Page 1

ALAMBDA

LAMBDA ELECTRONICS

MELVILLE.

L. I.. N. Y.

Page 2

INSTRUCTION MANUAL

FOR

REGULATED POWER SUPPLIES

LDS-P-SERIES

inis manual provides instructions intended for the operation of Lambda power supplies, and is not to be

reproduced without the written consent of Lambda Electronics. All information contained herein applies

to all LDS-P models unless otherwise specified.

LAMBDA ELECTRONICS MELVILLE, L.I., N.Y.

MAIN PLANT TELEPHONE: (516) 694-4200

IM-LDS-P

Page 3

TABLE OF CONTENTS

Section Page

SPECIFICATIONS AND FEATURES 1

OPERATING INSTRUCTIONS 4

Basic Mode of Operation 4

Connections for Operation 4

Supply Load Connections 4

Mounting of Optional Overvoltage Protector Accessories 6

Operation After Protective Device Shutdown 6

MAINTENANCE 6

General 6

Trouble Analysis 6

Checking Transistors and Capacitors 7

Printed Circuit Board Maintenance Techniques 7

Performance Checks 8

Adjustment of Calibration CoAtrol R105 8

SERVICE 9

PARTS ORDERING 9

ii IM-LDS-P

Page 4

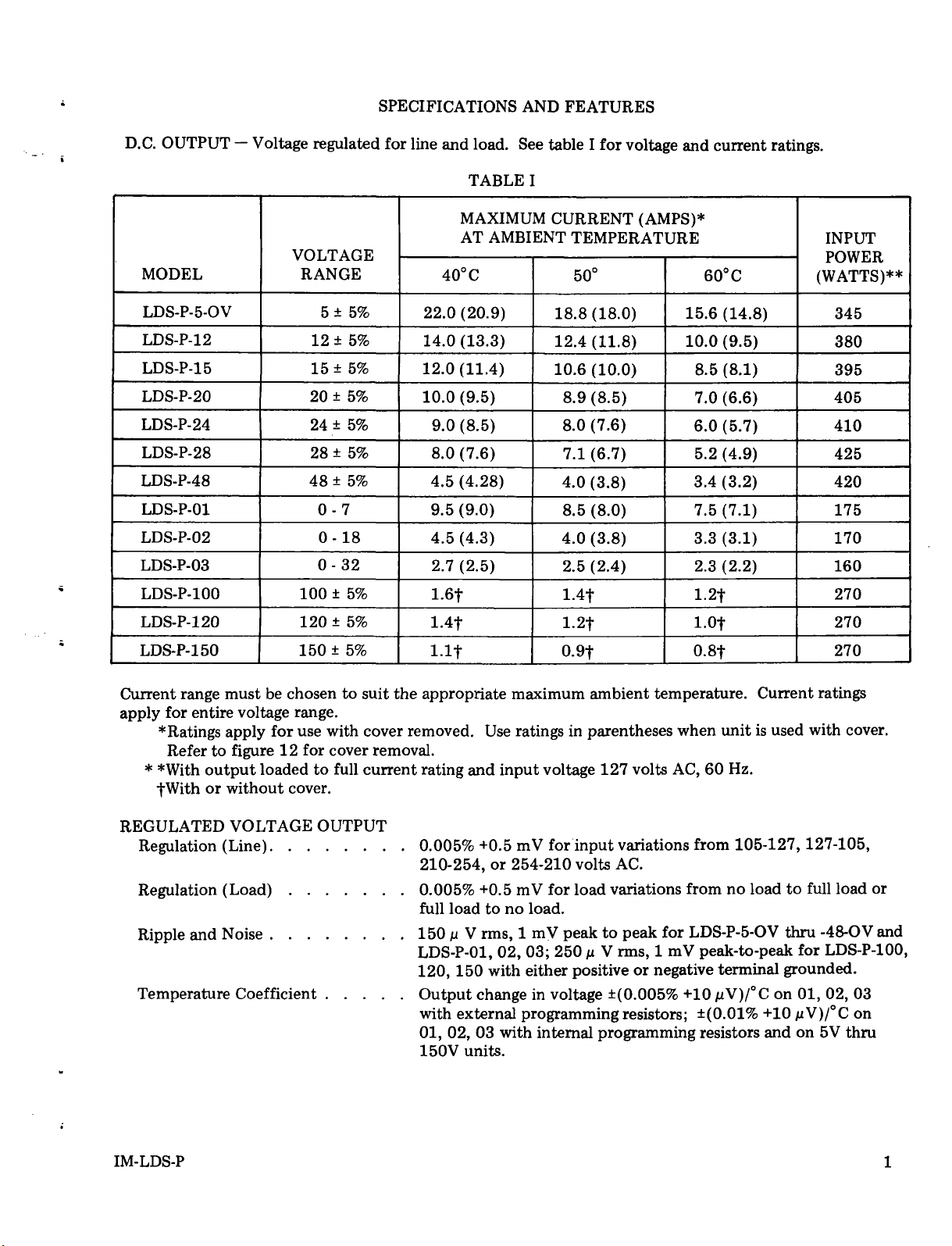

SPECIFICATIONS AND FEATURES

D.C. OUTPUT — Voltage regulated for line and load. See table I for voltage and cunent ratings.

TABLE 1

MAXIMUM CURRENT (AMPS)*

AT AMBIENT TEMPERATURE

VOLTAGE

MODEL

RANGE

40° C

50°

60°C

(WATTS)**

INPUT

POWER

LDS-P-5-0V

LDS-P-12

LDS-P-15

LDS-P-20

LDS-P-24

LDS-P-28

LDS-P-48

LDS-P-01

LDS-P-02

LDS-P-03

LDS-P-100

LDS-P-120

LDS-P-150

Current range must be chosen to suit the appropriate maximum ambient temperature. Cunent ratings

apply for entire voltage range.

*Ratings apply for use with cover removed. Use ratings in parentheses when unit is used with cover.

Refer to figure 12 for cover removal.

* *With output loaded to full cunent rating and input voltage 127 volts AC, 60 Hz.

fWith or without cover.

5± 5%

12 ± 5%

15 + 5%

20 ± 5%

24 ± 5%

28 ± 5%

48 ± 5%

0-7

0-18

0-32

100 ± 5%

120 ± 5%

150 ± 5%

22.0(20.9)

14.0(13.3)

12.0(11.4)

10.0(9.5)

9.0(8.5)

8.0(7.6)

4.5 (4.28)

9.5 (9.0)

4.5(4.3)

2.7 (2.5)

1.6t

1.4t

l.lt

18.8(18.0)

12.4(11.8)

10.6 (10.0)

8.9(8.5)

8.0 (7.6)

7.1 (6.7)

4.0(3.8)

8.5 (8.0)

4.0(3.8)

2.5 (2.4)

1.4t

1.2t

0.9t

15.6 (14.8)

10.0(9.5)

8.5(8.1)

7.0(6.6)

6.0(5.7)

5.2 (4.9)

3.4(3.2)

7.5(7.1)

3.3 (3.1)

2.3 (2.2)

1.2t

i.ot

0.8t

345

380

395

405

410

425

420

175

170

160

270

270

270

REGULATED VOLTAGE OUTPUT

Regulation (Line) 0.005%+0.5 mV for input variations from 105-127, 127-105,

210-254, or 254-210 volts AC.

Regulation (Load) 0.005%+0.5 mV for load variations from no load to full load or

full load to no load.

Ripple and Noise 150

Temperature Coefficient Output change in voltage ±(0.005%+10 MV)/°C on 01, 02, 03

IM-LDS-P

/n

V rms, 1 mV peak to peak for LDS-P-5-OV thru -48-OV and

LDS-P-01,

120,

with external programming resistors;

01,

02, 03 with intemal programming resistors and on 5V thm

150V units.

02, 03; 250

150 with either positive or negative terminal grounded.

