LAMBORGHINI ECO P N, ECO 3, 4 P N, ECO 5, 5 P N Instructions For Use, Installation And Maintenance

Page 1

ECO P N

6

cod. 3541S060 - Rev. 00 - 05/2019

IT -

ISTRUZIONE PER L’USO L'INSTALLAZIONE E LA MANUTENZIONE

EN -

INSTRUCTIONS FOR USE, INSTALLATION AND MAINTENANCE

ES -

INSTRUCCIONES DE USO, INSTALACIÓN Y MANTENIMIENTO

RO

-

INSTRUCğIUNI DE UTILIZARE, INSTALARE ùI ÎNTRETINERE

BG HR - UPUTE ZA UPORABU, POSTAVLJANJE I ODRŽAVANJE

EL HU - HASZNÁLATI, BESZERELÉSI ÉS KARBANTARTÁSI UTASÍTÁS

SR

ɂɇɋɌɊɍɄɐɂɂ ɁȺ ɍɉɈɌɊȿȻȺ, ɂɇɋɌȺɅɂɊȺɇȿ ɂ ɌȿɏɇɂɑȿɋɄɈ ɈȻɋɅɍɀȼȺɇȿ

ȅǻǾīǴǼȈ ȋȇdzȈǾȈ, ǼīȀǹȉDZȈȉǹȈǾȈ Ȁǹǿ ȈȊȃȉdzȇǾȈǾȈ

- ɍɉɍɌɋɌȼɈ ɁȺ ɍɉɈɌɊȿȻɍ, ɆɈɇɌȺɀɍ ɂ ɈȾɊɀȺȼȺȵȿ

Page 2

This symbol indicates “CAUTION” and is placed next to all safety warnings. Strictly follow these instructions in order to avoid

danger and damage to persons, animals and things

This symbols calls attention to a note or important notice.

This symbol, which is used on the product, packaging or documents, means that at the end of its useful life, this product must

not be collected, recycled or disposed of together with domestic waste.

Improper management of electric or electronic waste can lead to the leakage of hazardous substances contained in the product. For the purpose of preventing damage to health or the environment, users are kindly asked to separate this equipment

from other types of waste and to ask for it to be dealt with by the municipal waste service or dealer under the conditions and

according to the methods set down in national and international laws transposing the Directive 2012/19/EU.

Separate waste collection and recycling of unused equipment helps to save natural resources and to guarantee that this waste

is processed in a manner that is safe for health and the environment.

For more information about how to collect electric and electronic equipment and appliances, please contact your local Council

or Public Authority competent to issue the relevant permits.

E

ECO P N

B

• Read the warnings in this instruction booklet carefully since they provide important information on safe installation, use and

maintenance.

• This instruction booklet is an integral part of

the product and must be kept with care by

the user for future reference.

• If the unit is sold or transferred to another

owner or if it is to be moved, always make

sure the booklet accompanies the boiler so

that it can be consulted by the new owner

and/or installer.

• Installation and maintenance must be carried out by professionally qualified personnel, according to the current regulations

and the manufacturer's instructions.

• Incorrect installation or inadequate maintenance can result in damage or injury. The

manufacturer declines any responsibility

for damage caused by errors in installation

and use or by failure to follow the manufacturer's instructions.

• Before carrying out any cleaning or maintenance operation, disconnect the unit from

the electrical power supply using the switch

and/or the special cut-off devices.

• In case of a fault and/or poor operation, deactivate the unit and do not try to repair it or

directly intervene. Contact professionally

qualified personnel. Any repair/replacement of products must only be carried out

by qualified personnel using original re-

placement parts. Failure to comply with the

above could affect the safety of the unit.

• Periodical maintenance carried out by

qualified personnel is essential to ensure

proper operation of the unit.

• This unit must only be used for the purpose

for which it was designed. Any other use is

considered improper and therefore hazardous.

• After removing the packing, check the integrity of the contents. The packing materials are potentially hazardous and must not

be left within the reach of children.

• The unit must not be used by people (including children) with limited physical, sensory or mental abilities or without

experience and knowledge of it, unless instructed or supervised in its use by someone responsible for their safety.

• In case of doubt do not use the unit. Contact the supplier.

• The unit and its accessories must be disposed of appropriately, in conformity with

the current regulations.

• The images given in this manual are a simplified representation of the product. In this

representation there may be slight and insignificant differences with respect to the

product supplied.

The CE marking certifies that the products meet the essential requirements of the relevant directives in force.

The declaration of conformity may be requested from the manufacturer.

COUNTRIES OF DESTINATION: IT - ES - RO - BG - HR - GR - HU - RS

cod. 3541S060 - Rev. 00 - 05/2019

27EN

Page 3

ECO P N

1 Operating instructions .......................................................................................................... 29

1.1 Introduction...........................................................................................................................................29

1.2 Control panel ........................................................................................................................................ 29

1.3 Lighting and shutdown .........................................................................................................................30

1.4 Adjustments..........................................................................................................................................31

1.5 Operating instructions .......................................................................................................................... 37

1.6 Cleaning the burner grille .....................................................................................................................37

2 Installation.............................................................................................................................. 38

2.1 General Instructions ............................................................................................................................. 38

2.2 Installation in boiler...............................................................................................................................38

2.3 Electrical connections...........................................................................................................................41

2.4 Fuel supply ...........................................................................................................................................41

2.5 Connection to an external tank for domestic hot water production ...................................................... 42

3 Service and maintenance......................................................................................................44

3.1 Commissioning..................................................................................................................................... 44

3.2 Maintenance......................................................................................................................................... 45

3.3 Troubleshooting....................................................................................................................................47

4 TECHNICAL DATA AND CHARACTERISTICS ..................................................................... 48

4.1 Dimensions...........................................................................................................................................48

4.2 General view and main components ....................................................................................................49

4.3 Technical data table ............................................................................................................................. 49

4.4 Wiring diagram .....................................................................................................................................50

