Lake Shore 625 User Manual

User’s Manual

Model 625

Superconducting

Magnet Power Supply

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

E-mail Addresses:

sales@lakeshore.com

service@lakeshore.com

Visit Our Website At:

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake Shore Cryotronics, Inc. No government

or other contractual support or relationship whatsoever has existed which in any way affects or mitigates proprietary rights of Lake Shore Cryotronics,

Inc. in these developments. Methods and apparatus disclosed herein may be subject to U.S. Patents existing or applied for. Lake Shore Cryotronics, Inc.

reserves the right to add, improve, modify, or withdraw functions, design modifications, or products at any time without notice. Lake Shore shall not be

liable for errors contained herein or for incidental or consequential damages in connection with furnishing, performance, or use of this material.

Revision: 1.6 P/N 119-037 9 November 2015

Lake Shore Model 625 Superconducting MPS User’s Manual

A

Lake Shore Model 625 Superconducting MPS User’s Manual

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: THREE (3) YEARS

1. Lake Shore warrants that products manufactured by Lake Shore (the "Product") will be free from defects in materials and

workmanship for three years from the date of Purchaser's physical receipt of the Product (the "Warranty Period"). If Lake Shore

receives notice of any such defects during the Warranty Period and the defective Product is shipped freight prepaid back to Lake

Shore, Lake Shore will, at its option, either repair or replace the Product (if it is so defective) without charge for parts, service

labor or associated customary return shipping cost to the Purchaser. Replacement for the Product may be by either new or

equivalent in performance to new. Replacement or repaired parts, or a replaced Product, will be warranted for only the unexpired

portion of the original warranty or 90 days (whichever is greater).

2. Lake Shore warrants the Product only if the Product has been sold by an authorized Lake Shore employee, sales representative,

dealer or an authorized Lake Shore original equipment manufacturer (OEM).

3. The Product may contain remanufactured parts equivalent to new in performance or may have been subject to incidental use

when it is originally sold to the Purchaser.

4. The Warranty Period begins on the date the Product ships from Lake Shore’s plant.

5. This limited warranty does not apply to defects in the Product resulting from (a) improper or inadequate installation (unless

OT&V services are performed by Lake Shore), maintenance, repair or calibration, (b) fuses, software, power surges, lightning

and non-rechargeable batteries, (c) software, interfacing, parts or other supplies not furnished by Lake Shore, (d) unauthorized

modification or misuse, (e) operation outside of the published specifications, (f) improper site preparation or site maintenance (g)

natural disasters such as flood, fire, wind, or earthquake, or (h) damage during shipment other than original shipment to you if

shipped through a Lake Shore carrier.

6. This limited warranty does not cover: (a) regularly scheduled or ordinary and expected recalibrations of the Product; (b)

accessories to the Product (such as probe tips and cables, holders, wire, grease, varnish, feedthroughs, etc.); (c) consumables used

in conjunction with the Product (such as probe tips and cables, probe holders, sample tails, rods and holders, ceramic putty for

mounting samples, Hall sample cards, Hall sample enclosures, etc.); or, (d) non-Lake Shore branded Products that are integrated

with the Product.

7. To the extent allowed by applicable law,, this limited warranty is the only warranty applicable to the Product and replaces all

other warranties or conditions, express or implied, including, but not limited to, the implied warranties or conditions of

merchantability and fitness for a particular purpose. Specifically, except as provided herein.

8. Lake Shore undertakes no responsibility that the products will be fit for any particular purpose for which you may be buying the

Products. Any implied warranty is limited in duration to the warranty period. No oral or written information, or advice given by

the Company, its Agents or Employees, shall create a warranty or in any way increase the scope of this limited warranty. Some

countries, states or provinces do not allow limitations on an implied warranty, so the above limitation or exclusion might not

apply to you. This warranty gives you specific legal rights and you might also have other rights that vary from country to country,

state to state or province to province.

9. Further, with regard to the United Nations Convention for International Sale of Goods (CISC,) if CISG is found to apply in

relation to this agreement, which is specifically disclaimed by Lake Shore, then this limited warranty excludes warranties that: (a)

the Product is fit for the purpose for which goods of the same description would ordinarily be used, (b) the Product is fit for any

particular purpose expressly or impliedly made known to Lake Shore at the time of the conclusion of the contract, (c) the Product

is contained or packaged in a manner usual for such goods or in a manner adequate to preserve and protect such goods where it is

shipped by someone other than a carrier hired by Lake Shore.

10. Lake Shore disclaims any warranties of technological value or of non-infringement with respect to the Product and Lake Shore

shall have no duty to defend, indemnify, or hold harmless you from and against any or all damages or costs incurred by you

arising from the infringement of patents or trademarks or violation or copyrights by the Product.

11. THIS WARRANTY IS NOT TRANSFERRABLE. This warranty is not transferrable.

12. Except to the extent prohibited by applicable law, neither Lake Shore nor any of its subsidiaries, affiliates or suppliers will be

held liable for direct, special, incidental, consequential or other damages (including lost profit, lost data, or downtime costs)

arising out of the use, inability to use or result of use of the product, whether based in warranty, contract, tort or other legal

theory, regardless whether or not Lake Shore has been advised of the possibility of such damages. Purchaser's use of the Product

is entirely at Purchaser's risk. Some countries, states and provinces do not allow the exclusion of liability for incidental or

consequential damages, so the above limitation may not apply to you.

B

Lake Shore Model 625 Superconducting MPS User’s Manual

13. This limited warranty gives you specific legal rights, and you may also have other rights that vary within or between jurisdictions

where the product is purchased and/or used. Some jurisdictions do not allow limitation in certain warranties, and so the above

limitations or exclusions of some warranties stated above may not apply to you.

14. Except to the extent allowed by applicable law, the terms of this limited warranty statement do not exclude, restrict or modify the

mandatory statutory rights applicable to the sale of the product to you.

CERTIFICATION

Lake Shore certifies that this product has been inspected and tested in accordance with its published specifications and that this product met its

published specifications at the time of shipment. The accuracy and calibration of this product at the time of shipment are traceable to the United States

National Institute of Standards and Technology (NIST); formerly known as the National Bureau of Standards (NBS).

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 625 firmware is as free of errors as possible, and that the results you obtain from the instrument are

accurate and reliable. However, as with any computer-based software, the possibility of errors exists.

In any important research, as when using any laboratory equipment, results should be carefully examined and rechecked before final conclusions are

drawn. Neither Lake Shore nor anyone else involved in the creation or production of this firmware can pay for loss of time, inconvenience, loss of use

of the product, or property damage caused by this product or its failure to work, or any other incidental or consequential damages. Use of our product

implies that you understand the Lake Shore license agreement and statement of limited warranty.

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States copyright law and international treaty provisions. To maintain the warranty, the code

contained in the firmware must not be modified. Any changes made to the code is at the user’s risk. Lake Shore will assume no responsibility for

damage or errors incurred as result of any changes made to the firmware.

Under the terms of this agreement you may only use the Model 625 firmware as physically installed in the instrument. Archival copies are strictly

forbidden. You may not decompile, disassemble, or reverse engineer the firmware. If you suspect there are problems with the firmware, return the

instrument to Lake Shore for repair under the terms of the Limited Warranty specified above. Any unauthorized duplication or use of the Model 625

firmware in whole or in part, in print, or in any other storage and retrieval system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers and sellers claim designations used to distinguish their products as trademarks. Where those designations appear in this manual

and Lake Shore was aware of a trademark claim, they appear with initial capital letters and the ™ or

CalCurve™, Carbon-Glass™, Cernox™, Duo-Twist™,

High-Temperature Cernox™, Quad-Lead™, Quad-Twist™,

Rox™, SoftCal™, and Thermox™ are trademarks of

Lake Shore Cryotronics, Inc.

MS-DOS® and Windows/95/98/NT/2000® are trademarks of

Microsoft Corp.

NI-488.2™ is a trademark of National Instruments.

PC, XT, AT, and PS-2 are trademarks of IBM.

®

symbol.

Copyright © 2003, 2004, 2010 and 2014-2015 by Lake Shore Cryotronics, Inc. All rights reserved. No portion of this

manual may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the express written permission of Lake Shore.

A

Lake Shore Model 625 Superconducting MPS User’s Manual

D

Lake Shore Model 625 Superconducting MPS User’s Manual

C

Lake Shore Model 625 Superconducting MPS User’s Manual

Electromagnetic Compatibility (EMC) for the Model 625 Superconducting MPS

Electromagnetic Compatibility (EMC) of electronic equipment is a growing concern worldwide. Emissions of

and immunity to electromagnetic interference is now part of the design and manufacture of most electronics.

To qualify for the CE Mark, the Model 625 meets or exceeds the requirements of the European EMC Directive

89/336/EEC as a CLASS A product. A Class A product is allowed to radiate more RF than a Class B product

and must include the following warning:

WARNING: This is a Class A product. In a domestic environment, this product may cause

radio interference in which case the user may be required to take adequate

The instrument was tested under normal operating conditions with sensor and interface cables attached. If the

installation and operating instructions in the User’s Manual are followed, there should be no degradation in

EMC performance.

This instrument is not intended for use in close proximity to RF Transmitters such as two-way radios and cell

phones. Exposure to RF interference greater than that found in a typical laboratory environment may disturb the

sensitive measurement circuitry of the instrument.

Pay special attention to instrument cabling. Improperly installed cabling may defeat even the best EMC

protection. For the best performance from any precision instrument, follow the grounding and shielding

instructions in the User’s Manual. In addition, the installer of the Model 625 should consider the following:

• Shield measurement and computer interface cables.

• Leave no unused or unterminated cables attached to the instrument.

• Make cable runs as short and direct as possible. Higher radiated emissions is possible with long cables.

• Do not tightly bundle cables that carry different types of signals.

measures.

