Lakeshore 425 User Manual

User’s Manual

Model 425

Gaussmeter

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

Methods and apparatus disclosed and described herein have been developed solely on company funds of

Lake Shore Cryotronics, Inc. No government or other contractual support or relationship whatsoever has existed

which in any way affects or mitigates proprietary rights of Lake Shore Cryotronics, Inc. in these developments.

Methods and apparatus disclosed herein may be subject to U.S. Patents existing or applied for.

Lake Shore Cryotronics, Inc. reserves the right to add, improve, modify, or withdraw functions, design modifications,

or products at any time without notice. Lake Shore shall not be liable for errors contained herein or for incidental or

consequential damages in connection with furnishing, performance, or use of this material.

Rev. 1.0 P/N 119-053 24 March 2010

sales@lakeshore.com

service@lakeshore.com

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

| www.lakeshore.com

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: ONE (1) YEAR

1.Lake Shore warrants that this Lake Shore product (the "Product")

will be free from defects in materials and workmanship for the Warranty Period specified above (the "Warranty Period"). If Lake Shore

receives notice of any such defects during the Warranty Period and

the Product is shipped freight prepaid, Lake Shore will, at its option,

either repair or replace the Product if it is so defective without c harge

to the owner for parts, service labor or associated customary return

shipping cost. Any such replacement for the Product may be either

new or equivalent in performance to new. Replacement or repaired

parts will be warranted for only the unexpired portion of the original

warranty or 90 days (whichever is greater).

2.Lake Shore warrants the Product only if it has been sold by an authorized Lake Shore employee, sales representative, dealer or original

equipment manufacturer (OEM).

3.The Product may contain remanufactured parts equivalent to new

in performance or may have been subject to incidental use.

4.The Warranty Period begins on the date of delivery of the Product or

later on the date of installation of the Product if the Product is

installed by Lake Shore, provided that if you schedule or delay the Lake

Shore installation for more than 30 days after delivery the Warranty

Period begins on the 31st day after delivery.

5.This limited warranty does not apply to defects in the Product

resulting from (a) improper or inadequate maintenance, repair o r calibration, (b) fuses, software and non-rechargeable batteries, (c) software, interfacing, parts or other supplies not furnished by Lake Shore,

(d) unauthorized modification or misuse, (e) operation outside of the

published specifications or (f) improper site preparation or maintenance.

6. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER WARRANTY OR CONDITION,

WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED. LAKE

SHORE SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY QUALITY AND/OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THE PRODUCT.

Some countries, states or provinces do not allow limitations on an

implied warranty, so the above limitation or exclusion might not

apply to you. This warranty gives you specific legal rights and you

might also have other rights that vary from country to countr y, state

to state or province to province.

7.TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE REMEDIES IN

THIS WARRANTY STATEMENT ARE YOUR SOLE AND EXCLUSIVE REMEDIES.

8.EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, IN NO

EVENT WILL LAKE SHORE OR ANY OF ITS SUBSIDIARIES, AFFILIATES OR

SUPPLIERS BE LIABLE FOR DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR OTHER DAMAGES (INCLUDING LOST PROFIT, LOST DATA

OR DOWNTIME COSTS) ARISING OUT OF THE USE, INABILITY TO USE

OR RESULT OF USE OF THE PRODUCT, WHETHER BASED IN WARRANTY, CONTRACT, TORT OR OTHER LEGAL THEORY, AND WHETHER

OR NOT LAKE SHORE HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. Your use of the Product is entirely at your own risk.

Some countries, states and provinces do not allow the exclusion of liability for incidental or consequential damages, so the above limitation

may not apply to you.

9.EXCEPT TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE TERMS

OF THIS LIMITED WARRANTY STATEMENT DO NOT EXCLUDE, RESTRICT

OR MODIFY, AND ARE IN ADDITION TO, T HE MA NDATORY STAT UTORY

RIGHTS APPLICABLE TO THE SALE OF THE PRODUCT TO YOU.

CERTIFICATION

Lake Shore certifies that this product has been inspected and tested in

accordance with its published specifications and that this product

met its published specifications at the time of shipment. The accuracy

and calibration of this product at the time of shipment are traceable

to the United States National Institute of Standards and Technology

(NIST); formerly known as the National Bureau of Standards (NBS).

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 425 firmware is as

free of errors as possible, and that the results you obtain from the

instrument are accurate and reliable. However, as with any computer-based software, the possibility of errors exists.

In any important research, as when using any laboratory equipment,

results should be carefully examined and rechecked before final conclusions are drawn . Neither Lake Shore nor anyone else involved in the

creation or production of this firmware can pay for loss of time, inconvenience, loss of use of the product, or property damage caused by

this product or its failure to work, or any other incidental or consequential damages. Use of our product implies that you understand the

Lake Shore license agreement and statement of limited warranty.

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States copyright law and international treaty provisions. To maintain the warranty, the code contained in the firmware must not be modified. Any

changes made to the code is at the user's risk. Lake Shore will assume

no responsibility for damage or errors incurred as result of any

changes made to the firmware.

Under the terms of this agreement you may only use the Model 425

firmware as physically installed in the instrument. Archival copies are

strictly forbidden. You may not decompile, disassemble, or reverse

engineer the firmware . If you suspect there are problems with the

firmware, return the instrument to Lake Shore for repair under the

terms of the Limited Warranty specified above. Any unauthorized

duplication or use of the Mode l 425 firmware in whole or in p art, in

print, or in any other storage and retrieval system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers and sellers claim designations used to distinguish their products as trademarks. Where those designations appear

in this manual and Lake Shore was aware of a trademark claim, they

appear with initial capital letters and the ™ or ® symbol.

LabVIEW™ is a trademark of National Instruments.

Microsoft Windows®, Windows XP® and Windows Vista® are registered trademarks of Microsoft Corporation in the United States and

other countries.

WinZip™ is a trademark of Nico Mak of Computing, Inc.

Teflon® is a registered trademark of E.I. DuPont de Nemours and Co.

Manganin® is a registered trademark of Isabellenhütte Heuster Gmb

H & Co.

Copyright 2010 Lake Shore Cryotronics, Inc. All rights reserved. No portion of this manual may be reproduced, stored

in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording,

or otherwise, without the express written permission of Lake Shore.

Model 425 Gaussmeter

| www.lakeshore.com

The Model 425 is considered Waste Electrical and Electronic Equipment (WEEE) Category 9 equipment, therefore

falling outside the current scope of the RoHS directive. However, in recognition that RoHS compliance is in the best

interest of our customers, employees, and the environment, Lake Shore has designed the Model 425 to eliminate

the hazardous substances covered in the RoHS directive.

Model 425 Gaussmeter

i

Table of Contents

Chapter 1

Introduction

1.1 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 DC Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.3 AC Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Measurement Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Instrument Probe Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Probe Field Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2 Probe Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.3 The Probe Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.4 Extension Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.5 Hall Effect Generators (Magnetic Field Sensors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Display and Interface Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.1 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.2 Alarm, Relay and Sort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.3 Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.4 Computer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.5 Model 425 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Hall Probe Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.1 Axial Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.2 Transverse Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.3 Flexible Transverse Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Model 425 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.1 General Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.2 DC Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.3 AC Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.4 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6.5 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6.6 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.6.7 Probes and Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.7 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.8 Safety Summary and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2

Background

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.2 Model 425 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.1 DC Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.2 AC Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.3 Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Flux Density Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.1 What is Flux Density? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.2 How Flux Density (B) Differs from Magnetic Field Strength (H) . . . . . . . . . . . . . 12

2.4 Hall Measurement Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4.1 Active Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4.2 Temperature Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.4.3 Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 Probe Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.1 Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.2 Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.3 Gradient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5.4 Probe Durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.6 Probe Accuracy Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.1 Probe Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

| www.lakeshore.com

ii TABLE OF CONTENTS

2.6.2 Probe Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6.4 Off-Axis Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6.5 Induced AC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7 Cryogenic Measurement Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7.1 Thermal Stresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7.2 Temperature Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7.3 Probe Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.8 Hall Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 3

Installation

Chapter 4

Operation

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Inspection and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Rear Panel Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4 Line Input Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.1 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.2 Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.3 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5 Probe Input Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.6 Probe Handling and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.6.1 Probe Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.6.2 Probe Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.6.3 Probe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.7 Auxiliary I/O Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.8 Attaching a Hall Generator to the Model 425 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.8.1 Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.1 Keypad Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.2 General Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3 Display Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3.1 Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.2 Display Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4 Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.1 Field Units Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.2 Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5 DC and RMS Measurement Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5.1 DC Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5.1.1 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5.1.2 DC Operation Zero Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5.2 AC Measurement Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5.2.1 Narrow Band Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.5.2.2 Wide Band Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.5.3 Autorange and Range Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.5.4 Max Hold Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.5.5 Max Reset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.5.6 Relative Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6 Locking and Unlocking the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 5

Advanced

Operation

Model 425 Gaussmeter

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2 The Alarm and Relay Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.1 Low and High Alarm Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.2 Magnitude and Algebraic Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.3 Inside and Outside Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.2.4 Alarm Sort Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.2.5 Alarm Audible Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.2.6 Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

iii

5.2.7 Alarm and Relay Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.7.1Testing and Sorting of Discrete Magnets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.7.2Testing a Magnet Installed in an Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.2.7.3Monitoring a Static Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3 Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4 Probe Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4.1 Probe Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.4.2 Field Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.4.3 Extension Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.4.4 Clear Zero Probe Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.5 Hall Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5.1 User Programmable Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5.2 Ohms Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 6

Computer

Interface Operation

Chapter 7

Probes and

Accessories

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.2 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2.1 Physical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2.2 Hardware Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2.3 Installing the USB Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.2.3.1 Installing the Driver From Windows® Update in Windows Vista® . .46

6.2.3.2 Installing the Driver From Windows® Update in Windows® XP . . . . . 46

6.2.3.3 Installing the Driver From the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.2.3.3.1 Download the driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2.3.3.2 Extract the driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2.3.3.3 Manually install the driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.2.3.4 Installing the USB Driver from the Included CD-ROM . . . . . . . . . . . . . . . 48

6.2.4 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.2.4.1 Character Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2.4.2 Message Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2.5 Message Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