^i

V rms, 1 mV peak-to-peak for LDS-P-100,

±(0.01%

+10 /iV)/°C on

Page 5

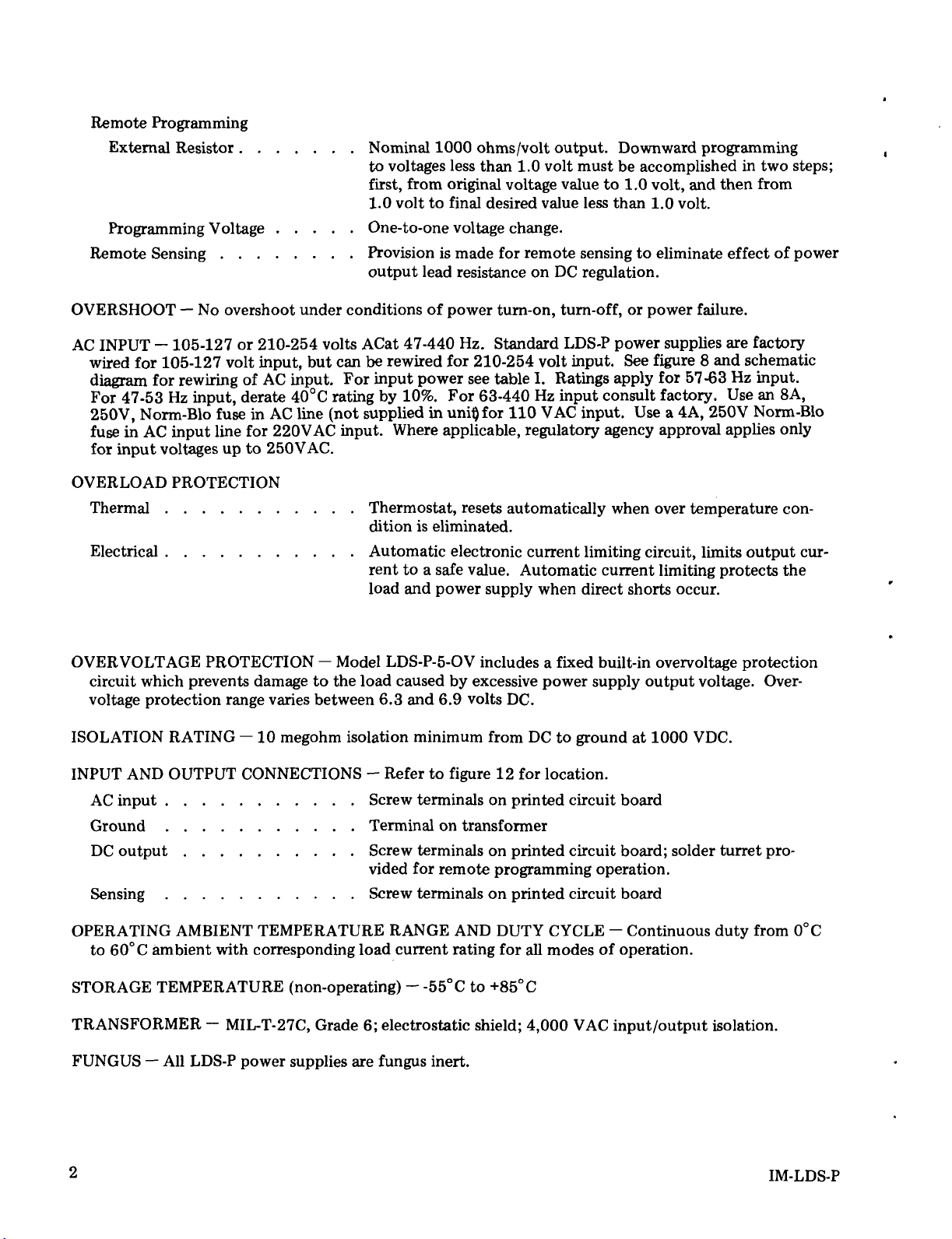

Remote Programming

Extemal Resistor Nominal 1000 ohms/volt output. Downward programming

to voltages less than 1.0 volt must be accomplished in two steps;

first, from original voltage value to 1.0 volt, and then from

1.0 volt to final desired value less than 1.0 volt.

Programming Voltage One-to-one voltage change.

Remote Sensing Provision is made for remote sensing to eliminate effect of power

output lead resistance on DC regulation.

OVERSHOOT — No overshoot under conditions of power tum-on,

AC INPUT — 105-127 or 210-254 volts ACat 47-440 Hz. Standard LDS-P power supplies are factory

wired for 105-127 volt input, but can be rewired for 210-254 volt input. See figure 8 and schematic

diagram for rewiring of AC input. For input power see table I. Ratings apply for 57-63 Hz input.

For 47-53 Hz input, derate 40°C rating by 10%. For 63-440 Hz input consult factory. Use an 8A,

250V, Norm-Blo fuse in AC line (not supplied in uni^for 110 VAC input. Use a 4A, 250V Norm-Blo

fuse in AC input line for 220VAC input. Where applicable, regulatory agency approval applies only

for input voltages up to 250VAC.

OVERLOAD PROTECTION

Thermal Thermostat, resets automatically when over temperature con-

dition is eliminated.

Electrical Automatic electronic cunent limiting circuit, limits output cur-

rent to a SEife value. Automatic cunent limiting protects the

load and power supply when direct shorts occur.

OVERVOLTAGE PROTECTION - Model LDS-P-5-OV includes a fixed built-in overvoltage protection

circuit which prevents damage to the load caused by excessive power supply output voltage. Over-

voltage protection range varies between 6.3 and 6.9 volts DC.

ISOLATION RATING — 10 megohm isolation minimum from DC to ground at 1000 VDC.

turn-off,

or power failure.

INPUT AND OUTPUT CONNECTIONS - Refer to figure 12 for location.

AC input Screw terminals on printed circuit board

Ground Terminal on transformer

DC output Screw terminals on printed circuit board; solder tunet pro-

vided for remote programming operation.

Sensing Screw terminals on printed circuit board

OPERATING AMBIENT TEMPERATURE RANGE AND DUTY CYCLE - Continuous duty from 0°C

to

60° C

ambient with conesponding load cunent rating for all modes of operation.

STORAGE TEMPERATURE (non-operating) - -55°C to +85°C

TRANSFORMER - MIL-T-27C, Grade 6; electrostatic shield; 4,000 VAC input/output isolation.

FUNGUS — All LDS-P power supplies are fungus inert.

IM-LDS-P

Page 6

DC OUTPUT CONTROL — Screwdriver voltage adjust control permits adjustment of DC output voltage.

Refer to figure 12 for location of control. On wide range models, an adjustment range of 1%

to

VQ

max is provided by the intemal programming potentiometer; programming over the full 0 to

VQ

max range can be accomplished by remote programming.

PHYSICAL DATA

Size 11" X 4-7/8" x 4-13/32" with or without cover in place

Weight 14 lbs. net., 15-1/2 lbs. shipping

Finish Gray, FED. STD. 595 No. 26081

MOUNTING — One surface, with tapped mounting holes, can be utilized for mounting this unit. The

supply must be mounted with top side facing up, in horizontal plane.

ACCESSORIES

Overvoltage Protector Internally mounted L-35-OV-5 series overvoltage protector,

standard on 5V unit. Intemally mounted L-20-OV series over-

voltage protectors optional on LDS-P-12 thm LDS-P-28; overvoltage protector L-35-OV-6 optional on LDS-P-6 smd overvoltage protector LMOV-3 optional on model LDS-P-48. LHOV

series adjustable overvoltage protector accessory optional for

models LDS-P-01 through LDS-P-03.

VQ

max

IM-LDS-P

Page 7

OPERATING INSTRUCTIONS

BASIC MODE OF OPERATION

This power supply operates as a constant voltage source provided the load cunent does not exceed

the rated value at 40°C. For continuous operation, load current must not exceed the rating for each

Eunbient temperature. When load exceeds 105% of

voltage reaches zero and the cunent at short circuit equals approximately 20 percent or less of the rated

current. (For wide range models, 01, 02 and 03 short circuit current equals the rated cunent).

CONNECTIONS FOR OPERATION

NOTE: Make all connections to the unit before applying AC input power.

Ground Connections. The Lambda power supply can be operated either with negative or positive output

tenninal grounded. Both positive and negative ground cormections Eire shown for all suggested output

connections illustrated in this manual.

Connection Terminals. Make all connections to the supply at the terminals provided. Apply input power

to AC terminals; always connect the ungrounded (hot) lead to terminal indicated in figures 3 through 9.

