Page 1

INSTRUCTIONS MANUAL

POT-WASHING MACHINE

LP31/L-ek

Page 2

2

Page 3

DECLARATION OF CONFORMITY

The following :

LAMBER – Via Italia 6 – 26855 Lodi Vecchio (LO) ITALY

Declare under our responsibility that:

Apparatus: Professional POT WASHER

Trademark: LAMBER

Manufacturer : LAMBER

Mod.

for which this declaration refers to the conformity of the following standards:

Safety of household and electrical appliances - General requirements EN 60335-1(2012) + EC/2014+A11:2014

Safety of household and electrical appliances - Part 2^ Particular requirements for commercial electric dishwashing machines EN

60335-2-58 (2005) + A1 (2008) + A11 (2010).

Household and similar electrical appliances – Electromagnetic fields – Measurement methods for electromagnetic fields of

household appliances and similar apparatus with regard to human exposure EN 62233 (2008)

Limits and methods of measurement of radio disturbance characteristics of electrical motor-operated and thermal appliances for

households and similar purposes, electric tools and similar electric apparatus - EN 55014-1 (2006) + A1 (2009) + A2 (2011)

Limits for harmonic current emissions (equipment input current

61000-3-12 (2011)

Limitation of voltage fluctuations and flicker in low-voltage supply systems for equipment with rated current

(2013) o >16A e 75A EN 61000-3-11 (2000)

Immunity requirements for household appliances, tools and similar apparatus. Product family standard EN 55014-2 (1997) + A1

(2001) + A2 (2008)

Safety of machinery Basic concepts, general principles for design - Basic terminology, methodology – EN ISO 12100 (2010).

on the basis of what is foreseen by the Directives - aufgrund der vorgesehenen Richtilinien:

2014/30/EC and 2006/42/EC.

We decline any responsability for injuries or damage derived from machine misuse, abuse by others or improper machine maintenance or repairs.

(date) Lodivecchio li………………………

The administrator

16 A per phase) - EN 61000-3-2 (2014) or >16A and 75A EN

16 A. EN 61000-3-3

technical file case manager : Ing Roberto Affaba

address : via italia 6 – 26855 – Lodi Vecchio (LO) Italy

Page 4

4

Page 5

WASTE OF ELECTRICAL AND ELECTRONIC EQUIPMENT DIRECTIVE (WEEE,RAEE in Italy) 2002/96/EC AND

SUBSEQUENT 2003/108/EC

The marking shown below indicates that the product cannot be disposed of as part of normal household waste.

Electrical and Electronic Equipment (EEE) can contain materials harmful to health and the environment, and therefore

is subject to separate waste collection: it must be disposed of at appropriate waste collection points or returned to the

distributor against purchase of new equipment of similar type or having the same functions.

The directive mentioned above, to which make reference for further details, provides for punitive actions in case of

illegal disposal of such waste.

Lamber guarantees a percentage of recovery at least of 90% in medium weight for each equipment. The 80% - always

as regards the medium weight- of recovered material is recycled or reused.

LAMBER, manufacturer of this equipment, is enrolled in the Italian WEEE Register – the Register of Producers of

Electrical and Electronic Equipment- from the 18

th

/02/2008 with the number IT08020000000617.

5

Page 6

CONTENTS ENGLISH

General norms pag. 06

Introduction and safety norms pag. 07

First section - FOR THE USER pag. 09

Control panel pag. 10

Working and use, cleansing agents, maintenance, possible troubles pag. 11

Placement of objets pag. 13

Cleaning and preventive maintenance pag. 14

Daily cleaning of the interior of the machine pag. 15

Detergents, rinse additives, descaling, sanitation pag. 18

Inconveniences – Possible causes-remedies pag. 19

Useful advices for the maintenance of stainless steel pag. 21

Second section - FOR THE INSTALLER pag. 23

Installation pag. 25

Unpacking and delivery checks pag. 27

Water drain, water connections, electrical connections pag. 28

Setting of fan’s stop time

pag. 31

Connections scheme pag. 33

Drawback, possible causes and remedies pag. 34

Wiring diagram pag. 38

Specifications pag. 45

GENERAL NORMS ENGLISH

Tank You for purchasing our POT WASHING MACHINE.

Perfect washing-up results as far as hygiene concerns and a correct operation of the dishwashing machine

can be assured only in case the instructions reported in the present manual are carefully followed.

We hope the information reported in the present manual will be helpful to You.

They are based on data and our best updated knowledge.

Carefully read the Instructions reported in the manual, recommendations and suggestions included.

Carefully read the terms of sale too, the ones limiting warranty included.

This appliance in not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance (EN 60335-2-102/7.12).

The dishwasher has to be installed in an area with air recirculation and that complies with the local

work hygiene rules !

6

Page 7

INTRODUCTION ENGLISH

AND SAFETY NORMS

INTRODUCTION

- The machines are Industrial pot-washing machines.

- Noise level of the machine, less than 70 dB(A).

PRELIMINARY OBSERVATION

Carefully read the instructions reported in the present user manual, as it gives important indications about

safety of installation, operation and maintenance:

- carefully keep the present manual for further consultations;

- the illustrations and drawings showing the machine are intended for general reference only and are

not necessarily accurate in every particular;

- the dimensions and characteristics of the machine, given in this Manual, are not to be considered

binding and may be changed without prior notice;

- having removed the packing material, check that all the equipment is present. If there is any doubt, do

not use it and contact qualified personnel. The packing elements (plastic bags, nails, etc.) should be

kept away from children, because they are dangerous.

This appliance in not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance (EN 60335-2-102/7.12).

GENERAL SAFETY REGULATIONS

THIS SAFETY CODE HAS BEEN COMPILED IN YOUR INTEREST. Strict adherence to these rules will

reduce the risks of injury both to yourself and to others;

Personnel working with this machine must adhere strictly to all statutory safety regulations as well as the

specific rules listed below. Failure to do so may result in personal inyury and damage to the machine;

- DO NOT attempt to move, install, set-up or operate this machine until you have read and fully

understood this Manual. If doubt persists, ask your supervisor;

- never leave tools, parts or other loose material on or in the machine;

- Before switching the equipment the equipment on, make sure that the model plate data conforms to

that of the electrical and water distribution network;

- remember that even with the mains isolator in the “OFF” position, the incoming cables are still live;

- BEFORE starting machine o cycle, after any maintenance or repair work, make sure all protective are

correctly installed;

- be vigilant at all times, remember that your safety and that of your fellow workers depend on you;

- when moving or lifting the machine, care must be taken to comply with all the relevant regulations

governing such operations;

- installation should be carried out by qualified personnel according to the manufacturer's instructions.

- this equipment should be destined to the use which it has been conceived for. Any other application

should be considered improper and consequently dangerous;

- the equipment should only be used by personnel trained for its use;

- Repeat regularly the training courses to avoid injury.

- Do not open the door when the machine is working. There is a risk of splashing boiling water

impregnated with detergent;

- When the door is open and the machine is on, do not immerse your bare hands in the washing tank;

- The machine must not be installed in areas at risk of explosion, freezing or not constructed in

accordance with local health and safety norms.

