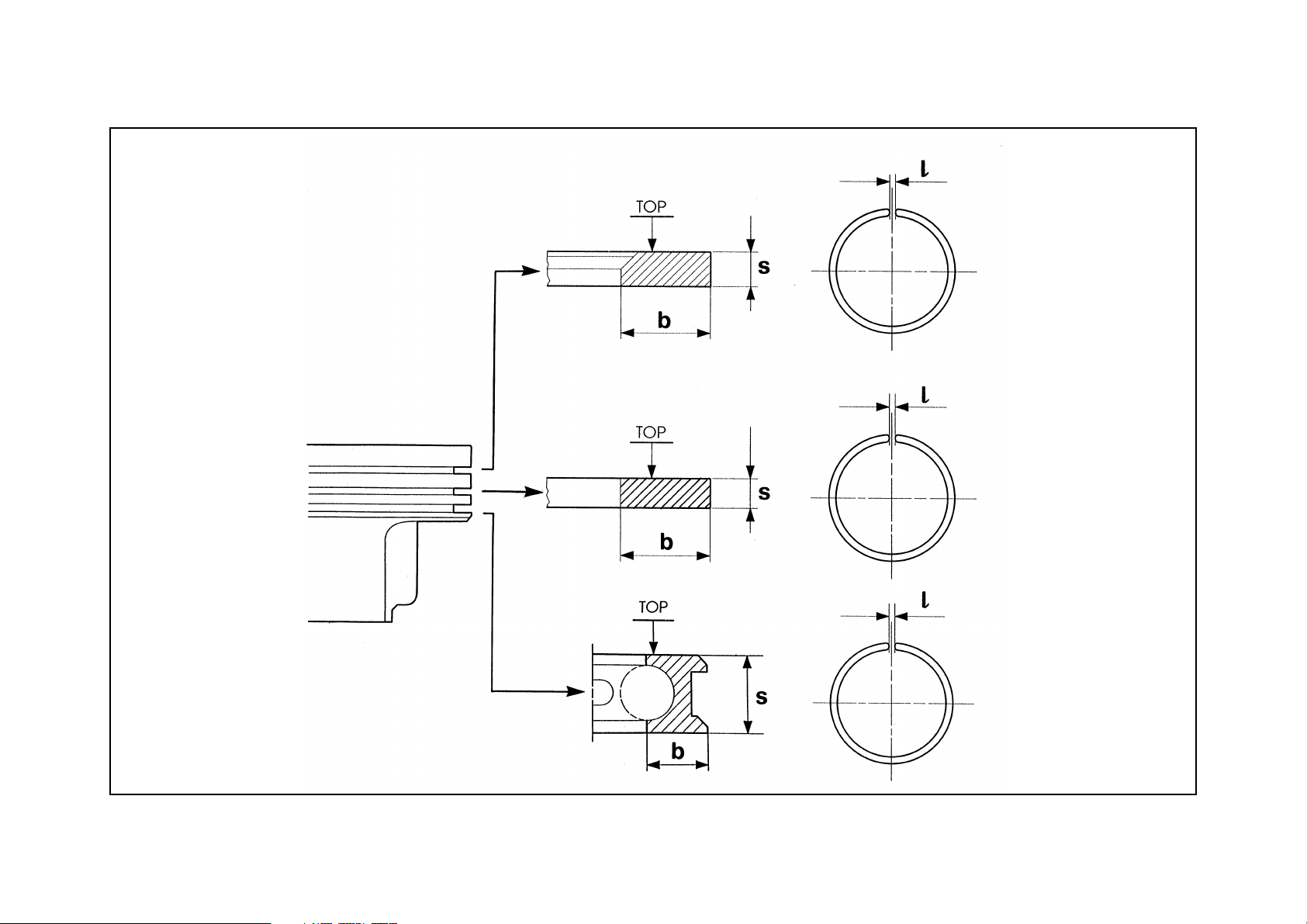

Piston rings

SLOT I

Height s 190 to 1.175

Thickness b 3.70 to 3.45

Gap between ends l 0.20 to 0.40 (*)

Slot-piston ring clearance 0.040 to 0.075

SLOT II

Height s 1.740 to 1.728

Thickness b 3.70 to 3.45

Gap between ends l 0.30 to 0.50 (*)

Slot-piston ring clearance 0.020 to 0.062

Diameter b

SLOT III

Height s 2.990 to 2.975

Thickness b 3.00 to 2.75

Workshop manual - Diablo 6.0

Gap between ends l 0.25 to 0.50 (*)

Slot-piston ring clearance 0.020 to 0.055

(*) measured with piston ring fitted in the liner.