The supply positive terminal is brought out to terminal +V. The supply negative terminal is brought

out to terminal -V. Recommended wiring of the power supply to the load and selection of wiring is shown

in figures 1 through 9. Selection of proper wiring is made on the basis of load requirements. Make all performance checks as shown in figure 11. Connect measuring devices directly to terminals or use the

shortest leads possible.

40° C

rating, both voltage and current decrease until

SUPPLY LOAD CONNECTIONS

Connections for Operation as a Constant Voltage Source

The output impedance and regulation of the power supply at the load may chemge when using the

supply as a constant voltage source and connecting leads of practical length are used. To minimize the

effect of the output leads on these characteristics, remote sensing is used. Recommended types of supplyload connections with local or remote sensing are described in the following paragraphs.

Refer to figure 1 to determine voltage drop for particular cable length, wire size and cunent condi-

tions.

Lead lengths must be measured from supply terminals to load terminals as shown in figure 2.

Local Sensing Connection, Figure 3. Local sensing is the connection suitable for application with relatively constant load or for applications with short power output leads.

Remote Sensing Connection, Figure 4. Remote sensing provides complete compensation for the DC

voltage drops in the connecting cables. Sensing leads should be a twisted pair to minimize AC pick-up. A

2.5 mf, elect., capacitor may be required between output terminals and sense tenninals to reduce noise

pick-up.

Programmed Voltage Connections, Using External Resistor, Figure 5. Discrete voltage steps can be programmed with a resistance voltage divider valued at 1000 ohms/volt change and shorting-type switch as

shown in figure 5. When continuous voltage variations axe required, use a variable resistor with the same

1000 ohms/volt ratio in place of the resistive voltage divider and shorting-type switch. Use a low

temperature coefficient resistor to assure most stable operation. On wide range models, downward

A IM-LDS-P

Page 8

programming to voltages less than 1.0 volt must be accomplished in two steps: first from original

voltage value to 1.0 volt and then from 1.0 volt to final desired value less than 1.0 volt.

Before programming, adjust programming resistor for zero resistance and set volteige adjust control

to the minimum rated output voltjige. Output voltage of programmed supply wiU be minimum output

voltage plus 1 volt per 1000 ohms.

As shown in figure 5, voltages can be programmed utilizing either local or remote sensing con-

nections, as desired.

Programmed Voltage Connections Using Programming Voltage, Figure 6. The power supply voltage

output can be programmed with an extemally connected programming power supply. The output

voltage change of the programmed supply will maintain a one-to-one ratio with the voltfige of the

programming supply. If the output voltage control of the programmed supply is set to minimum output voltage, output voltage of programmed supply will be minimum output voltage plus voltage of

programming supply.

The programming supply must have a reverse current capability of 2 ma. minimum.

Altematively, when supplies with less than 2 ma. reverse current capability are used, a resistor

capable of drawing 2 ma. at the minimum programming voltage must be connected across the out-

put terminals of the supply. This programming supply must be rated to handle all excess resistor current at the maximum programming voltage.

Connections For Series Operation, Figure 7.

The voltage capability of LDS-P power supplies can be extended by series operation. Figure 7

shows the connections for either local or remote sensing in a series connection where the voltage con-

trol of each unit functions independently to control the output.

A diode, having a current carrying capability equal to or greater than the maximum cunent

rating of the supply, must be used and connected as shown in figure 7. The diode blocking voltage

should be at least twice the maximum rated output voltage of the supply. See table I, of "Specifi-

cations and Features", for power supply current and voltage ratings.

Connections For Parallel Operation, Figure 9 (Applicable only to LDS-P-01 — LDS-P-03)

The current capability of LDS-P power supplies can be extended by parallel operation of LDS-P

power supplies of equal* voltage capacities.

Units "M" and "S" are shown connected for parallel operation in figures 9A and 9B. One power

supply, designated the "M" unit, controls its own output as well as the output of the second power

supply, designated the "S" unit.

*For applications using supplies of unequal voltage ratings, consult factory for details of

operation.

Unit S operates to regulate its current in a ratio to that of the M unit by comparing the current

in its internal sampling resistor with that cunent sampled by the master intemal sampling resistor.

CAUTION: Always set "S" unit voltage control to zero (fuUy CCW)

during parallel operation, otherwise excessive cunent will flow through

"M"

unit voltage control.

IM-LDS-P

Page 9

MOUNTING OF OPTIONAL OVERVOLTAGE PROTECTOR ACCESSORIES

Mount L-20-OV and L-35-OV protectors to the power supply using two 6-32 x 3/8" pan-head

screws and 2 #6 split lockwashers. Overvoltage protectors LMOV-3 and LHOV series have 6-32 captive screws for mounting the protector to the chassis.

Two 6-32 threaded holes are available on the chassis adjacent to the transformer for mounting

the OV protector.

After mounting, connect wires from overvoltage protector +V terminal to +V terminal on printed

circuit board and from -V to -V terminal on printed circuit board. For models LDS-P-01 thru LDS-P-03

and LDS-P-48, which use LHOV and LMOV protectors respectively, two tie points, adjacent to the

transformer, and provided for use as intermediate connection points between the protector and the unit

output voltage terminals. Protector red lead connects to one tie point and unit +V output terminal and

protector black lead connects to other tie point and unit -V output terminal.

OPERATION AFTER PROTECTIVE DEVICE SHUTDOWN

Thermostat Shutdown

The thermostat opens the input circuit only when the temperature of the intemal heat sink exceeds a maximum safe value. The thermostat will automatically reset when the temperature of the heat

sink decreases to a safe operating value. After eliminating the cause(s) for overheating and allowing

time for the power supply to cool to a proper temperature, resume operation of the supply.

Overvoltage Shutdown (LDS-P-5-0V only)

When the power supply output voltage increases above the overvoltage limit, the protector will

short circuit output of the supply. After eliminating the cause(s) for overvoltage, resume operation of

the supply by momentarily interrupting the AC input circuit.

MAINTENANCE

GENERAL

This section describes trouble analysis routine, replacement procedures, calibration and test procedures that are useful for servicing the Lambda LDS-P power supply. Refer to the section on specifications and features for the minimum performance standards.

TROUBLE ANALYSIS

Whenever trouble occurs, systematically check fuse, primary power lines, extemal circuit elements,

and extemal wiring for malfunction before trouble shooting the equipment. Failures and malfunctions

often can be traced to simple causes such as improper jumper and supply-load connections or fuse

failure due to metal fatigue.