D

Lake Shore Model 625 Superconducting MPS User’s Manual

E

Lake Shore Model 625 Superconducting MPS User’s Manual

TABLE OF CONTENTS

Chapter/Paragraph Title Page

1 INTRODUCTION .................................................................................................................................................... 1-1

1.0 GENERAL ................................................................................................................................................ 1-1

1.1 DESCRIPTION ......................................................................................................................................... 1-1

1.2 SPECIFICATIONS .................................................................................................................................... 1-4

1.3 SAFETY SUMMARY ................................................................................................................................ 1-7

1.4 SAFETY SYMBOLS ................................................................................................................................. 1-7

2 MAGNET SYSTEM DESIGN .................................................................................................................................. 2-1

2.0 GENERAL ................................................................................................................................................ 2-1

2.1 SUPERCONDUCTING MATERIALS ........................................................................................................ 2-1

2.2 SUPERCONDUCTING MAGNETS .......................................................................................................... 2-1

2.2.1 Superconducting Magnet Construction .............................................................................................. 2-1

2.2.2 Magnet Inductance ............................................................................................................................ 2-2

2.2.3 Maximum Ramp Rate ........................................................................................................................ 2-3

2.2.4 Maximum Magnet Current ................................................................................................................. 2-3

2.2.5 Magnet Quench Protection Diodes .................................................................................................... 2-3

2.3 PERSISTENT SWITCHES ....................................................................................................................... 2-3

2.4 MAGNET CURRENT LEADS ................................................................................................................... 2-4

2.5 HELIUM DEWARS ................................................................................................................................... 2-4

2.6 MAGNET QUENCH .................................................................................................................................. 2-5

3 INSTALLATION ...................................................................................................................................................... 3-1

3.0 GENERAL ................................................................................................................................................ 3-1

3.1 INSPECTION AND UNPACKING ............................................................................................................. 3-1

3.2 REAR PANEL DEFINITION ...................................................................................................................... 3-2

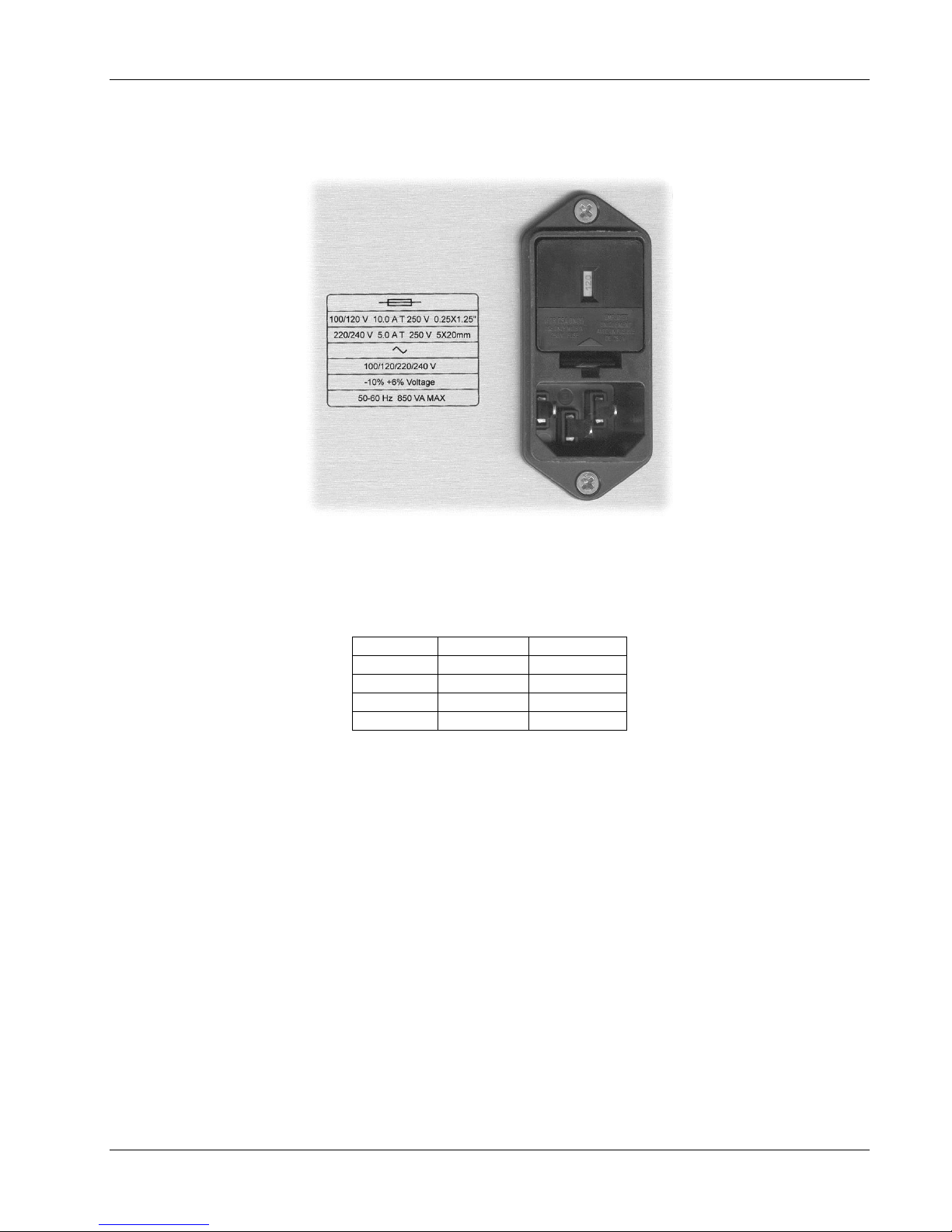

3.3 LINE INPUT ASSEMBLY .......................................................................................................................... 3-3

3.3.1 Line Voltage....................................................................................................................................... 3-3

3.3.2 Line Fuse and Fuse Holder ............................................................................................................... 3-3

3.3.3 Power Cord........................................................................................................................................ 3-3

3.3.4 Power Switch ..................................................................................................................................... 3-4

3.4 MAGNET CABLE CONNECTIONS .......................................................................................................... 3-4

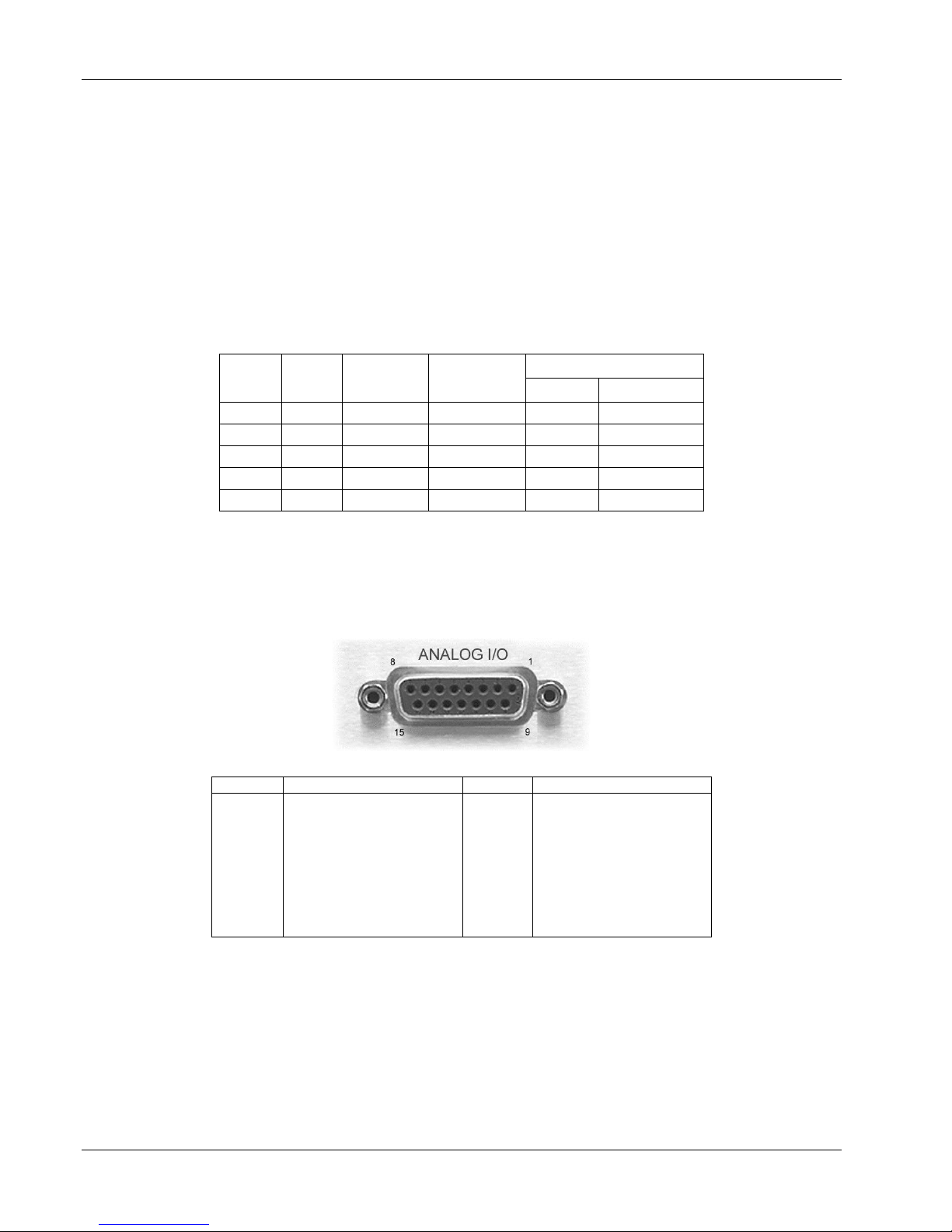

3.5 ANALOG INPUT/OUTPUT CONNECTIONS ............................................................................................ 3-4

3.5.1 External Current Programming .......................................................................................................... 3-4

3.5.2 Remote Voltage Sense ...................................................................................................................... 3-5

3.5.3 Output Current and Voltage Monitors ................................................................................................ 3-5

3.6 DIGITAL INPUT/OUTPUT CONNECTIONS ............................................................................................. 3-5

