Lakeshore 642 User Manual

pply

User’s Manual

Model 642

Electromagnet

Power Su

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

E-mail Addresses:

sales@lakeshore.com

service@lakeshore.com

Visit Our Website At:

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake Shore Cryotronics, Inc. No government

or other contractual support or relationship whatsoever has existed which in any way affects or mitigates proprietary rights of Lake Shore Cryotronics,

Inc. in these developments. Methods and apparatus disclosed herein may be subject to U.S. Patents existing or applied for. Lake Shore Cryotronics,

Inc. reserves the right to add, improve, modify, or withdraw functions, design modifications, or products at any time without notice. Lake Shore shall

not be liable for errors contained herein or for incidental or consequential damages in connection with furnishing, performance, or use of this material.

Revision 1.3 P/N 119-042 9 January 2008

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

1. Lake Shore warrants that this Lake Shore product (the “Product”) will

be free from defects in materials and workmanship for the Warranty

Period specified above (the “Warranty Period”). If Lake Shore receives

notice of any such defects during the Warranty Period and the Product

is shipped freight prepaid, Lake Shore will, at its option, either repair

or replace the Product if it is so defective without charge to the owner

for parts, service labor or associated customary return shipping cost.

Any such replacement for the Product may be either new or equivalent

in performance to new. Replacement or repaired parts will be

warranted for only the unexpired portion of the original warranty or 90

days (whichever is greater).

2. Lake Shore warrants the Product only if it has been sold by an

authorized Lake Shore employee, sales representative, dealer or

original equipment manufacturer (OEM).

3. The Product may contain remanufactured parts equivalent to new in

performance or may have been subject to incidental use.

4. The Warranty Period begins on the date of delivery of the Product or

later on the date of installation of the Product if the Product is installed

by Lake Shore, provided that if you schedule or delay the Lake Shore

installation for more than 30 days after delivery the Warranty Period

begins on the 31st day after delivery.

5. This limited warranty does not apply to defects in the Product resulting

from (a) improper or inadequate maintenance, repair or calibration, (b)

fuses, software and non-rechargeable batteries, (c) software,

interfacing, parts or other supplies not furnished by Lake Shore, (d)

unauthorized modification or misuse, (e) operation outside of the

published specifications or (f) improper site preparation or

maintenance.

6. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE

ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTY OR CONDITION, WHETHER WRITTEN OR ORAL,

IS EXPRESSED OR IMPLIED. LAKE SHORE SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY, SATISFACTORY QUALITY AND/OR

FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE PRODUCT. Some countries, states or provinces do not allow

limitations on an implied warranty, so the above limitation or

exclusion might not apply to you. This warranty gives you specific

legal rights and you might also have other rights that vary from

country to country, state to state or province to province.

7. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE

REMEDIES IN THIS WARRANTY STATEMENT ARE YOUR

SOLE AND EXCLUSIVE REMEDIES.

8. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE

LAW, IN NO EVENT WILL LAKE SHORE OR ANY OF ITS

SUBSIDIARIES, AFFILIATES OR SUPPLIERS BE LIABLE FOR

DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR

OTHER DAMAGES (INCLUDING LOST PROFIT, LOST DATA

OR DOWNTIME COSTS) ARISING OUT OF THE USE,

INABILITY TO USE OR RESULT OF USE OF THE PRODUCT,

WHETHER BASED IN WARRANTY, CONTRACT, TORT OR

OTHER LEGAL THEORY, AND WHETHER OR NOT LAKE

SHORE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. Your use of the Product is entirely at your own risk.

Some countries, states and provinces do not allow the exclusion of

liability for incidental or consequential damages, so the above

limitation may not apply to you.

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: ONE (1) YEAR

LIMITED WARRANTY STATEMENT (Continued)

9. EXCEPT TO THE EXTENT ALLOWED BY APPLICABLE LAW,

THE TERMS OF THIS LIMITED WARRANTY STATEMENT DO

NOT EXCLUDE, RESTRICT OR MODIFY, AND ARE IN

ADDITION TO, THE MANDATORY STATUTORY RIGHTS

APPLICABLE TO THE SALE OF THE PRODUCT TO YOU.

CERTIFICATION

Lake Shore certifies that this product has been inspected and tested in

accordance with its published specifications and that this product met its

published specifications at the time of shipment. The accuracy and

calibration of this product at the time of shipment are traceable to the

United States National Institute of Standards and Technology (NIST);

formerly known as the National Bureau of Standards (NBS).

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 642 firmware is as free

of errors as possible, and that the results you obtain from the instrument

are accurate and reliable. However, as with any computer-based software,

the possibility of errors exists.

In any important research, as when using any laboratory equipment,

results should be carefully examined and rechecked before final

conclusions are drawn. Neither Lake Shore nor anyone else involved in

the creation or production of this firmware can pay for loss of time,

inconvenience, loss of use of the product, or property damage caused by

this product or its failure to work, or any other incidental or consequential

damages. Use of our product implies that you understand the Lake Shore

license agreement and statement of limited warranty.

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States copyright

law and international treaty provisions. To maintain the warranty, the

code contained in the firmware must not be modified. Any changes made

to the code is at the user’s risk. Lake Shore will assume no responsibility

for damage or errors incurred as result of any changes made to the

firmware.

Under the terms of this agreement you may only use the Model 642

firmware as physically installed in the instrument. Archival copies are

strictly forbidden. You may not decompile, disassemble, or reverse

engineer the firmware. If you suspect there are problems with the

firmware, return the instrument to Lake Shore for repair under the terms

of the Limited Warranty specified above. Any unauthorized duplication

or use of the Model 642 firmware in whole or in part, in print, or in any

other storage and retrieval system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers and sellers claim designations used to distinguish

their products as trademarks. Where those designations appear in this

manual and Lake Shore was aware of a trademark claim, they appear with

initial capital letters and the ™ or

®

symbol.

CalCurve™, Cernox™, Duo-Twist™, Quad-Lead™, Quad-Twist™,

Rox™, and SoftCal™ are trademarks of Lake Shore Cryotronics, Inc.

®

MS-DOS

and Windows® are trademarks of Microsoft Corp.

NI-488.2™ is a trademark of National Instruments.

PC, XT, AT, and PS-2 are trademarks of IBM.

Copyright © 2006 by Lake Shore Cryotronics, Inc. All rights reserved. No portion of this manual may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the express written permission of Lake Shore.

ii

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

iii

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

This Page Intentionally Left Blank

iv

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

TABLE OF CONTENTS

Chapter/Section Title Page

1 INTRODUCTION ....................................................................................................................................................1-1

1.0 GENERAL.............................................................................................................................................1-1

1.1 DESCRIPTION......................................................................................................................................1-1

1.2 SPECIFICATIONS................................................................................................................................ 1-3

1.3 SAFETY SUMMARY............................................................................................................................. 1-7

1.4 SAFETY SYMBOLS.............................................................................................................................. 1-9

2 MAGNET SYSTEM DESIGN, INSTALLATION, AND OPERATION...................................................................... 2-1

2.0 GENERAL.............................................................................................................................................2-1

2.1 INTRODUCTION...................................................................................................................................2-1

2.2 MAGNET CONSTRUCTION.................................................................................................................2-2

2.3 CONNECTING THE MAGNET..............................................................................................................2-2

2.3.1 Water Hose Connection ....................................................................................................................2-2

2.3.2 Magnet Coil Wiring............................................................................................................................2-2

2.3.3 Temperature Switches and Flow Switches........................................................................................2-4

2.3.4 Cooling Water and Water Valve ........................................................................................................2-4

2.3.5 Grounding.......................................................................................................................................... 2-4

2.3.6 Final Check-Out.................................................................................................................................2-5

2.4 ELECTROMAGNET OPERATION........................................................................................................ 2-5

2.4.1 Air Gap and Pole Caps......................................................................................................................2-5

2.4.2 Maximum Power and Current............................................................................................................2-5

2.4.3 Operation Under Field Control........................................................................................................... 2-7

2.4.4 Avoiding Cooling Water Condensation.............................................................................................. 2-8

3 INSTALLATION......................................................................................................................................................3-1

3.0 GENERAL.............................................................................................................................................3-1

3.1 INSPECTION AND UNPACKING .........................................................................................................3-1

3.1.1 Moving and Handling ............................................................................................................................3-1

3.2 REAR PANEL DEFINITION..................................................................................................................3-2

3.3 POWER WIRING AND SET-UP............................................................................................................3-3

3.3.1 Line Voltage Selection.......................................................................................................................3-3

3.3.2 Circuit Breaker Setting..................................................................................................