28

cod. 3541S060 - Rev. 00 - 05/2019

Page 4

ECO P N

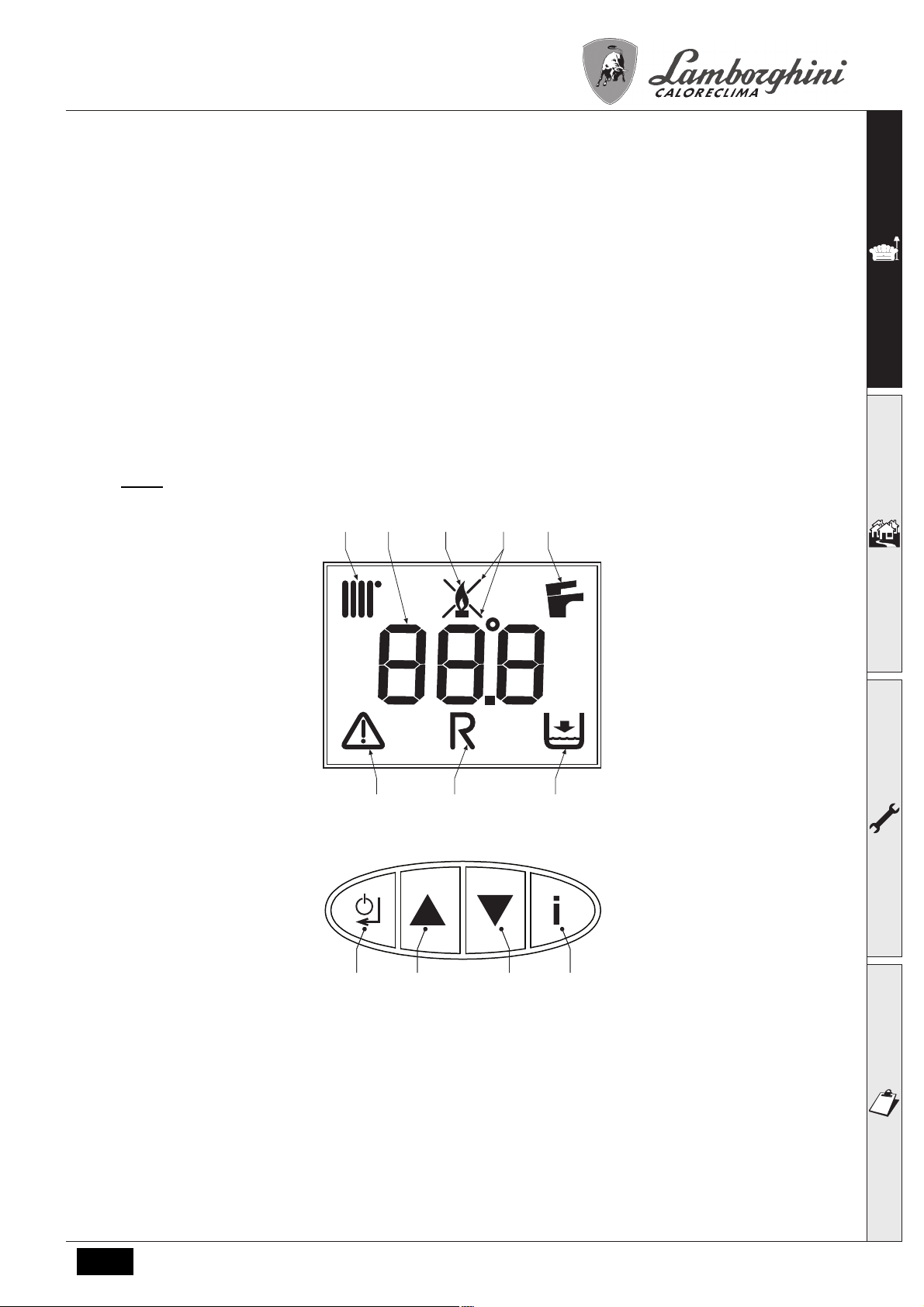

89 1011

25 7

1 4 3a 3b 6

1. Operating instructions

1.1 Introduction

Dear Customer,

Thank you for choosing ECO P N, a LAMBORGHINI burner featuring advanced design, cutting-edge technology, high

reliability and quality construction.

ECO P N is a pellet burner whose compact size and original design make it suitable for use with the majority of solid

fuel-burning boilers available on the market today. The care taken in its design and industrial production has resulted

in a well-balanced product offering high efficiencies, low CO and NOx emissions and a very quiet flame.

The burner is arranged for connection to an external domestic hot water storage tank (optional). In this manual, all the

functions regarding domestic hot water production are active only with the optional hot water tank connected as indicated in cap. 2.5 "Connection to an external tank for domestic hot water production".

1.2 Control panel

Panel

1 Heating mode

2 Fault

3a Burner lit

3b Shutdown Fault

4 Multifunction

5 Pellet Loading Request in progress

6 DHW mode

7 System Filling Request

fig. 1 - Control panel

8 Reset – Enter – On/Off button

9 Parameter selection button

10

11 Menu Access – Information button

cod. 3541S060 - Rev. 00 - 05/2019

Pellet Loading Function – Parameter selection button

29EN

Page 5

ECO P N

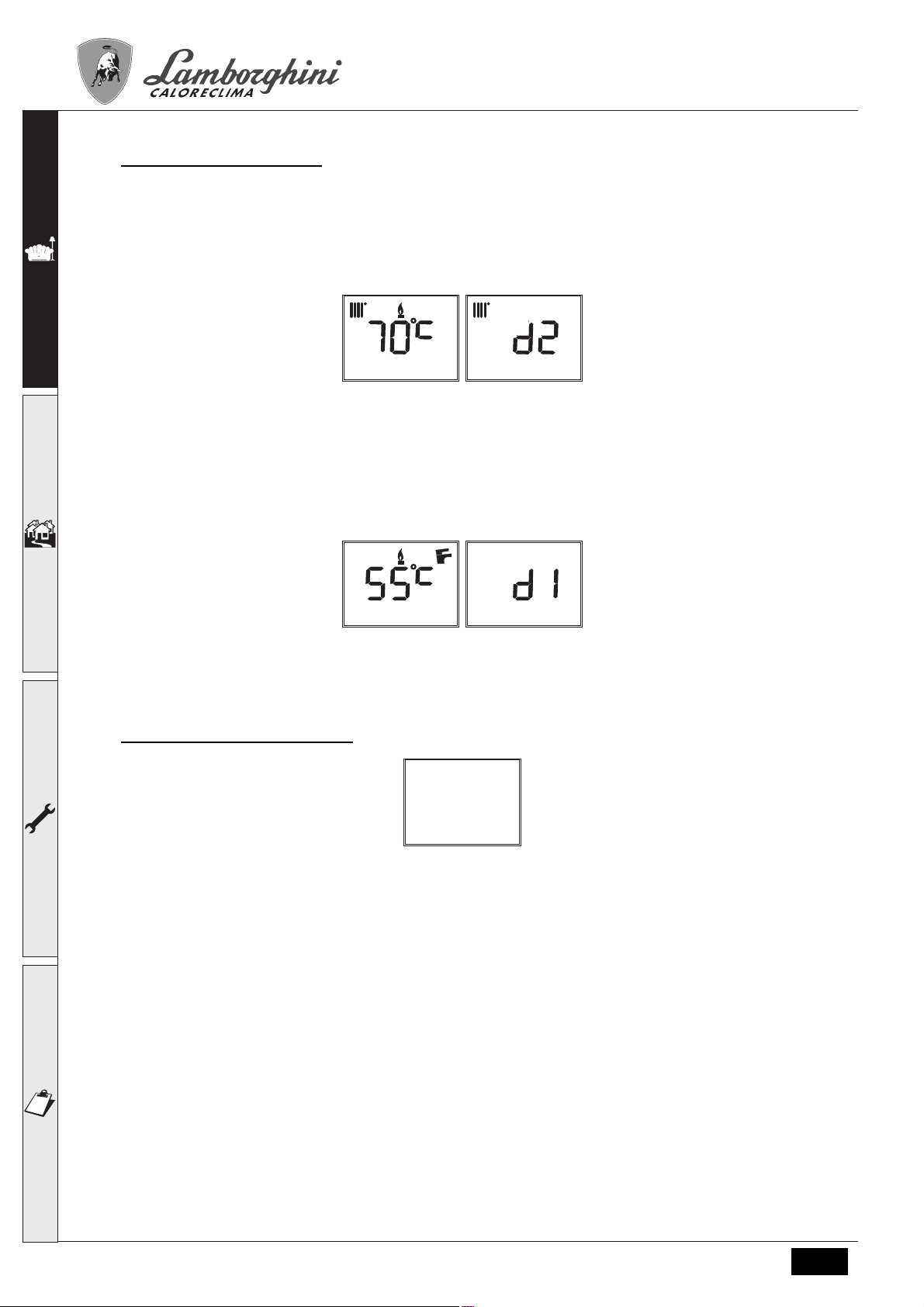

Indication during operation

Heating

A heating demand (generated by Request Contact, Room Thermostat or Remote Timer Control) is indicated by activation of the radiator (detail 1 - fig. 1).

The multifunction display (detail 4 - fig. 1) shows the heating sensor temperature and, during heating standby time, the

message “d2”.

fig. 2

Domestic hot water (DHW)

A DHW demand (generated by drawing hot water) is indicated by activation of the faucet (detail 6 - fig. 1).

The multifunction display (detail 4 - fig. 1) shows the DHW sensor temperature and, during DHW standby time, the mes-

sage “d1“.