10-14

Page 24

Workshop manual - Diablo 6.0

Fig. 10 – Piston rings

0310010

10-15

Page 25

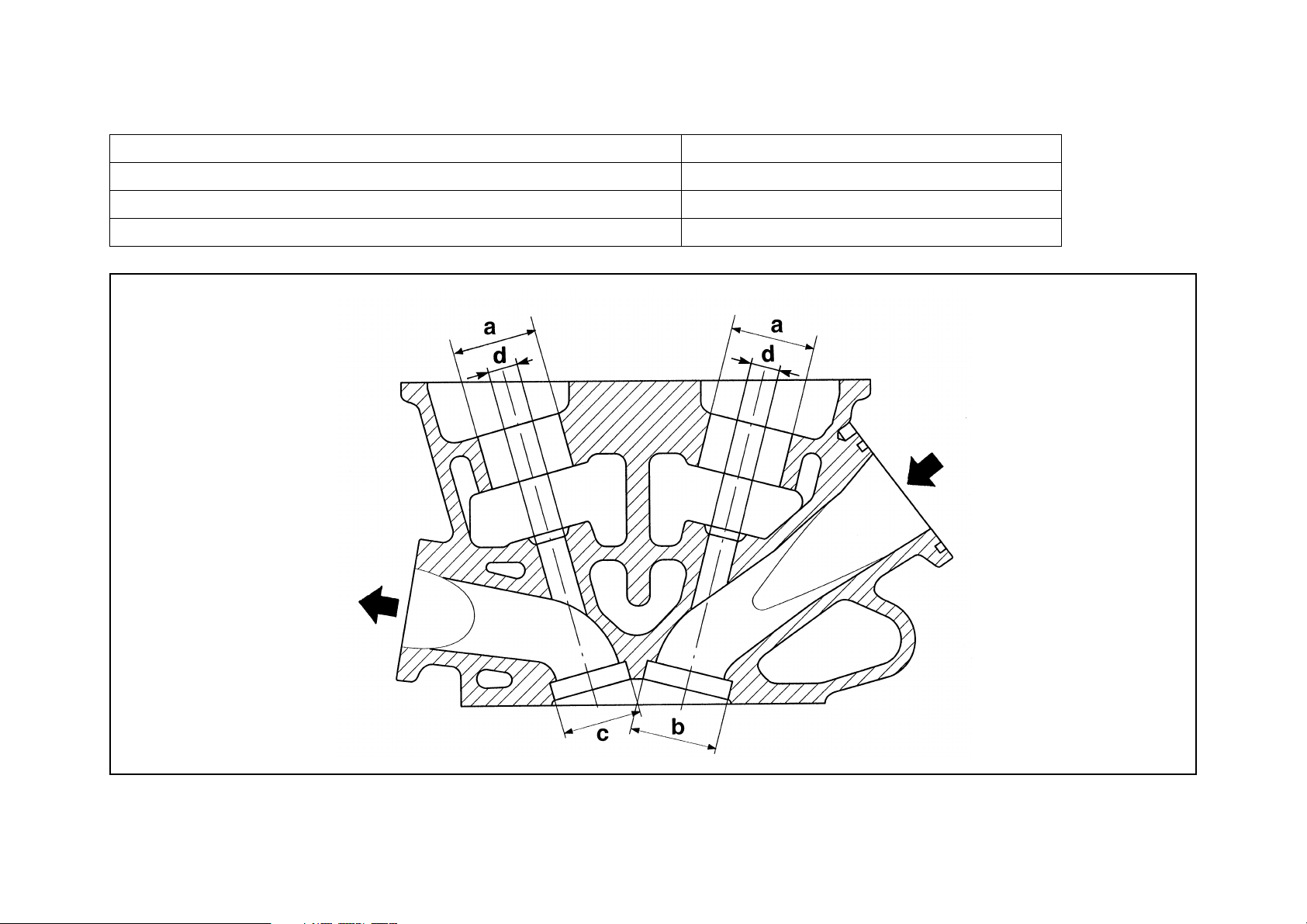

Cylinder heads

Tappet housing diameter (a) 33.015 to 33.030

Intake valve seat housing diameter (b) 30.560 to 30.580

Exhaust valve seat housing diameter (c) 30.560 to 30.580

Valve guide housing diameter (intake and exhaust) (d) 12.00 to 12.018

Workshop manual - Diablo 6.0

Fig. 11 – Cylinder head

0310011

10-16

Page 26

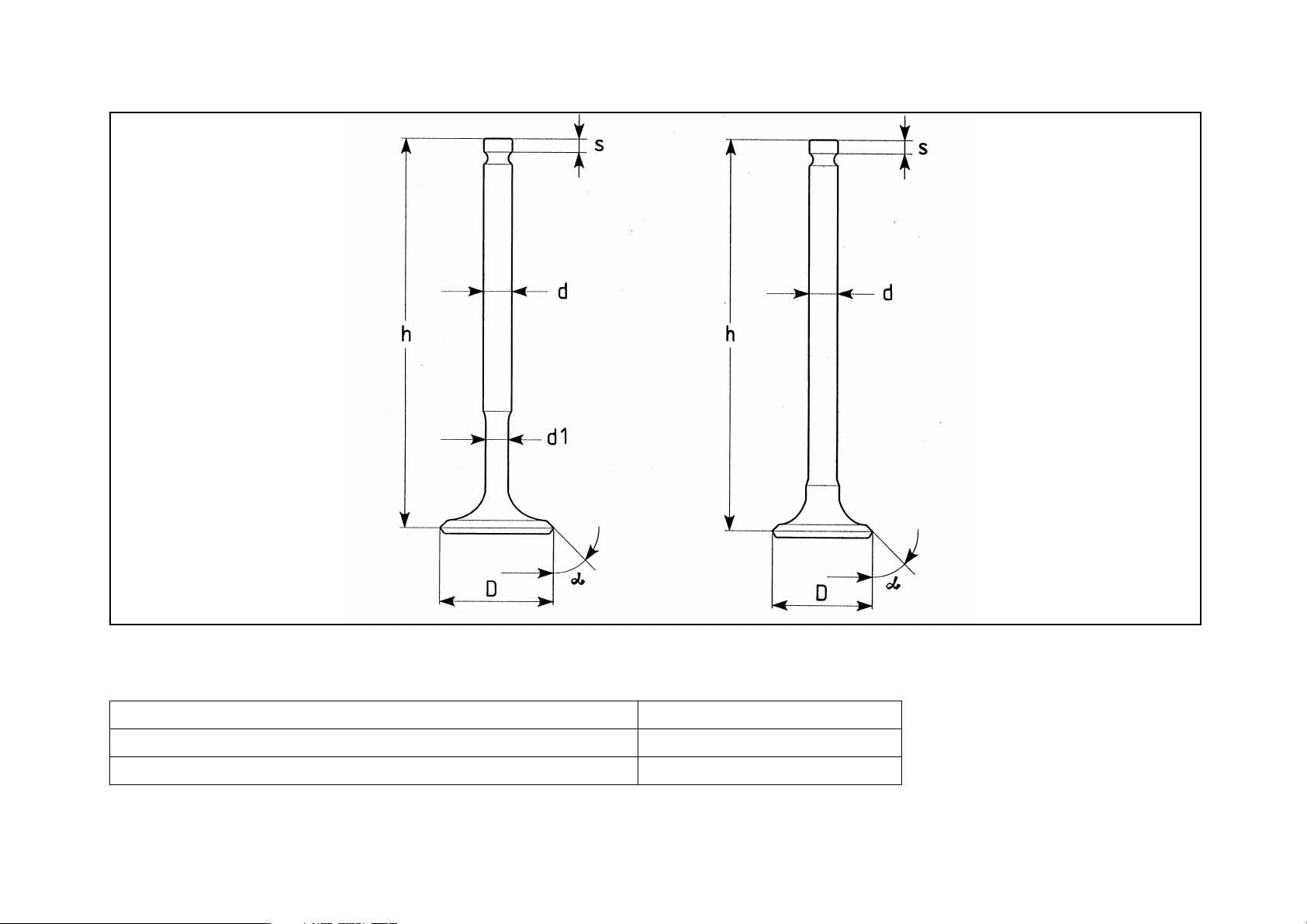

Valves

Intake

Stem diameter d 6.950 to 6.970

Reduced stem diameter d1 6.50 to 6.60

Valve head diameter D 33.3 to 33.5

Workshop manual - Diablo 6.0

Valve seat angle ° 45°

Height h 103.69 to 103.84

Tappets support thickness s 3.45

Exhaust

Stem diameter d 6.950 to 6.970

Valve head diameter D 29.3 to 29.5

Valve seat angle ° 45 °

Height h 103.59 to 103.74

Tappets support thickness s 3.35

Valve seats

Intake

Rated inner diameter 30

Rated outer diameter 34.7

Contact fascia angle 45°

Exhaust

± 5’

± 5’

± 0.10

± 0.01

Rated inner diameter 27

Rated outer diameter 32.7

Contact fascia angle 45°

10-17

± 0.10

± 0.01

Page 27

Workshop manual - Diablo 6.0

Fig. 12 – Valves

Tappets

Diameter 32.974 to 32.990

Washer thickness range 3.25 to 0.70

with intervals of 0.05

10-18

0310012

Page 28

Valve guides (intake and exhaust)

Rated outer diameter 12.040 to 12.050

Inner diameter with pressed and bored guide 7.0 to 7.015

Stem-guide clearance

Intake

Exhaust

Fitting between valve stem and relevant guide

Intake assembly clearance 0.025 to 0.055

Exhaust assembly clearance 0.035 to 0.065

Maximum shift between valve shank and head (head-stem

concentricity)

Intake

Exhaust

0.025 to 0.055

0.035 to 0.065

0.03

0.03

Workshop manual - Diablo 6.0

Assembly clearance between tappet and its seat (intakeexhaust)

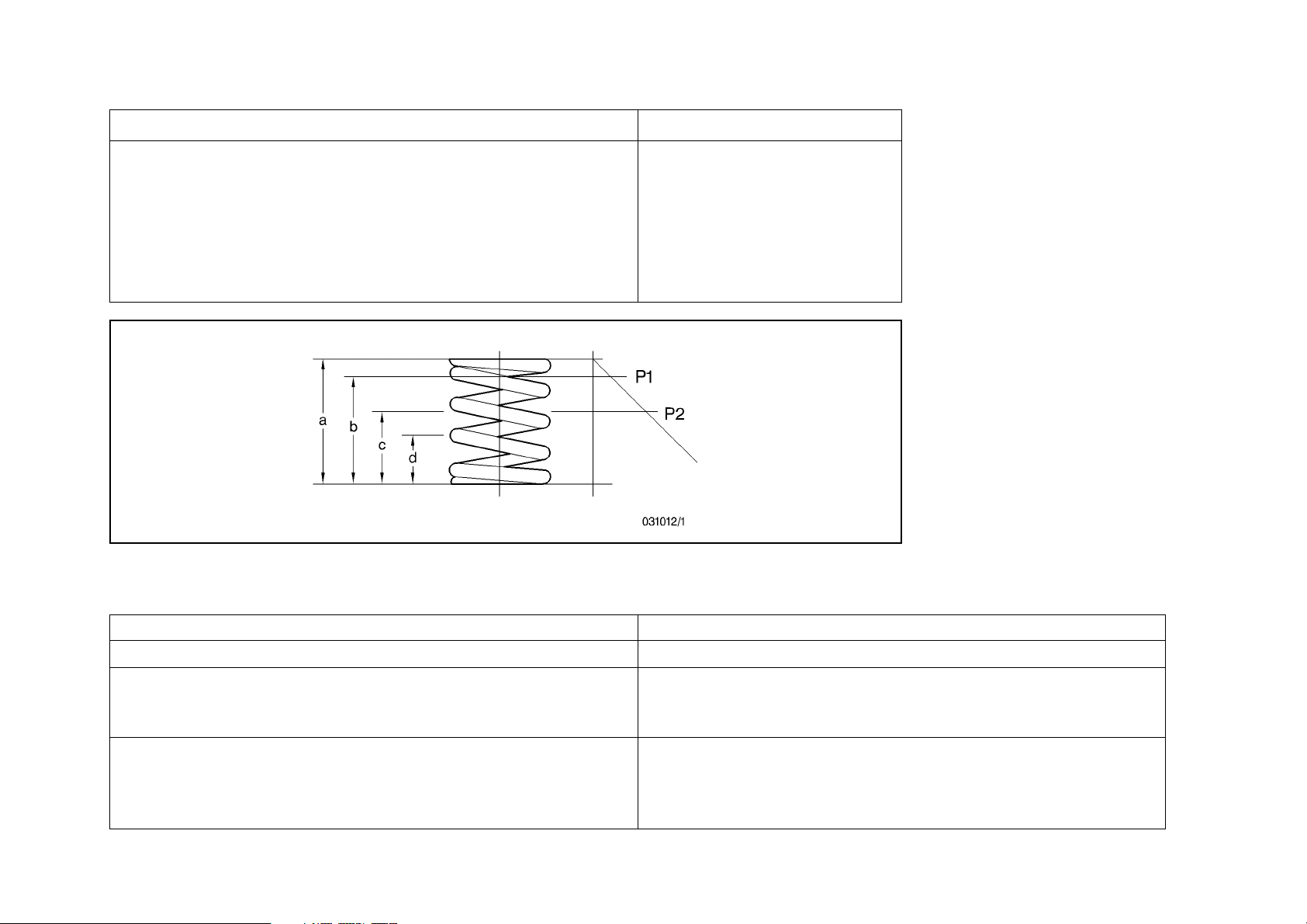

Valve springs (intake and exhaust)

