Lake Shore 480 User Manual

Fluxmeter

User’s Manual

Model 480

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

E-mail:

sales@lakeshore.com

service@lakeshore.com

Visit our website at:

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake Shore Cryotronics, Inc.

No government or other contractual support or relationship whatsoever has existed which in any way affects or mitigates proprietary

rights of Lake Shore Cryotronics, Inc. in these developments. Methods and apparatus disclosed herein may be subject to U.S. Patents

existing or applied for. Lake Shore Cryotronics, Inc. reserves the right to add, improve, modify, or withdraw functions, design

modifications, or products at any time without notice. Lake Shore shall not be liable for errors contained herein or for incidental or

consequential damages in connection with furnishing, performance, or use of this material.

Revision: 2.2 P/N 119-028 25 July 2017

Lake Shore Model 480 Fluxmeter User’s Manual

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: THREE (3) YEARS

1. Lake Shore warrants that products manufactured by Lake Shore (the "Product") will be free from defects in materials

and workmanship for three years from the date of Purchaser's physical receipt of the Product (the "Warranty Period"). If

Lake Shore receives notice of any such defects during the Warranty Period and the defective Product is shipped freight

prepaid back to Lake Shore, Lake Shore will, at its option, either repair or replace the Product (if it is so defective) without

charge for parts, service labor or associated customary return shipping cost to the Purchaser. Replacement for the

Product may be by either new or equivalent in performance to new. Replacement or repaired parts, or a replaced Product,

will be warranted for only the unexpired portion of the original warranty or 90 days (whichever is greater).

2.Lake Shore warrants the Product only if the Product has been sold by an authorized Lake Shore employee, sales

representative, dealer or an authorized Lake Shore original equipment manufacturer (OEM).

3.The Product may contain remanufactured parts equivalent to new in performance or may have been subject to

incidental use when it is originally sold to the Purchaser.

4. The Warranty Period begins on the date the Product ships from Lake Shore’s plant.

5.This limited warranty does not apply to defects in the Product resulting from (a) improper or inadequate installation

(unless OT&V services are performed by Lake Shore), maintenance, repair or calibration, (b) fuses, software, power

surges, lightning and non-rechargeable batteries, (c) software, interfacing, parts or other supplies not furnished by Lake

Shore, (d) unauthorized modification or misuse, (e) operation outside of the published specifications, (f) improper site

preparation or site maintenance (g) natural disasters such as flood, fire, wind, or earthquake, or (h) damage during

shipment other than original shipment to you if shipped through a Lake Shore carrier.

6.This limited warranty does not cover: (a) regularly scheduled or ordinary and expected recalibrations of the Product; (b)

accessories to the Product (such as probe tips and cables, holders, wire, grease, varnish, feed throughs, etc.); (c)

consumables used in conjunction with the Product (such as probe tips and cables, probe holders, sample tails, rods and

holders, ceramic putty for mounting samples, Hall sample cards, Hall sample enclosures, etc.); or, (d) non-Lake Shore

branded Products that are integrated with the Product.

7.To the extent allowed by applicable law, this limited warranty is the only warranty applicable to the Product and replaces

all other warranties or conditions, express or implied, including, but not limited to, the implied warranties or conditions of

merchantability and fitness for a particular purpose. Specifically, except as provided herein. Lake Shore undertakes no

responsibility that the products will be fit for any particular purpose for which you may be buying the Products. Any implied

warranty is limited in duration to the warranty period. No oral or written information, or advice given by the Company, its

Agents or Employees, shall create a warranty or in any way increase the scope of this limited warranty. Some countries,

states or provinces do not allow limitations on an implied warranty, so the above limitation or exclusion might not apply to

you. This warranty gives you specific legal rights and you might also have other rights that vary from country to country,

state to state or province to province.

8.Further, with regard to the United Nations Convention for International Sale of Goods (CISC,) if CISG is found to apply

in relation to this agreement, which is specifically disclaimed by Lake Shore, then this limited warranty excludes

warranties that: (a) the Product is fit for the purpose for which goods of the same description would ordinarily be used, (b)

the Product is fit for any particular purpose expressly or impliedly made known to Lake Shore at the time of the conclusion

of the contract, (c) the Product is contained or packaged in a manner usual for such goods or in a manner adequate to

preserve and protect such goods where it is shipped by someone other than a carrier hired by Lake Shore.

9.Lake Shore disclaims any warranties of technological value or of non-infringement with respect to the Product and Lake

Shore shall have no duty to defend, indemnify, or hold harmless you from and against any or all damages or costs

incurred by you arising from the infringement of patents or trademarks or violation or copyrights by the Product.

10.THIS WARRANTY IS NOT TRANSFERRABLE. This warranty is not transferrable.

11.Except to the extent prohibited by applicable law, neither Lake Shore nor any of its subsidiaries, affiliates or suppliers

will be held liable for direct, special, incidental, consequential or other damages (including lost profit, lost data, or

downtime costs) arising out of the use, inability to use or result of use of the product, whether based in warranty, contract,

tort or other legal theory, regardless whether or not Lake Shore has been advised of the possibility of such damages.

Purchaser's use of the Product is entirely at Purchaser's risk. Some countries, states and provinces do not allow the

exclusion of liability for incidental or consequential damages, so the above limitation may not apply to you.

A

12.This limited warranty gives you specific legal rights, and you may also have other rights that vary within or between

jurisdictions where the product is purchased and/or used. Some jurisdictions do not allow limitation in certain warranties,

and so the above limitations or exclusions of some warranties stated above may not apply to you.

13.Except to the extent allowed by applicable law, the terms of this limited warranty statement do not exclude, restrict or

modify the mandatory statutory rights applicable to the sale of the product to you.

CERTIFICATION

Lake Shore certifies that this product has been inspected and tested in accordance with its published specifications and that this product

met its published specifications at the time of shipment. The accuracy and calibration of this product at the time of shipment are traceable

to the United States National Institute of Standards and Technology (NIST); formerly known as the National Bureau of Standards (NBS).

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 480 firmware is as free of errors as possible, and that the results you obtain from the

instrument are accurate and reliable. However, as with any computer-based software, the possibility of errors exists.

In any important research, as when using any laboratory equipment, results should be carefully examined and rechecked before final

conclusions are drawn. Neither Lake Shore nor anyone else involved in the creation or production of this firmware can pay for loss of

time, inconvenience, loss of use of the product, or property damage caused by this product or its failure to work, or any other incidental or

consequential damages. Use of our product implies that you understand the Lake Shore license agreement and statement of limited

warranty.

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States copyright law and international treaty provisions. To maintain the warranty,

the code contained in the firmware must not be modified. Any changes made to the code is at the user’s risk. Lake Shore will assume no

responsibility for damage or errors incurred as result of any changes made to the firmware.

Under the terms of this agreement you may only use the Model 480 firmware as physically installed in the instrument. Archival copies are

strictly forbidden. You may not decompile, disassemble, or reverse engineer the firmware. If you suspect there are problems with the

firmware, return the instrument to Lake Shore for repair under the terms of the Limited Warranty specified above. Any unauthorized

duplication or use of the Model 480 firmware in whole or in part, in print, or in any other storage and retrieval system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers and sellers claim designations used to distinguish their products as trademarks. Where those designations appear

in this manual and Lake Shore was aware of a trademark claim, they appear with initial capital letters and the ™ or

MS-DOS® and Windows/95/98/NT/2000® are trademarks of Microsoft Corp.

NI-488.2™ is a trademark of National Instruments.

PC, XT, AT, and PS-2 are trademarks of IBM.

®

symbol.

Copyright © 1999 – 2017 by Lake Shore Cryotronics, Inc. All rights reserved. No portion of this manual may be

reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the express written permission of Lake Shore.

Lake Shore Model 480 Fluxmeter User’s Manual

EU DECLARATION OF CONFORMITY

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Manufacturer:

Lake Shore Cryotronics, Inc.

575 McCorkle Boulevard

Westerville, OH 43082

USA

Object of the declaration:

Model(s): 480

Description: Fluxmeter

The object of the declaration described above is in conformity with the relevant Union harmonization

legislation:

2014/35/EU Low Voltage Directive

2014/30/EU EMC Directive

References to the relevant harmonized standards used to the specification in relation to which

conformity is declared:

EN 61010-1:2010

Overvoltage Category II

Pollution Degree 2

EN 61326-1:2013

Class A

Controlled Electromagnetic Environment

Signed for and on behalf of:

Place, Date:

Westerville, OH USA Scott Ayer

29-SEP-2016 Director of Quality & Compliance

C

Lake Shore Model 480 Fluxmeter User’s Manual

Electromagnetic Compatibility (EMC) for the Model 480 Fluxmeter

Electromagnetic Compatibility (EMC) of electronic equipment is a growing concern worldwide.

Emissions of and immunity to electromagnetic interference is now part of the design and manufacture

of most electronics. To qualify for the CE Mark, the Model 480 meets or exceeds the generic

requirements of the European EMC Directive 89/336/EEC as a CLASS A product. A Class A product

is allowed to radiate more RF than a Class B product and must include the following warning:

WARNING: This is a Class A product. In a domestic environment, this product may

cause radio interference in which case the user may be required to take

The instrument was tested under normal operating conditions with sensor and interface cables

attached. If the installation and operating instructions in the User’s Manual are followed, there should

be no degradation in EMC performance.

Pay special attention to instrument cabling. Improperly installed cabling may defeat even the best

EMC protection. For the best performance from any precision instrument, follow the grounding and

shielding instructions in the User’s Manual. In addition, the installer of the Model 480 should consider

the following:

• Leave no unused or unterminated cables attached to the instrument.

• Make cable runs as short and direct as possible.

• Do not tightly bundle cables that carry different types of signals.

adequate measures.