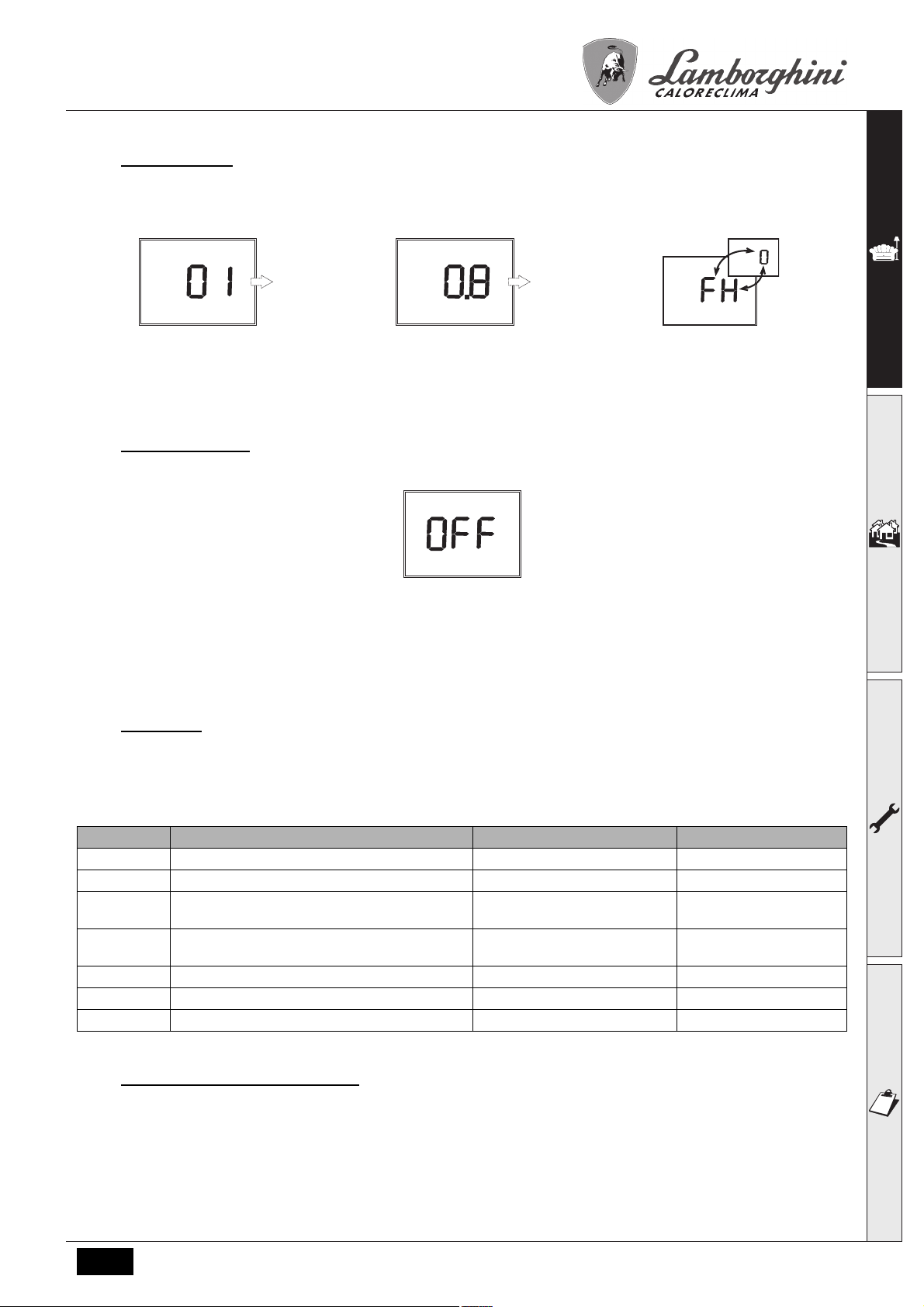

1.3 Lighting and shutdown

Burner not electrically powered

fig. 4 - Burner not electrically powered

The frost protection system does not work when the power and/or gas to the unit are turned off. To avoid dam-

B

age caused by freezing during long shutdowns in winter, it is advisable to drain all water from the boiler, the

DHW circuit and the heating system water; or drain just the DHW circuit and add a suitable antifreeze to the

heating system, as prescribed in sec. 1.3.

fig. 3

30 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 6

ECO P N

A

B

Burner ignition

Switch on the power to the burner.

•For the next 180 seconds the display will show 0/FH which identifies the heating system air venting cycle.

•During the first 10 seconds the display also shows the software version of the cards (A = Display card software version

/ B = Controller software version).

•When the message FH disappears, the burner is ready to work automatically whenever there is a room thermostat demand.

Burner shutdown

Press the on/off button (detail 8 - fig.1) for 5 seconds.

When the device is turned off, the PCB is still powered. Domestic hot water and heating are disabled. The frost protection system remains activated. To switch the device on again, press the on/off button (detail 8 - fig.1) for 5 seconds.

The device will be immediately ready to work whenever domestic hot water is drawn or in case of a heating demand

(generated by the Room Thermostat or Remote Timer control).

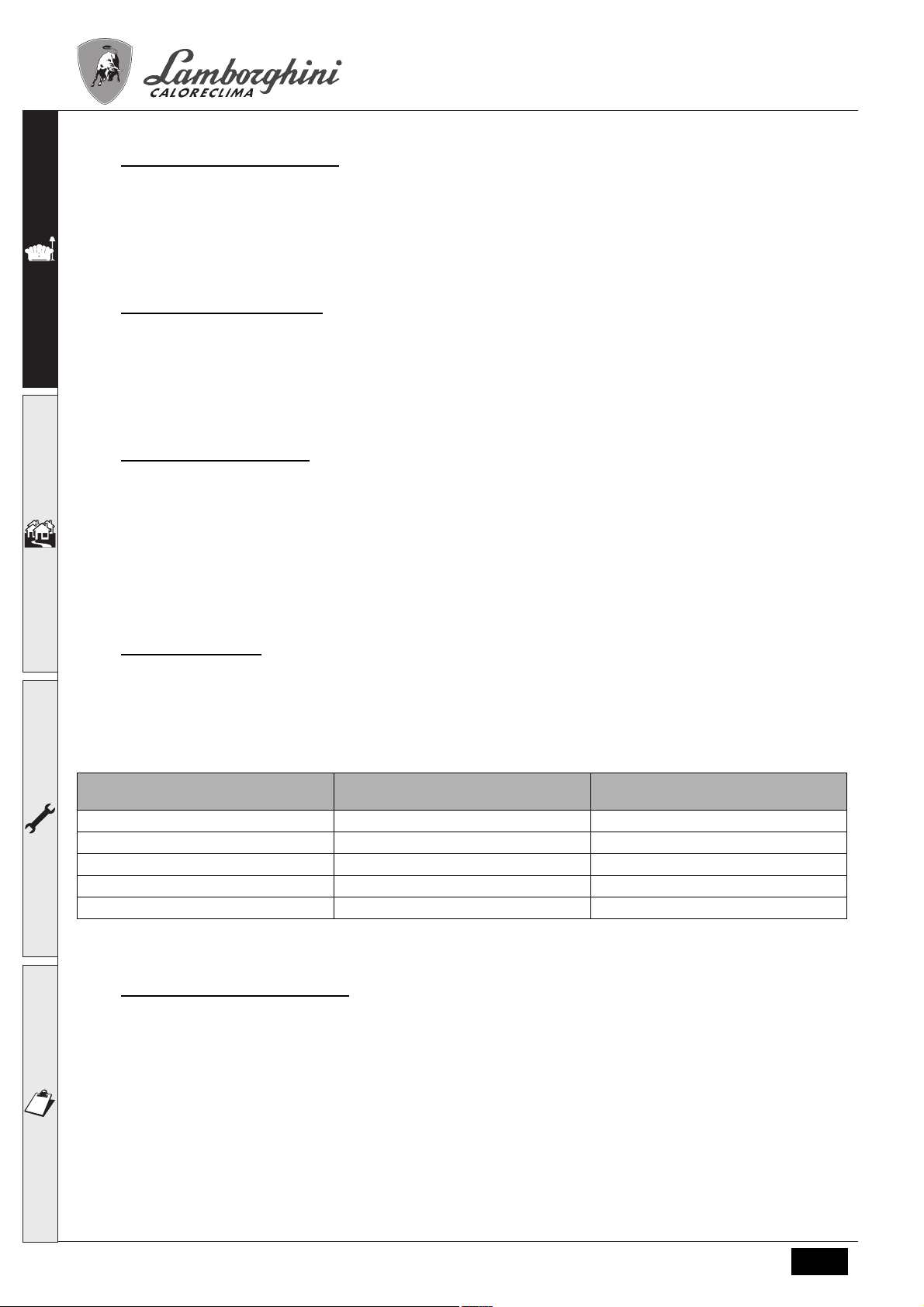

1.4 Adjustments

User menu

To access the user settings menu, press the Info button (detail 11 - fig. 1).

