Lakeshore 340 User Manual

User’s Manual

Model 340

Temperature Controller

340 Temperature Controller

Auto

Zone

Tune

Settings

P I D

Heater

Control

Range

Channel

Heater

Off Setpoint

Ramp Program

Control

Setup

Loop 1

Manual

Output Loop 2

Input

Setup

7

Scan

Setup

4

Alarm

Setup

1

Alarm

Reset

0

Display

SoftCal

Format

8

Curve

Entry5Interface

Math

Analog

Setup

Outputs

2

Math

Reset.Options

Cancel

Escape

Enter

Screen More

Previous

Setting Local

Next

Setting DataCard

Save

Screen Help

9

6

3

+/-

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

Internet Addresses:

sales@lakeshore.com

service@lakeshore.com

Visit Our Website:

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake Shore Cryotronics, Inc.

No government or other contractual support or relationship whatsoever has existed which in any way affects or mitigates proprietary

rights of Lake Shore Cryotronics, Inc. in these developments. Methods and apparatus disclosed herein may be subject to U.S. Patents

existing or applied for. Lake Shore Cryotronics, Inc. reserves the right to add, improve, modify, or withdraw functions, design

modifications, or products at any time without notice. Lake Shore shall not be liable for errors contained herein or for incidental or

consequential damages in connection with furnishing, performance, or use of this material.

Rev. 2.1 P/N 119-011 29 March 2004

Lake Shore Model 340 Temperature Controller User’s Manual

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: ONE (1) YEAR

1. Lake Shore warrants that this Lake Shore product (the “Product”) will

be free from defects in materials and workmanship for the Warranty

Period specified above (the “Warranty Period”). If Lake Shore receives

notice of any such defects during the Warranty Period and the Product

is shipped freight prepaid, Lake Shore will, at its option, either repair

or replace the Product if it is so defective without charge to the owner

for parts, service labor or associated customary return shipping cost.

Any such replacement for the Product may be either new or equivalent

in performance to new. Replacement or repaired parts will be

warranted for only the unexpired portion of the original warranty or

90 days (whichever is greater).

2. Lake Shore warrants the Product only if it has been sold by an

authorized Lake Shore employee, sales representative, dealer or

original equipment manufacturer (OEM).

3. The Product may contain remanufactured parts equivalent to new in

performance or may have been subject to incidental use.

4. The Warranty Period begins on the date of delivery of the Product or

later on the date of installation of the Product if the Product is installed

by Lake Shore, provided that if you schedule or delay the Lake Shore

installation for more than 30 days after delivery the Warranty Period

begins on the 31st day after delivery.

5. This limited warranty does not apply to defects in the Product

resulting from (a) improper or inadequate maintenance, repair or

calibration, (b) fuses, software and non-rechargeable batteries,

(c) software, interfacing, parts or other supplies not furnished by

Lake Shore, (d) unauthorized modification or misuse, (e) operation

outside of the published specifications or (f) improper site preparation

or maintenance.

6. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE

ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTY OR CONDITION, WHETHER WRITTEN OR ORAL,

IS EXPRESSED OR IMPLIED. LAKE SHORE SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY, SATISFACTORY QUALITY AND/OR

FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE PRODUCT. Some countries, states or provinces do not allow

limitations on an implied warranty, so the above limitation or

exclusion might not apply to you. This warranty gives you specific

legal rights and you might also have other rights that vary from

country to country, state to state or province to province.

7. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE

REMEDIES IN THIS WARRANTY STATEMENT ARE YOUR

SOLE AND EXCLUSIVE REMEDIES.

8. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE

LAW, IN NO EVENT WILL LAKE SHORE OR ANY OF ITS

SUBSIDIARIES, AFFILIATES OR SUPPLIERS BE LIABLE FOR

DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR

OTHER DAMAGES (INCLUDING LOST PROFIT, LOST DATA

OR DOWNTIME COSTS) ARISING OUT OF THE USE,

INABILITY TO USE OR RESULT OF USE OF THE PRODUCT,

WHETHER BASED IN WARRANTY, CONTRACT, TORT OR

OTHER LEGAL THEORY, AND WHETHER OR NOT LAKE

SHORE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. Your use of the Product is entirely at your own risk.

Some countries, states and provinces do not allow the exclusion of

liability for incidental or consequential damages, so the above

limitation may not apply to you.

LIMITED WARRANTY STATEMENT (Continued)

9. EXCEPT TO THE EXTENT ALLOWED BY APPLICABLE LAW,

THE TERMS OF THIS LIMITED WARRANTY STATEMENT DO

NOT EXCLUDE, RESTRICT OR MODIFY, AND ARE IN

ADDITION TO, THE MANDATORY STATUTORY RIGHTS

APPLICABLE TO THE SALE OF THE PRODUCT TO YOU.

CERTIFICATION

Lake Shore certifies that this product has been inspected and tested in

accordance with its published specifications and that this product met its

published specifications at the time of shipment. The accuracy and

calibration of this product at the time of shipment are traceable to the

United States National Institute of Standards and Technology (NIST);

formerly known as the National Bureau of Standards (NBS).

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 340 firmware is as free

of errors as possible, and that the results you obtain from the instrument

are accurate and reliable. However, as with any computer-based software,

the possibility of errors exists.

In any important research, as when using any laboratory equipment,

results should be carefully examined and rechecked before final

conclusions are drawn. Neither Lake Shore nor anyone else involved in

the creation or production of this firmware can pay for loss of time,

inconvenience, loss of use of the product, or property damage caused by

this product or its failure to work, or any other incidental or consequential

damages. Use of our product implies that you understand the Lake Shore

license agreement and statement of limited warranty.

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States copyright

law and international treaty provisions. To maintain the warranty, the

code contained in the firmware must not be modified. Any changes made

to the code is at the user’s risk. Lake Shore will assume no responsibility

for damage or errors incurred as result of any changes made to the

firmware.

Under the terms of this agreement you may only use the Model 340

firmware as physically installed in the instrument. Archival copies are

strictly forbidden. You may not decompile, disassemble, or reverse

engineer the firmware. If you suspect there are problems with the

firmware, return the instrument to Lake Shore for repair under the terms

of the Limited Warranty specified above. Any unauthorized duplication

or use of the Model 340 firmware in whole or in part, in print, or in any

other storage and retrieval system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers and sellers claim designations used to distinguish

their products as trademarks. Where those designations appear in this

manual and Lake Shore was aware of a trademark claim, they appear with

initial capital letters and the ™ or

Apiezon

®

is a trademark of Biddle Instruments.

®

symbol.

CalCurve™, Carbon-Glass™, Cernox™, DriftTrak™, Duo-Twist™,

Quad-Lead™, Quad-Twist™, Rox™, SoftCal™, and Thermox™ are

trademarks of Lake Shore Cryotronics, Inc.

Chromel™ and Alumel™ are trademarks of Hoskins Manufacturing

Company.

Formvar™ is a trademark of Monsanto Chemical Company.

MS-DOS

®

and Windows® are trademarks of Microsoft Corporation.

NI-488.2™ is a trademark of National Instruments.

PC, XT, AT, and PS-2 are trademarks of IBM.

®

is a trademark of Emerson & Cuming.

Stycast

®

Teflon

is a trademark of DuPont De Nemours.

Copyright ©1996 – 2001 and 2003 – 2004 by Lake Shore Cryotronics, Inc. All rights reserved. No portion of this

manual may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the express written permission of Lake Shore.

A

Lake Shore Model 340 Temperature Controller User’s Manual

Declaration of Conformity

We: Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, OH 43082-8888 USA

hereby declare that the equipment specified conforms to the following

Directives and Standards:

Application of Council directives: ....................... 73/23/EEC

89/336/EEC

Standard to which Conformity is declared:......... EN 61010-1:2001

Overvoltage II

Pollution Degree 2

EN 61326 A2:2001

Class A

Annex B

Model Number:................................................... 340

_________________________________________________ __________________________________

Signature Date

Ed Maloof

Printed Name

Vice President of Engineering

Position

B

Lake Shore Model 340 Temperature Controller User’s Manual

This Page Intentionally Left Blank

C

Lake Shore Model 340 Temperature Controller User’s Manual

TABLE OF CONTENTS

Chapter/Paragraph Title Page

1 INTRODUCTION .................................................................................................................................................... 1-1

1.0 GENERAL ......................................................................................................................................... 1-1

1.1 TEMPERATURE CONTROL SYSTEM ............................................................................................. 1-2

1.2 TEMPERATURE CONTROL SYSTEM WITH THE MODEL 340 ...................................................... 1-2

1.2.1 Cooling Source .............................................................................................................................. 1-2

1.2.2 Feedback ....................................................................................................................................... 1-3

1.2.3 Control Equation ............................................................................................................................ 1-3

1.2.4 Heating .......................................................................................................................................... 1-3

1.3 MODEL 340 FEATURES................................................................................................................... 1-3