- Touch the control screen only with your fingers, avoiding the use of sharp objects.

- At the end of the working day turn off the water tap and turn the master switch off.

7

Page 8

SPECIAL SAFETY REGULATIONS

- adjustement and repairs must be carried out only by personnel qualified. Repair carried out by

unskilled personnel may be dangerous;

- perfect washing-up results as far as hygiene concerns and a correct operation of the washing

machine can be assured only in case the instructions reported in the present handbook are carefully

followed;

- the machine must be only used by authorized personnel which must comply with sanitary measures;

- do not leave the machine in environment with temperatures inferior to 0°C;

- the machine protection degree is IP55 for Control board and IP21 for machine, therefore it should

not be washed with direct high pressure jets of water;

- If the power cable is defective, it must be replaced by your manufacturer or by a technical

assistance service or by a qualified technician in order to avoid risks.

USE OF CHEMICAL PRODUCTS (detergents, sparkling aid)

CAUTION: Observe the safety notes and dosage data for the use of chemicals. During the use of the chemical

substance wear protective clothing, gloves and protective glasses. Do not mix different cleaning products.

- Observe the safety notes indicated and the dosage recommendations for the use of chemicals.

- When using chemicals, wear protective clothing, gloves and goggles.

- Use only suitable products for industrial dishwashers directly recommended by Lamber.

- Do not mix cleaning products to avoid crystallization that could ruin the detergent dispenser.

- Do not use products that create foam as hand soap or detergent for manual washing.

These products should not be introduced into the machine not even by pre-treatment of dishes.

8

Page 9

INSTRUCTIONS FOR THE USER

9

Page 10

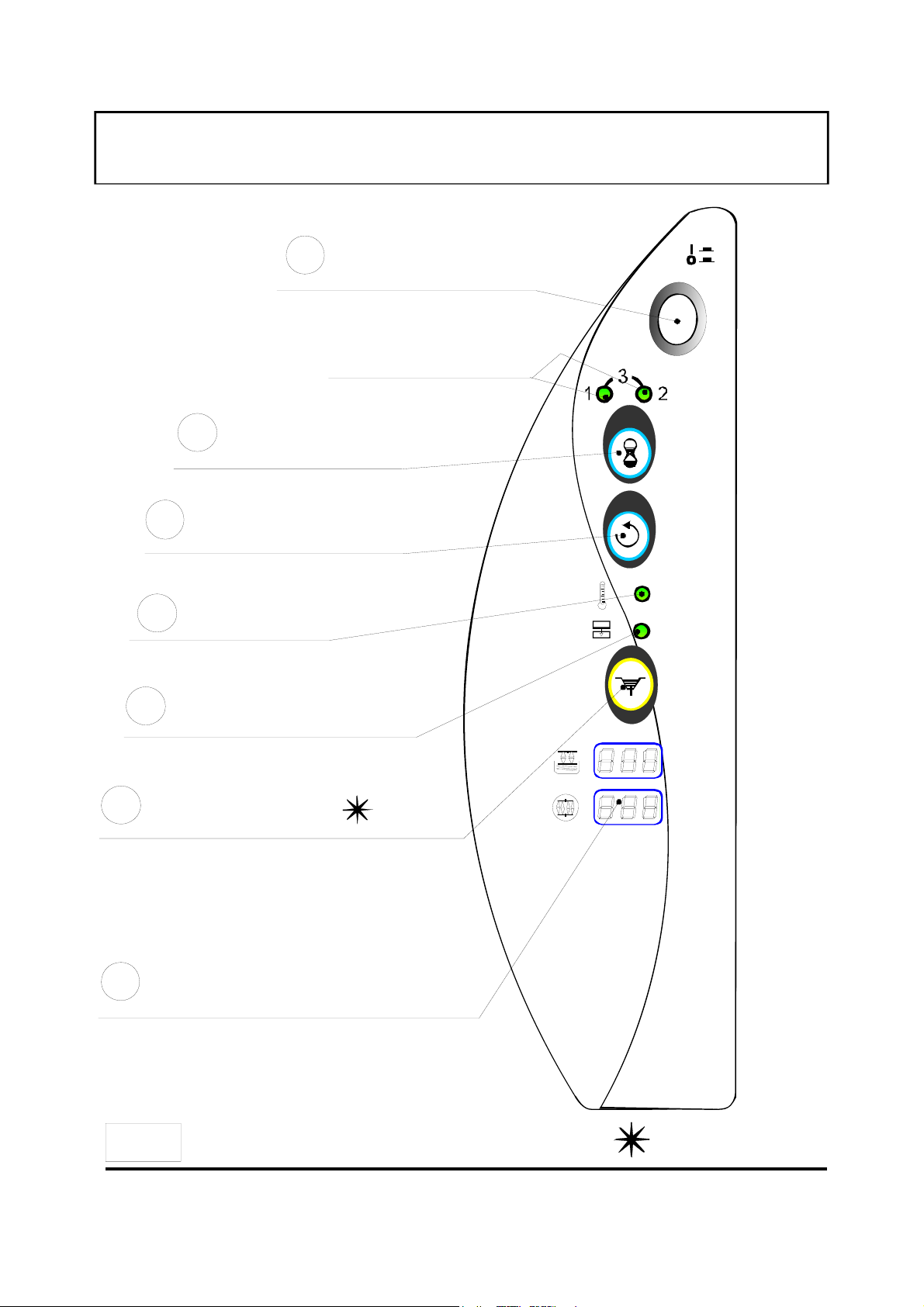

Wash time selection

B

pushbutton

Cycle pushbutton

C

CONTROL PANEL

Main switch

A

Cycle lamp

Tem pé ra tur e l a mp e

D

Door opening lamp

E

Drain pump pushbutton

F

Wash and rinse

G

thermometer

Dis.1

OPTIONAL

Page 11

ENGLISH

First Section - FOR THE USER

WORKING AND USE

The Pot-washing machines can wash up to 30-20-10 baskets every hour.

The machine protection degree is IP21, therefore it should not be washed with direct high

pressure jet water;

The objects to be washed should be correctly arranged for a good washing-up result;

We suggest to descale dishes, from time to time, in order to remove calcareous and/or

starchy sediments by soaking it in suitable solutions suggested by your cleansing agent

supplier.

OPERATION BEFORE WORKING

BEFORE STARTING THE WORKING OPERATION

BE SURE THAT

- the wall-mounted on/off switch is

switched on;

- the water and steam* cocks are open;

- the filters and the overflow are in

their housings;

- the wash arm and the rinse arm are

free to pivot;

* for steam machines only

CAUTION: Observe the safety notes and

dosage data for the use of chemicals. During

the use of the chemical substance wear

protective clothing, gloves and protective

glasses. Do not mix different cleaning

products.

T

HEN PROCEED:

A - Turn the machine on by wall switch

and push the switch "A" to the ON position

(draw 1).

The green lamp "C" becomes lighted and

the machine loads automatically.

B - Lift the inspection doors.

Put the detergent directly into the

tank, by paying

attention to distribute it uniformly on the

filters, the quantity being according to

supplier's instructions.