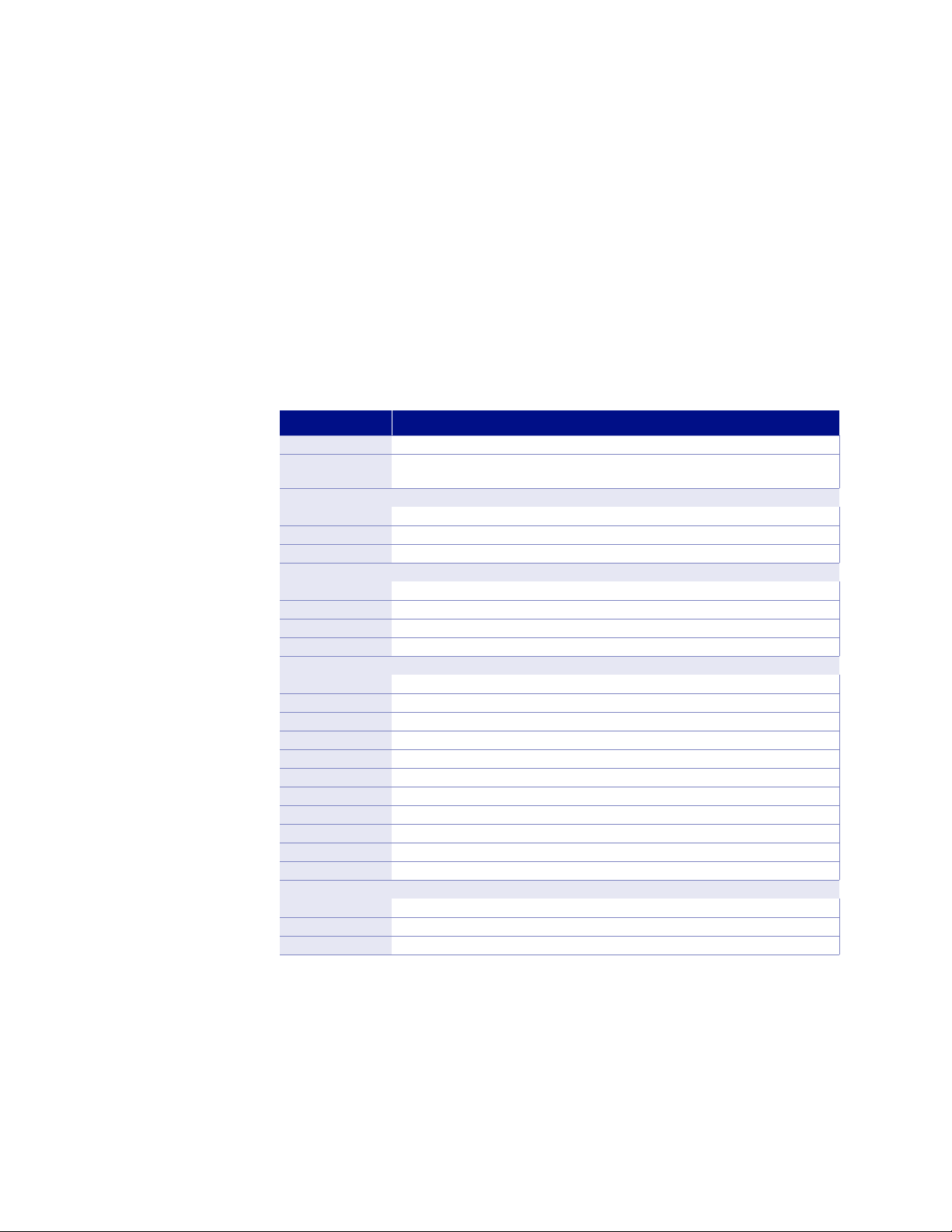

6.3 Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.3.1 Interface Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

7.2 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.4 Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.5 Probe Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.6 Hall Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter 8

Service

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8.2 General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.3 USB Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.3.1 New Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.3.2 Existing Installation No Longer Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.3.3 Intermittent Lockups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.4 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.5 Factory Reset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.5.1 Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.5.2 Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.6 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.7 Rear Panel Connector Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.8 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

8.9 Technical Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

| www.lakeshore.com

iv TABLE OF CONTENTS

8.9.1 Contacting Lake Shore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.9.2 Return of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.9.3 RMA Valid Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.9.4 Shipping Charges 68

8.9.5 Restocking Fee 68

Appendix A: Units for Magnetic Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Model 425 Gaussmeter

1.1 Product Description 1

Chapter 1: Introduction

FIGURE 1-1 Model 425 front view

1.1 Product Description

Features:

D Field ranges from 350 mG to 350 kG

D DC measurement resolution to 43/e digits (1 part of ±35,000)

D Basic DC accuracy of ±0.20%

D DC to 10 kHz AC frequency

D USB interface

D Large liquid crystal display

D Sort function (displays pass/fail message)

D Alarm with relay

D Standard probe included

D Standard and custom probes available

Designed to meet the demanding needs of the permanent magnet industry, the

Lake Shore Model 425 gaussmeter provides high end functionality and performance

in an affordable desktop instrument. Magnet testing and sorting have never been

easier. When used in combination with the built in relay and audible alarm features,

the Model 425 takes the guesswork out of pass/fail criteria. Additional features

including DC to 10 kHz AC frequency response, max hold and relative measurement

make the Model 425 the ideal tool for your manufacturing, quality control and R&D

flux density measurement applications. For added functionality and value, the

Model 425 also includes a standard Lake Shore Hall probe. Put the Model 425 gaussmeter to use with confidence knowing it’s supported by the industry leading experts

in magnet measurement instrument, sensor and Hall probe technology.

1.1.1 Throughput

Throughput involves much more than just the update rate of an instrument. An intuitive menu navigation and keypad, along with overall ease of use are equally important. The Model 425 is designed with these qualities in mind. The operation is

straightforward, with user display prompts to aid set-up. We understand that time is

money! In addition to being user friendly, the automated magnet testing and sorting

features of the Model 425 streamline sorting and testing operations. In addition, hot

swapping of Hall probes allows you to switch probe types without powering the

instrument off and back on. These features support increased productivity, allowing

you to spend less time setting up your instrument and more time working on the task

at hand.

| www.lakeshore.com

2 cHAPTER 1: Introduction

1.1.2 DC Measurement Mode

1.1.3 AC Measurement Mode

1.2 Measurement Features

Static or slowly changing fields are measured in DC mode. In this mode, the

Model 425 uses probe field compensation to correct for probe nonlinearities, resulting in a DC accuracy to ±0.20%. Measurement resolution is enhanced with internal

filtering, allowing resolution to 4¾ digits with reading rates to 30 readings per second over the USB interface.

In addition to the DC measurement mode, the Model 425 offers an AC measurement

mode for measuring periodic AC fields. The instrument provides an overall frequency

range of 10 Hz to 10 kHz and is equipped with both narrow and wide band frequency

modes. While in narrow band mode, frequencies above 400 Hz are filtered out for

improved measurement performance.

The Model 425 offers a variety of features to enhance the usability and convenience

of the gaussmeter.

Autorange: in addition to manual range selection, the instrument automatically

chooses an appropriate range for the measured field. Autorange works in DC and AC

measurement modes.

Probe zero: allows you to zero all ranges while in DC mode with the simple push

of a key.

Display units: field magnitude can be displayed in units of G, T, Oe, and A/m with

resistance in ).

Max hold: the instrument stores and displays the captured maximum DC or AC

field reading.

1.3 Instrument Probe Features

1.3.1 Probe Field Compensation

1.3.2 Probe Information

Relative reading: the relative mode calculates the difference between a live reading

and the relative setpoint to highlight deviation from a known field point. This feature

can be used in DC or AC measurement modes.

Instrument calibration: Lake Shore recommends an annual recalibration schedule

for all precision gaussmeters. Recalibrations are always available from Lake Shore,

but the Model 425 allows you to field calibrate the instrument if necessary. Recalibration requires a computer interface and precision low resistance standards of known

value.

The Model 425 offers the best measurement performance when used along with

Lake Shore Hall probes. Firmware-based features work in tandem with the probe’s

calibration and programming to ensure accurate, repeatable measurements and

ease of setup. Many of the features require probe characteristics that are stored in the

probe connector’s non-volatile memory.

The Hall effect devices used in gaussmeter probes produce a near linear response in

the presence of a magnetic field. The small nonlinearities present in each individual

device can be measured and subtracted from the field reading. Model 425 probes are

calibrated in a way to provide the most accurate DC readings.

The gaussmeter reads the probe information on power up or any time the probe is

changed to allow hot swapping of probes. Critical probe information can be viewed

on the front panel and read over the computer interface to ensure proper system configuration.

1.3.3 The Probe Connection

Model 425 Gaussmeter

The Model 425 is only half the magnetic measurement equation. For the complete

solution, Lake Shore offers a full complement of standard and custom Hall effect

probes in a variety of sizes and sensitivities. One of ten standard Hall probes is

included with the Model 425. Refer to page 5 for details on the Hall probes you can

choose to receive with the Model 425.