Inner spring

Free length (a)

With valve closed (b)

With valve open (c)

Compressed (d)

Load (with closed valve) P1

Load (with open valve) P2

Number of active coils

10-19

0.025 to 0.071

32.5

28

19

16.36

58.86

176.58

± 3.92 N

± 9.81 N

4.82

Page 29

External spring

Workshop manual - Diablo 6.0

Free length (a)

With valve closed (b)

With valve open (c)

Compressed (d)

Load (with closed valve) P1

Load (with open valve) P2

Number of active coils

Fig. 12/1 - Valve springs

Engine lubrication

38.9

20.9

245.25

549.36

3.81

31

22

± 3.92 N

± 9.81 N

Circuit Forced lubrication with radiator and thermostatic valve

Radiator oil Single, separated

Pressure in circuit with hot engine (90°C)

– at 1000 RPM

– at 6000 RPM

Thermostatic valve

– start

– 9 mm

– max. stroke

10-20

1.5 – 2.5 [bar]

5 – 7 [bar]

80 °C

95 °C

11

Page 30

Workshop manual - Diablo 6.0

Engine cooling

Circuit Forced circulation with thermostatic control

Radiators Two with fan

Fans

– on

80 °C

74 °C

– off

Circuit pressure with hot engine (max.) 1.2 [bar]

Thermostatic valve

– start

– 7 mm

– Max. stroke (at 95 °C)

80 °C

86 °C

11

10-21

Page 31

Workshop manual - Diablo 6.0

REMOVAL AND REFIT

This operation requires a car lift and a hoist with a rocking lever and 4 chains to sling the engine, to be fixed on the exhaust manifold hooks.

0310013

Fig. 13 – Engine–gearbox removal

List of operations to be carried out before the removal of the engine:

• disconnect the positive and negative wires from the battery

• disconnect the engine cooling hoses, oil system hoses, fuel system hoses and air conditioning hoses from their relevant radiators and accessories

10-22

Page 32

Workshop manual - Diablo 6.0

• disconnect the engine injection wiring from the general wiring and all the secondary electric connectors, the earth cables and

the starter motor wires

• disconnect the oil delivery hose from the clutch cylinder located on the clutch bell

• remove the gear knob and switch on the tunnel in the passenger compartment

• lift the car and working from underneath, remove the gearbox support; loosen the two engine supports on the sides of the

crankcase

• remove the catalysts and harness the engine as described above

• remove the engine supports and, after checking all the hoses and wirings are disconnected, remove the engine-gearbox group.

ASSEMBLY

Every time the engine is disassembled clean the crankcase, especially the lubrication ducts.

Replace all oil seals and gaskets.

After the crankcase has been carefully cleaned, assemble the liners as follows:

• fit the rings to the liners;

• insert the liners one after the other in the crankcase;

• check that liners protrusion from the crankcase is in accordance with the values prescribed. Make this check using the liner

holder tools (No. 961195027) tightened to the specified torque on the cylinder head bolts. Do not remove the tools before the

heads are assembled;

• assemble the main bearings on the engine block;

• fix the crankshaft to the engine block using special supports No. 961495014;

Special supports No. 961495014 must be installed with the main bearings between support and shaft.

• before fitting the piston rings on the pistons, check that the end clearance is within the prescribed value;

To make this check, fit the piston rings on the liner. When fitting the piston rings make sure that the caption ”TOP” is

facing upwards.

• before assembling the piston-conrod group in the cylinder liner, lubricate the piston rings and the liner with engine oil. Position

the piston ring notches so that they are displaced by about 120° and ensure that no notch coincides with the direction of the piston pin axis;

10-23

Page 33

Workshop manual - Diablo 6.0

• assemble the conrod-piston group to each cylinder;

When performing this operation turn the crankshaft in the direction of its rotation.

The grooves on the conrod big end must face the crank arms when assembling the conrod-piston group.

• tighten the connecting rod big ends following this procedure:

- clean the threads very carefully;

- lubricate the bolt under the big end and the thread;

- tighten the bolts following the specified procedure (see Section 02 – DRIVING TORQUES);

• before assembling the lower crankshaft support smear LOCTITE 518 paste on the contact surface;

• fit the main bearings on the lower support;

• tighten the lower support to the prescribed torque following the specified procedure (see Section 02 – DRIVING TORQUES);

• assemble the timing components on the front part of the crankcase; assemble the oil pump on the timing cover;

• place cylinder No.1 at T.D.C. using a dial gauge;

• it the pre-assembled cylinder heads taking care that the camshaft positions coincide with the reference marks on the supports;

Cool the guides and valve seats (about -190°) before assembling onto the head. Pre heat the head to about 190°.

• before tightening the heads lubricate the upper surface of the washers, nuts and bolt threads with Molycote 1000 paste;

• tighten the head bolts following the prescribed procedure (see Section 02 – DRIVING TORQUES) using wrench No. 9008019;

• proceed with engine timing;

• before assembling the oil sump smear the contact surface with LOCTITE 518.

10-24

Page 34

Workshop manual - Diablo 6.0

CHECKS AND ADJUSTMENTS

Valve clearance

Intake 0.35 [mm]

Exhaust 0.50 [mm]

Replace the spacer rings until the clearance required is found. Use tool No. 961195014 to remove and replace the spacer rings.

When the cylinder heads are removed it is advisable to use tool No. 961195004 for the intake valve and No. 961195003 for the

exhaust valve.

Position the spacer rings (pads) with the side indicating the thickness facing the tappet.

Check the valve clearance when the engine is cold.

031015

031014

Fig. 14 – Valve clearance check Fig. 15 – Spacer ring replacement

10-25

Page 35

Workshop manual - Diablo 6.0

Locking the phase variator

A phase variator is installed in the engine on the intake timing shafts.

If this is removed, or when setting up the timing system, make sure that the slots on the moving part are correctly positioned in

relation to the fixed part securing holes.

Position check

• visually check that the slot is centred to the hole (part A)

• if it is not (position B), proceed with the positioning.

Positioning

• take out the moving part (2) from the fixed part (1); find a new angle position of the moving part, making attempts by re-inserting it fully with a rotating movement and checking the position of the slots in relation to the holes (position A);

• when the correct position is found secure the moving part by inserting ring (4) and tightening the screws to the prescribed

torque.

031018/1

Fig. 16 – Locking the phase variator

1 Variator body

2 Fixed part

3 Moving part

4 Spacer ring

A: Correct position

B: Incorrect position

10-26

Page 36

Workshop manual - Diablo 6.0

Timing regulation

Intake Exhaust

Start before TDC [°] 40 –––

End after BDC [°] 68 –––

Start before BDC [°] ––– 68

End after TDC [°] ––– 22

Lift during overlap stage [mm]

• New timing chain (less than 6 hours)

• Adjusted timing chain (more than 6 hours)

Adjustment

To adjust proceed as follows:

• rotate the crankshaft until the dial gauge shows that piston No. 1 coincides with the ignition TDC (use dial gauge holder No.

961195025);

• fit the setting dial and lever No. 961495012 to rotate the crankshaft;

• fix the reference point on the crankcase and goniometer for the TDC;

1.15

1.00

± 0.05

± 0.05

0.20

0.35

± 0.05

± 0.05

10-27

Page 37

Workshop manual - Diablo 6.0

Fig. 17 – Checking TDC in cylinder No. 1

1 Tool No. 961495012

2 Tool No. 961195025

031016

10-28

Page 38

Workshop manual - Diablo 6.0

Exhaust:

• fit sprocket holder tool No. 961195042 to fix the gears on the camshafts;

• check that the reference marks (A) on the supports and the camshafts coincide;

• fix the centring dowel on the cams using the tool;

Intake:

• loosen the six variator screws;

• check that the reference marks (A) on the supports and the camshafts coincide;

• tighten the six variator screws without locking;

• make one turn (in the engine rotation direction) to recover the chain slack;

• check the reference marks (A) again on the supports and the camshafts and if necessary reposition the shafts;

• position holder No. 961195026 with the dial gauge to measure the valve lift on cylinder No. 6;

Exhaust:

• place the dial gauge on the exhaust valve tappet and check that the lift is that specified;

• if it is not, remove the centring dowel using tool No. 9611195024 and turn the exhaust side camshaft with a 26 mm wrench until

the correct exhaust valve lift of cylinder No. 6 is found (the position is at TDC overlap);

1 Tool No.

031017 031018

961495026

Fig. 18 – Reference marks Fig. 19 – Checking and adjustment of lifts

10-29

Page 39

Workshop manual - Diablo 6.0

• fit the centring dowel on the cams using the tool;

Intake:

• loosen the six variator screws;

• turn the intake side camshaft with a 26 mm wrench until the correct intake valve lift of cylinder No. 6 is found (the position is at

TDC overlap);

To obtain the prescribed values at the end of the operations it is necessary to double the adjusting values of the lifts to

be applied.

• tighten the six variator screws to the prescribed torque;

• repeat the whole procedure for the right-hand cylinder bank, bringing cylinder 7 to ignition TDC (60° after ignition TDC of cylinder 1) and measure the lifts on cylinder 12.