:

N.B. When using chlorinated detergent, it is

suggested to use an automatic dispenser; if

otherwise, brownish spots might appear on

the surfaces, because of chlorine reactions,

if powering the detergent directly in the

tank.

C - Turn the machines on by wall switch and

push the switch “A” ( Dis.1.).

At this moment the thermometer display

lights up

And the tank fills up. When the tank is full the

control lamp for cycle “2” lights up.

D – Introduce the basket in the ware-washer.

N.B.: When the objects to be washed

present burnt crusts, or a long time is

elapsed from cooking up tothe time of

washing, it is necessary to make a previous

softening in water at 50°C, by using an

appropriate softening product.

The control lamp “E” will flash in case the

door of the dishwasher is open.

Before you start the cycle be sure that the

control lamp “D” is flashing. This means that

the water for the washing cycle and the

rinsing water temperature reached the ideal

temperature for working.

E – Choose the washing period cycle and

push the button “B” between the following

items:

- lamp 1 flashing – short cycle of 3 minutes

Page 12

- lamp 2 flashing – medium cycle 5 minutes

- lamps 1 and 2 lightening at the same time

long cycle of 7 minutes.

The washing period cycle has to be chosen

regarding the dirt that has to be removed.

F – Close the door of the ware-washer.

Push the button cycle “C”

The dishwasher starts the washing with the

period you chosen. Additional to this period

will be a pause of 5 seconds and final

rinsing period of 35 seconds with clean

water about 85° to 90°C.

The control cycle lamp is flashing up to the

end of the complete washing period. Finished

the washing period the control lamps will stop

lightening.

Only for machines with steam condenser!

At the end of the washing, the steam suction

fan starts running automatically. The suction

continues for a time that can be programmed

from 5 to 80 seconds after the rinse end (as

default 20’’).

For the programming, look at the specific

paragraph in the installer section.

Cycle lamps flash till the completion of the

final phase of steam ventilation/suction.

At the end of the cycle, the lamps stop

flashing and an acoustic signal, with a

maximum duration of one minute, informs

that it is possible to open the door.

(Attention! During the cycle, at the door

opening also the steam suction fan starts

running for a maximum time of 20 seconds).

It is possible to interrupt the washing cycle at

any time simply pushing again button “B”.

The lighting of the control lamp “D” means

that the water reached the needed

temperature of 85° to 90°C.

The rinsing will start working of by the

reached temperature need. That means the

period of the washing cycle you chosed will

be extended up to having reached the exact

temperature (thermocontrol).

G - Take away the basket .

In order to make washing keep on,

load another basket and press pushbutton

"C". The cycle will automatically start

again.

- Endless cycle (maximum 15 minutes) :

the door being closed and the cycle put on

(any cycle), keep the button “B” pressed for

3 seconds: lamps 1 and 2 will flash at the

same time (thermocontrol excluded); the

cycle can be interrupted at any time pressing

again button “C” that will let final sequences

start.

- Self-washing cycle : Remove the

overflow from the tank and close the

warewasher door while the machine is on

(time 10 minutes).

DURING WASHING

1) When the machine is running never

change wash time selector position.

2) Only use specific anti-frothing

detergents

3) Deactivate the equipment in case of

fault or malfunction. For repairs, only

address to a technical assistance center

authorised by the manufacturer and impose

the use of original spare parts.

If these conditions are not met, the

equipment safety could be jeopardised.

ACHIEVEMENTS

Any deficiency in the washing process is

apparent when dirty residuals are visible.

Any halos might be caused by an

insufficuent rinsing: in this case, check that

the rinsing jets are clean and there is a

sufficient pressure in the water distribution

network.

In the case that residuals are present,

check that:

• the washing jets are clean

• there is detergent

• the pump suction filter is clean

• the positions of the objects in the rack are

correct.

12

Page 13

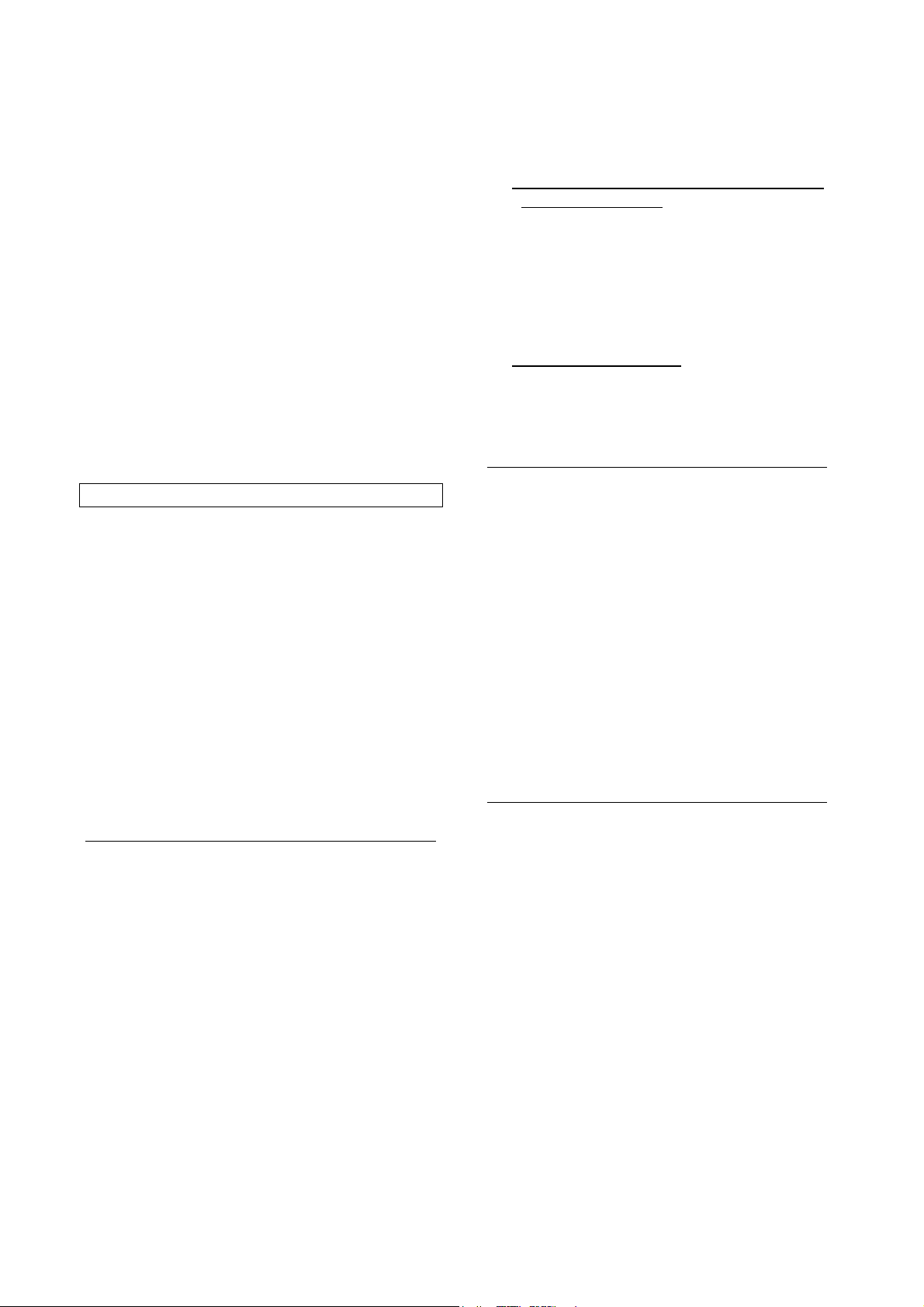

OBJETS POSITIONING

Warning !