7 parameters and information indicated by the letter “u”are available.

Table. 1

Parameters User settings Range Default

u01 Heating adjustment temperature 30-80°C 80°C

u02 DHW adjustment temperature 10-65°C 65°C

u03 Summer/Winter selection 0 = Summer

1 = Winter

u04 Economy/Comfort selection 0 = Economy

1 = Comfort

u05 Burner max. power 1=Min, 5=Max 3

u06 Burner operation methodology 0=request contact, 1, 2 0=request contact

u07 Burner power (Step) and Flame status 0-6 -

1 = Winter

0 = Economy

By pressing the Info button it is possible to scroll the list of user settings, only in ascending order, until exiting the menu.

Heating temperature adjustment

Press the Info button (detail 11 - fig. 1) until displaying the parameter u01 of the user settings menu.

Press Enter (detail 8 - fig. 1): the actual value of the parameter u01 is displayed.

Use the buttons (details 9 and 10 - fig. 1) to adjust the temperature from a min. of 30°C to a max. of 85°C.

Press Enter (detail 8 - fig. 1) to confirm the setting.

Then press the Info button (detail 11 - fig. 1) until exiting the menu.

cod. 3541S060 - Rev. 00 - 05/2019

31EN

Page 7

ECO P N

DHW temperature adjustment

Press the Info button (detail 11 - fig. 1) until displaying the parameter u02 of the user settings menu.

Press Enter (detail 8 - fig. 1): the actual value of the parameter u02 is displayed.

Use the buttons (details 9 and 10 - fig. 1) to adjust the temperature from a min. of 10°C to a max. of 65°C.

Press Enter (detail 8 - fig. 1) to confirm the setting.

Then press the Info button (detail 11 - fig. 1) until exiting the menu.

Summer/Winter Switchover

Press the Info button (detail 11 - fig. 1) until displaying the parameter u03 of the user settings menu.

Press Enter (detail 8 - fig. 1): the actual value of the parameter u03 is displayed.

Use the buttons (details 9 and 10 - fig. 1) to set Summer mode (0) or Winter mode (1).

Press Enter (detail 8 - fig. 1) to confirm the setting.

Then press the Info button (detail 11 - fig. 1) until exiting the menu.

ECO/COMFORT selection

Heating/hot water tank temperature maintaining (Comfort) can be excluded by the user.

If excluded (Economy), domestic hot water will not be delivered.

Press the Info button (detail 11 - fig. 1) until displaying the parameter u04 of the user settings menu.

Press Enter (detail 8 - fig. 1): the actual value of the parameter u04 is displayed.

Use the buttons (details 9 and 10 - fig. 1) to set Economy (0) or Comfort (1) mode.

Press Enter (detail 8 - fig. 1) to confirm the setting.

Then press the Info button (detail 11 - fig. 1) to exit the menu.

Burner Max. Power

Press the Info button (detail 11 - fig. 1) until displaying the parameter u05 of the user settings menu.

Press Enter (detail 8 - fig. 1): the actual max power step is displayed.

Use the buttons (details 9 and 10 - fig. 1) to vary the max power: from 1 (min Step) to 5 (max Step).

Table. 2 Burner max. power

Parameter value ECO 3,4 P N

Power - kW

1 14 30

2 20 36

3 25 41

4 30 48

5 34 55

Press Enter (detail 8 - fig. 1) to confirm the setting.

Then press the Info button (detail 11 - fig. 1) to exit the menu

ECO 5,5 P N

Power - kW

Burner operation methodology

Press the Info button (detail 11 - fig. 1) until displaying the parameter u06 of the user settings menu.

Press Enter (detail 8 - fig. 1): the actual value of the parameter u06 is displayed.

Use the buttons (details 9 and 10 - fig. 1) to vary the operation methodology:

•u06=0 (default): Burner activation with request contact (230Vac) or with Room Thermostat contact (voltage-free). (Re-

mote Control request by-passed).

•u06=1: Burner activation from Remote Control or with request contact (230Vac).

•u06=2: Burner activation from Remote Control and with request contact (230Vac).

Press Enter (detail 8 - fig. 1) to confirm the setting.

Then press the Info button (detail 11 - fig. 1) to exit the menu.

32 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 8

ECO P N

Actual burner power (Step) and Flame status

Press the Info button (detail 11 - fig. 1) until displaying the information u07 of the user settings menu.

Press Enter (detail 8 - fig. 1): the actual burner power (Step) and Flame status are displayed.

•1 = Minimum Power

•5 = Maximum power

•0/FH = During Pre-ventilation/Post-ventilation

•6 = During Post-ventilation2

Press Enter (detail 8 - fig. 1) to return to the list of parameters.

Then press the Info button (detail 11 - fig. 1) to exit the menu.

Room temperature adjustment (with optional room thermostat)

Using the room thermostat, set the temperature required in the rooms. If the room thermostat is not installed, the boiler

will keep the system at the set system delivery setpoint temperature.

Room temperature adjustment (with optional remote timer control)

Using the remote timer control, set the required temperature in the rooms. The burner will adjust the system water according to the required room temperature. For operation with remote timer control, refer to the relevant instruction manual.

