Page 1

INSTRUCTION MANUAL

POWER SUPPLY

MODEL ____71____ SPEC._______

LAMBDA ELECTRONICS CORP.

COLLEGE POINT 56, N. Y.

Page 2

INSTRUCTION MANUAL

FOR

REGULATED POWER SUPPLY

MODEL 71

MANUFACTURED BY

LAMBDA ELECTRONICS CORP.

CORONA 68, NEW YORK

ISSUE A MODEL NO. 71

1-55-123 SERIAL NO. 1525

Page 3

INSTRUCTION MANUAL

FOR

REGULATED POWER SUPPLY

MODEL 71

1. GENERAL DESCRIPTION

1. GENERAL DESCRIPTION.

The Model 71 power supply described in this manual is

designed for general purpose use in industry, laboratory,

radio station and school to supply power to electronic and

other equipment. The DC output voltages are electronically

regulated, are practically independent of normal line voltage

fluctuations and substantially free from hum and noise. The

high-voltage DC output is constant (within the specified

limits) from zero to maximum load and features a continuously-

variable voltage·control with an auxiliary vernier-control

for precise voltage adjustment. The DC bias-voltage output

is also continuously adjustable and is closely regulated for

line voltage variations. The following output voltages are

supplied:

Output #1: 0-500 VDC, 0-200 MA, regulated.

Output #2: 0-200 VDC, 0-50 VDC, bias output. Regulated

for line voltage variation.

Output #3: 6.5 VAC, 5A, unregulated.

Output #4: 6.5 VAC, 5A, unregulated.

The easy-to-read 3-1/2" panel meters permit monitoring

of output voltage and current. Magnetic circuit-breakers

provide convenient AC and DC overload protection. A time-

delay relay circuit protects the tubes during the initial

warm-up period. Sturdy, insulated binding-posts are

provided for front panel connections. A 5651 voltage

reference tube insures long time stability for operation.

Quality components, conservatlvély rated, guarantee long,

dependable trouble~free service.

1.

Page 4

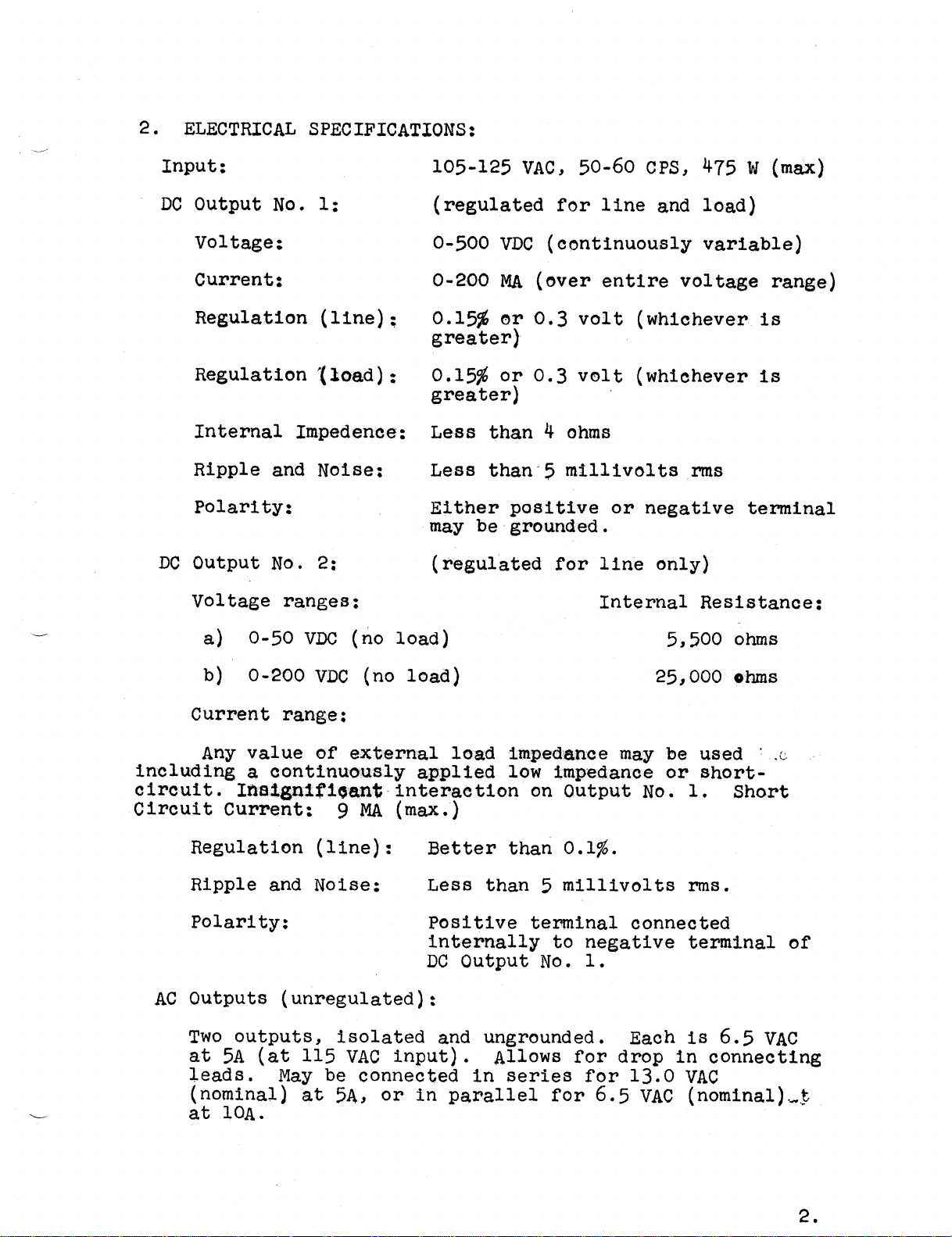

2. ELECTRICAL SPECIFICATIONS:

Input; 105-125 VAC, 50-60 CPS, 475 W (max)

