Lake Shore 648 User Manual

User’s Manual

Model 648

Electromagnet Power Supply

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

sales@lakeshore.com

service@lakeshore.com

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake Shore

Cryotronics, Inc. No government or other contractual support or relationship whatsoever has existed which in any

way affects or mitigates proprietary rights of Lake Shore Cryotronics, Inc. in these developments. Methods and

apparatus disclosed herein may be subject to U.S. Patents existing or applied for.

Lake Shore Cryotronics, Inc. reserves the right to add, improve, modify, or withdraw functions, design modifications,

or products at any time without notice. Lake Shore shall not be liable for errors contained herein or for incidental or

consequential damages in connection with furnishing, performance, or use of this material.

Rev. 1.4 P/N 119-058 25 July 2017

| www.lakeshore.com

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: THREE (3) YEARS

1. Lake Shore warrants that products manufactured by Lake Shore

(the "Product”) will be free from defects in materials and work

manship for three years from the date of Purchaser's physical

receipt of the Product (the "Warranty Period"). If Lake Shore

receives notice of any such defects during the Warranty Period

and the defective Product is shipped freight prepaid back to

Lake Shore, Lake Shore will, at its option, either repair or replace

the Product (if it is so defective) without charge for parts, service

labor or associated customary return shipping cost to the Pur

chaser. Replacement for the Product may be by either new or

equivalent in performance to new. Replacement or repaired

parts, or a replaced Product, will be warranted for only the

unexpired portion of the original warranty or 90 days (which

ever is greater).

2. Lake Shore warrants the Product only if the Product has been

sold by an authorized Lake Shore employee, sales representa

tive, dealer or an authorized Lake Shore original equipment

manufacturer (OEM).

3. The Product may contain remanufactured parts equivalent to

new in performance or may have been subject to incidental use

when it is originally sold to the Purchaser.

4. The Warranty Period begins on the date the Product ships from

Lake Shore’s plant.

5. This limited warranty does not apply to defects in the Product

resulting from (a) improper or inadequate installation (unless

OT&V services are performed by Lake Shore), maintenance,

repair or calibration, (b) fuses, software, power surges, lightning

and non-rechargeable batteries, (c) software, interfacing, parts

or other supplies not furnished by Lake Shore, (d) unauthorized

modification or misuse, (e) operation outside of the published

specifications, (f) improper site preparation or site maintenance

(g) natural disasters such as flood, fire, wind, or earthquake, or

(h) damage during shipment other than original shipment to

you if shipped through a Lake Shore carrier.

6. This limited warranty does not cover: (a) regularly scheduled or

ordinary and expected recalibrations of the Product; (b) acces

sories to the Product (such as probe tips and cables, holders,

wire, grease, varnish, feedthroughs, etc.); (c) consumables used

in conjunction with the Product (such as probe tips and cables,

probe holders, sample tails, rods and holders, ceramic putty for

mounting samples, Hall sample cards, Hall sample enclosures,

etc.); or, (d) non-Lake Shore branded Products that are inte

grated with the Product.

7. To the extent allowed by applicable law, this limited warranty is

the only warranty applicable to the Product and replaces all

other warranties or conditions, express or implied, including,

but not limited to, the implied warranties or conditions of mer

chantability and fitness for a particular purpose. Specifically,

except as provided herein,

-

-

-

-

-

Lake Shore undertakes no responsibility that the products will

be fit for any particular purpose for which you may be buying

the Products. Any implied warranty is limited in duration to the

warranty period. No oral or written information, or advice given

-

-

by the Company, its Agents or Employees, shall create a war

ranty or in any way increase the scope of this limited warranty.

Some countries, states or provinces do not allow limitations on

an implied warranty, so the above limitation or exclusion might

not apply to you. This warranty gives you specific legal rights

and you might also have other rights that vary from country to

country, state to state or province to province.

8. Further, with regard to the United Nations Convention for International Sale of Goods (CISC,) if CI SG is found to apply in relation

to this agreement, which is specifically disclaimed by Lake

Shore, then this limited warranty excludes warranties that: (a)

the Product is fit for the purpose for which goods of the same

description would ordinarily be used, (b) the Product is fit for

any particular purpose expressly or impliedly made known to

Lake Shore at the time of the conclusion of the contract. (c) the

Product is contained or packaged in a manner usual for such

goods or in a manner adequate to preserve and protect such

goods where it is shipped by someone other than a carrier hired

by Lake Shore.

9. Lake Shore disclaims any warranties o f technological value or of

non-infringement with respect to the Product and Lake Shore

shall have no duty to defend, indemnify, or hold harmless you

from and against any or all damages or costs incurred by you

arising from the infringement of patents or trademarks or viola

tion or copyrights by the Product.

10. THIS WARRANTY IS NOT TRANSFERRABLE. This warranty is not

transferable.

11. Except to the extent prohibited by applicable law, neither Lake

Shore nor any of its subsidiaries, affiliates or suppliers will be

held liable for direct, special, incidental, consequential or other

damages (including lost profit, lost data, or downtime costs)

arising out of the use, inability to use or result of use of the prod

uct, whether based in warranty, contract, tort or other legal theory, regardless whether or not Lake Shore has been advised of

the possibility of such damages. Purchaser's use of the Product

is entirely at Purchaser's risk. Some countries, states and prov

inces do not allow the exclusion of liability for incidental or consequential damages, so the above limitation may not apply to

you.

12. This limited warranty gives you specific legal rights, and you

may also have other rights that vary within or between jurisdic

tions where the product is purchased and/or used. Some jurisdictions do not allow limitation in certain warranties, and so the

above limitations or exclusions of some warranties stated above

may not apply to you.

13. Except to the extent allowed by applicable law, the terms of this

limited warranty statement do not exclude, restrict or modify

the mandatory statutory rights applicable to the sale of the

product to you.

-

-

-

-

-

Model 648 Electromagnet Power Supply

Copyright 2012-2017 Lake Shore Cryotronics, Inc. All rights reserved. No portion of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the express written permission of Lake Shore.

CERTIFICATION

Lake Shore certifies that this product has been inspected and tested

in accordance with its published specifications and that this product

met its published specifications at the time of shipment. The accuracy and calibration of this product at the tim

able to the United States National Institute of Standards and

T

echnology (NIST); formerly known as the National Bureau of Stan-

dards (NBS).

e of shipment are trace-

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 648 firmware is as

free of errors as possible, and that the results you obtain from the

instrument are accurate and reliable. However, as with any computer-based software, the possibi

In any important research, as when us

results should be carefully examined and rechecked before final conclusions are drawn. Neither Lake Shore nor anyone else involved in

creation or production of this firmware can pay for loss of time,

the

inconvenience, loss of use of the product, or property damage caused

by this product or its failure to work, or any other incidental or consequential damages. Use of our product impl

the Lake Shore license agreement and statement of limited warranty.

lity of errors exists.

ing any laboratory equipment,

ies that you understand

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States copyright law and international treaty pr

ranty, the code contained in the firmware must not be modified. Any

anges made to the code is at the user's risk. Lake Shore will assume

ch

no responsibility for damage or errors incurred as result of any

changes made to the firmware.

ovisions. To maintain the war-

Firmware License Agreement, continued:

Under the terms of this agreement you may only use the Model 648

mware as physically installed in the in strument. Archival copies are

fir

strictly forbidden. You may not decompile, disassemble, or reverse

engineer the firmware. If you suspect there are problems with the

firmware, return the instrument to Lake Shore for repair under the

terms of the Limited Warranty specified above. Any unauthorized

duplication or use of the Model 648 firmware in whole or in part, in

print, or in any other storage and retrieval system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers and sellers claim designations used to distinguish their products as trademarks. Where those designations

ear in this manual and Lake Shore was aware of a trademark

app

claim, they appear with initial capital letters and the ™ or ® symbol.

Alumel™ and Chromel™ are trademarks of

Conceptech, Inc., Corporation

CalCurve™, Cernox™, SoftCal™, Rox™, Curve Handler™ are trademarks of Lake Shore Cryotronics, Inc.

Java™ is a registered trademark of Sun Microsystems, Inc.

of Santa Clara, CA

LabVIEW® is a registered trademark of National Instruments.

Mac® is a registered trademark of Apple, Inc., registered in the U.S and

other countrie

Microsoft Windows®, Excel®, and Windows Vista® are registered

demarks of Microsoft Corporation in the United States and other

tra

countries.

Stycast® is a trademark of Emerson & Cuming.

WinZip™ is a registered trademark of Nico Mak of Connecticut.

s.

| www.lakeshore.com

EU DECLARATION OF CONFORMITY

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Manufacturer:

Lake Shore Cryotronics, Inc.