Lake Shore Model 480 Fluxmeter User’s Manual

This Page Intentionally Left Blank

C

Lake Shore Model 480 Fluxmeter User’s Manual

Table of Contents

Chapter/Paragraph Title Page

1 INTRODUCTION .................................................................................................................................... 1-1

1.0 GENERAL ........................................................................................................................... 1-1

1.1 PRODUCT DESCRIPTION ................................................................................................. 1-1

1.2 SPECIFICATIONS .............................................................................................................. 1-2

1.3 SAFETY SUMMARY ........................................................................................................... 1-4

1.4 SAFETY SYMBOLS ............................................................................................................ 1-4

2 MAGNETIC MEASUREMENT OVERVIEW ........................................................................................... 2-1

2.0 GENERAL ........................................................................................................................... 2-1

2.1 INTEGRATING INSTRUMENTS ........................................................................................ 2-1

2.1.1 What Is An Integrator? ..................................................................................................... 2-1

2.1.2 Why Integrators Are Used For Magnetic Measurement .................................................. 2-1

2.1.3 Important Integrator Characteristics ................................................................................ 2-2

2.1.4 Reducing Integrator Drift .................................................................................................. 2-3

2.1.5 Dielectric Absorption ........................................................................................................ 2-3

2.1.6 Analog Versus Digital Integrators .................................................................................... 2-4

2.1.7 Fluxmeter Measurements in Magnetizers ....................................................................... 2-4

2.1.8 Making AC Measurements .............................................................................................. 2-6

2.2 COIL CHARACTERISTICS ................................................................................................. 2-6

2.2.1 Coil Sensitivity.................................................................................................................. 2-6

2.2.2 Coil Size ........................................................................................................................... 2-7

2.2.3 Coil Resistance ................................................................................................................ 2-7

2.2.4 Coil Temperature Coefficient ........................................................................................... 2-8

2.2.5 Coil Orientation ................................................................................................................ 2-8

2.2.6 Field Uniformity ................................................................................................................ 2-9

2.2.7 Lead Pickup ..................................................................................................................... 2-9

2.2.8 Inductance, Capacitance, and Self Resonance ............................................................... 2-9

2.2.9 Lake Shore Coils and Probes .......................................................................................... 2-9

2.3 FLUX OVERVIEW ............................................................................................................. 2-10

2.4 FLUX DENSITY OVERVIEW ............................................................................................ 2-10

2.4.1 What is Flux Density? .................................................................................................... 2-10

2.4.2 How Flux Density (B) Differs from Magnetic Field Strength (H) .................................... 2-11

2.5 MAGNETIC MOMENT OVERVIEW .................................................................................. 2-11

2.5.1 What is Magnetic Moment? ........................................................................................... 2-11

2.5.2 Important Parameters of a Hemholtz Coil ..................................................................... 2-11

2.5.3 Hemholtz Coil Constant Determination (For Non-Lake Shore Coils) ............................ 2-12

2.6 MAGNETIC POTENTIAL OVERVIEW .............................................................................. 2-13

2.6.1 What is Magnetic Potential? .......................................................................................... 2-13

2.6.2 Important Parameters of a Potential Coil ....................................................................... 2-13

3 SETUP .................................................................................................................................................... 3-1

3.0 GENERAL ........................................................................................................................... 3-1

3.1 RECEIVING THE MODEL 480 ........................................................................................... 3-1

3.1.1 Inspection and Unpacking ............................................................................................... 3-1

3.1.2 Repackaging For Shipment ............................................................................................. 3-1

3.2 REAR PANEL DEFINITION ................................................................................................ 3-2

3.3 LINE INPUT ASSEMBLY .................................................................................................... 3-2

3.3.1 Line Voltage and Fuse Verification .................................................................................. 3-2

Table of Contents i

Lake Shore Model 480 Fluxmeter User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

3.3.2 Power Cord ...................................................................................................................... 3-2

3.3.3 Power Switch .................................................................................................................... 3-2

3.4 COIL INPUT CONNECTION ............................................................................................... 3-3

3.5 PROBE INPUT CONNECTION ........................................................................................... 3-3

3.5.1 Attachment To A Non-Lake Shore Coil ............................................................................ 3-3

3.6 TERMINAL BLOCK ............................................................................................................. 3-4

3.6.1 Alarm Relay Connection................................................................................................... 3-4

3.6.2 Analog Output Connections ............................................................................................. 3-4

3.6.3 External Reset Connections ............................................................................................. 3-4

3.6.4 Optional Input Connection ................................................................................................ 3-4

4 BASIC OPERATION ............................................................................................................................... 4-1

4.0 GENERAL ............................................................................................................................ 4-1

4.1 TURNING ON POWER ....................................................................................................... 4-1

4.2 DISPLAY DEFINITION ........................................................................................................ 4-1

4.3 READING FORMAT ............................................................................................................ 4-2

4.4 KEYPAD DEFINITION ......................................................................................................... 4-2

4.5 GENERAL KEYPAD OPERATION ..................................................................................... 4-3

4.6 QUICK START PROCEDURES .......................................................................................... 4-4

4.6.1 DC Integrator Measurement In Units of V·s, WbN, or MxN ............................................. 4-4

4.6.2 DC Flux Measurement In Units of V·s, Mx, or Wb ......................................................... 4-5

4.6.3 DC Flux Density Measurement In Units of G or T ............................................................ 4-6

4.6.4 Moment Measurement In Unit of Wb·cm ......................................................................... 4-7

4.6.5 Potential Measurement In Unit of A ................................................................................. 4-8

5 ADVANCED OPERATION ..................................................................................................................... 5-1

5.0 GENERAL ............................................................................................................................ 5-1

5.1 UNITS SELECTION ............................................................................................................ 5-1

5.2 COIL PARAMETERS .......................................................................................................... 5-2

5.3 COIL SETUP ....................................................................................................................... 5-2

5.3.1 Input Resistance ............................................................................................................... 5-3

5.3.2 Coil Resistance ................................................................................................................ 5-4

5.3.3 Number of Turns (N) ........................................................................................................ 5-4

5.3.4 Area (A) ............................................................................................................................ 5-4

5.3.5 Area Turns (AN) ............................................................................................................... 5-5

5.3.6 Helmholtz Constant .......................................................................................................... 5-5

5.3.7 Potential Constant ............................................................................................................ 5-5

5.4 MAKING MEASUREMENTS IN PERCENT ........................................................................ 5-6

5.4.1 Before Using Set Percent ................................................................................................. 5-6

5.4.2 Set Percent (%) ................................................................................................................ 5-6

5.4.3 Percent Scale Factor ........................................................................................................ 5-6

5.5 COIL CALIBRATION ........................................................................................................... 5-7

5.5.1 Before using Coil Calibration ............................................................................................ 5-7

5.5.2 Calibrating a Coil .............................................................................................................. 5-7

5.6 COIL SELECT AND PARAMETER STORAGE .................................................................. 5-7

5.6.1 Storing New Coil Parameters into Instrument Memory .................................................... 5-8

5.6.2 Storing New Coil Parameters into Probe Memory ........................................................... 5-8

5.6.3 Selecting Saved Coil Parameters .................................................................................... 5-8

ii Table of Contents

Lake Shore Model 480 Fluxmeter User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

5.7 RANGE SELECTION .......................................................................................................... 5-9

5.8 READING RESET ............................................................................................................... 5-9

5.9 DRIFT ADJUSTMENT ...................................................................................................... 5-10

5.9.1 Automatic Drift Adjustment ............................................................................................ 5-10

5.9.2 Manual Drift Adjustment ................................................................................................ 5-11

5.9.3 DriftTrak™ ...................................................................................................................... 5-11

5.10 DC AND AC MEASUREMENT MODES ........................................................................... 5-12

5.10.1 DC Measurement Mode ................................................................................................. 5-12

5.10.2 AC Measurement Mode ................................................................................................. 5-13

5.11 PEAK HOLD AND PEAK RESET ..................................................................................... 5-14

5.11.1 Peak Hold in DC Mode .................................................................................................. 5-14

5.11.2 Peak Hold in AC Mode .................................................................................................. 5-14

5.11.3 Activating Peak Mode .................................................................................................... 5-14

5.11.4 Peak Reset .................................................................................................................... 5-15

5.11.5 Choosing Positive, Negative or Both Peaks .................................................................. 5-15

5.12 FILTER .............................................................................................................................. 5-15

5.13 DISPLAY RESOLUTION .................................................................................................. 5-16

5.14 ALARM AND RELAY OPERATION .................................................................................. 5-16

5.14.1 Alarm Setup ................................................................................................................... 5-17

5.14.2 Relay Setup ................................................................................................................... 5-18

5.14.3 Turning Alarm On and Off .............................................................................................. 5-19

5.15 ANALOG OUT OPERATION ............................................................................................ 5-19

5.15.1 Corrected Analog Output ............................................................................................... 5-19

5.15.2 Monitor Analog Output ................................................................................................... 5-20

5.16 EXTERNAL RESET .......................................................................................................... 5-21

5.17 OPTIONAL INPUT ............................................................................................................ 5-21

5.18 LOCKING AND UNLOCKING THE KEYPAD ................................................................... 5-21

5.19 RESETTING TO DEFAULT VALUES ............................................................................... 5-22

6 COMPUTER INTERFACE OPERATION ............................................................................................... 6-1

6.0 GENERAL ........................................................................................................................... 6-1

6.1 IEEE-488 INTERFACE ....................................................................................................... 6-1

6.1.1 IEEE-488 Interface Settings ............................................................................................ 6-2

6.1.2 IEEE-488 Command Structure ........................................................................................ 6-2

6.1.3 Status Registers............................................................................................................... 6-3

6.1.4 IEEE Interface Example Programs .................................................................................. 6-5

6.1.5 Troubleshooting ............................................................................................................. 6-13

6.2 SERIAL I/O INTERFACE .................................................................................................. 6-14

6.2.1 Serial Interface Hardware Configuration ....................................................................... 6-14

6.2.2 Serial Interface Settings ................................................................................................. 6-14

6.2.3 Serial Interface Example Programs ............................................................................... 6-15

6.2.4 Troubleshooting ............................................................................................................. 6-19

6.3 IEEE-488/SERIAL INTERFACE COMMAND SUMMARY ................................................ 6-20

6.3.1 Command List Structure ................................................................................................ 6-21

6.3.2 IEEE-488/Serial Interface Commands (Alphabetical Listing) ........................................ 6-21

Table of Contents iii

Lake Shore Model 480 Fluxmeter User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

7 ACCESSORIES, COILS, AND PROBES ............................................................................................... 7-1

7.0 GENERAL ............................................................................................................................ 7-1

7.1 ACCESSORIES ................................................................................................................... 7-1

7.2 FIELD MEASURING PROBES ............................................................................................ 7-3

7.2.1 100 cm2 Field Probe ......................................................................................................... 7-3

7.2.2 30 cm2 Field Probe ........................................................................................................... 7-4

7.3 HELMHOLTZ COILS ........................................................................................................... 7-5

7.4 REFERENCE MAGNETS .................................................................................................... 7-7

8 SERVICE................................................................................................................................................. 8-1

8.0 GENERAL ............................................................................................................................ 8-1

8.1 GENERAL MAINTENANCE PRECAUTIONS ..................................................................... 8-1

8.2 ELECTROSTATIC DISCHARGE ........................................................................................ 8-1

8.2.1 Identification of Electrostatic Discharge Sensitive Components ...................................... 8-2

8.2.2 Handling Electrostatic Discharge Sensitive Components ................................................ 8-2

8.3 LINE VOLTAGE SELECTION ............................................................................................. 8-2

8.4 FUSE REPLACEMENT ....................................................................................................... 8-3

8.5 REAR PANEL CONNECTOR DEFINITIONS ...................................................................... 8-4

8.5.1 Serial Interface Cable Wiring............................................................................................ 8-6

8.5.2 IEEE-488 Interface Connector ......................................................................................... 8-7

8.6 TOP OF ENCLOSURE REMOVAL AND REPLACEMENT ................................................ 8-8

8.6.1 Removal Procedure .......................................................................................................... 8-8