1.3.1 Configurable Inputs........................................................................................................................ 1-3

1.3.2 Input Isolation................................................................................................................................. 1-4

1.3.3 Input Reading Capability................................................................................................................ 1-4

1.3.4 Temperature Response Curves and CalCurves™......................................................................... 1-5

1.3.5 SoftCal™........................................................................................................................................ 1-5

1.3.6 Configurable Heater Output ........................................................................................................... 1-5

1.3.7 Heater Output Protection ............................................................................................................... 1-5

1.3.8 Second Control Loop ..................................................................................................................... 1-5

1.3.9 AutoTune ....................................................................................................................................... 1-5

1.3.10 Setpoint Ramping and Zones......................................................................................................... 1-5

1.3.11 Internal Programming .................................................................................................................... 1-6

1.3.12 Math............................................................................................................................................... 1-6

1.3.13 Alarms, Analog Outputs, and Digital I/O ........................................................................................ 1-6

1.3.14 Memory Card ................................................................................................................................. 1-6

1.3.15 Computer Interface ........................................................................................................................ 1-6

2 COOLING SYSTEM DESIGN................................................................................................................................. 2-1

2.0 General.............................................................................................................................................. 2-1

2.1 Temperature Sensor Selection .......................................................................................................... 2-1

2.1.1 Temperature Range....................................................................................................................... 2-1

2.1.2 Sensor Sensitivity .......................................................................................................................... 2-1

2.1.3 Environmental Conditions .............................................................................................................. 2-2

2.1.4 Measurement Accuracy ................................................................................................................. 2-2

2.1.5 Sensor Package............................................................................................................................. 2-2

2.2 Calibrated Sensors ............................................................................................................................ 2-2

2.2.1 Traditional Calibration .................................................................................................................... 2-2

2.2.2 SoftCal™........................................................................................................................................ 2-3

2.2.3 Standard Curves ............................................................................................................................ 2-4

2.2.4 CalCurve™ .................................................................................................................................... 2-4

2.3 SENSOR INSTALLATION................................................................................................................. 2-4

2.3.1 Mounting Materials......................................................................................................................... 2-4

2.3.2 Sensor Location ............................................................................................................................. 2-4

2.3.3 Thermal Conductivity ..................................................................................................................... 2-5

2.3.4 Contact Area .................................................................................................................................. 2-5

2.3.5 Contact Pressure ........................................................................................................................... 2-5

2.3.6 Lead Wire....................................................................................................................................... 2-6

2.3.7 Lead Soldering............................................................................................................................... 2-6

2.3.8 Heat Sinking Leads........................................................................................................................ 2-6

2.3.9 Thermal Radiation.......................................................................................................................... 2-6

2.4 HEATER SELECTION AND INSTALLATION.................................................................................... 2-6

2.4.1 Heater Resistance and Power ....................................................................................................... 2-6

2.4.2 Heater Location.............................................................................................................................. 2-7

2.4.3 Heater Types ................................................................................................................................. 2-7

2.4.4 Heater Wiring ................................................................................................................................. 2-7

2.5 CONSIDERATIONS FOR GOOD CONTROL ................................................................................... 2-7

2.5.1 Thermal Conductivity ..................................................................................................................... 2-7

2.5.2 Thermal Lag................................................................................................................................... 2-8

2.5.3 Two-Sensor Approach ................................................................................................................... 2-8

2.5.4 Thermal Mass ................................................................................................................................ 2-8

2.5.5 System Nonlinearity ....................................................................................................................... 2-8

2.6 PID CONTROL .................................................................................................................................. 2-9

2.6.1 Proportional (P).............................................................................................................................. 2-9

Table of Contents i

Lake Shore Model 340 Temperature Controller User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

2.6.2 Integral (I)....................................................................................................................................... 2-9

2.6.3 Derivative (D) .................................................................................................................................2-9

2.6.4 Manual Heater Output.................................................................................................................. 2-11

2.7 MANUAL TUNING ........................................................................................................................... 2-11

2.7.1 Setting Heater Range................................................................................................................... 2-11

2.7.2 Tuning Proportional...................................................................................................................... 2-11

2.7.3 Tuning Integral ............................................................................................................................. 2-12

2.7.4 Tuning Derivative ......................................................................................................................... 2-12

2.8 AUTOTUNING................................................................................................................................. 2-13

2.9 ZONE TUNING................................................................................................................................ 2-14

3 INSTRUMENT HARDWARE INSTALLATION ....................................................................................................... 3-1

3.0 GENERAL ......................................................................................................................................... 3-1

3.1 RECEIVING THE MODEL 340 .......................................................................................................... 3-1

3.1.1 Inspection and Unpacking.............................................................................................................. 3-1

3.1.2 Repackaging For Shipment............................................................................................................ 3-1

3.1.3 Safety Summary............................................................................................................................. 3-2

3.1.4 Safety Symbols ..............................................................................................................................3-2

3.1.5 Handling Liquid Helium and Liquid Nitrogen .................................................................................. 3-3

3.2 REAR PANEL DEFINITION............................................................................................................... 3-4

3.3 LINE INPUT ASSEMBLY................................................................................................................... 3-5

3.3.1 Line Voltage and Fuse Verification................................................................................................. 3-5

3.3.2 Line Voltage Selection ...................................................................................................................3-5

3.3.3 Fuse Replacement ......................................................................................................................... 3-6

3.3.4 Power Cord ....................................................................................................................................3-6

3.3.5 Power Switch ................................................................................................................................. 3-6

3.4 STANDARD SENSOR INPUTS......................................................................................................... 3-6

3.4.1 Sensor Input Connector and Pinout ............................................................................................... 3-6

3.4.2 Sensor Lead Cable ........................................................................................................................3-7

3.4.3 Grounding and Shielding Sensor Leads......................................................................................... 3-7

3.4.4 Sensor Polarity............................................................................................................................... 3-7

3.4.5 Four-Lead Sensor Measurement ...................................................................................................3-7

3.4.6 Two-Lead Sensor Measurement.................................................................................................... 3-8

3.4.7 Lowering Measurement Noise........................................................................................................ 3-8

3.5 HEATER OUTPUT SETUP ...............................................................................................................3-8

3.5.1 Loop 1 Output ................................................................................................................................3-8

3.5.2 Heater Output Connector for Loop 1 .............................................................................................. 3-8

3.5.3 Heater Output Wiring for Loop 1 ....................................................................................................3-9

3.5.4 Heater Protection and Fuse for Loop 1 .......................................................................................... 3-9

3.5.5 Loop 1 Heater Noise ...................................................................................................................... 3-9

3.5.6 Model 3003 Heater Output Conditioner.......................................................................................... 3-9

3.5.7 Loop 2 Output ..............................................................................................................................3-10

3.5.8 Loop 2 Output Resistance............................................................................................................ 3-10

3.5.9 Loop 2 Output Connector............................................................................................................. 3-10

3.5.10 Loop 2 Heater Protection ............................................................................................................. 3-10

3.5.11 Boosting the Output Power .......................................................................................................... 3-11

3.6 ANALOG OUTPUTS........................................................................................................................ 3-11

3.7 DIGITAL I/O..................................................................................................................................... 3-12

3.8 RELAYS .......................................................................................................................................... 3-12

4 FRONT PANEL OPERATION ................................................................................................................................ 4-1

4.0 GENERAL ......................................................................................................................................... 4-1

4.1 TURNING POWER ON .....................................................................................................................4-1

4.2 DISPLAY FORMATS ......................................................................................................................... 4-1

4.2.1 Normal Display............................................................................................................................... 4-2

4.2.2 Setting Displays .............................................................................................................................4-2

4.2.3 Data Entry Displays........................................................................................................................ 4-2

4.2.4 Error Displays................................................................................................................................. 4-2

4.3 KEYPAD DESCRIPTION................................................................................................................... 4-2

4.4 KEYPAD NAVIGATION ..................................................................................................................... 4-3

4.4.1 Entering Settings............................................................................................................................ 4-3

4.4.2 Direct Settings................................................................................................................................ 4-3

ii Table of Contents

Lake Shore Model 340 Temperature Controller User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

4.4.3 Using Setting Screens ................................................................................................................... 4-4

4.4.4 Data Entry Screens........................................................................................................................ 4-4

4.4.5 The Help Key ................................................................................................................................. 4-4

4.4.6 Keypad Time-out............................................................................................................................ 4-4

4.4.7 Key Definitions............................................................................................................................... 4-5

4.5 CHANGING DISPLAY FORMAT ....................................................................................................... 4-6

4.5.1 Number of Readings Displayed ..................................................................................................... 4-6

4.5.2 Sensor Input................................................................................................................................... 4-6

4.5.3 Reading Source and Display Units ................................................................................................ 4-7

4.5.4 Control Loop Display...................................................................................................................... 4-7

4.5.5 Large Heater Display ..................................................................................................................... 4-7

4.5.6 Heater Output Display Units........................................................................................................... 4-8