575 McCorkle Boulevard

Westerville, OH 43082

USA

Object of the declaration:

Model(s): 648

Description: Electromagnet Power Supply

The object of the declaration described above is in conformity with the relevant Union harmonization

legislation:

2014/35/EU Low Voltage Directive

2014/30/EU EMC Directive

2011/65/EU RoHS

References to the relevant harmonized standards used to the specification in relation to which

conformity is declared:

EN 61010-1:2010

Overvoltage Category II

Pollution Degree 2

EN 61326-1:2013

Class A

Controlled Electromagnetic Environment

EN 50581:2012

Signed for and on behalf of:

Place, Date:

Westerville, OH USA Scott Ayer

29-SEP-2016 Director of Quality & Compliance

Model 648 Electromagnet Power Supply

Electromagnetic Compatibility (EMC) for the Model 648 Electromagnet Power Supply

Electromagnetic Compatibility (EMC) of electronic equipment is a growing concern worldwide. Emissions of and

immunity to electromagnetic interference is now part of the design and manufacture of most electronics. To qualify

for the CE Mark, the Model 648 meets or exceeds the requirements of the European EMC Directive 89/643/EEC as a

CLASS A product. A Class A product is allowed to radiate more RF than a Class B product and must include the follow

ing warning:

WARNING:This is a Class A product. In a domestic environment, this product may cause radio interference in which

case the user may be required to take adequate measures.

The instrument was tested under normal operating conditions with sensor and interface cables attached. If the

installation and operating instructions in the User's Manual are followed, there should be no degradation in EMC

performance.

This instrument is not intended for use in close proximity to RF Transmitters such as two-way radios and cell

phones. Exposure to RF interference greater than that found in a typical laboratory environment may disturb the

sensitive measurement circuitry of the instrument.

Pay special attention to instrument cabling. Improperly installed cabling may defeat even the best EMC protection.

For the best performance from any precision instrument, follow the grounding and shielding instructions in the

User's Manual. In addition, the installer of the Model 648 should consider the following:

-

D Shield measurement and computer interface cables.

D Leave no unused or unterminated cables attached to the instrument.

D Make cable runs as short and direct as possible. Higher radiated emissions are possible with long cables.

D Do not tightly bundle cables that carry different types of signals.

D When the instrument is subjected to EM fields of 1 V/m, the output voltage reading may shift as much as ±0.1V.

| www.lakeshore.com

Model 648 Electromagnet Power Supply

i

Table of Contents

Chapter 1

Introduction

Chapter 2

Magnet System

Design, Installation,

and Operation

1.1 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Output Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Output Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Output Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.7 Display and Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.8 3-Year Warranty and Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.9 Model 648 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.9.1 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.9.2 Output Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.9.3 Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.9.4 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.9.5 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.10 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.11 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.12 Safety Summary and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Major Components of the Magnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Magnet Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4 Connecting the Magnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.1 Water Hose Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4.2 Magnet Coil Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.3 Temperature Switches and Flow Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4.4 Cooling Water and Water Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4.5 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4.6 Final Check-Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Electromagnet Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5.1 Air Gap and Pole Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5.2 Maximum Current and Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.5.3 Operation Under Field Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.4 Avoiding Cooling Water Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3

Installation

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.2 Inspection and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3 Rear Panel Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Power Wiring and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Magnet Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.6 Auxiliary Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.7 Power Supply Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.8 Cooling Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.9 Magnet Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.1 Moving and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.4.1 Line Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.2 Circuit Breaker Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.4.3 Start-up Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4.4 Cable Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.4.5 Power Input Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.6 Wiring Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.7 Mains Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

| www.lakeshore.com

3.10 Analog Input/Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.10.1 External Current Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.10.2 Output Current and Voltage Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.11 Computer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.11.1 USB Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.11.2 IEEE-488 Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.12 Chassis Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.12.1 3-Phase Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.12.2 Attach the Floor Mounting Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 4

Operation

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1 Understanding Menu Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Turning Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Display Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 LED Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4.1 Fault LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.2 Compliance LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.3 Power Limit LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.4 Ramping LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.5 Remote LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5 Keypad Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5.1 General Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.6 Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.7 Setting Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.8 Output Current Ramp Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.9 Ramp Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.9.1 Setting Up the Ramp Segments Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.10 Pause Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.11 Zero Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.12 Maximum Setting Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.12.1 Maximum Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.12.2 Maximum Current Ramp Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.13 Magnet Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.14 Internal Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.15 Error Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.16 External Current Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.17 Locking the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.18 Computer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.18.1 Changing IEEE-488 Interface Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.19 Default Parameter Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 5

Computer

Interface Operation

Model 648 Electromagnet Power Supply

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2 IEEE-488 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2.1 Changing IEEE-488 Interface Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2.2 Remote/Local Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2.3 IEEE-488 Command Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2.4 Status System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.3.1 Bus Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2.3.2 Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2.3.3 Device Specific Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2.3.4 Message Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2.4.1 Condition Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.4.2 Event Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.4.3 Enable Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.4.4 Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.2.4.5 Service Request Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.4.6 Reading Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

iii

5.2.4.7 Programming Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.4.8 Clearing Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.5 Status System Detail: Status Register Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.5.1 Standard Event Status Register Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.5.2 Operation Event Register Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.6 Status System Detail: Error Status Register Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.2.6.1 Hardware Error Status Register Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.2.6.2 Operational Error Status Register Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

5.2.7 Status System Detail: Status Byte Register and Service Request (SRQ) . . . . . . 51

5.2.7.1 Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

5.2.7.2 Service Request Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.2.7.3 Using Service Request (SRQ) and Serial Poll . . . . . . . . . . . . . . . . . . . . . . . . .52

5.2.7.4 Using Status Byte Query (*STB?) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.2.7.5 Using Message Available (MAV)Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.2.7.6 Using Operation Complete (*OPC) and

Operation Complete Query (*OPC?) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3 Serial Interface Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.1 Physical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

5.3.2 Hardware Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.3 Installing the USB Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.3.1 Installing the Driver From Windows® Update in

Windows Vista® and Windows 7® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3.3.2 Installing the Driver From Windows® Update in Windows® XP . . . . . 55

5.3.3.3 Installing the Driver From the Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

5.3.3.3.1 Download the driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3.3.3.2 Extract the driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3.3.3.3 Manually install the driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.3.3.4 Installing the USB Driver from the Included CD . . . . . . . . . . . . . . . . . . . . .57

5.3.4 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

5.3.4.1 Character Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.4.2 Message Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

5.3.5 Message Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.4 Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Chapter 6

Service

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

6.2 USB Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

6.2.1 New Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.2.2 Existing Installation No Longer Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.2.3 Intermittent Lockups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.3 IEEE Interface Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.1 New Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.2 Existing Installation No Longer Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.3 Intermittent Lockups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.4 Fuse Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

6.5 Line Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

6.6 Circuit Breaker Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

6.7 Power Line Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

6.8 Factory Reset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6.8.1 Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6.9 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6.9.1 Types of Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.10 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.11 Connector and Cable Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

6.11.1 Analog I/O Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.11.2 Magnet Water Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.11.3 Auxiliary Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.11.4 Power Supply Water Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

| www.lakeshore.com

6.11.4.1 Flow Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.11.4.2 Water Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.11.5 USB Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.12 Technical Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.12.1 Contacting Lake Shore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.12.2 Return of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.12.3 RMA Valid Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.12.4 Shipping Charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.12.5 Restocking Fee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Model 648 Electromagnet Power Supply

1 . 1 P r o d u c t D e s c r i p t i o n 1

Chapter 1: Introduction

1.1 Product

Description

FIGURE 1-1 Model 648 front view

Features:

D Bipolar

D ±

D Low noise

D 1 m

D A

D Buil

The Model 648 electromagnet power supply is a

optimized for powering large 7 or 10 in research electromagnets. It is specifically

designed for high precision laboratory use requiring extremely low electrical noise.

The linear design removes undesirable higher frequency noise typical of switch mode

power supplies. Eliminating the need for external switching or operator intervention

to reverse current polarity, the Model 648 uses convenient bipolar, 4-quadrant operation. It is capable of supplying ±13

Model 648 is built to last with a rugged design, integrated fault protection, and a simple, clean interior electronic design.

This robust power supply is developed to minimiz

water cooling for quiet efficient operation compared to air-cooled power supplies.

The seamless water lines only have external junctions, eliminating internal water

leaks. In addition, safety interlocks ensure that magnet cooling water is always flowing to the supply while operating. Water can be interlocked into the power supply if

ired. Internal software controls manage water usage intelligently.

des

, linear, true 4-quadrant output

135 A/±75 V, 9.1 kW

A of programmed current resolution

nalog programming and IEEE-488 and USB interfaces

t-in fault protection

robust, fault-tolerant 9 kW supply

5 A/±75 V to a nominal 0.5 ,, 0.5 H load. The

e downtime. It uses worry-free

When combined with a Lake Shore EM7 7-inch electromagnet and Model 475 DSP

gaussmeter

ideal for a wide range of user defined applications, including magneto-optical studies, magnetic hysteresis tests, susceptibility measurements, Hall effect studies, spin

magnetic resonance demonstratio

, the Model 648 forms a versatile electromagnet characterization system

ns, and biological tests.

| www.lakeshore.com

2 cHAPTER 1: Introduction

1.2 Output

Architecture

1.3 Output

Programming

1.4 Output

Reading

The low electrical noise design of the Model 648 makes it the ideal power supply for

use with large electromagnets in high precision laboratory settings, ensuring greater

resolution and finer detail in data taken during highly sensitive measurements. Since

low noise is critical to measurement systems, the Model 648 implements both a lin

ear design and bipolar architecture. Linear magnet power supplies have several

advantages over switch mode power supplies, primarily smooth field generation that

is nearly free from offending electromagnetic signatures. The bipolar, 4-quadrant

operation required to safely operate an inductive load provides clean transitions

through zero without discontinuities.