Only use the baskets

supplied with the pot-washer

!

LP6-LP8

700

LP31-LP38

700

700

1350

Insert the baskets inside the

machine with the objets as

shown in the picture.

H

Clearance

LP6-LP31: H max=640 mm

LP8-LP38: H max=840 mm

To achieve optimal cleaning results, make sure that objets are correctly stored

inside the machine

LP6-LP8

CLP-70 cod.CC00091 (1x)

Make sure that objets are correctly

stored inside the machine

LP31-LP38

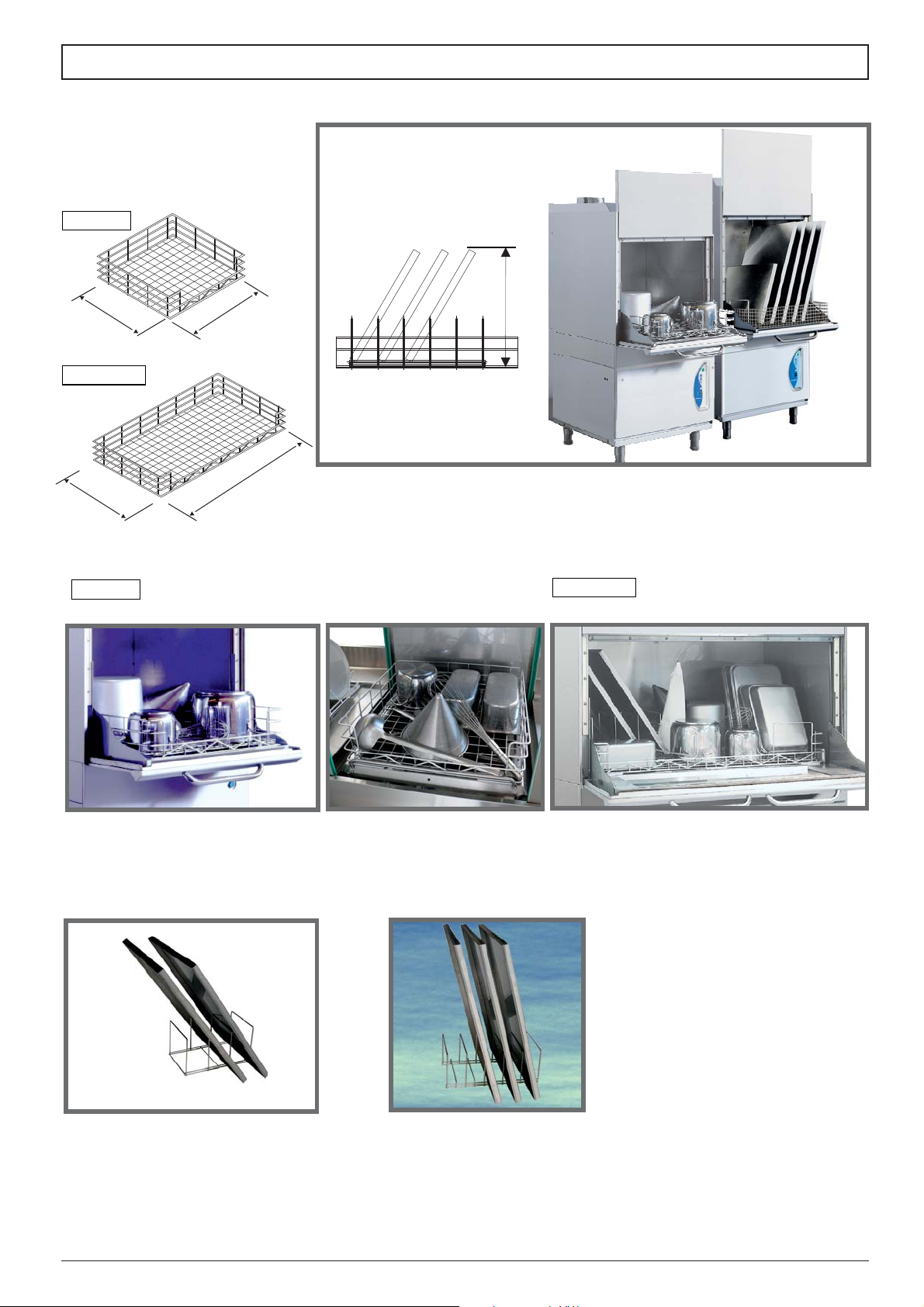

CLP-135 cod.CC00092 (1x)

ITL-3 cod.CC00059

(1x) - LP6-LP6/L

(2x) - LP31

Trays should be positioned concave

side below as shown in the picture.

ITP-8 cod.CC00051

(1x) - LP8-LP8/L

(2x) - LP38

Page 14

CLEANING AND PREVENTIVE

MAINTENANCE

- IMPORTANT : Before carrying out the

cleaning and maintenance operations,

disconnect the equipment from the

mains power supply:

- Follow the directions on the

maitenance in this guide;

- Wear protective clothing and gloves

when challenged elements are impregned

with clearing solution;

- High temperatures can be reached

inside the machine (90°C). After power

supply has been removed, wait until the

machine has reached room temperature,

before working on it.

- Never leave tools, parts or other loose

material in or on the machine;

- Chek that there are no rusting foreign

bodies, because of the material “stainless

steel” could begin to rust. Rust particles can

come from non- stainless steel dishes or

damaged wire baskets.

- Do not wash the machine and the

area surrounding it with fire hydrants, steam

jets of high-pressure cleaners;

- When clearing the floor be careful not

to saturate the base of the machine, in order

to avoid a prolonged stagnation of water;

- To clean the inside of the machine,

use a brush or a soft cloth;

- To clean the machine do not use

abrasive cleaners;

- BEFORE starting machine or cycle,

after any maintenance or repair work,

make sure all protectives are correctly

installed;

Please pay attention to the opening and

closing of the door of the machine. Do not use the

machine if you are wearing clothes/items that could

get entangles in the dishwasher parts. As they can

limit personnel’s regular moving ability!

DAY MAINTENANCE

Attention. Before carrying out cleaning

the inside of the machine, make sure that there

are no foreign objects that could damage the

rusty steel inside the tank. The eventual rust

particles could come from non-stainless steel

dishes, from baskets or damaged water pipes

not rust-proof.