8.6.2 Installation Procedure ....................................................................................................... 8-8

8.7 EPROM REPLACEMENT ................................................................................................... 8-8

8.8 ERROR MESSAGES .......................................................................................................... 8-9

8.9 CALIBRATION PROCEDURE........................................................................................... 8-10

8.9.1 Required Equipment List ................................................................................................ 8-10

8.9.2 A/D Reference Voltages ................................................................................................. 8-10

8.9.3 Initialize for Calibration ................................................................................................... 8-10

8.9.4 AC Peak Offset ............................................................................................................... 8-11

8.9.5 AC RMS and AC Peak Gain Calibration ........................................................................ 8-11

8.9.6 DC and DC Peak Calibration.......................................................................................... 8-12

8.9.7 Output Calibration .......................................................................................................... 8-13

8.9.8 Finalize Calibration ......................................................................................................... 8-14

APPENDIX A – GLOSSARY OF TERMINOLOGY ..................................................................................... A-1

APPENDIX B – UNITS FOR MAGNETIC PROPERTIES ............................................................................ B-1

iv Table of Contents

Lake Shore Model 480 Fluxmeter User’s Manual

LIST OF ILLUSTRATIONS

Figure No. Title Page

3-1 Model 480 Rear Panel ..................................................................................................................... 3-2

3-2 Line Input Assembly ......................................................................................................................... 3-3

4-1 Model 480 Normal Display Definition ............................................................................................... 4-1

4-2 Model 480 Front Panel ..................................................................................................................... 4-2

5-1 Model 480 AC Frequency Response ............................................................................................. 5-13

5-2 Examples of Alarm Activation Inside and Outside High and Low Setpoints .................................. 5-18

6-1 GPIB0 Setting Configuration ............................................................................................................ 6-6

6-2 DEV 12 Device Template Configuration .......................................................................................... 6-6

6-3 Typical National Instruments GPIB Configuration from IBCONF.EXE .......................................... 6-11

7-1 100 cm2 Field Probe ......................................................................................................................... 7-3

7-2 30 cm2 Field Probe ........................................................................................................................... 7-4

7-3 Model FH-2.5 Helmholtz Coil ........................................................................................................... 7-5

7-4 Model FH-6 Helmholtz Coil .............................................................................................................. 7-6

7-5 Model FH-12 Helmholtz Coil ............................................................................................................ 7-6

7-6 Lake Shore Reference Magnets ...................................................................................................... 7-7

7-7 Model RM-1/2 Half-Rack Mounting Kit ............................................................................................. 7-8

7-8 Model RM-2 Dual Rack-Mount Shelf ............................................................................................... 7-8

8-1 Power Fuse Access ......................................................................................................................... 8-3

8-2 COIL INPUT Connector Details ....................................................................................................... 8-4

8-3 PROBE INPUT Connector Details ................................................................................................... 8-4

8-4 Relays and Analog Signals Terminal Block ..................................................................................... 8-5

8-5 SERIAL I/O Connector Details ......................................................................................................... 8-5

8-6 IEEE-488 Rear Panel Connector Details ......................................................................................... 8-7

8-7 Location of Operating Software EPROM ......................................................................................... 8-9

LIST OF TABLES

Table No. Title Page

2-1 Examples of Copper Wire Resistance ............................................................................................. 2-8

3-1 Sample AC Line Input List ............................................................................................................... 3-3

5-1 Units and Associated Coil Parameters ............................................................................................ 5-1

5-2 Default Values ................................................................................................................................ 5-22

6-1 IEEE-488 Interface Program Control Properties .............................................................................. 6-8

6-2 Visual Basic IEEE-488 Interface Program ....................................................................................... 6-9

6-3 Quick Basic IEEE-488 Interface Program ...................................................................................... 6-12

6-4 Serial Interface Specifications ........................................................................................................ 6-14

6-5 Serial Interface Program Control Properties .................................................................................. 6-16

6-6 Visual Basic Serial Interface Program ........................................................................................... 6-17

6-7 Quick Basic Serial Interface Program ............................................................................................ 6-18

8-1 AC Calibration Table ...................................................................................................................... 8-11

8-2 DC Calibration Table ...................................................................................................................... 8-12

Table of Contents v

Lake Shore Model 480 Fluxmeter User’s Manual

This Page Intentionally Left Blank

vi Table of Contents

Lake Shore Model 480 Fluxmeter User’s Manual

CHAPTER 1

INTRODUCTION

1.0 GENERAL

This chapter provides introductory information for the Lake Shore Model 480 Fluxmeter. Product

description is in Paragraph 1.1, specifications in Paragraph 1.2, safety summary in Paragraph 1.3, and

safety symbols in Paragraph 1.4.

1.1 PRODUCT DESCRIPTION

The Model 480 is a precision integrating fluxmeter that works with a variety of sensing coils to measure changing

flux. It is fundamentally an analog integrator under microprocessor control. The analog integrator has excellent

specifications and is very flexible. It performs well in a variety of magnet applications from a fast pulse to a slow

ramp. The microprocessor optimizes the performance of the integrator and enables numerous features and

interfaces. The Model 480 fits well into test and measurement operations from all manual to fully automated with

quick setup and ease of use. The fluxmeter complements the existing line of Lake Shore gaussmeters.

Manual Magnet Testing

A bright display and fast reading update make the Model 480 ideal for manual magnet sorting and testing. The low

drift of the instrument improves productivity with fewer adjustments. Remote terminals allow for foot pedal reading

reset to keep hands on the work, not the instrument. Configurable alarms give an audible signal or relay closure to

signify pass/fail.

Automated Magnet Testing

In automated testing, time is money. The Model 480 has many features to enhance throughput. The instrument has

a fast update rate and settling time. It recovers quickly from reading reset to start a new reading cycle. IEEE-488

and serial computer interfaces included with the Model 480 can be used to control most instrument functions.

Relays and analog outputs can be used for automation without a computer interface.

Magnetizing

The magnetizing process places unique demands on all associated electronics. The Model 480 responds with very

fast peak capture that can keep up with the fastest magnetizing pulses. Both a positive and negative peak can be

captured from the same pulse. The input of the Model 480 is protected against the high voltages at its input present

during magnetizing.

Materials Analysis

High resolution and low drift define the role of the fluxmeter in analytical measurement. The high resolution of the

Model 480 is reinforced by a low noise floor. A configurable filter helps keep the readings quiet. Automatic and

manual drift adjustment modes help optimize the low-drift characteristics of the integrators. The IEEE-488 and

serial computer interfaces included with the Model 480 allow automated data taking.

AC Magnetic Fields

Sensing coils are sensitive to AC magnetic fields but many conventional integrating fluxmeters can not measure

AC fields. The Model 480 has an AC mode that enables it to measure fields over a wide frequency range using

simple sensing coils. Applications are limited to field volumes as large or larger than the coil but for some, it is an

inexpensive way to make low drift AC field measurements.

Drift Adjustment

Adjusting or nulling the drift of an analog integrator wastes time. It can be the only unpleasant part of using an

integrating fluxmeter. Lake Shore innovation brings some relief. The Model 480 has a built in drift algorithm that

continually adjusts drift when the instrument and coil are idle. It is ready when you are to make precision low drift

measurements. The adjustment algorithm has no effect during flux integration. Manual drift adjustment is also

available.

Coils and Probes

Coils and probes wound by the user or from other manufacturers can easily be used with the Model 480. The

Model 480 allows the user to save parameters for up to 10 existing coils/probes and quickly switch between them.

Lake Shore also offers several sensing coils and probe assemblies for use with the Model 480 which offer several

conveniences. They are factory calibrated for accuracy and interchangeability. Calibration data is loaded into

memory in the probe connector so it does not have to be entered by the user. Special coil assemblies are also

available and can be designed to meet customer specifications.

Introduction 1-1

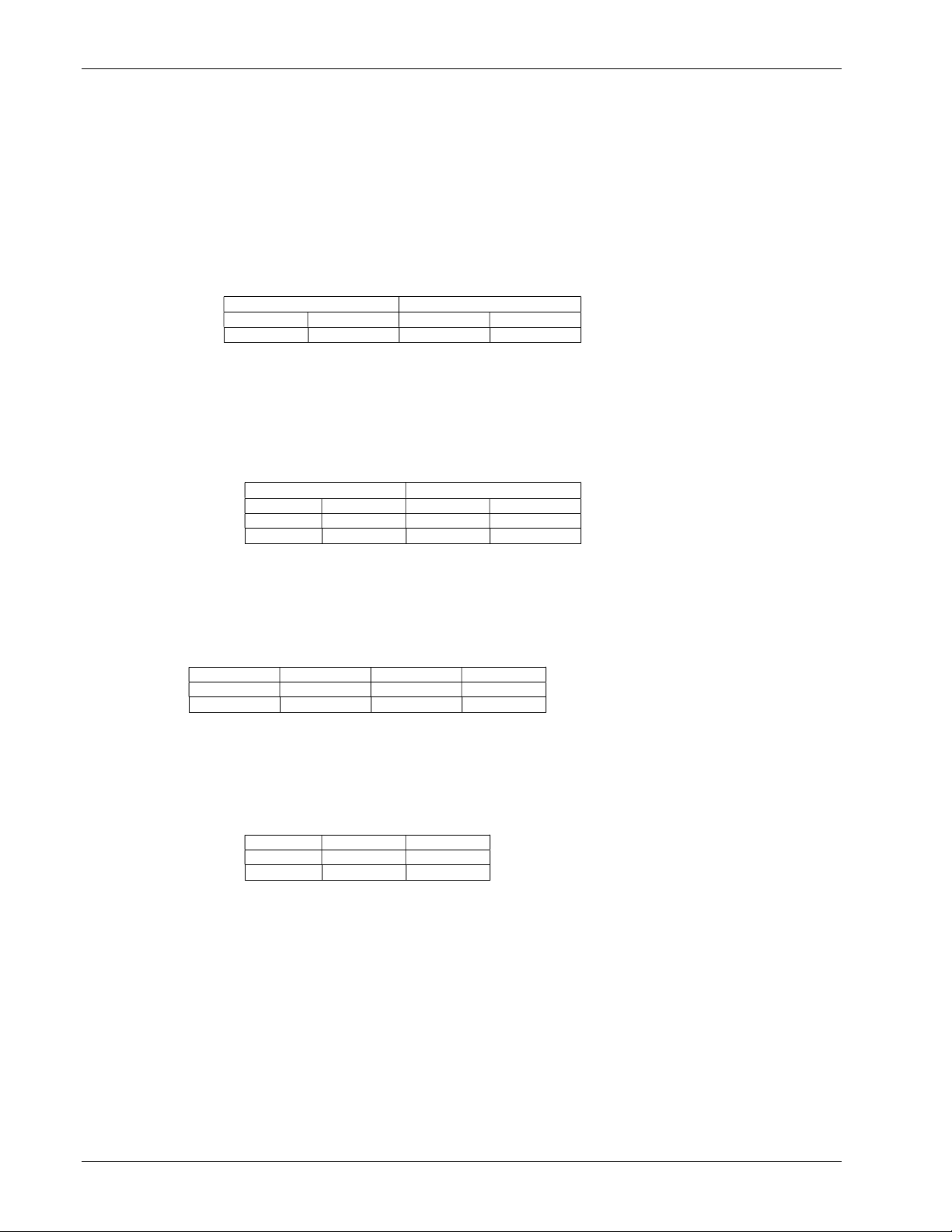

DC Ranges:

300 mVs

30 mVs

30 mVs

3 mVs

DC Resolution:

0.001 mVs

0.0005 mVs

0.0005 mVs

0.0005 mVs

DC Peak Ranges:

300 mVs

30 mVs

30 mVs

3 mVs

DC Peak Resolution:

0.01 mVs

0.001 mVs

0.001 mVs

0.001 mVs

DC Peak Min. Reading:

0.05 mVs

0.005 mVs

0.005 mVs

0.005 mVs

AC Ranges:

30 mVs

3 mVs

300 µVs

30 µVs

AC Resolution:

0.001 mVs

0.0001 mVs

0.01 µVs

0.01 µVs

AC Min. Rdg:

3.000 mVs

0.3000 mVs

30.00 µVs

3.00 µVs

AC Peak Ranges:

30 mVs

3 mVs

300 µVs

AC Peak

Resolution:

0.01 mVs

0.001 mVs

1 µVs

AC Peak Min. Reading:

0.01 mVs

0.001 mVs

5 µVs

Lake Shore Model 480 Fluxmeter User’s Manual

1.2 SPECIFICATIONS

Measurement

Number of Inputs: 1

Input Type: Two-lead, ground referenced

Input Resistance: 100 k or 10 k

Maximum Operating Input Voltage: 60 V

Absolute Maximum Input Voltage: 100 V; WARNING: Voltages between 60 V and 100 V will not

damage the instrument but could result in damage to other instruments or personal injury.

Update Rate: 5 readings per second on display, 30 readings per second IEEE-488, 30 readings per second serial

DC

DC Display Resolution: To 5¾ digits

DC Integrator Capacitance: 1 µF nominal

DC Input Resistance:

DC Accuracy: Offset: ±10 µVs ±DC Integrator Drift

Gain: ±0.25% of reading (<10 Vs/s max. rate of change)

DC Minimum d/dt: 20 µVs/minute

DC Maximum d/dt: 60 Vs/s

DC Integrator Drift: ±1 Vs/minute, 0.0004% FS/minute on 300 mVs range

(100 k input resistance constant temperature environment)

DC Peak

DC Peak Display Resolution: 4¾ digits

DC Peak Integrator Capacitance: 1 µF nominal

DC Peak Input Resistance:

100 k 10 k

100 k 10 k

DC Peak Accuracy: Offset: ±100 µVs ±DC Integrator Drift

Gain: ±5% of reading (<10 Vs/s max. rate of change)

DC Peak Maximum d/dt: 60 Vs/s

DC Peak Update Rate: May reduce update rate to ¼ normal

AC

AC Display Resolution: 4¾ digits

AC Integrator Capacitance: 0.1 µF nominal

AC Input Resistance: 100 k

AC Frequency Response: 2 Hz to 50 kHz (see Figure 5-1)

AC Accuracy: ±1% of reading ±10 µVs (10 Hz – 10 kHz sinusoidal)

±5% of reading: ±10 µVs (2 Hz – 50 kHz sinusoidal)

AC Integrator Drift: N/A

AC Peak

AC Peak Display Resolution: 3¾ digits

AC Peak Integrator Capacitance: 0.1 µF nominal

AC Peak Input Resistance: 100 k

AC Peak Accuracy: ±5% of reading ±10 µVs (10 Hz – 10 kHz sinusoidal)

±10% of reading ±10 µVs (2 Hz – 50 kHz sinusoidal)

AC Peak Update Rate: May reduce update rate to ¼ normal

Front Panel

Display Type: Two line by 20 character, vacuum fluorescent display

Display Resolution: To ±5¾ digits

Display Update Rate: 5 readings per second

Display Units: Vs, MxN, WbN, Vs, Mx, Wb, G, T, Wbcm, A, %

Units Multipliers: p, n, , m, k, M, G

Annunciators: AC AC input signal

DC DC input signal

Positive and Negative peaks

R Remote Operation

ª Alarm on

Keypad: 21 full travel keys

1-2 Introduction

Lake Shore Model 480 Fluxmeter User’s Manual

Specifications (Continued)

Interfaces

IEEE-488.2 Capabilities: SH1,AH1,T5,L4,SR1,RL1,PP0,DC1,DT0,C0,E1

Serial Interface: RS-232C Electrical, DA-9 Connector, 9600 BAUD

External Reset Type: Contact Closure

Alarms

Number: 2

Settings: High and low set point, Inside/Outside, Audible

Actuators: Display Annunciator, Beeper, Relays for High, Low, and Middle

Relays

Number of Relays: 3

Contacts: Normally open (NO), normally closed (NC), and common (C)

Contact Rating: 30 VDC at 2 A

Operation: Follows high and low alarms. Can be operated manually.

Connector: Detachable terminal block

Monitor Analog Output

Scale: ±3V = ±FS on Vs range

Accuracy: ±1% of reading ±10 mV, (DC to 10 kHz)

±5% of reading ±10 mV, (10 kHz to 50 kHz)

Minimum load resistance: 1 k

Connector: Detachable terminal block

Corrected Analog Output

Scale: User Selected

Range: ±10 V

Resolution: 0.3 mV

Accuracy: ±2.5 mV

Minimum load resistance: 1 k

Connector: Detachable terminal block

General

Ambient Temperature: 15 – 35 °C at rated accuracy. 5 – 40 °C with reduced accuracy

Power Requirement: 100, 120, 220, 240 VAC, +5% -10%, 50 or 60 Hz, 20 watts

Size: 217 mm W × 90 mm H × 317 mm D half rack (8.5 × 3.5 × 12.5 inches)

Weight: 3 kilograms (6.6 pounds)

Approval: CE Mark (consult Lake Shore for availability)

Ordering Information

Part number Description

Instrument

480 Fluxmeter

Specify line voltage when ordering

Instrument Accessories

RM-1/2 Rack Mount Kit for mounting one ½ rack fluxmeter in 482.6 mm rack

RM-2 Rack Mount Kit for mounting two ½ rack fluxmeters in 482.6 mm rack

4004 IEEE-488 cable, 1 meter

119-028* Model 480 User's Manual

106-739* Terminal Block Mating Connector (8 pin, quantity 2)

Probes and Coils (ordered separately)

FNT-6R04-100 Field Probe (100 cm2)

FNT-5R04-30 Field Probe (30 cm2)

FH-2.5 Helmholtz Coil (2.5 inch I.D.)

FH-6 Helmholtz Coil (6 inch I.D.)

FH-12 Helmholtz Coil (12 inch I.D.)

FCBL-6 User Programmable Cable with PROM (6 feet long)

Custom probes/coils/fixtures available (consult Lake Shore for more information)

* Accessories/options included with a new Model 480.

Introduction 1-3

Lake Shore Model 480 Fluxmeter User’s Manual

1.3 SAFETY SUMMARY

Observe these general safety precautions during all phases of instrument operation, service, and

repair. Failure to comply with these precautions or with specific warnings elsewhere in this manual

violates safety standards of design, manufacture, and intended instrument use. Lake Shore assumes

no liability for Customer failure to comply with these requirements.

The Model 480 protects the operator and surrounding area from electric shock or burn, mechanical

hazards, excessive temperature, and spread of fire from the instrument. Environmental conditions

outside of the conditions below may pose a hazard to the operator and surrounding area.

• Indoor use.

• Altitude to 2,000 meters.

• Temperature for safe operation: 5 °C to 40 °C.

• Maximum relative humidity: 80% for temperature up to 31 °C decreasing linearly to 50% at 40 °C.

• Power supply voltage fluctuations not to exceed ±10% of the nominal voltage.

• Overvoltage category II.

• Pollution degree 2.

Ground The Instrument. To minimize shock hazard, connect the instrument chassis and cabinet to an

electrical ground. The instrument is equipped with a three-conductor AC power cable. Plug the power

cable into an approved three-contact electrical outlet or use a three-contact adapter with the grounding

wire (green) firmly connected to an electrical ground (safety ground) at the power outlet. The power jack

and mating plug of the power cable meet Underwriters Laboratories (UL) and International

Electrotechnical Commission (IEC) safety standards.

Ventilation. The instrument has ventilation holes in its top and bottom covers. Do not block these holes

when the instrument is turned on.

Do Not Operate In An Explosive Atmosphere. Do not operate the instrument in the presence of

flammable gases or fumes. Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

Keep Away From Live Circuits. Operating personnel must not remove instrument covers. Refer

component replacement and internal adjustments to qualified maintenance personnel. Do not replace

components with power cable connected. To avoid injuries, always disconnect power and discharge

circuits before touching them.

Do Not Substitute Parts Or Modify Instrument. Do not install substitute parts or perform any

unauthorized modification to the instrument. Return the instrument to an authorized Lake Shore

Cryotronics, Inc. representative for service and repair to ensure that safety features are maintained.

Cleaning. Do not submerge instrument. Clean only exterior with a damp cloth and mild detergent.