1.3.4 Extension Ca ble 3

1.3.4 Extension Cable

1.3.5 Hall Effect Generators (Magnetic Field Sensors)

1.4 Display and Interface Features

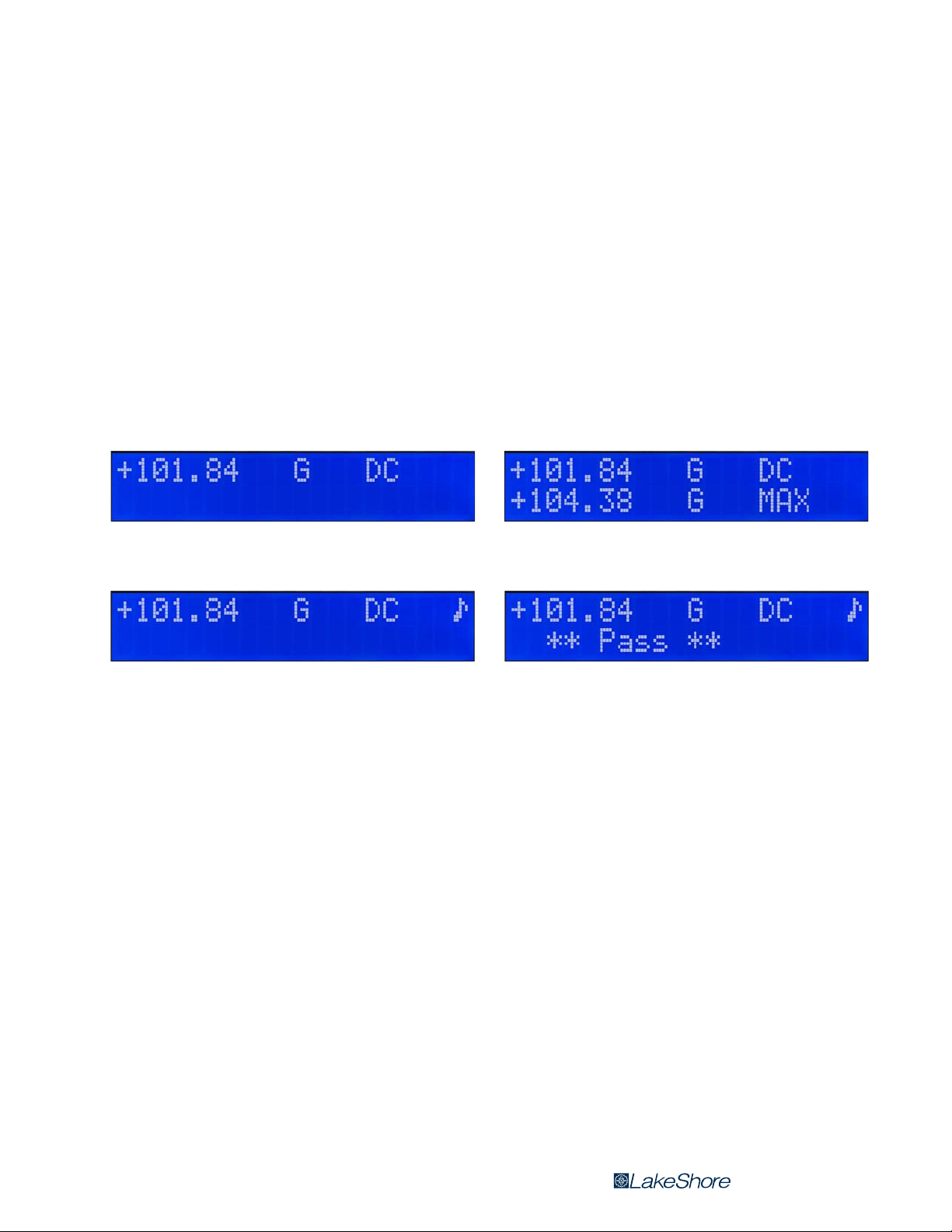

FIGURE 1-2 Left: Normal reading—the default mode with the display of the live DC field reading;

Right: Max DC hold on—the maximum value is shown in the lower display while the upper display contains the live DC field reading;

The complex nature of Hall effect measurements makes it necessary to match extension cables to the probe when longer cables are needed. Keeping probes and their

extensions from getting mixed up can become a problem when more than one probe

is used. The Model 425 alleviates most of the hassle by allowing you to match probes

to extension cables in the field. Stored information can be viewed on the front panel

and read over the computer interface to ensure proper mating.

The Model 425 will operate with a discrete Hall effect generator when a suitable

probe is not available. You can program the nominal sensitivity and serial number

into an optional HMCBL blank connector to provide all gaussmeter functions except

field compensation. If no sensitivity information is available, the Model 425 reverts to

resistance measurement.

The Model 425 has a 2-line by 20-character liquid crystal display. During normal

operation, the display is used to report field readings and give results of other features such as max or relative. When setting the instrument parameters, the display

gives you meaningful prompts and feedback to simplify operation.

Following are four examples of the various display configurations:

FIGURE 1-3 Left: Alarm on—the alarm gives an audible and visual indication of when the field value is selectively outside or inside a user

specified range; The relay can be associated with the alarm;

Right: Sort on—the live reading is shown in the upper display while the lower display contains the pass/fail (repetitive sorting or testing)

message. The relay facilitates pass/fail operation

1.4.1 Keypad

1.4.2 Alarm, Relay and Sort

1.4.3 Monitor Output

The instrument keypad has 14 keys with individual keys assigned to frequently used

features. Menus are reserved for less frequently used setup operations. The keypad

can be locked out to prevent unintended changes of instrument setup.

High and low alarm functions and one relay are included with the instrument, and

can be used to automate repetitive magnet testing and sorting operations. Alarm

actuators include display annunciator, audible beeper, and a relay. The alarm can be

configured to display a pass or fail message and the relay can be configured to activate a mechanism to separate parts that meet pre-set fail criteria. The relay can also

be controlled manually for other system needs.

The monitor output provides an analog representation of the reading that is corrected for probe offset and nominal sensitivity. This feature makes it possible to view

the analog signal, which has not been digitally processed. The monitor output can be

connected to an oscilloscope or data acquisition system.

| www.lakeshore.com

4 cHAPTER 1: Introduction

1.4.4 Computer Interface

1.4.5 Model 425 Rear Panel

1.5 Hall Probe Selection

The Model 425 is equipped with a universal serial bus (USB) interface. It emulates an

RS-232C serial port at a fixed baud rate of 57,600, but with the physical connections

of a USB. In addition to gathering data, nearly every function of the instrument can be

controlled through the USB interface. The reading rate over the interface is nominally

30 readings per second. A LabVIEW™ driver is available from the download section of

the Lake Shore website at www.lakeshore.com.

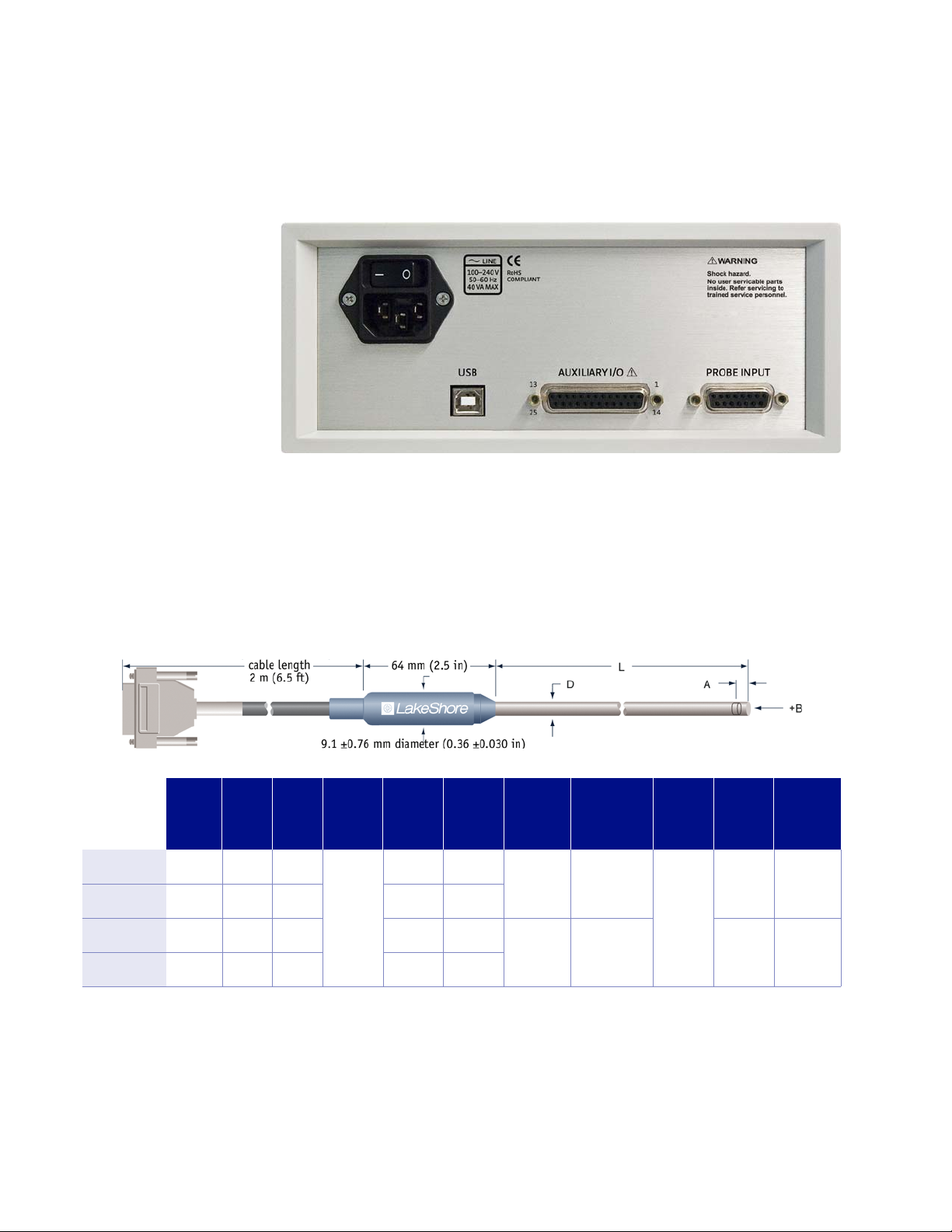

FIGURE 1-4 Model 425 rear panel showing the line input assembly,

USB interface, auxiliary I/O and the probe input

Listed below are the probes that you can choose from to include with your Model 425.

Our experts can guide you through the probe selection process. Other standard

probes are available at an additional cost. Lake Shore prides itself on making every

attempt to satisfy customer requests for special probes. If you need a custom probe,

contact Lake Shore for availability.

