Page 1

CONTENTS ENGLISH

General norms pag. 03

Introduction and safety norms pag. 04

Learn to use the appliance pag. 06

First section - FOR THE USER pag. 07

Control panel pag. 08

Working and use, cleansing agents, maintenance, possible troubles pag. 09

Dishes positioning pag. 11

Second section - FOR THE INSTALLER pag. 21

Installation pag. 22

Water drain, water connections, electrical connections pag. 23

Detergent replacement and cleaning of the detergent pump hoses pag. 25

Vacuum Breaker Valve connection pag. 26

Connections scheme pag. 31

Regulations scheme pag. 32

Wiring diagram pag. 33

Components pag. 36

Specifications pag. 37

SOMMAIRE FRANÇAIS

Remarque générales pag. 03

Introduction et normes de securité pag. 05

Faites connaissance avec l'appareil pag. 06

Première partie - INSTRUCTIONS POUR L'UTILISATEUR pag. 07

Emploi controles pag. 08

Fonctionnement et emploi, detersifs, entretien, inconvenients pag. 15

Placement de la vaisselle pag. 17

Deuxième partie - Instructions pour l'installateur: pag. 21

Installation pag. 22

Branchement hydraulique, vidange, branchement electrique pag. 27

Substitution du produit lessiviel et nettoyage des tuyaux du doseur de lavage pag. 29

Connection soupape antivide pag. 30

Schema branchements pag. 31

Schema regulations pag. 32

Schema electrique pag. 33

Composants pag. 36

Données techniques pag. 37

Page 2

WASTE OF ELECTRICAL AND ELECTRONIC EQUIPMENT DIRECTIVE (WEEE,RAEE in Italy) WASTE

OF ELECTRICAL AND ELECTRONIC EQUIPMENT DIRECTIVE (WEEE,RAEE in Italy) 2002/96/EC AND

SUBSEQUENT 2003/108/EC

The marking show n below indicates that the product c annot be disposed of as part of normal household w aste.

Electrical and Electronic Equipment ( EEE) can contain materials harmful to health and the environment, and therefore

is subject to separate w aste collection: it must be disposed of at appropriate waste collection points or returned to the

distributor against purchase of new equipment of similar type or having the same functions.

The directive mentioned above, to w hich make reference for fu rther details, provides for punitive actions in case of

illegal disposal of such waste.

LAMBER, manufacturer of this equipment, is enrolled in t he Italian WEEE Register – t he Register of Producers of

Electrical and Electronic Equipment- from the 18

th

/02/2008 with the number IT08020000000617.

DIRECTIVE “RAEE” 2002/96/CE ET MODIFICATIONS SUCCESSIVE 2003/108/CE CONCERNANT LES REBUTS

D’APPAREILLAGES ÉLECTRIQUES ET ÉLECTRONIQUES

Le symbole ci-dessous indique que le produit ne peut pas être éliminé comme un normal déchet urbain.

Les appareillages électriques et électr oniques (AEE) peuvent contenir des matéri aux nocifs pour l’env irronnement et la

santé et doivent donc être objet de collecte différenciée : éliminés donc auprès de dècharges prévues à cet effet ou

rendus au distributeur pour l’achat d’un nouveau, de type équivalent ou ayant les mêmes fonctions.

La réglementation susmenti onnée, à laquelle nous vous renvoy ons pour les détails et les approfondissements

ultérieurs, prévoit des sanctions pour la mise en décharge abusive des dits rebuts.

LAMBER, constructeur du présent appareillage, est inscrit dans le Bu reau National des producteurs de AEE

(Appareillages Electriques et Electroniques) à partir du 18/02/2008 avec le numéro IT08020000000617

Page 3

GENERAL NORMS ENGLISH

Tank You for purchasing our Dishwashing/Glasswashing Machine.

Perfect washing-up results as far as hygiene concerns and a correct operation of the dishwashing machine

can be assured only in case the instructions reported in the present manual are carefully followed.

We hope the information reported in the present manual will be helpful to You.

They are based on data and our best updated knowledge.

Carefully read the Instructions reported in the manual, recommendations and suggestions included.

Carefully read the terms of sale too, the ones limiting warranty included.

REMARQUES GENERALES FRANÇAIS

Nous Vous remercions de Votre choix lors de l'achat de votre LAVE-VAISSELLE/LAVE-VERRES.

Le fonctionnement parfait de l'appareil et les résult ats de lavage optimaux sous le profil hygiénique

sanitaire,peuvent seulement être garantis si tous les avertissements dans ce manuel-ci sont respectés.

Nous souhaitons que les renseignements contenus dans ce manuel vous soient utiles. Ils sont basés sur les

donneés et sur notre meilleure connaissance actuelle.

Lisez attentivement ce qui est énancé dans le manuel , y compris les recommandations et les suggestions.

Lisez aussi les conditions de vente, y compris celles qui limitent la garantie.

Page 4

4

INTRODUCTION ENGLISH

AND SAFETY NORMS

INTENDED USE

The dishw asher/glasswasher may only be used for cleaning plates, cups, dishes, and similar restaurant w are and

commercial catering. Any change in design or use of the dish washer carried out without the written permission will lead to

warranty nullification.

If damage is caused to the dishwasher due to failure to observe the instructions given in this manual, no claims under the

warranty agreement can be submitted to.

PRELIMINARY OBSERVATION

Carefully read the instructions reported in the present user manual, as it gives import ant indications about safety of

installation, operation and maintenance:

- carefully keep the present manual for further consultations;

- the illustrations and draw ings show ing the machi ne are intended for general reference only and are not

necessarily accurate in every particular;

- the dimensions and characteristics of the machine, given in this M anual, are not to be considered binding and

may be changed without prior notice;

- having removed the packing material, check that all the equipment is present. If there is any doubt, do not use it

and contact qualified personnel. T he packing elements (pla stic bags, nails, etc.) should be kept aw ay from

children, because they are dangerous.

GENERAL SAFETY REGULATIONS

THIS SAFETY CODE HAS BEEN COMPILED IN YOUR INTEREST. Strict adherence to these rules will reduce the risks

of injury both to yourself and to others;

Personnel working with this machine must adhere strictly to all statutory safety regulations as well as the specific rules

listed below. Failure to do so may result in personal inyury and damage to the machine;

- DO NOT attempt to move, install, set-up or operat e this machine until you have read and fully understood this

Manual. If doubt persists, ask your supervisor;

- never leave tools, parts or other loose material on or in the machine;

- Before switching the equipment the equi pment on, make sure that the model plate data conf orms to that of the

electrical and water distribution network;

- remember that even with the mains isolator in the “OFF” position, the incoming cables are still live;

- BEFORE starting machine o cy cle, after any maintenance or repair work, make sure all protective are correctly

installed;

- be vigilant at all times, remember that your safety and that of your fellow workers depend on you;

- when moving or lifting the machine, care must be taken to comply with all the relevant regulations governing such

operations;

- installation should be carried out by qualified personnel according to the manufacturer's instructions.

- this equipment should be destined to the use w hich it has been conceived for. Any other application should be

considered improper and consequently dangerous;

- the equipment should only be used by personnel trained for its use;

SPECIAL SAFETY REGULATIONS

- adjustement and repairs must be carried out only by personnel qualified. Repair carried out by unskilled personnel

may be dangerous;

- perfect washing-up results as far as hy giene concerns and a correct operation of the washing machine can be

assured only in case the instructions reported in the present handbook are carefully followed;

- the machine must be only used by authorized personnel which must comply with sanitary measures;

- do not leave the machine in environment with temperatures inferior to 0°C;

- the machine protection degree is IP21, therefore it should not be washed with direct high pressure jets of water;

- If the power cable is defective, it must be replaced by your manufacturer or by a technical assistance

service or by a qualified technician in order to avoid risks.

RESIDUAL RISK

Although the appliance is equipped with the above-mentioned safety devices, danger of burns to upper limbs persists.

As already mentioned in the paragraph “DURING WASHING OPERATIONS”, avoid dipping your naked hands into soapy

hot water of the tanks. This can cause burns and skin irritations.

In this case, immediately rinse them with plenty of water.Anyway consult the product card of the detergent employed.

Page 5

5

INTRODUCTION FRANÇAIS

ET NORMES DE SECURITE'

EMPLOI DE LA MACHINE

Le lave-vaisselle/lave-verres peut être utilis é seulement pour le lavage des assiettes, tasses, et vaisselle similaire des

restaurants et de la restaurat ion collective. T out changement dans design ou emploi de la lave-vaisselle fait sans

l’autorisation écrite du constructeur va annuler la garantie.

Si le dommage à la lave-vaisselle est causé par une insuffi sante ou mauvaise observation des instructions qui se

trouvent dans ce manuel d’instructions, aucune garantie ne sera accordée.

REMARQUES PRELIMINAIRES

Lisez attentivement les notices contenues dans ce mode d' emploi, car elle s fournissent d' importantes indications

concernant la sécurité d'installation, d'emploi et d'entretien.

- Garder avec soin ce livret pour toute consultations ultérieure des divers opérateurs;

- Les illustrations et les dessins qui moutent l'appareil ne sont à considérer que comme des points de refrére

génériques et ne sont pas nécessairement soignés dans tous les détails;

- Les dimensions et les caractéris tiques signalées dans ce manuel ne sont pas contraignantes et peuvent être

modifiées sans announce préalable.