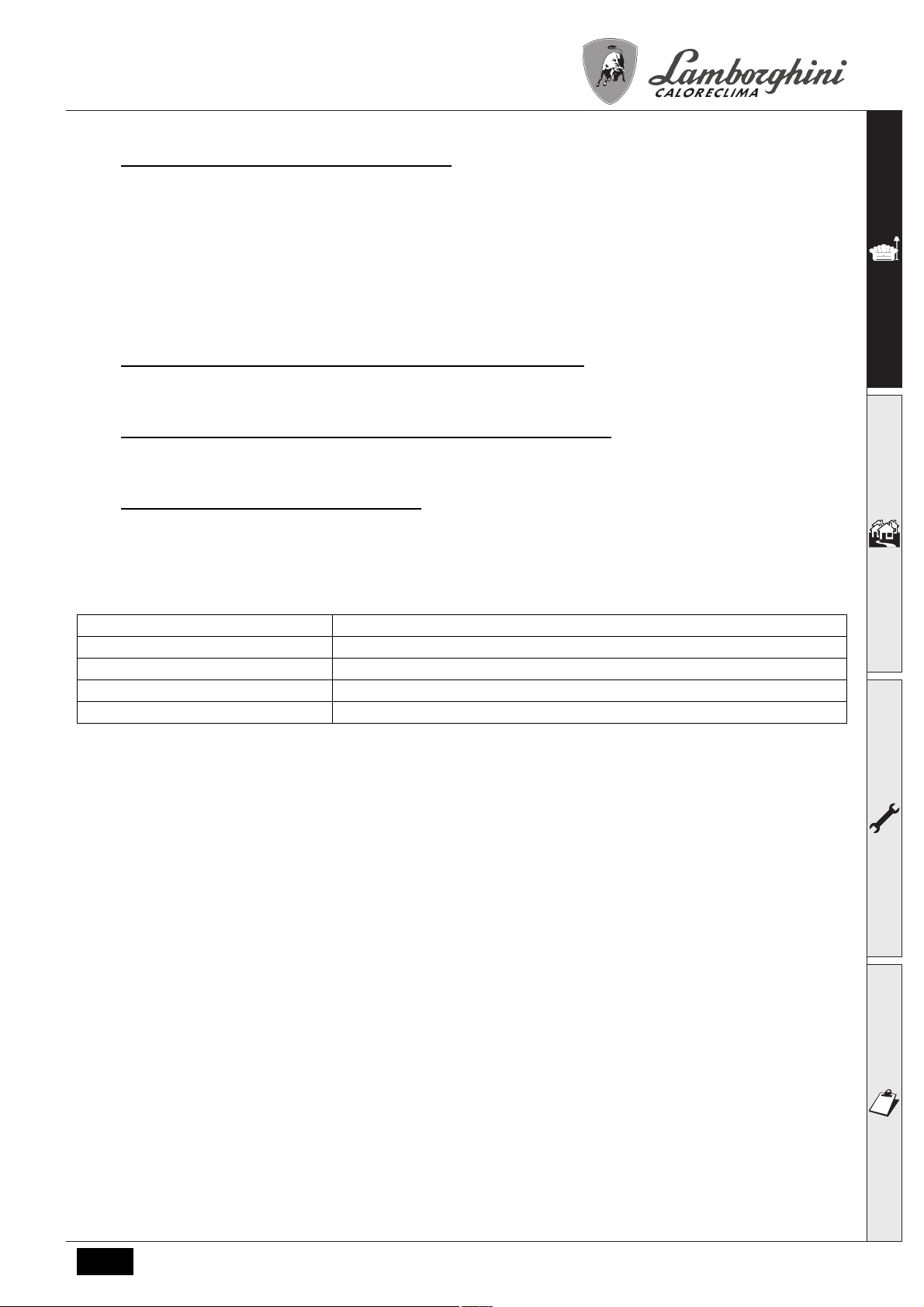

Adjustments from Remote Timer Control

A

If the Remote Timer Control (optional) is connected to the burner, the parameter “u06” must be modified (see

*** 'Burner operation methodology' on page 32 ***); the previously described adjustments are managed as described in table 3.

Table. 3

Heating temperature adjustment Adjustment can be made from the Remote Timer Control menu and the burner control panel.

DHW temperature adjustment Adjustment can be made from the Remote Timer Control menu and the burner control panel.

Summer/Winter Switchover Summer mode has priority over a possible Remote Timer Control heating demand.

Eco/Comfort selection Selection can only be made from the burner control panel

Burner shutdown (off) Off mode can only be done from Remote Timer Control.

cod. 3541S060 - Rev. 00 - 05/2019

33EN

Page 9

ECO P N

Parameters menu

The card Service Menu is accessed by pressing the Info button (detail 11 - fig. 1) for 10 seconds. Press the Up/Down

buttons to select “tS”, “In”, “Hi” or “rE”. “tS” means Transparent Parameters Menu, “In” means Information Menu, “Hi”

means History Menu, “rE” means History Menu Reset. After selecting the menu, press the Info button to access it.

“ts” - Transparent parameters menu

Table. 4

Remote

Control

01 t01 Pellet loading function 0=Disabled

02 t02 Delivery probe 0=Disabled

03 t03 Fan setpoint in Lighting 0-200 Pa 51 Pa 51 Pa

04 t04 Auger activation time in Lighting 0-100

05 t05 Adjustment calculation timer (only with t18=1 and

06 t06 Ramp function timer 0-255 seconds 150 seconds 150 seconds

07 t07 Auger operation period (activation time + deactiva-

08 t08 Fan setpoint at Power 1 0-200 Pa 51 Pa 51 Pa

09 t09 Auger activation time at Power 1 0-100

10 t10 Fan setpoint at Power 2 0-200 Pa 74 Pa 70 Pa

11 t11 Auger activation time at Power 2 0-100

12 t12 Fan setpoint at Power 3 0-200 Pa 120 Pa 100 Pa

13 t13 Auger activation time at Power 3 0-100

14 t14 Fan setpoint at Power 4 0-200 Pa 150 Pa 120 Pa

15 t15 Auger activation time at Power 4 0-100

16 t16 Fan setpoint at Power 5 0-200 Pa 170 Pa 155 Pa

17 t17 Auger activation time at Power 5 0-100

18 t18 Burner operation selection (only with t02=1) 0=On/Off

19 t19 Post-ventilation 2 Time 0-255

20 t20 Photoresistance voltage (display only) 0-50 (50=5Vdc) -- -21 t21 Auger activation function in Lighting 0=Continuous

22 t22 Photoresistance voltage threshold 0-100 (100=1Vdc) 50 50

23 t23 Burner type selection 1=P7/ECO 3.4 P

24 P24 System water pressure protection selection 0=No Pressure switch,

25 P25 Boiler type selection 1=Heating only

26 P26 Heating pump activation temperature (P25=1) 0-80°C 30°C 30°C

27 P27 Post-circulation

28 P28 Heating standby time 0-10 minutes 2 minutes 2 minutes

Card Transparent Parameters Range Default/

ECO 3,4 P N

1=Enabled

1=Enabled

(1=4 seconds)

0-100 seconds 5 seconds 5 seconds

t18=2)

0-50 seconds 15 seconds 12 seconds

tion)

(100=10 seconds)

(100=10 seconds)

(100=10 seconds)

(100=10 seconds)

(100=10 seconds)

1=Modulating

2=Modulating 2

(100=10 seconds)

1=Cycle On/Off

2=P12

3=ECO 5.5 P

1=Pressure switch

2=Storage with probe

3=Storage with probe

4=Instantaneous

Heating pump activation temperature (P25=2) 0-80°C 30°C 30°C

Heating pump activation temperature (P25=3) 0-80°C 30°C 30°C

Heating pump activation temperature (P25=4) 0-80°C 30°C 30°C

0-20 minutes 6 minutes 6 minutes

Heating pump

0=Disabled 0=Disabled

1=Enabled 1=Enabled

8 (32 seconds) 8 (32 seconds)

28 (2.8 seconds) 38 (3.8 seconds)

38 (3.8 seconds) 40 (4.0 seconds)

46 (4.6 seconds) 45 (4.5 seconds)

53 (5.3 seconds) 60 (6.0 seconds)

56 (5.6 seconds) 65 (6.5 seconds)

0=On/Off 0=On/Off

200 (20 seconds) 200 (20 seconds)

0=Continuous 0=Continuous

1=P7/ECO 3.4 P 2=P12

0=No Pressure

switch

11

ECO 5,5 P N

0=No Pressure

switch

34 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 10

ECO P N

Remote

Control

29 P29 Pump operation 0=Post-Circulation

30 P30 Pump deactivation temperature during Post-Circula-

31 P31 Heating user max. set point 31-90°C 80°C 80°C

32 P32 No function (P25=1) -- -- --

33 P33 DHW pump Post-Circulation 0-20 minutes 4 minutes 4 minutes

34 P34 DHW standby time 0-20 minutes 4 minutes 4 minutes

35 P35 DHW user max. setpoint (P25=1) -- -- --

36 P36 No function (P25=1) -- -- --

37 P37 No function (P25=1) -- - --

38 P38 Boiler shell warm-up activation temperature (P25=1) 0-80°C 0°C 0°C

39 P39 Boiler shell warm-up deactivation hysteresis (P25=1) 0-20°C 5°C 5°C

40 P40 Safety and heating sensor selection 0-2 0 0

41 P41 Variable output relay operation (P25=1) 0-4 0 0

42 P42 No function (P25=1) -- -- --

Card Transparent Parameters Range Default/

ECO 3,4 P N

1=Continuous

tion (P25=1)

Pump deactivation temperature during Post-Circula-

tion (P25=2)

Pump deactivation temperature during Post-Circula-

tion (P25=3)

Pump deactivation temperature during Post-Circula-

tion (P25=4)

DHW pump activation temperature (P25=2) 0-80°C 40°C 40°C

DHW pump activation temperature (P25=3) 0-80°C 40°C 40°C

DHW pump activation temperature (P25=4) 0-80°C 40°C 40°C

DHW user max. setpoint (P25=2) 55-65°C 65°C 65°C

DHW user max. setpoint (P25=3) 55-65°C 65°C 65°C

DHW user max. setpoint (P25=4) -- -- --

Hot water tank activation hysteresis temperature

(P25=2)

Hot water tank activation hysteresis temperature

(P25=3)

No function (P25=4) -- -- --

Hot water tank preparation delivery temperature

(P25=2)

Hot water tank preparation delivery temperature

(P25=3)

DHW mode delivery adjustment temperature (P25=4) 50-75°C 55°C 55°C

Boiler shell warm-up activation temperature (P25=2) 0-80°C 0°C 0°C

Boiler shell warm-up activation temperature (P25=3) 0-80°C 0°C 0°C

Comfort activation temperature (P25=4) 0-80°C 55°C 55°C

Boiler shell warm-up deactivation hysteresis (P25=2) 0-20°C 5°C 5°C

Boiler shell warm-up deactivation hysteresis (P25=3) 0-20°C 5°C 5°C

Comfort deactivation hysteresis (P25=4) 0-20°C 20°C 20°C

Legionella protection (P25=2) 0-7 0 0

Legionella protection (P25=3) 0-7 0 0

No function (P25=4) -- -- --

0-100°C 35°C 35°C

0-100°C 35°C 35°C

0-100°C 35°C 35°C

0-100°C 35°C 35°C

0-20°C 4°C 4°C

0-20°C 4°C 4°C

70-85°C 80°C 80°C

70-85°C 80°C 80°C

0=Post-Circulation 0=Post-Circulation

ECO 5,5 P N

Press the Up/Down buttons to scroll the list of parameters in ascending or descending order. To change the value of a

parameter just press Enter at the parameter and then modify it with the Up/Down buttons: the change will be saved

automatically.