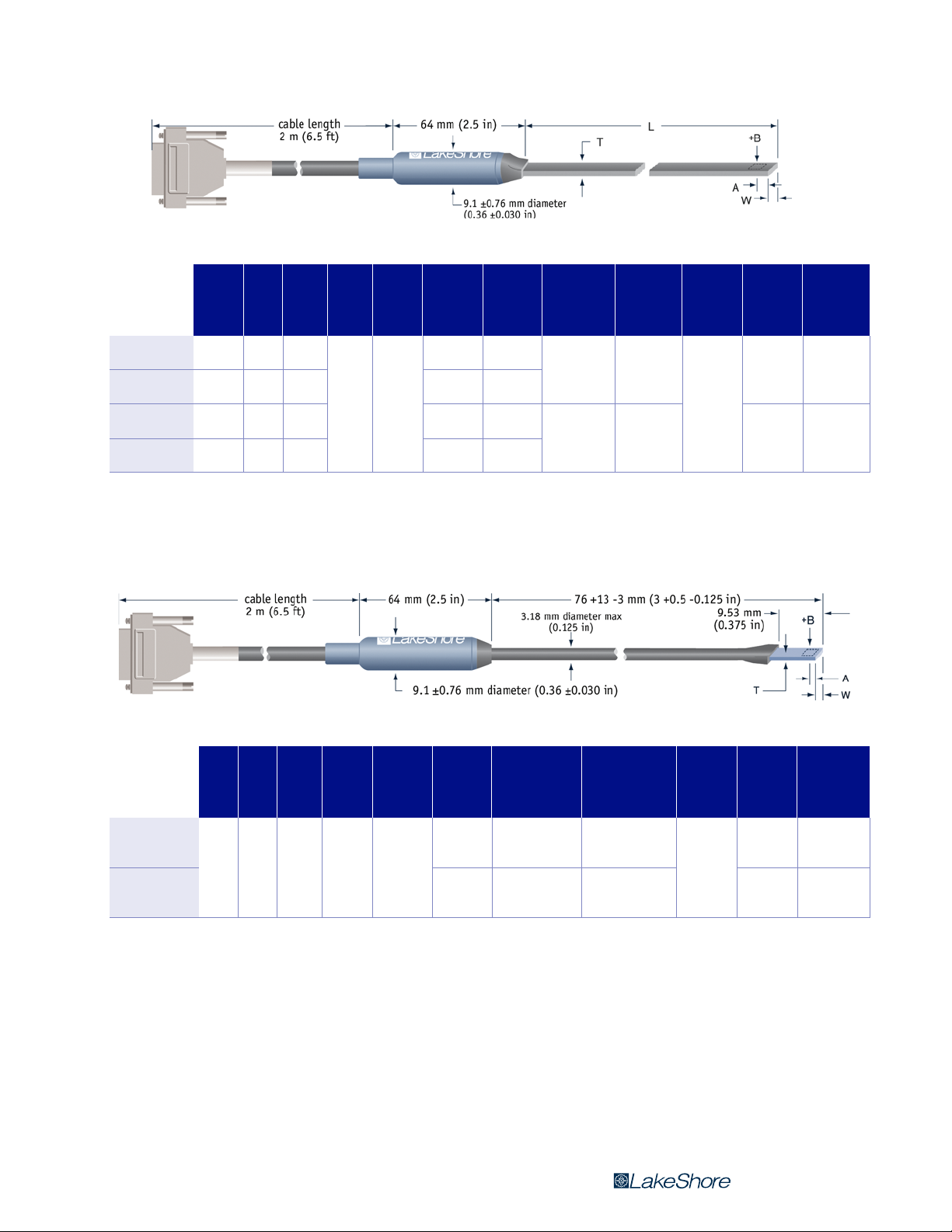

1.5.1 Axial Probes

L (in) D (in) A (in)

HMNA-1904-VR 4 ±0.125

HMMA-2502-VR 2 ±0.063

HMNA-1904-VF 4 ±0.125

HMMA-2502-VF 2 ±0.063

0.187 dia

±0.005

0.25 dia

±0.006

0.187 dia

±0.005

0.25 dia

±0.006

0.005

±0.003

0.015

±0.005

0.005

±0.003

0.015

±0.005

Active area

(in)

0.030 dia

(approx)

FIGURE 1-5 Axial probe

Stem

material

Fiberglass

epoxy

Aluminum

Fiberglass

epoxy

Aluminum

Frequency

range

DC to

10 kHz

DC to

10 kHz

DC to

800 Hz

DC to

400 Hz

TABLE 1-1 Axial probe

Usable full

scale ranges

HSE

35 G 350 G,

3.5 kG, 35 kG

HST-4

350 G, 3.5 kG,

35 kG

Corrected

accuracy

(% rdg)

±0.20% to 30 kG

and ±0.25% 30

to 35 kG

±0.10% to 30 kG

and ±0.15% 30

to 35 kG

Operating

temp

range

0 °C to

+75 °C

Tem p

coefficient

(max) zero

±0.09 G/°C -0.04%/°C

±0.13 G/°C -0.005%/°C

Tem p

coefficient

(max)

calibration

Model 425 Gaussmeter

1.5.2 Transverse Probes

1.5.2 Transverse Pr obes 5

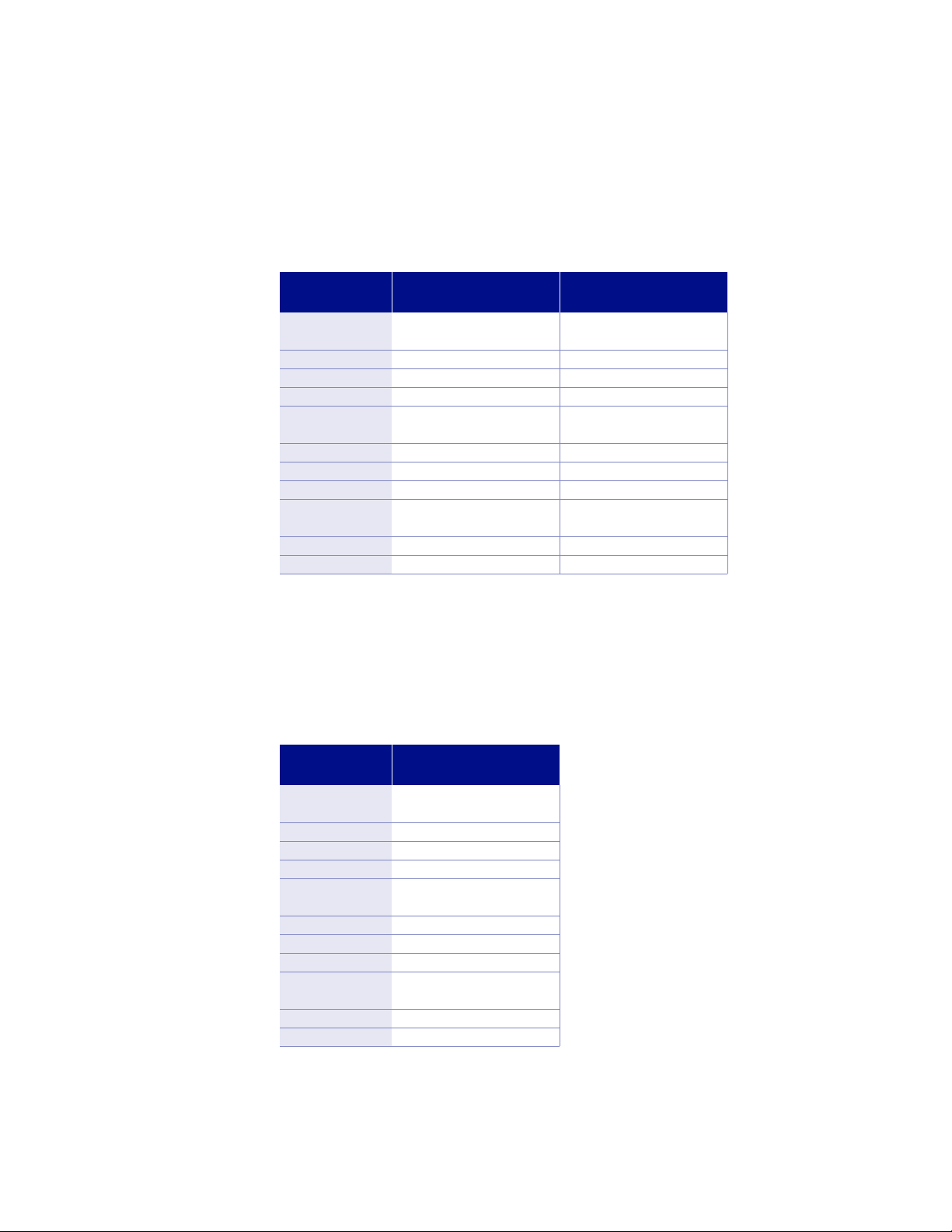

FIGURE 1-6 Transv ers e prob e

L (in) T (in) W (in) A (in)

HMMT-6J04-VR 4 ±0.125

HMNT-4E04-VR 4 ±0.125

HMMT-6J04-VF 4 ±0.125

HMNT-4E04-VF 4 ±0.125

1.5.3 Flexible Transverse Probes

0.061

max

0.045

max

0.061

max

0.045

max

0.180

±0.005

0.150

±0.005

0.180

±0.005

0.150

±0.005

0.150

±0.050

Active

area (in)

0.040 dia

(approx)

Stem

material

Aluminum

Fiberglass

epoxy

Aluminum

Fiberglass

epoxy

Frequency

range

DC to

800 Hz

DC to

10 kHz

DC to

400 Hz

DC to

800 Hz

TABLE 1-2 Transverse probe

FIGURE 1-7 Flexible transverse probe

Usable f ull

scale ranges

HSE

35 G, 350 G,

3.5 kG, 35 kG

HST-4

350 G, 3.5 kG,

35 kG

Corrected

accuracy

(% rdg)

±0.20% to

30 kG;

±0.25%

30 to 35 kG

±0.10% to

30 kG;

±0.15%

30 to 35 kG

Operating

temp

range

0 °C to

+75 °C

Te m p

coefficient

(max) zero

±0.09 G/°C -0.04%/°C

±0.13 G/°C -0.005%/°C

Tem p

coefficient

(max)

calibration

Operating

temp

range

0 °C to

+75 °C

HMFT-3E03-VR

HMFT-3E03-VF

W (in) T (in) A (in)