4.5.7 Display Contrast............................................................................................................................. 4-8

4.5.8 Display Backlight On/Off ................................................................................................................ 4-8

4.5.9 Locking the Keypad ....................................................................................................................... 4-8

4.6 DEFAULT VALUES ........................................................................................................................... 4-8

5 SENSOR INPUT AND TEMPERATURE MEASUREMENT OPERATION............................................................. 5-1

5.0 GENERAL ......................................................................................................................................... 5-1

5.1 SENSOR INPUT SETUP................................................................................................................... 5-1

5.1.1 Sensor Type................................................................................................................................... 5-1

5.1.2 Voltage Excitation (Current Autorange) ......................................................................................... 5-2

5.1.3 Thermal EMF Compensation with Voltage Excitation .................................................................... 5-2

5.1.4 Special Sensor Type Configuration................................................................................................ 5-2

5.1.5 Turning an Input Off ....................................................................................................................... 5-3

5.2 SELECTING A TEMPERATURE RESPONSE CURVE .................................................................... 5-3

5.3 FILTER AND MATH .......................................................................................................................... 5-4

5.3.1 Filter............................................................................................................................................... 5-4

5.3.2 Max/Min ......................................................................................................................................... 5-5

5.3.3 Linear Equation.............................................................................................................................. 5-6

5.4 SCANNER SUPPORT....................................................................................................................... 5-6

5.4.1 Scan Modes ................................................................................................................................... 5-6

5.4.2 Input Setup with a Scan Mode Active ............................................................................................ 5-7

5.4.3 Manual Scanning ........................................................................................................................... 5-7

5.4.4 Auto Scanning................................................................................................................................ 5-8

5.4.5 Slave Scanning .............................................................................................................................. 5-8

6 TEMPERATURE CONTROL OPERATION............................................................................................................ 6-1

6.0 GENERAL ......................................................................................................................................... 6-1

6.1 CONTROL LOOPS............................................................................................................................ 6-1

6.1.1 Control Loops on the Normal Display ............................................................................................ 6-1

6.1.2 Loop Indication on the Normal Display .......................................................................................... 6-1

6.1.3 Loop Indication on Setting Screens ............................................................................................... 6-1

6.1.4 Control Output Display................................................................................................................... 6-2

6.2 CONTROL LOOP ENABLE............................................................................................................... 6-2

6.3 CONTROL LOOP FILTER................................................................................................................. 6-2

6.4 CONTROL CHANNEL....................................................................................................................... 6-3

6.5 CONTROL MODES........................................................................................................................... 6-3

6.6 MANUAL SETTING OF PID CONTROL PARAMETERS .................................................................. 6-4

6.6.1 Proportional (P).............................................................................................................................. 6-4

6.6.2 Integral (I)....................................................................................................................................... 6-4

6.6.3 Derivative (D) ................................................................................................................................. 6-4

6.6.4 Manual Output ............................................................................................................................... 6-4

6.7 SELECTING AN AUTOTUNE CONTROL MODE ............................................................................. 6-4

6.8 ZONE CONTROL DATA ENTRY ...................................................................................................... 6-5

6.9 USING OPEN LOOP CONTROL....................................................................................................... 6-7

6.10 SETTING A SETPOINT AND SETPOINT UNITS.............................................................................. 6-7

6.11 SETPOINT RAMPING....................................................................................................................... 6-8

6.12 CONTROL OUTPUT ......................................................................................................................... 6-8

6.12.1 Heater Output Parameter Settings and Heater Range................................................................... 6-8

6.12.2 Analog Output as Loop 2 Control Output ..................................................................................... 6-10

Table of Contents iii

Lake Shore Model 340 Temperature Controller User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

6.13 CONTROL OUTPUT LIMITS........................................................................................................... 6-11

6.13.1 Setpoint Limit ...............................................................................................................................6-11

6.13.2 Control Output Slope Limit ........................................................................................................... 6-11

6.13.3 Heater Range Limit ...................................................................................................................... 6-11

7 ANALOG OUTPUT, DIGITAL I/O. ALARMS, AND RELAY OPERATION ............................................................ 7-1

7.0 GENERAL ......................................................................................................................................... 7-1

7.1 ANALOG OUTPUTS.......................................................................................................................... 7-1

7.1.1 Input Mode for Analog Output ........................................................................................................7-2

7.1.2 Example of Low and High Parameter Setting ................................................................................7-2

7.1.3 Loop 2 Mode for Analog Output 2 ..................................................................................................7-2

7.1.4 Manual Mode Operation of the Analog Outputs ............................................................................. 7-3

7.2 DIGITAL INPUTS AND OUTPUTS (I/O)............................................................................................7-3

7.2.1 Digital Output Modes...................................................................................................................... 7-3

7.2.2 Digital Outputs in Alarm Mode ....................................................................................................... 7-3

7.2.3 Digital Outputs in Scanner Mode.................................................................................................... 7-3

7.2.4 Digital Outputs in Manual Mode ..................................................................................................... 7-4

7.2.5 Digital Input Modes ........................................................................................................................ 7-4

7.3 INPUT ALARMS ................................................................................................................................7-4

7.3.1 Enabling an Input Alarm................................................................................................................. 7-4

7.3.2 Selecting an Input Alarm Source.................................................................................................... 7-5

7.3.3 Input Alarm High and Low Settings ................................................................................................ 7-5

7.3.4 Input Alarm Latching ...................................................................................................................... 7-5

7.3.5 Input Alarm Relay Setup ................................................................................................................ 7-5

7.3.6 Input Alarm Reset ..........................................................................................................................7-6

7.3.7 Audible Beeper............................................................................................................................... 7-6

7.4 HIGH AND LOW RELAYS................................................................................................................. 7-6

7.4.1 Selecting a Relay Mode ................................................................................................................. 7-6

7.4.2 Manually Setting a Relay ............................................................................................................... 7-6

8 INSTRUMENT PROGRAMMING............................................................................................................................ 8-1

8.0 GENERAL ......................................................................................................................................... 8-1

8.1 CURVE ENTRY FROM THE FRONT PANEL ...................................................................................8-1

8.1.1 Curve Numbers and Storage ......................................................................................................... 8-1

8.1.2 Front Panel Curve Entry Operations .............................................................................................. 8-1

8.1.3 Front Panel Curve Edit................................................................................................................... 8-2

8.1.4 Front Panel Curve Copy................................................................................................................. 8-3

8.1.5 Front Panel Curve Erase................................................................................................................ 8-3

8.2 SOFTCAL™ ...................................................................................................................................... 8-4

8.2.1 SoftCal and Silicon Diode Sensors ................................................................................................8-4

8.2.2 SoftCal Accuracy with Silicon Diode Sensors ................................................................................ 8-5

8.2.3 SoftCal and Platinum Sensors ....................................................................................................... 8-5

8.2.4 SoftCal Accuracy with Platinum Sensors ....................................................................................... 8-5

8.2.5 Creating a SoftCal Calibration Curve ............................................................................................. 8-6

8.3 INTERNAL PROGRAMMING ............................................................................................................8-6

8.3.1 Program Instructions ...................................................................................................................... 8-6

8.3.2 Internal Programming Operations ................................................................................................ 8-10

8.3.3 Enter or Edit an Internal Program................................................................................................. 8-10

8.3.4 Saving a Program ........................................................................................................................8-11

8.3.5 Summary of Key Operation.......................................................................................................... 8-11

8.3.6 Example of an Internal Program (Example 1) ..............................................................................8-11

8.3.7 Example of Using Subprograms (Example 2) .............................................................................. 8-12

8.3.8 Run an Internal Program.............................................................................................................. 8-12

8.3.9 Stop a Running Program.............................................................................................................. 8-12

8.3.10 Clear Internal Program Memory................................................................................................... 8-13

8.4 DATA CARD OPERATION.............................................................................................................. 8-13

8.4.1 Data Logging To A Data Card...................................................................................................... 8-13

8.4.2 Reading From A Data Card.......................................................................................................... 8-16

8.4.3 Writing To A Data Card ................................................................................................................ 8-16

8.4.4 Erasing A Data Card .................................................................................................................... 8-16

iv Table of Contents

Lake Shore Model 340 Temperature Controller User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

9 REMOTE OPERATION .......................................................................................................................................... 9-1

9.0 GENERAL ......................................................................................................................................... 9-1

9.1 IEEE-488 INTERFACE...................................................................................................................... 9-1

9.1.1 IEEE-488 Interface Settings........................................................................................................... 9-1

9.1.2 IEEE-488 Command Structure....................................................................................................... 9-1

9.1.3 Status Registers............................................................................................................................. 9-3

9.1.4 IEEE Interface Example Programs ................................................................................................ 9-4

9.1.4.1 IEEE-488 Interface Board Installation for Visual Basic Program ................................................ 9-4

9.1.4.2 Visual Basic IEEE-488 Interface Program Setup........................................................................ 9-6