To return to the list of parameters just press Enter.

To return to the Service Menu just press the Info button. To exit the card Service Menu press the Info button for 10

seconds or exiting will be automatic after 15 minutes

cod. 3541S060 - Rev. 00 - 05/2019

35EN

Page 11

ECO P N

“In” - Information Menu

The card can display the following information:

Contents

t01 NTC Heating sensor (°C) between 05 and 125°C

t02 NTC Safety sensor (°C) between 05 and 125°C

t03 Hot water tank NTC sensor (°C) (only with parameter P25=2, storage boiler) between 05 and 125°C

P04 Actual system water pressure (bar/10) 00-99 bar/10

P05 Burner power (Step) and Flame status 0-6

P06 Actual air pressure (Pa) 00-255 Pa

P07 Actual air pressure setpoint (Pa) 00-255 Pa (00 with burner off)

P08 Actual air pressure Switch Off setpoint (Pa) 00-255 Pa (00 with burner off)

C09 Auger (On/Off) On/Off

F10 Photoresistance voltage 0-50

Description Range

Flow switch status (On/Off) (only with parameter P25=4, instantaneous boiler) On/Off

Press the Up/Down buttons to scroll the list of information in ascending or descending order. To display the value just

press Enter at the parameter. In case of damaged sensor, the card displays hyphens.

To return to the list of parameters just press Enter.

To return to the Service Menu just press the Info button. To exit the card Service Menu press the Info button for 10

seconds or exiting will be automatic after 15 minutes.

"Hi" - History Menu

The microprocessor can memorize the total hours with card powered (Ht), the last 10 faults and the hours of burner

operation (Hb).

The History datum item H1 represents the most recent fault that occurred, whereas the History datum item H10 represents the least recent. The codes of the faults saved are also displayed in the corresponding menu of the Opentherm

remote control.

Press the Up/Down buttons to scroll the list of faults. To display the value just press Enter at the parameter.

To return to the list of faults just press Enter.

Ht Total hours with card powered

H1 Fault code

H2 Fault code

H3 Fault code

H4 Fault code

H5 Fault code

H6 Fault code

H7 Fault code

H8 Fault code

H9 Fault code

H10 Fault code

Hb Hours of burner operation

To return to the Service Menu just press the Info button. To exit the card Service Menu press the Info button for 10

seconds or exiting will be automatic after 15 minutes.

"rE" - History Reset

By pressing Enter for 3 seconds it will be possible to delete all the faults stored in the History Menu: the card will automatically exit the Service Menu, in order to confirm the operation.

To exit the card Service Menu press the Info button for 10 seconds or exiting will be automatic after 15 minutes.

36 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 12

ECO P N

1.5 Operating instructions

Once the burner is installed and correctly adjusted, its operation is fully automatic without requiring any control by the

user. In case of anomalies or no fuel, the burner stops and shuts down. To avoid irregular burner operation it is advisable

to top-up the fuel before it finishes.

Make sure the room where the burner is installed is free of flammable materials or objects, corrosive gases and volatile

substances, and that it is not dusty. In fact, dust drawn by the fan sticks to the blades and reduces the air flow or obstructs the flame stability disk thereby affecting its efficiency.

Do not allow unskilled persons or children to tamper with the burner.

B

1.6 Cleaning the burner grille

Before cleaning or any maintenance work, disconnect the power supply to the burner.

To avoid malfunctions and burner shutdowns, it is necessary to clean the combustion head grille.

Cleaning must be carried out at least once a week and in any case whenever the grille is obstructed by combustion

residues.

To clean, wait for the burner to cool down completely.

Lift the grille, remove the nozzle and suck the ash. If necessary, free the slots by removing combustion residues using

a metal brush.

Suck the ash present inside and outside the nozzle.

Refit the grille, making sure the pin is correctly positioned in the locking hole.

fig. 5- Cleaning the grille

cod. 3541S060 - Rev. 00 - 05/2019

37EN

Page 13

ECO P N

20/21

2. Installation

2.1 General Instructions

This unit must only be used for its intended purpose.

This unit can be used with heat generators for solid fuels, compatibly with its characteristics, performance and heating

capacity. Any other use is deemed improper and therefore hazardous. Opening or tampering with the unit's components

is not allowed (except for the parts requiring servicing); do not modify the unit to alter its performance or intended use.

If the burner is completed with optionals, kits or accessories, only use original products.

BURNER INSTALLATION AND SETTING MUST ONLY BE CARRIED OUT BY QUALIFIED AND SPECIAL-

B

2.2 Installation in boiler

Place of installation

The room where the boiler and burner are installed must have openings to the outside as required by the current regulations. If there are several burners or exhausters that can work together in the same room, the ventilation openings

must be sized for simultaneous operation of all the units.

The place of installation must be free of flammable materials or objects, corrosive gases, dusts or volatile substances

which, drawn by the fan, can obstruct the pipes inside the burner or the combustion head. The room must be dry and

not exposed to rain, snow or frost.

Fix the burner to the door. Make the electrical connections as shown in cap. 4.4 "Wiring diagram" (wiring diagram). If

the burner is installed in a boiler ECO-LOGIK, use the special conversion kit. Insert the temperature probe (contained

in the kit) in the sheathing on the cast-iron boiler shell and make the respective electrical connections.

B

ISED PERSONNEL, IN COMPLIANCE WITH ALL THE INSTRUCTIONS GIVEN IN THIS TECHNICAL MANUAL, THE CURRENT PROVISIONS OF LAW, THE PRESCRIPTIONS OF NATIONAL AND LOCAL

STANDARDS, AND THE RULES OF PROPER WORKMANSHIP.

THE BURNER IS DESIGNED TO WORK ON HEAT GENERATORS WITH COMBUSTION CHAMBER IN

NEGATIVE PRESSURE.

THE PELLET HOPPER MUST BE POSITIONED SO THAT THE AUGER/BURNER FLEXIBLE CONNEC-

TION TUBE IS NOT TWISTED AND/OR BENT.

Overtemperature safety device

The heat generator must be equipped with its own protection device against overtemperature. If the device provided for

is a safety thermostat, it must be connected to terminals 20 and 21 of the terminal block located inside the burner (after

removing the jumper). For LAMBORGHINI boilers not equipped with safety coil, the kit 033001X0 must be used.

fig. 6 - Safety thermostat connection

38 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 14

ECO P N

L

N

A

6

7

8

9

10

11

12

13

14

15

16

17

4

5

230V 50Hz

L

N

B

L

N

C

218

32

130

E

D

95

3.15 A

N

L

18

19

20

21

22

23

24

25

26

27

49

114

72 139

42

34

Instructions for installing the ECO P N pellet burner in the boiler ECO-LOGIK

Optional kits are available for use of the pellet burner with boilers ECO-LOGIK. For installation, refer to the instructions

contained in the kits.

After installing the kit in the boiler, fit the burner.

Secure the nozzle “L” with screws “M” and the burner with nut “N”. Connect the cable “E” to terminals 20 and 21, and

the cable “T” to sensor “V” and to terminals 4 and 5. Secure the casing "P” to the burner body with screws “R” and part

“S” on flange “K” of the burner.