DC Output No. 1; (regulated for line and load)

Voltage: 0-500 VDC (continuously variable)

Current; 0-200 MA (over entire voltage range)

Regulation (line); 0.15% or 0.3 volt (whichever is

greater)

Regulation (load); 0.15% or 0.3 volt (whichever is

greater)

Internal Impedence: Less than 4 ohms

Ripple and Noise: Less than 5 millivolts rms

Polarity: Either positive or negative terminal

may be grounded.

DC Output No. 2; (regulated for line only)

Voltage ranges: Internal Resistance:

a) 0-50 VDC (no load) 5,500 ohms

b) 0-200 VDC (no load) 25,000 ohms

Current range:

Any value of external load impedance may be used

including a continuously applied low impedance or short-

clrcult. Insignificant interactlon on Output No. 1. Short

Circuit Current: 9 MA (max.)

Regulation (line): Better than 0.1%.

Ripple and Noise; Less than 5 millivolts rms.

Polarity: Positive terminal connected

internally to negative terminal of

DC Output No. 1.

AC Outputs (unregulated):

Two outputs, isolated and ungrounded. Each is 6.5 VAC

at 5A (at 115 VAC input). Allows for drop in connecting

leads. May be connected in series for 13.0 VAC

(nominal) at 5A, or in parallel for 6.5 VAC (nom1nal)

at 10A.

2.

Page 5

Ambient Temperature And Duty Cycle:

Continuous duty at full load up to 40°C (104°F) ambient.

Overload Protection:

External overload protection AC and DC systems

utilize magnetic

circuit breakers. Trip-

Free. Instant manual

reset. Front panel.

Internal Failure Protection Fuses, access through

rear of cabinet.

Input And Output Connections:

Input 8 foot heavy duty rubber

covered line cord with

integral molded plug,

rear of cabinet.

Output Sturdy insulated "5-way"

binding posts, front

panel.

Meters:

Output Voltage Multi—range 3-1/2"

rectangular voltmeter

calibrated 0-50 VDC,

0-200 VDC, 0-500 VDC.

Output Current 3-1/2" rectangular

mllliammeter calibrated

0-200 MA.

Voltage Reference Tube:

A stable 5651 reference tube is used to obtain superior

long—t1me voltage stability.

Time·Delay Relay Circuit:

A 30-sec time delay circuit is provided to allow tube

heaters to come to proper operating temperature before

high voltage can be applied.

3.

