Page 1

CONTENTS ENGLISH

General notes pag. 03

Introduction and safety notes pag. 04

First section - FOR THE USER pag. 07

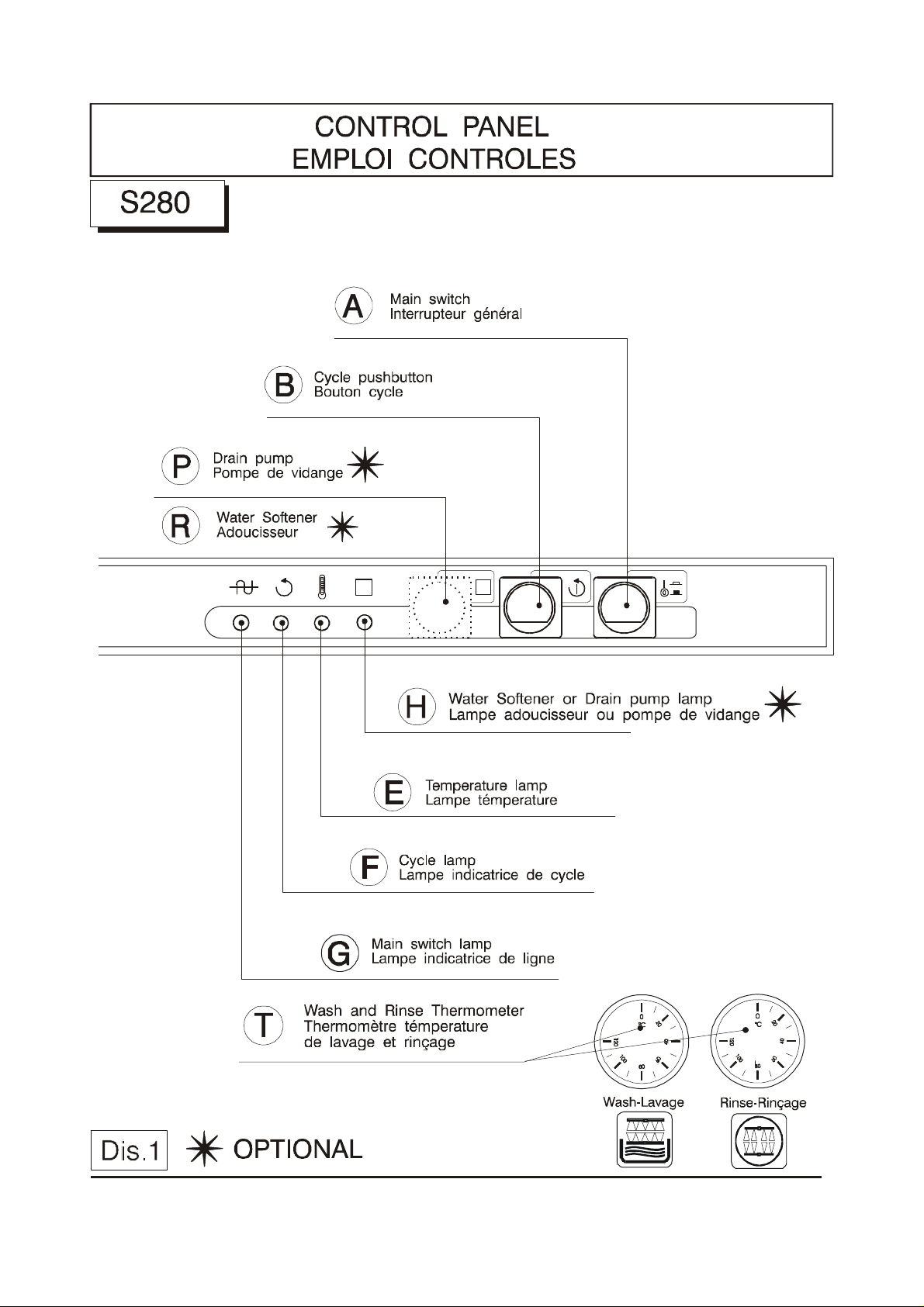

Control panel pag. 08

Working and use, cleansing agents, maintenance, possible troubles pag. 09

Second section - FOR THE INSTALLER pag. 17

Installation pag. 18

Water drain, water connections, electrical connections pag. 19

Regulations scheme pag. 23

Connections scheme pag. 24

Wiring diagram pag. 25

Specifications pag. 27

SOMMAIRE FRANÇAIS

Remarque générales pag. 03

Introduction et normes de securité pag. 05

Première partie - INSTRUCTIONS POUR L'UTILISATEUR pag. 07

Emploi controles pag. 08

Fonctionnement et emploi, detersifs, entretien, inconvenients pag. 13

Deuxième partie - Instructions pour l'installateur: pag. 17

Installation pag. 18

Branchement hydraulique, vidange, branchement electrique pag. 21

Schema regulations pag. 23

Schema branchements pag. 24

Schema electrique pag. 25

Données techniques pag. 27

GENERAL NORMS ENGLISH

Thank You for purchasing our Glasswashing Machine.

Perfect washing-up results as far as hygiene concerns and a correct operation of the dishwashing machine

can be assured only in case the instructions reported in the present manual are carefully followed.

We hope the information reported in the present manual will be helpful to You.

They are based on data and our best updated knowledge.

Carefully read the Instructions reported in the manual, recommendations and suggestions included.

Carefully read the terms of sale too, the ones limiting warranty included.

REMARQUES GENERALES FRANÇAIS

Nous Vous remercions de Votre choix lors de l'achat de votre LAVE-VERRES.

Le fonctionnement parfait de l'appareil et les résultats de lavage optimaux sous le profil hygiénique

sanitaire,peuvent seulement être garantis si tous les avertissements dans ce manuel-ci sont respectés.

Nous souhaitons que les renseignements contenus dans ce manuel vous soient utiles. Ils sont basés sur les

donneés et sur notre meilleure connaissance actuelle.

Lisez attentivement ce qui est énancé dans le manuel, y compris les recommandations et les suggestions.

Lisez aussi les conditions de vente, y compris celles qui limitent la garantie.

Page 2

INTRODUCTION ENGLISH

AND SAFETY NORMS

INTRODUCTION

- The machine S280 is an Industrial glass-washing machine .

- The machine is in conformity to the European Norms 89/336/CEE for the radio noises.