3.3.3 Start-Up Fuses ..................................................................................................................................3-5

3.3.4 Cable Entry........................................................................................................................................ 3-5

3.3.5 Power Input Terminals.......................................................................................................................3-5

3.3.6 Wiring Cover...................................................................................................................................... 3-6

3.3.7 Mains Wiring...................................................................................................................................... 3-7

3.4 MAGNET CONNECTOR....................................................................................................................... 3-7

3.5 AUXILIARY CONNECTOR...................................................................................................................3-7

3.6 POWER SUPPLY CONNECTOR .........................................................................................................3-8

3.7 COOLING WATER................................................................................................................................3-8

3.8 MAGNET CABLE CONNECTIONS.......................................................................................................3-9

3.9 ANALOG INPUT/OUTPUT CONNECTIONS ......................................................................................3-11

3.9.1 External Current Programming........................................................................................................3-11

3.9.2 Output Current and Voltage Monitors.............................................................................................. 3-11

3.10 COMPUTER INTERFACE..................................................................................................................3-11

3.10.1 RS-232C Interface Connection........................................................................................................ 3-11

3.10.2 IEEE-488 Interface Connection....................................................................................................... 3-11

3.11 CHASSIS CONNECTION ...................................................................................................................3-11

3.12 DETACHABLE HANDLES ..................................................................................................................3-12

3.13 RACK MOUNTING..............................................................................................................................3-12

.....................3-4

Table of Contents v

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Section Title Page

4 OPERATION...........................................................................................................................................................4-1

4.0 GENERAL.............................................................................................................................................4-1

4.1 TURNING POWER ON.........................................................................................................................4-1

4.2 DISPLAY DEFINITION..........................................................................................................................4-2

4.3 LED ANNUNCIATORS..........................................................................................................................4-2

4.3.1 Fault LED...........................................................................................................................................4-2

4.3.2 Compliance LED................................................................................................................................4-2

4.3.3 Power Limit LED................................................................................................................................4-2

4.3.4 Ramping LED....................................................................................................................................4-2

4.3.5 Remote LED......................................................................................................................................4-2

4.4 KEYPAD DEFINITION ..........................................................................................................................4-3

4.4.1 General Keypad Operation................................................................................................................4-4

4.5 DISPLAY SETUP..................................................................................................................................4-4

4.6 SETTING OUTPUT CURRENT ............................................................................................................4-4

4.7 CURRENT RAMP RATE.......................................................................................................................4-5

4.8 RAMP SEGMENTS...............................................................................................................................4-5

4.9 PAUSE RAMP.......................................................................................................................................4-6

4.10 ZERO OUTPUT ....................................................................................................................................4-6

4.11 MAXIMUM SETTING LIMITS................................................................................................................4-7

4.11.1 Maximum Output Current ..................................................................................................................4-7

4.11.2 Maximum Current Ramp Rate...........................................................................................................4-7

4.12 MAGNET WATER.................................................................................................................................4-8

4.13 INTERNAL WATER...............................................................................................................................4-8

4.14 ERROR STATUS DISPLAY..................................................................................................................4-8

4.15 EXTERNAL CURRENT PROGRAMMING............................................................................................4-9

4.16 LOCKING THE KEYPAD ......................................................................................................................4-9

4.17 COMPUTER INTERFACE ..................................................................................................................4-10

4.17.1 Changing Serial Baud Rate.............................................................................................................4-10

4.17.2 Changing IEEE-488 Interface parameters.......................................................................................4-11

4.18 DEFAULT PARAMETER VALUES..................................................................................................

5 COMPUTER INTERFACE OPERATION................................................................................................................ 5-1

5.0 GENERAL.............................................................................................................................................5-1

5.1 IEEE-488 INTERFACE..........................................................................................................................5-1

5.1.1 Changing IEEE-488 Interface Parameters.........................................................................................5-2

5.1.2 Remote/Local Operation....................................................................................................................5-2

5.1.3 IEEE-488 Command Structure ..........................................................................................................5-2

5.1.3.1 Bus Control Commands.................................................................................................................5-3

5.1.3.2 Common Commands.....................................................................................................................5-3

5.1.3.3 Device Specific Commands...........................................................................................................5-3

5.1.3.4 Message Strings ............................................................................................................................5-3

5.1.4 Status System ...................................................................................................................................5-4

5.1.4.1 Overview........................................................................................................................................5-4

5.1.4.1.1 Condition Registers....................................................................................................................5-4

5.1.4.1.2 Event Registers..........................................................................................................................5-4

5.1.4.1.3 Enable Registers........................................................................................................................5-4

5.1.4.1.4 Status Byte Register...................................................................................................................5-4

5.1.4.1.5 Service Request Enable Register............................................................................................... 5-4

5.1.4.1.6 Reading Registers......................................................................................................................5-7

5.1.4.1.7 Programming Registers..............................................................................................................5-7

5.1.4.1.8 Clearing Registers......................................................................................................................5-7

....4-11

vi Table of Contents

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Section Title Page

5.1.4.2 Status Register Sets......................................................................................................................5-8

5.1.4.2.1 Standard Event Status Register .................................................................................................5-8

5.1.4.2.2 Operation Event Register Set.....................................................................................................5-9

5.1.4.3 Error Status Register Sets ...........................................................................................................5-10

5.1.4.3.1 Hardware Error Status Register Set......................................................................................... 5-10

5.1.4.3.2 Operational Error Status Register Set...................................................................................... 5-11

5.1.4.4 Status Byte and Service Request (SRQ).....................................................................................5-12

5.1.4.4.1 Status Byte Register................................................................................................................. 5-12

5.1.4.4.2 Service Request Enable Register............................................................................................. 5-13

5.1.4.4.3 Using Service Request (SRQ) and Serial Poll..........................................................................5-13

5.1.4.4.4 Using Status Byte Query (*STB) ..............................................................................................5-13

5.1.4.4.5 Using Message Available (MAV) Bit)........................................................................................ 5-13

5.1.4.4.6 Using Operation Complete (*OPC) and Operation Complete Query (*OPC?).......................... 5-14

5.1.5 IEEE-488 Interface Example Programs...........................................................................................5-14

5.1.5.1 IEEE-488 Interface Board Installation for Visual Basic Program..................................................5-14

5.1.5.2 Visual Basic IEEE-488 Interface Program Setup.........................................................................5-16

5.1.5.3 Program Operation ......................................................................................................................5-20

5.1.6 Troubleshooting...............................................................................................................................5-20

5.2 SERIAL INTERFACE OVERVIEW...................................................................................................... 5-21

5.2.1 Changing Baud Rate.......................................................................................................................5-21

5.2.2 Physical Connection........................................................................................................................5-21

5.2.3 Hardware Support ...........................................................................................................................5-22

5.2.4 Character Format ............................................................................................................................5-22

5.2.5 Message Strings.............................................................................................................................. 5-22

5.2.6 Message Flow Control..................................................................................................................... 5-23

5.2.7 Serial Interface Example Programs.................................................................................................5-23

5.2.7.1 Visual Basic Serial Interface Program Setup ...............................................................................5-24

5.2.7.2 Program Operation ......................................................................................................................5-27

5.2.8 Troubleshooting...............................................................................................................................5-27

5.3 COMMAND SUMMARY......................................................................................................................5-28

5.3.1 Interface Commands (Alphabetical Listing)..................................................................................... 5-29

6 OPTIONS AND ACCESSORIES............................................................................................................................6-1

6.0 GENERAL.............................................................................................................................................6-1

6.1 ACCESSORIES INCLUDED.................................................................................................................6-1

6.2 ACCESSORIES AVAILABLE................................................................................................................6-1

7 SERVICE................................................................................................................................................................ 7-1

7.0 GENERAL.............................................................................................................................................7-1

7.1 CONTACTING LAKE SHORE CRYOTRONICS................................................................................... 7-1

7.2 RETURNING PRODUCTS TO LAKE SHORE......................................................................................7-1

7.3 LINE VOLTAGE SELECTION...............................................................................................................7-2

7.4 CIRCUIT BREAKER SETTING.............................................................................................................7-3

7.5 POWER LINE FUSE REPLACEMENT.................................................................................................7-4