- Après avoir enlevé l'emballage, il faut s'assurer de l'état de l'appareil. En cas de dout e, ne pas l'utiliser et

s'adresser à votre revendeur. Les éléments de l' emballage (sachets en plastique, pol ystyrène expansé, clous,

etc.), ne doivent pas être laisséz à la portée des enfants;

NORMES GÉNÉRALES DE SÉCURITÉ

Cette liste de normes a été établie dans votre intérét. Le respect de ces normes réduira les risques d' accidents pour

vous-mêmes et pour les autres.

Le personnel opérant sur cette machine doit rigoureusement res pecter toutes les normes générales de sécurité et les

normes spécifiques décrites ci-dessous. Le non respect de ce s normes peut être cause des lésions personnelles et des

endommagements sur la machine.

- Ne pas essayer de déplacer, installer, mettre au point ou actionner la machine avant d' avoir lu et avoir pleinement

compris le contenu du manuel. En cas de doutes, s'adresser à son supérieur.

- Ne jamais laisser ustensiles, objets ou autre matériel sur la machine ou à l'intérieur de cette dernière.

- Avant de brancher l' appareil, s' assurer que le s donnés de la plaque correspondent à celles du réseau

d'alimentation électrique et hydraulique.

- Se souvenir que même lorsque l' interrupteur général est sur la position "0", les câbles d' alimentation sont sous

tension.

- AVANT d'actionner la machine ou de réactiver le cycle de production à la suite d' opérations d'entretien ou de

réparation, s'assurer que tous les abris et couvertures de protection soient correctement installés.

- L'installation doit être effectuée selon les indications du constructeur par l'intermédiaire d'un personnel qualifié.

- Cette machine devra être destinée uniquement à l'utilisation pour laquelle elle a été c onçue. Tout autre usage est

considéré impropre et donc dangereux;

- Cette machine doit être utilisée uniquement par des personnes qui ont appriis à l'utiliser.

NORMES SPÉCIALES DE SÉCURITÉ

- Les réglages et les réparations ne doivent être effectués que par des personnes compétentes.

Les éventuelles réparations effectuées par des personnes non qualifiées peuvent être dangereuses.

- La sécurité de tout appareillage supplém entaire non directement f ourni par la maison cons tructrice et utilisé en

même temps que la machine est sous la responsabilité de l'utilisateur.

- Les résultats parfaits de lavage sous l'aspect hygiénique et le fonctionnement correct de la machine pourront être

garantis si tous les conseils contenus dans le manuel présent seront respectés.

- Le personnel préposé à la manipulation des vaisselles après le lavage doit respecter rigoureusement les normes

d'hygiène en vigueur.

- Ne pas utiliser la machine dans un endroit ou la température est inférieure à 0°C.

- L'indice de protection de la machine est IP21. Elle ne doit pas être lavée au jet d'eau direct à haute pression.

- Si le câble d'alimentation est défectueux, procéder à son remplacement par le fabricant ou par

le service d'assistance technique ou bien par un technicien qualifié afin de prévenir tout

risque.

AUTRES RISQUES

Même si la machine est munie des dispositifs de sécurité cités plus haut, le risque de brûlures aux membres supérieurs

est néanmoins présent.

Ainsi que nous l'avons déjà ex pliqué dans le paragraphe PRECAUTIONS PENDANT LE LAVAGE, il ne faut jamais

plonger les mains nues dans l' eau savonneuse et chaude des cuves. Ceci pourrait provoquer des brûlures et des

irritations cutanées. Si cela devait arri ver, les rincer immédiat ement et abondamment sous l' eau courante. Consulter en

tous les cas la fiche du produit détergent utilisé.

Page 6

6

Stainless steel Upper rotating washing

Lavage supérieur r otatif en acier inoxydable

Double skin

Double par oi

Stainless steel Lower rotating washing

Lavage inférieur rotatif en acier inoxydable

Stainless steel Tank filters

Filtres cuve en acier inoxydable

Stainless steel Suction pump filter

Filtre aspiration pompe en acier inoxydable

Overflow

Trop-plein

Contr ol panel

Panneau de contrôle

Washin g p ump

Pompe Lavage

Body,tank and Top in Stainless steel construction

Châssis, cuve et capot en acier inoxydable

Stainless steel Boil er wi th ins ul ation

Surchauffeur isolé en acier inox

Tank Heating element

Ré sis tan ce cuve

Stainless steel Lower rotating rinsing (90°)

Rinçage inférieur rotatif en acier inoxydable (cône 90°)

Tank drain

Vidange cuve

Rinsing solenoid valve

Electrovanne Rinçage

Water inlet sole noi d v alve

El ectrov an n e E n t rée d ' eau

F92-ek

des crf92-ek-UL-2010

Stainless steel Upper rotating rinsing (90°)

Rinçage supérieur rotatif en acier inoxydable (cône 90°)

Learn to use the appliance

Faites connaissance avec l'appareil

Detergent pump

Do se ur d e la va ge

Rinse-aid pump

D o se ur p r o d ui t de r i nç ag e

Drai n pump

Pompe de vidange

Page 7

INSTRUCTIONS FOR THE USER

INSTRUCTIONS POUR L'UTILISATEUR

Page 8

8

A

C

D

E

F

G

B

Dis.1

EMPLOI CONTROLES

CONTROL PANEL

OPTIONAL

Main switch

Interrupteur général

Cyc le pushbutton

Bouton cycle

Door opening lamp

Lampe indi catri ce de porte ouverte

Cyc le lamp

Lampe indi catri ce de cycle

Température lampe

Lampe température

Water Softener or drain pump pushbutton

Bou ton adouciss eur ou pompe de vi dange

Wash time selection pushbutton

Bouton sélecteur temps de lavage

Wash and rinse thermometers

Thermomètre témperature de lavage et rinçage

PRESS ION 20psi +/- 5psi

Press ure-gauge

Manomètre press ion

Drain pump

Pompe de vidange

Qc-f 92-ek-UL-2 010

Rinse detergent display

Affichage produit de rinçage

Wash detergent display

Affichage produit de lavage

Page 9

9

ENGLISH

First Section - FOR THE USER

WORKING AND USE

The dishwashing/glasswashing machine can wash up to 600 dishes per hour.

The machine protection degree is IP21, therefore it should not be washed with direct high-pressure jet water.

The objects to be washed should be correctly arranged for a good washing-up result.

We suggest rescaling dishes, from time to time, in order to remove calcareous and/or starchy sediments by soaking it in

suitable solutions suggested by your cleansing agent supplier.

If y ou need to buy new dishes remember the following: Dishes: preference must be gi ven to china or non-porous

pottery articles, with smooth surface.

OPERATION BEFORE WASHING

B

EFORE STARTING THE WO RKING O PERATION BE

SURE THAT

:

- the cock is open;

- the filters and the overflow are in

their housings;

- the wash arm and the rinse arm are free to

pivot;

- brightener and washing powder dispenser

containers are loaded.

T

HEN PROCEED:

A - Place the dishes in the basket minding to

previously remove all solid w aste and fat. Do

not overload baskets, dis hes must not be placed one

upon the other, w ater must have the w ay to run on

each part of the same (see page 11).

B - Turn the machines on by wall switch and push the

switch “A” situated in Dis.1.

At this moment the thermometer display lights up

And the tank fills up. When the tank is full the control

lamp for cycle “2” lights up.

C – Introduce the basket in the dishwasher.

The control lamp “E” will flash in case the door of the

dishwasher is open.

Before you start the cycle be sure that the control lamp

“D” is flashing. T his means that the w ater for the

washing cy cle and the rinsing water temperature

reached the ideal temperature for working.

D – Choose the washing period cycle and push the

button “B” between the following items:

- lamp 1 flashing – short cycle of 2 minutes

- lamp 2 flashing – medium cycle 3 minutes

- lamps 1 and 2 lightening at the same time

long cycle of 4 minutes.

The washing period cy cle has to be chosen regarding

the dirt that has to be removed.

E – Close the door of the dishwasher.

Push the button cycle “C”

The dishw asher starts the washing with the period y ou

chosen. Additional to this period w ill be a pause of 5

seconds and a rinsing period of 18 seconds w ith clean

water

about 82° to 90°C (180÷195°F).

The control cycle lamp is flashing up to the end of the

complete washing period. Finished the washing period

the control lamps will stop lightening.

It is possible to interrupt the washing cycle at any time

simply pushing again button “B”.

The lighting of the control lamp “D” means that the

water reached the needed temperature

of 82° to

90°C (180÷195°F).

The rinsing w ill start w orking of by the reached

temperature need. T hat m eans the period of the

washing cycle you chosed w ill be extended up to

having reached the exact temperature (thermocontrol).

F – Extracting the basket inclines and shakes it

carefully. So the rest of the water drops will be

eliminated.

Leave the dishes in the ba sket until its w ill be dry by

evaporation. Take the dis hes aw ay from the basket

and pay attention not to touc h the dishes on its border

and put the on clean shelves.

To continue carry a new basket, introduce it in the

machine, close the door and press button

“C”.

- End less cycle (maximum 15 minutes)

: the door

being closed and the cy cle put on (any cycle), keep the

button “B” pressed for 3 seconds: lamps 1 and 2 will

flash at the same time (thermocontrol excluded); the

cycle can be interrupted at any time pressing again

button “C” that will let final sequences start.