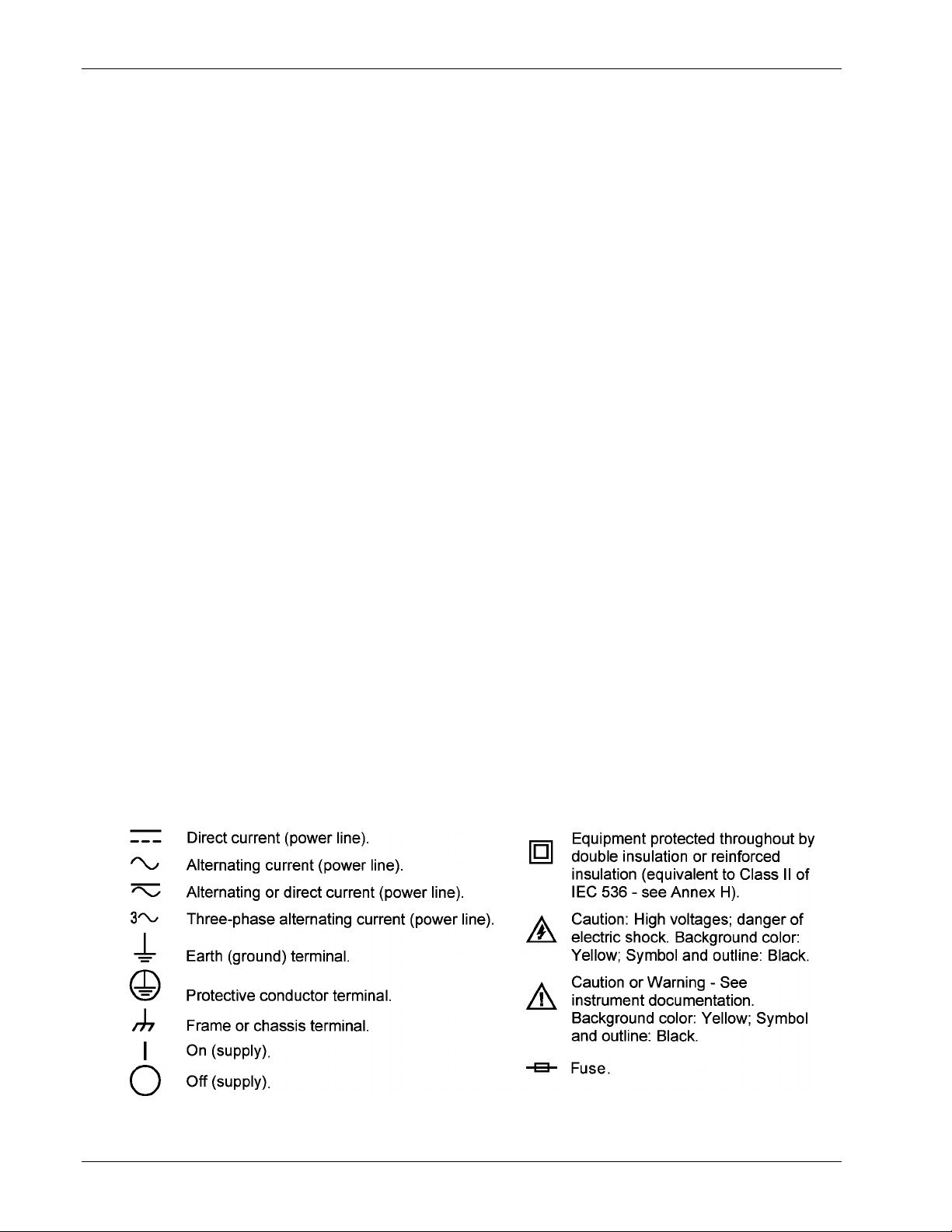

1.4 SAFETY SYMBOLS

1-4 Introduction

Lake Shore Model 480 Fluxmeter User’s Manual

CHAPTER 2

MAGNETIC MEASUREMENT OVERVIEW

2.0 GENERAL

This chapter provides an overview of magnetic measurements relating to the operation of the Lake

Shore Model 480 Fluxmeter. Integrating instruments is in Paragraph 2.1; coil characteristics in

Paragraph 2.2, flux overview in Paragraph 2.3, flux density overview in Paragraph 2.4, magnetic

moment overview in Paragraph 2.5, and magnetic potential overview in Paragraph 2.6.

2.1 INTEGRATING INSTRUMENTS

2.1.1 What Is An Integrator?

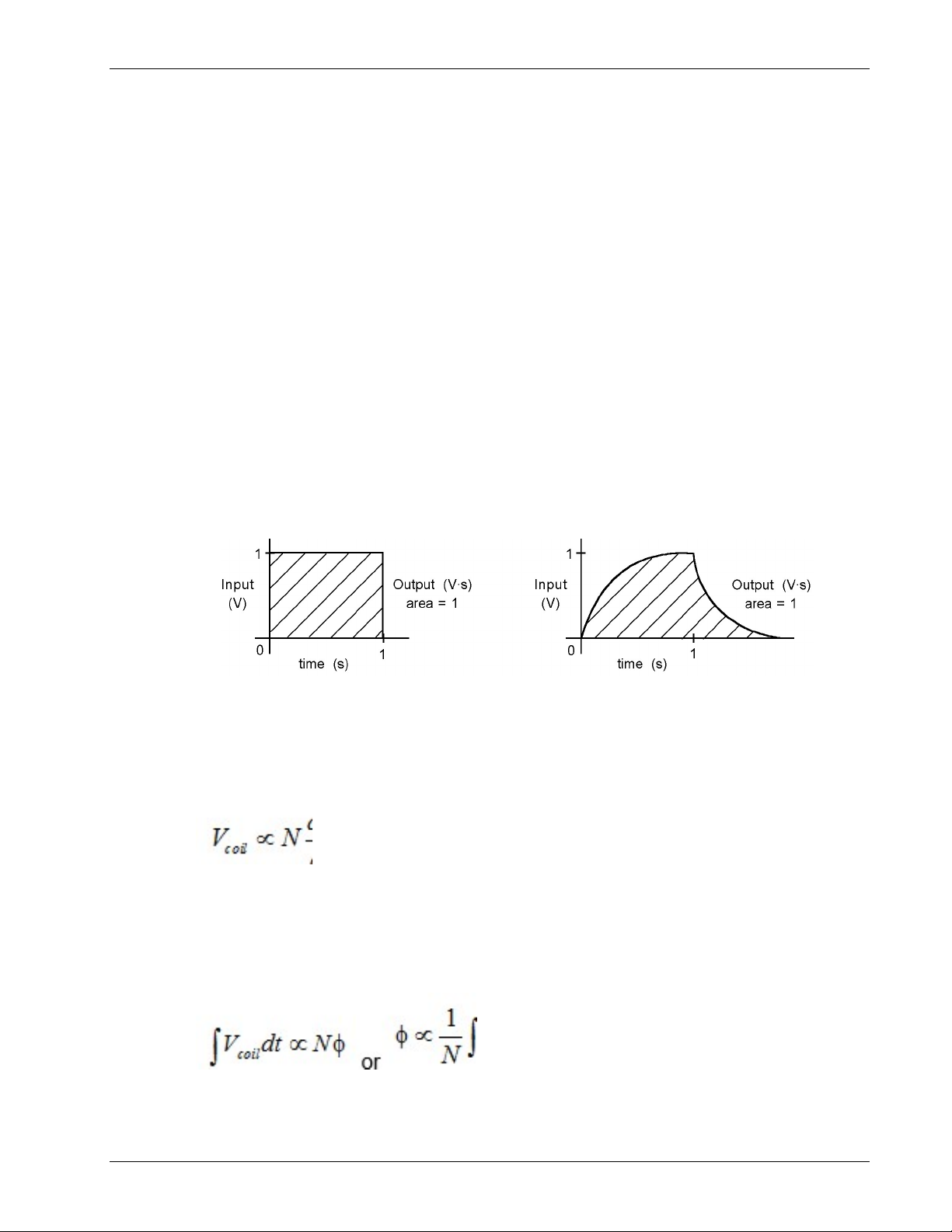

The output of the integrator in a fluxmeter is proportional to () the voltage at its input as it varies

with time. In the most simple example, a voltage of 1 volt (V) present at the input of a fluxmeter for

1 second (s) results in a reading of 1 volt second (V·s). Volt seconds are the primary unit of

measurement for an integrator. The product of volts and seconds is the area under the voltage line if

it were plotted on a graph against time. When the input voltage changes in an irregular way,

integrator output cannot be calculated by simply multiplying voltage and time. The integrator reacts

continuously to the changing input to give an accurate area measurement.

C-480-2-1.eps

2.1.2 Why Integrators Are Used For Magnetic Measurement

Integrators are used in magnetic measurements because of the physical relationship between coils of

wire and magnetic flux (). The instantaneous voltage produced across a coil (V

the number of turns in the coil (N) times the rate of change in flux (d/dt):

It is inconvenient to use this relationship directly for DC measurements because the voltage

disappears as soon as the flux stops changing. The voltage is also proportional to the rate of change

in flux and not the total change in flux which is often the desired measurement. If V

look at the area under V

plotted against time, the above problems disappear. The integrator output

coil

is proportional to the total change in flux and rate of change does not matter. Expressed

mathematically:

) is proportional to

coil

is integrated to

coil

Magnetic Measurement Overview 2-1

Lake Shore Model 480 Fluxmeter User’s Manual

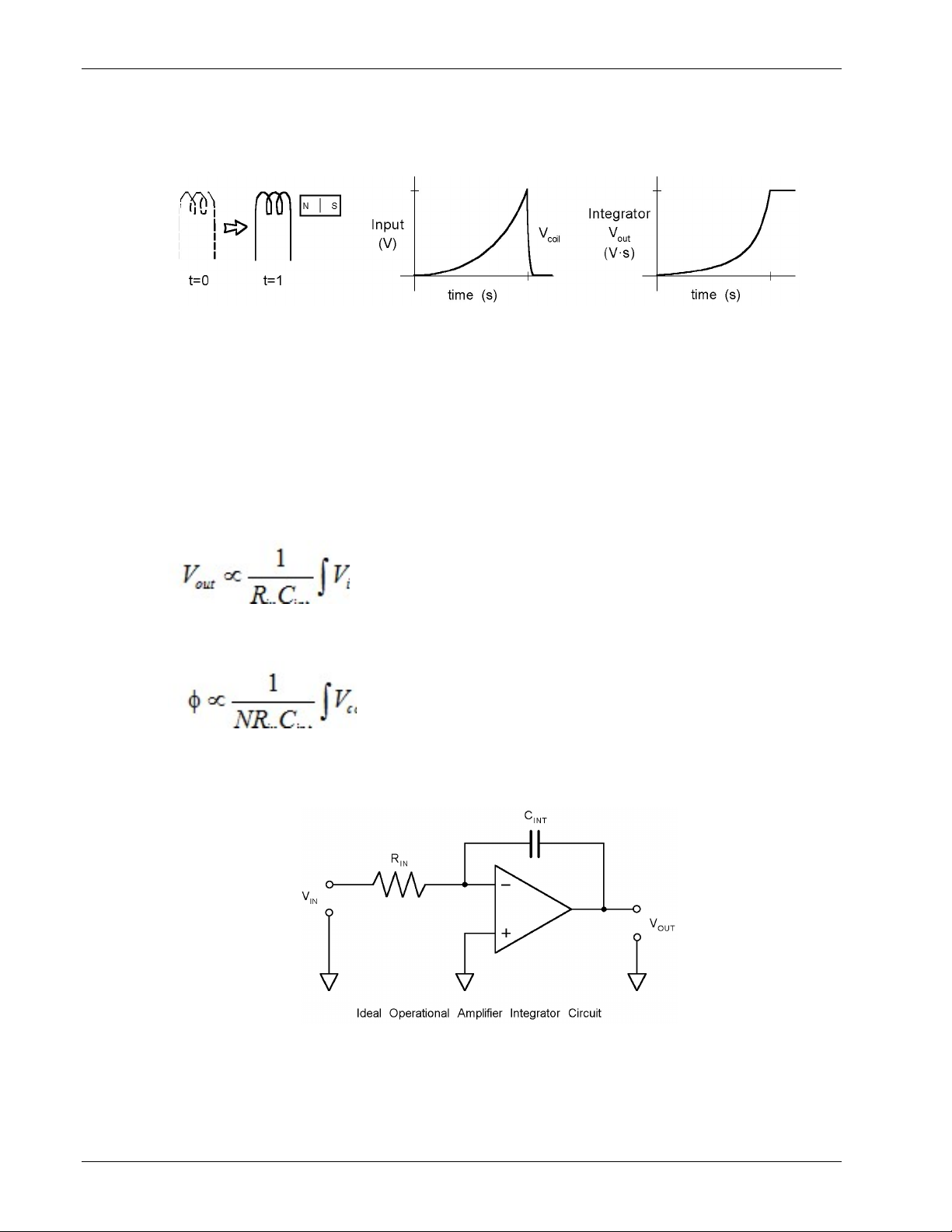

Why Integrators Are Used For Magnetic Measurement (Continued)

The total flux change can be measured with a fluxmeter as a coil moves near a magnet or as a

magnet moves near a coil.

