Lakeside Foodservice 757 Installation Manual

Installation, Maintenance, & Repair

Series 757, 757DCDA & LF757DCDA

Double Check Valve Assemblies

Double Check Detector Assemblies

Sizes: 21⁄2" – 10" (65 – 250mm)

RP/IS-757/757DCDA

®

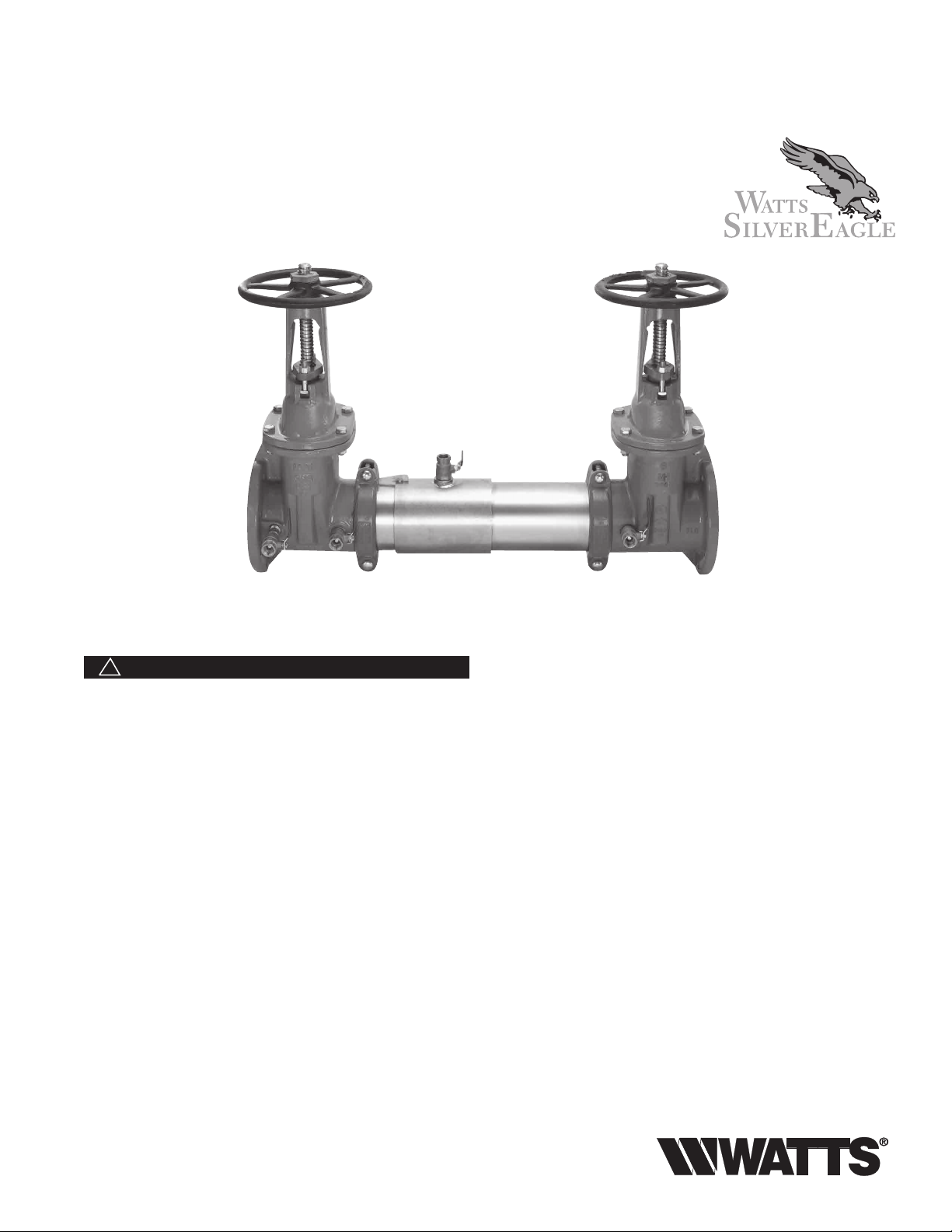

757 OSY

WARNING

!

You are required to thoroughly read all installation instructions

and product safety information before beginning the installation of this product. FAILURE TO COMPLY WITH PROPER

INSTALLATION AND MAINTENANCE INSTRUCTIONS

COULD RESULT IN PRODUCT FAILURE WHICH CAN

CAUSE PROPERTY DAMAGE, PERSONAL INJURY AND/

OR DEATH. Watts is not responsible for damages resulting

from improper installation and/or maintenance.