3.6.1 Fault Output ....................................................................................................................................... 3-5

3.6.2 Remote Inhibit ................................................................................................................................... 3-6

3.6.3 Trigger In ........................................................................................................................................... 3-6

3.7 PERSISTENT SWITCH HEATER OUTPUT ............................................................................................. 3-6

3.7.1 Heater Output Connection ................................................................................................................. 3-6

3.7.2 Heater Output Cabling ....................................................................................................................... 3-6

3.8 INSTRUMENT GROUNDING AND ISOLATION ...................................................................................... 3-7

3.9 CONNECTING MULTIPLE UNITS IN PARALLEL .................................................................................... 3-7

3.10 RACK MOUNTING ................................................................................................................................... 3-9

4 OPERATION ........................................................................................................................................................... 4-1

4.0 GENERAL ................................................................................................................................................ 4-1

4.1 TURNING POWER ON ............................................................................................................................ 4-1

4.2 DISPLAY DEFINITION ............................................................................................................................. 4-1

4.2.1 Output Current Display ...................................................................................................................... 4-1

4.2.2 Magnet Field Display ......................................................................................................................... 4-2

4.2.3 Persistent Switch Heater Display ....................................................................................................... 4-2

4.2.4 LED Annunciators .............................................................................................................................. 4-2

Table of Contents i

Lake Shore Model 625 Superconducting MPS User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

4.3 KEYPAD DEFINITION .............................................................................................................................. 4-2

4.3.1 Key Descriptions ................................................................................................................................ 4-2

4.3.2 General Keypad Operation ................................................................................................................ 4-3

4.4 DISPLAY SETUP ...................................................................................................................................... 4-4

4.4.1 Display Mode ..................................................................................................................................... 4-4

4.4.2 Display Remote Voltage Sense ......................................................................................................... 4-4

4.4.3 Display Brightness ............................................................................................................................. 4-5

4.5 SETTING OUTPUT CURRENT ................................................................................................................ 4-5

4.6 CURRENT RAMP RATE .......................................................................................................................... 4-6

4.7 COMPLIANCE VOLTAGE LIMIT .............................................................................................................. 4-7

4.8 ZERO OUTPUT CURRENT ...................................................................................................................... 4-7

4.9 STOP OUTPUT CURRENT ...................................................................................................................... 4-7

4.10 PAUSE OUTPUT CURRENT ................................................................................................................... 4-7

4.11 MAXIMUM SETTING LIMITS ................................................................................................................... 4-7

4.11.1 Maximum Output Current .................................................................................................................. 4-7

4.11.2 Maximum Compliance Voltage Limit .................................................................................................. 4-8

4.11.3 Maximum Current Ramp Rate ........................................................................................................... 4-8

4.12 RAMP SEGMENTS .................................................................................................................................. 4-9

4.13 FIELD CONSTANT ................................................................................................................................. 4-10

4.13.1 Field Constant Units ........................................................................................................................ 4-10

4.13.2 Field Constant Value ....................................................................................................................... 4-10

4.14 PERSISTENT SWITCH HEATER OUTPUT ........................................................................................... 4-10

4.14.1 Persistent Switch Heater Output Enable .......................................................................................... 4-11

4.14.2 Persistent Switch Heater Current Setting ........................................................................................ 4-11

4.14.3 Persistent Switch Heater Delay ....................................................................................................... 4-12

4.14.4 Persistent Mode Ramp Rate ............................................................................................................ 4-12

4.15 PSH ON/OFF .......................................................................................................................................... 4-13

4.16 QUENCH DETECTION ........................................................................................................................... 4-14

4.16.1 Quench Detection Enable ................................................................................................................ 4-14

4.16.2 Current Step Limit ............................................................................................................................ 4-14

4.17 ERROR STATUS DISPLAY .................................................................................................................... 4-15

4.18 EXTERNAL CURRENT PROGRAMMING .............................................................................................. 4-15

4.19 LOCKING THE KEYPAD ........................................................................................................................ 4-16

4.20 INTERFACE ........................................................................................................................................... 4-17

4.20.1 Changing Serial Baud Rate ............................................................................................................. 4-17

4.20.2 Changing IEEE-488 Interface Parameters ....................................................................................... 4-17

4.21 DEFAULT PARAMETER VALUES ......................................................................................................... 4-18

5 COMPUTER INTERFACE OPERATION ................................................................................................................ 5-1

5.0 GENERAL ................................................................................................................................................. 5-1

5.1 IEEE-488 INTERFACE ............................................................................................................................. 5-1

5.1.1 Changing IEEE-488 Interface Parameters ......................................................................................... 5-2

5.1.2 Remote/Local Operation .................................................................................................................... 5-2

5.1.3 IEEE-488 Command Structure .......................................................................................................... 5-2

5.1.3.1 Bus Control Commands ............................................................................................................. 5-3

5.1.3.2 Common Commands .................................................................................................................. 5-3

5.1.3.3 Device Specific Commands ........................................................................................................ 5-3

5.1.3.4 Message Strings ......................................................................................................................... 5-3

5.1.4 Status System ................................................................................................................................... 5-4

5.1.4.1 Overview .................................................................................................................................... 5-4

5.1.4.2 Status Register Sets ................................................................................................................... 5-8

5.1.4.3 Error Status Register Sets .......................................................................................................... 5-9

5.1.4.4 Status Byte and Service Request (SRQ) .................................................................................. 5-12

ii Table of Contents

Lake Shore Model 625 Superconducting MPS User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

5.1.5 IEEE Interface Example Programs .................................................................................................. 5-15

5.1.5.1 IEEE-488 Interface Board Installation for Visual Basic Program .............................................. 5-15

5.1.5.2 Visual Basic IEEE-488 Interface Program Setup ...................................................................... 5-17

5.1.5.3 IEEE-488 Interface Board Installation for Quick Basic Program ............................................... 5-20

5.1.5.4 Quick Basic Program ................................................................................................................ 5-20

5.1.5.5 Program Operation ................................................................................................................... 5-23

5.1.6 Troubleshooting ............................................................................................................................... 5-23

5.2 SERIAL INTERFACE OVERVIEW ......................................................................................................... 5-24

5.2.1 Changing Baud Rate ....................................................................................................................... 5-24

5.2.2 Physical Connection ........................................................................................................................ 5-24

5.2.3 Hardware Support ........................................................................................................................... 5-25

5.2.4 Character Format ............................................................................................................................ 5-25

5.2.5 Message Strings .............................................................................................................................. 5-25

5.2.6 Message Flow Control ..................................................................................................................... 5-26

5.2.7 Serial Interface Example Programs ................................................................................................ . 5-26

5.2.7.1 Visual Basic Serial Interface Program Setup ............................................................................ 5-27

5.2.7.2 Quick Basic Serial Interface Program Setup ............................................................................ 5-30

5.2.7.3 Program Operation ................................................................................................................... 5-31

5.2.8 Troubleshooting ............................................................................................................................... 5-31

5.3 COMMAND SUMMARY ......................................................................................................................... 5-32

5.3.1 Interface Commands (Alphabetical Listing) ..................................................................................... 5-34

6 OPTIONS AND ACCESSORIES ................................................................ ............................................................ 6-1

6.0 GENERAL ................................................................................................................................................ 6-1

6.1 MODELS .................................................................................................................................................. 6-1

6.2 ACCESSORIES ........................................................................................................................................ 6-1

7 SERVICE ................................................................................................................................................................ 7-1

7.1 CONTACTING LAKE SHORE CRYOTRONICS ....................................................................................... 7-1

7.2 RETURNING PRODUCTS TO LAKE SHORE ......................................................................................... 7-1

7.3 FUSE DRAWER ....................................................................................................................................... 7-2

7.4 LINE VOLTAGE SELECTION .................................................................................................................. 7-2

7.5 FUSE REPLACEMENT ............................................................................................................................ 7-3

7.6 ERROR MESSAGES ................................................................................................................................ 7-3

7.7 OUTPUT SOURCE IMPEDANCE ............................................................................................................ 7-5

7.8 ELECTROSTATIC DISCHARGE .............................................................................................................. 7-5

7.8.1 Identification of Electrostatic Discharge Sensitive Components ........................................................ 7-5

7.8.2 Handling Electrostatic Discharge Sensitive Components .................................................................. 7-6

7.9 ENCLOSURE BOTTOM REMOVAL AND REPLACEMENT .................................................................... 7-6

7.10 FIRMWARE REPLACEMENT .................................................................................................................. 7-7

7.11 PSH OUTPUT COMPLIANCE VOLTAGE CONFIGURATION ................................................................. 7-7

7.12 CONNECTOR AND CABLE DEFINITIONS .............................................................................................. 7-9

7.12.1 Serial Interface Cable Wiring ........................................................................................................... 7-11

7.12.2 IEEE-488 Interface Connector ......................................................................................................... 7-12

7.13 CALIBRATION ........................................................................................................................................ 7-13

APPENDIX A – GLOSSARY OF TERMINOLOGY ........................................................................................................ A-1

APPENDIX B – UNITS FOR MAGNETIC PROPERTIES .............................................................................................. B-1

APPENDIX C – HANDLING LIQUID HELIUM AND NITROGEN .................................................................................. C-1

C1.0 GENERAL ................................................................................................................................................ C-1

C2.0 PROPERTIES........................................................................................................................................... C-1

C3.0 HANDLING CRYOGENIC STORAGE DEWARS ..................................................................................... C-1

C4.0 LIQUID HELIUM AND NITROGEN SAFETY PRECAUTIONS ................................................................. C-2

C5.0 RECOMMENDED FIRST AID .................................................................................................................. C-2

Table of Contents iii

Lake Shore Model 625 Superconducting MPS User’s Manual

LIST OF ILLUSTRATIONS

Figure No. Title Page

1-1 Model 625 Front Panel ................................................................................................................................. 1-3

2-1 Typical Superconducting Magnet ................................................................................................................. 2-2