- According to EEC directive no.23 of 19/02/1973 and the law of actuation no.791 of 18/10/1987, our

appliances are built-up according to the good technique notes in force in Italy and abroad.

- Noise level of the machine, less than 70 dB(A).

PRELIMINARY OBSERVATION

Carefully read the instructions reported in the present user manual, as it gives important indications about

safety of installation, operation and maintenance:

- carefully keep the present manual for further consultations;

- the illustrations and drawings showing the machine are intended for general reference only and are

not necessarily accurate in every instance;

- the dimensions and characteristics of the machine, given in this Manual, are not to be considered

binding and may be changed without prior notice;

- having removed the packing material, check that all the equipment is present. If there is any doubt,

do not use it and contact qualified personnel. The packing elements (plastic bags, nails, etc.) should

be kept away from children, because they are dangerous.

GENERAL SAFETY REGULATIONS

THIS SAFETY CODE HAS BEEN COMPILED IN YOUR INTEREST. Strict adherence to these rules will

reduce the risks of injury both to yourself and to others;

Personnel working with this machine must adhere strictly to all statutory safety regulations as well as the

specific rules listed below. Failure to do so may result in personal injury and damage to the machine;

- DO NOT attempt to move, install, set-up or operate this machine until you have read and fully

understood this Manual. If doubt persists, ask your supervisor;

- never leave tools, parts or other loose material on or in the machine;

- Before switching the equipment the equipment on, make sure that the model plate data conforms to

that of the electrical and water distribution network;

- remember that even with the mains indicator in the “OFF” position, the incoming cables are still live;

- BEFORE starting the machine or the cycle, after any maintenance or repair work, make sure all

protective are correctly installed;

- be vigilant at all times, remember that your safety and that of your fellow workers depends on you;

- when moving or lifting the machine, care must be taken to comply with all the relevant regulations

governing such operations;

- installation should be carried out by qualified personnel according to the manufacturer's instructions.