Connect the cable "T" so that it is not in direct contact with the flange "K" (fig. 7).

B

E

M

V

S

M

fig. 7

N

R

P

39EN

L

K

T

cod. 3541S060 - Rev. 00 - 05/2019

Page 15

ECO P N

min. 600

Y

W

X

OK

Insert the motor-operated feed pipe “Y” in the pellet hopper “X” and carry out the auger-burner connection in such a way

that the flexible tube “W” (fig. 8) is not twisted and/or bent and is not touching hot parts that can damage it. Respect

the distance given in the fig. 8.

Adjust the burner as described in the relevant instruction manual and, in particular, set the parameter u05 on the burner

controller as indicated in the table.

Burner model ECO 3,4 P N ECO 5,5 P N

Boiler model ECO-LOGIK ECO-LOGIK 3ECO-LOGIK 4ECO-LOGIK 5ECO-LOGIK 6ECO-LOGIK

7

Nominal heating capacity kW 24.9 33.4 41 48 55

Nominal heat output kW 22 30 36 42 48

Parameter u0525345

fig. 8

fig. 9

40 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 16

ECO P N

2.3 Electrical connections

The burner is equipped with a multi-pole terminal block for the electrical connections; refer to the wiring diagram in section “4 Technical data and characteristics" for the connections. The connections to be made by the installer are all

those indicated by the dashed lines in the wiring diagram (see fig. 18).

The length of the connection cables must allow the burner and, if necessary, the boiler door to be opened. If the burner

power cable is damaged, it must only be replaced by qualified personnel.

The burner must be connected to a single-phase 230 Volt-50 Hz electric line.

Have the efficiency and suitability of the earthing system checked by professionally qualified personnel; the

B

2.4 Fuel supply

General Instructions

The burner must be fed with the type of fuel for which it is arranged, as specified on the unit's dataplate and in the technical data table on sec. 4.3 of this manual.

The user is advised to use good quality pellets, since low quality pellets result in low heat outputs, high ash content with

subsequent need of frequent cleaning, possible early wear of burner parts exposed to the fire, clogging of the auger and

burner due to excess loose sawdust, and operation shutdowns due to sedimentation of unburnt materials inside the

burner.

To identify quality pellets it is advisable to proceed as follows:

•They must be cylinders of constant diameter and have a smooth and bright surface.

•Check that the labels give the details of the quality certifications

•Check that the packs are intact so that the pellets do not absorb humidity.

Manufacturer declines any liability for damage caused by failure to earth the system. Also make sure the electrical system is adequate for the maximum power absorbed by the unit, as specified on the boiler data plate.

Make sure to respect the polarities (LINE: brown wire / NEUTRAL: blue wire / GROUND: yellow-green wire)

in the connections to the electric line.

Pellet loading

Pellet loading can be activated within 40 minutes after switching on the power to the burner.

Within this time, the system makes available three 5-minute attempts, during which only the auger is activated.

The burner cannot be lit during pellet loading.

Sequence:

1.Switch on the power to the burner.

2.Wait for the pre-ventilation stage to end.

3.Remove burner ignition request.

4.Press and hold down the button (detail 10 - fig. 1) for 3 seconds.

- “R” (detail 5 - fig. 1) flashes, identifying the imminent start of the PELLET loading procedure.

- After two seconds, the auger will be electrically powered and continuously for a maximum time of 5 minutes.

- The PELLET loading procedure can be terminated at any time by pressing and holding down the button (detail

10 - fig. 1) for 3 seconds.

5.If the maximum pellet loading time (5 minutes) is reached, the power to the auger is switched off.

6.Press and hold down the button (detail 10 - fig. 1) for 3 seconds.

- The message "R" will disappear and the display returns to normal operation.

7.If the first attempt was not sufficient, repeat the previous sequence from point 4 to start the second attempt

8.If the second attempt was not sufficient, repeat the previous sequence from point 4 to start the third and last attempt

9.In order to do another 3 attempts, switch the power to the unit off and then on again

10.After the loading of pellets, reinstate the burner ignition request.

cod. 3541S060 - Rev. 00 - 05/2019

41EN

Page 17

ECO P N

8

9

10

11

32

130

42

2.5 Connection to an external tank for domestic hot water production

Connection with circulating pump

The unit's electronic board is arranged for managing an external storage tank for domestic hot water production. Carry

out the plumbing connections according to the diagram fig. 10 (pumps and non-return valves must be supplied separately). Carry out the electrical connections as shown in the wiring diagram (see fig. 18). A LAMBORGHINI probe must

be used. At the next lighting, the boiler control system detects the hot water tank probe and automatically configures

the DHW function, activating the display and relevant controls.

fig. 10 - Diagram of connection with circulating pump

Legend

8 Domestic hot water outlet

9 Cold water inlet

10 System delivery

11 System return

32 Heating circulating pump

42 DHW temperature sensor

130 Hot water tank circulating pump

42 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 18

ECO P N

8

9

10

11

95

42

32

Connection with diverter valve

The unit's electronic board is arranged for managing an external storage tank for domestic hot water production. Carry

out the plumbing connections according to the diagram fig. 11 (the 3-way valve must be supplied separately). Carry out

the electrical connections as shown in the wiring diagram (see fig. 18). A LAMBORGHINI probe must be used.

Change parameter P25 of the "Transparent Parameters Menu" to 3.

At the next lighting, the boiler control system detects the hot water tank probe and automatically configures the DHW

function, activating the display and relevant controls.

fig. 11 - Diagram of connection with diverter valve

Legend

8 Domestic hot water outlet

9 Cold water inlet

10 System delivery

11 System return

95 3-way valve - 2 wires with spring return (not supplied)

•Powered (230 Vac) = Heating position

•Not powered = DHW position

cod. 3541S060 - Rev. 00 - 05/2019

43EN

Page 19

ECO P N

1

3. Service and maintenance

All adjustment, commissioning and maintenance operations must be carried out by Qualified Personnel in compliance with

the current regulations. The personnel of our sales organization and the Local After-Sales Technical Service are at your

disposal for any further information.

LAMBORGHINI declines any liability for damage and/or injury caused by unqualified and unauthorised persons tampering

with the unit.

3.1 Commissioning

Checks to be made at first lighting, and after all maintenance operations involving disconnection of the systems or any

operation on safety devices or parts of the burner:

Before lighting the burner

•Make sure the burner is correctly fixed in the boiler with the preliminary settings indicated above.

•Make sure the boiler and system are filled with water or diathermic oil, the plumbing circuit valves are open and that

the flue is free and correctly sized.

•Check closing of the boiler door, so that the flame is only generated inside the combustion chamber.

•Check the correct positioning of the auger and the burner connection flexible tube.

•Fill the hopper with pellets.

•Check the correct positioning and connection of the temperature probe.

A

Make sure the grille (detail 1 - fig. 12) is clean.

fig. 12 - Burner grille

Burner lighting

•Switch on the power, operating the main switch ahead of the burner.

•To fill the auger with pellets, see sec. 2.4.

•close the thermostat line (boiler/room).

44 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 20

ECO P N

Burner setting

1.Connect a combustion analyser to the boiler outlet and leave the burner working at max. for 30 minutes; in the meantime check the fume extraction duct.

2.MAKE SURE THE COMBUSTION CHAMBER IS IN NEGATIVE PRESSURE

3.Check the combustion at max. burner power (adjusted according to boiler rated output).

4.Combustion parameters:

between 5% and 9%

•O

2

•CO between 150 and 1000 ppm

NOTE

The CO value is affected by the quality of the pellets, the amount of dirt in the combustion head, and boiler draft.

If necessary, for burner calibration, vary the fan set point by modifying the relevant parameter (see par. “Parameters

menu” on page 34 and Table 2, “Burner max. power,” on page 32).

5.After checking combustion at maximum power, also check the other burner steps, repeating the procedure described

above and reducing the value of the parameter u05 to 1 (see par. “Parameters menu” on page 34 and Table 2,

“Burner max. power,” on page 32).