The Model 648 output current is programmed internally via the keypad or the computer interface, externally by analog programming input, or by the sum of the external and internal settings. External programming via analog input signal provides

analog resolution. The Model 648 generates extremely smooth and continuous

ramps —the digitally generated constant current ramp rate is variable between

0.1

mA/s and 50.000 A/s. To ensure a smooth ramp rate, the power supply updates

the high-resolution DAC 12.3 times per second.

The Model 648 provides high-resolution output current readings that reflect the

actual current in the magnet, and have a resolution of 1 mA. The output voltage read

ing reports the voltage at the output terminals with a resolution of 1 mV. All output

readings can be prominently displayed on the front panel and read over the computer

interface.

-

-

1.5 Protection

1.6 Interfaces

1.7 Display and

Keypad

The Model 648 provides built-in protection against short circuit, open circuit, line

loss, low line voltage, high line voltage, output over voltage, output over current, over

temperature, and abrupt change of the external programming input. A proprietary

circuit limits the power dissipated in the water-cooled cold plate should low resis

tance and high line conditions exist. The Model 648 protects itself if operated into

resistances outside of nominal limits. By limiting current output, it will safely operate

into a shorted load, and operate safely into high resistance loads by limiting voltage

output. The Model 648 is also protected against power loss under full operation and

nominal magnet load. Both low and high power line conditions are reported on the

front panel display.

The Model 648 includes both parallel IEEE-488 and universal serial bus (USB) computer interfaces that provide access to operating data, stored parameters, and

remote control of all front panel operating functions. The USB interface emulates an

RS-232C serial port at a fixed 57,600 baud rate, but with the physical connections of

a USB. This allows you to download firmware upgrades, ensuring your supply is using

the most current firmware version with no need for any physical changes. The Model

648 also provides two analog monitors for output current and voltage.

The Model 648 has a large screen displaying output current and output voltage readings simultaneously. Five front panel LEDs provide quick verification of instrument

status, including ramping, compliance, fault, power limit, and computer interface

mode. Error conditions are indicated on the main display along with an audible

beeper. The most common functions of the power supply are accessed using a single

button press.

-

1.8 3-Year

Warranty and

Technical Support

Model 648 Electromagnet Power Supply

The Model 648 is supported by a 3-year standard warranty, our confirmation of quality and commitment for the long term. Our physicists understand your applications

and measurements and provide support throughout your decision making process

and beyond the sale.

1.9 Model 648

Specifications

1 . 9 M o d e l 6 4 8 S p e c i f i c a t i o n s 3

1.9.1 Output

Typ e: Bipolar, 4-quadrant, DC voltage/current source

Current generation: Fully linear regulation with digital setting and analog control

Current range: ±135 A

Compliance voltage (DC): ±75 V

Power: 9.1 kW nominal

Nominal load: 0.5 ), 0.5 H

Maximum load resistance: 0.55 ) for ±135 A DC operation at +10% to -5% line

voltage

Minimum load resistance: 0.41 ) for ±135 A DC operation at +5% to -10% line

voltage

Load inductance range: 0 H to 1 H

Current ripple: 10 mA RMS (0.007%) at 135 A into nominal load

Current ripple frequency: Dominated by the line frequency and its harmonics

Temperature coefficient: ±50 ppm of full scale/°C

Line regulation: ±75 ppm of full scale/10% line change

Stability (1 h): 2 mA/h (after warm-up, internal setting)

Stability (24 h): 10 mA/24 h (typical, internal setting, dominated by temperature

coefficient and line regulation)

Isolation: Differential output is optically isolated from chassis to prevent ground

loops

Slew rate: 50 A/s into nominal load (dominated by magnet characteristics),100 A/s

maximum into a resistive load

Settling time: <1 s for 10% step to within 1 mA of output into nominal load

Harmonic distortion: ≤0.1 Hz at ±135 A sine wave into resistive load, <0.02% THD;

≤10 Hz at ±10 A sine wave into resistive load, <0.30% THD

Attenuation: -0.5 dB at 10 Hz (external programming input)

Protection: Short circuit, line loss, low line voltage, high line voltage, output over

voltage, output over current, and over temperature

Connector: Two lugs with 8.64 mm (0.34 in) holes for M8 or 5/16 in bolts

1.9.2 Output

Programming

Internal current setting

Resolution: 1.0 mA (20-bit)

Settling time: 600 ms for 1% step to within 1 mA (of internal setting)

Accuracy: ±20 mA ±0.05% of setting

Operation: Keypad, computer interface

Protection: Programmable current setting limit

Internal current ramp

Ramp rate: 0.1 mA/s to 50.000 A/s (compliance limited)

Update rate: 12.3 increments/s

Ramp segments: 5

Operation: Keypad, computer interface

Protection: Programmable ramp rate limit

External current programming

Sensitivity: 10 V/135 A

Resolution: Analog

Accuracy: ±20 mA ±1% of setting

Input resistance: 20 k) differential, 50 k) common-mode

Operation: Voltage program through rear panel, can be summed with internal

current setting

Limits: Internally clamped at ±10.1 V and bandwidth limited -3 dB at 40 Hz (2 pole,

low pass filter)

| www.lakeshore.com

4 cHAPTER 1: Introduction

Connector: Shared 15-pin D-sub

1.9.3 Readings

1.9.4 Front Panel

1.9.5 Interface

Output current

Resolution: 1.0 mA

Accuracy: ±20 mA ±0.05% of rdg

Update rate: 2.5 rdg/s display, 10 rdg/s interface

Output voltage (at supply terminals)

Resolution: 1.0 mV

Accuracy: ±10 mV ±0.05% of rdg

Update rate: 2.5 rdg/s display, 5 rdg/s interface

Display type: 8-line by 40-character graphic vacuum fluorescent display module

Display readings: Output current, output voltage, and internal water temperature

Display settings: Output current and ramp rate

Display annunciators: Status and error conditions

LED annunciators: Fault, Compliance, Power Limit, Ramping, Remote

Audible annunciator: Errors and faults

Keypad type: 20 full travel keys

Keypad functions: Direct access to common operations, menu-driven setup

Power: Green flush ON and red extended OFF push buttons

IEEE-488.2 interface

Features: SH1, AH1, T5, L4, SR1, RL1, PP0, DC1, DT0, C0, E1

Reading rate: To 10 rdg/s

Software support: National Instruments LabVIEW™ driver (consult Lake Shore for

availability)

USB interface

Function: Emulates a standard RS-232 serial port

Baud rate: 57,600

Reading rate: To 10 rdg/s

Connector: Type B USB connector

Software support: National Instruments LabVIEW™ driver (consult Lake Shore for

availability)

Output current monitor

Sensitivity: 7 V/135 A

Accuracy: ±1% of full scale

Noise: 5 mV RMS

Source impedance: 20 )

Connector: Shared 15-pin D-sub

Output voltage monitor

Sensitivity: 7 V/70 V

Accuracy: 1% of full scale

Noise: 2 mV RMS

Source impedance: 20 )

Connector: Shared 15-pin D-sub

Power supply cooling water

Remote enable input: TTL low or contact closure to enable output;

used for mandatory 1 gal/min flow switch (included)

Connector: 2-pin detachable terminal block connector

Valve power output: 24 VAC at 1.5 A maximum, automatic or manual control

Connector: 2-pin detachable terminal block connector

Water valve optional

Model 648 Electromagnet Power Supply

1 . 1 0 G e n e r a l 5

Magnet cooling water

Remote enable input: TTL low or contact closure to enable output;

jumper required if unused

Valve power output: 24 VAC at 1.5 A maximum, automatic or manual control

Connector: Shared 4-pin detachable terminal block

Flow, temperature switch, and water valve not included

Auxiliary

Emergency stop: Requires 1 A, 24 VAC normally closed (NC) contact to enable powerup; jumper required if unused

Fault output: Relay with normally open (NO) or normally closed (NC) contact, 30 VDC

at 1 A

Remote enable input: TTL low or contact closure to enable output; jumper required

if unused

Connector: Shared 8-pin detachable terminal block

Emergency stop and inhibit switches not included

1.10 General

Line power

Power: 15.5 kVA max

Voltage and current: 200 VAC ±10%, 41 A/phase; 208 VAC ±10%,

40 A/phase; 220 VAC ±10%, 38 A/phase; 230 VAC ±10%, 37 A/phase; 380 VAC ±10%,

23 A/phase; 400 VAC ±10%, 21 A/phase; 415 VAC ±10%, 21 A/phase

Protection: 3-phase thermal relay with adjustable current setting; two class CC 2 A

fuses; over-voltage lockout circuit

Frequency: 50 Hz or 60 Hz

Configuration: 3-phase delta

Connector: 4-pin terminal block

Line voltage must be specified at time of order but is field reconfigurable; cable from

power supply to facility power not included

Cooling water

Flow rate: 7.6 L (2.0 gal)/min minimum

Maximum pressure: 552 kPa (80 psi)

Pressure drop: 159 kPa (23 psi) at 7.6 L (2.0 gal)/min minimum for power supply and

mandatory flow switch

Temperature: 15 °C to 30 °C (non-condensing)

Connection: Two 12.7 mm (0.5 in) hose barbs

Internal condensation can cause damage to the power supply

Enclosure type: Custom 19 in rack cabinet

Size: 559 mm W x 673 mm D x 1054 mm H (22 in W x 26 in D x 42 in H)