Self-washing cycle:

with machine on, carry out the

following operations:

- Remove the overflow from the tank and w ait

for the tank’s empty ing (for machines with

drain pump, look at t he instructions in the

specific paragraph),

Page 10

10

- Close the door of the dishwasher,

- Keep pressed the cy cle button ‘’C’’ during 3

seconds: lamp ‘’2’’ flashes during all the length

of the 5 or 10 minutes cy cle, according to the

rinse’s duration fixed by default.

ACHIEVEMENTS

Any deficiency in the w ashing process is apparent

when dirty residuals are visible. An insufficient rinsing

might cause any halos: in this case, check that the

rinsing jets are clean and there is a sufficient pressure

in the water distribution network.

In the case that residuals are present, check that:

• the washing jets are clean

• there is detergent

• the pump suction filter is clean

• the positions of the objec ts in the rack are correct

(see page 11)..

Adding Rinse Aid and Detergent

CAUTION: Only use detergent and rinse aid w hich

are suitable for commercia l w ashers, a non-foaming

industrial alkaline detergent.

Do not use any soap intended for a residential

dishwasher. This leads to large amounts of foam

building up in the w asher and w ill void y our

manufacturers warranty.

CAUTION: Detergents for commercial dishw ashers

cause corrosion. Always follow the instructions on the

packaging and drums.

CAUTION: Do not mix different detergent products,

this could cause the dos ing pump to break dow n due

to crystallization.

NSF 3-2009 requirements for detergent and

chemical sanitizer dispensers

Feeders (rinse-aid, or detergent) are OPTIONAL.

When provided see instructions on page 31 in this

manual.

RINSING ADDITIVES

To grant a perfect rinsing, a quick drying and to

avoid calcareous sediments on glasses and

cups

you must add a surfactant on water (Brightener).

Your cleansing agent supplier w ill be able to suggest

the most suitable product. Your machine is equipped

with a rinse aid dispenser. Mean concentration used

is 0,15 g/lt.

CLEANSING AGENTS

The choice of a suitable cleansing agent is an

essential condition if y ou want to obtain extremely

good w ashing results as regards hygienic results.

That’s w hy it’s important to consider some points.

First of all only highly alkaline and chlorine-active

antifoam products, especially made for industrial dishwashing machines, must be used and they must be

produced by w ell-known reliable F irms. Mean

concentration of the cleansing agents in powder must

be 1,5÷2,5 g/lt. Mean concentration of liquid cleansing

agents must be 2÷4 g/lt.

DRAIN PUMP INSTRUCTION

(only for machines with drain pump)

The drain pump starts up automatically just

during the washing cycle to discharge the

exceeding water coming from the rinsing cycle.

At the end of the working day, in order to

completely discharge the tank, it is necessary

to perform the following operations:

1. Open the door of the dishwasher

2. Remove the overflow pipe from the tank;

3 .Afterwards push button “F” for 3 seconds.

Alternatively are flashing the control lamp “ E” and

the cycle lamp (chosen before)

The discharge will stop automatically after 5

minutes. The control lamps will stop flashing.

The drain can be stopped at any time by pressing

again button ‘’F’’ .

Please note: in case the door is open the control

lamp “E” will continue flashing.

Reinstall the flow over and shut the door.

DESCALING

When hard water is used y ou can find inside the

machine and also on dishes calcareous sediments

which must be removed both for hy gienic and

operating reasons by a descaling operation.

Operating process and frequenc y of this intervention

are suggested by y our cl eansing agent supplier w ho

has suitable products, generally containing phosphoric

acid.

In order to avoid damage to the machine do not

increase the quantities and once operations end rinse

abundantly.

SANIFICATION

At least each 30 days it w ould be useful to do this

operation which guarantees the complete hy gienic

conditions of the machine. We suggest to contact your

cleansing agent supplier w ho w ill give y ou quantity

and name of the most suit able product y ou can use

and that is generally an active chloride pow der

(100÷200 ppm).

In order to avoid damage to the machine do not

increase the quantities and once operations end rinse

abundantly.

Page 11

work/cdr/cestelli-posizionamento/Cestelli-F92-ek-ING-2013

F92-ek

112

2

3

3

4

PP12-18 cod.CC00024 (2x)

CB cod.CC00019 (1x)

G cod.CC00045 (2x)

4

556

6

7

89

320

Plates clearance

500

500

5

1

2

3

4

6

21

3

4

5678

9

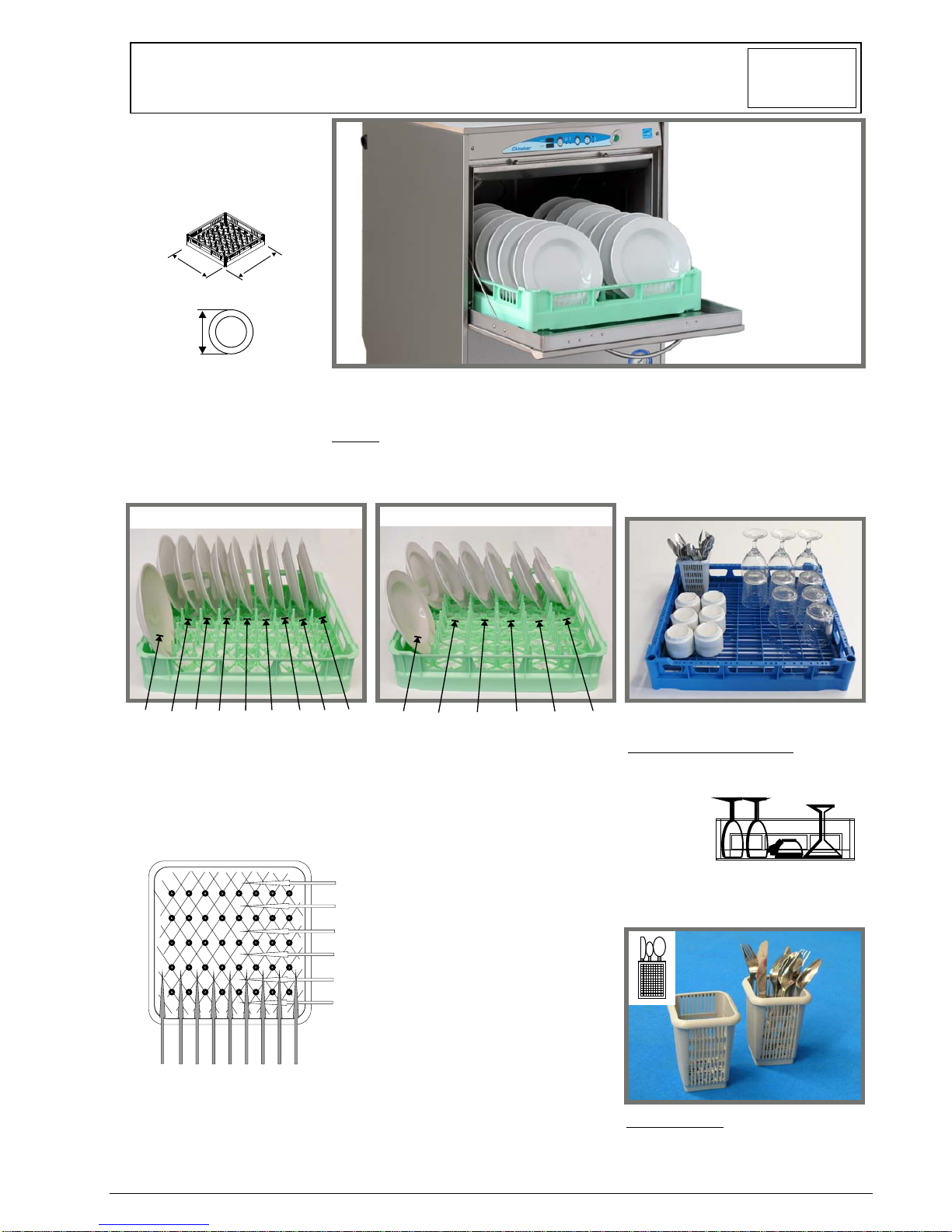

DISHES POSITIONING

To achieve optimal cleaning results, make sure that tableware is correctly stored

inside the dishwasher.

must be placed inthe plastic baskets, concave sideup.Dishes

Put the cutlery into the small baskets,

handles down. Avoid overlapping it

(see picture above).

Dinner plates type " 1" should be

positioned concave side up and on

the side of the rack with 9 storage

compartments - that is a maximum

storage capacity of 18 flat plates, as

shown in the abovepicture

Insert the baskets inside

the dishwasher with the

plates in the direction

shown in the picture.

Warning !

Only use the baskets

supplied with the

dishwasher !

Dinner plates type " 2" should be

placed concave side up and on the

side of the basket with 6 storage

compartments that is a maximum

storage capacity of 12 deep plates,

as shown in the above picture

Glasses, bowls and cups should be

positioned face downinto the proper

compartment as shown below.

dinner plates type"1"

dinner plates type"2"

Page 12

CLEANING AND PREVENTIVE

MAINTENANCE

PRECAUTION AND CLEANING

INSTRUCTIONS

- IMPORTANT: Before carrying out the

cleaning and maintenance operations,

disconnect the equipment from the mains

power supply.