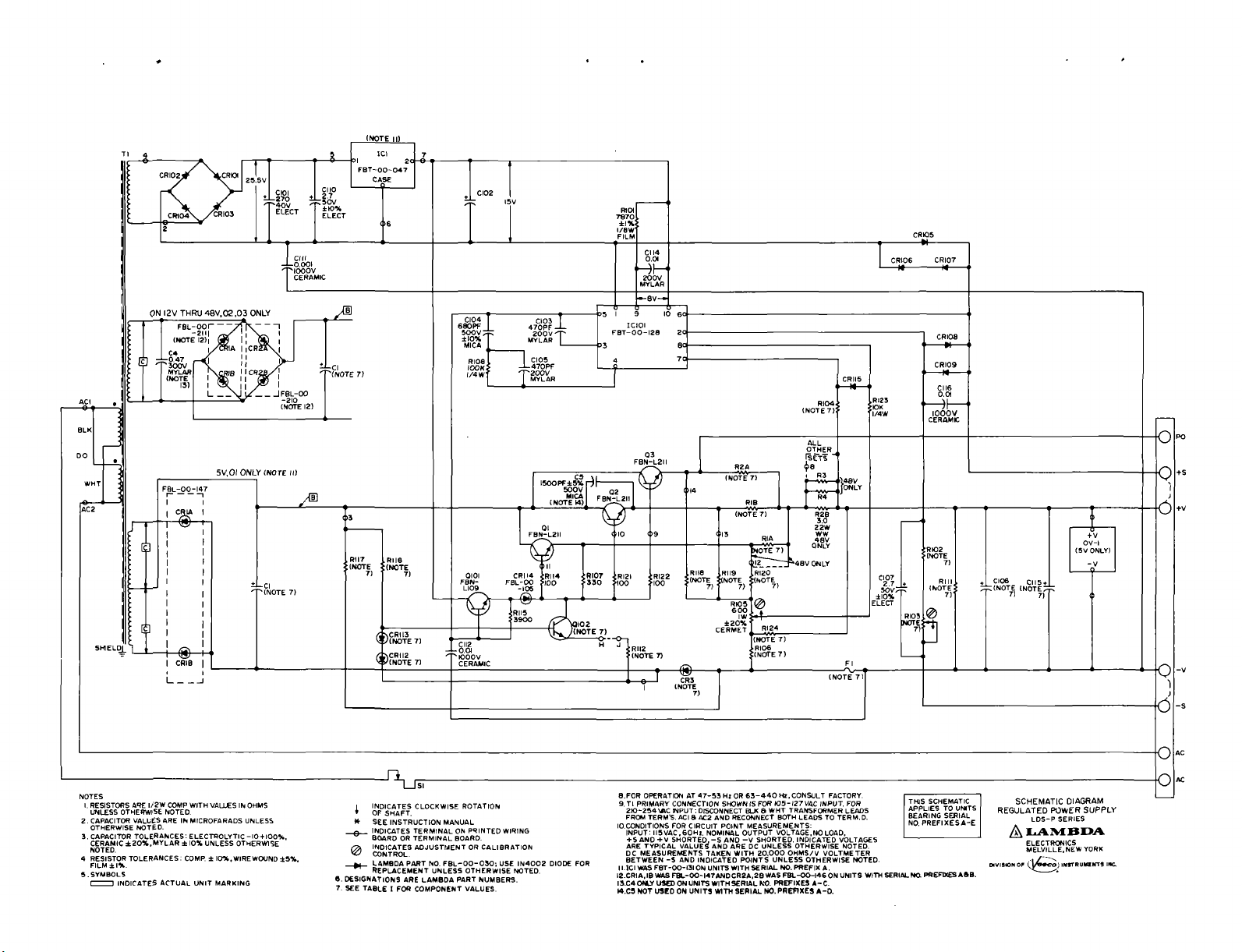

Use the electrical schematic diagram and block diagram, figure 11 as an aid to locating trouble

causes. The schematic diagram contains various circuit voltages that are averages for normal operation.

Measure these voltages using the conditions for measurement specified on the schematic diagram. Use

measuring probes carefully to avoid causing short circuits and damaging circuits components.

IM-LDS-P

Page 10

CHECKING TRANSISTORS AND CAPACITORS

Check transistors with an instrument that has a highly limited current capability. Observe proper

polarity to avoid enor in measurement. The forward transistor resistance is low but never zero; backward resistance is always higher than the forward resistance.

For good transistors, the forward resistance for any function is always greater than zero.

Do not assume trouble is eliminated when only one part is replaced. This is especially true when

one transistor fails, causing other transistors to fail. Replacing only one tnmsistor and tuming power

on, before checking for additional defective components could damage the replaced component.

When soldering semi-conductor devices, wherever possible, hold the lead being soldered with a pair

of pliers placed between the component and the solder joint to provide an effective heat sink.

NOTE: The leakage resistance obtained from a simple resistance check of a capacitor

is not always an indication of a faulty capacitor. In all cases the capacitors are

shunted with resistances, some of which have low values. Only a dead short is

a true indication of a shorted capacitor.

PRINTED CIRCUIT BOARD MAINTENANCE TECHNIQUES

1.

If foil is intact but not covered with solder, it is a good contact. Do not attempt to cover with

solder.

2.

Voltage measurements can be made from either side of the board. Use a needle point probe to

penetrate to the wiring whenever a protective coating is used on the wiring. A brass probe can be soldered to an alligator clip adapted to the measuring instrument.

3.

Wherever possible use a heat sink when soldering transistors.

4.

Broken or damaged printed wiring is usually the result of an imperfection, strain or careless

soldering. To repair small breaks, tin a short piece of hook-up wire to bridge the break, and holding the

wire in place, flow solder along the length of wire so that it becomes part of the circuitry.

5.

When unsoldering components from the board never pry or force loose the part; unsolder the

component by using the wicking process described below:

a) Select a 3/16 inch tinned copper brziid for use as a wick; if braid is not available, select

AWG No. 14 or No. 16 stranded wire with 1/2 inch insulation removed.

b) Dip the wick in liquid rosin flux.

c) Place the wick onto the soldered connection and apply soldering iron onto the wick.

d) When sufficient amount of solder flows onto the wick, freeing the component, simul-

taneously remove iron and wick.

IM-LDS-P

Page 11

PERFORMANCE CHECKS

Check the ripple and regulation of the power supply using the test connection diagram shown in

figure

11.

Use suggested test equipment or equivalent to obtain accurate results. Refer to SPECIFI-

CATIONS AND FEATURES for minimum performance standards.

Set the differential meter, DC DVM (John Fluke Model 891A or equivalent) to the selected

power supply operating voltage. Check the power supply load regulation accuracy while switching

from the load to no-load condition. Long load leads should be a twisted pair to minimize AC pick-up.

Use a Variac to vary the line voltage from 105-127 or 127-105 volts AC and check the power

supply line regulation accuracy on the DVM differential meter.

Use a TVM, John Fluke Model 893AB or equivjilent, to measure rms ripple voltage of the power

supply DC output. Use oscilloscope to measure peak-to-peak ripple voltage of the power supply DC

output. Connect oscilloscope probes directly across the +V and -V output terminals. Position probes

upward and take care to use short probe leads placed away from any otiier wires.

ADJUSTMENT OF CALIBRATION CONTROL R105

Whenever R104, R105, R106, R124, RIA, RIB, R2B, R3, R4 or ICIOI are replaced, and voltage

and current indications do not reflect maximum ratings, adjust R105 as follows. The adjustment procedure requires that the power supply is removed from associated equipment, is at an ambient temperature of 25-30° C, and is stabilized and not operating.

1.

Remove AC input power to the supply.

2.

Break seal on wiper of R105 from resistor housing.

3.

Operate power supply for constant voltage with local sensing, connected as shown in figure 3

with no extemal load.

4.

Tum voltage adjust control until minimum rated output voltage is obtained.

5.

Apply load so that output current is 105% of 40°C rating for the unit. It may be necessary to

tum R105 CW in order to achieve this value of current.

6. Using a DVM John Fluke 891A or equivalent, observe output voltage while adjusting R105 in

CCW direction. Adjust R105 until output voltage begins to decrease.

7.

Tum voltage adjust control until maximum rated output voltage is obtained.

8. Increase load. Maximum attainable load current shaU not exceed 110% of 40° C rating for the

unit.

9. After adjustment is completed, remove AC power input to the supply and use glyptol sealant

to seal wiper of R105 to resistor housing.

10.

After sealing, check setting and repeat adjustment procedure if required.

IM-LDS-P

Page 12

SERVICE

When additional instructions are required or repair service is desired, contact the nearest Lambda

office where trained personnel and complete facilities are ready to assist you.

Please include the power supply model and serial number together with complete details of the

problem. On receipt of this information Lambda will supply service data or advise shipping for factory

repair service.

All repairs not covered by the warranty will be billed at cost and an estimate forwarded for ap-

proval before work is started.

PARTS ORDERING

Standard components and special components used in the Lambda power supply can be obtained

from the factory. In case of emergency, critical spare parts are available through any Lambda office.

The following information must be included when ordering parts:

1.

Model number and serial number of power supply and purchase date.

2.

Lambda part number.

3.

Description of part together with circuit designation.

4.

If part is not an electronic part, or is not listed, provide a description, function, and location,

of the part.

IM-LDS-P

Page 13

350

300

K 250

X^ 200

Z^

SiD 150

^

5 100

-

-

-

-

- /

/ /

'/

/

/

/

./I

/

*y

^

itp^

^

/

•

-

^-

^^

^//H

50

^s

CABLE LENGTH 'W IN FEET (SEE FIG. 2)

Figure 1. Cable Connection Chart

+

DC»-

POWER

SUPPLY

-DC^

Figure 2. Cable Length "A" in Feet

OPTIONAL

OVERVOLTAGE

PROTECTOR

AC INPUT

105-127 VAC

+0V -OV

+S +V -V -S 47-440 Hz ^

^M.