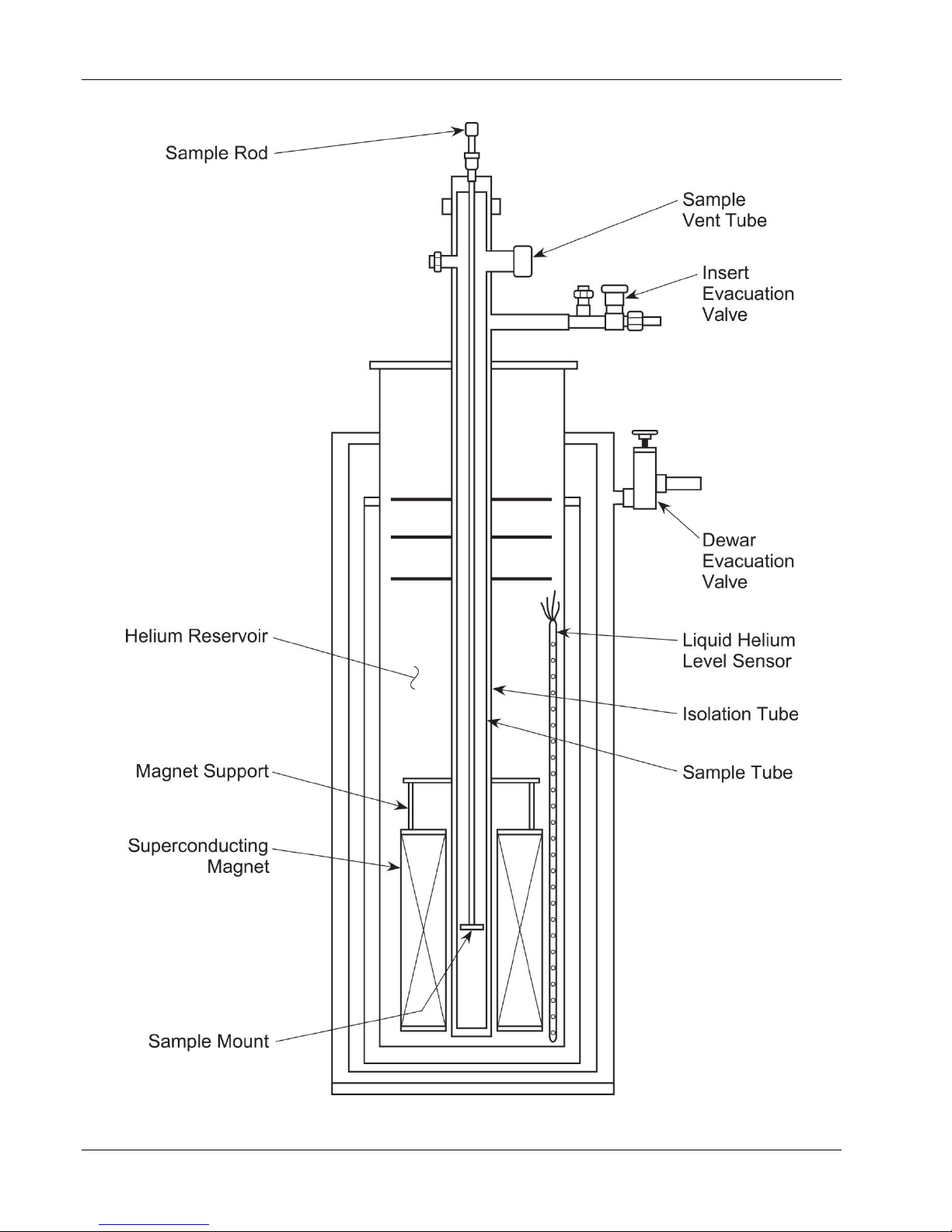

2-2 Cutaway of a Typical Helium Dewar, Magnet, and Insert ............................................................................. 2-2

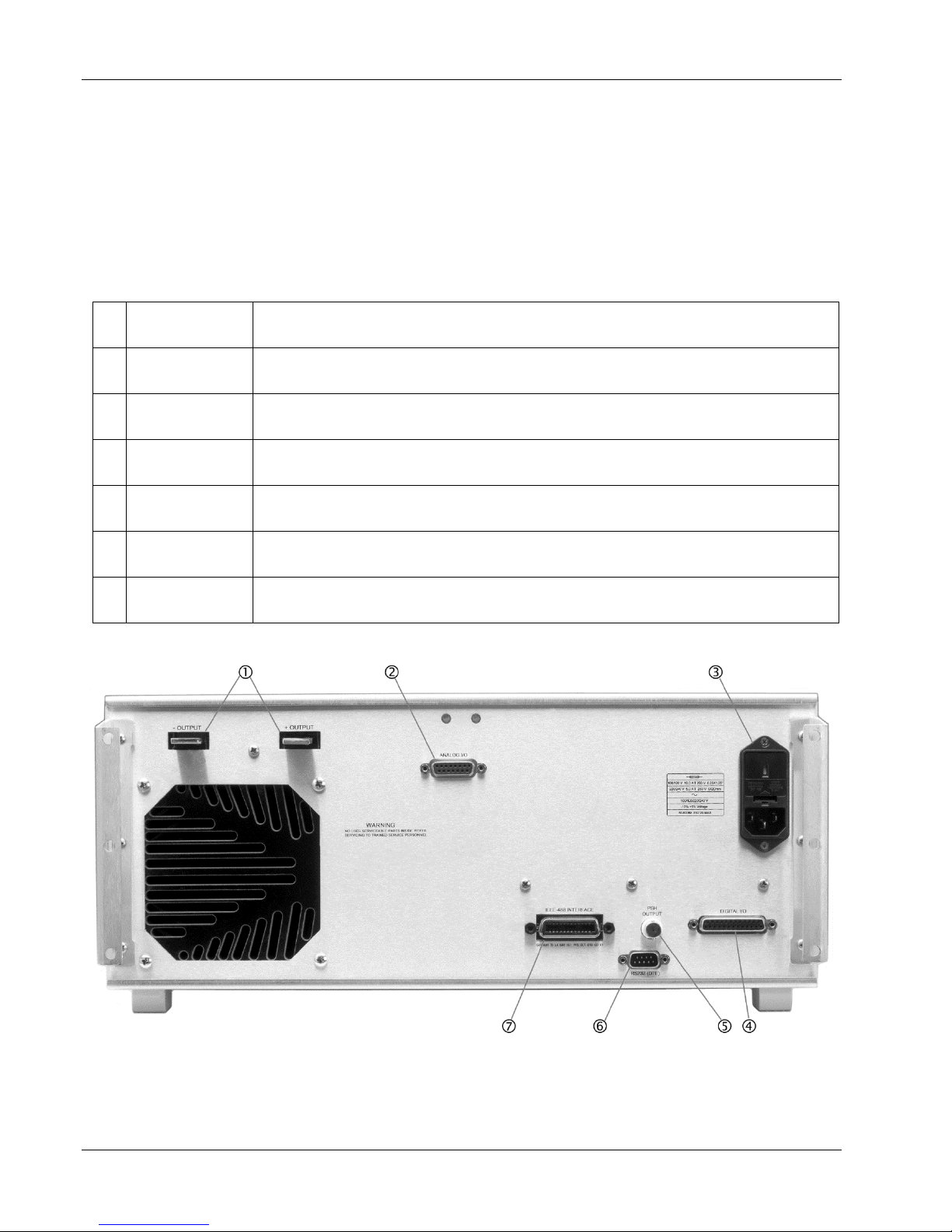

3-1 Model 625 Rear Panel ................................................................ .................................................................. 3-2

3-2 Line Input Assembly ..................................................................................................................................... 3-3

3-3 Model 625 Analog Input/Output Connector .................................................................................................. 3-4

3-4 Model 625 Digital Input/Output Connector.................................................................................................... 3-5

3-5 Remote Inhibit and Trigger In Operation ...................................................................................................... 3-6

3-6 Persistent Switch Heater Output Connector ................................................................................................. 3-6

3-7 Connecting Two Power Supplies In Parallel ................................................................................................. 3-8

3-8 Rack Mounting a Model 625 Power Supply .................................................................................................. 3-9

4-1 Model 625 Output Current Display ............................................................................................................... 4-1

4-2 Model 625 Magnet Field Display .................................................................................................................. 4-2

5-1 Model 625 Status System............................................................................................................................. 5-5

5-2 Standard Event Status Register ................................................................................................................... 5-8

5-3 Operation Event Register ............................................................................................................................. 5-9

5-4 Hardware Error Status Register ................................................................................................................. 5-10

5-5 Operational Error Status Register .............................................................................................................. 5-11

5-6 PSH Error Status Register .......................................................................................................................... 5-11

5-7 Status Byte Register and Service Request Enable Register ...................................................................... 5-13

5-8 GPIB0 Setting Configuration ...................................................................................................................... 5-16

5-9 DEV 12 Device Template Configuration ..................................................................................................... 5-16

5-10 Typical National Instruments GPIB Configuration from IBCONF.EXE ........................................................ 5-21

7-1 Fuse Drawer ................................................................................................................................................. 7-2

7-2 Power Fuse Access ...................................................................................................................................... 7-3

7-3 Location Of Important Internal Components ................................................................................................. 7-8

7-4 ANALOG I/O Connector Details ................................................................................................................... 7-9

7-5 PSH OUTPUT Connector Details ................................................................................................................. 7-9

7-6 DIGITAL I/O Connector Details .................................................................................................................. 7-10

7-7 RS232 (DTE) Connector Details ................................................................................................................ 7-10

7-8 IEEE-488 Rear Panel Connector Details ................................ .................................................................... 7-12

C-1 Typical Cryogenic Storage Dewar ............................................................................................................... C-1

LIST OF TABLES

Table No. Title Page

2-1 Current Capacity and Total Lead Lengths .................................................................................................... 2-4

3-1 Current Capacity and Total Lead Lengths .................................................................................................... 3-4

4-1 Default Parameter Values .......................................................................................................................... 4-18