Page 6

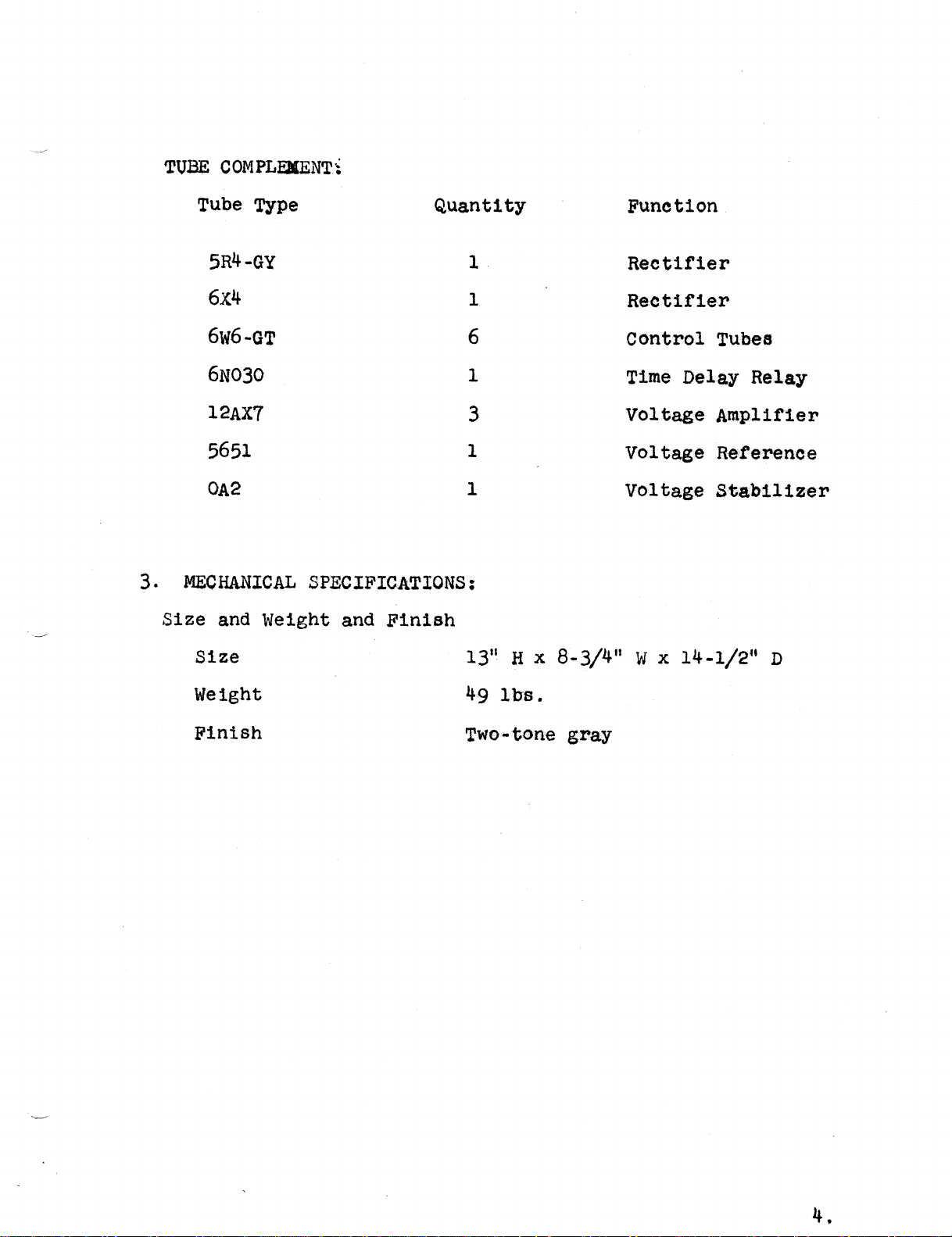

TUBE COMPLEMENT:

Tube Type Quantity Function

5R4·GY 1 Rectifier

6X4 1 Rectifier

6w6-GT 6 Control Tubes

6N030 1 Time Delay Relay

12AX7 3 Voltage Amplifier

5651 1 Voltage Reference

0A2 1 Voltage Stabilizer

3. MECHANICAL SPECIFICATIONS:

Size and Weight and Finish

Size 13" H x 8-3/4" W x 14-1/2" D

Weight 49 lbs.

Finish Two-tone gray

4.

Page 7

II. OPERATING INSTRUCTIONS.

MODEL 71

1. OPERATING CONTROLS.

a) The "AC" circuit-breaker is in series with the AC

line and controls power to the supply. When the toggle of

the "AC" breaker is in the "ON" position, the adjacent pilot-

light indicator marked "AC" is illuminated, the heaters of

all the tubes in the supply are energized, and a thirty-second

protective thermal time·delay relay is set into operation.

b) The "DC" circuit·breaker contacts are in series

with the plate power relay and controls the application of

plate voltage to the rectifiers of the high—voltage DC and

bias supplies. The “DC“ circuit breaker is interlocked with

the thermal time-delay relay so that the delay cycle is

completed after the tube heaters reach operating temperature.

After the delay cycle is completed the “DC" breaker, when

thrown to the ‘DC—ON" position, will apply "DC" power, and

the adjacent pilot—light indicator will be illuminated. The

"DC" breaker may then be used in normal switch fashion to

turn DC power on and off without delay.

c) The "VOLTMETER" toggle~switch connects the

"OUTPUT VOLTAGE" meter to either the "HV" output or the

"BIAS" output circuits so that either voltage can be monitored

as desired. The voltmeter circuit is designed so that

switching from bias to high·voltage reading will disturb

neither output voltage.

d) The "HV" control consists of a variable transformer

and a precision wirewound potentiometer ganged together,

and permits the high voltage DC output to be set at any

value from 0 to 500 VDC. The calibration of this control

indicates the value of the DC output—voltage and permits

presetting of the "HV" control before the "DC" breaker is

turned on. It also provides an indication of the high—voltage

DC output when the "OUTPUT VOLTAGE" meter is used to monitor

the bias output voltage.

e) The "/\HV" control is a wirewound potentiometer

permitting vernier control of the high voltage DC output

for precise voltage adjustment. It has a range of plus or

minus 5 volts and a calibration accuracy of 5%.

f) The "BIAS RANGE" toggle switch provides two ranges

of bias output voltage, 0-50 or 0-200 volts DC.

5.

Page 8

g) The "BIAS" control is a wirewound potentiometer

which permits the bias output voltage to be set to any

value from zero to the maximum output voltage of either

bias voltage range.

h) The "OUTPUT VOLTAGE" meter is a 3-1/2 inch panel

instrument which indicates either the "HV" output or "BIAS"

voltage output depending upon the position of the "VOLTMETER"

toggle switch. In the "HV" position it reads 0-500 VDC full

scale (black numerals). In the "BIAS" position it reads

either 0-200 VDC or 0-50 VDC (red numerals) depending upon

the position of the "BIAS RANGE" switch.

i) The "OUTPUT CURRENT" meter is a 3-1/2 inch panel

instrument in series with the "HV" output and indicates the

external load current of the high—voltage DC output only.

2. OUTPUT TERMINALS.

a) FRONT PANEL TERMINALS:

The output terminals are sturdy insulated "captive—

head" binding-posts which can be used in a number of ways

and are sufficiently sturdy to take a substantial amount of

handling and abuse. They will accept "wrap·around" wire

connections, "alligator clips", banana plugs, spade lugs,

and wire as large as #12 AWG for permanent feed—through

clamping. The 'HV" "BIAS" and each of the "6.5 vAc" output

terminal—pairs are spaced on 3/4 inch centers so that they

will accept standard double banana plugs.

b) "HV" OUTPUT CONNECTIONS:

The regulated high-voltage DC output is available

at the front panel terminals marked "HV".