OR

210-254 VAC

® o 9

MM

-J

^-

_#JQ

—\ '

5 10 15 20

1

"A" 1

_-^

1

OPTIONAL

OVERVOLTAGE

PROTECTOR

1

LOAD

6^

+0V

+S +V -V -S 47-440 Hz i

-OV

25

ACINPUT

105-127 VAC

210-254 VAC

OR

LOAD

M CONNECT UNGROUNDED(HOT)LEAD

TO THIS TERMINAL

MM FOR NEGATIVE

JUMPER FROM TERMINALS +Va^

AND RECONNECT TO TERMINALS-V 8 •#.

Figure 3. Local Sensing Connection.

GROUND.

DISCONNECT

LOAD

M CONNECT UNGROUNDED (HOT) LEAD

TO THIS TERMINAL

M M A 2.5MF,ELECT.,CAR MAY BE REQUIRED

MMMFOR NEGATIVE GROUND.DISCONNECT

JUMPER FROM TERMINALS +V8^

AND RECONNECT TO TERMINALS-V8^.

Figure 4. Remote Sensing Connection.

Page 14

OPTIONAL

OVERVOLTAGE

PROTECTOR

AC INPUT

'^~5

+0V -OV

+S +V -V

(A) LOCAL SENSING (B) REMOTE SENSING

105-127 VAC

OR

210-254 VAC ,

SRP47-440HZ -^

99 ® o

MM*

I.

-^^-

-)^^

2.5 MF

200V

M CONNECT UNGROUNDED (HOT) LEAD TO THIS TERMINAL.

M M

A 2.5

MMM FOR NEGATIVE GROUND.DISCONNECT JUMPER FROM

TERMINALS +V 8 ^ AND RECONNECT TO TERMINALS

1

MF,

ELECT.CAR MAY BE REQUIRED.

PO

o

OPTIONAL

OVERVOLTAGE

PROTECTOR

5

+0V -OV OR

+S W -V -SRP47-440HZ *

77 AC INPUT

vJ 105-127 VAC

- ')oq> ®o o

-^AAr-

TsMF

-va-i-.

+ LDS-01,02,03 OM.Y,USE RP TERMINAL INSTEAD OF-S;

-S IS LEFT OPEN.

210-254VAC ,

I

»J^m I

-^^r

200V

PROGRAMMING

VOLTAGE

.^

(A) LOCAL SENSING

MMA2.5 MF,ELECT..CAP. MAY BE REQUIRED.

M)»i(FOR NEGATIVE GROUND. DISCONNECT JUMPER FROM

Figure 5. Programmed Voltage, With Extemal Resistor.

OPTIONAL

OVERVOLTAGE

PROTECTOR

Z~^

+0V -OV

S

RP

ACINPUT

105-127 VAC

OR

210-254 VAC ,

47-440 Hz +

OPTIONAL

OVERVOLTAGE

PROTECTOR

'^~5

+0V

+S

-OV OR

+V -V -SRP47-440HZ +

• 99 ®o

PROGRAMMING

VOLTAGE

^

(B) REMOTE SENSING

^CONNECT UNGROUNDED (HOT) LEAD TO THIS TERMINAL

TERMINALS +Va ^ AND RECONNECT TO TERMINALS

-va*.

+ LDS-01,02,03 ONLY, USE RP TERMINAL INSTEAD OF -S;

-S LEFT OPEN.

Figure 6. Programmed Voltage, With Extemal Programming Voltage Source.

AC INPUT

I05-I27V!AC

210-254 VAC ,

Page 15

OPTIONAL

OVERVOLTAGE

PROTECTOR

^^

+0V -OV

•l-S +V -V -S 47-440 Hz ^

AC INPUT

105-127 VAC

OR

210-254 VAC

@

o

MMM

1

OPTIONAL

OVERVOLTAGE

PROTECTOR

-l-OV

•l-S -l-V

-OV

-V -S

QO

iM-

^

AC INPUT

105-127 VAC

OR

210-254 VAC ,

47-440 Hz i

@o 9

i\

MMM

I

LOAO

OPTIONAL

OVERVOLTAGE

PROTECTOR

LOAD

MMA2.5MF.ELECT,CAR MAY BE REQUIRED.

MMMMAKE ONLY ONE GROUND CONNECTION FOR SERIES

LOAD

(A) LOCAL SENSING

OPTIONAL

OVERVOLTAGE

PROTECTOR

AC INPUT

105-127 VAC

OR

210-254 VAC I

47-440 Hz ^

® O

_««.•*_

MCONNECTUNGROUNDED(HOT)LEAD TO THIS TERMINAL.

COMBINATION.

JUMPER FROM TERMINALS +V 8 ^ ON LEFT UNIT AND

CONNECT ANY ONE OF THE JUMPERS AS SHOWN IN

DOTTED LINE.

9

/

(B) REMOTE SENSING

TO

CHANGE GROUND AS SHOWN.REMOVE

+0V -OV

+ S -fV -V -S 47-440 Hz ^

QQ QQ

M P

LOAD

ACINPUT

105-127 VAC

210-254 VAC

_

OR

® o

?

/I

Figure 7. Series Connection.

o

Tl

4

AQ D AC2

Lk UUl

BLK WHT

CONNECTION SHOWN IS FOR 105-127 VAC FOR 2I0-254V

INPUT,DISCONNECT BLK 8 WHT TRANSFORMER LEADS

FROM TERMS ACI 8 AC2 AND RECONNECT BOTH LEADS

TO TERM D.

Figure 8. Transformer Connections for AC Input Conversion.

Page 16

(S)UNIT (M) UNIT

OPTIONAL

OVERVOLTAGE

PROTECTOR

6^

+0V -OV

PO -l-S -l-V -V -S

00 Q ®O O

^

OPTIONAL

OVERVOLTAGE

PROTECTOR

AC INPUT

105-127 VAC

OR

210-254 VAC

47-440 Hz

* CONNECT UNGROUNDED (HOT) LEAD TO THIS TERMINAL.

* a FOR NEGATIVE

TERMINALS -l-V

J-

GROUND.

a^AN6

DISCONNECT JUMPER FROM

RECONNECT TO TERMINALS-Va

^^

-l-OV -OV

PO -f-S -HV -V -S

AC INPUT

105-127 VAC

OR

210-254 VAC

47-440 Hz

-L

® o 9

MM

(A) LOCAL SENSING

(S)UNIT

OPTIONAL

OVERVOLTAGE

PROTECTOR

^6

•l-OV

PO -l-S -l-V -V -S 47-440 Hz 4^

^

-OV

QO

I

AC INPUT

I05-I27VAC

OR

210-254 VAC

® O O

(M)UNIT

OPTIONAL

OVERVOLTAGE

PROTECTOR

^6

-^ov -OV

PO -l-S -FV -V -s

MM

MM MM

LOAD

ACINPUT

105-127 VAC

OR

210-254 VAC

47-440 Hz

® o 9

*MM

._/

M

CONNECT UNGROUNDED (HOT) LEAD TO THIS TERMINAL.

** A2.5MF.ELECT.CAP.MAY BE REQUIRED.

MMM FOR NEGATIVE GROUND. DISCONNECT JUMPER FROM

TERMINALS -FV 8 ^AND RECONNECT TOTERMINALS-va-

(B)REMOTE SENSING

Figure 9. Parallel Connection

Page 17

PREREGULATOR

ICI

CURRENT

COMPARATOR

AUX.RECT

8 FILTER

CRI0I-CRI04

ClOI

—^THANSFORMEF

MTHIS CIRCUIT ELEMENT IS LOCATED IN ICIOI

XX ONLY USED ON LDS-P-48

Tl

Figure 10. Typical Block Diagram

OSCILLOSCOPE

1^

AMPLIFIER

SERIES

REGULATOR

01,02,03

POWER SUPPLY

+S +V -V -S

CURRENT

SENSING

RIA,RIB

KKR2B.R3J»1

ACINPUT

105-127 VAC

210-254 VAC

47-440 Hz

® Q

OR

VOLTAGE

COMPARA"rOR

VOLTAGE

SENSING

NETWORK

DC.

OUTPUT

J

RIPPLE

METER

M

CONNECT UNGROUNDED (HOT) LEAD TO THIS TERMINAL

NOTES:

I. REGULATION AND RIPPLE CHECKMETERS MUST NOT BE

GROUNDED THROUGH THREE-WIRE LINE CORD TO GROUND.