C-480-2-2.eps

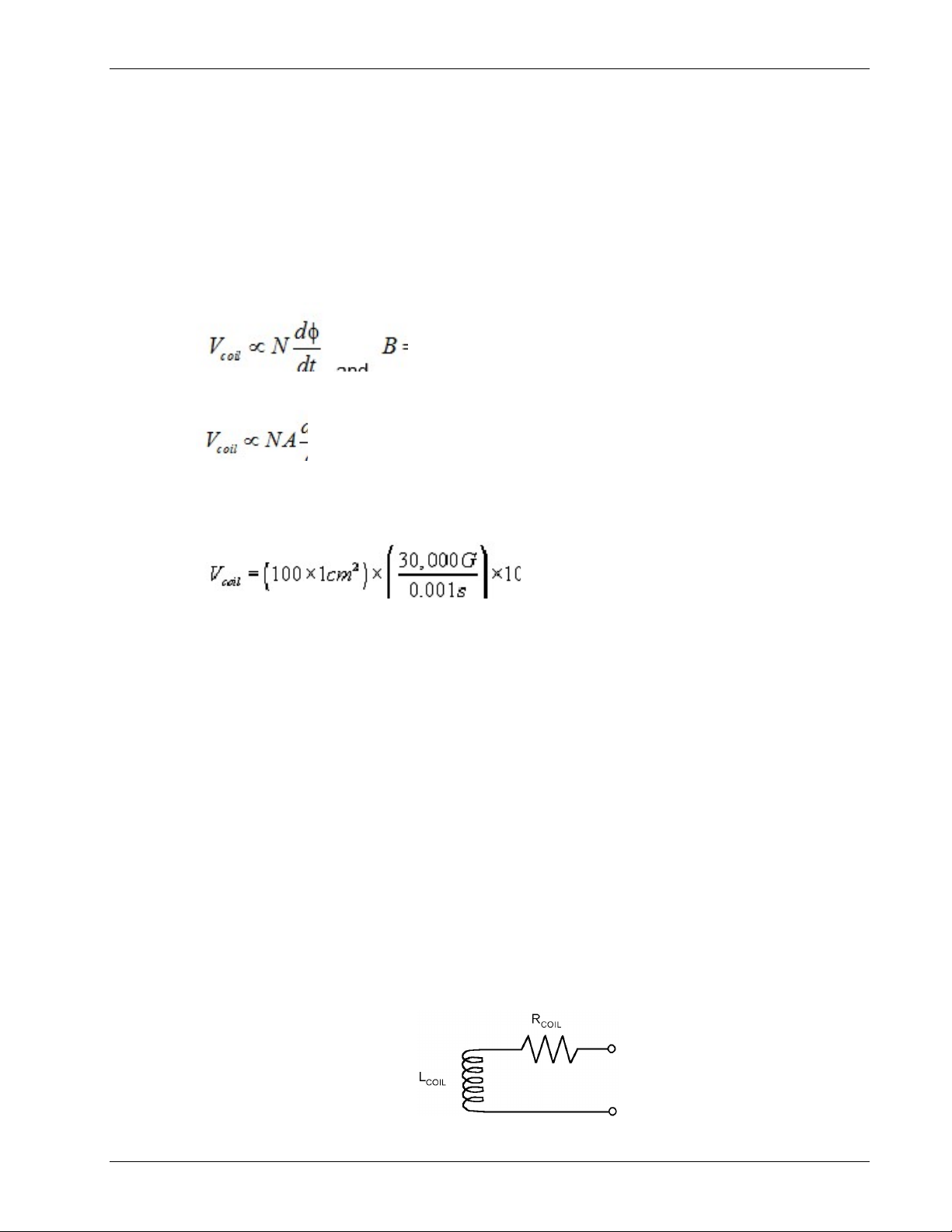

2.1.3 Important Integrator Characteristics

Some parameters that describe the integrator in a fluxmeter are familiar like range and resolution. If

the measurement range is too small, an over range condition can exist. If the range is too large, there

is not enough resolution to make accurate measurements. Available integrator ranges should be

taken into account when designing sensing coils. Ranges are often expressed in volt seconds which

is the fundamental measurement of the integrator. Range can be expressed in flux units if the number

of coil turns is known.

Some characteristics of integrators are not seen in other measurements. Two components dominate

the behavior of an integrator, its input resistance (Rin) and integrating capacitor (C

for a voltage integrator is:

The product Rin C

considered the integrator gain. A more complete expression for flux is:

is called the integrator time constant, but for practical purposes, 1/RinC

int

In the ideal case, Rin and C

could be any value and only their product would matter. In reality there

int

are practical limits to both. Instrument manufacturers optimize the two values for best performance.

Many specifications are given based on specific values of Rin and C

int

).The expression

int

can be

int

.

C-480-2-3.eps

For most users, the choice of fluxmeter Rin and C

has little meaning to their measurement. There

int

are exceptions. The integrator resistance is the sum of input resistance and coil resistance. Coil

resistance must be accounted for when it is a meaningful percentage of Rin. Refer to Paragraph 2.2.3

for more details.

2-2 Magnetic Measurement Overview

Important Integrator Characteristics (Continued)

Lake Shore Model 480 Fluxmeter User’s Manual

Other integrator characteristics that may affect measurements are drift, maximum input voltage, and

maximum and minimum rate of input change. These characteristics are a result of fluxmeter design;

the user often has little control. Check specifications carefully before choosing a fluxmeter for any

application or designing a coil for a fluxmeter.

2.1.4 Reducing Integrator Drift

Drift is the most noticeable and often the largest source of error in integrating fluxmeters. Drift is a

slow change in reading when no change in flux exists. It is caused by any small error voltage at the

integrator input.

Manufacturers spend significant time and effort reducing the drift in instrument integrators.

Component type and value, circuit board layout and manufacturing methods are all optimized to

reduce drift. Temperature change contributes so much to drift that critical components are often

thermally isolated from other parts of the circuit.

Low drift is a result of good fluxmeter design, but users can do things to maintain low drift:

1. Use the instrument on the range specified for lowest drift.

2. Attach sensing coil leads tightly and avoid unnecessary junctions or connections.

3. Keep drafts or other temperature changes away from the coil lead contacts.

4. Allow the instrument to warm up before drift is adjusted and adjust drift as often as practical

during use.

5. Reset the integrator often, before every critical measurement if possible.

Some instruments have built in software algorithms that help adjust drift to zero before measurement.

Other algorithms work in a different way to cancel drift during measurement. It is important to

understand the difference and the affects on measurements.

2.1.5 Dielectric Absorption

All capacitors exhibit a characteristic that can be described as a tendency to rebound from any fast

change. When capacitors are discharged to zero volts momentarily, a small voltage will rise a few

seconds later across the capacitor. Likewise, a rapid charge of a capacitor to some voltage will be

followed by a slight reduction of that potential occurring over several seconds. This characteristic is

usually referred to as Dielectric Absorption. The effect of dielectric absorption in the Model 480

fluxmeter is a slight reading change over several seconds after a larger reading change. This occurs

predictably during reading changes from 0 to some level and more notably occurs when the reading

is reset. A reset from a large, full scale reading will show a “creeping up” of the reading for several

seconds after the reset. The level of this effect is approximately 0.03% of the reading change. The

effect is most noticeable in the first few seconds and stabilizes after 20-30 seconds. For the most

accurate reset of larger measurements an initial reset should be followed by a second reset a few

seconds later.

As inconvenient as this is, capacitor limitations create this condition and cannot be easily remedied.

The capacitor selection for the Model 480 included testing of many vendors and capacitor dielectric

types. The selected capacitors offer the best overall characteristics including that of dielectric

absorption. It is felt that even though this is certainly a source of error for all analog integrating

fluxmeters, the Model 480 is capable of seeing this characteristic with it’s increased resolution while

others have simply ignored it. During instrument factory calibration readings are taken 1 to 2 seconds

after any signal transition. DC Peak, AC and AC Peak readings do not suffer from this anomaly.

Magnetic Measurement Overview 2-3

Lake Shore Model 480 Fluxmeter User’s Manual

2.1.6 Analog Versus Digital Integrators

Most of the integrator discussion in this manual is based on analog integrators. Analog integrators are

made with analog amplifiers, resistors and capacitors. Digital integrators approximate the action of

analog integrators by combining voltage sampling and software integration algorithms. There are

advantages and disadvantages to both types of integrators.

The performance of digital circuitry continues to improve and the price continues to decline. There are

now few analog functions that cannot be approximated digitally. Digital circuits are generally smaller

and have fewer discrete components. Their behavior is more repeatable with fewer calibrations.

Digital integration is likely the best choice to integrate predictable and well behaved signals.

Analog circuit technology is not standing still. Fast changing, high voltage, or very low voltage signals

are still integrated most accurately with analog integrators. The general purpose Model 480 uses an

analog integrator. The instrument must perform well with any type of input signal. The digital circuitry

surrounding the analog integrator offers most of the advantages of a fully digital circuit.

2.1.7 Fluxmeter Measurements In Magnetizers

Magnet materials such as Alnico and Samarium Cobalt are not permanent magnets until they are

conditioned in a magnetizer. The magnetizer produces strong fields by passing current through a coil

fixture. The magnetizer and coil fixture are optimized based on the magnet material and shape. If the

magnetizing field is not strong enough the magnet will not be fully magnetized.

Best cycle times and coil life are achieved when the magnetizer is operated at the minimum voltage

required to attain the needed magnetic field. The Model 480 provides an easy way to measure the

peak field when the magnetizer voltage is being determined during initial setup. Peak field is best

measured in an empty magnetizer fixture. During production magnetizing fixtures age and it is not

uncommon for a coil turn to short. Magnetizer current measurements are not enough to identify many

fixture problems. Peak field should be measured periodically as part of a quality control process and

to determine the general health of the fixture.

Many users want a way to determine if the Model 480 is fast enough to capture the peak field

generated by their magnetizer. The remainder of this section describes how the Model 480 can be

used with even the fastest magnetizers if the sense coil is designed properly. Discussion begins with

an approximation of the wave shape of the field generated by a magnetizer. The maximum rate of

change is then identified and it is shown how that rate of change is the only true limit on peak speed.