- High temperatures can be reached inside

the machine (90°C). After power supply has

been removed, wait until the machine has

reached room temperature, before working

on it.

- The machine protection degree is IP21,

therefore it should not be washed with

direct high-pressure jets of water.

- never leave tools, parts or other loose

material on the machine or inside of it.

- BEFORE starting machine or cycle, after

any maintenance or repair work, make sure

all protective are correctly installed.

DAILY MAINTENANCE

- Disconnect the machine with pushbutton

"A";

ATTENTION!!

- Disconnect the machine from the

main power supply source by means

of the wall-mounted switch.

- Lift the overflow pipe and let the water

drain out of the tank;

- Wash thoroughly the tank and the filter

housings to remove all impurities;

- Take the filters out and clean them under

running water;

- Re-assemble the overflow pipe and the

filters in their housings;

- Check and clean the washing and the

rinsing jets;

- Clean the outer surface of the machine by

using a wet sponge; do not use water jets

because, besides being dangerous, they

could damage the electrical parts; do not

use abrasive detergents;

- When the machine is to remain idle for a

long time, drain all the water from the

boiler and from the electro pump.

Also leave the door open.

NEVER WASH THE EXTERNAL PART OF

THE MACHINE WITH A WATER JET

POSSIBLE TROUBLES - CAUSES - SOLUTIONS

PROBLEMS CAUSES SOLUTIONS

The machine doesn't catch Main switch is switched off Turn ON the main switch

The water doesn't go in Water cock closed Open water cock

The Overflow is not in place Reassemble the Overflow in

place

Insufficient Washing Wrong detergent or insufficient

dosage Use anti-foam detergent in the

right dosage and never with

cold water

Low temperature in the tank Wait until the water gets hot

Dirty wash filter Clean filter

Insufficient Rinsing Rinsing nozzles blocked Unscrew and clean nozzles

under running water

Hydraulic pressure lower than Wait until the pressure is on or

1 bar - 100 kPa buy a booster pump

CAUTION! FOR ANY OTHER TROUBLE, CALL SERVICE

Page 13

13

USEFUL HINTS FOR STAINLESS STEEL MAINTENANCE

Stainless steel is so called because it is not affected by oxidation; this dues its resistance to a thin molecular

layer of oxide on the surface which protects againts further oxidation. There are, however, substances which

can modify or destroy this layer, giving rise to corrosion: besides preventing the prot ective film of oxide from

reforming, these substances corr ode the stainless steel itself and can cause irreparable damage. It is

therefore necessary to prevent th is by choosing correct cleaning pr oducts and by complying with the

following simple recommendations: never forget that when using these appliances, the first and

fundamental rule is to guarantee that the cleaning products are both non-toxic and hygienic.

Before using any detergent to clean either the stainl ess steel or the immediate and sorrounding floor area,

always ask your supplier for the most suitable product which does not cause corrosion on the steel itself; the

onset of rust is most commonly caused by the use of unsuitable cleaning materials (strongly acid chlorate

based detergents) or on inadequate maintenance.

Our appliances are made of stainless steel AISI 304 (18-10 type) for exterior panelling,upper tops, tanks etc.

Comply with the following instructions when cleaning and servicing parts in stainless steel.

Ordinary daily maintenance

Carefully and frequently clean the surfaces using a damp cloth; use soap and water or normal detergents,so

long as these do not contain abrasives or chlorine based substances such as sodium hypochlorite

(bleech) ,hydrochloric acid or other such solutions:These products quickly and irreparably corrode stainless

steel. When cleaning floors underneath or near the appli ances, never use the above mentioned products as

vapours or splashes could subject the steel to similar destructive effects.

Only ever rub in the direction of the satining, then thoroughly rinse with clean water and carefully dry.

Rust : water supply pipes, inevitably convey particles of rust dissolved in the water especially in new

installation plants or when taps are opened after a per iod of inactivity. These iron deposits must not be

allowed to remain on the stainless steel since they produce rust by contamination.

Use suitable products to remove any rust marks,from companies which produce detergents for industrial

use. After application, thoroughly rinse with clean water, neutralizing the action of the product with an

alkaline detergent normally used to clean such appliances or with another specific product.

DO NOT USE METAL MATS TO CLEAN THE STAINLESS STEEL

Page 14

Page 15

15

FRANÇAIS

Première partie - INSTRUCTIONS POUR L'UTILISATEUR

FONCTIONNEMENT ET EMPLOI

L'appareil Lave-vaisselle/Lave-verres assure une production horaire de 600 assiettes.

L'indice de protection de la machine est IP21. Elle ne doit pas être lavée au jet d'eau directe et à haute pression.

La disposition correcte de la vaisselle est condition essentie lle pour obtenir les meilleures résultats de lavage. Ne pas

utiliser de la vaisselle vieille, usée ou crevassée vu que la rugos ité et la réglure retiennent plus facilement la crasse et

offrent un abri aux bactéries. Il est à conseiller de procéder de temps à autre à la désincrustation en utilisant un détersif

approprié, afin de faire décoller les dépôts calcaires et/ou amylacées.

Lors d' un achat de vaisselle nouvelle il convient d' observer les indications suivantes: pour les assiettes donner la

préférence à celles en porcelaine ou céramique non poreuse à surface lisse.

AVANT LE LAVAGE

AVANT DE COMMENCER LES OPERATIONS DE

LAVAGE

, S'ASSURER QUE:

- le Robinet de l' alimentation hy drique soit

ouvert et que l'eau ne manque pas dans le

réseau;

- les F iltres et le T rop-plein soient dans leurs

emplacements;

- le T ourniquet de lavage soit libre de sorte

qu'il puisse tourner;

- les récipients de l' appareil doseur de produit

pour le rinçage et de détersif pour le lavage

soient remplis.

A

PRES CELA , PRO CEDER AUX O PERATIONS

SUIVANTES

:

A - Introduire la vaisselle dans les paniers

appropriés (voir page 17) après avoir enlevé

tous les restes solides et les graisses. Mettre dans

l'eau les couverts, et éventuellement aussi les

assiettes si celles-ci sont lavées longtemps après

l'usage, afin de faire décoller les restes de la

nourriture.

Ne pas entasser les paniers, la vaisselle ne peut pas

être superposée, l'eau doit avoir la

possibilité de recouvrir la vaisselle directement de

tous les côtés.

B - Mettre la tension à l' interrupteur mural et

pousser l'interrupteur "A" (DIS.1)

Dans ce moment s’allumer ont les lampes de contrôles

des thermomètres et le bac se va remplir.

A remplissage terminé la lampe indicatrice de cy cle "2"

s’allumera.

La lampe de contrôle "E" clignote quand la porte de la

machine est ouverte.

C - Ouvrir la porte et introduire le panier avec la

vaisselle dans la machine.

Quand la porte est ouverte la lampe de contrôle "E"

continue à clignoter.

Avant de faire démarrer la machine contrôler que la

lampe "D" sera fonctionnant.

Cette lampe vous informe que la température de l’eau

de lavage et de rinçage est idéal.

D

– Choisir la durée du lavage en poussant le bouton

“B” selon les critères suivants :

Lampe 1 allumée : cycle court 2 minutes

Lampe 2 allumée : cycle intermède 3 minutes

Lampes 1 et 2 allumées cont emporairement cycle long

4 minutes

La durée du cy cle doit être choisie en fonction du

genre de vaisselle à laver et du degré de la crasse à

enlever.

E - Fermer la porte et pousser le bouton "C".

Commençera le cy cle de lavage que vous avez choisi.

En plus il y aura une pause de 5 secondes et une

phase de rinçage de 18 secondes utilisant de l’eau

propre entre 82° ÷ 90° C

(180÷195°F).

Les lampes de contrôle c lignotent jusqu’à la fin du

lavage. A la fin du lavage les lampes ferment de

clignoter.

Il est possible d’interrompre le cycle de lavage à

n’importe quel moment, simplement en poussant de

nouveau le bouton “B”.

La lampe "D" allumée indique la température idéale

pour le rinçage (82°÷90°C/

180÷195°F).

Le rinçage commençera qu’au moment de la

température idéale. La durée de période de lavage

sera prolongée jusqu’à la stabilisation de la

température (thermocontrôle).

F

- Enlever le panier, incliner le et secouer

légèrement afin de faire tomber les gouttes restantes.

Laisser sécher par évaporation la vaisselle. Ensuite

enlever la vaisselle du panier, en veillant à ne pas

toucher les parties internes ni les bords.

Remettre la vaisselle sur des rayons hygiéniques.

Pour continuer le lavage charger la machine encore

une fois avec un panier, fermer la porte et pousser

l’interrupteur "C"

- Cycle infini (maximum 15 minutes) :

avec la porte

fermée et cycle inséré (n’importe quel), pousser pour 3

secondes le bouton “B” : les lampes 1 et 2 clignoterons

en même temps (thermocontrôle exclu). Le cy cle peut

être interropu à quelque moment que ce soit en

poussant de nouveau le bouton “C”, que fera

commencer les séquences finales de pause-rinçage.

Cycle Auto-lavage: avec machine allumée, effectuer

les opérations suivantes :

- Enlever le trop-plein de la cuve et attendre que

la même soit vide (pour machines équipées de

pompe de vidange, voir les instructions au

paragraphe spécifique),

Page 16

16

- Fermer la porte du lave-vaisselle,

- Maintenir pressé le poussoir du cy cle ‘’C’’

pendant 3 seconds : la lampe ‘’2’’ clignote pour

toute la durée du cy cle de 5 ou 10 minutes en

fonction du temps de rinçage fixé par default.