9.1.4.3 IEEE-488 Interface Board Installation for Quick Basic Program................................................. 9-9

9.1.4.4 Quick Basic Program.................................................................................................................. 9-9

9.1.4.5 Program Operation................................................................................................................... 9-12

9.1.5 Troubleshooting ........................................................................................................................... 9-12

9.2 SERIAL INTERFACE OVERVIEW .................................................................................................. 9-13

9.2.1 Changing Baud Rate.................................................................................................................... 9-13

9.2.2 Physical Connection .................................................................................................................... 9-13

9.2.3 Hardware Support........................................................................................................................ 9-14

9.2.4 Character Format......................................................................................................................... 9-14

9.2.5 Message Strings .......................................................................................................................... 9-14

9.2.6 Message Flow Control ................................................................................................................. 9-15

9.2.7 Serial Interface Example Programs ............................................................................................. 9-15

9.2.7.1 Visual Basic Serial Interface Program Setup............................................................................ 9-16

9.2.7.2 Quick Basic Serial Interface Program Setup ............................................................................ 9-19

9.2.7.3 Program Operation................................................................................................................... 9-20

9.2.8 Troubleshooting ........................................................................................................................... 9-20

9.3 IEEE-488/SERIAL INTERFACE COMMANDS................................................................................ 9-21

10 OPTIONS AND ACCESSORIES.......................................................................................................................... 10-1

10.0 GENERAL ....................................................................................................................................... 10-1

10.1 OPTIONS ........................................................................................................................................ 10-1

10.2 ACCESSORIES............................................................................................................................... 10-1

10.3 MODEL DUAL STANDARD 3462 INPUT OPTION CARD .............................................................. 10-5

10.3.1 Field Installation ........................................................................................................................... 10-5

10.3.2 Operation ..................................................................................................................................... 10-7

10.3.3 Specifications............................................................................................................................... 10-7

10.4 MODEL 3464 DUAL THERMOCOUPLE INPUT OPTION CARD.................................................... 10-7

10.4.1 General ........................................................................................................................................ 10-7

10.4.2 Option Installation ........................................................................................................................ 10-8

10.4.3 Sensor Installation ....................................................................................................................... 10-8

10.4.3.1 Sensor Input Terminals ............................................................................................................ 10-8

10.4.3.2 Measurement Point Connection ............................................................................................... 10-9

10.4.3.3 Grounding and Shielding .......................................................................................................... 10-9

10.4.4 Operation ..................................................................................................................................... 10-9

10.4.4.1 Default Settings ........................................................................................................................ 10-9

10.4.4.2 Input Selection.......................................................................................................................... 10-9

10.4.4.3 Displaying Option Readings ..................................................................................................... 10-9

10.4.4.4 Curve Selection ...................................................................................................................... 10-10

10.4.4.5 Curve Data Format................................................................................................................. 10-10

10.4.4.6 Range Selection ..................................................................................................................... 10-10

10.4.4.7 Room Temperature Compensation ........................................................................................ 10-10

10.4.5 Computer Interface Commands ................................................................................................. 10-11

10.4.6 Thermocouple Temperature Curves .......................................................................................... 10-12

10.4.7 Specifications............................................................................................................................. 10-12

10.5 MODEL 3465 SINGLE CAPACITANCE INPUT OPTION CARD................................................... 10-12

10.5.1 Option Installation ...................................................................................................................... 10-12

10.5.2 Sensor Installation ..................................................................................................................... 10-12

10.5.2.1 Sensor Input Connector ......................................................................................................... 10-12

10.5.2.2 Measurement Point Connection ............................................................................................. 10-12

10.5.2.3 Grounding and Shielding ........................................................................................................ 10-12

Table of Contents v

Lake Shore Model 340 Temperature Controller User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

10.5.3 Operation ................................................................................................................................... 10-13

10.5.3.1 Input Selection........................................................................................................................ 10-13

10.5.3.2 Displaying Option Readings ...................................................................................................10-13

10.5.3.3 Curve Selection ...................................................................................................................... 10-13

10.5.3.4 Range Selection ..................................................................................................................... 10-13

10.5.3.5 Temperature Coefficient ......................................................................................................... 10-13

10.5.3.6 Control Channel Changes ......................................................................................................10-13

10.5.4 Computer Interface Commands ................................................................................................. 10-13

10.5.5 Specifications ............................................................................................................................. 10-13

10.6 MODEL 3468 EIGHT-CHANNEL INPUT OPTION CARD ............................................................. 10-14

10.6.1 General ...................................................................................................................................... 10-14

10.6.2 Option Installation ......................................................................................................................10-14

10.6.3 Sensor Installation...................................................................................................................... 10-14

10.6.3.1 Sensor Input Connector.......................................................................................................... 10-14

10.6.3.2 Sensor Input Cabling .............................................................................................................. 10-14

10.6.3.3 Reading Rate.......................................................................................................................... 10-14

10.6.4 Operation ................................................................................................................................... 10-15

10.6.4.1 General Operation .................................................................................................................. 10-15

10.6.4.2 Input Setup ............................................................................................................................. 10-15

10.6.4.3 Temperature Control .............................................................................................................. 10-15

10.6.5 Computer Interface Commands ................................................................................................. 10-16

10.6.6 Specifications ............................................................................................................................. 10-16

11 SERVICE .............................................................................................................................................................. 11-1

11.0 GENERAL ....................................................................................................................................... 11-1

11.1 GENERAL MAINTENANCE PRECAUTIONS.................................................................................. 11-1

11.2 ELECTROSTATIC DISCHARGE..................................................................................................... 11-1

11.2.1 Identification of ESDS Components ............................................................................................. 11-2

11.2.2 Handling of ESDS Components................................................................................................... 11-2

11.3 GENERAL MAINTENANCE ............................................................................................................ 11-2

11.4 REAR PANEL CONNECTOR DEFINITIONS .................................................................................. 11-2

11.4.1 IEEE-488 Interface Connector .....................................................................................................11-5

11.5 SERIAL INTERFACE CABLE AND ADAPTERS ............................................................................. 11-6

11.6 TOP OF ENCLOSURE REMOVE AND REPLACE PROCEDURE.................................................. 11-7

11.7 EPROM AND NOVRAM REPLACEMENT ...................................................................................... 11-7

11.8 ERROR MESSAGES....................................................................................................................... 11-8

11.9 FIRMWARE IC REPLACEMENT..................................................................................................... 11-9

11.10 UPDATING THE MASTER FIRMWARE FROM A DATA CARD ................................................... 11-11

APPENDIX A –CURVE TABLES.................................................................................................................................. A-1

A1.0 General..............................................................................................................................................A-1