Checking

To check, proceed as follows:

• rotate the crankshaft until the dial gauge shows that piston No. 1 coincides with the ignition TDC (use dial gauge holder No.

961195025);

• fit the setting dial and lever No. 961495012 to rotate the crankshaft;

• fix the reference point on the crankcase and goniometer for the TDC;

• position holder No. 961195026 with the dial gauge to measure the valve lift on cylinder No. 6;

• place the dial gauge on the intake tappet and check the lift is that specified;

• place the dial gauge on the exhaust valve tappet and repeat the procedure;

• repeat the whole procedure for the right-hand cylinder bank, bringing cylinder 7 to ignition TDC (60° after ignition TDC of cylinder 1) and measure the lifts on cylinder 12.

• make the necessary adjustment if these conditions are not found.

Locking check on phonic wheel for engine timing sensor

Proceed as follows:

• remove the cover of the phonic wheel on the camshaft, then rotate it in the direction of engine rotation to bring the tooth near

to cylinder bank 1-6 sensor using the starter motor;

• move the sensor tooth along the last section engaging the 5th gear and moving the vehicle in the travel direction;

10-30

Page 40

Workshop manual - Diablo 6.0

• lift the vehicle and with a large screwdriver turn the camshaft to bring the reference notch 30° in advance of the flywheel to

correspond with the reference on the engine block (two holes not in line);

Do not reverse the direction of engine rotation to avoid errors caused by backlash: if you go beyond the point, make two

complete engine rotations then repeat the procedure.

The 30° do not represent the ignition advance, but only an assembly reference.

• check that the tooth is perfectly centred to the sensor;

• if it is not, loosen the screw and direct the phonic wheel until centring is obtained;

• check that the distance between the tooth and the sensor (gap) is between 0.7 and 1 mm. If necessary shim the sensor.

10-31

Page 41

Workshop manual - Diablo 6.0

Fig. 20 – Timing sensor-phonic wheel locking references

1 Speed sensor and TDC

2 Engine flywheel

3 Mechanical TDC reference

4 30° advance reference

5 Timing sensor cylinder bank 1-6

6 Timing sensor cylinder bank 7-12

7 Phonic wheel

A Crankshaft

B Camshaft

131022

10-32

Page 42

COOLING CIRCUIT

Workshop manual - Diablo 6.0

Fig. 21 – Cooling circuit

1 Water pump

2 Thermostatic body

3 Radiator

4 Electric fan

5 Expansion reservoir

6 Gauge temperature sensor

7 Engine control system temperature sensors

8 Self-drain pipe

9 Climate control unit

131023

10-33

Page 43

Description

Closed loop cooling system with forced circulation by centrifugal pump belt-driven by the crankshaft.

Main components:

• two radiators

• two electric fans

• thermostatic valve in thermostat body

• centrifugal pump

• sensor for temperature gauge

• pipes for self-drain system

Workshop manual - Diablo 6.0

Fig. 22 – Water pump and thermostat

1 Coolant temperature sensor

2 Coolant temperature sensor

3 Thermostat

4 Thermostat cover

5 Pump impeller

6 Front seal

7 Shaft

131024

8 O-ring

9 Pump casing

10 Belt

11 Pulley

12 Belt tensioner assembly

13 Coolant temperature sensor

10-34

Page 44

Workshop manual - Diablo 6.0

Radiators and electric fans

The radiators are fitted with a tap in the lower part to drain off the water, and two caps in the upper part to bleed off the air.

The engine control unit governs the switching on of the electric fans according to the coolant temperature and when the air conditioning system is activated.

Since the coolant temperature is read by the relevant sensor the thermal contact is no longer installed on the radiator.

Thermostatic valve

The thermostatic valve is located in the thermostat body.

Expansion reservoir

The expansion reservoir compensates the coolant volume variations caused by engine heating.

The reservoir cap is fitted with a gauged valve that controls the system maximum pressure.

Always fill and top up the cooling system through the expansion reservoir filler.

Radiator removal

To remove the radiators proceed as follows:

• take off the exhaust system and the catalytic converters;

• remove the left and right wheel housings;

• remove the water sleeves;

• unscrew the radiator fixing bolts;

• take off the radiators from the side towards the car centre.

Filling up the system

• fill up the system through the expansion reservoir;

• remove the expansion reservoir cap;

• check the level in the expansion reservoir during heating;

• heat the engine to operating temperature to allow the thermostat valve to open;

• select HI C/F on the digital display of the air conditioner so that the heating radiator liquid starts to circulate;

• top up the expansion reservoir;

• as soon as the fans start, fit on the expansion reservoir cap;

• check the level again when the engine is cold.

10-35

Page 45

Workshop manual - Diablo 6.0

LUBRICATION CIRCUIT

Description

Force feed lubrication system with gear pump with oil vapours re-cycling. Oil cooling system with thermostatic valve.

Main components

• oil pump with internal gears and pressure regulator valve;

• thermostatic valve in thermostat body-filter seat

• radiator;

• cartridge filter;

• pressure sender;

• temperature sender;

Fig. 23 - External circuit

10-36

031025

1 Oil pressure sensor

2 Thermostatic valve body

and filter seat

3 Oil return pipe

4 Oil delivery pipe

5 Oil radiator

6 Oil filter

Page 46

Workshop manual - Diablo 6.0

Thermostatic valve

The lubrication system is equipped with a thermostatic valve that according to the oil temperature allows the oil passage through

the heat exchanger. The thermostatic valve is located on the thermostatic body/filter seat.

The main checking data is:

Temperature (°C) Stroke

80 start

95 9 mm

Max. stroke 11 mm

Fig. 24 - Thermostatic valve

1 From oil pump : 1a – To oil

radiator; 1b – From oil

radiator

2 To filter

3 To engine

A Valve open, oil path 1-1a-

1b-2-3

B Valve closed, oil path: 1-

2-3

031026

10-37

Page 47

Oil pump check

• check the pump body and cover, replace the parts if there are scorings;

• clean suction and delivery carefully with a petroleum jet and compressed air;

• check the driving and driven gears; if they are in bad condition or worn replace them;

• check clearances;

• check that the relief valve piston moves properly in its seat;

• check the bearing.

Workshop manual - Diablo 6.0

Fig. 25 - Oil pump

10-38

181027

1 Crankshaft

2 Coupling

3 Pump body

4 Driven gear

5 Driving gear

6 Timing system cover

7 Pressure regulator

8 Pulley

9 Oil seal

Page 48

Workshop manual - Diablo 6.0

Check conditions of calibrated hole (arrow) and clean if required.

Level check and oil replacement

Check the oil level with the dipstick every 500 km, preferably with the engine cold. If the engine is hot, wait a few minutes to allow

the oil to flow back to the sump.

Replace the oil when the engine is hot, draining it through the drain hole (A) in the bottom of the sump.

To have access to the engine oil filter remove the panel in the bottom of the car.

• remove the oil filter and replace it with a new one, after lubricating the seal with engine oil.

• fit the filter and tighten by hand.

031028

Fig. 26 – Engine oil drainage cap Fig. 27 – Engine oil filter

10-39

181029

Page 49

PNEUMATIC UTILITY CONNECTIONS

(EEC versions only)

Workshop manual - Diablo 6.0

Fig. 28 - Pneumatic utility connections

1 Vacuum reservoir

2 Intake manifold block 7-12

3 ENCS system solenoid valve

4 ENCS system actuators

181030

10-40

Page 50

15 – ENGINE CONTROL SYSTEM

Workshop manual - Diablo 6.0

15-1

Page 51

CONTENTS

Workshop manual - Diablo 6.0

DESCRIPTION P. 3

SYSTEM MANAGEMENT STRATEGIES P. 4

Operating principle

Signal frame management

EEC engine control system functional layout

USA engine control system functional layout

Injection system

Activated carbon filter washing

Ignition system

Engine idle speed control

ELECTRICAL/ELECTRONIC SYSTEM P. 17

Engine speed and TDC sensor

Engine timing sensor

Absolute pressure sensor

Lambda sensor

Ignition coil

Spark plugs

Engine coolant temperature sensor

Intake air temperature sensor

GFA control unit

FUEL SUPPLY SYSTEM P. 25

Fuel pump

Fuel filter

Fuel manifold

Fuel pressure regulator

Injectors

INTAKE SYSTEM P. 31

Throttle opening actuator

Throttle case

Throttle position sensor

EXHAUST SYSTEM P. 35

Catalytic converter

Exhaust gas temperature control device

Exhaust noise control system ENCS

ANTI-EVAPORATION DEVICES P. 40

Recycling system for gas coming from the crankcase (blow-by)

Fuel anti-evaporation system

CHECKS AND ADJUSTMENTS P. 44

General overview

Basic adjustment of idle speed

Idle speed adjustment

CO and HC contents check

Idle mixture strength (Arabia version)

Fuel circuit checks

SELF-DIAGNOSTICS SYSTEM P. 50

General overview

OBD II self diagnostics system

SYSTEM DIAGNOSTICS P. 53

Preliminary checks

OBDII scan tool

LDAS (Lamborghini Data Acquisition System)

OBDII strategy error codes

15-2

Page 52

Workshop manual - Diablo 6.0

DESCRIPTION

The LIE system is a system that integrates a digital electronic ignition spark advance and static timing system with an electronic

indirect fuel injection system of the multiple timed sequential type.