0.135

0.025

0.125

max

max

±0.005

Active

area (in)

0.040 dia

(approx)

Stem

material

Flexible

plastic

tubing

Frequency

range

DC to

10 kHz

DC to

800 Hz

Usable f ull

scale ranges

HSE

35 G, 350 G,

3.5 kG, 35 kG

HST-4

350 G, 3.5 kG,

35 kG

Corrected

accuracy (% rdg )

±0.20% to 30 kG;

±0.25% 30 to 35 kG

±0.10% to 30 kG;

±0.15% 30 to 35 kG

TABLE 1-3 Flexible transverse probe

Te m p

coefficient

(max) zero

±0.09 G/°C -0.04%/°C

±0.13 G/°C -0.0 05%/°C

Tem p

coefficient

(max)

calibration

| www.lakeshore.com

6 cHAPTER 1: Introduction

1.6 Model 425 Specifications

1.6.1 General Measurement

1.6.2 DC Measurement

(Does not include probe error, unless otherwise specified)

Input type: Single Hall effect sensor

Maximum update rate: 30 rdg/s

Probe features: Linearity compensation, probe zero, and hot swap

Measurement features: Autorange, max hold, relative mode, and filter

Probe connector: 15-pin D-sub socket

Probe type

Range

HST Probe

350 kG 000.01 kG 000.1 kG

35 kG 00.001 kG 00.01 kG

3.5 kG 0.0001 kG 0.001 kG

350 G 000.02 G 000.1 G

HSE Probe

35 kG 00.001 kG 00.01 kG

3.5 kG 0.0001 kG 0.001 kG

350 G 000.01 G 000.1 G

35 G 00.001 G 00.01 G

UHS Probe

35 G 00.001 G 00.01 G

3.5 G 0.0001 G 0.001 G

350 mG 000.02 mG 000.1 mG

TABLE 1- 4 DC measurement resolution

Filter on

4 r-digit resolution

Filter off

3 r-digit resolution

Measurement resolution (RMS noise floor): Indicated by value in above table for

shorted input

Display resolution: Indicated by number of digits in above table

DC accuracy: ±0.20% of reading ±0.05% of range

DC temperature coefficient: -0.01% of reading -0.003% of range/°C

DC filter: 16-point moving average

1.6.3 AC Measurement

Model 425 Gaussmeter

Probe type

Ranges

HST Probe

350 kG 000.1 kG

35 kG 00.01 kG

3.5 kG 0.001 kG

350 G 000.1 G

HSE Probe

35 kG 00.01 kG

3.5 kG 0.001 kG

350 G 000.1 G

35 G 00.01 G

UHS Probe

35 G 00.01 G

3.5 G 0.001 G

350 mG 000.1 mG

3r-digit re solution

TABLE 1-5 AC measurement resolution

Measurement resolution (RMS noise floor): Indicated by value in above table, measured at mid-scale range

Display resolution: Indicated by number of digits in above table

1.6.4 Front Panel 7

Narrow band mode Wide band mode

±2% of reading, ±0.05% of range

AC accuracy

AC frequency response 10 Hz to 400 Hz 50 Hz to 10 kHz

Minimum input signal >1% of range

AC specifications based on sine wave inputs or signals with crest factors <4.

(20 Hz to 100 Hz);

±2.5% of reading, ±0.05% of range

(10 Hz to 400 Hz)

TABLE 1-6 AC specifications

±2% of reading, ±0.05% of

range (50 H z to 10 kHz)

>1% of range, except >2% of

range on lo west range

AC temperature coefficient: ±0.01% of reading ±0.006% of range/°C

1.6.4 Front Panel

1.6.5 Interfaces

Display: 2-line × 20-character LCD display module with 5.5 mm high characters and

LED backlight

Display units: Gauss (G), tesla (T), oersted (Oe), and ampere per meter (A/m)

Display update rate: 3 rdg/s

Display resolution: To ± 4r

digits

Units multipliers: µ, m, k, M

Display annunciations: DC—DC measurement mode; RMS—AC RMS measurement

mode; MAX—Max hold value;ª

— Alarm on

Keypad: 14-key membrane

Front panel features: Display contrast control and keypad lock-out

USB

Function: Emulates a standard RS-232 serial port

Baud rate: 57,600

Connector: B-type USB connector

Reading rate: To 30 rdg/s

Software support: LabVIEW™ driver (consult Lake Shore for availability)

Alarm

Settings: High setpoint, low setpoint, inside or outside, algebraic or magnitude, audible on/off, and sort

Actuators: Display annunciator, sort message, beeper, and relay

Relay

Number: 1

Contacts: Normally open (NO), normally closed (NC), and common (C)

Contact rating: 30 VDC at 2 A

Operation: Follows alarm or operated manually

Connector: Shared 25-pin D-sub socket

Monitor output

Configuration: Real time analog voltage output proportional to measured field

Range: ±3.5 V

Scale: ±3.5 V = ±full scale on selected range

Frequency response: DC to 10 kHz

Accuracy: Offset and single point gain corrected to ±0.5% of reading ±0.1% of range,

linearity is probe dependent

Minimum load resistance: 1 k) (short circuit protected)

Connector: Shared 25-pin D-sub socket

| www.lakeshore.com

8 cHAPTER 1: Introduction

1.6.6 General

1.6.7 Probes and Extensions

1.7 Ordering Information

The Model 425 is the replacement for the Model 421 with a new software

command set.

Ambient temperature: 15 °C to 35 °C at rated accuracy; 5 °C to 40 °C with reduced

accuracy

Ambient field: Up to 100 G DC, measured at the instrument chassis

Power requirement: 100 VAC to 240 VAC, 50 Hz or 60 Hz 40 VA

Size: 216 mm W × 89 mm H × 318 mm D (8.5 in × 3.5 in ×12.5 in), half rack

Weight: 2.1 kg (4.6 lb)

Approval: CE mark, RoHS compliant

Probe compatibility: Full line of standard and custom probes (compatible with

Model 425/455/475 probes)

Hall sensor compatibility: Front panel programmable sensitivity and serial number

for user supplied Hall sensor using HMCBL cable

Extension cable compatibility: Calibrated or uncalibrated probe extension cables

with an EEPROM are available from 10 ft to 100 ft

Part number Descrip tion

425 Model 425 gaussmeter

425-HMXX-XXXX-XX

Specify power cord option

VAC-120 Instrument shipped with U.S. power cord for 120 VAC

VAC-220 Instrument shipped with European power cord for 220 VAC

VAC-120-ALL Instrument shipped with U.S. power cord (120 VAC) and European power cord (220 VAC)

Accessories included

G-106-253 I/O mating plug

G-106-264 I/O mating connector shell

4060 Zero g auss ch amber

MAN-425 Model 425 user manual

Accessories available

4065 Large zero gauss chamber for gamma probe

HMCBL-6 User programmable cable with EEPROM (6 ft)

HMCBL-20 User programmable cable with EEPROM (20 ft)

HMPEC-10-U Probe extension cable with EEPROM (10 ft), uncalibrated

HMPEC-25-U Probe extension cable with EEPROM (25 ft), uncalibrated

HMPEC-50-U Probe extension cable with EEPROM (50 ft), uncalibrated

HMPEC-100-U Probe extension cable with EEPROM (100 ft), uncalibrated

RM-q Rack mount kit for one q-rack gaussmeter in 483 mm (19 in) rack

RM-2 Rack mount kit for two q-rack gaussmeter in 483 mm (1 9 in) rack

4030-12 Hall probe stand; 305 mm (12 in) post

4030-24 Hall probe stand; 610 mm (24 in) post

Calibration service

CAL-N7-DATA New instrument calibration for Model 425/455/475 with certificate and data

CAL-425-CERT Instrument recalibration with certificate

CAL-425-DATA Instrument recalibration with certificate and data

One probe included (additional probes ordered separately)

Custom probes available—consult Lake Shore

Model 425 gaussmeter with standard probe choice—specify selected probe number for

HMXX-XXXX-XX (see list in section 1.5)

TABLE 1-7 Ordering information

Model 425 Gaussmeter

1.8 Safety Summary and Symbols 9

1.8 Safety Summary and Symbols

Observe these general safety precautions during all phases of instrument operation,

service, and repair. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and

intended instrument use. Lake Shore Cryotronics, Inc. assumes no liability for user

failure to comply with these requirements.

The Model 425 protects the operator and surrounding area from electric shock or

burn, mechanical hazards, excessive temperature, and spread of fire from the instrument. Environmental conditions outside of the conditions below may pose a hazard

to the operator and surrounding area.

D Indoor use

D Altitude to 2000 m

D Temperature for safe operation: 5 °C to 40 °C

D Maximum relative humidity: 80% for temperature up to 31 °C decreasing

linearly to 50% at 40 °C

D Environments with conducted RF of 1 V

in field readings up to 10% and monitor output up to 5%

D Power supply voltage fluctuations not to exceed ±10% of the nominal voltage

D Overvoltage category II

D Pollution degree 2

Ground the Instrument

To minimize shock hazard, the instrument is equipped with a 3-conductor AC power

cable. Plug the power cable into an approved 3-contact electrical outlet or use a

3-contact adapter with the grounding wire (green) firmly connected to an electrical

ground (safety ground) at the power outlet. The power jack and mating plug of the

power cable meet Underwriters Laboratories (UL) and International Electrotechnical

Commission (IEC) safety standards.

or EM fields of 1 V/m can cause a shift

rms

Ventilation

The instrument has ventilation holes in its side covers. Do not block these holes when

the instrument is operating.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any electrical instrument in such an environment constitutes a definite safety

hazard.

Keep Away from Live Circuits

Operating personnel must not remove instrument covers. Refer component replacement and internal adjustments to qualified maintenance personnel. Do not replace

components with power cable connected. To avoid injuries, always disconnect power

and discharge circuits before touching them.

Do Not Substitute Parts or Modify Instrument

Do not install substitute parts or perform any unauthorized modification to the

instrument. Return the instrument to an authorized Lake Shore Cryotronics, Inc. representative for service and repair to ensure that safety features are maintained.