vi Table of Contents

Lake Shore Model 340 Temperature Controller User’s Manual

LIST OF ILLUSTRATIONS

Figure No. Title Page

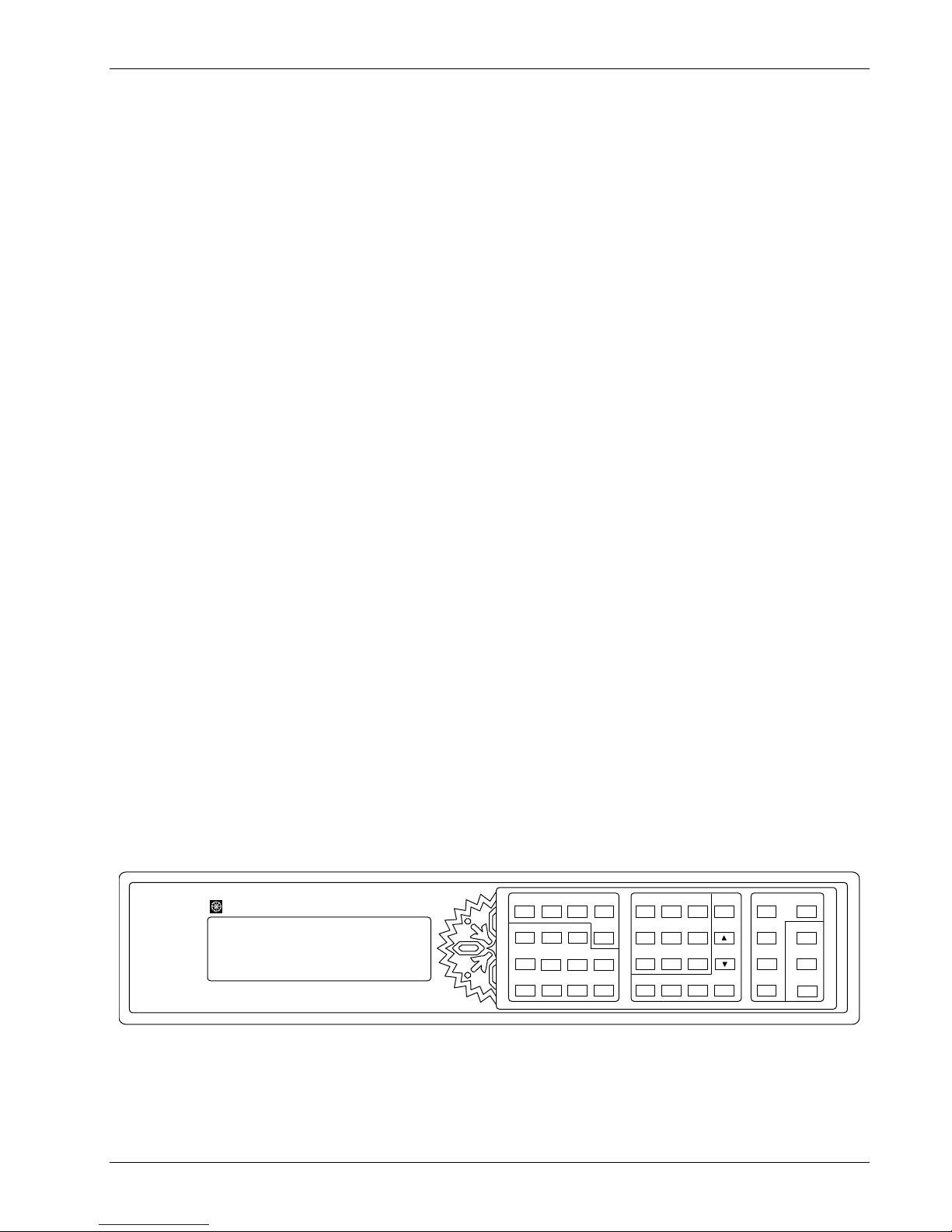

1-1 Model 340 Front Panel ................................................................................................................. 1-1

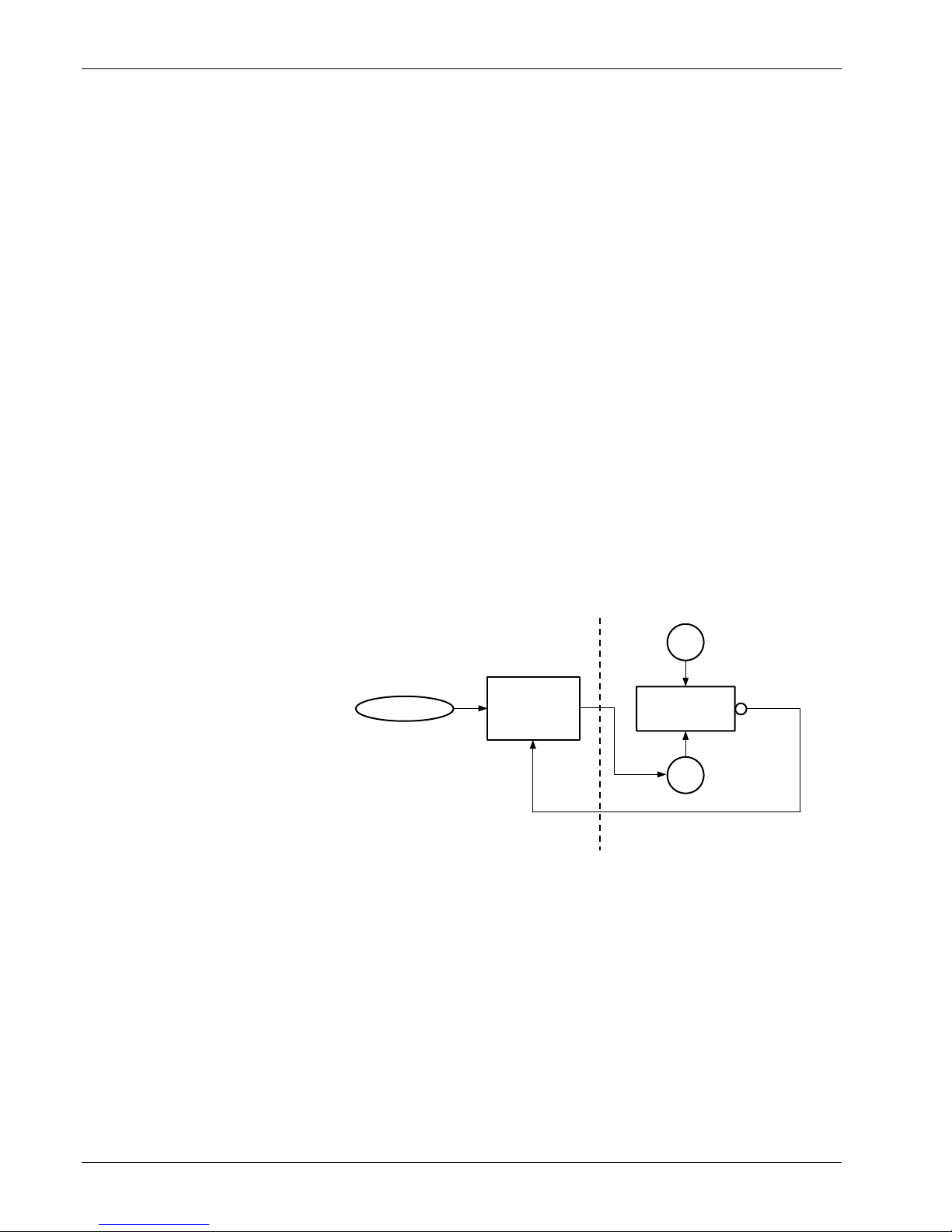

1-2 Typical Temperature Control System with Model 340.................................................................. 1-2

1-3 Model 340 Temperature Controller Block Diagram ...................................................................... 1-4

2-1 Silicon Diode Sensor Calibrations and CalCurve ......................................................................... 2-3

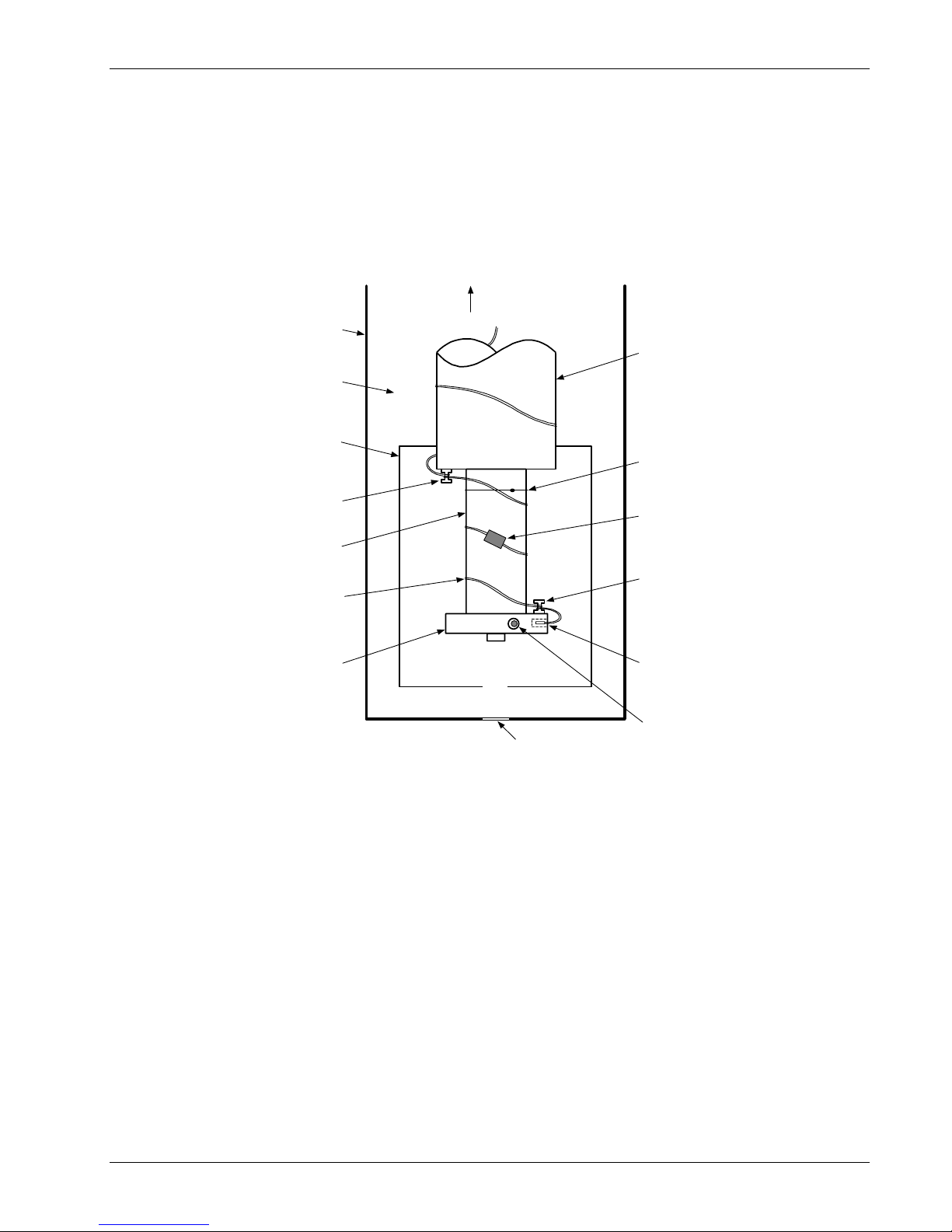

2-2 Typical Sensor Installation in a Mechanical Refrigerator.............................................................. 2-5