Finally coil sensitivity is discussed and examples are given of how to determine appropriate area

turns of a coil.

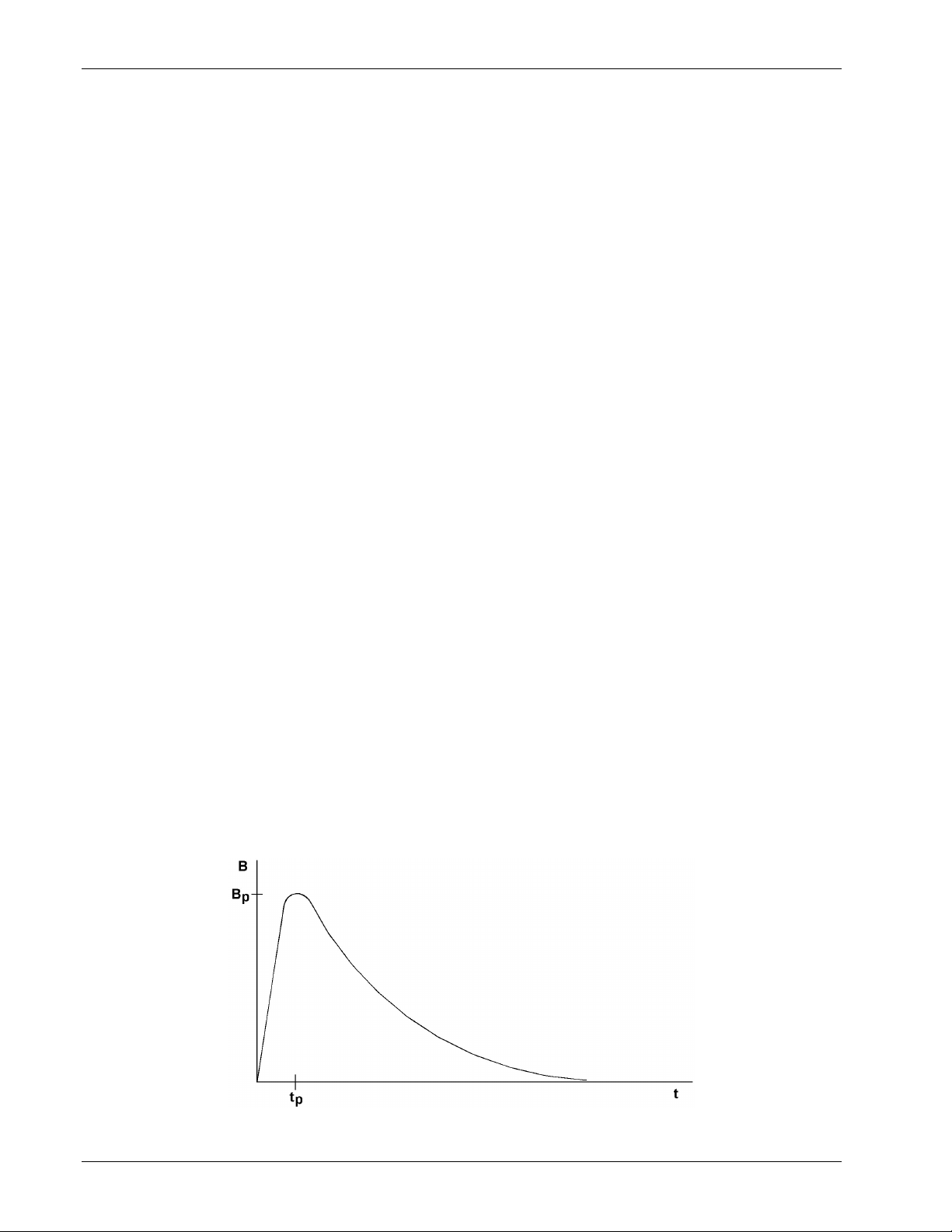

2.1.7.1 The Magnetizer Pulse

In many cases the magnetizer current is provided by a quick, high current discharge of a capacitor

bank. The shape of the magnetic field during this discharge is shown in the figure below.

P-Mag_pulse.bmp

2-4 Magnetic Measurement Overview

Lake Shore Model 480 Fluxmeter User’s Manual

The Magnetizer Pulse (Continued)

The time “tp” to reach peak magnetic field “Bp” is considered the rise time of the pulse. These are

two important parameters to consider when selecting or designing the sense coil for the 480.

2.1.7.2 Coil Output Voltage Limits

Because of slew rate requirements and safety considerations, the maximum voltage at the coil

output should be limited to 60 volts. The Model 480 Fluxmeter is capable of measuring the fastest

of magnetizer pulses, so long as the 60 volt limit is not exceeded. Therefore, the area turns of the

coil must be matched to the peak field and rise time of the magnetic field pulse.

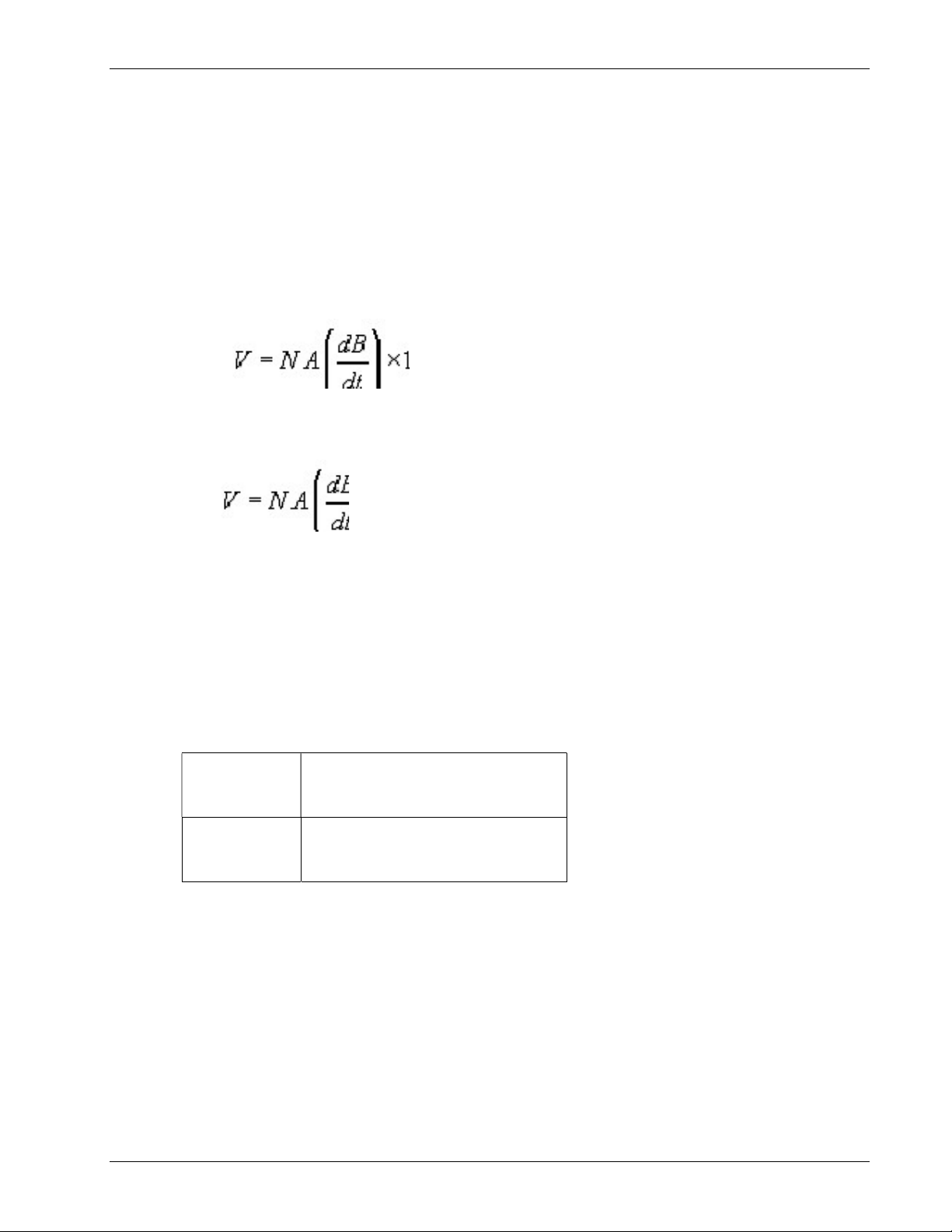

The equation for calculating the coil voltage in CGS units is:

where V = volts, A = cm2, B = gauss, N = number of coil turns, and t = seconds.

The equation for calculating the coil voltage in SI units is:

where V = volts, A = meters2, B = tesla, N = number of coil turns, and t = seconds.

2.1.7.3 Calculation of Minimum Rise Time

What is the fastest pulse allowable? When the area·turns (NA) of the coil and the desired peak field

(Bp) are known, the above equations can be used to calculate the minimum rise time.

tp = NAB/V (SI units)

Calculations of minimum rise times are given for two standard Lake Shore probes.

V = 60 volts and cm2 × 10-4 = meters2

NA = 30 cm2

If Bp = 3 tesla, tp > 150 s

If Bp = 5 tesla, tp > 250 s

If Bp = 7 tesla, tp > 350 s

NA = 100 cm2

If Bp = 3 tesla, tp > 500 s

If Bp = 5 tesla, tp > 833 s

If Bp = 7 tesla, tp > 1200 s (1.2 ms)

2.1.7.4 Calculation Of Area·Turns

Often the user will make his own coil to be used with a specific magnetizing fixture. The maximum

areaturns (NA) needs to be calculated, to ensure the 60 volt input limit is not exceeded. The

equation below can be used.

NA Vtp/Bp meters2 (SI units)

For example, if the rise time tp is 5 s and the peak field Bp is 3 tesla, then the following is a

calculation of the maximum areaturns (NA) to ensure the coil voltage will not exceed 60 volts.

NA (60V) (5 × 10-6 s) / 3 T = 1 × 10-4 meter2 = 1 cm2

Magnetic Measurement Overview 2-5

Lake Shore Model 480 Fluxmeter User’s Manual

2.1.8 Making AC Measurements

Traditionally, integrating fluxmeters make DC flux measurements where the measured field changes

in a non-periodic way. With only slight modifications to the integrator, a fluxmeter can measure

periodic AC fields. AC measurements are useful in measuring stray fields around transformers or the

poles of a rotating magnet.

A simple expression for a sinusoidal AC flux ((t)) as it varies with time is:

where

is the maximum amplitude of flux, f is the frequency, and t is time.

max

The voltage generated by a sense coil in a field changing this way is proportional to the derivative of

the field:

Note that coil voltage amplitude depends on frequency (f) and flux amplitude (

).

max

The integrator in the instrument reverses the action of the coil and removes the direct frequency

dependence:

The integrator output voltage can be processed by a peak detector to find

converter to find the RMS flux value. The relationships hold true for non-sinusoid AC fields also.