Cleaning

Do not submerge instrument. Clean only with a damp cloth and mild detergent. Exterior only.

| www.lakeshore.com

10 cHAPTER 1: Introduction

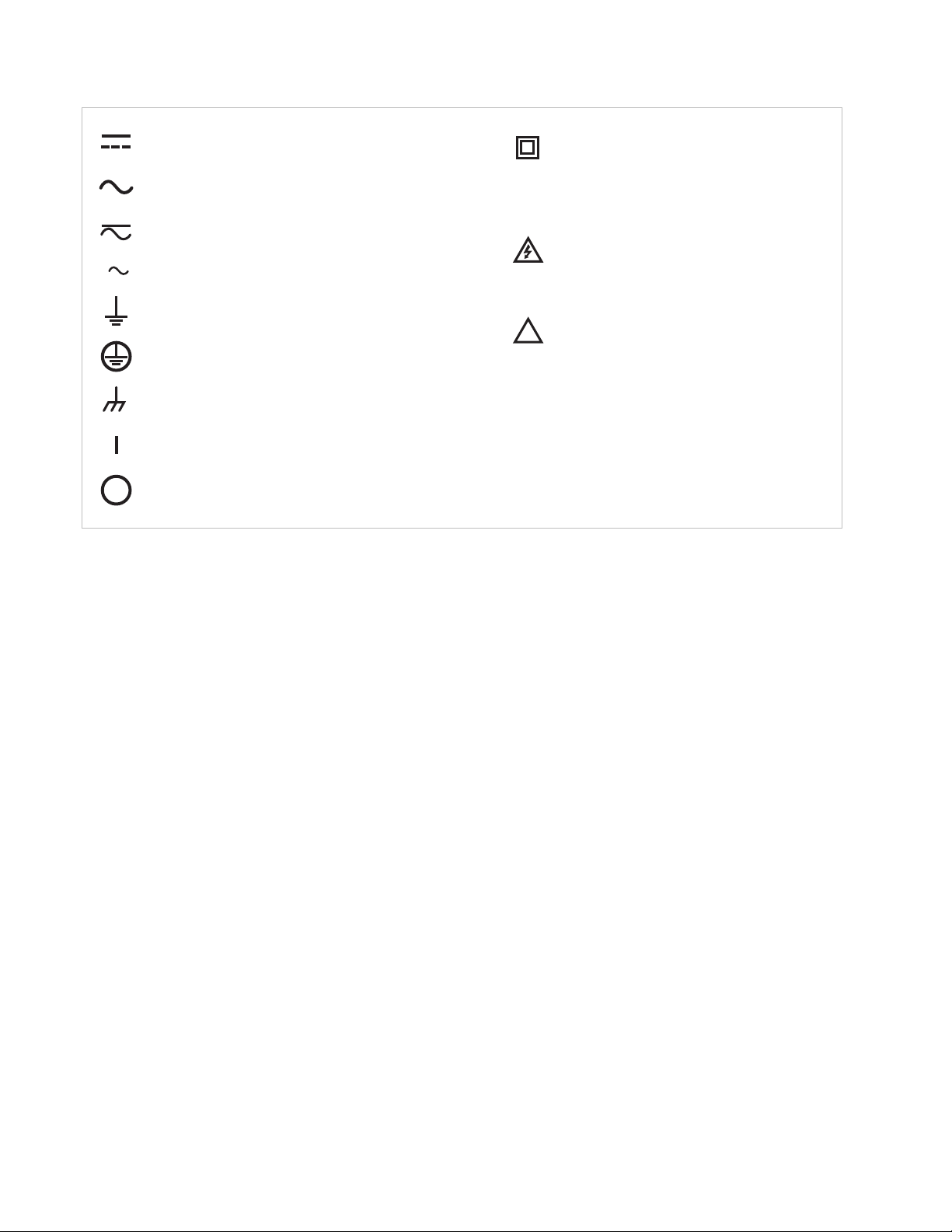

!

Direct current (power line)

Equipment protected throughout

by double insulation or reinforces

insulation (equivalent to Class II of

IEC 536—see Annex H)

CAUTION: High voltages; danger of

electric shock; background color:

yellow; symbol and outline: black

CAUTION or WARNING: See

instrument documentation;

background color: yellow;

symbol and outline: black

Off (supply)

On (supply)

Frame or chassis terminal

Protective conductor terminal

Earth (ground) terminal

3

Three-phase alternating current (power line)

Alternating or direct current (power line)

Alternating current (power line)

FIGURE 1-8 Safety symbols

Model 425 Gaussmeter

2.2.1 DC Measurem ent 11

Gain

Low pass

filter

Product

detector

RMS-to-DC

converter

Computer

interface

µPA/D

Monitor out Display

Switch

Switch

Wide band

DC or narrow band

DC

AC modes

Ic

B

Chapter 2: Background

2.1 General

2.2 Model 425 Overview

2.2.1 DC Measurement

This chapter provides background information related to the Model 425 gaussmeter.

It is intended to give insight into the benefits and limitations of the instrument and

help apply the features of the Model 425 to a variety of situations. It covers flux density, Hall measurement, and probe operation. For information on how to install the

Model 425, please refer to Chapter 3. Instrument operation information is contained

in Chapter 4 and Chapter 5.

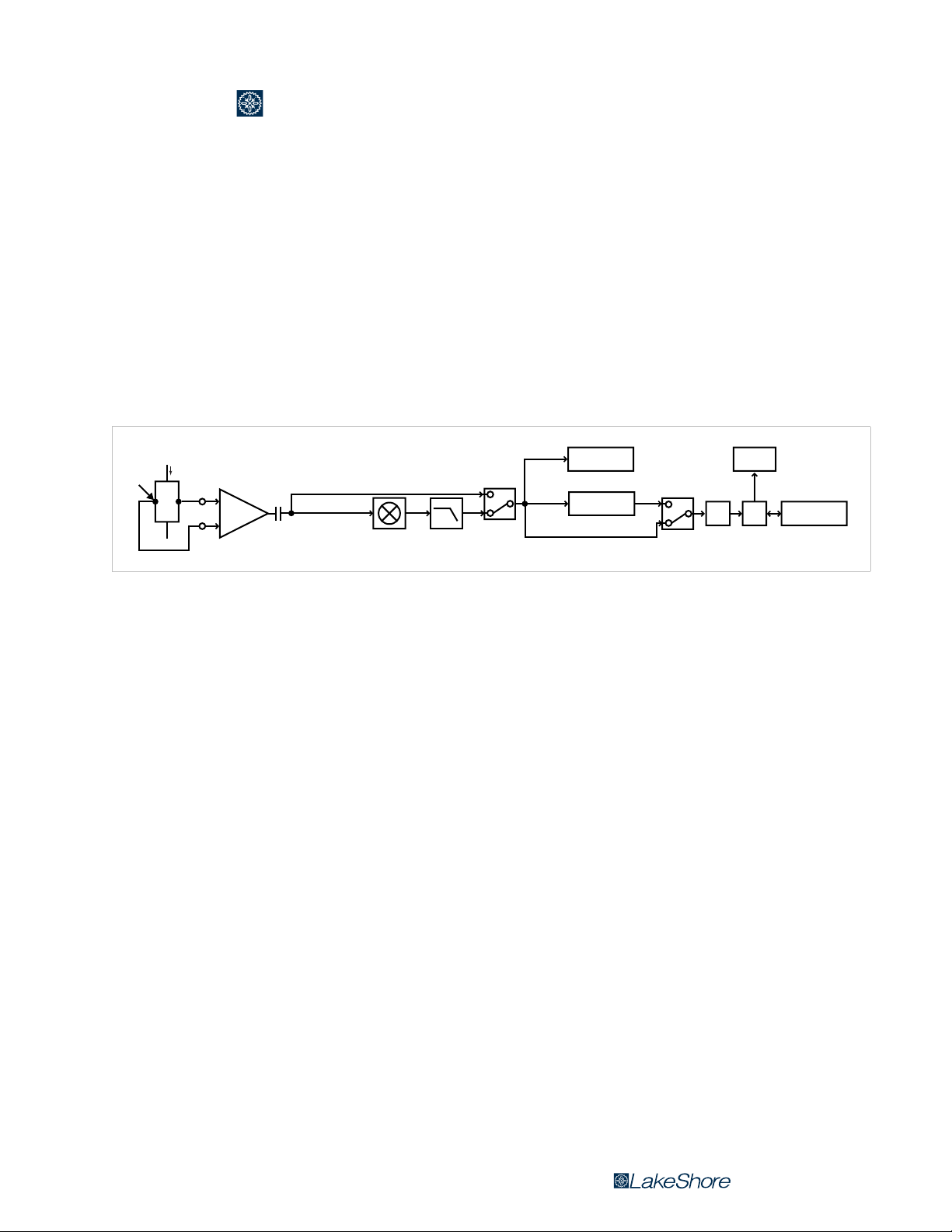

The Model 425 gaussmeter is a highly configurable device with many built-in features. It offers a DC mode to measure static or slowly changing fields, two different

modes to measure AC fields, narrow band and wide band, and a monitor output. Refer

to section 2.2.1 and section 2.2.2 for more information on these modes. To better

illustrate the capabilities of the gaussmeter, refer to the Model 425 system block diagram, FIGURE 2-1.

FIGURE 2-1 Model 425 system block diagram

When in DC mode, the instrument uses a 100 mA, 5.4 kHz square wave excitation current. The voltage that is generated by the Hall sensor goes through an AC coupled programmable gain stage. From there it passes through the product detector for

demodulation, a low pass filter, and the A/D converter. The digitized data is then sent

to the microprocessor. The monitor output will provide a DC voltage proportional to

the measured DC field. Refer to section 4.5.1 for the procedure to set the DC measurement mode. Refer to section 5.3 for information on monitor output.

2.2.2 AC Measurement

Narrow band mode: in this mode, the instrument uses a 100 mA, 5.4 kHz square wave

excitation current. This type of excitation provides the benefit of noise cancellation

characteristics of the product detector, but it limits the maximum field frequency of

the Model 425 to approximately 400 Hz.