RESULTATS OPTIMAUX

Une insuffisance éventuelle du lavage est visible

lorsqu’ils restent des traces de saleté. Elles peuvent

être causées par un rinçage insuffisant. Dans ce cas,

contrôler que les jets de rinç age sont propres et qu'il y

ait une pression suffisante dans le réseau de

distribution de l'eau (idéale entre 2~4 bar).

En cas des traces de saleté, vérifier que:

• les gicleurs de lavage sont propres

• le détergent est approprié en qualité et quantité

• les filtres de la cuve sont propres

• la position des objets dans la machine est correcte

(voir page 17).

Emploi du détergent et du produit de rinçage

ATTENTION : utilisez seulement détergents et produits

de rinçage spécifiques pour lave-vaisselle industriels,

un détergent industriel alcalin qui ne produit pas de

mousse.

N’utilisez pas un détergent pour lave-vaisselle

domestiques. Ce ty pe de détergent en effet produit

beaucoup de mousse dans le lave-vaisselle et cela va

annuler la garantie.

ATTENTION : les détergents pour lave-vaisselle

industriels causent corrosion. Suivez toujours les

instructions que vous trouvez sur les emballages et les

enveloppes.

ATTENTION : ne mélangez pas produits détergents

différents, cela pourrait pr ovoquer la rupture du doseur

de détergent à cause de la cristallisation.

NSF 3-2009 qualités requises pour les

doseurs détergent et désinfectant

chimique

Les doseurs du detergent et de produit de rinçage sont

OPTIONAL.

Quand ils sont en dotation voir les instructions à la page

31 de ce manuel.

ADDITIFS DE RINÇAGE

Pour garantir un rinçage parfa it et un séchage rapide,

et pour éviter le dépôt calcai re sur la vaisselle, il faut

ajouter un tensioactif (dét ersif de rinçage) à l' eau. Le

fournisseur du détersif pourra Vous conseiller le

produit le plus opportun.

La machine est dotée du doseur automatique de

détersif liquide pour le rinçage. La concentration

moyenne d'usage est de 0,15 g/litre.

DETERSIFS

Le choix d' un détersif approprié est une condition

indispensable pour obtenir des résultats optimaux de

lavage sous le profil hy giénique. Il est donc important

de tenir compte de quelques facteurs.

Tout d'abord, il est nécessaire d'utiliser seulement des

produits non-moussants fortem ent alcalins et chloreactifs spécifiques pour les lave-vaisselle industriels,

fabriqués par des firmes de bonne renommée. La

concentration moy enne des détersifs en poudre doit

être de 1,5 à 2,5 g/litre . La concentration moy enne

des détersifs liquides doit être de 2 à 4 g/litre.

FONCTIONNEMENT POMPE DE VIDANGE

(seulement pour machines avec pompe de vidange)

Le fonctionnement de la pompe de vidange est

automatique seulement pendant le cycle afin de

vider l’eau de trop qui rentre pendant la phase de

rinçage. À la fin de la journée de travail, pour

vidanger complètement la cuve, il faudra par ailleurs

effectuer les suivantes opérations:

-1 Ouvrir la porte de la lave-vaisselle

-2 Enlever le TROP-PLEIN de la cuve;

-3 Pousser le bouton « F » pour 3 secondes

Clignotent alternativ ement la lampe « E » et la lampe

de cycle (dernière selles.)

Le vidange s’arrête automatiquement après 5 minutes.

Le vidange peut être interrompu à n’importe quel

moment en pressant de nouveau le bouton ‘’F’’.

Les lampes s’arrêtent à clignotées

Quand la porte de la machine est ouverte la lampe de

contrôle « E » clignote.

Remonter le trop-plein dans sa position correcte.

DESINCRUSTATION

A cause des eaux dures, il se forment à l'intérieur de

la cuve, parfois aussi sur la vaisselle, des dépôts

calcaires qui, pour des raisons d' hygiène et de

fonctionnement, doivent être enlevés par

désincrustation.

Le procès et la fréquence de cette intervention sont

conseillés par le fournisseur du détersif qui dispose

de produits appropriés en général à base d' acide

phosphorique. Pour ne pas endommager la machine,

ne pas exagérer dans le s dosages et rincer

abondamment après les opérations.

ASSAINISSEMENT

Il est bien de procéder au moins tous les 30 jours à

cette opération qui garantit un état hy giénique parfait

de la machine. Pour les procédés il convient de

s'adresser au fournisseur de détersif , qui conseillera

les doses et le produit le plus approprié. Ce dernier

consiste en général d' une poudre à base de chloreactif (100÷200 ppm). Pour ne pas endommager la

machine, ne pas exagérer dans les dosages et rincer

abondamment après les opérations.

Page 17

work/cdr/cestelli-posizionamento/Cestelli-F92-ek-FRA-2013

F92-ek

112

2

3

3

4

PP12-18 cod.CC00024 (2x)

CB cod.CC00019 (1x)

G cod.CC00045 (2x)

4

556

6

7

89

320

Ouverture de chargement

500

500

5

1

2

3

4

6

21

3

4

5678

9

PLACEMENT DE LA VAISSELLE

- Les couverts doivent être placés

dans les petits paniers spéciaux, les

manchesvers lebas enayant soinde

ne pas les superposer comme

indiquésurla photoci-dessus.

- Afin d'optimiser le lavage de votre vaisselle, assurez vous du bon

positionnementdecette dernière.

doivent être placées dans les paniers en plastique, la partie

concaveversle haut.

- Les assiettes

- Les verres, les coupes et les

tasses doivent être placés face vers

le bas, dans les compartiments

appropriés comme indiqué sur la

figuresuivante.

- Les assiettes plates doivent être

disposées, la partie concave vers le

hautet sur le côté du panier avec les

9 lignes de rangement - soit un total

de 18 assiettes plates, comme

illustrésurla photo.

Insérez les paniers

dans le lave-vaisselle

avec les assiettes

positionnées dans le

sens indiqué sur la

photo.

Attention!

Utilisez uniquement les

paniers en dotation avec le

lave-vaisselle!

- Les assiettes creuses doivent être

disposées, la partie concave vers le

haut et sur le côtédu panieravec les

6 lignes de rangement - soit un total

de 12 assiettes plates, comme

illustrésurla photo.

Page 18

NETTOYAGE ET ENTRETIEN

PREVENTIF

AVERTISSEMENTS ET

INSTRUCTIONS DE NETTOYAGE

- IMPORTANT: Avant d'effectuer toute

opération de nettoyage et d'entretien, débrancher

l'appareil du réseau électrique;

- A’ l'intérieur de la machine on a des

températures élevées (90°C).

Débrancher l'appareil du réseau électrique et

attendre que la machine soit à température

idéale avant d'opérer dans la même;

- Ne pas laisser ustensiles ou autres

objectes dans la machine;

- AVANT d'actionner la machine ou de

réactiver le cycle de production à la suite

d'opérations d'entretien ou de réparation,

s'assurer que tous les abris et couvertures de

protection seraient correctement installés.

EVITER ABSOLUMENT DE NETTOYER

L'APPAREIL PAR UN JET D'EAU

ENTRETIEN JOURNALIER

- Mettre hors tension la machine en

poussant l'interrupteur "A" et faire écouler

l'eau de la cuve en enlevant le Tropplein;

IMPORTANT!: Débrancher l’appareil du

réseau d’alimentation électrique au

moyen du disjoncteur mural.

- Attendre jusqu'à ce que toute l'eau se soit

écoulée et qu'il ne reste pas d'ordures sur

le fond de la cuve;

- Enlever les tourniquets de lavage et de

rinçage, et les filtres de l'intérieur de la

machine et les laver à l'eau courante

chaude;

- Contrôler que les gicleurs de rinçage ne

seraient pas bouchés;

- Remettre les pièces enlevées dans leurs

emplacements;

- Nettoyer l'extérieur de la machine au

moyen d'une éponge humide; ne pas

utiliser de jets d'eau car, en autre d'être

dangereux, il pourrait endommager les

composants électriques;

- Afin d'éviter la formation de mauvaises

odeurs, il est à conseiller de laisser la

porte du lave-vaisselle ouverte;

- En prévision d'une inactivité prolongée de

la machine il est bien de procéder aux

opérations de désincrustation et

d'assainissement .

INCONVENIENTS POSSIBLES - CAUSES - REMEDES

PROBLEMES CAUSES REMEDES

La machine ne démarre pas Interrupteur général débranché Insérer l'interrupteur

La machine ne charge pas l'eau Robinet à l'eau fermée Ouvrir le Robinet

Le Trop-plein n'est pas dans son Remettre le Trop-plein dans son

siège siège

Lavage insuffisant Faux dosage du détergent, Employer détergent antiécume

Détergent insuffisant avec dosage correct et jamais

avec eau froide

Température dans la cuve Attendre le chauffage de l'eau

insuffisante

Filtre de lavage sale Nettoyer le filtre

Rinçage insuffisant Gicleurs de rinçage bloqués Dévisser et nettoyer les gicleurs

à l'eau courante

Pression hydraulique inférieure Attendre que la pression arrive

à 1 bar - 100 kPa ou acheter une pompe à

pression

ATTENTION! POUR TOUT AUTRE INCONVENIENT S'ADDRESSER AU SERVICE APRES-VENTE

Page 19

19

CONSEILS UTILES POUR L'ENTRETIEN DE L'ACIER INOXYDABLE

L'acier inoxydable est ainsi appelé parce qu'il ne subit pas l'action agressive de l'oxygène contenu dans

l'air. Sa résistance est due à une mince couche molécula ire d'oxyde qui se forme à la surface et le protège

contre l'oxydation.