7.6 ERROR MESSAGES............................................................................................................................7-5

7.7 ELECTROSTATIC DISCHARGE.......................................................................................................... 7-6

7.7.1 Identification of Electrostatic Discharge Sensitive Components........................................................ 7-6

7.7.2 Handling Electrostatic Discharge Sensitive Components.................................................................. 7-7

7.8 ENCLOSURE BOTTOM REMOVAL AND REPLACEMENT................................................................. 7-7

7.8.1 Removal............................................................................................................................................7-7

7.8.2 Installation .........................................................................................................................................7-7

Table of Contents vii

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Section Title Page

7.9 FIRMWARE REPLACEMENT...............................................................................................................7-7

7.10 CONNECTOR AND CABLE DEFINITIONS........................................................................................7-11

7.10.1 Analog I/O Connector...................................................................................................................... 7-11

7.10.2 Magnet Connector...........................................................................................................................7-11

7.10.3 Auxiliary Connector..........................................................................................................................7-12

7.10.4 Power Supply Connector.................................................................................................................7-13

7.10.5 RS-232C Serial Interface Connector ...............................................................................................7-13

7.10.6 Serial Interface Cable Wiring...........................................................................................................7-14

7.10.7 IEEE-488 Parallel Interface Connector............................................................................................7-14

7.11 CALIBRATION ....................................................................................................................................7-16

7.11.1 Calibration Interface.........................................................................................................................7-16

7.11.2 Calibration Equipment .....................................................................................................................7-17

7.11.3 Calibration Procedure......................................................................................................................7-17

7.11.3.1 Calibrate Current Output Zero......................................................................................................7-17

7.11.3.2 Calibrate Current Reading Zero...................................................................................................7-17

7.11.3.3 Calibrate Output Voltage Reading Zero.......................................................................................7-18

7.11.3.4 Calibrate External Program Voltage Reading Zero...................................................................... 7-18

7.11.3.5 Calibrate Output Current Gain (Span)..........................................................................................7-18

7.11.3.6 Calibrate Current Reading Gain...................................................................................................7-20

7.11.3.7 Calibrate Voltage Reading Gain................................................................................................... 7-20

7.11.3.8 Calibrate External Current Programming Voltage Reading Gain .................................................7-21

7.11.4 Calibrate Specific Interface Commands...........................................................................................7-21

APPENDIX A – GLOSSARY OF TERMINOLOGY....................................................................................................... A-1

APPENDIX B – UNITS FOR MAGNETIC PROPERTIES............................................................................................. B-1

viii Table of Contents

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

LIST OF ILLUSTRATIONS

Figure No. Title Page

1-1 Model 642 Front Panel .............................................................................................................................1-2

2-1 A Typical Electromagnet...........................................................................................................................2-1

2-2 Typical Magnet Water Hook-Up................................................................................................................ 2-2

2-3 Typical Magnet Coil Wiring Showing Series and Parallel Connections..................................................... 2-3

2-4 Typical Thermal Switch, Flow Switch and Valve Wiring............................................................................ 2-4

2-5 Typical Curves of Field vs. Current for Various Air Gaps and Pole Cap Sizes......................................... 2-5

3-1 Model 642 Rear Panel..............................................................................................................................3-3

3-2 Voltage Change Detail..............................................................................................................................3-4

3-3 Circuit Breaker..........................................................................................................................................3-4

3-4 Fuses........................................................................................................................................................3-5

3-5 Typical Cable Entry with Bushing............................................................................................................. 3-5

3-6 Typical Power Input Wiring....................................................................................................................... 3-6

3-7 Wiring Cover Installation...........................................................................................................................3-6

3-8 Typical Magnet Connector Wiring............................................................................................................. 3-7

3-9 Typical Auxiliary Connector Wiring........................................................................................................... 3-7

3-10 Typical Power Supply Connector Wiring................................................................................................... 3-8

3-11 Typical Water Hose Connection ............................................................................................................... 3-8

3-12 Water Valve Connection...........................................................................................................................3-9

3-13 Output Cable Connection....................................................................................................................... 3-10

3-14 Output Lug Cover Installation .................................................................................................................3-10

3-15 Analog Input/Output Connector.............................................................................................................. 3-11

3-16 Mounting Hole Pattern............................................................................................................................ 3-12

4-1 Model 642 Power Push Buttons ............................................................................................................... 4-1

4-2 Model 642 Keypad and LED Layout......................................................................................................... 4-3

5-1 Model 642 Status System.........................................................................................................................5-5

5-2 Standard Event Status Register.............................................................................................

5-3 Operation Event Register .........................................................................................................................5-9

5-4 Hardware Error Status Register.............................................................................................................. 5-10

5-5 Operational Error Status Register........................................................................................................... 5-11

5-6 Status Byte Register and Service Request Enable Register ..................................................................5-12

5-7 GPIB0 Setting Configuration................................................................................................................... 5-15

5-8 DEV 12 Device Template Configuration................................................................................................. 5-15

5-9 Typical National Instruments GPIB Configuration from IBCONF.EXE....................................................5-19

7-1 Model 642 Rear Panel..............................................................................................................................7-2

7-2 Voltage Change Detail..............................................................................................................................7-3

7-3 Circuit Breaker..........................................................................................................................................7-4

7-4 Fuse Holder Detail....................................................................................................................................7-5

7-5 Board Locations........................................................................................................................................ 7-9

7-6 Digital Board Parts Locations ................................................................................................................. 7-10

7-7 Analog I/O Connector Details.................................................................................................................7-11

7-8 Magnet Connector Details......................................................................................................................7-11

7-9 Auxiliary Connector Detail ......................................................................................................................7-12

7-10 Power Supply Connector Details............................................................................................................7-13

7-11 RS-232C (DTE) Connector Details......................................................................................................... 7-13

7-12 IEEE-488 Connector Details................................................................................................................... 7-15

...................5-8

Table of Contents ix

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

LIST OF TABLES

Table No. Title Page

3-1 Rear Panel Connector Identification.........................................................................................................3-2

3-2 Voltage and Current Selection..................................................................................................................3-3

3-3 Current Capacity and Total Lead Lengths ................................................................................................3-9

4-1 Model 642 LED Descriptions ....................................................................................................................4-2

4-2 Model 642 Key Descriptions.....................................................................................................................4-3

4-3 Default Parameter Values.......................................................................................................................4-12

5-1 Binary Weighting of an 8-Bit Register.......................................................................................................5-7

5-2 Register Clear Methods............................................................................................................................ 5-7

5-3 Programming Example to Generate an SRQ..........................................................................................5-13

5-4 IEEE-488 Interface Program Control Properties.....................................................................................5-17

5-5 Visual Basic IEEE-488 Interface Program ..............................................................................................5-18

5-6 Serial Interface Specifications.................................................................................................................5-22

5-7 Serial Interface Program Control Properties...........................................................................................5-25

5-8 Visual Basic Serial Interface Program.....................................................................................................5-26

5-9 Command Summary...............................................................................................................................5-29

7-1 Voltage and Current Selection..................................................................................................................7-3

7-2 Instrument Hardware Errors......................................................................................................................7-5

7-3 Operational Errors ....................................................................................................................................7-6

B-1 Conversion from CGS to SI Units.............................................................................................................B-1

B-2 Recommended SI Values for Physical Constants.....................................................................................B-2

x Table of Contents

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

CHAPTER 1

INTRODUCTION

1.0 GENERAL

This chapter provides an introduction to the Model 642 Electromagnet Power Supply. The Model 642 was designed and

manufactured in the United States of America by Lake Shore Cryotronics, Inc. The Model 642 features include the

following.

• True 4-quadrant (bipolar) 70 A, 35 V output

• 0.1 mA output setting resolution

• Linear regulation minimizes noise and ripple to 0.007% of maximum current into a 0.50 Ω load

• 1.0 mA stability per hour, 5 mA per 24 hour

• CE compliance to both the low voltage directive and the electromagnetic compatibility (EMC) directive

1.1 DESCRIPTION

The Model 642 Electromagnet Power Supply is the ideal supply for small- to medium-sized magnets used in

high-sensitivity materials research applications. The Model 642 is a practical alternative to both the larger one-size-fitsall magnet supplies and the endless adaptations of generic power supplies. By optimizing output power, Lake Shore was

able to concentrate on the performance requirements of the most demanding magnet users. The resulting Model 642

provides high precision, low noise, safety, and convenience.