- Disconnect the machine with

pushbutton "A";

- Lift the overflow pipe and let the

water drain out of the tank;

- Wash thoroughly the tank and the

filters housing to remove all

impurities;

- Take the filters and clean it under

running water;

- Re-assemble the overflow pipe and

the filters in their housings;

- Check and clean the washing and the

rinsing jets;

- Clean the filter of the steam condenser

that is placed in the upper part of the

hood;

(only for machines with steam

condenser!)

- Clean the outer surface of the

machine by using a wet sponge; don't

use water jets because, beside being

dangerous they could damage the

electrical parts; don't use abrasive

detergents;

- When the machine is to remain idle

for a long time, drain all the water

from the boiler (the drain

plug is located on the lower

side of the boiler) and from the

electropump. Also leave the wash

tank open.

NEVER WASH THE EXTERNAL PART

OF THE MACHINE WITH A WATER JET

14

Page 15

DAILY CLEANING OF THE INTERIOR OF THE POT-WASHER

Attention. Before carrying out cleaning the inside of the machine, make sure that there are no foreign

objects that could damage the rusty steel inside the tank. The eventual rust particles could come from nonstainless steel dishes, from baskets or damaged water pipes not rust-proof.

Open the door of the machine

Remove disc inox cod.

0800902

Unscrew the lower rinse arm

Remove the washing lower

arm

ATTENTION! Daily

disassemble the lower and

upper wash arms by

working on the „big“ ring

nut, like in the picture.

Unscrew the upper rinse arm

ATTENTION! Daily

disassemble the upper rinse

arm by working on the „big“

ring nut, like in the picture.

Keeping with a hand the

washing arm in place, screw

the disc cod.0201010.

Unscrew the upper washing

arm

Page 16

Remove the tank filters

Remove the frontal tank filter.

Remove the overflow pipe

Remose support

Clean the rinse arm

Clean the pump filter by

means of a brush

Wipe with a cloth the tank

Clean the washing arm

Insert the central support .

and check for any debris on

the bottom.

Page 17

Before insertion of the

overflow check the presence

of the silicon joint

cod.0200304

After insert the overflow in his

place

Remove the frontal tank filter.

Insert all tank filter in their

place

Replace the s.s.disc cod.

0800902

Replace the lower washing

arm

Screw the lower rinse arm.

Make sure is correctly in his

place

ATTENTION! Daily

assemble the lower and

upper wash arms by

working on the „big“ ring

nut, like in the picture.

17

Page 18

Replace the upper wash arm

Control the wash arm is in his

place

Keeping with a hand the

washing arm in place, screw

the s.s. disc cod.0201010

Screw the upper rinse arm.

ATTENTION! Daily

assemble the lower and

upper rinse arms by

working on the „big“ ring

nut, like in the picture.

Completely close the door of

the machine. If there is an

extended downtime, it is

advisable to leave the

dooropen.

Check that the wash and

rinse arms are free to rotate

(upper and lower)

(only for machines with

steam condenser CVP-S)

Clean the filter of the steam

condenser that is placed in the

upper part of the hood;

18

Page 19

DETERGENT and RINSE-AID

Attention. During the use of chemicals is advisable to wear appropriate clothing, such as gloves

and protectives glasses.

It’s therefore important to consider some factors.

Firsf of all, it is necessary to use only strongly anti-foaming Alkali and Chlore Products specific for

industrial dishwasher, manufactured by Companies recognized as seriousness. By way of illustration, we

list a few: Ecolab-Soilax; Henkel; Lever; Diversey; Relativ.

Detergent

The detergent s needed to remove dirt and food from the dishes.

The detergent may by determined in various ways:

- Manually if powder

- Automatically from one external box via a dosing device embedded or external.

The mean concentration of powder detergents should be of 1,5÷2,5 g/liters

For dosing instructions refer to the initial notices before washing.

If automatic, always check the presence of liquid in the tanks and set the dosages by the installer.

.

The mean concentration of liquid detergents should be of 2÷4 g/liters.

In order to avoid corrosion and scalling, the placing of the detergent must be made above the water level in

the area closest to the pump suction filter, so that it enters immediately in solution and does not deposit on

the tank bottom.

The detergent dispenser is not standard on all the machines.

Then check the presence of it in the order data.

Periodically check the presence of product in external tanks!

Rinse-aid

To ensure proper rinsing and fast drying and prevent scale deposits on the dishes, you need to add to the

water an additive such as a surfactant (Rinse-Aid)

The rinse-aid is dosed automatically and its dosage is set by the authorized service technician.

The average concentration of use is of 0.15 g/liter.

The supplier of detergent will be able to recommend the most suitable product.

The machine is equipped with rinse-aid dispenser.

Periodically check the presence of the products in the external tanks!

Page 20

PROBLEMS - CAUSES - SOLUTIONS

PROBLEMS CAUSES SOLUTIONS

The machine doesn't catch Main switch is switched off; Turn ON the main switch;

Power plug is not inserted Insert the power plug

The water doesn't go in Water cock closed; Open water cock;

The Overflow is not in place; Reassemble the Overflow in place

The water inlet hose is blocked Change the water inlet hose

Insufficient Washing Wrong detergent or dosage Use anti-foam detergent in the right

dosage and never with cold water;

Detergent is inappropriate Use a non-foaming detergent and

never in cold water;

Low temperature in the tank; Wait until the water gets hot and wait

for the achievement of the ideal

temperature indicator light stop

blilnking

Dirty wash filter; Clean filter;

The washing arms are not free to

rotate

Insufficient Rinsing Rinsing nozzles blocked; Unscrew and clean nozzles under

Hydraulic pressure lower than 1

bar - 100 kPa;

The machine will not drain Drain hose obstructed Check and remove any obstruction

The filter of the drain pump (if

included) is obstructed

The objets are not dry Rinse-aid has not been used or it

has been used only in small

quantity

On the objets it forms a

layer

In the case of a film of starch,

CAUTION! FOR ANY OTHER TROUBLE, CALL SERVICE

If there is a layer of limestone,

the water is too hard

high temperatures during the prewashing

Check the presence of obstacles or

the correct positioning of the objets

running water;

Wait until the pressure is on or buy a

booster pump;

Clean the filter of pump suction

Set the dosage according to the

manufacture directions

Check that the dosing tubes are not

blocked

Clean the detergent suction filters

placed in the tanks

Also check the entry of the water from

the mains and clean the filter may be

clogged

Check for the presence of operation

of water treatment system external or

embedded

Not perform manual pre-washing with

temperatures above 30°C

20

Page 21

DESCALING

When hard water is used you can find inside the machine and also on dishes calcareous sediments which

must be removed both for hygienic and operating reasons by a descaling operation.

Operating process and frequency of this intervention are suggested by your cleansing agent supplier who

has suitable products, generally containing phosphoric acid.

In order to avoid damage to the machine do not increase the quantities and once operations end rinse

abundantly.

SANIFICATION

At least each 30 days it would be useful to do this operation which guarantees the complete hygienic

conditions of the machine. We suggest to contact your cleansing agent supplier who will give you quantity

and name of the most suitable product you can use and that is generally an active chloride powder

(100÷200 ppm).

In order to avoid damage to the machine do not increase the quantities and once operations end rinse

abundantly.