According to the structure of the engine, which has the cylinders divided into two cylinder banks, two complete systems have been

applied that are opportunely synchronised with each other, and each controls a cylinder bank of six cylinders. As a consequence

there are two engine control units, connected to each other by the CAN line, managing the injection and ignition of each cylinder

bank. These control units are also connected by the CAN line to the GFA control unit that co-ordinates and manages many functions, especially concerning diagnostics.

The system can be divided into the following sub-systems:

ELECTRICAL/ELECTRONIC SYSTEM

FUEL SUPPLY SYSTEM

INTAKE SYSTEM

EXHAUST SYSTEM

ANTI-EVAPORATION DEVICES

The system can acquire the following parameters:

• engine rpm;

• correct TDC sequence of the cylinders (injection timing);

• absolute pressure in the intake manifold;

• throttles position and position variation;

• intake air temperature;

• engine coolant temperature;

• exhaust gas internal temperature;

• mixture titration ;

• battery voltage;

• start-up of air conditioner;

• exhaust manifold pressure;

• fuel anti-evaporation circuit pressure.

This information if analogue, is converted to digital signals by the A/D converters so that it can be used by the control unit.

15-3

Page 53

Workshop manual - Diablo 6.0

A software management program is installed in the control unit memory which contains several strategies, each of which manages

a certain system control function.

Using the information (input) listed above, each strategy processes a series of parameters based on the data maps stored in special areas of the control unit, then controls the system actuators (output) (the devices that permit the engine to operate).

All the system components can operate on both cylinder banks. Furthermore all the connectors are marked with a

coloured band:

cylinder bank 1-6 : white;

cylinder bank 7-12: yellow.

For further information on the LIE and GFA control unit layouts, the pin-outs and electrical connections, see the Electric

Wiring Diagrams Manual.

SYSTEM MANAGEMENT STRATEGIES

Operating principle

Any operating point of the engine is found by two parameters:

• rotation speed;

• engine load.

Having found these parameters through the relevant processing, it is possible to calculate and obtain the injection (quantity of fuel

delivered and relevant timing in relation to bursting TDC), ignition (correct spark advance) and any other function for each engine

operating point.

In the LIE system the rotation speed is measured directly through the relevant sensor, whereas the engine load is determined indirectly, through a “density” parameter (representing the engine load) according to the absolute pressure in the intake manifold and

the temperature of the intake air.

When testing the engine – and afterwards the car – specific maps are prepared in which, for a certain number of speed-load parameter pairs, the time/injection timing values and ignition spark advance required for correct engine operation are stored.

These injection time values are further corrected according to the signal coming from the lambda sensor that, based on certain

operation strategies, determines a continuous fluctuation of the mixture titration around a stoichiometric value.

The system is therefore defined as “speed-density-lambda” type since the injection time is fundamentally determined by these

three parameters.

15-4

Page 54

Workshop manual - Diablo 6.0

All operation situations that require special adaptation of the calculated time/injection timing values, spark advance and boosting

pressure are managed by the engine control unit, correcting the calculated base values through suitable strategies according to

the signals coming from the system sensors.

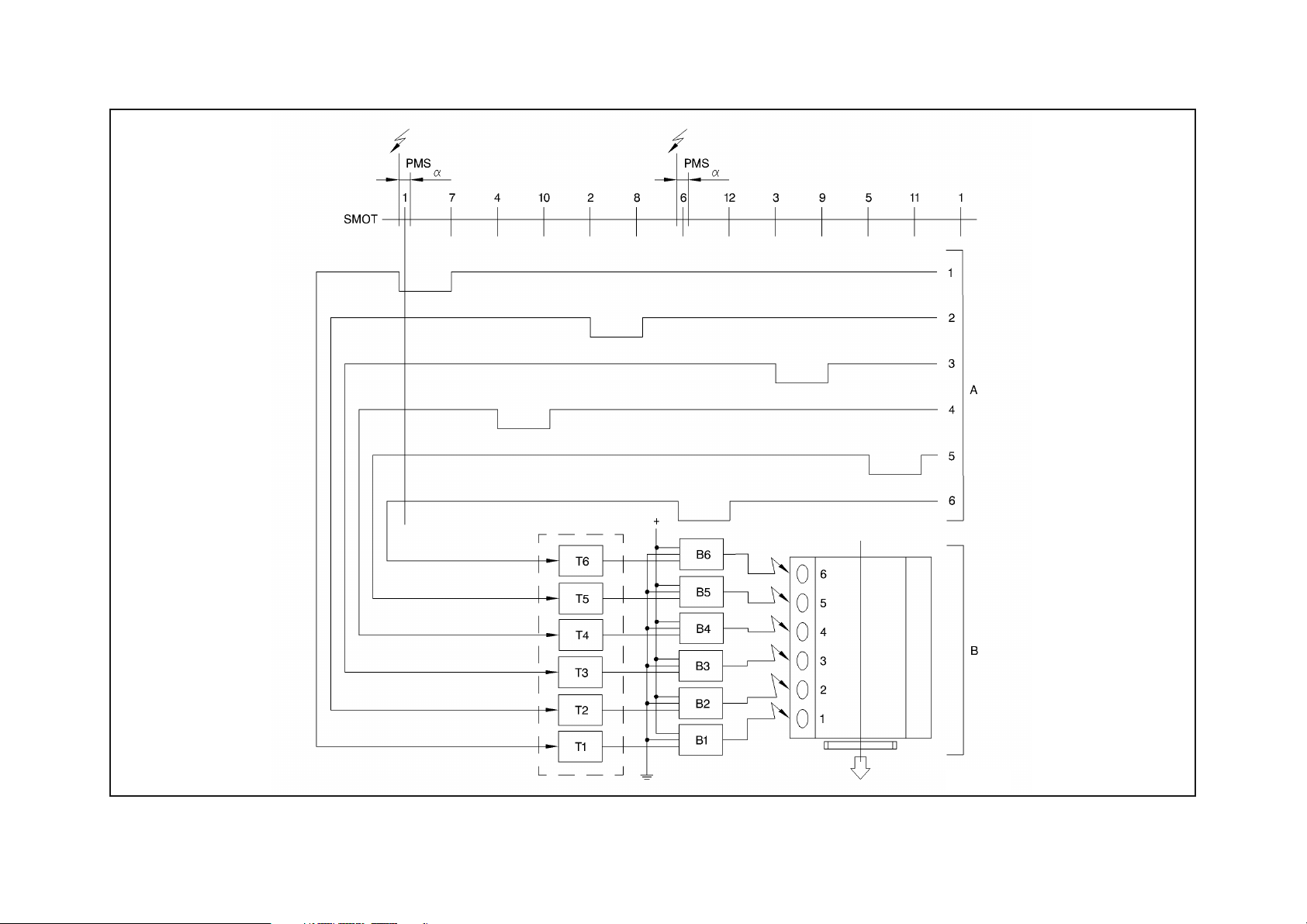

Signal frame management

The name “signal frame” implies the group of signals coming from the sensor on the crankshaft and the sensor on the

camshaft which, since they each have a well-defined reciprocal position send to the control unit a synchronised

sequence of signals that the control unit is able to acknowledge.

Upon ignition, the control unit acknowledges the injection and ignition timing, which are fundamental for the subsequent operation

of all the strategies.

This acknowledgement takes place on the basis of the interpretation of the sequence of signals coming from the engine speed sensor (one which serves both systems), on the engine flywheel and from the engine timing sensor on the camshaft.

On the engine flywheel there is a phonic wheel with six equidistant teeth: the angle between two consecutive teeth is therefore

60°. The phonic wheel is locked so that the teeth reach the sensor with an advance of 10° in relation to the relevant bursting TDC

(electric dead centre advanced by 10° in relation to the mechanical dead centre)

A cam is locked on the camshaft of the 7-12 cylinder bank that generates a signal for each of the two sensors. The two sensors are

shifted by 30°, corresponding to the opening 60° of the two engine cylinder banks.

The signal is sinusoidal and has to be converted to a digital signal by the A/D converter inside the control unit.

The cylinder sequence obviously depends on the engine bursting order which is:

1 – 7 – 4 – 10 – 2 – 8 – 6 – 12 – 3 – 9 – 5 – 11.