- this equipment should be destined to the use which it has been conceived for. Any other application

should be considered improper and consequently dangerous;

- the equipment should only be used by personnel trained for its use;

SPECIAL SAFETY REGULATIONS

- adjustement and repairs must be carried out only by personnel qualified. Repair carried out by

unskilled personnel may be dangerous;

- perfect washing-up results as far as hygiene concerns and a correct operation of the washing machine

can be assured only in case the instructions reported in the present handbook are carefully followed;

- the machine must be only used by authorized personnel which must comply with sanitary measures;

- do not leave the machine in an environment with temperatures lower than 0°C;

- the machine protection degree is IP21, therefore it should not be washed with direct high pressure

jets of water;

2

Page 3

INSTRUCTIONS FOR THE USER

INSTRUCTIONS POUR L'UTILISATEUR

Page 4

5 6

Page 5

ENGLISH

First Section - FOR THE USER

WORKING AND USE

The glasswashing machine S280 can wash up to 20÷30 baskets every hour.

The machine protection degree is IP21, therefore it should not be washed with direct high pressure jet water;

The objects to be washed should be correctly arranged for a good washing-up result;

We suggest to descale dishes, from time to time, in order to remove calcareous and/or starchy sediments

by soaking it in suitable solutions suggested by your cleansing agent supplier.

If you need to buy new dishes remember the following: Dishes and cups: preference must be given to

china or non-porous pottery articles, with smooth surface. Glasses: choose a glass suitable to be washed

in dish-washing machines. Surfaces must be smooth and bottoms the least concave possible.

OPERATION BEFORE WORKING

BEFORE STARTING THE WORKING OPERATION BE

SURE THAT:

- the cock is open;

- the filter and the overflow are in

their housings;

- the wash arm and the rinse arm are free to

pivot;

- rinse aid dispenser containers are loaded.

THEN PROCEED:

A - Open the door and put into the tank,

possibly over the pump-filter, about 30 gr.

of non-lathering detergent in powder. If the

machine is provided with an automatic dosing

device, control the detergent that is in its

container.

B - Place the dishes in the basket minding to

previously remove all solid waste and fat.

Do not overload baskets, dishes must not be

placed one upon the other, water must have the

way to run on each part of the same.

C - Turn the machine on by wall switch and

push the switch "A" on the ON position.

The green lamp "G" becomes lighted and the

machine loads automatically (with closed Door).

When the level has been reached, the lamp "E"

lights up .

D - Put the basket into the machine.

Close the door and push the button "B".

The green lamp "F" will become lighted and the

cycle start for 2 minutes, including besides the

washing, a five seconds stop and the rinsing of

fifteen seconds with clean water at 82°÷90°C,

will start. At the end of the cycle the lamp "F"

will go out.

Note: The rinse start only when the

temperature of the water is 90°C.

Bear in mind that the opening of the door

interrupts the cycle and therefore the machine

at any moment. Pratically, the opening of the

tank works as an emergency device.

E - Take away the basket and repeat the

operation "D".

Every 10 cycles add about 20 gr. of detergent.

ACHIEVEMENTS

Any deficiency in the washing process is

apparent when dirty residuals are visible. Any

halos might be caused by an insufficient rinsing:

in this case, check that the rinsing jets are clean

and there is a sufficient pressure in the water

distribution network.