2-3 Examples of PID Control ............................................................................................................ 2-10

3-1 Typical Cryogenic Storage Dewar ................................................................................................ 3-3

3-2 Model 340 Rear Panel .................................................................................................................. 3-4

3-3 Power Fuse Access ...................................................................................................................... 3-6

3-4 Model 3003 Heater Output Conditioner...................................................................................... 3-10

3-5 ANALOG OUT 1 and 2 BNC Rear Panel Connector Details...................................................... 3-11

3-6 DIGITAL I/O DA-15 Rear Panel Connector Details .................................................................... 3-12

3-7 RELAYS LO and HI Rear Panel Connector Details ................................................................... 3-12

4-1 Model 340 Front Panel ................................................................................................................. 4-1

5-1 Data Flow...................................................................................................................................... 5-5

6-1 Record of Zone Settings ............................................................................................................... 6-6

8-1 SoftCal Temperature Ranges for Silicon Diode Sensors ............................................................. 8-4

8-2 SoftCal Temperature Ranges for Platinum Sensors .................................................................... 8-5

8-3 Sample Program #1.................................................................................................................... 8-12

9-1 GPIB Setting Configuration........................................................................................................... 9-5

9-2 DEV 12 Device Template Configuration ....................................................................................... 9-5

9-3 Typical National Instruments GPIB Configuration from IBCONF.EXE ....................................... 9-10

9-4 Serial Interface Connections....................................................................................................... 9-13

10-1 Model 2001 RJ-11 Cable Assembly ...........................................................................................10-3

10-2 Model 2003 RJ-11 to DE-9 Adapter............................................................................................ 10-3

10-3 Optional Model 2002 RJ-11 to DB-25 Adapter ........................................................................... 10-4

10-4 Model 3012 Rack-Mount Kit ....................................................................................................... 10-4

10-5 Cover and Option Plate Screws.................................................................................................. 10-5

10-6 Model 340 Mounting Holes and Analog Option Plug.................................................................. 10-6

10-7 Model 3462 Mounting Holes and Analog Plug ........................................................................... 10-6

10-8 Model 340 Rear Panel with Model 3462 Option Card Installed.................................................. 10-7

10-9 Model 340 Rear Panel with Model 3464 Option Card Installed.................................................. 10-8

11-1 SERIAL I/O RJ-11 Rear Panel Connector Details...................................................................... 11-2

11-2 DIGITAL I/O DA-15 Rear Panel Connector Details .................................................................... 11-3

11-3 RELAYS LO and HI Rear Panel Connector Details ................................................................... 11-3

11-4 ANALOG OUT 1 and 2 BNC Rear Panel Connector Details...................................................... 11-4

11-5 SENSOR INPUT A and B Rear Panel Connector Details .......................................................... 11-4

11-6 HEATER OUTPUT Rear Panel Connector Details..................................................................... 11-4

11-7 IEEE-488 Rear Panel Connector Details.................................................................................... 11-5

11-8 Model 2001 RJ-11 Cable Assembly Wiring ............................................................................... 11-6

11-9 Model 2003 RJ-11 to DE-9 Adapter Wiring Details .................................................................... 11-6

11-10 Optional Model 2002 RJ-11 to DB-25 Adapter Wiring Details.................................................... 11-6

11-11 Location of Internal Components................................................................................................ 11-8

Table of Contents vii

Lake Shore Model 340 Temperature Controller User’s Manual

LIST OF TABLES

Table No. Title Page

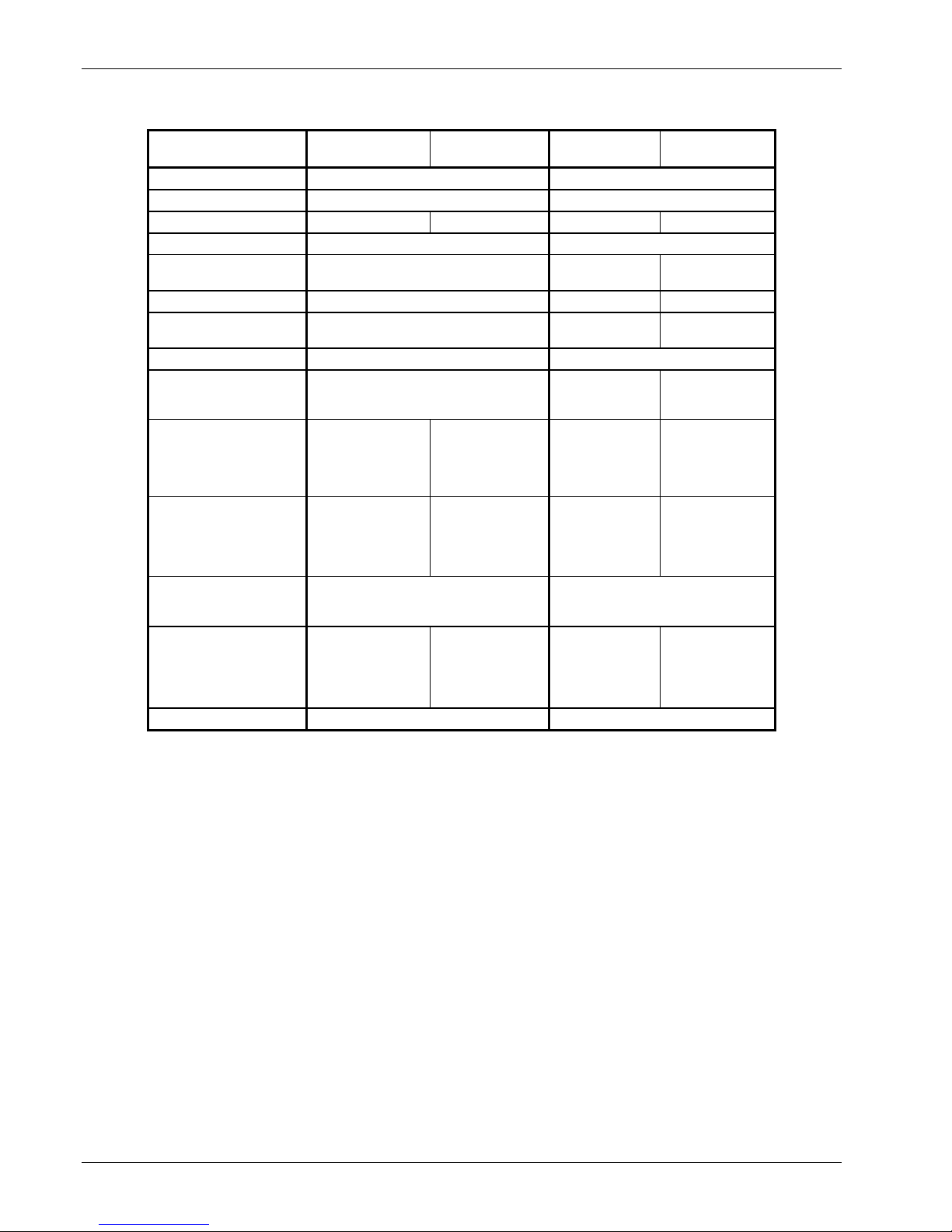

1-1 Comparison of Control Loops 1 and 2 ..........................................................................................1-6

