Lakeshore 340, 3464, 3465, 3462, 3468 Installation Instructions Manual

p

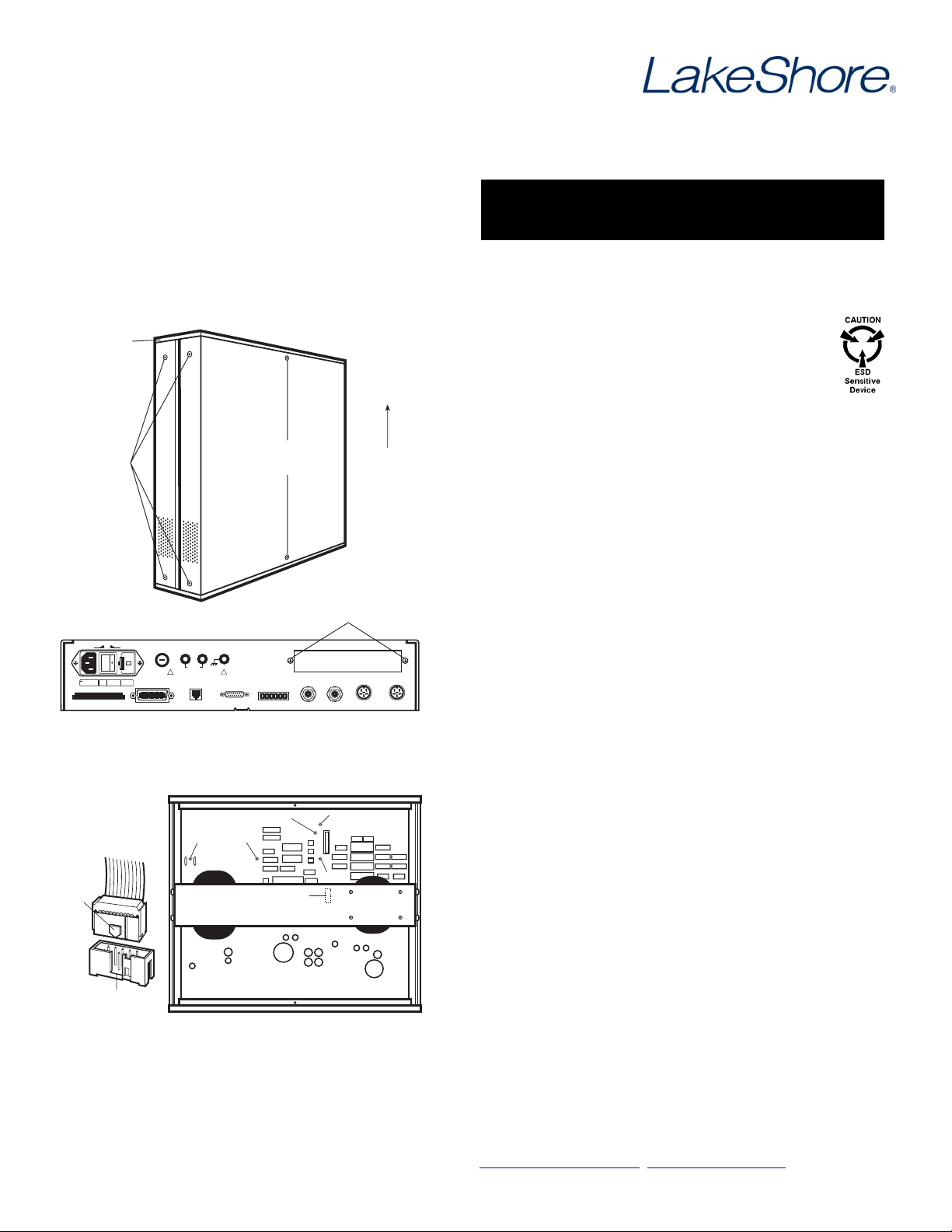

Model 340 Input Option Card Installation

Field Installation

Input option card kit:

(1) 10-conductor ribbon cable

(1) Option card

(4) 32 mm (1.25 in) metal standoffs

(8) 4-40 machine screws

REAR PLASTIC

BEZEL

SIDE COVER

SCREWS

(On Both Sides)

TOP COVER SCREWS

(Remove bottom

cover screws also)

OPTION PLATE SCREWS

To remove top

and bottom

covers, slide

them to the rear

on the tracks.

REAR PANEL

These instructions apply to 3462,

3464, 3465, and 3468 o

Required tools: Small Phillips-head screwdriver and

5/64-inch Allen wrench

CAUTION: The components on this board are

electrostatic discharge sensitive (ESDS)

devices. Wear shock-proof wrist straps

(resistor limited to <5 mA) to prevent injury to

service personnel and to avoid inducing an

electrostatic discharge (ESD) into the device.