15-5

Page 55

Fig. 1 - Signal panel (crankshaft degrees)

SMOT: engine speed and TDC sensor signal

SCAM 1-6: cylinder bank 1-6 timing sensor signal

SCAM 7-12: cylinder bank 7-12 timing sensor signal

Workshop manual - Diablo 6.0

031501

15-6

Page 56

Workshop manual - Diablo 6.0

Fig. 2 - EEC engine control system function layout

181502

15-7

Page 57

Key

EEC engine control system function layout

Workshop manual - Diablo 6.0

1 Engine control ECU

2 Throttle position actuator ECU

3 Engine rpm and TDC sensor

4 Injectors block 1-6

5 Single ignition coil

6 Roll-over valve

7 Fuel pump

8 Fuel vapour pressure sensor

9 Absolute pressure sensor block 7-12

10 Exhaust gas pressure sensor

11 Air temperature sensor

12 Catalyser lambda sensor block 1-6

13 ENCS solenoid valve

14 Radiator fans

15 Throttle casing block 7-12

16 Throttle position sensor (single)

17 Timing variator solenoid valve block 1-6

18 Catalyser block 1-6

19 ENCS valve

20 Pressure regulator block 1-6

21 Coolant temperature sensors

22 Catalyser block 7-12

23 Pressure regulator block 7-12

24 Throttle casing block 1-6

25 Engine timing sensor

26 Catalyser lambda sensor block 7-12

27 Absolute pressure sensor block 1-6

28 Battery

29 Carbon canister washout solenoid valve

30 Carbon canister

31 Rear relay and fuse box

32 Injectors block 7-12

33 Throttle opening actuator

34 GFA ECU

35 Instrument connection

36 Ignition switch

37 Climate control system connection

38 Front relay and fuse box

15-8

Page 58

Workshop manual - Diablo 6.0

Fig. 3 - USA engine control system function layout

181503

15-9

Page 59

Key

USA engine control system function layout

Workshop manual - Diablo 6.0

1 Engine control ECU

2 Throttle position actuator ECU

3 Engine rpm and TDC sensor

4 Injectors block 1-6

5 Single ignition coil

6 Roll-over valve

7 Fuel pump

8 Fuel vapour pressure sensor

9 Absolute pressure sensor block 7-12

10 Floating valve

11 Exhaust gas pressure sensor

12 Air temperature sensor

13 Pre-catalyser upstream lambda sensor block 1-6

14 Pre-catalyser block 1-6

15 ENCS solenoid valve

16 Thermocouple control unit

17 Pre-catalyser thermocouple

18 Pre-catalyser downstream lambda sensor block 1-6

19 Radiator fans

20 Throttle casing block 7-12

21 Throttle position sensor (single)

22 Timing variator solenoid valve block 1-6

23 Catalyser block 1-6

24 ENCS valve

25 Pressure regulator block 1-6

26 Coolant temperature sensors

27 Catalyser block 7-12

28 Pressure regulator block 7-12

29 Throttle casing block 1-6

30 Pre-catalyser downstream lambda sensor block 7-12

31 Engine timing sensor

32 Pre-catalyser block 7-12 (USA)

33 Pre-catalyser upstream lambda sensor block 7-12

34 Absolute pressure sensor block 1-6

35 Battery

36 Carbon canister washout solenoid valve

37 Carbon canister

38 Rear relay and fuse box

39 Injectors block 7-12

40 Throttle opening actuator

41 GFA ECU

42 Instrument connection

43 Ignition switch

44 Climate control system connection

45 Front relay and fuse box

15-10

Page 60

Workshop manual - Diablo 6.0

Injection system

The aim of the injection management strategies is to supply the engine with the correct quantity of fuel at the required moment

according to the engine operating conditions.

The injection management is essentially the calculation of the injection time, the determination of the injection timing and the subsequent actuation through the injector command.

The “basic” injection time is calculated by a mathematical interpolation of the speed-load map: the values contained in the map,

obtained experimentally, also depend on the injector specifications.

The “final” injection time is obtained by a calculation algorithm in which the “basic” time is corrected by coefficients that take into

account the different engine operating conditions, which are indicated by the various sensors installed in the system.

Mixture titration check

(check in feedback, closed loop)

This strategy corrects the injection times so that the mixture titration fluctuates continually.

The frequency of the fluctuation changes according to the engine load and speed: it ranges in tens of Hertz.

The ratio below is the mixture ratio and is indicated with the Greek letter

α (alpha):

quantity of air taken in by the engine

quantity of fuel injected

α

The ratio below is the stoichiometric mixture ratio and is indicated with

st

:

theoretical quantity of air to

burn all the injected fuel

quantity of injected fuel

The ratio below is the mixture titration and is indicated with the Greek letter

λ (lambda):

quantity of air taken in by the engine

theoretical quantity of air to burn

all the injected fuel

The stoichiometric ratio depends on the type of fuel: for current unleaded petrol it is equivalent to approx. 14.7, that corresponds

to a lambda titration = 1.

A “rich” mixture is when the quantity of air is less than the stoichiometric quantity and in this case we have lambda <1;

A “weak” mixture is when the quantity of air is greater than the stoichiometric quantity and in this case we have lambda >1.

15-11

Page 61

Workshop manual - Diablo 6.0

The feedback operation (closed loop) permits the catalytic converters to operate efficiently. This operating condition also enables

the engine control unit to run its self-learning function.

Cold start and running

The injection time during the starter motor actuation is determined by a special mapping according to the coolant temperature:

after ignition has taken place the system passes over to the standard speed-load mapping.

When there is a cold start, since there is a natural impoverishment of the mixture due to reduced evaporation and heavy condensation on the inner walls of the fuel intake manifold, the “basic” injection time is increased by a multiplying coefficient according to

the engine temperature.

Full load

The strategy is enabled when the throttle exceeds a certain threshold. The “basic” injection time is increased by a multiplying coefficient according to the engine speed.

Acceleration and deceleration

Acceleration and deceleration are interpreted by the system as transient stages between two stationary conditions: this may be

positive (acceleration) or negative (deceleration).

The transient strategy is very complicated since many factors have to be taken into consideration.

Usually the injection time is increased for positive transients and decreased for negative transients.

The size of the correction depends basically on the engine load variation: however also values such as throttle movement speed,

engine speed, engine temperature (coolant and intake air) are also involved.

Injectors control

The injectors control is a timed sequential type.

Rpm limiting

The strategy limits the peak speed that can be reached by enabling the cut-off when the engine reaches this speed.

Peak rpm = 7800 rpm

15-12

Page 62

Workshop manual - Diablo 6.0

Fuel pump control

Each of the fuel pumps is controlled by the engine control unit through a single relay.

The pump is stopped:

• if the engine speed goes down to less than 250 rpm approx.;

• after a certain time (about 3 seconds) with the key on MAR without starting up (timed enable)

Self learning

The control unit has a self-learning function that memorises any deviation between basic mapping and corrections set by the

lambda sensor that persists during operation, within certain load and speed limits. These deviations (due to production tolerances

and ageing of system and engine components) are permanently stored, enabling adaptation of the system operation upon progressive engine and component alterations compared to the original condition.

The self-learning strategy uses the signals coming from the lambda sensor to continually update a specific mapping

contained in a special area of the memory, which contains the correction values to perform during the calculation of

the final injection time.

If a control unit is replaced a road test is necessary to allow the engine to reach its temperature and so that the strategy can perform its self-learning.

Activated carbon filter washing

This strategy checks the position of the activated carbon filter washing solenoid valve in this way:

• with the engine hot the control unit controls the solenoid valve so as to check the quantity of fuel vapours sent to the intake

(activated carbon filter washing), according to the engine speed and load. The system alternates washing periods with no

washing periods: during the latter the self-adaptation strategy can be enabled under these conditions:

• during start-up the solenoid valve remains closed, preventing the fuel vapours from enriching the mixture;

• after a cold start the solenoid valve remains closed during the entire engine warming up.

15-13

Page 63

Workshop manual - Diablo 6.0

Ignition system

The ignition control mainly consists of determining the spark advance required according to the engine operating conditions and

its actuation by the piloting of the power transistor incorporated in the power module inside the engine control unit.

The spark advance calculated on the basis of the engine load and speed is then corrected according to different engine operating

conditions.

Each coil primary is supplied by the battery voltage through a relay which, in its turn is controlled by the engine control unit: the

earth connection is through the power transistor.

The engine control unit, after a cylinder TDC signal, sends a signal, with a certain delay, to the relevant power module, that starts

at that moment (conduction start moment) to send current to the coil primary circuit to bring the value to about 6 Amperes (saturation current).

Obviously this moment varies in angle in relation to the bursting TDC of each cylinder since the dwell needed to saturate the current in the coil primary circuit is constant, whereas the time required by the engine to make two revolutions (cycle) reduces as the

rpm increases.

The engine control unit signal remains until the moment of the desired spark advance on the specific cylinder.

The moment the control unit removes the signal to the power module, the current in the coil primary circuit is cut off. This, by

induction, generates a sudden rise in voltage on the secondary circuit that is discharged to earth, generating a spark on the ignition spark plug.

Each cylinder has a coil fitted directly onto the spark plug without a high voltage cable.

The coils are operated when the engine is started in advance by a few cycles with respect to ignition. In a similar way,

the coils are operated for a few additional cycles after the engine has been stopped.

15-14

Page 64

Workshop manual - Diablo 6.0

Fig. 4 - Ignition system functional layout (cylinder bank 1-6)

131504

15-15

Page 65

Workshop manual - Diablo 6.0

SMOT: crankshaft sensor/signal

a: spark advance

A cylinder bank 1-6 modules commands

B cylinder bank 1-6 connection diagram

B1/../B6: cylinder bank 1-6 coils

T1/../T6: cylinder bank 1-6 power transistors

Firing

order: 1-4-2-6-3-5

The cylinder bank 7-12 commands are delayed by 60° of crankshaft in relation to cylinder bank 1-6 commands shown in

the figure.