Weight : 225 kg (495 lb)

Shipping size: 914 mm W × 1168 mm D × 1219 mm H (36 in × 46 in × 48 in)

Shipping weight: 281 kg (620 lb)

Ambient temperature: 15 °C to 35 °C at rated accuracy, 5 °C to 40 °C at reduced

accuracy

Humidity: Non-condensing

Warm-up: 30 min at output current setting

Approvals: CE mark-low voltage compliance to EN61010-1, EMC compliance

to EN61326-1

| www.lakeshore.com

6 cHAPTER 1: Introduction

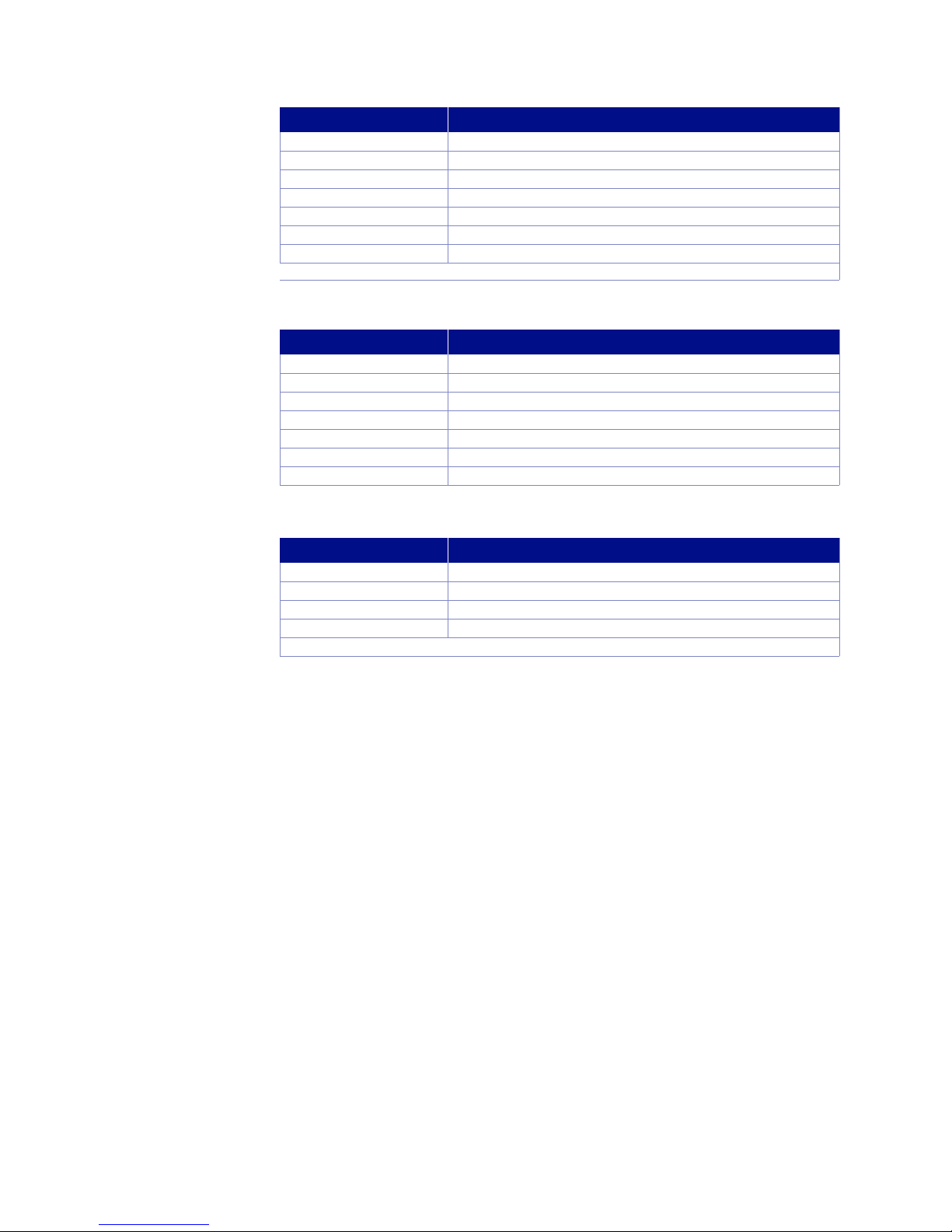

1.11 Ordering

Information

Part number Description

648-200 Model 648 ±135 A ±76 V, 9.1 kW, 200 VAC

648-208 Model 648 ±135 A ±76 V, 9.1 kW, 208 VAC

648-220 Model 648 ±135 A ±76 V, 9.1 kW, 220 VAC

648-230 Model 648 ±135 A ±76 V, 9.1 kW, 230 VAC

648-380 Model 648 ±135 A ±76 V, 9.1 kW, 380 VAC

648-400 Model 648 ±135 A ±76 V, 9.1 kW, 400 VAC

648-415 Model 648 ±135 A ±76 V, 9.1 kW, 415 VAC

All specifications are subject to change without notice

TABLE 1-1

Part number Description

6051 Terminal block, 4-pin

6052 Terminal block, 8-pin

6252 15-pin D-sub mating connector, analog I/O

— Hose clamps

— Power cable strain relief (power cable not included)

— Calibration certificate

MAN-Model 648 Model 648 user manual

TABLE 1-2

Model 648 accessories included

Model 648

Part number Description

6043 Wate r val ve

6201 1 m (3.3 ft long) IEEE-488 (GPIB) c

CAL-648-CERT Instrument recalibration with certificate

CAL-648-DATA Instrument recalibration with

All specifications are subject to change without notice

TABLE 1-3

Model 648 accessories available

omputer interface cable assembly

certificate and data

Model 648 Electromagnet Power Supply

1. 1 2 S a f e t y S u m m a r y a n d S y m b o l s 7

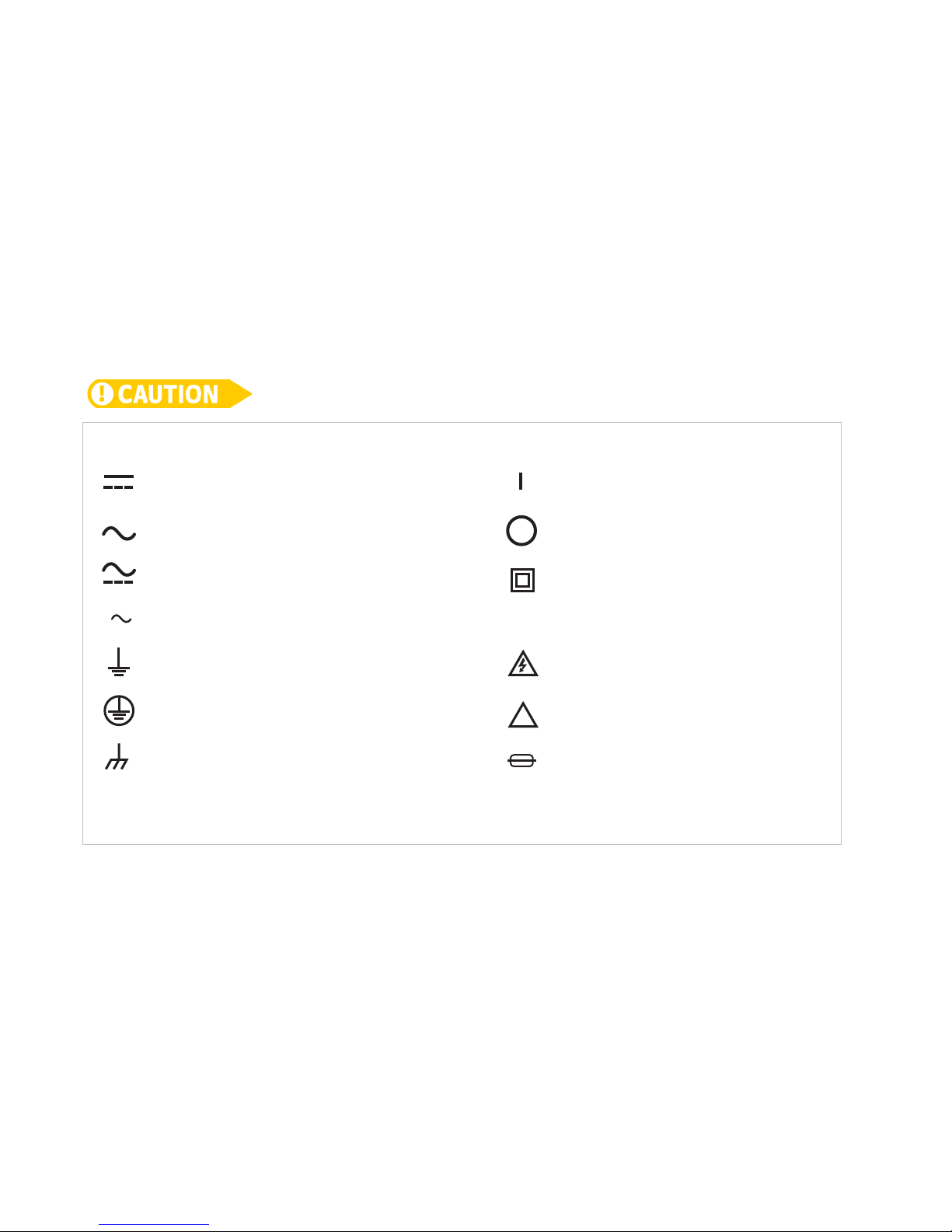

1.12 Safety

Summary and

Symbols

Observe these general safety precautions during all phases of instrument operation,

service, and repair. Failure to comply with these precautions or with specific warn

ings elsewhere in this manual violates safety standards of design, manufacture, and

intended instrument use. Lake Shore Cryotronics, Inc. assumes no liability for Cus

tomer failure to comply with these requirements.