The positive connection is brought out through

the red binding post marked "+". The negative connection

is brought out through the black binding post marked "—".

In most applications, it is usual for the negative

terminaleto be at ground potential. In some cases, it may

be desired to place the positive terminal at ground potential.

Still other applications may require that neither positive nor

negative terminal be at ground potential. In such cases

where either the positive or negative terminal is to be at

ground potential, the appropriate terminal on the panel

should be connected by means of a Jumper wire to the binding e

post, marked "INT GND".

6.

Page 9

For minimum output ripple, it is recommended

that either the positive or negative high voltage DC

output terminal be grounded.

c) "BIAS° OUTPUT CONNECTIONS:

The regulated DC bias-output voltage is available

at the front panel terminals marked "BIAS". The positive

"BIAS" connection is internally tied to the negative "HV"

connection and is brought out through the black binding

post marked "BIAS+" and "HV-". The negative "BIAS" connection

is brought out through the black binding post marked "BIAS-".

d) AC OUTPUT CONNECTIONS:

The AC output connections marked "6.5 VAC 5A"

provide two independent sources of unregulated voltage for

vacuum-tube heater—circuits. Both output sources are

available at the front-panel binding-posts. The AC output

terminals may be connected in series to provide 13.0 VAC

at 5 amperes, or in parallel to provide 6.5 VAC at 10 amperes.

The schematic diagram on the panel below the AC output binding

posts shows the proper connections of the terminals for

correct "phasing' of these voltages.

_SAFETY NOTICE_

DANGEROUS VOLTAGES EXIST IN THIS EQUIPMENT.

OBSERVE THE USUAL SAFETY PRECAUTIONS WHEN OPERATING OR

SERVICING THE EQUIPMENT TO AVOID SEVERE SHOCK OR INJURY.

3. PLACING MODEL 71 INTO OPERATION.

a) Both the "AC" and "DC" circuit·breakers snouid be

in the "OFF" position. The "HV" control and the "BIAS"

control should be in their extreme counter—clockwise positions,

the "/\HV" control in the center or "O" position.

b) Plug the power cord into a source of 115 volts AC

50/60 cycles.

c) Connect the desired AC and DC loads to the output

terminals of the supply. Note the schematic diagram on the

front panel showing proper phasing of the 6.5 VAC outputs

for series or parallel operation.

d) Throw the "AC" circuit breaker to the "ON" position.

The AC pilot indicator marked "AC" will be illuminated, and

6.5 volts AC will be present at the front panel bind1ng·posts.

The thermal time-delay circuit will start itS 30·second delay-

cycle.

7.

Page 10

e) After approximately 30 seconds, throw the "DC"

circuit-breaker to the "ON" position. The pilot-light

indicator marked "DC" will be illuminated, and the internal

plate-power·relay will close. If the "DC" circuit breaker

is thrown to the "ON" position before the 30 second time

delay has elapsed, the pilot indicator will not light nor

will the plate-power-relay close until the time-delay cycle

is complete.

f) After the pilot "DC" indicator 1e illuminated throw

the "VOLTMETER" selector switch to the "HV" position. Turn

the "HV" control clockwise to the desired DC output voltage

as indicated on the "OUTPUT VOLTAGE" voltmeter. The "/\HV"

vernier control may be utilized for precise voltage adjustment.

If an external load is connected to the "HV" output terminals,

the output current will be indicated on the "OUTPUT CURRENT"

meter.

g) If use of the "BIAS" output voltage is desired,

throw the "DC" breaker off, connect the bias-load to the

"BIAS" terminals, set the "BIAS RANGE" switch to the bias

voltage range desired, the "VOLTMETER" selector switch

to "BIAS" and the "BIAS" control to zero. Throw the "DC"

breaker on. Turn the "BIAS" control clockwise to the required

voltage as indicated on the proper red scale of the "0UTPUT

VOLTAGE" meter. The "OUTPUT VOLTAGE" meter may be used to

monitor the bias voltage, the calibration on the "HV" control

then serving as an indication of the "HV" output voltage.

h) If it is desired to turn off the DC output only,

use the "DC" circuit breaker, leaving the "AC" breaker in

the "ON" position. In this manner, the supply will be in

a standby condition ready for instant use.

CAUTION: Turning the supply on and off rapidly

by means of the "AC" breaker (with the DC breaker in the

"ON" position) may seriously damage or impair the life of

the high voltage rectifier tube. If less than one minute

elapses between the time the "AC” breaker is turned off and

turned on again (the time required for the protective

thermal time-delay relay to re—cycle) the "DC" breaker should

be kept in the ”OFF" position for at least 20 seconds after

the "AC" breaker is turned on to permit the rectifier heaters

to return to proper operating temperature.

4. OVERLOAD PROTECTION.

a) AC OUTPUT CIRCUITS:

An overload or short circuit of the 6.5 VAC 5A

output circuits will trip the "AC" circuit breaker shutting

off the entire supply. Removing the overeload and turning

8.

Page 11

the "AC" breaker on again will restore operation. If the

supply is off for more than one minute the thermal delay-

relay may re-cycle before DC voltage will be present at

the output terminals. (see CAUTION note in paragraph 3

above).

b) HIGH VOLTAGE DC OUTPUT CIRCUITS:

An overload or short circuit of the "HV" output

will trip the "DC“ circu1t—breaker releasing the plate-

power·relay and disconnecting the plate-voltage from the

rectifier tubes of both the high-voltage DC and bias supplies.