5-1 Binary Weighting of an 8-Bit Register ........................................................................................................... 5-7

5-2 Register Clear Methods ................................................................................................................................ 5-7

5-3 Programming Example to Generate an SRQ ............................................................................................. 5-13

5-4 IEEE-488 Interface Program Control Properties ......................................................................................... 5-18

5-5 Visual Basic IEEE-488 Interface Program .................................................................................................. 5-19

5-6 Quick Basic IEEE-488 Interface Program................................................................................................... 5-22

5-7 Serial Interface Specifications .................................................................................................................... 5-25

5-8 Serial Interface Program Control Properties ............................................................................................... 5-28

5-9 Visual Basic Serial Interface Program ........................................................................................................ 5-29

5-10 Quick Basic Serial Interface Program ......................................................................................................... 5-30

5-11 Command Summary .................................................................................................................................. 5-33

7-1 Instrument Hardware Errors ......................................................................................................................... 7-4

7-2 Operational Errors ........................................................................................................................................ 7-4

B-1 Conversion from CGS to SI Units ................................................................................................................. B-1

B-2 Recommended SI Values for Physical Constants ........................................................................................ B-2

C-1 Comparison of Liquid Helium and Liquid Nitrogen ...................................................................................... C-1

iv Table of Contents

Lake Shore Model 625 Superconducting MPS User’s Manual

CHAPTER 1

INTRODUCTION

1.0 GENERAL

This chapter provides an introduction to the Model 625 Superconducting Magnet Power Supply. The Model 625 was

designed and manufactured in the United States of America by Lake Shore Cryotronics, Inc. The Model 625 features

include the following.

• True 4-quadrant (bipolar) 60 A, 5 V output

• 0.1 mA output setting resolution

• Linear regulation minimizes noise and ripple to 0.006% of maximum current into a 1 m load.

• 1.0 mA stability per hour

• Two units can be connected in parallel for ±120 A operation

• CE compliance to both the low voltage directive and the electromagnetic compatibility (EMC) directive (pending)

1.1 DESCRIPTION

The Model 625 Superconducting Magnet Power Supply is the ideal supply for small to medium sized superconducting

magnets used in high sensitivity materials research applications. The Model 625 is a practical alternative to both the

larger, one size fits all, superconducting magnet supplies and the endless adaptations of generic power supplies. By

limiting output power, Lake Shore was able to concentrate on the performance requirements of the most demanding

magnet users. The resulting Model 625 provides high precision, low noise, safety, and convenience.

Precision in magnetic measurements is typically defined as smooth continuous operation with high setting resolution and

low drift. Achieving these goals while driving a challenging load, such as a superconducting magnet, requires a unique

solution. The Model 625 delivers up to 60 A at a nominal compliance voltage of 5 V, with the supply acting as either a

source or a sink in true 4-quadrant operation. Its current source output architecture with analog control enables both

smooth operation and low drift. A careful blending of analog and digital circuits provides high setting resolution of

0.1 mA and flexible output programming.

Lake Shore chose linear input and output power stages for the moderate 300 W output of the Model 625. Linear

operation eliminates the radiated radio frequency (RF) noise associated with switching power supplies, allowing the

Model 625 to reduce the overall noise in its output and the noise radiated into surrounding electronics.

Safety should never be an afterthought when combining stored energy and liquid cryogens in a superconducting magnet

system. The Model 625 incorporates a variety of hardware and firmware protection features to ensure the safety of the

magnet and supply. For improved operator safety, the power supply was also designed for compliance with the safety

requirements of the CE mark, including both the low voltage and the electromagnetic compatibility (EMC) directive.

Instrument users have come to rely on Lake Shore for convenience and ease of use. The Model 625 includes the features

necessary to conveniently manage a superconducting magnet. Features such as a persistent switch heater output,

calculated field reading, current ramping, and quench detection are all included. Computer interfaces are also integrated

for automation of the magnet system. The Model 625 is truly an excellent one-box solution for controlling a

superconducting magnet.

Output Architecture

True 4-quadrant output capability of the Model 625 is ideal for the charge and discharge cycling of superconducting

magnets for both positive and negative fields. Tightly integrated analog control of the 4-quadrant output provides smooth

current change with very low overshoot on output change. The Model 625 has the ability to charge and discharge

magnets up to a 5 V rate.

True 4-quadrant operation eliminates the need for external switching or operator intervention to reverse the current

polarity, significantly simplifying system design. The transition through zero current is smooth and continuous, allowing

the user to readily control the magnetic field as polarity changes.

Introduction 1-1

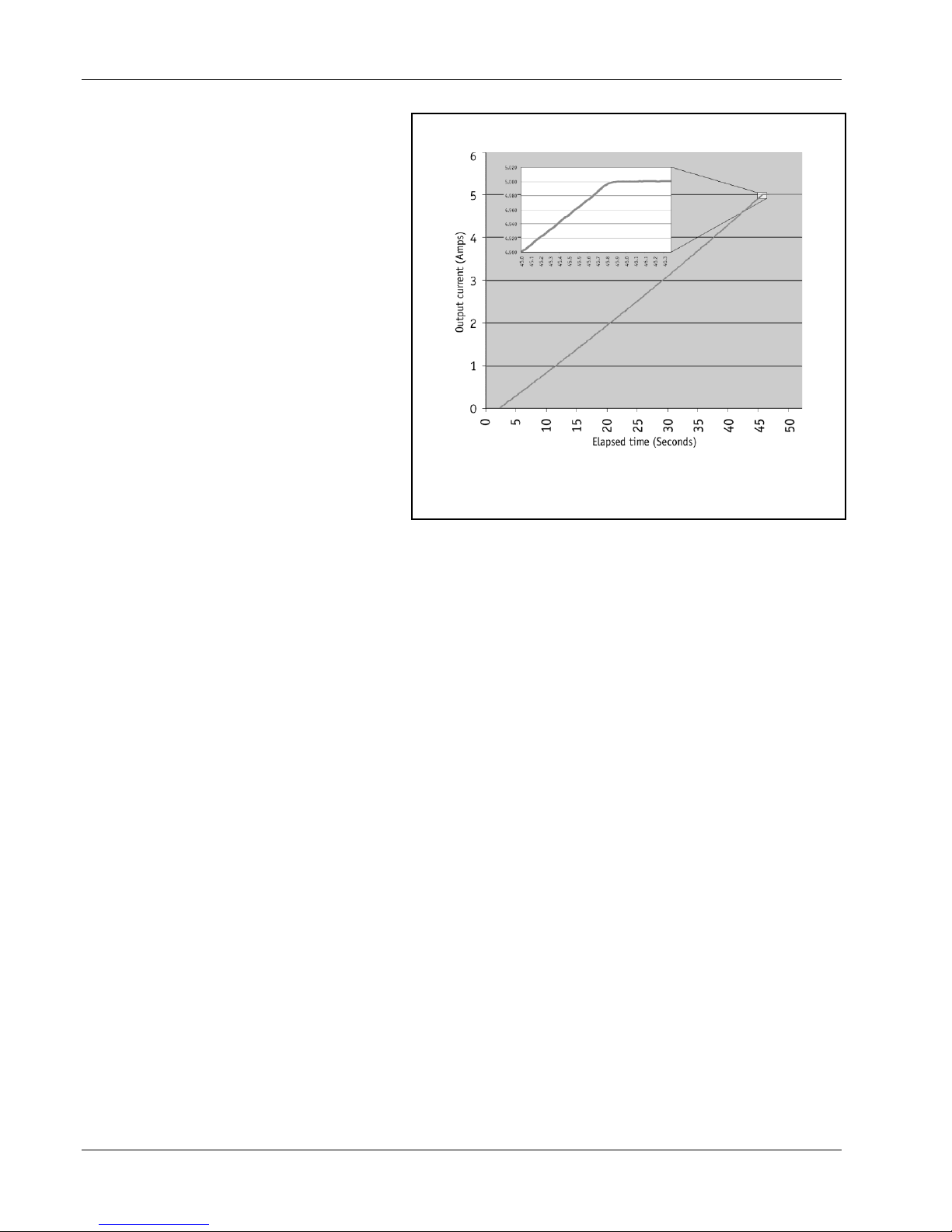

5 Ampere Charge of an 8 Henry Superconducting Magnet*

* 5 A charge of an 8.6 H AMI magnet with a 95 mA/s ramp rate;

output current monitor measured at 58.88 Hz. rate with a HP

34401 – data multiplied by 10× to obtain output current results.

Lake Shore Model 625 Superconducting MPS User’s Manual

At static fields, output current drift is also kept

low by careful attention in the analog control

circuits and layout. The high stability and low

noise of the Model 625 make it possible in many

situations to run experiments without going into

persistent mode. This can help to reduce the time

necessary to gather data.

The Model 625 output architecture relies on low

noise, linear input and output stages. The linear

circuitry of the Model 625 permits operation with

less electrical noise than switch-mode

superconducting magnet power supplies. One key

benefit of this architecture is CE compliance to

the electromagnetic compatibility (EMC)

directive, including the radiated emissions

requirement.

Output Programming

The Model 625 output current is programmed

internally via the keypad or the computer

interface, externally by the analog programming

input, or by the sum of the external and internal

settings. For the more popular internal

programming, the Model 625 incorporates a proprietary digital-to-analog converter (DAC) that is monotonic over the

entire output range and provides a resolution of 0.1 mA.

The Model 625 generates extremely smooth and continuous ramps with virtually no overshoot. The digitally generated

constant current ramp rate is variable between 0.1 mA/s and 99.999 A/s. To ensure a smooth ramp rate, the power supply

updates the high-resolution DAC 28 times per second. A low-pass filter on the DAC output smoothes the transitions at

step changes during ramping. Ramping can also be initiated by the trigger input.

The output compliance voltage of the Model 625 is settable to a value between 0.1 V and 5 V, with a 100 µV resolution.

The voltage is an absolute setting, so a 2 V setting will limit the output to greater than –2.0 V and less than +2.0 V.