The voltage that is generated by the Hall sensor goes through an AC coupled programmable gain stage. From there it passes through the product detector for demodulation, a low-pass filter, and an RMS-to-DC converter, before it is sent into the A/D

converter. The digitized data is then sent to the microprocessor. The monitor output

will provide an AC voltage proportional to the measured AC field. Refer to

section 4.5.2.1 for the procedure to set the narrow band AC measurement mode.

Wide band mode: in this mode, the instrument uses a 100 mA, DC excitation current to

drive the Hall sensor. This excitation type provides the greatest frequency range for

AC RMS measurements, up to 10 kHz. Since the signal doesn’t pass through the product detector and low pass filter, it has a higher noise floor than narrow band mode.

| www.lakeshore.com

12 cHAPTER 2: Background

φ

φ

The voltage that is generated by the Hall sensor goes through an AC coupled programmable gain stage and is sent directly to an RMS-to-DC converter. The signal is

then sent into the A/D converter. The digitized data is then sent to the microprocessor.

The monitor output will provide an unfiltered AC voltage proportional to the measured AC field. Refer to section 4.5.2.2 for the procedure to set the AC wide band

mode.

2.2.3 Monitor Output

2.3 Flux Density Overview

2.3.1 What is Flux Density?

The Model 425 has a monitor output that provides an analog representation of the

reading and is corrected for probe offset and nominal sensitivity. This monitor output

makes it possible to view the analog signal, which has not been digitized. The monitor

output can be connected to an oscilloscope or data acquisition system for analysis.

A magnetic field can be envisioned as lines of force measured in maxwells (Mx). In the

cgs system, magnetic flux ( ) is the Mx, where 1 Mx = 1 line of flux. In the SI system,

magnetic flux is the weber (Wb), where: 1 Wb = 10

Flux density is the number of flux lines passing perpendicular through a plane of unit

area (A). The symbol for flux density is B, where B = /A. The cgs system measures flux

2

density in gauss (G), where 1 G = 1 Mx/cm

tesla (T), where 1 T = 1 Wb/m

Flux density is important when magnet systems concentrate flux lines into a specific

area like the pole pieces of an electromagnet. Forces generated on current carrying

wires like those in a motor armature are proportional to flux density. Saturation of

magnetic core material is also a function of flux density.

Additional conversion factors can be found in the Appendix.

2

.

. The SI system measures flux density in

8

Mx.

2.3.2 How Flux Density (B) Differs from Magnetic Field Strength (H)

Flux density is often confused with magnetic field strength. Magnetic field strength is

a measure of the force producing flux lines. The symbol for magnetic field strength is

H. In the cgs system, it is measured in oersteds (Oe). In the SI system, it is measured in

amperes per meter (A/m):

1 Oe = 79.58 A/m

Flux density and magnetic field strength are related by the permeability (µ) of the

magnetic medium. B = µH. Permeability is a measure of how well a material makes a

path for flux lines.

The confusion of flux density and magnetic field strength is also related to permeability. In the cgs system, the permeability of air (of vacuum) is 1. Therefore, 1 G = 1 Oe or

B = H in air. Many people incorrectly assume, therefore, that in the cgs system, B = H at

all times. Adding to the confusion, in the SI system, permeability of air is not 1, so B is

not equal to H even in air.

Model 425 Gaussmeter

2 . 4 . 1 A c t i v e A r e a 13

BF

F = –e (v × B)

(force on electron)

v

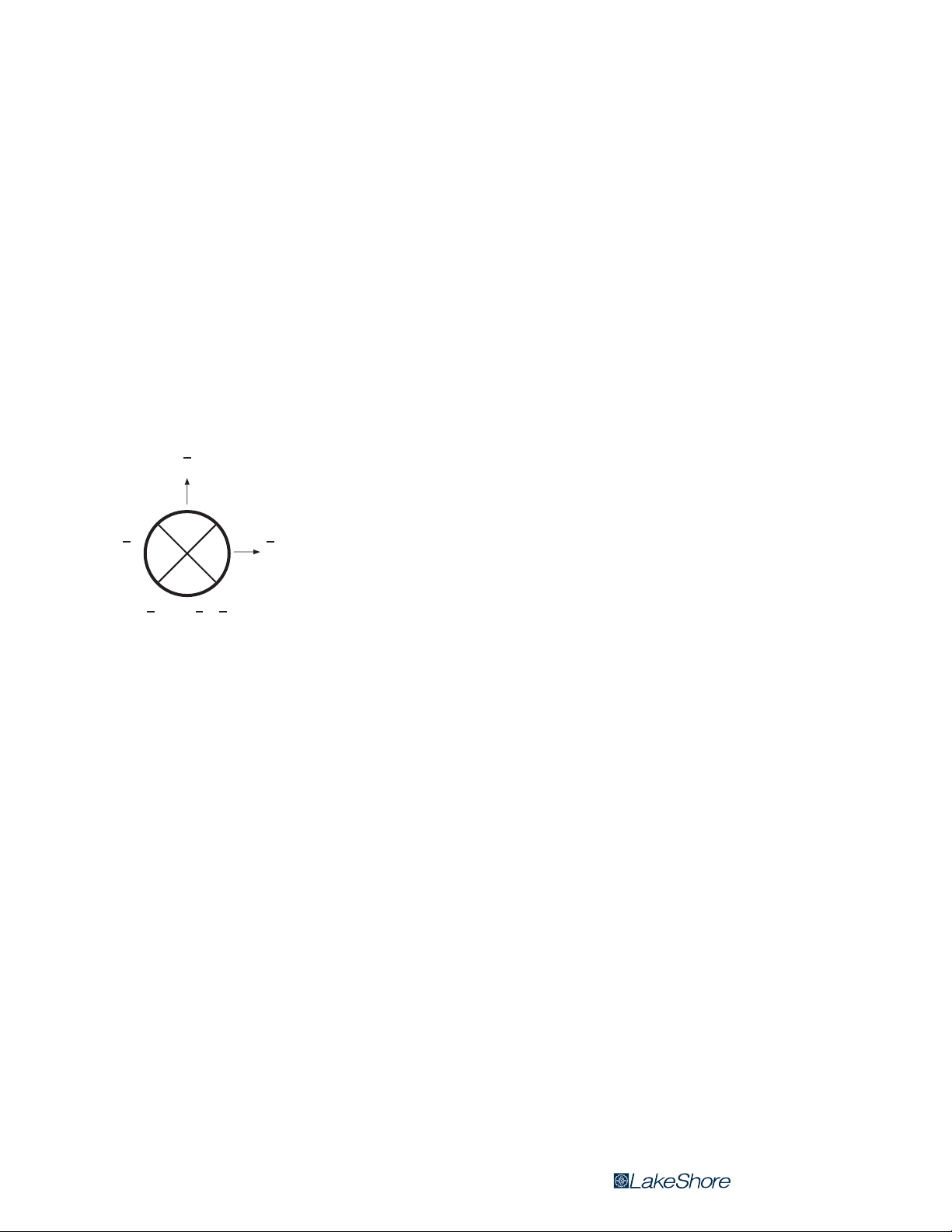

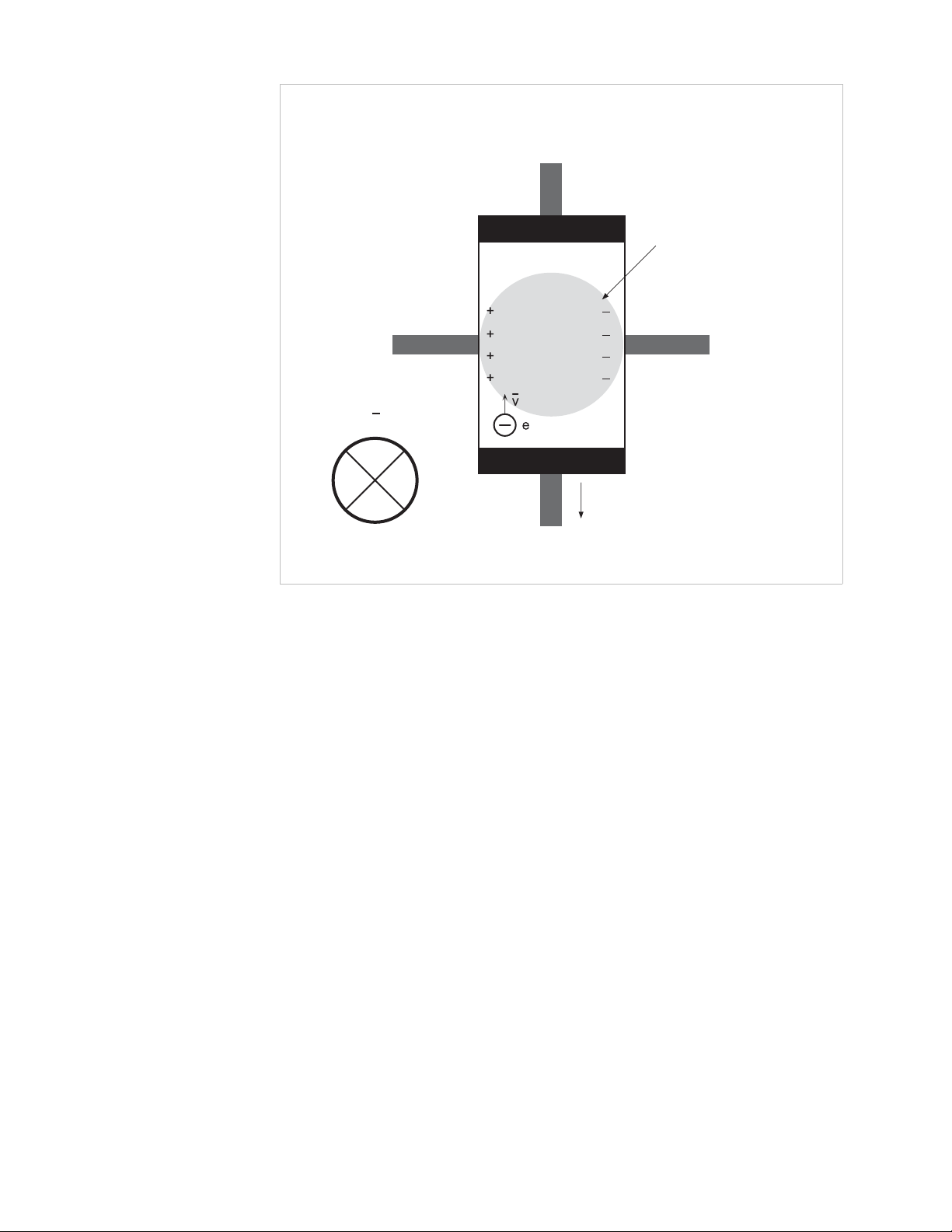

2.4 Hall Measurement Theory

The Hall effect is the development of a voltage across a sheet of conductor when current is flowing and the conductor is placed in a magnetic field (FIGURE 2-2).