Engine idle speed control

The target is to hold the engine speed around the stored value, in its turn a reverse function of the coolant temperature, suitably

changing the position of the throttle (cold engine) or the spark advance (hot engine).

• Start up and cold engine

When the key is inserted, the throttle opening actuator opens the throttle of each throttle case by an amount that depends on

the engine temperature, so as to ensure the amount of air needed to hold the set speed, according to the engine temperature.

While heating, the actuator modulates the throttle position – and consequently the engine speed – until they close completely at

an engine temperature of about 70 °C.

• Hot engine

When the key is inserted, the throttle opening actuator opens the throttle of each throttle case sufficiently to ensure the quantity of air needed for a hot start-up.

The engine idle speed is held steady close to the set value changing the spark advance so as to offset any speed fluctuations.

15-16

Page 66

Workshop manual - Diablo 6.0

ELECTRICAL/ELECTRONIC SYSTEM

Engine speed and TDC sensor

The sensor is fixed to the crankcase, engine flywheel side.

Operation principle

The sensor (fig. 5) consists of a tubular casing (1) inside which there is a permanent magnet (3) and an electrical winding (2).

The magnetic flow created by the magnet (3) due to the passing of the phonic wheel teeth, fluctuates according to the gap variation.

These fluctuations induce an electromotive force in the coil (2) at the ends of which alternate a positive voltage (tooth facing sensor) and a negative voltage (gap facing the sensor). The peak value of the output voltage depends, other factors remaining unaltered, on the distance between the sensor and the tooth (air gap).

Air gap: 0.75

The phonic wheel is locked so that the teeth arrive to the sensor with an advance of 10° in relation to the relevant bursting TDC

(Fig. 6).

No adjustment can be made to the sensor angle position.

÷ 0.90 [mm]

15-17

Page 67

031505 031506

Fig. 5 - Speed and TDC sensor Fig. 6 - Assembly diagram

Workshop manual - Diablo 6.0

1 Sensor

2 Engine flywheel

3 Tooth

4 Reference on

cup

Engine timing sensor

The timing sensors are installed on the end of the exhaust camshaft of the 7-12 cylinder bank. They are shifted by 30°, corresponding to the 60° of the two engine cylinder banks.

Operating principle

The operation is exactly the same as described for the speed and TDC sensor.

15-18

Page 68

Workshop manual - Diablo 6.0

Absolute pressure sensor

The absolute pressure sensors are at the sides of the engine near the ignition coils of the respective cylinder banks.

Operating principle

The sensitive element, enclosed in a plastic container, consists of a Wheatstone bridge stencilled on a very thin ceramic plate

(diaphragm) installed on the lower part of an annular support.

The diaphragm separates two chambers: in the lower chamber, which is sealed, a vacuum has been created, whereas the upper

chamber is in direct communication through piping with the measuring point.

When operating, the pressure that generates on the measuring point produces a mechanical action on the sensor diaphragm which

deflects, thus varying the resistor values.

Since the power supply is constant (+5 V) the resistor variation causes an output voltage variation (V) which is proportional to the

pressure value.

1 Pulse generator

eccentric

2 Cylinder bank

1-6 sensor

3 Cylinder bank

7-12 sensor

131507 031508

Fig. 7 - Timing sensor Fig. 8 - Absolute pressure sensor

15-19

Page 69

Workshop manual - Diablo 6.0

Lambda sensor

This is a sensor that generates an electric signal directly bound to the ratio between the oxygen in the exhaust gas and the oxygen

in the outside air. Through this it is possible to find the deviation from the correct stoichiometric ratio of the air-fuel mixture sent

to the cylinders.

Each cylinder bank has its own oxygen sensor installed on the exhaust gas inlet coupling in the catalytic converter of the exhaust

system.

The lambda sensor is connected to the outside air by special holes, and in any case there is no connection between the

exhaust gas and the air.

1 Contact

2 Ceramic support

3 Sensor ceramic

4 Protective pipe

5 Electric cable

6 Spring

7 External casing

8 Metal frame

9 Electrode

10 Electrode

031509

Fig. 9 - Heated lambda sensor and characteristic curve

Once the operating temperature has been reached (between approx. 350 and 800°C) the generated electric signal fluctuates continually between 0 and 800 mV. In the case of weak mixture with too much oxygen in the exhaust gas, the output signal is low, less

than 100 mV; if instead the mixture is rich – low oxygen content in the exhaust gas, the signal is high, over 800 mV.

To start its operation sooner, and to avoid the danger of splattering if the engine runs for a long time at idle speed, the lambda sensor is heated not only by the exhaust gas, but also by an electric resistor.

15-20

Page 70

Workshop manual - Diablo 6.0

Ignition coil

The ignition circuit is static type with inductive discharge; the high voltage is provided by six pencil coils fitted directly onto the

cylinder head for each block.

The coils have a magnetic closed circuit with the windings in a plastic container immersed in epoxy resin. Each coil is directly connected to the spark plug without high voltage cables.

1 Ignition switch

2 Battery

3 Power supply relay

4 Pencil coil

5 Spark plug

6 Engine control unit

131510

Fig. 10 - Pencil ignition coil

The coil primary circuit is supplied by relay, controlled by the engine control unit after it has acknowledged the rating signal

coming from the relevant sensor (thus with engine rotating driven by the starter motor).

15-21

Page 71

Workshop manual - Diablo 6.0

Spark plugs

It is most important to use spark plugs with a thermal degree and specifications that correspond to the standards. If another type

of spark plug is used for replacement it must be verified that it has the same specifications as the original ones.

Engine coolant temperature sensor

The sensor is installed on the thermostat.

It has a brass body that protects the actual resistive element, which consists of an NTC thermistor (Negative Temperature Coefficient) in which electrical resistance decreases as there is an increase in temperature and of the relevant connector.

Operating principle

The reference voltage is 5 Volts: since the control unit input circuit has been designed as a voltage divider, the reference voltage is

divided between a resistor in the control unit and the sensor itself.

As a result the control unit is able to assess the resistance variations of the sensor through the voltage changes, thus receiving

information on the temperature.

Intake air temperature sensor

The sensor is installed on the intake manifold.

It has a synthetic material cage that protects the actual resistive element, which consists of an NTC thermistor (Negative Temperature Coefficient) in which electrical resistance decreases as there is an increase in temperature and of the relevant body with connector.

Operating principle

The operation is exactly the same as described for the coolant temperature sensor.

15-22

Page 72

Workshop manual - Diablo 6.0

031511

Fig. 11 - Spark plugs electrode gap Fig. 12 - NTC type sensor characteristic curve

031512

15-23

Page 73

Workshop manual - Diablo 6.0

GFA control unit

The GFA control unit (Auxiliary Functions Management) is an on board computer that governs the operation of many devices.

Moreover, the GFA is connected by CAN line to the LIE engine control unit and co-ordinates and manages many operations, especially concerning diagnostics.

The main functions controlled or co-ordinated by the GFA control unit are:

• cutting out accessory devices when the engine oil pressure is below 1 bar (pressure switch contact closed);

• key inserted check and sounding the beeper if the key is inserted and the driver’s door open after at least one KEY ON;

• control of light intensity on the dashboard instrument panel;

• lights on check, activating the beeper if lights are on, key inserted and driver’s door open;

• check on driver’s side seat belt with timed activation of buzzer and key inserted warning lamp;

• passenger compartment lights check;

• exhaust gas temperature in catalyst check (see GR.15 .– Engine Control);

• instruments (fuel level indicator) and other indicators check;

• front differential temperature check;

• lifting system check;

• ENCS system check;

• OBDII management;

Fig. 13 - LIE - GFA control units connection diagram

035524

15-24

Page 74

FUEL SUPPLY SYSTEM

The fuel supply circuit is divided into two parts and consists of the following:

• a tank;

• two independent delivery lines each with pre-filter, electric pump and fuel filter;

• two independent manifolds, each including fuel pressure regulator and six injectors;

• a return line in common.

Workshop manual - Diablo 6.0

1 Tank

2 Pre-filter

3 Electric pump

4 Filter

5 Fuel manifold

6 Pressure regulator

Fig. 14 - Fuel circuit diagram

181513

15-25

Page 75

Workshop manual - Diablo 6.0

Fuel pump

The two fuel pumps are supplied by one relay. They are roller type positive displacement pumps with permanent magnet energising.

Inside the pump there is a pressure relief valve that short circuits the intake with the delivery if the pressure exceeds 5 bar.

The pump also has a non return valve that, for a certain period of time, can hold the system under pressure with the pump still.

This valve is especially important since by holding the system pressure it prevents fuel vapour forming (vapour-lock) which causes

damage when starting up with a hot engine.

At the pump intake there is a protective pre-filter installed.

Fig. 15 - Fuel pump

1 Intake clearance

2 Impeller

3 Non return valve

4 Roller

5 Delivery clearance

6 Pressure relief valve

031514

15-26

Page 76

Workshop manual - Diablo 6.0

Fuel filter

The filter is fitted along the fuel delivery pipe downstream of the pump.