In the case that residuals are present, check

that:

• the washing jets are clean

• there is detergent

• the positions of the objects in the rack are

correct.

REGENERATING

(for machines with Water-softener)

If the glasswasher is equipped with a Watersoftener it is possible to Regenerate the water

(water cleaning).

Every evening, after MAINTENANCE

operations, lift the overflow out of the tank,

close the door and push the switch "A" on the

OFF position.

Page 6

Push the button "R" until the lamp "H" is

lighted. After twenty (20) minutes the lamp "H"

is OFF.

Every 6 days add 1 kg of salt in tablet-form in

the bottle placed on the bottom of the tank.

Attention!: the regeneration start only when

the machine is on the OFF position.

SALT CONTROL

Unscrew the plug of the salt container at the bottom of

the tank and put 1 kg coarse salt tablets in it.

Clean the gasket and screw the plug.

The lack of sault in the container causes damages for

the machine because of limestone, besides a defective

washing of glasses and dishes.

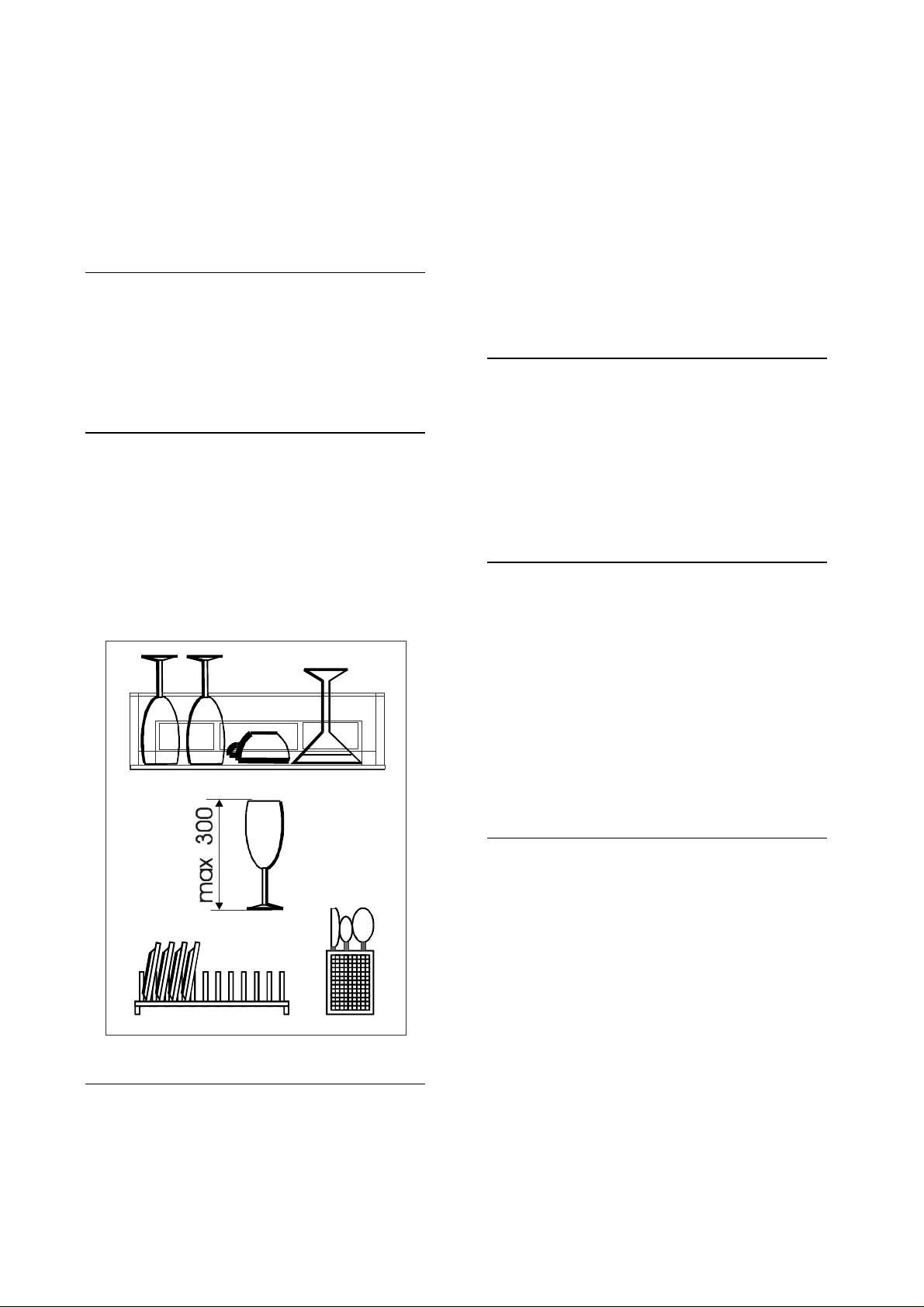

GLASSES POSITIONING

In order to obtain a successful dishwashing, it is

suitable to take care of the way dishes are

placed. It is suitable to place glasses, inside the

wire basket with the concave side towards the

bottom. Place mixed cutlery in a vertical

position into the suitable container minding not

to cram them and with hafts towards the bottom

(see the drawing).

CLEANSING AGENTS

Choice of the suitable cleansing agent is an

essential condition if you want to obtain

extremely good washing results as concerns

hygienic results. It is then important to consider

some points. First of all only highly alkaline and

chlorine-active antifoam products, especially

made for industrial dish-washing machines,

must be used and they must be produced by

well known reliable Firms. Mean concentration

of the cleansing agents in powder must be