Precision in magnetic measurements is typically defined as smooth continuous operation with high setting resolution and

low drift. Achieving these goals while driving an inductive load requires unique solutions. The Model 642 delivers up to

70 A at a nominal voltage of 35 V, with the supply acting as either a source or a sink in true 4-quadrant operation. Its

current source output architecture with analog control enables both smooth operation and low drift. A careful blending of

analog and digital circuits provides high setting resolution of 0.1 mA and flexible output programming.

Lake Shore chose linear input and output power stages for the nominal 2450 W output of the Model 642. Linear

operation eliminates the radiated radio frequency (RF) noise associated with switching power supplies, allowing the

Model 642 to reduce the overall noise in its output and the noise radiated into surrounding electronics.

Safety should never be an afterthought when driving an inductive load. The Model 642 incorporates a variety of

hardware and firmware protection features to ensure the safety of the magnet and supply. For improved operator safety,

the power supply was also designed for compliance with the safety requirements of the CE mark, including both the low

voltage and the electromagnetic compatibility (EMC) directive.

Instrument users have come to rely on Lake Shore equipment for convenience and ease of use. The Model 642 includes

features such as built-in current and power limits, internal cooling-water and magnet-water control to minimize

condensation, current ramping and the capability to modulate the output current. Computer interfaces are also integrated

for automation of the magnet system. The Model 642 is truly an excellent one-box solution for controlling an

electromagnet.

Output Architecture

True 4-quadrant output capability of the Model 642 is ideal for the charge and discharge cycling of electromagnets for

both positive and negative fields. Tightly integrated analog control of the 4-quadrant output provides smooth current

change with very low overshoot on output change. The Model 642 has the ability to charge and discharge magnets up

to a 50 A per second rate into a nominal 0.5 Ω, 0.5 H load.

True 4-quadrant operation eliminates the need for external switching or operator intervention to reverse the current

polarity, significantly simplifying system operation. The transition through zero current is smooth and continuous,

allowing the user to readily control the magnetic field as polarity changes.

At static fields, output current drift is also kept low by careful attention in the analog control circuits and layout.

The high stability and low noise of the Model 642 provides a quiet and uniform magnetic field.

Introduction 1-1

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Output Architecture (Continued)

The Model 642 output architecture relies on low noise, linear input and output stages. The linear circuitry of the Model

642 permits operation with less electrical noise than switch-mode electromagnet power supplies. One key benefit of this

architecture is CE compliance to the electromagnetic compatibility (EMC) directive, including the radiated emissions

requirement.

Output Programming

The Model 642 output current is programmed internally via the keypad, externally by the computer interface, externally

by the analog programming input, or by the sum of the external and internal settings. For internal programming, the

Model 642 incorporates a proprietary digital-to-analog converter (DAC) that is monotonic over the entire output range

and provides a resolution of 0.1 mA.

The Model 642 generates extremely smooth and continuous ramps with virtually no overshoot. The digitally generated

constant current ramp rate is variable between 0.1 mA/s and 99.999 A/s. To ensure a smooth ramp rate, the power supply

updates the high-resolution DAC 23.7 times per second. A low-pass filter on the DAC output smoothes the transitions at

step changes during ramping.

Output Readings

The Model 642 provides high-resolution output readings. The output current reading has a resolution of 0.1 mA. The

output voltage reading reports the voltage at the output terminals with a resolution of 0.1 mV. All output readings can be

prominently displayed on the front panel and read over the computer interface.

Protection

The Model 642 continuously monitors the line voltage, load power, internal power, and load resistance as well as a

variety of other internal circuit parameters for signs of trouble. Some fault conditions result in a warning message while

others will provide a warning message and zero the output. When hazardous conditions exist, the Model 642 will shut

itself off.

NOTE: The Model 642 is equipped with a high-line lockout circuit which will prevent the unit from being turned

on if it is connected to a voltage source that is much higher than the voltage for which it is configured.

Figure 1-1. Model 642 Front Panel

1-2 Introduction

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Description (Continued)

Interfaces

The Model 642 includes IEEE-488 and RS-232C interfaces that provide access to operating data, stored parameters, and

remote control of all front panel operated functions. A keypad lock-out feature is provided to prohibit any changes made

from the front panel. The Model 642 can then be operated solely with the computer via the RS-232C or IEEE-488

interface.

The Model 642 provides two analog outputs to monitor the output current and voltage. Each output is a buffered,

differential, analog voltage representation of the signal being monitored. The current monitor has a sensitivity of

7 V = 70 A, while the voltage monitor has a sensitivity of 3.5 V = 35 V.

Display and Keypad

The Model 642 incorporates a large 8-line by 40-character vacuum fluorescent display. Output current and output

voltage readings are displayed simultaneously. Five LEDs on the front panel provide quick verification of instrument

status, including ramping, power limit, compliance, fault, and computer interface mode. Error conditions are indicated on

the main display along with an audible tone. Extended error descriptions are available in an error message screen by

pressing the Status key.

The keypad is arranged logically to separate the different functions of the instrument. The most common functions of the

power supply are accessed using a single key press. The keypad can be locked to either lock out all changes or to lock

out just the instrument setup parameters allowing the output of the power supply to be changed.

1.2 SPECIFICATIONS

Output

Type Bipolar, 4-quadrant, DC current source

Current generation Fully linear regulation with digital setting and analog control

Current range ±70 A

Compliance voltage (DC) ±35 V nominal

Power 2450 W nominal

Nominal load 0.5 Ω, 0.5 H

Maximum load resistance 0.6 Ω for ±70 A DC operation at +10% to –5% line voltage

Minimum load resistance 0.4 Ω for ±70 A at +5% to –10% line voltage

Load inductance range 0 H to 1 H

Current ripple 5 mA RMS (0.007%) at 70 A into nominal load

Current ripple frequency Dominated by the line frequency and its harmonics

Temperature coefficient ±15 ppm of full scale/°C

Line regulation ±60 ppm of full scale/10% line change

Stability (1 h) 1 mA/h (after warm-up)

>Stability (24 h) 5 mA/24 h (typical, dominated by temperature coefficient and line regulation)

Isolation Differential output is optically isolated from chassis to prevent ground loops

Slew rate 50 A/s into nominal load

650 A/s maximum into a resistive load

Compliance voltage (AC) ±43 V at +10% to –5% line

Settling time <1 s for 10% step to within 1 mA of output into nominal load

Modulation response ≤ 0.17 Hz at ±70 A sine wave into nominal load, <0.02% THD

≤ 10 Hz at ±10 A sine wave into nominal load, <0.10% THD

Attenuation –0.5 dB at 10 Hz

Protection Short circuit, line loss, low line voltage, high line voltage, output over voltage, output

over current, and over temperature

Connector Two lugs with 6.4 mm (0.25 in) holes for M6 or 0.25 in bolts

Introduction 1-3

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Specifications (Continued)

Output programming

Internal current setting

Resolution 0.1 mA (20 bit)

Settling time 600 ms for 1% step to within 1 mA (of internal setting)

Accuracy ±10 mA ±0.05% of setting

Operation Keypad, computer interface

Protection Programmable current setting limit

Internal current ramp

Ramp rate 0.1 mA/s to 99.999 A/s (compliance limited)

Update rate 23.7 increments/s

Ramp segments 5

Operation Keypad, computer interface

Protection Programmable ramp rate limit

External current programming

Sensitivity 10 V/70 A

Resolution Analog

Accuracy ±10 mA ±1% of setting

Input resistance 20 kΩ

Operation Voltage program through rear panel, can be summed with internal current setting

Limits Internally clamped at ±10.1 V and bandwidth limited at 40 Hz to protect output

Connector Shared 15-pin D-sub

Readings

Output current

Resolution 0.1 mA

Accuracy ±5 mA ±0.05% of rdg

Update rate 2.5 rdg/s display, 10 rdg/s interface

Output voltage (at supply terminals)

Resolution 1mV

Accuracy ±5 mV ±0.05% of rdg

Update rate 2.5 rdg/s display, 5 rdg/s interface

Front panel

Display type 8-line by 40-character graphic vacuum fluorescent display module

Display readings Output current, output voltage, and internal water temperature

Display settings Output current and ramp rate

Display annunciators Status and errors

LED annunciators Fault, Compliance, Power Limit, Ramping, Remote

Audible annunciator Errors and faults

Keypad type 26 full travel keys

Keypad functions Direct access to common operations, menu-driven setup

Power White flush ON and black extended OFF push buttons

1-4 Introduction

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Specifications (Continued)