Local building or plumbing codes may require modifications to

the information provided. You are required to consult the local

building and plumbing codes prior to installation. If this information is not consistent with local building or plumbing codes,

the local codes should be followed.

Need for Periodic Inspection/Maintenance: This product

must be tested periodically in compliance with local codes, but

at least once per year or more as service conditions warrant.

Replace internal components every 5 years.

Corrosive water conditions, and/or unauthorized adjustments

or repair could render the product ineffective for the service

intended. Regular checking and cleaning of the product’s

internal components helps assure maximum life and proper

product function.

NOTE: For Australia and New Zealand, line strainers should be

installed between the upstream shutoff valve and the inlet of

the backflow preventer.

Its important that this device be tested periodically in compliance with local codes, but at least once per year or more as

service conditions warrant. If installed on a fire sprinkler system,

all mechanical checks, such as alarm checks and backflow

preventers, should be flow tested and inspected internally in

accordance with NFPA 13 and NFPA 25.

Testing

For field testing procedure, send for IS-TK-DL,

IS-TK-9A, IS-TK-99E AND IS-TK-99D.

For other repair kits and service parts, send for PL-RP-BPD.

For technical assistance, contact your local Watts

representative.

Installation Instructions

Series 757, 757DCDA & LF757DCDA

Guidelines

Most field problems occur because dirt and debris present in

the system at the time of installation become trapped in the #1

check. The system should be flushed before the backflow valve

is installed. If the system is not flushed until after the backflow

valve is installed, remove both check modules from the valve

and open the inlet shutoff to allow water to flow for a sufficient

time to flush debris from the water line. If debris in the water

system continues to cause fouling, a strainer can be installed

upstream of the backflow assembly.

Watts Series 757 and 757DCDA/LF757DCDA may be installed

in either horizontal or vertical position as long as the backflow assembly is installed in accordance with the direction of

the flow arrow on the assembly and the local water authority

approves the installation. The assembly should be installed with

adequate clearance around the valve to allow for inspection,

testing and servicing. 12" should be the minimum clearance

between the lower portion of the assembly and the floor or

grade.

NOTE: Assembly body should not be painted.

Maintenance Instructions

Horizontal Installation

Vertical

Installation

N Pattern

21/2" – 6" (65 – 150mm)

Figure A

Figure D

Prior to servicing any Watts valve, it is mandatory to shut

down the water system by closing both the inlet and outlet

shutoff valves. After shutoff valves are closed, open test

cock #2, #3 and #4 to relieve pressure within the backflow

assembly.

1. After #3 test cock has been opened to relieve pressure,

remove #3 test cock from housing. (Figure A)

2. Insert a #3 screwdriver through the hole on the top of the

cover sleeve and using both hands rotate the cover sleeve

approximately

wise to break the sleeve O-ring seals. Using the screwdriver,

slowly slide the cover sleeve to the downstream side of the

housing. (Figure B)

3. Remove the stainless steel check retainer from the housing.

(Figure B)

4. Remove the #1 check module (Figure C) by inserting two

flat blade screwdrivers into the slots on either side of the

check module and gently pry the check module toward the

open zone.

2

1

/4-turn clockwise and 1/4-turn counterclock-

Figure B

Figure E

5. Remove #2 check module with the same instructions as in

#4 above. For servicing 6" (150mm) checks see 8" – 10"

(200 – 250mm) instructions on p. 3.

6. To clean or inspect either check module, insert a #3 screwdriver through the downstream side of the check module as

shown in Figure D and E. When the screwdriver is in place,

remove the E-clip (Figure F) and pin connecting the structural members and the check clapper will open with no tension.

7. Thoroughly clean the seating area. The sealing disc may be

removed, if necessary, by removing the screws connecting

the keeper plate to the clapper. The sealing disc may be

reversed and reinstalled if the elastomer is cut or damaged.

8. Wash check module and O-ring and inspect for any damage. If damaged, reinstall new parts.

9. After thorough cleaning, lubricate O-ring w/FDA approved

lubricant, replace pin and E-clip in structural members,

remove screw driver and reinstall check modules and

assemble housing in reverse order of these instructions.

Figure C

Figure F

Loading...

Loading...