2.

PERFORM CHECKS WITH LOCAL SENSING CONNECTK>NS ONLY.

3 FOR RIPPLE MEASUREMENTS DRESS LOAD WIRES CLOSE TO

EACH OT«R AND AWAY FROM THE AC-LINE CORD TO PREVENT

PICK-UP.

SWITCH-

-/.

DIFFERENTIAL

METER

II5VAC

Figure 11. Test Connections for Constant Voltage Performance <3iecks.

LINE

GND

Page 18

VOLTAGE ADJUST-

L-35-0V-5,OVERVOLTAGE PROTECTOR

STANDARD FOR 5V UNITS

L-35-0V-6 ACCESSORY FOR 6V UNITS

L-20-0V

SERIES ACCESSOflY FOR

12V THRU 2eV UNITS.

LMOV-3 ACCESSORY

FOR LDSP-48V UNIT

TOP VIEW (COVER WRTIALLY CUTAWAY)

OUTPUT INPUT TY-WRAP HOLE

TERMINALS TERMINALS \ AC CABLE

88

ooo

ooo

!

1

i

1

1 (« (<0

n

® @ ^ ®

CHASSIS GROUND ^

i

'—n

• II .

LEFT SIDE VIEW

(COVER PARTIALLY CUTAWAY)

y

^

LH-OV- ADJ. OV ACCESSORY

FOR-OI THRU-03 UNITS

-6-32 X 3/8 MACHINE

BD.

HD. SCREWS W/LOCKWASHERS

(6 REQ'D) SEE NOTE 2

FRONT VIEW

MODEL NQ.RATINGS.ETC. SCREENED

ON THIS SURFACE

NOTES:

I. CUSTOMER MOUNTING SCREWS MUST NOT

PROTRUDE INTO POWER SUPPLY BY MORE

THAN 1/4"

2 COVER SCREWS ARE INDICATED BY » 8

AND MUST BE REMOVED BEFORE COVER

IS REMOVED (6 PLACES)

N0.8-32UNC-2B TAPPED

HOLES (4) FOR CUSTOMER

CHASSIS MOUNTING.

BOTTOM VIEW

Figure 12. Outline Drawing.

Page 19

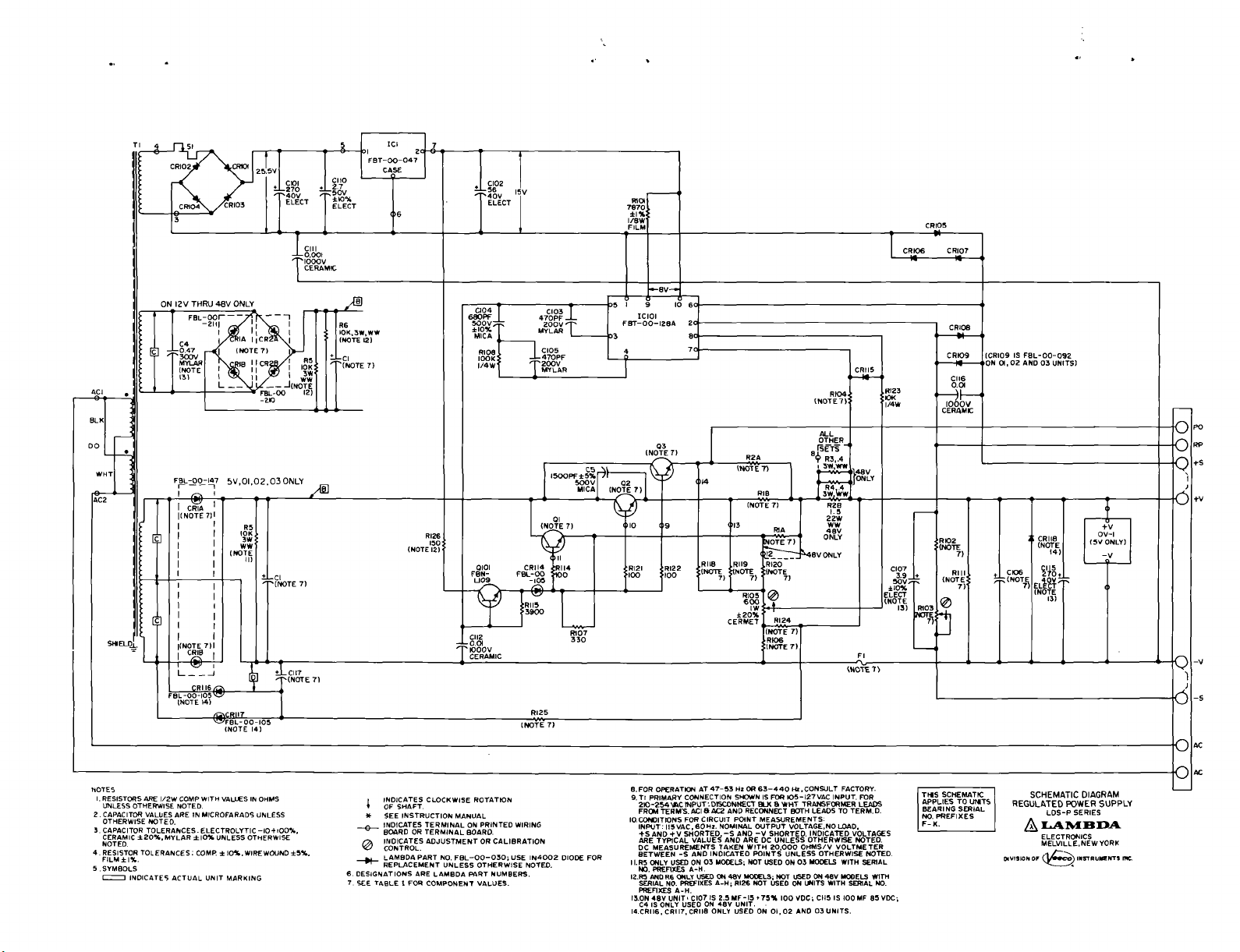

NOTES

I. RESISTORS ARE I/2W COMP WITH VAUJES IN OHMS

UNLESS OTHERWISE NOTED.

2.

CAPACITOR VALUES ARE IN MICROFARADS UNLESS

OTHERWISE NOTED.

3. CAPACITOR TOLERANCES: ELECTROLYTIC-10 + 100%.

CERAMIC ±20%,MYLAR ± 10% UNLESS OTHERWISE

NOTED.

4 RESISTOR TOLERANCES : COMP ± 10%,WIREWOUND ±5%.

FILM±I%.

5.SYMBOLS

I 1 INDICATES ACTUAL UNIT MARKING

I INDICATES CLOCKWISE ROTATION

• OF SHAFT.

•«•

SEE INSTRUCTION MANUAL

O INDICATES TERMINAL ON PRINTED WIRING

BOARD OR TERMINAL BOARD.

INDICATES ADJUSTMENT OR CALIBRATION

0

CONTROL.

M LAMBDA PART NO. FBL-00-05O; USE IN4002 DIODE FOR

" REPLACEMENT UNLESS OTHERWISE NOTED.

. DESIGNATIONS ARE LAMBDA PART NUMBERS.

SEE TABLE I F0« COMPONENT VALUES.

8.FOR OPERATION AT 47-53 Hz OR 63-440 Hz,CONSULT FACTORY.

9. Tl PRIMARY CONNECTION SHOWN IS FOR W5-127M4C INPUT. FOR

2KJ-254\*C INPUT: DISCONNECT BLK 8 WHT TRANSFORMER LEADS

FROM TERM'S. ACI a AC2 AND RECONNECT BOTH LEADS TO TERM.D,

10.CONDITIONS FOR CIRCUIT POINT MEASUREMENTS:

INPUT: II5VAC,60HI. NOMINAL OUTPUT VOLTAGE,NO LOAD.

•fSANO-fV SHORTEO.-S AND -V SHORTED. INDICATED VOLTAGES

ARE TYPICAL VALUES AND ARE DC UNLESS OTHERWISE NOTED.

DC MEASUREMENTS TAKEN WITH 20.000 OHMS/V VOLTMETER

BETWEEN -S AND INDICATED POINTS UNLESS OTHERWISE NOTED.