6.To operate the burner in Modulating mode, it is necessary to modify the parameter t18 (see par. Parameters Menu)

7.Restore the burner maximum power parameter u05 to the desired value (adjusted according to boiler nominal power)

3.2 Maintenance

Checks and controls

A

A

The burner requires periodical maintenance which must be performed by qualified personnel at least once a year.

The basic operations to carry out are:

•check and cleaning of the internal parts of the burner and boiler as indicated in the following sections;

•complete combustion analysis (after at least 10 minutes' operation) and check of correct settings;

Opening the casing and removing the burner

B

To open

Undo the screws (A) and remove the casing (B). The internal components, motor, damper, etc., are directly accessible.

Periodically check the cleanness of the burner parts which will tend to get dirty depending on the quality of the

pellets or due to incorrect burner adjustment.

Periodically check the pellet hopper and remove dust from the bottom. An excessive amount of dust can affect

the proper supply of fuel to the burner.

Before carrying out any checking or cleaning inside the burner, disconnect the power to the burner by means of

the main system switch.

A

B

fig. 13 - Casing opening

cod. 3541S060 - Rev. 00 - 05/2019

45EN

Page 21

ECO P N

C

D

E

To disassemble the burner

After removing the casing, unscrew the nut (C) and disconnect the body, undo the fixing screws (D) and remove the

nozzle (E).

fig. 14 - Burner disassembly

Checks on parts and components

Fan

Make sure no dust has accumulated inside the fan and on the blades: it reduces the air flow, thus causing pollutant

combustion.

Combustion head

Make sure all parts of the combustion head are intact, not warped by the high temperature, free of impurities coming

from the room, and correctly positioned.

Photoresistance

Remove any dust on the glass. The photoresistance is press-on; to remove, pull it outwards.

46 EN

cod. 3541S060 - Rev. 00 - 05/2019

Page 22

ECO P N

3.3 Troubleshooting

The burner is equipped with an advanced self-diagnosis system. In case of a burner fault, the display (detail 4 - fig. 1)

flashes indicating the fault code.

There are faults the cause permanent shutdowns (marked with the letter "A"): to reinstate operation, press the “Reset”

button (detail 8 - fig. 1) for 1 second; if the burner fails to restart, it is necessary to firstly eliminate the fault.

Other faults cause temporary shutdowns (marked with the letter "F") which are automatically reset as soon as the value

returns within the burner's normal operating range.

Table. 5 - List of faults

Fault Fault Cause Cure

Pellet container empty Fill the container with pellets

Auger cable broken or disconnected Restore the connection

A01 No ignition shutdown

F02 Parasite flame elimination

A02 Shutdown for parasite flame

A03 Wiring fault Jumper of terminals 20-21 not connected Check the wiring

A04 Auger safety thermostat block

F05

F06

F10

F11 DHW sensor fault

F14 Card parameter fault Wrong card parameter setting

F34 Supply voltage under 170V. Electric mains trouble Check the electrical system

F37 Card parameter fault Wrong card parameter setting

F42 Card parameter fault Wrong card parameter setting

Incorrect pipe pressure adjustment

Pressure transducer fault (disconnected)

Boiler shell probe fault (if enabled)

Faulty igniter resistance Replace and empty the head of pellets

Combustion head dirty Empty and clean it

Pellet feed duct obstructed

The demand for heat has ended, but the

burner detects flame

Incorrect ignition parameters Check ignition parameters

Photoresistance short circuit Replace the photoresistance

Extraneous light strikes the photoresistance Eliminate the light source

Incorrect ignition parameters Check ignition parameters

Boiler under pressure

Faulty safety thermostat Replace it

Auger cable broken or disconnected Restore the connection

Pressure sensor connection tube squashed Replace

Fan motor damaged Replace

Fan dirty Clean it

Wiring disconnected Check the wiring or replace the sensor

Sensor damaged

Wiring disconnected

Sensor damaged

Wiring disconnected

Free it, make sure the combustion head is

not clogged and empty it if necessary

Wait for end of post-ventilation

Clean it and check correct minimum flue

draft (10Pa)

Check the wiring or replace the sensorWiring shorted

Check the wiring or replace the sensorWiring shorted

Check the card parameter and modify it if

necessary

Check the card parameter and modify it if

necessary

Check the card parameter and modify it if

necessary

cod. 3541S060 - Rev. 00 - 05/2019

47EN

Page 23

ECO P N

250

312

217

447

165282

Ø min 180

Ø

60

Ø max 194

250

337

490

325 165

217

Ø min 210

Ø

60

Ø max 234

4. TECHNICAL DATA AND CHARACTERISTICS

4.1 Dimensions

fig. 15 - Dimensional ECO 3,4 P N

48 EN

fig. 16 - Dimensional ECO 5,5 P N

cod. 3541S060 - Rev. 00 - 05/2019

Page 24

ECO P N

7

1

2

3

4

5

9

6

13

11

9

12

8

6

10

4.2 General view and main components

fig. 17

Legend

1 Pressure transducer

2 Controller

3 Burner body

4 Terminal block

5 User interface

6 Heating element

7 Photoresistance

8 Thermostat 85°

9 Burner loading tube

10 Motor

11 Fan

12 Nozzle

13 Grille

4.3 Technical data table

Data Unit ECO 3,4 P N ECO 5,5 P N

Identification codes 0U2F6DXD 0U2F8DXD

Max. heating capacity kW 34.1 55.0 (Q)

Min. heating capacity kW 13.7 30.0 (Q)

Max. fuel delivery kg/h 7.2 11.6

Min. fuel delivery kg/h 2.9 6.3

Electrical protection rating IP X0D X0D

Power voltage/frequency V/Hz 230/50 230/50

Electrical power input W 100 100

Electrical power in lighting W 430 430

Empty weight kg 11 13.5

Hopper capacity liters 195 323

Hopper content kg 140 226

Pellet dimensions (max. diameter/length) mm 6/35 6/35

Combustion chamber negative pressure mbar -0.2 -0.2

cod. 3541S060 - Rev. 00 - 05/2019

49EN

Page 25

ECO P N

4.4 Wiring diagram

L

N

A

6

7

8

9

10

11

12

13

14

15

16

17

OUT

+15V

GND

4

5

230V 50Hz

18

19

20

21

22

23

24

25

26

27

X1

297

L

N

X8

X2

X5

FR

49

114

72

B

L

N

C

139

42

218

DSP13

ABM09

34

2

3

4

5

6

7

8

3.15 A

4

3

2

1

1

2

3

4

5

6

1

239

16

X3

11

10

9

8

7

6

5

4

3

2

1

32

130

E

D

95

N

L

DO NOT CONNECT "LINE" OR "NEUTRAL" SIGNALS COMING FROM THE ELECTRICAL SYSTEM TO

B

THE TERMINAL BLOCK.

ALL CONNECTIONS MUST BE MADE AS SHOWN IN THE WIRING DIAGRAM.

EXTERNAL ELECTRICAL LOADS TO BE WIRED TO THE TERMINAL BLOCK MUST NOT EXCEED 100W

FOR EACH SINGLE OUTPUT. FOR THE CONNECTION OF LOADS AND CONTACT "C" (230V), USE A

DOUBLE INSULATION CABLE.

N.B. Remove the jumper on contacts 9-10 before connecting the remote timer control or room thermostat.

Key - Wiring diagram fig. 18

A electrical power supply

B Motor auger

C Request contact

D Shutdown signal

E Burner reset

FR Photoresistance

16 Fan

32 Heating circulating pump (not supplied)

fig. 18 - Wiring diagram

34 Heating temperature sensor

42 DHW temperature sensor (optional)

49 Boiler safety thermostat

50 EN

cod. 3541S060 - Rev. 00 - 05/2019

72 Room thermostat (optional)

95 Diverter valve (optional)

•Powered (230 Vac) = Heating position

•Not powered = DHW position

114 Water pressure switch (not supplied)

130

139 Remote timer control (optional)

218 Pellet safety thermostat

239 Igniter

297 Air pressure transducer

Hot water tank circulating pump (not supplied)

Loading...

Loading...