1,5÷2,5 g/lt. Mean concentration of liquid

cleansing agents nust be 2÷4 g/lt.

In order to avoid scales and corrosions, put

cleansing agent above water level on the

nearest area of the sucking pump filter, in this

way it will immediately dilute and will not deposit

on the tank bottom.

RINSING ADDITIVES

To grant a perfect rinsing, a quick drying and to

avoid calcareous sediments on glasses and

cups you must add a surfactant on water

(Brightner).

Your cleansing agent supplier's will be able to

suggest the most suitable product. Your

machine is equipped with a rinse-aid dispenser.

Mean concentration used is 0,15 g/lt.

DESCALING

When hard water is used you can find, inside

the machine and also on dishes, calcareous

sediments which must be removed both for

hygienic and operating reasons by a descaling

operation.

Operating process and frequency of this

intervention are suggested by your cleansing

agent supplier who has suitable products,

generally containing phosphoric acid.

In order to avoid damage to the machine do not

increase the quantities and once operations end

rinse abundantly.

SANIFICATION

At least each 30 days it would be useful to do

this operation which guarantees the complete

hygienic conditions of the machine. We suggest

to contact your cleansing agent supplier who will

give you quantity and name of the most suitable

product you can use and that, generally, is an

active chloride powder (100÷200 ppm).

In order to avoid damage to the machine do not

increase the quantities and, once operations

end, rinse abundantly.

7

Page 7

CLEANING AND PREVENTIVE

MAINTENANCE

PRECAUTION AND CLEANING

INSTRUCTIONS

- IMPORTANT : Before carrying out the

cleaning and maintenance operations,

disconnect the equipment from the mains

power supply:

- high temperatures can be reached inside

the machine (90°C). After power supply has

been removed, wait until the machine has

reached the room temperature, before

working on it.