Interface

IEEE-488.2 interface

Features SH1, AH1, T5, L4, SR1, RL1, PP0, DC1, DT0, C0, E1

Reading rate To 10 rdg/s

Software support National Instruments LabVIEW

™ driver (consult Lake Shore for availability)

Serial interface

Electrical format RS-232C

Baud rates 9600, 19200, 38400, 57600

Reading rate To 10 rdg/s

Connector 9-pin D-sub (DTE)

Output current monitor

Sensitivity 7 V/70 A

Accuracy ±1% of full scale

Noise 1 mV RMS

Source impedance 20 Ω

Connector Shared 15-pin D-sub

Output voltage monitor

Sensitivity 3.5 V/35 V

Accuracy 1% of full scale

Noise 1 mV RMS

Source impedance 20 Ω

Connector Shared 15-pin D-sub

Power supply cooling water

Remote enable input TTL low or contact closure to enable output; jumper required if unused

Valve power output 24 VAC at 1 A maximum, automatic or manual control

Connector Shared 4-pin detachable terminal block

Flow switch and water valve optional

Magnet cooling water

Remote enable input TTL low or contact closure to enable output; jumper required if unused

Valve power output 24 VAC at 1 A maximum, automatic or manual control

Connector Shared 4-pin detachable terminal block

Flow switch, temperature switch, and water valve not included

Auxiliary

Emergency stop Requires 1 A, 24 VAC normally closed (NC) contact to enable power-up; jumper required if

unused

Fault output Relay with normally open (NO) or normally closed (NC) contact, 30 VDC at 1 A

Remote enable TTL low or contact closure to enable output, jumper required if unused

Connector Shared 8-pin detachable terminal block

Emergency stop and enable switches not included

Introduction 1-5

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Specifications (Continued)

General

Line power

Power 5500 VA max

Voltage and current 200/208 VAC ±10%, 13 A/phase

220/230 VAC ±10%, 12 A/phase

380 VAC ±10%, 7 A/phase

400/415 VAC ±10%, 6.5 A/phase

Protection Three phase thermal relay, with adjustable current setting

Two class CC 1/4 A fuses

Over-voltage lockout circuit

Frequency 50 Hz or 60 Hz

Configuration 3-phase delta

Connector 4-pin terminal block

Line voltage must be specified at time of order but is field reconfigurable

Cable from power supply to facility power not included

Cooling water

Flow rate 5.7 L (1.5 gal)/min minimum

Pressure range 34 kPa (5 psi) to 552 kPa (80 psi)

Pressure drop 10 kPa (1.5 psi) at 5.7 L (1.5 gal)/minute minimum for power supply only

Temperature 15 °C to 30 °C (non condensing)

Connection Two 10 mm (0.38 in) hose barbs

CAUTION: Internal condensation can cause damage to the power supply

Enclosure type 7 U high, 19 in rack mount with integral rack mount ears (25 mm (1 in) air space required on

each side for ventilation

Size 483 mm W × 310 mm H × 572 mm D (19 in × 12.2 in × 22.5 in) with front handles removed

Weight 74 kg (163 lb)

Shipping size 635 mm W × 559 mm H × 736 mm D (25 in × 22 1n × 29 in)

Shipping weight 79.5 kg (175 lb)

Ambient temperature 15 °C to 35 °C at rated accuracy, 5 °C to 40 °C at reduced accuracy

Humidity Non condensing

Warm-up 30 min at output current setting

Approvals CE mark – low voltage compliance to EN61010-3, EMC compliance to EN55022-1

Calibration schedule 1 year

Ordering Information

Part Number Ordering Information

642-204 Model 642 ±70 A ±35 V, 2.5 kW, 204/208 VAC

642-225 Model 642 ±70 A ±35 V, 2.5 kW, 220/230 VAC

642-380 Model 642 ±70 A ±35 V, 2.5 kW, 380 VAC

642-408 Model 642 ±70 A ±35 V, 2.5 kW, 400/415 VAC

Options

6041 Water flow switch, 2 gallons/min

6042 64X MPS water valve with mounting bracket and hose barb fittings

1-6 Introduction

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Accessories included

MAN-642 Model 642 user manual

6031 Two front handles

6032 Two rear handles

6051 Terminal block, 4 pin

6052 Terminal block, 8 pin

6252 15-pin D-sub mating connector, analog I/O

108-654 Strain relief bushing kit

----- Calibration certificate

Accessories available

6201 1 m (3.3 ft) long IEEE-488 (GPIB) computer interface cable

6261 3 m (10 ft) magnet cable kit, AWG 4

6262 6 m (20 ft) magnet cable kit, AWG 4

CAL-642-CERT Instrument recalibration with certificate

CAL-642-DATA Instrument recalibration with certificate and data

1.3 SAFETY SUMMARY

Observe these safety precautions during all phases of instrument operation, service, and repair. Failure to comply with

these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture,

and intended instrument use. Lake Shore assumes no liability for Customer failure to comply with these requirements.

The Model 642 protects the operator and surrounding area from electric shock or burn, mechanical hazards, excessive

temperature, and spread of fire from the instrument. Environmental conditions outside of the conditions below may pose

a hazard to the operator and surrounding area.

• Indoor use.

• Altitude to 2000 meters.

• Temperature for safe operation: 5 °C to 40 °C.

• Over voltage category II.

• Maximum relative humidity: 80% for temperature up to

31 °C decreasing linearly to 50% at 40 °C.

• Power supply voltage fluctuations not to exceed ±10%

of the nominal voltage.

• Pollution degree 2.

Power and Ground Connections

This instrument must be connected to a dedicated three-phase power circuit with proper size of circuit breaker. (Refer

to Chapter 3 – Installation) Verify that the unit has been configured for the correct input voltage. The neutral line, if

available, is not used. The unit may be hard-wired or connected with a flexible cable and plug. In all cases the correct

size wire must be chosen for the current drawn and the length of cable used. To minimize shock hazard, the electrical

ground (safety ground) lead must be connected. If a flexible cable and plug are used, plug the power cable into an

approved electrical outlet. The power jack and mating plug of the power cable must meet Underwriters Laboratories

(UL) and International Electromechanical Commission (IEC) safety standards. Power wiring must comply with

electrical codes of the locality in which the unit is installed.

Ventilation

The instrument has ventilation holes in its side panels. Do not block these holes when the instrument is operating.

Provide at least 25 mm (1 in) of air space on each side for ventilation.

Do Not Operate In An Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any electrical instrument

in such an environment constitutes a definite safety hazard.

Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Refer component replacement and internal adjustments to

qualified maintenance personnel. Do not replace components with power cable connected. To avoid injuries, always

disconnect power and discharge circuits before touching them.

Introduction 1-7

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Safety Summary (Continued)

Do Not Substitute Parts Or Modify Instrument

Do not install substitute parts or perform any unauthorized modification to the instrument. Return the instrument to an

authorized Lake Shore representative for service to ensure that safety features are maintained.

Prevent Cooling Water Condensation

Do not operate the power supply when cooling water temperature is at or lower than the dew point for local

atmospheric conditions. Condensation on cooling water lines inside the power supply can cause severe damage.

Refer to Section 2.4.4 for additional details.

Cleaning

Do not submerge instrument. Clean only with a damp cloth and mild detergent on exterior surfaces only.

Moving and Handling

Four handles are provided for ease of moving and handling the Model 642. The handles can be used in place of

lifting lugs when cloth straps are used. Always use all four handles when moving the unit. Because of its weight, the

Model 642 should be handled by mechanical means. If for some reason it is necessary to move it by hand, a minimum

of two people is required.

CAUTION: To avoid injury to personnel, always observe proper lifting techniques in accordance with OSHA and

other regulatory agencies.