11.ICI V«AS F8T-OO-13I0N UNITS WITH SERIAL NO. PREFIX A.

12.CRIA.IBWASFBL-<XJ-I47ANDCR2A,2BWASFBL~OOH46 0NUNITS WITH SERIAL NO PREFD(ESAftB.

I3.C4 OND* USED ON UNITS WITH SERIAL NO. PREFIXES A-C.

I4.C9 NOT USED ON UNITS WITH SERIAL NO. PREFIXES A-D.

THIS SCHEMATIC

APPLIES TO Ut«TS

BEARING SERIAL

NO.

PREFIXESA-E

SCHEMATIC DIAGRAM

REGULATED POWER SUPPLY

LDS-P SERIES

ELECTRONICS

ELECTRO

MELVILLE,NEW YORK

MELVILLE

itON OF (^•co;

<; INSTRUPKINT9 INC

Page 20

tiOTES

I. RESISTORS ARE I/2W COMP WITH VALUES IN OHMS

UNLESS OTHERWISE NOTED.

2.

CAPACITOR VALUES ARE IN MICROFARADS UNLESS

OTHERWISE NOTED.

3. CAPACITOR TOLERANCES. ELECTROLYTIC-10 +iOO%,

CERAMIC ±20%.MYLAR ±10% UNLESS OTHERWISE

NOTED.

SYMBOLS

I— I INDICATES ACTUAL UNIT MARKING

I INDICATES CLOCKWISE ROTATION

» OF SHAFT.

M- SEE INSTRUCTION MANUAL

_ft__

INDICATES TERMINAL ON PRINTED WIRING

BOARD OR TERMINAL BOARD.

fy^ INDICATES ADJUSTMENT OR CALIBRATION

^ CONTROL.

fc. LAMBDA PART NO. FBL-00-030j USE IN4002 DIODE FOR

•" REPLACEMENT UNLESS OTHERWISE NOTED.

6. DESIGNATIONS ARE LAMBDA PART NUMBERS.

7. SEE TABLE I FOR COMPONENT VALUES.

8.F0R OPERATWM AT 47-53 Hz OR 63-440 Hz.CONSULT FACTORY,

9,Tl PRIMARY CONNECTION SHOWN IS FOR K>S-127VAC INPUT. FDR

2Kl-254'*CtNPUT-.DISC0NNECTBLKaWHT TRANSFORMER LEADS

FROM TERM'S. ACI 8 AC2 AND RECONNECT BOTH LEADS TO TERM.D.

10.CONDITIONS FOR CIRCUIT PONT MEASUREMENTS:

INPUT: 115VAC,60H2. NOMINAL OUTPUT VOLTAGE,NO U3AD.

-^SANO•*•V SHORTED,-SAND -V SHORTED. INDICATED VOLTAGES

ARE TYPICAL VALUES AND ARE DC UNLESS OTHERWISE NOTED.

OC MEASUREMENTS TAKEN WITH 2O.00O OHMS/V VOLTMETER

BETWEEN -S AND INDICATED POINTS UNLESS OTHERWISE NOTED.

I I.R5 ONLY USED ON 03 MODELS; HOT USED ON 03 MODELS WITH SERIAL

NO.

PREFIXES A-H.

I2.R5 AND R6 ONLY USED ON ABV MODELS; NOT USED ON 48V MODELS WITH

SERIAL NO. PREFIXES A-H; RI26 NOT USED ON \»i\T% WITH SERIAL NO.

PRERXES A-H.

13.0N48V UNIT> CI07IS 2.5MF-I5 t75% IOO VDC; CII5 IS lOOMF 65 VDC;

C4 IS ONLY USED ON 48V UNIT.

I4.CRII6,CRII7,CRII8 ONLY USED ON 01,02 ANO 03 UNITS.

THIS SCHEMATIC

APPLIES TO UMTS

BEARING SERIAL

NO.

PREFIXES

F-K.

SCHEMATIC DIAGRAM

REGULATED POWER SUPPLY

LOS-P SERIES

ELECTRONICS

MELVILLE. NEW YORK

f (^tfCO)!*

Page 21

rorui

±i%5

i/ew

CRI06 CRI07

—w

«—

NOTES

I RESISTORS

ARE

l.'4wC0MP

WITH

UNLESS OTHERWISE NOTED.

2 CAPACITOR VALUES

OTHERWISE NOTED.

3 CAPACITOR TOLERANCES: ELECTROLYTiC

CERAMIC

NOTED

4 RESISTOR TOLERANCES- COMP

FILM±|%UNLES5 OTHERWISE f^OTED.

5. SYMBOLS

I I INDICATES ACTUAL UNIT VARKING

ARE IN

±20%.MYLAH±10%

VALJFS

MICROFARADS UNLESS

UNLESS OTHERWISE

± 0% . W'.REWOUND

IN

CHMS

-O

+100%.

!&%.

CI04

680PF

500 v:

±10%

MICA

oil

0

001.

^ooov

CERAMIC

i,K

2(^P£J04SD"ffi_

r^

CII2

0.01-

lOOOV

CERAMIC

INDICATES CONNECTION

NDICATES CLOCKWISE ROTATION

OF SHAFT.

SEE INSTRUCTION MANUAL

_

INDICATES TERMINAL

BOARD

OR

> INDICATES ADJUSTMENT QR CALIBRATION

CONTROL

LAMBDA PART

REPLACEMENT UNLESS OTHERWISE NOTED

.OESI

GNATIONS

TABLE

ARE

n FOR

SEE

TQ

CHASSIS

ON

TERMINAL BOARD.

LAMBDA PART NUMBERS

COMPONENT VALUES.

PRINTED WIRING

NO.

FBL-00-030iUSE IN4002 DIODE

CI03

or

470

PF-

200V

"T

MYLAR

[

C105

-L470f

470 PF

'T^200^

200V

I MYLi

f

RIB

(NOTE

7)

RI04

30.1

1/4

t5%

FILM

W

-o,^

-o

.

•']

R205

22O0

VIA

•

8

SEE

CONDITIONS FOR CIRCUIT POINT MEASUREMENTS

INPUT:|l9VAC,60Hz

irCICATED VOLTAGES

OTHERWISE NOTED. DC MEASUREMENTS TAKEN WITH

20,000 OHMS/VOLT

POINTS UNLESS NOTED OTHERWISE.

TABLE

H FOR

T4 ILE Ii

MODEL

LOS-P-lOO

LDS-P-120

L0S-P-I5C

O

VOi-TAGES

Va

>-iJ>.i%ot

174.25

VDC

2I6.00VDC

ARE

VOLTP^TER

TYPICAL VALUES

BETWEEN -hSAND INDICATED

:RI2O

(NOTE

RI05 f0

600 , Y

±20%:--t-

IIU.'

AND ARE DC

7)

UNLESS

CI07

0.68.

400V

ELECT

RI03

11—I5OK

±10%

-,

3/4W

CERtilET

THIS SCHEMATIC

APPLIES T0UNI7S

BEARING SERIAL

UO PREFIXESA-K

cioe

•245

•250V

ELECT

SCHEMATIC DIAGRAM

REGULATED POWER SUPPLY

LDS-P-100.120,150

^ ]L.>%.^<BI»%.