The Model 648 protects the operator and surrounding area from electric shock or

burn, mechanical hazards, excessive temperature, and spread of fire from the instru

ment. Environmental conditions outside of the conditions below may pose a hazard

to the operator and surrounding area.

D Indoor use

D Altitude to 2000 m

D Temperature for safe operation: 5 °C to 40 °C

D Maximum relative humidity: 80% for temperature up to 31 °C decreasing

linearly to 50% at 40 °C

D Power supply voltage fluctuations not to exceed ±10% of the nominal voltage

D Overvoltage category II

D Pollution degree 2

Power and Ground Connections

This instrument must be connected to a dedicated three-phase power circuit with

proper size of circuit breaker (refer to Chapter 3). The connection installation must be

performed by a licensed electrician. Verify that the unit has been configured for the

correct input voltage. The neutral line, if available, is not used. Power to the unit must

be hard-wired, and never connected using a detachable cord. In all cases the correct

size wire must be chosen for the current drawn, working voltage, and the length of

cable used. To minimize shock hazard, the electrical ground (safety ground) lead must

be connected. Power wiring must comply with electrical codes of the locality in which

the unit is installed.

-

-

-

Ventilation

The instrument has an exhaust fan and ventilation holes on the rear panel. Do not

block these holes when the instrument is operating. Provide at least 25 mm (1 in) of

air space on each side for ventilation.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any electrical instrument in such an environment constitutes a definite safety

hazard.

Keep Away from Live Circuits

Operating personnel must not remove instrument covers. Refer component replacement and internal adjustments to qualified maintenance personnel. Do not replace

components with power cable connected. To avoid injuries, always disconnect power

and discharge circuits before touching them.

Do Not Substitute Parts or Modify Instrument

Do not install substitute parts or perform any unauthorized modification to the

instrument. Return the instrument to an authorized Lake Shore Cryotronics, Inc. rep

resentative for service and repair to ensure that safety features are maintained.

Do not Use the Equipment In a Manner Not Specified

If the equipment is used in a manner not specified by the manufacturer, the safety

protection provided by the equipment may be impaired.

-

| www.lakeshore.com

8 cHAPTER 1: Introduction

Direct current

Equipment protected throughout

by double insulation or reinforced

insulation (equivalent to Class II of

IEC 536—see Annex H)

CAUTION: risk of electric shock

!

CAUTION or WARNING: Refer to

instrument documentation

Off (supply)

On (supply)

Frame or chassis ground

Protective conductor terminal

Earth (ground) terminal

3

Three-phase alternating current

Both direct and alternating current

Alternating current

Fuse

Prevent Cooling Water Condensation

Do not operate the power supply when cooling

the dew point for local atmospheric conditions. Condensation on cooling water lines

inside the power supply can cause severe damage. Refer to section 2.5.4 for additional details.

Cleaning

Do not submerge instrument. Clean only with a damp cloth and mild detergent. Exterior only.

Moving and Handling

Casters are installed on the base to allow the unit to be rolled around. Four lifting lugs

provided for ease of moving and handling the Model 648. Always use all four lift-

are

ing lugs when lifting the unit. Because of its weight, the Model 648 should be handled

y mechanical means.

b

To avoid injury to personnel, always observe proper lifting techniques in accordance with

OSHA and other regulatory agencies.

water temperature is at or lower than

Model 648 Electromagnet Power Supply

FIGURE 1-2 Safety symbols

9

Chapter 2: Magnet System Design,

Installation, and Operation

2.1 General

2.2 Major

Components of the

Magnet

This chapter provides the user insight into the design, installation, and operation of a

typical electromagnet. For information on how to install the Model 648 please refer

to Chapter 3. For Model 648 operation information, refer to Chapter 4.

A magnet used with the Model 648 electromagnet power supply typically has an iron

pole, twin coil, 7 in or 10 in pole diameter, variable air gap, and is water cooled. Larger

magnets can be used depending on their electrical parameters and the magnetic field

requirements. The electromagnet provides a uniform magnetic field in the air gap

between two adjustable poles. The samples, which are to be tested for their magnetic

properties, are placed in the air gap with appropriate monitoring equipment

attached. By varying the polarity and intensity of the field, useful data can be

collected. A typical electromagnet is shown in FIGURE 2-1.

A typical electromagnetFIGURE 2-1

| www.lakeshore.com

10 CHAPTER 2: Magnet System Design, Installation, and Operation

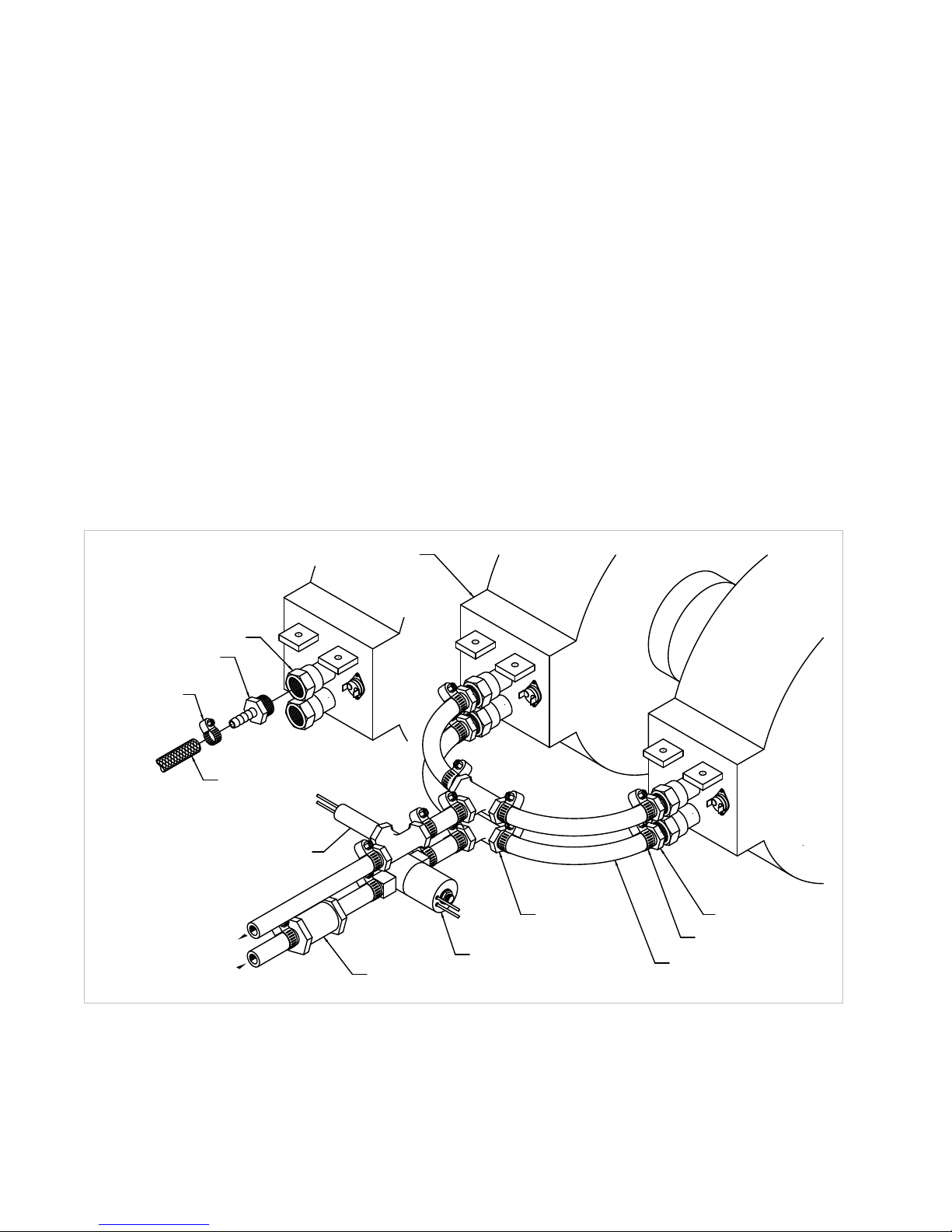

Reenforced hose

Optional water filter

Optional water valve

Te e

Optional flow switch

Magnet coil

Hose barb fitting

Hose clamp

Reenforced hose

Hose clamp

Hose barb fitting

Magnet water connection

2.3 Magnet

Construction

2.4 Connecting

the Magnet

2.4.1 Water Hose

Connection

The magnet consists of two water-cooled coils surrounding adjustable iron poles,

which are fitted into an iron frame. The frame supports the poles and coils, and

improves the magnet’s efficiency. The iron poles are fitted with adjusting

mechanisms so that the air gap width can be set. Lock mechanisms are provided to

hold the poles in place after adjustment is made. The poles faces have pole caps

attached, which provide the desired magnetic focus. The size and shape of the pole

caps are chosen according to the size of the sample being tested and the magnetic

field requirement.