Output Readings

The Model 625 provides high-resolution output readings. The output current reading reflects the actual current in the

magnet, and has a resolution of 0.1 mA. The output voltage reading reports the voltage at the output terminals with a

resolution of 100 µV. A remote voltage reading is also available to more accurately represent the magnet voltage by

bypassing voltage drops in the leads connecting the power supply to the magnet. All output readings can be prominently

displayed on the front panel and read over the computer interface.

Protection

Managing the stored energy in superconducting magnets necessitates several different types of protection. The Model

625 continuously monitors the load, line voltage, and internal circuits for signs of trouble. Any change outside of the

expected operating limits triggers the supply to bring the output to zero in a fail-safe mode. When line power is lost, the

output crowbar (SCR) will activate and maintain control of the magnet, discharging at a rate of 1 V until it reaches zero.

Quench detection is necessary to alert the user and to protect the magnet system. The Model 625 uses a basic and reliable

method for detecting a quench. If the current changes at a rate greater than the current step limit set by the operator, a

quench is detected and the output current is safely set to zero.

The remote inhibit input allows an external device to immediately set the output current to zero in case of a failure. This

input is normally tied to an external quench detection circuit, the fault output of a second power supply, or an emergency

shutdown button. The fault output is a relay contact that closes when a fault condition occurs. The contact closure alerts

other system components of the fault.

1-2 Introduction

Lake Shore Model 625 Superconducting MPS User’s Manual

Parallel Operation

If an application requires more output current than a single Model 625 can provide, two supplies can be connected in

parallel for 120 A/5 V operation. Each unit is programmed for half of the total output current, operates independently,

and retains 0.1 mA resolution at 60 A operation. When the units are properly configured, either unit can detect a fault,

protect itself, and issue a fault output signaling the other unit to automatically enter the proper protection mode.

Persistent Switch Heater Output

The integrated persistent switch heater output is a controlled DC current source capable of driving most switch heaters. It

sources from 10 mA to 125 mA with a setting resolution of 1 mA and selectable compliance voltage of 12 V or 21 V.

The minimum load that the persistent switch heater can drive is 10 W. Persistent mode operation is integrated into the

instrument firmware to prevent mis-operation of the magnet.

Interfaces

The Model 625 includes IEEE-488 and RS-232C interfaces that provide access to operating data, stored parameters, and

remote control of all front panel operating functions. In addition, the Model 625 includes a trigger function that is used to

start an output current ramp. When the trigger is activated, either by an external trigger or by computer interface

command, the power supply will begin ramping to the new setpoint.

The Model 625 provides two analog outputs to monitor the output current and voltage. Each output is a buffered,

differential, analog voltage representation of the signal being monitored. The current monitor has a sensitivity of 1 V =

10 A, while the voltage monitor has a sensitivity of 1 V = 1 V.

Display and Keypad

The Model 625 incorporates a large 8-line by 40-character vacuum fluorescent display. Output current, calculated field

in tesla or gauss, output voltage, and remote voltage sense readings can be displayed simultaneously. Five LEDs on the

front panel provide quick verification of instrument status, including ramping, compliance, fault, PSH status, and

computer interface mode. Error conditions are indicated on the main display along with an audible beeper. Extended

error descriptions are available under the Status key.

The keypad is arranged logically to separate the different functions of the instrument. The most common functions of the

power supply are accessed using a single button press. The keypad can be locked to either lock out all changes or to lock

out just the instrument setup parameters allowing the output of the power supply to be changed.

625_Front.bmp

Introduction 1-3

Figure 1-1. Model 625 Front Panel

Lake Shore Model 625 Superconducting MPS User’s Manual

1.2 SPECIFICATIONS

Output

Type: Bipolar, Four Quadrant, DC Current Source

Current Generation: Linear regulation with digital setting and analog control

Current Range: ±60 A

Compliance Voltage: ±5 V maximum (nominal, both source and sink)

Maximum Power: 300 W

Load Reactance: 0 H to 100 H

Current Ripple (Max): 4 mA RMS at 60 A, (0.007%) into 1 m load

(significantly reduced into a reactive load or at lower current)

Current Ripple Frequency: Dominated by line frequency and its harmonics

Temperature Coefficient: ±15 ppm of full scale/°C

Line Regulation: 15 ppm/6% line change

Source Impedance: 25

Stability (1 h): 1 mA/h (after warm-up)

Stability (24 h): 10 mA/24 h (typical, dominated by temperature coefficient and line regulation)

Isolation: Output optically isolated from chassis to prevent ground loops

Parallel Operation: 2 units can be paralleled for ±120 A, ±5 V operation

Protection: Quench, Line Loss, Low Line Voltage, High Line Voltage, Output Over Voltage,

Output Over Current, Over Temperature, Remote Inhibit

(on critical error conditions, magnet discharges at 1 V nominal)

Output Programming

Internal Current Setting

Resolution: 0.1 mA (20 bit)

Settling Time: 600 ms for 1% step to within 0.1 mA into a resistive load

Accuracy: ±10 mA ±0.05% of setting

Operation: Keypad, computer interface

Protection: Current setting limit

Internal Current Ramp

Ramp Rate: 0.1 mA/s to 99.999 A/s (compliance limited)

Update Rate: 27.7 increments/s

Ramp Segments: 5

Operation: Keypad, computer interface, trigger input

Protection: Ramp rate limit

External Current Programming

Sensitivity: 6 V = 60 A

Resolution: Analog

Accuracy: ±10 mA ±1% of setting

Bandwidth (3 dB): 40 Hz, 2-pole, low-pass filter (10 Hz pass band, compliance limited)

Input Resistance: >50 k

Operation: Voltage program through rear panel

Connector: Shared 15-pin D-sub

Limits: Internally clamped at 6.1V

Compliance Voltage Setting

Range: 0.1 V to 5.0 V

Resolution: 100 µV

Accuracy: ±10 mV ±1% of setting

1-4 Introduction

Lake Shore Model 625 Superconducting MPS User’s Manual

Readings

Output Current

Resolution: 0.1 mA

Accuracy: ±1 mA ±0.05% of reading

Update Rate: 2.5 readings/s display, 10 readings/s interface

Compensation: Compensated for lead resistance and 25 source resistance

Output Voltage (at supply terminals)

Resolution: 100 µV

Accuracy: ±1 mV ±0.05% of reading

Update Rate: 2.5 readings/s display, 5 readings/s interface

Remote Voltage (at magnet leads)

Resolution: 100 µV

Accuracy: ±1 mV ±0.05% of reading

Update Rate: 1.25 readings/s

Input Resistance: >50 k

Connector: Shared 15-pin D-sub

Persistent Switch Heater Output (PSHO)

Current Range: 10 mA to 125 mA

Compliance Voltage (minimum): 12 V or 21 V selectable

Heater Resistance (minimum): 10

Setting Resolution: 1 mA

Accuracy: ±1 mA

Operation: On/Off with lockout delay of 5 s to 100 s

Protection: Open or shorted heater detection, error message if off and on output currents differ

Connector: BNC

Front Panel

Display Type: 8-line by 40 character, graphic vacuum fluorescent display module

Display Readings: Output current, calculated field (T or G), output voltage, remote voltage sense

Display Settings: Output current, calculated field, compliance voltage, ramp rate

Display Annunciators: Status and errors

LED Annunciators: PSHO on, remote, compliance limit, fault, ramping

Keypad Type: 26 full travel keys

Keypad Functions: Direct access to common operations, menu driven setup

Interface

IEEE-488.2 Interface

Features: SH1,AH1,T5,L4,SR1,RL1,PP0,DC1,DT1,C0,E1

Reading Rate: To 10 readings/s

Software Support: National Instruments LabVIEW driver (consult Lake Shore for availability)

Serial Interface

Electrical Format: RS-232C

Baud Rates: 9600, 19200, 38400, 57600

Reading Rate: To 10 readings/s

Connector: 9-pin D-sub

Output Current Monitor

Sensitivity: 60 A = 6 V

Accuracy: ±1% of full scale

Noise: 1 mV

Source Impedance: 20

Connector: Shared 15-pin D-sub

Introduction 1-5

Lake Shore Model 625 Superconducting MPS User’s Manual

Output Voltage Monitor

Sensitivity: 1 V = 1 V

Accuracy: ±1% of full scale

Noise: 1 mV

Source Impedance: 20

Connector: Shared 15-pin D-sub

Fault Output

Type: Relay (closed on fault)

Relay Contact: 30 VDC @ 1 A

Connector: Shared 25-pin D-sub

Remote Inhibit Input

Type: TTL or contact closure

Connector: Shared 25-pin D-sub

Trigger Input

Type: TTL or contact closure

Connector: Shared 25-pin D-sub

General

Ambient Temperature: 15 °C to 35 °C

Cooling: Air cooled with internal 2 speed fan

Warm-up: 30 minutes at output current setting

Line Power: 100, 120, 220, 240 VAC +6% –10%, single phase, 50 or 60 Hz, 850 VA

Size: 483 mm W × 178 mm H × 520 mm D (19 in × 7 in × 20.5 in),

rack mount (integrated rack mount ears)

Weight: 27.2 kg (60 lbs)

Approval (pending): CE Mark – Low voltage compliance to EN61010-3, EMC compliance to EN55022-1

Calibration Schedule: 1 year

Ordering Information

Part Number Description

625 Superconducting Magnet Power Supply

625-DUAL Two Model 625s, one dual supply interconnect cable kit

Select a power configuration:

VAC-100-B Instrument configured for 100 VAC with U.S. power cord

VAC-120-B Instrument configured for 120 VAC with U.S. power cord

VAC-120-BC Instrument configured for 120 VAC with U.S. power cord and universal European

power cord and fuses for 220/240 setting (extra charge for this option)

VAC-220-C Instrument configured for 220 VAC with European power cord

VAC-240-C Instrument configured for 240 VAC with European power cord

VAC-220-D Instrument configured for 220 VAC with a 220 V (6-15P) U.S. power cord

Accessories included:

6271 Model 625 user's manual

6241 Two front handles

6242 Two rear handles/protectors

6243 Output shorting bar and terminal fasteners

6251 25-pin D-sub mating connector, digital I/O

6252 15-pin D-sub mating connector, analog I/O

— Calibration Certificate

Accessories available

6201 1 m (3.3 ft) long IEEE-488 (GPIB) computer interface cable assembly

6261 10 ft – 60 A magnet cable kit, AWG 4

6262 20 ft – 60 A magnet cable kit, AWG 4

6263 Dual supply interconnect cable kit (including magnet cables and safety interlock cable)

CAL-625-CERT Instrument recalibration with certificate

CAL-625-DATA Instrument recalibration with certificate and data

1-6 Introduction

• Indoor use.