ATTENTION: Observe the safety notes and dosage data for the use of chemicals. During the use of the

chemical substance wear protective clothing, gloves and glasses. Do not mix different cleaning products.

21

Page 22

USEFUL HINTS OF STAINLESS STEEL MAINTENANCE

Stainless steel is so called because it is not affected by oxidation,this is due to a thin molecular layer of oxide

on the surface which protects againts further oxidation. There are, howevwr, substances which can modify or

destroy this layer,giving rise to corrosion:besides preventing the protective film of oxide from reforming,these

substances corrode the stainless steel itself and can cause irreparable damage. It is therefore necessary to

prevent this by choosing correct cleaning products and by complying with the following simple

recommendations:never forget that when using these appliances,the first and fundamental rule is to

guarantee that the cleaning products are both non-toxic and hygienic.

Before using any detergent to clean either the stainless steel or the immediate and sorrounding floor area,

always ask your supplier for the most suitable product which does not cause corrosion on the steel itself; the

onset of rust is most commonly caused by the use of unsuitable cleaning materials (strongly acid chlorate

based detergents) or on inadequate maintenance.

Our appliances are made of stainless steel AISI 304 for exterior panelling,upper tops,tanks etc.

Comply with the following instructions when cleaning and servicing parts in stainless steel.

Ordinary daily maintenance

Carefully and frequently clean the surfaces using a damp cloth; use soap and water or normal detergents,so

long as these do not contain abrasives or chlorine based substances such as sodium hypochlorite

(bleech),hydrochloric acid or other such solutions:These products quickly and irreparably corrode stainless

steel. When cleaning floors underneath or near the appliances, never use the above mentioned products as

vapours or splashes could subject the steel to similar destructive effects.

Only ever rub in the direction of the satining, then thoroughly rinse with clean water and carefully dry.

Rust : water supply pipes, inevitably convey particles of rust dissolved in the water especially in new

installation plants or when taps are opened after a period of inactivity. These iron deposits must not be

allowed to remain on the stainless steel since they produce rust by contamination.

Use suitable products to remove any rust marks,from companies which produce detergents for industrial

use. After application, thoroughly rinse with clean water, neutralizing the action of the product with an

alkaline detergent normally used to clean such appliances or with another specific product.

DO NOT USE METAL MATS TO CLEAN THE STAINLESS STEEL

22

Page 23

INSTRUCTIONS FOR THE INSTALLER

The following instructions are addressed to a qualified personnel, the only one

authorised to carry-out checks and repair, if any.

The Manufacturer declines any responsibility in the case of interventions

made by a non qualified personnel.

23

Page 24

Page 25

Page 26

Page 27

ENGLISH

Second Section - FOR THE INSTALLER

UNPACKING AND DELIVERY CHECKS

When the case with the machine has been received, unpack it as follows:

- Remove the upper cover and the wooden case side walls, take care not to damage the

machine,

- Remove possible accessories boxes,

- Remove the protecting cellophane,

- Make sure that the machine has not been damaged during transport,

- Make sure that all covers and panels have been correctly fixed and that no loosen part is

present,

- Visually inspect that all electrical components are integral.

TRANSPORT AND INSTALLATION

- To lift and transport the machine, insert the truck forks under the frame connected to the points

indicated by the yellow adhesives applied on the machine front side (see draw below).

draw “A”

- Before plugging the machine, make sure that the supply voltage of the domestic wiring system

and the water supply from water connection corresponds to the ones reported on the rating

plate

- Installation should be carried out by qualified personnel according to the manufacturer's

indications

During instalation, it is recommended to level the machine in order to ensure a correct operation.

The Manufacturer cannot assume any responsability for any damage to persons or

property deriving from the non-observance of the above-specified norms.

For correct installation see draw page 25.

Page 28

ELECTRICAL CONNECTION

WARNING:: Danger to life due to live

components!

During all electric operation, disconnect the machine

from the network and verify the absence of

power.

The machine and its accessories must be connected

in accordance with local regulations, by a

Company specialized in electrical installations

and authorized by competent authorities.

Before connecting the machine,

check to make sure the voltage

outlet of the mains is the same as

the voltage specified on the data

plate of the machine.

A main switch must be installed between

the mains and the machine. This safety

measure also requires that the minimum

distance between the switch contacts is at

least 3 mm and the disconnection on all

poles according to EN 60204 (VDE 113).

Fuses on the main switch must be 20 A.

The mains must be wired to be able to

handle the current drawn by the

machine.The system must also be provided

with a proper ground lead in accordance

with the existings norms. The electric cable

must be of the following type H07RN-F.

For the right choice of the cross section

area refer to the following table:

mod. Volt

LP-6-8-ek

electric 13 20 2,5

steam 4 8 2,5

PLP31-38ek

electric 26 38 10

steam 6 12 2,5

400/3

400/3

total

power

(kW)

The electrical safety of this equipment is

only assured if it is connected as follows.

It is necessary to connect the equipment to

an effective ground installation, as specified

by the electrical safety regulations in force.

Current

intensit

y max

(A)

Cable

(mm²)

Chack that this basic requirement is

complied with and, in case of doubt, ask for

a careful check of the installation by a

qualified personal.

In addition, the equipment shall be part of

an equipotential system, the effectiveness

of which should be checked according to

the regulations in force.

The connection should be made at the

screw marked by the respective label

located on the equipment back side (

).

MOD.

PT850-LP6-8

L

170

P

150

MOD.PT1500-LP31-38

L

180

630

DIS-CAVO-PT

THE MACHINE SHALL BE

CONNECTED WITH AN EFFECTIVE

GROUND CLAMP.

The manufacturer declines any

responsibility for any damages

caused by lack of an effective

ground installation.

P

L- I ng r e sso c a v o

P-Connessione alla

cassetta elettrica

Page 29

WATER CONNECTIONS

Carefully comply with any national or

regional regulations in force.

Water installation must have the following

characteristics:

Temperature: 55°C

Dynamic Pressure 2 ÷ 4 bar

(200÷400 kPa).

If the dynamic pressure is lower than

2 bar, it is advisable to install a Pump for

pressure

increase. If the dynamic pressure is higher

than 4 bar, it is advisable to install a

pressure reduction.

Hardness: between 7,2 and 12,5 °French.

If the hardness values are higher than

those mentioned above, it is advisable to

install a

water-softener.

TEMPERATURES

Water temperature 55°-60°C

Rinse temperature 80°-85°C

DO NOT TAMPER WITH THE

THERMOSTAT CALIBRATION

ATTENTION !

At the first test , be sure the boiler is full of

water, make four (n.4) one minute complete

cycles (WASHING + RINSING).

WATER DRAIN

Reachable from the machine front side after

opening the front panel (to do this turn the

two front screws out);

Arrange a discharge at floor level provided

with siphon and connect to the floor drain by

means of a hose provided with an adequate

inclination. Make sure the drain hose is not

choked in any way.

Make sure the drain hose is resistant to a

temperature of 70 °C.

Carefully comply with any national or

regional regulations in force.