Connecting the magnet to the power supply requires three separate circuits: the

cooling water hoses, the main high current power lines, and the safety switches.

These may include any combination of temperature and flow switches. These

connections are shown in FIGURE 2-2.

Water-cooling is essential for these magnets. The power dissipated can raise the

temperature of the coils to the point where they will be destroyed. In addition, the

samples being tested may exhibit changes in their magnetic performance with

changes in temperature causing errors in the collected data. Typical water

connection is shown in FIGURE 2-2. The magnets may be supplied with hose barbs or

standard hose fittings. The coils are conne

temperature rise is the same for both. Every effort should be made to insure that the

flow rate in both coils is the same. The minimum flow required is usually specified by

the magnet vendor.

cted in parallel so that the water

Model 648 Electromagnet Power Supply

FIGURE 2-2

Typical magnet water hook-up

2 . 4 . 2 M a g n e t C o i l W i r i n g 11

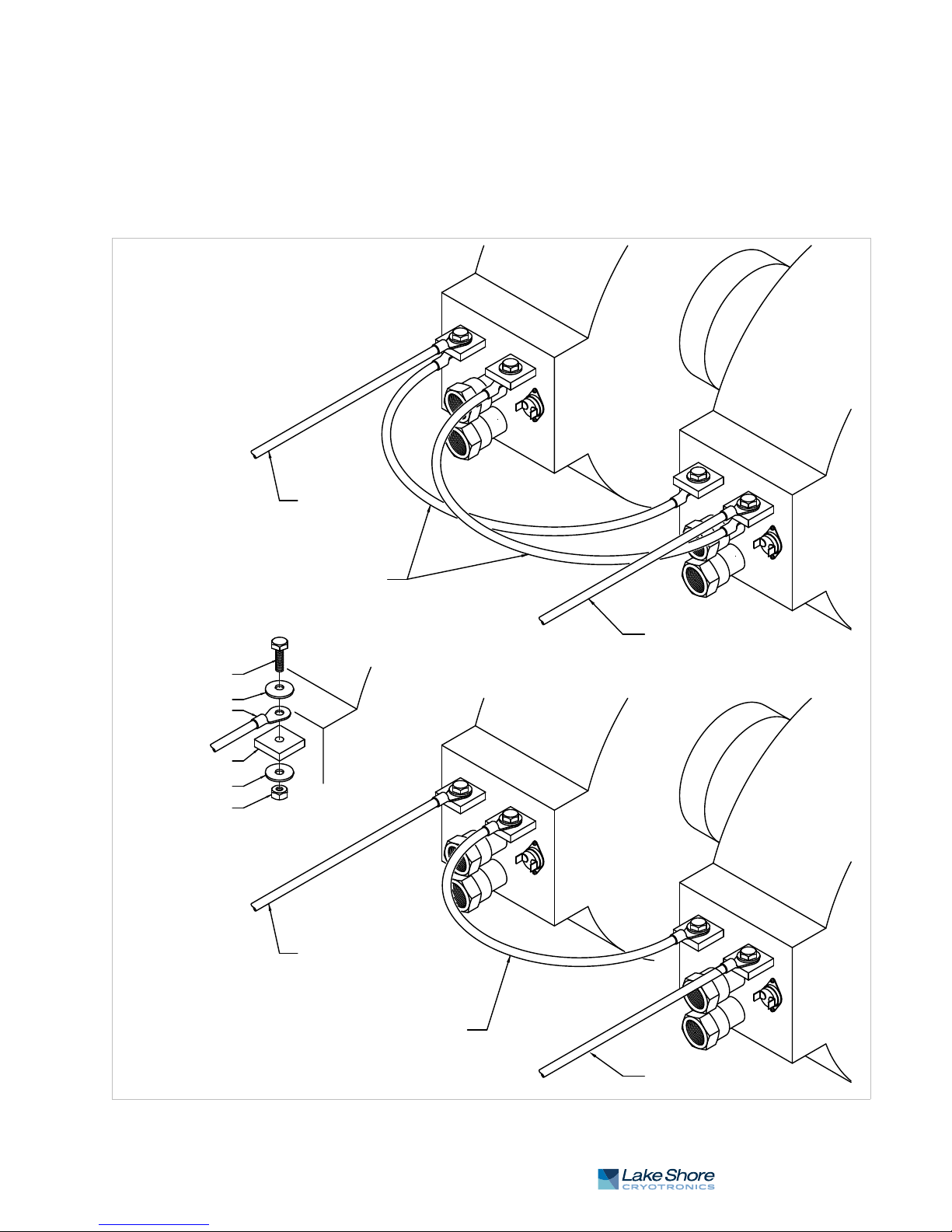

Power lead

Power lead

Cross connection wiring

Power lead

Power lead

Cross connection wiring

Bolt

Belleville washer

Cable connection

Magnet power lug

Plain washer

Nut

-

+

-

+

-

+

-

+

(parallel wiring)

(series wiring)

2.4.2 Magnet Coil

Wiring

Typical magnet coil wiring is shown in FIGURE 2-3. The connecting cable used should

be of sufficient gage to prevent excessive voltage drop and heat rise in the cable. The

bles should be as short as possible to minimize the voltage drop. Current carrying

ca

capacities for various sizes of cables and cable lengths are shown in TABLE 3-3. The

connections must be made with the correct siz

We recommend the use of a spring or Belleville washer for cable terminations. When

the parts of a connection expand and contract with changes in temperature, they

tend to loosen. A spring washer will reduce this tendency.

e of hardware for the magnet terminal.

FIGURE 2-3

Typical magnet coil wiring showing series and parallel connections

| www.lakeshore.com

12 CHAPTER 2: Magnet System Design, Installation, and Operation

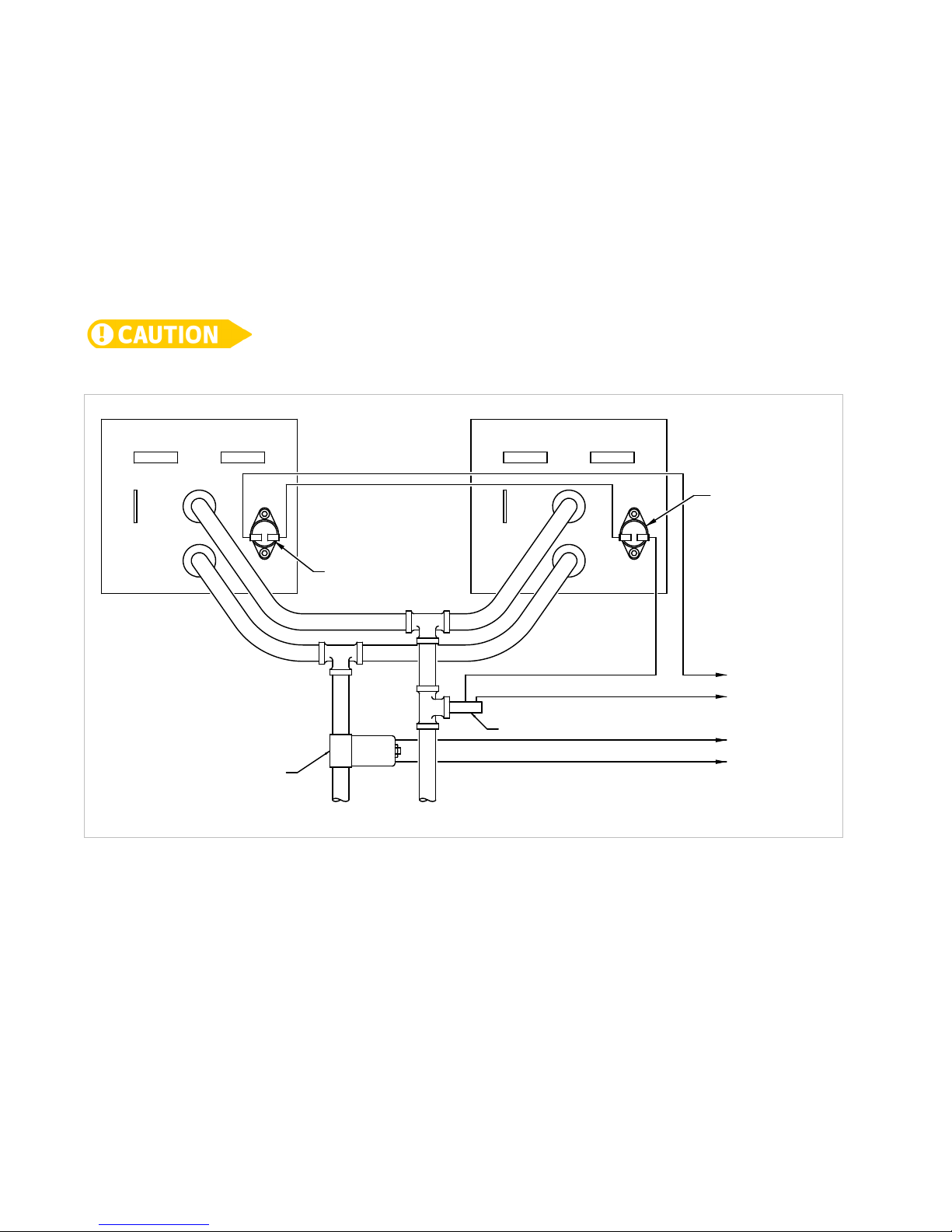

To Model 648 magnet connector valve contacts

To Model 648 magnet connector flow switch contacts

Inlet Outlet

Thermal switch

Flow switch

Water valve

Thermal switch

2.4.3 Temperature

Switches and Flow

Switches

As discussed in section 2.4.1, water-cooling for the magnet is essential. To protect the

magnet from damage resulting from an interruption in cooling water, a flow switch,

erature switches, or both should be installed. The switches must have a

temp

normally open contact (switch is open when no water is flowing), and if switches are

used, they must be connected in series. The switches are then connected to the flow

switch terminals of the magnet connector on the Model 648. The Model 648

monitors the switches and if an open is detected, the output current is ramped to

zero. (Flow switch monitoring depends on water valve mode setting. See section 4.13

and section 4.14 for details.) Given the cost of the magnet, it is prudent to use both

temperature and flow switches. Some install

ations use two flow switches, one in the

exhaust line of each coil so that if a clog occurs in only one coil, it can be detected.