Removing the overload or short-circuit and throwing the "DC"

breaker to the "ON" position will restore operation

immediately.

c) DC BIAS OUTPUT CIRCUIT:

The bias output circuit is so designed that it

may be short·circuited for indefinitely long periods of

time without damage to any component or effect on the high

voltage DC output.

5. INTERNAL POWER SUPPLY FAILURE PROTECTION:

a) In general, external overload of the output voltage

circuits will result in tripping of the circuit breakers.

Internal failure of the power supply components may result

in tripping of the breakers or blowing of the internal

protective fuses mounted as the rear of the unit. Failure

of F1, the I/2 ampere 3AG "Slo-Blo" fuse, indicates failure

of a component of the bias reference supply. Failure of this

fuse will probably require servicing of the power supply.

Refer to Section III for maintenance data before servicing

of equipment or replacement of the fuse.

NOTE: Failure of this fuse will result in removal

of voltage from all DC output terminals.

b) F2, a 10-ampere 3AG "Slo-Blo" input line fuse

located adjacent to F1 provides protection against failure

of the powerstat TA-1, Lambda Part No. TA-549, and input

wiring. This fuse will also protect the power supply in

event that the unit is accidentally plugged into a 220 VAC

circuit or into a DC.circuit. This fuse will not fail in

the case of overloads of the DC or AC output circuits.

Thls protection is provided by the circuit breakers.

9.

Page 12

6. NOISE AND RIPPLE OUTPUT:

The noise and ripple output of the high-voltage

DC supply should be less then 5 millivolts rms and the

DC bias supply less than 5 millivolts rms at all voltages

and load conditions within the specifications. Measurement

of thls level of voltage may be made with an AC VTVM

capable of reading 5-8 millivo1ts rms. Meesurements of

these low values of voltege should be made using a shielded

cable connecting the power supply output to the AC VTVM.

It is recommended that either the positive or

negative terminal of the "HV" output be connected by a Jumper

wire to the "INT-GND" terminal for minimum ripple output.

7 . INTERNAL IMPEDANCE.

a) "HV" OUTPUT:

The internal impedance of the hlgh voltage DC

supply is approximately 4 ohms for DC. A 2 mfd oll-filled

paper capacitor is ln shunt with the DC output circuit

for two purposes: 1) to maintain this low value of output

lmpedence at audio, and at low and medium radio frequencies,

2) to provide a reservoir to supply transient currents of

short duratlon having peak values greater than 200 MA.

An additional external capacitor shunted across

the "HV" output will provide even lower AC output impedance

and allow even higher peak transient currents to be drawn.

For low impedance to high frequency RF·currents, the common

practice is to use a mica capacitor shunt close to the RF unit.

b) DC BIAS OUTPUT:

The internal resistance of the DC bias supply

O-200 VDC range is approximately 25,000 ohms. For low

impedance to AC, an external capacitor should be shunted

across the "BIAS OUTPUT" terminals. For low impedance to

high-frequency RF currents, the common practice is to use

a mica capacitor shunt close to the RF unit. The internal

resistance of the bias supply 0-50 VDC range is 5,500 ohms.

10.

Page 13

III. MAINTENANCE

SAFETY NOTICE

DANGEROUS VOLTAGES EXIST IN THIS EQUIPMENT.

OBSERVE THE USUAL SAFETY PRECAUTIONS WHEN OPERATING OR

SERVICING THE EQUIPMENT TO AVOID SHOCK OR INJURY.

1. GENERAL.

Under normal conditions no special maintenance

of the Model 71 regulated power supply is required except

for occasional tube replacement. In the event of failure,

or inability of the regulated DC output circuits to function

properly a list of typical symptoms and their probable causes

is given in paragraph "6" of this section.

2. REMOVAL OF POWER SUPPLY UNIT FROM CABINET.

If tube replacement or servicing of the unit is

necessitated, the power susply unit must be removed from

its cabinet. This is accomplished by removing the four

large diameter nickel-plated screws on the rear face of

the cabinet and sliding the unit out.

NOTE: It is not necessary to loosen any screws

other than the four mentioned above for removal of the

supply from the cabinet. At no time should removal of

the painted screws in the rear of the cabinet be attempted.

3. SERVICING OF POWER SUPPLY WHEN REMOVED FROM CABINET.

a) Upon removal of the cabinet, all tubes are made

accessible, and tube replacement is simply accomplished.

6W6-GT tubes and the 6N030 tube are secured to their

sockets by means of spring~type retainer clamps. These

retaining clamps must be depressed into and held in a

flattened position before removing these tubes. when

replacing the miniature type tubes, they should be inserted

into a pin straightener before putting them into the sockets

to avoid bending pins. Bent pins create strain on the glass

bases with the resulting possibility of breakage or cracking

in time. When tubes are replaced, adjustment of calibrating

potentiometers should be checked.

11.

Page 14

b) 6N030 TIME-DELAY·RELAY:

The 6N030 1s most readily checked under actual

operatlng conditions. If the power supply is turned on

from a cold start, and the "DC" circuit·breaker left in

the "ON" position, the internal plate-power-relay will

c1ose with an audible click, and the "DC ON" pilot light

lndlcator will be llluminated within 30 to 45 seconds.