1. Turn Model 340 power switch OFF. Unplug power cord

from wall outlet, then instrument.

2. Stand the unit on its face. Use the Allen wrench to

remove the 4 screws on each side of the covers

(Figure 1).

3. Use the small Phillips screwdriver to remove any top

and bottom cover screws; instrument may have 1 or 2

screws on the top and bottom covers.

tion cards

OFF ON

-10% +5%

LINE 100 / 120

FUSE

50-60 Hz

DATA

175 VA MAX

DATA CARD

HEATER FUSE

HEATER OUTPUT

2.5 A

120

220 / 240

2.0 A

1.0 A

IEEE-488 INTERFACE

.25x1.25in SB

5x25mm SB

S

H1 AH1 T5 L4 SR1 RL1 PP0 DC1 DT0 C0 E1

60V MAX

!

WARNING

NO USER SERVICEABLE PARTS INSIDE. REFER

SERVICING TO TRAINED SERVICE PERSONNEL.

EXT

SERIAL I/O

LOHI

!

FOR CONT5INUED PROTECTION AGAINST FIRE HAZARD,

REPLACE FUSE WITH SAME TYPE AND RATING.

DIGITAL I/O

WARNING

RELAYS

LO HI

NC C NO NC C NO

OPTION PLATE

ANALOG

OUT 1

Figure 1. Cover and Option Plate Screws

IGNORE

HOLE #1 HOLE #2

ARROW

NUB

PLUG

SLOT

ANALOG OPTION PLUG

TRANSFORMER ASSEMBLY

Figure 2. Model 340 Mounting Holes

and Analog Option Plug

ANALOG

OUT 2

HOLE #4

HOLE #3

INPUT A

l+V+l-

4. Remove rear plastic bezel. The covers are tracked.

Slide the top and bottom covers to the rear on the

INPUT B

l+V+l-

V-

V-

tracks to remove them.

5. Remove rear panel option plate screws and set aside.

Remove rear panel option plate.

6. With the instrument still standing on its face, turn it to

view the inside circuit board. The upper half of the

circuit board above the transformer assembly contains

four holes where metal standoffs install (Figure 2).

Find Hole #1 to the left between C245 and C265.

Find Hole #2 114 mm (4.5 in) to the right of Hole #1,

and just to the left of C298 and U154.

Find Hole #3 114 mm (4.5 in) to the right of Hole #2,

and just to the left and below the Digital Option plug

(J9).

Find Hole #4 64 mm (2.5 in) above Hole #3, just to the

left and above the digital option plug (J9). Ignore hole to

left and beneath Hole #4.

Into each hole, insert a 4-40 screw through the bottom

of the circuit board, and thread it into a metal standoff

on the top of the circuit board.

Lake Shore Cryotronics, Inc. 575 McCorkle Blvd Westerville, Ohio 43082

Tel: (614) 891-2244 Fax: (614) 818-1600 e-mail: service@lakeshore.com

www.lakeshore.com

F023-07-00 Revision A 1/24/2008

INPUTS

HOLE #1 HOLE #2

Figure 3. Option Card Mounting Holes

and Analog Plug

HOLE #4

PLUG

7. Just beneath the transformer assembly is the analog

option plug (J18). Plug either end of the ribbon cable

into the analog option plug (J18). Slide the arrow nub

down the plug slot for correct positioning (Figure 2).

8. Plug the other end of the ribbon cable into the option

card plug (J3), on the lower right corner of the card

(Figure3).

9. Place the option card on top of the metal standoffs in

the instrument. Fit the card sensor inputs out the rear

panel option opening. Retrieve option plate screws from

Step 5 and use to slightly tighten the option card to the

HOLE #3ANALOG

rear panel.