1-8 Introduction

Safety Summary (Continued)

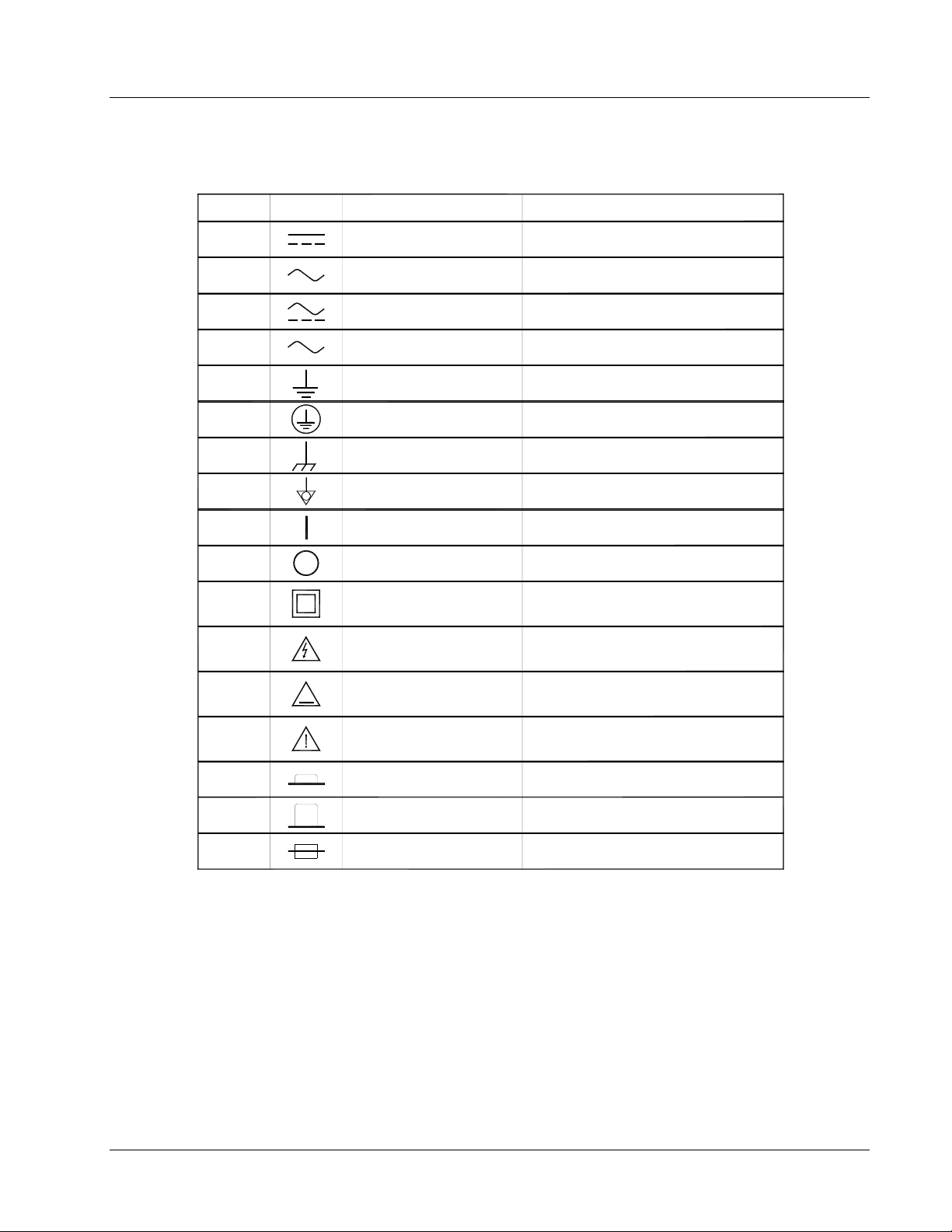

1.4 SAFETY SYMBOLS

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Symbol

3

Publication Description

IEC 417, No. 5031 Direct current

IEC 417, NO. 5032

IEC 417, No. 5033 Both direct and alternating current

IEC 617-2, No. 02-02-06 Three-phase alternating current

IEC 417, No. 5017 Earth (ground) TERMINAL

IEC 417, No. 5019 PROTECTIVE CONDUCTOR TERMINAL

IEC 417, No. 5020 Frame or chassis ground

IEC 417, No. 5021 Equipotentiality

IEC 417, No. 5007 On (supply)

IEC 417, No. 5008 Off (supply)