At high AC line-voltages, the relay may close

1n as early as 20 seconds, at low line-voltages as late

as 1 minute. If the plate·power-relay closes much earlier

than 20 seconds or later than 1 minute from a cold start,

the 6N030 should be replaced.

c) 0A2 VOLTAGE REGULATOR TUBE:

Upon placing the Model 71 power supply into an

operating condition at any setting of output voltage the

0A2 should exhibit an lnternal pale purple glow. If tube

falls to glow or appears to flicker, the tube should be

replaced. If the new tube does not operate properly, the

circuit voltages should be checked against the circuit

diagram.

d) 5651 VOLTAGE REFERENCE TUBE:

No special check of the 5651 tube is required.

The tube operates normally with a bright orange glow on the

surface of its dlsc-shaped cathode. If the tube fails to

glow or appears to flicker, it should be replaced. If

then the fault is not remsved, a voltage check should be

made of the tube and its associated circuits. The voltage

across the 5651 should range between 82 and 92 VDC and

should not fluctuate.

4. ADJUSTMENT OF CALIBRATING POTENTIOMETERS R35 & R36:

If any of the tubes other than the rectifiers,

(5R4-GY and 6x4), the series control tubes, (6w6·GT), and

the time·delay relay, (6N030), are replaced, the calibrating

and alignment potentiometers, R35 and R36, may require

readjustment. This readjustment should be made according

to the following procedure:

a) With AC and DC circuit breakers in the "OFF"

position, zero-set the "Output Voltage" and "Output Current"

meters accurately.

b) Turn the "HV" control to its extreme clockwise

position. The pointer on the control knob should line up

with the 500 volt callbratlon line or very close to it.

12.

Page 15

If a major discrepancy exists, loosening of the two set

screws in the knob will permit readjustment of its position.

c) Set the "/\HV" control to its center or "0"

position.

d) Set the "Voltmeter" switch to the "HV" position.

e) With no external AC or DC load on the power supply,

turn both "AC" and "DC" circuit breakers on and allow the

supply to warm up for at least 10 mlnutes.

f) With the "HV" control set to 500, adjust R36 so

that the "Output Voltage" voltmeter reads 500 volts (black

scale).

g) Turn the "HV" control to the zero mark. Adjust

R35 so that the "Output Voltage" voltmeter reads zero.

h) Repeat steps "f" and "g" until the "HV" control

reads zero in its extreme counter clockwise position and

500 volts ln its extreme clockwise position.

5. OPERATIONAL CHECK.

a) REGULATION WITH LOAD:

After tubes have been replaced or the equipment

serviced, a simple check of the proper operation of the

0-500 VDC output circuit supply may be made by alternately

connecting and disconnecting a 200 MA load to the supply

with the 'Output Voltage" meter in the "HV" position.

Except for a transient kick of the meter needle when the

load is connected to the supply, the change in output

voltage should be barely perceptable (less than 1/10 of

1 division on the meter scale) for proper operation. An

AC VTVM capable of reading 5 millivolts rms may be employed

to check the noise and ripple level output of the supply

when making this check. Shielded leads should be employed

to connect the AC VTVM to the power supply output terminals.

Note that the "DC" "BIAS OUTPUT" circuit is not

regulated for load variations. (See Electrical Specifications)

b) REGULATION WITH LINE:

A Variac or Powerstat connected between the AC

power line and the input to the Model 71 may be employed

to check the regulation of the DC output circuits. With

the "Output Voltage" voltmeter ln the circuit being monitored

and the line voltage varied from 105 to 125 VAC, the change

in output voltage should be barely perceptible (less than

l/10 of 1 meter division) for proper operation.

13.

Page 16

6. TYPICAL POWER SUPPLY FAILURE CONDITIONS AND THEIR

PORTABLE CAUSES.

SAFETY NOTICE

DANGEROUS VOLTAGES EXIST IN THIS EQUIPMENT.

OBSERVE THE USUAL SAFETY PRECAUTIONS WHEN OPERATING OR

SERVICING THE EQUIPMENT TO AVOID SEVERE SHOCK OR INJURY.

Refer to the Schematic Diagram for proper

operating voltages in the equipment.

It is recommended that the input plug be removed

from the 115 VAC source when removing or replacing tubes.

OPERATING CONDITION REMEDY OR SOLUTION

a) AC circuit breaker Check AC output for overload

trips repeatedly or short circuit. Remove

overload condition.

b) DC circuit breaker 1) Check "HV" output load

trips repeatedly circuit for overload or short

circuit. Remove overload

condition.

2), If this does not eliminate

tripping of DC breaker, then

check for faulty 5R4-GY tube.

This tube should be tested in

a tube checker. If found

faulty, it should be replaced.

3) If tube is found to be

good or if replacement by a new

tube does not eliminate breaker

tripping, check capacitors,

C1 and C2A for breakdown or

short circuit. If these are

found to be cause of breaker

tripping, replacement of these

capacitors is required.

c) Presence of high DC 1) Shorted 6W6-GT tubes, V2

positive voltage at through V6. Shorting of tube

terminals compared to elements within tube envelope

that indicated on "HV" will result in loss of control.

dial, along with high A visual inspection of the

ripple and poor individual tubes may lead to

regulation. (no external identification of faulty tube.

load is applied to "HV" If this is not the case, each

output.) tube individually should be

removed while the output

voltage is monitored on the

"Output Voltage" meter.