• Altitude to 2000 meters.

• Temperature for safe operation: 5 °C to 40 °C.

• Overvoltage category II.

• Pollution degree 2.

• Maximum relative humidity: 80% for temperature up to

31 °C decreasing linearly to 50% at 40 °C.

• Power supply voltage fluctuations not to exceed ±10%

of the nominal voltage.

Lake Shore Model 625 Superconducting MPS User’s Manual

1.3 SAFETY SUMMARY

Observe these safety precautions during all phases of instrument operation, service, and repair. Failure to comply with

these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture,

and intended instrument use. Lake Shore assumes no liability for Customer failure to comply with these requirements.

The Model 625 protects the operator and surrounding area from electric shock or burn, mechanical hazards, excessive

temperature, and spread of fire from the instrument. Environmental conditions outside of the conditions below may pose

a hazard to the operator and surrounding area.

Ground The Instrument

To minimize shock hazard, the instrument is equipped with a 3-conductor AC power cable. Plug the power cable into

an approved three-contact electrical outlet or use a three-contact adapter with the grounding wire (green) firmly

connected to an electrical ground (safety ground) at the power outlet. The power jack and mating plug of the power

cable meet Underwriters Laboratories (UL) and International Electrotechnical Commission (IEC) safety standards.

Ventilation

The instrument has ventilation holes in its side covers. Do not block these holes when the instrument is operating.

Do Not Operate In An Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any electrical instrument in

such an environment constitutes a definite safety hazard.

Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Refer component replacement and internal adjustments to

qualified maintenance personnel. Do not replace components with power cable connected. To avoid injuries, always

disconnect power and discharge circuits before touching them.

Do Not Substitute Parts Or Modify Instrument

Do not install substitute parts or perform any unauthorized modification to the instrument. Return the instrument to an

authorized Lake Shore representative for service and repair to ensure that safety features are maintained.

Cleaning

Do not submerge instrument. Clean only with a damp cloth and mild detergent. Exterior only.

Moving and Handling

Four handles are provided for ease of moving and handling the Model 625. Always use at least two, and if possible

four, handles when carrying the unit.

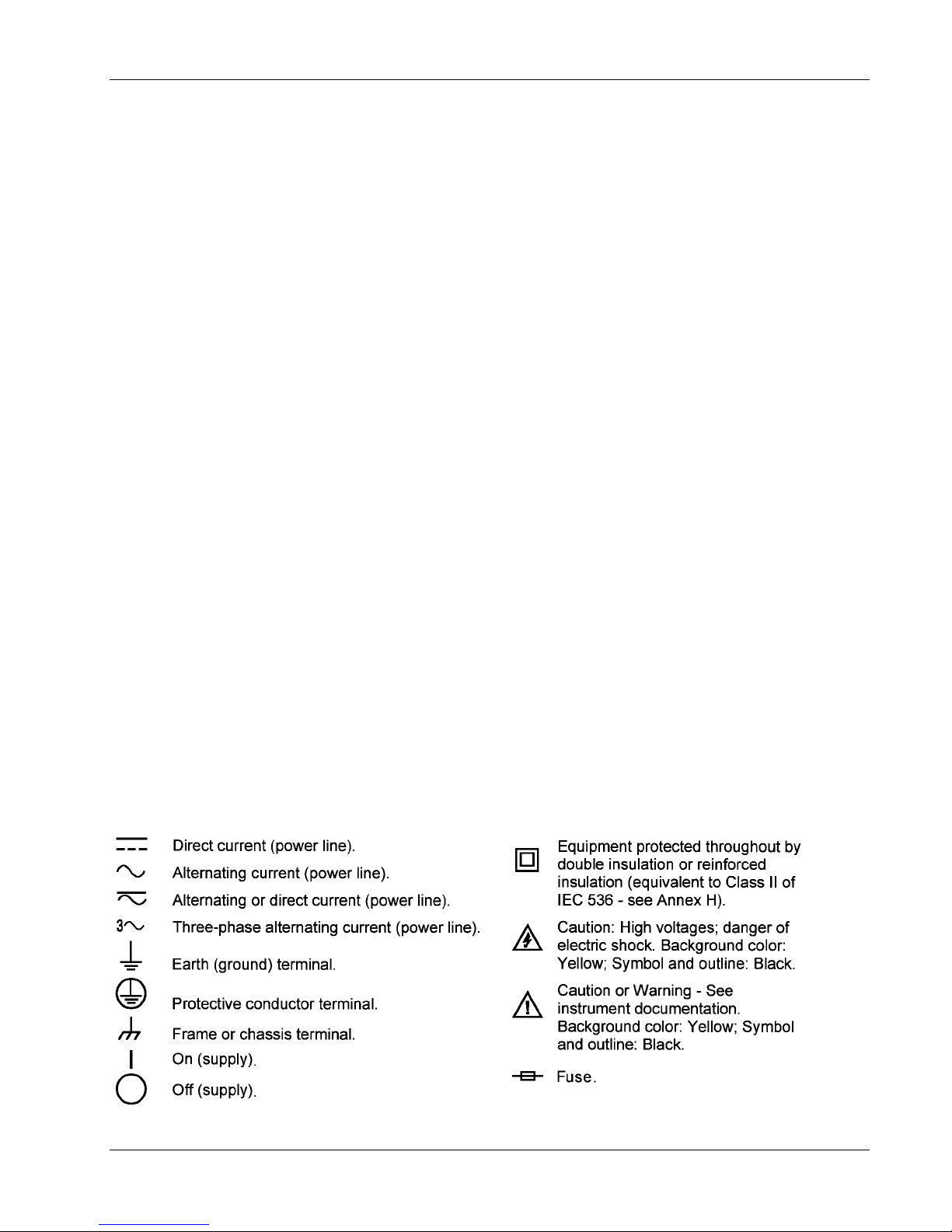

1.4 SAFETY SYMBOLS

Introduction 1-7

Lake Shore Model 625 Superconducting MPS User’s Manual

This Page Intentionally Left Blank

1-8 Introduction

Lake Shore Model 625 Superconducting MPS User’s Manual

CHAPTER 2

MAGNET SYSTEM DESIGN

2.0 GENERAL

This chapter provides information on general magnet system design. It is intended to give the user insight into

superconducting materials, superconducting magnets, persistent switches, dewars, and cabling issues. For information on

how to install the Model 625 please refer to Chapter 3. Instrument operation information is contained in Chapter 4.

2.1 SUPERCONDUCTING MATERIALS

Superconducting materials have a very special property, that when cooled to very low temperatures, they become perfect

conductors of electricity. The transition to the superconducting state happens abruptly as the critical temperature is

reached. When the material is in its superconducting state, it has absolutely zero resistance. Such materials have a variety

of applications, one of which is for the construction of high field magnets.

The unique properties of superconductors make them ideal for use in high field magnets. Since a superconductor has no

resistance it requires no voltage to maintain a current through it. Magnet grade superconductors also have a very high

current density allowing a relatively small wire to carry a large amount of current that can be used to generate large

magnetic fields.

There are three properties that determine if a material is in its superconducting state. The first property is critical

temperature. A superconductor needs to be cooled in order to transition to a superconducting state. This temperature is

called its critical temperature. Most materials need to be cooled with liquid helium in order to reach their critical

temperatures although some ceramics have shown to have a critical temperature as high as 125 K which would be

suitable for nitrogen cooling.

The second property is critical current density. A superconducting wire can only carry a certain amount of current in its

superconducting state. The current density of a typical superconducting wire made from niobium-titanium is on the order

of 1010 A/m2, about three orders of magnitude greater than normal house wiring. If the critical current density is

exceeded, the wire will return to its normal resistive state.

The last property is critical field. A superconductor will return to its normal resistive state if it is exposed to a magnetic

field larger than its critical field. Superconducting wire such as niobium-titanium and niobium-tin have critical fields in

excess of 10 T and 20 T respectively. Elemental superconductors, such as lead, have very low critical fields, in this case

0.08 T, and are not suited for creating superconducting magnets.

All three of these properties are related to one another. For instance, a superconducting wire is able to carry more current

and withstand a higher magnetic field as it is cooled to a lower temperature. In the case of niobium-titanium, a common

superconducting wire, the critical temperature is 9.3 K but at that temperature both the critical field and critical current

density are both zero. At a temperature of 6 K, the critical field increases to approximately 7 T and at 4 K it is

approximately 11 T.

2.2 SUPERCONDUCTING MAGNETS

Superconducting magnets are wound from many turns of superconducting wire. They are used to generate magnetic

fields that are larger than can be achieved with permanent magnets or electromagnets or when field stability is important.

They can also be more economical to run than electromagnets since the power needed to maintain the charge is minimal.

2.2.1 Superconducting Magnet Construction

The magnetic field (B) that can be generated by a solenoid is given by the equation B=μ0In/l, where μ0 is the

permeability of air, I is the current in the wire, n is the number of turns, and l is the length of the solenoid. Most

superconducting magnets are wound using a conductor made from many fine strands of niobium-titanium (NbTi) or

niobium-tin (Nb3Sn) embedded in a copper matrix. The copper matrix is used for mechanical stability and to provide a

path for large currents in the case of a magnet quench. Typically, niobium-tin is only used in magnets that can generate

fields in excess of 9 Tesla because it is more expensive and harder to work with than niobium-titanium.