- the machine protection degree is IP21,

therefore it should not be washed with

direct high pressure jets of water;

- never leave tools, parts or other loose

material on or in the machine;

- BEFORE starting machine or cycle, after

any maintenance or repair work, make sure

all protective are correctly installed;

DAY MAINTENANCE

- Disconnect the machine with pushbutton

"A";

- Lift the overflow pipe and let the water

drain out of the tank;

- Wash thoroughly the tank and the filter

housing to remove all impurities;

- Take the filters and clean it under running

water;

- Re-assemble the overflow pipe and the

filters in their housings;

- Check and clean the washing and the

rinsing jets;

- Clean the outer surface of the machine by

using a wet sponge; don't use water jets

because, beside being dangerous they

could damage the electrical parts; don't

use abrasive detergents;

- When the machine is to remain idle for a

long time, drain all the water from the

boiler and from the electropump.

Also leave the wash tank open.

NEVER WASH THE EXTERNAL PART OF

THE MACHINE WITH A WATER JET

POSSIBLE TROUBLES - CAUSES - SOLUTIONS

PROBLEMS CAUSES SOLUTIONS

The machine doesn't catch Main switch is switched off; Turn ON the main switch;

The water doesn't go in Water cock closed; Open water cock;

The Overflow is not in place; Reassemble the Overflow in

place;

Insufficient Washing Wrong detergent or dosage Use anti-foam detergent in the

insufficient; right dosage and never with

cold water;

Low temperature in the tank; Wait untill the water gets hot;

Dirt wash filter; Clean filter;

Insufficient Rinsing Rinsing nozzles blocked; Unscrew and clean nozzles

under running water;

Hydraulic pressure lower than Wait till the pressure is on or buy

1 bar - 100 kPa; a booster pump;

CAUTION! FOR ANY OTHER TROUBLE, CALL SERVICE

8

Page 8

DRAIN PUMP INSTRUCTION

(only for machines with drain pump)

The drain pump automatically starts up at each cycle to discharge the exceeding water

coming from the rinsing cycle.

In order to completely discharge the tank it is necessary to perform the following operations:

1. Switch the machine main switch "A" off;

2. Remove the overflow from the tank;

3. Soon afterwards press the drain pump pushbutton "P" (the lamp "H" is lighted).

After the water has completely flowed down, press the drain pump pushbutton "P" to switch the

pump off.

WARNING!

DO NOT FORGET THE PUSHBUTTON "P" ON "ON" POSITION; THIS CAN CAUSE

DAMAGES TO THE PUMP.

USEFUL HINTS OF STAINLESS STEEL MAINTENANCE

Stainless steel is so called because it is not affected by oxidation,this is due to a thin molecular layer of

oxide on the surface which protects againts further oxidation. There are, howevwr, substances which can

modify or destroy this layer,giving rise to corrosion:besides preventing the protective film of oxide from

reforming,these substances corrode the stainless steel itself and can cause irreparable damage. It is

therefore necessary to prevent this by choosing correct cleaning products and by complying with the

following simple recommendations:never forget that when using these appliances,the first and

fundamental rule is to guarantee that the cleaning products are both non-toxic and hygienic.

Before using any detergent to clean either the stainless steel or the immediate and sorrounding floor area,

always ask your supplier for the most suitable product which does not cause corrosion on the steel itself; the

onset of rust is most commonly caused by the use of unsuitable cleaning materials (strongly acid chlorate

based detergents) or on inadequate maintenance.

Our appliances are made of stainless steel AISI 304 (18/10 type) for exterior panelling,upper tops,tanks etc.

Comply with the following instructions when cleaning and servicing parts in stainless steel.

Ordinary daily maintenance

Carefully and frequently clean the surfaces using a damp cloth; use soap and water or normal detergents,so

long as these do not contain abrasives or chlorine based substances such as sodium hypochlorite

(bleech),hydrochloric acid or other such solutions:These products quickly and irreparably corrode stainless

steel. When cleaning floors underneath or near the appliances, never use the above mentioned products as

vapours or splashes could subject the steel to similar destructive effects.

Only ever rub in the direction of the satining, then thoroughly rinse with clean water and carefully dry.

Rust : water supply pipes, inevitably convey particles of rust dissolved in the water especially in new

installation plants or when taps are opened after a period of inactivity. These iron deposits must not be

allowed to remain on the stainless steel since they produce rust by contamination.