14.

Page 17

If upon removal of any tube

V2-V6, this condition is

eliminated, replace this

faulty tube with a new tube.

2) Filament burnout of 12AX7.

V8. lf tubes V2-V6 ere all

found to be good, the 12AX7,

V8 may have a burned out

filament. This is slmply

checked for by replacing the

l2AX7 with a new tube.

3) Loss of bias supply voltage

will result in rise of output

voltage. If bias supply output

voltage approaches zero volts,

and 5651, V14 is extinguished

and voltage across C5A is zero,

the bias supply system fuse,

F1, 1/2 A has failed. Insert

a 1 Ampere AC ammeter in place

of the fuse and turn on the

supply. lf current exceeds

0.4 Amperes check 6X4, V10 for

short or gassy condition, and

C5A, CSB for shorted capacitors.

If any of these components are

found to be faulty, replace

these components.

4) Absence of voltage across

filter capacitors C5A, C5B.

check V10, 6X4 tube for open

or burned out filament. This

is most simply accomplished by

replacing tube with a new tube.

5) Presence of bias supply

input filter voltage and

absence of supply output

voltages a) 6W6—GT, V1

filament is burned out, replace

tube.

b) Filament burnout of 12AX7,

V12. This is easily checked

for by replacement with e new

tube.

15.

Page 18

d) Presence of positive 1) Filament burnout of l2AX7,

low level "HV" voltage as V11. This is easily checked

compared with that by replacement with a new

indicated on the "HV" dial, tube.

poor regulation and high

ripple. (no external load 2) Check voltage across

applied to "HV" output.) capacitor, C2A for voltage

conditions specified on

schematic diagram. If far

below indicated voltage, check

filter capacitor for open

circuit.

3) An abnormal increase of

reference supply voltage

results in reduced power

supply "HV" output voltage.

High bias supply voltage with

associated high reference

supply ripple voltage. This may

be the result of internal grid

to cathode or screen grid short of

6W6-GT, V1. Replace with a new

6W6-GT tube.

4) Burnout of V8, 12AX7 will

cause the bias voltage to rise.

It will have a similar effect

on the "HV" supply of greater

magnitude in the "HV" supply.

Therefore the net result of

filament burnout of this tube

is a rise of "HV" voltage.

e) Apparent satisfactory 6W6-GT tubes, V2 through V6,

operation at 200 MA load exhibit poor cut-off

with rise of ripple voltage characteristic. To check

at zero external load. cut—off characteristic,

operate at zero load and low

"HV" output voltage. Monitor

the "HV" output with a VTVM

or high impedance AC voltmeter.

Remove one tube at a time

until faulty tube is identified.

Faulty tube is identified by

return to normal of "HV"

output ripple voltage. Care

should be exercised in

handling 6W6-GT tubes to

prevent burning of hands due

to touching hot glass envelope.

In removing 6W6-GT tube,

depress retaining clamp

maintaining this position of

the clamp while tube is

removed.

16.

Page 19

f) Apparent satisfactory 1) Faulty 6W6-GT tubes, V2

operation at low current through v6, will cause

values with supply failure remaining 6W6-GT tubes to

at 200 MA external and carry excess load. Tubes

105 line. should be visually inspected

for filament burnout. If

burnout is not apparent, then

tubes should be checked on

a tube checker.

2) Faulty 5R4-GY, V9,

rectifier tube. A similar

condition applies to the 5R4-GY

rectifier. If tube drop is

excessive under load, then

operation at 200 MA and at

105 VAC line will be impaired.

The tube should be checked in

a tube checker, and if faulty,

it should be replaced.

g) Apparent instability Faulty bias and main amplifier

ln Power Supply Voltage, input tubes cause this voltage

drift of order 1 volt wandering. The tubes involved

magnitude or greater. are 12AX7 tubes, V11 and V12.

One tube should be first

replaced and the output voltage

monitored. If this condition

is not removed, replace the

second l2AX7 tube.

A schematic diagram of the

power supply will be found in

the rear of this manual. The

diagram contains typical

operating voltages for a

specific set of operating

conditions.

The pilot light indicator

lamps are NE51 neon lamps.

They are accessible from the

front panel by merely

unscrewlng the pilot·1ight dome.

_SAFETY NOTICE_

DANGEROUS VOLTAGES EXIST IN

THIS EQUIPMENT. OBSERVE THE

USUAL SAFETY PRECAUTIONS WHEN

OPERATING OR SERVICING THE

EQUIPMENT TO AVOID SEVERE

SHOCK OR INJURY.

17.

Page 20

7. MAINTENANCE OF THE POWERSTAT ("HV" CONTROL).

a) DETERMINING DEFECTIVE OPERATION:

When the brush contact of the "Powerstat"

indicates excessive wear (less than 1/32" of the carbon

brush extends from the brush holder) or arcing occurs when

the "Powerstat" is rotated with a load on the supply

resulting in high noise output from the equipment or hash

in RF equipment in the laboratory, the brush contact should

be examined. A properly adjusted "Powerstat" should not

arc or spark under load when the rotor shaft is turned.

If arcing is present, the "Powerstat" should be examined

and serviced.

b) SERVICING THE "POWERSTAT".

The "Powerstat" can be easily reached by removal

of the cabinet from the power supply. If closer examination

or adjustment of the powerstat is required, greater

accessibility is realized by removal of the front panel.