STEAM FEEDING *

As far as steam feeding is concerned,

connect to the machine fittings indicated in

the installation drawings. In order to make

the equipment independent from the

general steam distribution network, it is

necessary to use gate and 1" gas on/off

valves.

This type of feeding should be supplied at a

pressure ranging from 1bar (100°C) to 2bar

(121°C).

The steam used should be absolutely

saturated and dry.

STEAM EXHAUST *

The condensed steam exhaust shall have

an appropriate slope toward the recovery

installation or a blow-by pump, in order to

guarantee an autonomous scavenging of

the condensed steam.

*

for steam machines only

29

Page 30

VAPOUR EXHAUST *

During washing and rinsing cycles, vapours

come out of the upper chimney.

To convey these vapours, connect with the

cap as showed in the drawing.

30

Page 31

Setting of fan’s stop time

(Only for machines with steam condenser CVP)

At the end of the washing, the steam suction fan starts running automatically. The suction continues for a

time that can be programmed from 5 to 80 seconds after the rinse end .

As default, the fan’s functioning time is programmed for a 20’’ duration from the ending of the final rinse at

every wash cycle.

It’s anyway possible to program the duration of this phase according to one’s own requirements.

After having programmed the seconds for the additional functioning of the fan, configure the dip-switch on

the PCB board, that is inside the control box, by following the instructions below.

FAN SETTING PROGRAMMING

1 - With the machine stopped, check the position of the dip-switches on the electronic board and

memorise it;

ON

LP-CV

2- Then set the dip-switch in accordance with the following table, according to the seconds that are

programmed for the fan’s additional functioning;

123

4

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1234

123

1234

1234

1234

1234

SECONDI

SECONDS

5

SEKUNDEN

SECONDI

4

SECONDS

20

SEKUNDEN

SECONDI

SECONDS

35

SEKUNDEN

SECONDI

SECONDS

50

SEKUNDEN

SECONDI

65

SECONDS

SEKUNDEN

SECONDI

SECONDS

80

SEKUNDEN

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

123

123

1234

1234

1234

SECONDI

4

SECONDS

10

SEKUNDEN

SECONDI

4

SECONDS

25

SEKUNDEN

SECONDI

SECONDS

40

SEKUNDEN

SECONDI

SECONDS

55

SEKUNDEN

SECONDI

SECONDS

70

SEKUNDEN

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

1234

1234

1234

1234

123

SECONDI

SECONDS

15

SEKUNDEN

SECONDI

SECONDS

30

SEKUNDEN

SECONDI

SECONDS

45

SEKUNDEN

SECONDI

SECONDS

60

SEKUNDEN

SECONDI

4

SECONDS

75

SEKUNDEN

3- Open the door of the machine;

4 - Press the START button;

5 - Keep the START button pressed and turn the machine ON by using the “A” switch;

6 - Wait for the lighting of the “E” lamp;

7 - Turn the machine OFF by using the “A” switch;

8 - Reset the dip-switches according to the original position of the washing period programming;

LP-CV

ON

123

4

Page 32

How to disable-enable the AUTOMATIC START

By default the machine is provided with MANUAL start by cycle pushbutton ‘C’.

It’s possible to set (enable) the AUTOMATIC start of the cycle at the door closing by following the

instructions below:

1. Turn on the machine by wall switch and press switch ‘A’ that you can find on the control panel. At

this moment the thermometers’ displays light up and the tank fills up. When the tank is full, the cycle

lamp lights up,

2. Turn the machine off by pressing pushbutton ‘A’,

3. Press the Wash time selection pushbutton ‘B’,

4. Always keeping pressed the pushbutton ‘B’, turn the machine on by pressing switch ‘A’,

5. Keep the pushbuttons pressed for 7 seconds,

6. Release the pushbuttons and turn the machine off by pressing switch ‘A’.

To enable again the MANUAL start function, follow the same steps.

32

Page 33

CONNECTIONS SCHEME

Black

Black

Black

Staples

Black

Black

Black

Staples

Page 34

A LIST OF DRAWBACKS POSSIBLY OCCURRING WITH THE

USE OF THE POT-WASHING MACHINE, THEIR CAUSES AND

POSSIBLE REMEDIES

DRAWBACK POSSIBLE CAUSES AND REMEDIES

Lamp "C" does not turn on a) check that the wall-mounting switch is

ON and the respective fuses are not burnt.

b) check that fuses of the transformer

are not burnt.

Lamp "G" of overload cut-out a) check the thermal overload protections of

devices turning ON. each remote control switch and restore

the one that has tripped.

b) check that the power supply voltage is

not subject to variations in excess of 6% of

the nominal value.

c) check that the current absorbed by the

motor does not exceed the rated values.

The tank does not fill up a) check that pressure switches are correctly

calibrated or that they are not out of service.

b) check that the cock is open and there is

water inside the net

c) check that the overflow is in the

respective position.

d) check that the coil of the solenoid valve is

not broken and that voltage is fed there to.

DRAWBACK POSSIBLE CAUSES AND REMEDIES

Page 35

The tank does not stop being a) check that the air traps of the pressure

filled upon reaching switches have no porosities and the

the desired level connection pipe is not disconnected.

b) check that the pressure switches are

working and correctly calibrated.

c) check that there is no dirt in the solenoid

valve. This drawback can be noted because

the machine continues to load water even if

the main on/off switch is off.

Insufficient washing a) check that the detergent is effective, is of

the type recommended for industrial pot washing machines, and it is proportioned for

the right concentration.

b) check that the detergent container, if

installed,is not empty and operates

correctly.

c) check that the nozzles of the washing

arms are not clogged. If necessary, clean

them.

d) check that the tank temperature is the

specified one.

e) one or several pumps don't work, in

this case check that:

- the overload cut-out did not cut out the

pump in question and, if necessary, restore

it (this drawback is displayed by lamp "G"

turning ON).

- the coil of the respective remote control

switch is not broken.

- the pump is not blocked or rotates in the

reverse direction.

35

Page 36

DRAWBACK POSSIBLE CAUSES AND REMEDIES

Tank temperature insufficient a) check that the thermostat is not faulty or

not calibrated.

b) check that the temperature of the feeding

water is in the range from 50°-0/10°C, as

specified.

c) check that the thermostat is set to the

right temperature and operates correctly.

d) check that the coil of the remote control

switch for the tank heating element is not

broken (this is for electric heating machines

only).

e) check that the heating element is working

correctly

Insufficient rinsing Prior to checking the rinsing system make

sure that the washing system operates

correctly, because a good rinsing also

depends on a correct washing. Having

ascertained that the washing works

correctly, check that:

a) the dynamic pressure of the feeding

water is between 2 and 4 bar.

b) the jets are not clogged by calcareous

residuals.

c) solenoid valves operate correctly.

d) the water inlet filter is not clogged.

e) the boiler is not scaled to such an

extent as to limit the water flow rate.

Insufficient rinsing temperature Check that:

a) the thermometer is not broken

or not calibrated.

b) the temperature of the feeding water is in

range from 55° to 65°C, as specified.

c) the dynamic pressure of the feeding

water is between 2 and 4 bar.