MAX

or through an RMS

The above discussion assumes that the coil inductance and capacitance are small and that the

frequency band of the instrument is not exceeded. Refer to Paragraph 2.2.8 for more details.

2.2 COIL CHARACTERISTICS

One reason fluxmeters are popular is the low cost and simple construction of sensing coils. Some coils

are as simple as a few turns of copper wire. Coil construction gets more complicated to meet special

measurement needs. The inclusion of magnetic materials or special geometries can make a coil a

specialized measurement tool.

2.2.1 Coil Sensitivity

Sensitivity is the instantaneous voltage (V

seen in the equation

) produced for a given rate of change in flux (d/dt). As

coil

the coil voltage is directly proportional to the number of turns (N), as well as the rate of change in flux.

Total change in flux can be measured as the fluxmeter integrates the instantaneous voltage over the

measurement interval.

The following is an example of coil sensitivity related to a permanent magnet. Consider a permanent

magnet has a pole area (A) = 1 cm2 and internal flux density (B) of 1000 G. The flux () = BA =

1,000 Mx. A typical coil of 100 turns (N) that fits snugly around the magnet pole generates an

integrator output of 1000 Mx times 100 turns = 105 MxN = 1mV·s as the magnet is moved into the

coil. A coil of more turns would give a larger output.

2-6 Magnetic Measurement Overview

Coil Sensitivity (Continued)

Number of turns is important to coil design because it determines coil sensitivity. Ideally, increasing

the number of turns always improves coil sensitivity, but in the real world, several factors limit the

number of turns. The most important are coil size, DC resistance of the wire, and peak output voltage.

It is possible for a coil to be too sensitive. Coils should be designed so the instantaneous coil voltage

does not exceed the rated input voltage of the integrator. Magnetizers can create very large

instantaneous coil voltages because their flux changes so quickly (d/dt is large). It is not difficult to

calculate the maximum instantaneous coil voltage if the maximum rate of field change is known.

Using the equations:

Lake Shore Model 480 Fluxmeter User’s Manual

gives us

If V

is in volts, N in turns, A in cm2, B in gauss, and t in seconds, V

coil

magnetizer of modest energy can achieve a flux density change (dB) of 3 T (30,000 G) in 1 ms (dt).

If a coil of 1 cm2 area (A) and 100 turns (N) is in that field, the voltage generated during firing is:

Note that high energy magnetizers with faster rise times can produce dangerous voltages with many

fewer turns.

2.2.2 Coil Size

Application often dictates coil size. Some low field coils may be several feet in diameter to contain

enough changing flux for a measurable coil voltage. Coils for high gradient fields are small as

possible so the coil area does not exceed the uniform field area. Coil size often limits the number of

turns and therefore the sensitivity.

Coils of any length can be used with a fluxmeter, from a single turn to a long solenoid. In practice, the

coil should be limited in length so the same flux lines link all turns. Substantial error occurs when the

flux lines curve out of the coil and link only part of the turns. The fluxmeter assumes all of the turns

see the same flux.

Some coil geometries count on coil length to achieve specific measurement goals. Coil length can

help eliminate the effect of field non-uniformity (Paragraph 2.2.6) or measure magnetic potential

(Paragraph 2.6).

= NA(dB/dt) 10-8. A

coil

2.2.3 Coil Resistance

Coil resistance is sometimes overlooked because it does not appear in ideal equations for a coil or

integrator, but it can limit sensitivity. Wire does have resistance and with enough turns it can become

applicable. Coil resistance must be accounted for when it is a meaningful percentage of the integrator

input resistance.

C-480-2-4.eps

Magnetic Measurement Overview 2-7

Coil Resistance (Continued)

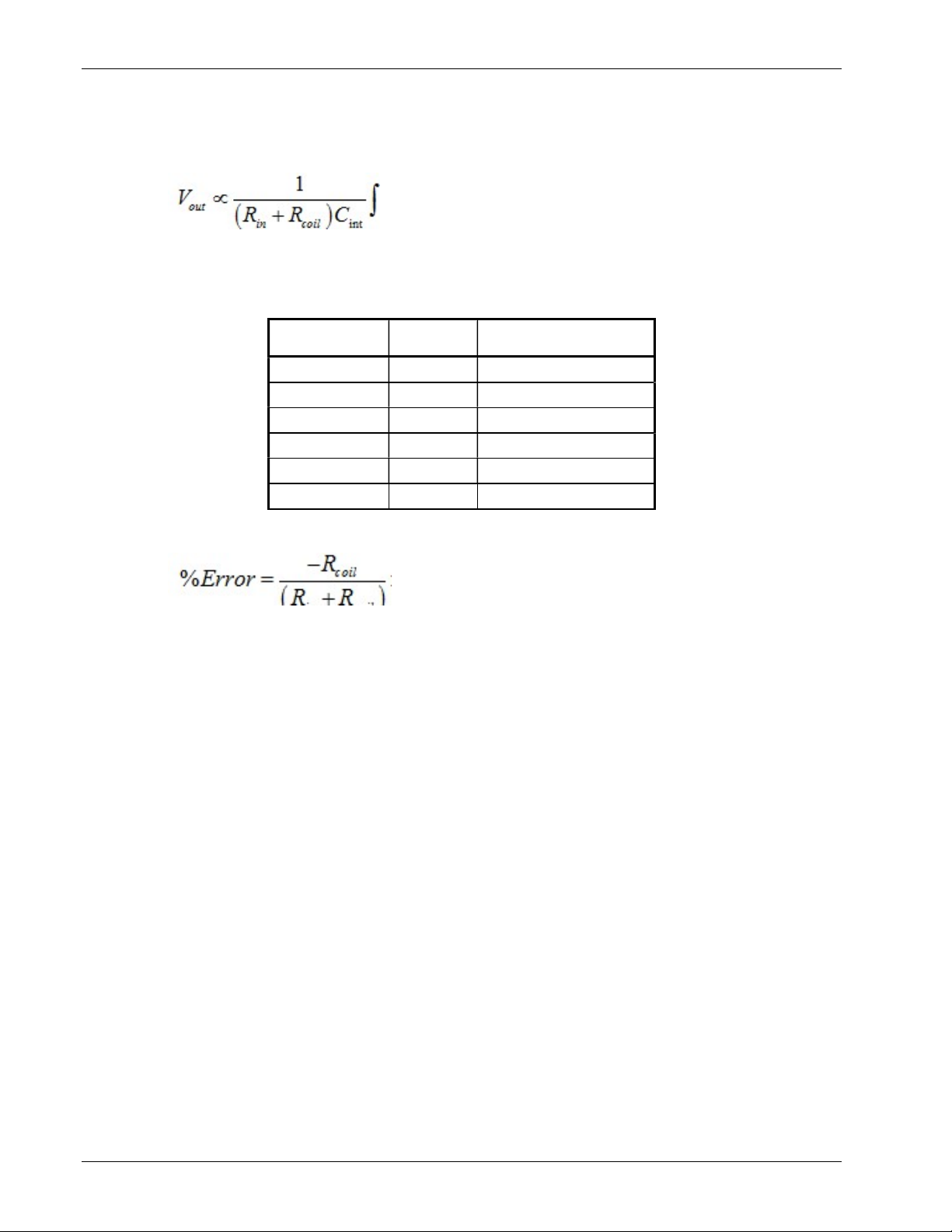

The DC resistance of the coil must be added to the input resistance of the integrator to get an

accurate volt second reading. The expression for a voltage integrator becomes:

Lake Shore Model 480 Fluxmeter User’s Manual

Manufacturers specify integrator resistance for a fluxmeter typically between 1 k to 100 k.

Table 2-1 lists examples of copper wire resistance.

Table 2-1. Examples of Copper Wire Resistance

AWG Annealed

Copper

O.D. inches

at 20 °C

Ohms per 1,000 feet

at 20 °C

40 0.0031 1079.2

38 0.0040 648.2

36 0.0050 414.8

34 0.0063 261.3

32 0.0080 162.0

30 0.0100 103.7

To calculate the percentage error in reading due to coil resistance:

As an example, if R

= 100 k and R

in

= 1 k, an error of -1% results. If R

coil

= 10 k and R

in

an error of -9.1% results if coil resistance is not taken into account.

= 1 k,

coil

2.2.4 Coil Temperature Coefficient

Since coil resistance is temperature dependent, care must be taken when large temperature changes

are expected. The temperature coefficient of resistance for copper magnet wire is +0.4%/°C

(+0.22%/°F). For example, a temperature increase of 10 °C in a 1000 coil causes a resistance

increase of 40 to 1040 . If R

changes from -9.1% to -9.43%.

2.2.5 Coil Orientation

Coil voltage is related to the number of changing flux lines passing through the center of the coil. The

flux measured is a true indication of the number of lines passing through. The angle of the flux lines

passing through the coil does not matter, that is not to say that the orientation of a coil to a magnet

does not matter. Changing coil orientation relative to a magnet often changes the number of flux lines

that pass through the coil. Orient the coil perpendicular to the flux lines for the most repeatable

measurements.

= 10 k, the attenuation from R

in

in the Paragraph 2.2.3 example

coil

2-8 Magnetic Measurement Overview

Lake Shore Model 480 Fluxmeter User’s Manual

2.2.6 Field Uniformity

Flux measurement is a true indication of lines of flux passing through a coil. Field uniformity does not

affect flux measurement, but other magnetic measurements such as flux density assume uniform flux

over the coil area. When measuring flux density in a non-uniform field, the fluxmeter reads the

average flux density.

There are some unique coil configurations that help eliminate the effect of field non-uniformity. The

length to outer diameter ratio of a coil can be optimized to measure flux density at the center of the

coil rather than the average flux density. For more information consult:

Zijlstra, H. Experimental Methods in Magnetism, Wiley, pg. 3, 1967.

Herzog & Tischler, Measurement of Inhomogeneous Magnetic Fields, Review of Scientific

Instruments, Vol. 24, pg. 1000, 1953.

2.2.7 Lead Pickup

Loops other than the sensor coil should be eliminated or minimized. Loops in lead wires see changing

flux just like a coil. Their voltage is an error added or subtracted from the coil voltage. Twisted leads

from the coil to the fluxmeter are recommended to reduce loop area and minimize error voltage.

2.2.8 Inductance, Capacitance, and Self Resonance

There are error sources that are only important when making AC or very fast peak DC

measurements.

Keep coil inductance (L

impedance of a coil due to inductance is 2 f L

) small, or it acts similar to coil resistance and reduces sensitivity. The real

coil

coil

resistance of the integrator, or the signal is attenuated. The attenuation changes with frequency

because the impedance does. The equation for calculating inductance of an ideal long solenoid is:

. That value should be small compared to the input

where 0 = 410-7 H/m, N = turns, A = area in m2, l = length in m, and L

Equations for flat search and Helmholtz coils are more complicated because there is no simple