FIGURE 2-4 shows the typical flow and temperature switch connection.

Care must be used in the selection of the flow switch. Some switches use a sensitive reed

switch, which can be overpowered by stray flux from the magnet and will not open when

the magnet is operating at high field. The flow switch must be tested by turning off the

water while the magnet is operating at full current.

FIGURE 2-4

2.4.4 Cooling Water

and Water Valve

The cooling water for the magnet can be drawn from the municipal water facility or

from a dedicated re-circulating water chiller designed for this purpose. When water is

drawn from the municipal water facility, the water should be turned on only when it

is required to reduce consumption and reduce the likelihood of scale build-up and

condensation in the magnet. The water can be turned on and off manually when the

magnet is used, or automatically with a solenoid valve. The Model 648 provides

automatic control and a 24 VAC at 1 A output for this purpose. The optional water

valve is shown in FIGURE 2-2. The water inlet line should also be fitted with a

sediment filter (not shown) to reduce scale build-up in the magnet coils and

ecting lines.

conn

Model 648 Electromagnet Power Supply

Typical thermal switch, flow switch and valve wiring

2 . 4 . 5 G r o u n d i n g 13

2.4.5 Grounding

2.4.6 Final Check-Out

2.5 Electromagnet

Operation

2.5.1 Air Gap and Pole

Caps

A ground connection (tapped hole) is usually available at the rear of the

electromagnet frame. This ground point is provided for customers who would like to

use the electromagnet frame as a signal ground or will be bringing hazardous live

voltages near the electromagnet and would like to make it an electrical safety

ground. Please verify suitability for such a function and compatibility with local and

national electrical codes before making ground connections. Scrape off excess paint

near the connecting screw to ensure a good electrical contact with the bare steel of

the electromagnet frame.

When all of the connections have been made, the system should be tested to be sure it

is operating correctly. The settings for the magnet water should be checked to verify

that they are correct for the configuration which has been installed (

The maximum current setting for the magnet should be set also (section 2.5.2 and

section 4.12.1).

This section provides a brief description of the typical operation of an electromagnet.

For operation of the Model 648, refer to Chapter 4.

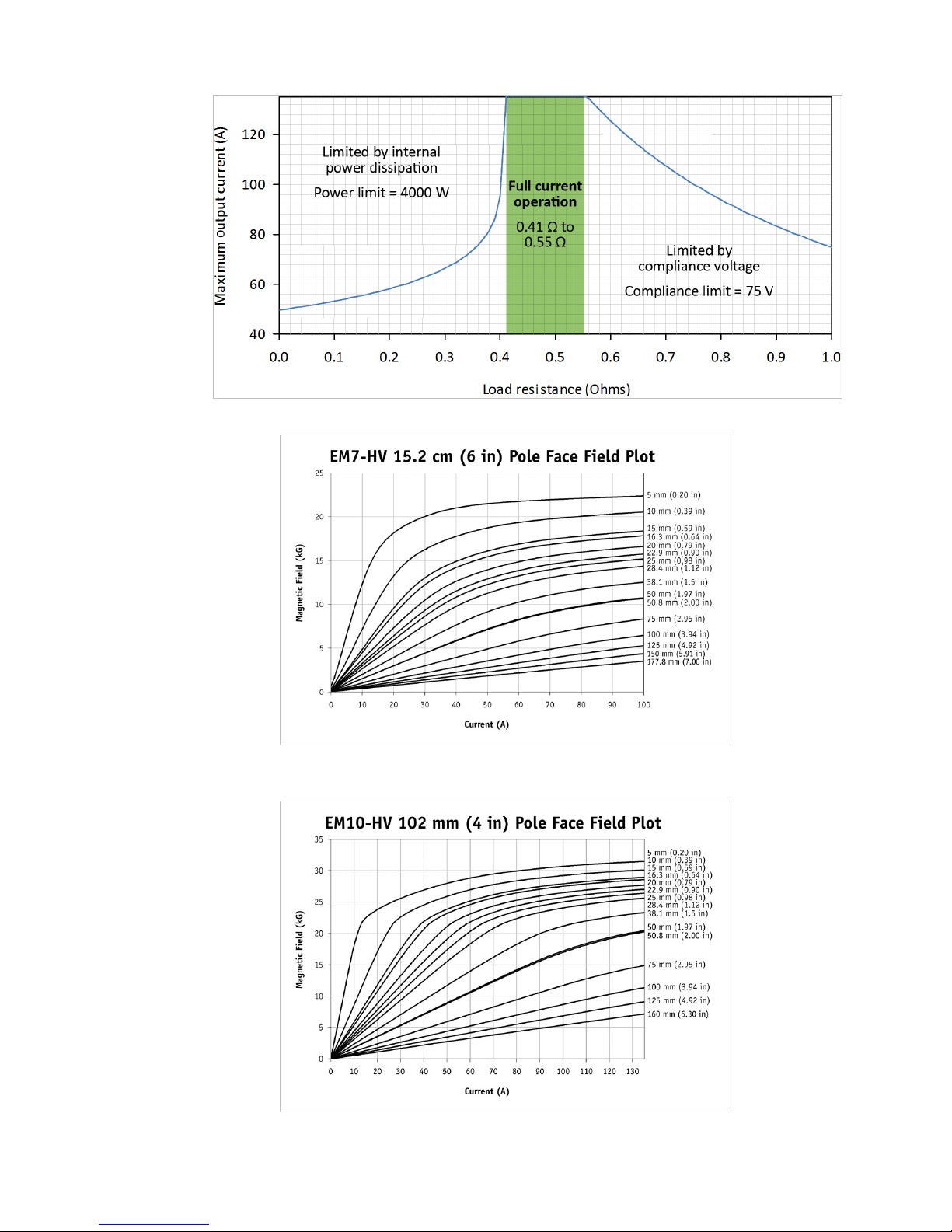

The first step in setting up a magnet for operation is to select the proper pole caps and

adjust the air gap. These parameters are determined by the size and shape of the

sample, and the connections that must be made to the sample. Generally, a smaller

pole face provides a higher field within the air gap. A smaller air gap also provides a

higher field. The pole faces must be selected to accommodate the size of the sample

being tested. The air gap is selected based on the size of the sample and the other

equipment being used. The curves for field versus current for various air gaps and pole

cap sizes for the Lake Shore Model EM7-HVA are shown in

FIGURE 2-7. It also shows that these parameters are not linear. This must be taken

into account when operating an electromagnet. To obtain linearity, it is necessary to

operate the magnet and power supply under field control(

FIGURE 2-6 through

section 2.5.3).

section 4.13).

2.5.2 Maximum

Current and Power

The Model 648 was designed to operate with a magnet load resistance of 0.50 ), but

will provide full current output within a resistance range of 0.41 ) to 0.55 ). The

Model 648 will also work outside of the previously mentioned resistance range, but

will be limited by two factors: internal power dissipation and compliance voltage.

FIGURE 2-5 plots the maximum current output versus a resistance range of 0.00 ) to

1.00 ).

Also to be taken into account, the resistance of a magnet will rise with a rise in

temperature. The power dissipated in the magnet is given by: P = I

remains constant, the power dissipated will rise proportionately with the rise in

resistance.

2

R. If the current

| www.lakeshore.com

14 CHAPTER 2: Magnet System Design, Installation, and Operation

FIGURE 2-6

FIGURE 2-5

Maximum current output vs. resistance

Typical curves of field vs. current for 6 inch pole face on the EM7

FIGURE 2-7

Model 648 Electromagnet Power Supply

Typical curves of field vs. current for 4 inch pole face on the EM10

2 . 5 . 3 O p e r a t i o n U n d e r F i e l d C o n t r o l 15

2.5.3 Operation Under

Field Control

To obtain a linear field ramp, a magnetic sensor such as a Hall probe is placed in the

air gap along with the sample being tested. The sensor is connected to a gaussmeter.

The output of the gaussmeter is used to correct the programming input to the power

supply. In this way non-linearity can be corrected. Lakeshore manufactures probes

and gaussmeters for this purpose.