Toutefois il y a des substances qui peuvent modifi er ou détruire cette couche et entraîner donc des

phénomènes de corrosion; ces substances non seulement empêchent la formation d'une nouvelle pellicule

d'oxyde mais corrodent aussi l'acier inoxydable en provoquant ainsi des dégâts irrémédiables. Pour que

cela ne se produise pas il faudra donc faire attention au choix des produits spéciaux pour le nettoyage et

respecter simplement les conseils ci-après: ne jamais oublier que la première règle fondamentale pour

l'emploi de ces appareils est de garantir l'absence de toxicité et l'hygiéne maximale des produits

traités. Avant d'utiliser un produit détergent pour le nettoy age de l'acier inoxydable ou du carrelage qui se

trouve au dessous des appareils ou bien tout à côté, demandez toujours à votre revendeur quel est le type

de détergent le plus indiqué et qui ne provoque pas de corrosi on sur l'acier: si l'acier se corrode (il rouille),

cela est dû dans la plupart des cas au produit utilisé pour le nettoyage qui n'est pas approprié (détergents

fortement acides à base chloratée) ou bien à un mauvais entretien. Nos appareillages sont réalisés en

acier inox AISI 304 (type 18-10) pour revêtements extérieurs, tuyautages et cuves.

Nettoyage ordinaire journalier

Nettoyer souvent et soigneusement le s surfaces avec un chiffon humi de; on pourra utiliser de l'eau avec

du savon ou bien les détergents ordinaires pourvu qu'ils ne contiennent pas de substances abrasives

ou à base de chlore comme l'hypochlorite de sodium (eau de Javel), l'acide chlorydrique (acide

muriatique), ou d'autres solutions de cet acide: ces produits corrodent l'acier inox de façon irréversible et

en très peu de temps. Pour nettoyer le carrelage qui se trouve en dessous ou tout à côté, ne jamais

utiliser les produits ci-dessus car les vapeurs ou les gouttes pourraient produire sur l'acier des effets

destructifs analogues. Frotter doucement exclusivement dans le sens du satinage.Rincer abondamment à

l'eau pure et bien essuyer. Ne pas utiliser des jets d'eau qui pourraient provoquer des infiltrations.

Taches de rouille :les tuyauteries des installations d'alimentation en eau des éviers, casseroles et

cuisinières débitent inévitablement de la rouille di ssoute dans l'eau, notamment dans les installations

toutes neuves ou si on ouvre les robinets après une longue période d'inactivité. Eviter donc de laisser des

dépôts ferreux stagner sur l'acier inoxydable ca r ils provoqueraient des phénomênes de corrosion par

contamination. Il est conseillé de fa ire construire les installations av ec des tuyauteries galvanisées et

laisser couler l'eau longtemps jusqu'à ce qu'elle soit claire.

Pour éliminer les taches de rouille éventuelles,ut iliser des produits spéciaux recommandés par les

maisons qui produisent des détergents à usage industr iel: après l’usage, rincer avec beaucoup d'eau pure

et neutraliser l'action du produit avec un détergent alcalin normalement utilisé pour le nettoyage de l'acier

ou avec un produit spécial.

EVITER DE NETTOYER L’ACIER INOXYDABLE AVEC PAILLETTES ABRASIVES !

Page 20

Page 21

INSTRUCTIONS FOR THE INSTALLER

The following instructions are addressed to a qualified personnel, the only one

authorised to carry out checks and repair, if any.

The Manufacturer declines any responsibility in the case of interventions

made by a non qualified personnel.

INSTRUCTIONS POUR L'INSTALLATEUR

Les instructions suivantes sont adressées à un personnel qualifié, qui est le

seul autorisé à effectuer les vérifications et les réparations éventuelles.

Le constructeur décline toute responsabilité en cas d'interventions effectuées

par du personnel non qualifié.

Page 22

Dis.2

L

E

E

S

23,62 in 25,59 in

59,00 in

13,78 in

32,28 in

24 in

12,60 in

14,57 in

1,97 in

2,56 in

25,59 in

A

L

S

E

14,96 in

6,0 in

MINIMUM FLOOR CLEARANCE

HAUTER MINIMAL DU SOL

10,24 in

7.9 in

S

INSTALLATION

UNDERCOUNTER DISHWASHER/GLASSWASHER

LAVE-VAISSELLE/LAVE-VERRE SOUS TABLE

FREE STANDING/LAVE-VAISSELLE FRONTAL

OPTION

INSTALLATIONSBLATT

E

L

S

D

Water inlet - Electrovanne chargement

Electric input - Branchement eléctrique

3/4" G

32 mm - 1"1/4 G

Drain - Evacuation Eau

Drain System:Separate drain pump lift up to 24 inches a bove floor level

Système de vidange: pompe de vidange séparée soulevée de 61 cm (24 inch) du sol

A

Maximum height for drain to wall

Hauteur maximale pour vidange à mur

Max height

Hauteur max

208/1 60Hz

1,38 in

F92-ek

D

Dr ain Pipe

Tu y a u v id an g e

Cable Length:

Longueur des ca ble/Tu yau:

Page 23

ENGLISH

Second Section - FOR THE INSTALLER

During installation carry out a good machine levelling, which is a prerequisite for a correct operation

thereof.

The Manufacturer cannot assume any responsability for any damage to persons or property

deriving from the non-observance of the above specified norms.

For a correct installation see the drawing on page 22

The dishwasher shall be installad in accordance wi th local codes, or in the absence of local codes,

installed in accordance with the applicable require ments in the National Electrical Code, NFPA 70,

Canadian Electrical Code (CEC), C22.1, and Standards for Ventilation Control and Fire Protection of

Commercial Cooking Oper 96.

ELECTRICAL CONNECTION

Before connecting the machine, make sure

the voltage outlet of the mains is the same as

the voltage specified on the data plate of the

machine.

A flexible cord used in a power-supply shall be

Type S, SE, SO, SOO, ST, STO or STOO. The

length of the cord - measured from the face of

the attachment plug to the point of entry into the

dishwasher – shall not be less than 59,00 in.

Ground Markings

- States “G”, “GND”, “GR” or

equivalent markings such as the ground symbol.

Located near equipment grounding terminal

inside the field wiring compartment.

Supply Connection Markings

- Each unit will be

marked as follows, “Minimum Supply Conductor

GROUNDING - All products shall have means

for grounding through the supply cord of a cord

connected product or through a grounding

terminal of a field wired product. The ground

shall be separated from the neutral conductor.

All exposed dead-metal parts of the enclosure

and all dead-metal parts within the enclosure

likely to be contacted by the operator or

serviceman during normal use or servicing, shall

be conductively bonded to the ground

connection.

The conductors used for bonding individual

dead-metal shall be insulated and equal to or

greater than the largest AWG size of the

conductor of the component mounted to the

dead-metal or routed along the dead-metal in

accordance with the National Electric Code,

ANSI/NFPA 70.

The ground shall be connected to the frame or

enclosure by a positive means penetrating any

nonconductive coatings and located so that it is

unlikely to be removed during normal servicing.

Ground wires shall be identified by green with or

without one or more yellow striped, and no other

lead shall be so identified.

Ground terminals shall be identified by the use

of one of the following:

1) Identified by the ground symbol (IEC

Publication 417, Symbol No. 5019) on or

adjacent to the connector. (Ill. 0 Fig. 17.1).

2) Identified by “G”, “GR”, “GND”, “Ground” or

equivalent.

3) Use of a hexagonal or slotted (or both)

green head wire-binding screw.

4) Use of a threaded stud with a green

hexagonal nut.

5) Use of a green pressure terminal connector.

THE MACHINE SHALL BE CONNECTED

WITH AN EFFECTIVE GROUND CLAMP.

The manufacturer declines any responsibility

for any damages caused by lack of an

effective

ground installation.

Page 24

24

CONNECTIONS TO THE POWER

SUPPLY

Before using the dishwashing machine, check

that all electrical protection systems are working

correctly.

Attention: The machine should not be regarded

as isolated from the power supply unless

switched off at the customer’s main switch.

- Connect the power cord to the customers

power system. (The power cord can be

wired directly into the customers power

supply or a plug may be added to the end

of the cord. The ground wire is green,

neutral is black and live is black.) make

sure the unit is properly grounded.

- The power cord comes attached from the

factory, if replacement is required note:

the ground wire is yellow-green and the

live wires are black or brown.

WATER SUPPLY CONNECTIONS

Water and waste piping and connections shall

comply with the International Plumbing

Code, International Code Council (ICC) or the

Uniform Plumbing Code, International

Association of Plumbing and Mechanical

Officials (IAPMO).

Ensure that the water supply line is thoroughly

flushed before the dishwashing machine is

connected. It is necessary to remove all foreign

debris from the water supply line so that they do

not cause any damage to dishwashing machine

components.