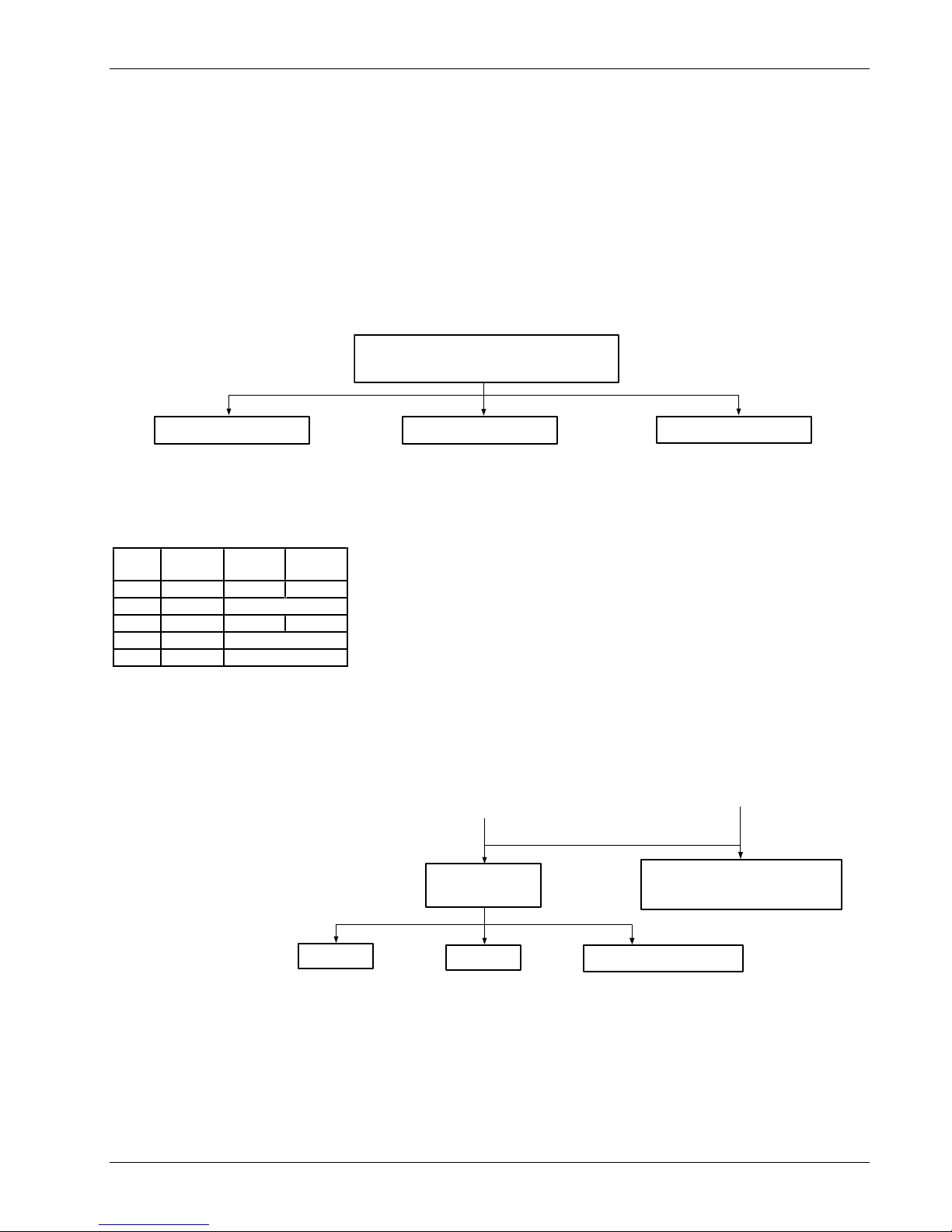

1-2 Model 340 Sensor Performance Chart..........................................................................................1-8

3-1 Comparison of Liquid Helium to Liquid Nitrogen...........................................................................3-3

3-2 AC Line Input Definitions...............................................................................................................3-5

3-3 Sensor INPUT A and B Connector Definitions..............................................................................3-6

5-1 Sensor Types Recognized by the Model 340 ...............................................................................5-1

5-2 Special Sensor Type Configuration...............................................................................................5-3

5-3 Standard Curve Table ...................................................................................................................5-4

5-4 Linear Equation Configuration.......................................................................................................5-6

6-1 Control Mode Description..............................................................................................................6-3

6-2 Full Scale Heater Power at Typical Resistance ............................................................................6-9

6-3 Example of Maximum Current Settings.........................................................................................6-9

8-1 Recommended Curve Parameters................................................................................................8-2

8-2 Storage Capability for a 1 MB Data Card....................................................................................8-13

9-1 IEEE-488 Interface Program Control Properties...........................................................................9-7

9-2 Visual Basic IEEE-488 Interface Program ....................................................................................9-8

9-3 Quick Basic IEEE-488 Interface Program ...................................................................................9-11

9-4 Serial Interface Specifications .....................................................................................................9-14

9-5 Serial Interface Program Control Properties ...............................................................................9-17

9-6 Visual Basic Serial Interface Program.........................................................................................9-18

9-7 Quick Basic Serial Interface Program .........................................................................................9-19

10-1 Thermocouple Polarity ................................................................................................................10-8

10-2 Standard Thermocouple Curves .................................................................................................10-9

A-1 Lake Shore DT-470 Standard Curve 10....................................................................................... A-1

A-2 Standard DT-500-D and -E1 Silicon Diode Curves...................................................................... A-2

A-3 Standard Platinum Curves ........................................................................................................... A-2

A-4 Standard K (Nickel-Chromium vs. Nickel-Aluminum) Thermocouple Curve................................ A-3

A-5 Standard E (Nickel-Chromium vs. Copper-Nickel) Thermocouple Curve.................................... A-4

A-6 Standard T (Copper vs. Copper-Nickel) Thermocouple Curve.................................................... A-5

A-7 Standard Chromel-AuFe0.03% Thermocouple Curve ................................................................. A-6

A-8 Standard Chromel-AuFe0.07% Thermocouple Curve ................................................................. A-7

A-9 Standard DT-670 Diode Curve..................................................................................................... A-8

viii Table of Contents

Lake Shore Model 340 Temperature Controller User’s Manual

CHAPTER 1

INTRODUCTION

1.0 GENERAL

This chapter provides an introduction to the Model 340 Temperature Controller. The Model 340 was

designed and manufactured in the United States of America by Lake Shore Cryotronics, Inc. The Lake Shore

Model 340 is our most advanced temperature controller to date. It is a result of 25 years of experience in the

cryogenics industry and reflects our dedication to customer service. Combined with the complete line of Lake

Shore temperature sensors, the Model 340 is one of the most useful and flexible tools available for cryogenic

temperature measurement and control.

Many features requested by our users are included without the need for additional plug-in circuitry. Every

effort was made to make these features available for automatic instrument control, manual control, or

computer control. This ensures that the Model 340 can work effectively in any experimental environment. The

Model 340 has the best display capability and provides the most operator feedback of any Lake Shore

instrument. The Model 340 has also not lost sight of its primary functions: accurate temperature measurement

and stable temperature control.

If you have just received your new Model 340, please read Chapters 2 thru 4 completely before attempting to

setup and use the instrument. Chapter 2 contains cooling system design and setup considerations. Chapter 3

contains instrument hardware setup instructions. Chapter 4 contains initial instrument startup and setup

instructions. Input sensor reading operation is described in Chapter 5. Temperature control operation is

described in Chapter 6. Analog and digital I/O operation is described in Chapter 7. Instrument programming is

provided in Chapter 8. Remote interface operation (IEEE-488 and Serial) is covered in Chapter 9. Service is

provided in Chapter 10. Options and accessories are detailed in Chapter 10. Finally, various curve tables are

provided in Appendix A.

We welcome your comments concerning this manual. Although every effort has been made to keep it free

from errors, some may occur. When reporting a specific problem, please describe it briefly and include the

applicable paragraph, figure, table, and page number. Send comments to Lake Shore Cryotronics, Attn:

Technical Publications, 575 McCorkle Blvd, Westerville, Ohio 43082-8888. The material in this manual is

subject to change without notice.

Due to the Lake Shore commitment to continuous product improvement, it is reasonable to expect that

modifications will be made in the Model 340 software with time. Some of these changes are the result of

Customer feedback regarding operation on various cryogenic systems. We encourage you to contact us with

any observations or suggestions which you have regarding the use of this controller. Also, please return your

warranty card to ensure that any software updates are sent to you.