2.5.4 Avoiding Cooling

Water Condensation

If the temperature of the cooling water is too cool relative to the air temperature and

humidity, condensation can occur. Condensation inside the power supply can cause

severe damage. To avoid condensation, the power supply operator must remain

cognizant of the ambient air temperature, cooling water temperature, and the

relative humidity. Lake Shore defines the limits of these conditions as follows:

D a

mbient temperature = 18 - 28 °C (64 - 82 °F)

D cooling w

D humidity = 20

Knowing the actual state of these conditions, th

ater temperature = 15 - 25 °C (59 - 77 °F)

- 80% (non-condensing).

e operator can calculate the dew

point, or temperature at which condensation will occur. TABLE 2-1 and TABLE 2-2 are

included to aid in dew point calculation.

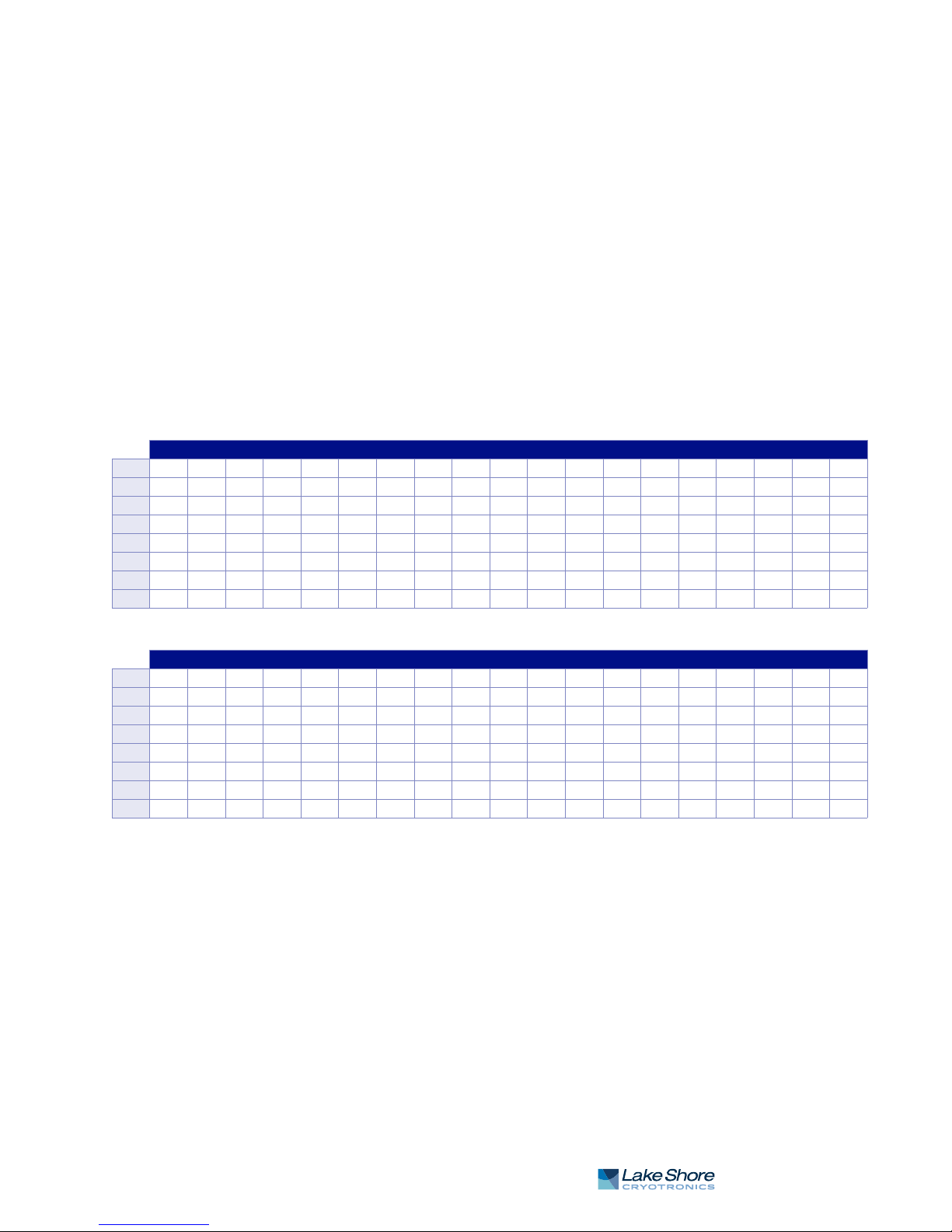

% Relative Humidit y

°C 100 95 90 85 80 75 70 65 60 55 50 45 40 35 30 25 20 15 10

32 32 31 31 29 28 27 26 24 23 22 20 18 17 15 12 9 6 2 0

29 29 28 27 27 26 24 23 22 21 19 18 16 14 12 10 7 3 0 —

27 27 26 25 24 23 22 21 19 18 17 15 13 12 10 7 4 2 0 —

24 24 23 22 21 20 19 18 17 16 14 13 11 9 7 5 2 0 — —

21 21 20 19 18 17 16 15 14 13 12 10 8 7 4 3 0 — — —

18 18 17 17 16 15 14 13 12 10 9 7 6 4 2 0 — — — —

16 16 14 14 13 12 11 10 9 7 6 5 3 2 0 — — — — —

TABLE 2-1

Dew point calculation (in degrees Celsius)

% Relative Humidit y

°F 100 95 90 85 80 75 70 65 60 55 50 45 40 35 30 25 20 15 10

90 90 88 87 85 83 81 79 76 74 71 68 65 52 59 54 49 43 36 32

85 85 83 81 80 78 76 74 72 69 67 64 61 58 54 50 45 38 32 —

80 80 78 77 75 73 71 69 67 65 62 59 56 53 50 45 40 35 32 —

75 75 73 72 70 68 66 64 62 60 58 55 52 49 45 41 36 32 — —

70 70 68 67 65 63 61 59 57 55 53 50 47 44 40 37 32 — — —

65 65 63 62 60 59 57 55 53 50 48 45 42 40 36 32 — — — —

60 60 58 57 55 53 52 50 48 45 43 41 38 35 32 — — — — —

TABLE 2-2

Dew point calculation (in degrees Fahrenheit)

Example: Determine the actual air temperature and relative humidity. Find the

closest air temperature in the left-hand column and the closest relative humidity

across the top. If the air temperature is 24 °C (75 °F) and the relative humidity is 35%,

the intersection of the two shows a dew point of 7 °C (45 °F). Therefore, for the given

conditions, the cooling water must remain above 7 °C (45 °F) to prevent

condensation.

| www.lakeshore.com

16 CHAPTER 2: Magnet System Design, Installation, and Operation

Model 648 Electromagnet Power Supply

17

Chapter 3: Installation

3.1 General

3.2 Inspection and

Unpacking

This chapter provides general installation instructions for the Model 648

electromagnet power supply.

To ensure the best possible performance and maintain operator safety, read this entire

chapter before installing the instrument and applying power. Serious hazards can exist

when an instrument of this power capacity is used incorrectly. If you do not understand

any section of this manual, consult Lake Shore for clarification. Lake Shore Cryotronics,

Inc. assumes no responsibility for damage or injuries incurred due to improper

installation, defeat of any of the safety features, or misuse of this power supply.

Inspect shipping containers for external damage before opening them. Photograph

any container that has significant damage before opening it. If there is visible damage

to the contents of the container, contact the shipping company and Lake Shore

immediately, preferably within five days of receipt of goods. Keep all damaged

shipping materials and contents until instructed to either return or discard them.

Open the shipping container and keep the container and shipping materials until all

ents have been accounted for. Check off each item on the packing list as it is

cont

unpacked. Instruments themselves may be shipped as several parts. The items

included with the Model 648 are described in the following list. Contact Lake Shore

immediately if there is a shortage of parts or accessories. Lake Shore is not

responsible for any missing items if not notified within 60 days of shipment.

Inspect all items for both visible and hidden

If damage is found, contact Lake Shore immediately for instructions on how to file a

proper insurance claim. Lake Shore products are insured against damage during

shipment, but a timely claim must be filed before Lake Shore will take further action.

Procedures vary slightly with shipping companies. Keep all shipping materials and

damaged contents until instructed to either return or discard them.

damage that occurred during shipment.

If the instrument must be returned for recalibration, replacement or repair, a

returned

representative prior to return. The Lake Shore RMA procedure is in section 6.12.2.

Items Included with the Model 648 electromagnet power supply:

D 1

D 1

D 1 analog I/O mating connect

D 1 s

D 1

D 1

D 2

D 1

D 2 h

D 1 output lug co

D Flow switch (shipped attached)

D 1 water ho

D 1 4

D 1 power cable

D 1 floo

goods authorization (RA) number must be obtained from a factory

Model 648 instrument

Model 648 User’s Manual

or

et of output terminal fasteners

wiring cover plate and screws (shipped attached)

2-pin detachable terminal block

4-pin detachable terminal blocks

8-pin detachable terminal block

ose clamps

ver and screws

se cover (shipped attached)

mm hex key

strain relief assembly

r mounting kit

| www.lakeshore.com

Loading...

Loading...