For service purposes, it is recommended that a

shut-off valve be installed in the water supply

line before the connection to the dishwashing

machine

The water supply line must be of 15-25 psi “flow”

pressure at the temperature specified on the

machine dataplate. “Flow” pressure is the

pressure in the water supply line when the

machine’s water solenoid valve is opened during

the cycle.

A ½” pipe size (minimum) is recommended. In

installations where the pressure in the water

supply line fluctuates or is greater than the

required pressure, it is recommended to install a

water pressure regulator (not included with

dishwashing machine).

It is also recommended to install a shock

absorber (not included with dishwashing

machine) in the water supply line. This prevents

damage to the machine from water line

“hammer” (hydraulic shock) in the water supply

line.

Water installation must have the following

characteristics:

Inlet Temperature MAX : 55°C – (131°F)

Work Dynamic Pressure :

1,38 +/- 0,34 bar - (138 +/- 38kPa)

20 +/-5 psi

(Look at data pressare-gauge on the front panel)

WARNING!

If the dynamic pressure is lower than specified

on the data plate of the machine, it is advisable

to install a Booster Pump.

Hardness: between 7,2 and 12,5 °French.

If the hardness values are higher than

those mentioned above, it is advisable to install

a water-softener.

WORK TEMPERATURES

Water temperature >66°C (>150 °F)

Rinse temperature 82°÷90°C (180÷195 °F)

n.b.: To help a correct working of the

thermocontrol system, do NOT adjust the

thermostat during the washing cycle.

DO NOT TAMPER WITH THE THERMOSTAT

CALIBRATION

WATER DRAIN

According to the dimensions of the drawing;

water drain and feeding pipe should have the

same diameter as the water inlet of the

machine.

It must be furnished with a siphon and have

a right slope.

Page 25

25

The machine is provided with a flexible pipe for

the connection with the water-work.

Make sure there are no throttlings along the

pipe.

Carefully comply with any national or regional

regulations in force.

Connencting the drain line:

All plumbing connections must comply with all

applicable national, state and local plumbing

codes.

DETERGENT REPLACEMENT AND

CLEANING OF THE DETERGENT

PUMP HOSES

Guidelines to be followed when replacing

detergent :

- If you leave the machine without detergent,

crystallization arises due to the formation of air

bubbles

- Set up again detergent pump hose anytime you

use a new detergent

- The whole system consists of a container,

dosage hoses and detergent pump hoses and

must be cleaned before using a new detergent.

- Call on your authorized technical assistance to

fulfil the necessary operations to obtain a good

cleaning result.

- You are recommended to proceed with the

cleaning of the dosage hoses and the detergent

pump with water once a month.

Failure to comply with these guidelines will

render this guarantee invalid. Lamber

disclaims any liability for consequential

damage on the product.

You can clean yourself the dosage hoses and

the detergent pump with water.

Guidelines:

A - Disconnect the suction hose from the

detergent can.

B - Connect the suction hose to a new water

recipient.

C

- Switch the Self-cleaning cycle on (see

paragraph page 9)

D

– Once self-cleaning is finished, connect the

suction hose to the detergent can.

WARNING: Respect security and

chemical dosage guidelines.

When using chemical products y ou must wear

personnal protection equipment, gloves and

protection glasses. Do not mix different

detergents together.

WARNING: Replace one a year the peristaltic

pumps suction pipe cod. 0500094 (see

draw)

Page 26

Vacuum Breaker Valve connection:

The machine is supplied with an air gap comply with ANSI/ASSE 1001.

Connect this valve by connecting it to the inlet hose of the dishwasher, as in the picture below , comply with

ANSI/ASSE 1004.

Supply Valve

Water inlet

Inlet Pipe

Vacuum Breakers

min 6”

6” for

ASSE standards

Overflow or Maximum

Liquid Level

Water inlet

to weld !

Vacuum breaker Installation

Dish/Glassw asher

Inlet Pipe cod.0900007

Nipple ½ ”

cod.0200944

Reduced Nipple 3/4 -½”

cod.0200919

”

cod.0500603

Vacuum Breakers

Page 27

FRANÇAIS

Deuxième partie - INSTRUCTIONS POUR L'INSTALLATEUR

Positionner la machine près des attaches.

Pendant l'installation, effectuer la mise à niveau de la machine et contrôler à l'aide d'un niveau que la

machine soit parfaitement en équilibre.

La Maison décline toute responsabilité pour les éventuels dommages dérivants du manque

d'observation des normes citées.

Pour le positionnement correcte voir le dessin à la page 22.

Le lave-vaisselle doit être installé selon les règles

locales ou, en absence de normes locales,

installé selon les directives du National Electrical

Code NFPA 70, du Canadian Electrical Code

(CEC), C22.1, et des Standards for Ventilation

Control and Fire Protection of Commercial

Cooking Oper 96.

BRANCHEMENT ELECTRIQUE

Avant d'utiliser l'appareil, vérifier que la tension

de réseau soit la même que celle qui est

indiquée sur la plaque de l'appareil.

Le câble flexible utilisé pour la connexion au

réseau électrique doit être du type S, SE, SO,

SOO, ST, STO ou STOO. La longueur du câble,

mesurée à partir de la fiche jusqu’au point

d’entrée dans la machine, ne doit pas être

inférieure de 59,00 in.

Marquage de terre

- ‘G’, ‘GND’, ‘GR’ ou

marquages équivalents comme le symbole de

terre. Ils se trouvent à côté de la borne de la mise

à terre à l’intérieur de la boîte électrique.

La sécurité électrique de cet équipement n'est

assurée que lorsque l'équipement est raccordé

comme suit.

MISE A LA TERRE

– Tous les produits doit avoir

les moyens pour la mise à terre par le câble

d’alimentation (en cas d’ un objet connecté par

un câble) ou par une borne de mise à la terre.

La masse doit être séparée du neutre.

Tous les éléments en métal non-conducteur qui

peuvent entrer en contact avec l’utilisateur ou le

technicien qui s’occupe de l’entretien pendant le

normal emploi de la machine ou l’entretien de la

même, doivent être connectés à la terre.

Les conducteurs utilisés pour connecter à la terre

le métal non-conducteur doivent être isolés et

équivalents ou supérieurs à la plus grosse

dimension AWG du conducteur qui fait partie du

composant du métal non-conducteur sur la base

du National Electrical Code ANSI/NFPA 70.

La terre doit être connectée par un élément positif

qui pénètre tous les gaines isolantes et positionné

si de rendre presque impossible de la déplacer

pendant le normal entretien.

Les fils de masse doivent être identifiés par la

couleur vert ou par une ou plusieurs raies jaunes,

et aucun autre conducteur ne doit être ainsi

identifié .

Les bornes de masse doit être identifiées en

utilisant un des moyens suivants :

1. identifié par le symbole de masse

(publication IEC 417, symbole n. 5019)

qui se trouve sur ou à côté du connecteur

(Ill. 0 Fig. 17.1)

2. identifié par ‘G’, ‘GR’, ‘GND’ ‘Terre’ ou

équivalent

3. emploi d’une vis avec tête vert

hexagonale ou avec fente ou les deux

4. emploi d’un goujon fileté avec un écrou

hexagonal vert

5. emploi d’un connecteur terminal à

pression vert .

LA MACHINE DOIT ETRE BRANCHEE A UNE

PRISE DE TERRE QUI FONCTIONNE BIEN

Le constructeur décline toute responsabilité pour

tout endommagement éventuellement provoqué

par l'absence d'une installation efficace de mise à

la terre.

BRANCHEMENT AU RESEAU

ELECTRIQUE

Avant d’utiliser la machine, vérifiez que tous les

systèmes de protection électrique fonctionnent

correctement.

Attention : la machine ne doit pas être

considérée comme isolée du réseau électrique à

moins que elle ne soit pas débranchée de

l’interrupteur principal du client.

- Connecter le cordon d’alimentation au

réseau électrique du client (le câble peut être

relié directement au réseau électrique du

client ou une fiche peut être rajoutée à la

partie finale du cordon. Le fil de terre est vert,

Page 28

28

le neutre est noir et la phase est noir).

Assurez vous que l’unité est correctement

mise à terre.

- Le cordon d’alimentation est attaché d’usine,

si un remplacement est nécessaire faites

attention que : le câble de terre est jaune-vert

et les câbles conducteurs sont noirs ou

marrons.

BRANCHEMENTS AU RESEAU

HYDRAULIQUE

Tous les branchements hydrauliques doivent

être conformes aux normes du International

Plumbing Code, International Code Council

(ICC) et du Uniform Plumbing Code,

International Association of Plumbing and

Mechanical Officials (IAPMO).

Assurez vous que la conduite d’alimentation

hydraulique est soigneusement lavée avant de

connecter le lave-vaisselle.

Il faut enlever tous les déchets étrangers de la

conduite d’alimentation hydraulique afin d’ éviter

qu’ils puissent causer des dommages aux

composants de la machine.

En cas d’entretien, c’est conseillé d’installer un

soupape à fermeture dans la conduite

d’alimentation hydraulique avant de la connexion

à la machine.

La conduite d’alimentation hydraulique doit avoir

une pression du flux entre 1-1,7 bar (15-25 psi) et

la température indiquée dans la plaquette avec

les donnés de la machine.