This is accomplished.by unscrewing the six large phillips

head screws on the front panel. After removing the six

screws, draw the panel forward then tilt it being careful

to clear the powerstat from the frame in doing so. The

powerstat brush is now free and clear. If wear is

indicated, replacement of the brush is effected by

loosening the two set screws in the brush holder and

removing the holder. Care must be exercised in replac1ng

the holder to insure the new holder very nearly assumes

its former position.

1. DIRTY OR PITTED COMMUTATOR SEGMENTS.

Dirty or pitted commutator segments may

be cleaned with carbon-tetrachloride.and/or sanded

lightly with fine crocus-cloth. Excessively pitted

commutator segments are a result of failure to replace

a worn brush or severe overload of the "Powerstat".

Replacement of the entire "Powerstat" assembly may

be necessary. (See paragraph 8a) Refer to Lambda

Part No. TA-549 when ordering.

8. SERVICE NOTES.

a) REMOVAL OF THE "HV" POWERSTAT AND PRECISION

POTENTIOMETER ASSEMBLY.

1. Remove the connections to the powerstat

and the precision potentiometer. Identify

leads to facilitate replacement of entire

assembly.

2. Remove the "HV" control knob.

18.

Page 21

3. Separate the assembly from panel by

unscrewing of the four phillips head

screws holding the unit to the front

panel.

4. Powerstat and precision potentiometer

assembly may now be separated from

panel.

b) REPLACEMENT OF POWERSTAT OR PRECISION

POTENTIOMETER.

1. Remove powerstat potentiometer assembly

from the equipment as per (a) above.

2. Loosen the set screws holding the flexible

coupling between the two units.

3. Loosen the nut securing the powerstat

to the bracket and remove the powerstat.

4. Replace the powerstat if required, insuring

that at the extremes of rotation of the

potentiometer shaft, the powerstat brush

takes symmetrical positions with regard

to the mounting screw in the rear of the

powerstat.

(NOTE: At no time should the stop collar screws

of the potentiometer be loosened and the collar

moved with regard to the potentiometer shaft.

These set screws are set hard and should remain

untouched.)

5. If the potentiometer is to be replaced,

after removal of the powerstat, loosen

the three pan head phillips head screws

securing the potentiometer to the bracket.

Replace the potentiometer with the new

unit. Refer to Lambda Part No. RW—559V

when ordering. Before tightening the

screws securing the potentiometer to the

bracket estimate the center to center

distance between the shaft of the

potentiometer and the stop screw in

the spacer plate. This is best done

with a pair of calipers. This distance

should approximate 29/64. The powerstat

should now be remounted, and the Millen

coupling joined to the powerstat and

potentiometer shafts. Rotation of the

potentlometer should now be tried and

the Millen coupling should be adjusted

so that at the extreme clockwise and

counter-clockwise positions of the shaft,

the brush holder of the powerstat should

take symmetrical positions with regard to

the mounting screw in the rear of the powerstat.

19.

Page 22

6. Check the assembly for smooth

rotation and reassemble into

equipment.

b) REPLACEMENT OF THE "VOLTMETER" AND "BIAS RANGE"

SWITCHES.

The replacement of either of these switches

can be facilitated by removing the panel as outlined

above.

_SAFETY NOTICE_

DANGEROUS VOLTAGES EXIST IN THIS EQUIPMENT. OBSERVE

THE USUAL SAFETY PRECAUTIONS WHEN OPERATING OR SERVICING

THE EQUIPMENT TO AVOID SEVERE SHOCK OR INJURY.

********************************************************

* *

* *

* _W A R R A N T Y_ *

* *

* We warrant each Instrument manufactured by us, and sold *

* by us or our authorized agents, to be free from defects *

* in material and workmanship; our obligation under this *

* warranty being limited to repairing or replacing any *

* instrument or part thereof (except tubes and fuses) *

* which shall, within one year after delivery to the *

* original purchaser, be returned to us with transpor- *

* tation charges prepaid, prove after our examination *

* to be thus defective. *

* *

* we reserve the right to discontinue instruments without *

* notice, and to make modifications in design at any time *

* without incurring any obligation to make such modifi- *

* cations to instruments previously sold. *

********************************************************

L A M B D A E L E C T R O N I C S C O R P .

103-02 Northern Boulevard

Corona, New York

Page 23

Page 24

NOTES

1. Tolerance of wirewound resistors is +/-5%, unless noted. SCHEMATIC DIAGRAM

2. Voltage rating of capacitors is 600 VDC, unless noted.

3. Tolerance of capacitors is +/-10%, unless noted. REGULATED POWER SUPPLY

4. Arrows indicate clockwise rotation of potentiometer shafts.

5. V Indicates connection to chassis. MODEL 71

6. * Indicates factory adjustments. See instruction manual.

7. (/) Indicates screwdriver slot. /L\

8. (2) Encircled numbers designate terminal board markings.

CONDITIONS OF VOLTAGE MEASUREMENT LAMBDA ELECTRONICS CORP.

b. "HV" control set to 500VDC, no load. "/\HV" control set to zero. CORONA NEW YORK

"BIAS" control set to zero.

c. Indicated voltages (italicized numbers) are average values.

d. Measurements made using 20,000 ohm per volt meter between "HV"

negative terminal and indicated points except as otherwise noted.

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Loading...

Loading...