Use suitable products to remove any rust marks,from companies which produce detergents for industrial

use. After application, thoroughly rinse with clean water, neutralizing the action of the product with an

alkaline detergent normally used to clean such appliances or with another specific product.

DO NOT USE METAL MATS TO CLEAN THE STAINLESS STEEL

9

Page 9

INSTRUCTIONS FOR THE INSTALLER

The following instructions are addressed to a qualified personnel, the only one

authorised to carry-out checks and repair, if any.

The Manufacturer declines any responsibility in the case of interventions

made by a non qualified personnel.

INSTRUCTIONS POUR L'INSTALLATEUR

Les instructions suivantes sont adressées à un personnel qualifié, qui est le

seul autorisé à effectuer les vérifications et les réparations éventuelles.

Le constructeur décline toute responsabilité en cas d'interventions effectuées

par du personnel non qualifié.

Page 10

Page 11

ENGLISH

Second Section - FOR THE INSTALLER

During installation, carry-out a good machine levelling, which is a prerequisite for a correct

operation thereof.

The Manufacturer cannot assume any responsability for any damage to persons or

property deriving from the non-observance of the above-specified norms.

For correct installation see draw page 18.

ELECTRICAL CONNECTION

Before connecting the machine,

check to make sure the voltage

outlet of the mains is

the same as the voltage specified

on the data plate of the machine.

A main switch must be installed between

the mains and the machine. This safety

measure

also requires that the minimum distance

between the switch contacts is at least 3

mm and the

disconnection on all poles according to EN

60204 (VDE 113).

Fuses on the main switch must be 16 A .

The mains must be wired to be able to

handle the current drawn by the

machine.The system must

also be provided with a proper ground lead

in accordance with the existings norms.

The electric

cable must be of the following

type H07RN-F.

For the right choice of the cross section

area refer to the following table:

Cross Section area Total loading

mm² A

0,75 < 6

1 6 ÷ 10

1,5 10 ÷ 16

2,5 16 ÷ 25

The electrical safety of this equipment is

only assured if it is connected as follows.

It is necessary to connect the equipment to

an effective ground installation, as

specified by the

electrical safety regulations in force.

Chack that this basic requirement is

complied with and, in case of doubt, ask for

a careful check of

the installation by a qualified personal.

In addition, the equipment shall be part of

an equipotential system, the effectiveness

of which

should be checked according to the

regulations in force.

The connection should be made at the

screw marked by the respective label

located on the

equipment back side ( ).

THE MACHINE SHALL BE

CONNECTED WITH AN EFFECTIVE

GROUND CLAMP.

The manufacturer declines any

responsibility for any damages

caused by lack of an effective

ground installation.

16

Page 12

WATER CONNECTIONS

Carefully comply with any national or

regional regulations in force.

Water installation must have the following

characteristics:

Temperature: 10÷12 °C

Dynamic Pressure : 20 ± 5 psi

If the dynamic pressure is lower than

specified on the data plate of the machine,

it is advisable to install a Pump for pressure

increase.

If the dynamic pressure is higher than 4

bar, it is advisable to install a pressure

reduction.

Hardness: between 7,2 and 12,5 °French.

If the hardness values are higher than

those mentioned above, it is advisable to

install a water-softener.

WORK TEMPERATURES

The machine is provided with a flexible pipe

for the connection with the water-work.

Make sure there are no throttlings along the

pipe.

Carefully comply with any national or

regional regulations in force.

Water temperature >74°C

Rinse temperature 82°÷90°C

DO NOT TAMPER WITH THE

THERMOSTAT CALIBRATION

WATER DRAIN

According to the dimensions of the

drawing; water drain and feeding pipe

should have the same

diameter of the water inlet of the machine.

It must be furnished with a siphon and have

a right slope.

17

Page 13

Loading...

Loading...