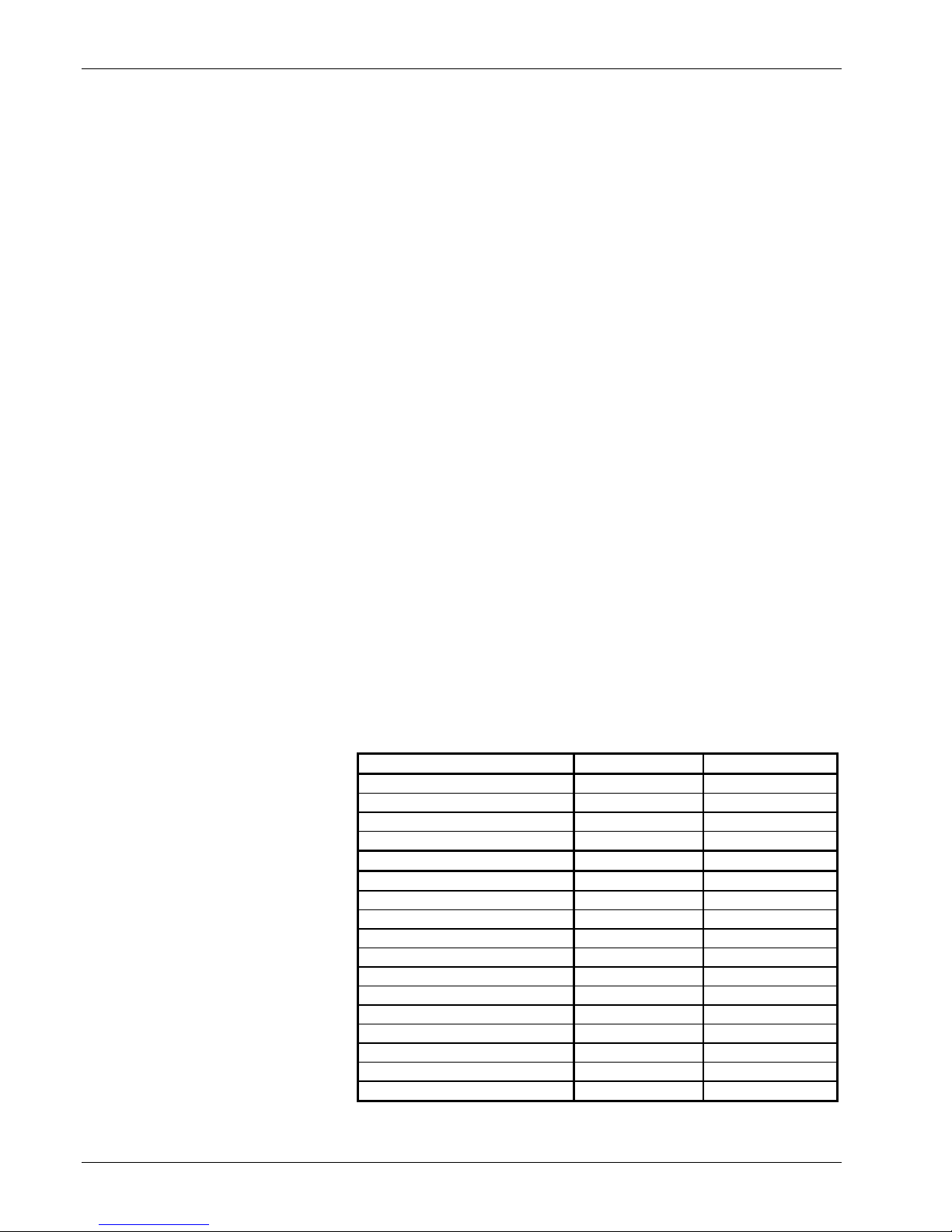

LakeShore

340 Temperature Controller

340-1-1.eps

Introduction 1-1

Auto

Zone

Ramp

Manual

Output

Pro gr am

Control

D

Setup

Loop 1

Loop 2

Tune

Settings

PI

Heater

Control

Range

Channel

Heater

Setpoint

Off

Figure 1-1. Model 340 Front Panel

Input

Setup

Scan

Setup

Alarm

Setup

Alarm

Reset

Display

SoftCal

Format

789

Curve

Inte r f a ce

Ent r y

456

Analog

Math

Outputs

Setup

123

Math

Options

Reset

0

+/-

.

+/-

Cance l

Escape

Sc r e en M o r e

Previous

Setting

Loca l

Next

DataCard

Setting

Save

Ent er

Help

Sc r e en

Lake Shore Model 340 Temperature Controller User’s Manual

1.1 TEMPERATURE CONTROL SYSTEM

The goal of a temperature control system is to balance the effect of heating and cooling to provide a stable

temperature in an area of interest. In order to control temperature, you need the following elements:

1. A heating source.

2. A cooling source.

3. A means to measure temperature.

4. A means to compare the measured temperature to a desired temperature (called the setpoint).

5. A means to make any necessary changes to either the heating, the cooling, or both.

One familiar example is the temperature control system in a typical home. When the outside temperature

(cooling source) lowers the temperature inside (area of interest) below the temperature setting (desired

temperature) the thermostat measures the temperature and detects the difference (comparison) and turns on

the furnace (changes heat source). Substituting some control jargon would result in the description of a

temperature control loop: When the cooling source reduces the temperature of the load below the

setpoint, a temperature sensor provides feedback to the control equation which detects the error and

actuates the heat source.

In our house example, there is only one actuator: the heat of the furnace. If the house is equipped with air

conditioning, the cooling source is a second actuator allowing control over a greater range of temperature. All

of the parts are called a closed loop control system and the operation is referred to as a control loop

because there is a cycle of cause and effect: From the control equation to the actuator to the load to the

sensor to the control loop and so on. The loop operation allows the heat source to turn on and off repeatedly,

keeping the temperature constant over a long period of time.

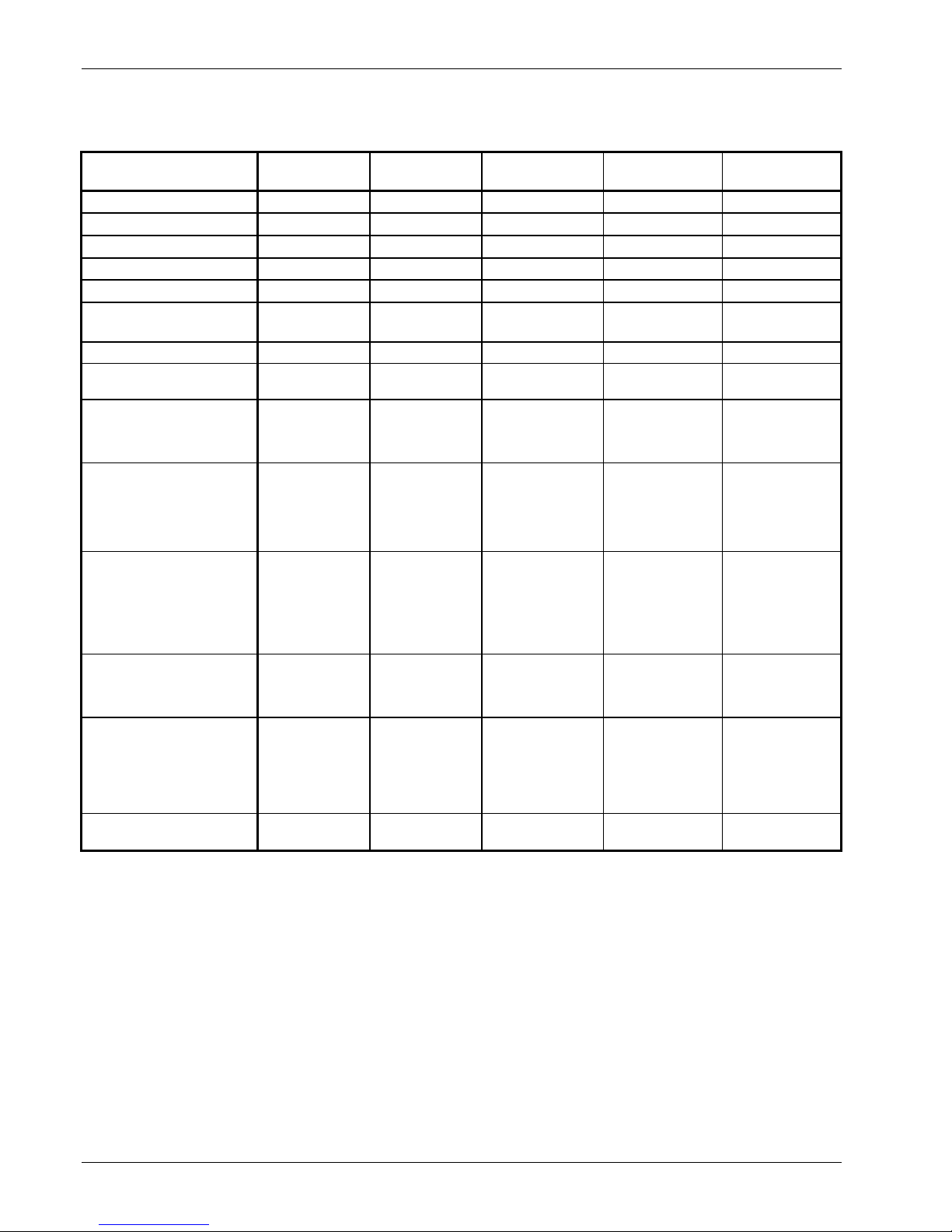

1.2 TEMPERATURE CONTROL SYSTEM WITH THE MODEL 340

The Model 340 is designed to work

as an integral part of a cryogenic

temperature control system (as

Cooling Source

(Cryogen)

described in Paragraph 1.1). The

Model 340 has many specialized

features that uniquely qualify it for

this difficult job. These features are

built on a fundamentally sound

design that can be used in many

applications requiring stable and

Setpoint

Temp erature

You Want

Model 340

(Control

Equation)

Load

(Cryostat)

Heater

Sensor

(Actual Temp.)

accurate control from cryogenic

temperatures, to room temperature

and above. Much of the information

in this manual refers to cryogenic

Warm Side Cold Side

Feedback

systems, but the ideas generally

apply at any temperature.

Figure 1-2. Typical Temperature Control System With Model 340

1.2.1 Cooling Source

The Model 340 integrates many of the elements of a complete control system. There are a few parts that the

Model 340 does not provide. The largest and most notable part missing is a cooling source. The Model 340

provides power to a resistive heater acting as the heating source, but it does not provide cooling. When