IEC 417, No. 5172 DOUBLE INSULATION OR REINFORCED

ISO 3864, No. B.3.6

Bcakground color-yellow Caution, risk of electric shock

Symbol and outline-black

IEC 417, No. 5041

Background color-yellow Caution, hot surface

~~~

Symbol and outline-black

ISO 3864, No. B.3.1

Background color-yellow Caution (refer to accompanying documents)

Symbol and outline-black

Alternating current

Equipment protected by

INSULATION

15

16

None

IEC 417, No. 5268-a In-position of bistable push control

IEC 417, No. 5269-a Out-position of bistable push control

IEC 1010-1 Fuse

Introduction 1-9

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

This Page Intentionally Left Blank

1-10 Introduction

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

CHAPTER 2

MAGNET SYSTEM DESIGN,

INSTALLATION, AND OPERATION

2.0 GENERAL

This chapter provides the user insight into the design, installation, and operation of a typical electromagnet. For

information on how to install the Model 642 please refer to Chapter 3. For Model 642 operation information, refer to

Chapter 4.

2.1 INTRODUCTION

A magnet used with the Model 642 Power Supply is typically an iron pole, twin coil, 4-inch pole diameter, variable air

gap, water cooled electromagnet. Larger magnets can be used depending on their electrical parameters and the magnetic

field requirements. The electromagnet provides a uniform magnetic field in the air gap between two adjustable poles.

The samples, which are to be tested for their magnetic properties, are placed in the air gap with appropriate monitoring

equipment attached. By varying the polarity and intensity of the field, useful data can be collected. A typical

electromagnet is shown in Figure 2-1.

Figure 2-1. A Typical Electromagnet

Magnet System Design 2-1

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

2.2 MAGNET CONSTRUCTION

The magnet consists of two water-cooled coils surrounding adjustable iron poles, which are fitted into an iron frame.

The frame supports the poles and coils, and improves the magnet’s efficiency. The iron poles are fitted with adjusting

mechanisms so that the air gap width can be set. Lock mechanisms are provided to hold the poles in place after

adjustment is made. The poles faces have pole caps attached, which provide the desired magnetic focus. The size and

shape of the pole caps are chosen according to the size of sample being tested and the magnetic field requirement.

2.3 CONNECTING THE MAGNET

Connecting the magnet to the power supply requires three separate circuits: the cooling water hoses, the main high

current power lines, and the safety switches which may include any combination of temperature and flow switches.

These connections are shown below.

2.3.1 Water Hose Connection

Water-cooling is essential for these magnets. The power dissipated can raise the temperature of the coils to the point

where they will be destroyed. In addition, the samples being tested may exhibit changes in their magnetic performance

with changes in temperature causing errors in the collected data. Typical water connection is shown in Figure 2-2. The

magnets may be supplied with hose barbs or standard hose fittings. The coils are connected in parallel so that the water

temperature rise is the same for both. Every effort should be made to insure that the flow rate in both coils is the same.

The minimum flow required is usually specified by the magnet vendor.

MAGNET COIL

MAGNET WATER CONNECTION

HOSE BARB FITTING

HOSE CLAMP

REENFORCED HOSE

OPTIONAL FLOW SWITCH

TEE

WATER VALVE

WATER FILTER

HOSE BARB FITTING

HOSE CLAMP

REENFORCED HOSE

Figure 2-2. Typical Magnet Water Hook-Up

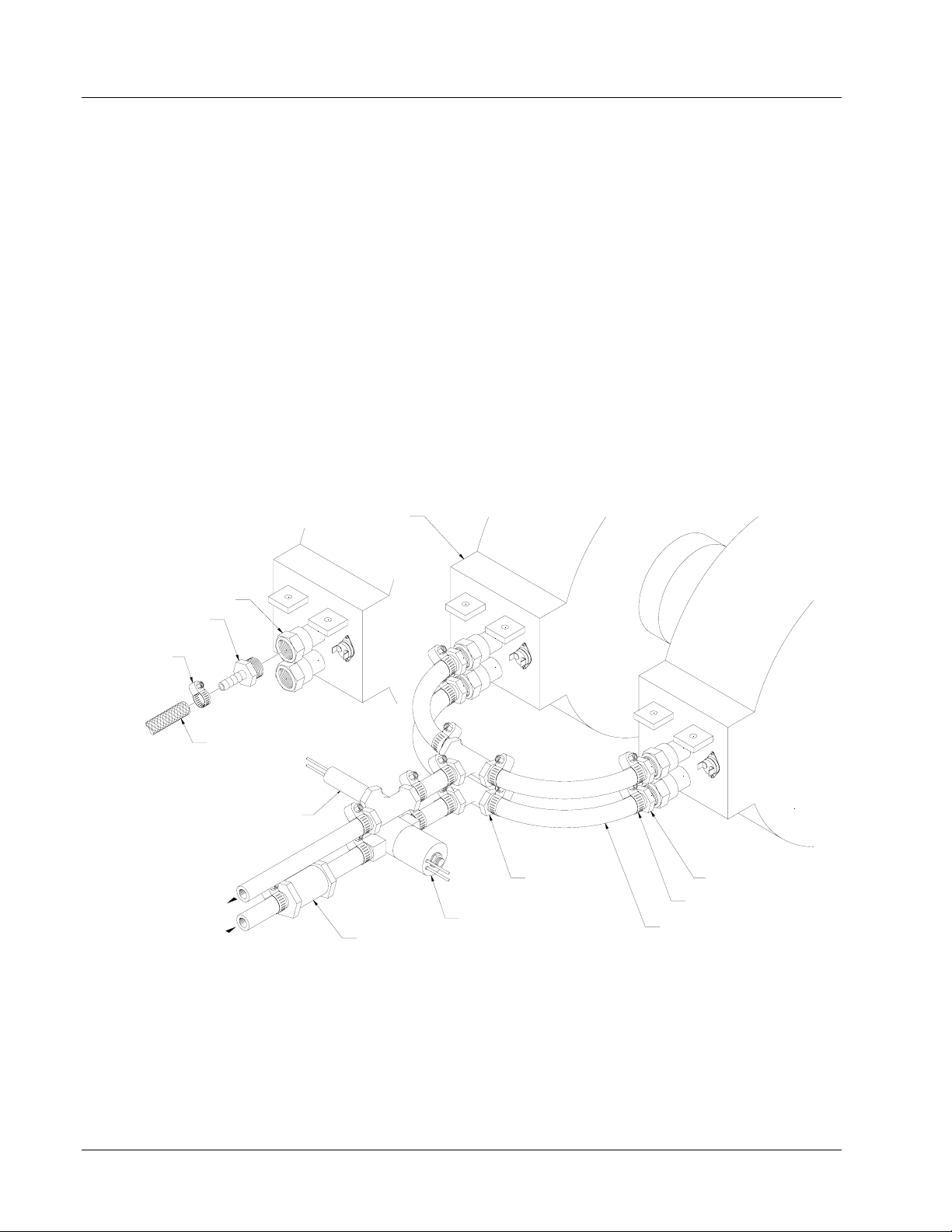

2.3.2 Magnet Coil Wiring

Typical magnet coil wiring is shown in Figure 2-3. The connecting cable used should be of sufficient gage to prevent

excessive voltage drop and heat rise in the cable. The cables should be as short as possible to minimize the voltage drop.

Current carrying capacities for various sizes of cables and cable lengths are shown in Table 3-3. The connections must be

made with the correct size of hardware for the magnet terminal. We recommend the use of a spring or Belleville washer

for cable terminations. When the parts of a connection expand and contract with changes in temperature, they tend to

loosen. A spring washer will reduce this tendency.

2-2 Magnet System Design

BELLEVILLE WASHER

CABLE CONNECTION

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

POWER LEAD

CROSS CONNECTION WIRING

(PARALLEL WIRING)

POWER LEAD

BOLT

MAGNET POWER LUG

PLAIN WASHER

NUT

POWER LEAD

CROSS CONNECTION WIRING

(SERIES WIRING)

POWER LEAD

Figure 2-3. Typical Magnet Coil Wiring Showing Series and Parallel Connections

Magnet System Design 2-3

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

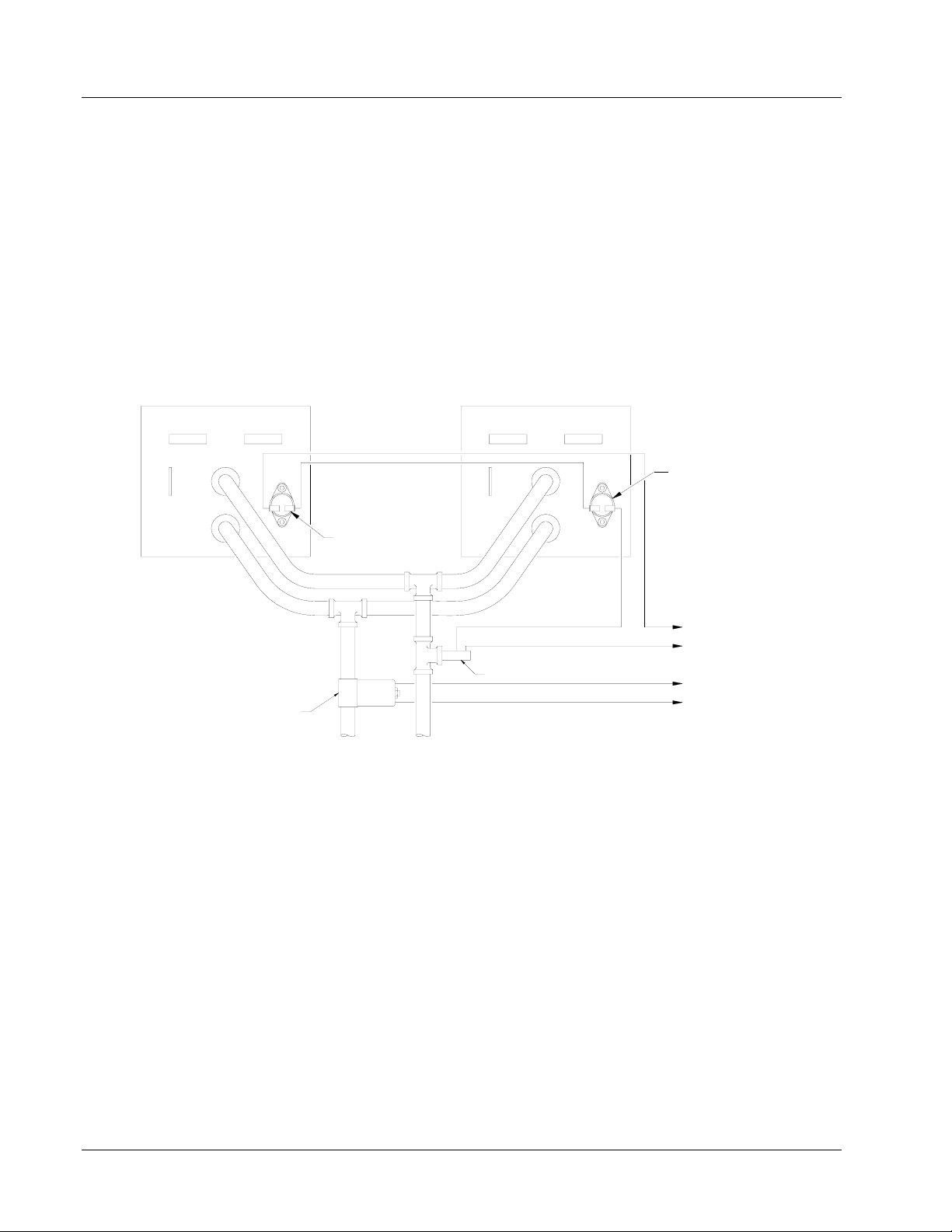

2.3.3 Temperature Switches and Flow Switches

As discussed in Section 2.3.1, water-cooling for the magnet is essential. To protect the magnet from damage resulting

from an interruption in cooling water, a flow switch, temperature switches or both should be installed. The switches must

have a normally closed contact, and if multiple switches are used, they must be connected in series. The switches are

then connected to the Flow Switch terminals of the Magnet Connector on the Model 642. The Model 642 monitors the

switches and if an open is detected, the output current is ramped to zero. (Flow switch monitoring depends on water

valve mode setting. See sections 4.12 and 4.13 for details.)Given the cost of the magnet, it is prudent to use both

temperature and flow switches. Some installations use two flow switches, one in the exhaust line of each coil so that if a