10. Align the holes in the card with the corresponding metal

standoffs. Insert a 4-40 screw through each option card

hole and thread it to the metal standoff beneath. Go

back and tighten the two screws securing the option

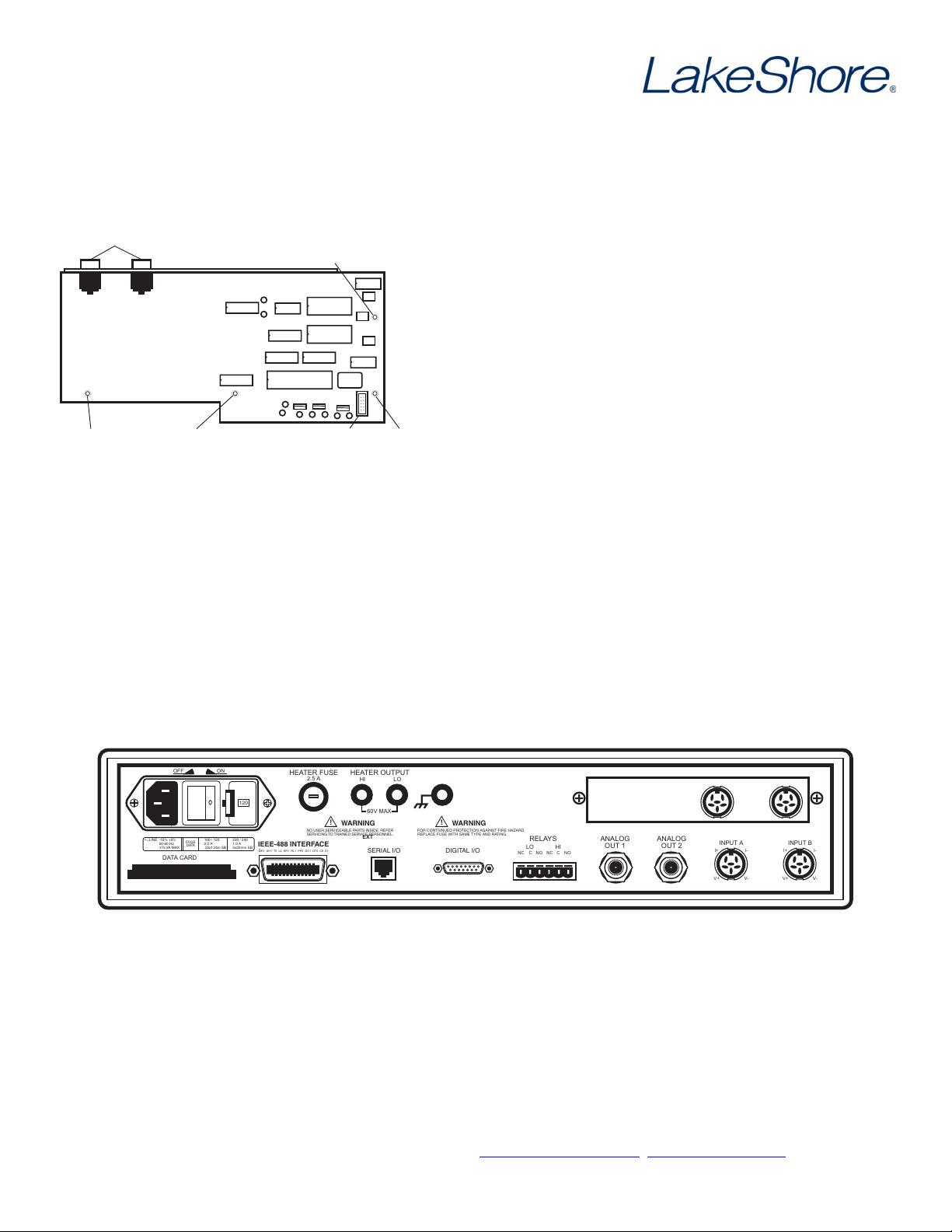

card to the rear panel.

11. Stand instrument on face. Slide top and bottom covers

on. Reposition rear plastic bezel, then rethread all cover

screws. The completed installation of the 3462 card

should look like Figure 4. (Others will look similar.)

LINE

-10% +5%

50-60 Hz

175 VA MAX

DATA CARD

12. Replace power cord. Turn on power switch. To verify

option card installation, press Options, then press

More three times. The Model 340 displays the option in

the REVISION INFORMATION.

OFF ON

100 / 120

FUSE

2.0 A

DATA

.25x1.25in SB

220 / 240

1.0 A

5x25mm SB

120

HEATER FUSE

2.5 A

NO USER SERVICEABLE PARTS INSIDE. REFER

IEEE-488 INTERFACE

S

SERVICING TO TRAINED SERVICE PERSONNEL.

H1 AH1 T5 L4 SR1 RL1 PP0 DC1 DT0 C0 E1

HEATER OUTPUT

!

WARNING

60V MAX

EXT

SERIAL I/O

LOHI

!

WARNING

FOR CONT5INUED PROTECTION AGAINST FIRE HAZARD,

REPLACE FUSE WITH SAME TYPE AND RATING.

DIGITAL I/O

RELAYS

LO HI

NC C NO NC C NO

MODEL 3462

ANALOG

OUT 1

Figure 4. Model 340 Rear Panel with Model 3462 Option Card Installed

ANALOG

OUT 2

INPUT C INPUT D

l+V+l-

INPUT A

l+V+l-

l+V+l-

V-

V-

V-

INPUT B

l+V+l-

V-

Lake Shore Cryotronics, Inc. 575 McCorkle Blvd Westerville, Ohio 43082

Tel: (614) 891-2244 Fax: (614) 818-1600 e-mail: service@lakeshore.com

www.lakeshore.com

F023-07-00 Revision A 1/24/2008

Loading...

Loading...