;iN9TKUHIItTS

IHC

-Or

-O

^o<

—O^

•O'

Page 22

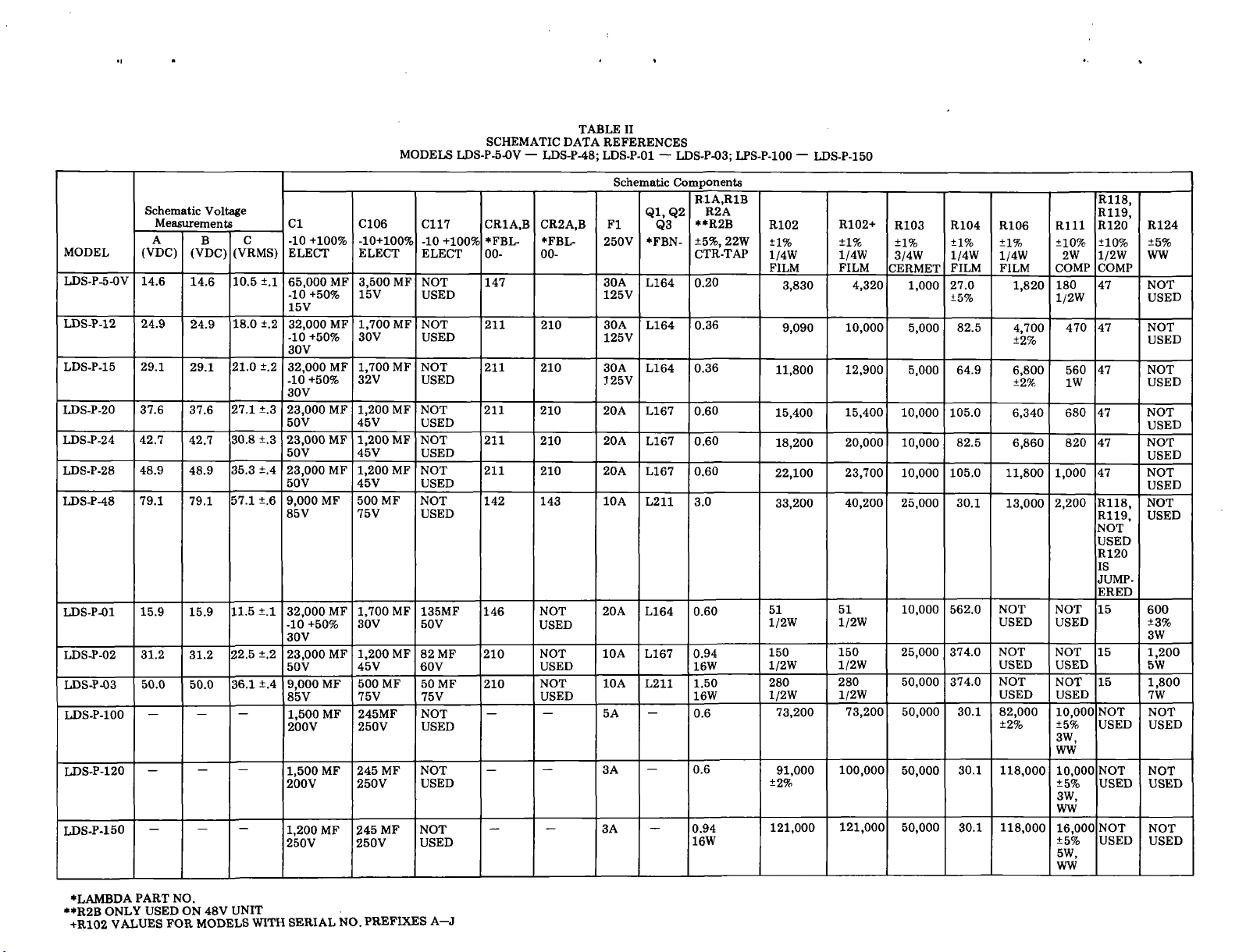

MODEL

LDS-P-5-0V

LDS-P-12

LDS-P-15

LDS-P-20

LDS-P-24

LDS-P-28

LDS-P-48

LDS-P-01

LDS-P-02

LDS-P-03

LDS-P-100

LDS-P-120

LDS-P-150

Schematic Voltage

Measurements

A

(VDC)

14.6

24.9

29.1

37.6

42.7

48.9

79.1

15.9

31.2

50.0

B

(VDC)

14.6

24.9

29.1

37.6

42.7

48.9

79.1

15.9

31.2

50.0

C

(VRMS)

10.5 ±.1

18.0 ±.2

21.0 ±.2

27.1 ±.3

30.8 ±.3

35.3 ±.4

57.1 ±.6

11.5 ±.1

22.5 ±.2

36.1 ±.4

Cl

-10 +100%

ELE(7r

65,000

MF

-10 +50%

15V

32,000

MF

-10 +50%

30V

32,000

MF

-10 +50%

30V

23,000

MF

SOV

23,000

MF

SOV

23,000

MF

50V

9,000

MF

85V

32,000

MF

-10 +50%

30V

23,000

MF

SOV

9,000

MF

85V

1,500 MF

200V

1,500 MF

200V

1,200 MF

250V

MODELS LDS-P-5-0V

C106

-10+100%

ELECT

3,500

15V

1,700 MF

30V

1,700 MF

32V

1,200 MF

45V

1,200 MF

45V

1,200 MF

45V

500 MF

75V

1,700 MF

30V

1,200 MF

45V

500 MF

75V

245MF

250V

245 MF

250V

245 MF

250V

MF

C117

-10 +100%

ELECT

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

135MF

SOV

82 MF

60V

50 MF

7SV

NOT

USED

NOT

USED

NOT

USED

TABLE

SCHEMATIC DATA REFERENCES

— LDS-P-48;

CR1A,B

*FBL-

00-

147

211

211

211

211

211

142

146

210

210

CR2A,B

*FBL-

00-

210

210

210

210

210

143

NOT

USED

NOT

USED

NOT

USED

II

LDS-P-01

Fl

250V

30A

125V

30A

125V

30A

3 25V

20A

20A

20A

lOA

20A

lOA

lOA

SA

3A

3A

— LDS-P-03;

Schematic Ck)mponents

Q1,Q2

Q3

*FBN-

L164

L164

L164

L167

L167

L167

L211

L164

L167

L211

LPS-P-lOO — LDS-P-150

R1A,R1B

R2A

**R2B

+5%,

22W

CTR-TAP

0.20

0.36

0.36

0.60

0.60

0.60

3.0

0.60

0.94

16W

l.SO

16W

0.6

0.6

0.94

16W

R102

±1%

1/4W

FILM

3,830

9,090

11,800

1S,400

18,200

22,100

33,200

51

1/2W

150

1/2W

280

1/2W

73,200

91,000

±2%

121,000

R102+

±1%

1/4W

FILM

4,320

10,000

12,900

15,400

20,000

23,700

40,200

51

1/2W

ISO

1/2W

280

1/2W

73,200

100,000

121,000

R103

±1%

3/4W

CERMET

1,000

5,000

S.OOO

10,000

10,000

10,000

25,000

10,000

25,000

50,000

50,000

50,000

S0,000

R104

±1%

1/4W

FILM

27.0

±5%

82.5

64.9

105.0

82.5

lOS.O

30.1

562.0

374.0

374.0

30.1

30.1

30.1

R106

±1%

1/4W

FILM

1,820

4,700

±2%

6,800

±2%

6,340

6,860

11,800

13,000

NOT

USED

NOT

USED

NOT

USED

82,000

±2%

118,000

118,000

Rill

±10%

2W

COMP

180

1/2W

470

560

IW

680

820

1,000

2,200

NOT

USED

NOT

USED

NOT

USED

10,000

±5%

3W,

WW

10,000

±5%

3W,

WW

16,000

±5%

SW,

WW

R118,

R119,

R120

±10%

1/2W

COMP

47

47

47

47

47

47

R118,

R119,

NOT

USED

R120

IS

JUMPERED

15

15

15

NOT

USED

NOT

USED

NOT

USED

R124

±5%

WW

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

NOT

USED

600

±3%

3W

1,200

5W

1,800

7W

NOT

USED

NOT

USED

NOT

USED

•LAMBDA PART

**R2B ONLY USED

+R102 VALUES

FOR

NO.

ON 48V

UNIT

MODELS WITH SERIAL

NO.

PREFIXES

A-J

Page 23

V"'-

5 -Ifeflr

Guarantee

We warrant each instrument manufactured by

us,

and sold by us or our authorized agents, to be

free from defects in material and workmanship, and

that it will perform within applicable specifications

for a period of five years after original shipment. Our

obligation under this guarantee is limited to repairing

or replacing any instrument or part thereof, (except tubes

and fuses) which shall, within five years after delivery to

the original purchaser, be returned to us with transportation

charges prepaid, prove after our examination to be thus defective.

\Ne reserve the right to discontinue instruments without notice, and

to make modifications In design at any time without incurring any

obligation to make such modifications to instruments previously

sold.

\ _

lMMBDA£UGniOlillCSm.A

Lambda Group of Unitech pic i ' \

\

515 BROAD HOLLOW ROAD • MELVILLE, L.I., NEW YORK • 516-694-4200

\

\

Loading...

Loading...