Magnet System Design 2-1

Lake Shore Model 625 Superconducting MPS User’s Manual

The superconducting wire is wound around a non-magnetic former made from aluminum, brass, stainless steel, or other

material as needed. The individual windings are electrically insulated by the insulation on the wire and by an epoxy that

is applied to the windings. The epoxy is also necessary to keep the individual windings from moving when the magnet is

charged.

Figure 2-1. Typical Superconducting Magnet

2.2.2 Magnet Inductance

The inductance of a solenoid (L) is defined as L = μ0n2A/l, where μ0 is the permeability of air, n is the number of turns, A

is the cross sectional area of the coil, and l is the length of the solenoid. The inductance of superconducting magnets is

fairly large, typically between 10 and 100 Henries. The magnet’s inductance limits the rate at which the magnet can be

charged or discharged because of the increased voltage required to change current. The formula V = L (di/dt) relates

charging voltage to inductance where V is the charging voltage, L is the magnet inductance, and di/dt is the rate of

change in current. The Model 625 can charge a magnet up to a 5 V rate, although many magnets are not designed to be

charged at that rate. For instance, a 10 Henry magnet can be charged at a rate of 0.5 A/s with a 5 V limit. A rate of 0.1

A/s is more typical.

2-2 Magnet System Design

Lake Shore Model 625 Superconducting MPS User’s Manual

The resistance of the leads must be taken into account when calculating charge rate since a voltage drop across the leads

will limit the voltage that can be delivered to the terminals of the magnet. This becomes especially important as the

charging current rises since the voltage drop across the leads will increase.

2.2.3 Maximum Ramp Rate

Not only is the rate at which a magnet can be charged limited to the magnet’s inductance but it is also limited by the

magnet’s construction. When a magnet is charged or discharged, heat is generated in the coils. The faster the ramp rate,

the more heat that will be generated. If the heat cannot be conducted out of the magnet fast enough, a section of the

superconducting windings can go normal and cause a quench. The magnet manufacturer should state the maximum ramp

rate of the magnet. In some magnets, the current cannot be changed at the same rate over the entire current range of the

magnet. These magnets need to be charged at a slower rate as they reach their maximum current rating.

2.2.4 Maximum Magnet Current

Although superconducting wire can carry more current than non-superconducting wire of the same size, the amount of

current that it can carry is not unlimited. If the critical current of the wire is exceeded, the wire will no longer be

superconducting and will revert to its normal state causing the magnet to quench. Commercially purchased magnets have

been designed to work up to a maximum stated current. The magnet should be able to handle a quench up to the rated

current of the magnet. Do not exceed the maximum current rating of the magnet or the magnet can quench and possibly

be damaged.

2.2.5 Magnet Quench Protection Diodes

Many superconducting magnets have protection diodes installed across the terminals of the magnet. These diodes will

turn on in the event of a quench and will help dissipate some of the magnets energy. Typically the diodes are attached to

the magnet itself and are submerged in the cryogen. At 4.2 K the forward voltage of the diodes may be on the order of 10

volts. If the magnet quenches, the energy dissipated in the diodes will warm them, resulting in a decrease in their forward

voltage. If this voltage drops below the compliance voltage limit of the power supply, the power supply will continue to

source current to the diodes eventually damaging them and causing them to short. This would require that the protection

diodes be replaced which could be a significant expense especially if the magnet is in a sealed dewar.

To ensure that the diodes are not damaged by the power supply, the compliance voltage limit of the supply should be set

to a voltage below the protection diode range. It is also recommended that some form of quench detection be used to

force the output of the power supply to 0 amps when a quench is detected ensuring that no additional current is being

supplied to the diodes. The Model 625 offers both internal quench detection and a remote inhibit line that can be

connected to an external quench detection circuit.

2.3 PERSISTENT SWITCHES

Some superconducting magnets are constructed with a persistent switch. A persistent switch is a length of

superconducting wire that shorts across the terminals of the magnet. This length of wire can be heated and drives it into a

resistive state so that a voltage can be applied across the magnet terminals and the magnet can be charged or discharged.

When the heater is shut off, this section of wire will cool and become superconducting again and the magnet will be in

persistent mode. At this time, the power supply can be ramped to zero current and even removed from the system while

the magnet holds its charge.

One of the reasons to use a persistent switch is when a very stable field is required. When the magnet is in persistent

mode, all of the current is being circulated within the magnet with no interference from outside sources. Another reason

to use a persistent switch is when it is desired to hold a particular magnet field for an extended period of time, such as in

a MRI system. Once the magnet is in persistent mode, the power supply can be removed from the system and used

elsewhere. It is also possible on some systems to remove the vapor cooled leads from the dewar to further reduce the

amount of helium boil off.

The magnet manufacturer will specify the current necessary to turn on the persistent switch heater. Do not use any more

current than is necessary since that will result in excess helium boil off. It is important when turning on the persistent

switch heater that the current setting of the power supply is equal to the current in the magnet. If the current does not

match, the current in the magnet will ramp to the current setting of the power supply at the compliance voltage limit.

This may cause the power supply to incorrectly detect a quench.

Magnet System Design 2-3

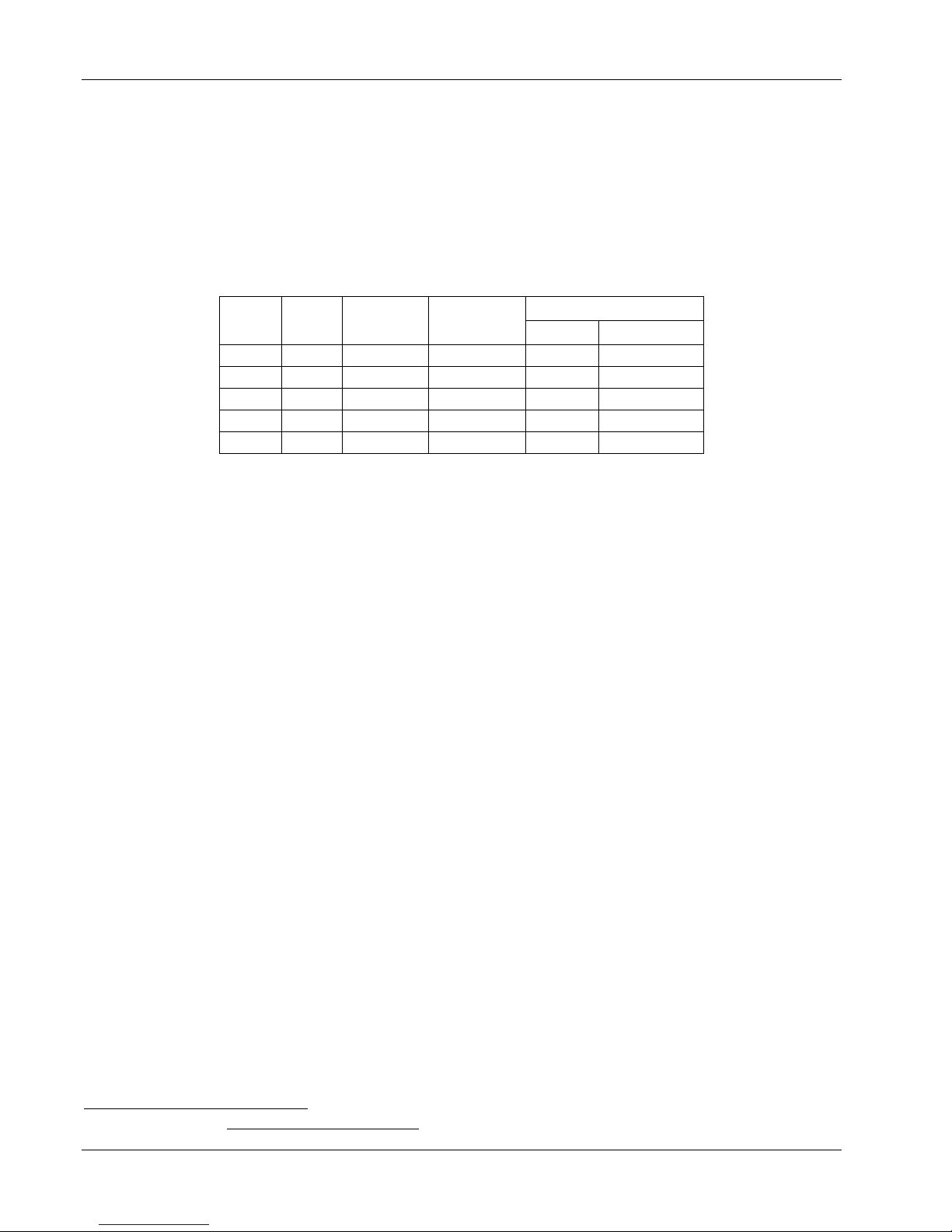

AWG

Area

(mm2)

Capacity

(A)

Resistivity

/1000 feet

Total Lead Length (feet)

60 A

120 A

0

53.5

245

0.09827

170

85

2

33.6

180

0.1563

107

53

4

21.2

135

0.2485

67

34

6

13.3

100

0.3951

42

—

8

8.4

75

0.6282

27

—

1

Lake Shore Model 625 Superconducting MPS User’s Manual

2.4 MAGNET CURRENT LEADS

The power supply should be placed close to the magnet to reduce the length of the lead wires. The resistance of the wires

becomes very important when such large currents are being supplied to the magnet. The rate at which a magnet can be

charged depends on the voltage that can be supplied across the terminals of the magnet given by the equation V = L

(di/dt). The voltage is limited by the maximum voltage the power supply can output minus the voltage that is lost

through the magnet leads. Use lead wires heavy enough to limit the voltage drop to less than 0.5 volts per lead and keep

conductor temperature under 85 °C for a 35 °C ambient temperature. Table 2-1 lists the current capacity and total lead

lengths for load connections.

Table 2-1. Current Capacity and Total Lead Lengths

The Remote Voltage Sense connection can be used to monitor the voltage directly across the terminals of the magnet.