The Hall effect was discovered by E. H. Hall in 1879 and it remained a laboratory curiosity for nearly 70 years. Finally, development of semiconductors brought Hall generators into the realm of the practical. A Hall generator is a solid state sensor with a

conductor that provides an output voltage proportional to magnetic flux density. As

implied by its name, this sensor relies on the Hall effect.

Electrons (the majority carrier most often used in practice) drift in the conductor

when under the influence of an external driving electric field. When exposed to a

magnetic field, these moving charged particles experience a force perpendicular to

both the velocity and magnetic field vectors. This force causes the charging of the

edges of the conductor, one side positive, the other side negative. This edge charging

sets up an electric field which exerts a force on the moving electrons equal and opposite to that caused by the magnetic-field-related Lorentz force. The voltage potential

across the width of the conductor is called the Hall voltage. This Hall voltage can be

used in practice by attaching two electrical contacts to each of the sides of the conductor.

The Hall voltage can be given by the expression:

V

= γ

B sin θ

H

B

where: V

= Hall voltage (mV)

H

= Magnetic sensitivity (mV/kG) (at a fixed current)

γ

B

B = Magnetic field flux density (kG)

θ = Angle between magnetic flux vector and the plane of Hall generator.

As can be seen from the formula above, the Hall voltage varies with the angle of the

sensed magnetic field, reaching a maximum when the field is perpendicular to the

plane of the Hall generator.

2.4.1 Active Area The Hall generator assembly contains the semiconductor material to which the four

contacts are made. This entity is normally called a Hall plate. In its simplest form, the

Hall plate is a conductor, rectangular in shape, and of fixed length, width, and thickness. Due to the shorting effect of the current supply contacts, most of the sensitivity

to magnetic fields is contained in an area approximated by a circle, centered on the

Hall plate, the diameter of which is equal to the plate width. This circle is considered

an approximation of the active area. FIGURE 2-2 illustrates an image of the approximate active area.

| www.lakeshore.com

14 cHAPTER 2: Background

VH (+) VH (–)

Approximate

active area

B

IC (+)

I

C

(–)

FIGURE 2-2 Approximate active area

2.4.2 Temperature Coefficients

There are two technically different temperature coefficients that always affect a

gaussmeter probe: the temperature coefficient of zero and the temperature coeffecient of sensitivity (section 2.4.2.1 and section 2.4.2.2). Under normal usage (reading a magnetic field), it is virtually impossible to separate the effect of each.

The Model 425 gaussmeter does not possess circuitry to allow compensation for

these temperature errors. Thus, a user operating a probe in a variable temperature

environment must be aware that both errors exist and what the maximum effect

could be. The temperature coefficients are repeatable for an individual probe. A user

can pre-measure the changes and manually correct the data for zero and sensitivity

effects, or the combination of both at specific magnetic field values. The Model 425

gaussmeter also has its own temperature coefficients, which are typically less than

probe coefficients. These are listed in section 1.6.

2.4.2.1 The Temperature Coefficient of Zero

The temperature coefficient of zero is a change in the zero field offset with temperature. This change is always present whether or not a field is measured. However, the

temperature error caused by zero change is often the dominant source of error at

magnetic field levels <100 G. If you have the ability to zero the gaussmeter at operating temperature, this coefficient is nullified and has no effect on accuracy. If the

gaussmeter cannot be zeroed, then the zero change effect is present.

Model 425 Gaussmeter

The unit of measure is G/° C. It is generally a fixed number, and can be either a positive

or negative value. This error is specific to each probe and can be a fixed magnitude

anywhere from the negative maximum to positive maximum value.

2.4.3 Radiation 15

Example of zero error: assume that the Model 425 is zeroed at +25 °C and then the temperature rises to +50 °C (,T = +25 °C). For an HMMT-6J04-VR, the worst-case zero

drift would be ±0.09 G/°C × 25 °C = ±2.25 G (maximum).

This is the maximum temperature error to be expected. Most Lake Shore probes exhibit

lower temperature coefficients.

2.4.2.2 The Temperature Coefficient of Sensitivity (Calibration)

The temperature coefficient of sensitivity is related to a change in the magnetic sensitivity of the Hall device with temperature. This change is present only when a field is

measured. The larger the field, the greater the error in G for the same temperature

change.

This characteristic is present in all probes and is specified in units of %G/° C. The

intrinsic value is always negative for Lake Shore HSE and HST probes, meaning that

the sensitivity of the Hall sensor decreases with increased temperature. Therefore,

the reading will be lower than the actual magnetic field when the probe is at a temperature higher than room temperature. Lake Shore Hall probes are calibrated at

room temperature (25 °C); when they are used in temperatures other than this, temperature coefficient becomes another source of error. Lake Shore HST probes normally exhibit a temperature coefficient of sensitivity about ten times better (lower)

than the HSE probes.

2.4.3 Radiation

Simply handling the probe at the stem can cause sufficient temperature change of the

sensor, which can cause the reading to drift; handling the probe by the stem is not recommended as it can break the probe.

Examples of sensitivity error: assume that the Model 425 is zeroed at +25 °C and then

the temperature rises to +50 °C (Delta T = +25 °C). For an HMMT-6J04-VR and

Model 425 (no compensation), measuring a 1.000 kG field, the worst-case sensitivity

change would be -0.04%/°C × 25 °C = -1% (maximum); -1% of 1.000 kG = -10 G

(reads low 10 G).

Also note that if the probe were a Model HMMT-6J04-VF, the worst case sensitivity

change would be -0.005%/°C × 25 °C = -0.125% (maximum); -0.125% of 1.000 kG =

-1.25 G (reads low 1.25 G).

This is the maximum temperature error to be expected. Most Lake Shore probes exhibit

lower temperature coefficients.

The HST and HSE probes use a highly doped indium arsenide conductor. The HST

material is the more highly doped of the two and therefore will be less affected by

radiation. Some general information relating to highly doped indium arsenide Hall

generators is provided in the following list. The changes in sensitivity are the maximums expected if the sensor is exposed at the given rates indefinitely.

D Gamma radiation seems to have little effect on the Hall generators

D Proton radiation up to 10 Mrad causes sensitivity changes less than 0.5%

D Neutron cumulative radiation (>0.1 MeV, 10

15

/cm2) can cause a 3% to 5%

decrease in sensitivity

In all cases the radiation effects on the Hall sensors seem to saturate and diminish

with cumulative exposure; the length of time for these effects to diminish varies

depending upon radiation intensity.

| www.lakeshore.com

16 cHAPTER 2: Background

2.5 Probe Considerations

2.5.1 Orientation

This section defines and discusses things to consider when selecting a probe.

Because accessing the field is part of the challenge when selecting a probe, field orientation dictates the most basic probe geometry choice of transverse versus axial.

Other variations are also available for less common, more challenging applications.

Listed below are the standard configurations for HSE and HST probes; UHS probes

require special construction that is not described here.

D Tra ns ver se : most often rectangular in shape, transverse probes measure fields per-

pindicular to their stem width. They are useful for most general purpose field

measurements and are essential for work in magnet gaps. Several stem lengths

and thicknesses are available as standard probes.

D Axial: usually round, axial probes measure fields perpindicular to their end. They

can also be used for general-purpose measurements, but are most commonly

used to measure fields produced by solenoids. Several stem lengths and diameters are available as standard probes.

D Flexible: with a flexible portion in the middle of their stem, flexible probes have an

active area at the tip that remains rigid and somewhat exposed. This unique feature makes them significantly more fragile than other transverse probes. Flexible

probes should only be selected for narrow-gap measurement applications.

D Ta ng en ti a l: these probes are transverse probes designed to measure fields parallel

to and near a surface. The active area is very close to the stem tip. These probes

are intended for this specific application and should not be selected for general

transverse measurements.

2.5.2 Frequency

Flexible and tangential probes are significantly more fragile than other transverse

probes.

D Multiple axis: multi-axis probes are available for multi-axis gaussmeters like the

Lake Shore Model 460. These probes are not compatible with the Model 425.

Hall effect gaussmeters are equally well suited for measuring either static, DC fields

or periodic, AC fields, but proper probe selection is required to achieve optimal

performance. HST probes are not recommended for use in wide band mode because

of their lower sensitivity. These probes perform better with the the noise cancellation

benefits of the narrow band mode.

D Metal stem: these probe stems are the best choice for DC and low frequency AC

measurements. Non-ferrous metals are used for probe stems because they

provide the best protection for the delicate Hall effect sensor without altering

the measured field. Aluminum is the most common metal stem material, but

brass can also be used. Metal stems do have one drawback: eddy currents are

generated in them when they are placed in AC fields. These eddy currents oppose

the field and cause measurement error. The error magnitude is proportional to

frequency, and is most noticeable above 800 Hz.

D Non-metal stem: these probe stems are required for higher frequency AC fields and

for measuring pulse fields—fiberglass/epoxy is a common non-metal stem

material. Alternatively, the Hall effect sensor can be left exposed on its ceramic

substrate, but provides less protection for the sensor. Eddy currents do not limit

the frequency range of these non-conductive materials, but other factors may.

Model 425 Gaussmeter

None of these probe types are suitable for direct exposure to high voltage. The possibility

exists for damage to equipment or injury to the operator if the probe is exposed to high

voltage.

Loading...

Loading...