It consists of an aluminium foil wrapping and an internal polyurethane support around which is wound a powerful filtering element.

A

B

Fig. 16 - Fuel filter

A: Pre-filter

B: Filter

The arrow indicates direction of assembly

031515

15-27

Page 77

Fuel manifold

Each cylinder bank is fitted with a fuel manifold, that distributes the fuel to the injectors.

Workshop manual - Diablo 6.0

1 Cylinder bank 7-12 fuel

manifold

2 Cylinder bank 7-12 pres-

sure regulator

3 Injector

4 Cylinder bank 1-6 fuel

manifold

5 Cylinder bank 1-6 pres-

sure regulator

6 Return line

Fig. 17 - Fuel manifold

031516

15-28

Page 78

Workshop manual - Diablo 6.0

Fuel pressure regulator

This is a differential device with a diaphragm, located in the front part of each fuel manifold and adjusted in the factory to a pressure of 3.00

± 0.05 bar.

The fuel under pressure coming from the pump pushes onto the diaphragm (3) of the downflow valve (4) opposed by the calibrated

spring (2).When the pressure exceeds the set pressure, the downflow valve opens and the excess fuel returns to the tank.

Furthermore, through the pressure tap (1) the vacuum in the intake manifold (where the injector shutter is also located), operating

on the regulator diaphragm, proportionally reduces the load from the calibrated spring.

In this way the pressure difference is kept constant between the fuel and the environment in which the injector is located (intake

manifold) under all engine operating conditions.

The fuel pressure is taken as a fixed parameter, i.e. not checked by the control unit when calculating the quantity of

injected fuel: therefore the regulator must not be tampered with to avoid altering the engine metering.

1 Vacuum signal tap

2 Calibrated spring

3 Diaphragm

4 Downflow valve

5 Fuel return

6 Fuel inlet

Fig. 18 - Pressure regulator

031517

15-29

Page 79

Workshop manual - Diablo 6.0

Injectors

The task of the injector is to deliver the amount of fuel required for the engine operation: the fuel is injected into the intake duct,

immediately upstream of the intake valves.

As the pressure differential is constant between inside and outside the injector (due to the regulator), the quantity of fuel delivered, with the same electric power depends only on the opening time, established by the control unit.

The injector is the “top-feed” type with the fuel fed from the rear of the body (8) where the electric winding (4) is also located,

connected to connector (5). The needle (2) integral with the anchor (3) is thrust against the seal seat by a spring (9).

When current passes through the winding the magnetic field created attracts the anchor (3) and as a consequence the needle (2)

opens the injector and the fuel flows through.

When the current ceases, the shutter is called back into position by the spring (9).

1 Snug

2 Needle

3 Magnetic anchor

4 Winding

5 Connector

6 Filter

7 Spring thruster

8 Body

9 Contrast spring

Fig. 19 - Injector

031518

15-30

Page 80

INTAKE SYSTEM

The intake circuit is divided into two parts and consists of the following:

• Two air cleaners with connecting sleeves to the relevant throttle case;

• Two intake manifolds, each of which has the throttle case and fuel manifold fitted on it;

• One throttle position actuator.

Workshop manual - Diablo 6.0

1 Brake booster

2 Service vacuum (vacuum

tank)

3 Activated carbon filter sole-

noid valve

4 Activated carbon filter sole-

noid valve

5 Oil vapours recirculation

6 Not used

7 Canister washing valve

8 Absolute pressure sensor

9 Fuel pressure regulator

Fig. 20 - Intake manifolds pneumatic connections

031519

15-31

Page 81

Workshop manual - Diablo 6.0

Throttle opening actuator (CARTER MOTOR)

The actuator, the same for both blocks, is fitted in the middle of the blocks, in a position opposite to the timing.

It consists of an electric motor (1) controlled by a specific control unit that adjusts the throttle position by means of control levers

(2) through a push rod (3). The angle position of the throttles is checked through a signal coming from the throttle position sensor.

The push rod has a microswitch that opens when the throttles stop against the anti-crawling screw.

When the engine is hot there should be a clearance of 6-8 mm between push rod (3) and lever (2).

Operating principle

The CARTER MOTOR device operates on the accelerator control for a certain time only after engine ignition.

The driver control unit (CARTER DRIVER) acts as an interface to the engine control unit to control the CARTER MOTOR.

The operating strategy of this device is co-related to the time that passes from engine ignition and the different temperatures picked up by the engine control sensors.

The CARTER MOTOR uses these parameters to bring the accelerator opening to a calculated value. This decreases as time passes,

and the accelerator control is released when the engine reaches the correct rpm.

In this condition the microswitch does not sense the contact with the accelerator levers and deactivates its electric circuit, deenergising the control relay.

If there is a fault, a recovery function of the device is activated.

Fig. 21 - Throttle opening actuator

6-8 mm

181520

15-32

Page 82

Workshop manual - Diablo 6.0

The injection system goes into stand-by after a CARTER MOTOR microswitch test.

This test causes and induces the system to detect a certain number of microswitch openings and closings after the

engine has been shut off and the ignition key is in OFF position.

As a consequence it is perfectly normal to note a slight movement of the accelerator rods immediately after the engine

has been switched off.

If the CARTER MOTOR is disconnected, the system activates the code in OBDII P1503, therefore it is not possible to

accelerate the engine since the feed has been cut off, causing the activation of code P1508 in OBDII.

Throttle case

This meters the amount of air taken in by the engine (and therefore the power that this develops) according to the driverís requirement through the accelerator pedal.

The throttle case, fixed to the intake manifold, has two throttles (1) with differed opening: the throttles are opened by a kinematic

system (2) that performs a progressive opening law (partial opening of the first throttle for most of the accelerator pedal stroke,

and full opening of both throttles for the last part of the stroke).

With the pedal fully released (engine released or idling) the throttle opening lever stops against an anti-crawl screw (3). On the

right-hand case a throttle position sensor is installed.

Fig. 22 - Throttle case

031522

15-33

Page 83

Workshop manual - Diablo 6.0

Throttle position sensor

This consists of a potentiometer supplied with 5V from the control unit, this potentiometer sends an output voltage to the control

unit that varies according to the throttle position.

The control unit makes an electronic reset when the throttle is in closed position.

The angle position of the sensor can be adjusted.

181522

Fig. 23 - Throttle position sensor

15-34

Page 84

15-35

Fig. 24 - Exhaust system with catalytic converters (USA)

181523

13 ENCS valve

12 ENCS solenoid valve

11 Exhaust gas pressure sensor

minal

10 Cylinder bank 1-6 exhaust ter-

terminal

9 Cylinder bank 7-12 exhaust

8 Exhaust silencer

7 Catalytic converter

of the pre-catalyst

6 Lambda sensor downstream

5 Thermocouple

4 Pre-catalyst

the pre-catalyst

3 Lambda sensor upstream of

2 CO pick-up pipe

1 Exhaust manifold

that taken from the left-hand exhaust pipe comes from cylinder bank 7-12.

Coming out from the silencer, the gas taken from the right-hand exhaust pipe comes from cylinder bank 1-6, whereas

• exhaust silencer.

• catalytic converter with pre-catalyst (USA) or single (EEC)

• six in two in one insulated manifold;

The exhaust system consists of these parts:

EXHAUST SYSTEM

Workshop manual - Diablo 6.0

Page 85

15-36

from the left-hand exhaust pipe is relevant to block 7-12.

Coming out from the silencer. the gas taken from the right-hand exhaust pipe is relevant to block 1-6 and that taken

Fig. 25 - Exhaust system with catalytic converters (EEC)

031524

13 ENCS valve

12 ENCS solenoid valve

11 Exhaust gas pressure sensor

minal

10 Cylinder bank 1-6 exhaust ter-

terminal

9 Cylinder bank 7-12 exhaust

8 Exhaust silencer

7 Catalytic converter

6 Not used

5 Thermocouple

4 Not used

3 Catalyst lambda sensor

2 CO pick-up pipe

1 Exhaust manifold

Workshop manual - Diablo 6.0

Page 86

Workshop manual - Diablo 6.0

Catalytic converter

The catalytic converter is a device that simultaneously damps the three main pollution components in the exhaust: unburnt hydrocarbons (HC), carbon monoxide (CO) and nitrogen oxides (NOx).

Inside the catalyst two chemical reactions take place:

• oxidising of the CO and HC, converted to carbon dioxide (CO2) and water (H2O);

• reduction of the NOx converted into nitrogen (N2).

These reactions are possible in a very short time due to the presence inside the structure (metal block) of the catalyst, of a coating

of active substances (platinum and rhodium) that considerably speed up the conversion of the harmful substances.

The efficiency of this conversion process however, depends on the fact that the mixture titration that is used by the engine continually fluctuates around the stoichiometric value that is obtained by the feedback carried out by the control unit based on the

lambda sensor signals.

Moreover the conversion processes take place with temperatures over 300 to 350°C: therefore it is essential that the catalyst reaches this temperature as soon as possible so as to operate correctly.

1 Metal block

2 Metal support

3 External steel wrapping

Fig. 26 - Catalytic converter

031525

15-37

Page 87