36

Page 37

DRAWBACK POSSIBLE CAUSES AND REMEDIES

If the drawback is not due to any of the

causes listed here above, proceed as follows:

In the case of electrical heating machines

1) check that the coil of remote control

switch MT3 is not broken.

2) check that the safety thermostat did

not trigger.

3) check all elements of boiler heater.

In the case of steam heating machines

1) check that the steam inlet gate is open

and is present at a pressure not less than

0,5 bar (50 kPa).

2) check that the condensed steam

drainage filter is not clogged.

3) check that the steam solenoid valve

operates correctly.

4) check that the inlet steam filter is not

clogged to such an extent as to prevent the

normal flow rate.

5) check that the condensed steam outlet

pipe can freely drain by drop.

6) check that the pipe coil is not scaled to

such an extent as to limit heat exchange

thereof.

The manufacturer declines any responsibility for any printing errors contained in this booklet. The

manufacturer also reserves the right to make any modifications to its products that don't affect the

basic characteristics thereof.

37

Page 38

Page 39

Page 40

Page 41

Page 42

SCHEDA ELETTRONICA FICHE ELECTRONIQUE

P.C.BOARD ELEKTRONISCHE STEURUNG

.

.

FU NZI O NE CICLO

FONCT IO N CY CLE

CYCLE FUNCT I O N

ABLAUFSAUFGABE

CI CLO MA NU A LE

CYCLE M A NUEL

MANUA L CY CLE

HANDABLAUF

ON

CICLO AUTOMA TICO

CYCLE AUTOMATIQUE

AUTOMATI C CY CLE

SELBSTTÄTIGER

ON

1

4

1122334

- TABELLA SELEZIO NE

TE M P I DI RISCIACQUO

- TABLEAU SELECTION

TE M P S DE RINÇAGE

- RINSE TIME

SELECTI O N TABLE

- AUSWAHL ST AFEL

FÜR S P ÜLUNGSZEIT

2-4

ON

1122334

ON

- TABELLA SELEZIO NE TEMPI DI LAVAGGI O

- TABLEAU SELECTION TEMPS DE LAVAGE

- WASH TI ME SELECTIO N TABLE

- AUS W A HLS TAFEL F ÜR S P ÜLUNGSZ E IT

DIP

ON

ON

lavaggio-lavage

washing-wasch

risciacquo-rinçage

rinse-spülung

LED1=ON LED2=ON LED1+2=ON

120”

4

1122334

180”

PC-BO ARD

180”

300”

3

240”

420”

ON

ON

ON

ON

DIP

1122334

112

334

2

12”+12"

15”+15"

18”+18"

4

21”+21"

4

consum o acqua

consom m ati on eau

water consumption

wasserverbrauch

3+3

= 6 Lt

3,75+3,75

= 7,5 Lt

4,5+4,5

= 9 Lt

5,25+5,25

= 10,5 Lt

Cod.0500403

FA1

FA2

FA3

FA4

FA5

FA6

FA7

FA8

REL 3 REL4

4

B

A

REL 1

1234

REL 2

Cod.0300828

B

FA9

FA10

A

FA11

FA13

FA12

Cod.0502001-LP6ek-LP8ek

LP31Lek-LP38Lek -PT 1500L-ek

0300828-SCHEDA ELETTRONICA-LP-ek-2015

FA 14

FA15

Page 43

mm

Nr.

Min.

Min.

mm

mm

mm

l

V

W

W

W

W

kg/V

kg/V

A

Lt

W

Lt

l

°C

Bar

Bar

°F

°C

kg

"G

kg

"G

mm

dB(A)

W

2'-3'-4' 2'-3'-4' 2'-3'-4' 2'-3'-4'

SPECIFICATIONS - FRONTAL POT-WASHING MACHINES

8 8 2x8 12 2x8 12

LP6-ek LP8-ek LP31-ek LP31/L-ek LP38-ek LP38/L-ek

20/12/8 20/12/8 20/12/8 20/12/8 20/12/8 20/12/8

885x965x1835 885x965x2035 1535x965x1835 1535x965x1835 1535x965x2035 1535x965x2035

3'-5'-7' 3'-5'-7' 3'-5'-7' 3'-5'-7' 3'-5'-7' 3'-5'-7'

865 865 865 865 865 865

640 840 640 640 840 840

700x700 700x700 1350x700 1350x700 1350x700 1350x700

550 550 550 550 550 550

9000 9000 9000 9000 9000 9000

2x1500 2x1500 4x1500 2x3000 4x1500 2x3000

400 V3/N~50Hz 400 V3/N~50Hz 400 V3/N~50Hz 400 V3/N~50Hz 400 V3/N~50Hz 400 V3/N~50Hz

10 10 10 10 10 10

(steam)

16 10 30 30 30 30

9000 9000 2x9000 2x6000 2x9000 2x6000

(steam)

12000 12000 24000 18000 24000 18000

(steam)

26/4000 26/4000 40/8950 40/8950 40/8950 40/8950 kg/W

20 20 38 38 38 38

110 110 177 177 177 177

669999

2 ÷ 4 2 ÷ 4 2 ÷ 4 2 ÷ 4 2 ÷ 4 2 ÷ 4

50 ÷ 55 50 ÷ 55 50 ÷ 55 50 ÷ 55 50 ÷ 55 50 ÷ 55

0,5 ÷ 2 0,5 ÷ 2 0,5 ÷ 2 0,5 ÷ 2 0,5 ÷ 2 0,5 ÷ 2

120-72-48 120-72-48 240-144-96 240-144-96 240-144-96 240-144-96

5 ÷ 10 5 ÷ 10 5 ÷ 10 5 ÷ 10 5 ÷ 10 5 ÷ 10

80 ÷ 90 80 ÷ 90 80 ÷ 85 80 ÷ 85 80 ÷ 90 80 ÷ 90

1" 1" 1" 1" 1" 1"

266 200 220 220 220 220

295 280 300 300 300 300

1"1/2 1"1/2 1"1/2 1"1/2 1"1/2 1"1/2

si si si si si

<70 <70 <70 <70 <70

1070x930xh2080 1125x1000x2300 1700x1150x2200 1700x1150x2200 1700x1150x2400 1700x1150x2400

30 30 30 30 30 30

MODEL

DIMENSIONS l x w x h

WASHING CAPACITY baskets/H

WASH CYCLE

BASKET SIZE

WORK HEIGHT

DAYLIGHT

VOLTAGE

WASHING PUMP

RINSING PUMP

WASH TANK ELEMENTS (electric)

RINSE TANK ELEMENTS (electric)

TOTAL RATING (electric)

MAX CURRENT INTENSITY

TANK CAPACITY

BOILER CAPACITY

WATER CONNECTION

CYCLE WATER CONSUMPTION

HOUR WATER CONSUMPTION

WATER PRESSURE

STEAM PRESSURE

WATER HARDNESS

RINSING WATER TEMPERATURE

WATER INLET

WATER OUTLET

NET WEIGHT

GROSS WEIGHT

PACKING DIMENSIONS

NOISE

OPTIONALS

AUTODRAINING WASHING PUMP

DRAIN PUMP

Loading...

Loading...