clog occurs in only one coil, it can be detected. Figure 2-4 shows the typical flow and temperature switch connection.

CAUTION: Care must be used in the selection of the flow switch. Some switches use a sensitive reed switch,

which can be overpowered by stray flux from the magnet and will not open when the magnet is

operating at high field. The flow switch must be tested by turning off the water while the magnet is

operating at full current.

THERMAL SWITCH

THERMAL SWITCH

TO 642 MAGNET CONNECTOR FLOW SWITCH CONTACTS

FLOW SWITCH

TO 642 MAGNET CONNECTOR VALVE CONTACTS

WATER VALVE

INLET OUTLET

Figure 2-4. Typical Thermal Switch, Flow Switch and Valve Wiring

2.3.4 Cooling Water and Water Valve

The cooling water for the magnet can be drawn from the municipal water facility or from a dedicated re-circulating water

chiller designed for this purpose. When water is drawn from the municipal water facility, the water should be turned on

only when it is required to reduce consumption and reduce the likelihood of scale build-up in the magnet. The water can

be turned on and off manually when the magnet is used, or automatically with a solenoid valve. The Model 642 provides

automatic control and a 24 VAC at 1 A output for this purpose. The optional water valve is shown in Figure 2-2. The

water inlet line should also be fitted with a sediment filter (not shown) to reduce scale build-up in the magnet coils and

connecting lines.

2.3.5 Grounding

A ground connection (tapped hole) is usually available at the rear of the electromagnet frame. This ground point is

provided for customers who would like to use the electromagnet frame as a signal ground or will be bringing hazardous

live voltages near the electromagnet and would like to make it an electrical safety ground. Please verify suitability for

such a function and compatibility with local and national electrical codes before making ground connections. Scrape off

excess paint near the connecting screw to ensure a good electrical contact with the bare steel of the electromagnet frame.

2-4 Magnet System Design

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

2.3.6 Final Check-Out

When all of the connections have been made the system should be tested to be sure it is operating correctly. The settings

for the magnet water should be checked to verify that they are correct for the configuration which has been installed

(Refer to Section 4.12 – Magnet Water). The maximum current setting for the magnet should be set also (Refer to

Section 2.4.2 and Section 4.11.1.)

2.4 ELECTROMAGNET OPERATION

This section provides a brief description of the typical operation of an electromagnet. For operation of the Model 642,

refer to Chapter 4.

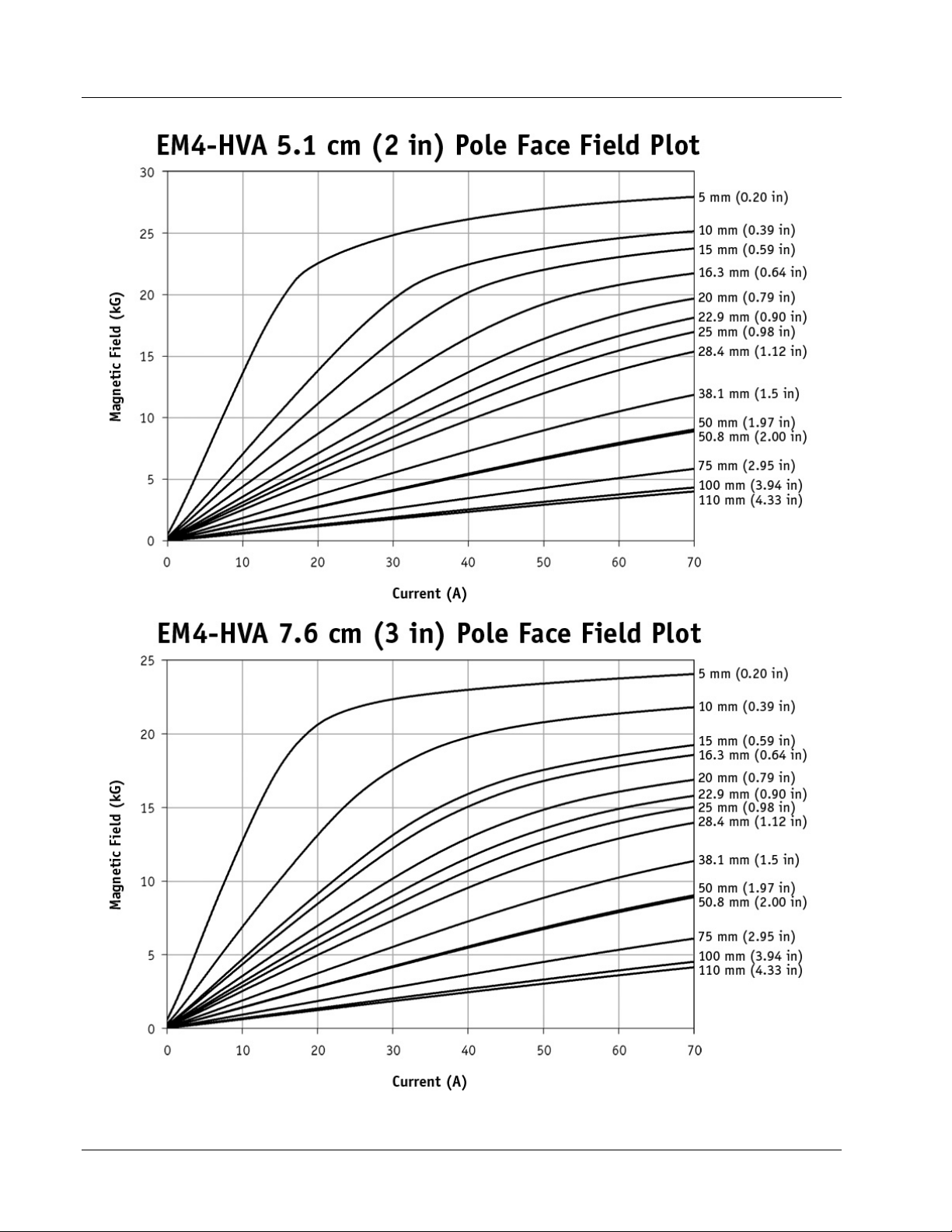

2.4.1 Air Gap and Pole Caps

The first step in setting up a magnet for operation is to select the proper pole caps and adjust the air gap. These

parameters are determined by the size and shape of the sample, and the connections that must be made to the sample.

Generally, a smaller pole face provides a higher field within the air gap. A smaller air gap also provides a higher field.

The pole faces must be selected to accommodate the size of the sample being tested. The air gap is selected based on the

size of the sample and the other equipment being used. The curves for Field versus Current for various air gaps and pole

cap sizes for the Lake Shore Model EM4-HVA are shown in Figure 2-5. It also shows that these parameters are not

linear. This must be taken into account when operating an electromagnet. To obtain linearity, it is necessary to operate

the magnet and power supply under field control. (Refer to Section 2.4.4)

2.4.2 Maximum Current and Power

The Model 642 was designed to operate with a magnet load resistance of 0.50 Ω, but will work with a resistance range of

0.40 Ω to 0.60 Ω. The resistance of a magnet will rise with a rise in temperature and this should be taken into account.

The power dissipated in the magnet is given by: P=I

2

R. If the current remains constant, the power dissipated will rise

proportionately with the rise in resistance. The Model 642 allows the user to set a maximum current limit to prevent

damage to the magnet. (Refer to Section 4.11.1.)

Figure 2-5. Typical Curves of Field vs. Current for Various Air Gaps and Pole Cap Sizes (Sheet 1 of 3)

Magnet System Design 2-5

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Figure 2-5. Typical Curves of Field vs. Current for Various Air Gaps and Pole Cap Sizes (Sheet 2 of 3)

2-6 Magnet System Design

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Figure 2-5. Typical Curves of Field vs. Current for Various Air Gaps and Pole Cap Sizes (Sheet 3 of 3)

2.4.3 Operation Under Field Control

To obtain a linear field ramp, a magnetic sensor such as a Hall probe is placed in the air gap along with the sample being

tested. The sensor is connected to a Gaussmeter. The output of the Gaussmeter is used to correct the programming input

to the power supply. In this way non-linearity can be corrected. Lakeshore manufactures probes and Gaussmeters for this

purpose.

Magnet System Design 2-7

Lake Shore Model 642 Electromagnet Power Supply User’s Manual

2.4.4 Avoiding Cooling Water Condensation

If the temperature of the cooling water is too cool relative to the air temperature and humidity, condensation can occur.

Condensation inside the power supply can cause severe damage. To avoid condensation, the power supply operator must

remain cognizant of the ambient air temperature, cooling water temperature, and the relative humidity. Lake Shore

defines the limits of these conditions as follows: ambient temperature = 18