La pression de flux est la pression dans la

conduite d’alimentation quand l’ électrovanne de

la machine est ouverte pendant le cycle.

La dimension minimale conseillée pour le tube est

de ½’’ .

Pour des installations dans lesquelles la pression

dans la conduite d’alimentation est fluctuante ou

plus haute de la pression nécessaire, c’est

conseillé d’installer un régulateur de la pression

de l’eau ( qui n’est pas inclus dans la machine).

C’est aussi conseillé d’installer un amortisseur

(qui n’est pas inclus dans la machine) dans la

conduite d’alimentation. Cela va éviter des

dommages à la machine causés par le choc

hydraulique dans la conduite d’alimentation.

L'installation doit avoir les caractéristiques

suivantes:

Température eau entrée : 55°C – (131°F)

Pression Dynamique machine en marche :

1,38 +/- 0,34 bar - (138 +/- 38kPa)

20 +/-5 psi

(Voir les données du manomètre pression sur le

panneau frontal)

ATTENTION!

Si la pression d’eau est inférieure à celle

indiquée sur la plaque de l’appareil, il faut

installer une pompe augmentation pression.

Duréte : de 7,2 à 12,5 °f

.

Si les valeurs de dureté sont supérieures à

celles citées il est à conseiller d'utiliser un

adoucisseur d'eau; à défaut de celui-ci il faudra

souvent procéder aux opérations de

désincrustation et augmenter la concentration

de détersif.

Il est conseillé d'utiliser seulement des

adoucisseurs à "échange ionique" à "Osmose

inverse": les procédés basés aux champs

électriques ou aux radiations

électromagnétiques sont tout à fait inutiles pour

l'usage en lave-vaisselle.

CONDUIT: Disposer près de la machine un

robinet d'arrêt d'eau avec filetage taraudé de

3/4" Gas. La machine est dotée d'un tuyau

flexible et d'un filtre pour le branchement au

réseau hydraulique.

TEMPERATURES DE TRAVAIL

Eau de lavage >66°C (>150 °F)

Eau de rinçage 82°÷90°C (180÷195 °F)

NE PAS VIOLER LE TARAGE DES

THERMOSTATS

n.b. Pour un correct fonctionnement du

dispositif “Thermocontrôle ne pas violer le

tarage des thermostats pendant le

fonctionnement du cycle de lavage !

VIDANGE

On peut l'atteindre par la façade de la machine en

enlevant le panneau antérieur.

Le Vidange doit être disposé si possible au sol et

avoir un diamètre de 1"¼ (42 mm) au minimum, muni

d'un siphon et avoir une inclinaison adéquate.

S'il y a déjà une telle installation, mais autrement

disposée, il est possible de brancher le vidange par

Page 29

29

le tuyau flexible de 32 mm de diamètre et le coude en

dotation.

S'assurer qu' il n' y ait pas d' étranglements le long de

celui-ci.

Respecter rigoureusement les normes Nationales et

Régionales concernantes la matière.

Connecter la conduite de vidange

Tous les branchements hy drauliques doit être

conformes aux normes nationales , provinciales et

locales.

SUBSTITUTION DU PRODUIT

LESSIVIEL ET NETTOYAGE DES

TUYAUX DU DOSEUR DE LAVAGE

Lors de la substitution du liquide lessiviel nous vous

recommandons de suivre les consignes suivantes :

- En laissant la machine sans produit lessiviel des

bulles d’air se forment et produisent des

cristallisations.

- Á chaque emploi d’un nouveau produit lessiviel

, il est

nécessaire de procéder au réglage du doseur

- Un nettoyage soigné avec de l’eau de l’ensemble du

système composé d’un bac, de tuyaux de dosage et du

doseur de produit lessiviel doit être effectué avant

toute utilisation de nouveau liquide lessiviel.

- Confier les opérations néc essaires à l’obtention d’un

résultat d’un lavage optimal au technicien du service

d’assistance technique autorisé.

- La fréquence avec laquelle, nous vous

conseillons de procéder au lavage avec de l’eau

des tuyaux de dosage et du doseur est une fois

par mois.

Les conditions de garantie ne s’appliquent pas en

cas de non respect des instructions telles que

décrites ci-dessus. Lamber décline toute

responsabilité sur le produit dans le cas où vous

ne vous conformeriez pas à celles-ci.

Il est possibile de nettoyer vous-même les

tuyaux de dosage et le doseur avec de l’eau.

Veuillez suivre les instructions ci-après:

A - Extraire le tuyau d’aspiration du bac contenant

le liquide lessiviel .

B - Immerger le tuy au d’aspiration dans un

nouveau récipient plein d’eau.

C - Actionner le cycle d’ “Autolavage”

(voir paragraphe spécifique page 15)

D – Une fois la phase d’auto-lavage terminée,

connecter le tuyau d’aspiration au bac

contenant le produit lessiviel .

ATTENTION: Suivre les consignes de

sécurité ainsi que les indications de dosage

concernant l’emploi de produits chimiques.

Porter l’équipement de protection individuelle,

gants et lunettes de protection pendant le

maniement de substances chimiques.

Ne pas mélanger des produits détergents

différents.

ATTENTION! Remplacer une fois par an le tube

d’aspiration de la pompe péristaltique

cod. 0500094 (voir dessin).

Page 30

Connexion soupape antivide:

La machine est livrée avec une soupape antivide conforme à la norme ANSI/ASSE 1001.

Connecter cette soupape en la raccordant au tuyau entrée de la Lave-vaisselle, comme dessin ci-dessous

conformements à la norme ANSI/ASSE 1004.

idr- ul- vacu um

min 6”

Vanne d’arrêt

Branchement eau

Tuy au c h a r geme nt eau

Soupape antivide

6” pour

ASSE standards

Niveau maximum

de l’eau

Branchement eau

Souder !

Installation Soupape antivide

Lave-vaisselle/Verres

Tuy au c h a r geme nt eau

cod.0900007

Raccord ½ ”

cod.0200944

Raccord reduit 3/4 -½”

cod.0200919

”

cod.0500603

Soupape antivide

Page 31

SCHEMA BRANCHEMENTS

CONNECTIONS SCHEME

1

1

2

1

3

2

2

3

3

White - Blanc

Blue - Bleu

Staples - Ponts

TANK Elements

Résistance CUVE

21

Brown

Marron

Blue

Bleu

+

+

Regulation screw

Vis de regulation

Regulation screw

Vis de regulation

- To increase t he

detergent do se t urn

CW t he regulation

screw .

- To increase t he

detergent d ose tur n

CW t he regulation

screw .

- Tourner da ns l e

sens de s aiguilles

d’une mo ntre la

vis de régulation.

- Tourner d ans l e

sens d es aiguilles

d’une m ontre la

vis de ré gulation.

RINSE AID PUMP

DETERGENT PUMP

DOSEUR PRODUIT DE RINÇAGE

DOSEUR PRODUIT DE LAVAGE

Lava ge

Wash

Rinse

Rinçage

BOILER Elements

Résistance SURCHAUFFEUR

English :

Feeders (rinse-aid, or detergent) are OPTIONAL. When provided see instructions below :

"The machine must be operated with an automatic detergent feeder, including a visual means to verify that

detergents and sanitizers are delivered or a visual or audible alarm to signal if detergents and sanitizers

are not available for delivery to the respective washing and sanitizing systems.

Please see instructions for electrical and plumbing connections located in this manual and in the feeder

equipment manual."

Français

Les doseurs du detergent et de produit de rinçage sont OPTIONAL. Quand ils sont en dotation voir les

instructions suivantes :

Il faut faire fonctionner la machine avec un doseur automatique du détergent, incluant un moyen visuel pour

vérifier que les détergents et les produits de rinçage so ient distribués ou une alerte visuelle ou acoustique

pour signaler si les détergents et les produits de rinç age ne sont pas disponibles pour être distribués aux

systèmes de lavage et rinçage. SVP veuillez voir les instructions pour les branchements électriques et

hydrauliques qui se trouvent dans ce manuel et dans le manuel du doseur.

Page 32

SCDOSF92-EK-UL-2013

A-

+

Wash and rinse thermostats

Thermostats Lava ge et rinç age

Rinse-aid inlet

Entrée du produit de rinçage

REGULATION SCHEME

SCHEMA REGULATION

W

A

S

H

I

N

G

L

A

V

A

G

E

R

I

N

S

E

R

I

N

Ç

A

G

E

Wash and rinse thermostats

Thermostats Lavage et rinçage

Rinse thermostat

Thermostat rinçage

Wash thermostat

Thermostat Lavage

A

82 ÷90 ° C

(180÷195 °F )

(>150 °F )

>6 6 ° C

Page 33

Page 34

Page 35

123

4

1234

FA9

FA1

FA2

FA3

FA4

FA5

FA6

FA7

FA8

FA10

FA11

FA12

FA13

FA14

FA15

F92-ek

Cod.0300824

FONCTION CYCL E

CYC LE FUNC TION

MANUAL CYCLE

CYCL E MA NUEL

AUTOMATIC CY CLE

CYCLE AUTOMATIQ UE

1

OFF

ON

2

- WASH TIME SELECTION TABLE

- TABLEAU SELECTION TEMPS DE LAVAGE

LED1=ON LED2=ON

LED1+2=ON

60”

120”

120”

180”